Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

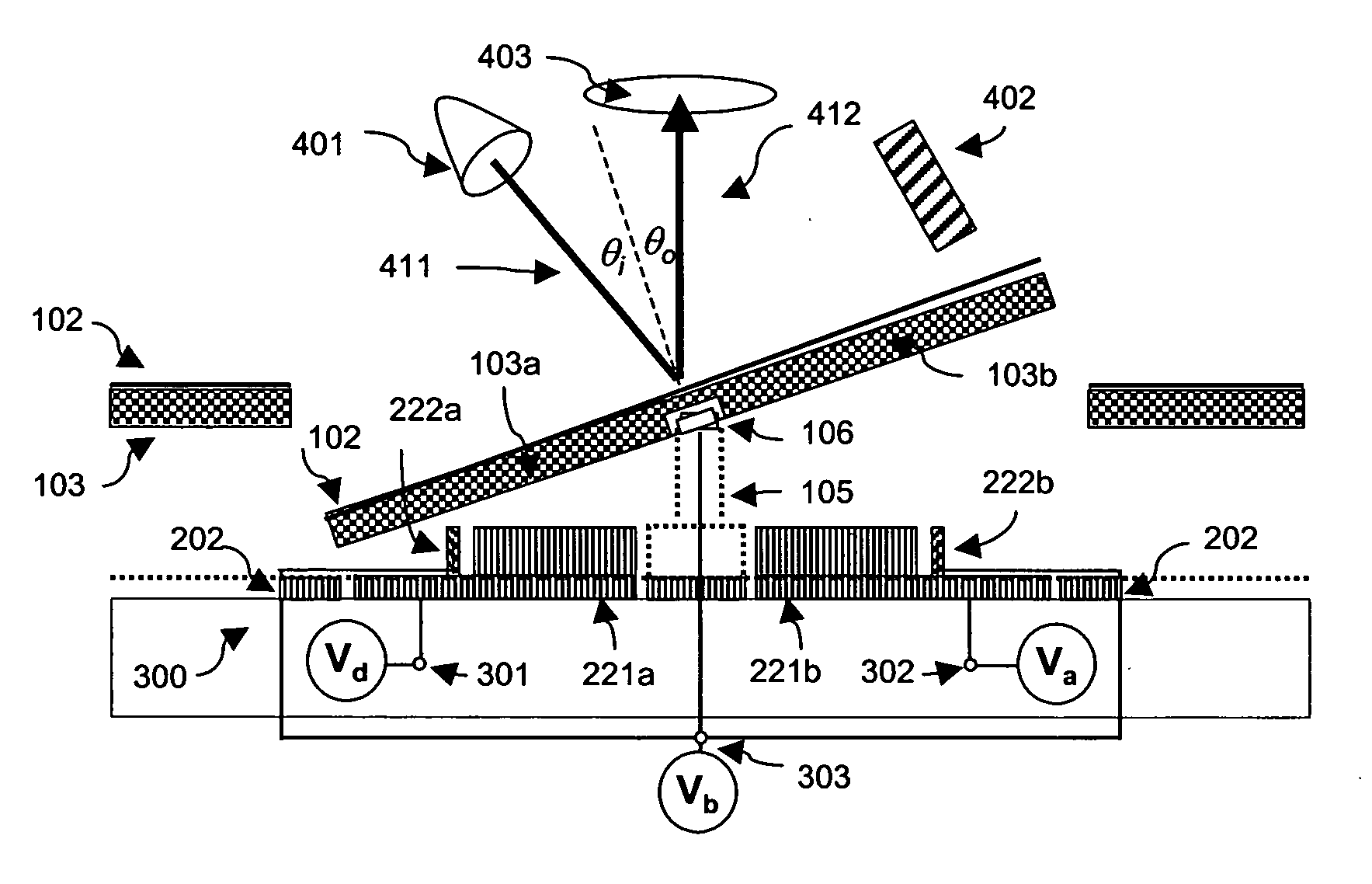

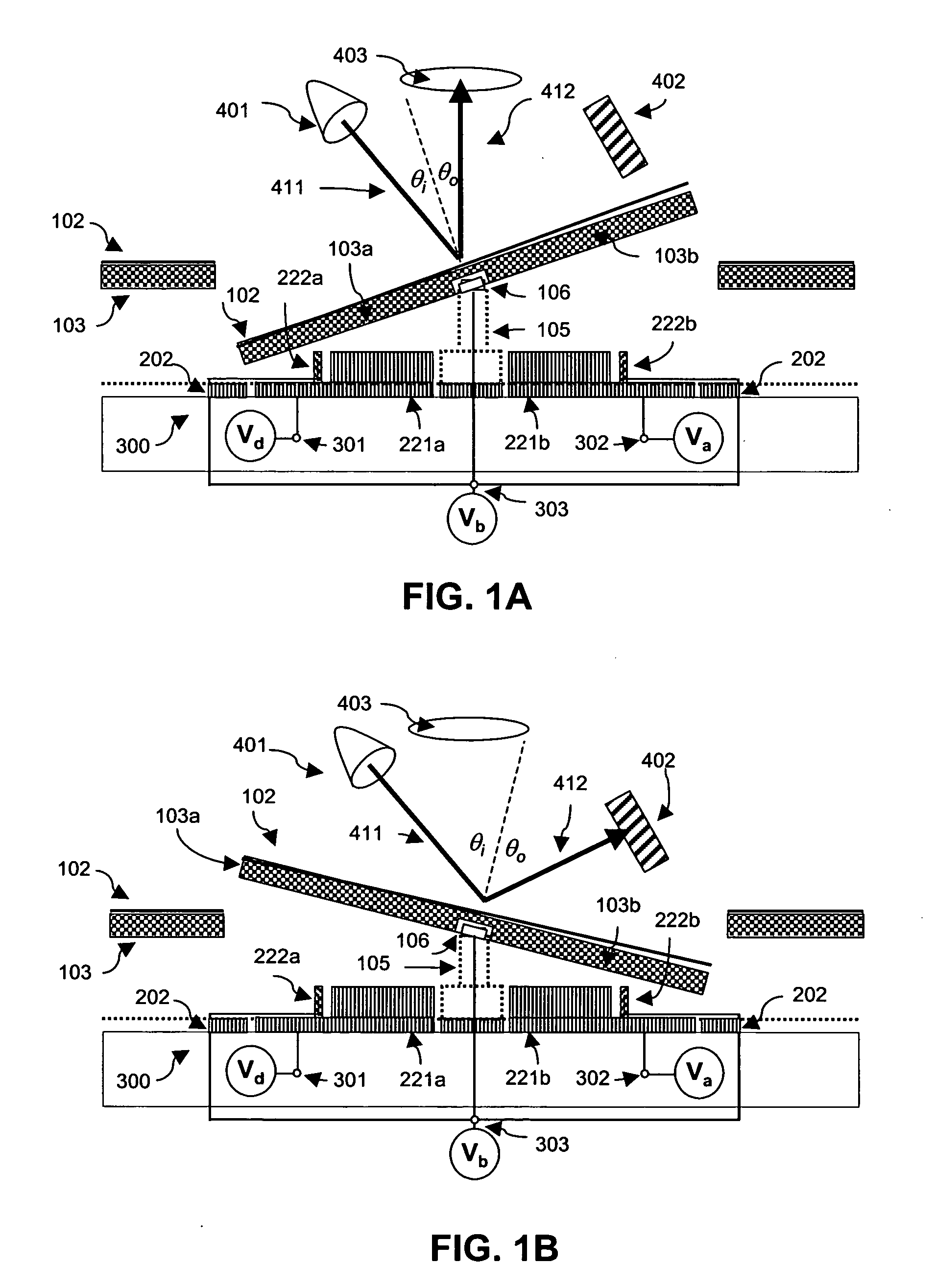

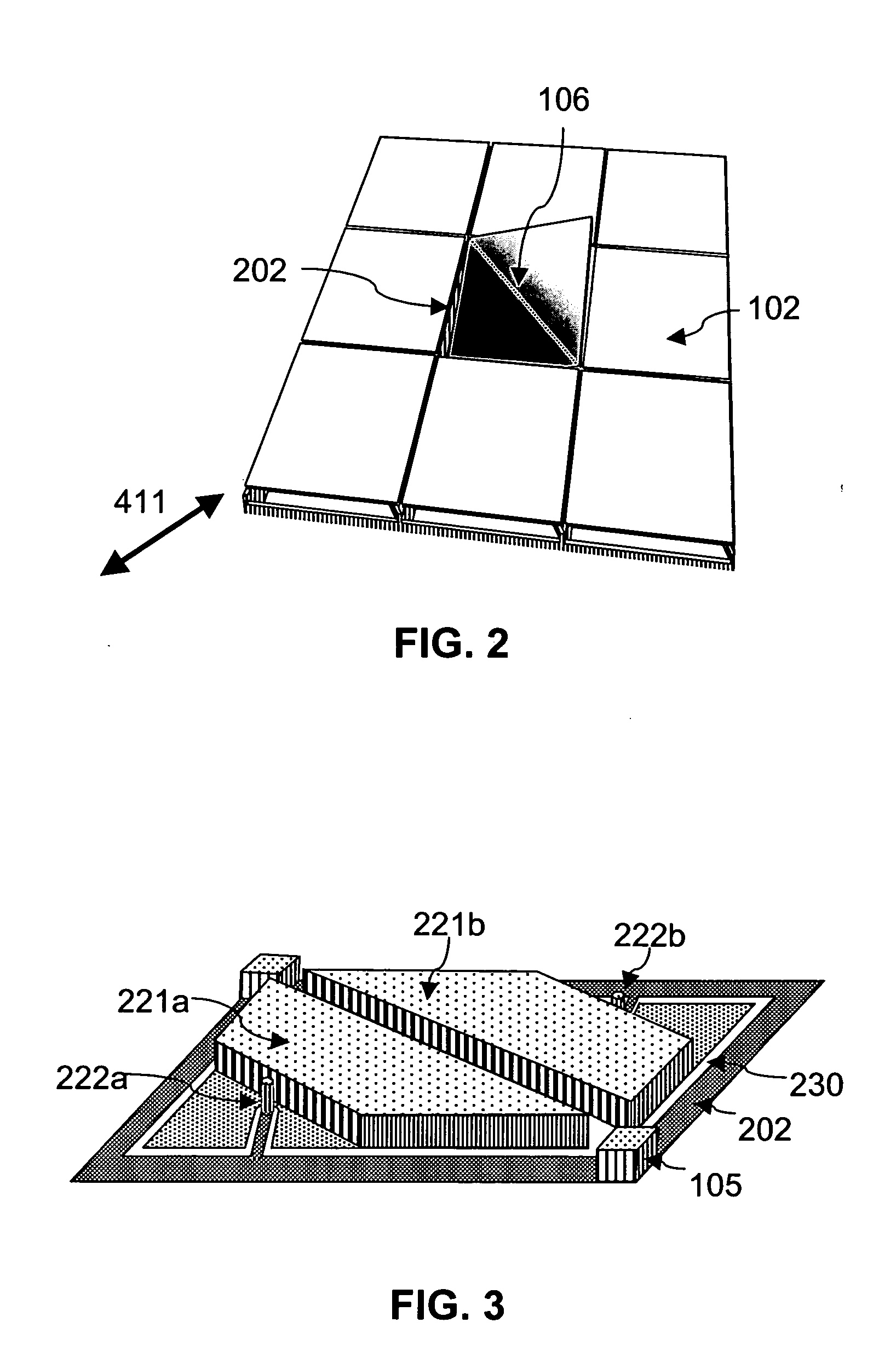

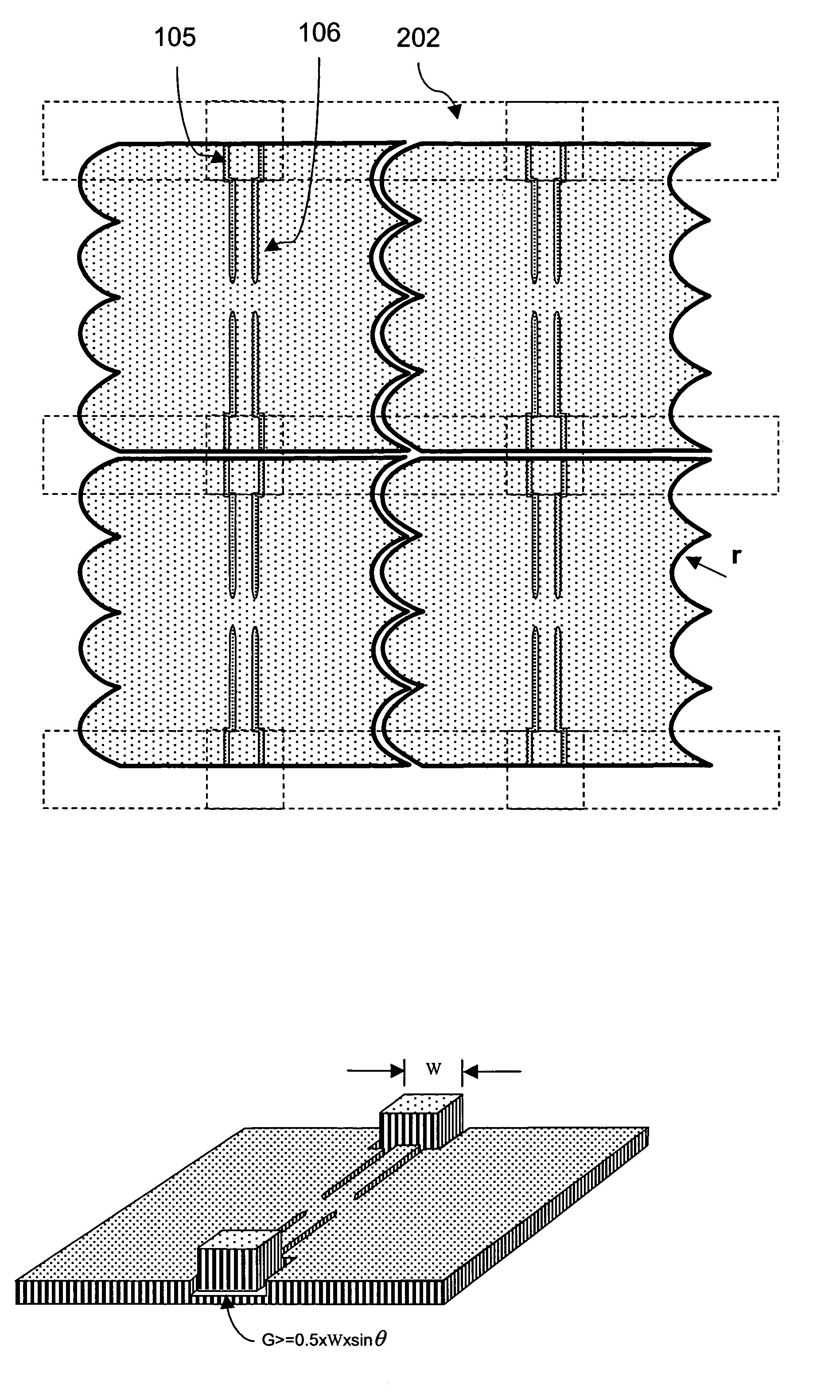

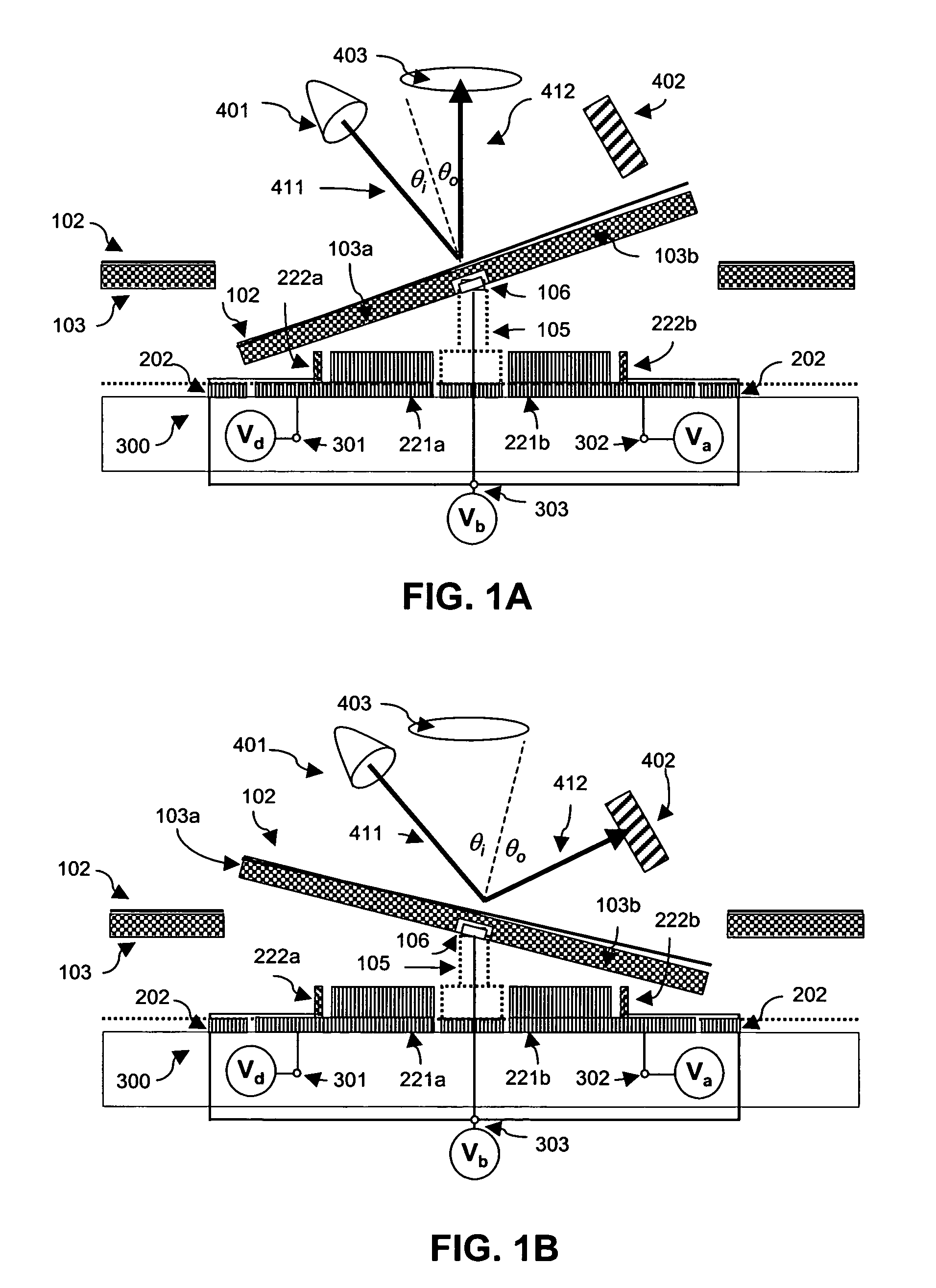

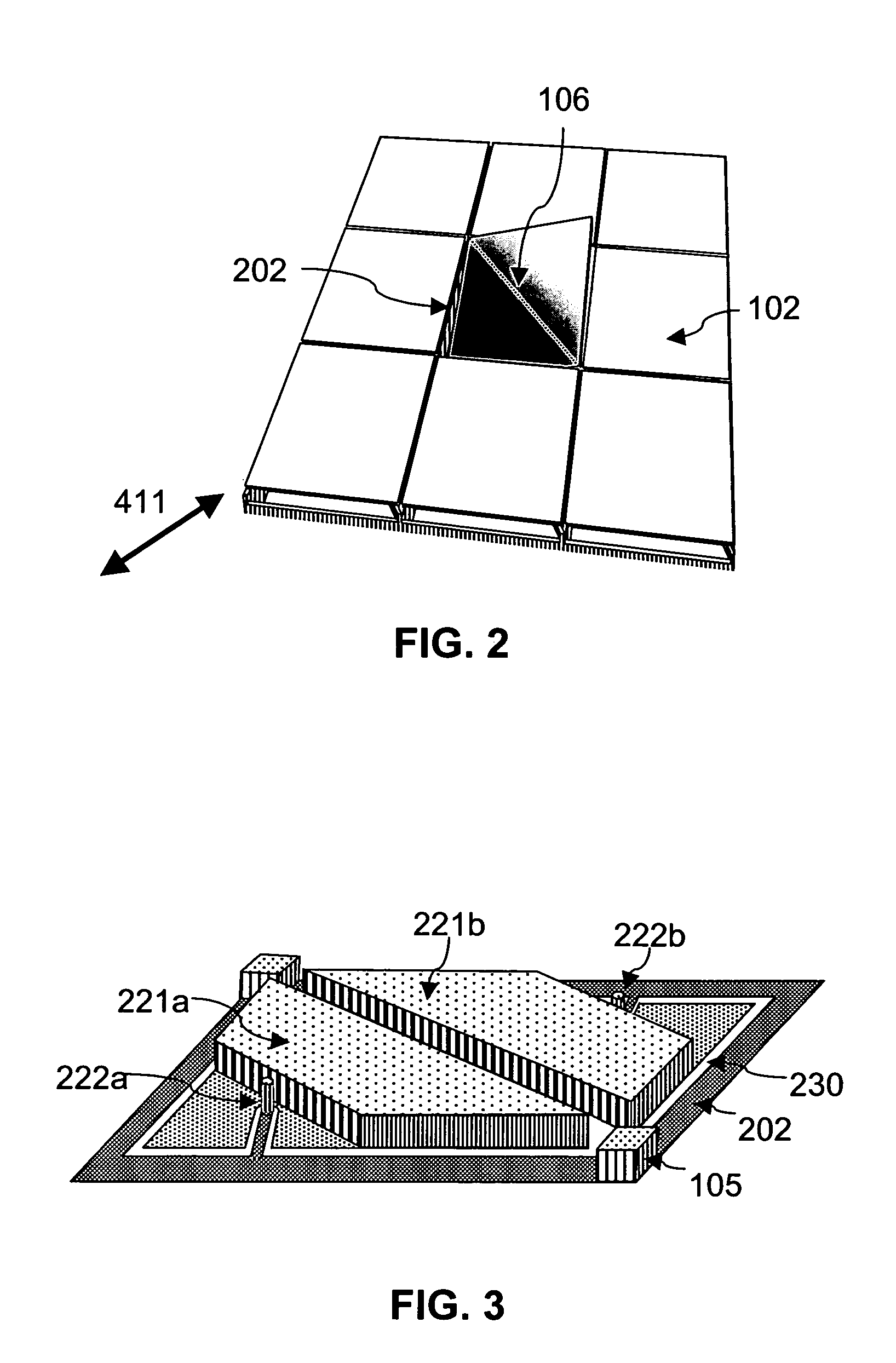

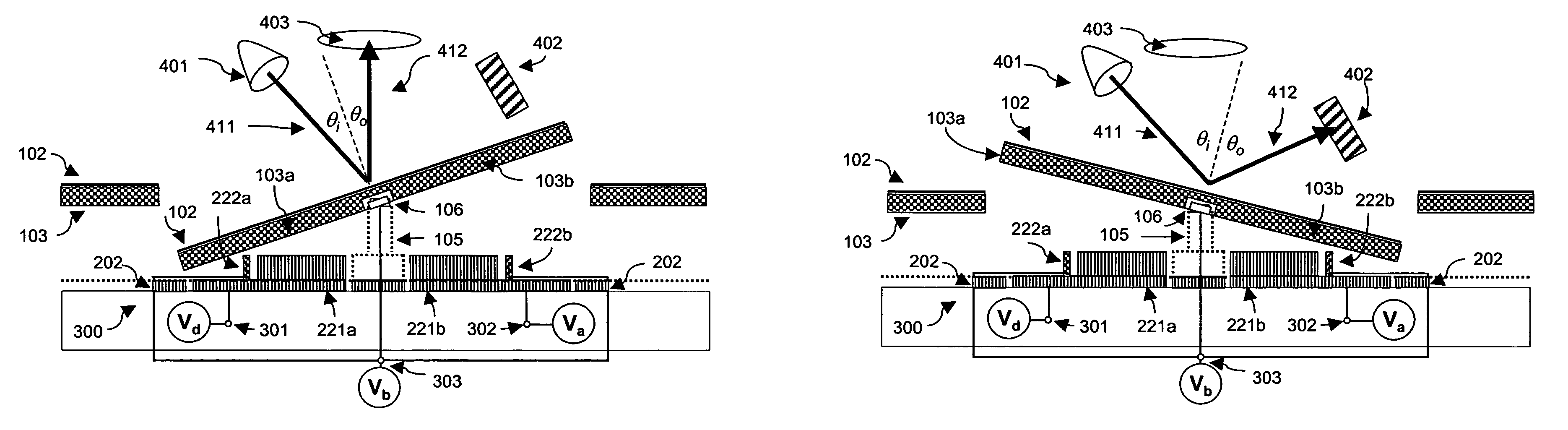

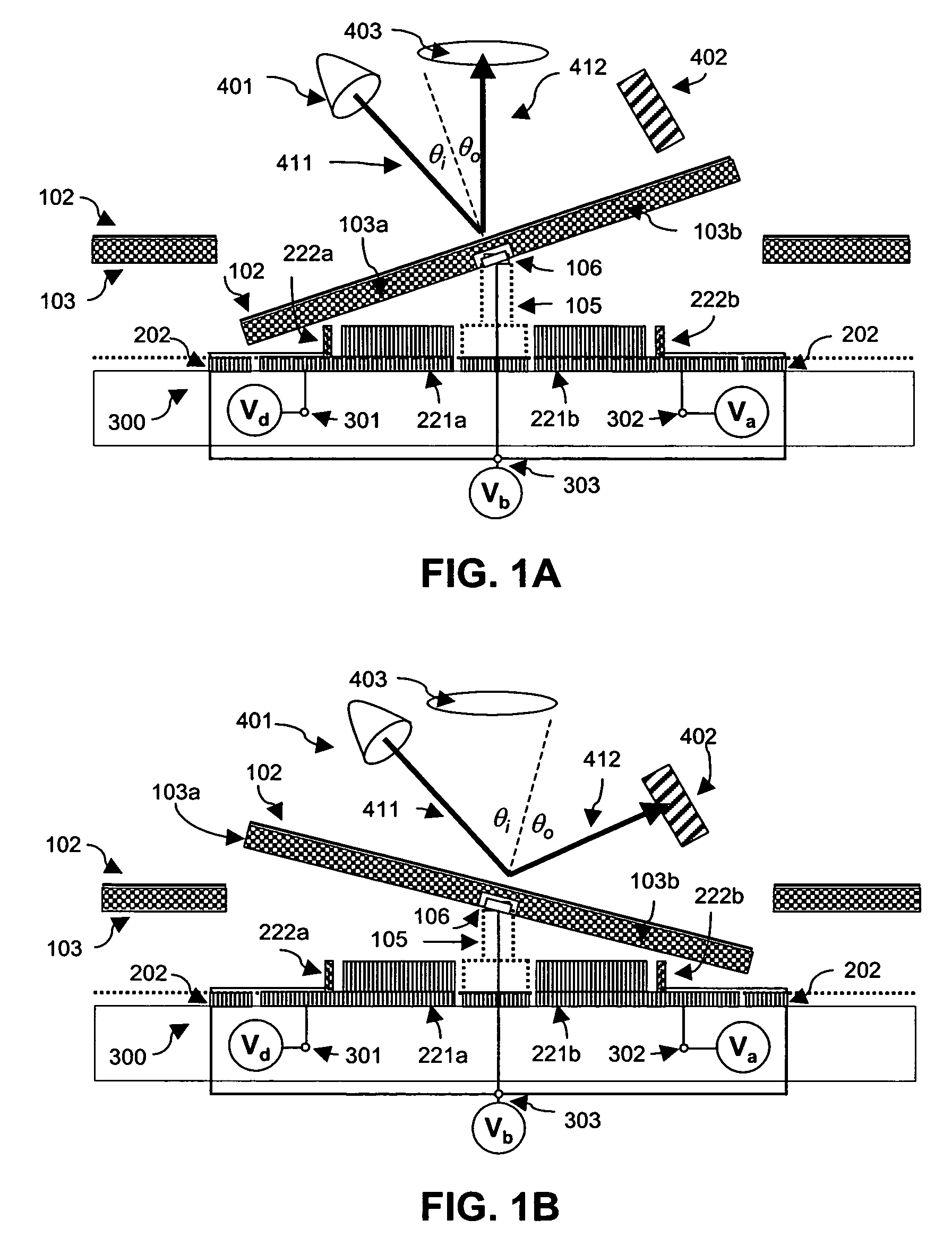

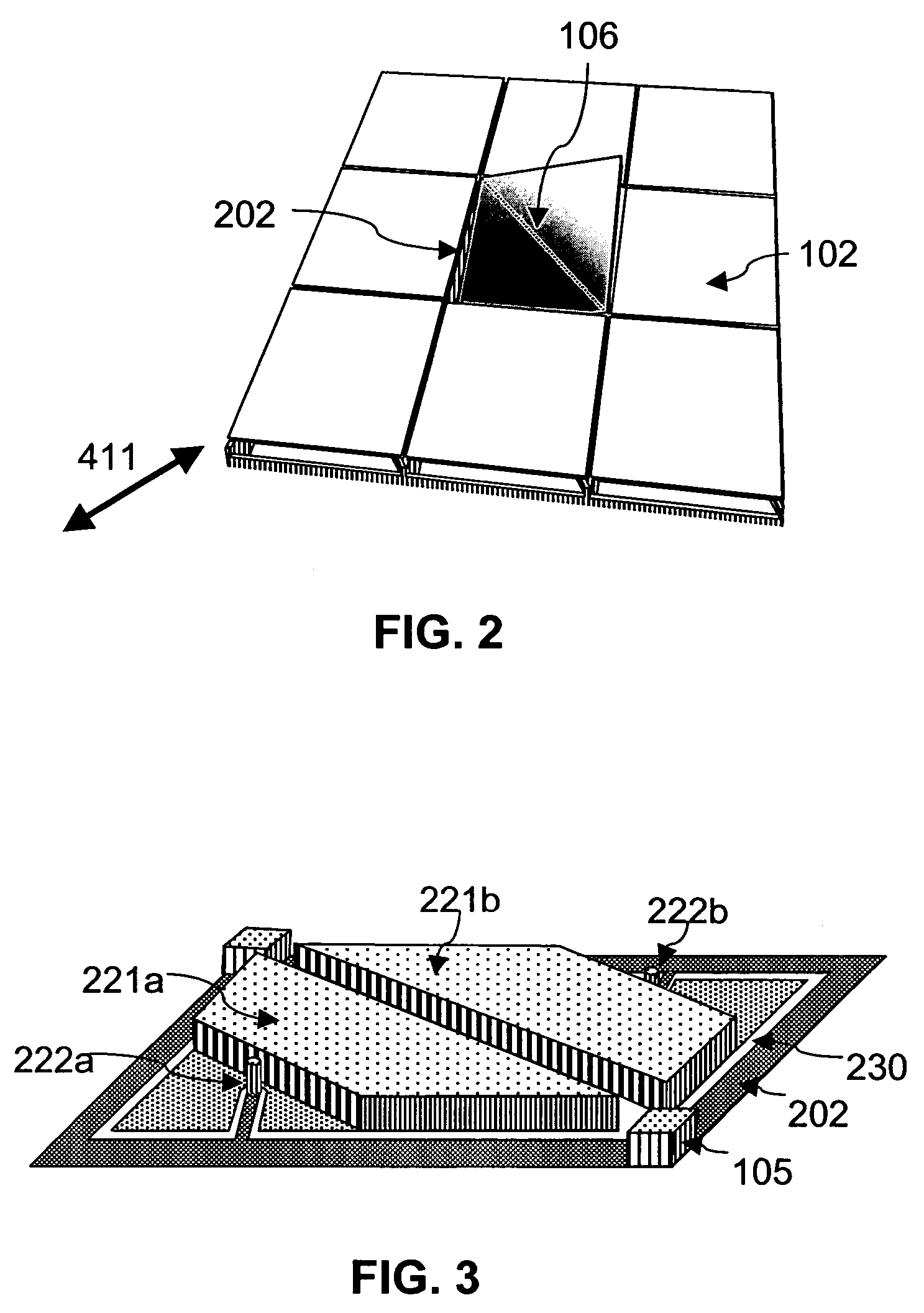

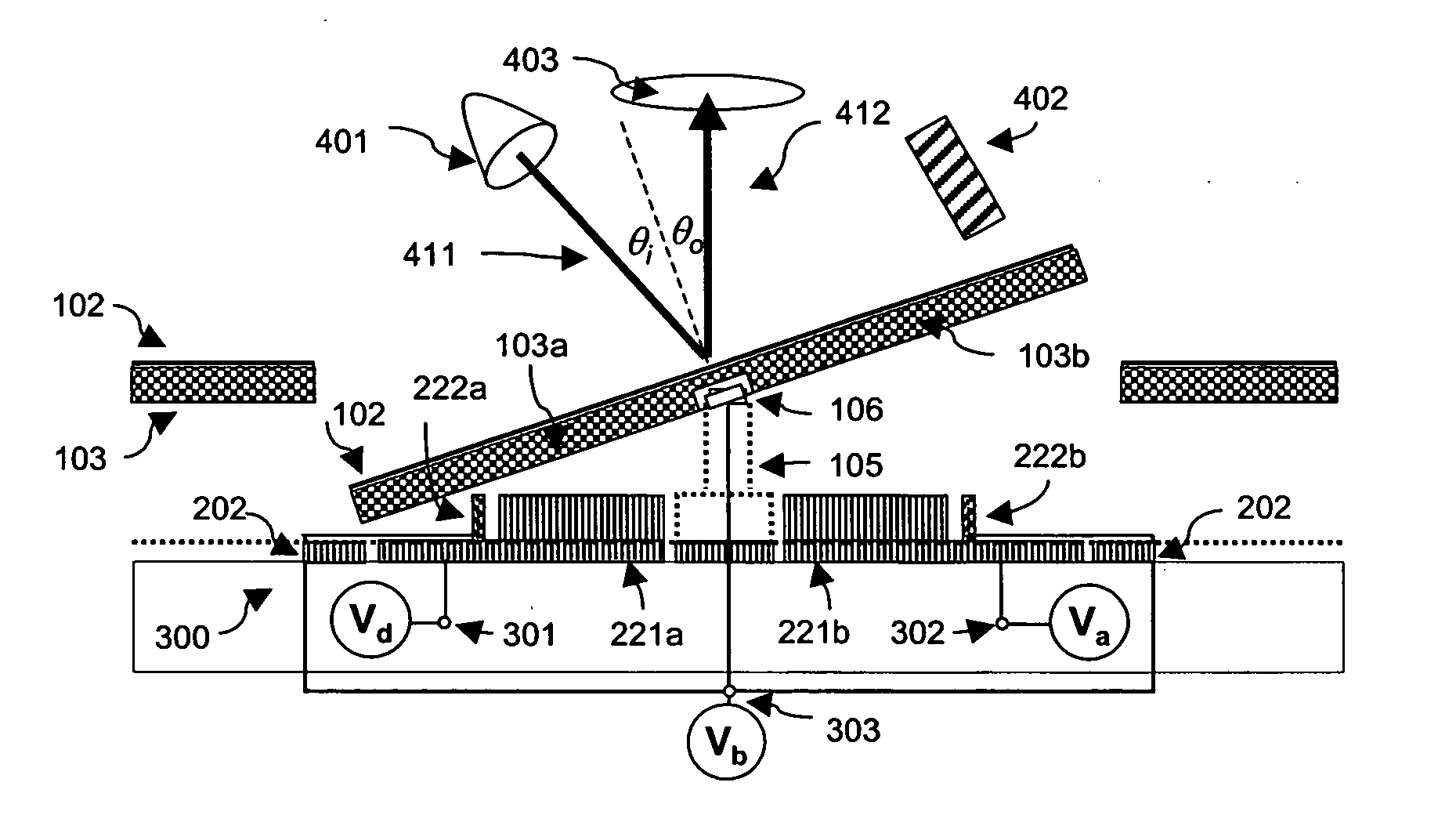

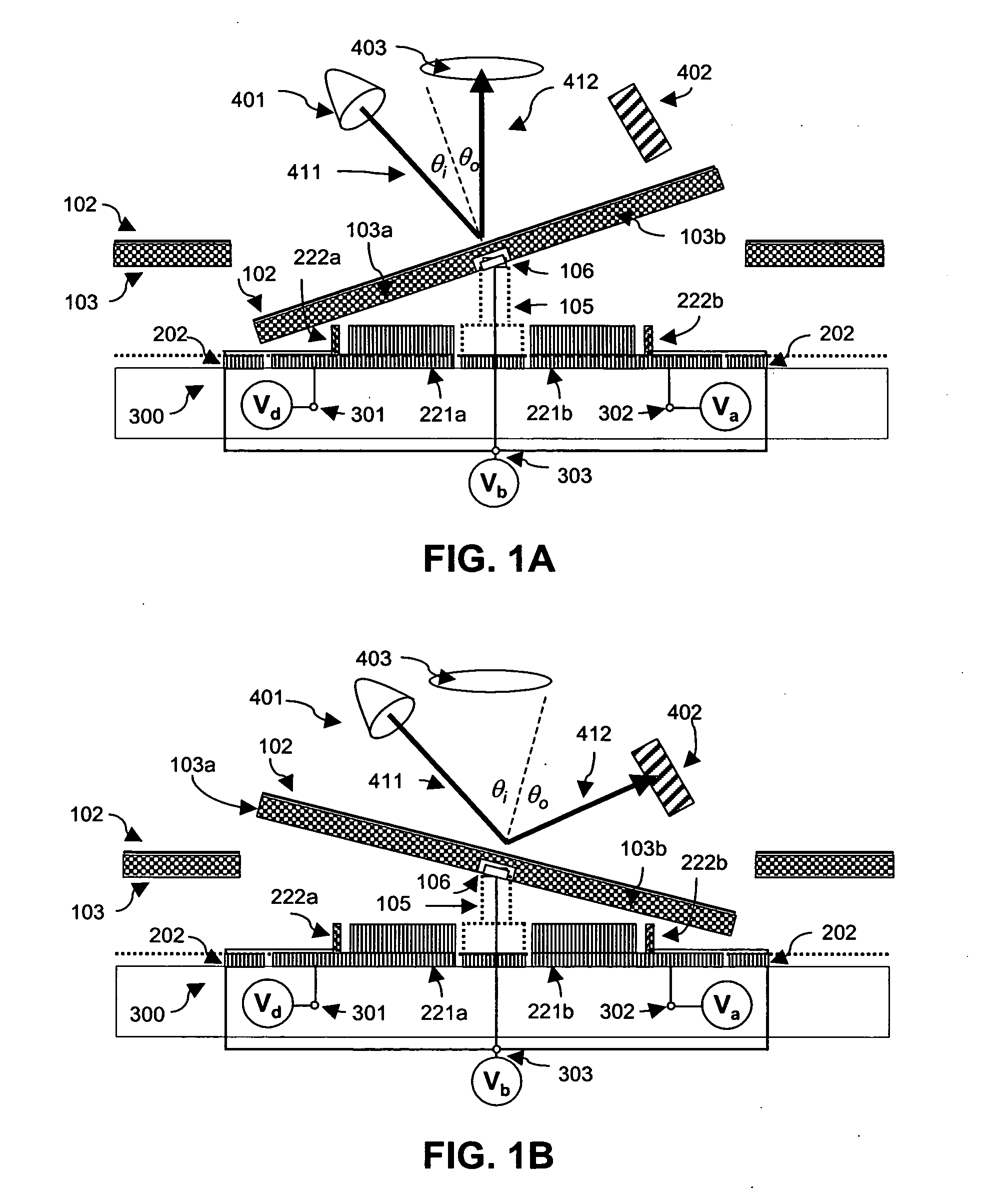

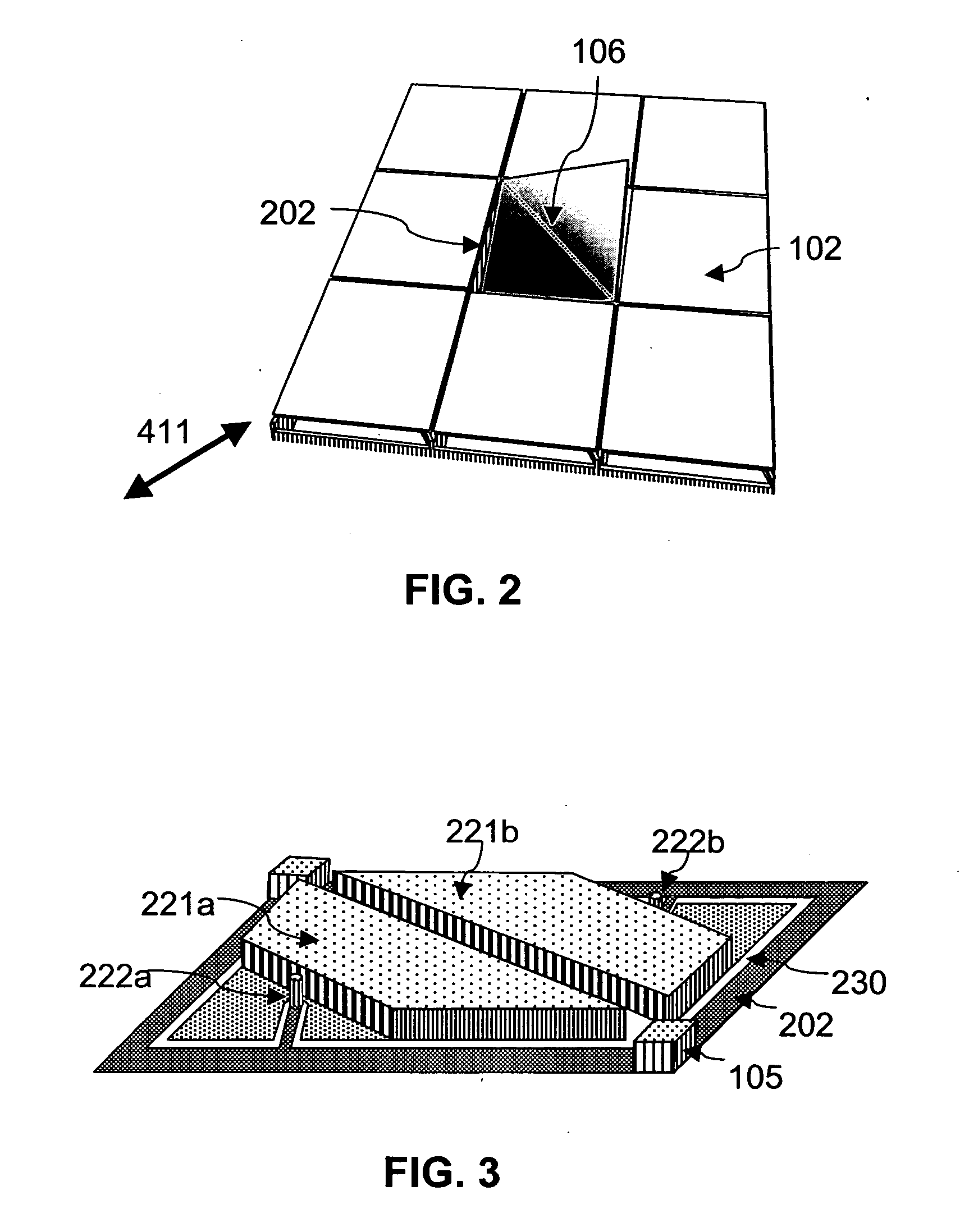

High contrast spatial light modulator and method

ActiveUS20050128564A1Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro-mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

