Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Expand the scope of safe work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

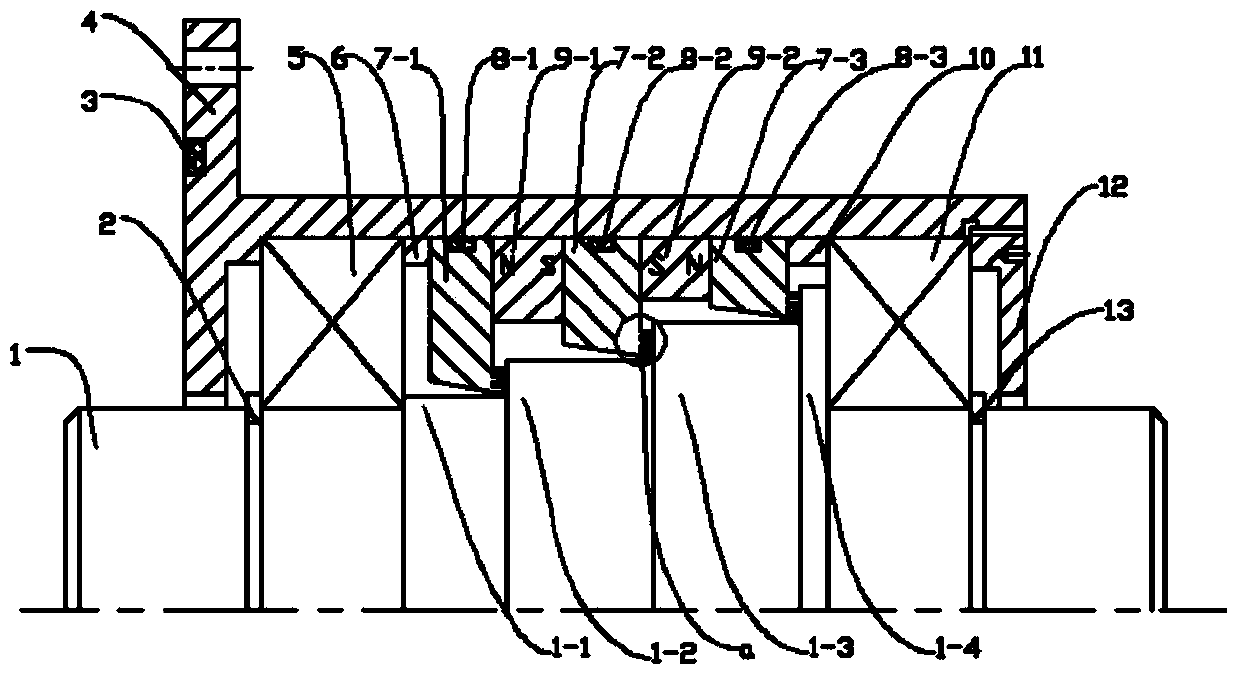

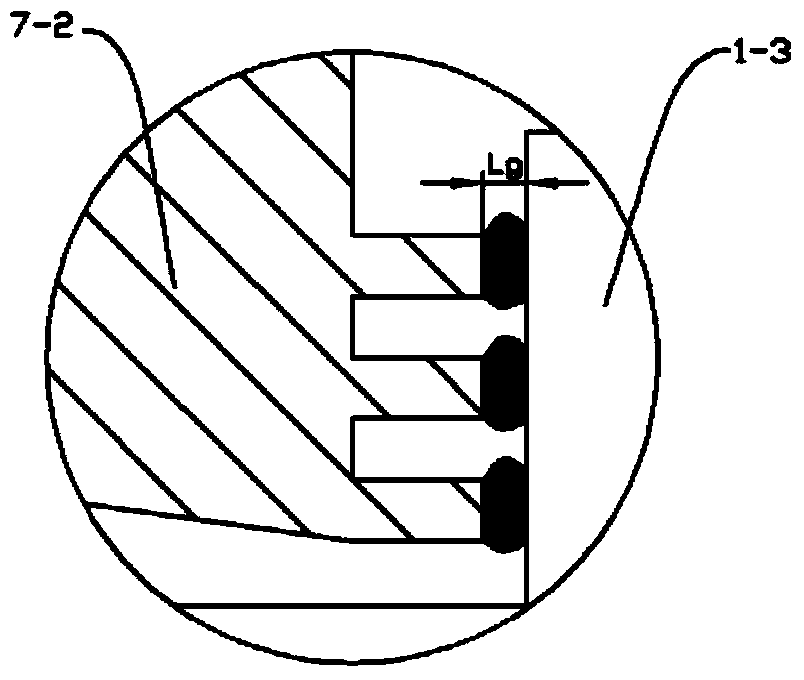

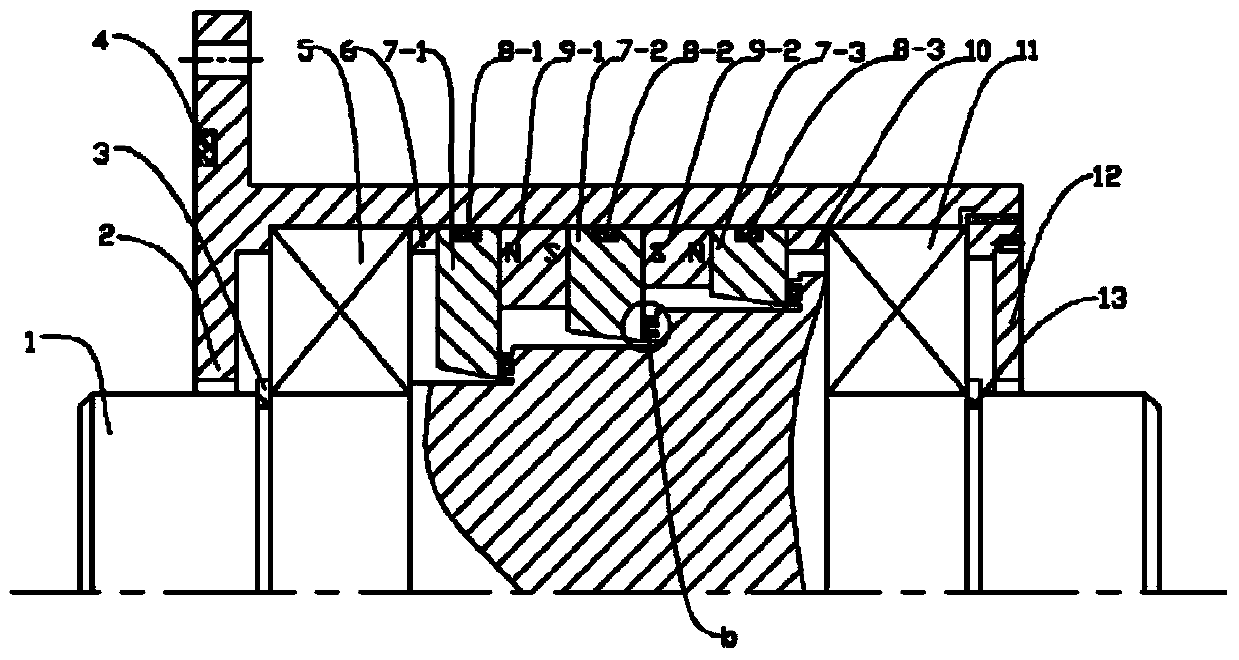

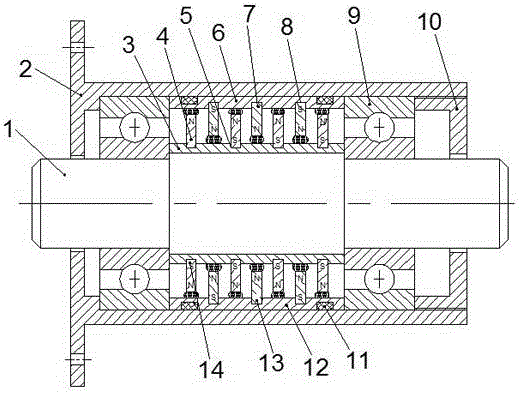

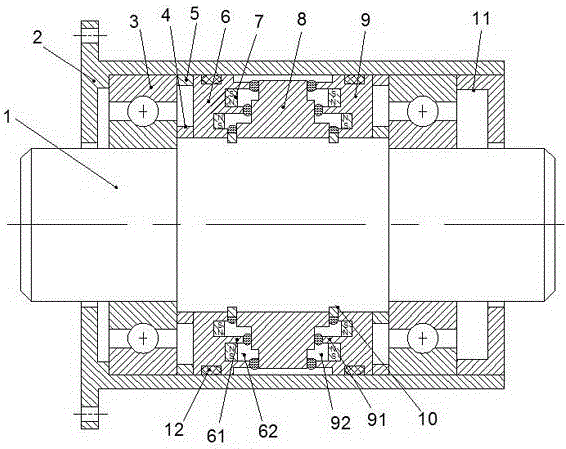

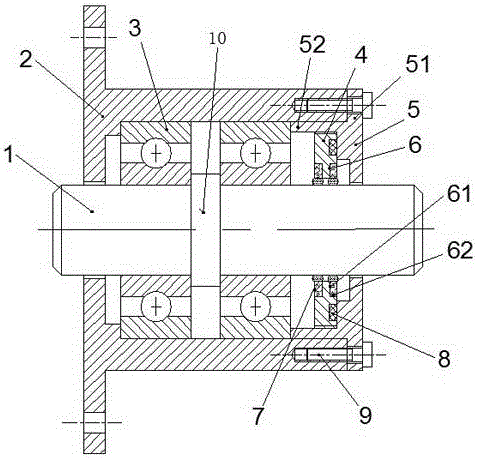

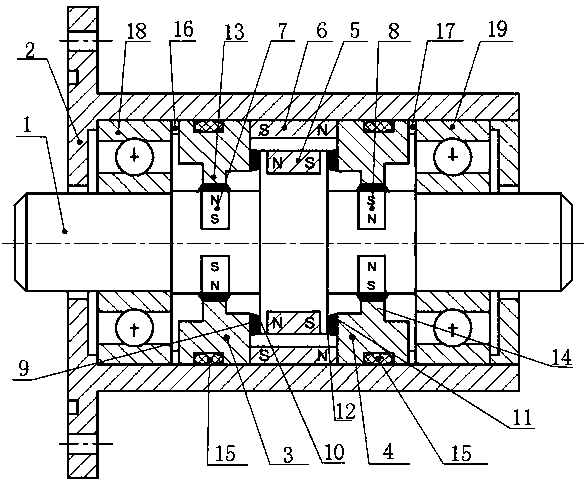

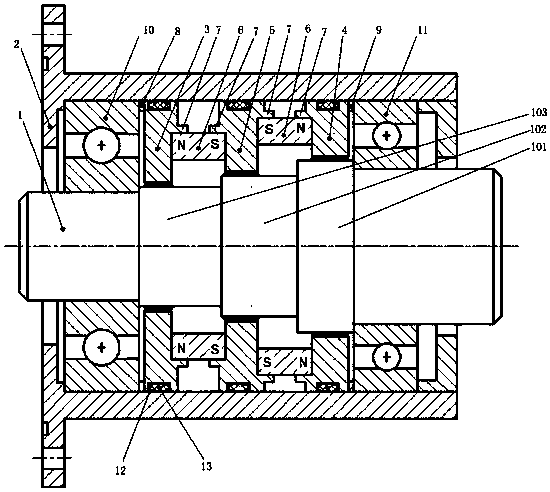

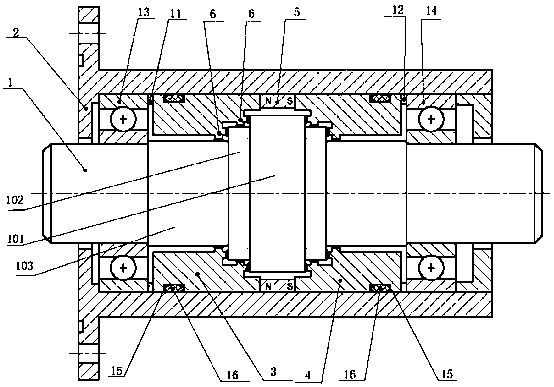

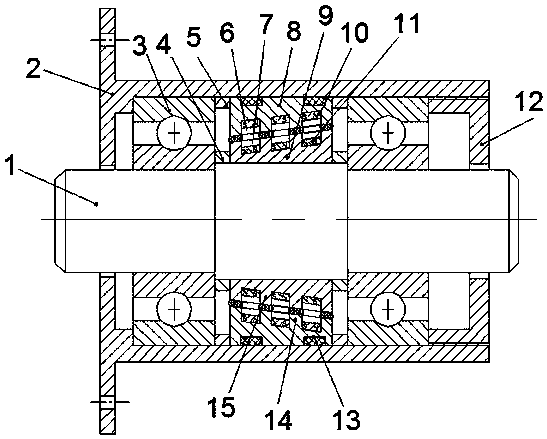

Sealing device for improving sealing anti-pressure capability and sealing reliability of magnetic liquid

