Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Does not affect the cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

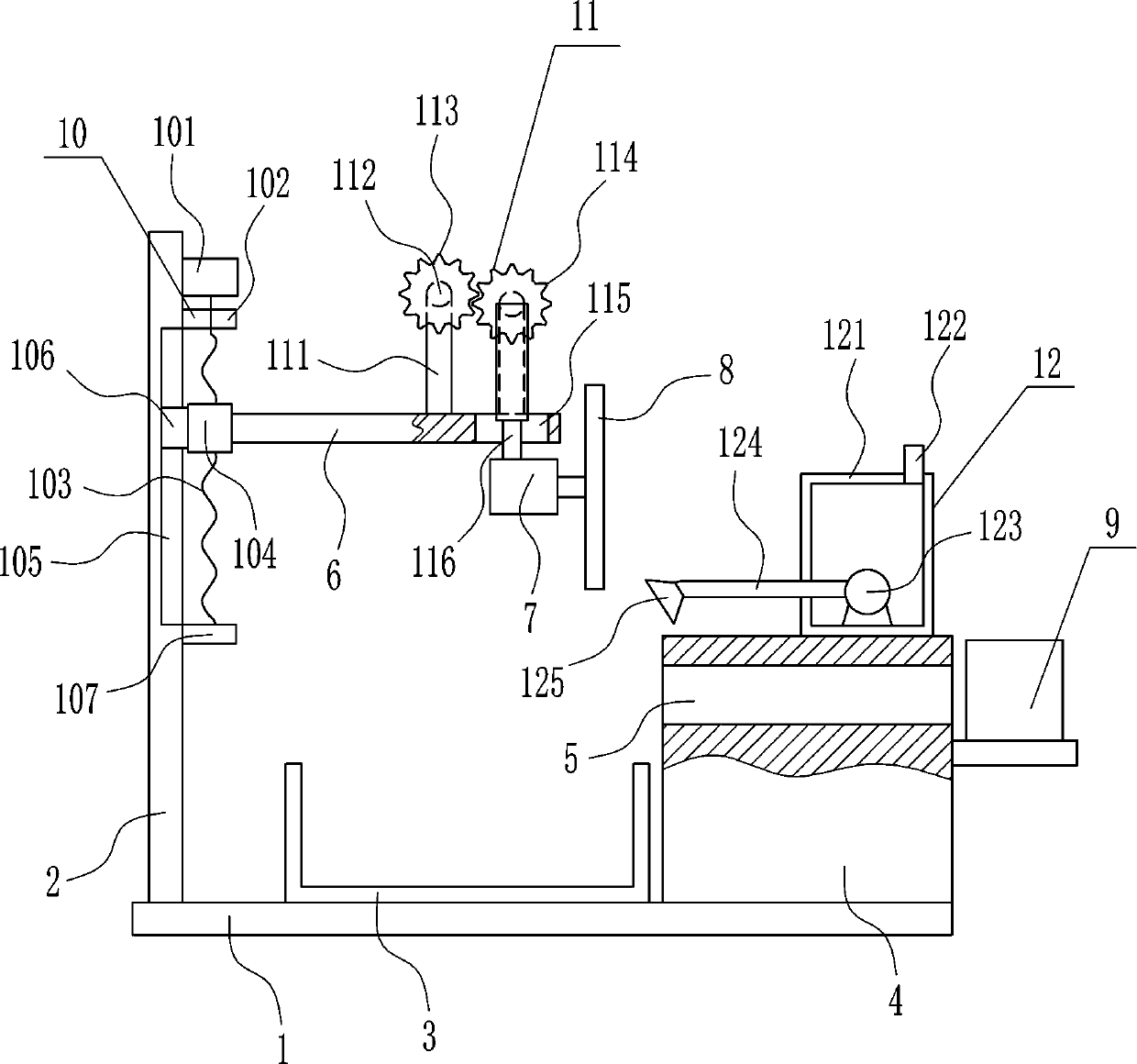

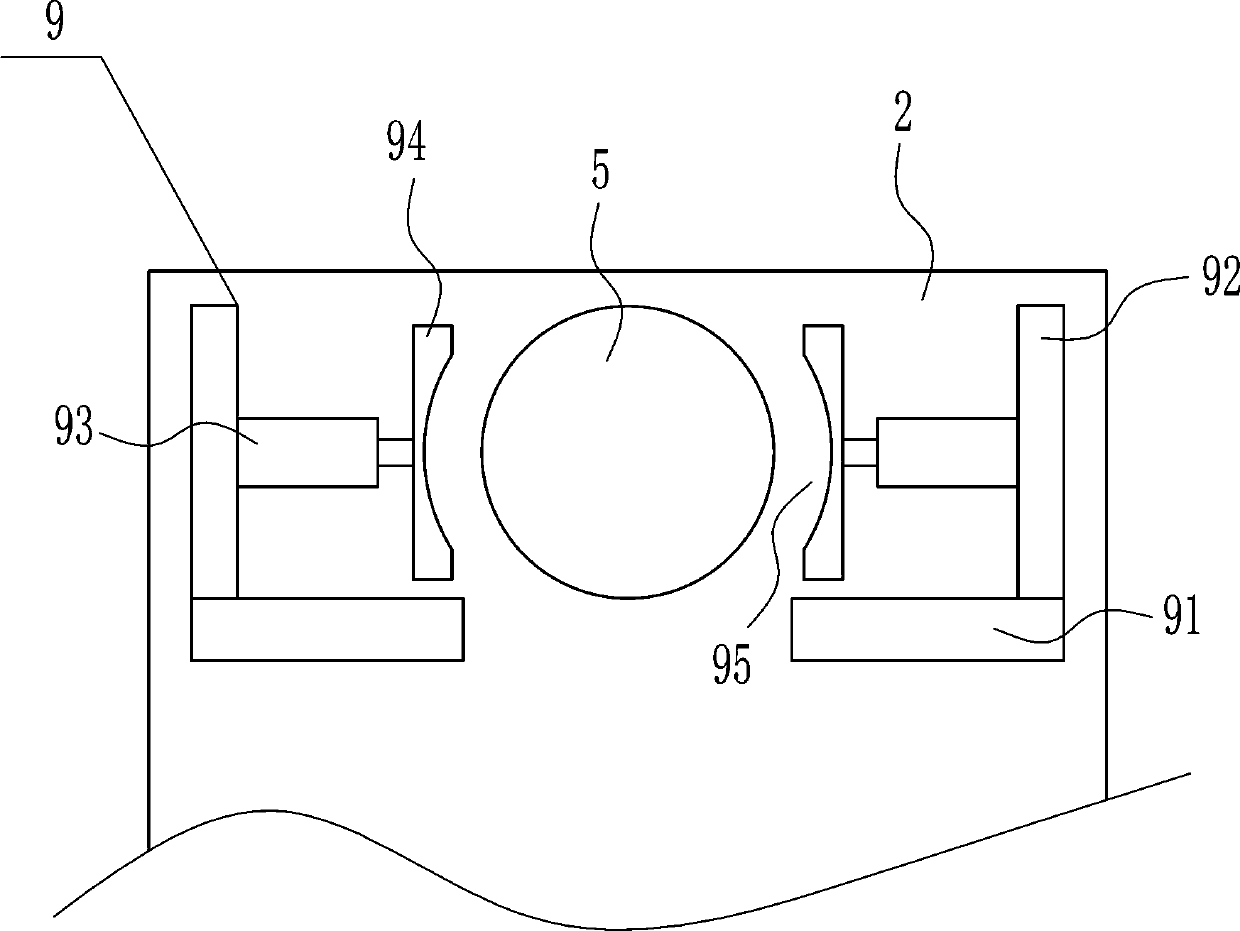

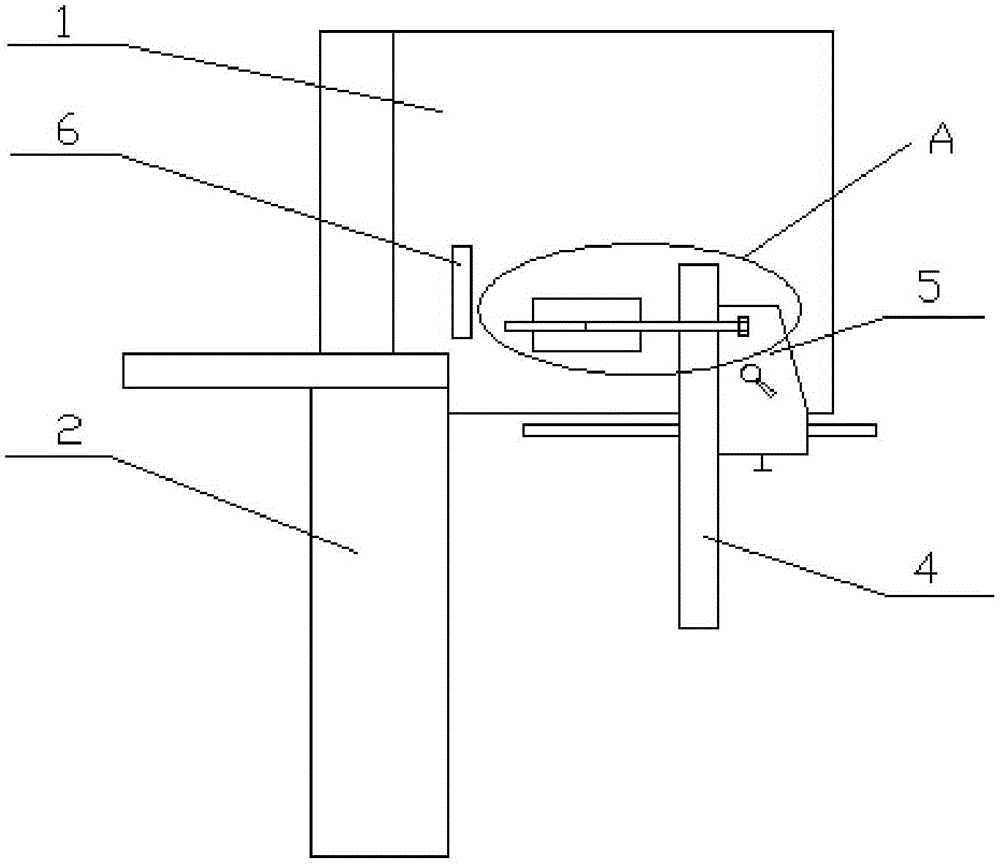

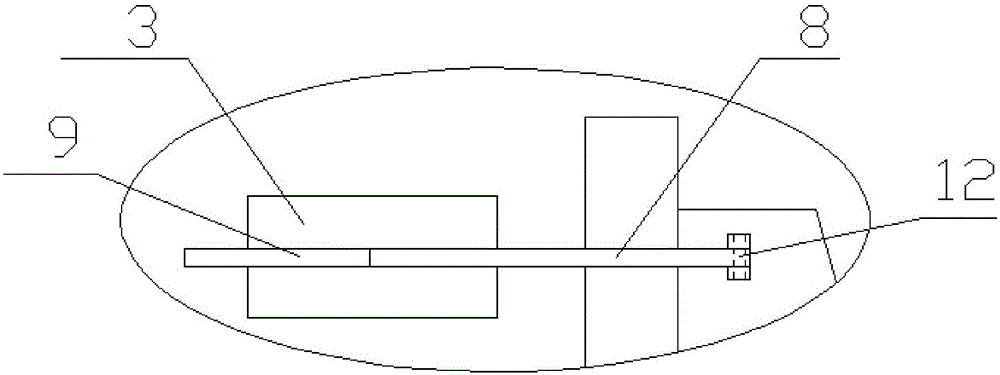

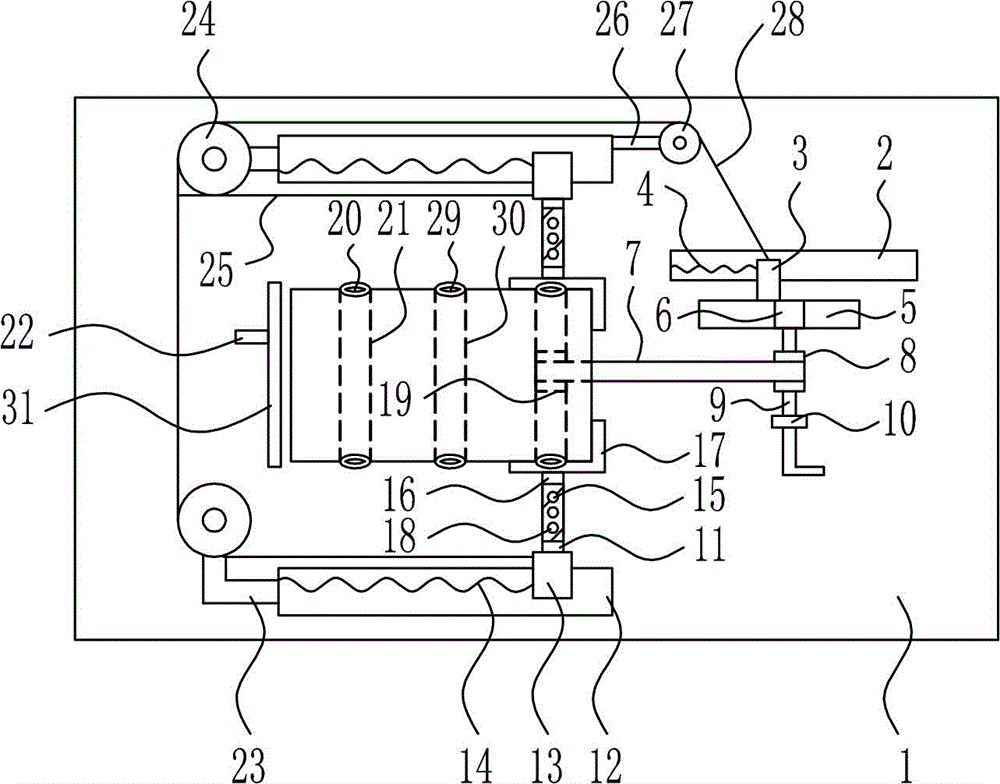

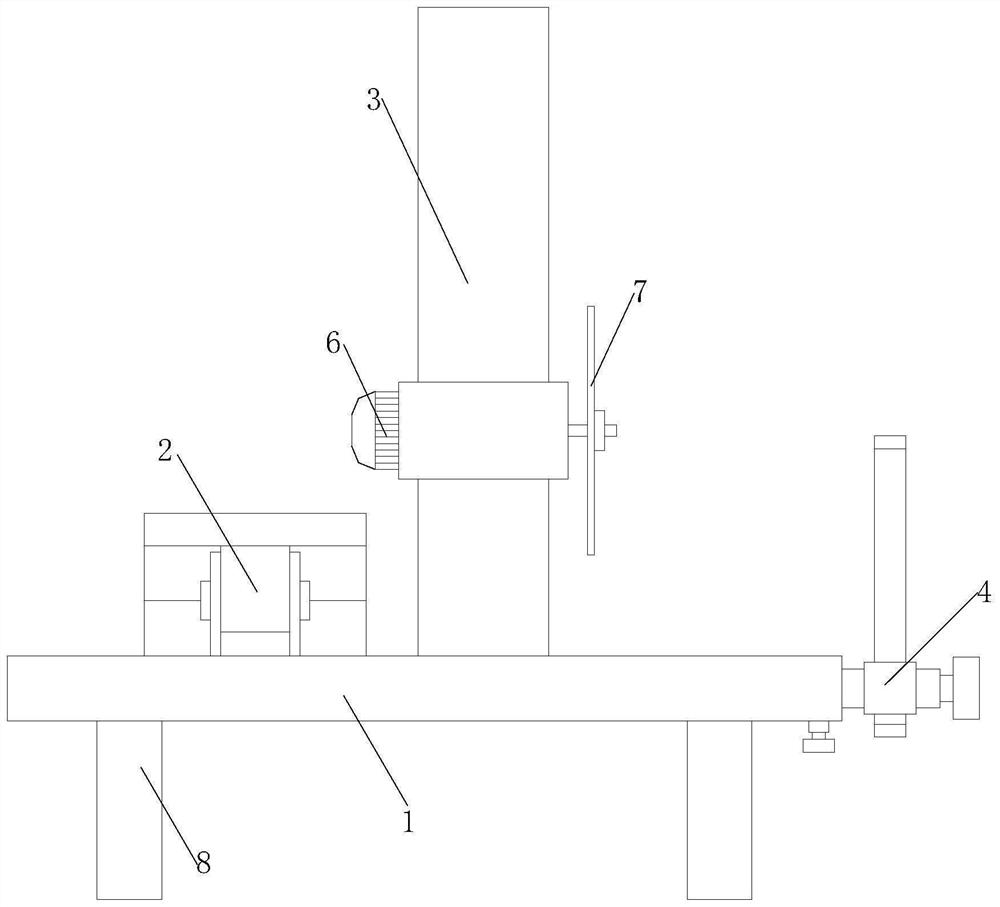

Steel pipe cutting device for engineering material

InactiveCN107824864AEasy to cutDoes not affect the cutting effectTube shearing machinesLarge fixed membersRebarSteel tube