High contrast spatial light modulator and method

ActiveUS7167298B2Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro-mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

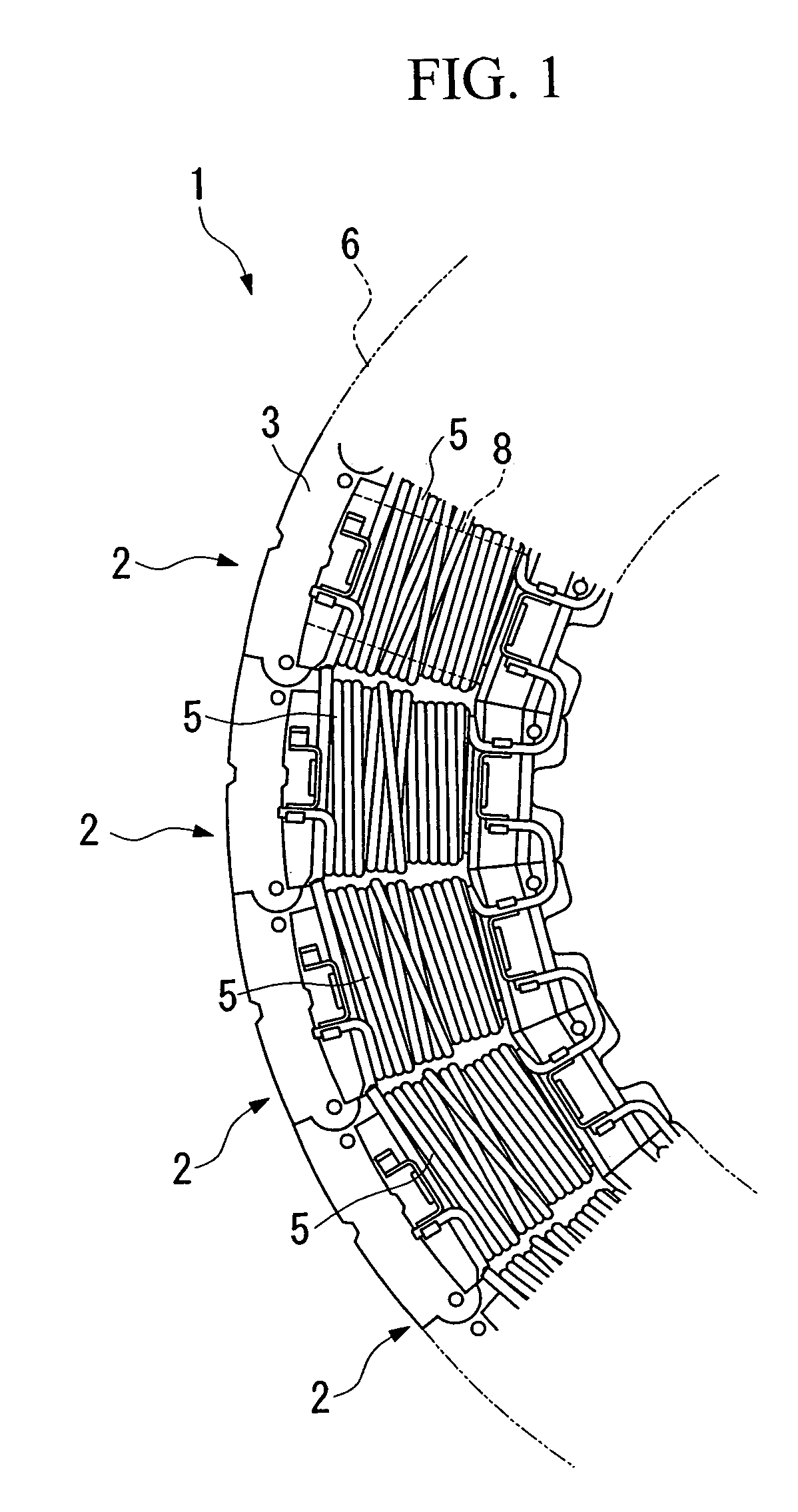

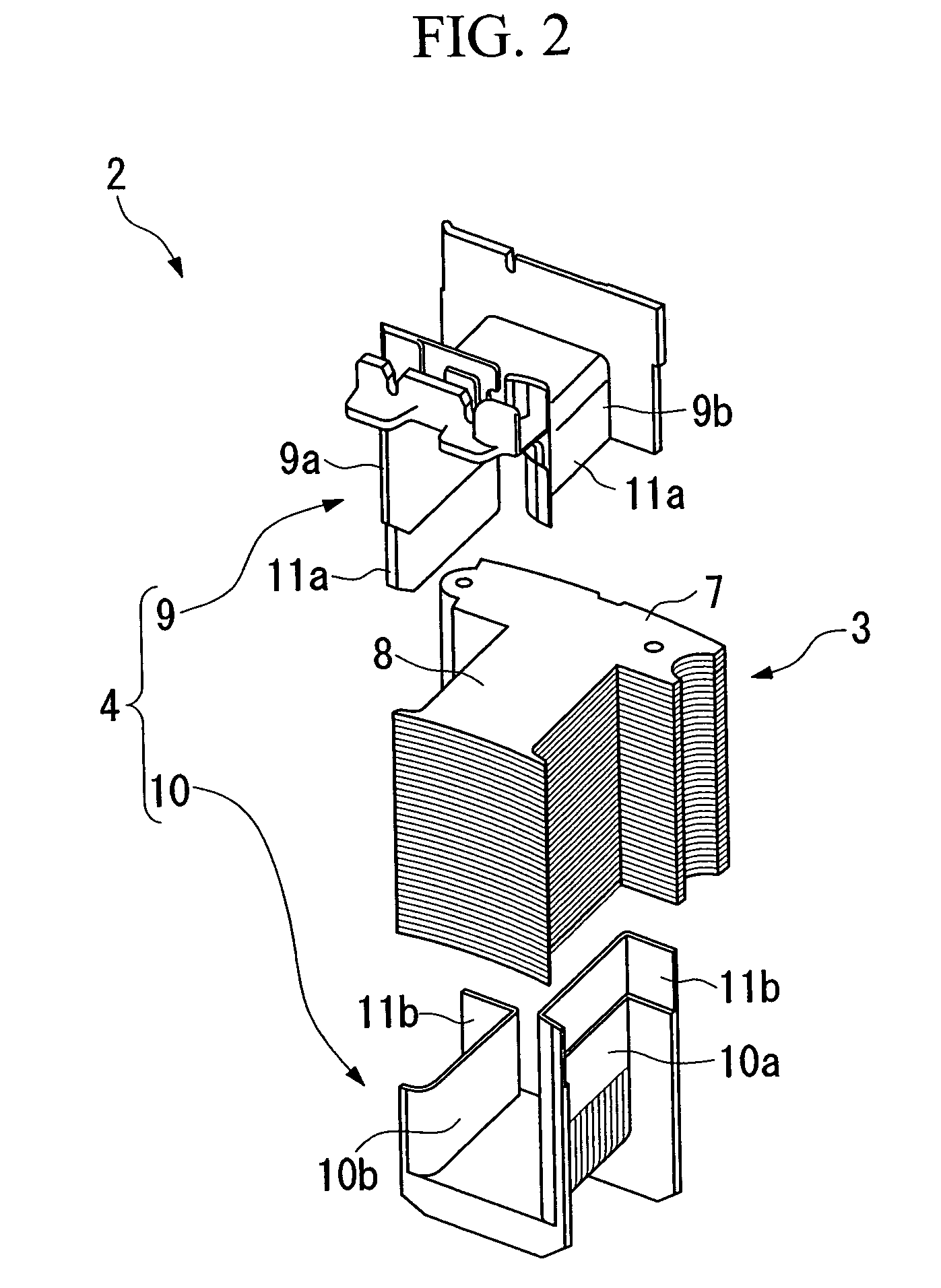

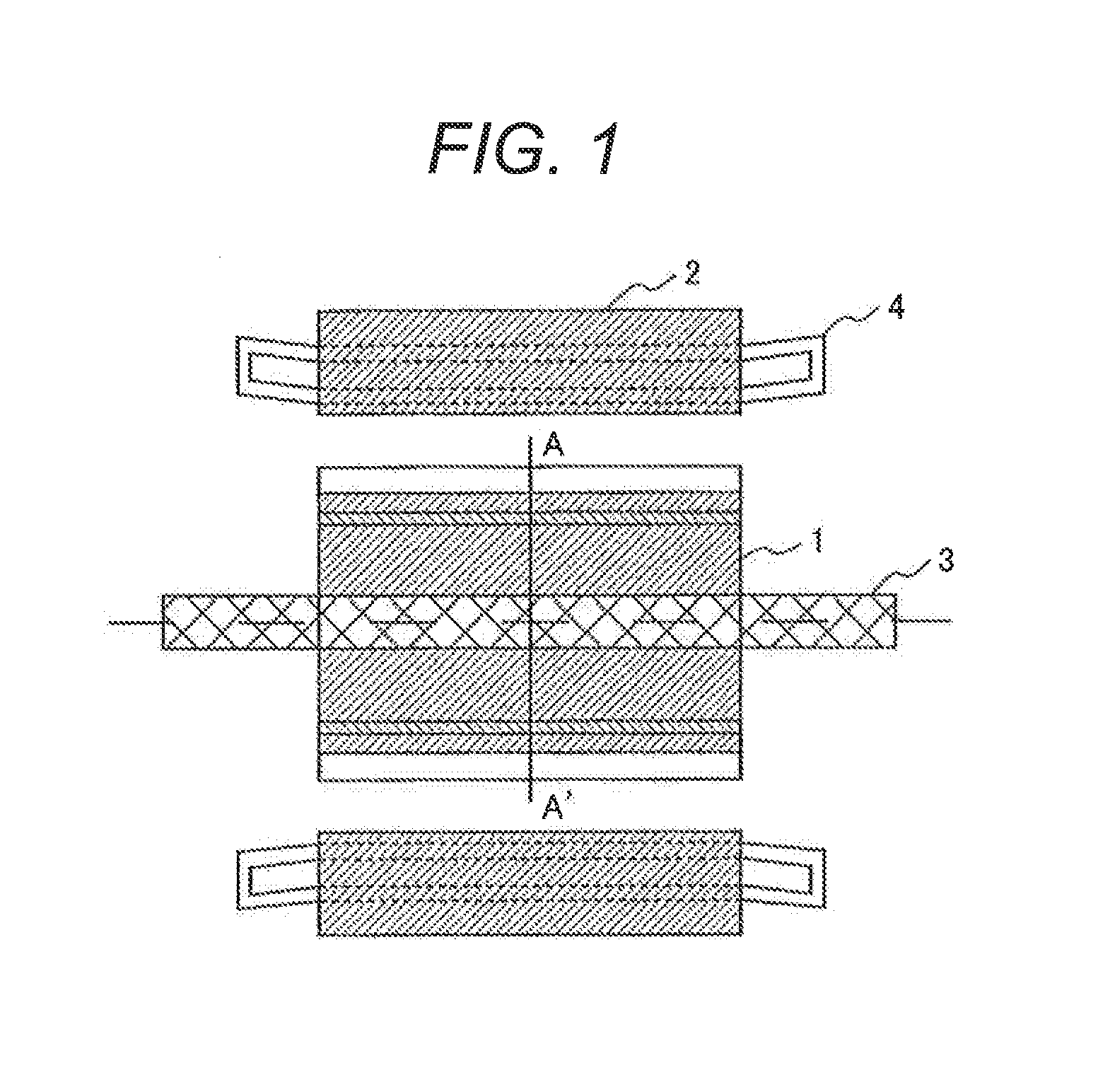

Rotary electric machine stator

InactiveUS6984911B2Improve space factorIncrease the number of lapsSynchronous generatorsWindings insulation shape/form/constructionElectric machinePhysics

A stator for use in a rotating electrical machine is constituted by arranging the prescribed number of stator units in the circumferential direction of a stator core having a circular ring shape. The stator units provide magnetic teeth that project inwardly in the radial direction of the stator core. Coils are wound about the magnetic teeth via insulating members. Each of the insulating members arranges thick portions that slightly project opposite to each other in the width direction of the magnetic tooth, wherein the thick portions are shifted in positions in the thickness direction of the stator core with respect to opposite sides of the magnetic teeth arranged opposite to each other. Thus, it is possible to noticeably improve the space factor in the stator.