InactiveCN103498939AOvercome the shortcomings of low sealing pressure resistanceImprove pressure resistanceEngine sealsMagnetic liquidsEngineering

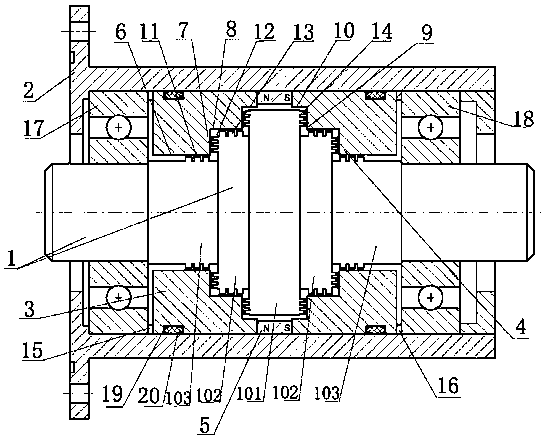

The invention provides a sealing device for improving the sealing anti-pressure capability and the sealing reliability of magnetic liquid, and belongs to sealing devices of rotating shafts. The problems that large-gap sealing is low in anti-pressure capability and poor in reliability are solved. A shaft of the sealing device is a step shaft, the right side face of a first pole shoe, the right side face of a second pole shoe and the right side face of a third pole shoe, or shaft shoulders of steps from the second to the fourth are provided with pole teeth, the axial gap widths of the pole shoes and the shaft shoulders are smaller than the radial gap widths between the pole shoes and the step shaft, and the sealing device for improving the sealing anti-pressure capability and the sealing reliability of the magnetic liquid is achieved. The defect that the large-gap magnetic liquid is low in sealing anti-pressure capability is overcome, the transformation from an axial drainage channel to a radial drainage channel is achieved, the sealing anti-pressure capability and the sealing reliability of the magnetic liquid under the condition of large gaps are improved, and the safety working range is widened. Therefore, the sealing device is an ideal sealing device for solving the problems of being low in large-gap sealing anti-pressure capability and poor in reliability.

