Method and device for analyzing external contour command and colored 3D printing machine

A 3D printer and 3D printing technology, applied in the computer field, can solve the problems of low inkjet printing efficiency and long inkjet printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

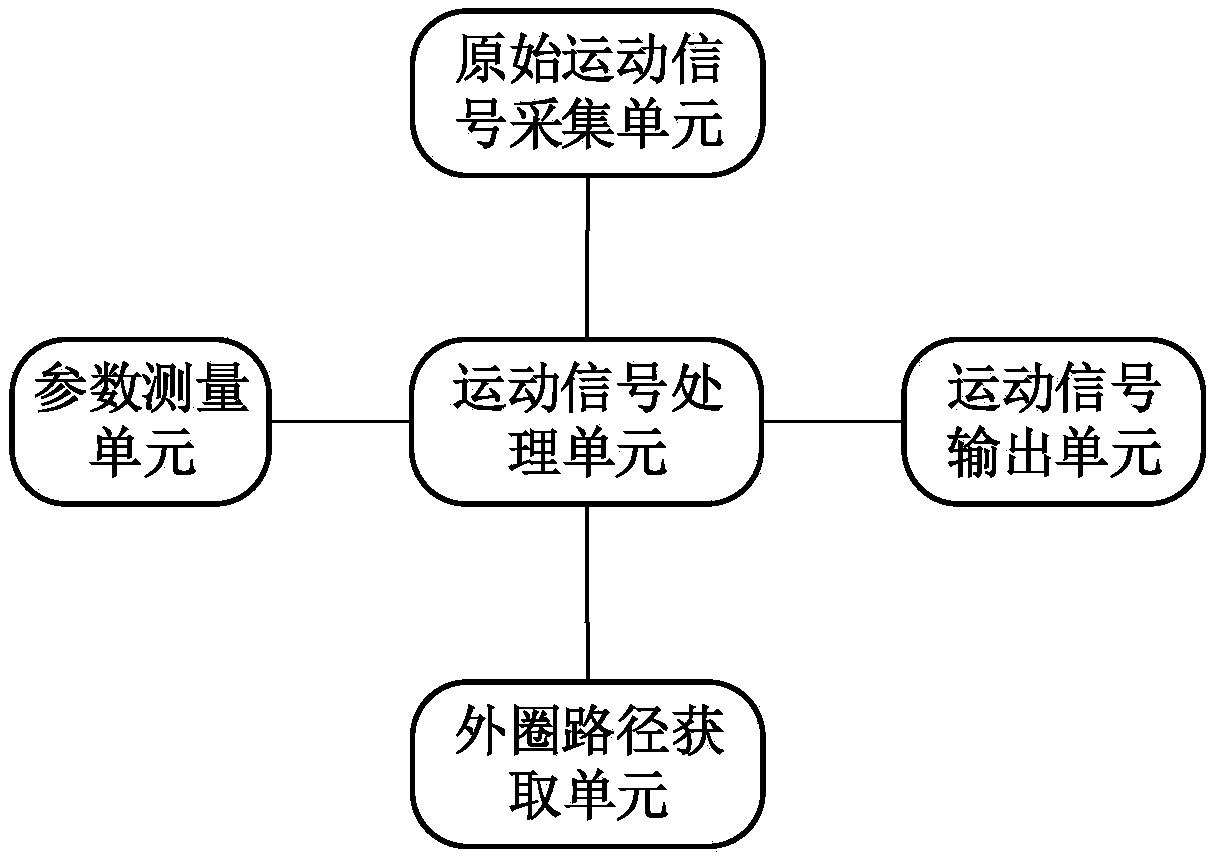

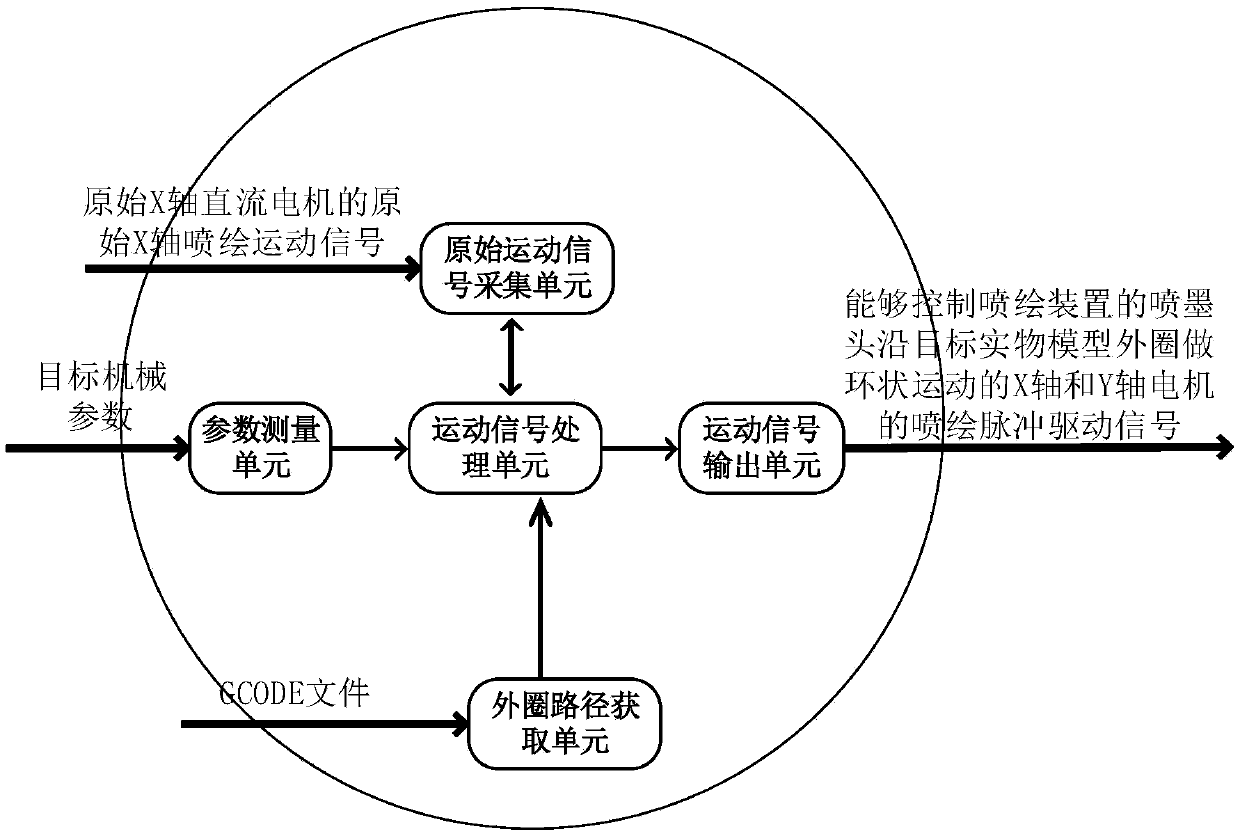

AI Technical Summary

Problems solved by technology

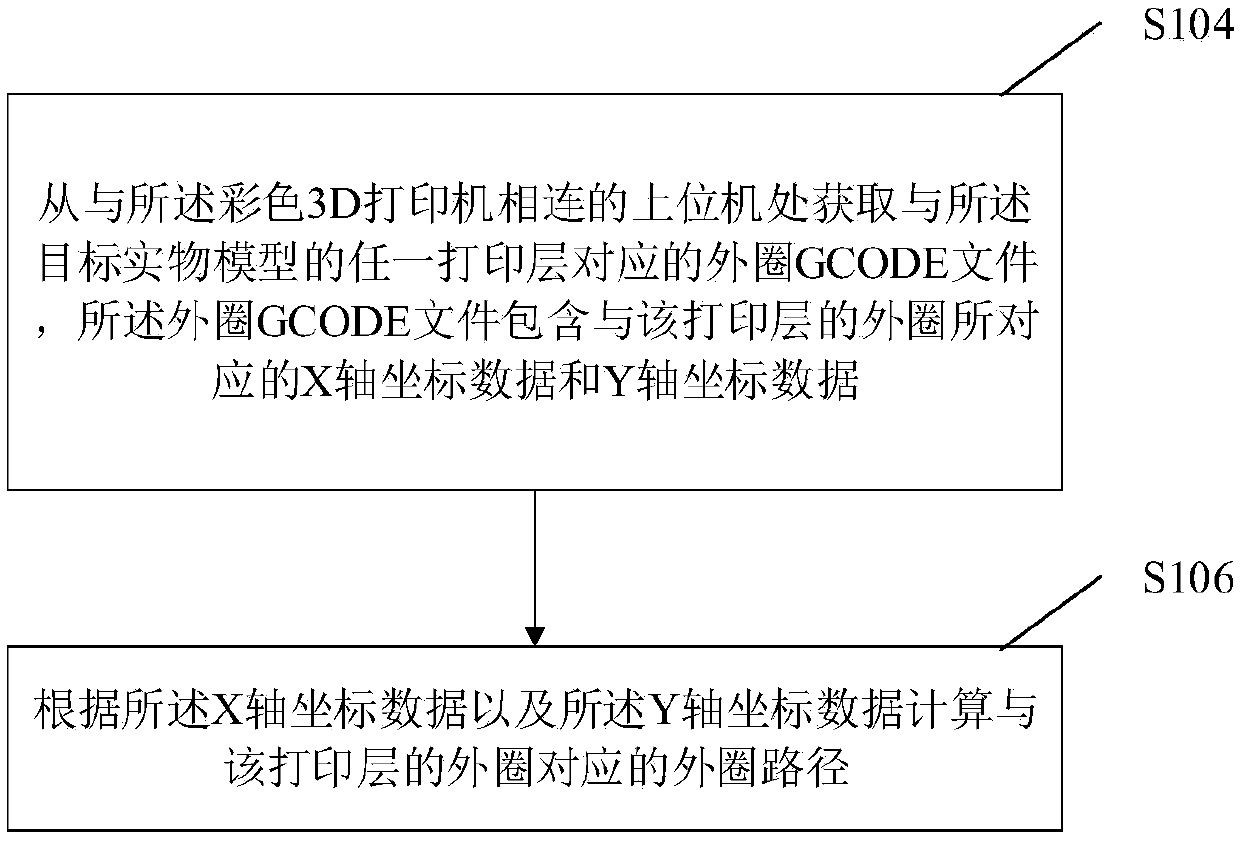

Method used

Image

Examples

Embodiment 1

[0164] In the present embodiment, the mechanical structure of the color 3D printer is the first mechanical structure, and the core device (jet printing device) of the color inkjet printer in the prior art is installed on the frame of the FDM color 3D printer, and discarded Toner carriage that acts as the X-axis motion mechanism. The spatial coordinates of 3D modeling and coloring printing are named in Table 1. The mechanical structure of coloring printing shares the X-axis and Y-axis of 3D modeling, that is, the X-axis and Y-axis of 3D modeling and coloring printing are both mechanically Shared, but they are controlled alternately in electrical control, and both the X-axis and the Y-axis are equipped with stepper motors.