Owner:HONDA MOTOR CO LTD

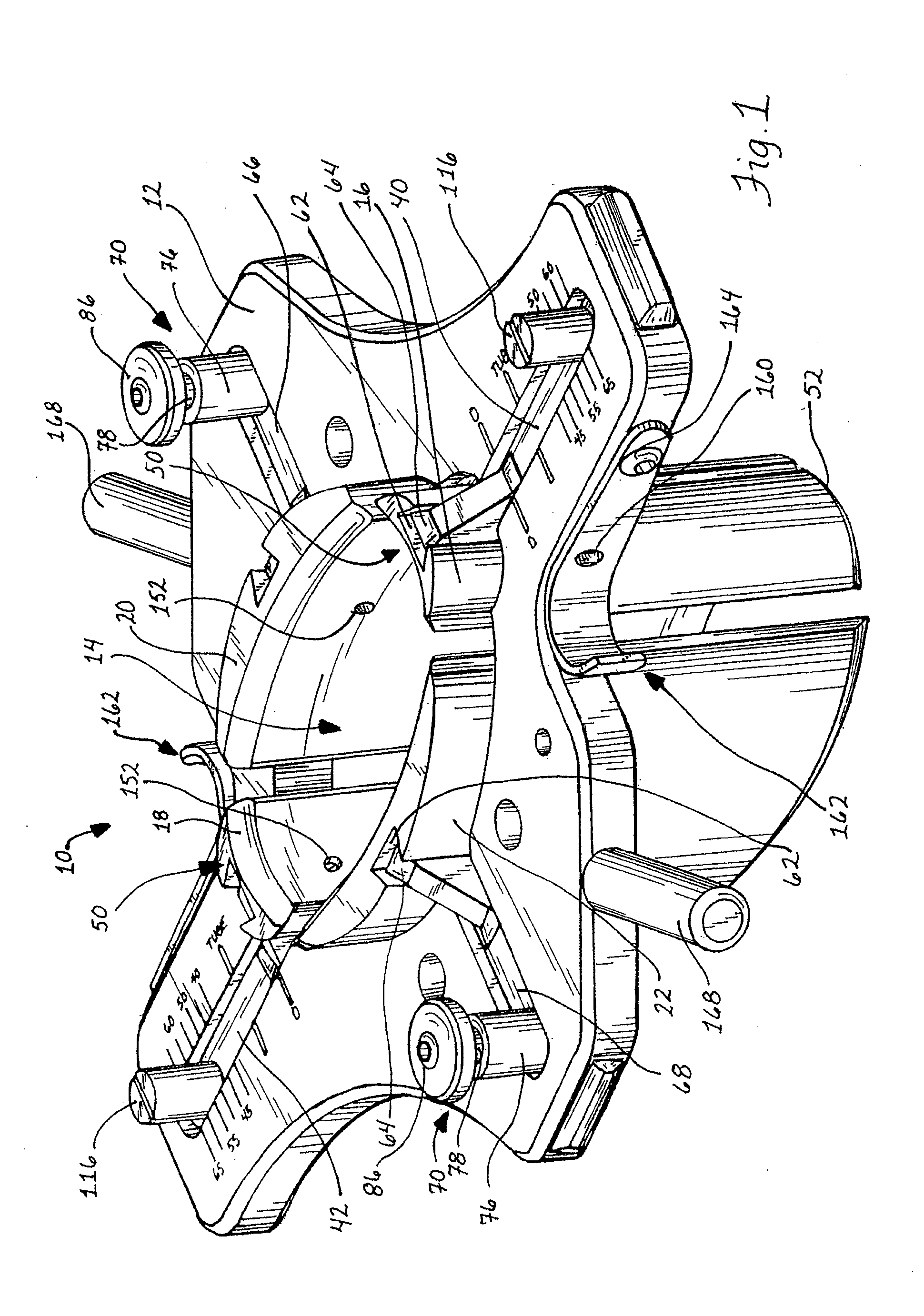

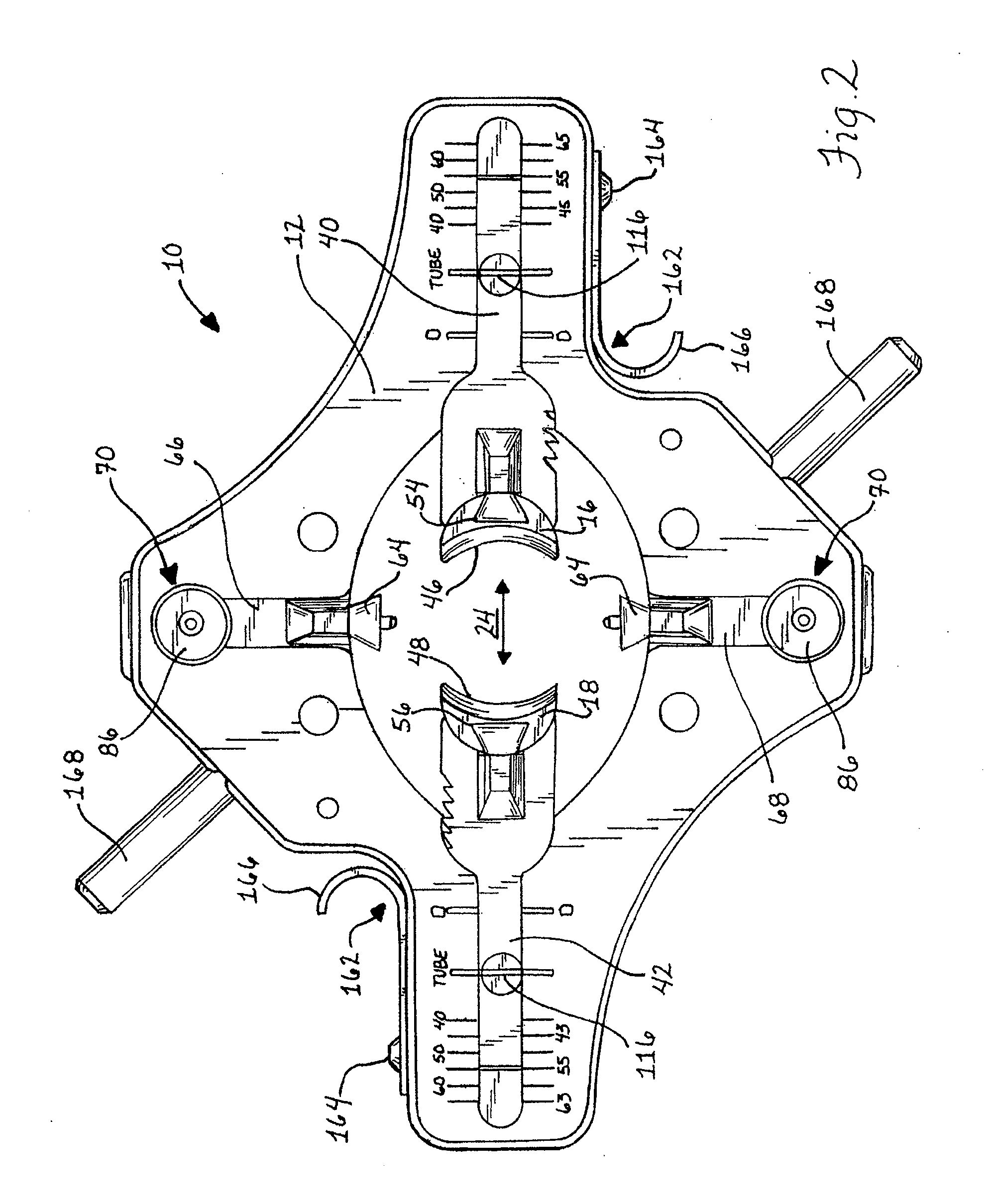

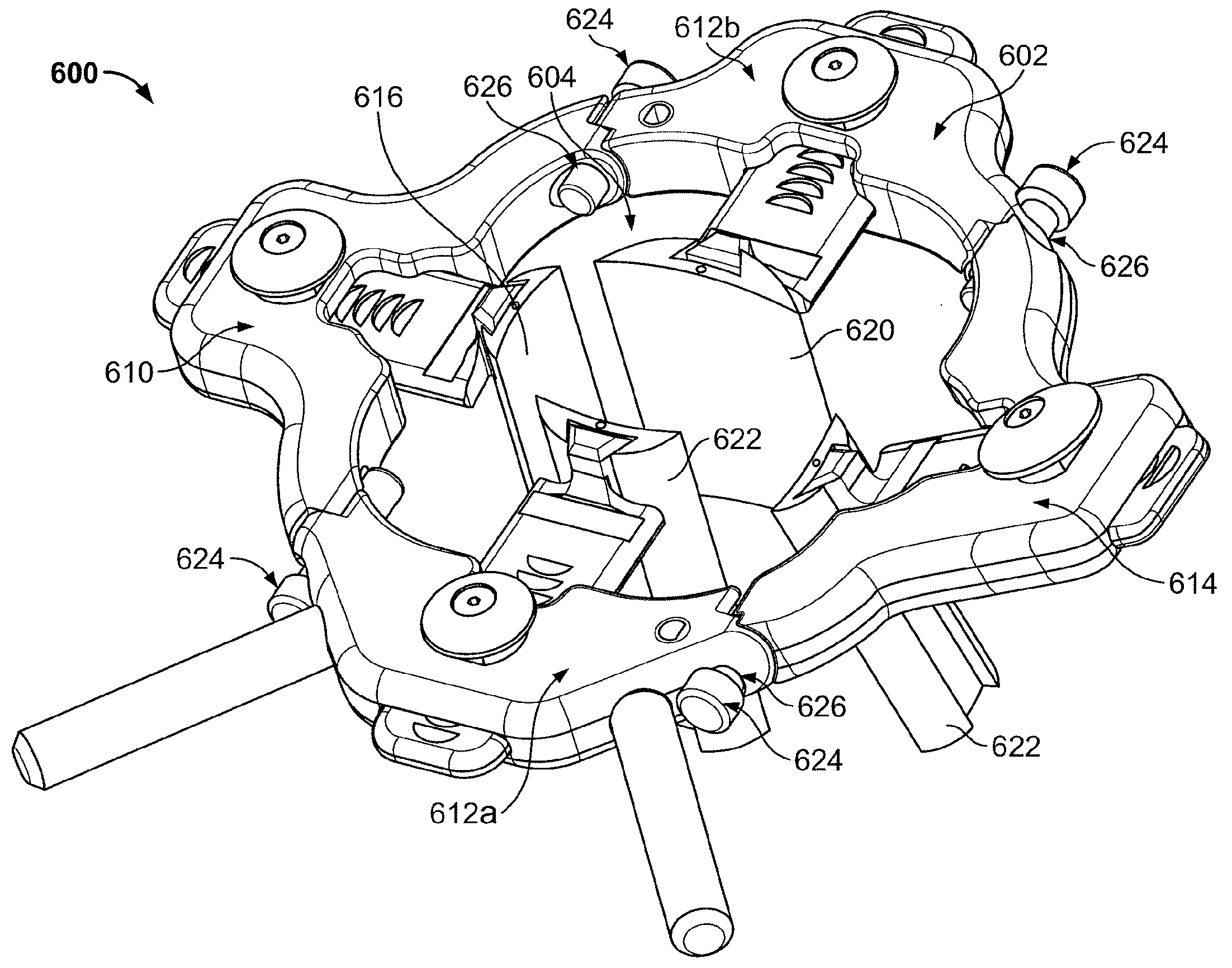

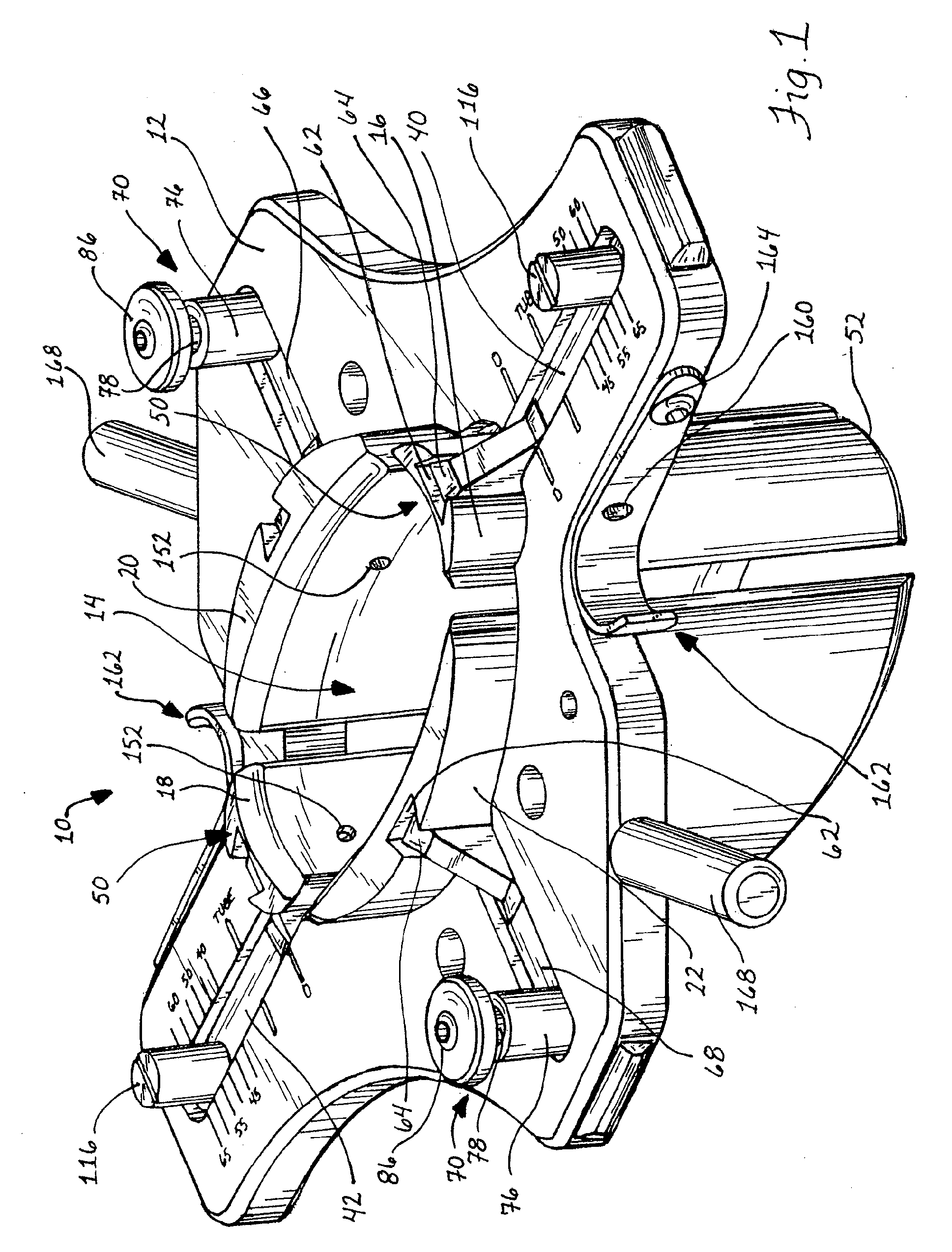

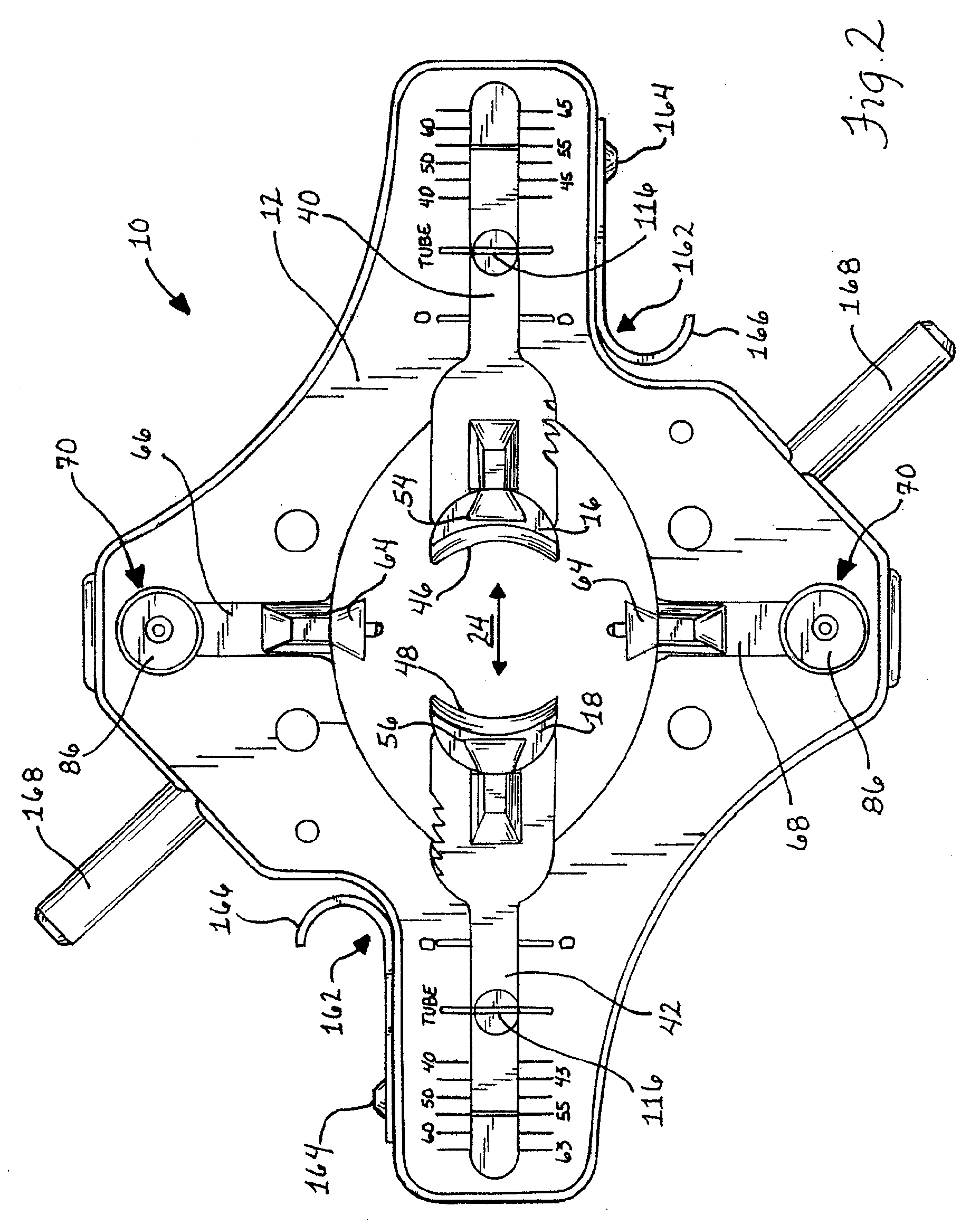

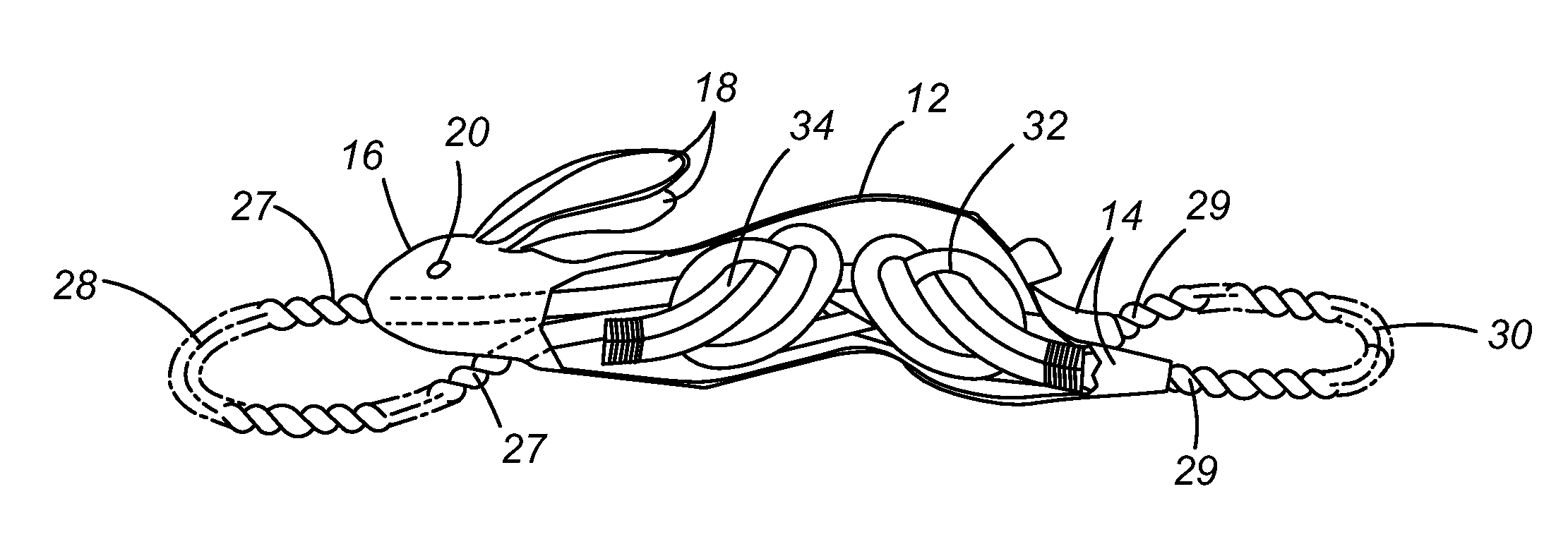

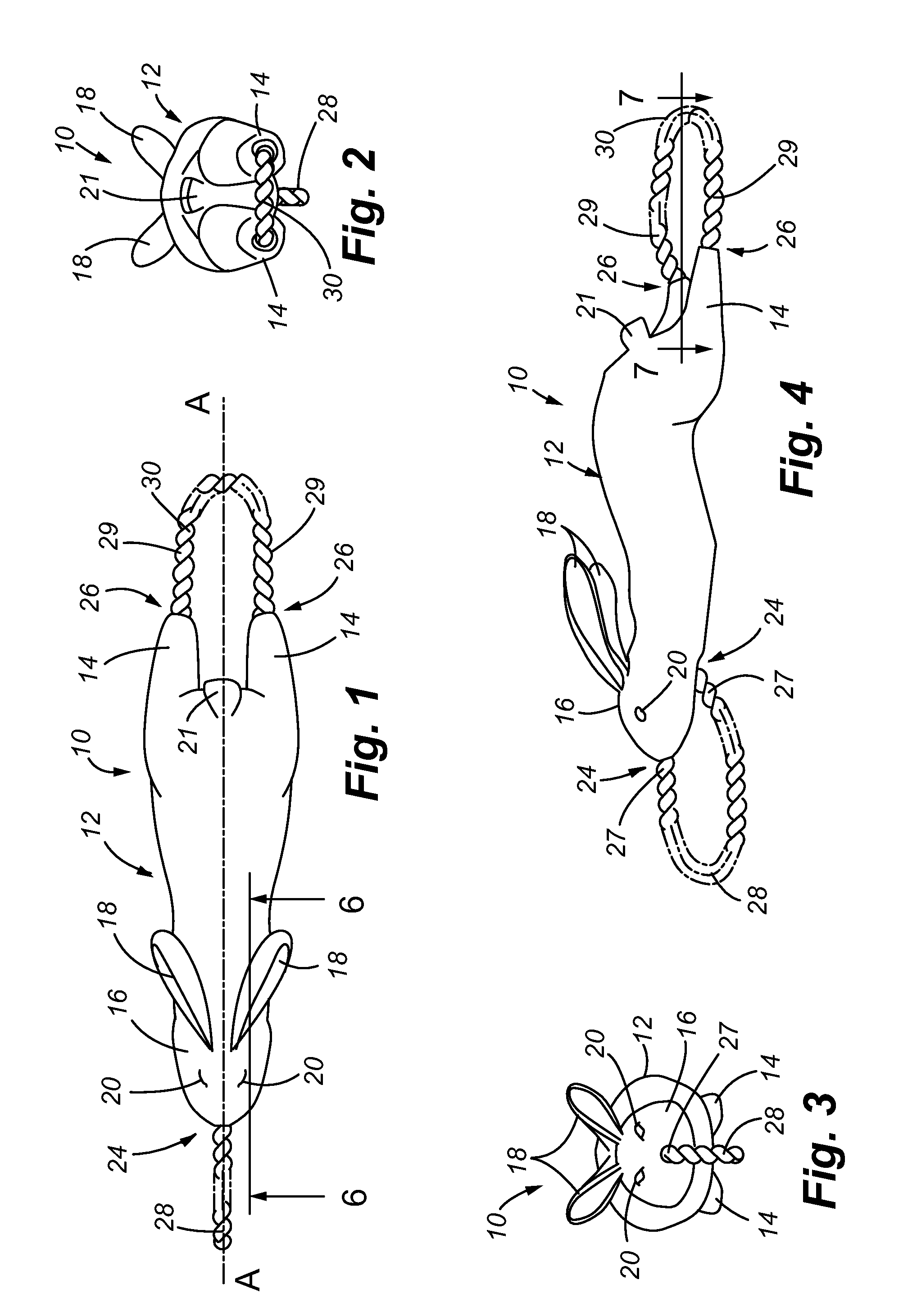

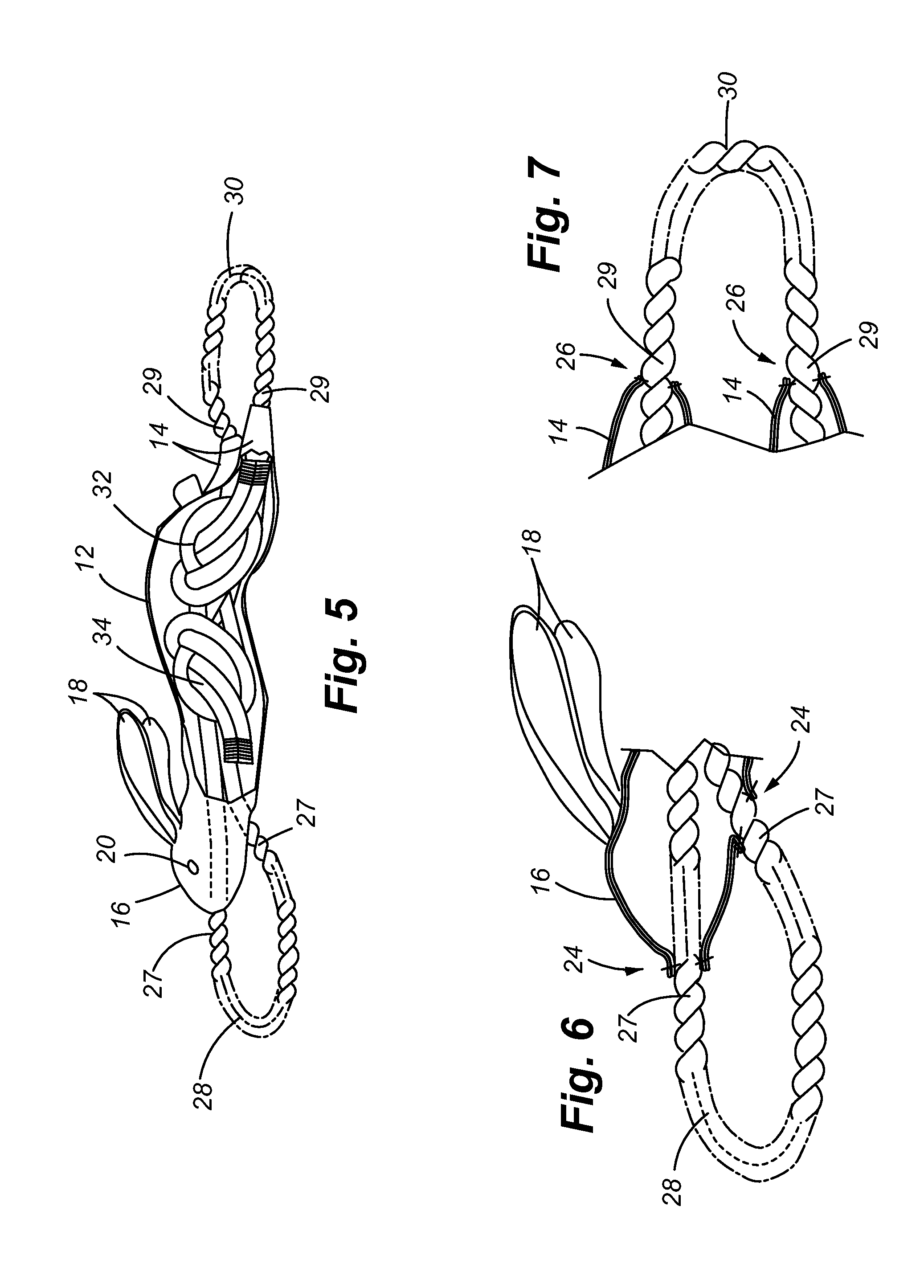

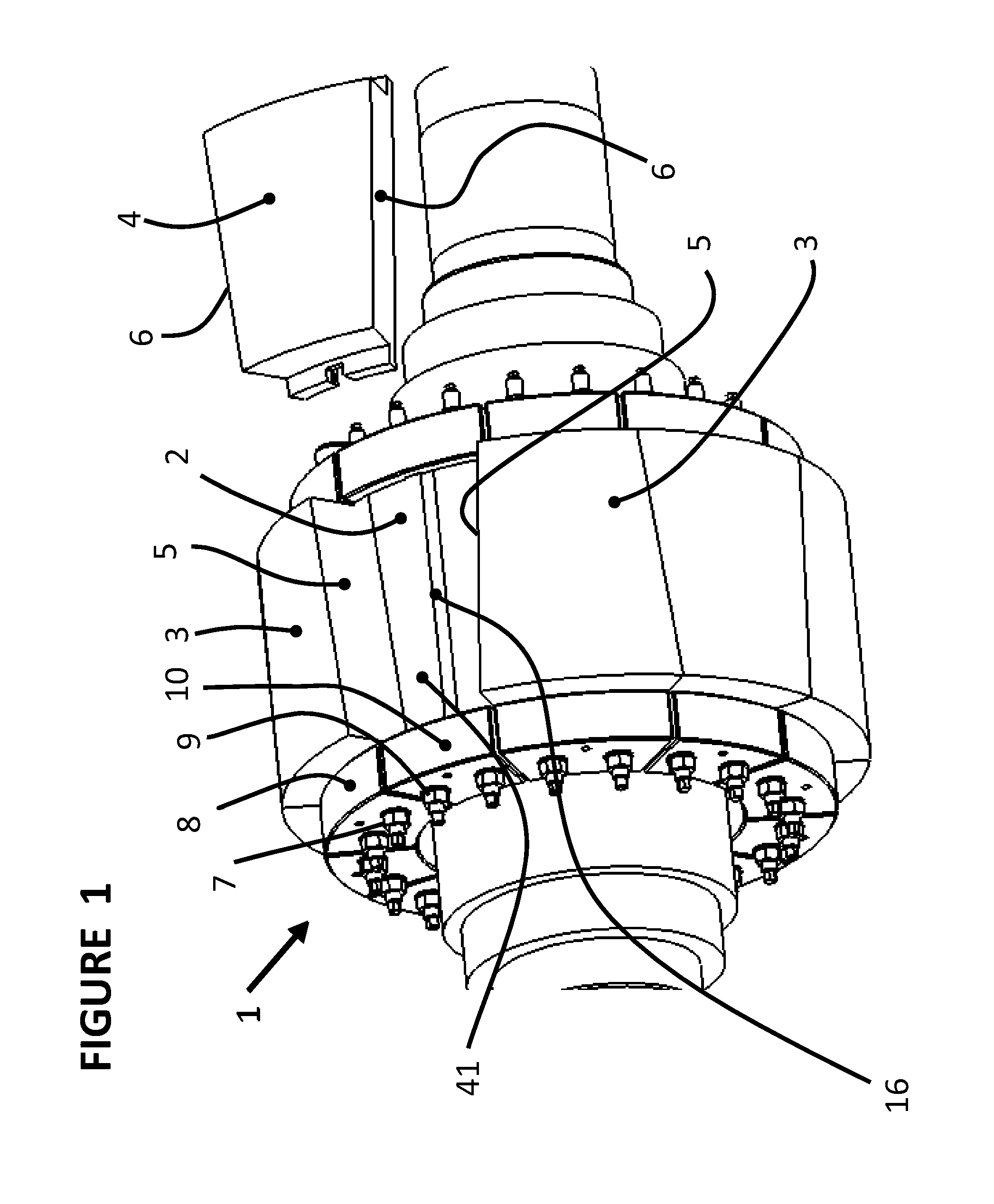

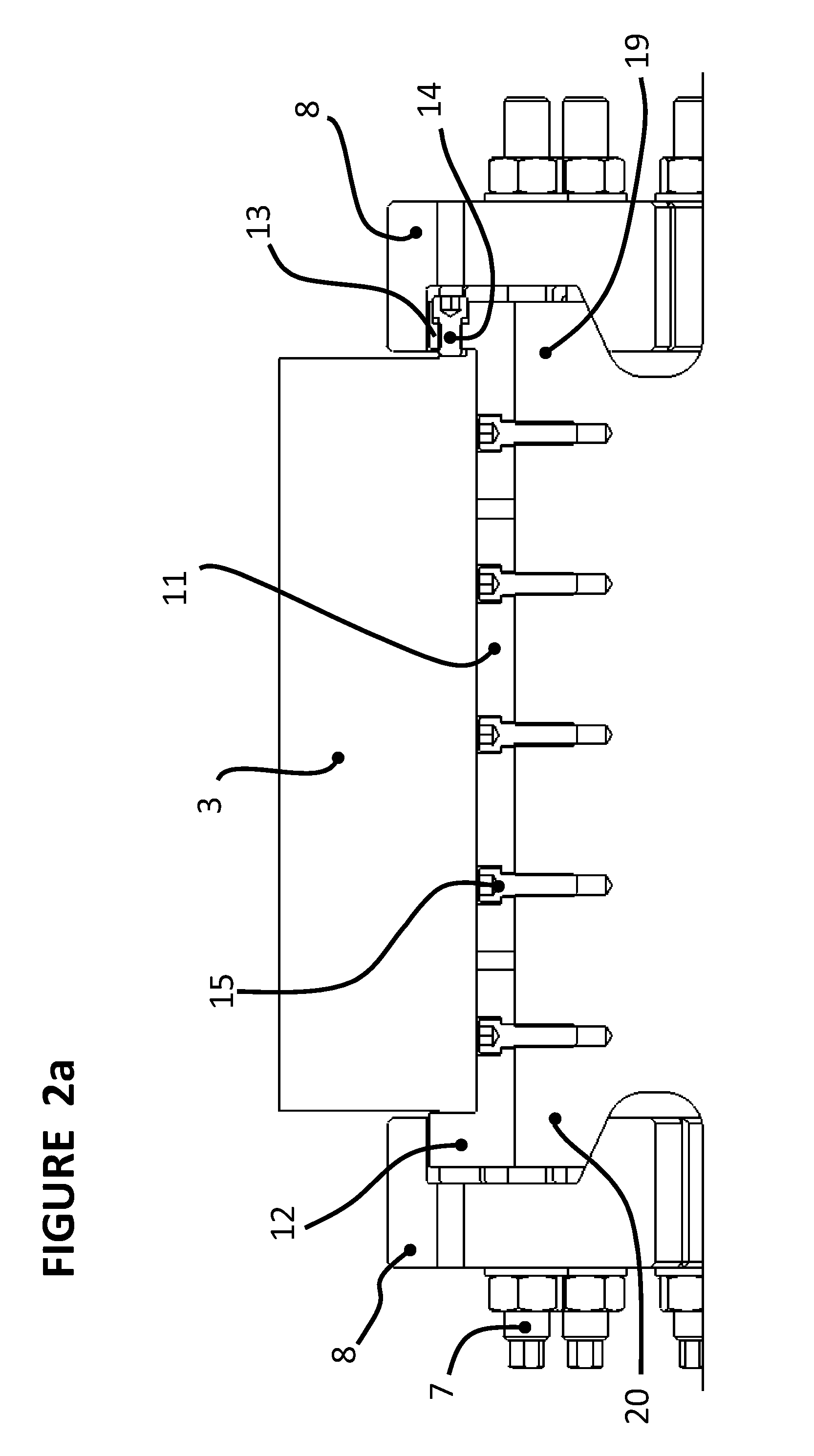

Retraction Apparatus and Method of Use

InactiveUS20070203399A1Minimizing tissueMinimizing blood encroachmentSurgerySurgical siteEngineering

A retraction apparatus and method are disclosed that provide optimized access to a surgical site. In one form, a retraction frame has a retraction opening with two sets of blades operating therein. The blades are used to sequentially retract the tissue from about an incision. The sequential retraction of the blades generates only narrow gaps between the blades so that tissue and blood encroachment during the surgical procedure are minimized.

Owner:PIONEER SURGICAL TECH INC

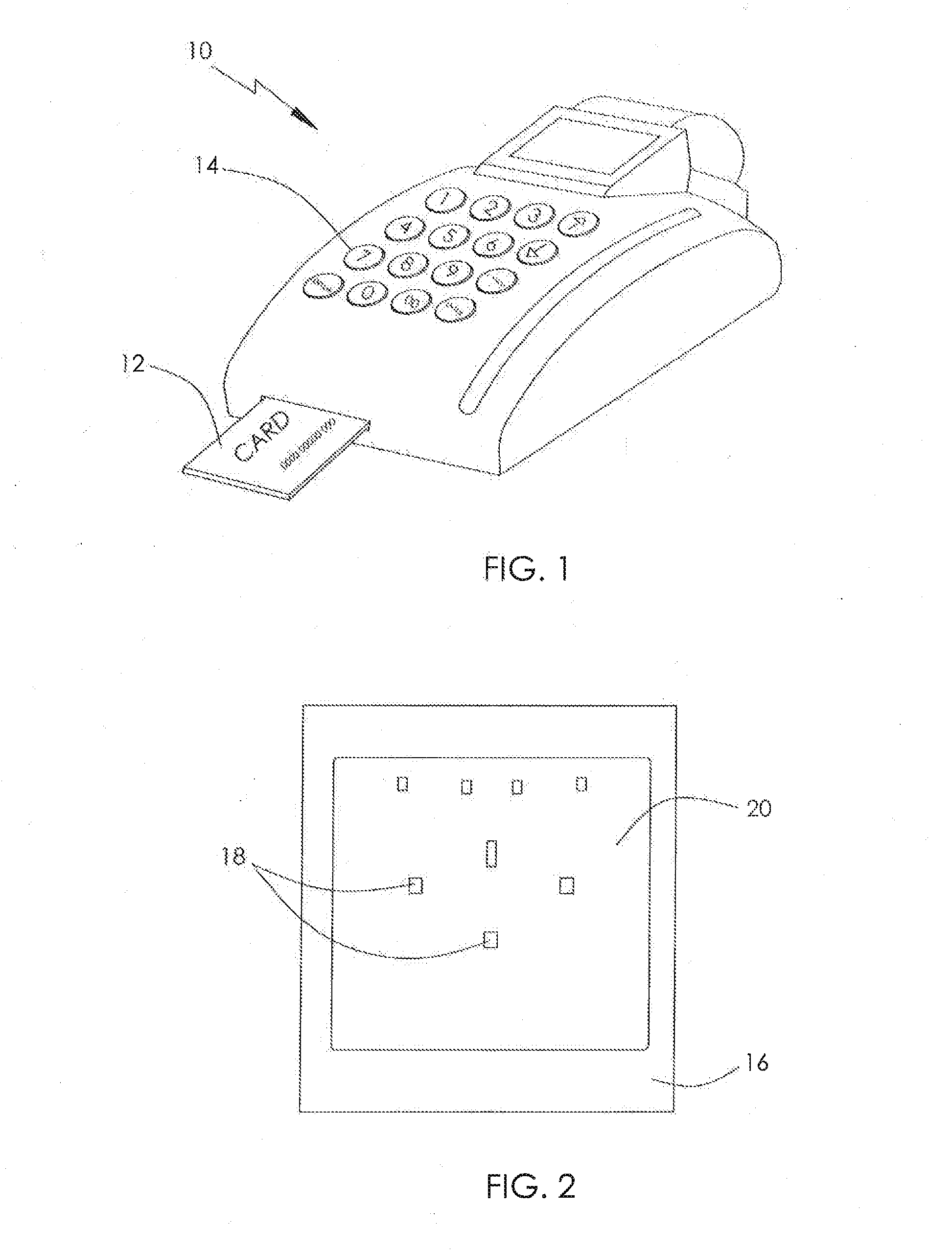

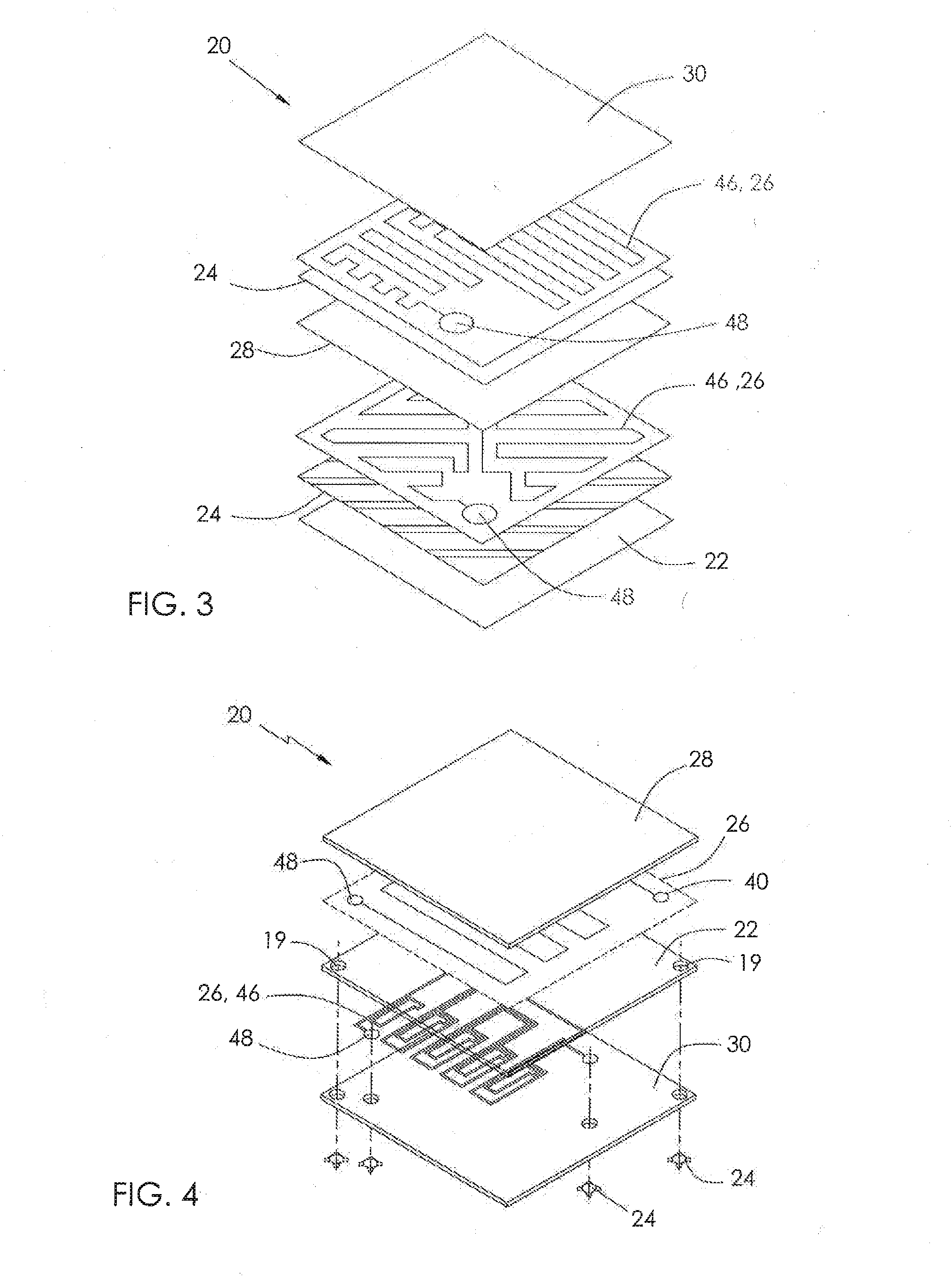

Multilayer security wrap

A security wrap (20) for protecting an electronic component (16) having a bonding surface includes a substrate (22) having a first side and a second side opposite to each other. A first security screen (26) is disposed over the first side of the substrate (22) and includes a first pair of screen terminals (48) and a first conductive track (46) between the first pair of screen terminals (48). A second security screen (26) includes a second pair of screen terminals (48) and a second conductive track (46) between the second pair of screen terminals (48) and overlaying the first conductive track (46) on the first security screen (26). A layer of adhesive (30) is over a side of the second security screen (26) remote from the substrate (22) and bonds the second security screen (22) to the bonding surface of the electronic component (16).

Owner:JOHNSON ELECTRIC INTERNATIONAL AG

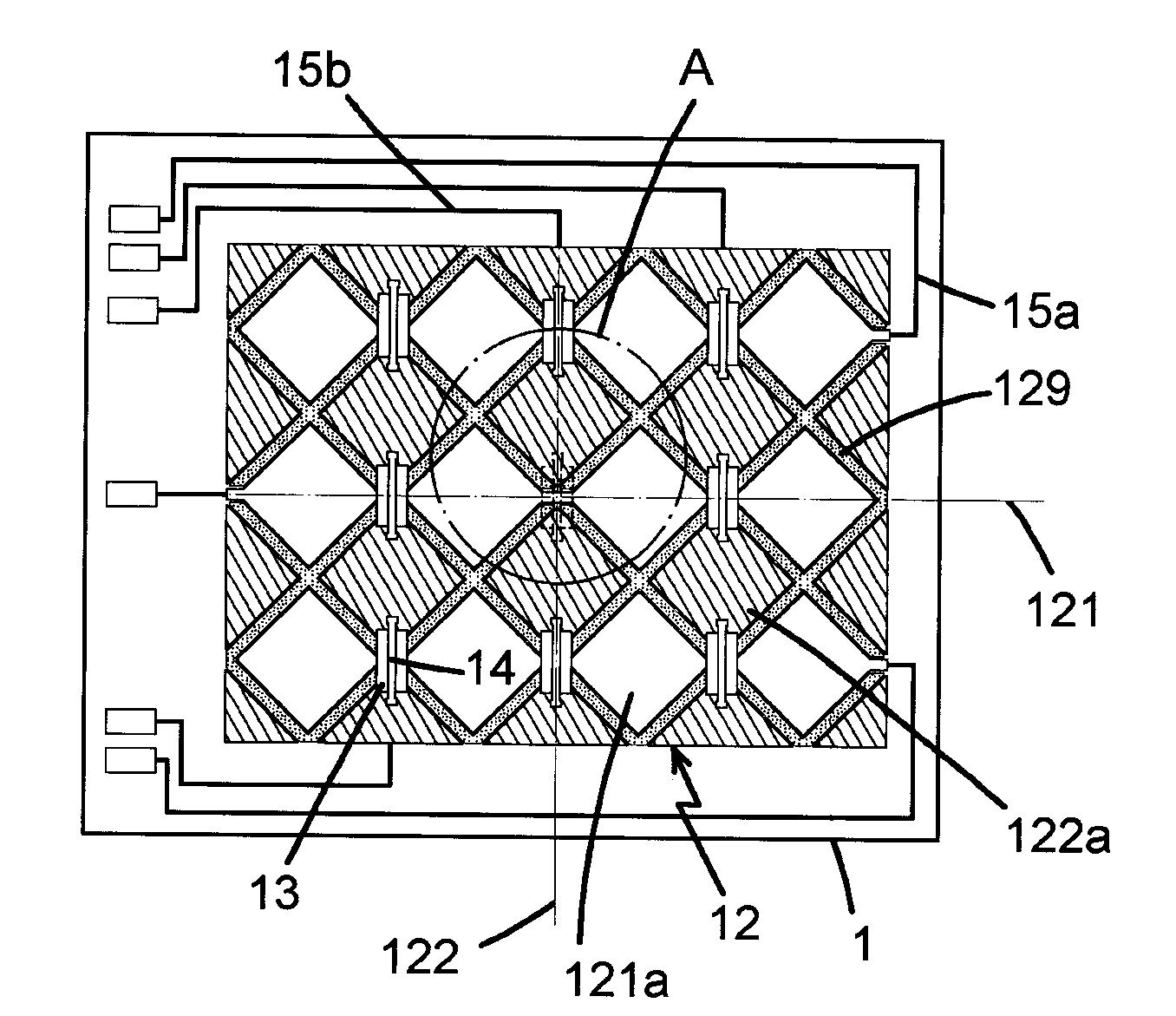

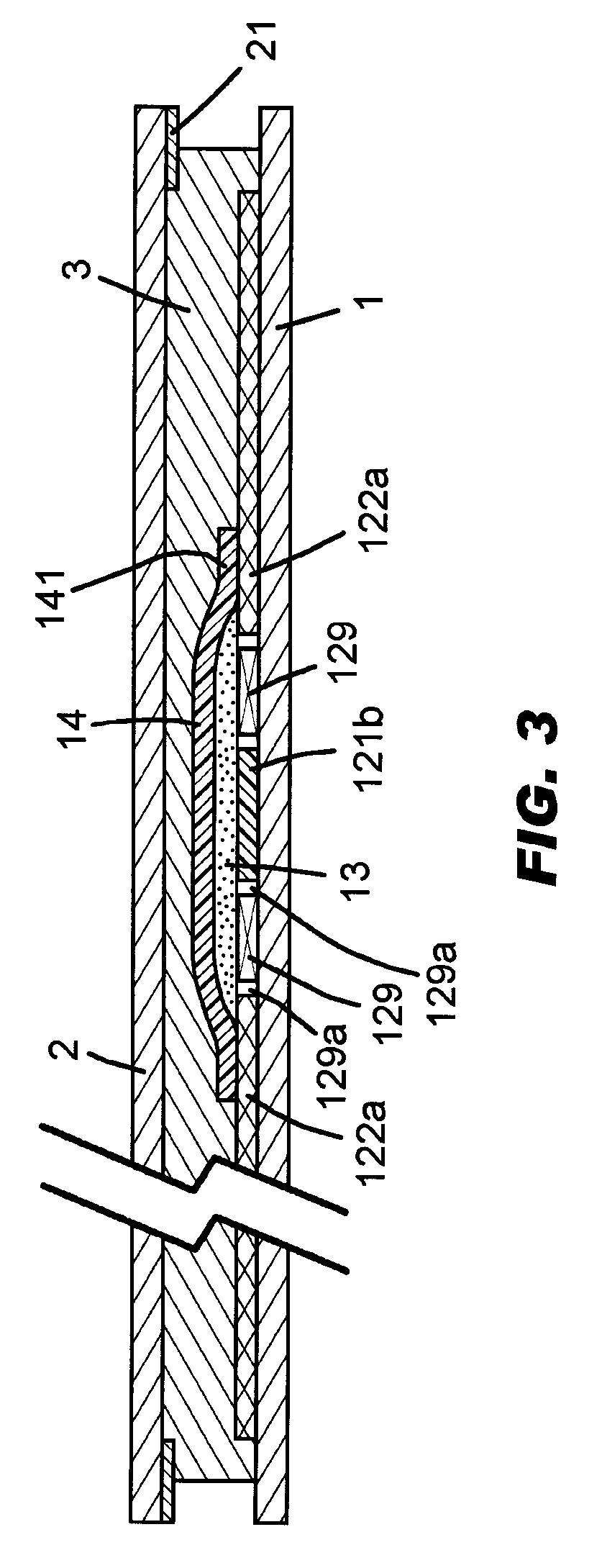

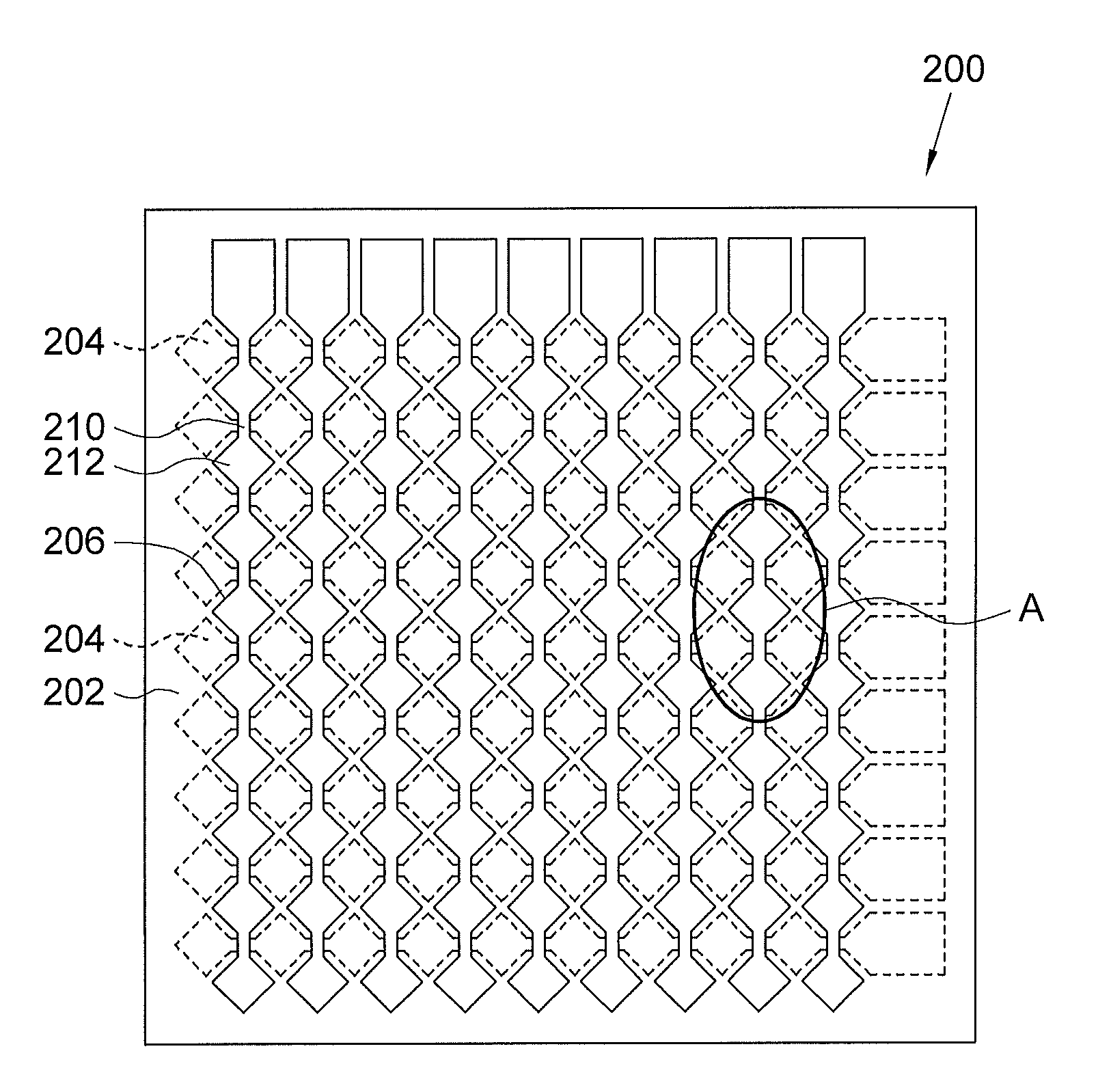

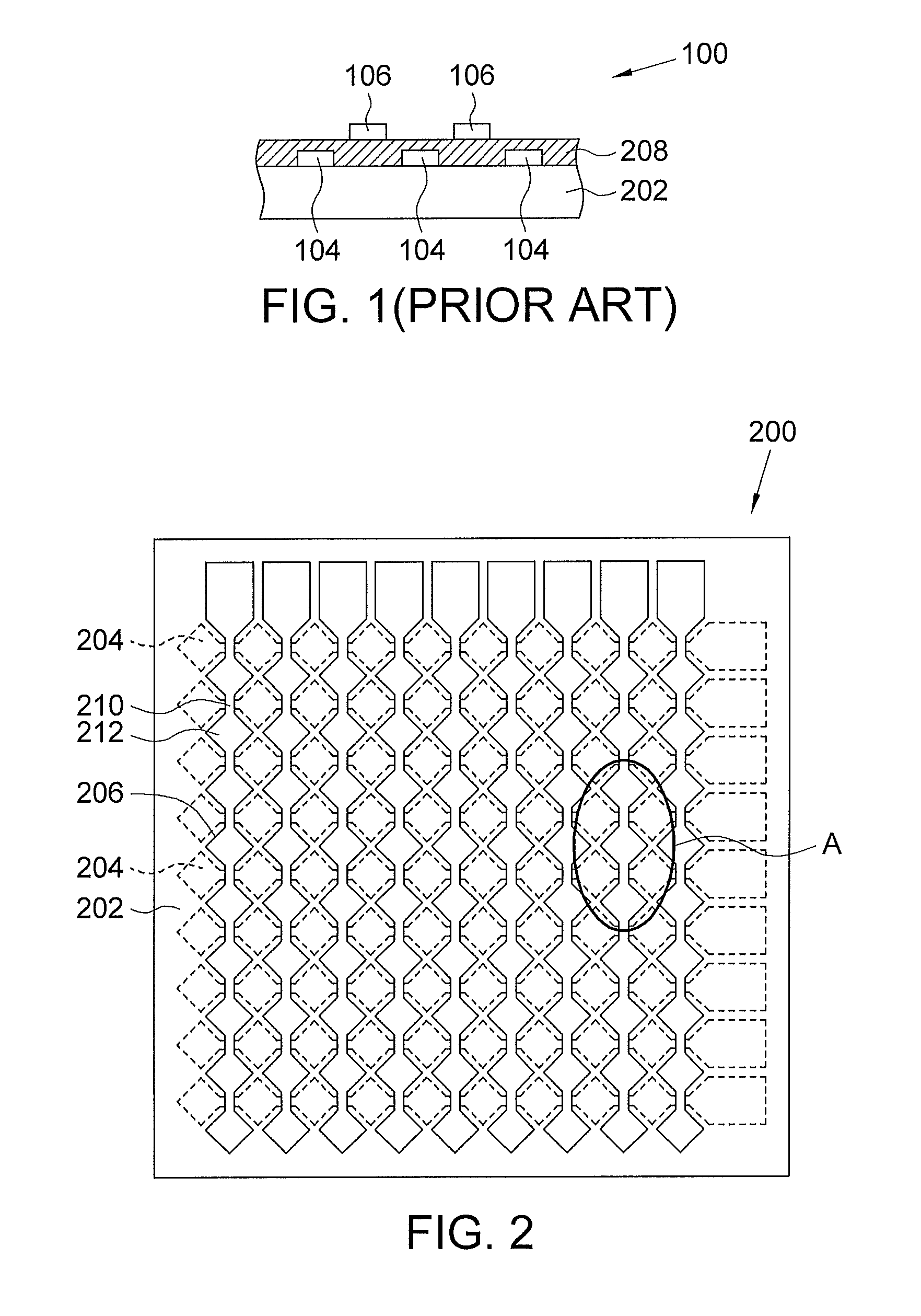

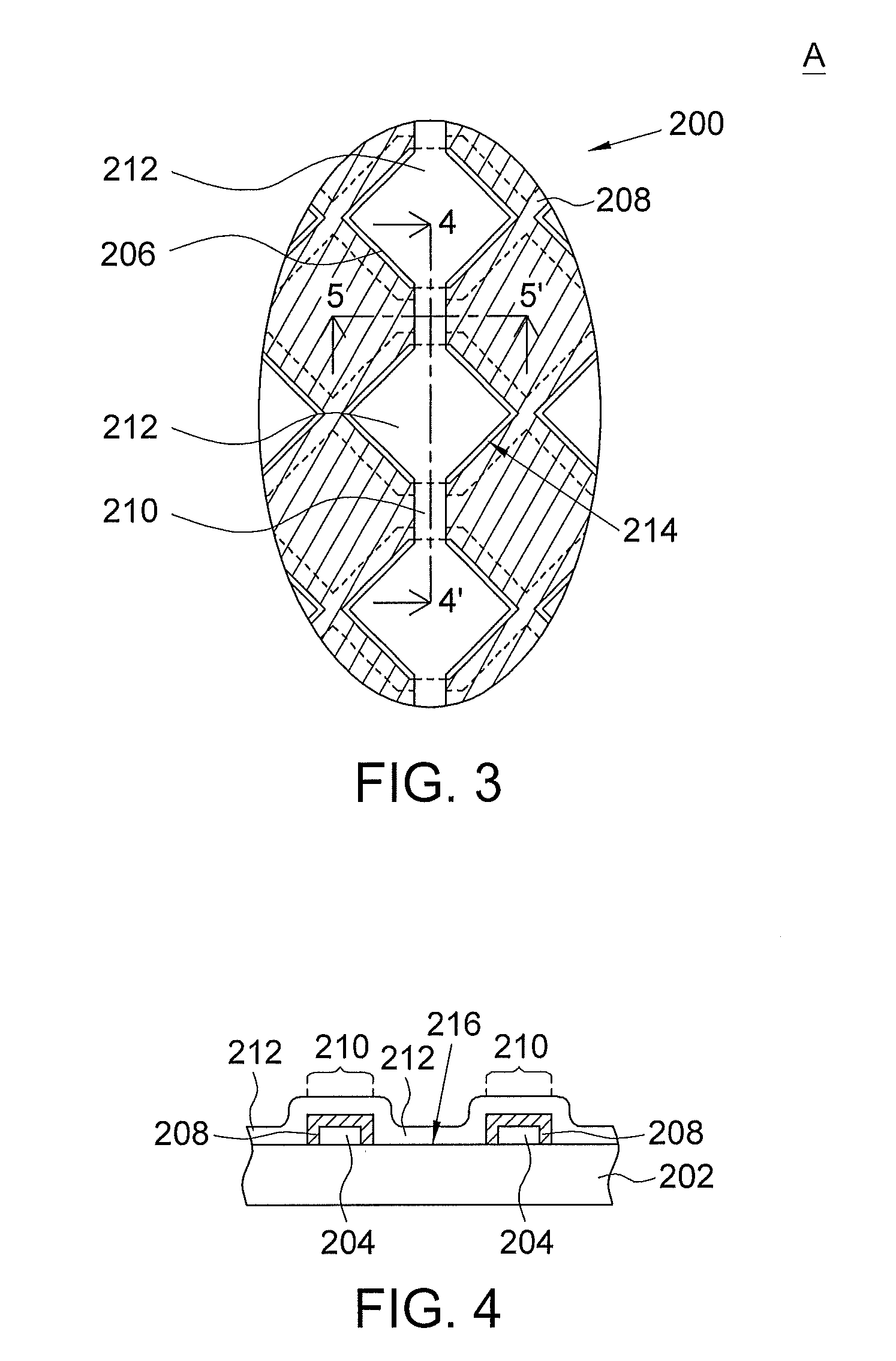

Capacitive sensing assembly of touch panel

InactiveUS20100309160A1Reduce capacitanceFlatness be increaseInput/output processes for data processingPhysicsTouch panel

A capacitive sensing assembly of a touch panel comprises a plurality of transparent X axis traces having a plurality of X axis sensing units; a plurality of transparent Y axis traces having a plurality of connected Y axis sensing units. The Y axis traces are alternatively arranged with the X axis traces so that the X axis sensing units and Y axis sensing units are arranged as a matrix at a working area of a touch panel. Gaps between the X axis traces and Y axis traces are arranged with dummy patterns. Furthermore, a capacitive sensing assembly of a touch panel is provided, which includes a lower substrate; an upper panel; a capacitive sensing layer installed connected the lower substrate and the upper panel. In a working area of a touch panel, the capacitive sensing layer having a plurality of sensing units which are arranged alternatively and gaps between the sensing units are filled with dummy patterns.

Owner:YOUNG FAST OPTOELECTRONICS

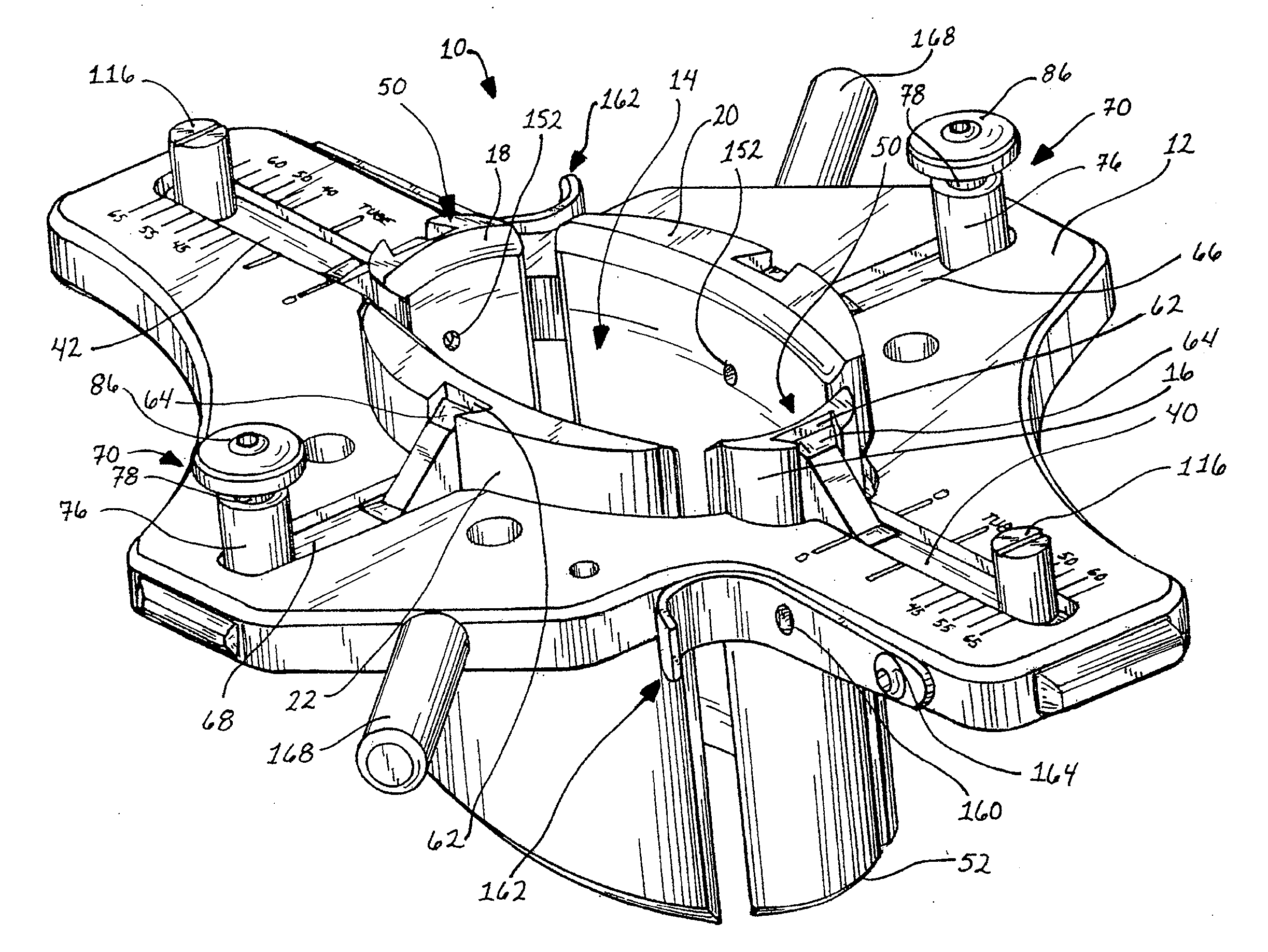

Retraction Apparatus And Method Of Use

ActiveUS20090069635A1Easy accessMinimizing tissue and blood encroachmentSurgerySurgical siteEngineering

A retraction apparatus and method are disclosed that provide optimized access to a surgical site. In one form, a retraction frame has a retraction opening with two sets of blades operating therein. The blades are used to sequentially retract the tissue from about an incision. The sequential retraction of the blades generates only narrow gaps between the blades so that tissue and blood encroachment during the surgical procedure are minimized.