Owner:BEIJING JIAOTONG UNIV

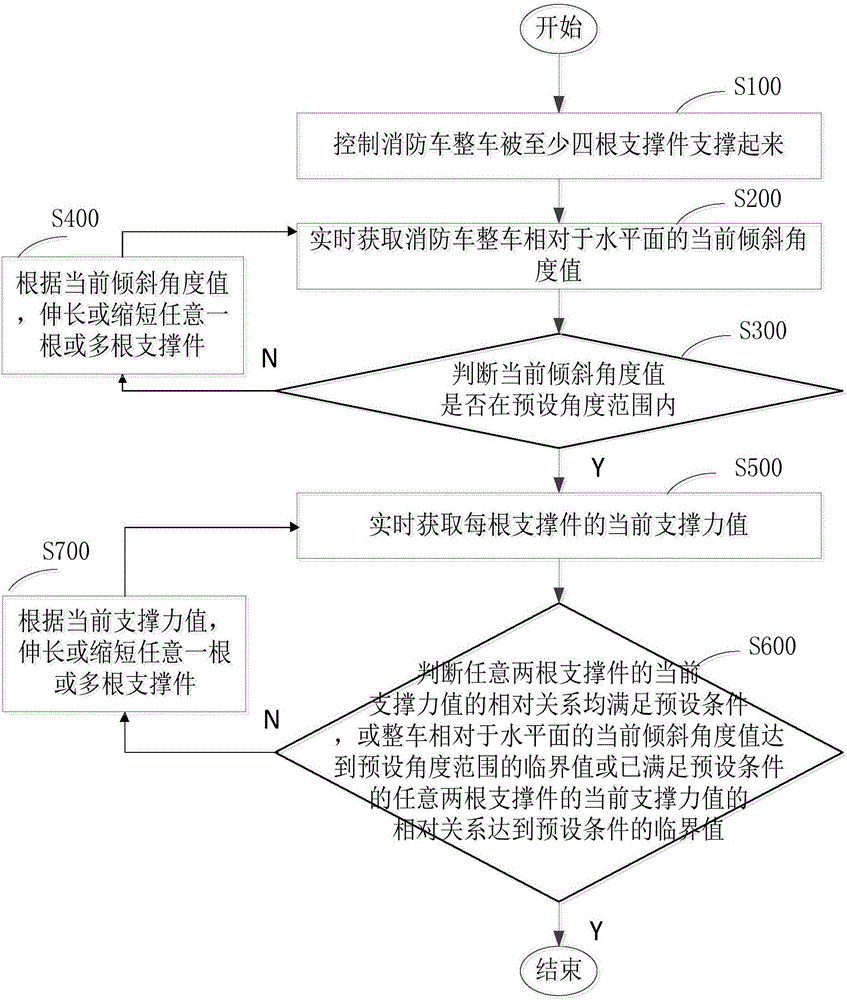

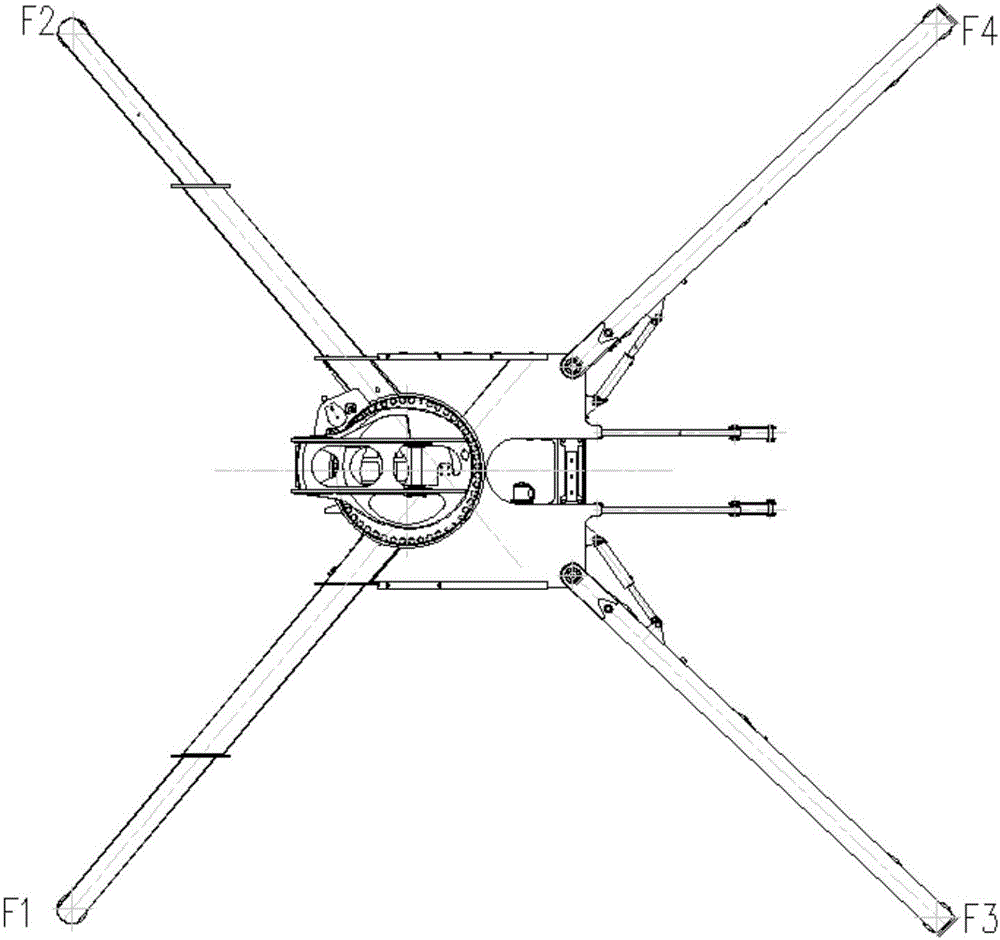

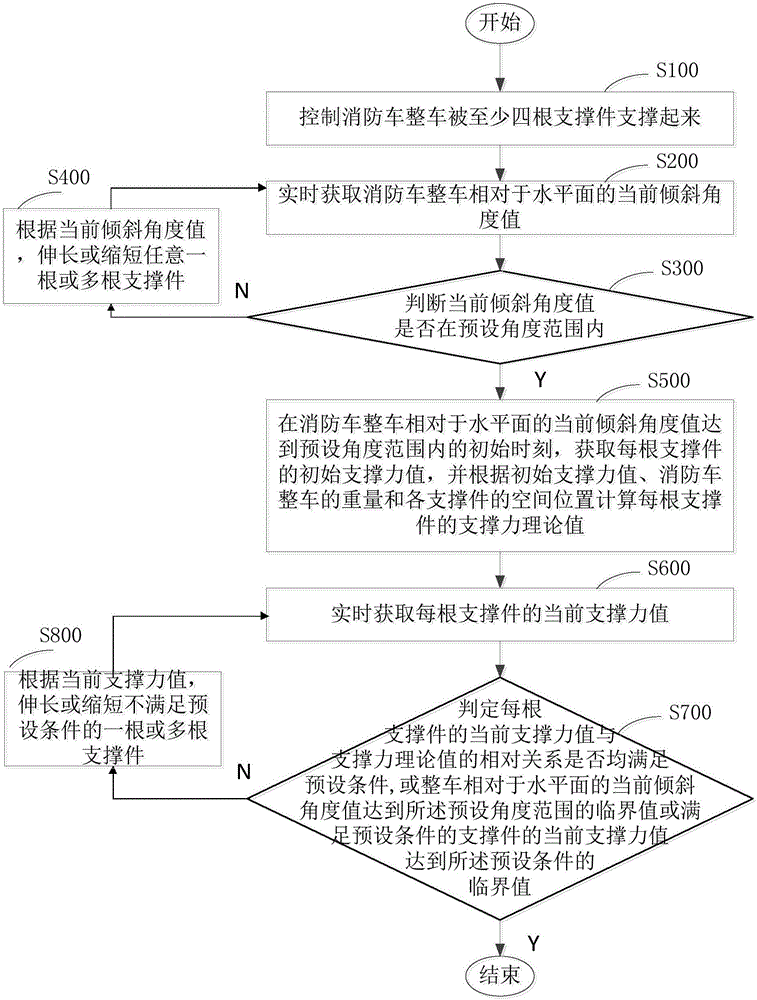

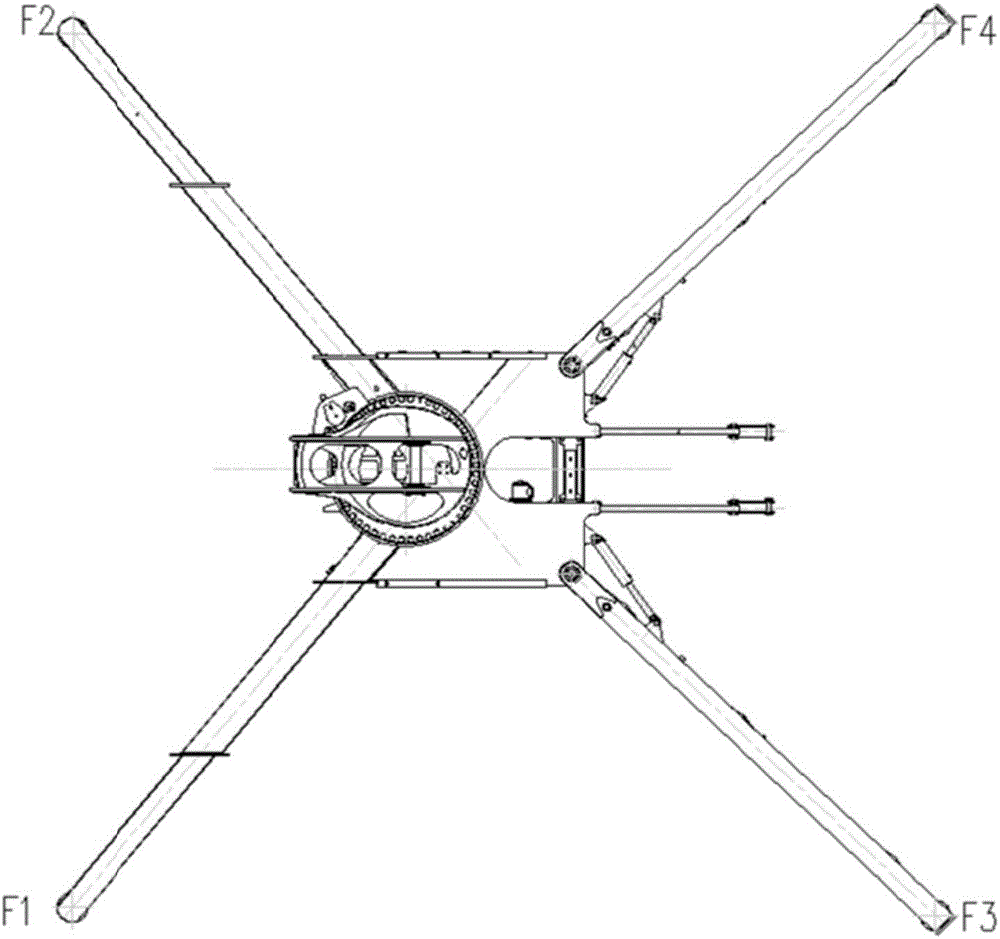

Leveling control method and system for fire engine

ActiveCN106740735AExpand the scope of safe workIncrease job securityVehicle fittings for liftingFire rescueWorking rangeEngineering

The invention discloses a leveling control method and system for a fire engine. According to the method and the system, a force leveling control strategy is introduced after angle leveling when supporting pieces of the fire engine are automatically unfolded, angle leveling is adopted as rough leveling means, and force leveling is adopted as fine leveling means, so that the angle leveling of the whole fire engine is sensuously implemented, supporting force is more balanced to prevent a certain support leg from leaving from the ground or leaves from the ground by a height exceeding the limit (the standard forbids excess of 20mm) in an unfolding process of a cantilever crane, the safe working range of an elevating fire engine is maximally widened, and the working safety and stability of the elevating fire engine are improved.

Owner:SANY AUTOMOBILE MFG CO LTD

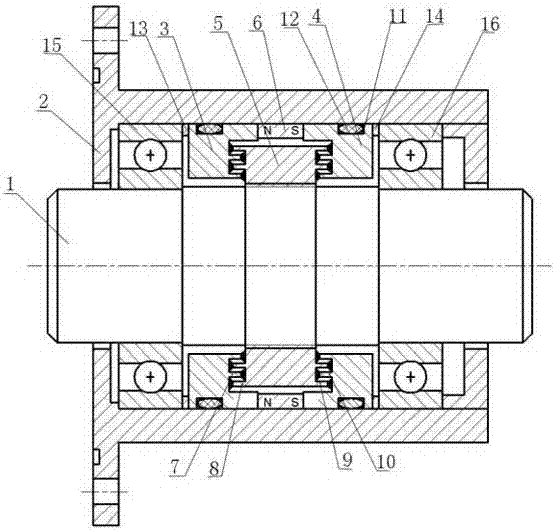

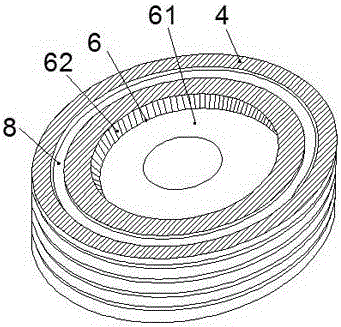

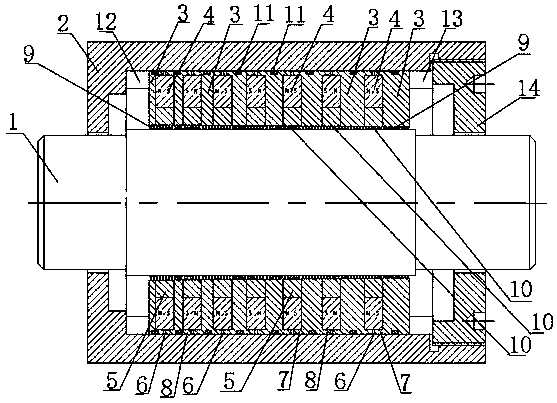

Split alternating magnetofluid sealing device

The invention relates to the technical field of mechanical engineering sealing, in particular to a split alternating magnetofluid sealing device. The device comprises an inner pole shoe ring, a split outer pole shoe, split inner permanent magnets and a split outer permanent magnets, wherein the split outer pole shoe is positioned outside the inner pole shoe ring, and the inner diameter of the split outer pole shoe is more than the outer diameter of the inner pole shoe ring; a plurality of annular grooves I are alternately formed in the outer circumference of the inner pole shoe ring, and the split inner permanent magnets are arranged in the annular grooves; a plurality of annular grooves II are alternately formed in the inner circumference of the split outer pole shoe, and the split outer permanent magnets are arranged in the annular grooves II; the annular grooves I are positioned on the center line of every two annular grooves II, and the annular grooves II are positioned on the center line of every two annular grooves I; the split inner permanent magnets extend into the space among the split outer permanent magnets, and the split outer permanent magnets extend into the space among the split inner permanent magnets. The sealing device can be used for improving the pressure resistance of a split magnetofluid sealing device.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

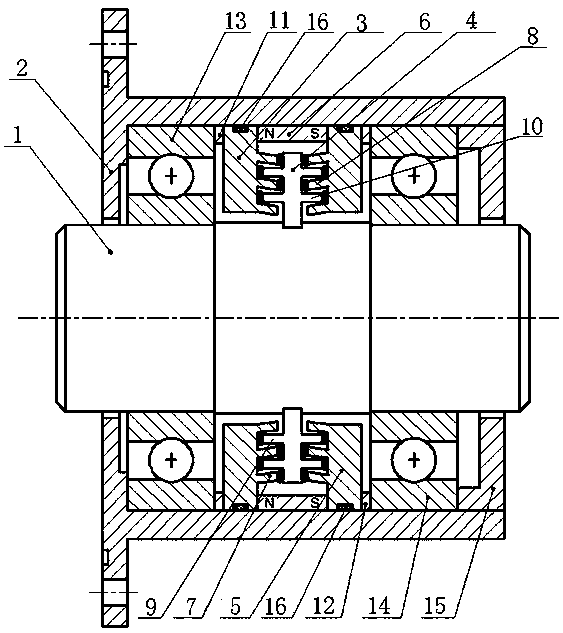

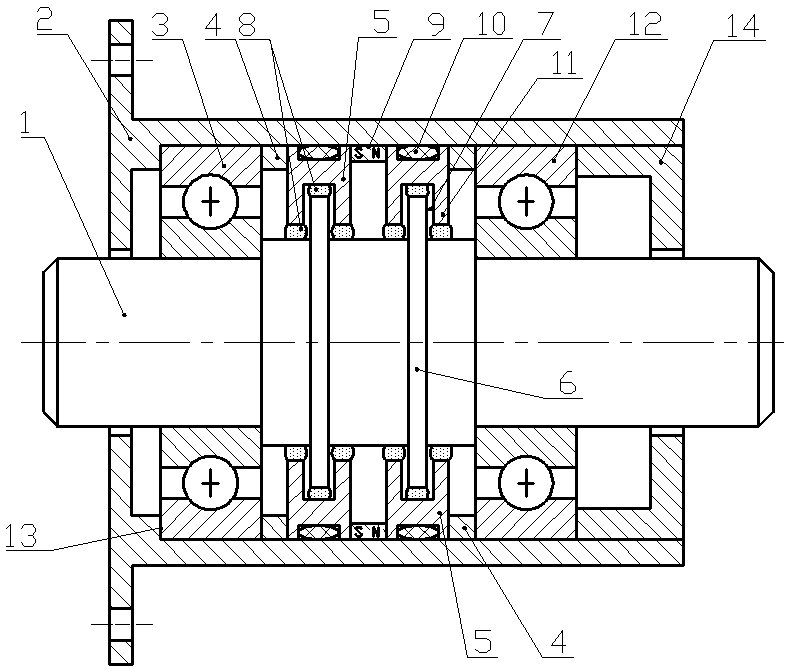

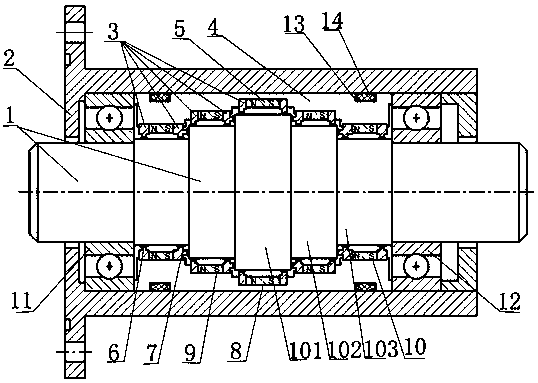

Radial sleeve type labyrinth type magnetic fluid sealing device

InactiveCN107956883AReduce lossesIncrease magnetic fluxEngine sealsEngineeringMechanical engineering

