Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve inkjet efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

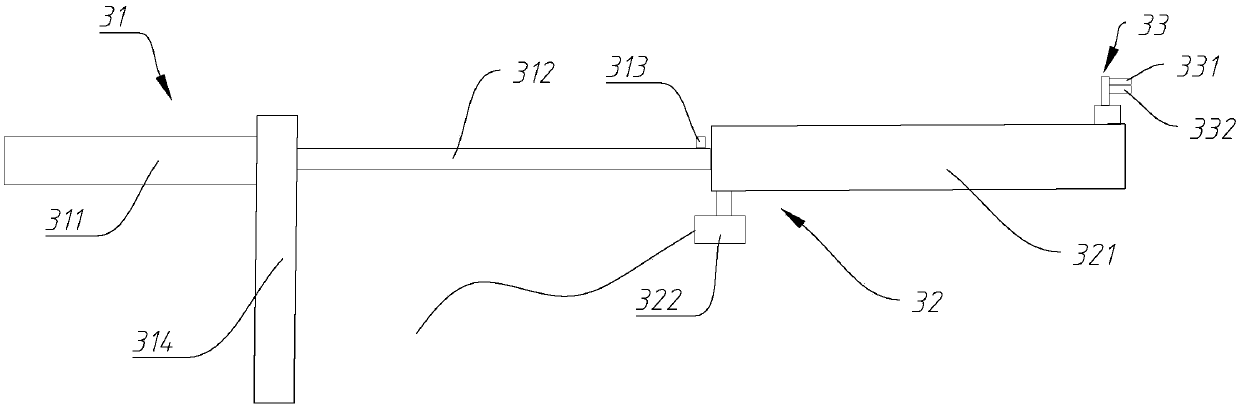

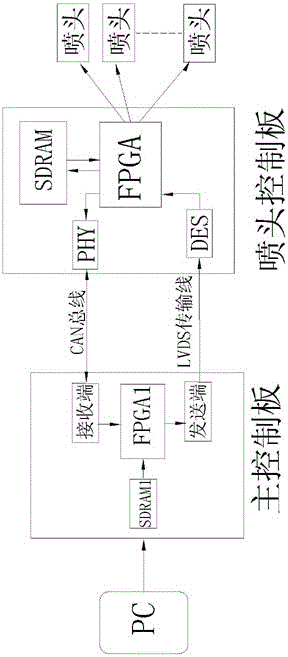

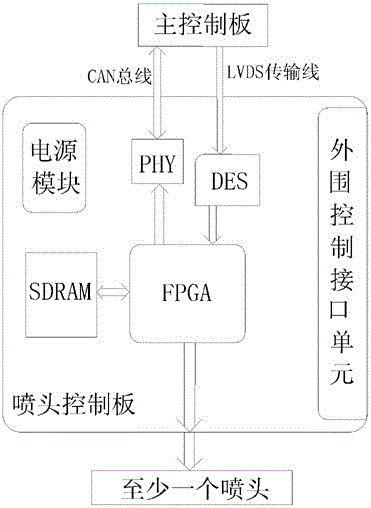

Ink-jet head control panel of ink-jet printer and method for transmission of printable data

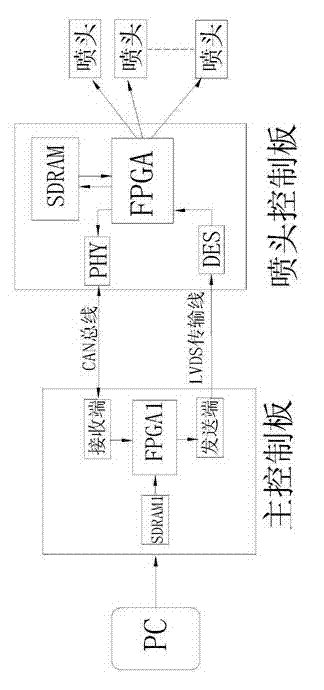

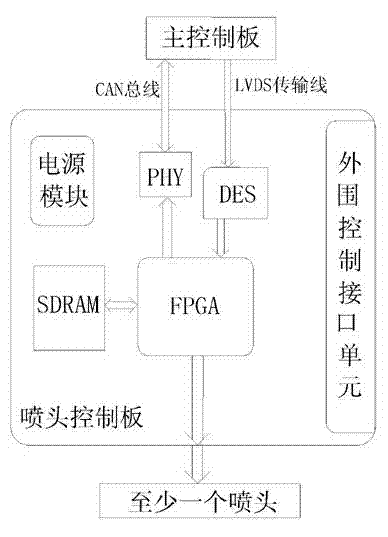

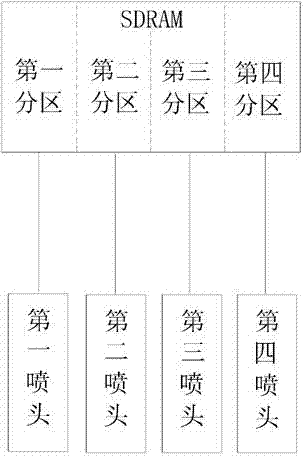

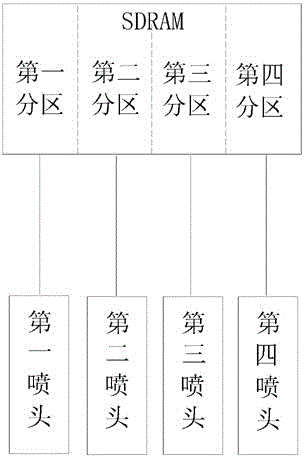

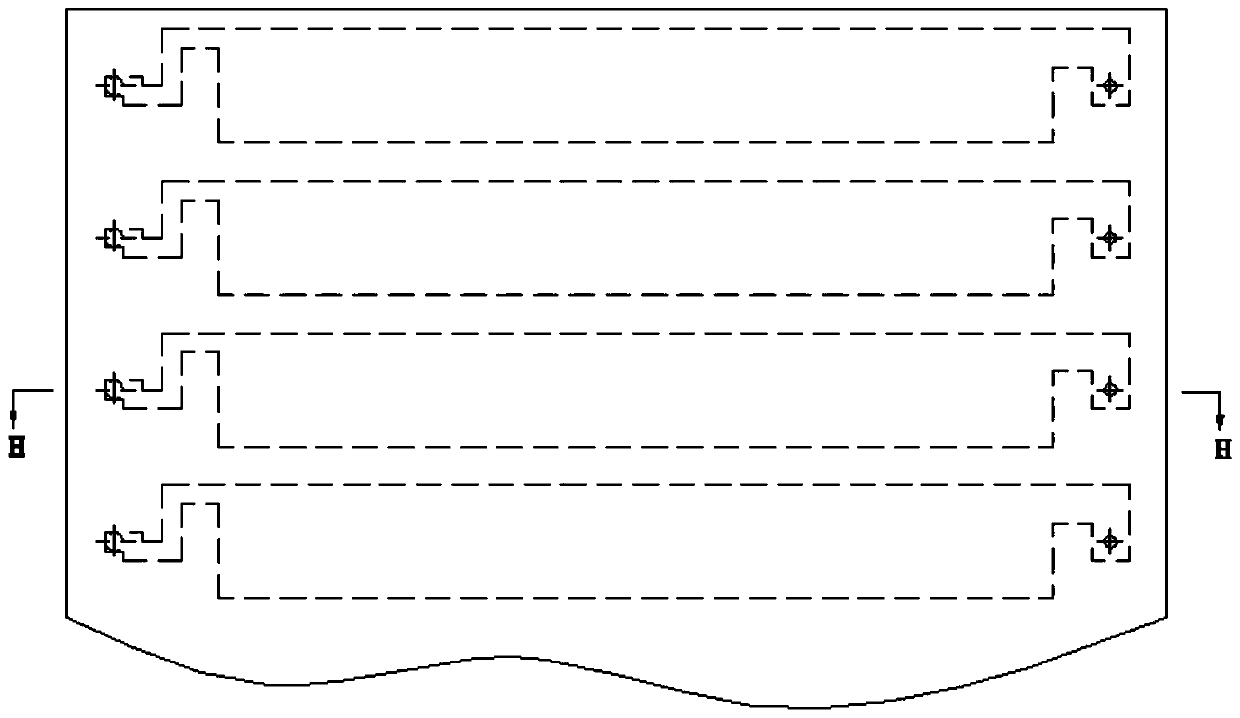

The invention discloses an ink-jet head control panel of an ink-jet printer and a method for transmission of printable data. One end of the ink-jet head control panel is connected with a master control panel and used for receiving serial printed data after the data are processed and the other end of the ink-jet head control panel is connected with ink-jet heads and used for sending the printable data with no error after verification to the ink-jet heads. The ink-jet head control panel mainly comprises an FPGA, a DES, a CAN chip sending end (PHY), a power module and a peripheral control interface unit. The ink-jet head control panel is characterized in that an SDRAM is additionally arranged on the ink-jet head control panel and connected with the FPGA, bi-directional data transmission can be conducted between the SDRAM and the FPGA, and the SDRAM is used for storing the printable data with no error after the data are verified through the FPGA and finally outputting the printable data with no error after verification to at least one ink-jet head for printing. The SDRAM is provided with multiple zones, the number of the zones is identical to that of the ink-jet heads, and the printable data with no error after verification needed by each ink-jet head are stored in the corresponding zone. In the printing process, the stored printable data with no error after verification are sent to the corresponding ink-jet head for image-text printing by the SDRAM, the phenomenon that the data are transmitted to the ink-jet heads mistakenly after printing operation is started can be avoided, the functions of the ink-jet head control panel are completed, and the ink-jetting efficiency is improved.

Owner:BEIJING MEIKEYI

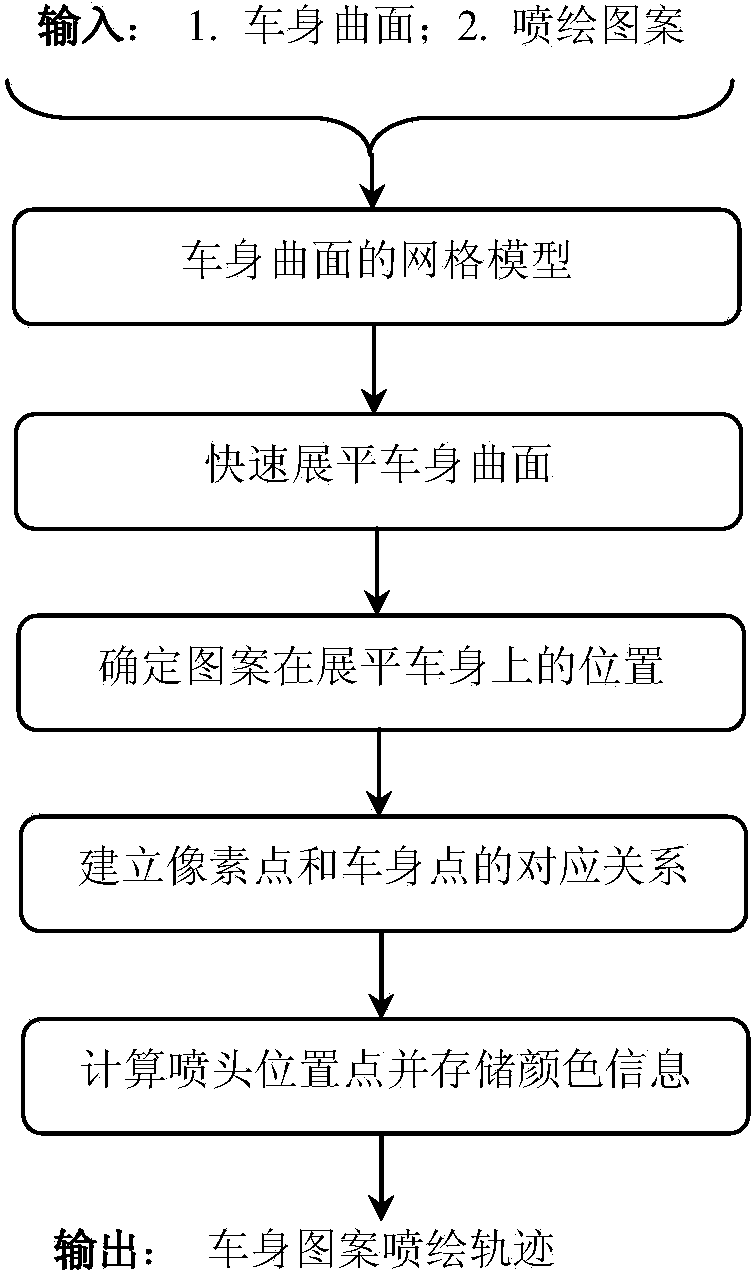

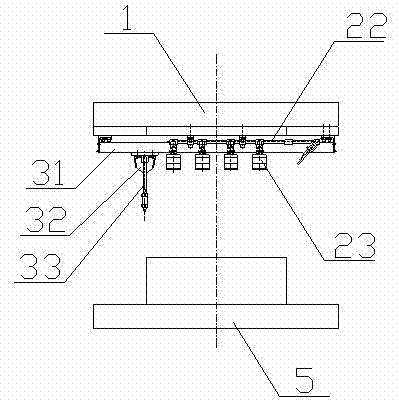

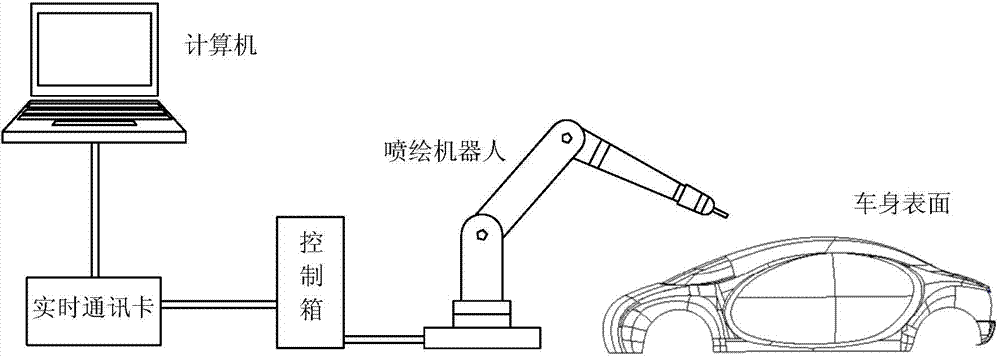

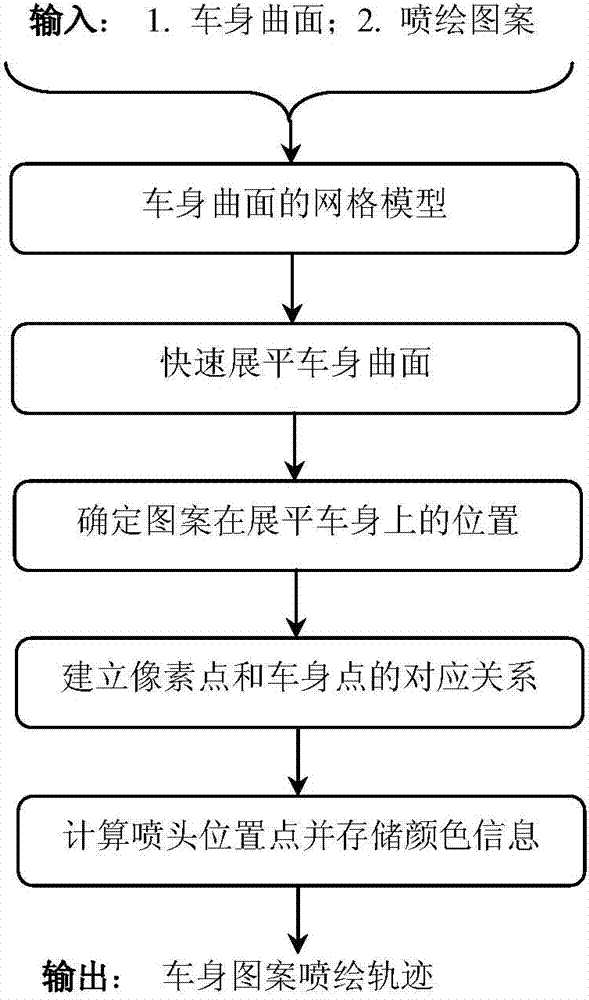

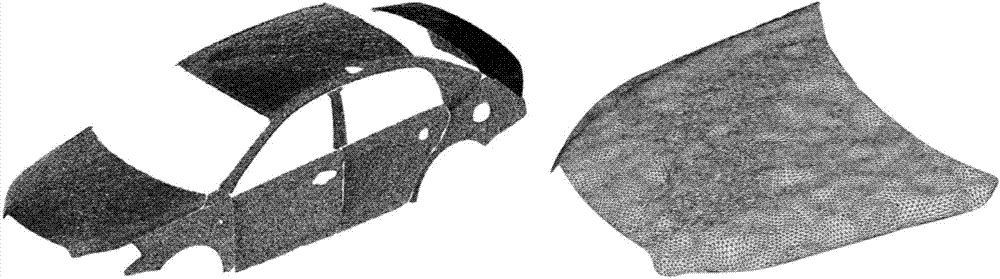

Method for automatically spray painting three-dimensional patterns on vehicle body surface

ActiveCN103521410AImprove inkjet efficiencyThe principle is simpleCoatingsSpecial surfacesDesign softwareEngineering

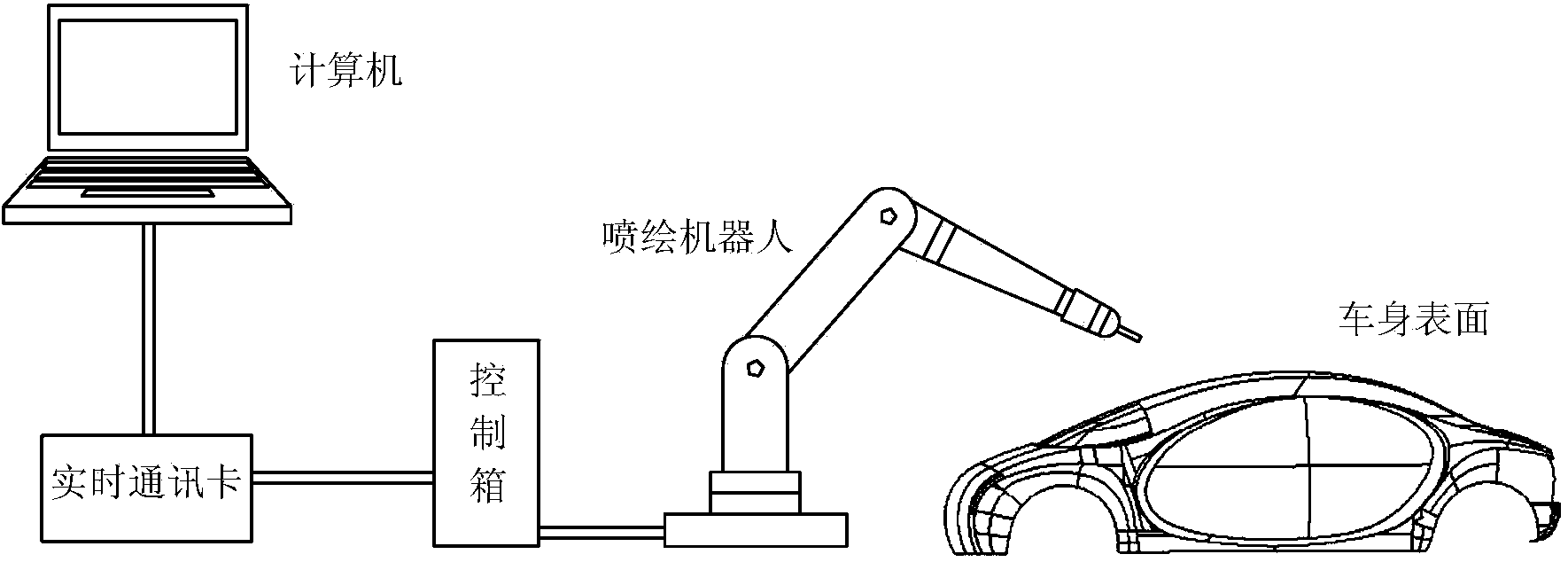

The invention discloses a method for automatically spray painting three-dimensional patterns on a vehicle body surface, and belongs to the field of vehicle digital design and manufacturing. The method for automatically spray painting the three-dimensional patterns on the vehicle body surface includes the steps of setting up a vehicle outer covering piece model through three-dimensional design software, dispersing the vehicle outer covering piece model into a triangular mesh model, thereby setting up the mapping relation between the triangular mesh model and a planar parameter region, inversely mapping points, corresponding to pattern pixel points, in the planar parameter region onto a vehicle body three-dimensional model based on the mapping relation, setting up the corresponding relation between the pattern pixel points and vehicle body three-dimensional points, storing color information of pixels, generating spray paint paths on the vehicle body three-dimensional model, adjusting the spray paint colors of the patterns according to the pixel color information corresponding to the path points, and then completing the process of automatically spray painting the three-dimensional patterns on the vehicle body surface by driving a spray painting robot. Various individualized patterns are automatically spray painted on the vehicle body surface under the control of a computer according to the spray painting paths generated through the method, and the principle is simple, the spray painting is even, the patterns are vivid, and the pattern spray painting efficiency is effectively improved.

Owner:DALIAN UNIV OF TECH

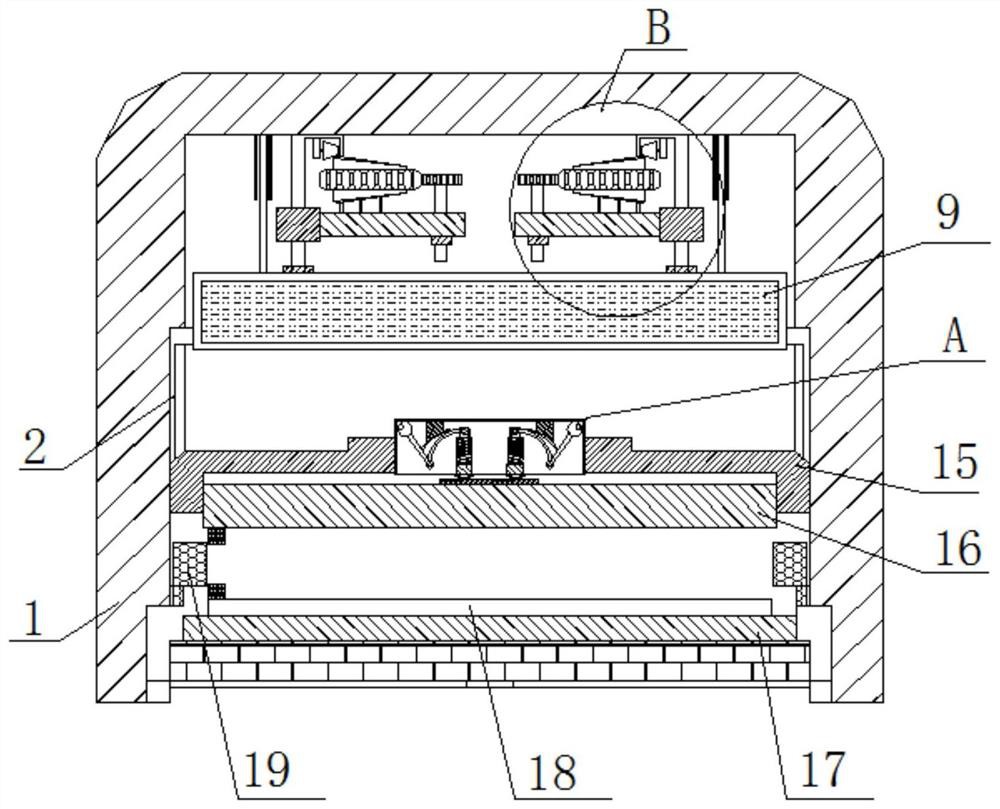

Automatic ink-jet blowing system for hot die forging press

InactiveCN103111574AQuality improvementExtended service lifeForging/hammering/pressing machinesMechanical engineering

The invention discloses an automatic ink-jet blowing system for a hot die forging press. The automatic ink-jet blowing system comprises an ink-jet system and a blowing system, which are arranged on an upper die seat of the hot die forging press, wherein the ink-jet system is used for jetting ink to cavities of dies on upper and lower die seats of the hot die forging press; and the blowing system is used for blowing air to the cavity of the die on the lower die seat of the hot die forging press. The automatic ink-jet blowing system is simple in structure, reduces the labor intensity of workers, can shorten production takt and improve the production efficiency; and particularly, the system is good in blowing cleaning effect, uniform and disperse in spraying, high in spraying speed and stable and reliable in operation.