Owner:XTANT MEDICAL HLDG INC

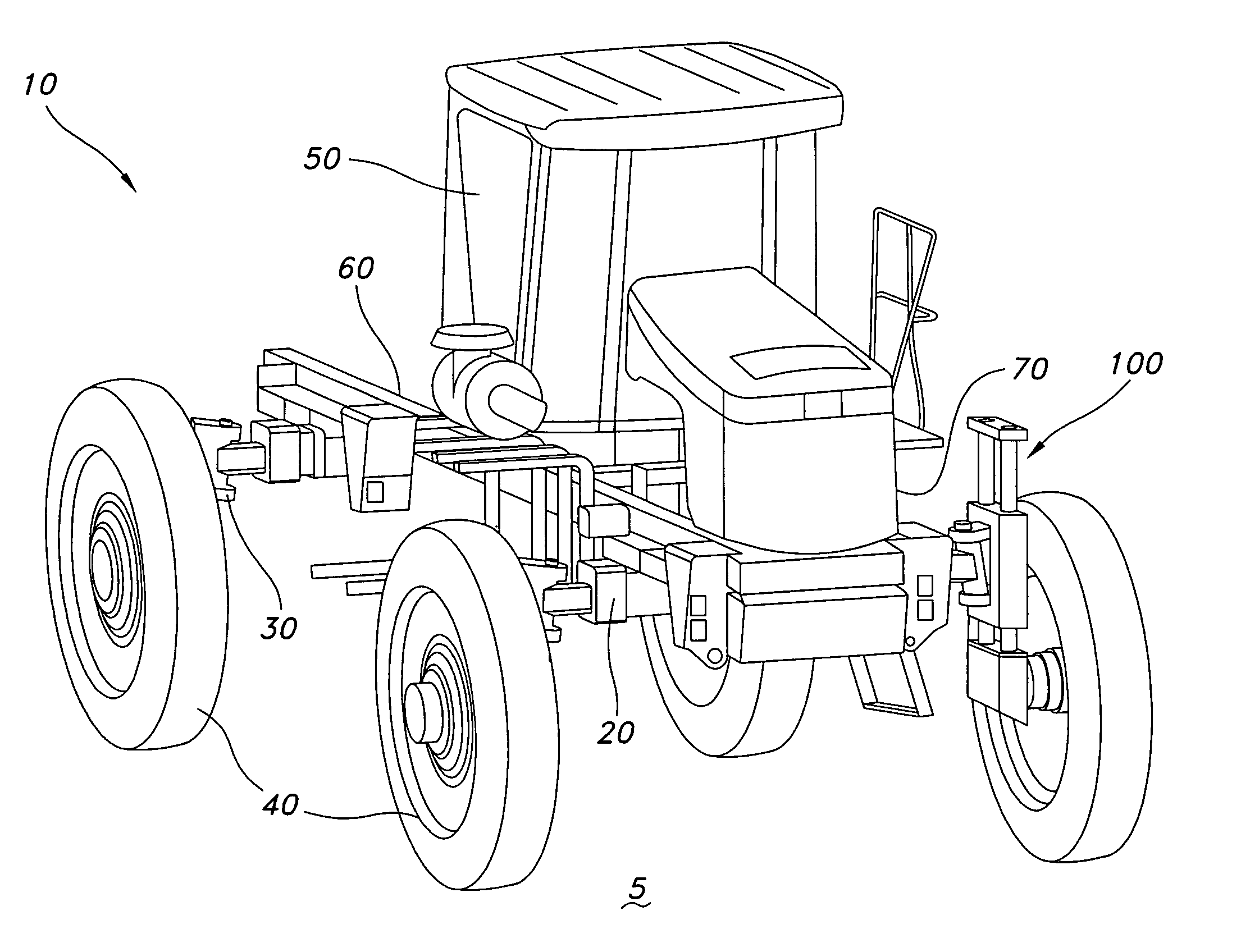

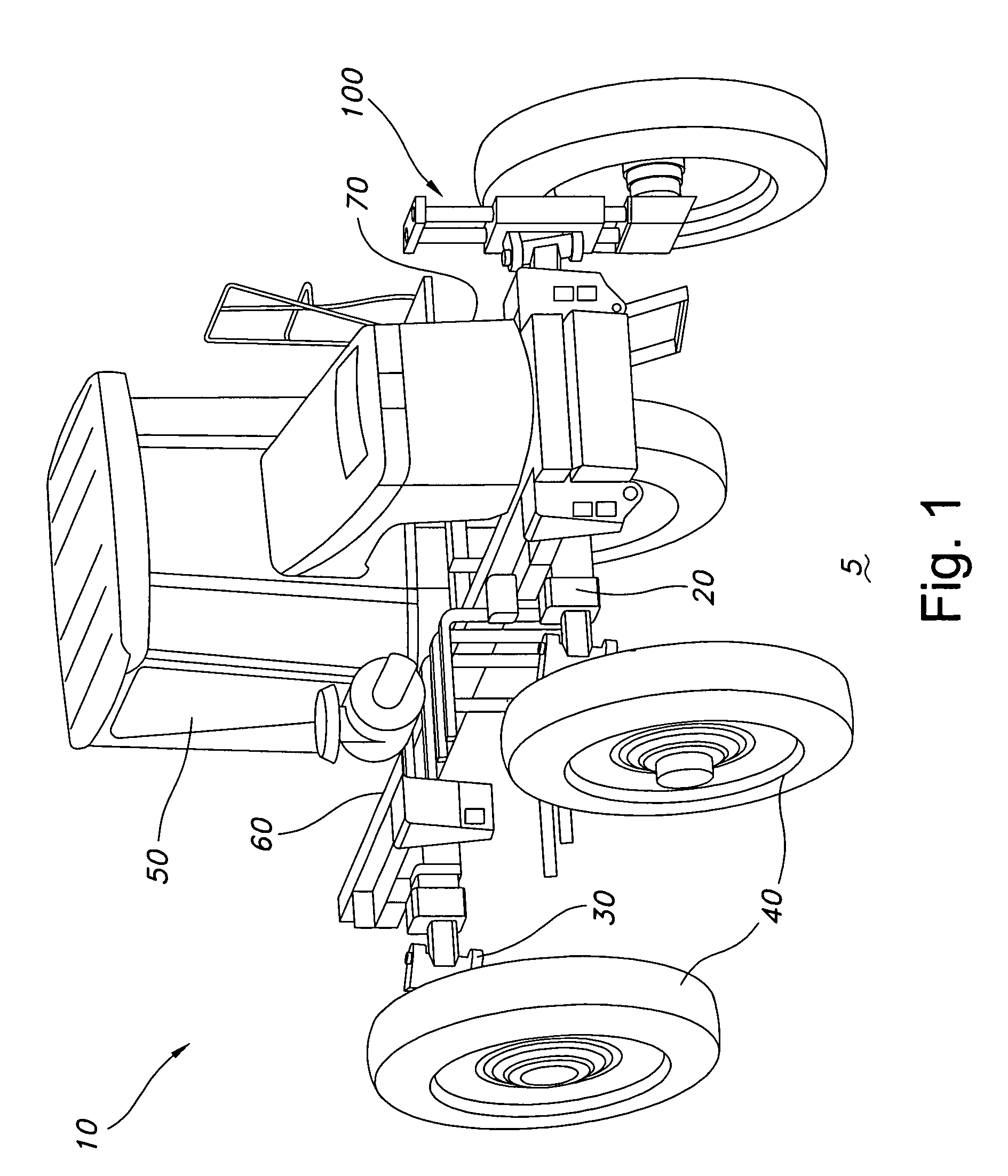

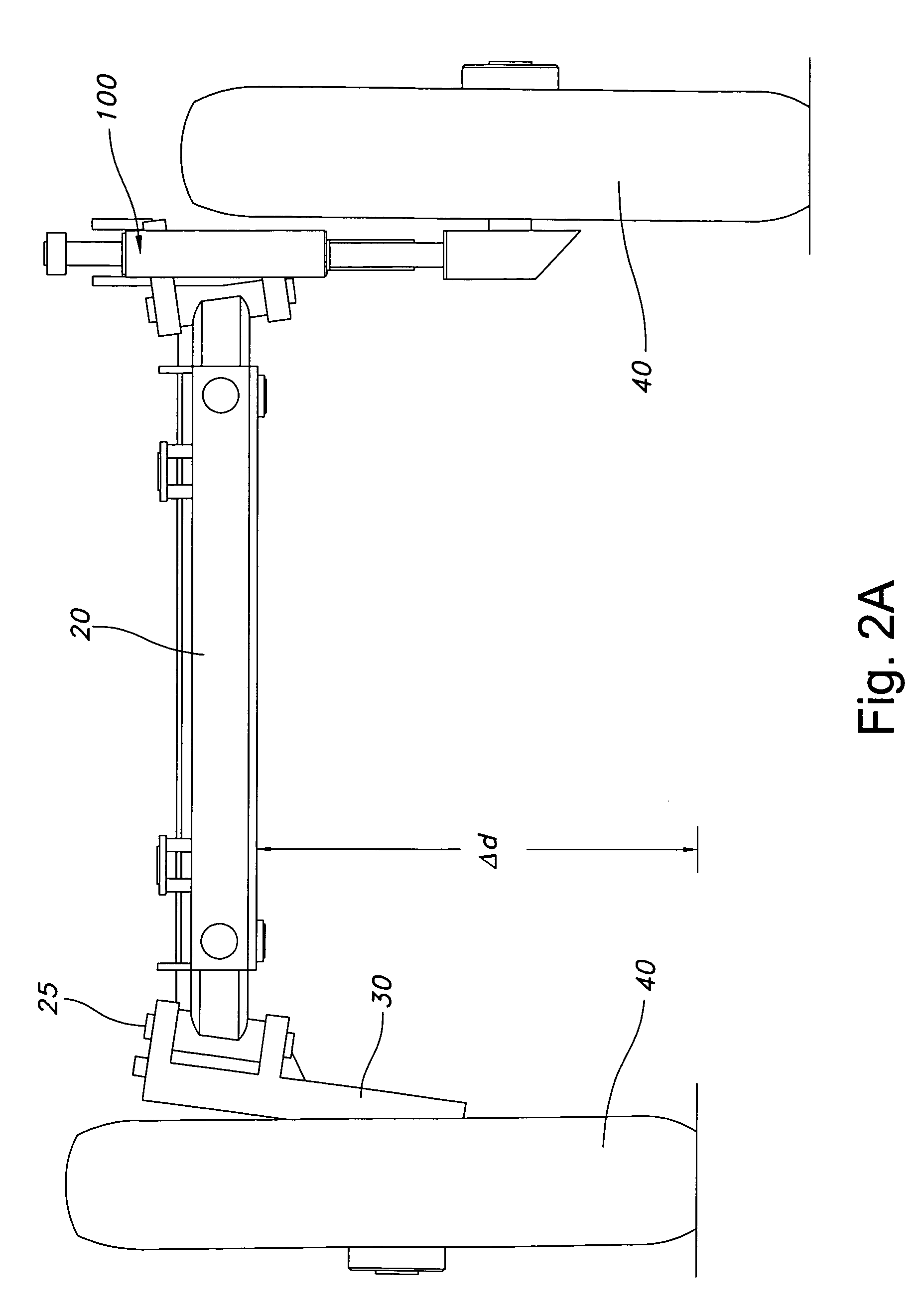

Chassis adjustment system

ActiveUS7837207B2Easy to sprayIncrease the lengthVehicle fittings for liftingVehicle cleaning apparatusAgricultural engineeringRolling chassis

A machine, such as a mobile asset, vehicle, or agricultural vehicle, includes a chassis, an adjustment system, and a wheel. The adjustment system replaces a conventional non-extendable leg connected between the chassis and the wheel of the machine. The adjustment system can extend and withdraw in length, such that the height of the machine can vary as needed.

Owner:AGCO CORP

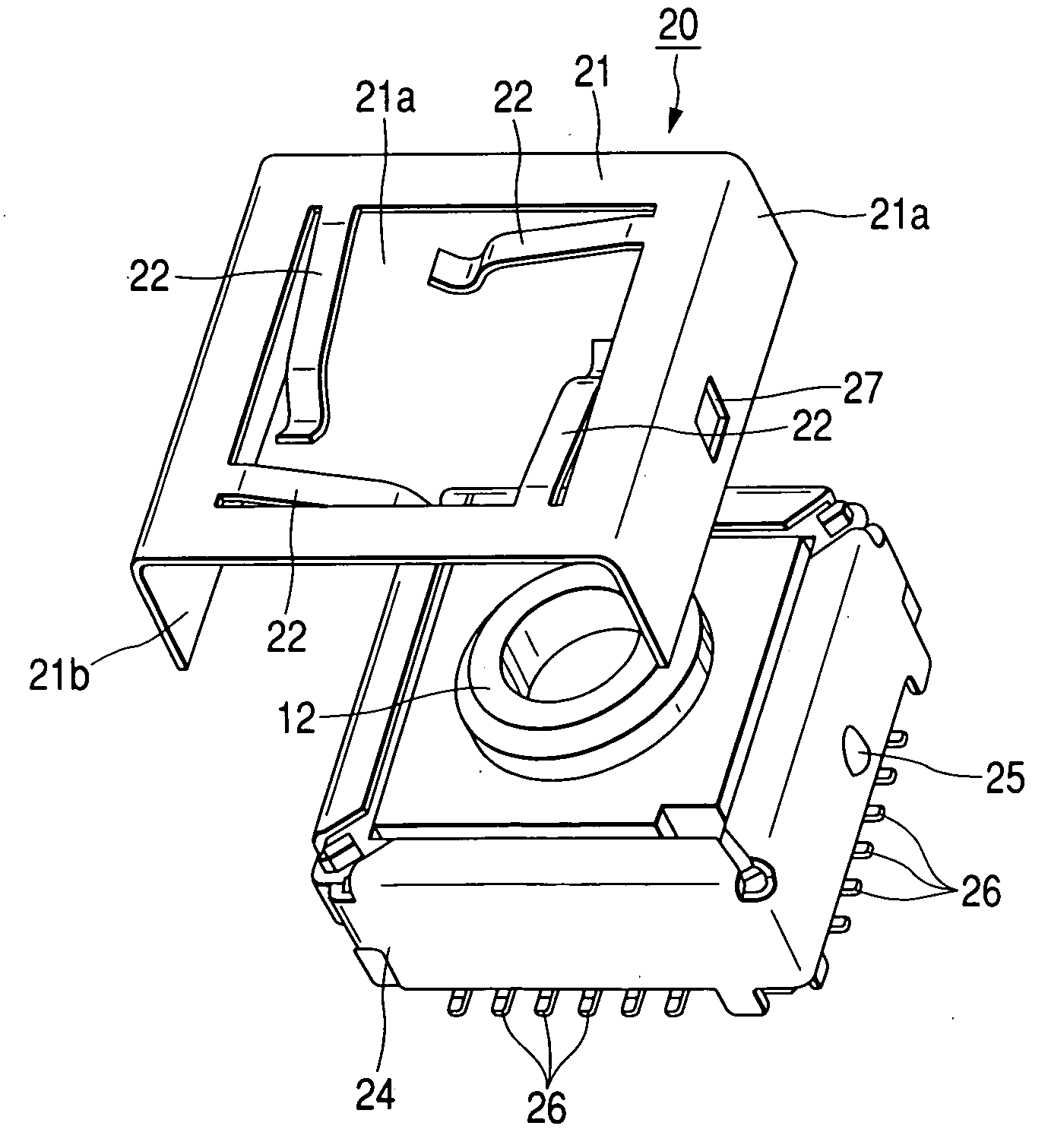

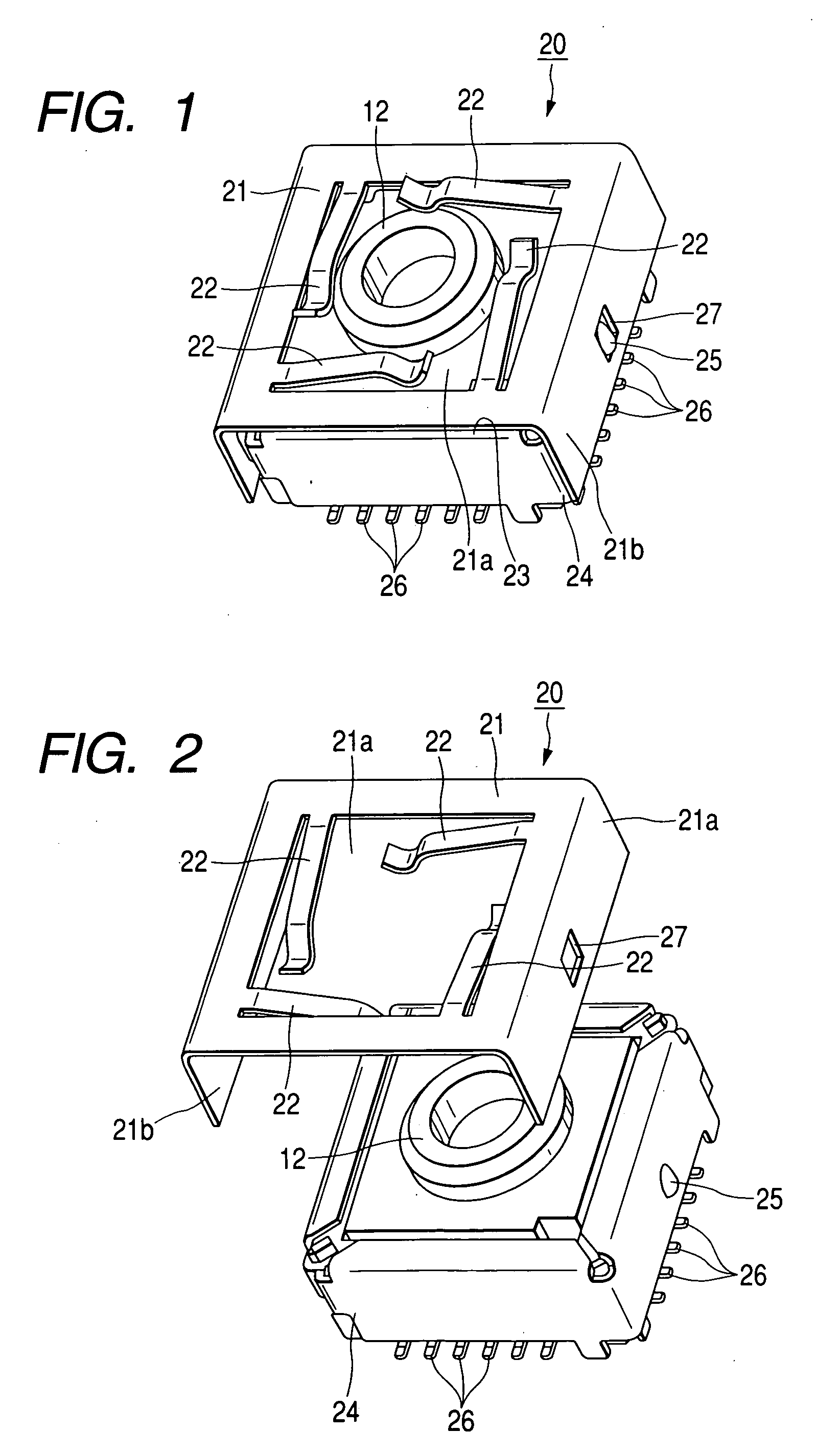

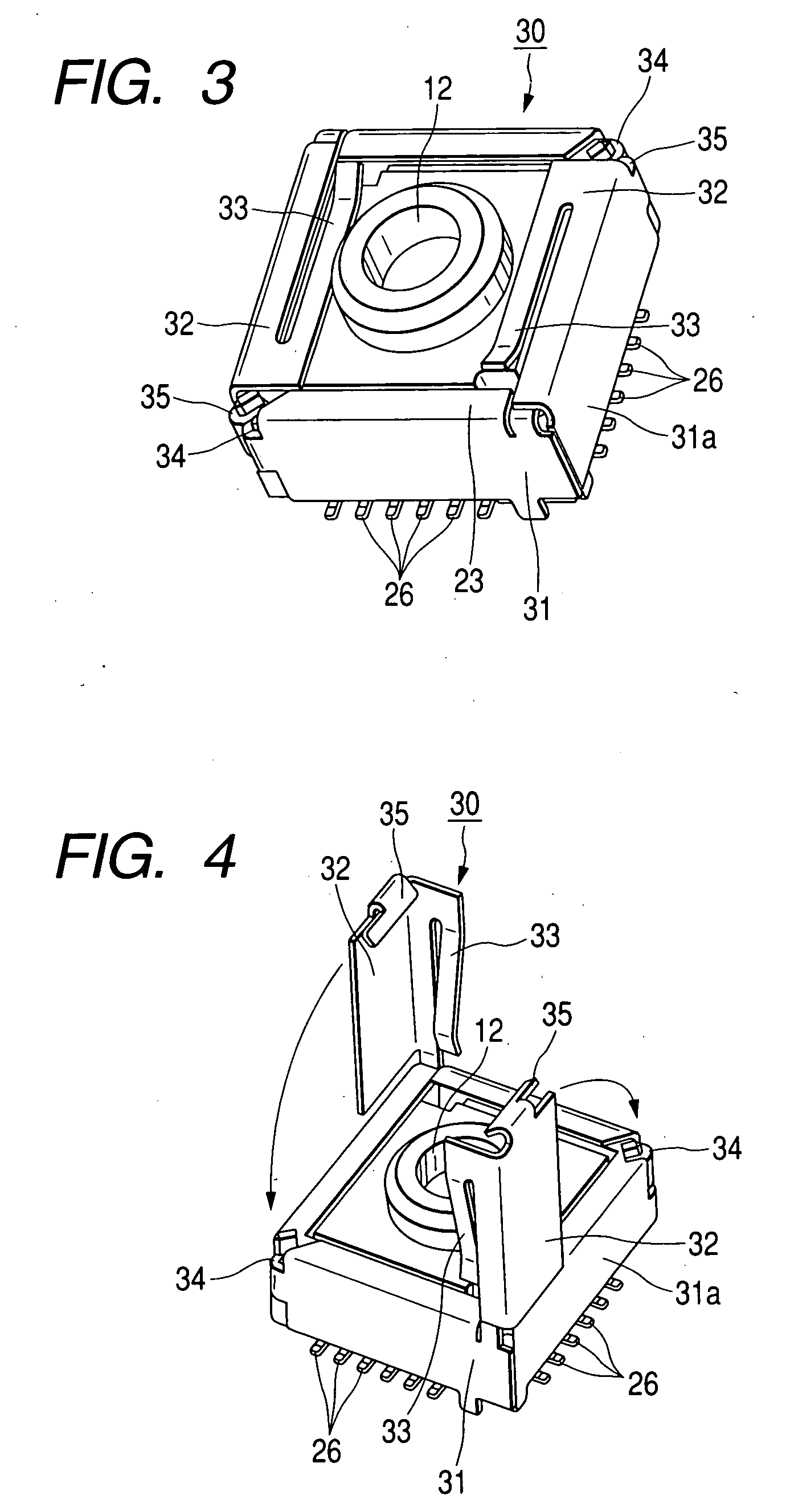

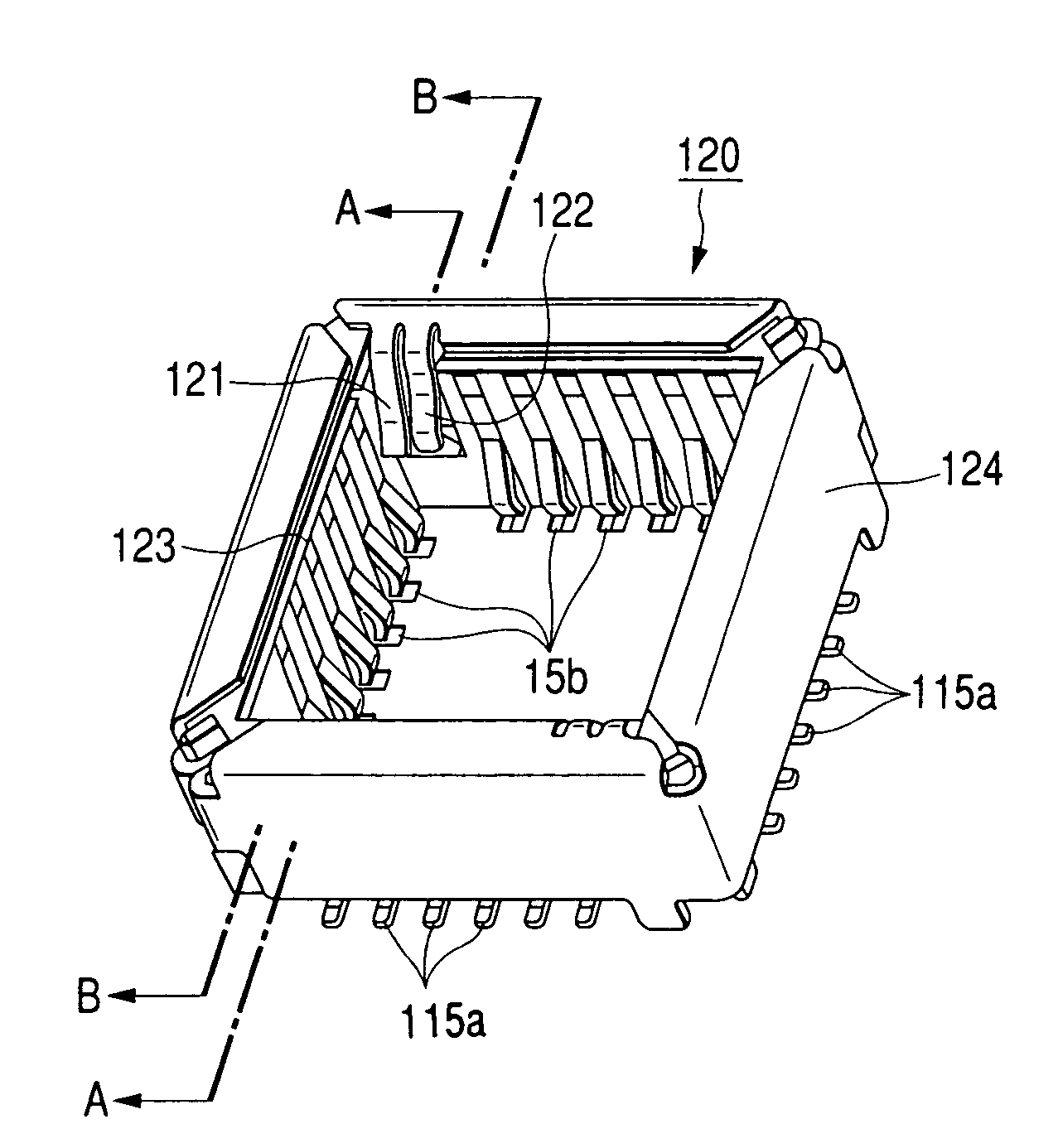

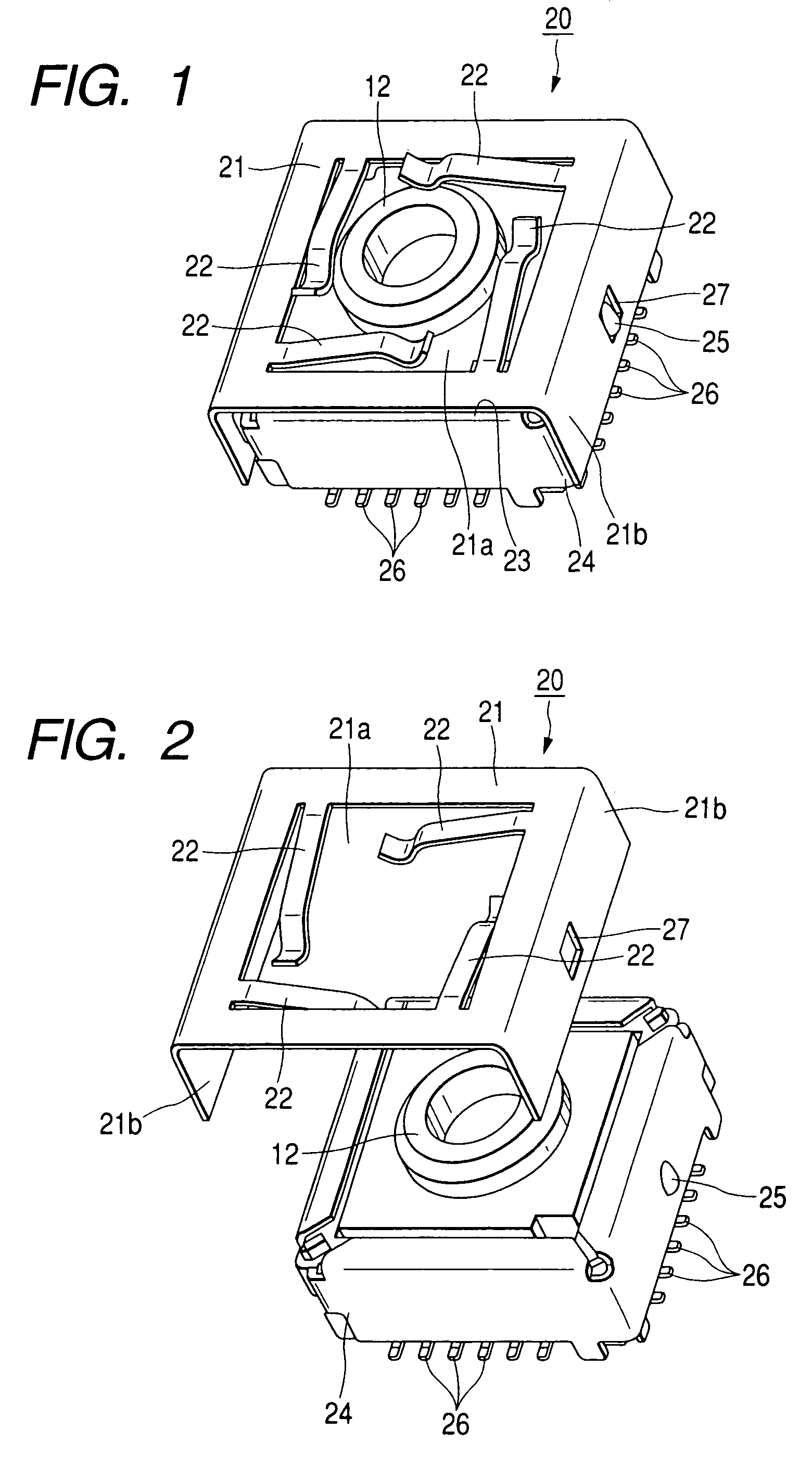

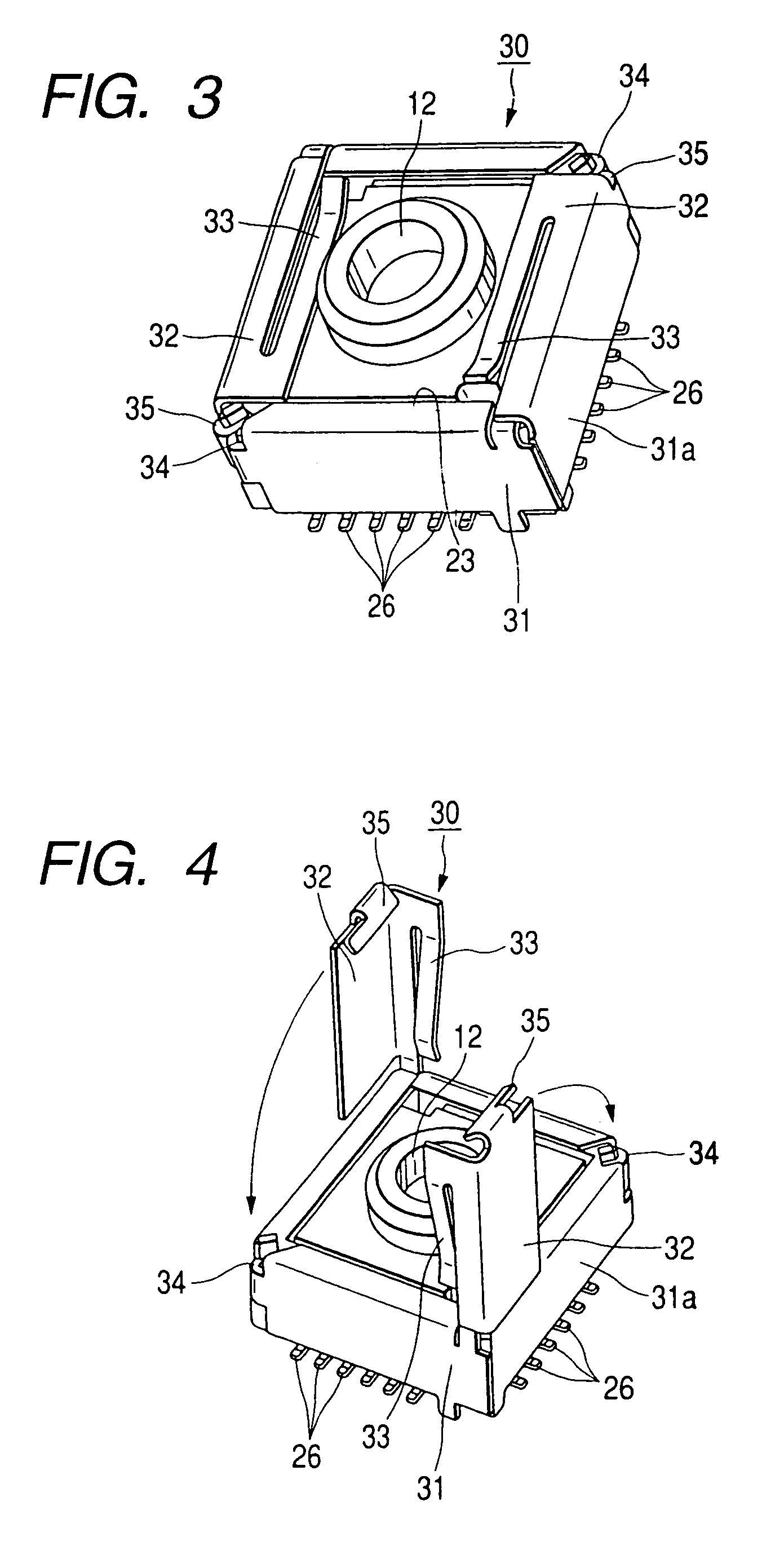

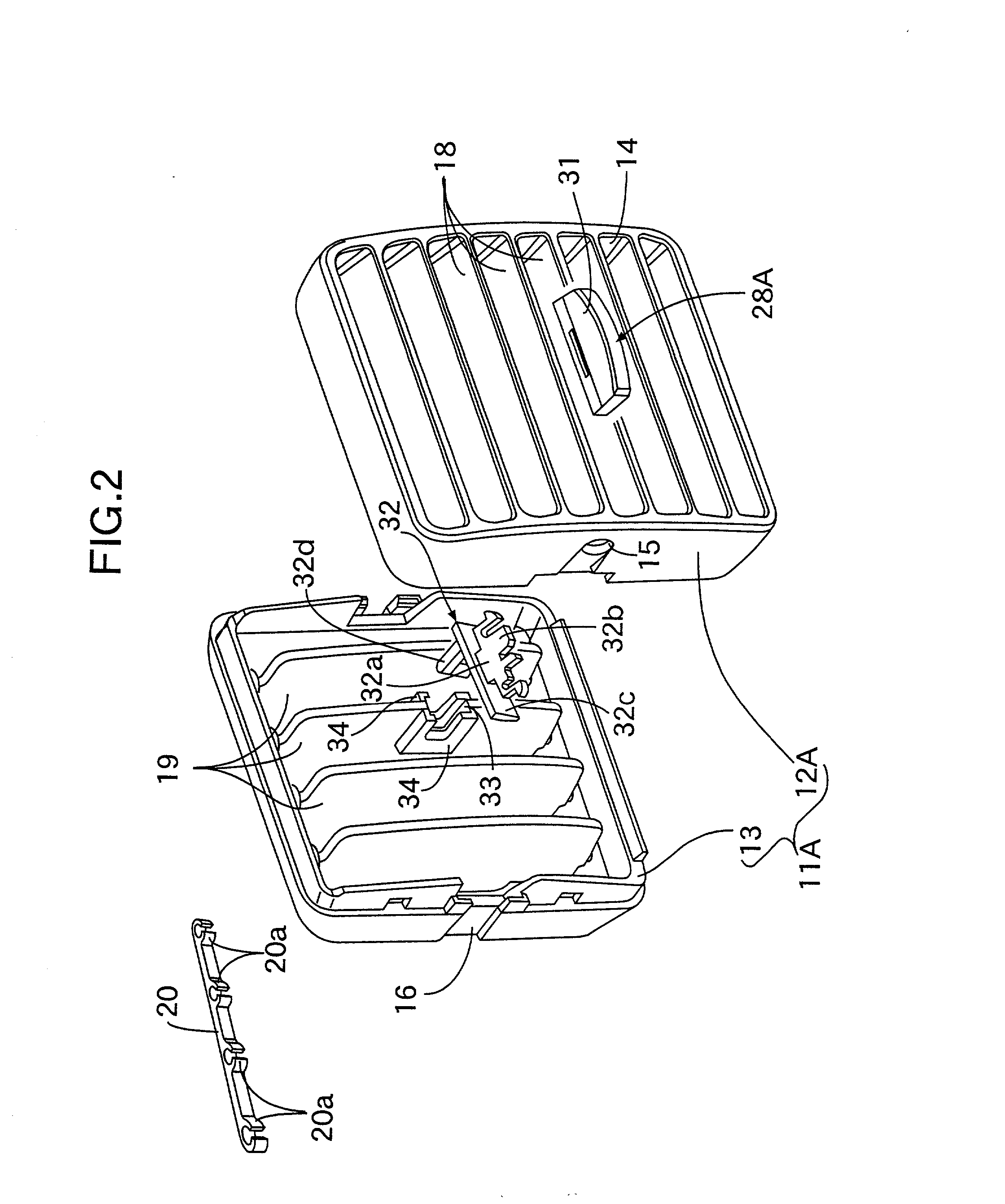

Connector for camera module use

InactiveUS20050048829A1Increase contactGapEngagement/disengagement of coupling partsTelevision system detailsEngineeringCamera module

To provide a connector for camera module use capable of preventing a defective contact of the connector. A connector for camera module use in which a camera module 12 is accommodated in a connector box 23, which is covered with a shield case, and engaged by an engaging member, the camera module 12 including: a solid image pickup element; a lens unit having a lens for guiding light to the solid image pickup element; and a lens holder by which the solid image pickup element is held, wherein a distance between the lens and the solid image pickup element is adjusted to a predetermined focal distance by the lens holer, and the connector for camera module use comprises a pushing member 21, and the pushing member 21 includes: an opening portion 21a formed at the center, the size of which is larger than that of the lens unit; leaf-spring-shaped elastic members 22, 22 . . . protruding along inner edges of the opening portion; and both side plates 21b, 21b on which an engaging hole 27 to be engaged with an engaging portion 25 formed on a circumferential side of the shield case 24 is formed, wherein the pushing member 21 is formed into a reverse U-shape when it is viewed from the front, and when the pushing member 21 is engaged with the shield case, it pushes the camera module body to a bottom face by elastic forces of the elastic members.