The invention relates to a radial sleeve type labyrinth type magnetic fluid sealing device. The radial sleeve type labyrinth type magnetic fluid sealing device comprises a shaft, a shell, a left poleshoe ring, a right pole shoe ring, a sleeve and a permanent magnet ring. The left pole shoe ring and the right pole shoe ring are arranged in the shell in a spaced mode; the shaft is sleeved with thesleeve located between the left pole shoe ring and the right pole shoe ring; the permanent magnet ring is arranged in the shell and located between the left pole shoe ring and the right pole shoe ring; a gap is reserved between the outer circular face of the sleeve and the inner circle face of the permanent magnet ring; pole teeth I are arranged on the right end face of the left pole shoe ring atintervals; pole teeth II are arranged on the left end face of the sleeve at intervals, and pole teeth III are arranged on the right end face of the sleeve at intervals; and pole teeth IV are arrangedon the left end face of the right pole shoe ring at intervals. The radial sleeve type labyrinth type magnetic fluid sealing device is used for solving the problem of low pressure-resistant performanceof an existing sealing device, and the sealing technology is successfully applied to the fields such as the high-speed and heavy-load field.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

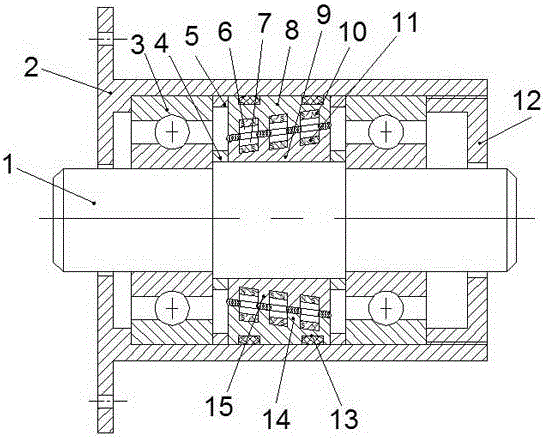

Stepped end face type magnetic fluid sealing device

The invention relates to the field of mechanical engineering sealing, in particular to a stepped end face type magnetic fluid sealing device. The stepped end face type magnetic fluid sealing device comprises a housing, a left pole shoe, a middle pole shoe, a right pole shoe and permanent magnets, wherein the middle pole shoe is installed in the middle of a shaft, and step structures are symmetrically arranged on the left side and the right side of the middle pole shoe in the radial direction. The left pole shoe is installed on the left side of the middle pole shoe, the right pole shoe is installed on the right side of the middle pole shoe, pole teeth I and an annular groove I are arranged on the right end face of the left pole shoe, the pole teeth I correspond to the step side face of the left end of the middle pole shoe, and the annular groove I is formed among the pole teeth I. Pole teeth II and an annular groove II are arranged on the left end face of the right pole shoe, the pole teeth II correspond to the step side face of the right end of the middle pole shoe, and the annular groove II is formed among the pole teeth II. The permanent magnets are installed in the annular groove I and the annular groove II. The sealing device has good sealing properties and can meet the using requirements of working conditions including large gap, high speed, heavy load and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

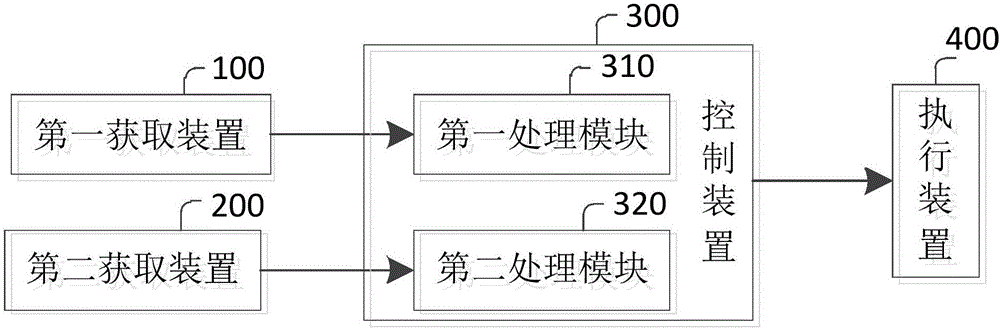

Leveling control method and leveling control system of firefighting vehicle

ActiveCN106585579AExpand the scope of safe workIncrease job securityVehicle fittings for liftingFire rescueControl systemFirefighting

The invention discloses a leveling control method and a leveling control system of a firefighting vehicle. The leveling control method aims to lead into a force leveling control strategy after angle leveling in automatic expansion of a firefighting vehicle supporting member. Angle leveling is used as a coarse leveling facility, and force leveling is used as a fine leveling facility so that the angle leveling of the integral firefighting vehicle is visually realized, and furthermore supporting force balance is realized, thereby preventing certain supporting leg off-ground or off-ground height limit exceeding (wherein the standard height requirement is not larger than 20mm) in an arm bracket expansion process, thereby maximally increasing a safe operation range of hoisting firefighting vehicles, and improving operation safety and stability of the hoisting firefighting vehicles.

Owner:SANY AUTOMOBILE MFG CO LTD

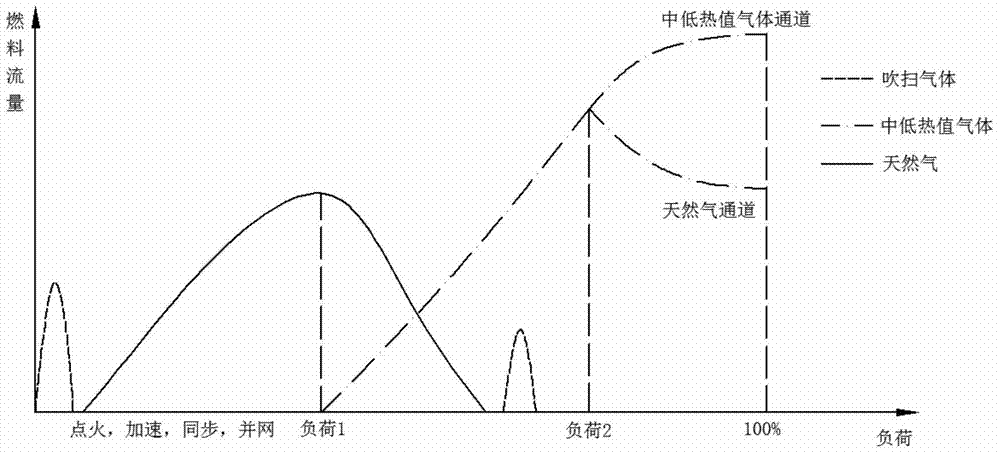

Fuel switching device for multi-fuel combustion chamber of gas turbine and control device of fuel switching device

ActiveCN104727946AGuaranteed jet velocityExpand the scope of safe workGas turbine plantsTurbine/propulsion fuel controlSyngasCombustion chamber

The invention relates to the technical field of gas turbines, and particularly discloses a fuel switching device for a multi-fuel combustion chamber of a gas turbine. The fuel switching device comprises a flame tube, a natural gas fuel channel, a synthesis gas fuel channel and a fuel front-end system, wherein the fuel front-end system comprises a natural gas purge system and a synthesis gas purge system; an inlet of the natural gas purge system is connected with a natural gas source; the outlet of the natural gas purge system is connected with the inlet of the natural gas fuel channel; the inlet of the synthesis gas purge system is connected with a medium and low heat value gas source; the outlet of the synthesis gas purge system is connected with the inlet of the synthesis gas fuel pipeline; a natural gas pressure-stabilizing valve is arranged at the upstream of the natural gas purge system; a third control valve is arranged at the downstream of the natural gas purge system; a synthesis gas pressure-stabilizing valve is arranged at the upstream of the synthesis gas purge system; a second control valve is arranged at the downstream of the synthesis gas purge system; and a first control valve is arranged between the downstream of the third control valve and the upstream of the second control valve. According to the fuel switching device, the required effective jet area of the head part of a nozzle when a lot of synthesis gas is jet is effectively reduced.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Magnetofluid sealing device with bearing cap

ActiveCN106195026APrevent axial movementPrevent leakageEngine sealsBearing componentsEngineeringScrew thread

The invention relates to the technical field of sealing for mechanical engineering, in particular to a magnetofluid sealing device with a bearing cap. The magnetofluid sealing device comprises a shell, bearings, a pole shoe ring, the bearing cap and permanent magnets. The shell sleeves the left end of a shaft, the bearings are arranged in the shell, and the bearing cap comprises a ring-shaped plate and a threaded ring. The outer diameter of the ring-shaped plate is larger than the outer diameter of the threaded ring and the inner diameter of the shell. The threaded ring and the left end of the ring-shaped plate are connected integrally. The outer diameter of the threaded ring is as same as the inner diameter of the shell. The shell sleeves the threaded ring from the right end of the shell. An inner thread is arranged on the inner surface of the threaded ring. An outer thread is arranged on the outer surface of the pole shoe ring. The outer thread of the pole shoe ring is matched with the inner thread of the threaded ring. The pole shoe ring is screwed into the threaded ring. A gap is reserved between the inner surface of the pole shoe ring and the shaft. A clamp seat is arranged at a position, clear to the shaft, of each of the left end face and the right end face of the pole shoe ring. The permanent magnets are mounted in the two clamp seats respectively. The sealing device has simple structure and reliable sealing performance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

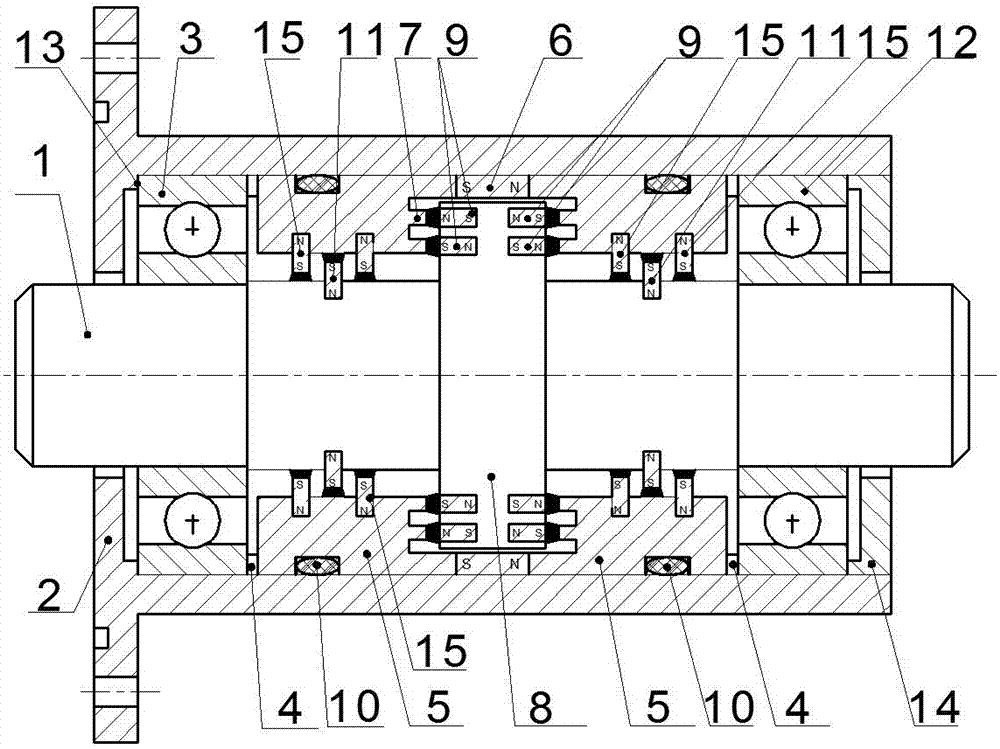

Staggered type magnetic fluid sealing device

ActiveCN107956881AExpand the scope of safe workMeet the needs of high-speed and other occasionsEngine sealsPole pieceCondensed matter physics