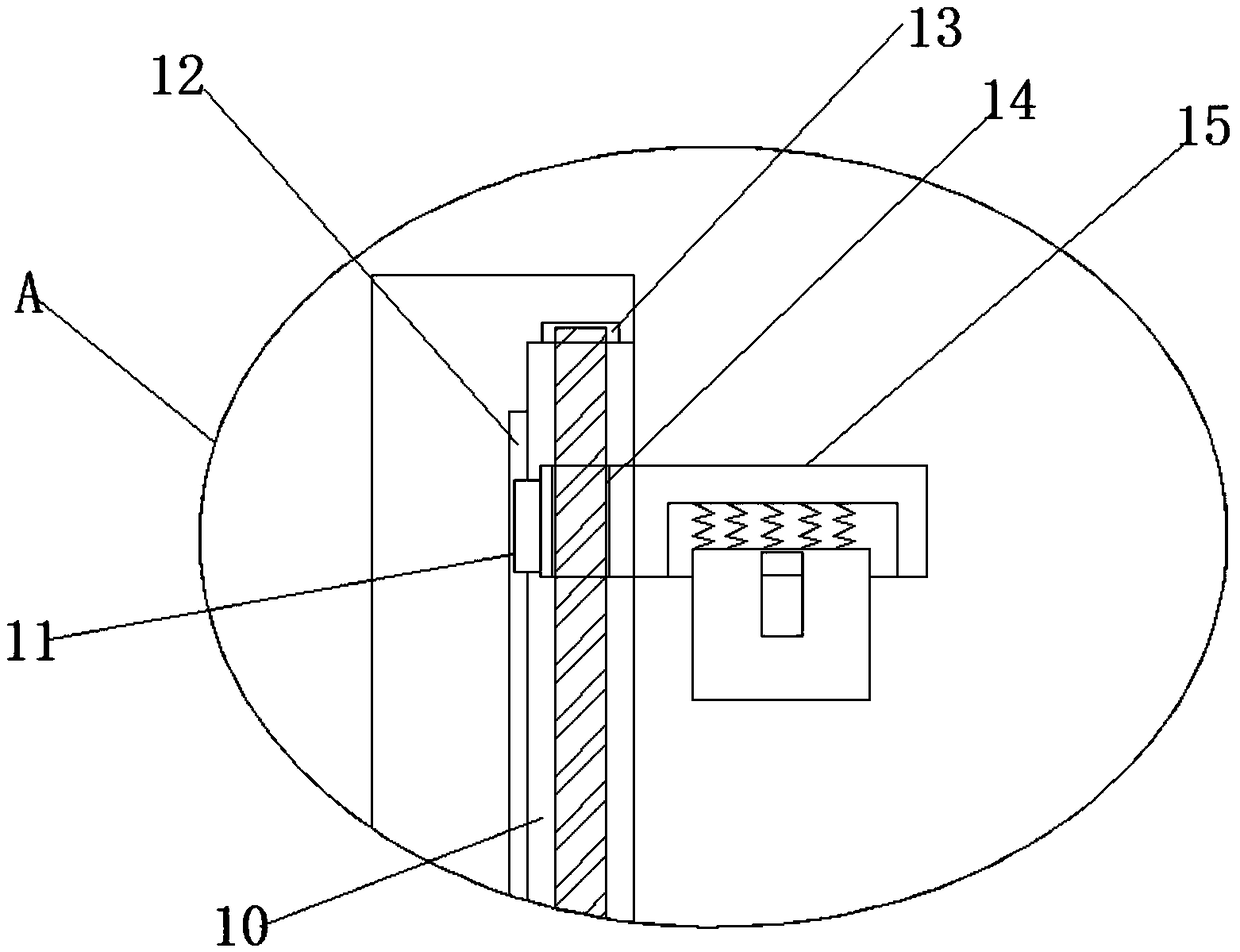

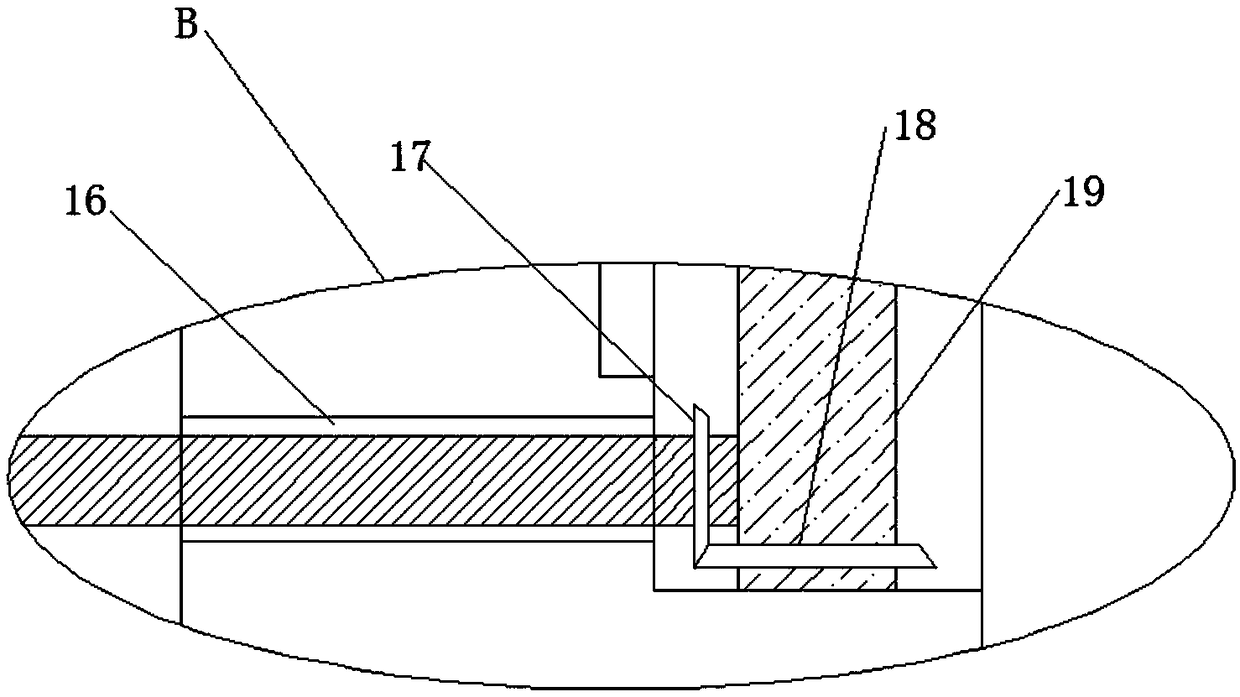

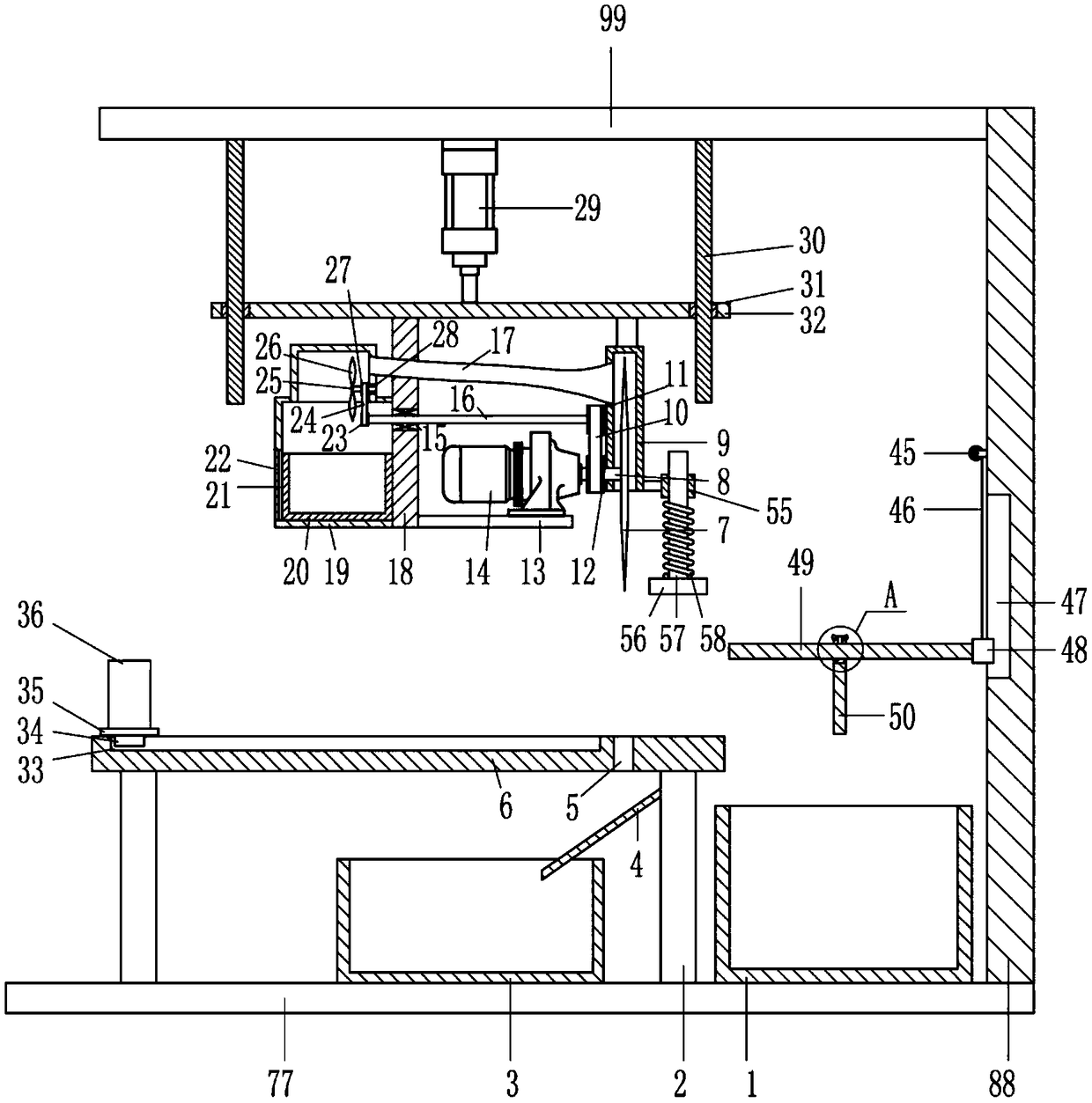

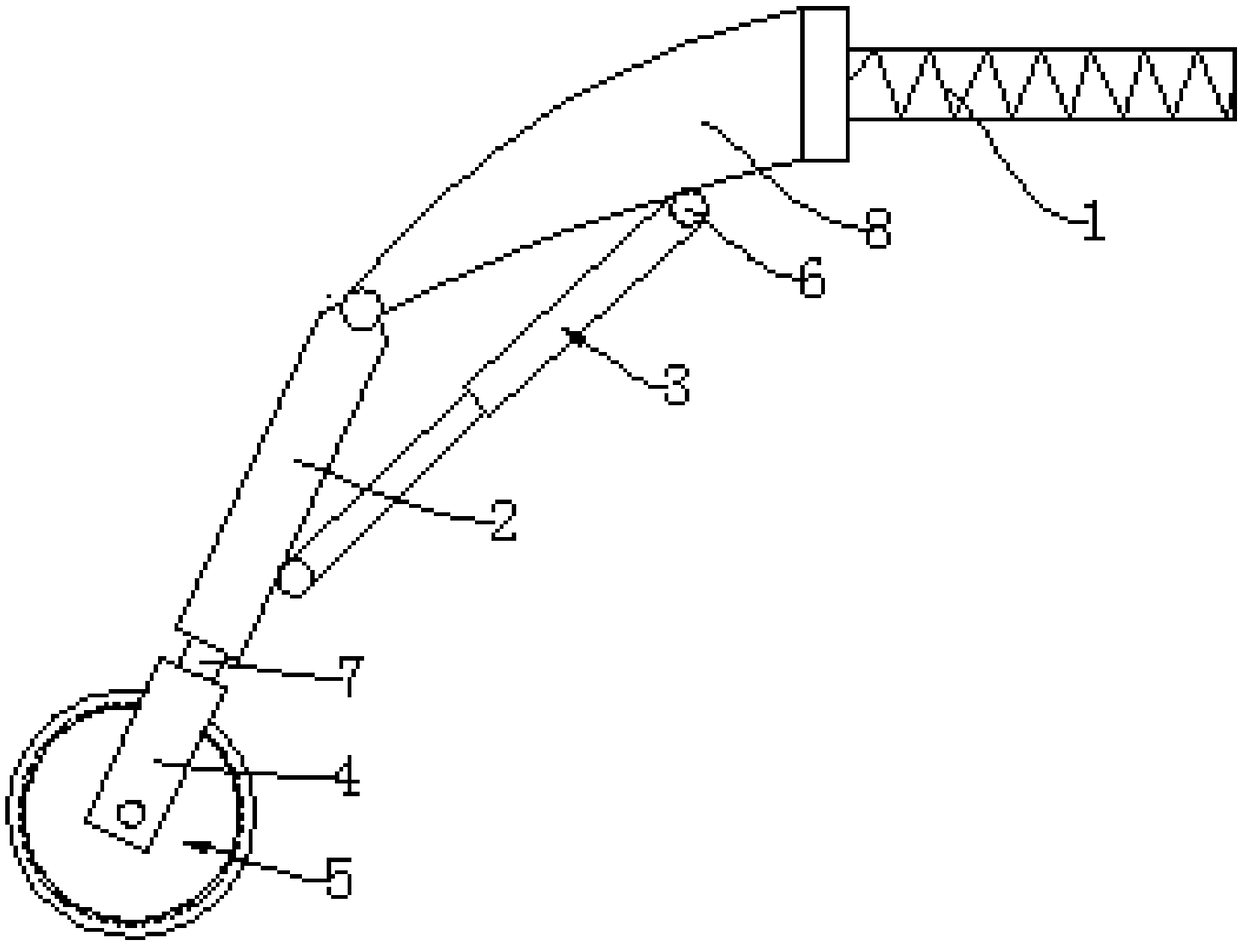

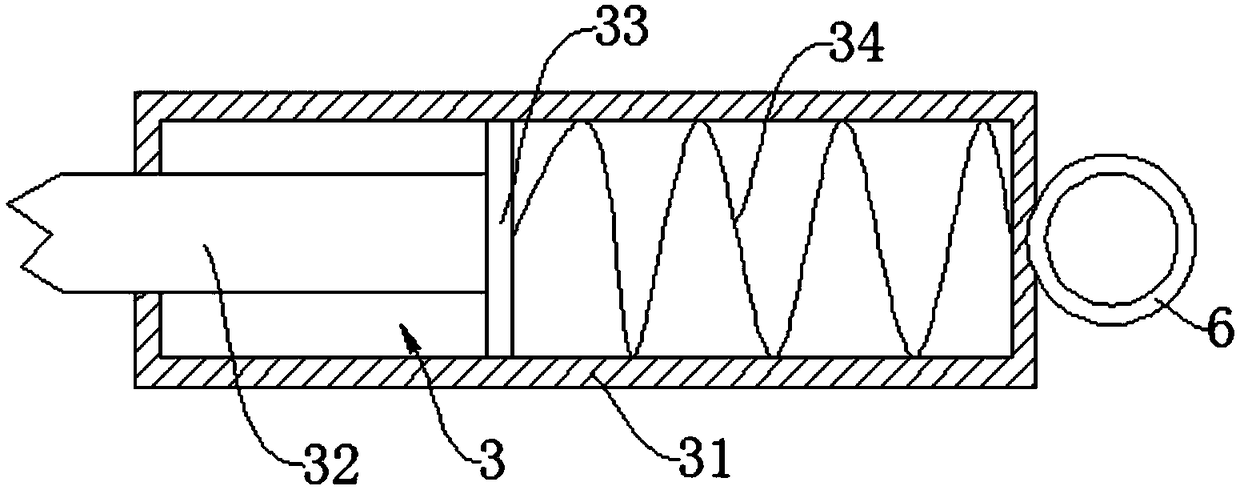

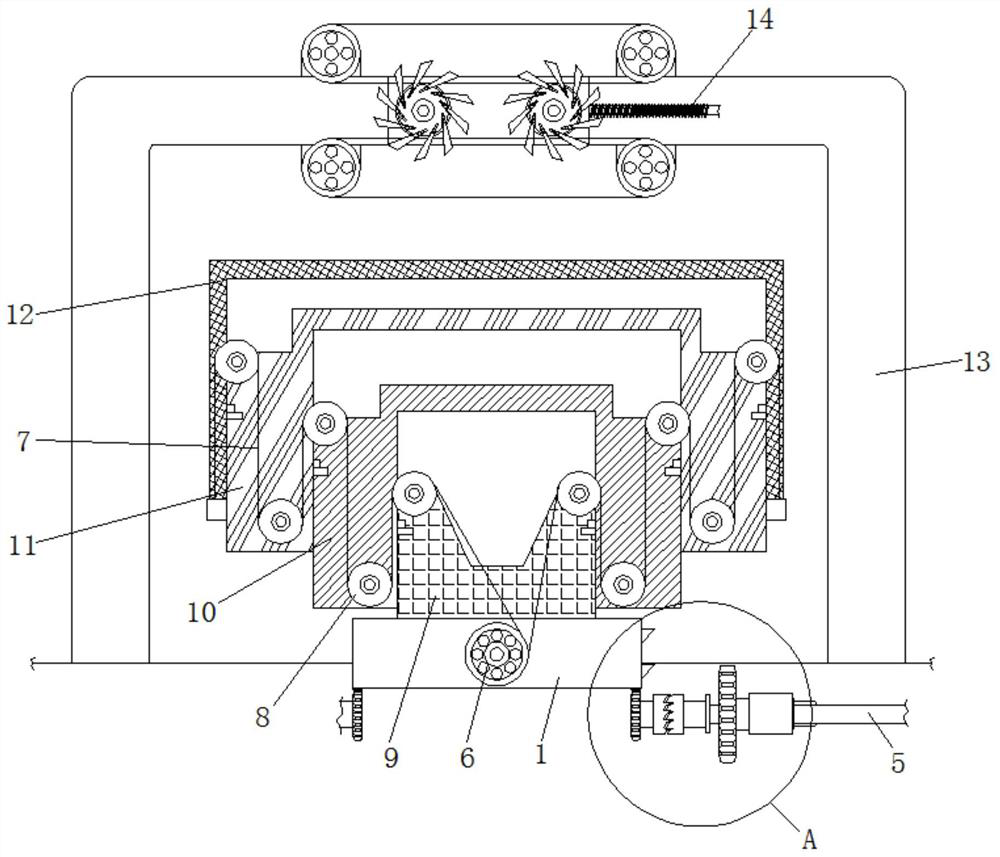

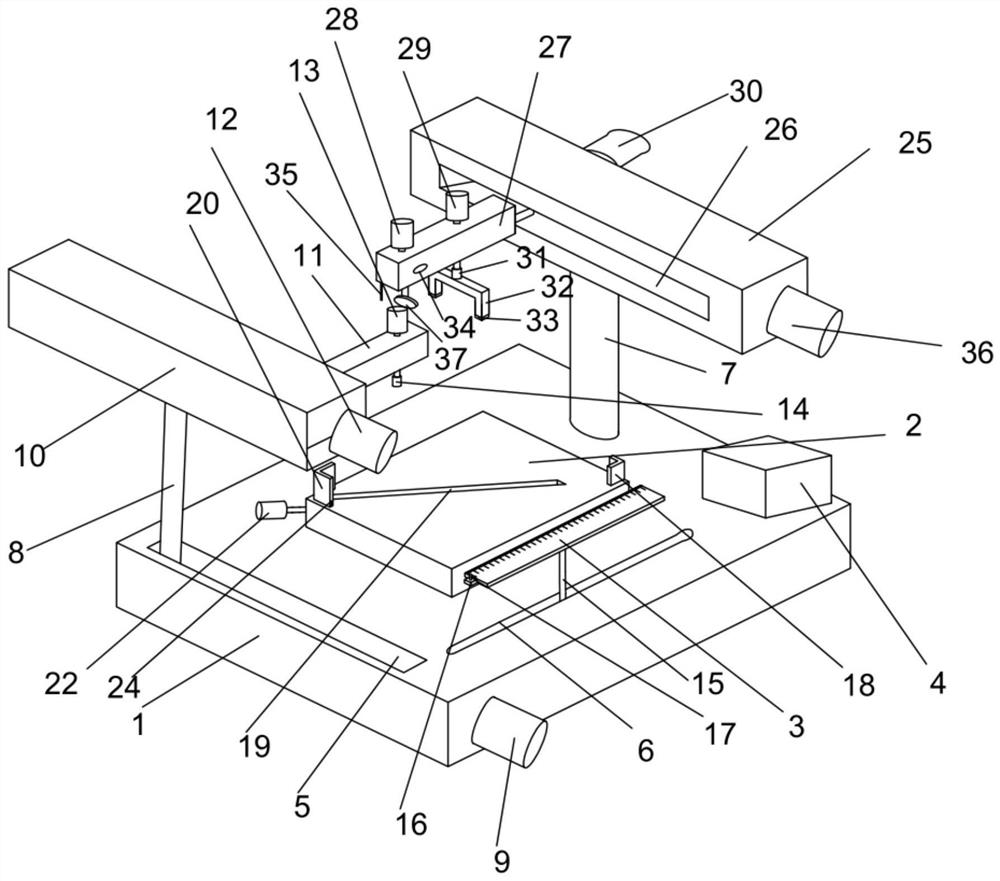

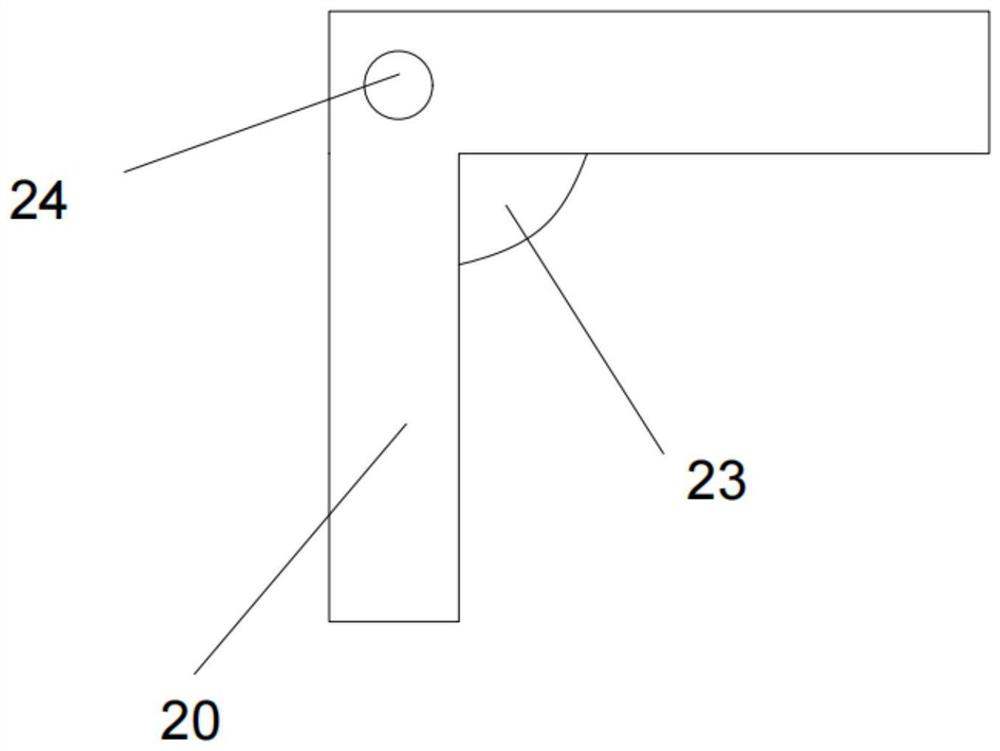

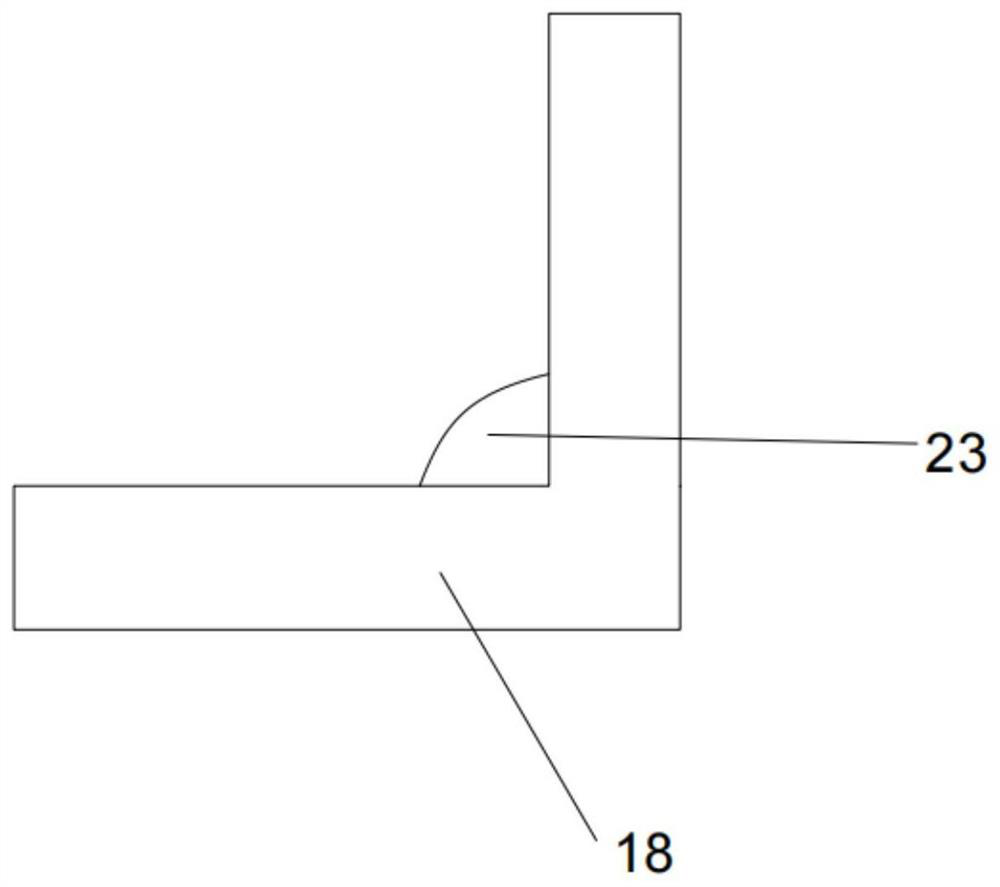

The invention relates to a cutting device, in particular to a steel pipe cutting device for an engineering material. According to the technical purposes of the steel pipe cutting device for the engineering material, time and labor are saved, a user is not injured in the cutting process, operation is easy, and the cutting angle can also be adjusted. In order to achieve the technical purposes, the steel pipe cutting device for the engineering material comprises a bottom plate and the like; a supporting plate, a collecting frame and a fixed base are sequentially installed on the top of the bottomplate from left to right in a bolt connection manner; the upper portion of the fixed base is provided with a containing hole; and a fixed device is arranged on the upper portion of the right side face of the fixed base, and is located on the right side of the containing hole. According to the steel pipe cutting device for the engineering material, by adjusting the cutting angle, a steel bar can be cut to a needed angle, water is sprayed onto a cutter, the cutter can be cooled, the service life is longer, and the effects that time and labor are saved, the user is not injured in the cutting process, operation is easy, and the cutting angle can also be adjusted are achieved.