Owner:MITSUMI ELECTRIC CO LTD

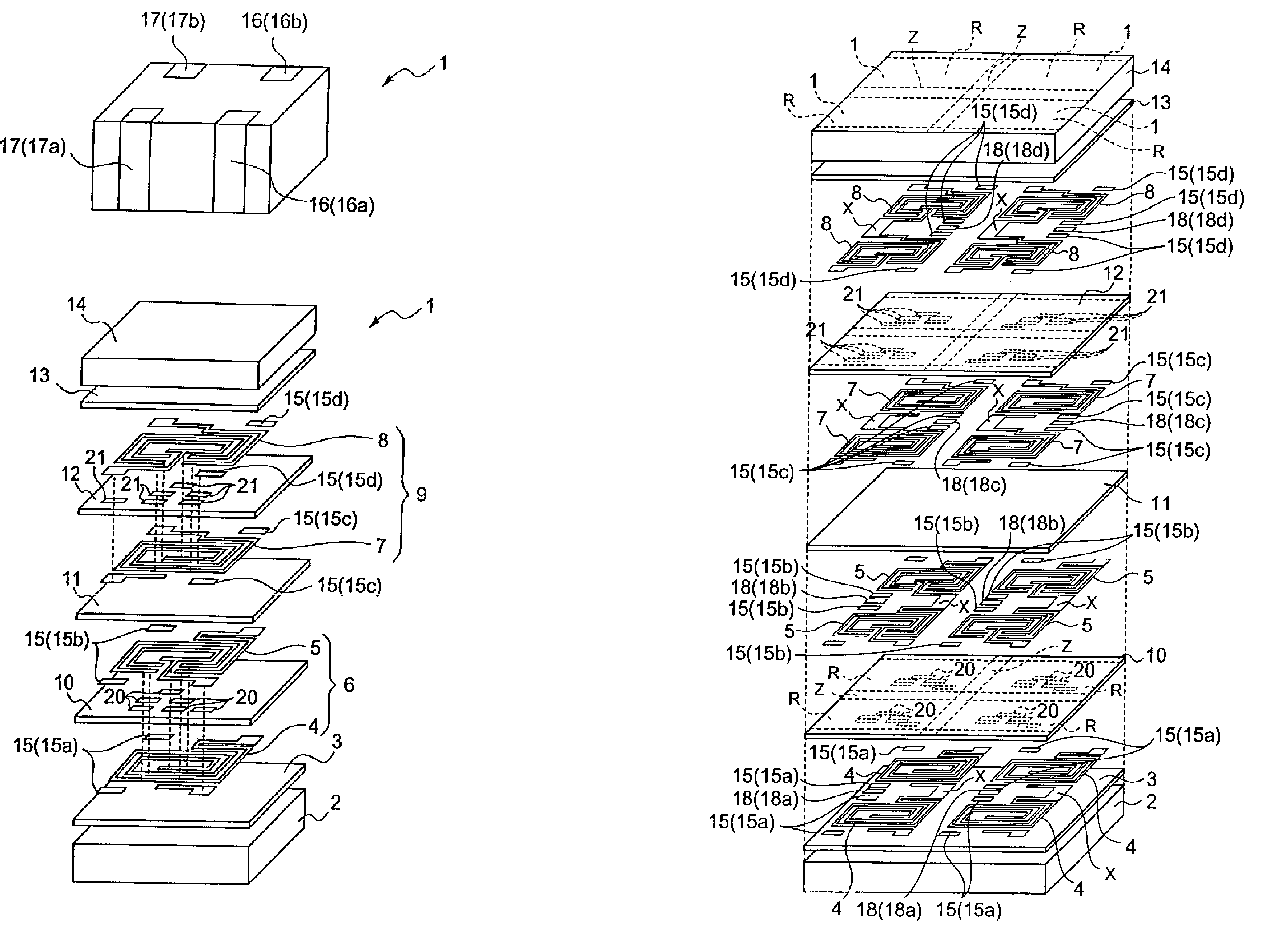

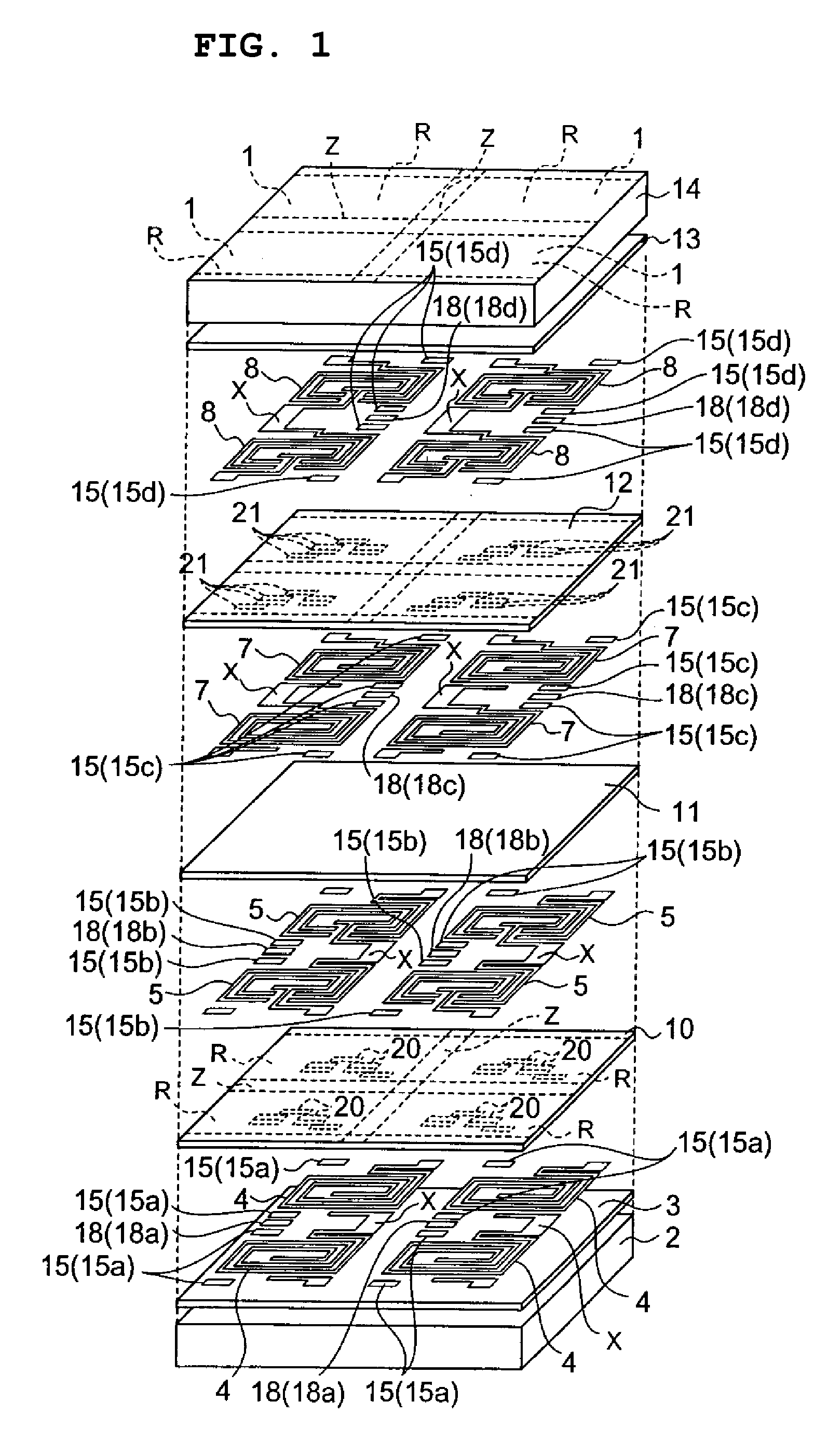

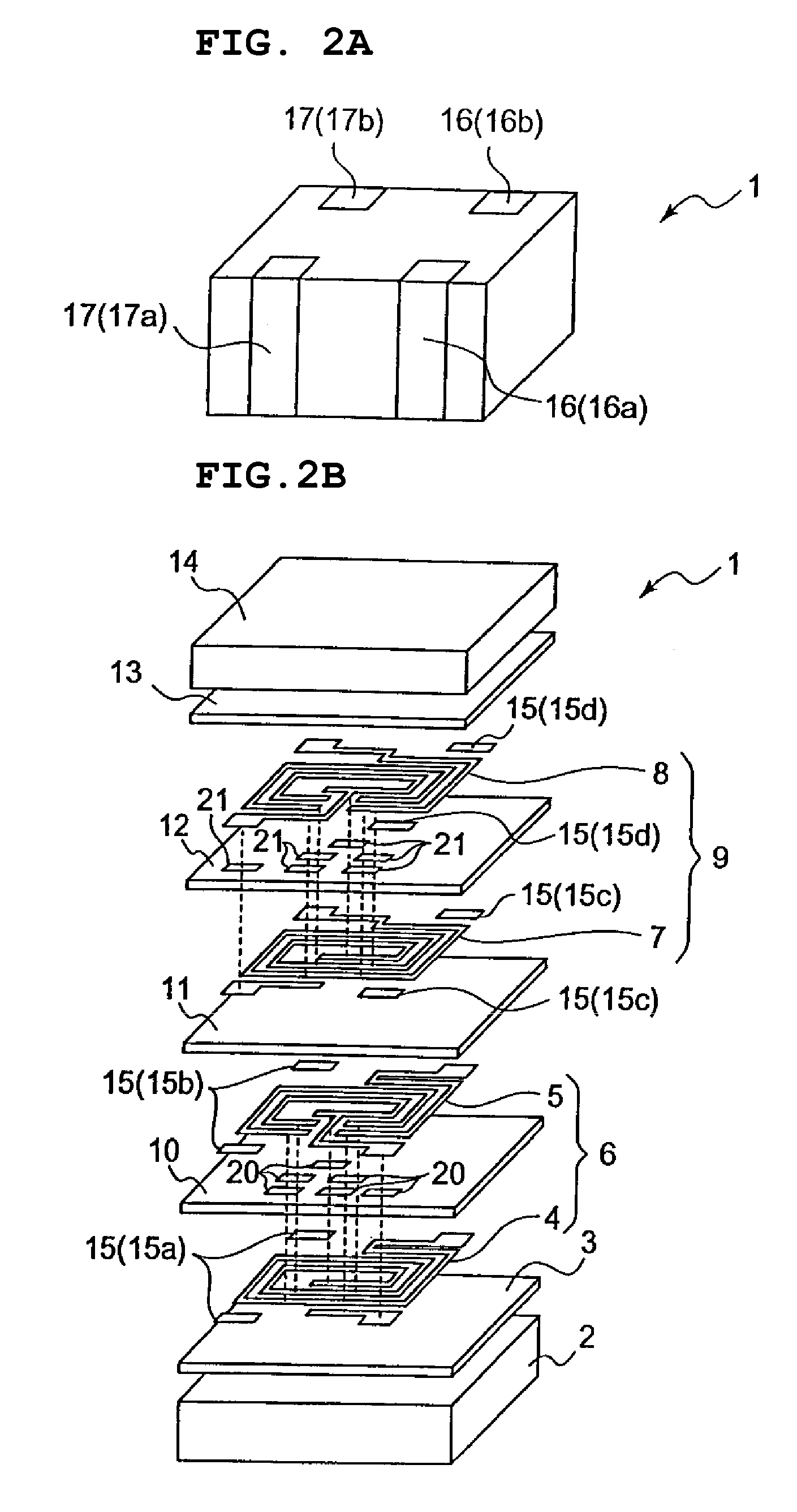

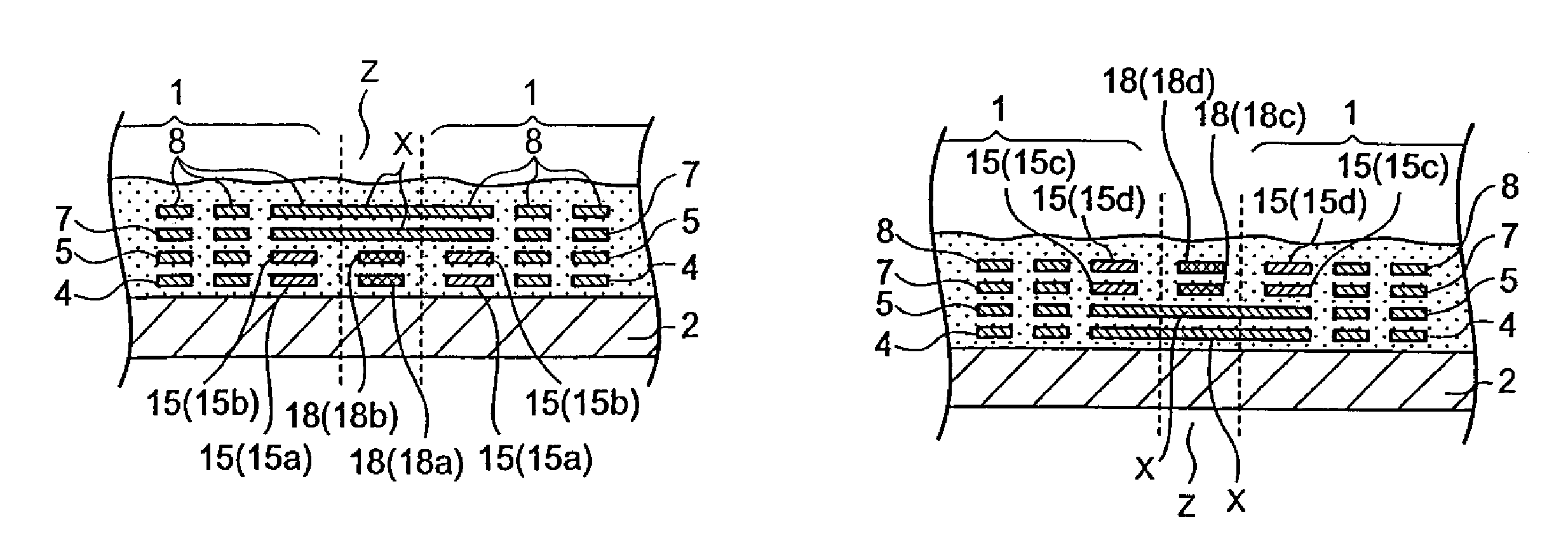

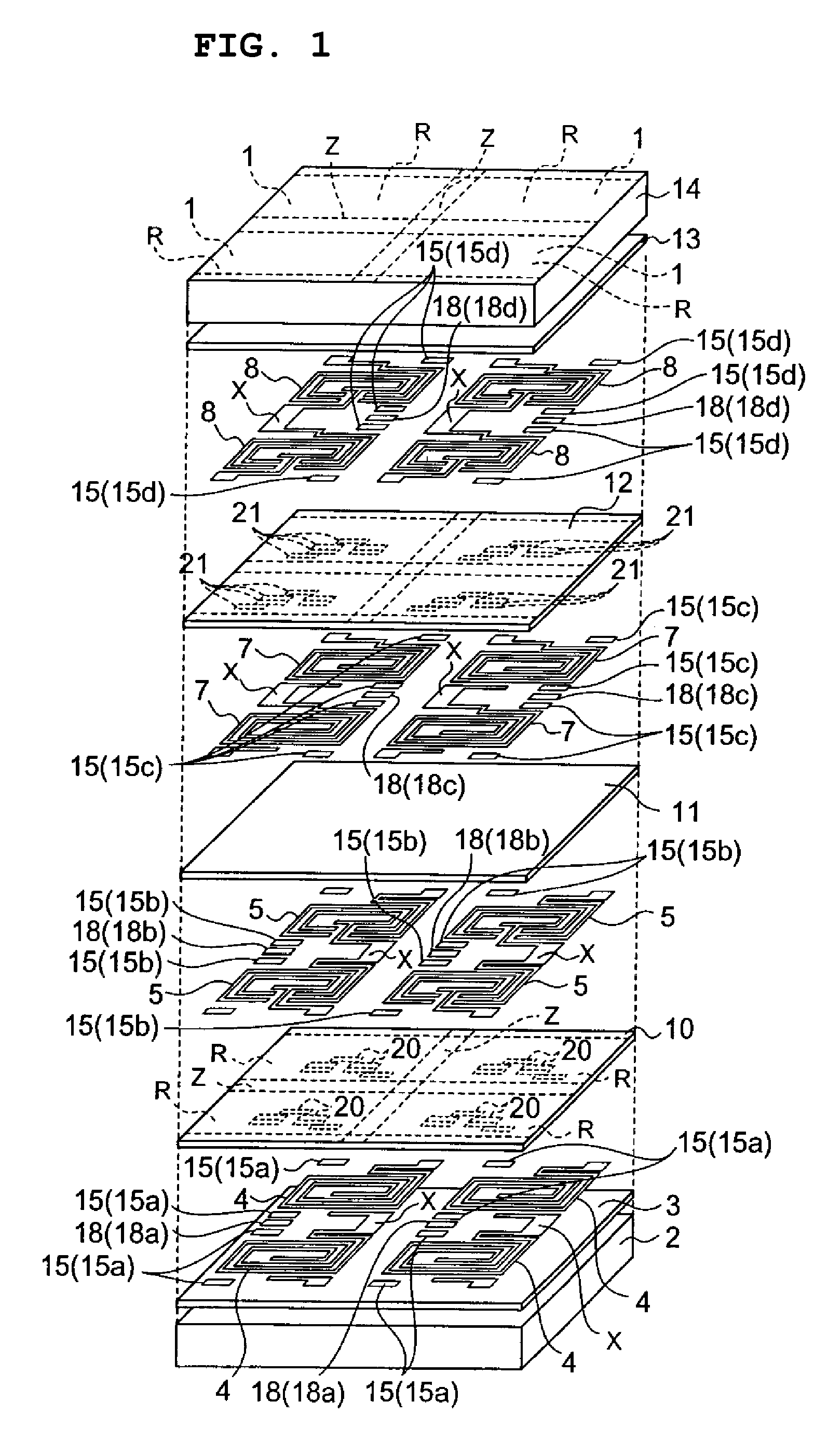

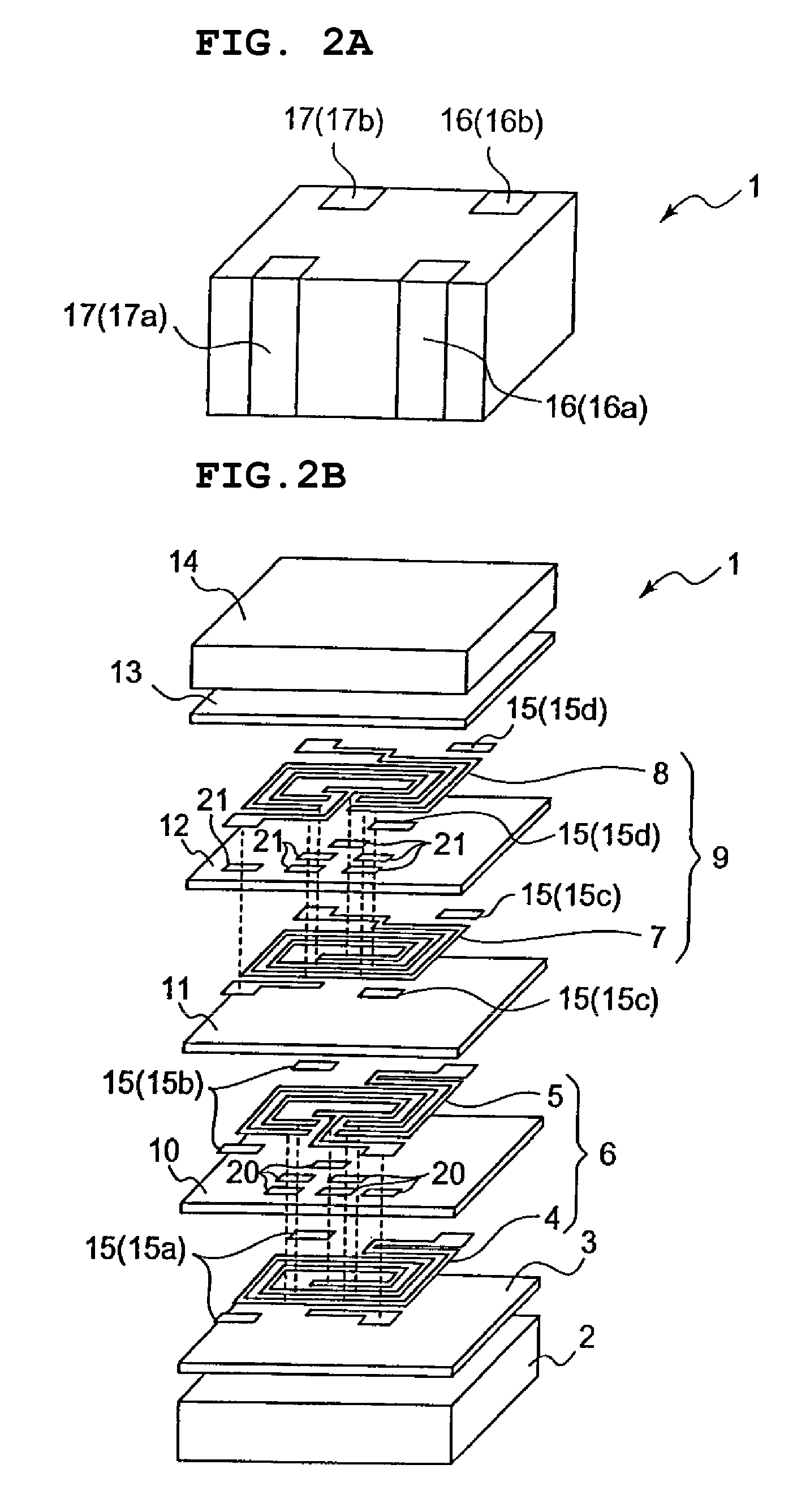

Method For Manufacturing Electronic Components, Mother Substrate, And Electronic Component

InactiveUS20070199734A1Easy to getGapSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEngineeringElectronic component

In a manufacturing process of electronic components which include conductive patterns laminated with insulating layers provided therebetween, conductive pattern layers having conductive patterns formed at intervals therebetween along layer surfaces and insulating layers are alternately laminated to each other. The laminate is pressed by applying a force thereto in the lamination direction, followed by cutting of the laminate along cutting lines provided along boundaries between the electronic components, so that the electronic components are separated from each other. In a cutting-removal region of a mother substrate from which the electronic components are separated from each other by cutting, removal dummy patterns having a size allowing it to be disposed within the above region are formed. In the electronic component, floating dummy patterns which are not electrically connected to the conductive patterns are formed at intervals from the cutting-removal region.

Owner:MURATA MFG CO LTD

Connector for camera module use

InactiveUS7112083B2Increase contactGapEngagement/disengagement of coupling partsTelevision system detailsCamera moduleComputer science

To provide a connector for camera module use capable of preventing a defective contact of the connector.A connector for camera module use in which a camera module 12 is accommodated in a connector box 23, which is covered with a shield case, and engaged by an engaging member, the camera module 12 including: a solid image pickup element; a lens unit having a lens for guiding light to the solid image pickup element; and a lens holder by which the solid image pickup element is held, wherein a distance between the lens and the solid image pickup element is adjusted to a predetermined focal distance by the lens holder, and the connector for camera module use comprises a pushing member 21, and the pushing member 21 includes: an opening portion 21a formed at the center, the size of which is larger than that of the lens unit; leaf-spring-shaped elastic members 22, 22 . . . protruding along inner edges of the opening portion; and both side plates 21b, 21b on which an engaging hole 27 to be engaged with an engaging portion 25 formed on a circumferential side of the shield case 24 is formed, wherein the pushing member 21 is formed into a reverse U-shape when it is viewed from the front, and when the pushing member 21 is engaged with the shield case, it pushes the camera module body to a bottom face by elastic forces of the elastic members.

Owner:MITSUMI ELECTRIC CO LTD

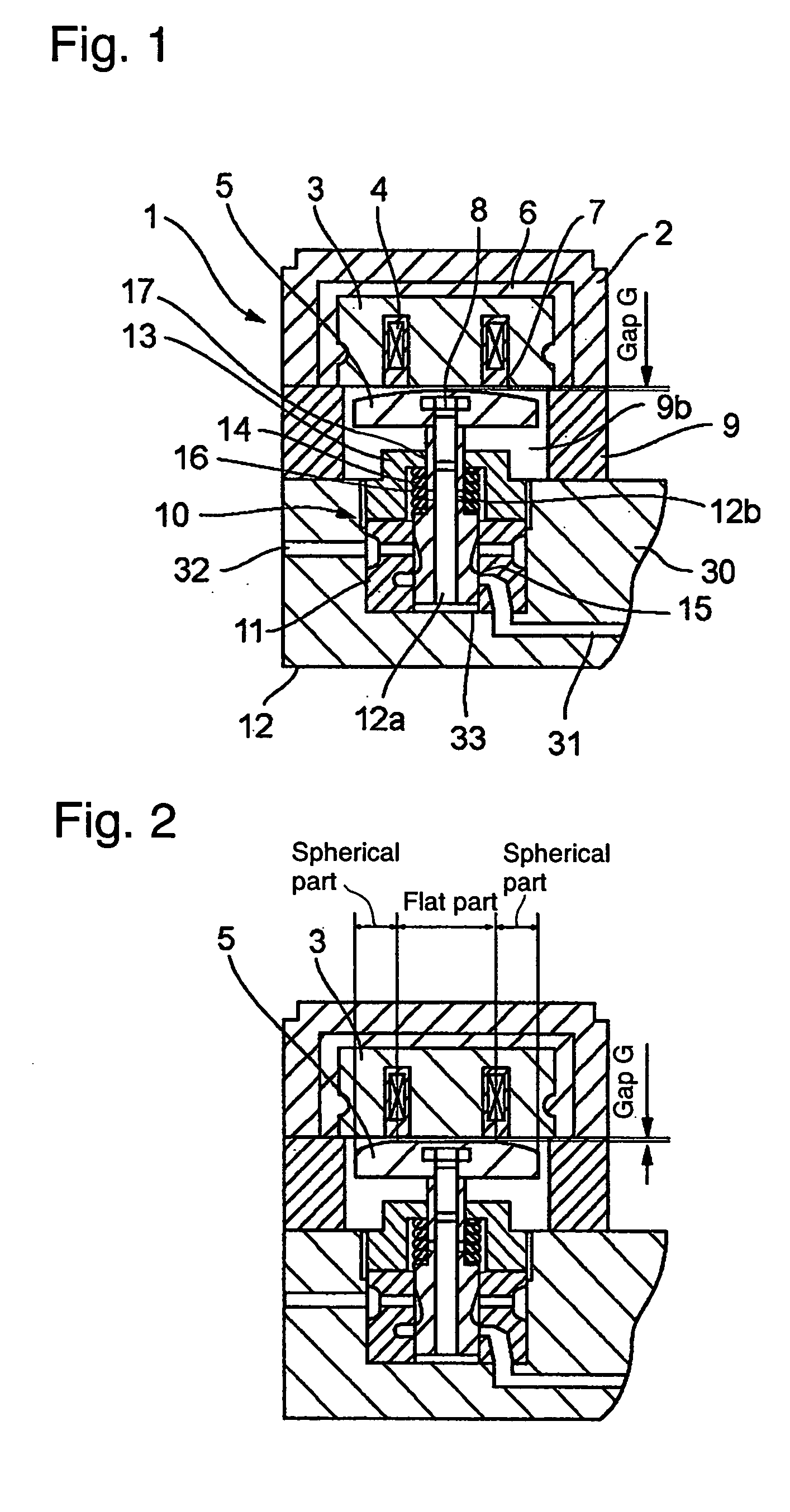

Electromagnetic valve gear

ActiveUS20050189512A1GapIncrease attractivenessOperating means/releasing devices for valvesMachines/enginesSolenoid valveEngineering

To increase the force to draw the armature of an electromagnetic valve gear for driving a valve for opening or closing a high-pressure liquid passage and to alleviate valve bouncing, the surface of the core with a coil embedded therein is shaped flat and the surface of the armature facing to the surface of the core is shaped convexly spherical, or the surface of the core is shaped convexly spherical and the surface of the armature is concavely spherical such that the curvature radius of the concavely spherical surface is larger than that of the convexly spherical surface, or the armature is composed by piling thin plates of different diameters such that the surface of the armature facing to the surface of the core forms an approximate convexly spherical surface, so that the gap between the surfaces of core and armature is smaller in the central part compared to that in the peripheral part of the surfaces. By this, the interference of the surfaces is prevented with smaller initial gap in the central portion of the faces even when the armature is installed aslant caused by insufficient accuracy of the component parts, and strong electromagnetic attraction can be secured because the smaller the gap is, the stronger the electromagnetic attraction is.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Pet toy with flexible body and rope support configurations

ActiveUS8393300B2Less stressRobust constructionFilament handlingOther apparatusEngineeringCompanion animal

Owner:THE KONG

High contrast spatial light modulator

ActiveUS7245415B2Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

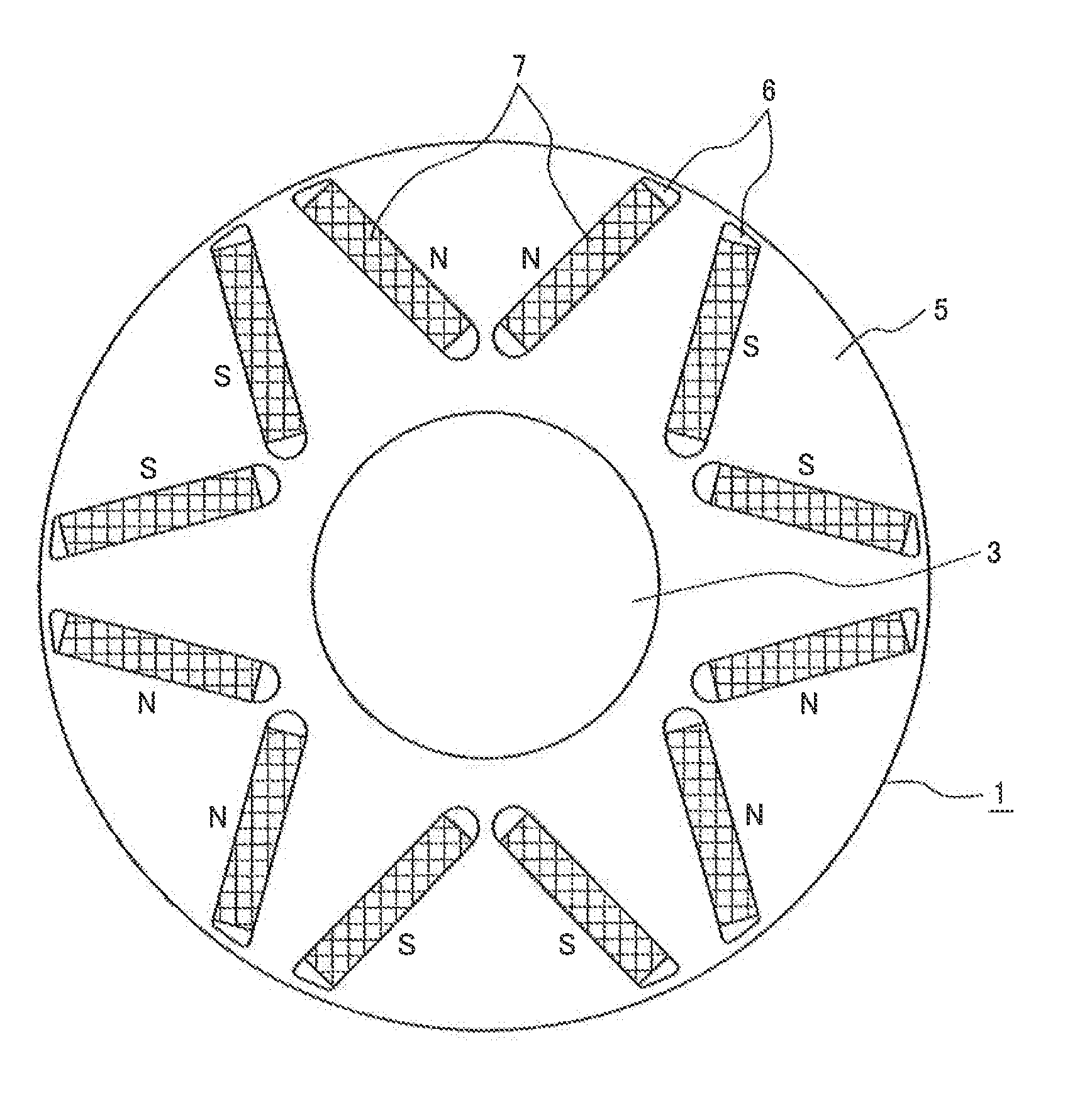

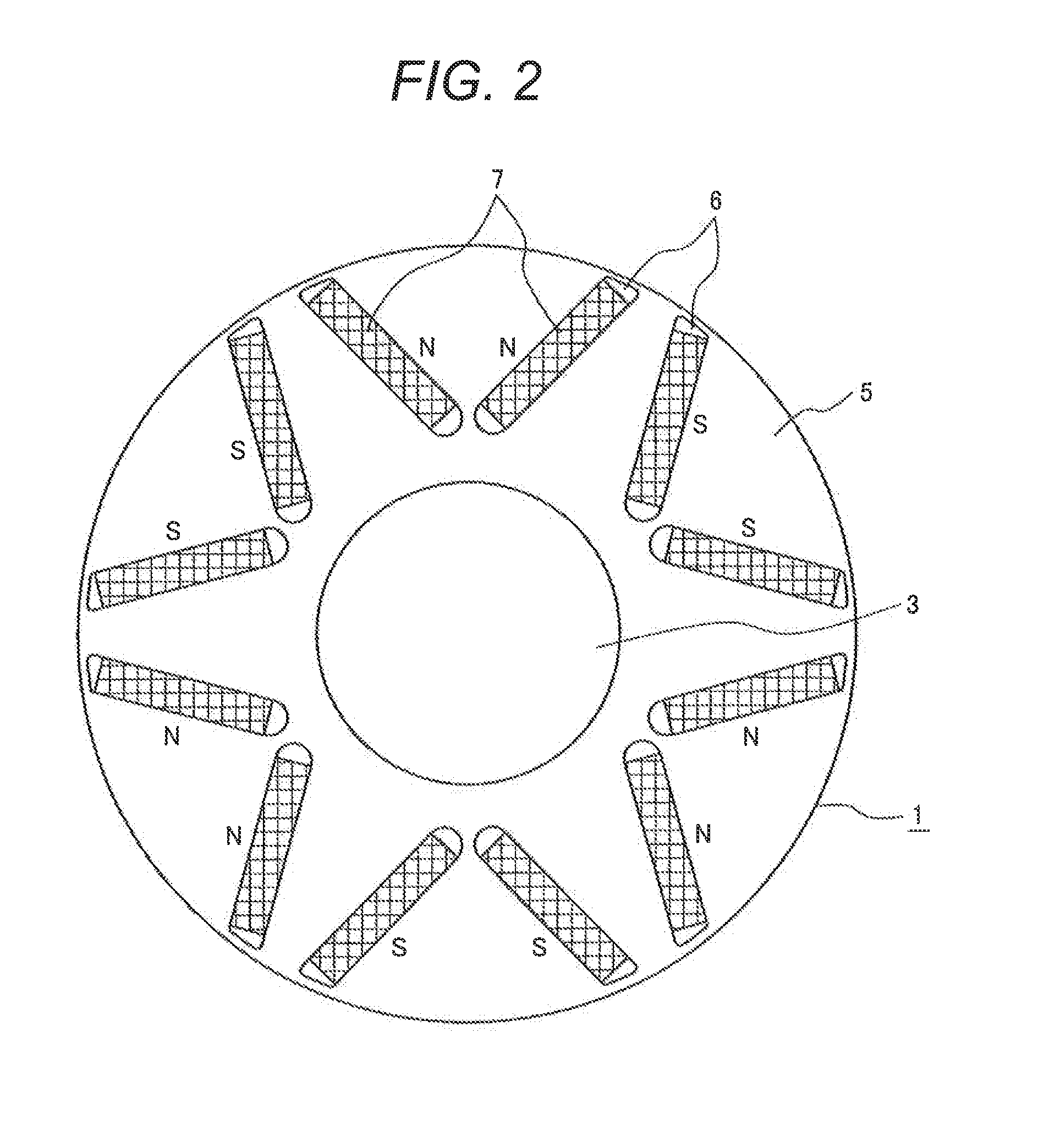

Permanent Magnet Rotating Machine

InactiveUS20120032539A1Improve efficiencyMagnetic flux concentration can be avoidedMagnetic circuit rotating partsWind energy generationElectrical polarityConductor Coil

A permanent magnet rotating machine has a stator, in which armature windings are formed in a plurality of slots formed in a stator iron core, and also has a rotor, in which two magnet insertion slots are formed for each pole in a rotor iron core in a V shape when viewed from the outer circumference of the rotor and one permanent magnet is embedded in each magnet insertion slot with polarity alternating for each pole; a wall at one end of the magnet insertion slot on the external diameter side of the rotor is formed with three arcs having different curvatures, one of the three arcs being parallel to the outer circumference of the rotor, and a wall at the other end of the magnet insertion slot on the internal diameter side of the rotor is formed in an arc shape.

