LED support inkjet equipment and inkjet method thereof

A LED bracket and inkjet technology, applied in the direction of copying/marking methods, printing, electrical components, etc., can solve the problems of increased production cost, high mold cost, low production efficiency, etc., achieve fast operation speed, improve product quality, and spray Ink layer tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

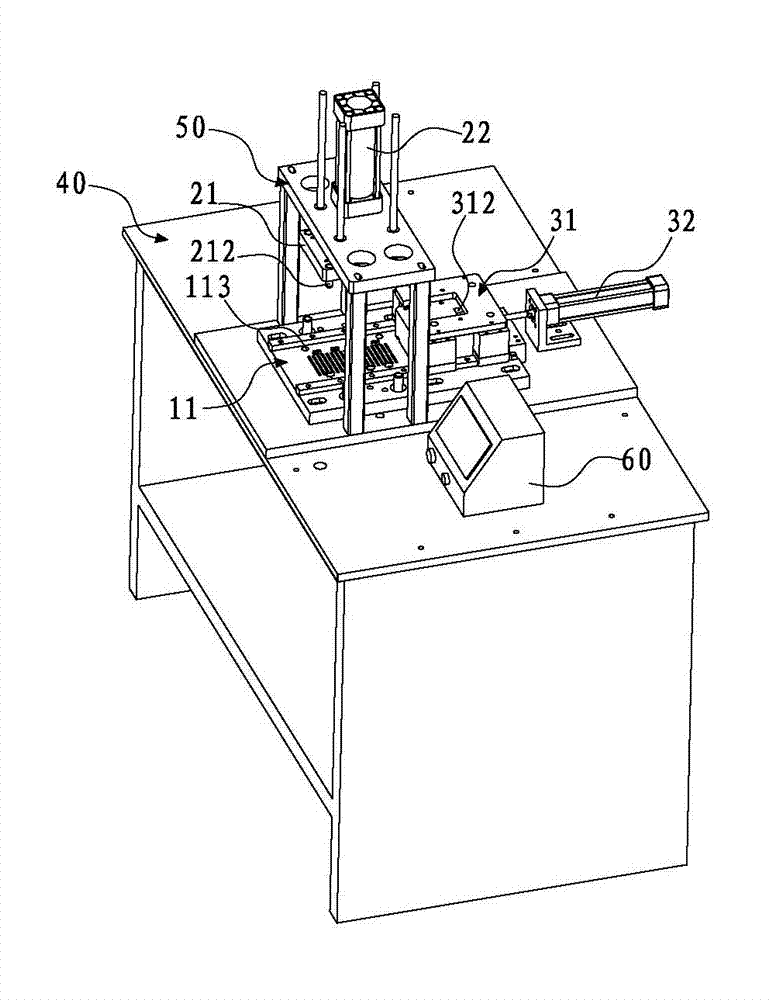

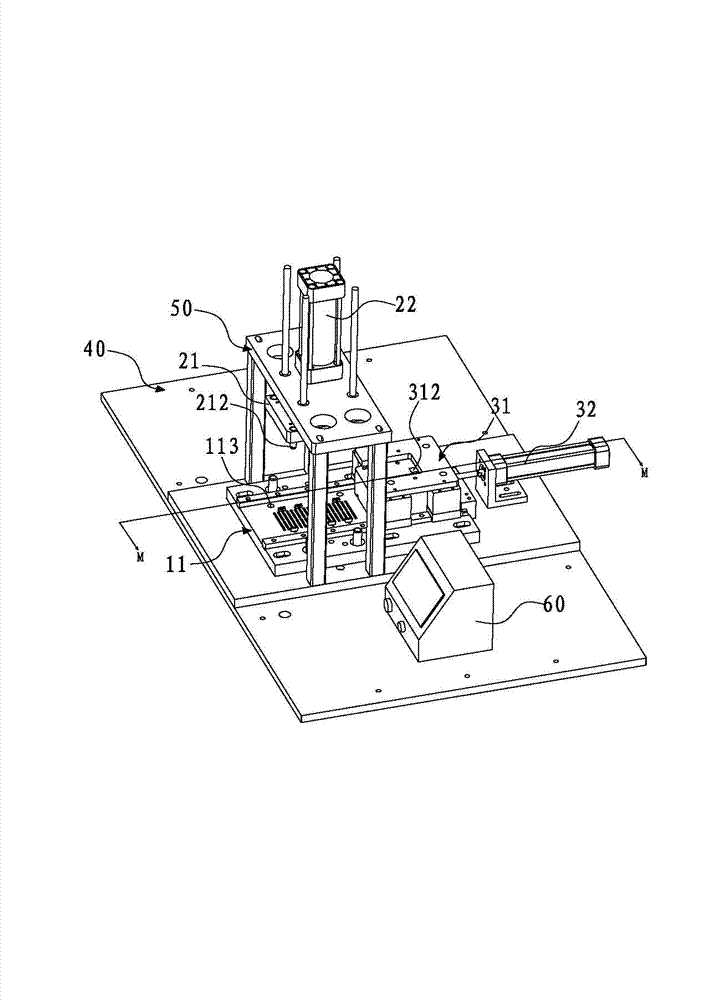

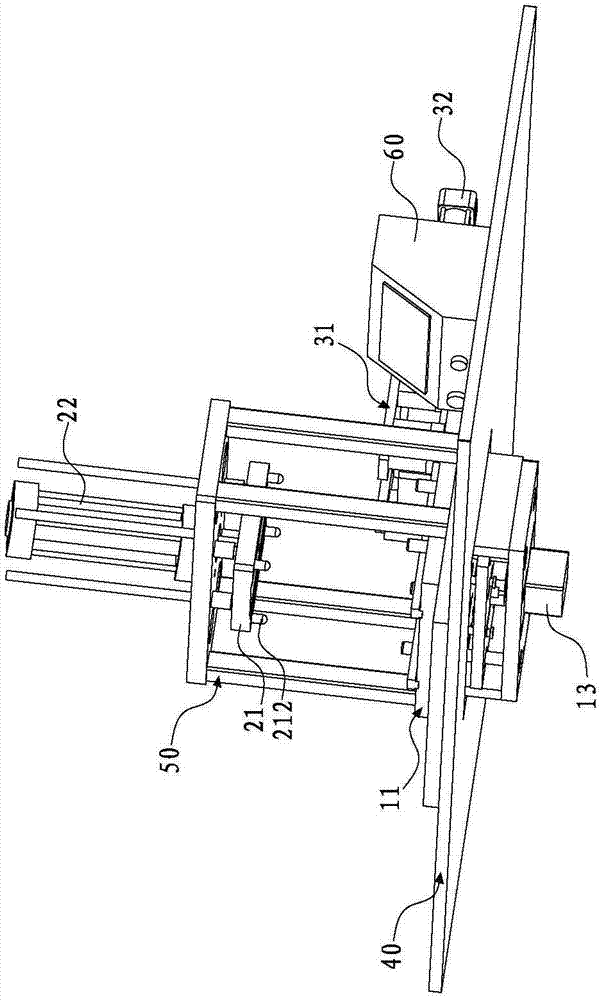

[0048] Please refer to Figure 1 to Figure 6 Shown, it has shown the concrete structure of preferred embodiment of the present invention, and this LED bracket ink-jet equipment includes upper mold 21, lower mold 11, ink cartridge 31, thimble 12, ink suction cylinder 13, inkjet cylinder 22 , scraping ink cylinder 32, horizontal workbench 40, vertical support frame 50 and controller 60.

[0049] Wherein, the controller 60 is arranged on the horizontal workbench 40, and the controller 60 includes a control module and a control panel for setting data, and its control module is connected to the ink suction cylinder 13, the inkjet cylinder 22 and the ink scraping cylinder respectively. 32.

[0050] The lower mold 11 is set on the horizontal workbench 40, and the lower mold 11 is provided with positioning protrusions 111 for matching with the positioning holes on the material belt of the LED assembly bracket. Each LED bracket corresponds to the cavity 112; one end of the thimble 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com