Owner:刘世荣

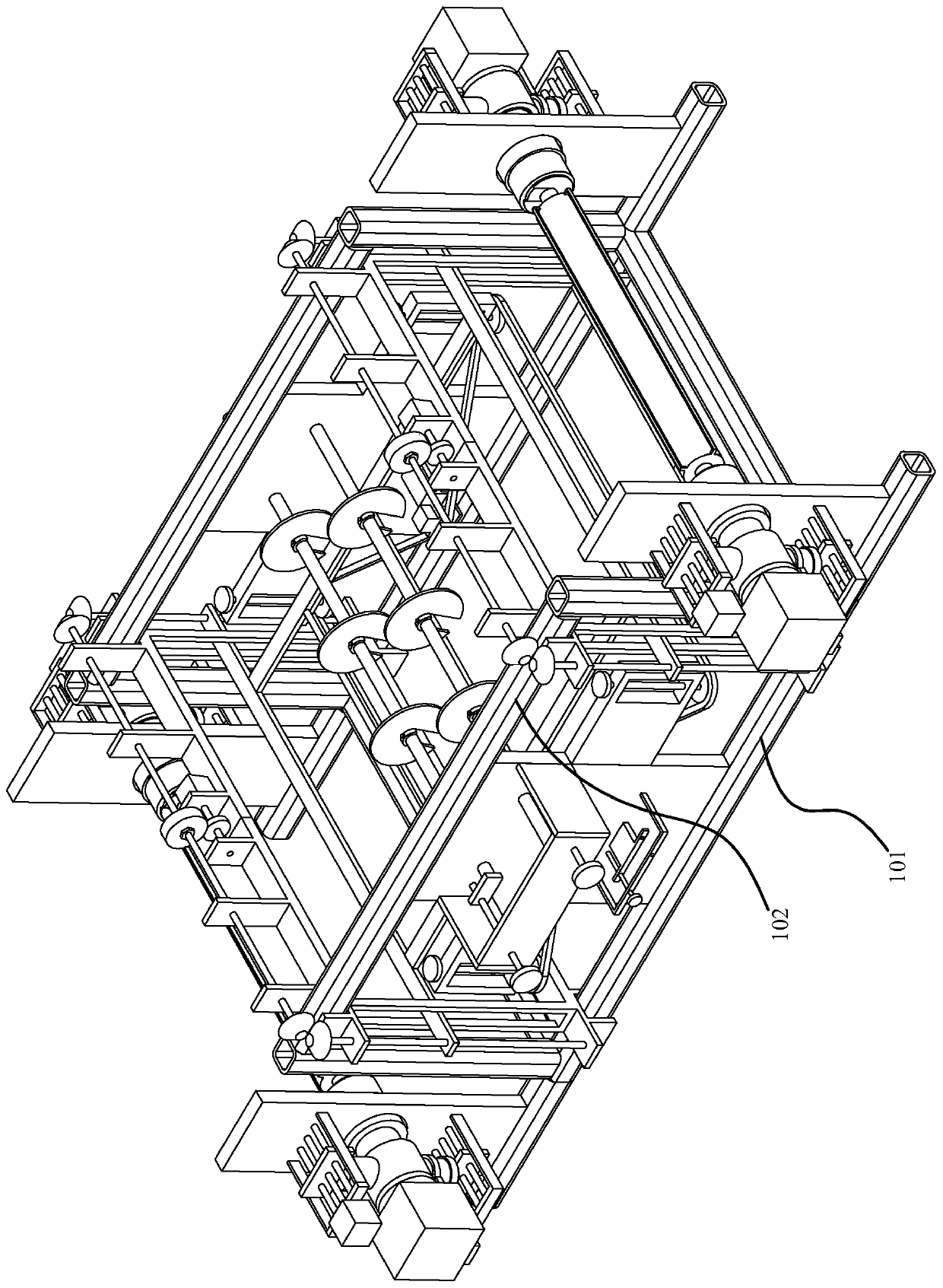

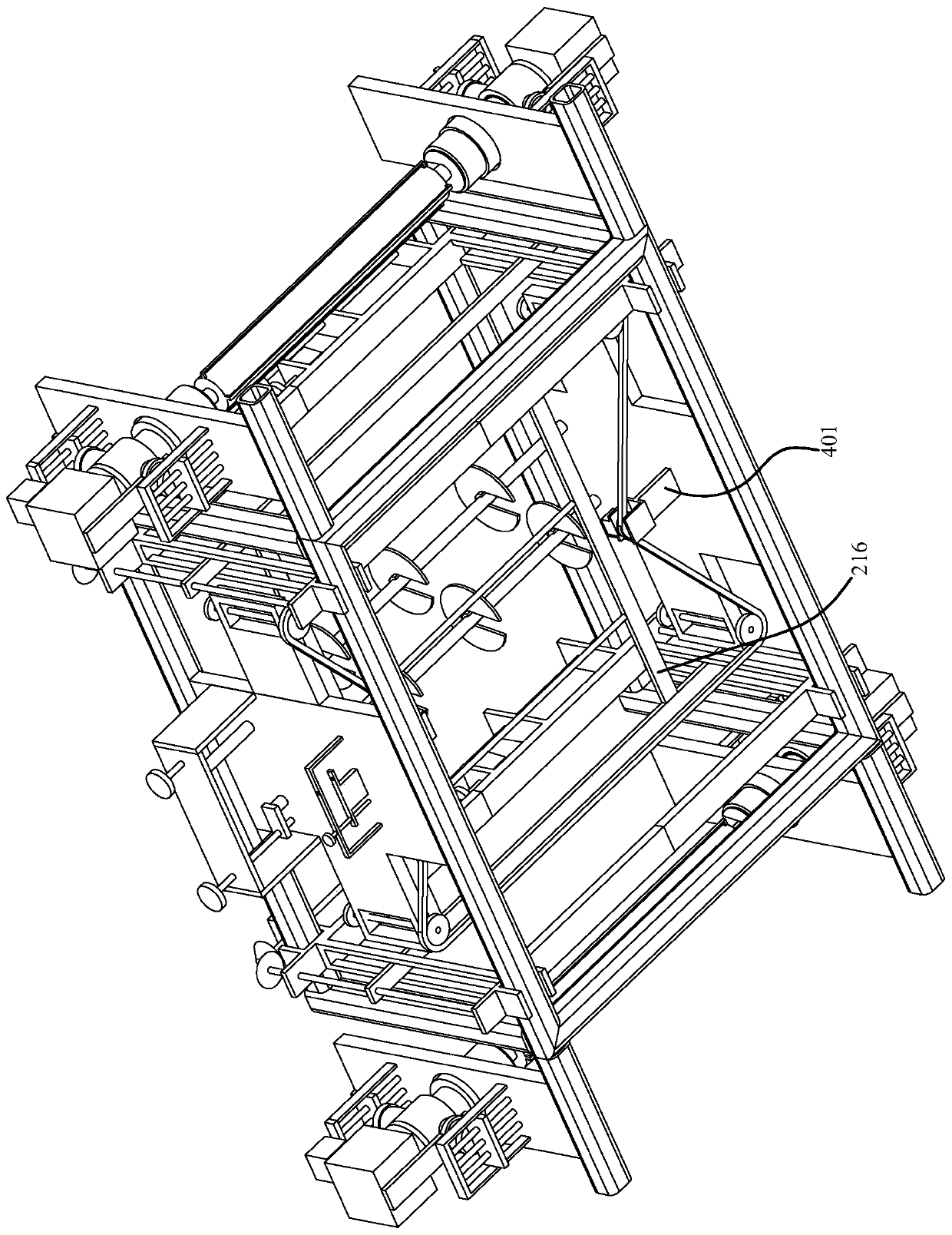

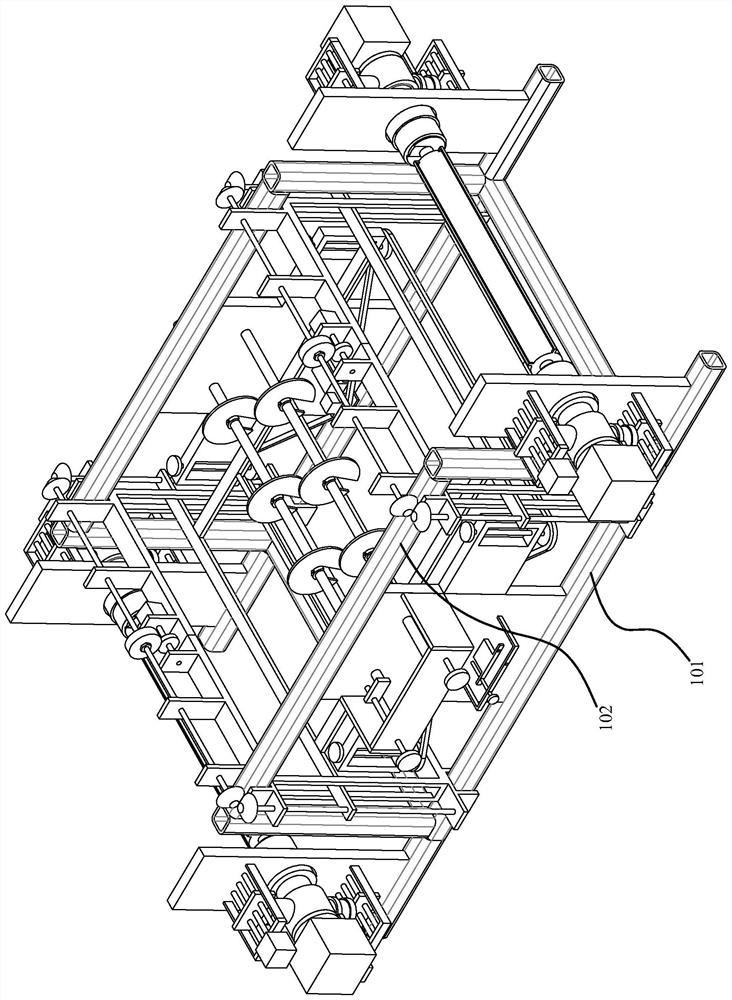

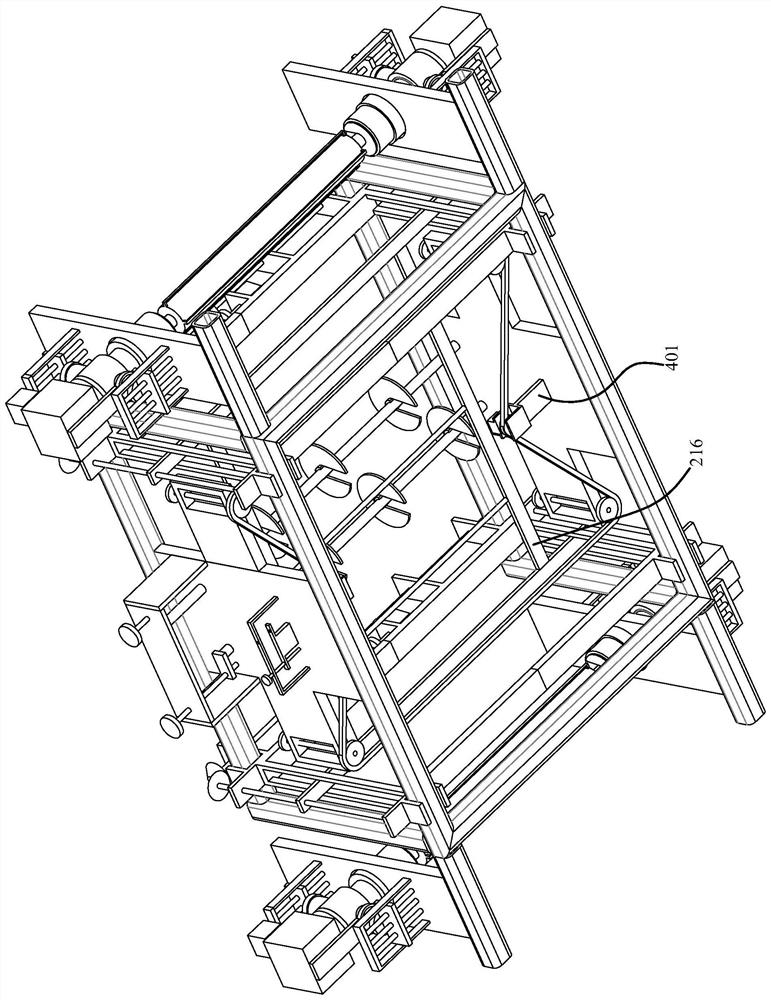

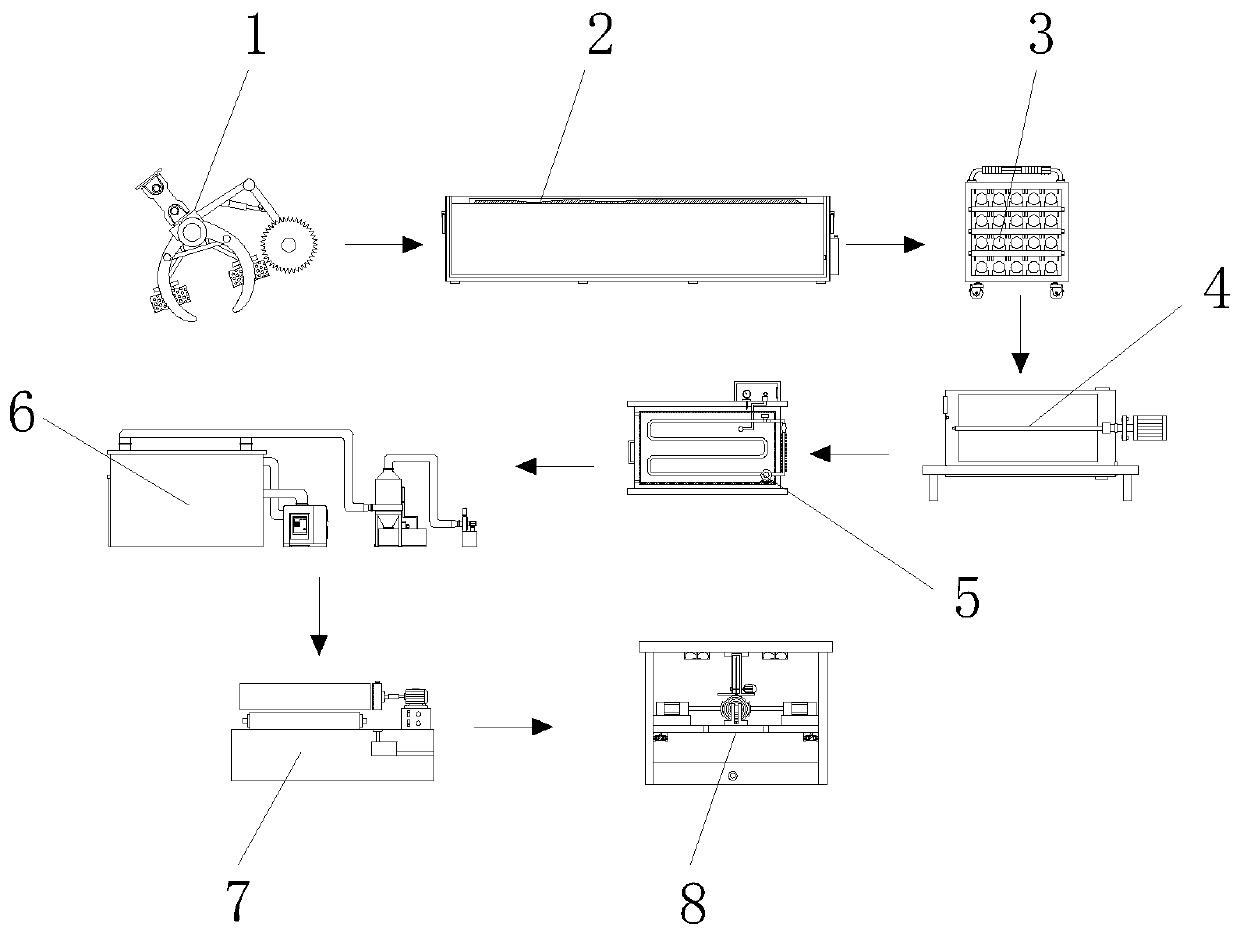

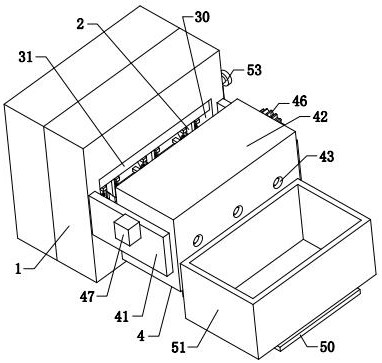

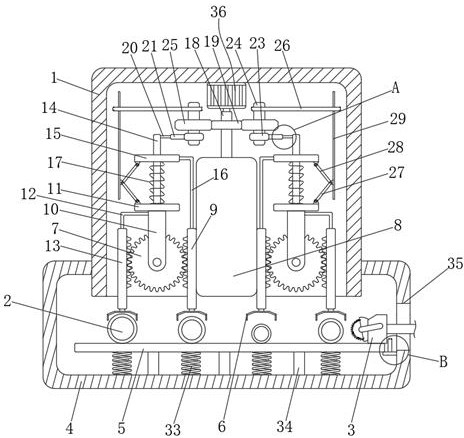

Wood processing treatment integrated system and treatment method thereof

ActiveCN108501124AAvoid damageHigh degree of automationWood treatment detailsProfiling/shaping machinesThermal insulationIntegrated systems

The invention discloses a wood processing treatment integrated system. The system comprises wood sectional acquisition equipment, wood thermal insulation and moisturizing transportation equipment, wood collision preventing storage equipment, automatic temperature-adjusting wood soaking equipment, layered freezing equipment, wood standing and drying equipment, end part oiling sealing equipment andwood section slitting equipment. The invention also discloses the wood processing treatment integrated system and a treatment method thereof. The automation degree is high, wood cannot be damaged, thesystem and the method have broad market competitiveness, the wood quality can be effectively guaranteed, atmosphere pollution is avoided, the production cost is saved, and the production environmentis effectively improved.