Owner:HITACHI LTD

Method for manufacturing electronic components, mother substrate, and electronic component

InactiveUS7663225B2Easy to getGapSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEngineeringElectronic component

Owner:MURATA MFG CO LTD

High contrast spatial light modulator

ActiveUS20060245030A1Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

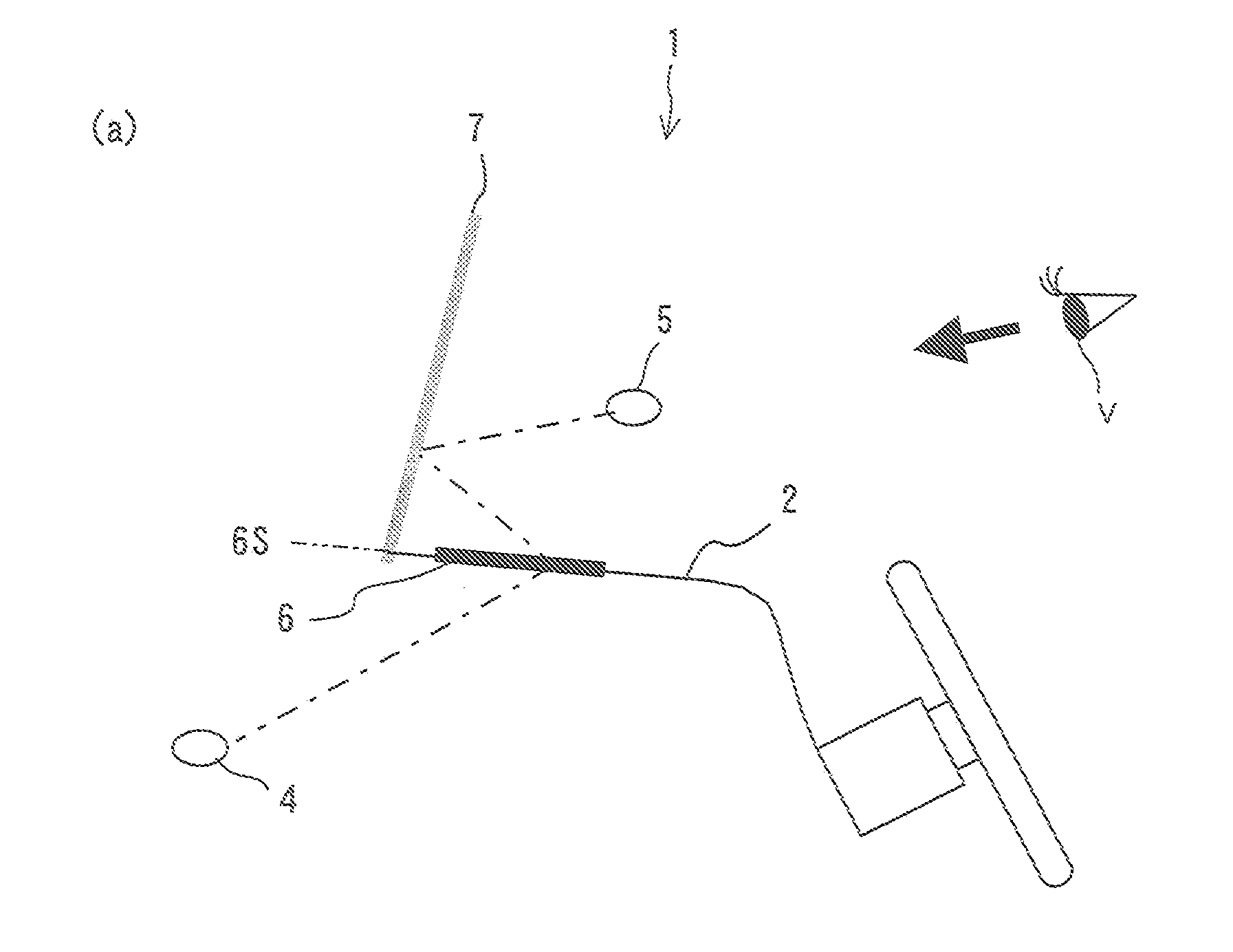

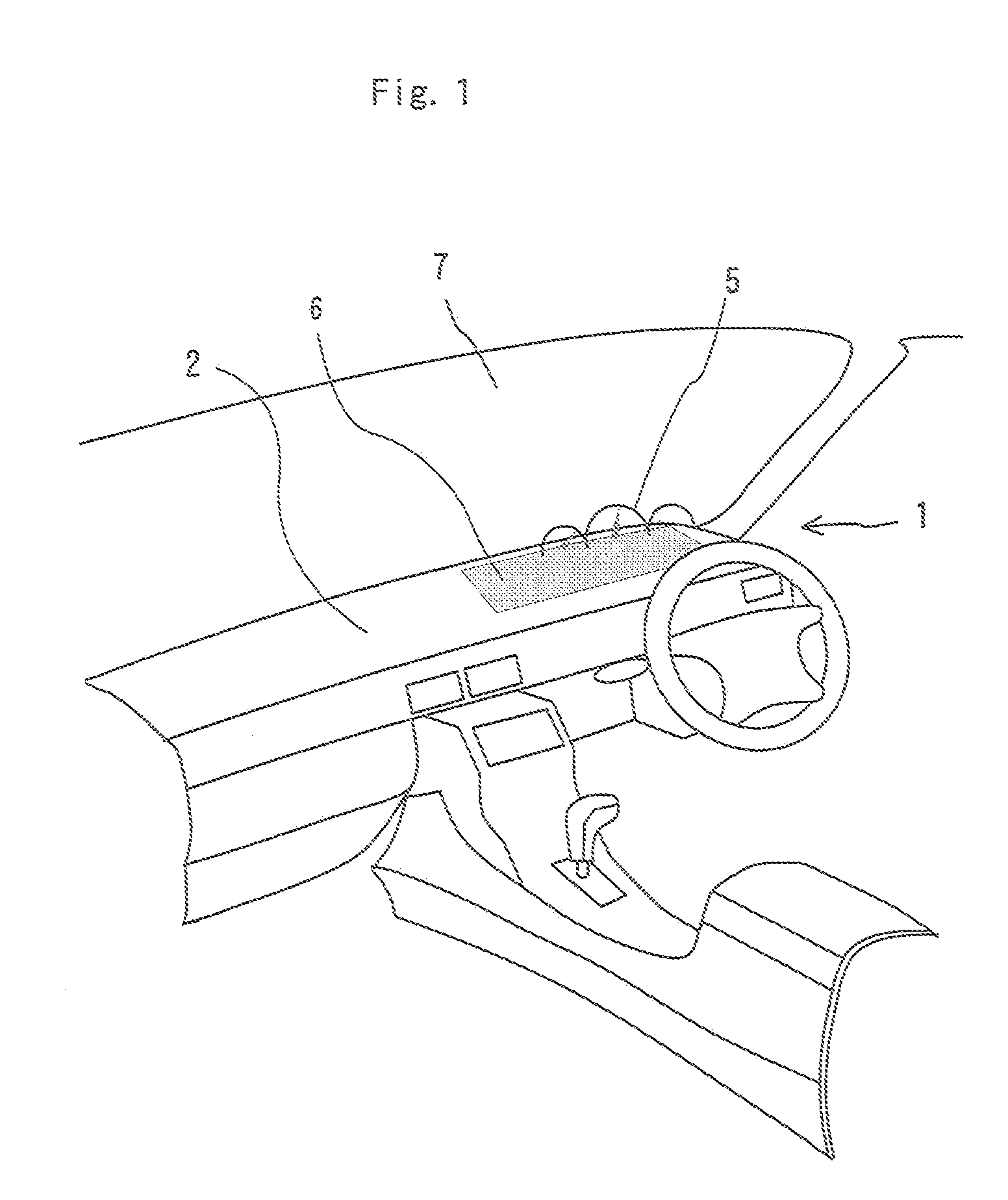

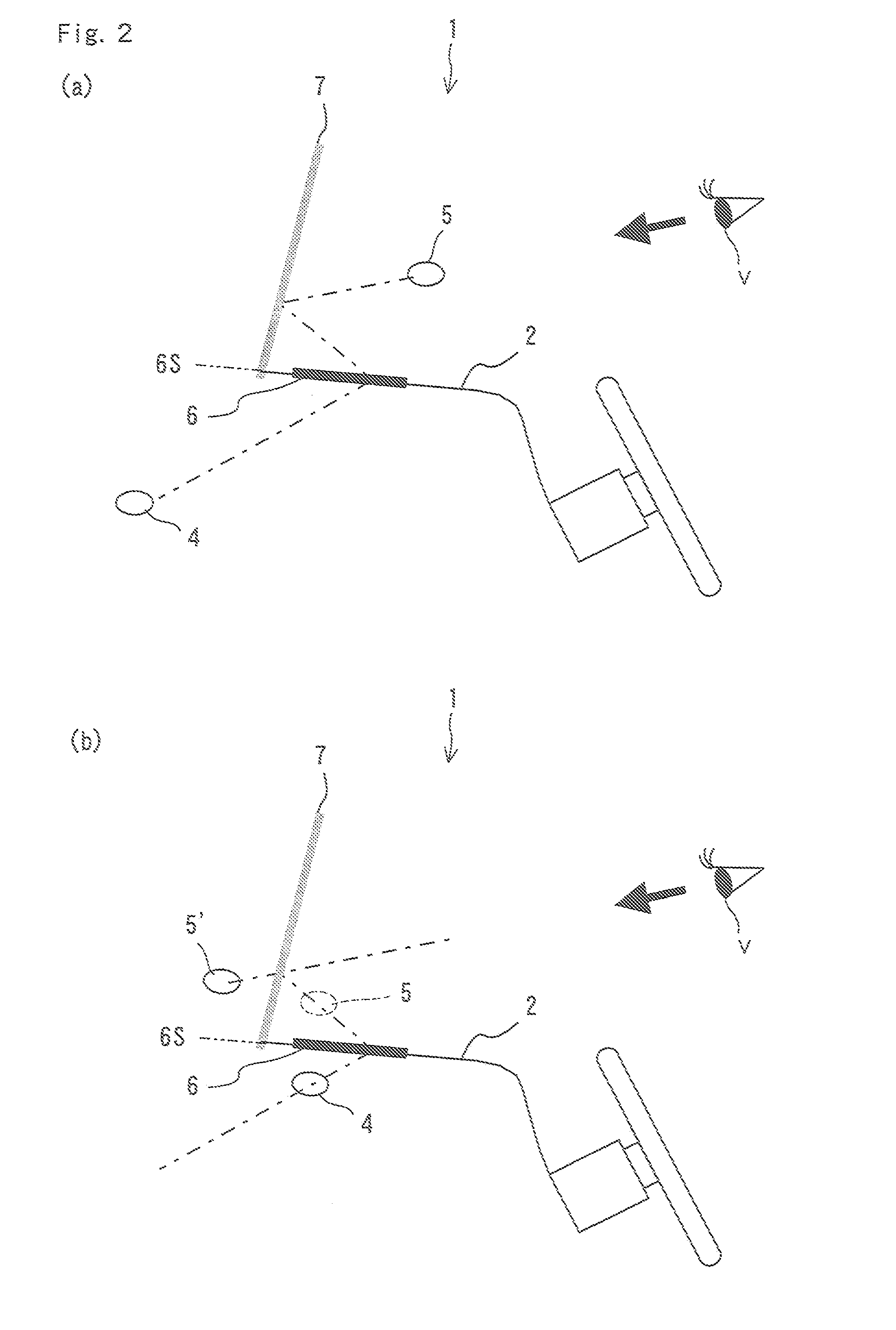

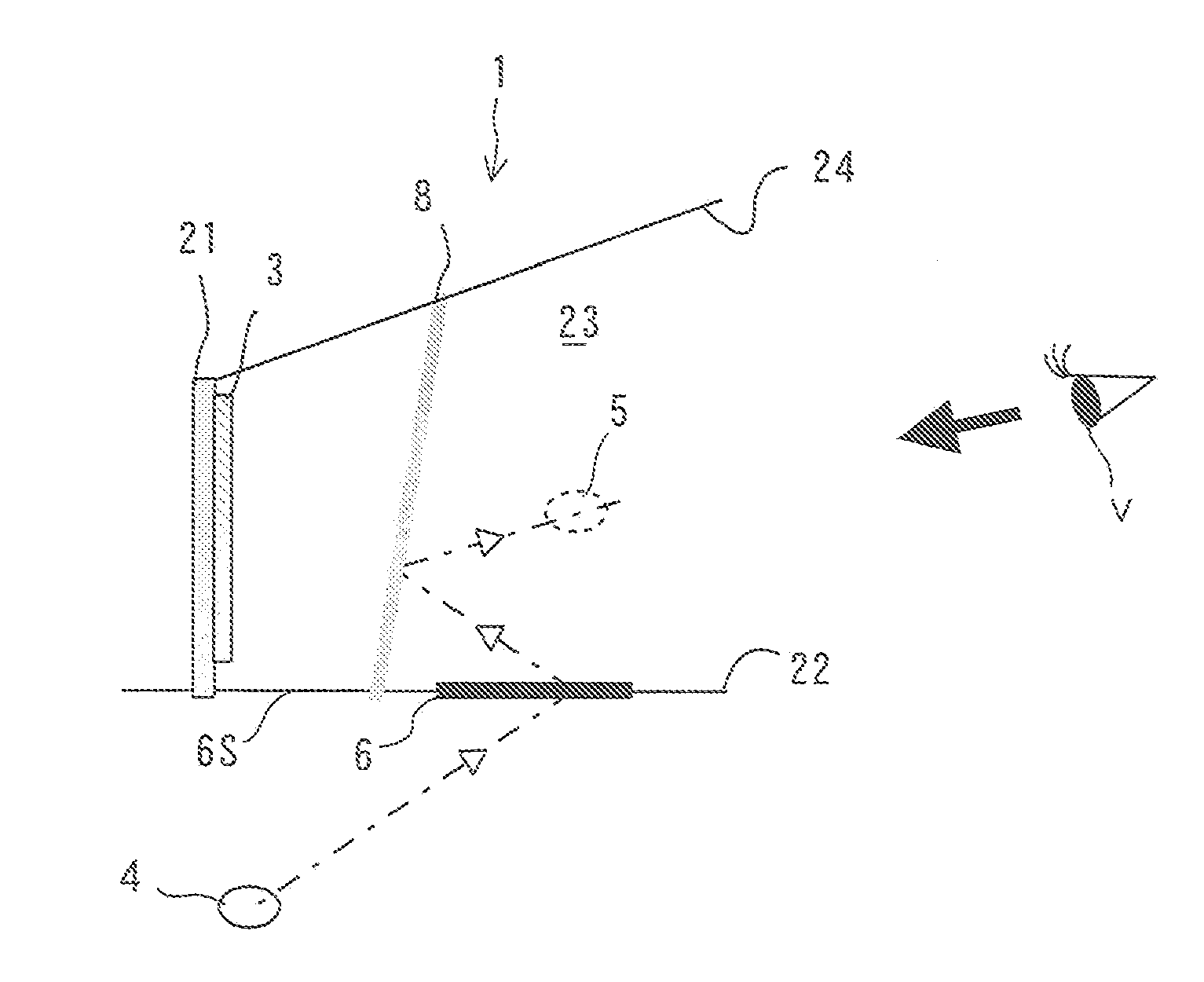

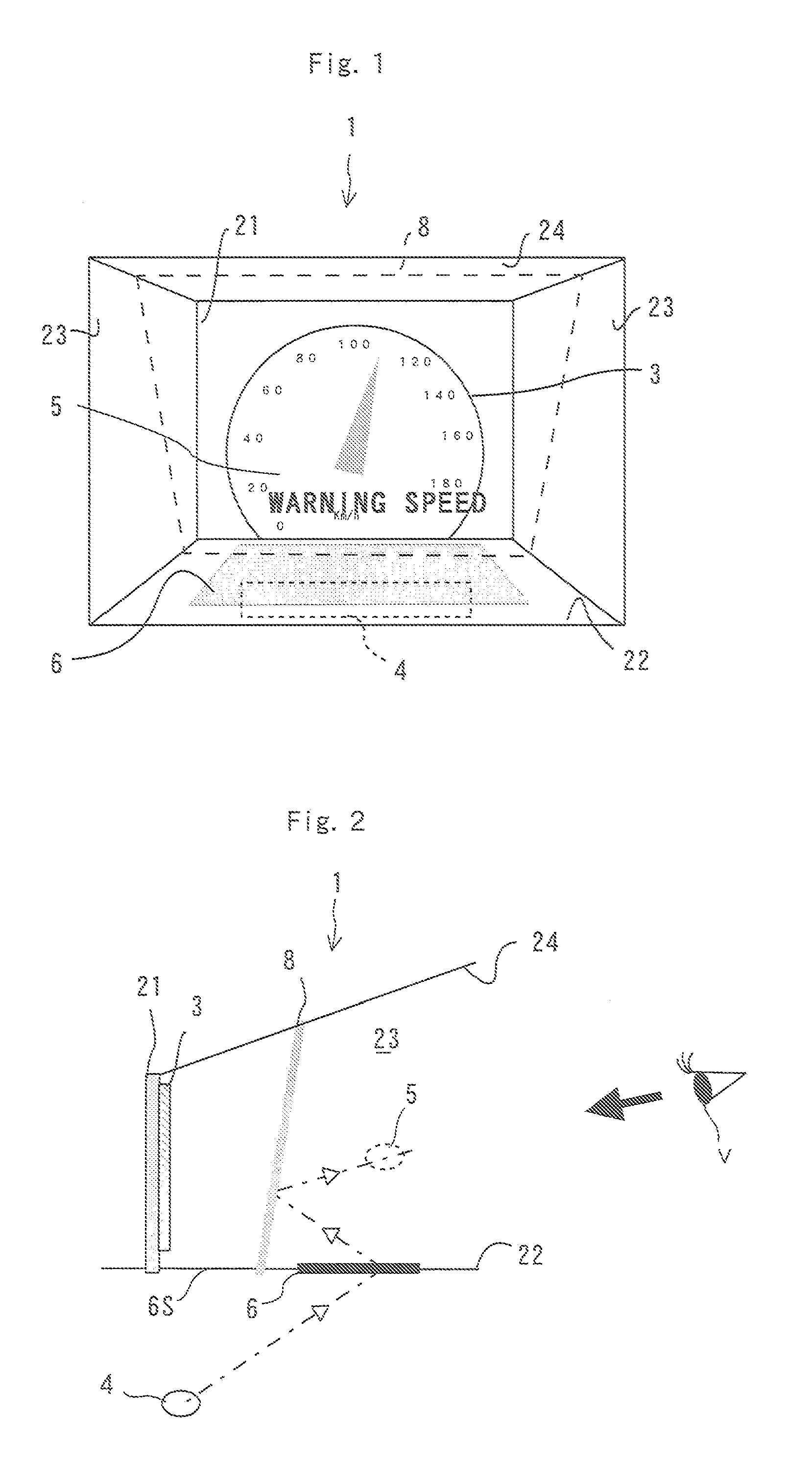

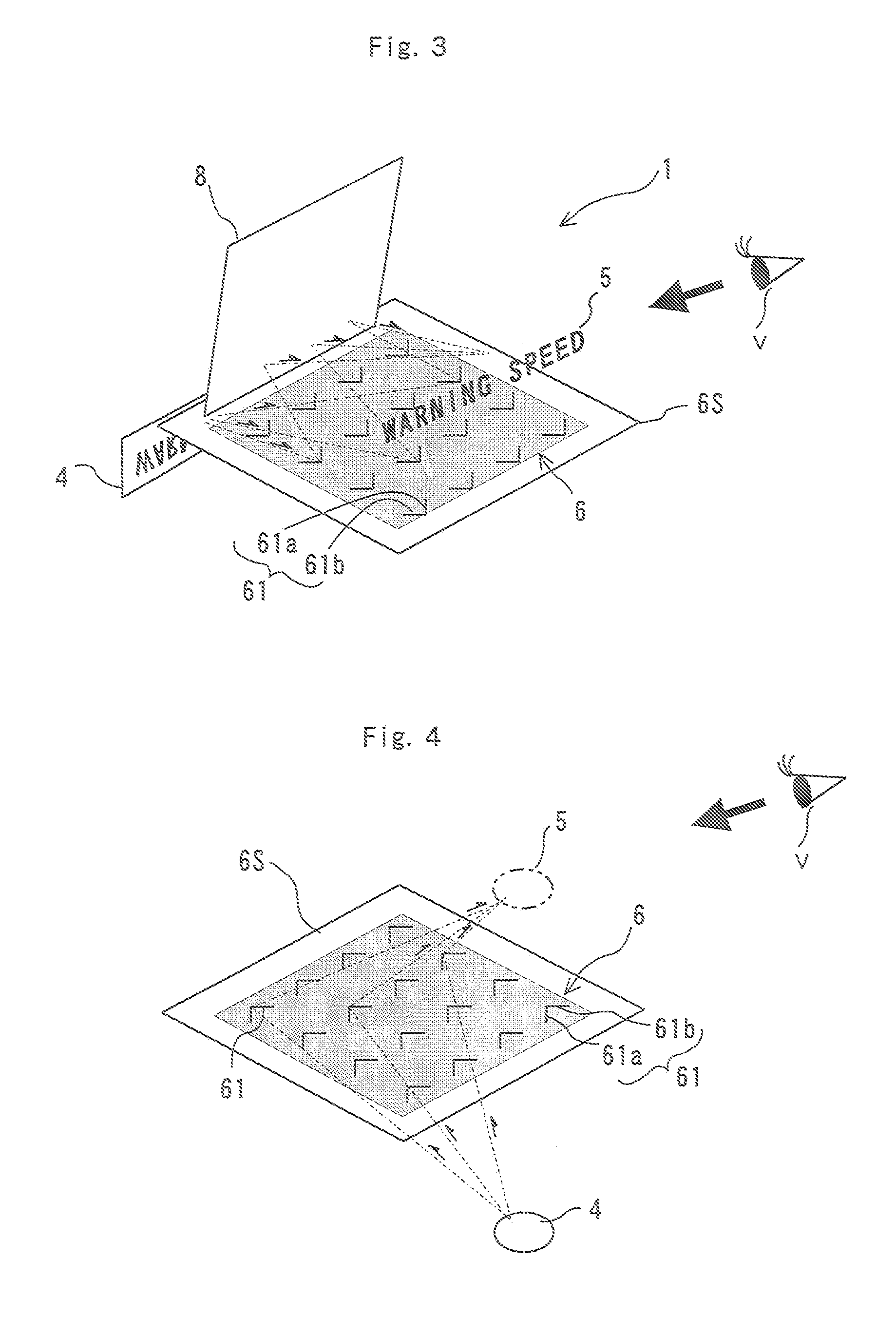

Head-up display device

ActiveUS20110074657A1Gap minimizationGapCathode-ray tube indicatorsOptical elementsHead-up displayDisplay device

A head-up display device placed on an upper surface of a dashboard, includes: an object of view arranged in an inside space of the dashboard; an imaging optical system of real specular image for defining a space where a viewer exists and the inside space of the dashboard, the imaging optical system of real specular image including a semitransparent substrate with a plane of symmetry, the imaging optical system of real specular image forming a real image of the object of view in the space of the viewer with light passing through the substrate; and a reflective screen arranged in the space of the viewer, the reflective screen reflecting light beams of the real image of the object of view supplied from the imaging optical system of real specular image to guide the reflected light beams to the viewer, while allowing formation of an image to be seen by the viewer.

