Lens ink-jet tooling

A lens and inkjet technology, which is applied in the direction of spraying devices, optics, instruments, etc., can solve the problems of affecting the inkjet efficiency of the lens and complicated operation steps, and achieve the effect of improving the inkjet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and embodiments.

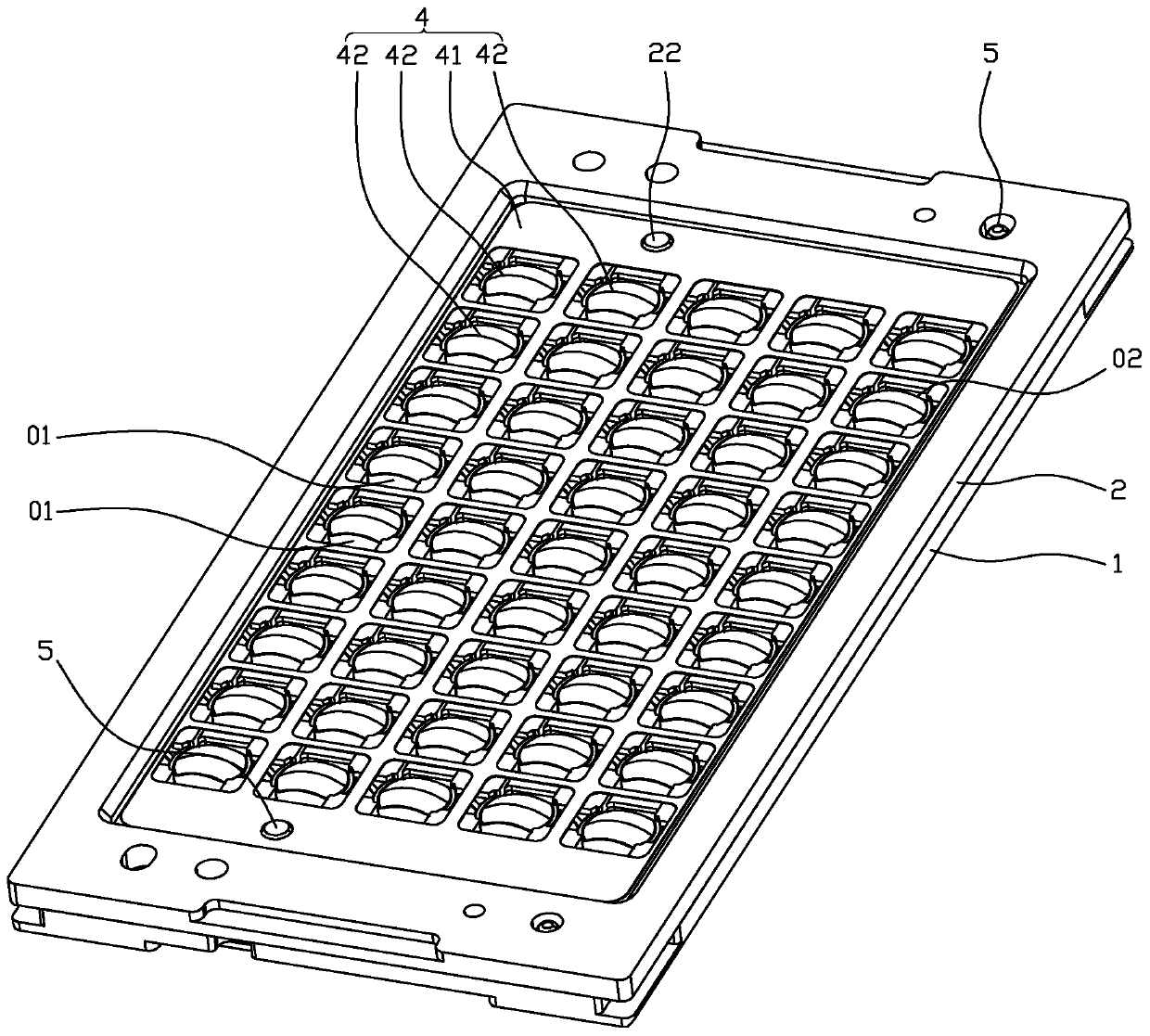

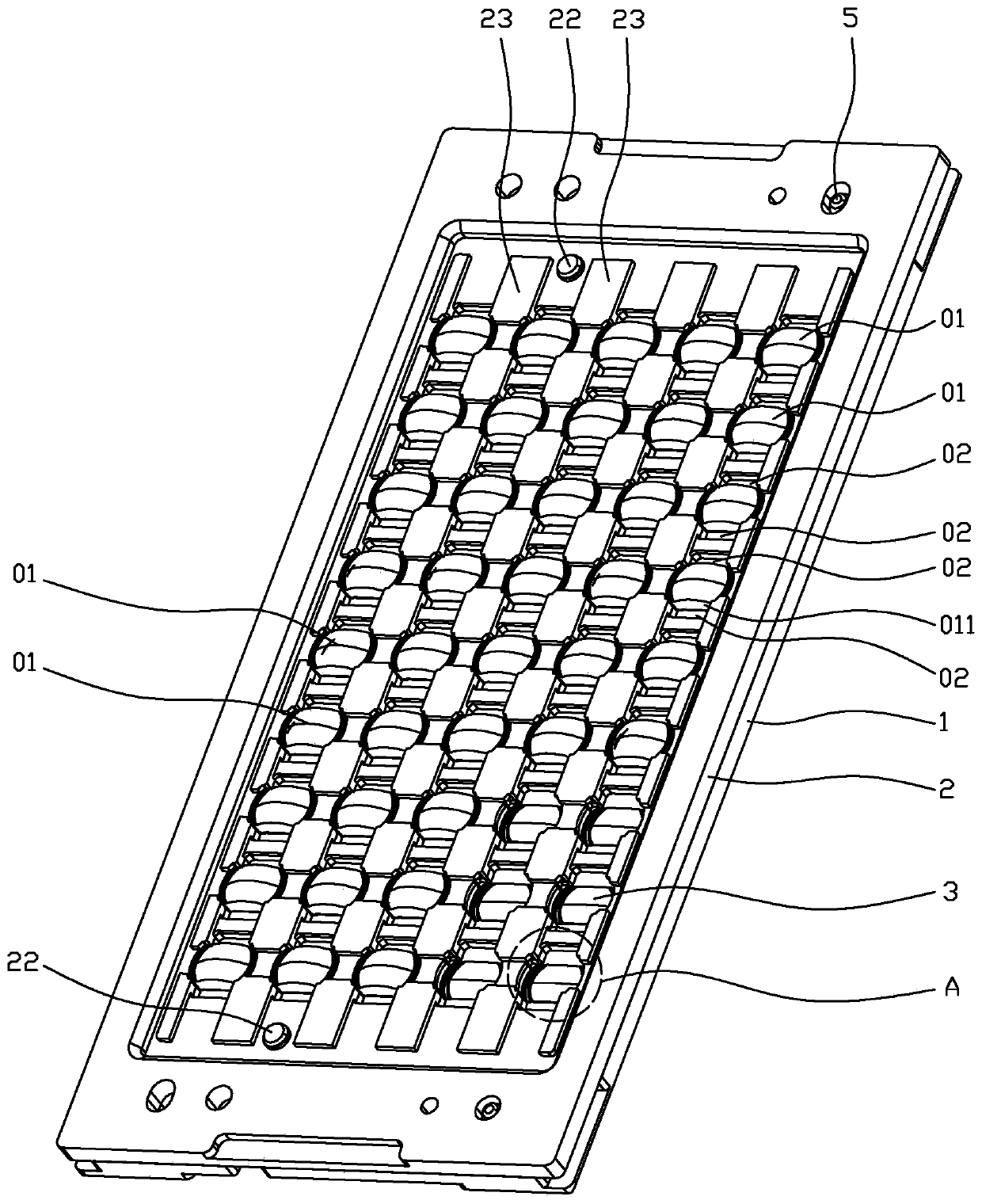

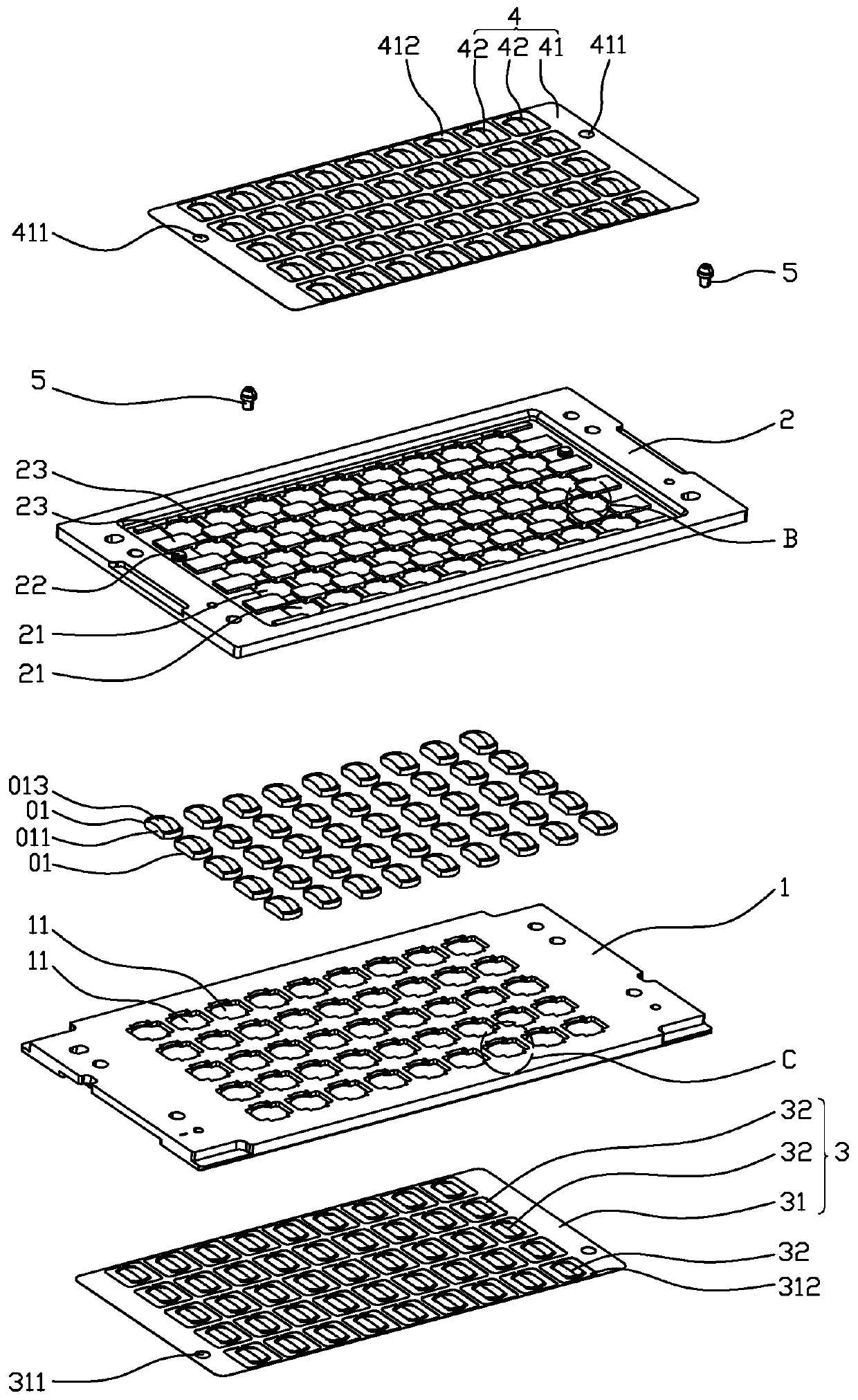

[0029] Such as Figure 1-9 As shown, a lens inkjet tooling is provided for installing the lens 01. The lens 01 has an inkjet side wall 011 on the peripheral side that needs to be ejected, and is located at both ends of the optical axis and is adjacent to the inkjet side wall 011. On the first surface 012 and the second surface 013, the inkjet tooling includes a first tooling plate 1 with a number of first accommodating holes 11 for assembling a number of lenses 01, covering the first tooling plate 1 and opening and A second tooling plate 2 of a plurality of second housing holes 21 corresponding to a accommodating hole 11, a first covering film 3 attached to the side of the first tooling plate 1 away from the second tooling plate 2 for covering the first surface 012 And a second covering film 4 attached to the side of the second tooling plate 2 away from the first toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com