Owner:新沂市超华木业有限公司

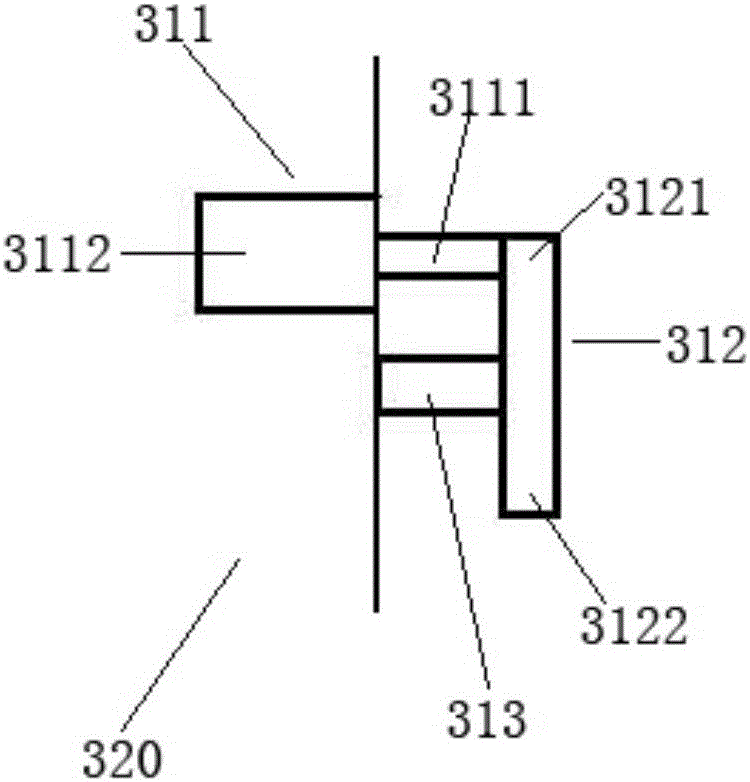

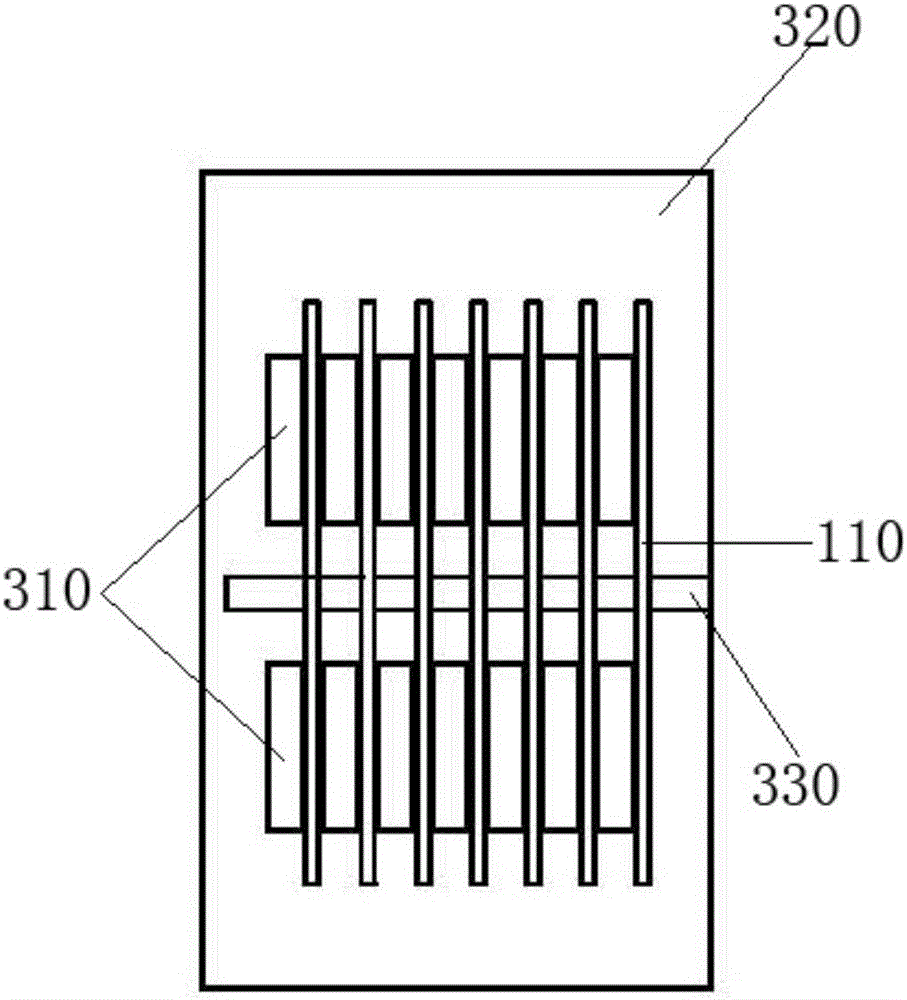

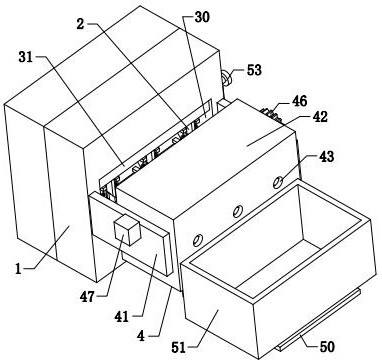

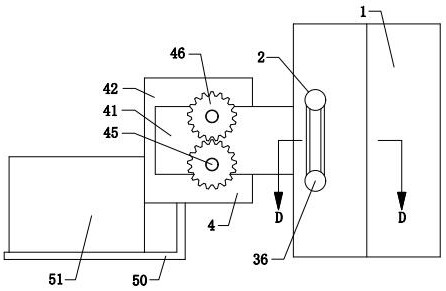

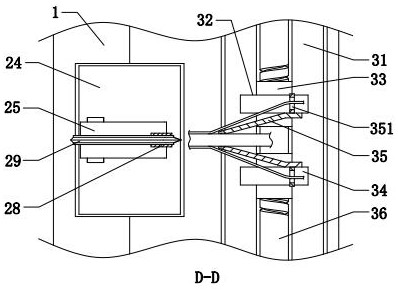

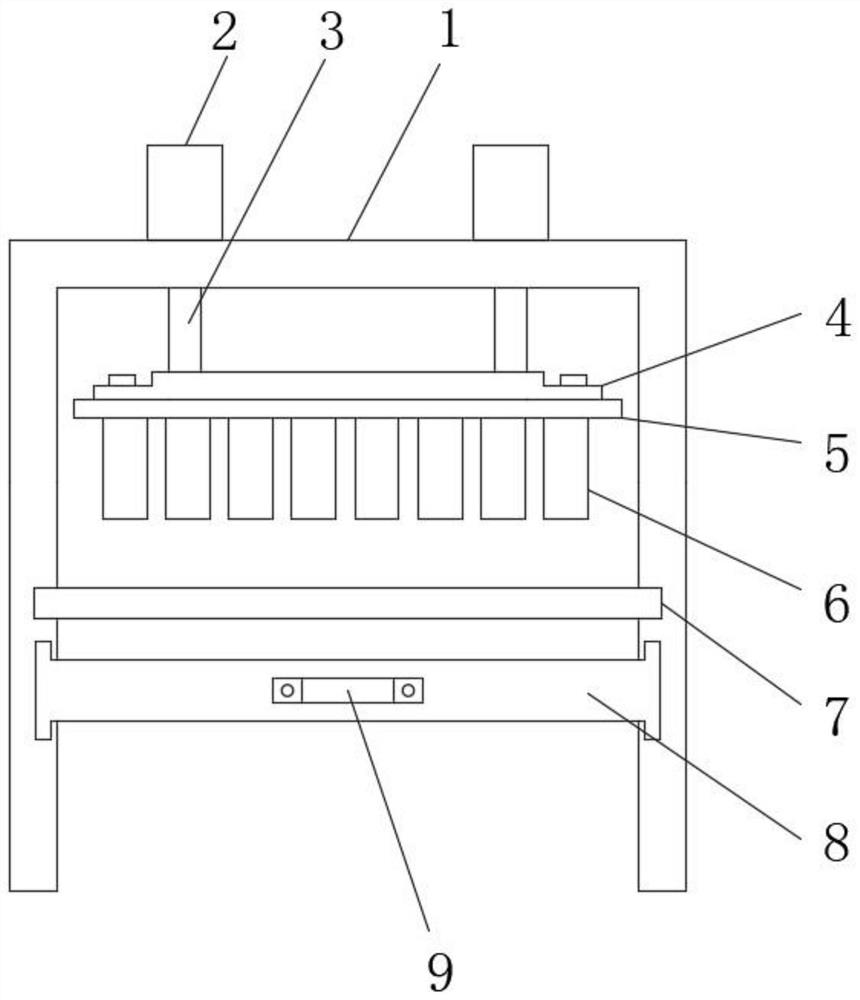

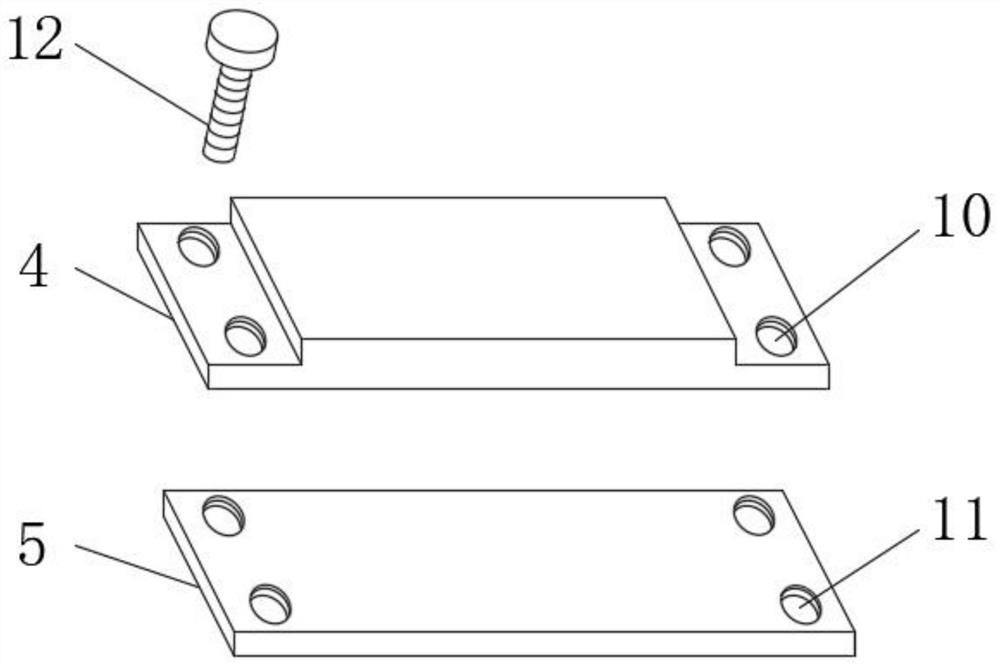

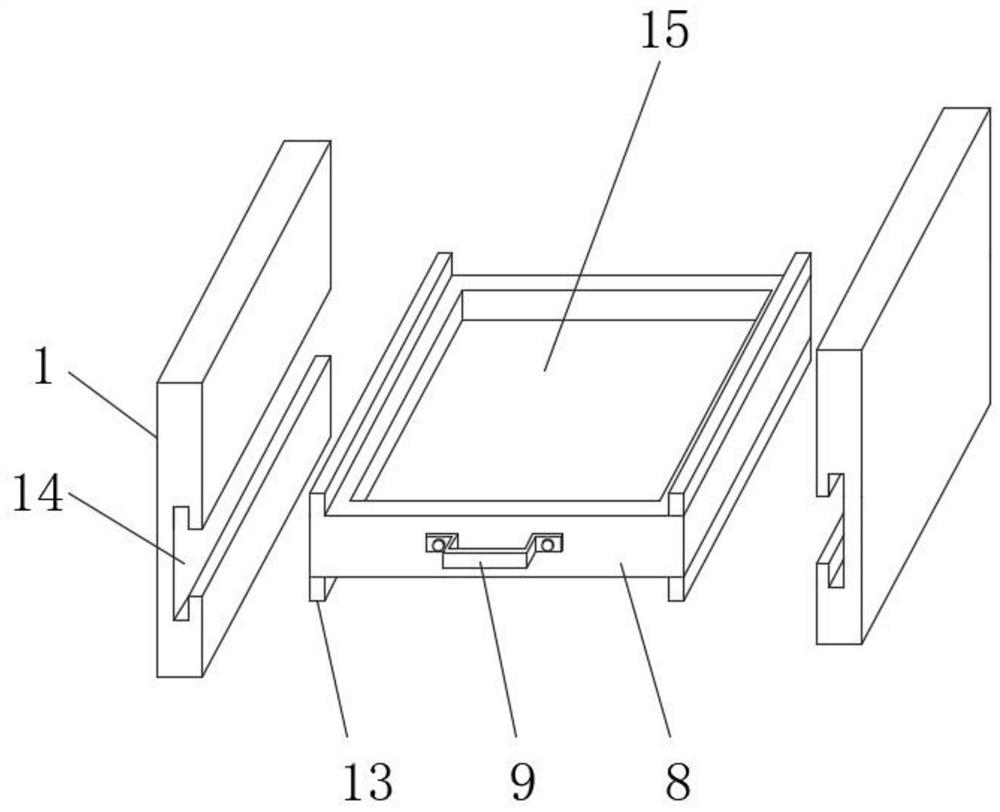

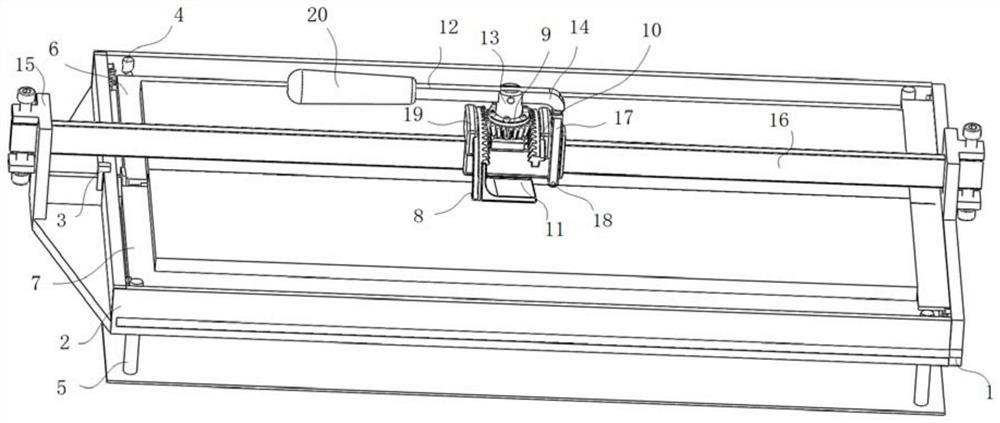

Sliding table saw with press roller device

InactiveCN105058506ADoes not affect the cutting effectGuarantee personal safetyFeeding devicesCircular sawsNatural stateEngineering

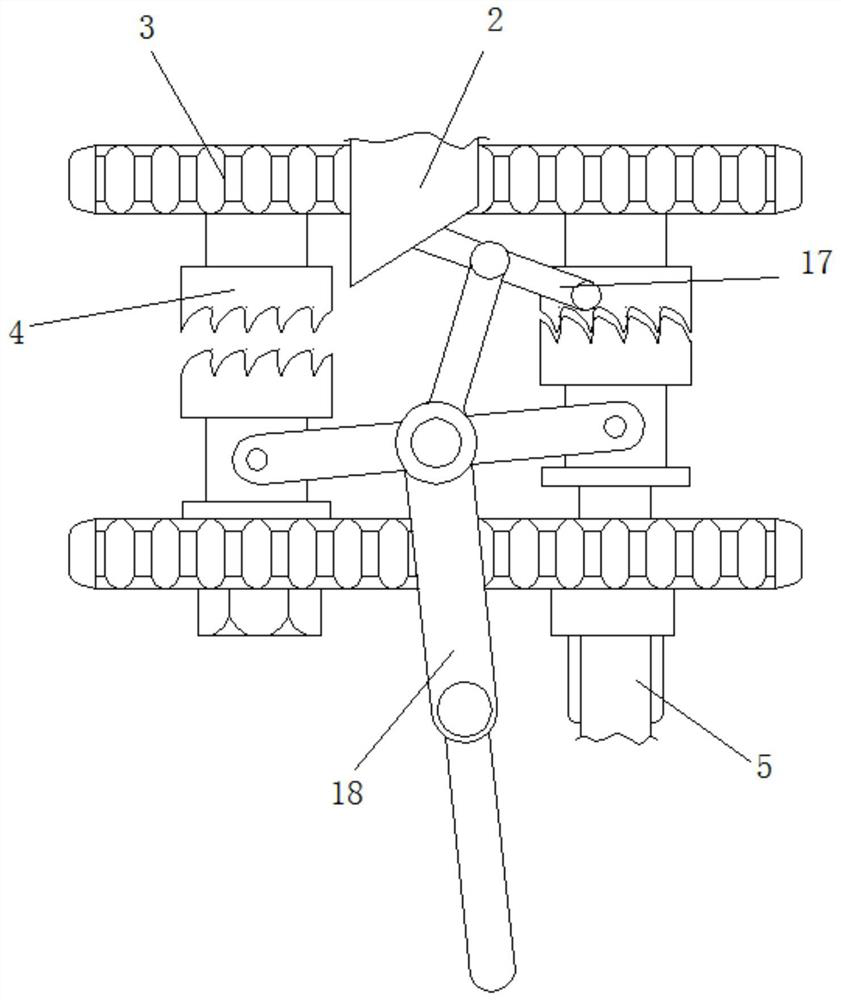

The invention discloses a sliding table saw with a press roller device. The sliding table saw with the press roller device comprises a workbench, a sliding table, a longitudinal limiting device and a cutter saw. The sliding table and the longitudinal limiting device are arranged on the two sides of the workbench in a sliding manner respectively. The longitudinal limiting device comprises a press roller, a longitudinal limiting bar and a locating device. The press roller is fixed to the upper end of the locating device through a connecting rod device. The cutter saw is arranged between the press roller and the sliding table. The press roller is pressed downwards to the upper end of the workbench in the natural state. The perpendicular distance between the press roller and the workbench is adjusted through the connecting rod device. The sliding table saw has the beneficial effects that a wooden board cannot be warped upwards in the cutting process, the cutting effect cannot be affected, and personal safety is guaranteed as well.