Owner:CHONGQING UNIV +2

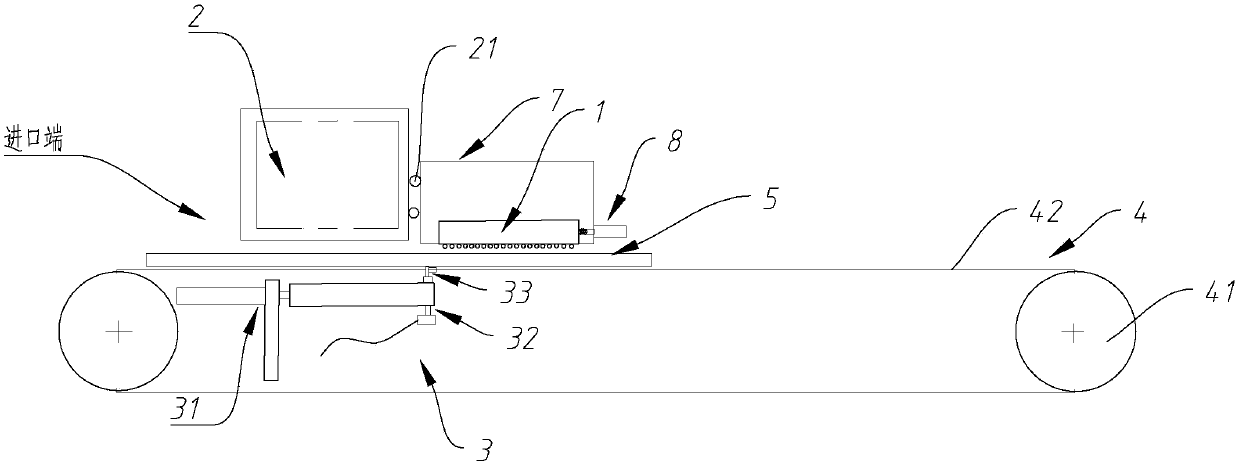

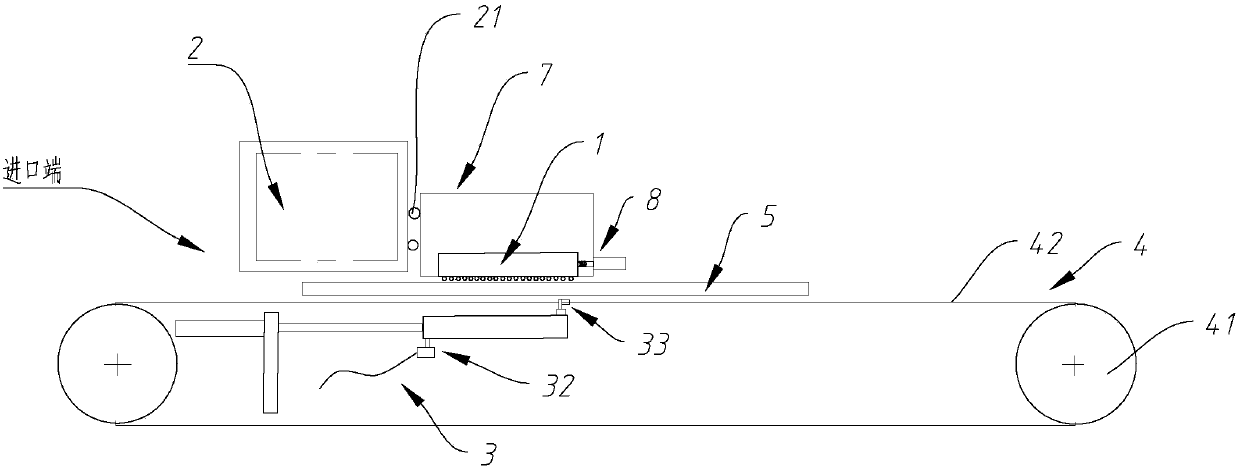

Ink jet printing machine with guiding belt transmission error compensation function

InactiveCN108032629ASave human effortImprove inkjet efficiencyPower drive mechanismsOther printing apparatusImage contrastTransmission errors

The invention discloses an ink jet printing machine with the guiding belt transmission error compensation function, and belongs to the field of ink jet printing equipment. An ink jet printing machinein the prior art cannot measure moving errors accurately and thus automatic and accurate ink jet printing cannot be achieved. According to the ink jet printing machine, a driving system drives an object to be printed to move automatically, manpower can be effectively saved and ink jet efficiency is improved; and meanwhile compared with manual regulation, more accuracy can be achieved. By means ofthe ink jet printing machine, no light source detection (sensing) equipment and camera shooting equipment need to be arranged, invested cost is low, the structure is compact, the moving errors can beobtained at once, no repeated measurement and image contrast are required, and the working efficiency is high. A position correction mechanism is arranged, an ink jet printing head device can be automatically adjusted to move accurately according to the moving errors of the object to be printed, the moving errors are accurately compensated for, and the scheme is detailed and practicable. The ink jet printing head device can be adjusted automatically through a mechanical structure, manpower can be effectively saved, and the ink jet efficiency is improved; and meanwhile compared with manual regulation, more accuracy can be achieved.

Owner:HANGZHOU HONGHUA DIGITAL TECH

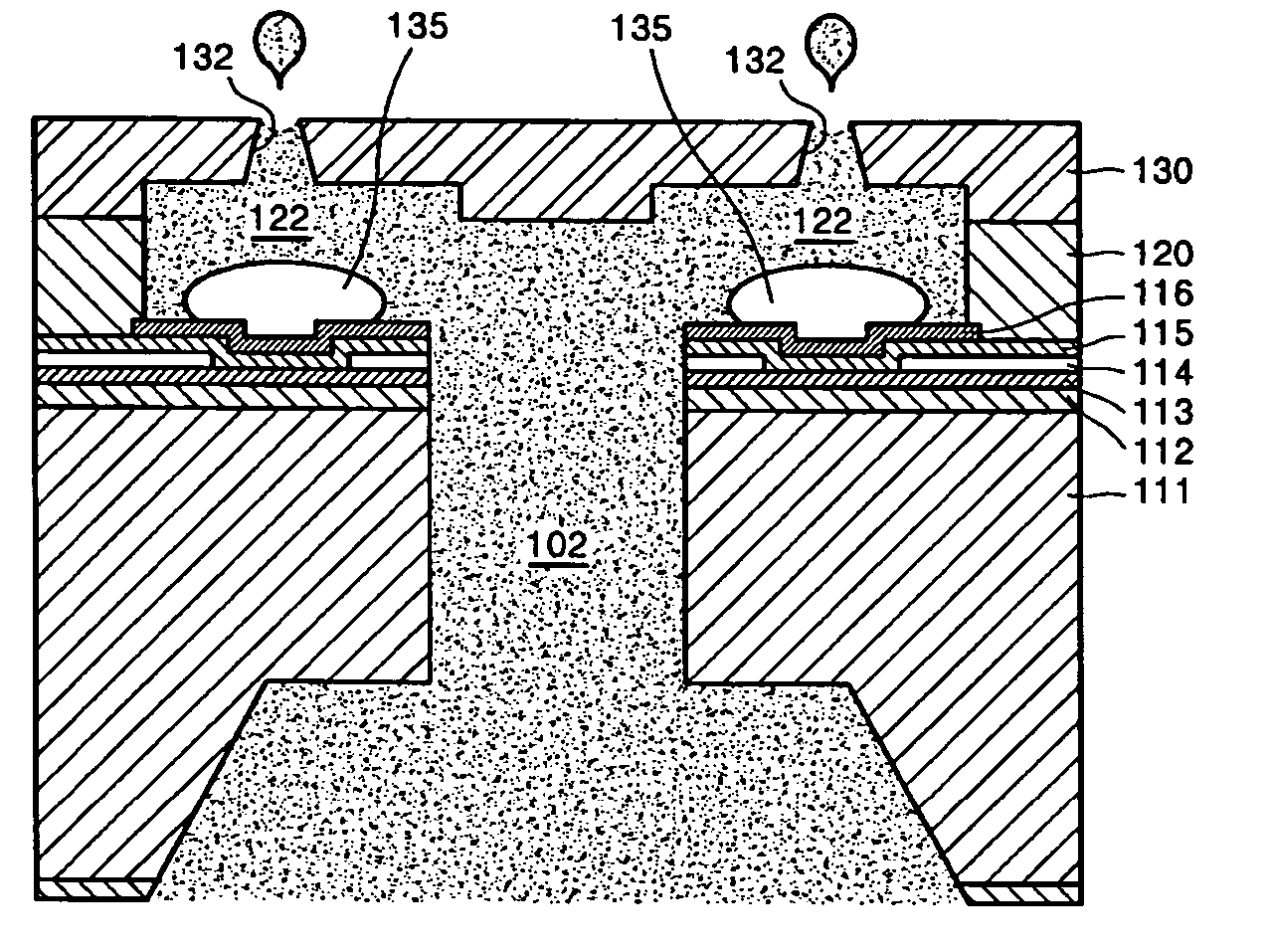

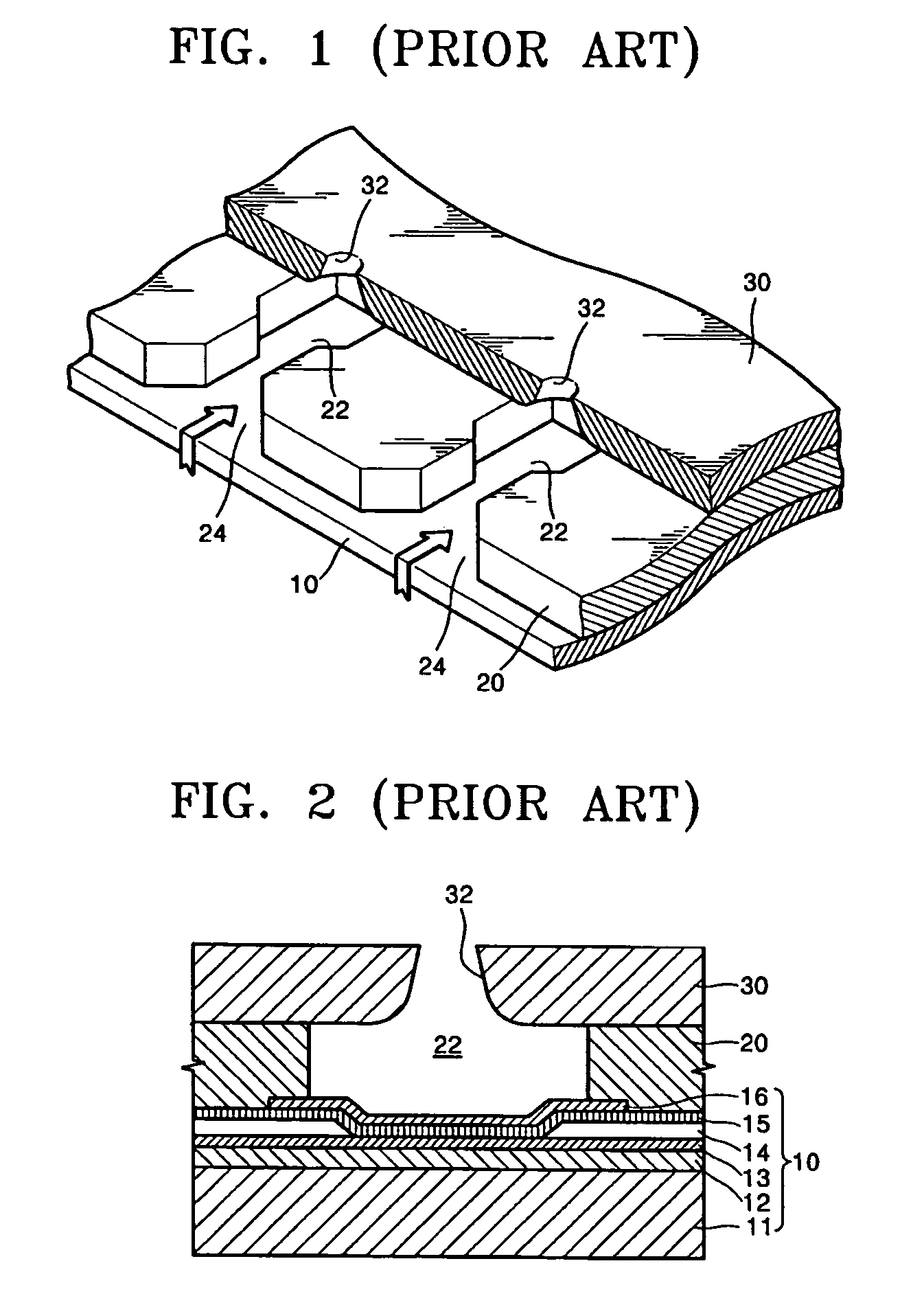

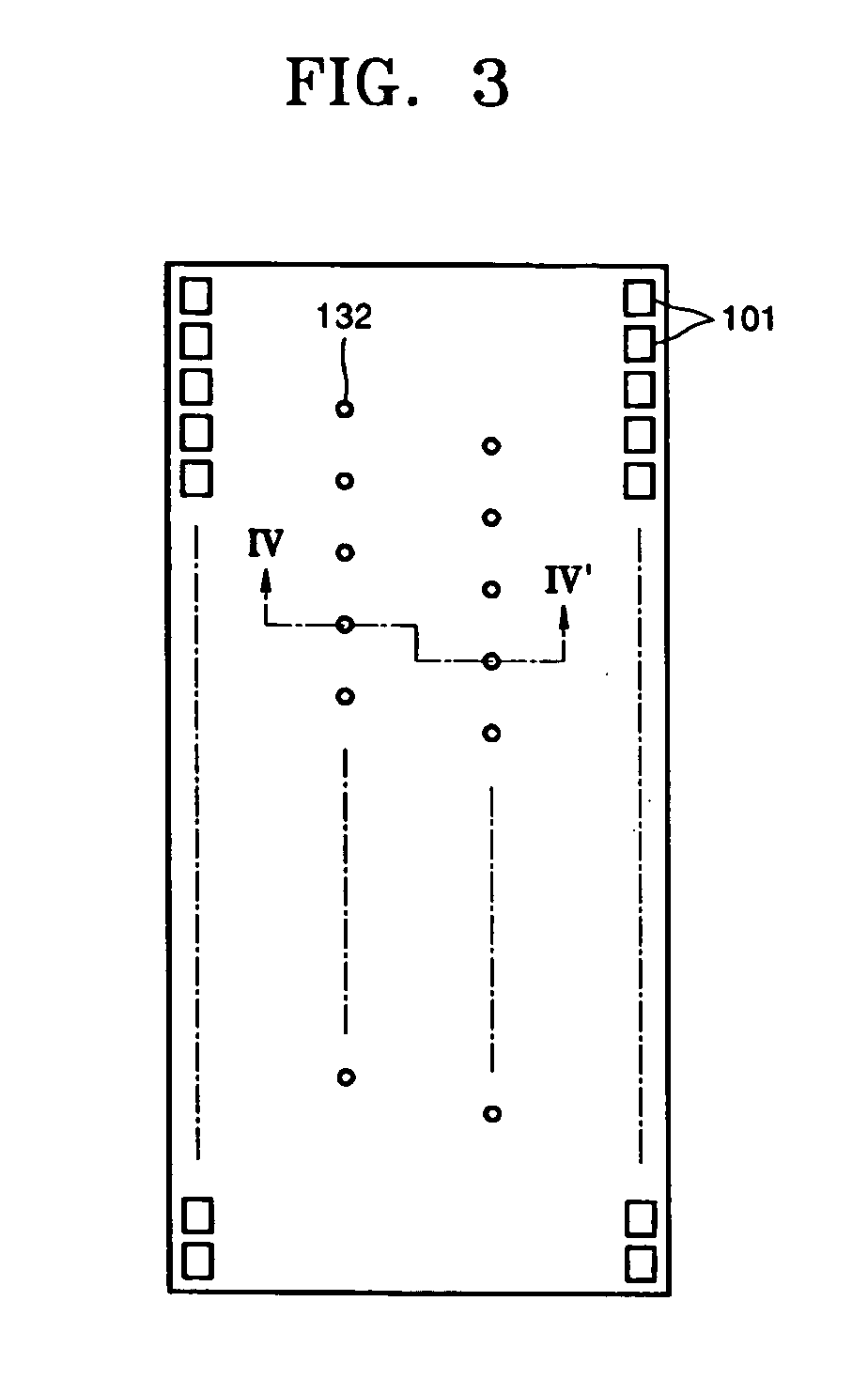

Ink-jet printhead and method of manufacturing the same

An ink-jet printhead and a method of manufacturing the same. The ink-jet printhead includes a substrate on which a heater to boil ink and a conductor to supply a current to the heater are formed, a chamber layer disposed on the substrate, the chamber layer defining an ink chamber containing the ink and being composed of at least polyimide, and a nozzle plate disposed on the chamber layer, the nozzle plate having nozzles through which the ink is ejected.

Owner:SAMSUNG ELECTRONICS CO LTD

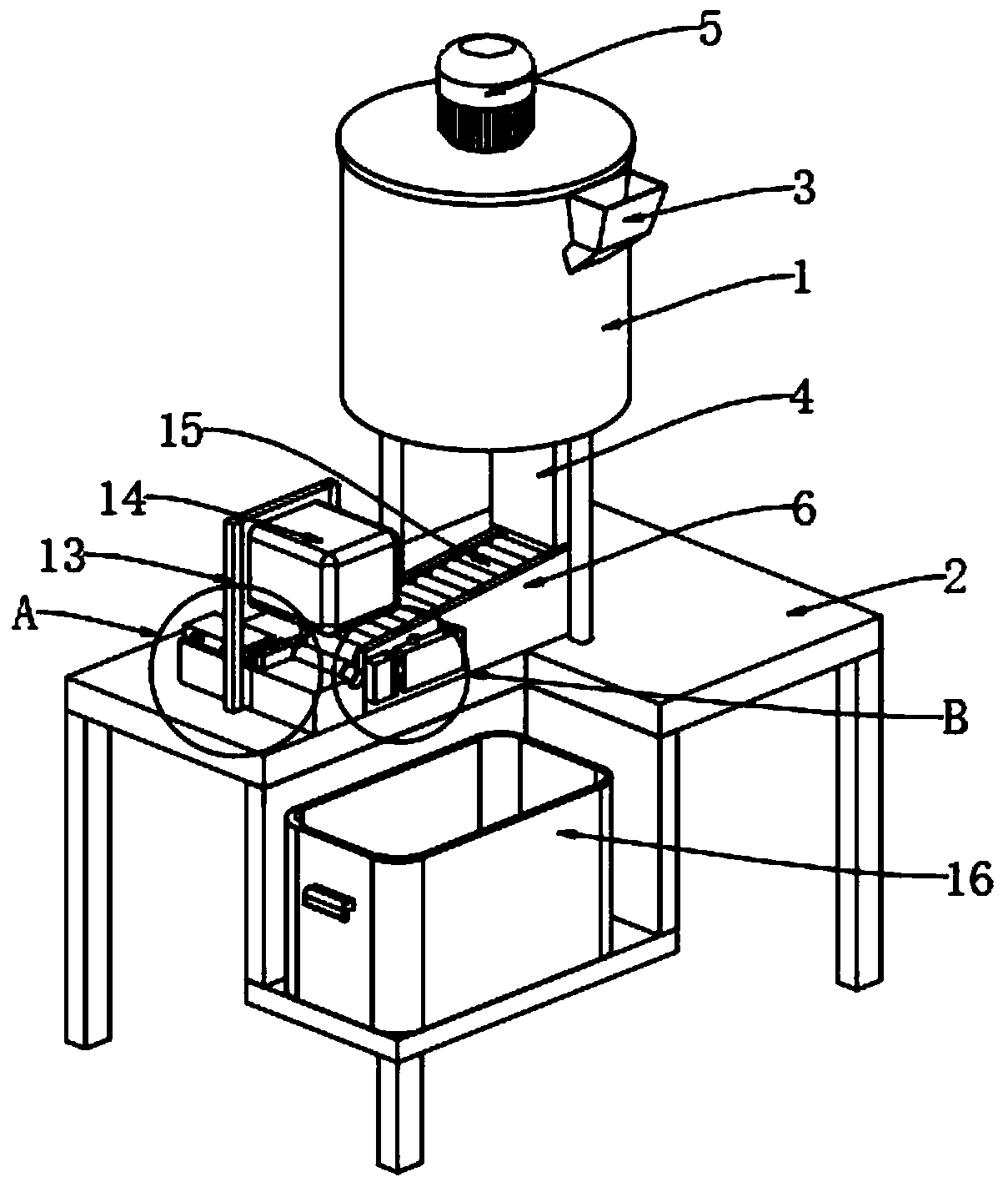

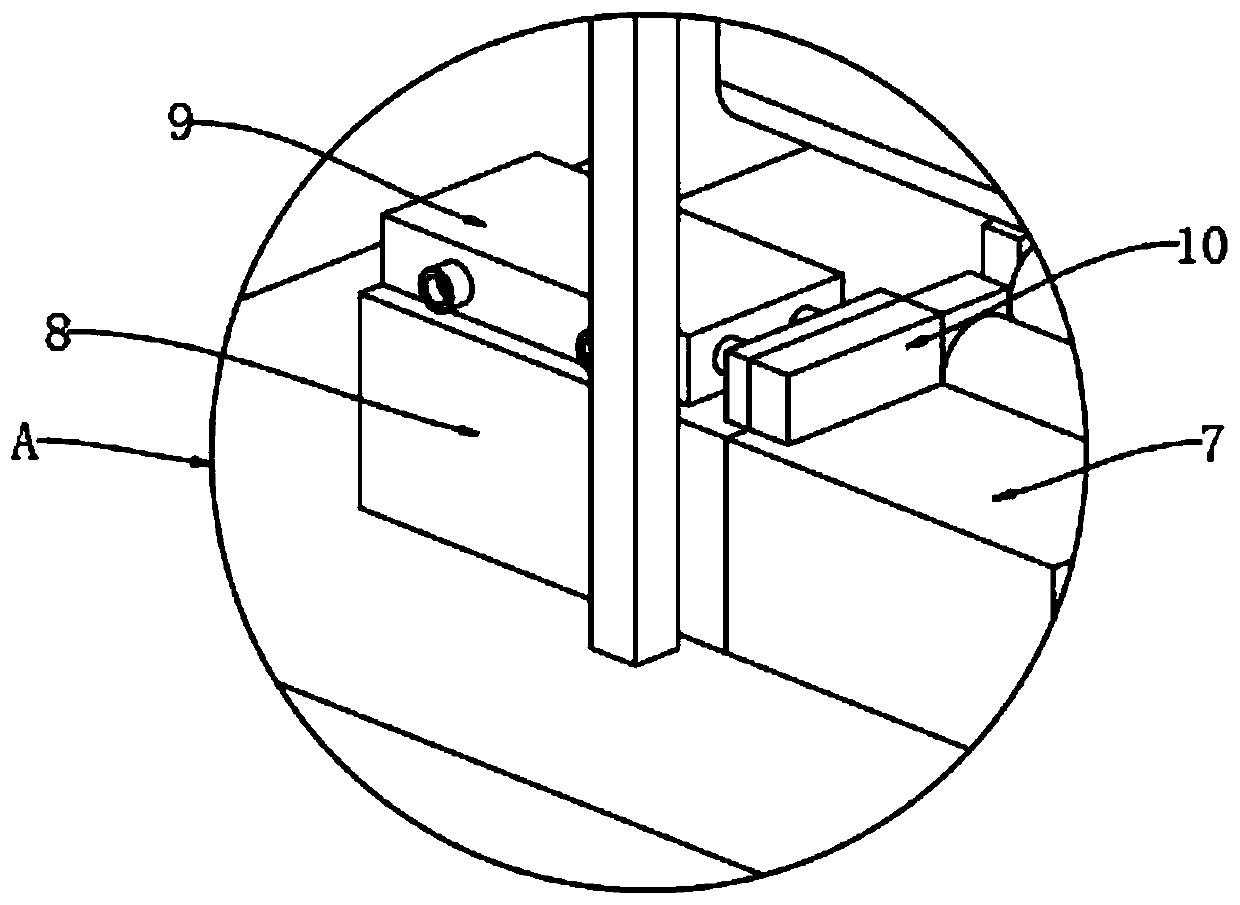

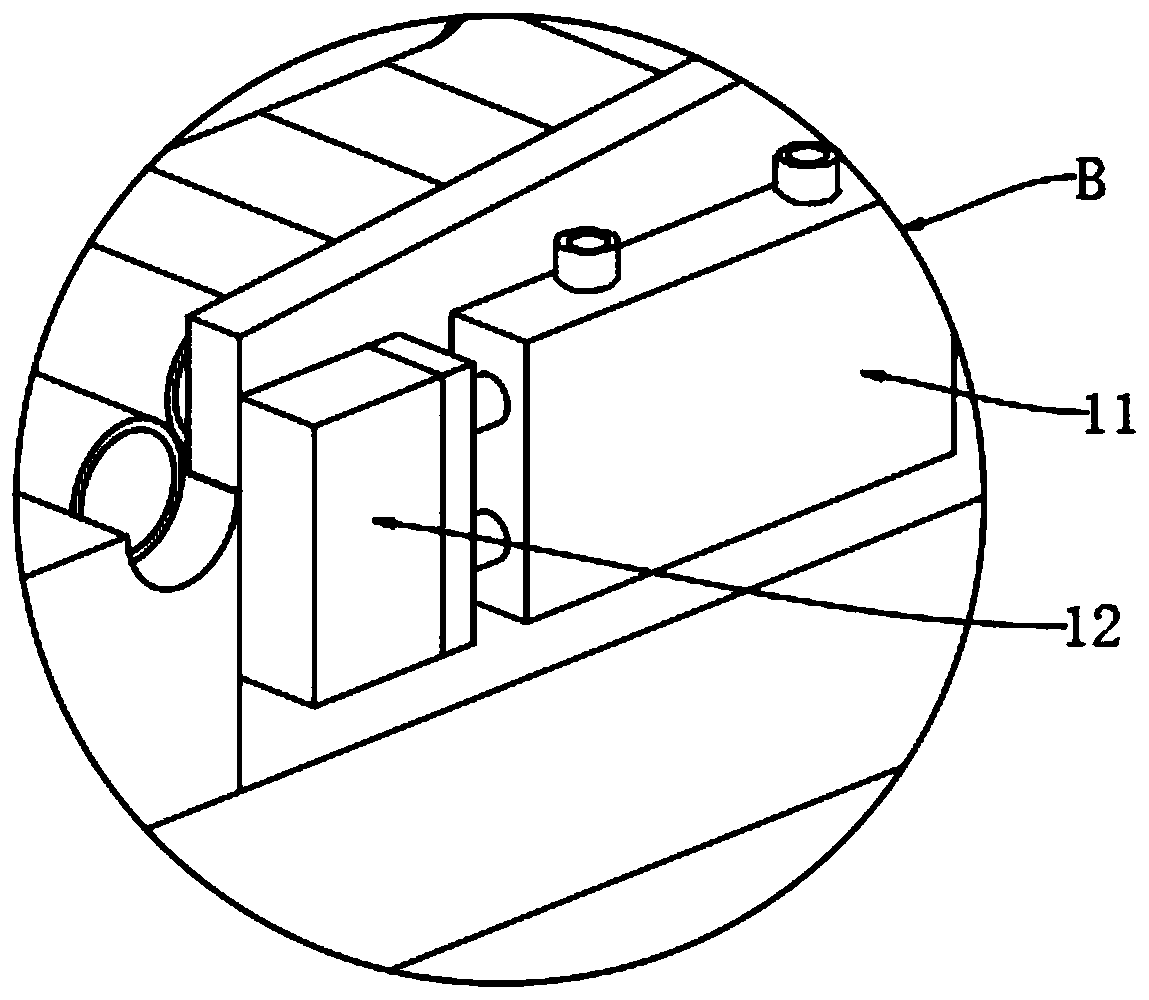

LED support inkjet equipment and inkjet method thereof

InactiveCN103943732AWork fasterImprove inkjet efficiencyDuplicating/marking methodsSemiconductor devicesHigh pressureAdhesion force