Owner:STANLEY ELECTRIC CO LTD

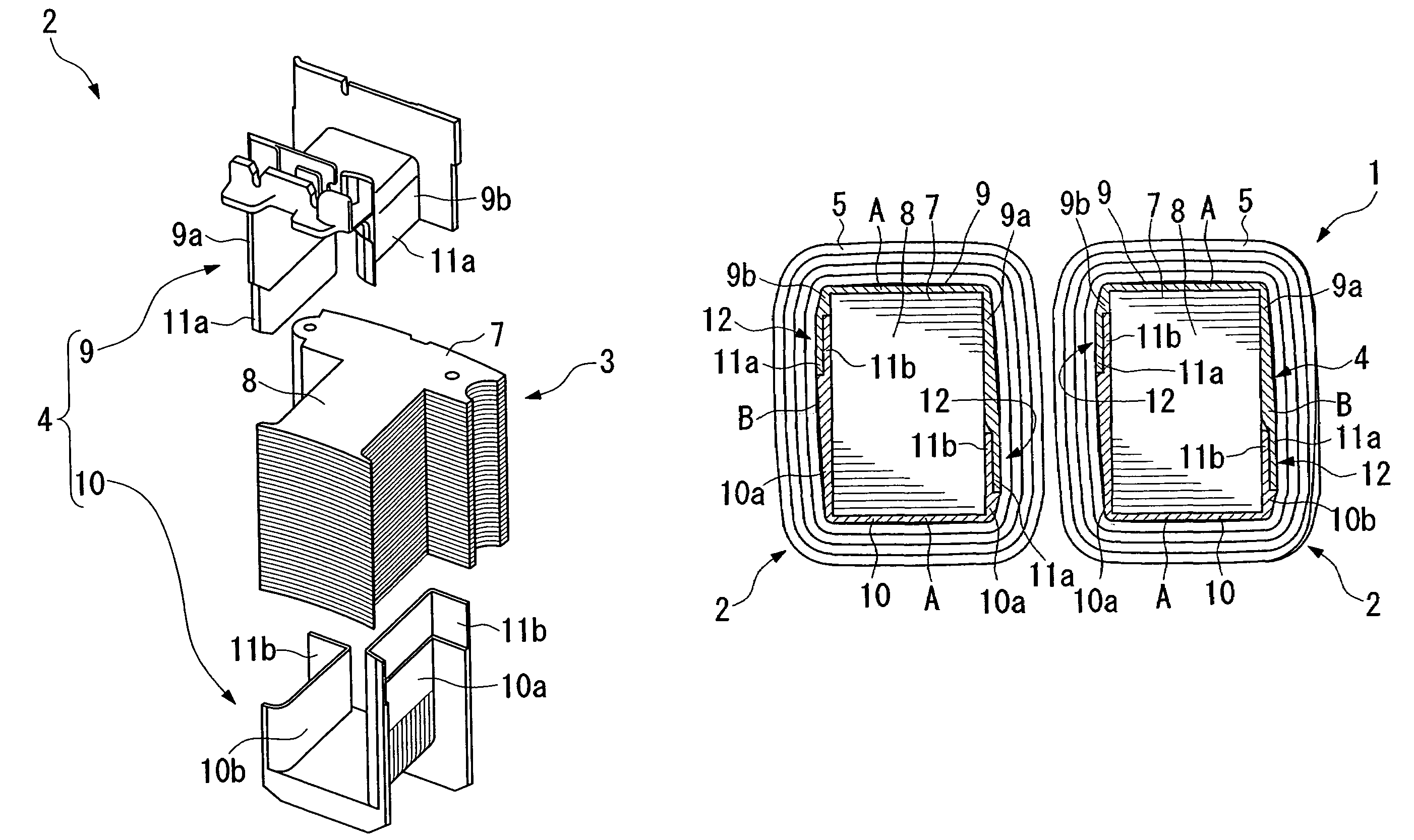

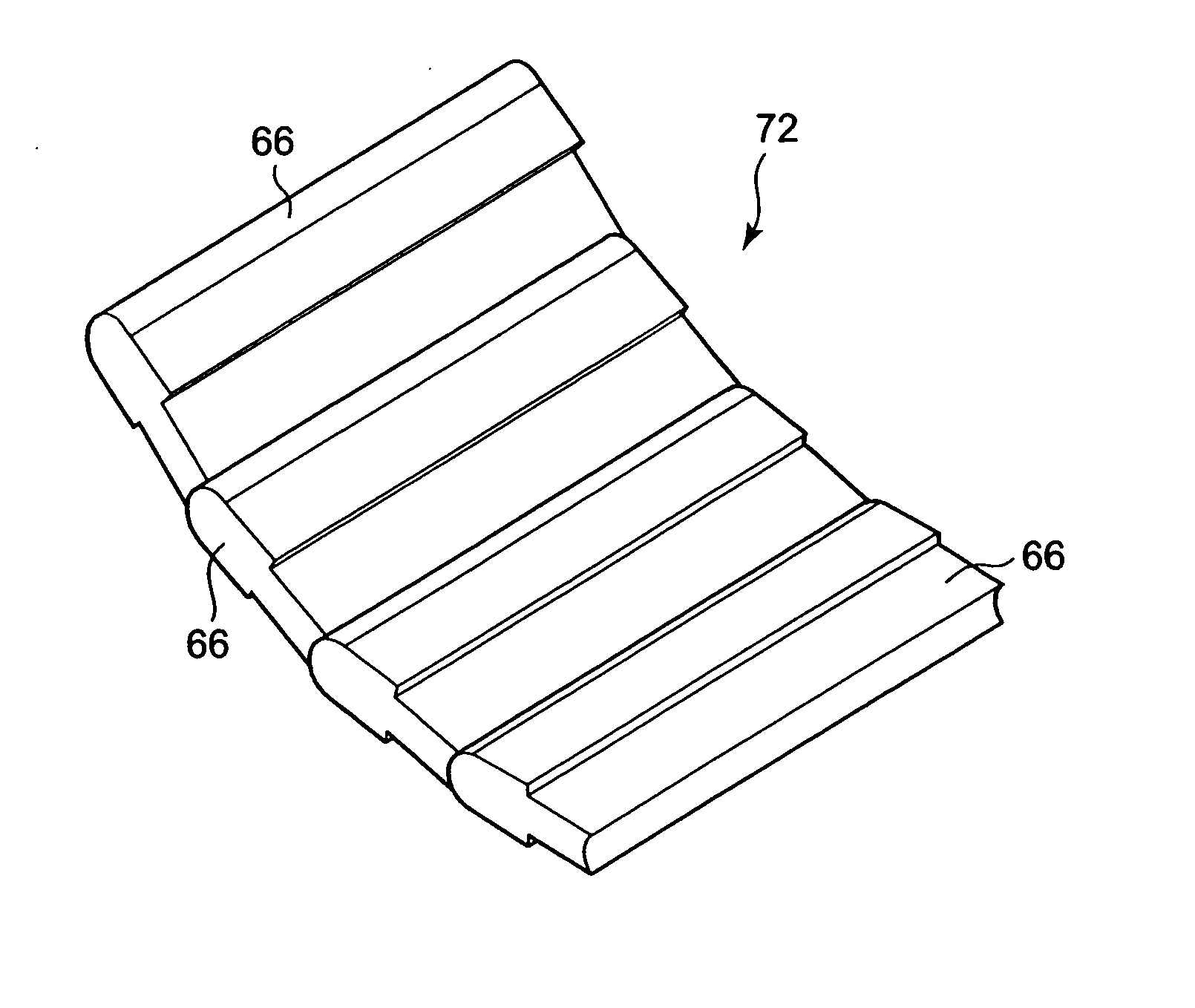

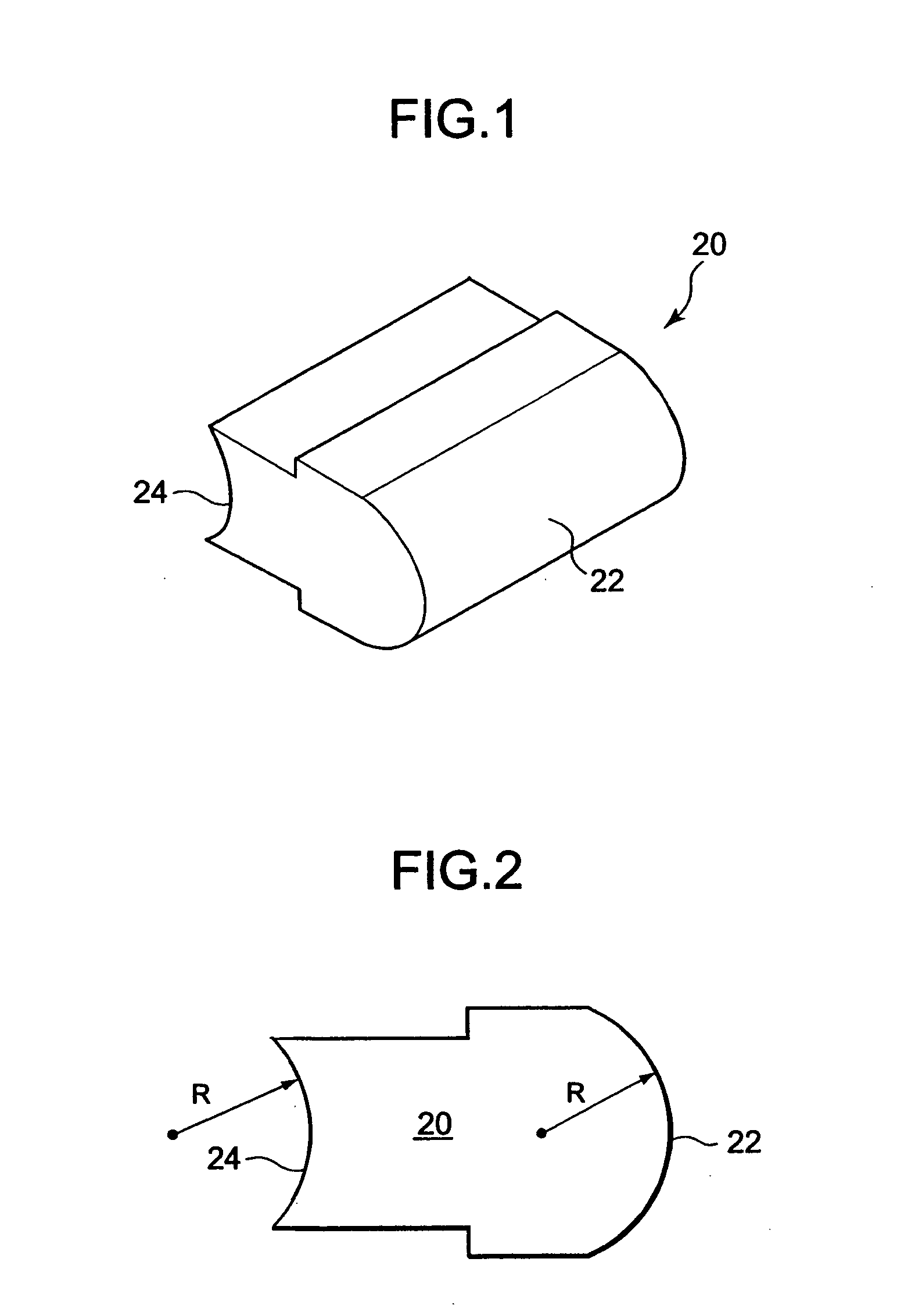

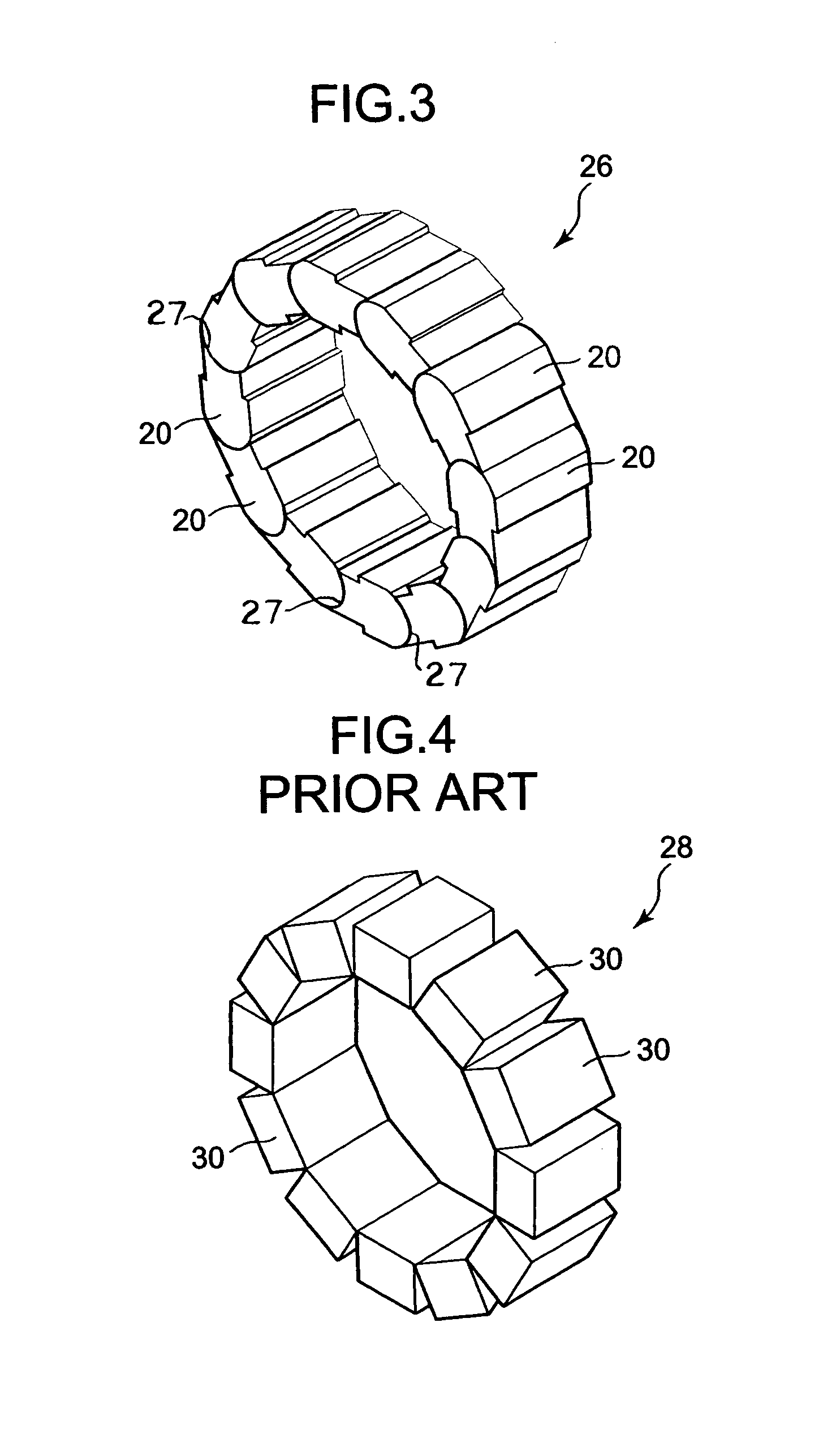

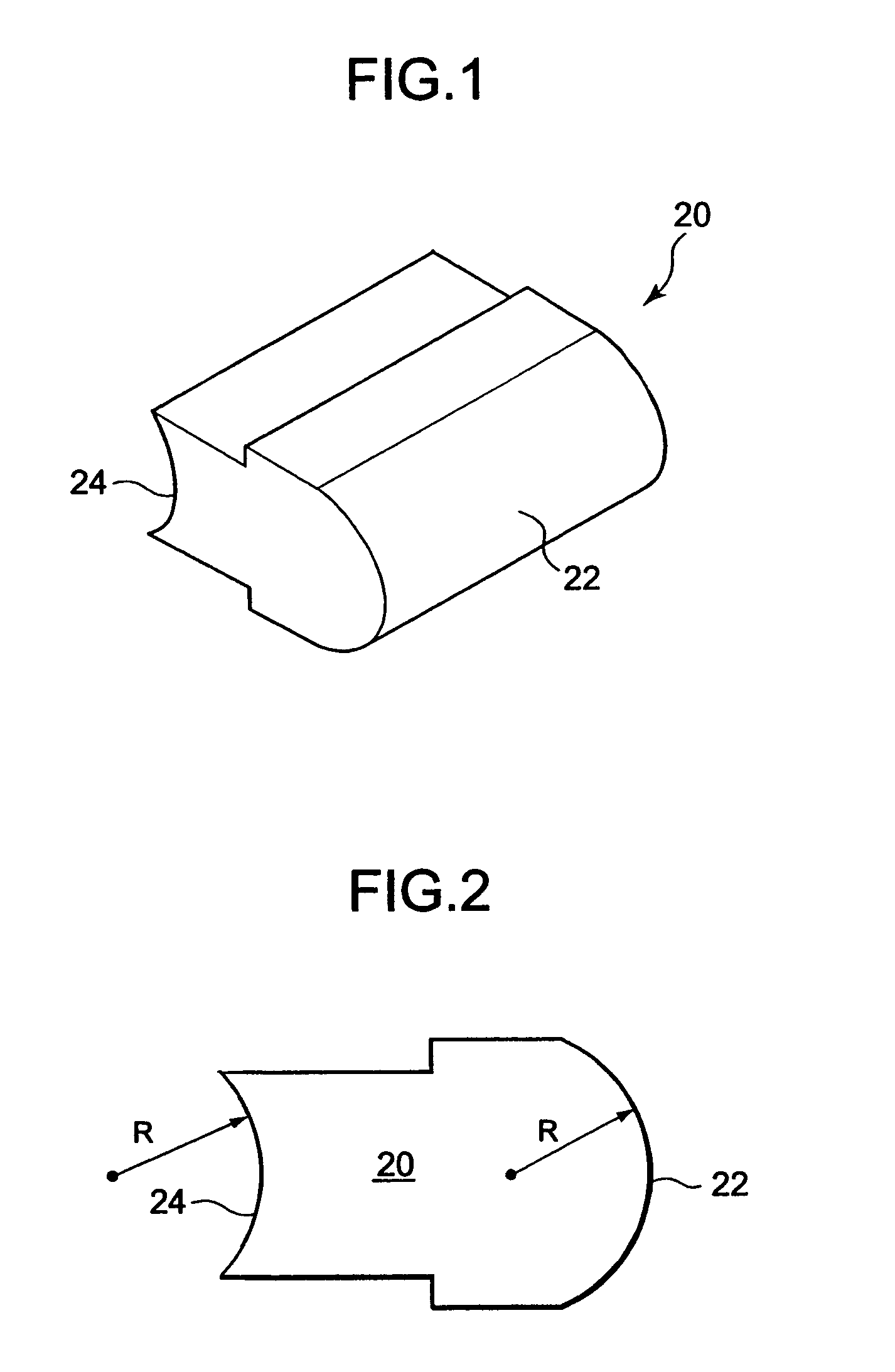

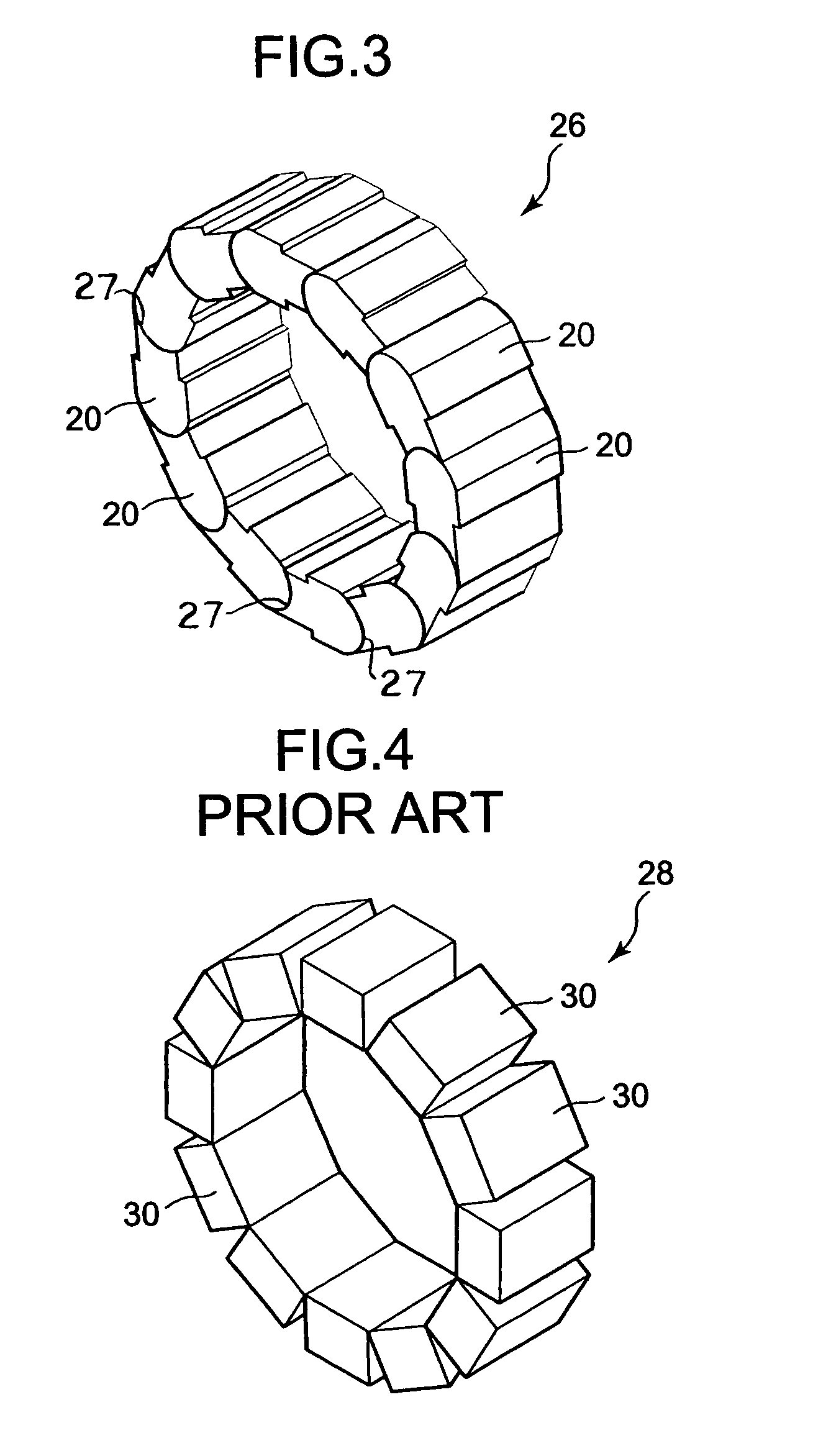

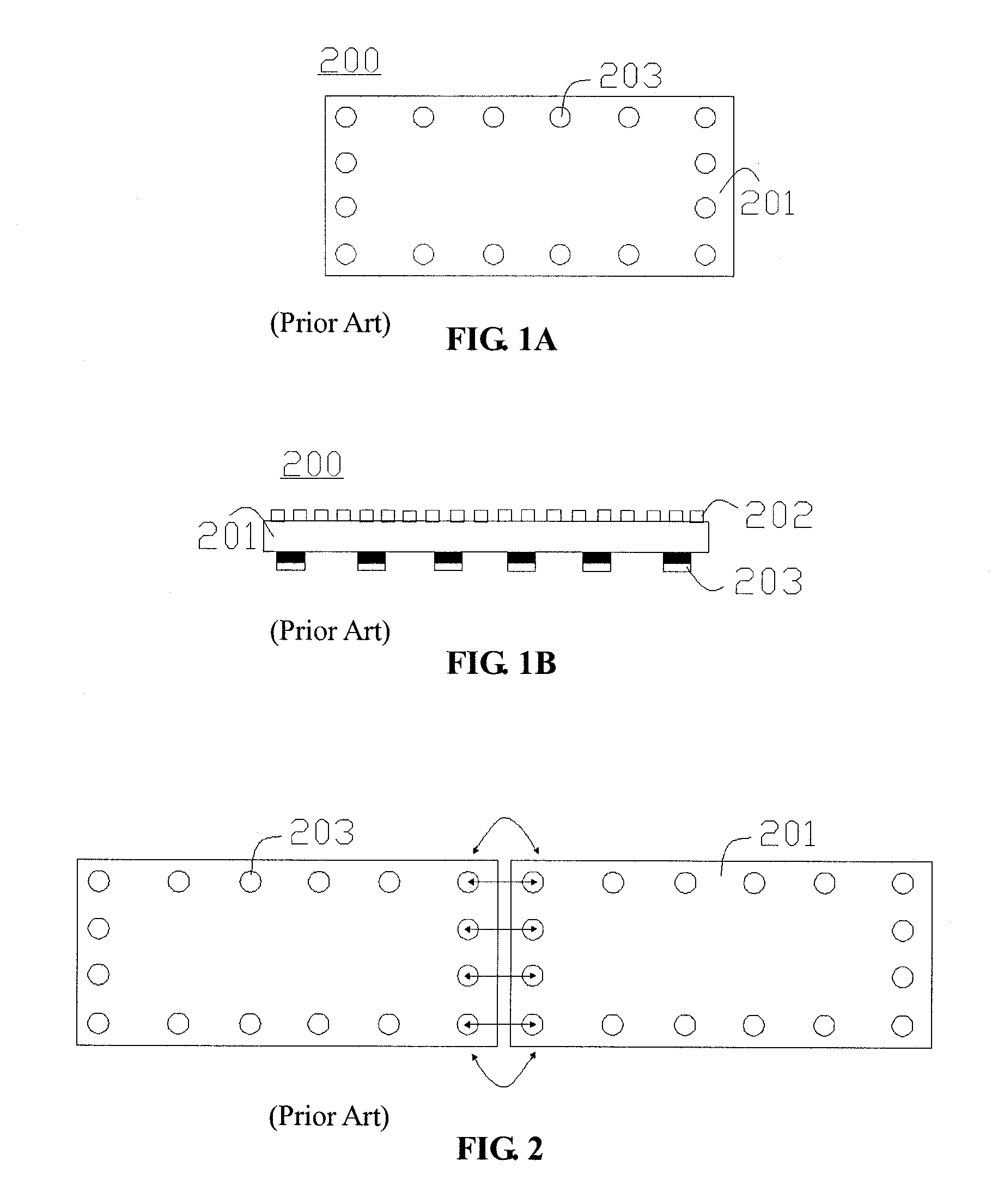

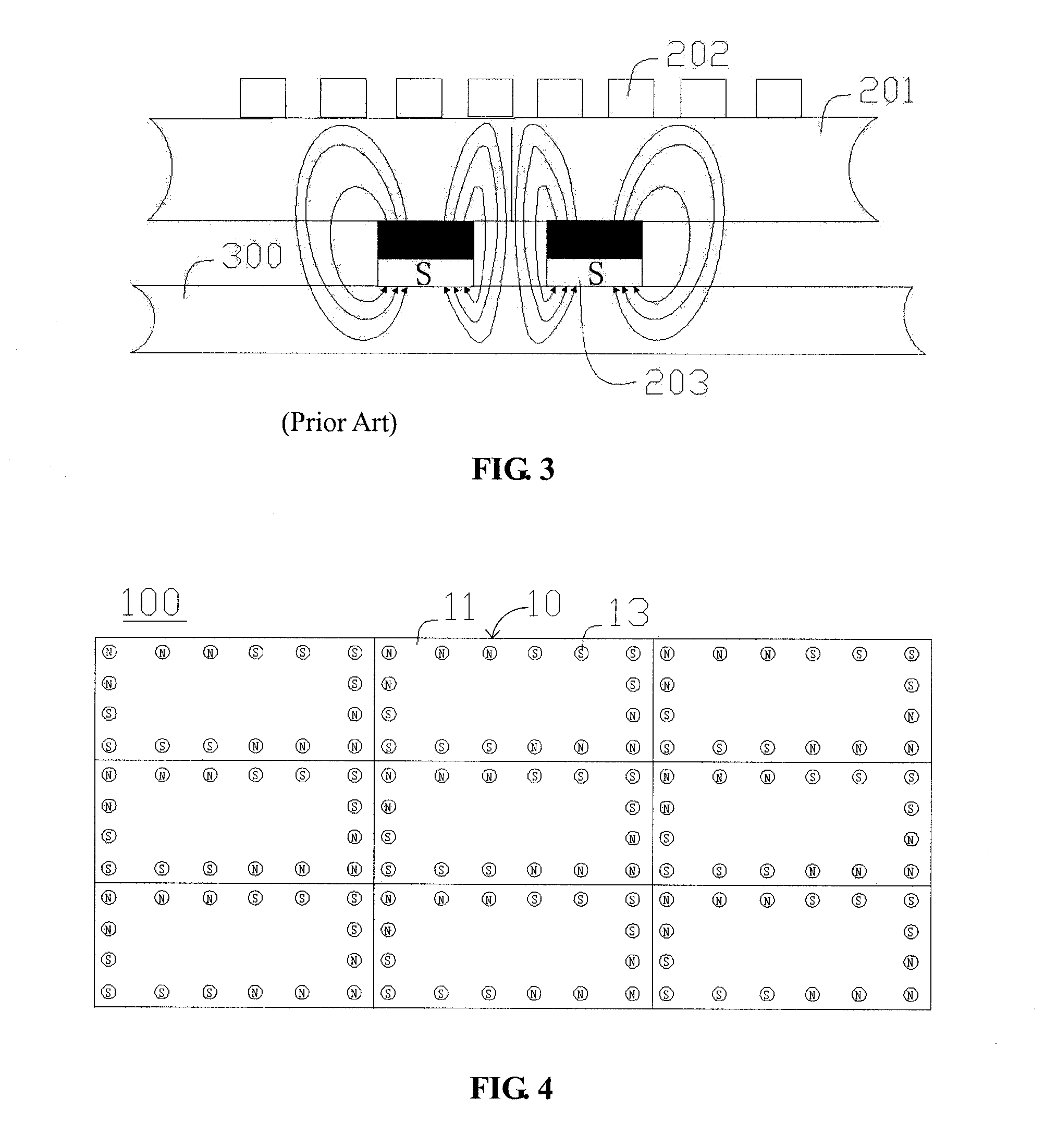

Ferrite core, and flexible assembly of ferrite cores for suppressing electromagnetic interference

InactiveUS20050285708A1EMI suppressionGap minimizationTransformers/inductances casingsTransformers/inductances magnetic coresElectromagnetic interferenceEngineering

Ferrite cores are provided with rounded, convex head ends and complimentary rounded, concave tail ends. The configuration of the head and tail ends permits a reduction in gap width between adjacent cores when they are joined together into a core assembly that suppresses electromagnetic interference emitted from a cable.

Owner:IBM CORP

Ferrite core, and flexible assembly of ferrite cores for suppressing electromagnetic interference

InactiveUS7138896B2Gap minimizationGapTransformers/inductances casingsTransformers/inductances magnetic coresElectromagnetic interferenceEngineering

Ferrite cores are provided with rounded, convex head ends and complimentary rounded, concave tail ends. The configuration of the head and tail ends permits a reduction in gap width between adjacent cores when they are joined together into a core assembly that suppresses electromagnetic interference emitted from a cable.

Owner:INT BUSINESS MASCH CORP

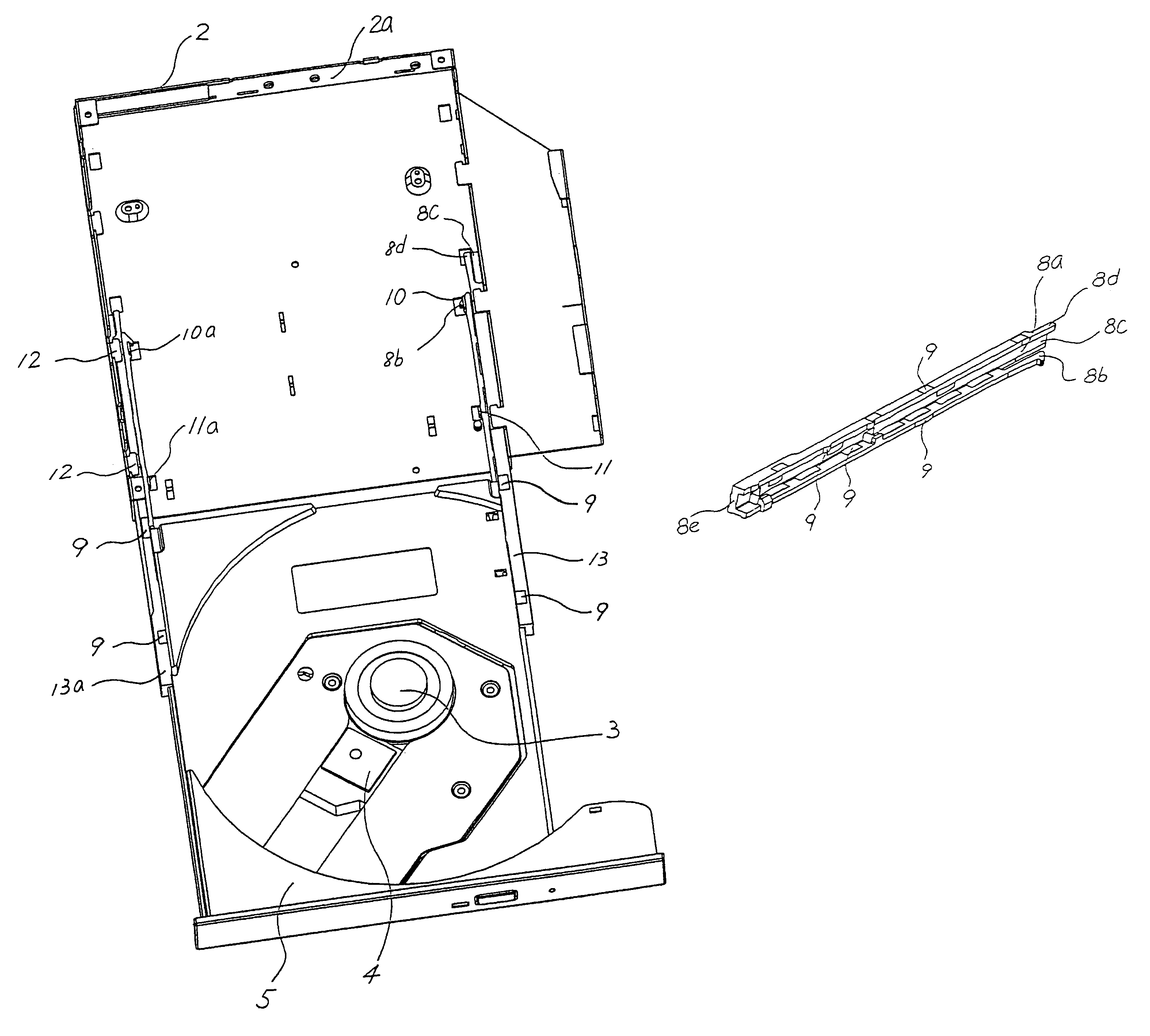

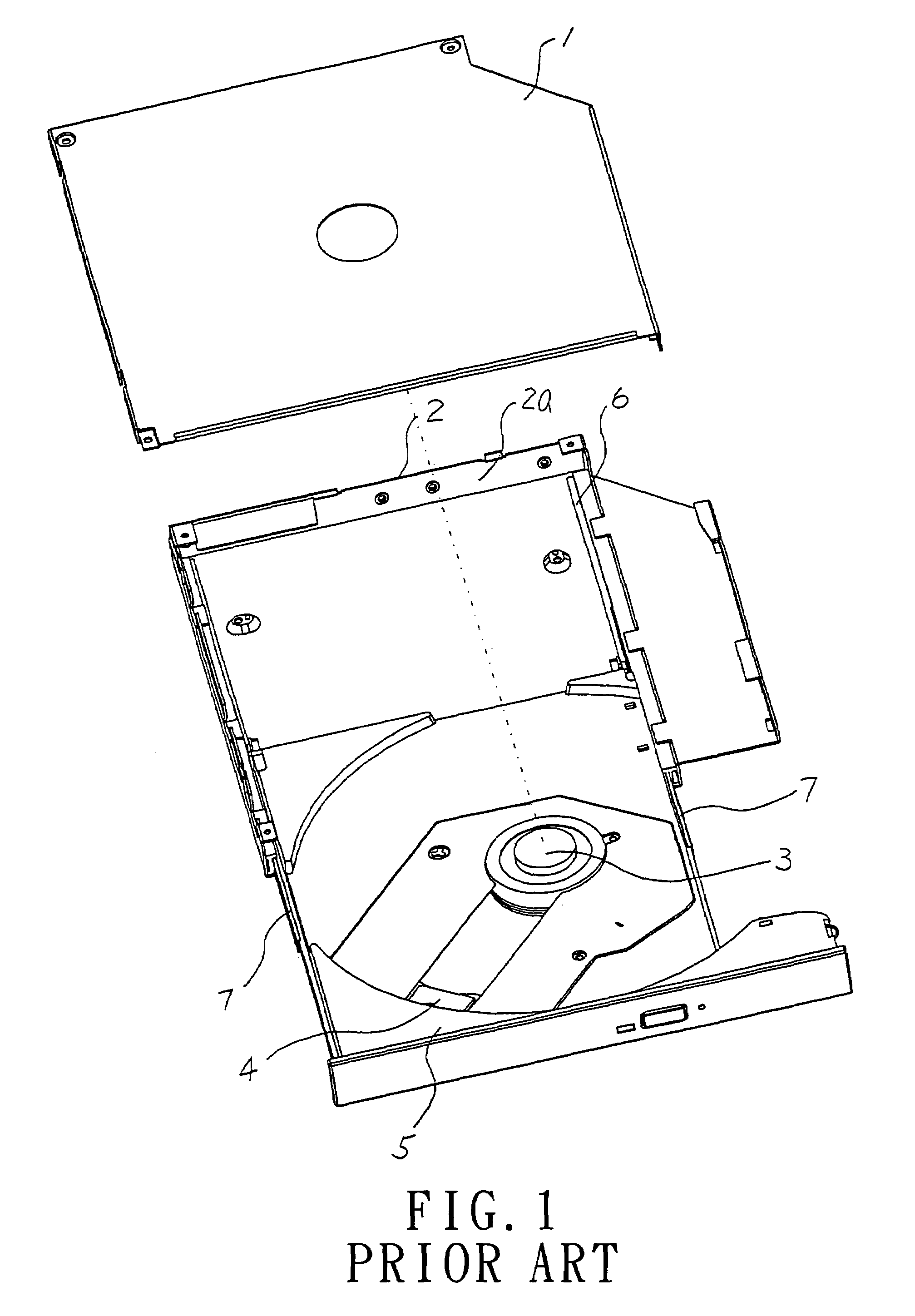

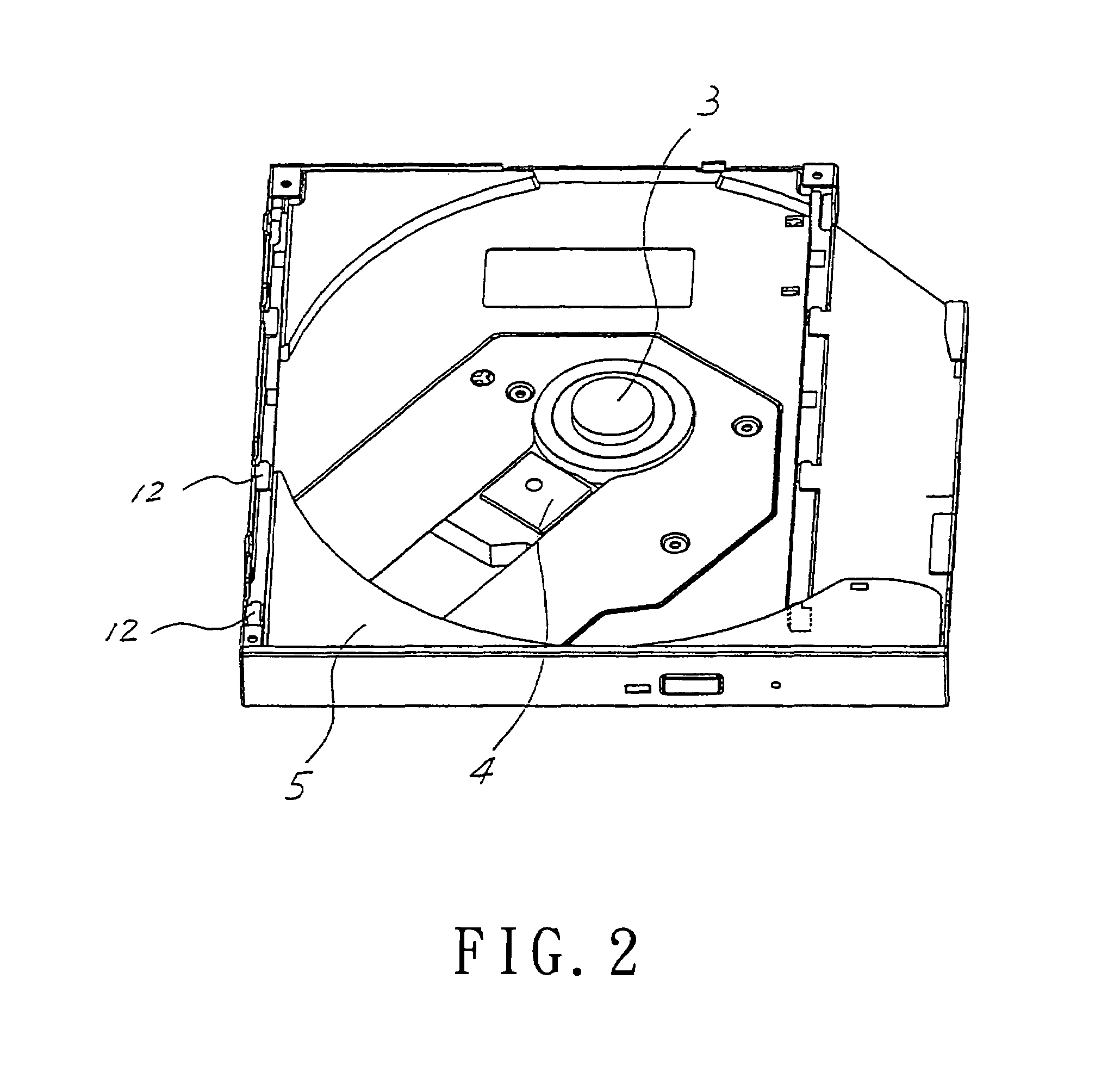

Sliding mechanism for optical compact disk drive

InactiveUS7140029B2Reduce frictionReduce slipRecord information storageRecord carrier contruction detailsEngineeringSpherical shaped

A sliding mechanism for an optical compact disk drive includes right and left slide tracks respectively mounted at opposite sides of a tray of the optical compact disk drive. A plurality of bulbous contacts are formed on the right and left slide tracks respectively to fit with a plurality of retaining portions of a lower cover of the optical compact disk drive. By respectively having the bulbous contacts in point to point contact with the corresponding retaining portions, the tray smoothly moves in a stable manner between its outermost and innermost positions. A slide body of each slide track is provided with a hook, a protection piece and a fastening piece to hold the tray at its outermost or innermost positions. Thereby, the stability and effectiveness of the optical compact disk drive assembled with the sliding mechanism of the invention is increased.

Owner:MICRO-STAR INTERNATIONAL

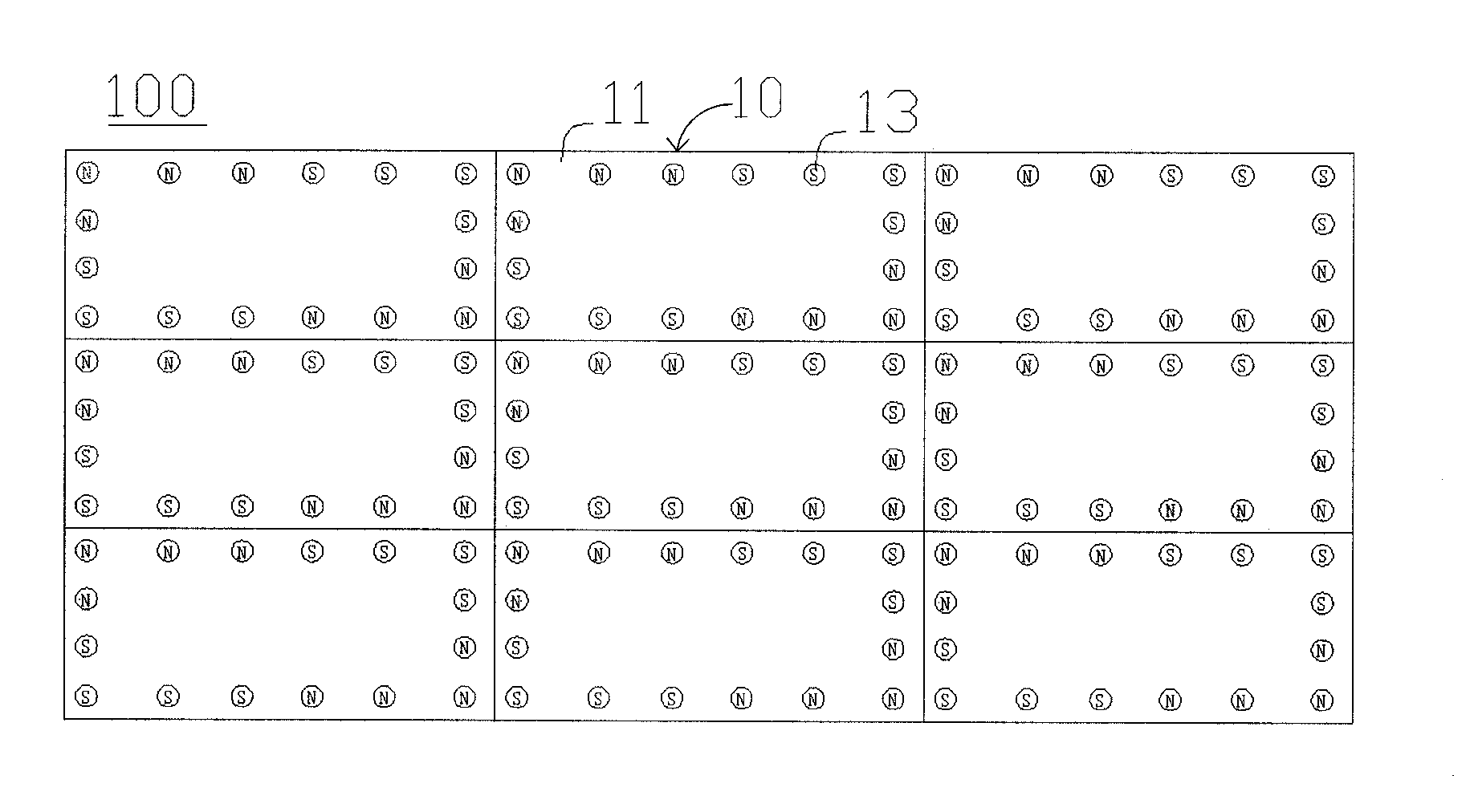

Flexible display screen

InactiveUS20100265668A1Quality improvementImprove visualizationPrinted circuit aspectsPrinted circuit manufactureFlexible circuitsFlexible display

A flexible display screen includes a plurality of flexible display modules joined side by side, each flexible display module having a flexible circuit board, which is fixedly arranged with a plurality of display chips on its front face, and a plurality of magnets on its back face, so that the flexible display screen can be attracted on a metal medium by the magnets, wherein the magnets are distributed at least on the perimeter of the back face of the flexible circuit board so that the joining sides of two adjoining flexible circuit boards are arranged respectively and symmetrically with a same number of magnets, and each pair of magnets disposed on the respective joining sides having opposite polarity orientations.

Owner:YUEN RONALD SIK HUNG +2

Capacitive touch panel

InactiveUS20110102367A1Improve color uniformityImprove display qualityInput/output processes for data processingSubstrate surfaceTouch panel

A capacitive touch panel including a transparent substrate, a plurality of first sensing wires, a plurality of second sensing wires and an insulation layer is provided. The transparent substrate has a substrate surface. The first sensing wires are disposed on the substrate surface along a first axis direction. The second sensing wires include a plurality of bridge wires and a plurality of sensing units. The sensing units are disposed on the substrate surface along the second axis direction. The insulation layer is disposed on the substrate surface, covers the first sensing wires, and has a plurality of through holes. The through holes correspondingly expose the sensing units. Each bridge wire strides the insulation layer to electrically connect two of the sensing units.

Owner:TRANSTOUCH TECH

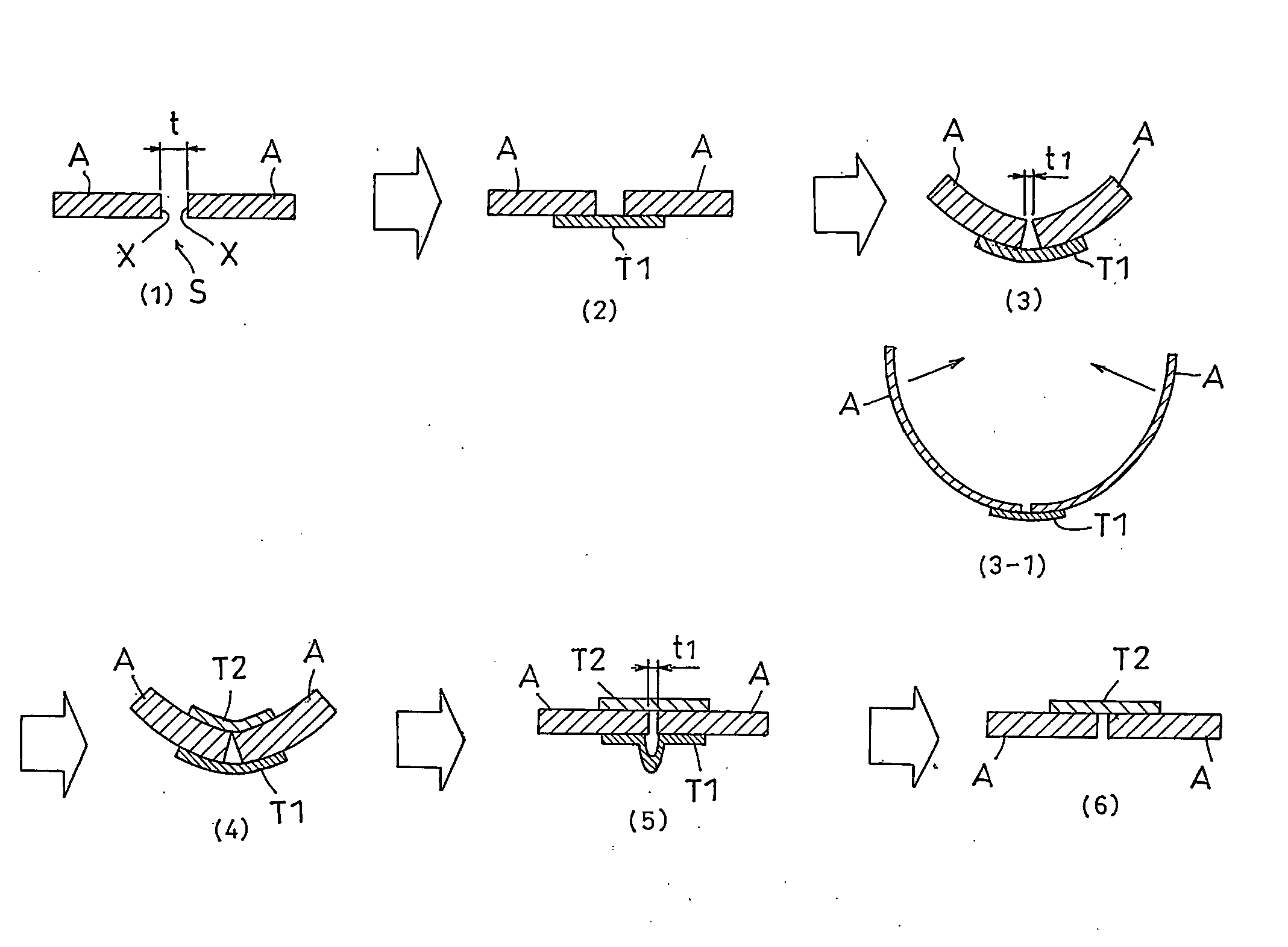

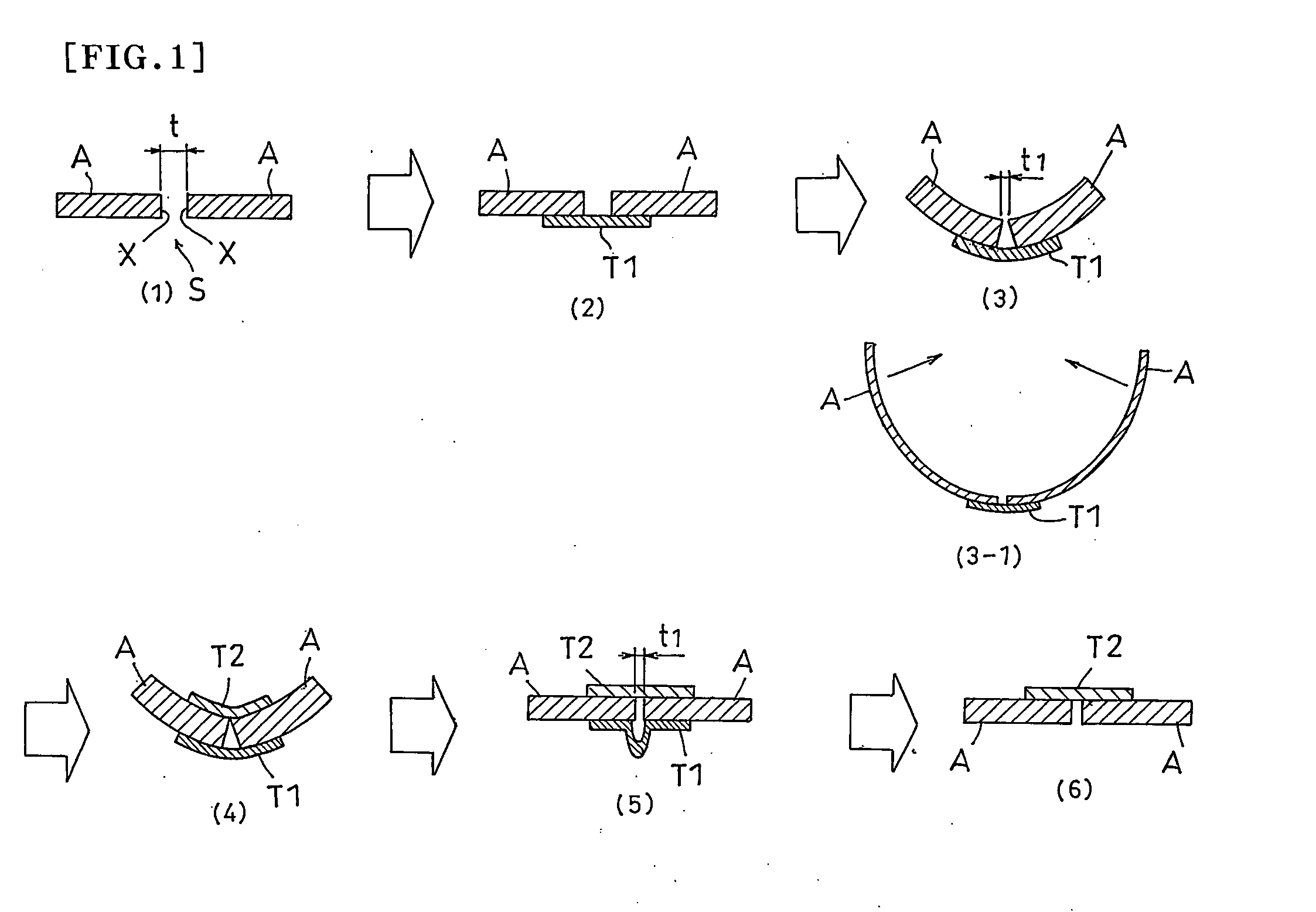

Method and apparatus for producing combined optical film, combined optical film, image display, and methods for producing liquid crystal panel and laminated optical film

InactiveUS20080099128A1Efficient implementationEasy to transportLaminationOptical articlesEngineeringOptical thin film

It is an object of the invention to provide a method for producing a combined optical film that includes opposing the end faces of a plurality of optical films to one another and can narrow the gap between the opposed end faces. A method for producing a combined optical film comprising a plurality of optical films each having at least one end face at which the optical films are opposed to one another, comprising the steps of: (1) opposing the end faces of the optical films to one another with a gap provided therebetween; (2) bonding a first seal material to the opposed portions of the optical films on a first side of each optical film to join the optical films; (3) bending the joined opposed portions of the optical films such that the joined opposed portions become concave on a second side of each optical film where the first seal material is not bonded and such that the gap is narrowed on the second side; (4) bonding a second seal material to the opposed portions on the second side, while the joined optical films are bent such that the gap is narrowed on the second side; and (5) cancelling the bending of the joined optical films to make them flat.

Owner:NITTO DENKO CORP

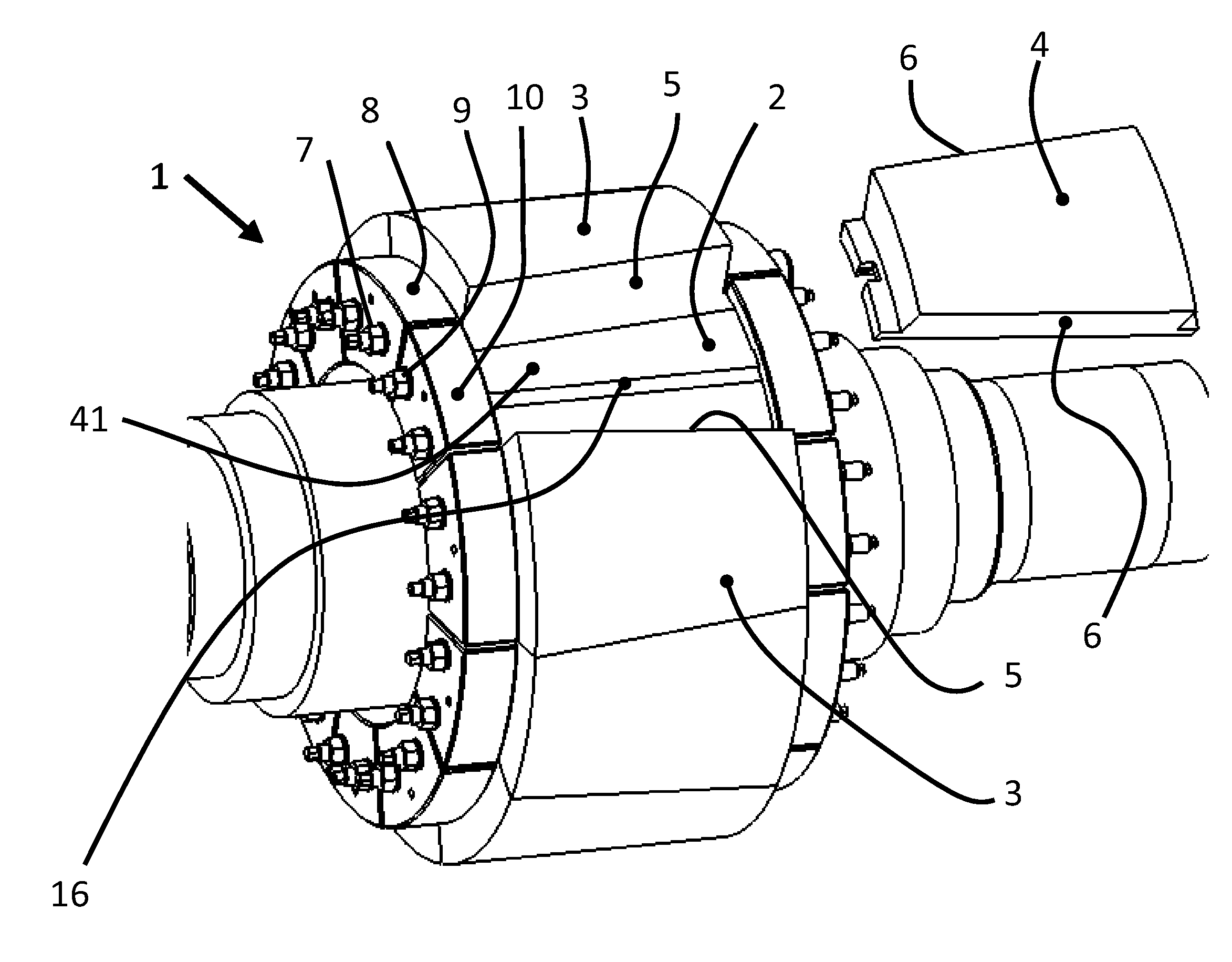

Crushing roller

InactiveUS20140158801A1Minimize and eliminate gapExtended service lifeMetal-working apparatusCocoaEngineeringParticulate material

Described is a roller for crushing of particulate material, such as crude ore for use in the mineral industry, where the roller body is provided with a roller shell having a plurality of individual wear segments. The roller shell is characterized in that adjacent wear segments have complementary sides and in that a number of the wear segments, prior to mounting of the remaining wear segments, are initially fixed to the roller body in order to provide guiding and fixation for the remaining wear segments which are wedged-in between the number of initially fixed wear segments.