Owner:天津宏达联合包装材料科技有限公司

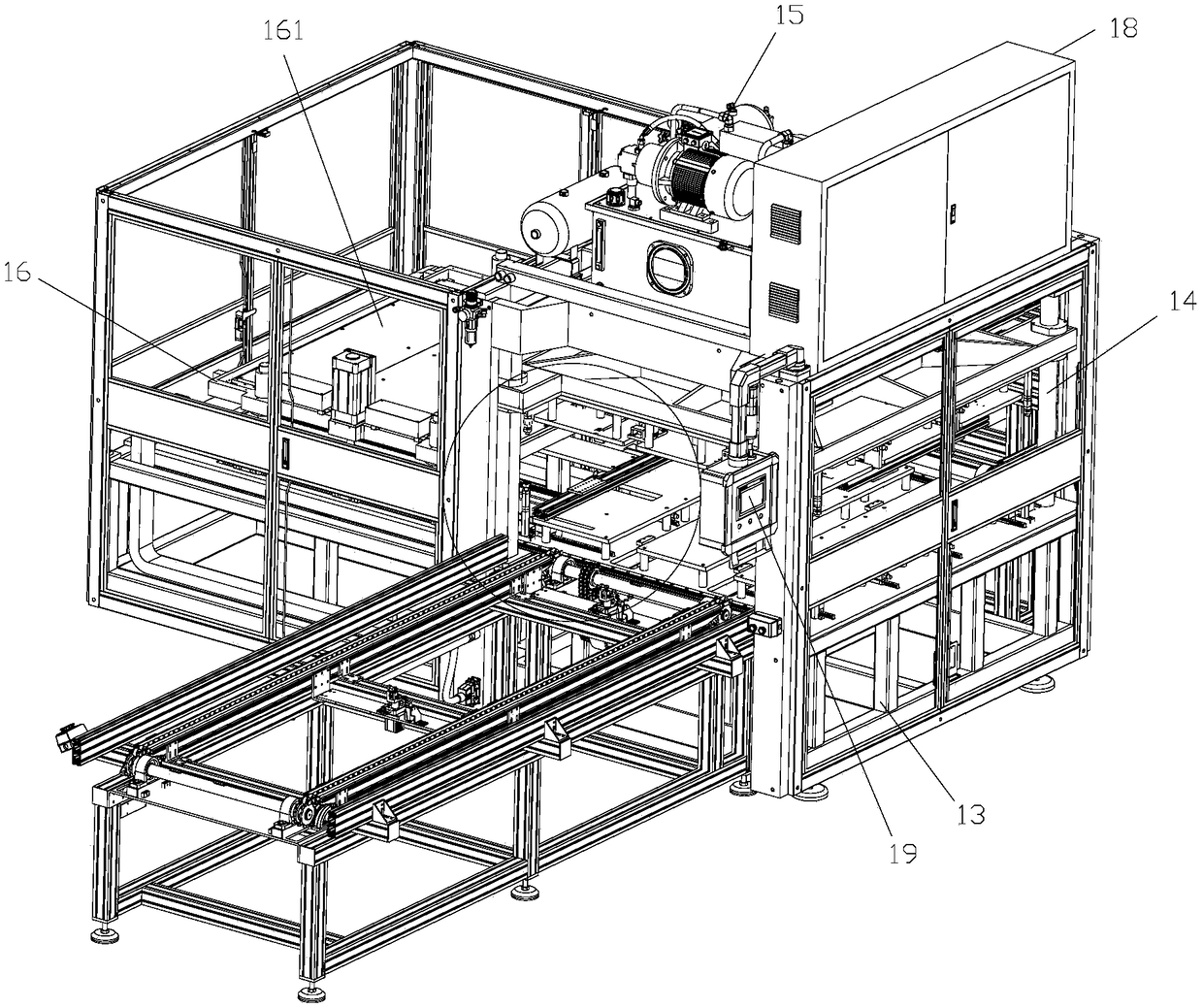

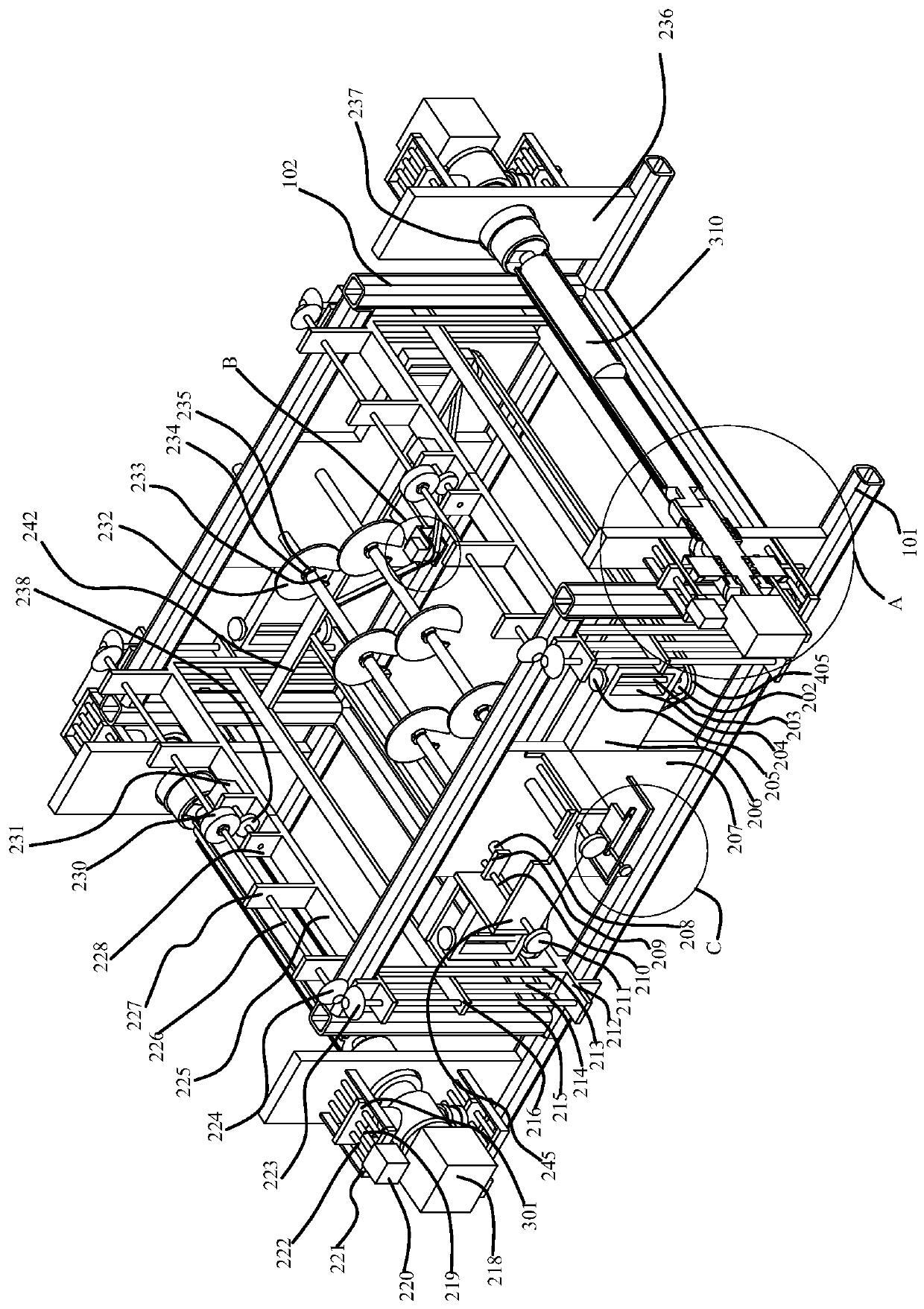

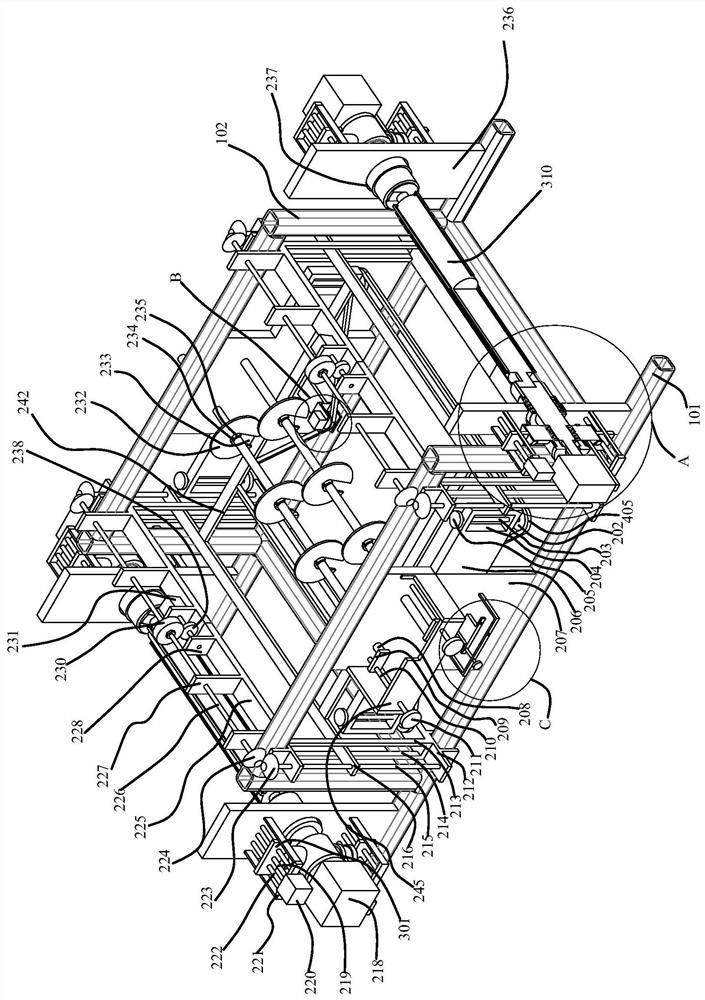

Tray welding assembly line

The invention discloses a tray welding assembly line, and relates to the field of heat plate welding assembly line equipment for plastic trays. The tray welding assembly line is sequentially providedwith a material distribution working station, a heat plate welding working station, an edge milling working station, a hot air welding working station, a splitting working station and a material discharge working station; after the tray raw material is welded by a heat plate, the tray is sent into a second chain group to perform edge milling, and a milling knife is used for treating the spilled material at the welding edge of the tray; then, the tray is sent into a third chain group to perform hot air welding on antislip strips, and a hot air gun is used for performing heat melting welding onthe crossing part of the antislip and the tray; after the welding is completed, the synchronous splitting is performed; finally, the single tray after splitting is sent into the material discharge working station on a fourth chain group, and the trays are sequentially stacked up; after ten trays are overlapped, the trays are fetched out and delivered out by an operator. The tray welding assembly line has the advantages that the automation degree is high; a plurality of processing structures are integrated into one assembly line; on the basis of heat melting welding of the plastic tray, each procedure is performed on the sustained running material delivery line, and the working efficiency of the tray welding assembly line is outstanding.

Owner:SUZHOU KEBER PRECISION MACHINERY

Wood slab cutting device for furniture production and processing

InactiveCN108621260AEasy to fixSimple structureProfiling/shaping machinesEngineeringMechanical engineering

The invention discloses a wood slab cutting device for furniture production and processing. The wood slab cutting device for furniture production and processing comprises a fixed seat, wherein a fixedslot is formed in the top of the fixed seat; a wood slab body is placed on the inner wall of the bottom of the fixed groove; two symmetrically arranged connecting plates are fixedly mounted on the top of the fixed seat; grooves are formed in one sides, close to each other, of the two connecting plates; turn holes are formed in one sides of the connecting plates and communicate to the grooves; twoservo motors are fixedly mounted on the top of the fixed seat; the output shafts of the servo motors penetrate through the turn holes and stretch into the grooves and are fixedly provided with firstbevel gears in a sleeved manner; turn troughs are formed in the top inner walls of the grooves; rotating seats are rotatably mounted in the turn troughs; lifting seats are slidably mounted on the rotating seats; and chutes are formed in the inner walls on one sides of the grooves. The wood slab cutting device for furniture production and processing disclosed by the invention is simple in structureand convenient to use, and can fix wood slab bodies conveniently without affecting the cutting effect.

Owner:湖州亚信科技孵化有限公司

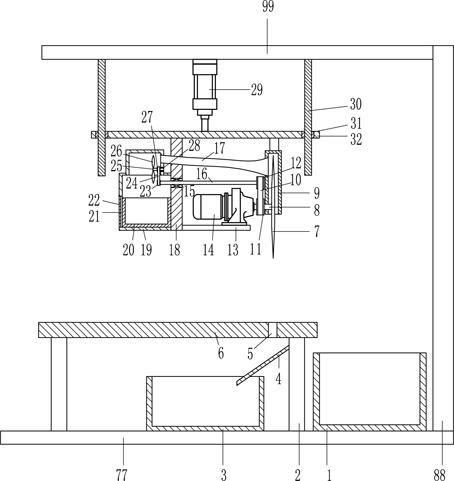

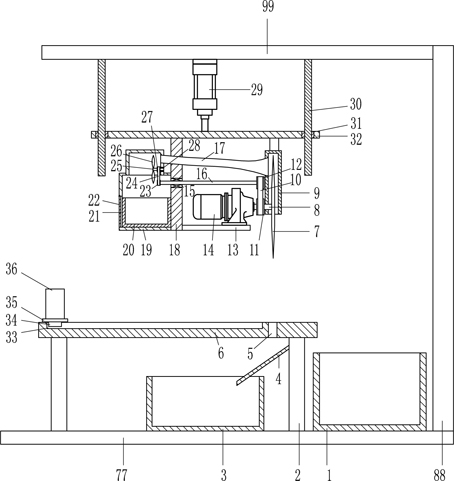

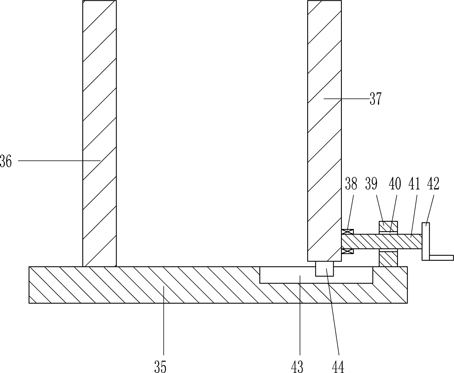

Dustproof type cutting device for wood machining

InactiveCN109015927AReduce dustReduce labor intensityProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningEngineering

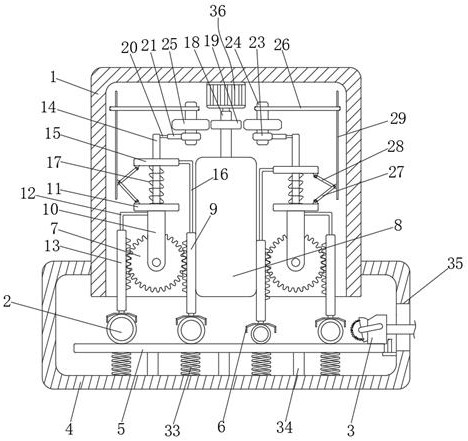

The invention belongs to the field of wood machining and particularly relates to a dustproof type cutting device for wood machining. The dustproof type cutting device for wood machining can reduce generated dust during wood cutting and lower the labor intensity of work personnel. The dustproof type cutting device for wood machining comprises a base plate, a side plate, a top plate, a first collecting frame, supporting seats, a second bearing seat, an air cylinder, first sliding rods, first sliding sleeves, a lifting plate and the like. The side plate is fixedly connected to one side portion ofthe base plate. A cutting platform is fixedly connected to the top of the base plate through the supporting seats. The first collecting frame is arranged between the corresponding supporting seat andthe side plate. A second collecting frame is arranged at the bottom of the cutting platform. The dustproof type cutting device for wood machining achieves the effects of reducing dust in the wood cutting process, collecting wood chips generated during cutting and lowering the labor intensity in the cutting process.