The invention discloses a staggered type magnetic fluid sealing device. The magnetic fluid sealing device comprises a hollow shell, a rotating shaft and first permanent magnets; pole shoes are arranged on the two sides of each first permanent magnet, at least one third groove is formed in the rotating shaft in the circumferential direction, and third permanent magnets are arranged in the third grooves respectively; at least one fourth groove is formed in the inner circular surface of each pole shoe in the circumferential direction, and fourth permanent magnets are arranged in the fourth grooves respectively; the third permanent magnets and the fourth permanent magnets are radially magnetized permanent magnet rings, and the polarities of the third permanent magnets and the fourth permanentmagnets are opposite; third gaps exist between the outer circular surfaces of the third permanent magnets and the inner circular surfaces of the pole shoes; fourth gaps exist between the inner circular surfaces of the fourth permanent magnets and the outer surface of the rotating shaft; the third permanent magnets and the fourth permanent magnets are distributed alternately in the axial directionin a staggered mode; and magnetic fluids are injected into the third gaps and the fourth gaps. According to the magnetic fluid sealing device, structure is improved, so that the intensity of a magnetic field in the gaps is increased, and the pressure resistance and the sealing performance of the magnetic fluid seal are improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Multistage disc magnetic fluid sealing device

ActiveCN107956882ASolve the problem of insufficient pressure resistanceAchieve sealingEngine sealsMagnetic sourceCircular disc

The invention relates to a multistage disc magnetic fluid sealing device. The multistage disc magnetic fluid sealing device comprises a shaft, a shell, a left pole shoe ring, a middle pole shoe ring,a right pole shoe ring, inner permanent magnet rings and outer permanent magnet rings; the left pole shoe ring and the right pole shoe ring sleeve the portion between the shell and the shaft; two or more permanent magnet ring groups are arranged between the left pole shoe ring and the right pole shoe ring in the axial direction; and every two adjacent permanent magnet ring groups are separated bythe middle pole shoe ring, and the middle pole shoe ring sleeves the portion between the shell and the shaft. According to the multistage disc magnetic fluid sealing device, the problem that the pressure resistance of an existing single-stage disc magnetic fluid sealing device and a multi-magnetic-source magnetic fluid sealing device is low can be solved, so that the sealing technology is successfully applied to the fields such as high-speed heavy load.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Cone magnetic fluid sealing device

ActiveCN106122285ADelay leakStrong magnetic fieldEngine sealsBearing componentsPole pieceHigh pressure

The invention relates to the technical field of mechanical engineering sealing, and particularly relates to a cone magnetic fluid sealing device. The device comprises an outer pole piece, an inner pole piece, outer permanent magnets and inner permanent magnets, wherein the inner pole piece sleeves a shaft, the outer wall of the inner pole piece is a conical surface, a plurality of annular grooves I are formed in the conical surface at intervals, and pole teeth I are formed between two adjacent annular grooves I; the inner permanent magnets are installed in the annular grooves I; the outer pole piece is installed on the inner wall of a shell, the inner wall of the outer pole piece is a conical surface, the inner wall of the outer pole piece is parallel to the outer wall of the inner pole piece, a plurality of annular grooves II which correspond to the annular grooves I are formed in the inner wall of the outer pole piece, and pole teeth II are formed between two adjacent annular grooves II; the outer permanent magnets are respectively installed in the annular grooves II; the pole teeth I respectively correspond to the pole teeth II, and gaps are formed between the pole teeth I and the pole teeth II. The sealing device has high pressure-resistant capacity, and the problem of poor sealing performance and reliability of an existing large-gap magnetic fluid sealing device is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Magnetofluid sealing device for high vacuum

The invention relates to the field of mechanical engineering sealing, in particular to a magnetofluid sealing device for high vacuum. The magnetofluid sealing device comprises a stepped shaft, a shell, a left pole shoe, a right pole shoe and a permanent magnet ring. The stepped shaft comprises a middle shaft with the maximum diameter and a plurality of sets of secondary shafts with the sequentially reduced diameters. The permanent magnet ring is arranged at the position, corresponding to the outer circle face of the middle shaft, of the inner wall of the shell. The left pole shoe and the rightpole shoe are arranged on the two sides of the permanent magnet ring and are symmetric. The end face and the annular face of the left pole shoe and the end face and the annular face of the right poleshoe correspond to the outer circle faces and the end faces of the middle shaft and the secondary shafts correspondingly. The end face of the middle shaft and the outer circle faces and the end facesof the secondary shafts are each provided with pole teeth which extend in the radial direction or the axial direction, gaps are reserved between the pole teeth and the corresponding end faces and theannular faces of the left pole shoe and the right pole shoe, and the magnetofluid is located in the gaps. By means of the magnetofluid sealing device for high vacuum, the problem that an existing sealing device is relatively low in pressure resistance and other problems can be solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

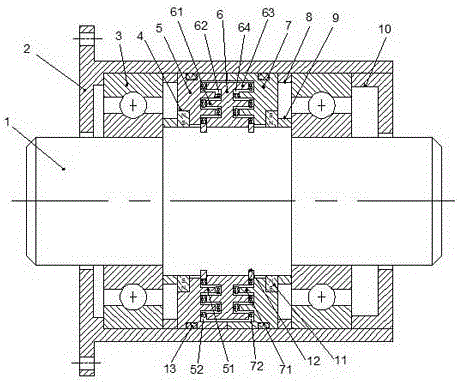

Convex step shaft magnetofluid sealing device

ActiveCN107893853ASolve the problem of insufficient pressure resistanceImprove sealing pressure resistanceEngine sealsMagnetSelf repair

The invention relates to a convex step shaft magnetofluid sealing device. The convex step shaft magnetofluid sealing device comprises a shell, a sealing assembly and an end cover. The sealing assemblycomprises a shaft. The shaft is rotationally arranged in the shell through a bearing. The shaft comprises at least one convex step part. The convex step part comprises a plurality of steps sequentially arranged in the axial direction, and the outer walls of the adjacent steps are connected through arc chamfered transition faces. Each transition face is sleeved with a pole shoe matched with the transition face, wherein the pole shoe extends towards one or two sides of the transition face to the position corresponding to the corresponding step on the side portion of the transition face. Gaps are reserved between the inner walls of the pole shoes and the corresponding transition faces and between the inner walls of the pole shoes and the steps. Pole teeth are arranged on the inner walls of the pole shoes and / or the parts, corresponding to the inner walls of the pole shoes, of the shaft. Permanent magnets are arranged between the adjacent pole shoes. The convex step shaft magnetofluid sealing device is high in pressure resisting capability, the secondary pressure bearing capability and the self-repairing capability are high, the pressure resisting capability and the sealing reliability of magnetic fluid seals under the condition of large gaps are high, and the safety work range is wide.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Magnetofluid sealing device

The invention relates to a magnetofluid sealing device which comprises a shell, a sealing assembly and an end cover. The two ends of the shell are provided with openings, and the end cover is used forpressing the sealing assembly into the shell. The sealing assembly comprises a shaft, the shaft is rotationally installed in the shell through a bearing, the shaft comprises at least one concave portion, the outer side of the shaft is provided with split shoe poles, the concave portion is located in a cavity defined by the split shot poles, the shape of the outer wall of the split shot poles is matched with the appearance of the shaft corresponding portion, the split shoe poles are provided with a first permanent magnet and a second permanent magnet which are located on the two sides of the concave portion correspondingly, a gap is reserved between the inner wall of the split shoe poles and the outer wall of the shaft, and the inner wall of the split shoe poles is provided with pole teeth. Assembling is easy, the structure is simple, magnetofluid sealing pressure resistance is high, the secondary pressure bearing capacity and self-repair ability of the device are high, pressure resistance and sealing reliability under the large gap condition are good, the safe working range is large, and the requirements of occasions such as high-speed heavy load can be met.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

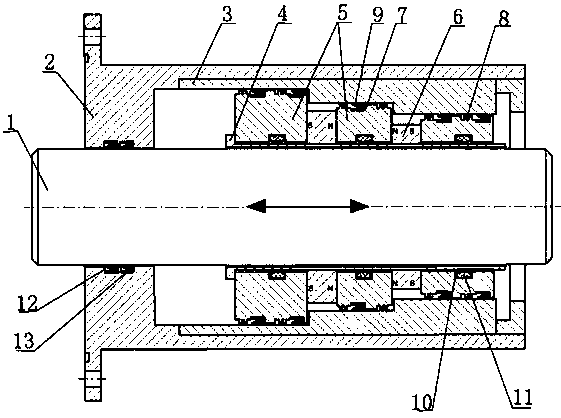

Reciprocating sealing device for hydraulic cylinder magnetic fluid

The invention relates to a reciprocating sealing device for hydraulic cylinder magnetic fluid. The reciprocating sealing device for the hydraulic cylinder magnetic fluid comprises a shell, pole shoe rings, permanent magnet rings, non-magnetic conductive rings and magnetic isolation rings. According to the reciprocating sealing device for the hydraulic cylinder magnetic fluid, a magnetic source isprovided through multiple permanent magnets, the non-magnetic conductive rings are arranged in a space formed by pole shoes, the permanent magnets and shafts in an enclosing mode, the non-magnetic conductive rings are provided with pole teeth, therefore, the problem that the pressure resistance of an existing single-magnetic-source magnetic fluid sealing device and an existing multi-magnetic-source magnetic fluid sealing device is low is solved, and meanwhile the problem that the magnetic fluid utilization rate of an existing magnetic fluid sealing device is low is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Oblique-tooth magnetofluid sealing device

ActiveCN109027251AReduce the impact of withstand voltageStop lossEngine sealsCentrifugal forceMagnet

The invention relates to an oblique-tooth magnetofluid sealing device. The oblique-tooth magnetofluid sealing device comprises a shell, a left pole shoe ring, an inner pole shoe ring, a right pole shoe ring and a permanent magnet ring. The left pole shoe ring and the right pole shoe ring are arranged on the inner wall of the shell. One or more oblique pole teeth I are arranged on the right end face of the left pole shoe ring in the radial direction at intervals. One or more oblique pole teeth II are arranged on the left end face of the inner pole shoe ring in the radial direction at intervals.One or more axial pole teeth II are arranged on the right end face of the inner pole shoe ring in the radial direction at intervals. The oblique pole teeth II and the axial pole teeth I are distributed in a staggered mode, and the oblique pole teeth I do not make contact with the axial pole teeth I. The permanent magnet ring is arranged on the inner wall of the shell and is located between the left pole shoe ring and the right pole shoe ring. By adoption of the oblique-tooth magnetofluid sealing device, the problem that the pressure resistance of an existing sealing device is affected due torotating axis eccentricity and large eccentric force of the existing sealing device can be solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