The invention discloses a set of LED support inkjet equipment and an inkjet method of the LED support inkjet equipment. The inkjet equipment comprises an upper mold, a lower mold, an ink box, an ejector pin, an ink suction air cylinder, an inkjet air cylinder, an ink scraping air cylinder, a horizontal workbench, a vertical supporting frame and a controller. Driving actions of all the air cylinders on the ink box, the ejector pin and the upper mold can be intelligently controlled by the controller so that ink storage space can be automatically reserved and automatic ink filling and automatic inkjet and the like can be achieved, the inkjet efficiency is improved, and the production cost is reduced. High-seal high-pressure inkjet operation can be performed on LED supports in a mode of an immersion cavity, so that the inkjet layer of each LED support is compact and uniform, the adhesion force is increased, ink overflow, leaky white, irregularity and other undesirable phenomena cannot happen easily, and the quality of the products is improved. Meanwhile, a plastic base of each LED support does not need to be formed for the second time, the production cost is reduced, and the performance of the products is improved. In the inkjet mode, the distance between the LED supports can be smaller (larger than 0.3 mm), and complex LED supports with high density, large area and multiple particles can all be produced efficiently.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

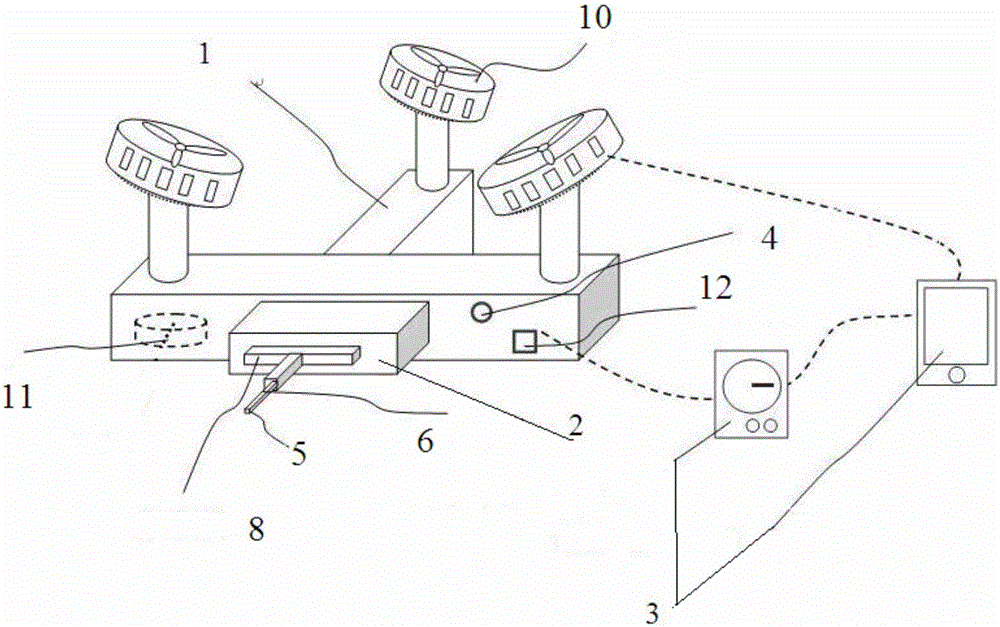

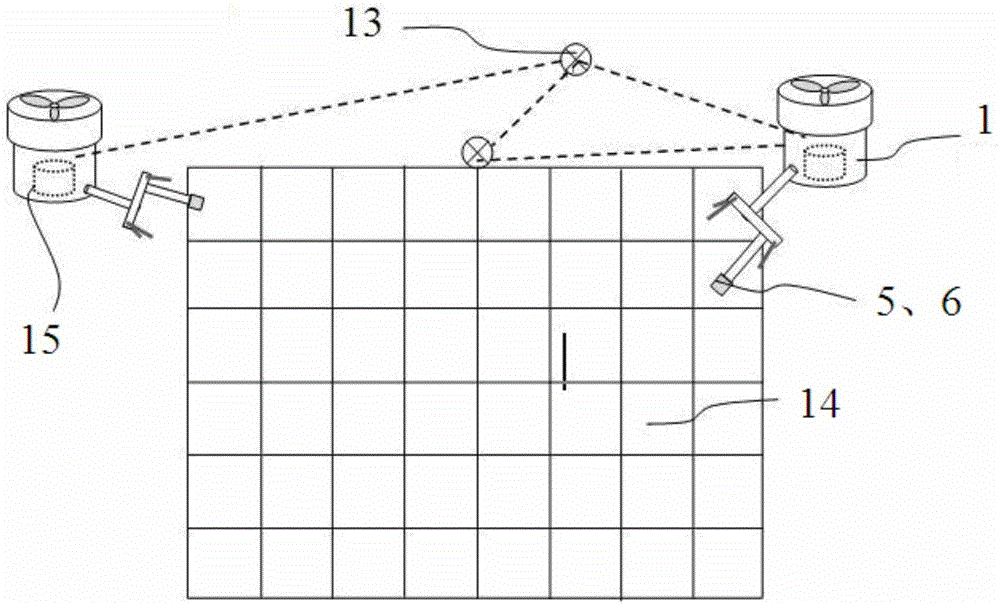

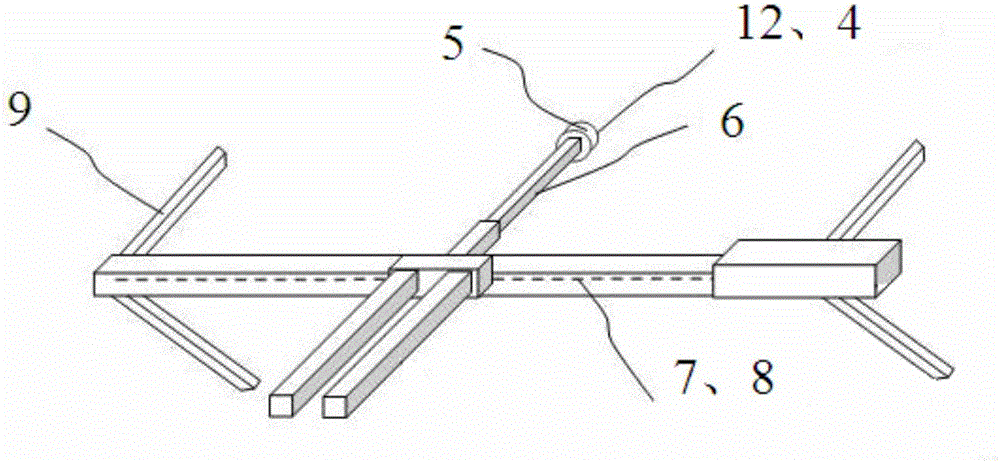

Unmanned aerial vehicle automatic airbrushing device

InactiveCN105923162AEnsure safetyInkjet flexibleAircraft componentsTypewritersRemote controlEnergy conservation

Disclosed is an unmanned aerial vehicle automatic airbrushing device. The unmanned aerial vehicle automatic airbrushing device is characterized by comprising an unmanned aerial vehicle, an automatic airbrushing device body mounted on the unmanned aerial vehicle, and a remote control device, the remote control device comprises a remote control device controlling end and a remote control device controlled end mounted on the unmanned aerial vehicle, and the remote control device comprises a device controlling flying direction and flying speed of the unmanned aerial vehicle and an automatic airbrushing control device controlling the automatic airbrushing device body. By using the unmanned aerial vehicle automatic airbrushing device, climbing for manual airbrushing of a tall wall is avoided, safety of airbrushing personnel is guaranteed, and airbrushing effect is good. Extra work for manual climbing and arranging of safety equipment is omitted, so that energy resources are saved, and working efficiency is improved.

Owner:SUZHOU UNIV

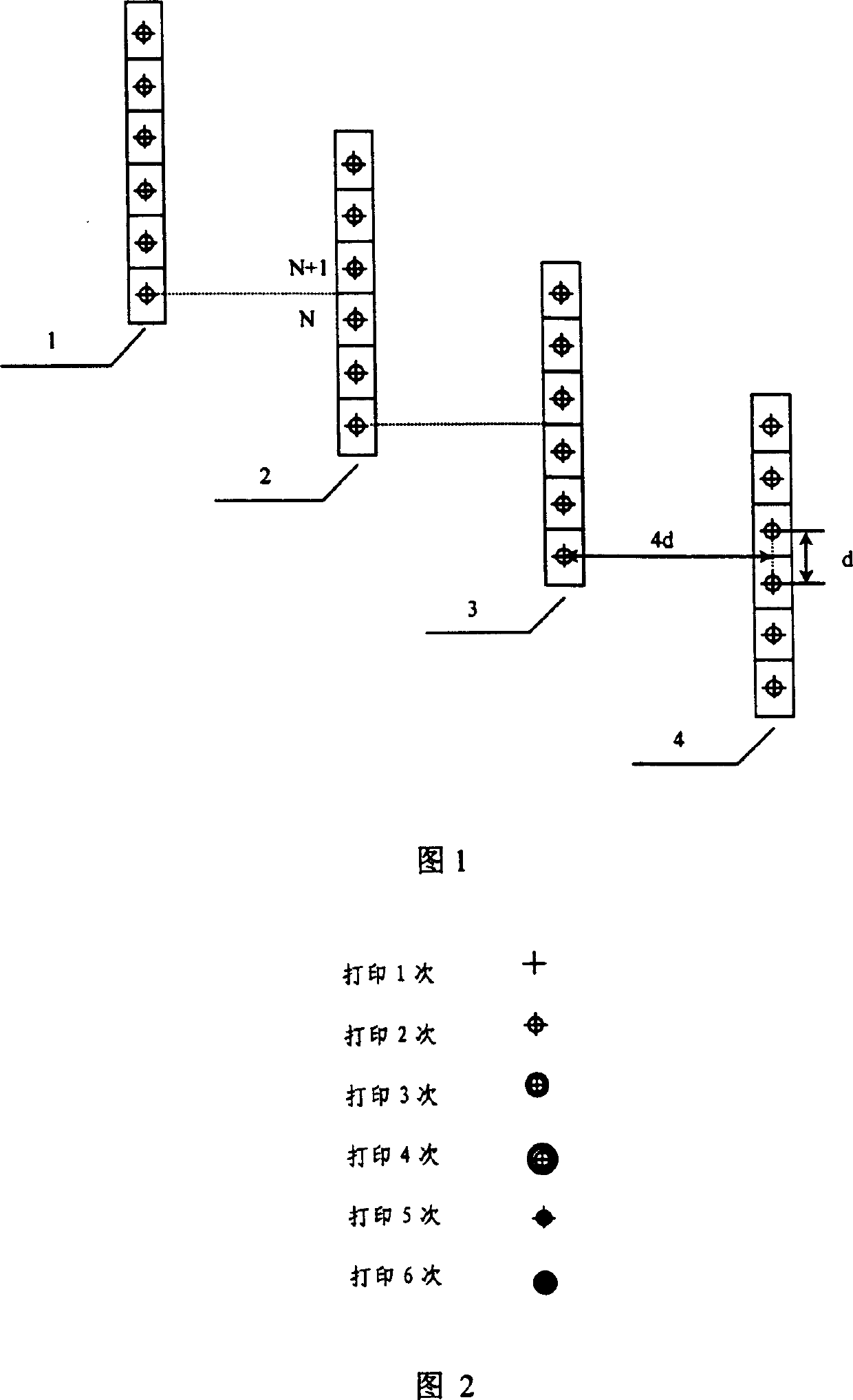

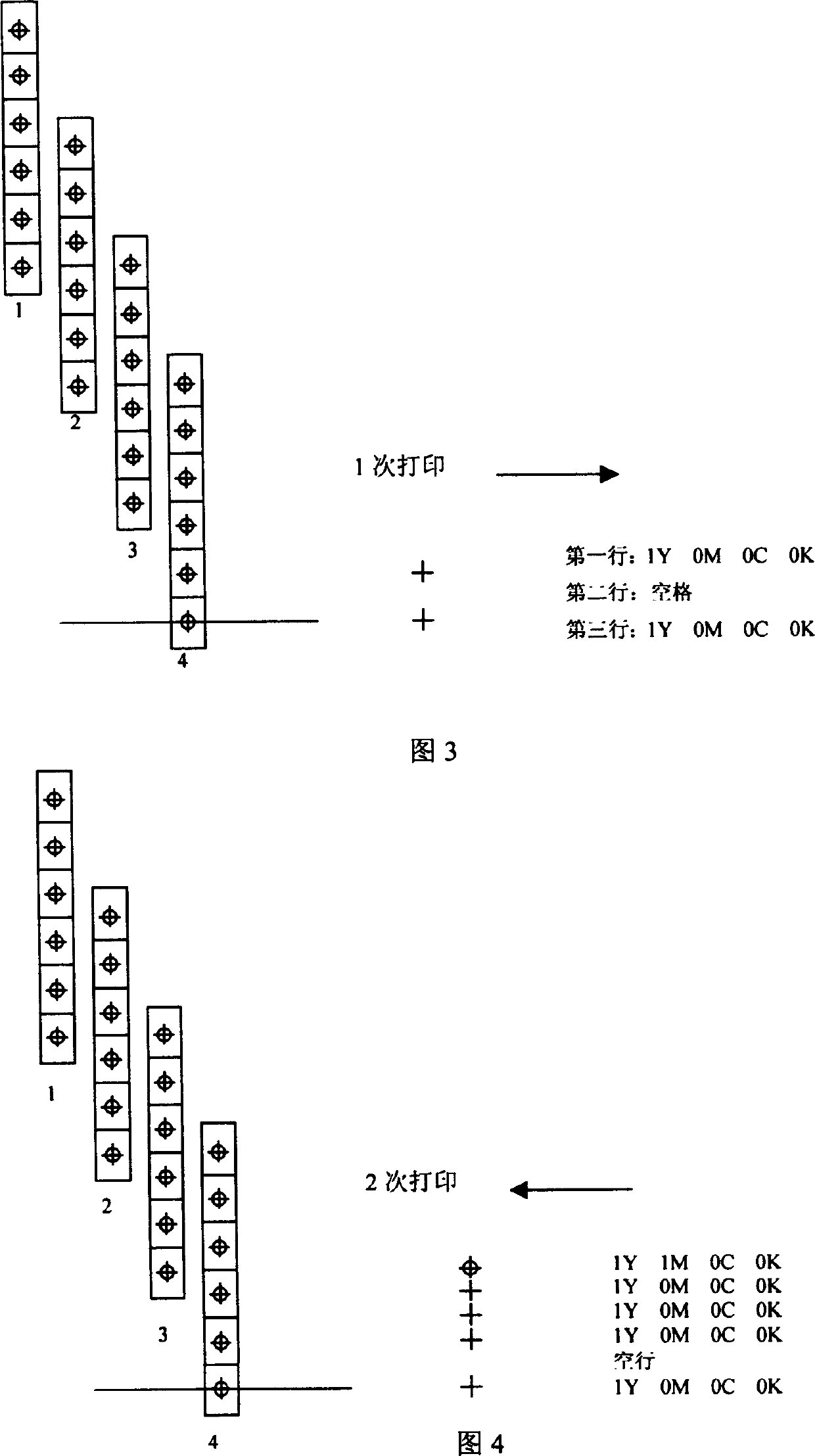

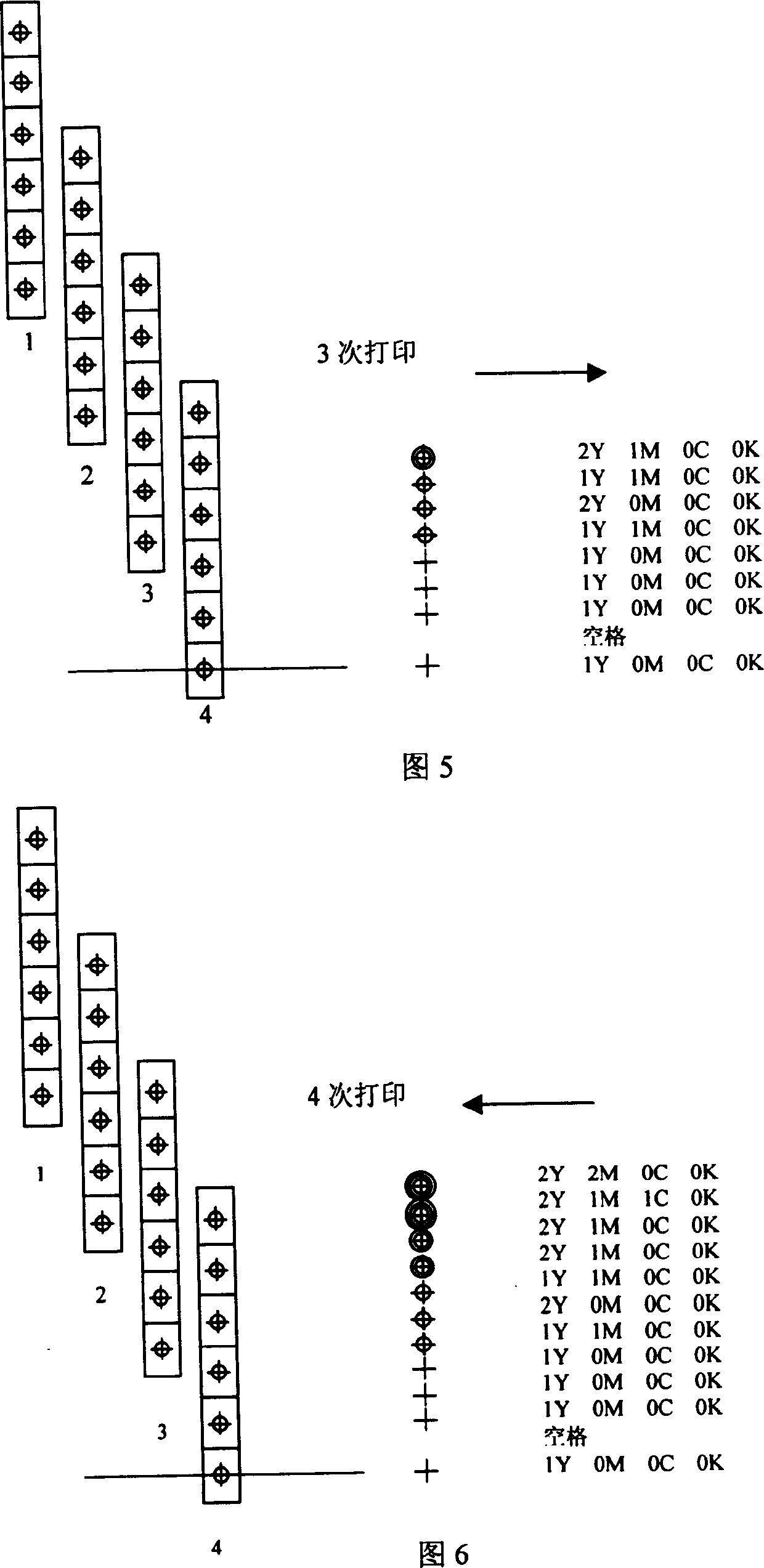

Method for vertical arranging color ink jet plotter nozzles

InactiveCN1451541AReduced rearrangement operationsImprove inkjet efficiencyPrintingHorizontal and verticalPlotter

A vertical arranging method for the nozzles of color ink-jet plotter is characterized by that 4 nozzles for yellow ink, pinkish red ink, green ink and black ink are sequentially arranged in vertical direction. Each nozzle has 2N jet pinholes, where N-32-256. The position of the nozzle for yellow ink is used as the horizontal reference. The horizontal position of the first jet pinhole of next nozzle is between N and N+1 pinholes of previous nozzle. Its advantages are high print precision in X and Y directions and high printing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Spraying technology for colored sculpture of ceramic tile and product thereof

InactiveCN103407317AStrong three-dimensional senseStrong aestheticsDecorative surface effectsMetallurgyCeramic tiles

The invention discloses a spraying technology for colored sculpture of a ceramic tile. The technology comprises the following steps: 1) pasting a protection membrane; 2) cutting edge; 3) peeling off the protection membrane; 4) sculpturing; 5) cleaning; 6) spraying paint. The invention further discloses a ceramic tile product which implements the technology. The technology provided by the invention has simple steps, can be implemented easily, is high in spraying efficiency, strong in character, high in flexibility, and free from limitation of bottom color of the ceramic tile, and can have customized color, pattern and size, enable the surface of the ceramic tile to display stereoscopic embossing quickly, and spray corresponding colors on the embossing according to personal preference, so that the ceramic tile has richer and more various patterns and colors, stronger attraction and artistry, and better decoration, and can enable people to perceive the art during busy and boring working and living and to enjoy life; the pattern of the ceramic tile product provided by the invention is colorful, various, beautiful, elegant, fashionable, and suitable for popularization and application.

Owner:陈权胜

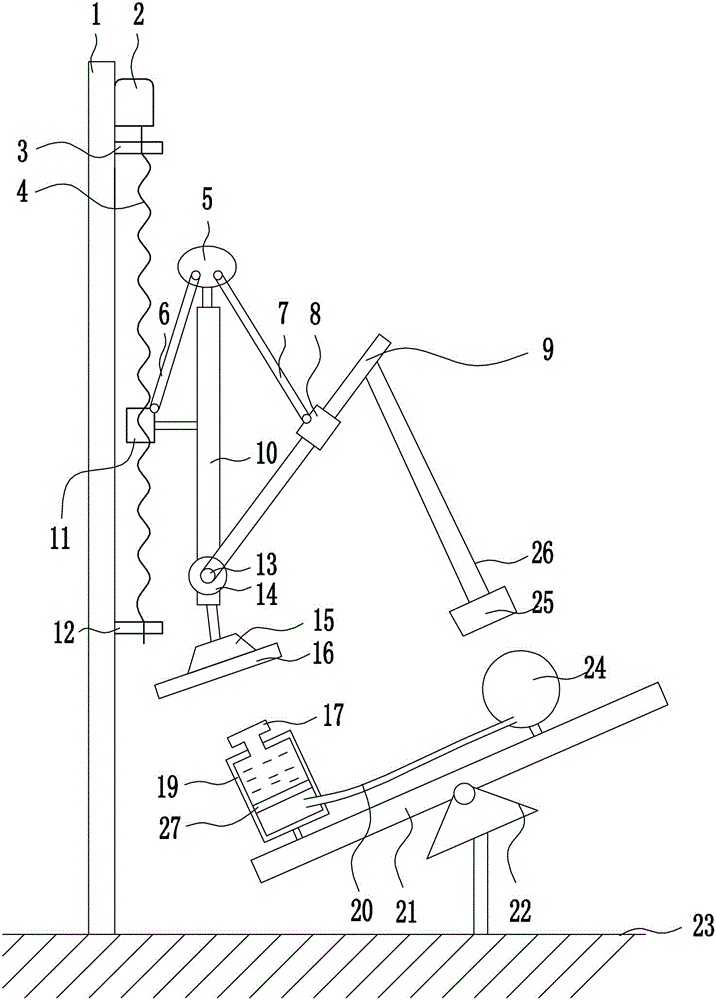

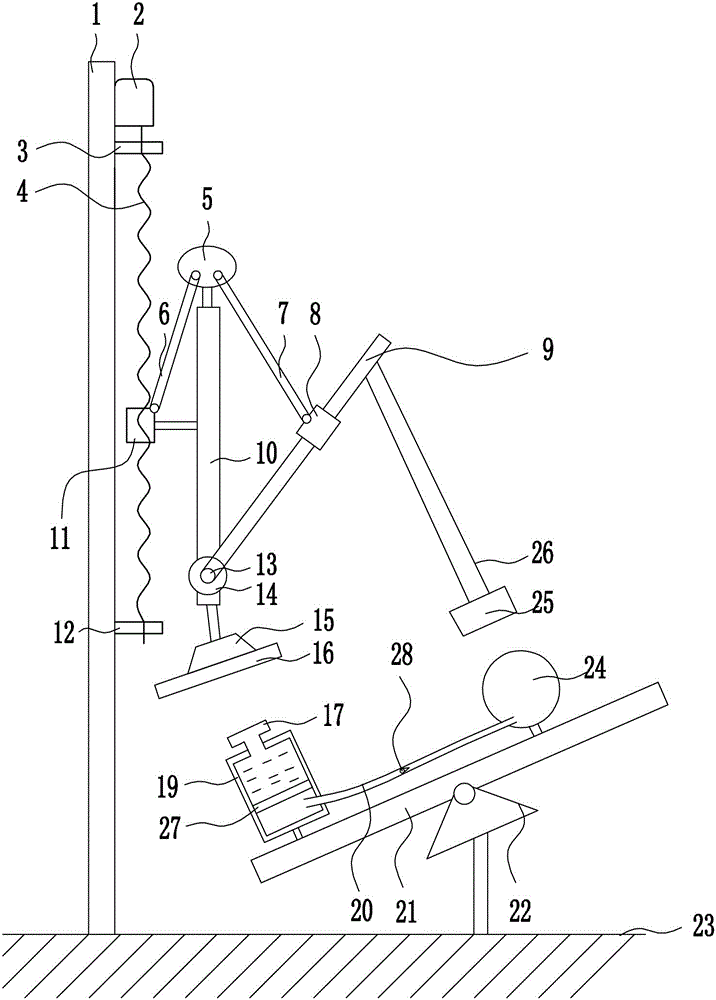

Pattern spray-painting device for glass curtain wall

InactiveCN106142864AImprove inkjet efficiencyInkjet effect is goodTypewritersElectric machineryEngineering

The invention relates to a spray-painting device, in particular to a pattern spray-painting device for a glass curtain wall. The pattern spray-painting device for the glass curtain wall aims to achieve the purposes of high spray-painting efficiency, remarkable spray-painting effect and high practicability. The pattern spray-painting device for the glass curtain wall comprises a first support, a motor, an upper bearing block, a screw rod, a disc, a first connecting rod, a second connecting rod, a sliding sleeve, a leftward-rightward swinging rod, a fixing plate, a nut, a lower bearing block and the like, wherein the first support and a triangular support are arranged on the ground; the motor, the upper bearing block and the lower bearing block are sequentially arranged on the right side of the first support from top to bottom; the screw rod is connected between the upper bearing block and the lower bearing block; the upper end of the screw rod is connected with the motor; the nut is installed on the screw rod and matched with the screw rod; and the fixing plate is arranged on the right side of the nut. The pattern spray-painting device for the glass curtain wall achieves the effects of high spray-painting efficiency, remarkable spray-painting effect and high practicability.