[0165] In the color 3D printer of this embodiment, in the printing stage, the inkjet head or the target physical model moves horizontally along the X-axis or the Y-axis to complete the coloring and printing. When the i-th (i=1, 2, 3,...,n) layer of the targ...

Embodiment 2

[0184] In this embodiment, the mechanical structure of the color 3D printer is the second mechanical structure. The inkjet device that can match the DC motor in the existing color inkjet printer is installed on the frame of the FDM color 3D printer, and the function as Carriage holder for X-axis motion mechanism. The space coordinates of 3D modeling and coloring printing are named as shown in Table 2. The mechanical structure of coloring printing shares the X-axis of 3D modeling, that is, the X-axis of 3D modeling and coloring printing is shared mechanically, but in terms of electrical control But it is controlled alternately, and the X-axis is equipped with a stepper motor. The Y axes of 3D modeling and coloring inkjet printing are Y1 axis and Y2 axis respectively. They are completely independent and have no coupling relationship with each other. The Y1 axis and Y2 axis are equipped with stepper motors and DC motors respectively.

[0185] As shown in Table 2, the difference ...

Embodiment 3

[0196]In this embodiment, the mechanical structure of the color 3D printer is the third mechanical structure, and the spatial coordinates of its 3D modeling and coloring inkjet are named as shown in Table 2, and the X axes of the 3D modeling and coloring inkjet are respectively X1 axis and The X2 axis is completely independent and has no coupling relationship with each other. The X1 axis and X2 axis are equipped with stepping motors and DC motors respectively; the coloring and printing mechanical structure shares the Y axis of 3D modeling, namely 3D modeling and The Y-axis of coloring inkjet printing is shared mechanically, but it is controlled alternately in electrical control, and the Y-axis is equipped with a stepping motor. The inkjet device that can match the DC motor in the existing color inkjet printer is installed on the frame of the FDM color 3D printer, and the ink holder that acts as the X2 axis movement mechanism is retained.

[0197] In the color 3D printer of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com