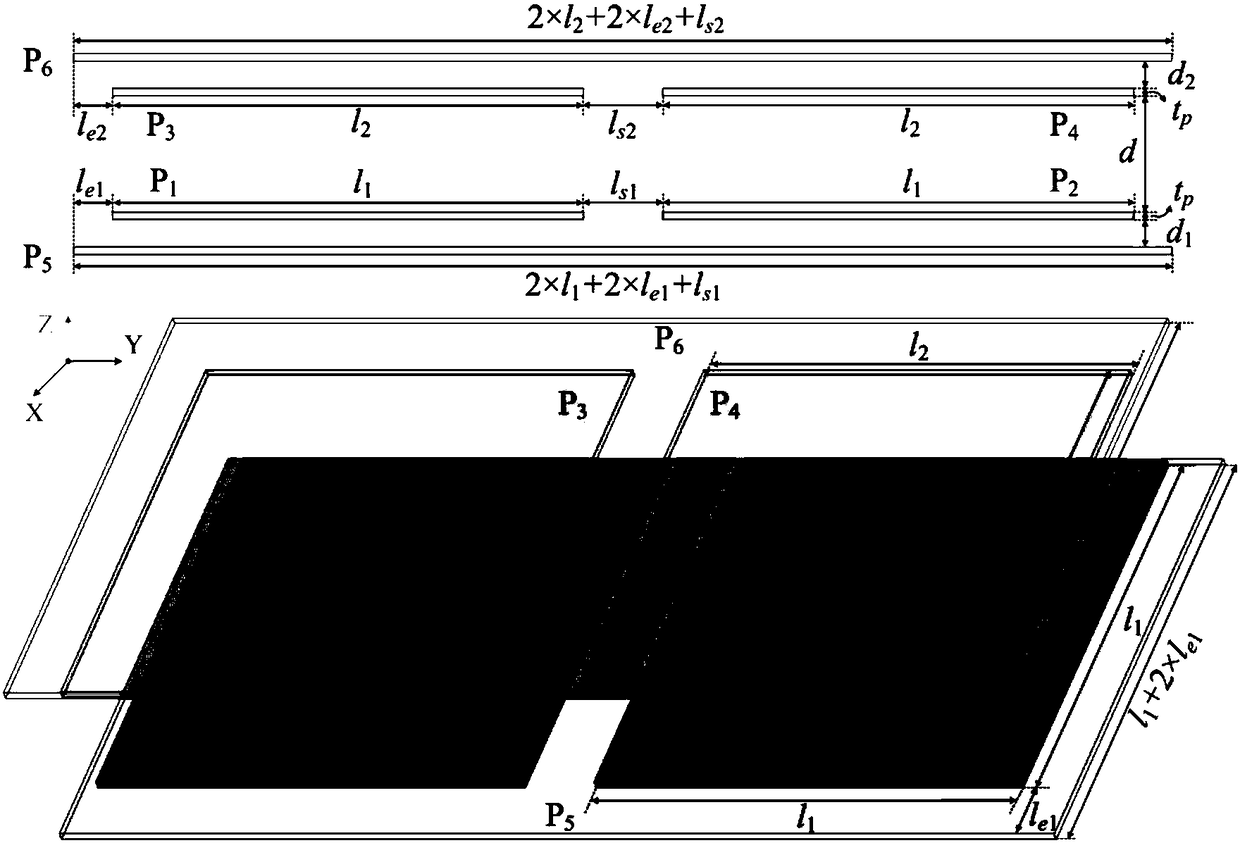

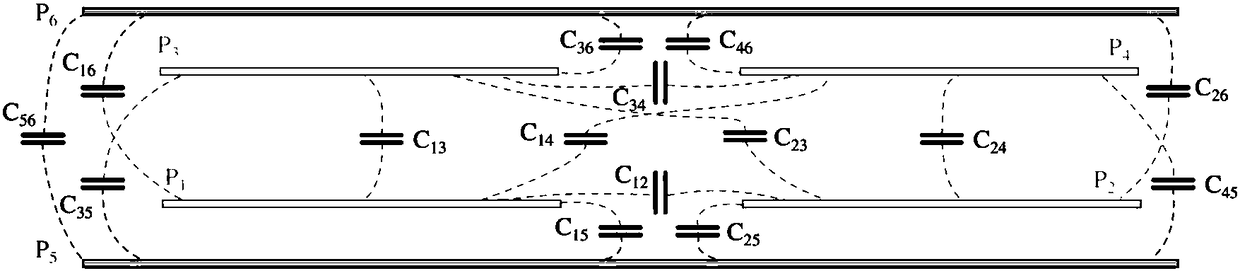

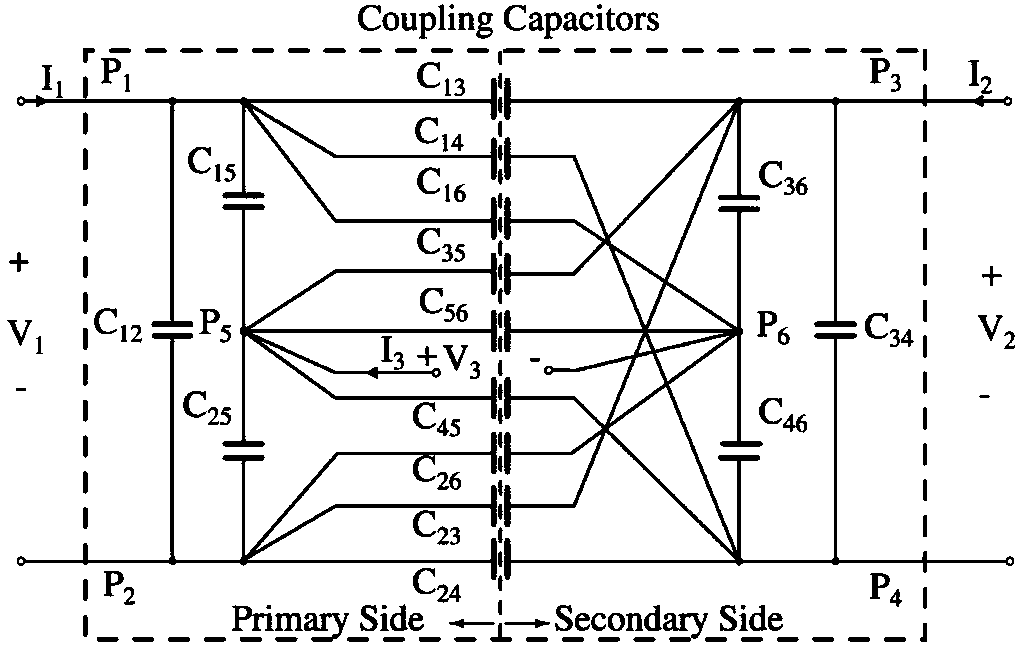

Six-pole plate applied to capacitive wireless charging system

PendingCN108258812AExpand the scope of safe workReduced electric field radiationCircuit arrangementsTransmitted powerElement analysis

The invention provides a novel six-pole plate type coupling structure for a capacitive wireless charging system, so as to reduce electric field radiation to the external environment. The six-pole plate comprises six electrode plates, wherein four of the electrode plates are used for transmitting power, and the other two are used as shielding pole plates for reducing the electric field radiation tothe external environment. In the six-pole plate structure, a coupling capacitor exists between every two electrode plates, a total of 15 coupling capacitors are arranged, and the difficulty of analyzing a pole plate model and circuit performance is increased. The invention provides a novel three-port model, which can be further simplified into a two-port model for analyzing the working process ofa circuit. The finite element analysis based on Maxwell proves that the six-pole plate structure can effectively reduce the electric field radiation, and the safety range is increased from 0.6 meteraway from the six-pole plate to 0.1 meter away from the six-pole plate. The experimental results show that when an air gap distance is 150 mm, the efficiency from input DC power supply to output loadreaches 91.6%.

Owner:开沃新能源汽车集团股份有限公司

Sealing device for magnetic source embedded series-parallel type stepped shaft magnetic fluid

The invention relates to a sealing device for magnetic source embedded series-parallel type stepped shaft magnetic fluid. According to the sealing device for the magnetic source embedded series-parallel type stepped shaft magnetic fluid, the diameter of a middle shaft of a stepped shaft is the largest, the diameter of a secondary shaft on the left side of the middle shaft sequentially decreases from right to left, and the diameter of a secondary shaft on the right side of the middle shaft is gradually decreased from left to right; and the sealing device comprises a shell, a left pole shoe ring, a right pole shoe ring, a first permanent magnet ring, a second permanent magnet ring, a third permanent magnet ring and a fourth permanent magnet ring. The problem that an existing sealing device is low in pressure resistance can be solved, and meanwhile the assembling is simple, the processing is easy, and the sealing technology is successfully applied to the fields of high-speed heavy load and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Staggered magnetofluid sealing structure

The invention discloses a staggered magnetofluid sealing structure. The staggered magnetofluid sealing structure comprises a hollow shell and a rotary shaft, wherein the rotary shaft and the shell areassembled and connected through a bearing; at least one permanent magnet is assembled on the inner wall of the shell; pole shoes mounted on the inner wall of the shell in a sleeving manner are separately arranged on two side of each permanent magnet, at least two polar teeth are arranged on each pole shoe, and a groove is formed between adjacent two polar teeth; at least one disc-shaped shaft isarranged in the radial direction of the rotary shaft, and the diameter of the disc-shaped shaft is greater than that of the rotary shaft; the outer edge of the at least one disc-shaped shaft is correspondingly inserted into the groove of the pole shoe; a gap X exists between the outer edge surface of the disc-shaped shaft and the inner circumferential surface of the groove, and a magnetofluid is injected to the gap X; a gap exists between the polar teeth and the outer circumferential surface of the rotary shaft, and a magnetofluid is injected to the gap Y. By arranging the structure in a staggered manner, the magnetofluid can be blocked well, so that the loss of the magnetofluid is reduced greatly. Meanwhile, the self-repairing ability of the sealing structure is increased, so that the pressure resistance and sealing property of magnetofluid sealing are improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Stepped magnetofluid sealing device

The invention aims to provide a stepped magnetofluid sealing device. The stepped magnetofluid sealing device comprises a stepped shaft, a shell, a left pole shoe, a right pole shoe, one or more middlepole shoes and permanent magnet rings. The stepped shaft is arranged in the shell in a sleeved mode. The stepped shaft comprises a plurality of secondary shaft bodies, and the diameters of the multiple secondary shaft bodies become smaller gradually leftwards in the axial direction. The left pole shoe, the middle pole shoes and the right pole shoes are sequentially mounted on the inner wall of the shell at intervals from left to right. The left pole shoe, the middle pole shoes and the right pole shoe correspond to the outer circumferential surfaces of the secondary shaft bodies separately, gaps are reserved between left, middle pole and right pole shoes and the outer circumferential surfaces of the secondary shaft bodies, and magnetofluid is located in the gaps. The permanent magnet ringsare arranged between the pole shoes. By adoption of the stepped magnetofluid sealing device, sealing can be achieved in special working conditions such as high-speed and heavy-load working conditions.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Symmetrical double-step magnetic fluid sealing device

ActiveCN109764137AImprove sealing pressure resistanceOvercoming the Difficulty of Decreasing Sealing PerformanceEngine sealsEngineeringSecondary stage