Owner:张美容

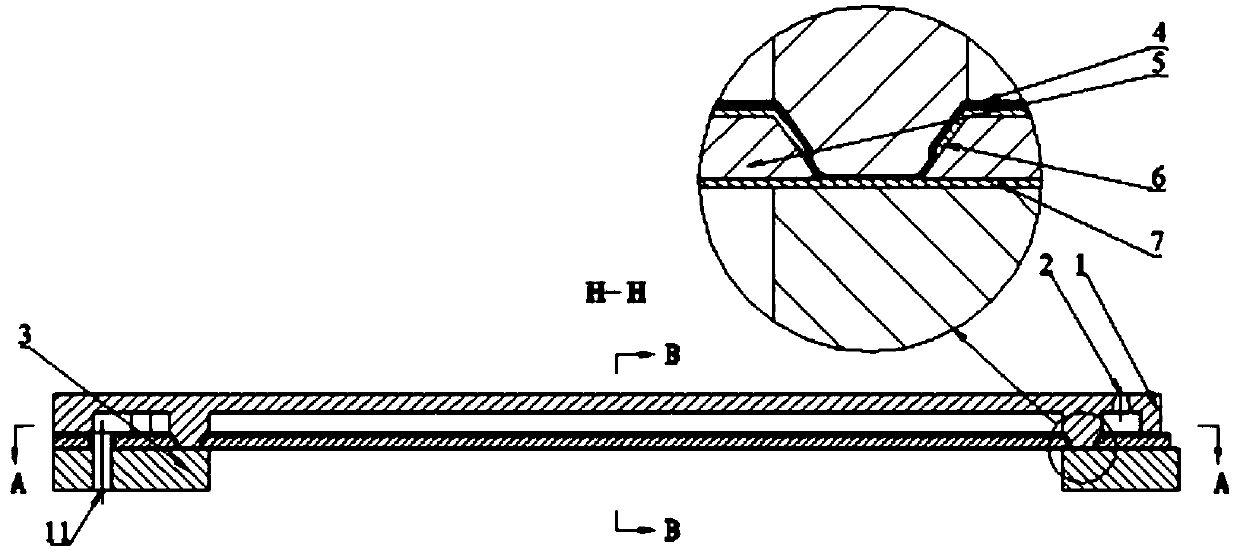

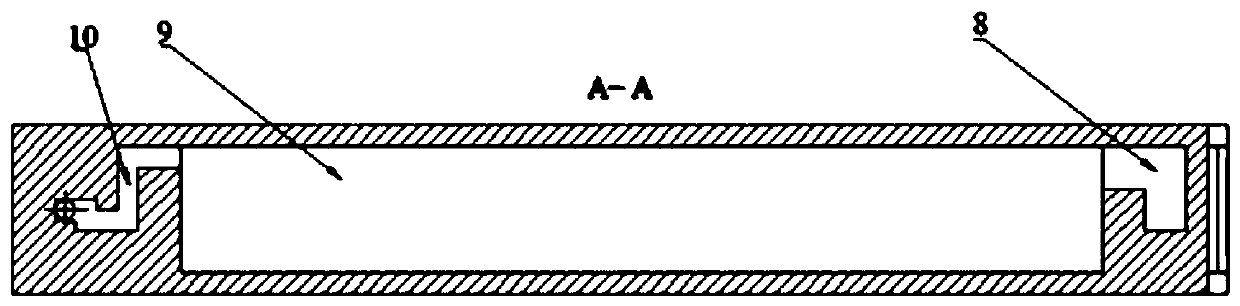

Piezoelectric inkjet printing spray head structure preventing ink backflow

The invention provides a piezoelectric inkjet printing spray head structure preventing ink backflow. An ink supply channel is connected with an ink box. Due to capillary force action, the ink supply channel, a flow limiting part, a pressure generation cavity and a flow guide part are full of ink sequentially, and the ink reaches a nozzle. An upper electrode, piezoelectric ceramics, a lower electrode and a vibration plate form a driving element, when the upper electrode and the lower electrode are electrified simultaneously, the piezoelectric ceramics deform due to an inverse piezoelectric effect, then the vibration plate is driven to deform, the vibration plate deforms to extrude the ink in the pressure generation cavity, the flow limiting part and the flow guide part prevent the ink fromflowing back to the ink supply channel, and the ink is sprayed out from the nozzle. The piezoelectric ceramics are used for the piezoelectric inkjet printing spray head structure, the driving elementgenerate driving force, removing machining is conducted on the base part corresponding to the pressure generation cavity, and the driving element is in a suspension state and is located in the e pressure generation cavity. The piezoelectric inkjet printing spray head structure is simple in manufacture process, low in cost and good in process repeatability and has an ink backflow prevention effect.

Owner:大连瑞林数字印刷技术有限公司

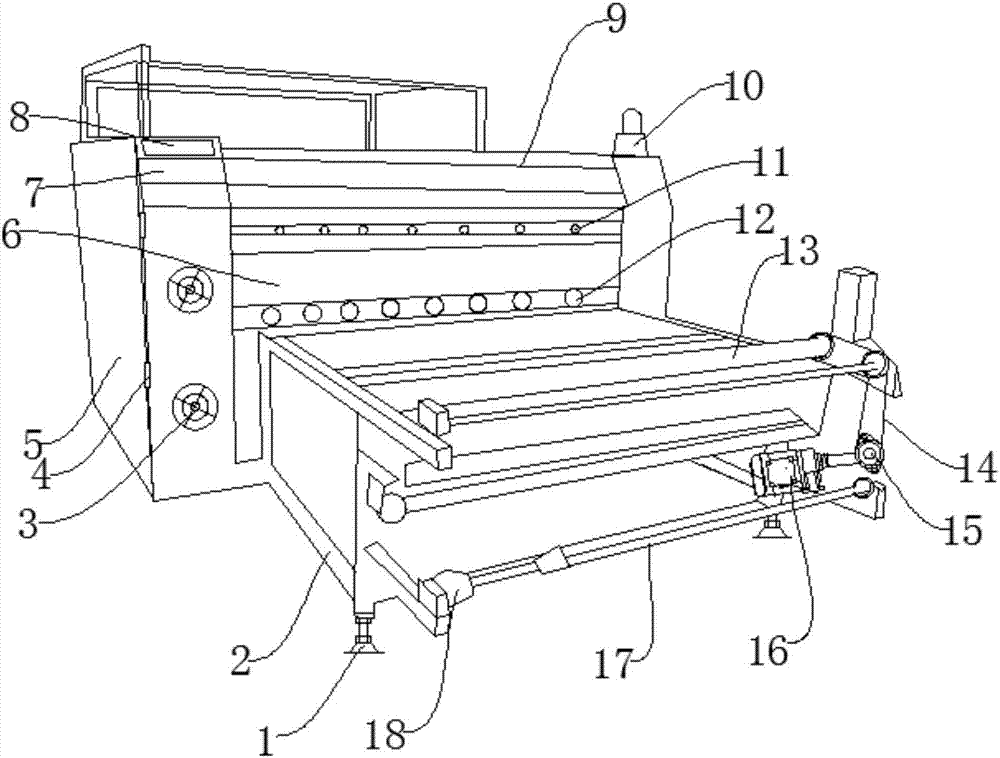

A fully-automatic cloth printing machine

InactiveCN107571627AImprove inkjet efficiencySolid colorTypewritersOther printing apparatusFully automaticConductor Coil

The invention discloses a fully-automatic cloth printing machine which comprises bottom fixed sucking discs, a rack, exhaust fans, an intelligent controller and a drag motor. The rack is arranged above the bottom fixed sucking discs. A bearing is arranged above the frame. A cloth winding shaft is arranged beside the bearing. The drag motor is arranged beside the cloth winding shaft. A pulley is arranged beside the drag motor. A belt is arranged above the pulley. A rolling shaft is arranged above the belt. The exhaust fans are arranged in front of the rolling shaft. Hinges are arranged beside the exhaust fans. Side-opening type protection doors are arranged beside of the hinges. Drying openings are arranged above the side-opening type protection doors; a roller is arranged above the dryingopenings; printing nozzles are arranged above the roller; and an operation table is arranged above the printing nozzles. The beneficial effects are that the painting efficiency is greatly raised; thepatterns are more beautiful; and the colors are firmer and better.

Owner:SHENGZHOU BINGE CLOTHING CO LTD

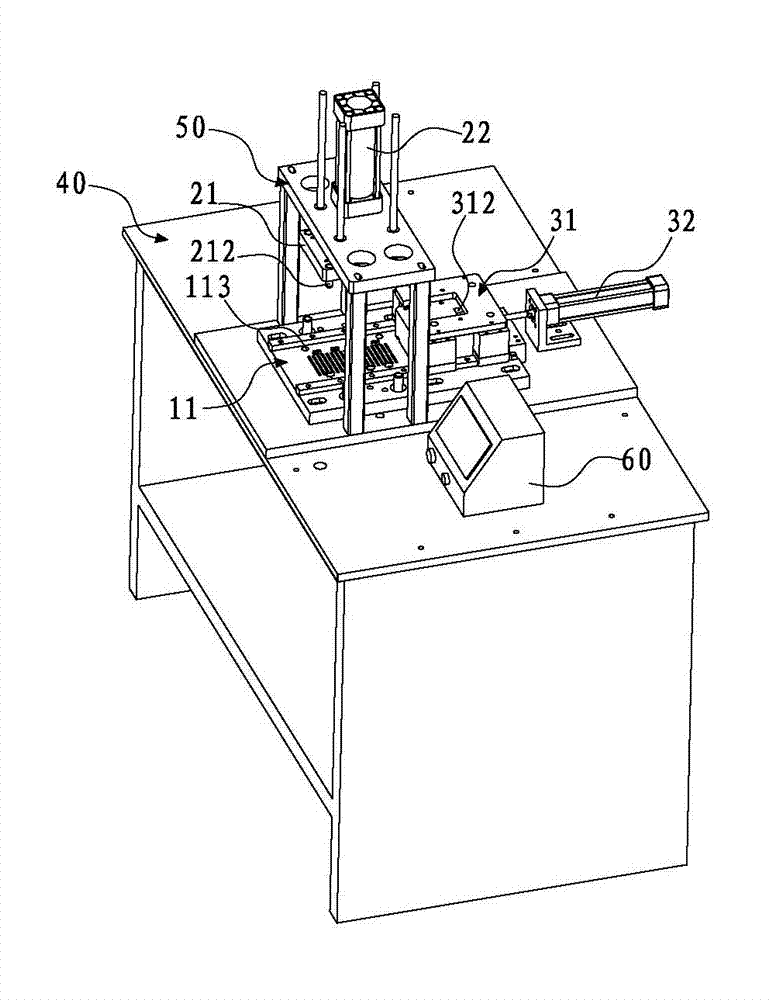

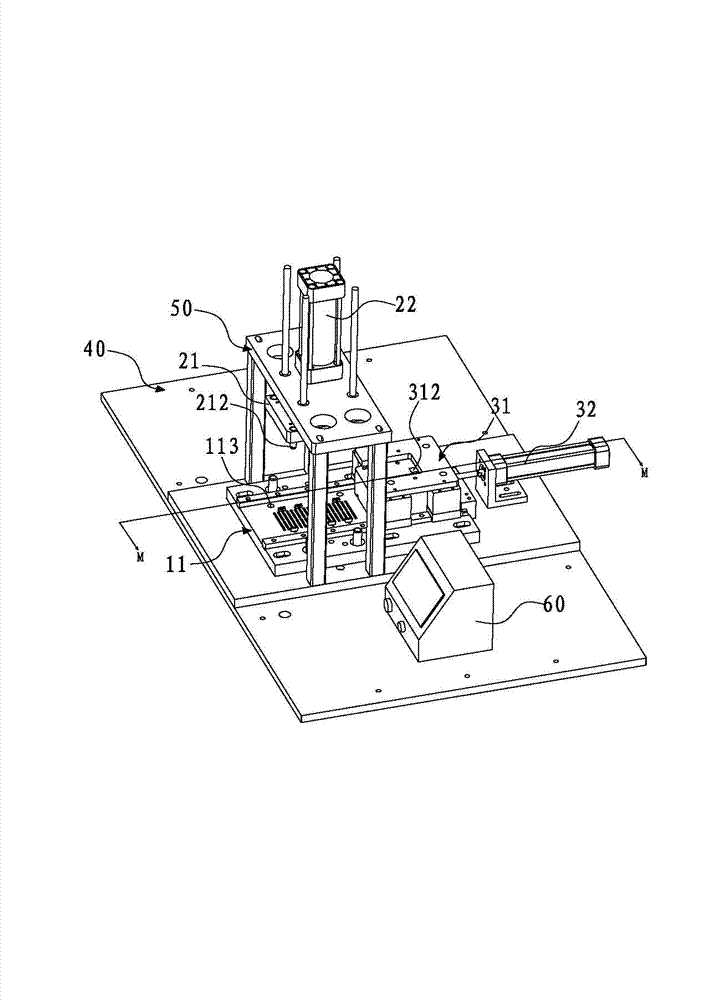

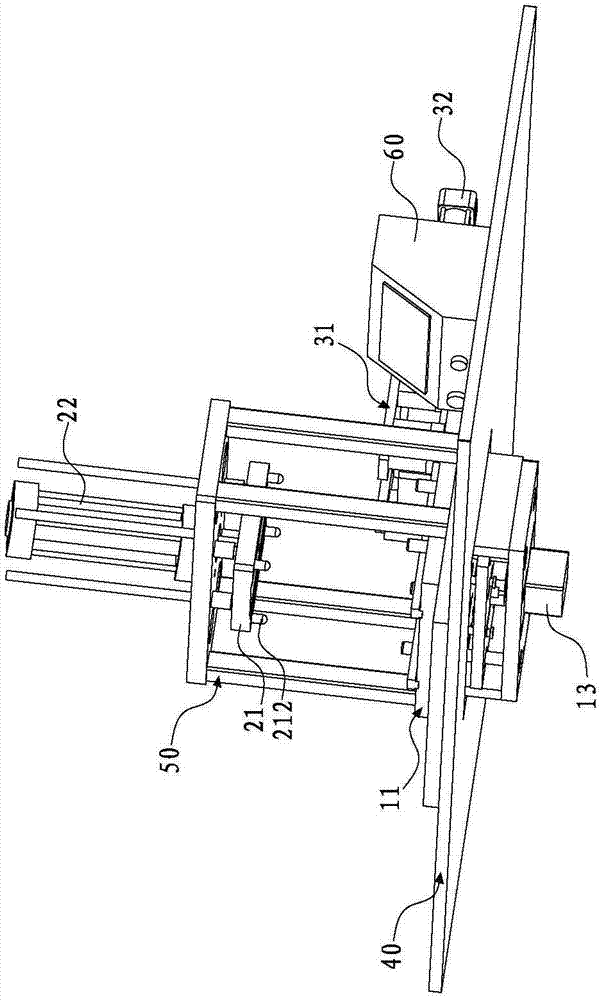

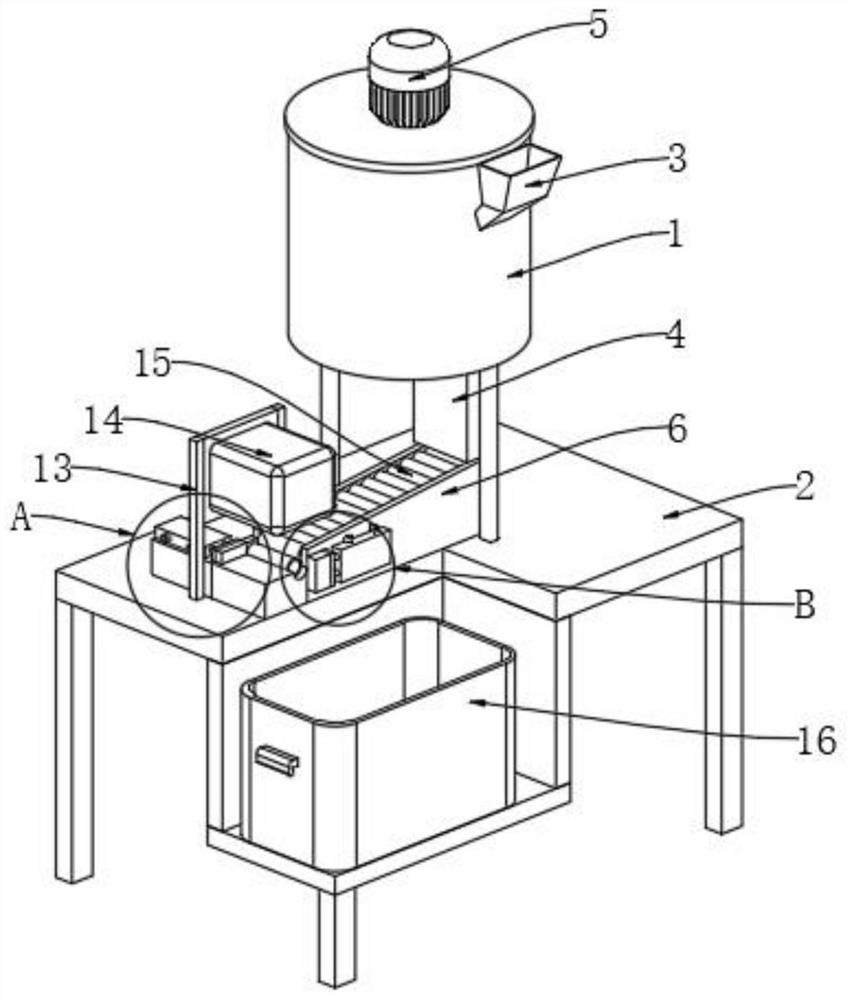

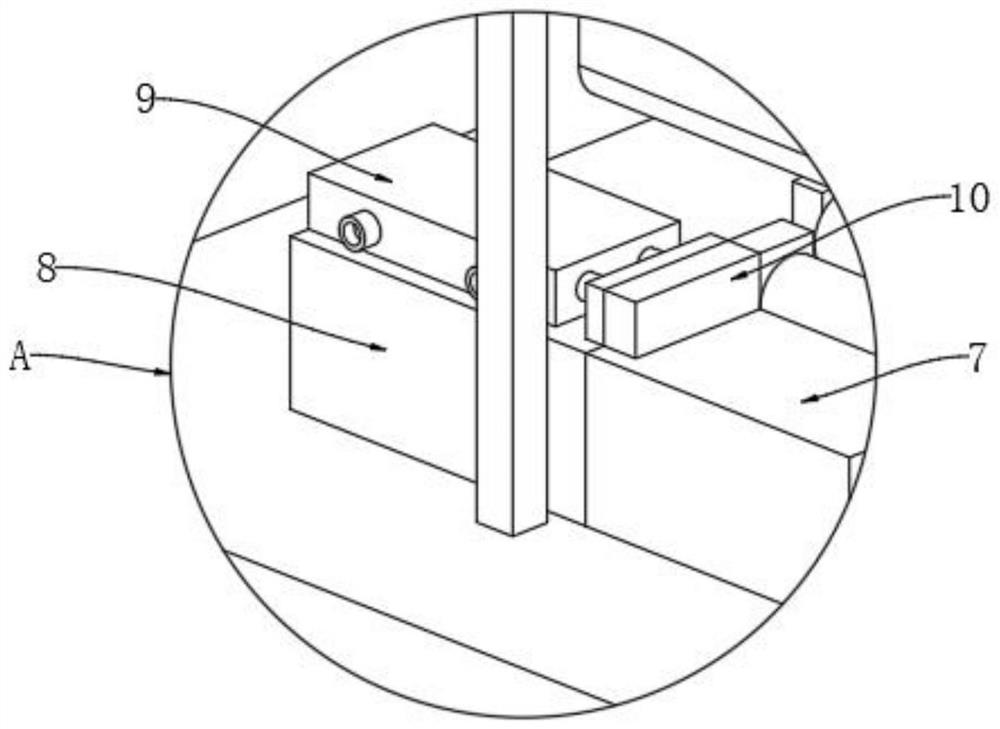

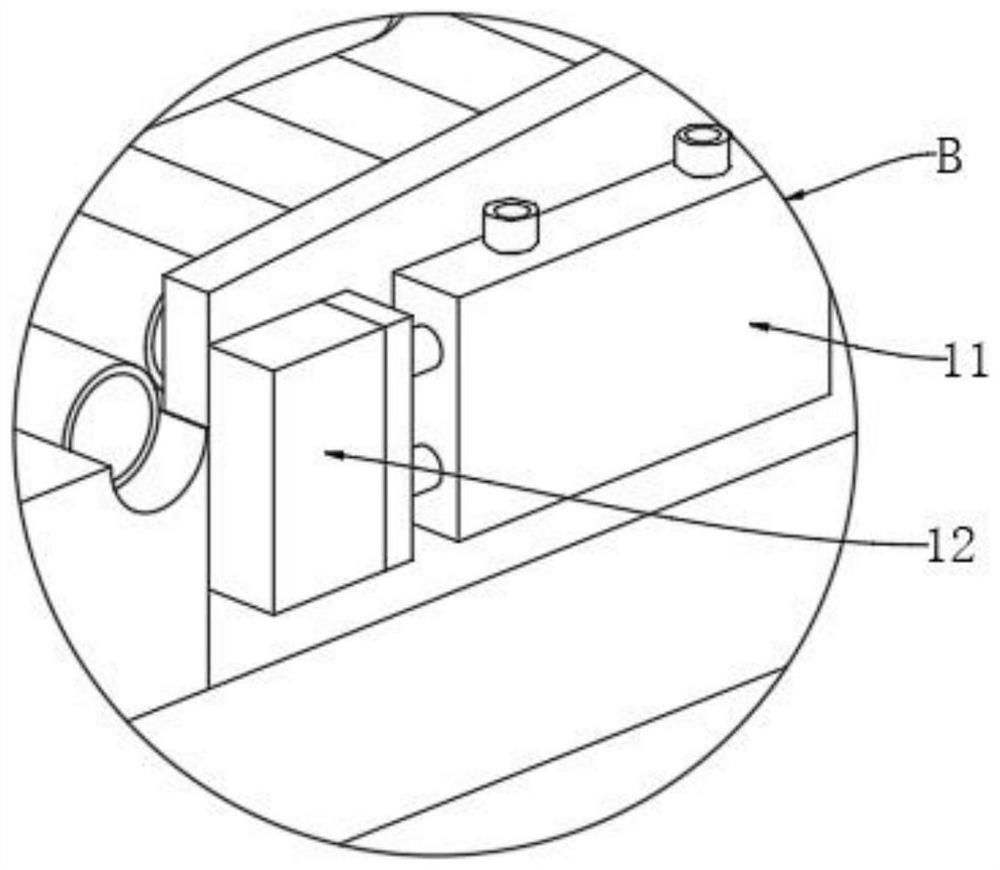

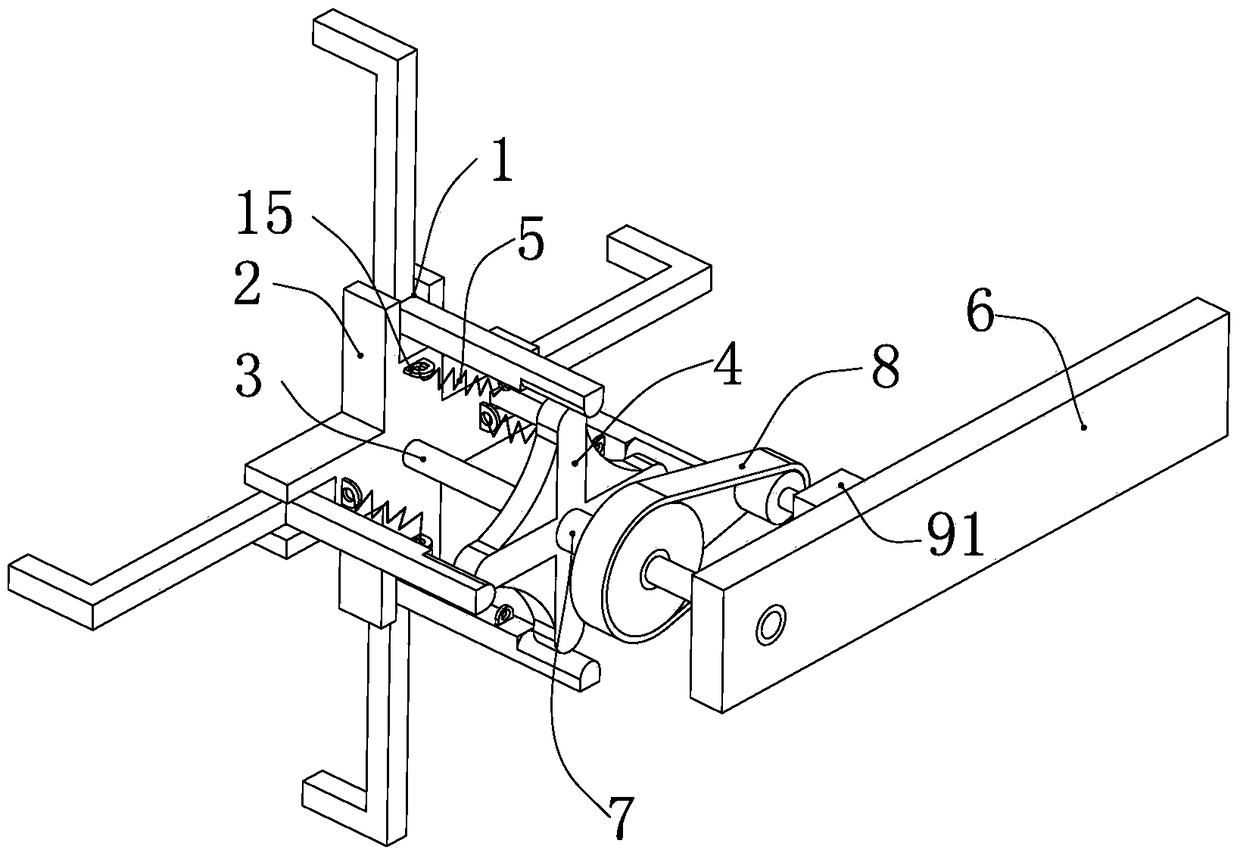

Printing device for cable markers

The invention relates to the technical field of printing devices, and particularly relates to a printing device for cable markers. The printing device comprises a workbench, a material storage box anda guide block is arranged on the top part of the workbench, a discharge channel is arranged at the bottom of the material storage box, a guide groove which is inclined downwards is formed in the topof the guide block, the tail end of the top part of the guide groove is located right below the discharge channel, and a printing table is arranged on the front side of the guide block; a cable markergroove is formed in the top part of the printing table, a first air cylinder is arranged on the left side of the printing table, a piston rod of the first cylinder faces the printing table and the tail end of the piston rod of the first air cylinder is provided with a first push block, a second air cylinder is arranged on the right side of the guide block, a piston rod of a second cylinder facesthe front and the tail end of the piston rod of the second cylinder is provided with a second push block, a machine frame is arranged on the left side of the printing table, and an ink-jet printer isarranged on the right side of the machine frame. According to the printing device for the cable markers, the cable markers in the material storage box are fallen one by one passing through the discharging channel, the cable markers are arranged in an orderly manner, after the printing is completed, the cable markers are pushed out by the first push block, the cable markers located above are rolleddownwards to continue to be printed, the cable markers do not need to be replaced manually, and the printing efficiency is improved.