Owner:FLSMIDTH AS

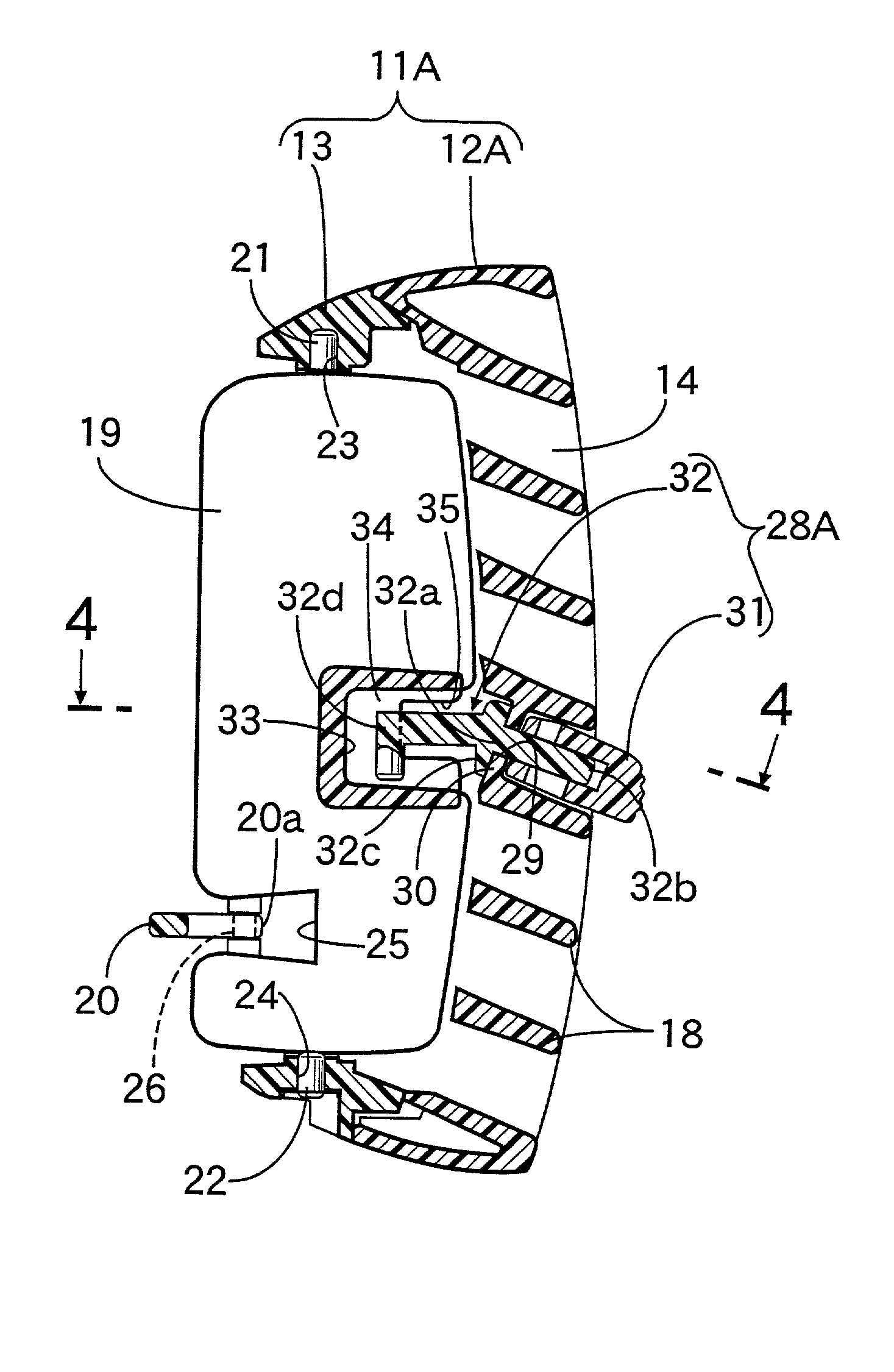

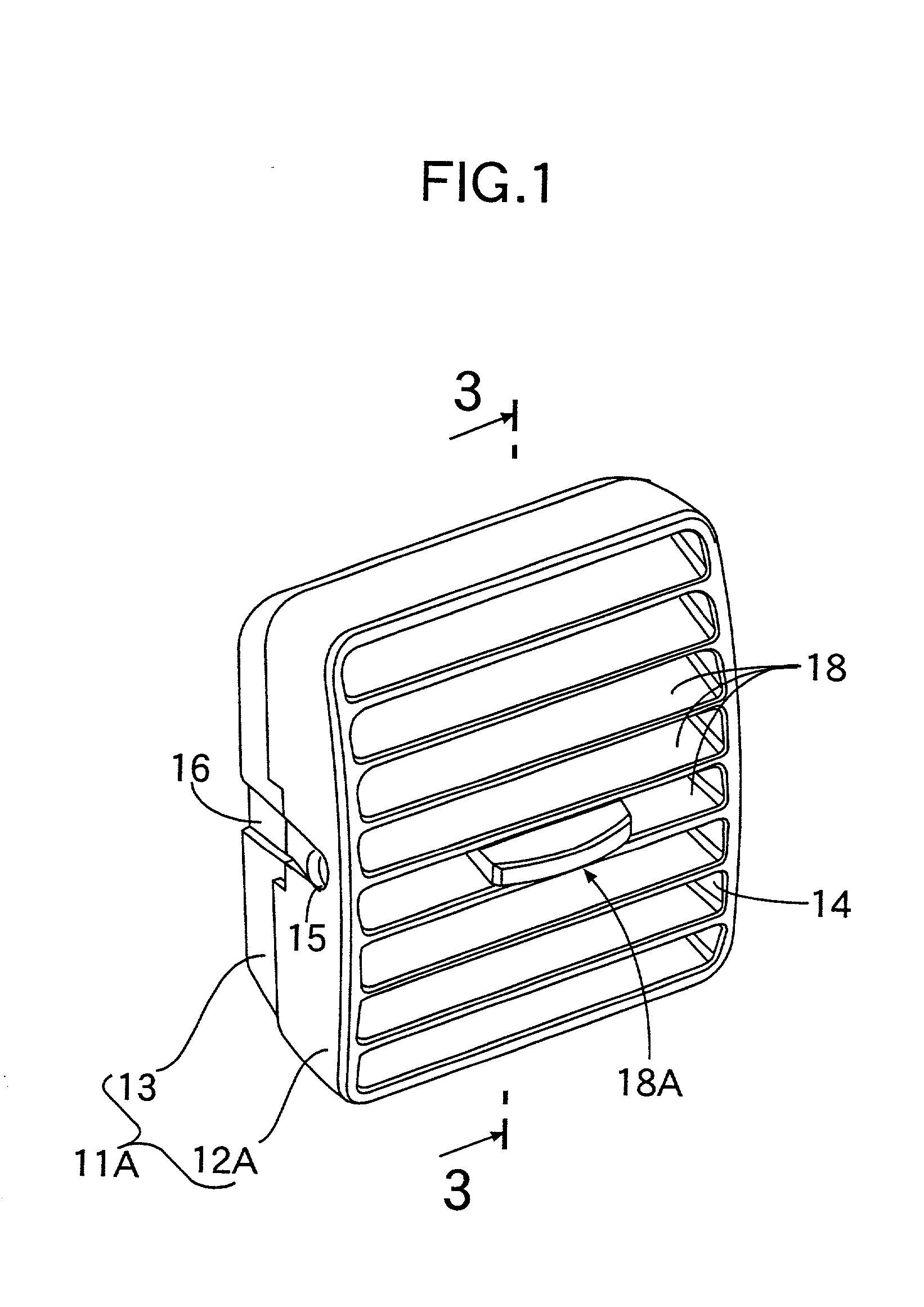

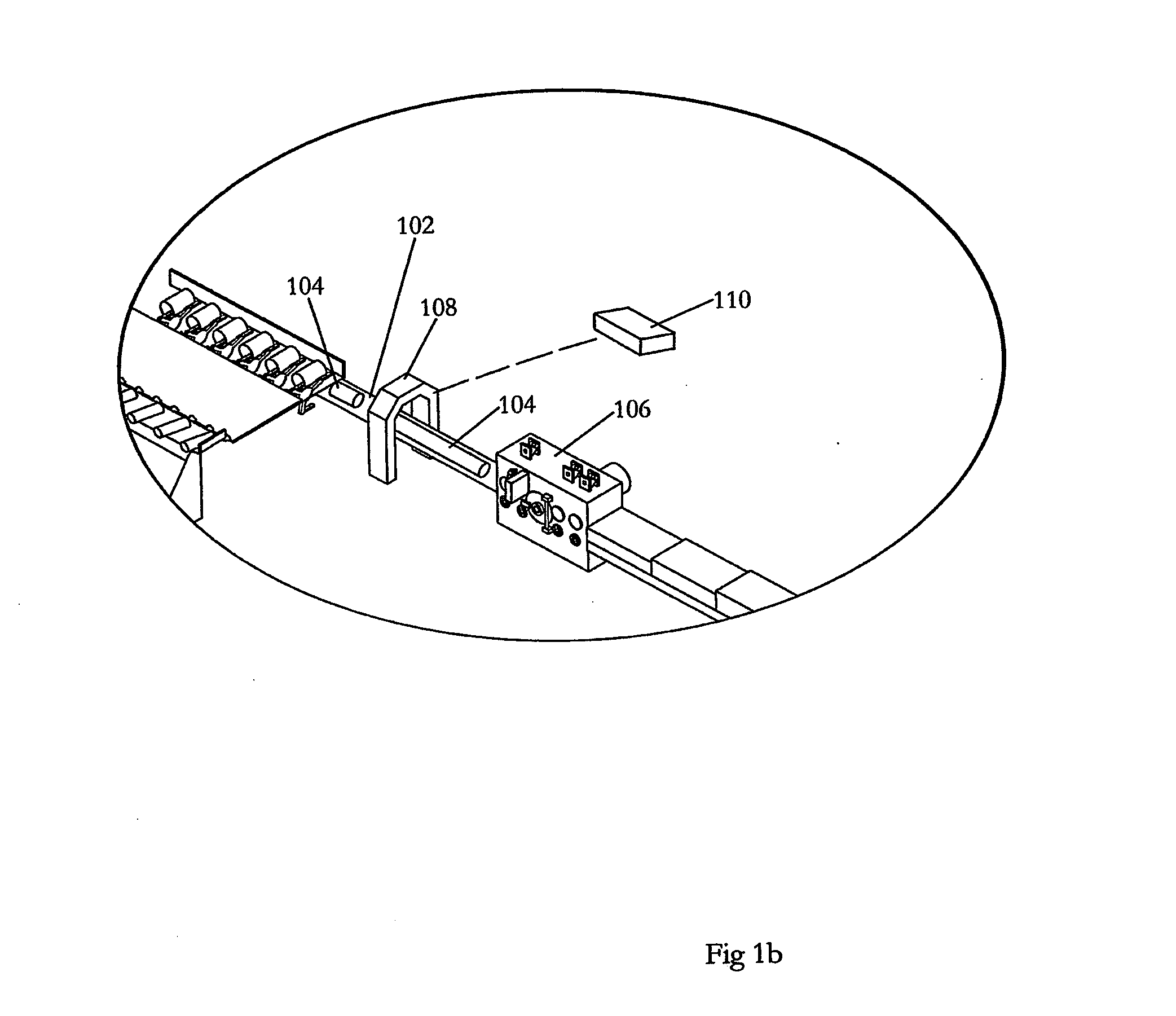

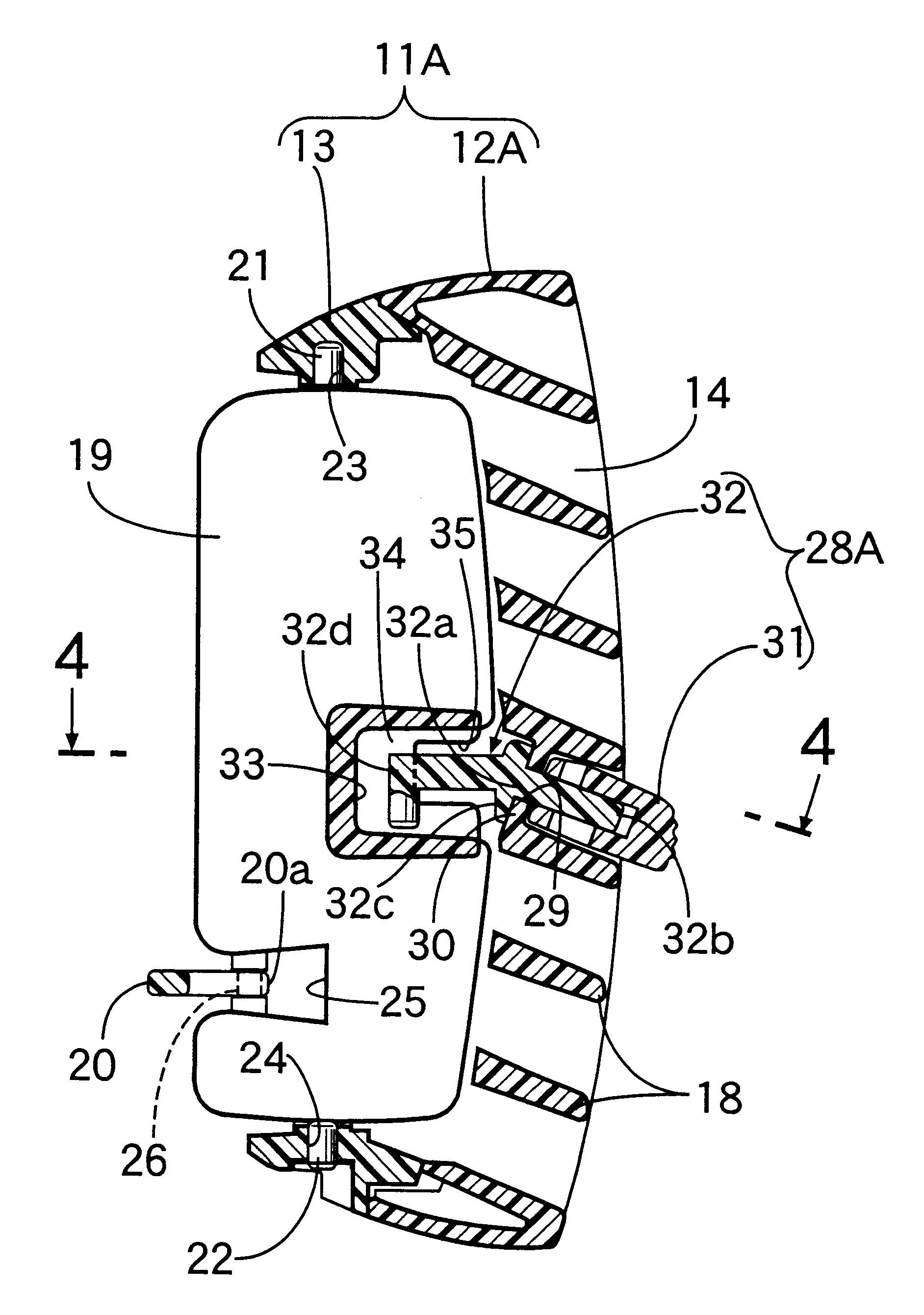

Air conditioner outlet vent device

InactiveUS20020025774A1Increase air volumeLower performance requirementsDucting arrangementsAir-treating devicesEngineeringBlow out

In an air conditioner outlet vent device in which a plurality of second blades are arranged behind a plurality of first blades in a direction perpendicular to the direction in which the first blades are arranged. The second blades are linked to a common link member, supported in a housing in a pivotable manner, and can be pivoted by an operating knob that can slide in the direction in which the second blades are arranged. A cut out recess opening toward the first blades and a pair of covers covering opposite sides of the cut out recess are provided on one of the second blades, and an engaging arm provided on the operating knob is inserted into the cut out recess so that the engaging arm can engage with one of the two covers. It is possible thereby to increase the amount of air blown out, and to enhance the air directing performance by making the gaps between the second blades relatively small.

Owner:MORIROKU

Display device

A display device includes: a display part containing a first display region visually recognized by a viewer; an object of view arranged in a second display region; an imaging optical system of real specular image for defining a first space in which the first display region exists and a second space in which the second display region exists, the imaging optical system of real specular image including a semitransparent substrate with a plane of symmetry, the imaging optical system of real specular image forming a real image of the object of view in the first space of the first display region with light passing through the substrate; and a half mirror arranged in the first space of the first display region, the half mirror reflecting light beams emitted from the imaging optical system of real specular image to guide the reflected light beams to the viewer, while allowing an image formed in the first display region to be seen by the viewer.

Owner:STANLEY ELECTRIC CO LTD

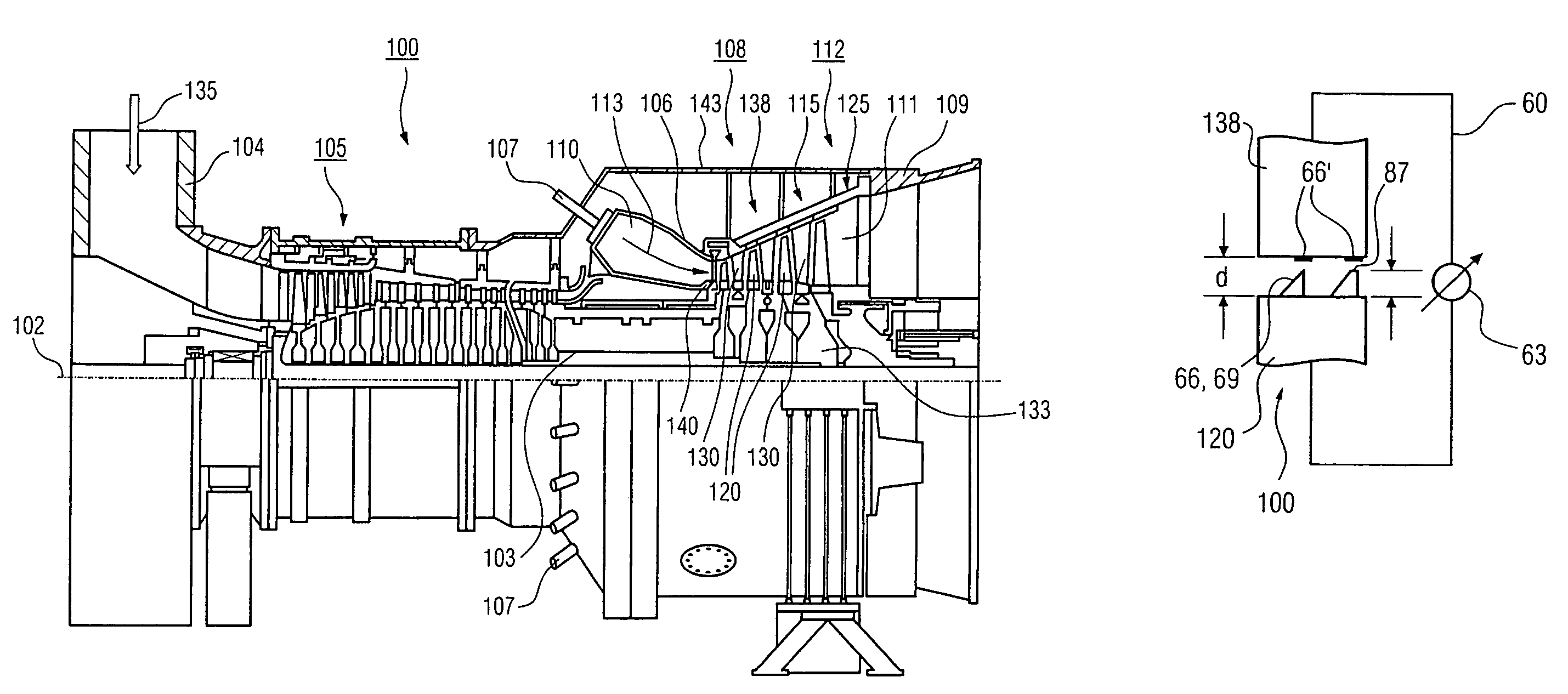

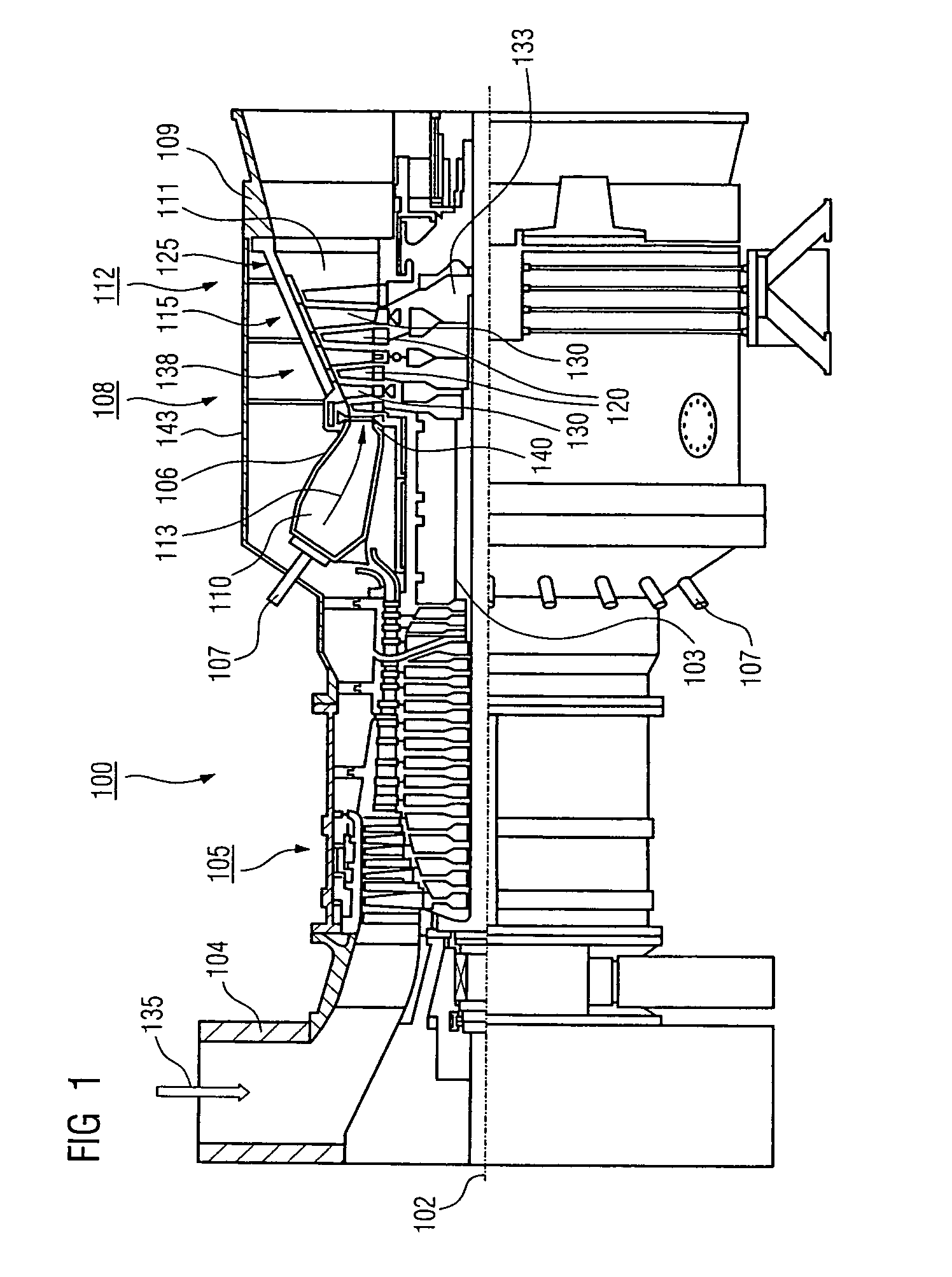

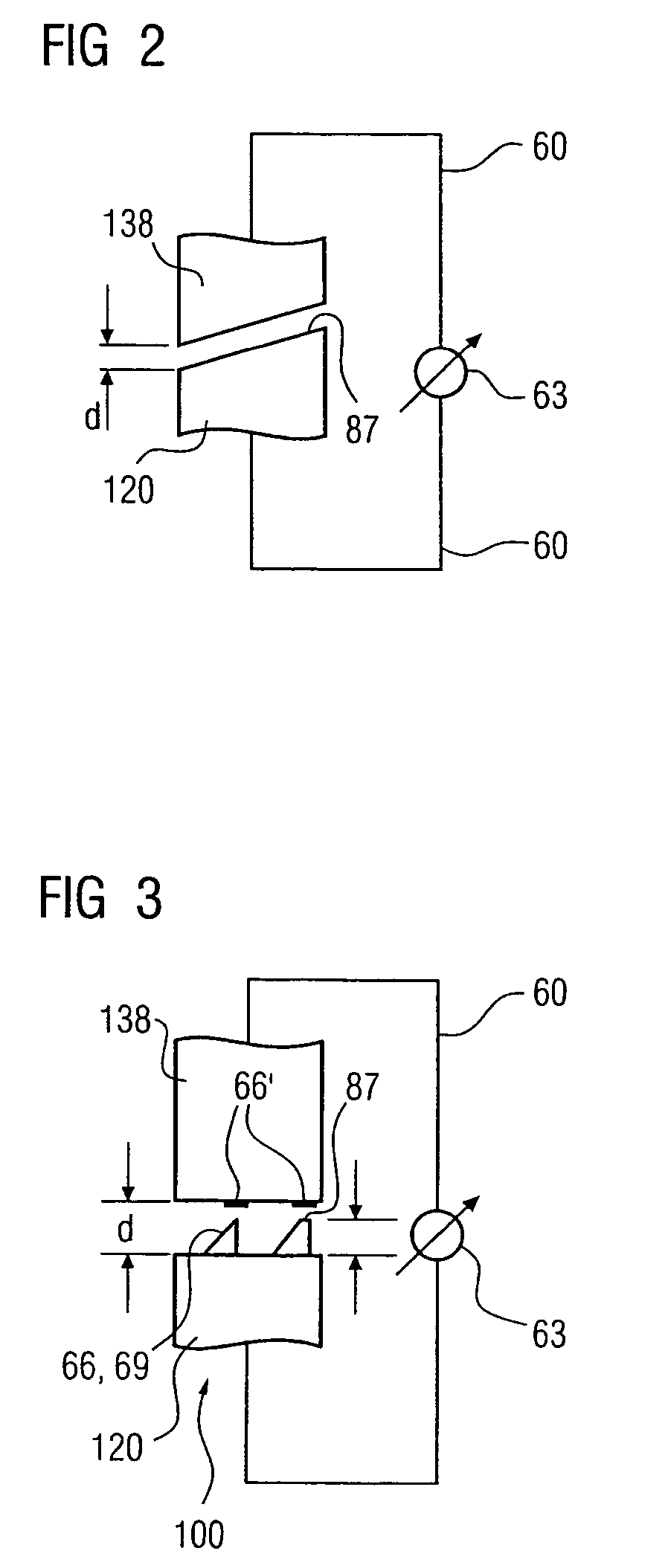

Method of minimizing the gap between a rotating turbine blade and a casing of a turbine, a turbine, and a method of determining the wear behavior of a wheel of a rotor

InactiveUS7018165B2GapGap minimizationPump componentsReaction enginesElectrical resistance and conductanceElectricity

Method of minimizing the gap between a wheel and a casing of a turbine, a turbine, and a method of determining the wear behavior of a wheel of a rotor. To minimize the gap between a wheel and a casing in a turbine, optical methods are also often used in order to minimize the gap. However, this is very expensive. The method according to the invention proposes that the wheel and the casing (be part of an electric circuit, so that an electrical parameter, such as resistance for example, can be measured, the value of which shows whether a contact is present.

Owner:SIEMENS AG

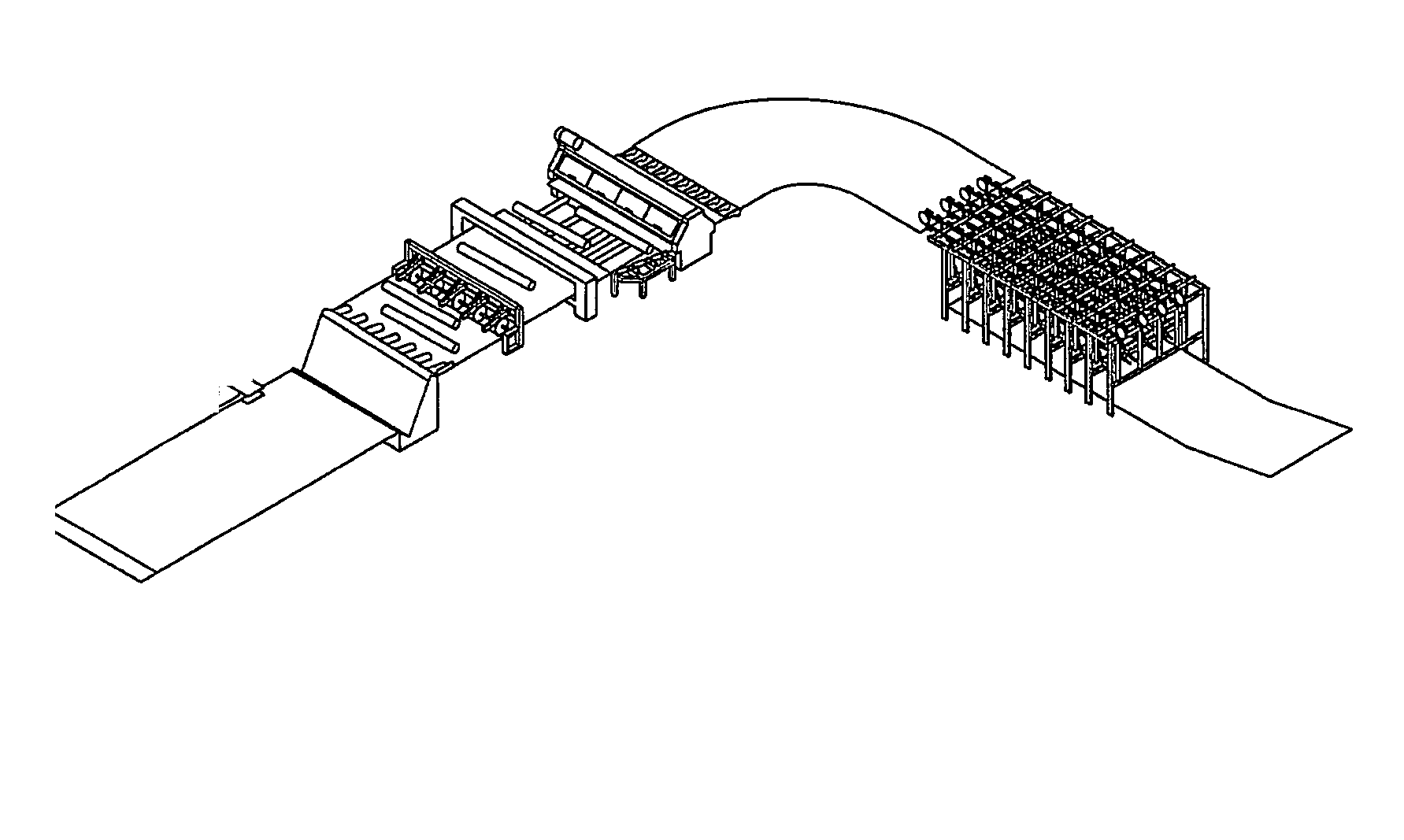

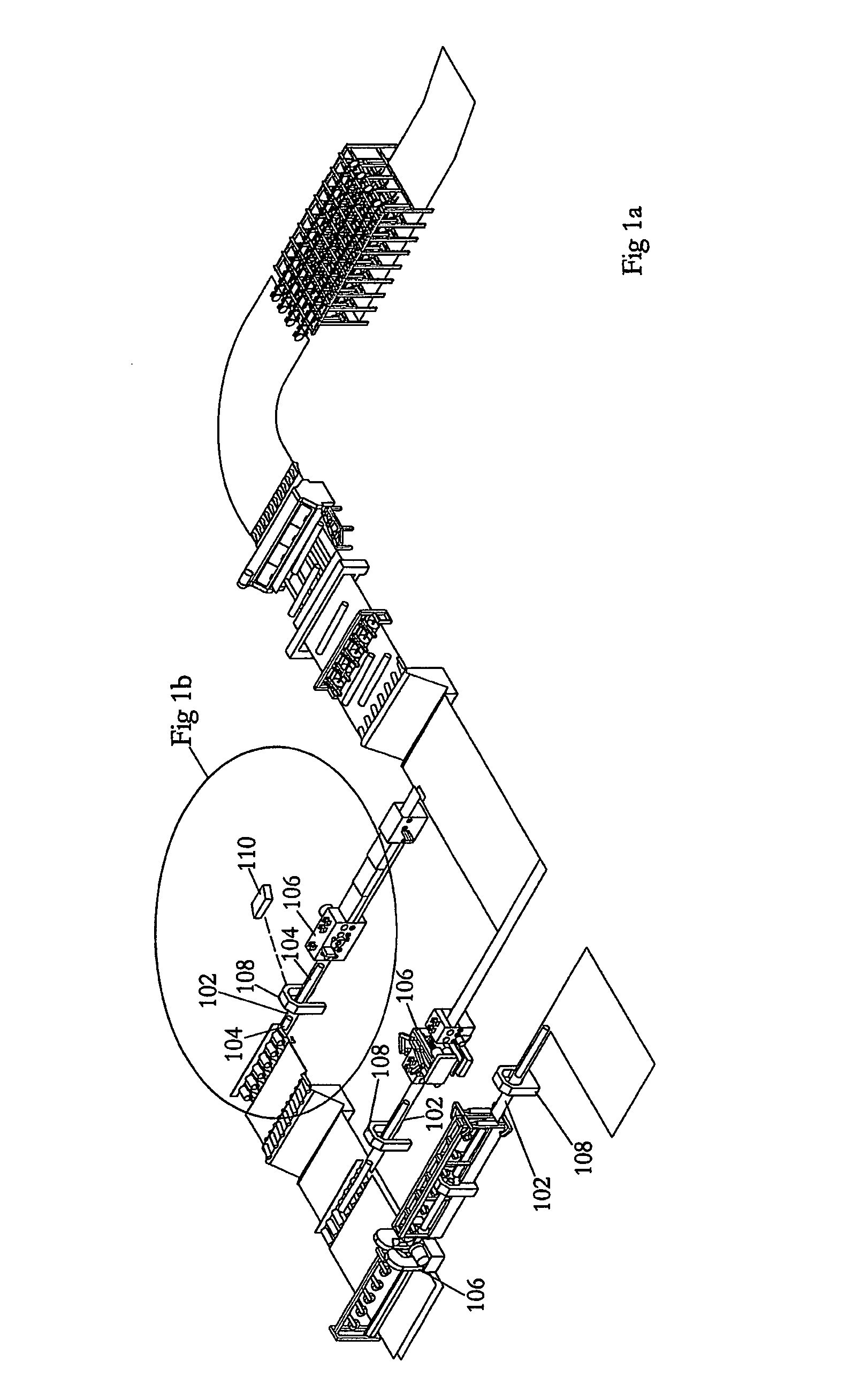

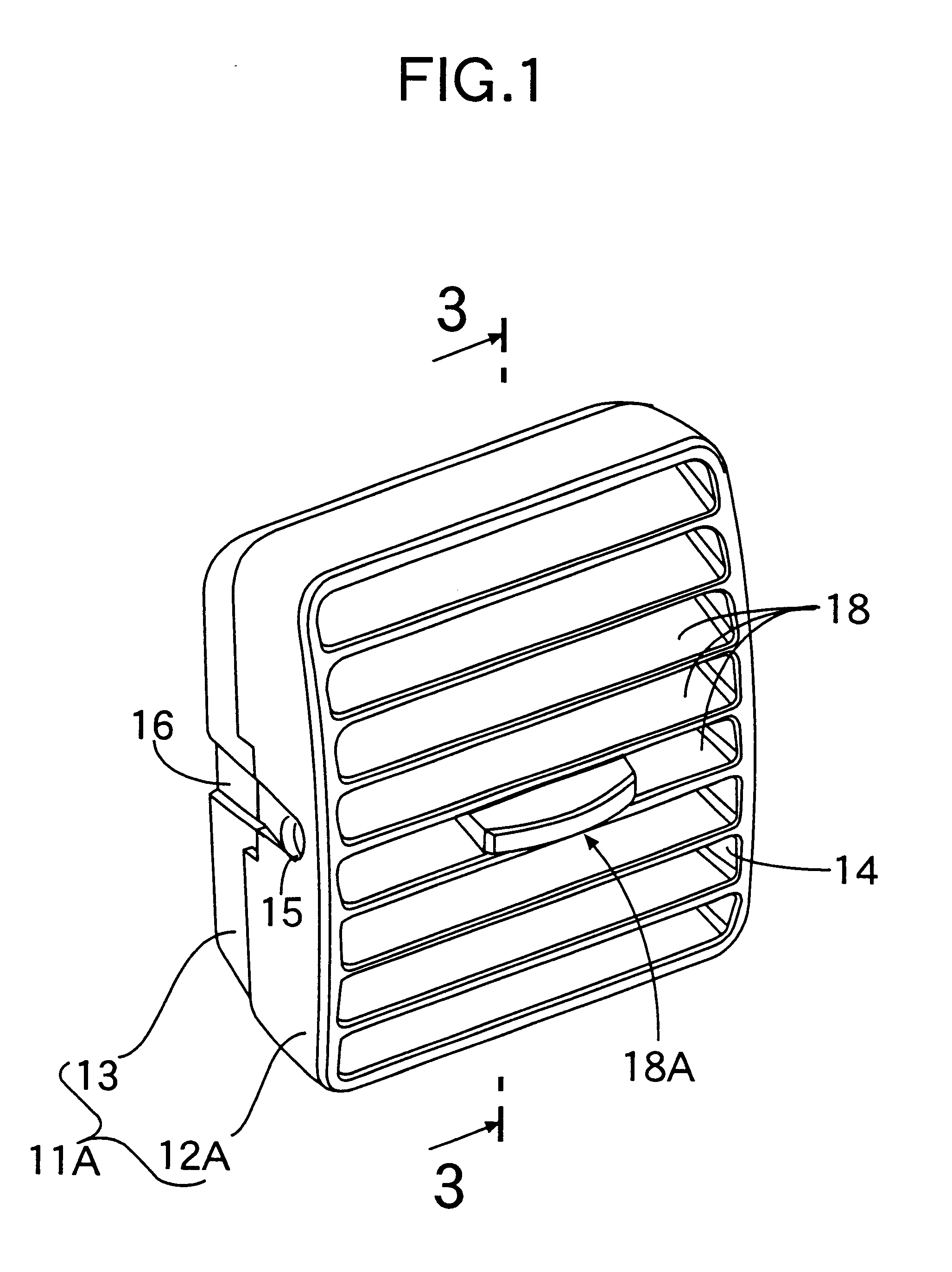

Method of optimizing processing of successive workpieces through cutting machines

InactiveUS20060219071A1Reduce gapGapAdjusting equipmentMetal working apparatusSufficient timeEngineering

A method of optimizing processing of successive workpieces through cutting machines, includes the steps of determining and optimizing a first cut pattern for a preceding workpiece infeeding into an active cutting device, determining and optimizing a second cut pattern for a succeeding workpiece succeeding the preceding workpiece infeeding into the cutting device, synchronizing the preceding workpiece with the active cutting device such that the active cutting device is pre-positioned to achieve an optimized first cut pattern of the preceding workpiece prior to the preceding workpiece engaging the active cutting device, processing through the cutting device the preceding workpiece according to the first cut pattern; adjusting an infeed gap between the preceding workpiece and the succeeding workpiece so that the active cutting device has sufficient time to pre-position to achieve the optimized second cut pattern of the succeeding workpiece prior to the active cutting device engaging the succeeding workpiece.

Owner:USNRKOCKUMS CANCAR

Air conditioner outlet vent device

InactiveUS6497616B2Increase air volumeLower performance requirementsDucting arrangementsAir-treating devicesEngineeringBlow out

In an air conditioner outlet vent device in which a plurality of second blades are arranged behind a plurality of first blades in a direction perpendicular to the direction in which the first blades are arranged. The second blades are linked to a common link member, supported in a housing in a pivotable manner, and can be pivoted by an operating knob that can slide in the direction in which the second blades are arranged. A cut out recess opening toward the first blades and a pair of covers covering opposite sides of the cut out recess are provided on one of the second blades, and an engaging arm provided on the operating knob is inserted into the cut out recess so that the engaging arm can engage with one of the two covers. It is possible thereby to increase the amount of air blown out, and to enhance the air directing performance by making the gaps between the second blades relatively small.

Owner:MORIROKU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com