The invention aims to provide a symmetrical double-step magnetic fluid sealing device. The symmetrical double-step magnetic fluid sealing device comprises a stepped shaft, a shell, a left first-stageshoe ring, a right first-stage shoe ring, an intermediate sleeve and an intermediate permanent magnet ring. The stepped shaft comprises a first-stage shaft with the largest diameter and more than twogroups of secondary-stage shafts with diameters reducing in sequence, the secondary-stage shafts are sequentially arranged to the two sides along the side surface of the first-stage shaft, and left and right symmetric is realized by taking the middle radial section of the first-stage shaft as a boundary. The problem of low pressure resistance of an existing sealing device is solved, so that the sealing technology can be successfully applied to fields such as high speed and heavy load.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Mixed tooth split type magnetofluid seal device

ActiveCN107654657AImprove pressure resistanceImproves sealing reliabilityEngine sealsShaftsStructural engineeringMechanical engineering

The invention relates to a mixed tooth split type magnetofluid seal device. The mixed tooth split type magnetofluid seal device comprises a stepped shaft, a shell, pole shoe rings, a sectioning non-magnetizer ring and permanent magnet rings. The inner wall of the shell is provided with the sectioning non-magnetizer ring. The stepped shaft is arranged in the inner ring face of the sectioning non-magnetizer ring in a sleeved manner. The outer circle faces of the stepped shaft correspond to the inner ring faces of the sectioning non-magnetizer ring. Each of the inner ring faces of the sectioningnon-magnetizer ring is provided with the corresponding pole shoe rings and the corresponding permanent magnet ring making contact with the pole shoe rings. Gaps are reserved between the pole shoe rings and the corresponding outer circle faces of the stepped shaft and between the permanent magnet rings and the corresponding outer circle faces of the stepped shaft. The pole shoe rings are provided with pole teeth, the pole teeth extend towards the outer circle faces or the end face of the stepped shaft in the radial direction, gaps are reserved between the pole teeth and the outer circle faces or the end face of the stepped shaft, and the magnetofluid is arranged in the gaps. The mixed tooth split type magnetofluid seal device can solve the problems that an existing sealing device is low inpressure resisting performance, and magnetism leakage happens to an inner magnetic field of the sealing device.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Stepped shaft type magnetofluid sealing device

ActiveCN107816553AImprove sealing pressure resistanceReduce lossesEngine sealsShaftsHeavy loadMagnet

The invention discloses a stepped shaft type magnetofluid sealing device. The stepped shaft type magnetofluid sealing device comprises a shaft, an outer shell, sealing rings, pole shoes, magnetofluidand permanent magnets. The shaft penetrates the outer shell, extends out of the two ends of the outer shell and comprises a stepped shaft part, wherein the stepped shaft part is located inside the outer shell. The diameter of a middle step of the stepped shaft part is the maximum, and the diameters of steps at the left side and the right side are decreased progressively and sequentially. Every twoadjacent steps are in circular-truncated-cone transition. The stepped shaft part is provided with cylinder side faces and multiple circular-truncated-cone side faces, wherein the cylinder side facesare parallel with the axis of the shaft, and the circular-truncated-cone side faces are symmetrical about the axis. The inner surface of the outer shell is provided with the two or more pole shoes. Each annular permanent magnet is arranged between the corresponding two adjacent pole shoes. Each pole shoe is provided with radial pole teeth and bevel pole teeth, wherein the radial pole teeth protrude toward the cylinder side faces, and the bevel pole teeth protrude toward the circular-truncated-cone side faces. The magnetofluid is arranged between the radial pole teeth and the cylinder side faces as well as between the bevel pole teeth and the circular-truncated-cone side faces. By means of the stepped shaft type magnetofluid sealing device, the sealing capability and pressure endurance capability of the magnetofluid are greatly enhanced; and the problem that existing sealing devices cannot meet the high-sealing-performance requirement under special working conditions such as the high speed and heavy load is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Step type reciprocating sealing device with pole shoes and lip-shaped sealing rings alternatively mixed

The invention relates to a step type reciprocating sealing device with pole shoes and lip-shaped sealing rings alternatively mixed. The step type reciprocating sealing device comprises a shaft, a housing, outer ring concentrating flux sleeves, inner ring concentrating flux sleeves, polar shoe rings and permanent magnet rings, wherein the inner walls of the outer ring concentrating flux sleeve arestep ring surfaces, and the diameter of the step ring surface at each stage is sequentially reduced from left to right; the inner ring concentrating flux sleeves sleeve the shaft and are positioned within the outer ring concentrating flux sleeves; one or more groups of polar shoe rings are arranged on the outer circular surfaces of the inner ring concentrating flux sleeves at intervals; the permanent magnet rings are arranged among the polar shoe rings; each permanent magnet ring is separately in contact with the end surface of the adjacent polar shoe ring; one or more groups of ring-shaped grooves I and polar teeth are axially formed in the outer circular surfaces of the polar shoe rings at intervals; and the ring-shaped grooves A and the polar teeth are alternatively distributed. The step type reciprocating sealing device aims to solve the problem that an existing single-magnetic-source magnetic fluid sealing device and an existing multi-magnetic-source magnetic fluid sealing deviceare low in pressure resistance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

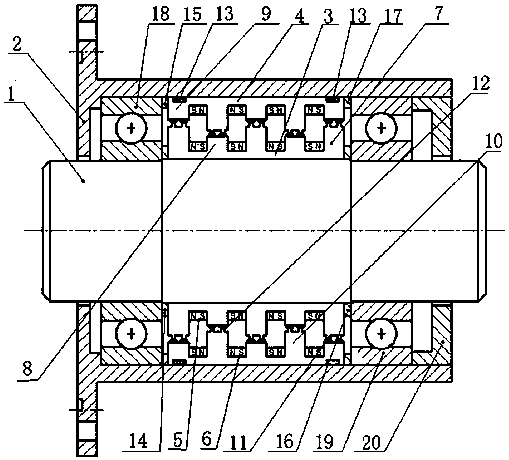

Tooth-aligning labyrinth magnetic fluid sealing device

The invention relates to a tooth-aligning labyrinth magnetic fluid sealing device. The tooth-aligning labyrinth magnetic fluid sealing device comprises a housing, an inner pole shoe ring, an outer pole shoe ring, permanent magnet rings I and permanent magnet rings II, wherein the inner pole shoe ring is arranged on a shaft in a sleeving manner; the outer pole shoe ring is mounted on the inner wallof the housing, and the outer pole shoe ring and the inner pole shoe ring are oppositely arranged; a plurality of pole terminals I and pole terminals II are alternately arranged on the inner pole shoe ring in the axial direction in a spaced manner; each permanent magnet ring I is arranged between each pole terminal I and the adjacent pole terminal II; a plurality of pole terminals III and pole terminals IV are alternately arranged on the outer pole shoe ring in the axial direction in a spaced manner; each permanent magnet ring II is arranged between each pole terminal III and the adjacent pole terminal IV; the permanent magnet rings and the permanent magnets II are oppositely arranged, and a gap is formed between each permanent magnet ring and the corresponding permanent magnet II; and pole teeth are arranged on the pole terminals I and the pole terminals IV. Through the adoption of the tooth-aligning labyrinth magnetic fluid sealing device disclosed by the invention, the problem thatthe pressure resistance performance of a conventional sealing device is influenced by the eccentricity of a rotating shaft of the conventional sealing device can be solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Cross-shaped stepped magnetofluid sealing device

ActiveCN107740865AIncrease magnetic fluxReduce lossesEngine sealsStructural engineeringMechanical engineering

The invention provides a cross-shaped stepped magnetofluid sealing device. The cross-shaped stepped magnetofluid sealing device comprises a stepped shaft, a shell, a left pole shoe, a right pole shoeand a permanent magnet ring. The stepped shaft is arranged in the shell in a sleeved mode. The stepped shaft comprises an intermediate shaft body with the maximum diameter and a plurality of secondaryshaft bodies with the diameters becoming smaller gradually, and the stepped shaft is bilaterally symmetrical with the intermediate radial section of the intermediate shaft body as the boundary. The permanent magnetic ring is arranged at the position, corresponding to the outer circumference surface of the intermediate shaft body, of the inner wall of the shell, and a gap is reserved between the permanent magnet ring and the outer circumferential surface of the intermediate shaft body. The left pole shoe and the right pole shoe are arranged on the two sides of the permanent magnet ring correspondingly and are symmetrical. Cross-shaped pole teeth are arranged at the junctions of the upper outer circumferential surfaces and end faces of the left and right pole shoes and extend towards the outer circumferential surfaces of the secondary shaft bodies and the end faces of the secondary shaft bodies or the end face of the intermediate shaft body correspondingly, gaps are reserved between theouter circumferential surfaces and the end faces, and magnetofluid is located in the gaps. By adoption of the cross-shaped stepped magnetofluid sealing device, sealing can be achieved in special working conditions such as high-speed and heavy-load working conditions.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