Owner:HUNAN CITY UNIV

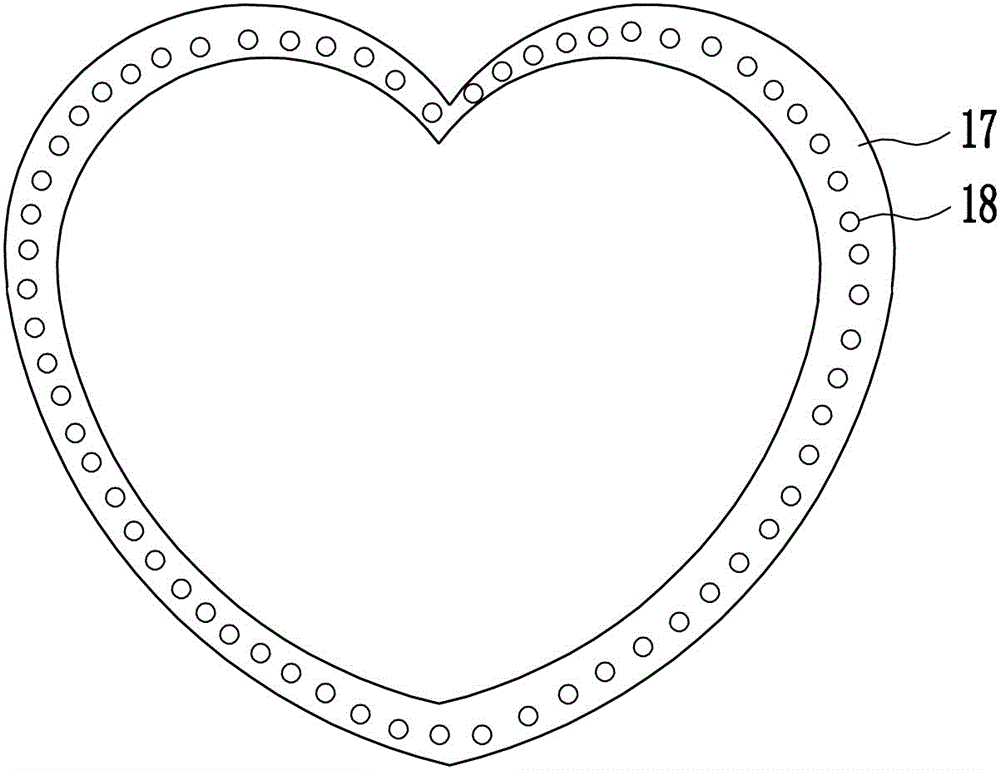

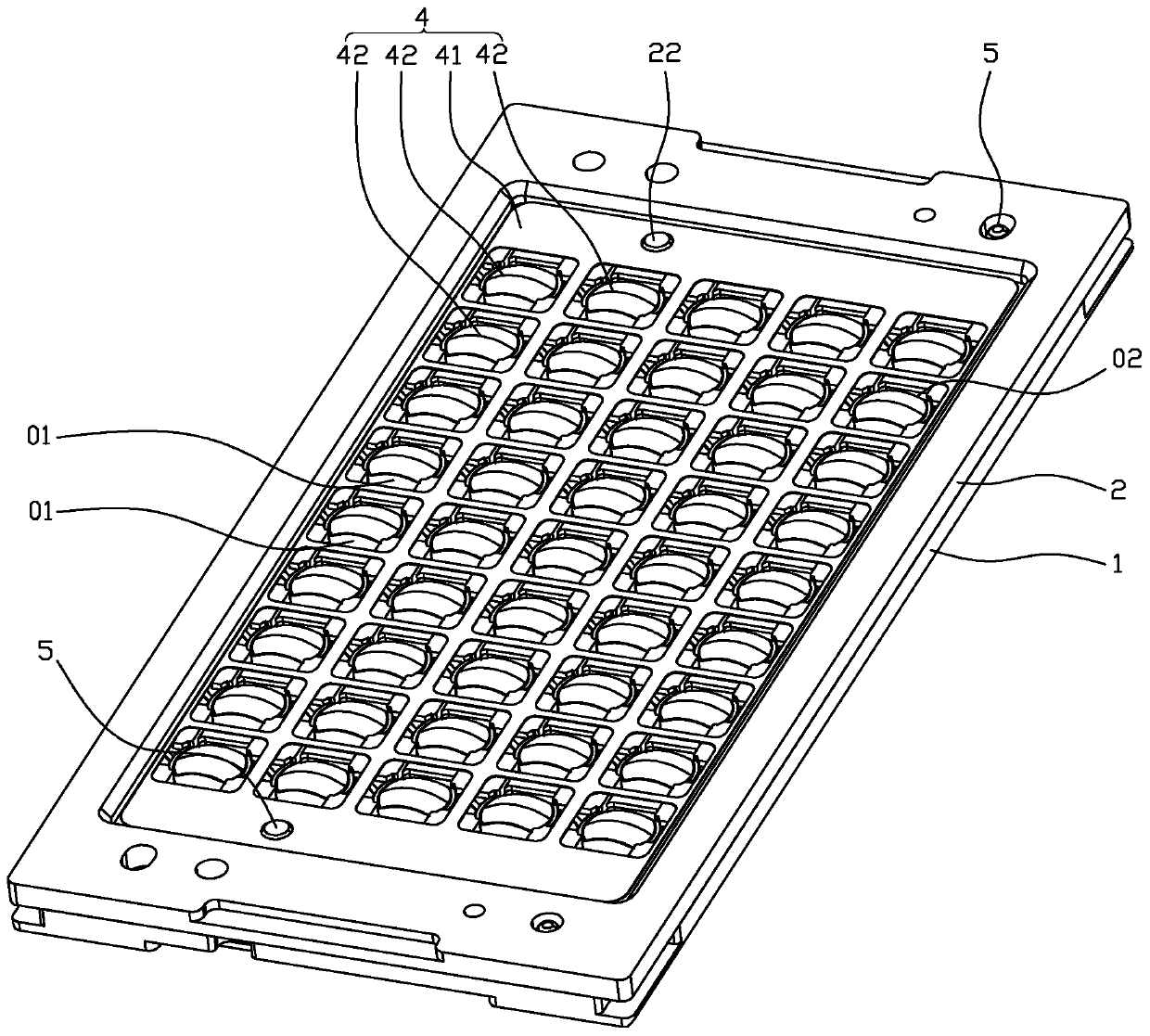

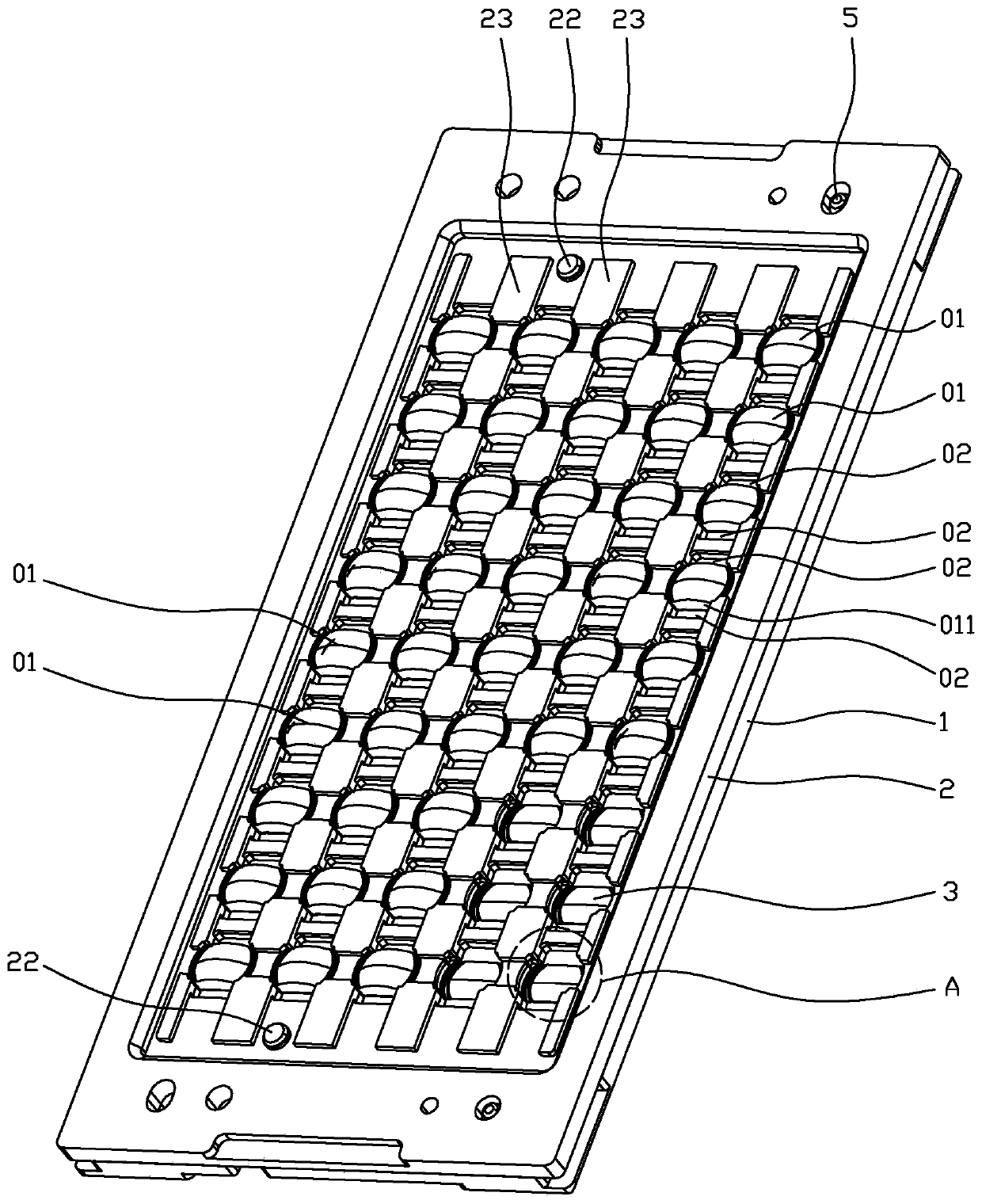

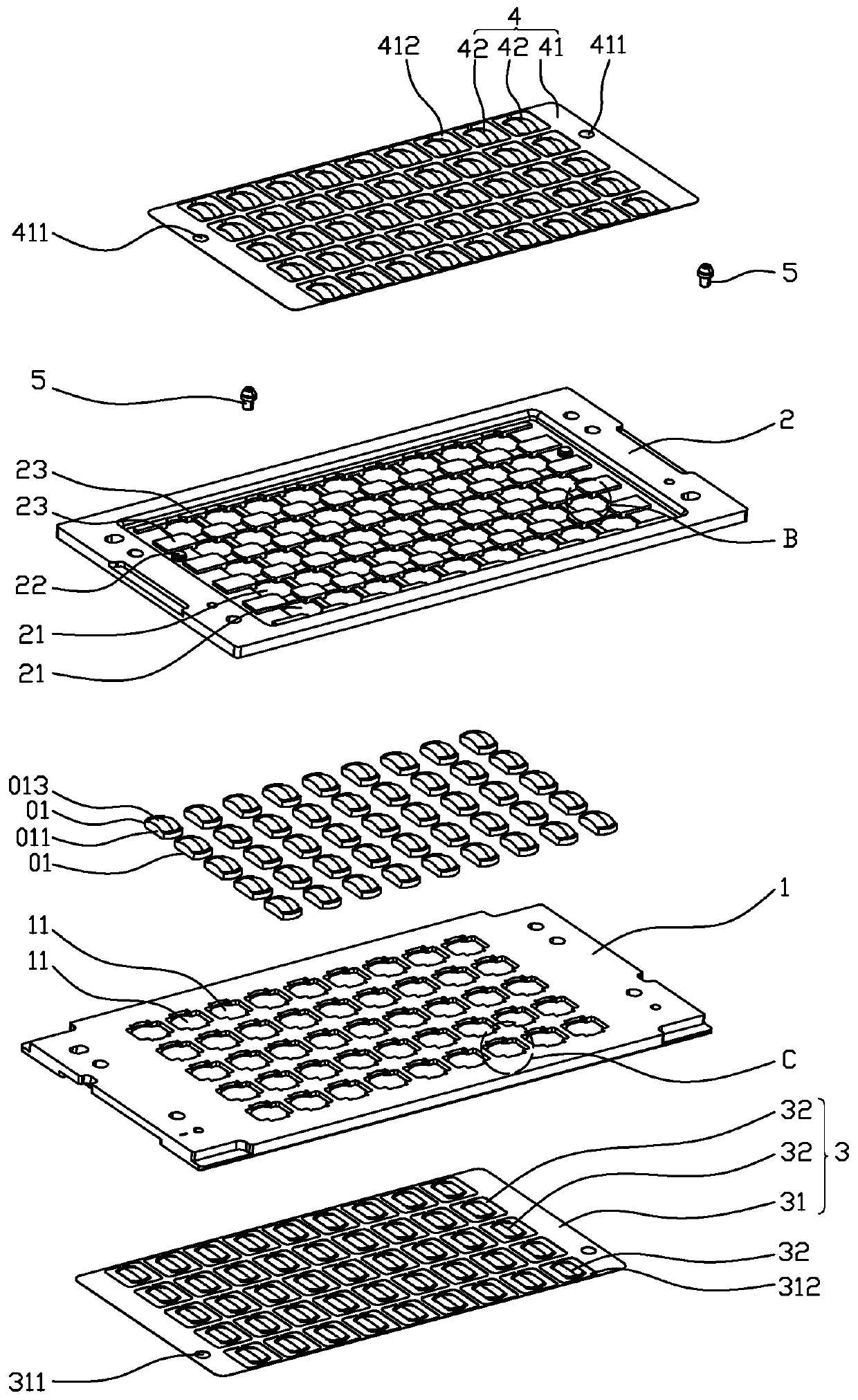

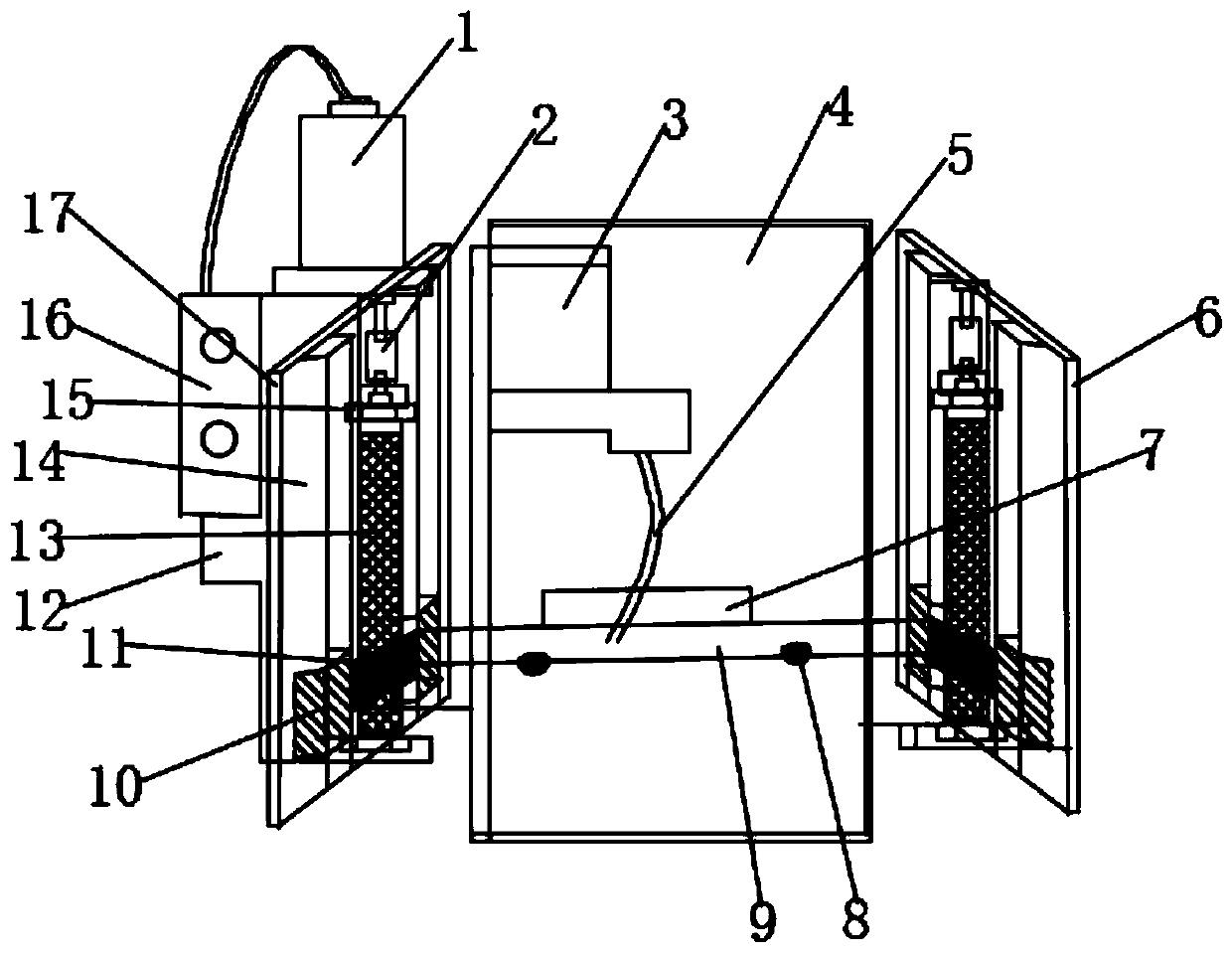

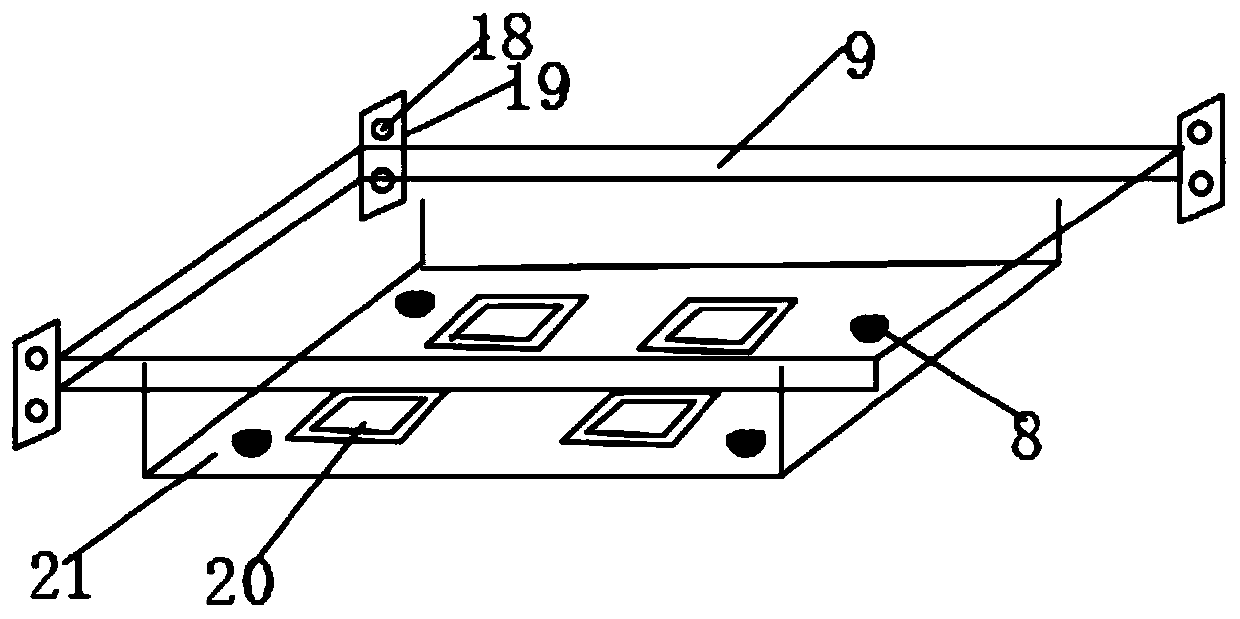

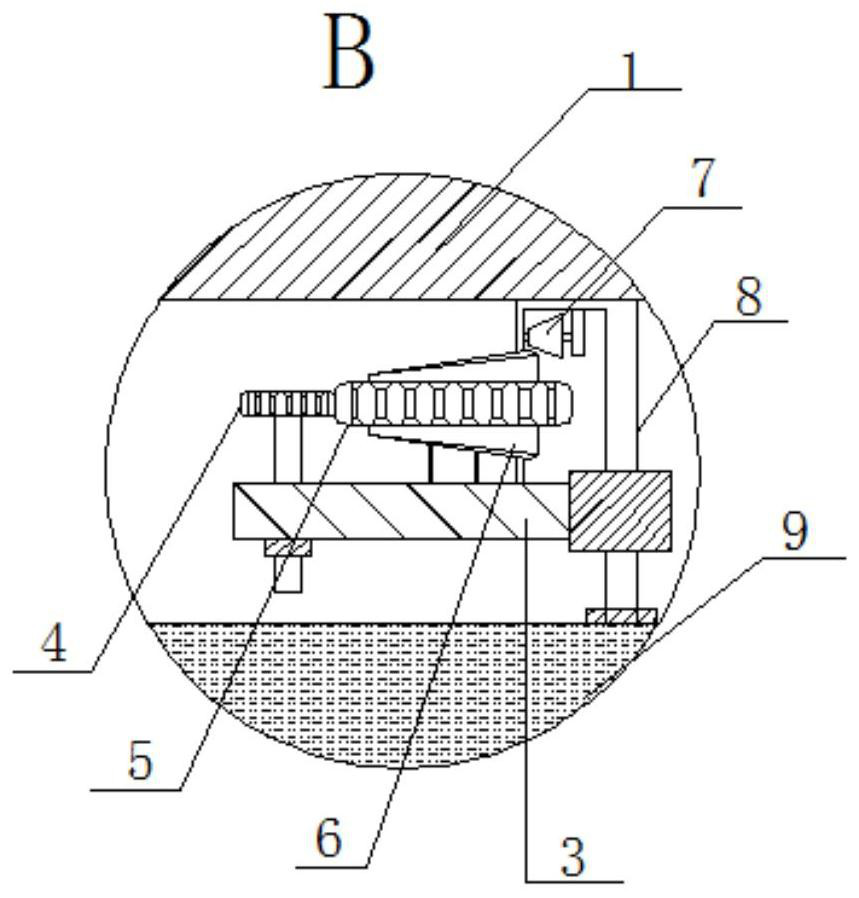

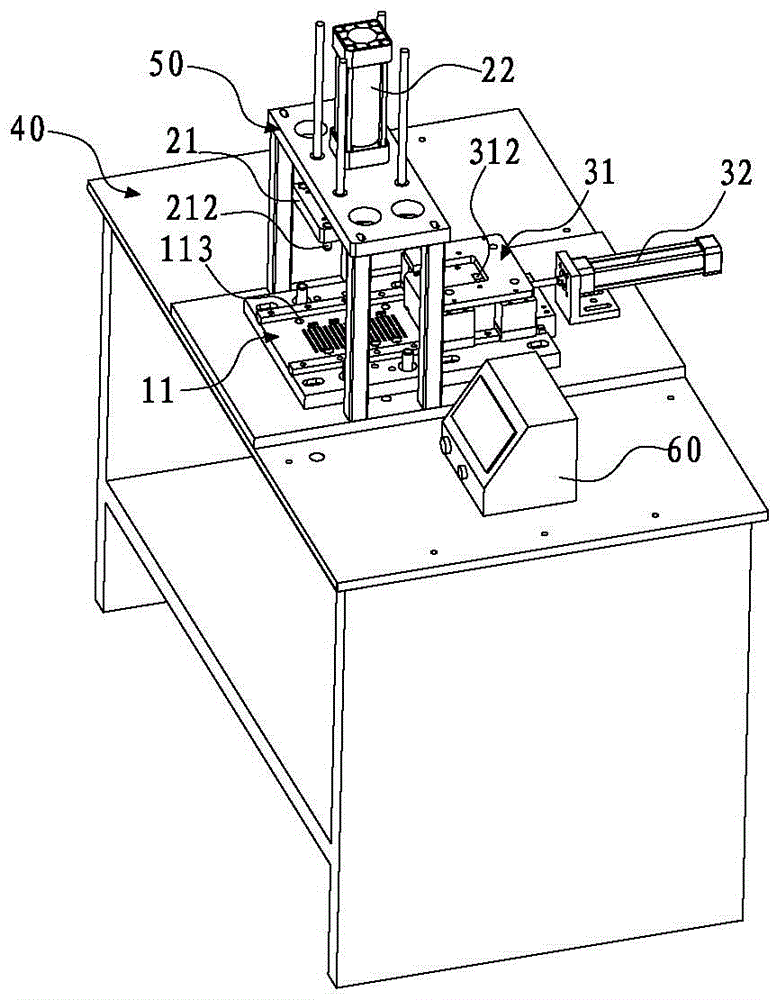

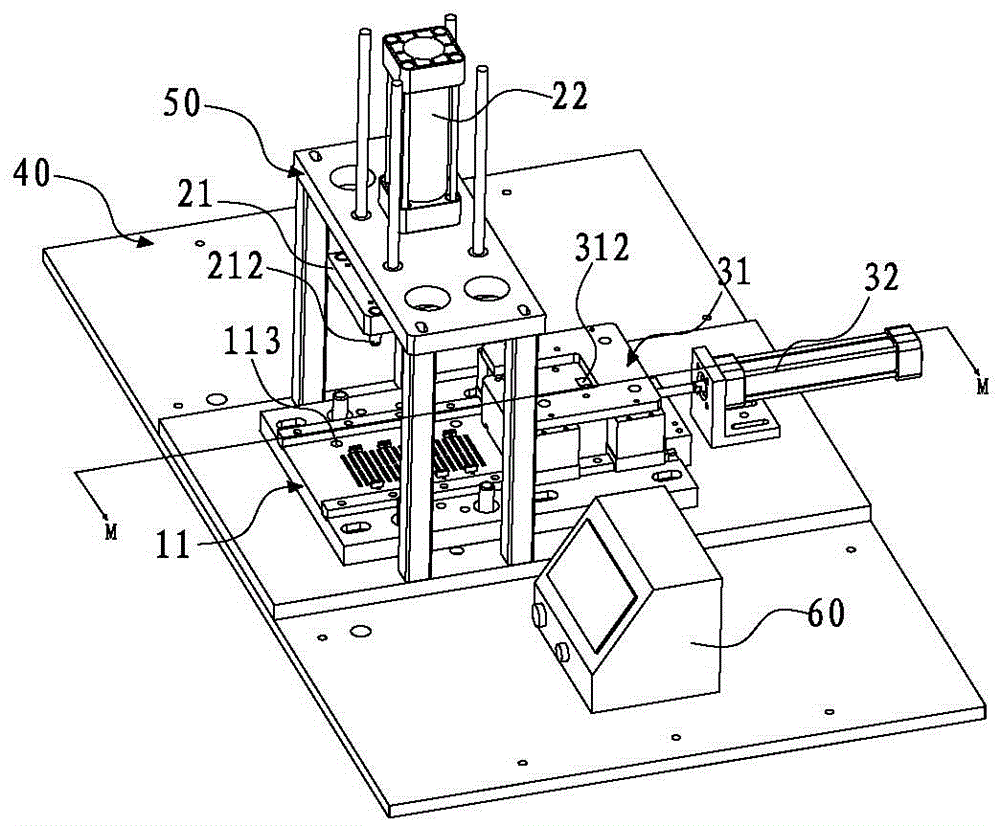

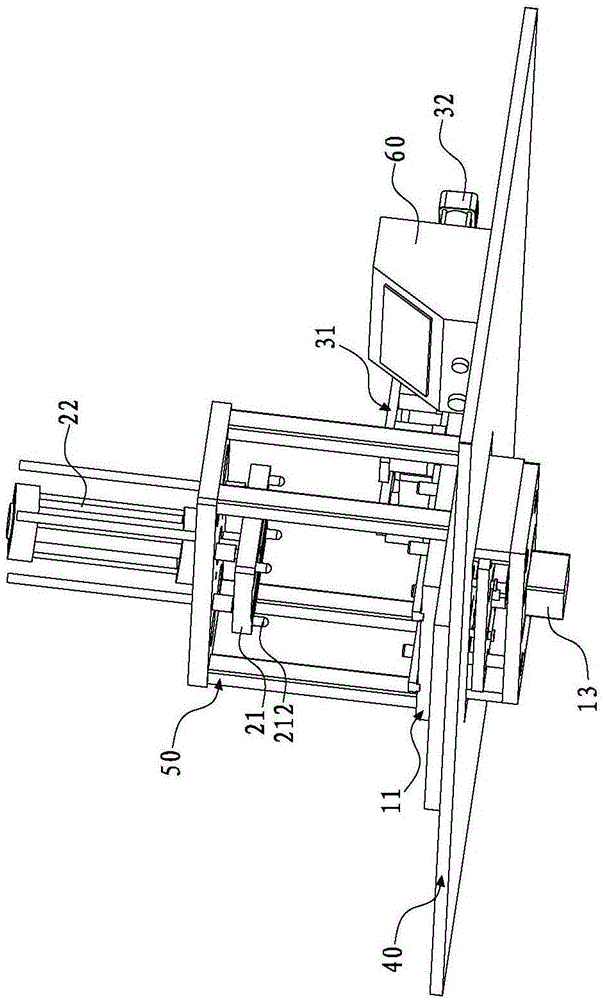

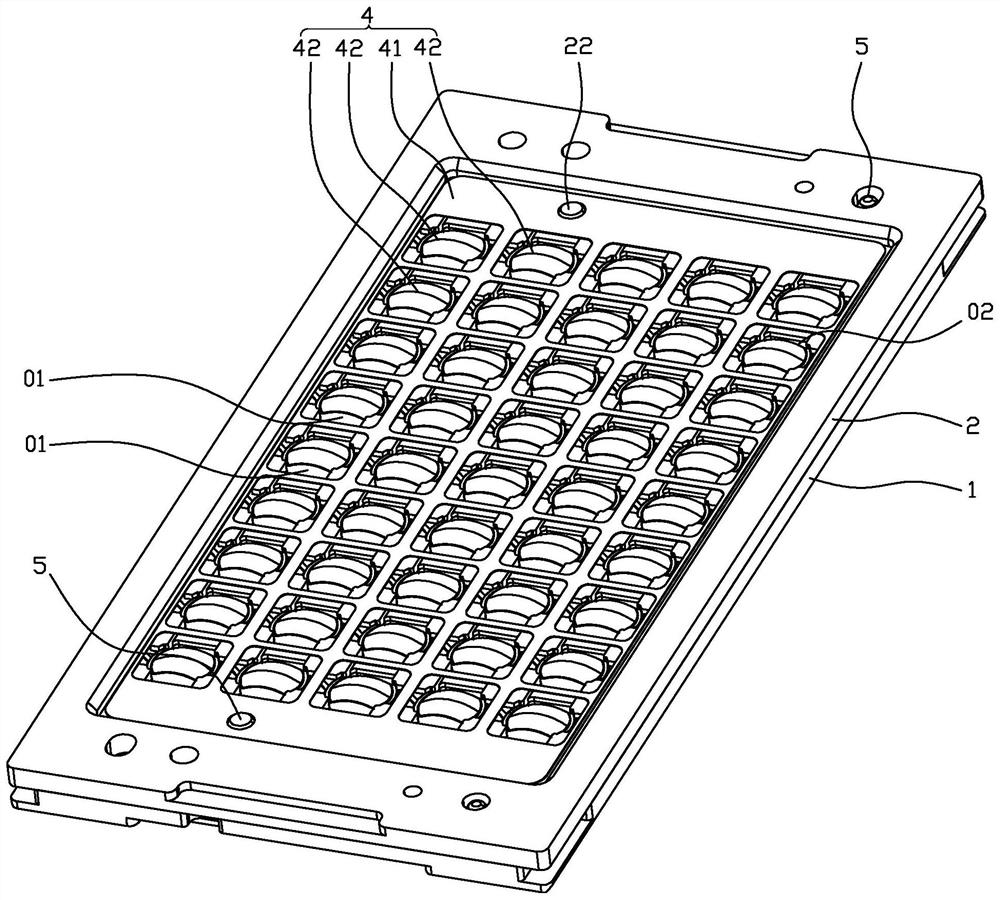

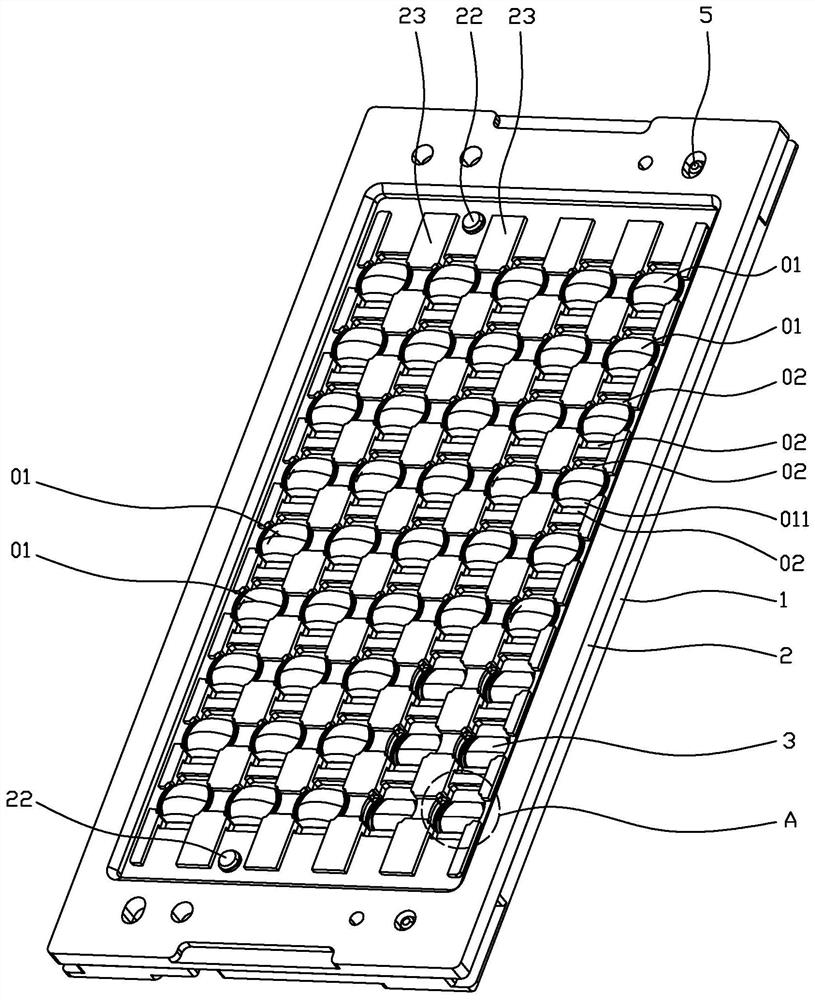

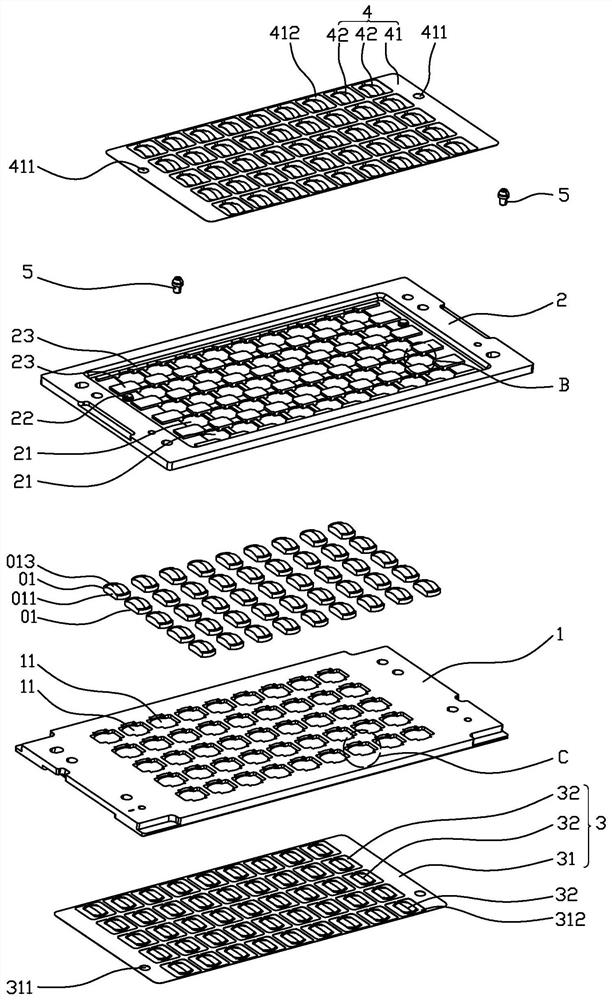

Lens ink-jet tooling

ActiveCN111013868AImprove inkjet efficiencyPrevent disengagementSpraying apparatusOptical elementsPhysicsMechanical engineering

Owner:AAC OPTICS (CHANGZHOU) CO LTD

Automatic printing method of three-dimensional pattern on vehicle body surface

ActiveCN103521410BImprove inkjet efficiencyThe principle is simpleCoatingsSpecial surfacesDesign softwareEngineering

An automatic inkjet printing method for three-dimensional patterns on the surface of a vehicle body, belonging to the field of vehicle digital design and manufacturing. This automatic inkjet printing method uses three-dimensional design software to construct a car exterior cover model and discretizes it into a triangular grid model, and then establishes a mapping relationship between the triangular grid model and the plane parameter domain; based on this, the pattern pixels are The corresponding points in the plane domain are inversely mapped to the three-dimensional model of the car body, establishing the corresponding relationship between the pattern pixel points and the three-dimensional car body points, and saving the color information of the pixels; generating an inkjet path on the three-dimensional car body model, and based on the path points The corresponding pixel color information adjusts the inkjet color of the pattern, thereby driving the inkjet printing robot to complete automatic inkjet printing of the three-dimensional pattern on the car body surface. The inkjet trajectories generated by this automatic inkjet printing method automatically complete the automatic inkjet printing of various personalized patterns on the vehicle body surface under computer control. The principle is simple, the inkjet printing is uniform, and the patterns are realistic, which effectively improves the efficiency of pattern inkjet printing.

Owner:DALIAN UNIV OF TECH

Automatic height adjusting spray head moving device of inkjet printer

InactiveCN110077165ASimple structurePrevent Offset DirectionOther artistic work equipmentsCouplingElectric machinery

The invention discloses an automatic height adjusting spray head moving device of an inkjet printer. The automatic height adjusting spray head moving device comprises a jet cavity. An ink box is arranged at the top end of the jet cavity, a left side plate and a right side plate are separately arranged on the left and right sides of the jet cavity, a connecting seat is arranged on the left side ofthe left side plate, a controller is arranged on the connecting seat, a driving motor is arranged at the upper end of the controller, lead screws are arranged in the left and right side plates, a coupling is arranged at the top end of each lead screw, guide rails are arranged on two sides of the lead screw, a slideway is arranged on each guide rail, a pulley is arranged in each guide rail, a connecting block is arranged between the pulleys, the connecting block is connected to a spray head seat, spray head grooves are uniformly formed in the spray head seat, distance sensors are arranged at four straight corners of the spray head seat, and a balancer is arranged on the upper surface of the spray head seat. The automatic height adjusting spray head moving device is simple in structure, canadjust the height automatically, improves the inkjet efficiency, and is high in accuracy and high in degree of automation.

