Method for vertical arranging color ink jet plotter nozzles

A vertical arrangement, inkjet technology, applied in printing and other directions, can solve problems such as heavy workload, low efficiency, and difficulty in ensuring the consistency of printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

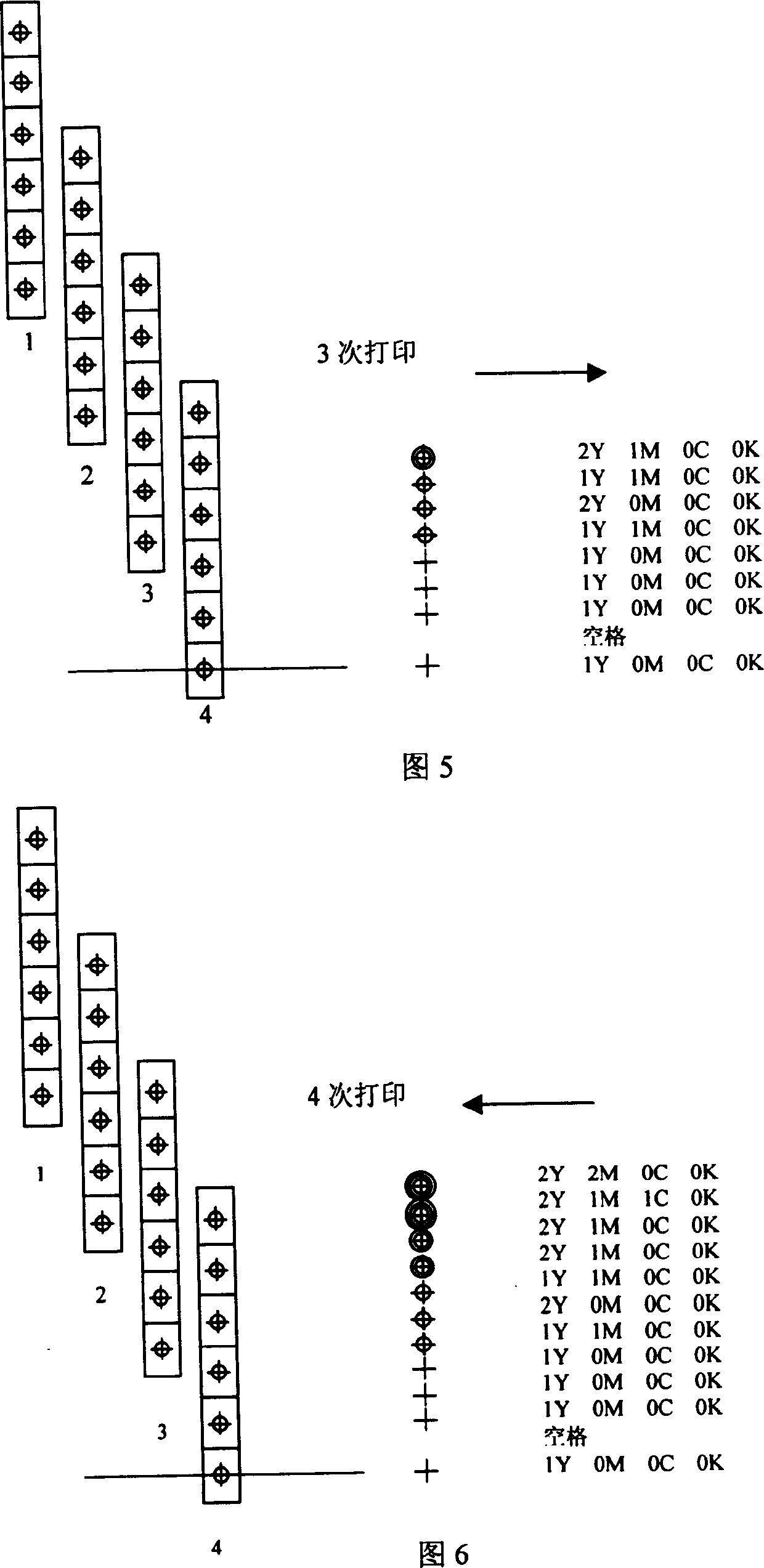

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

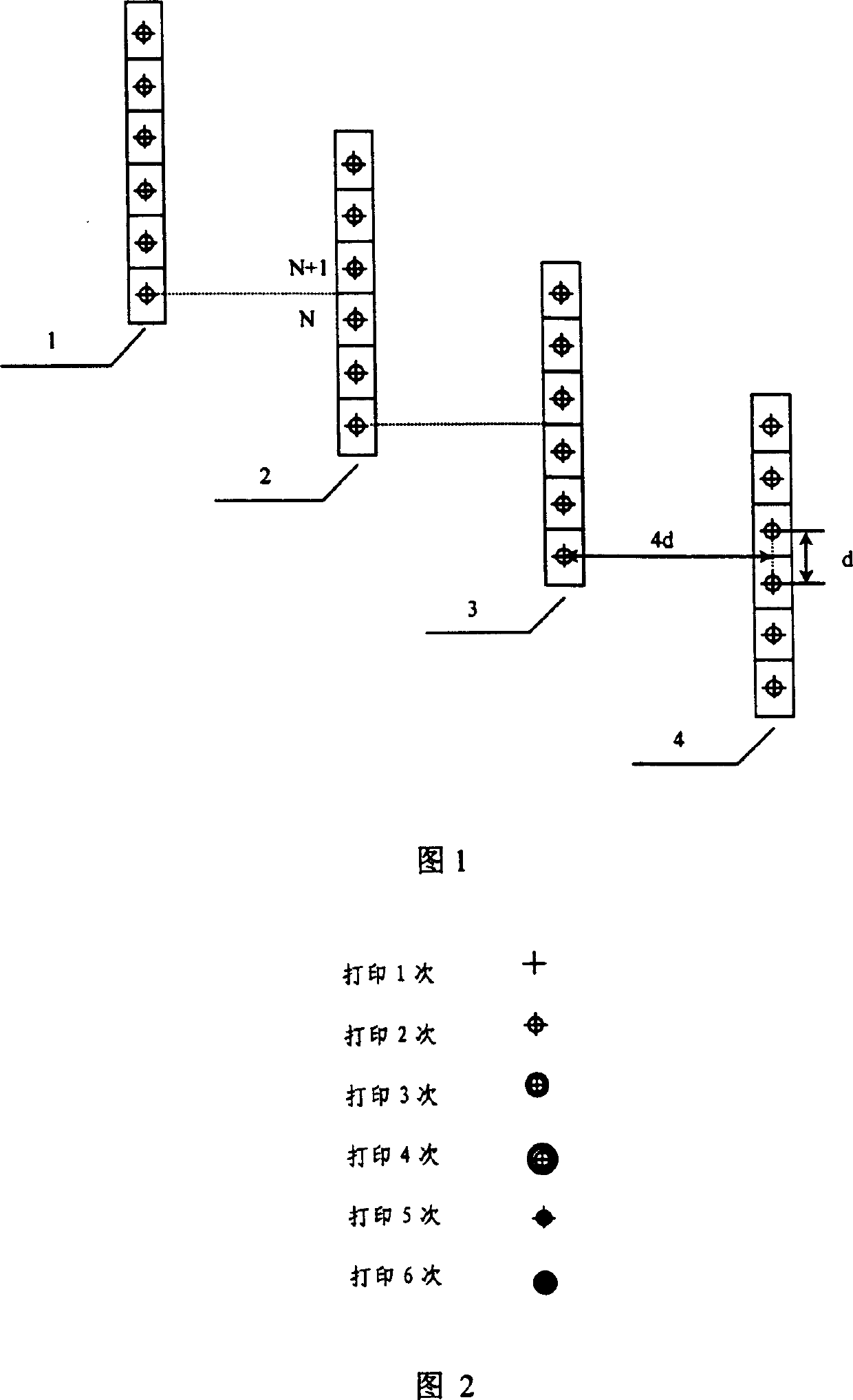

[0026] Fig. 1 shows a schematic diagram of a method for vertically arranging four nozzles according to an embodiment of the present invention.