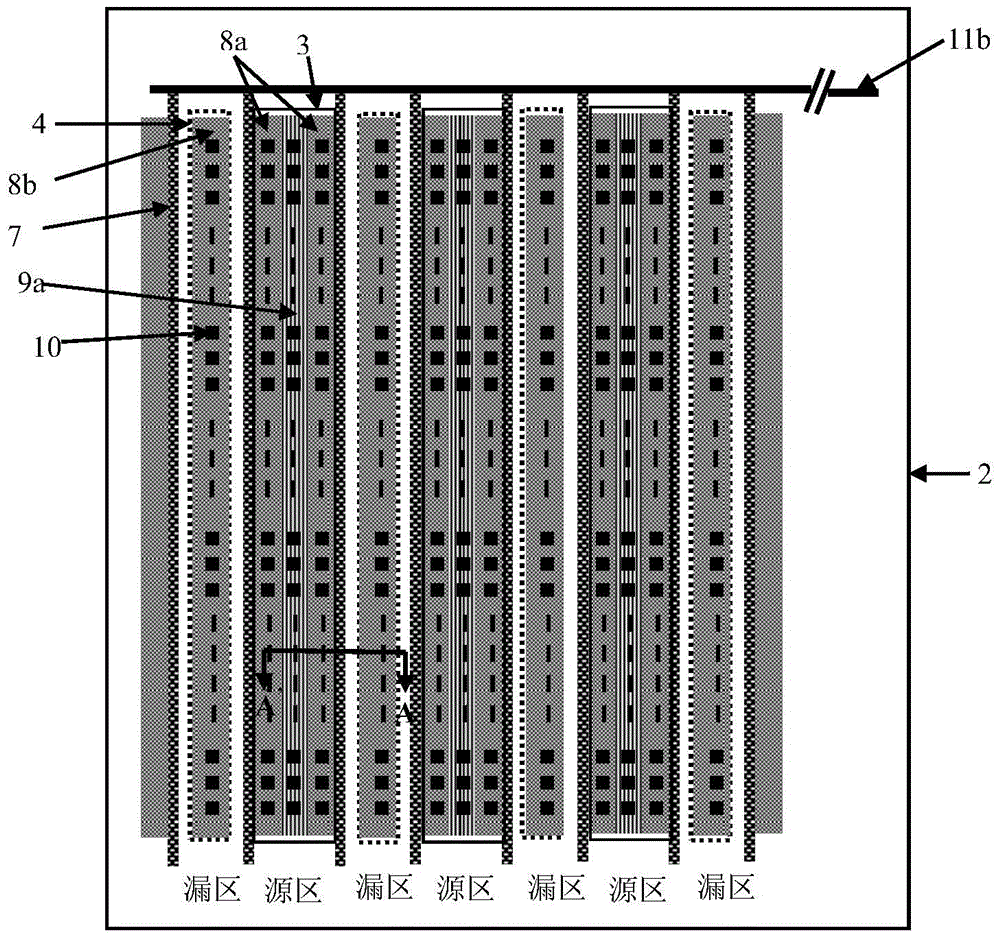

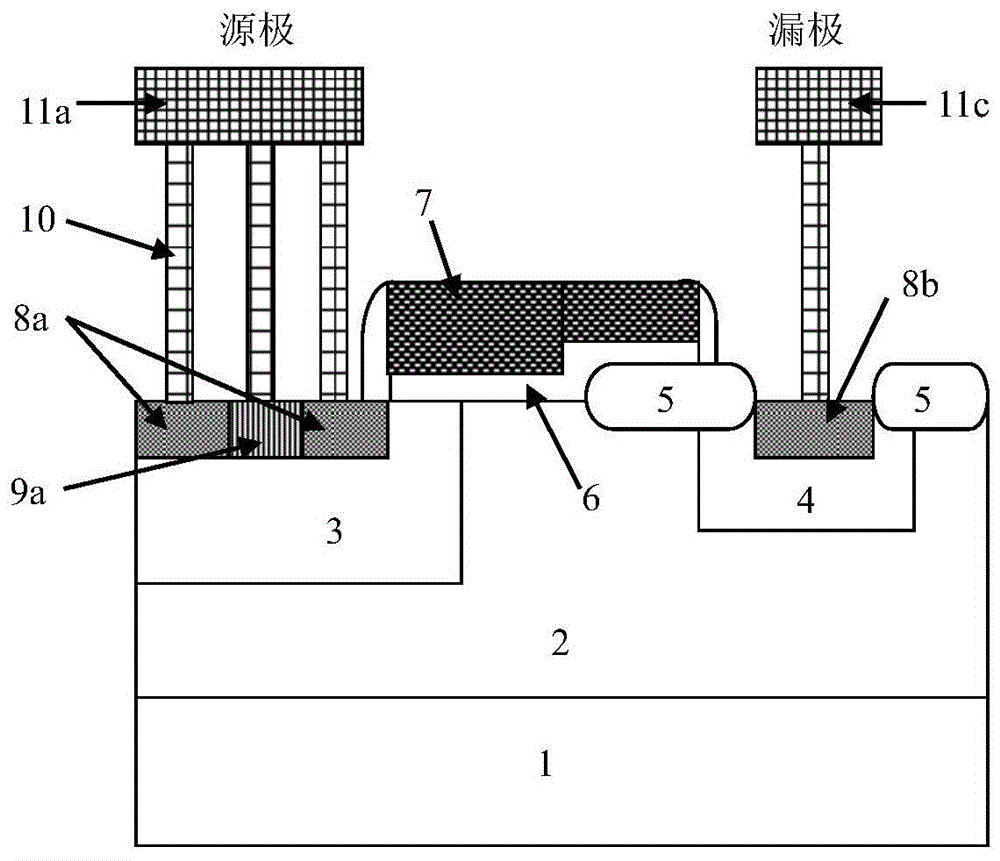

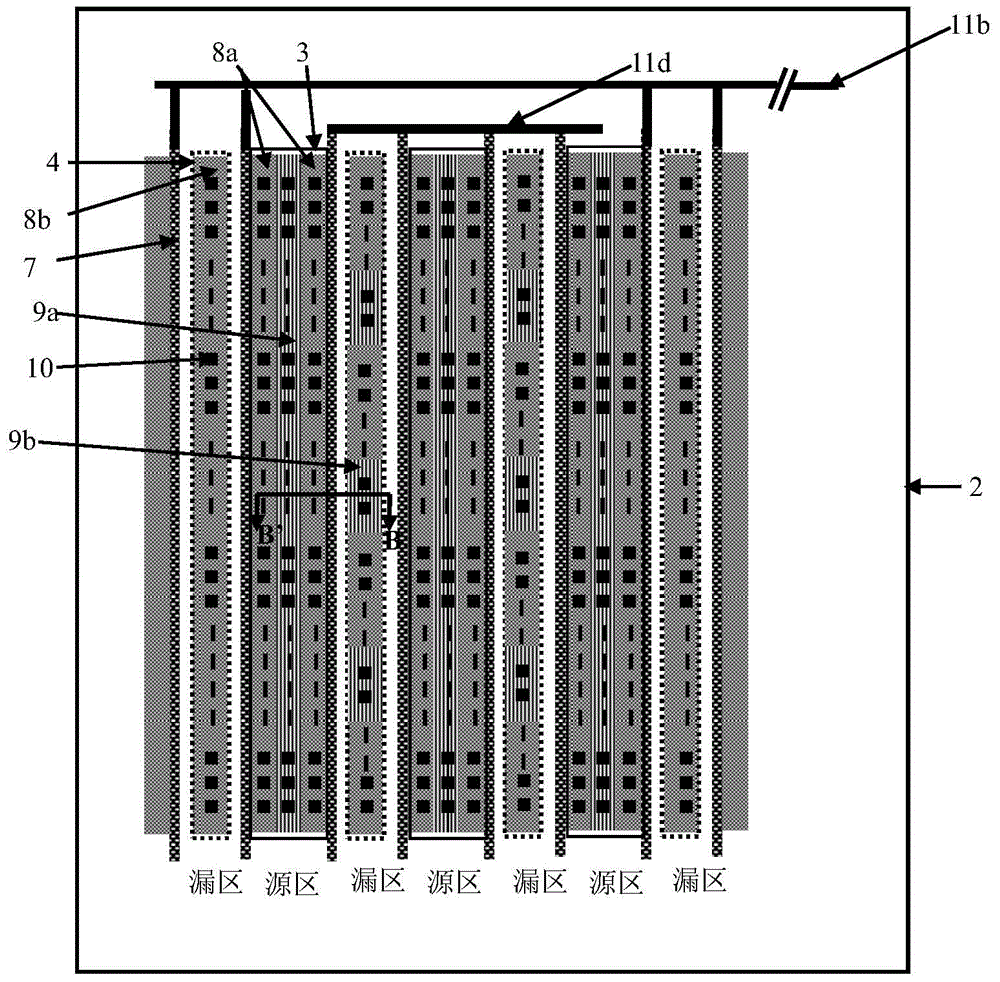

Power transistor array structure with electrostatic protection circuit integrated

ActiveCN104637935AImprove electrostatic protection abilityReduce false triggeringThyristorSolid-state devicesTransistor arraySilicon-controlled rectifier

The invention discloses a power transistor array structure with an electrostatic protection circuit integrated. Embedding of an electrostatic protection circuit formed by an SCR (silicon controlled rectifier) can be realized by partially replacing region sections of a drain region of a first unit structure of a power transistor with a region P+, and a grid electrode of the SCR is not connected with a grid electrode of the first unit structure but connected with a source electrode of the first unit structure. On the premise that performances of a power transistor array are unaffected and the process is unchanged, electrostatic protection capability of the power transistor array can be improved, false triggering accidents of the silicon controlled rectifier can be effectively reduced, and accordingly safety operation range of the power transistor array can be expanded. In addition, a grid gate structure of the SCR is designed to be recessed towards a drain side, and the region P+ is injected to a body region of a source side, so that the false triggering accidents of the silicon controlled rectifier can be further reduced, and the safety operation range of the power transistor array can be further expanded.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Step-type magnetofluid sealing device

The invention discloses a step-type magnetofluid sealing device. The step-type magnetofluid sealing device comprises a shaft, an outer shell, pole shoes, magnetofluid and permanent magnets. The shaftpenetrates through the outer shell and extends out of two ends of the outer shell. The shaft comprises a stepped shaft part located in the outer shell. The diameter of a middle step of the stepped shaft part is the maximum, and the diameters of the steps on the left side and the right side of the stepped shaft part are gradually reduced. The stepped shaft part is provided with a plurality of firstside surfaces parallel to the axis of the shaft and a plurality of second side surfaces perpendicular to the axis. The at least two pole shoes are arranged on the inner surface of the outer shell. Each annular permanent magnet is arranged between every two adjacent pole shoes. Each pole shoe is provided with radial pole teeth protruding towards the first side surfaces and axial pole teeth protruding towards the second side surfaces, wherein the radial pole teeth and the axial pole teeth are all annular, and the magnetofluid is arranged between the radial pole teeth and the first side surfacesas well as between the axial pole teeth and the second side surfaces. The sealing pressure resistance of the magnetofluid is greatly improved, and the problem that an existing sealing device can notmeet the high sealing performance requirement under special work conditions like high speed and heavy loads is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A conical magnetic fluid sealing device

ActiveCN106122285BDelay leakStrong magnetic fieldEngine sealsBearing componentsPole pieceEngineering

The invention relates to the technical field of mechanical engineering sealing, and particularly relates to a cone magnetic fluid sealing device. The device comprises an outer pole piece, an inner pole piece, outer permanent magnets and inner permanent magnets, wherein the inner pole piece sleeves a shaft, the outer wall of the inner pole piece is a conical surface, a plurality of annular grooves I are formed in the conical surface at intervals, and pole teeth I are formed between two adjacent annular grooves I; the inner permanent magnets are installed in the annular grooves I; the outer pole piece is installed on the inner wall of a shell, the inner wall of the outer pole piece is a conical surface, the inner wall of the outer pole piece is parallel to the outer wall of the inner pole piece, a plurality of annular grooves II which correspond to the annular grooves I are formed in the inner wall of the outer pole piece, and pole teeth II are formed between two adjacent annular grooves II; the outer permanent magnets are respectively installed in the annular grooves II; the pole teeth I respectively correspond to the pole teeth II, and gaps are formed between the pole teeth I and the pole teeth II. The sealing device has high pressure-resistant capacity, and the problem of poor sealing performance and reliability of an existing large-gap magnetic fluid sealing device is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Staggered tooth end face type magnetic fluid sealing device

The invention relates to the field of mechanical engineering sealing, in particular to a staggered tooth end face type magnetic fluid sealing device. The staggered tooth end face type magnetic fluid sealing device comprises a left pole shoe, a middle pole shoe, a right pole shoe and a permanent magnet. Pole teeth I and annular grooves I are formed in the left end face of the middle pole shoe, and pole teeth II and annular grooves II are formed in the right end face of the middle pole shoe. Pole teeth III and annular grooves III are formed in the right end face of the left pole shoe, and pole teeth IV and annular grooves IV are formed in the left end face of the right pole shoe. The pole teeth I on the middle pole shoe extend into the annular grooves III of the left pole shoe, the pole teeth III of the left pole shoe extend into the annular grooves I of the middle pole shoe, the pole teeth II of the middle pole shoe extend into the annular grooves IV of the right pole shoe, and the pole teeth IV of the right pole shoe extend into the annular grooves II of the middle pole shoe. A step notch is formed in the position, close to an axle, of the left end face of the left pole shoe, and a step notch is formed in the position, close to the axle, of the right end face of the right pole shoe. The permanent magnet is installed in the step notches. The sealing device is good in sealing effect and stable in sealing performance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com