Owner:褚培基

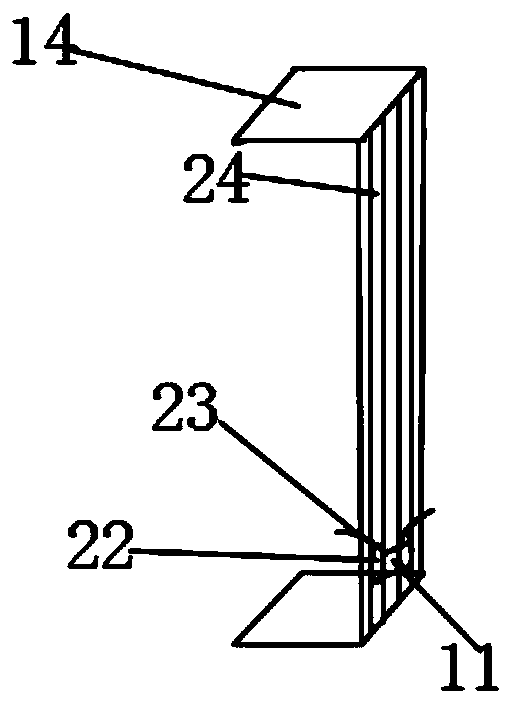

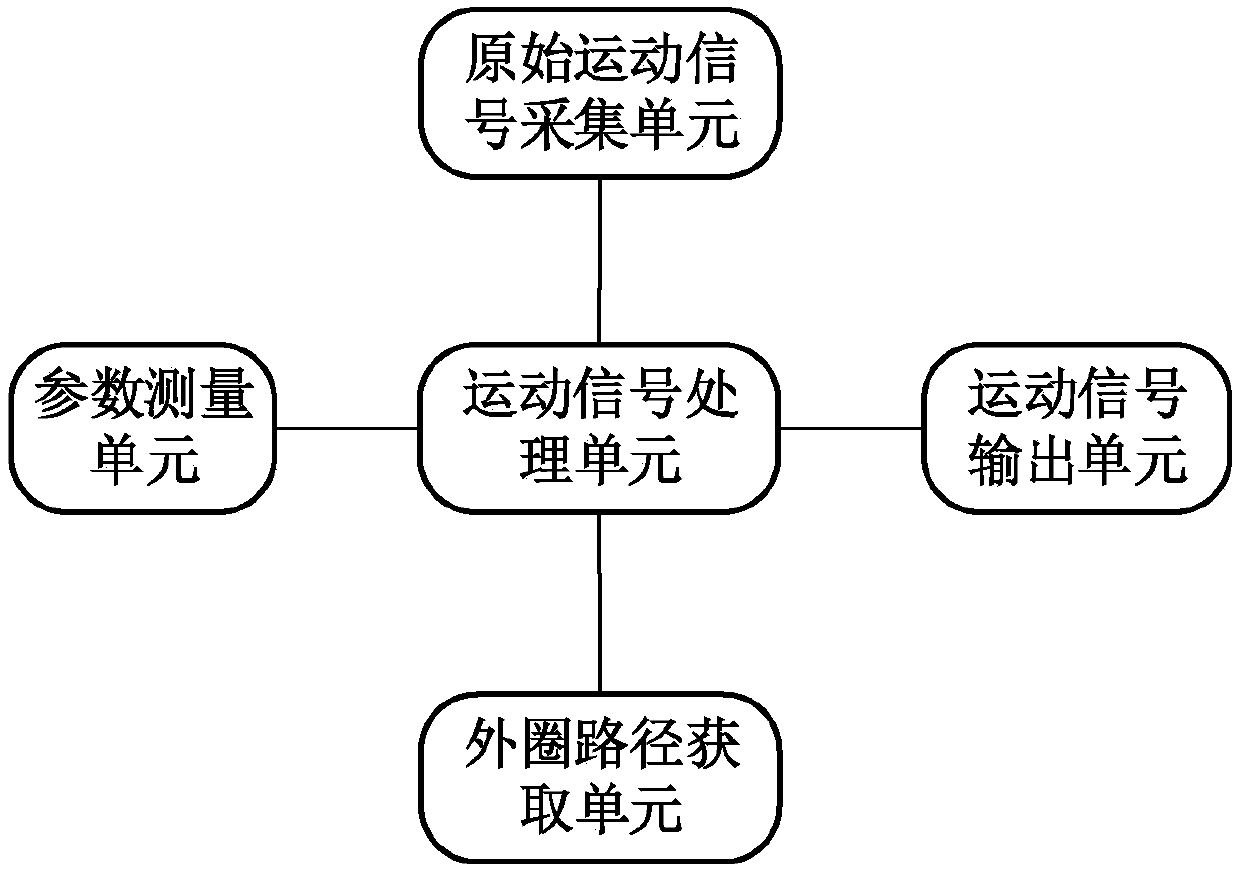

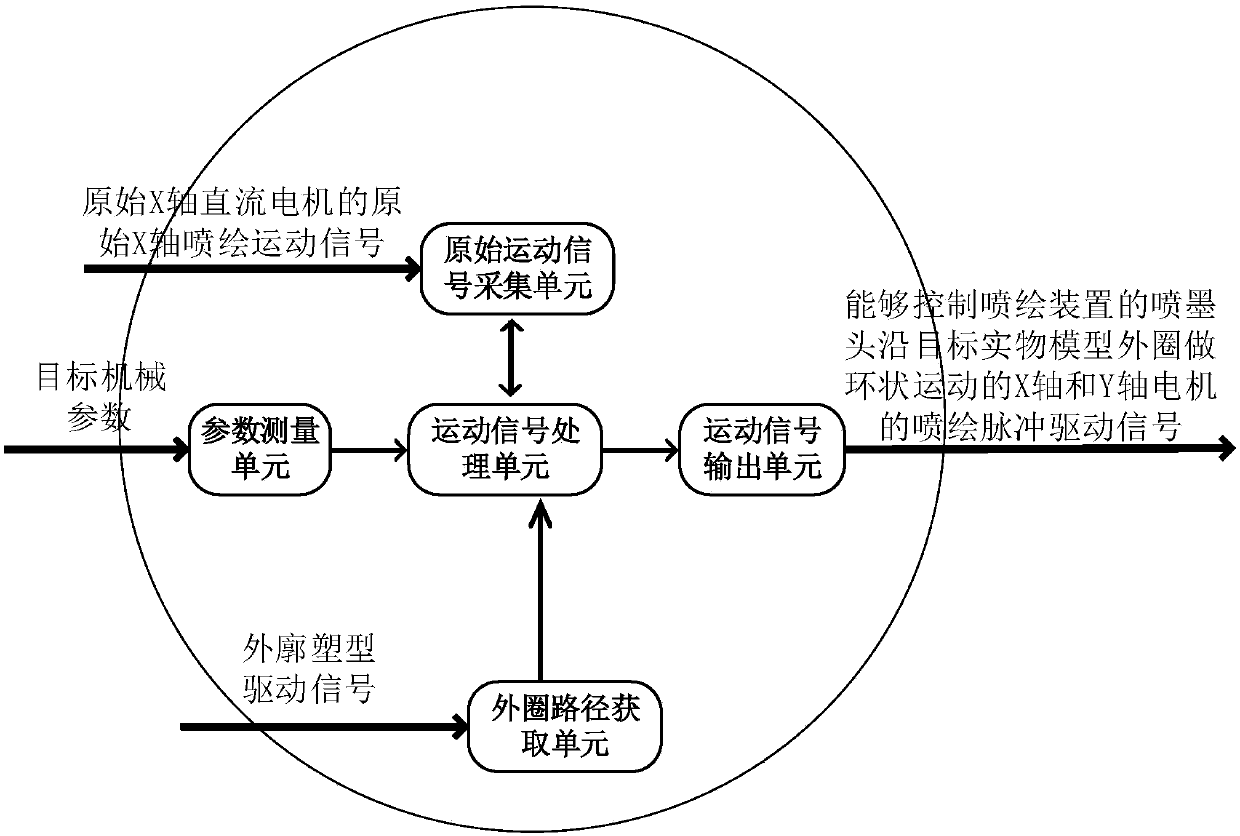

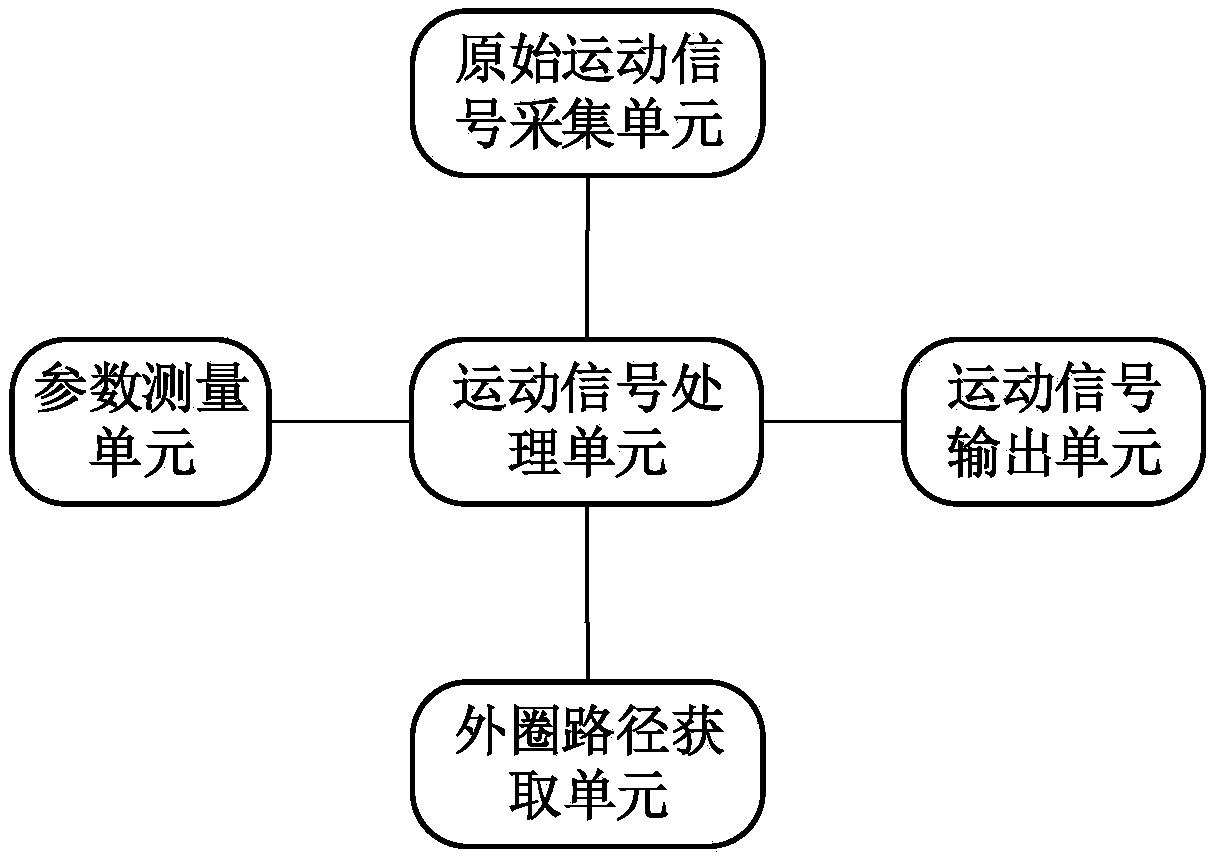

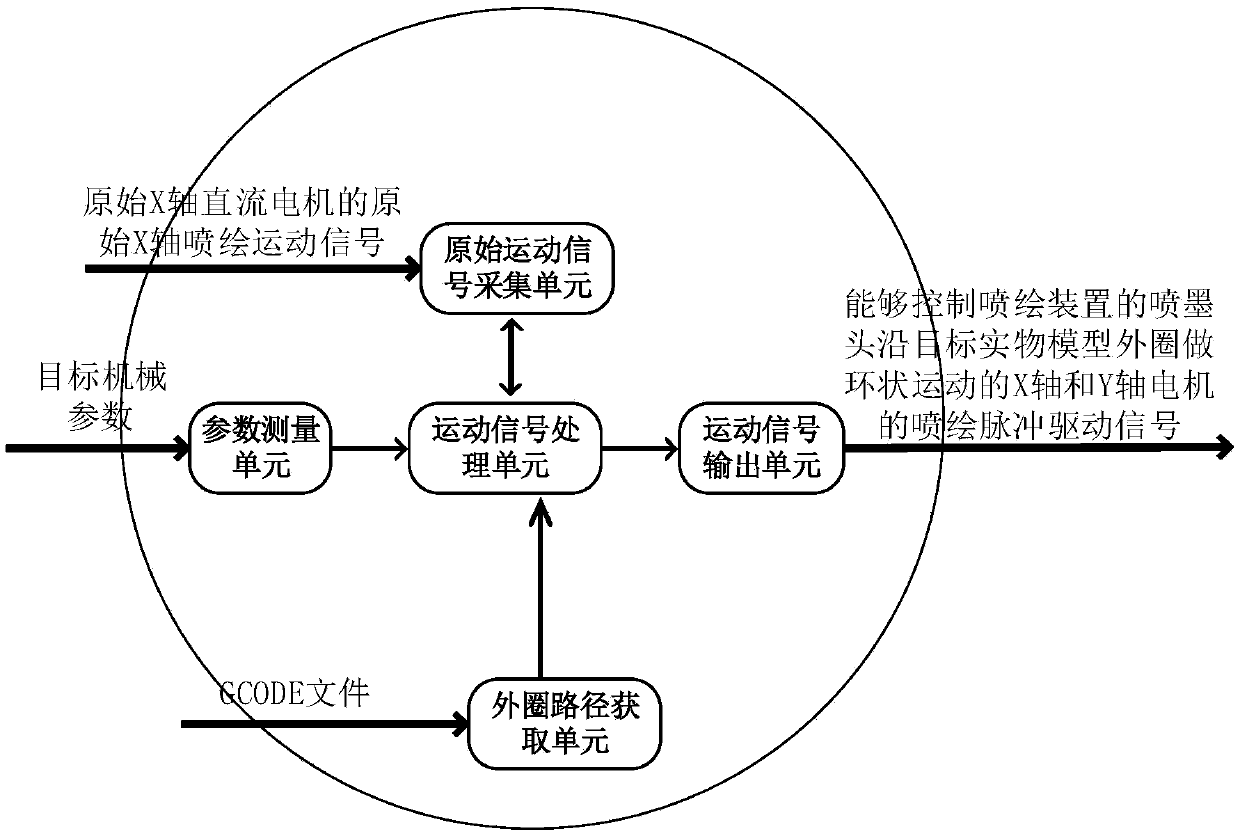

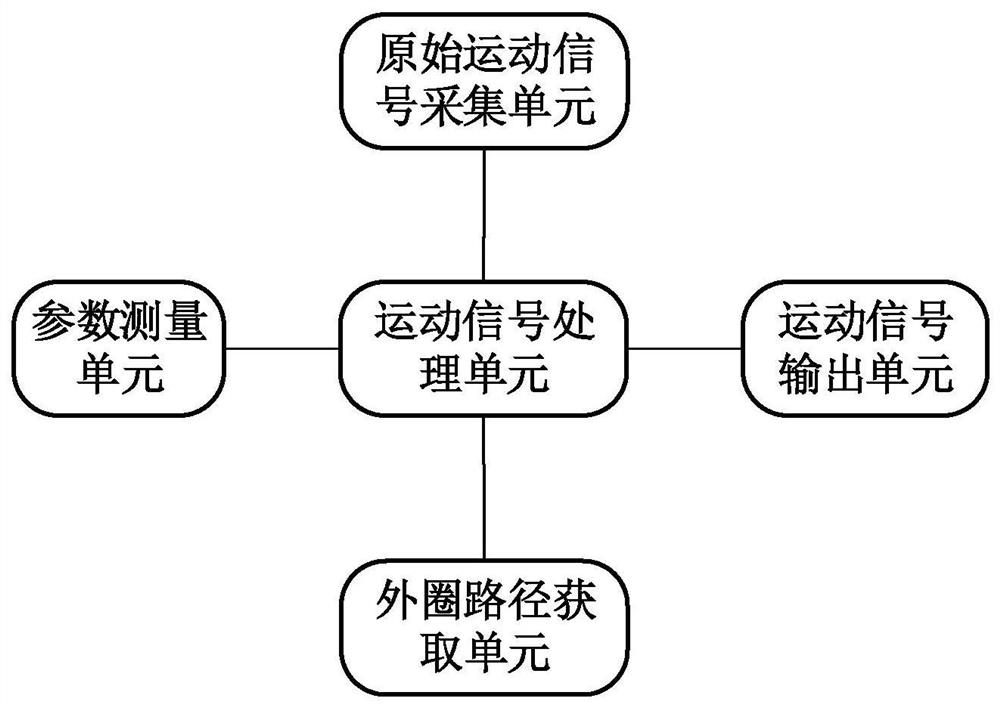

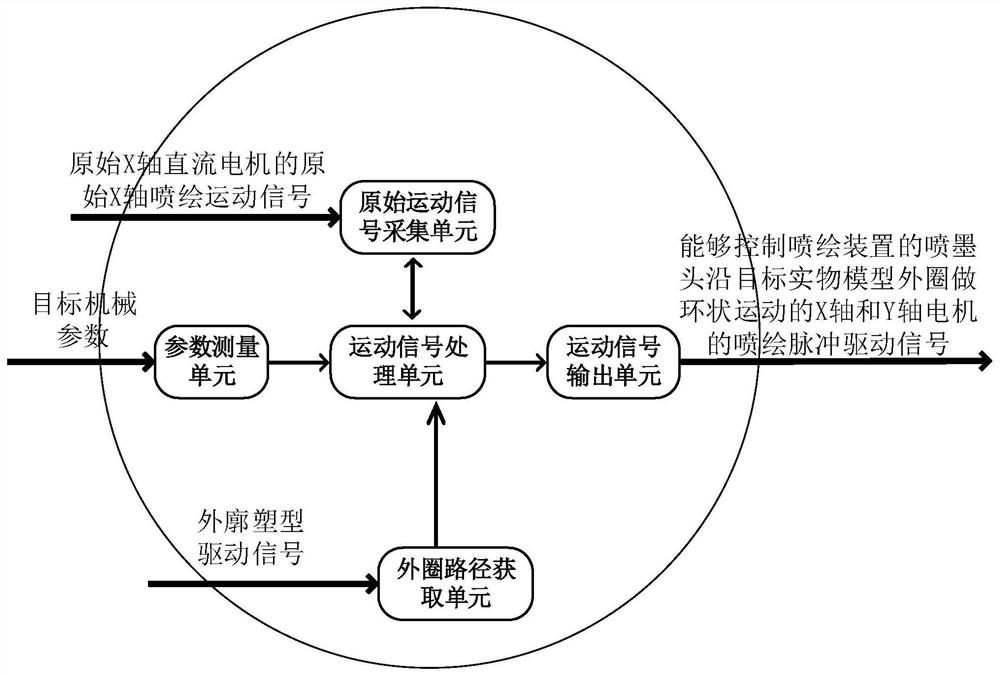

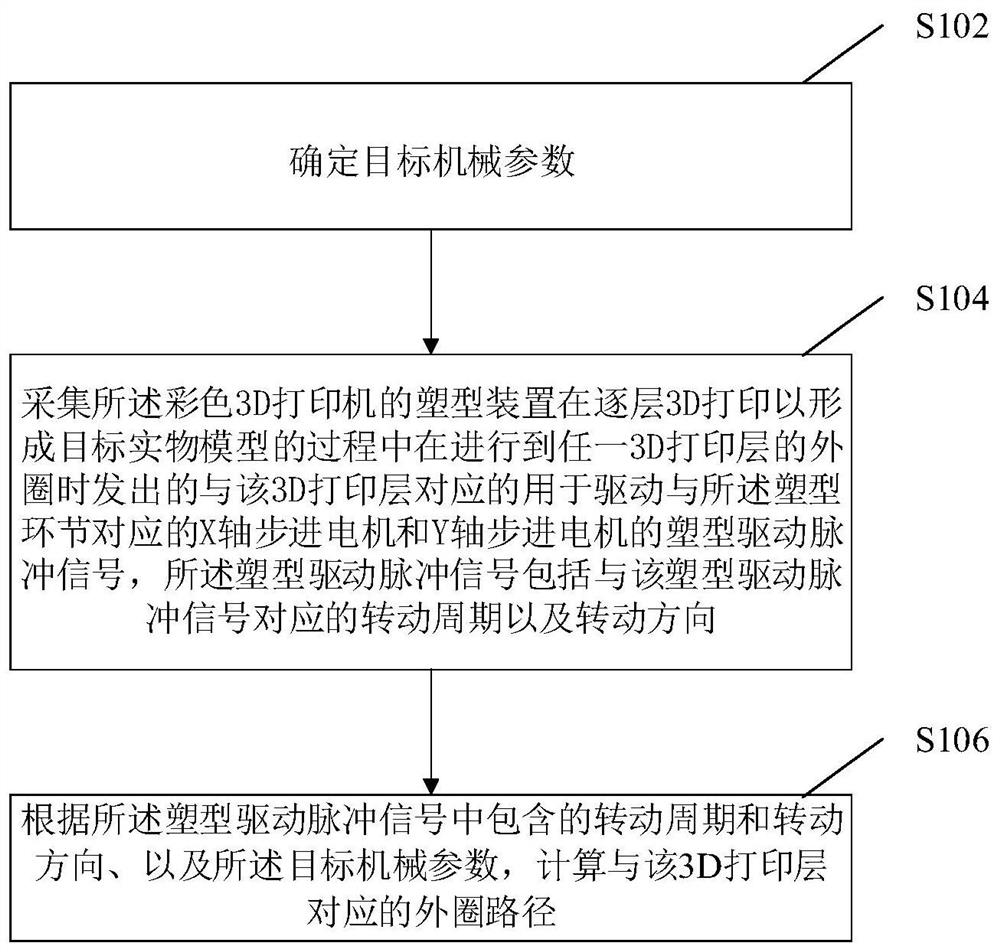

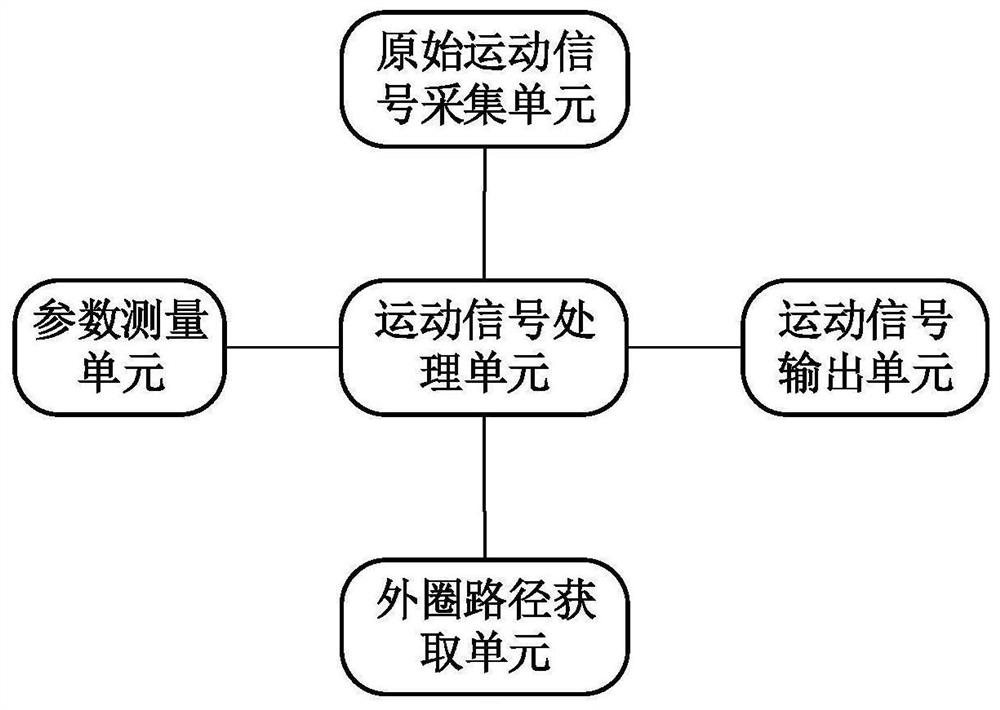

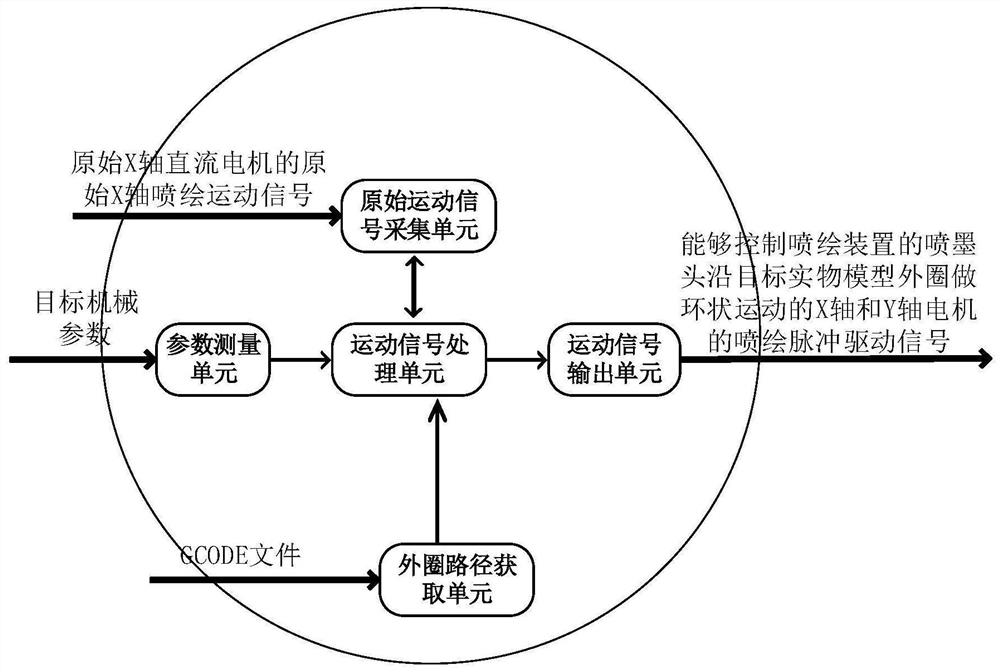

Device for analyzing outline molding drive signals and colorful 3D printer

ActiveCN109927279AReduce mechanical sizeReduce idle motionAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineering3d printer

The embodiment of the invention discloses a method and a device for analyzing outline molding drive signals and a colorful 3D printer. The outline molding drive signals are pulse signals used for driving an X-axis stepping motor and a Y-axis stepping motor corresponding to the molding link when the outline of the outermost circle is molded in the process that the colorful 3D printer conducts molding in a layer-by-layer stacking manner in the molding link so as to gradually form a target real object model. The method comprises the steps that target mechanical parameters are determined; moldingdrive pulse signals sent by a molding device when the process is conducted on the outer circle of any 3D printing layer in the layer-by-layer 3D printing process are collected, wherein the molding drive pulse signals are used for driving the X-axis motor and the Y-axis motor corresponding to the molding link; and according to the molding drive pulse signals and the target mechanical parameters, the outer circle path corresponding to the 3D printing layer is calculated. By adoption of the method and the device for analyzing the outline molding drive signals and the colorful 3D printer, the inkjet time needed in the colorful 3D printing inkjet link can be shortened, and the inkjet efficiency is improved.

Owner:SHENZHEN 7TH TECH CO LTD

An inkjet device for number pipes

Owner:HUNAN CITY UNIV

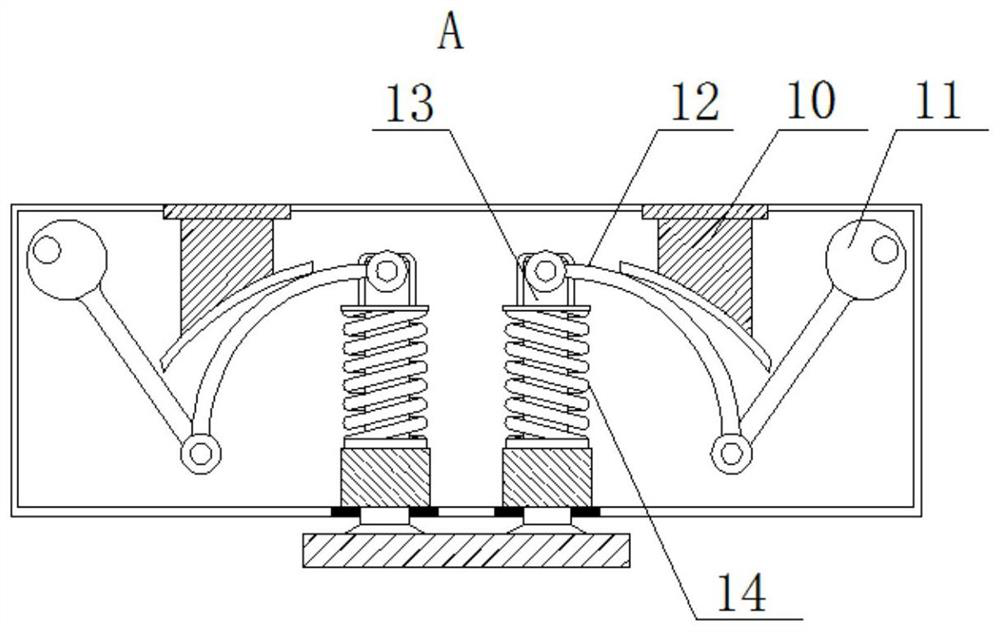

A solar water heater water tank clamping tool