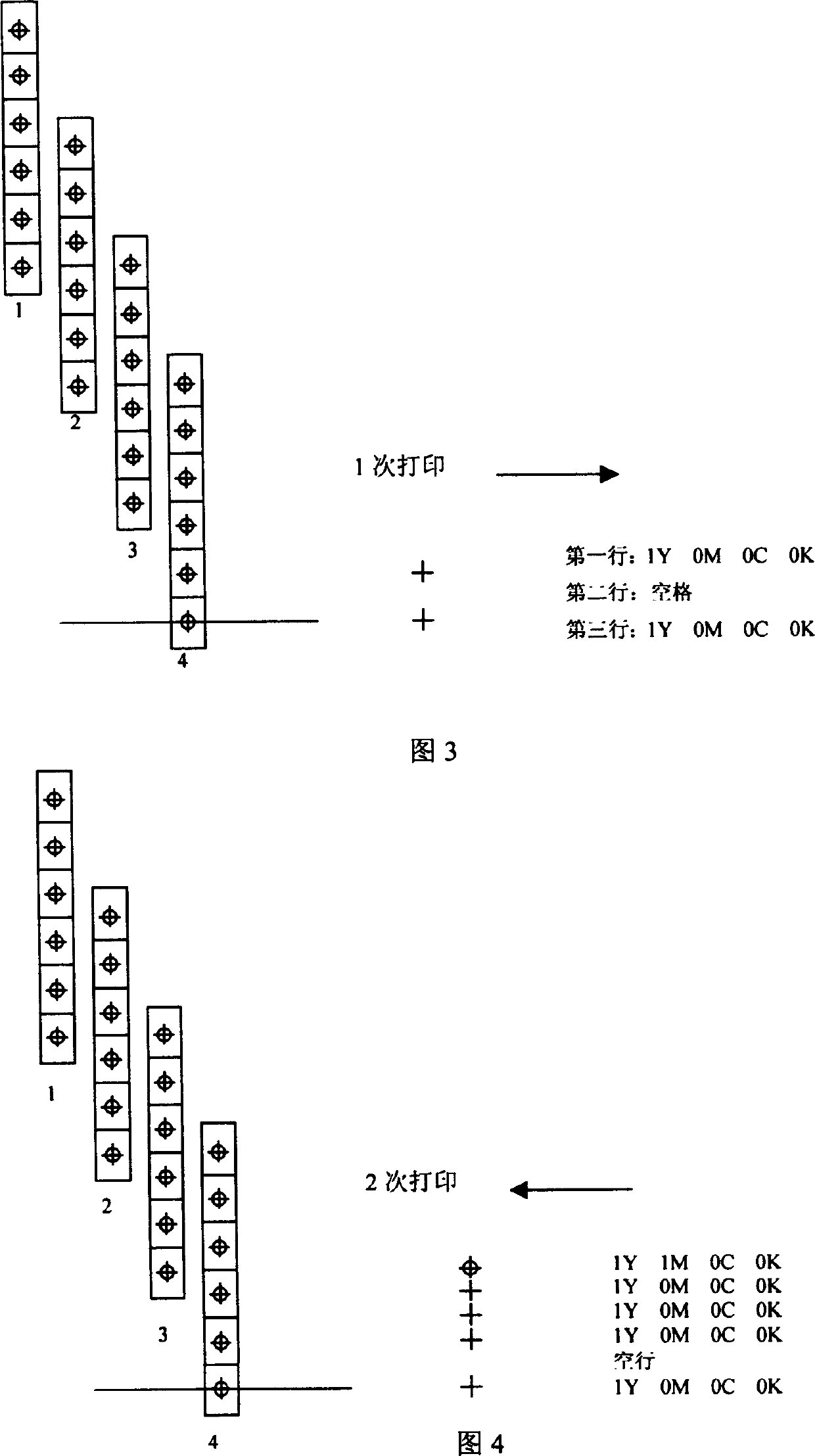

[0027] For the convenience of description and understanding, it is assumed that each nozzle has six nozzle holes, that is, N=3, 2N=6. Nozzle 1 is for spraying black ink, Nozzle 2 is for cyan ink, Nozzle 3 is for magenta ink, Nozzle 4 is for yellow ink. Arrange in the order of cyan and black, the first nozzle hole of each nozzle faces down, and the nozzle holes are represented as a, b, c, d, e, f from top to bottom. The distance between two nozzle holes is d, and the distance between two adjacent nozzles is 4d, which is the distance between 4 nozzle holes.

[0028] It can be seen from Fig. 1 that the horizontal position of nozzle a of nozzle 3 is aligned with the middle of nozzle c a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com