The invention discloses a solar water heater water tank clamping tool. The tool comprises two clamping parts oppositely arranged, and transmission devices and swing arms connected with the clamping parts; free ends of the two swing arms are connected to form a U shape; the clamping parts include clamping jaws and chucks; the transmission devices include rotating shafts, cams and belt drives; the chucks are crossed; U-shaped grooves are respectively formed in four extension arms of the chucks; the clamping jaws are hinged with the U-shaped grooves in the chucks; the rotating shafts are arranged at the middle parts of the chucks; one ends of the rotating shafts are vertically connected with the chucks, and the other ends are vertically connected with the inner sides of one ends of the swing arms; the rotating shafts are coated with the cams and the synchronous belt drives; motor control the rotation of the belt drives and the cams; one ends of the clamping jaws are contacted with the cams; and springs are arranged between the clamping jaws and the inner sides of the chucks. The clamping tool is simple in structure, improves the working efficiency, guarantees the trademark image inkjet beauty, relieves the labor intensity, and is convenient for use.

Owner:浙江巨力宝纺织科技有限公司

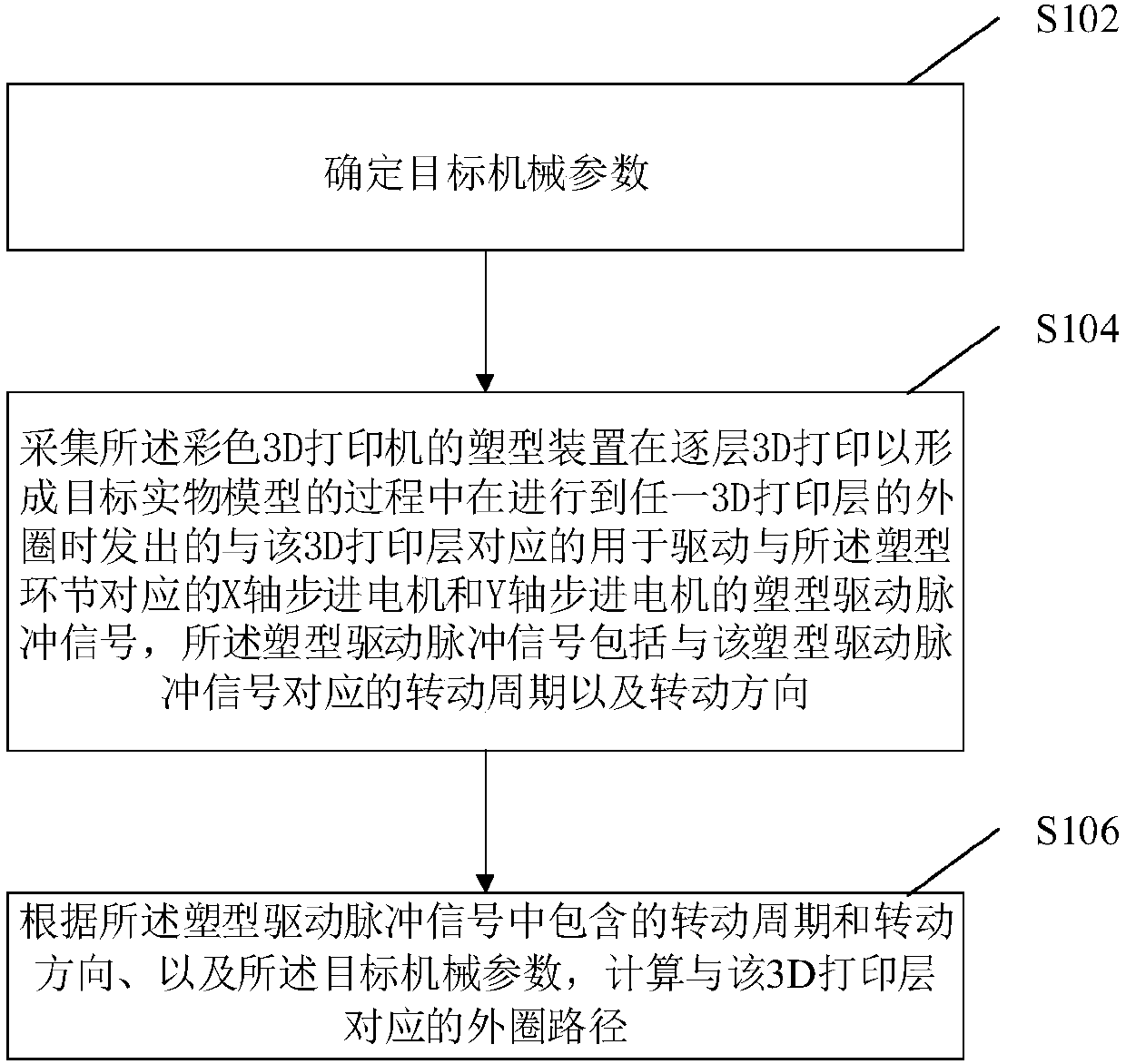

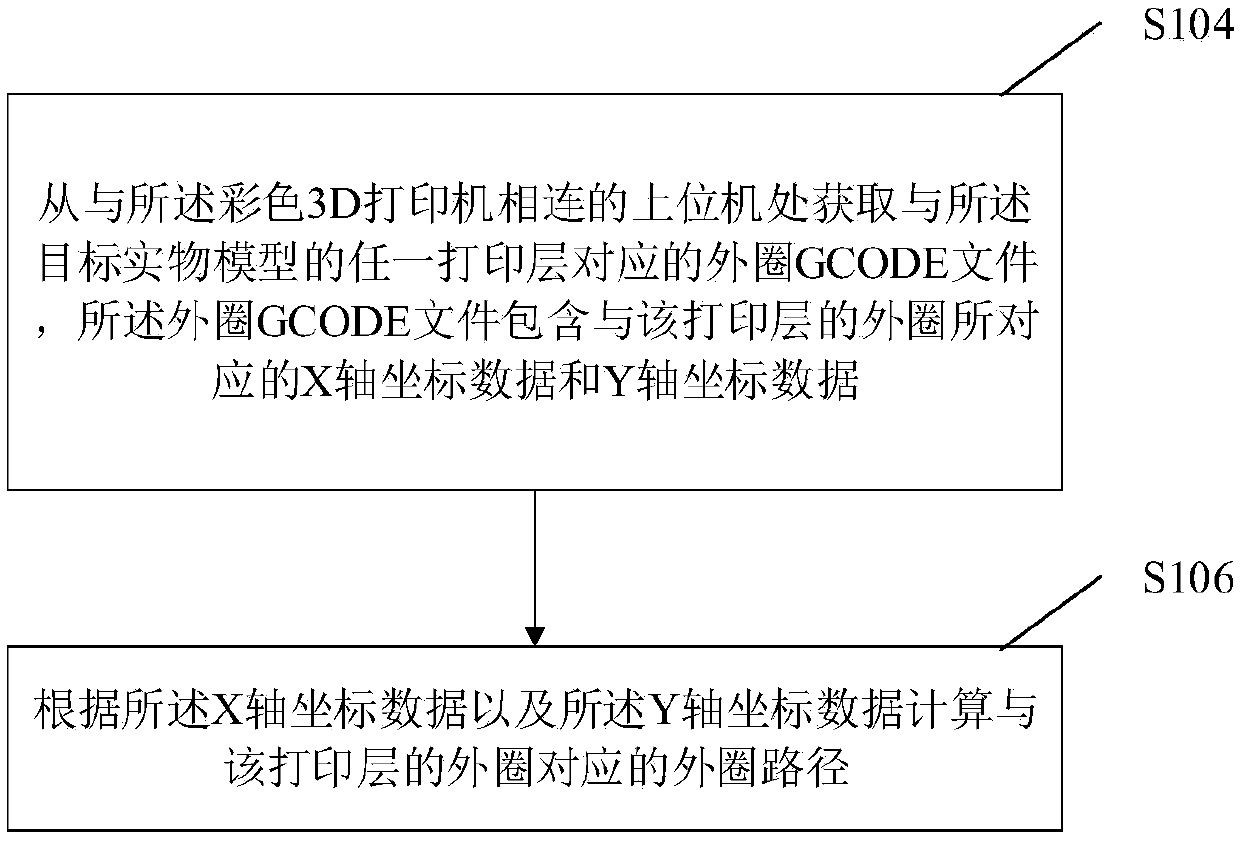

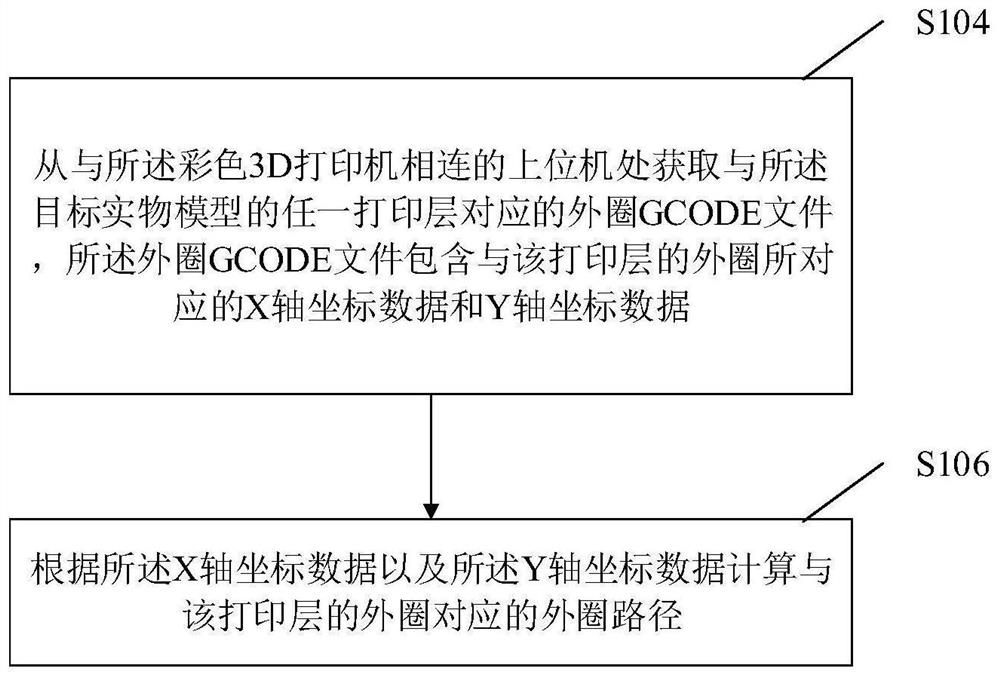

Method and device for analyzing external contour command and colored 3D printing machine

ActiveCN109927280AReduce mechanical sizeReduce idle motionAdditive manufacturing apparatus3D object support structuresPhysical modelEngineering

The embodiment of the invention discloses a method and device for analyzing an external contour command and a colored printing machine. The external contour command is a GCODE instruction instructingthe colored 3D printing machine to move on the outermost ring of each 3D printing layer in the process that molding is performed in a layer-by-layer accumulation manner in a molding ink to gradually form a target physical model. The method includes the steps that an outer ring GCODE file corresponding to any 3D printing layer of the target physical model is acquired from the position of an upper computer connected with the colored 3D printing machine; the outer ring GCODE file comprises X axis coordinate data and Y axis coordinate data corresponding to the outer ring of the 3D printing layer;and according to the X axis coordinate data and the Y axis coordinate data, an outer ring path corresponding to the outer ring of the 3D printing layer is calculated. By adopting the method and devicefor analyzing the external contour command and the colored printing machine, the inkjet time needed in the injet link of colored 3D printing can be shortened, and the inkjet efficiency is improved.

Owner:SHENZHEN 7TH TECH CO LTD

Glass inkjet printing device

InactiveCN111993796ARegulation stabilityNo splashingTypewritersPower drive mechanismsUltraviolet lightsEngineering

The invention relates to the technical field of computer inkjet printing and discloses a glass inkjet printing device. The glass inkjet printing device comprises a gantry frame. The two sides of the inner side of the gantry frame are provided with ink delivery flow channels. An ink storage box is movably connected to the interior of the gantry frame. The top of the ink storage box is movably connected with a lifting platform. By adjusting the distance of inkjet rollers, patterns obtained through inkjet printing are clear, vivid and beautiful. Springs on the outer side of spindles can achieve the shock absorption effect. An inkjet support and the inkjet rollers remain stable during adjustment without ink leakage, ink break and ink splashing. A heater can heat glass to be subjected to inkjetprinting, so that jet printing ink and glass have better bonding performance and are connected more firmly, and the jet printed patterns can be preserved for longer time. Meanwhile, ultraviolet lamps19 on the two sides can make jet printing ink rapidly dried and shaped, and the jet printing efficiency is improved. Lifting shafts drive the ink storage box to move up and down, so that the inkjet support and the inkjet rollers have the enough lifting distance. Therefore, the glass inkjet printing device has wider practicality.

Owner:成都成研创科科技有限公司

Device for analyzing driving signals for contour shaping, color 3D printer

ActiveCN109927279BReduce mechanical sizeReduce idle motionAdditive manufacturing apparatusAdditive manufacturing with liquidsComputer printingEngineering

The embodiment of the invention discloses a method and a device for analyzing outline molding drive signals and a colorful 3D printer. The outline molding drive signals are pulse signals used for driving an X-axis stepping motor and a Y-axis stepping motor corresponding to the molding link when the outline of the outermost circle is molded in the process that the colorful 3D printer conducts molding in a layer-by-layer stacking manner in the molding link so as to gradually form a target real object model. The method comprises the steps that target mechanical parameters are determined; moldingdrive pulse signals sent by a molding device when the process is conducted on the outer circle of any 3D printing layer in the layer-by-layer 3D printing process are collected, wherein the molding drive pulse signals are used for driving the X-axis motor and the Y-axis motor corresponding to the molding link; and according to the molding drive pulse signals and the target mechanical parameters, the outer circle path corresponding to the 3D printing layer is calculated. By adoption of the method and the device for analyzing the outline molding drive signals and the colorful 3D printer, the inkjet time needed in the colorful 3D printing inkjet link can be shortened, and the inkjet efficiency is improved.

Owner:SHENZHEN 7TH TECH CO LTD

Inkjet device for led support and inkjet method thereof

InactiveCN103943732BWork fasterImprove inkjet efficiencyDuplicating/marking methodsSemiconductor devicesAdhesion forceHigh density

The invention discloses a set of LED support inkjet equipment and an inkjet method of the LED support inkjet equipment. The inkjet equipment comprises an upper mold, a lower mold, an ink box, an ejector pin, an ink suction air cylinder, an inkjet air cylinder, an ink scraping air cylinder, a horizontal workbench, a vertical supporting frame and a controller. Driving actions of all the air cylinders on the ink box, the ejector pin and the upper mold can be intelligently controlled by the controller so that ink storage space can be automatically reserved and automatic ink filling and automatic inkjet and the like can be achieved, the inkjet efficiency is improved, and the production cost is reduced. High-seal high-pressure inkjet operation can be performed on LED supports in a mode of an immersion cavity, so that the inkjet layer of each LED support is compact and uniform, the adhesion force is increased, ink overflow, leaky white, irregularity and other undesirable phenomena cannot happen easily, and the quality of the products is improved. Meanwhile, a plastic base of each LED support does not need to be formed for the second time, the production cost is reduced, and the performance of the products is improved. In the inkjet mode, the distance between the LED supports can be smaller (larger than 0.3 mm), and complex LED supports with high density, large area and multiple particles can all be produced efficiently.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

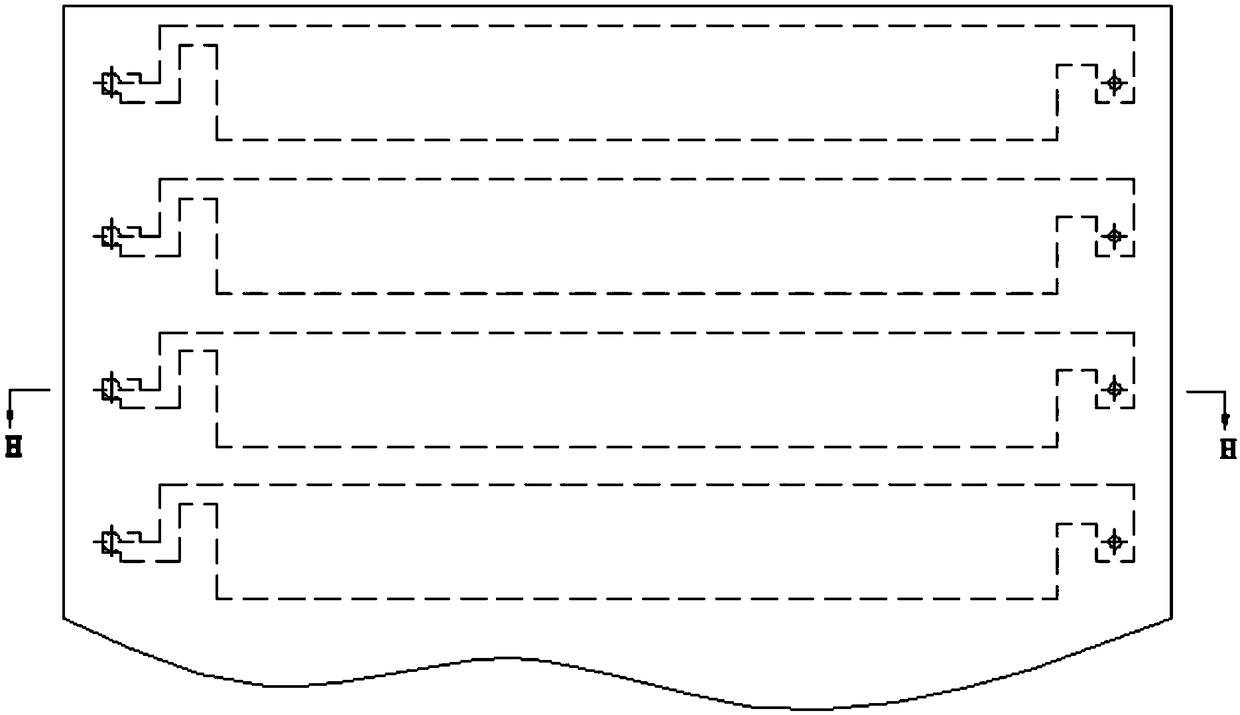

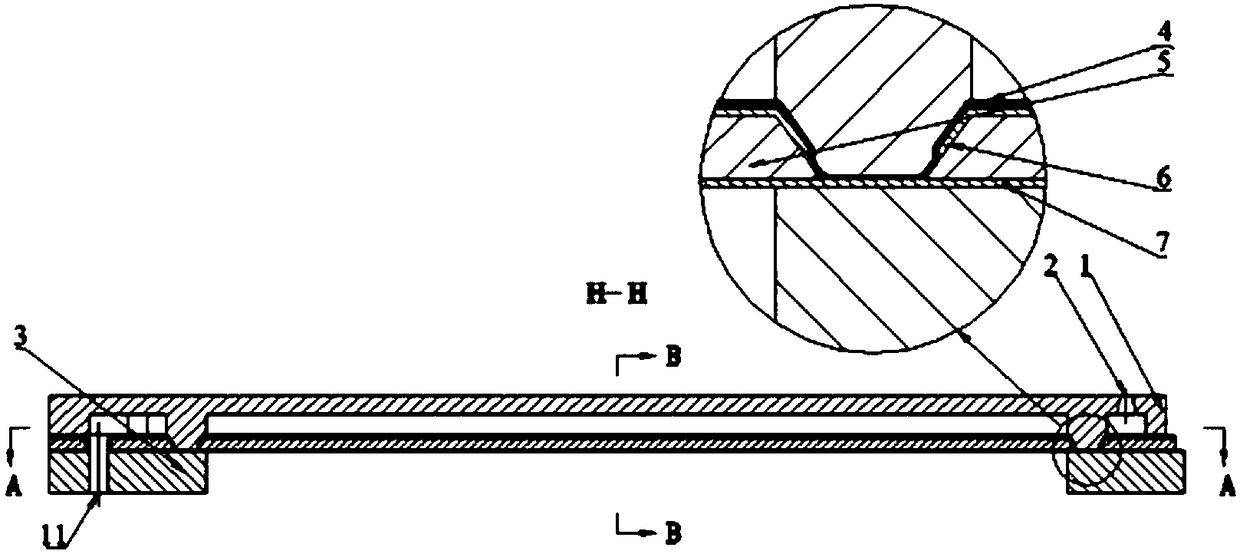

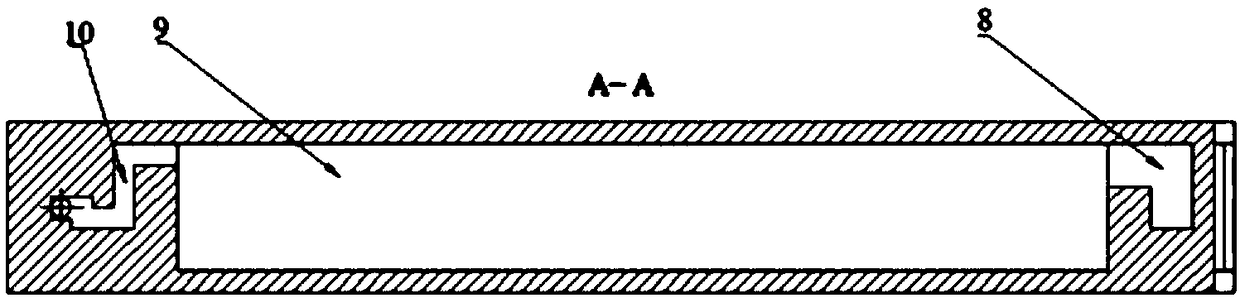

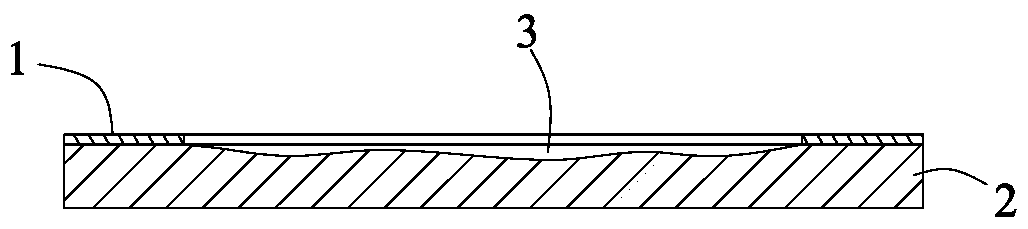

Lens inkjet tooling

ActiveCN111013868BPrevent disengagementEasy to fixSpraying apparatusOptical elementsEngineeringMechanical engineering

The invention provides a lens inkjet tooling. The lens ink-jet tooling of the present invention is used for installing lenses. The lens has an ink-jet side wall and a first surface and a second surface. The second tooling plate with a number of second accommodation holes, the first cover film attached to the first tooling plate, and the second cover film attached to the second tooling plate. The first accommodation hole has a first installation wall and the first enclosing wall, where the first installation wall is far away from the second tooling plate and extends toward the first accommodating hole to form a first abutting portion, and the second accommodating hole has a second installation wall and a second enclosing wall , the part of the second installation wall far away from the first tooling plate extends toward the second accommodating hole to form a second abutting portion, the inkjet side wall and the first enclosing wall on the corresponding side, and the second enclosing wall on the corresponding side Combined to form ink ejection holes. The tooling of this solution can fix the lens, and can spray on both sides by directly turning over the tooling, which improves the inkjet efficiency of the lens.

Owner:AAC OPTICS (CHANGZHOU) CO LTD

Ceramic tile color carving inkjet painting process and its products

InactiveCN103407317BStrong three-dimensional senseStrong aestheticsDecorative surface effectsPersonalizationMaterials science

The invention discloses a ceramic tile color carving inkjet process, which comprises the following steps: 1) pasting a protective film; 2) edge cutting; 3) tearing off the protective film; 4) engraving; 5) cleaning; A ceramic tile product obtained by implementing the process; the process steps provided by the invention are simple, not only easy to implement, but also high in printing efficiency, strong in personalization, high in flexibility, not limited by the background color of the ceramic tile, and the color, pattern and size can be adjusted Personalized customization can quickly make the surface of the tiles present a three-dimensional pattern concave pattern, and then spray the corresponding color spray paint on the pattern concave pattern according to personal preferences, making the pattern color of the tile more colorful, beautiful and artistic. Stronger, better decorative effect, allowing people to experience art and enjoy life in busy and boring life at the same time. The ceramic tile product provided by the invention has bright and diverse patterns, strong three-dimensional effect, elegant appearance and fashion, and is favorable for wide popularization and application.

Owner:陈权胜

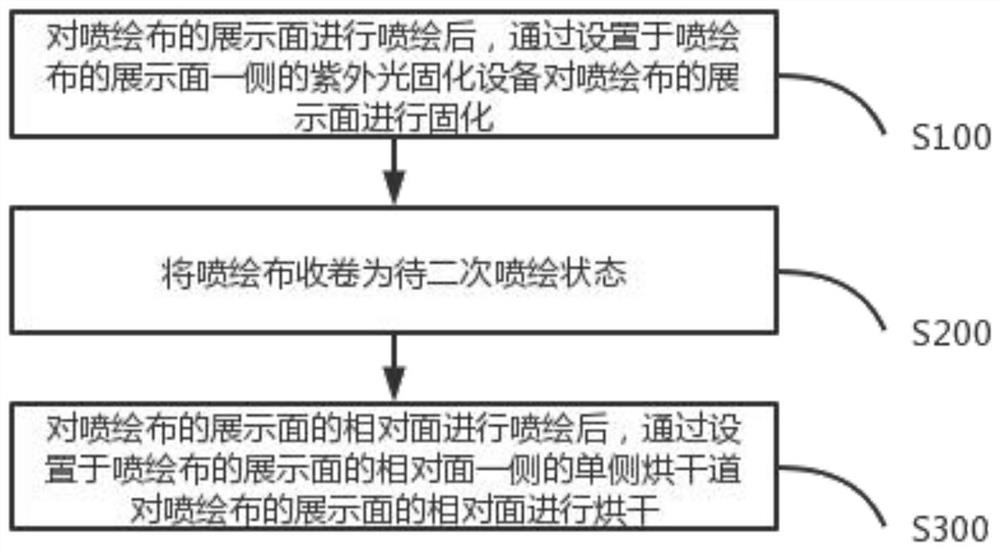

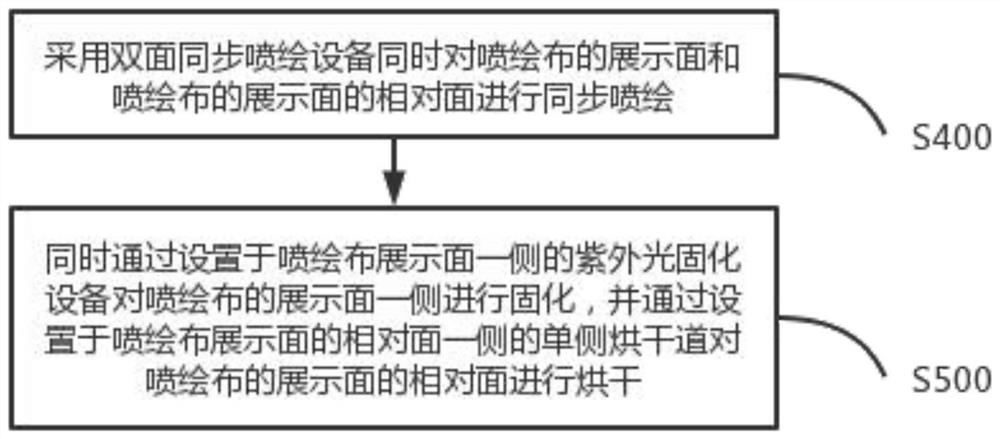

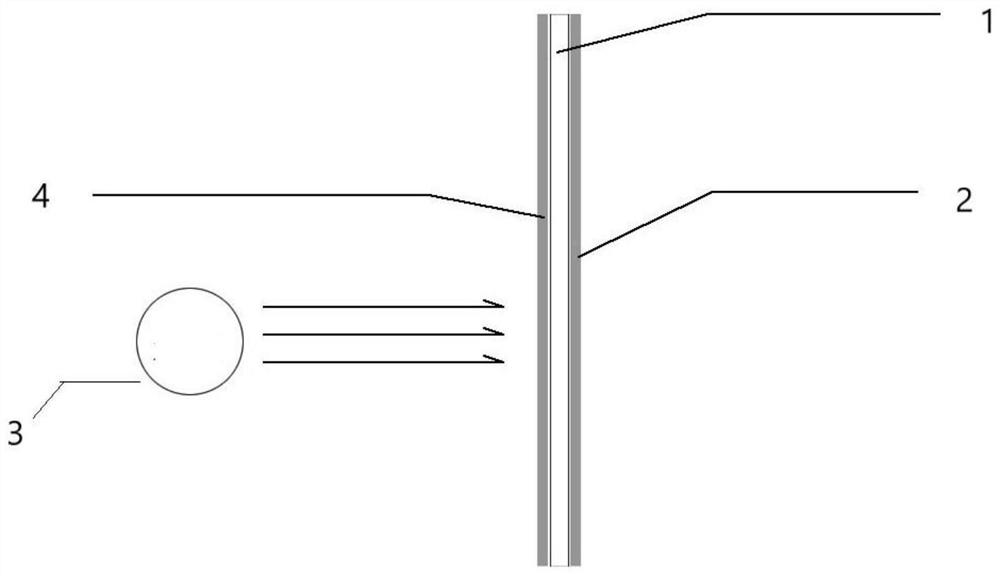

Double-sided painting method capable of splicing painting cloth, advertising cloth, lamp box and painting unit

ActiveCN114537008ARealize productized inkjet effectAccuracy meetsDuplicating/marking methodsTypewritersSolvent basedEngineering

The invention discloses a double-sided inkjet printing method capable of splicing inkjet printing cloth, advertising cloth, a lamp box and an inkjet printing unit. The method comprises the following steps: performing inkjet printing on a display surface of the inkjet printing cloth by adopting light-cured ink; solvent type ink which can be fused with the flex banner material is adopted to conduct flex banner on the opposite faces of the display faces of the flex banner, and the opposite faces of the display faces of the flex banner can be spliced. According to the invention, the spray-painting product which is high in picture quality and can be spliced can be produced, and the spray-painting effect of the ultra-large-breadth lamp box picture which keeps good visual impression day and night is realized.

Owner:SHANGHAI BIGIMAGE CO LTD

Method and device for parsing outline commands, color 3D printer

ActiveCN109927280BReduce mechanical sizeReduce idle motionAdditive manufacturing apparatus3D object support structuresComputer printingPhysical model

The embodiment of the invention discloses a method and device for analyzing an external contour command and a colored printing machine. The external contour command is a GCODE instruction instructingthe colored 3D printing machine to move on the outermost ring of each 3D printing layer in the process that molding is performed in a layer-by-layer accumulation manner in a molding ink to gradually form a target physical model. The method includes the steps that an outer ring GCODE file corresponding to any 3D printing layer of the target physical model is acquired from the position of an upper computer connected with the colored 3D printing machine; the outer ring GCODE file comprises X axis coordinate data and Y axis coordinate data corresponding to the outer ring of the 3D printing layer;and according to the X axis coordinate data and the Y axis coordinate data, an outer ring path corresponding to the outer ring of the 3D printing layer is calculated. By adopting the method and devicefor analyzing the external contour command and the colored printing machine, the inkjet time needed in the injet link of colored 3D printing can be shortened, and the inkjet efficiency is improved.

Owner:SHENZHEN 7TH TECH CO LTD

Efficient carpet printing system

InactiveCN109677130AHigh degree of automationImprove inkjet efficiencyTypewritersOther printing apparatusEngineeringAutomation

The invention provides an efficient carpet printing system. The system comprises a support, a conveying device, a printing device and a printing solidifying device. The conveying device is located onthe support and comprises a front roll, an annular conveying belt and a rear roll. The two ends of the annular conveying belt are supported by supporting rolls. The printing device comprises a cross beam, an inkjet device and sliding rails which right face the upper portion of the annular conveying belt. The inkjet device moves along the cross beam left and right through the sliding rails. The printing solidifying device comprises a shell, and a heating plate and a fan which are located in the shell. The conveying device conveys a carpet to be within the scope of the printing device progressively, the inkjet device jets ink line by line, and then the carpet enters the printing solidifying device to be subjected to primary drying, and preparation is well made for the next procedure. The efficient carpet printing system is high in automation degree, high in efficiency in the inkjet process, and capable of effectively reducing human intervention at the same time.

Owner:TIANJIN ZEZHI TECH DEV CO LTD

Inkjet printer nozzle control board and printable data transmission method

The invention discloses an ink-jet head control panel of an ink-jet printer and a method for transmission of printable data. One end of the ink-jet head control panel is connected with a master control panel and used for receiving serial printed data after the data are processed and the other end of the ink-jet head control panel is connected with ink-jet heads and used for sending the printable data with no error after verification to the ink-jet heads. The ink-jet head control panel mainly comprises an FPGA, a DES, a CAN chip sending end (PHY), a power module and a peripheral control interface unit. The ink-jet head control panel is characterized in that an SDRAM is additionally arranged on the ink-jet head control panel and connected with the FPGA, bi-directional data transmission can be conducted between the SDRAM and the FPGA, and the SDRAM is used for storing the printable data with no error after the data are verified through the FPGA and finally outputting the printable data with no error after verification to at least one ink-jet head for printing. The SDRAM is provided with multiple zones, the number of the zones is identical to that of the ink-jet heads, and the printable data with no error after verification needed by each ink-jet head are stored in the corresponding zone. In the printing process, the stored printable data with no error after verification are sent to the corresponding ink-jet head for image-text printing by the SDRAM, the phenomenon that the data are transmitted to the ink-jet heads mistakenly after printing operation is started can be avoided, the functions of the ink-jet head control panel are completed, and the ink-jetting efficiency is improved.

Owner:BEIJING MEIKEYI

A Piezoelectric Inkjet Printing Nozzle Structure to Prevent Ink Backflow

Owner:大连瑞林数字印刷技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com