Owner:阜阳双乔木业有限公司

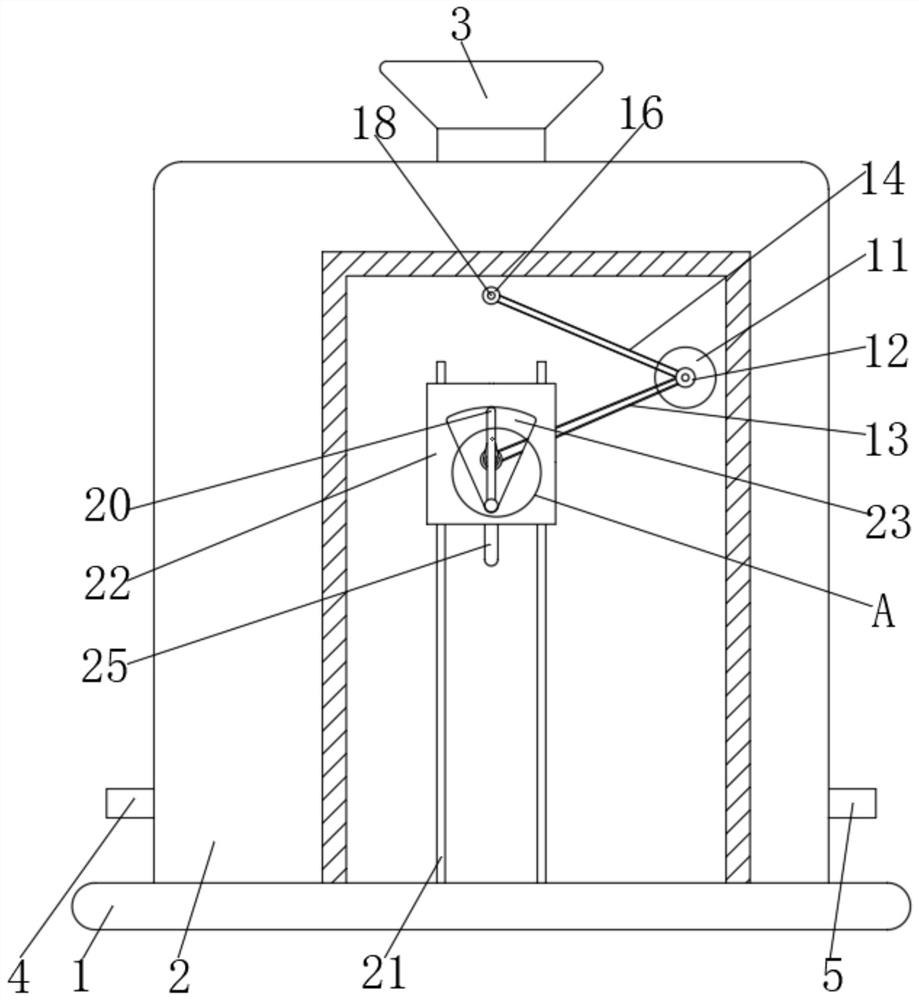

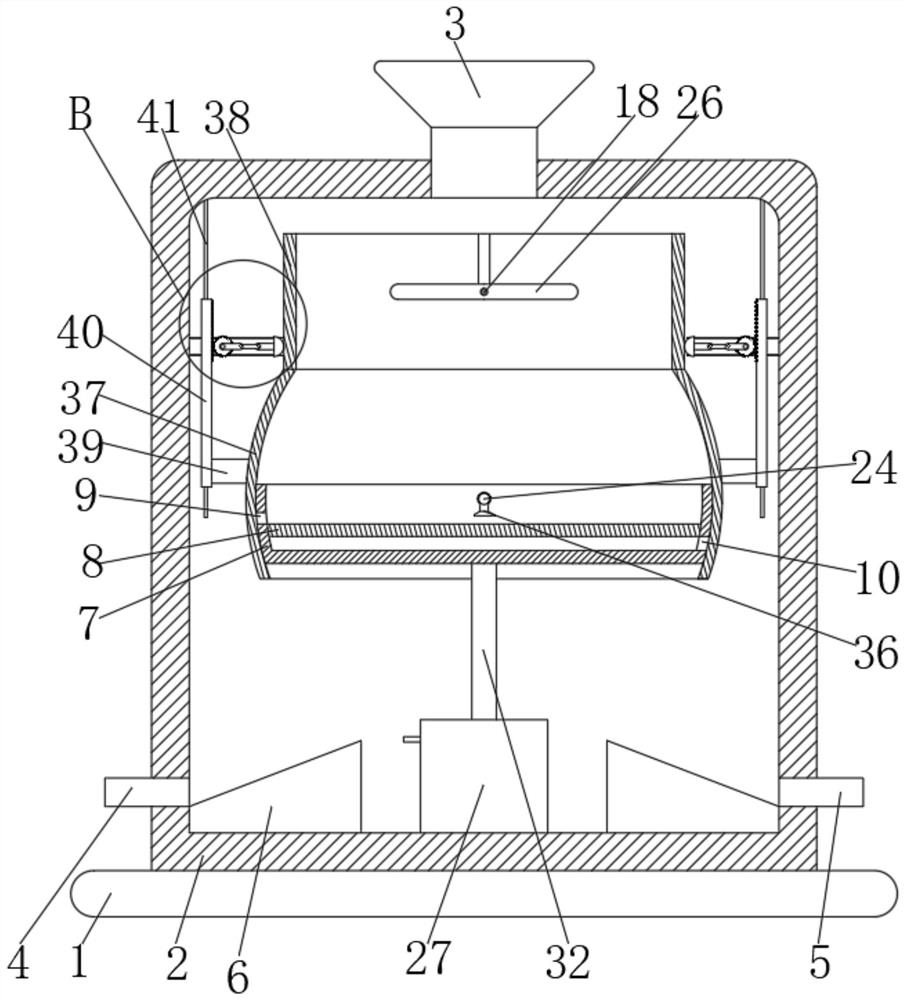

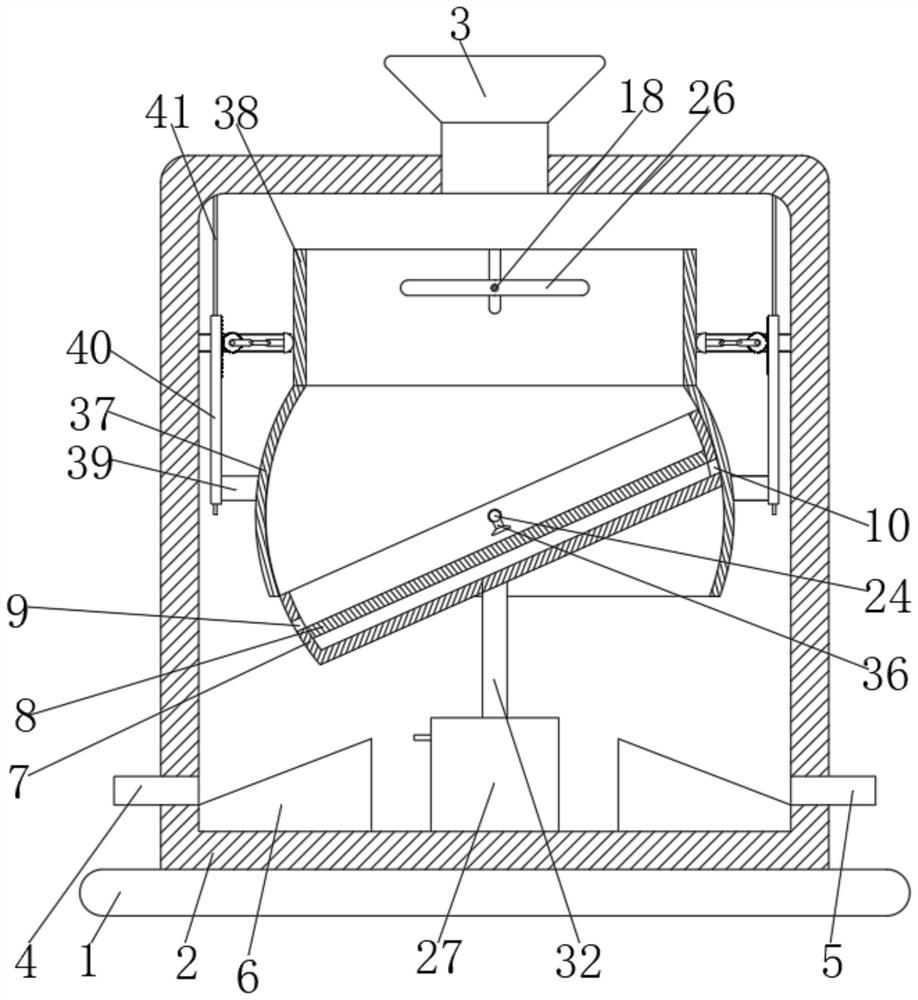

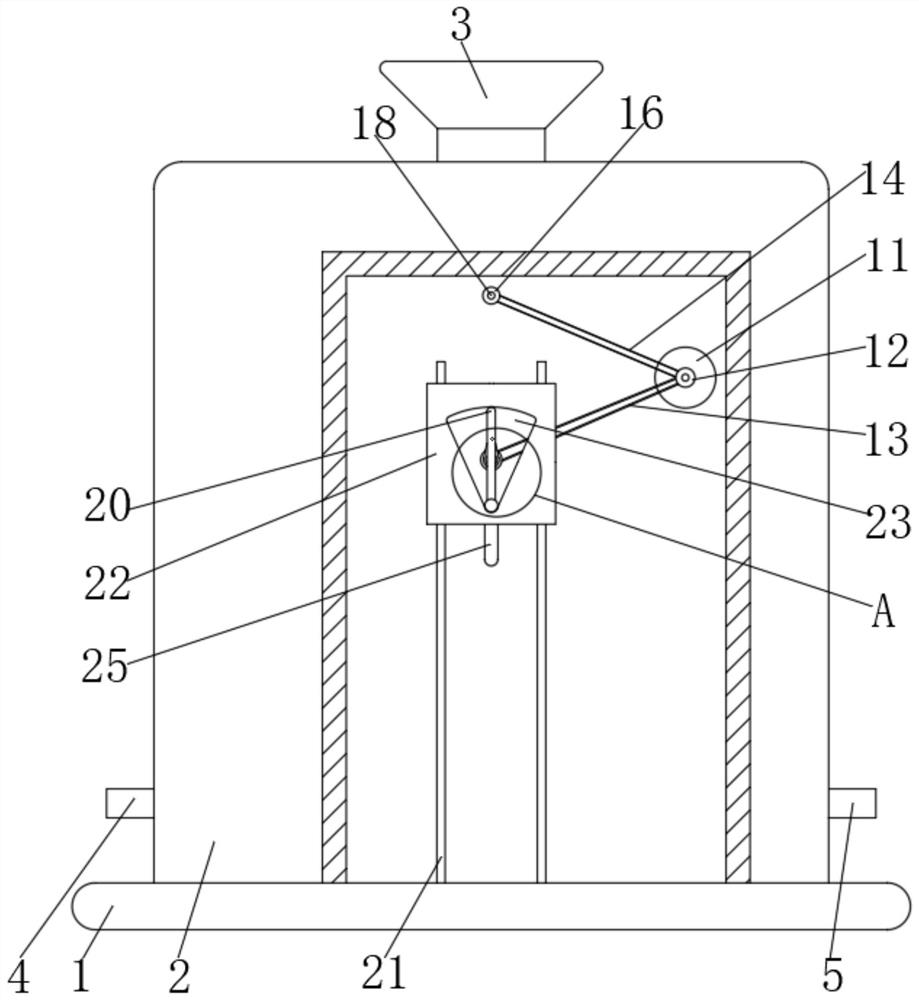

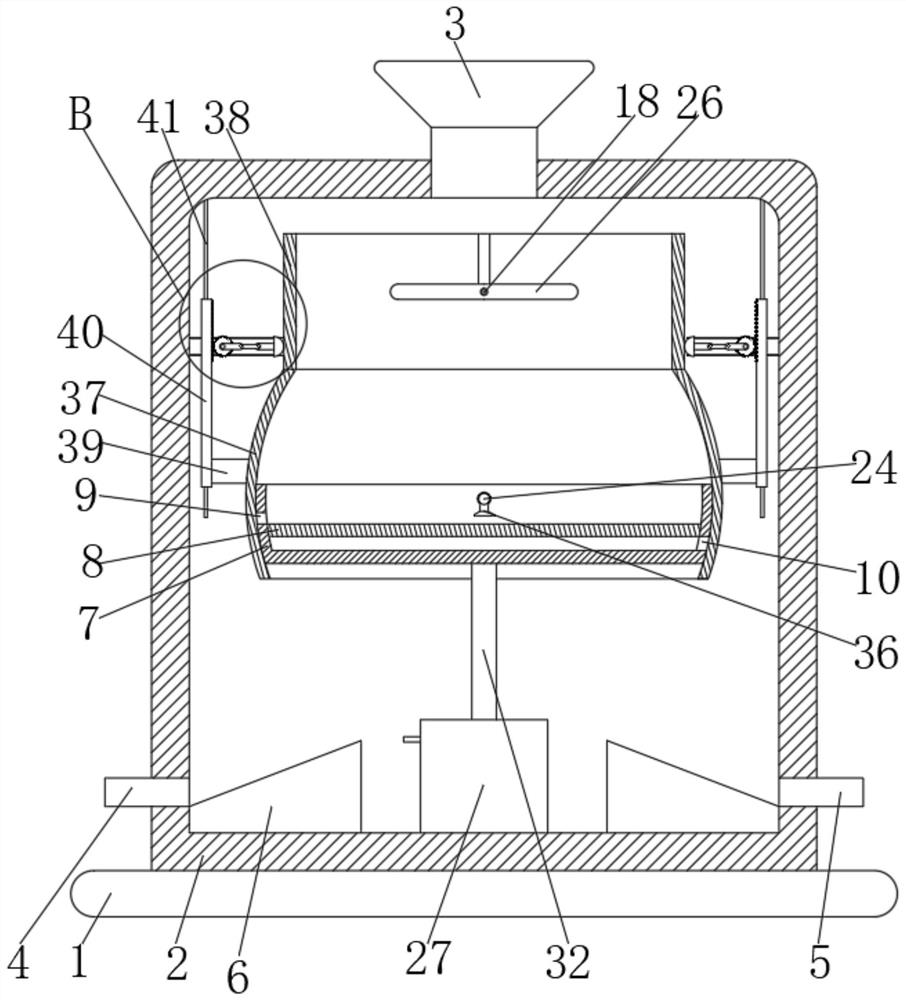

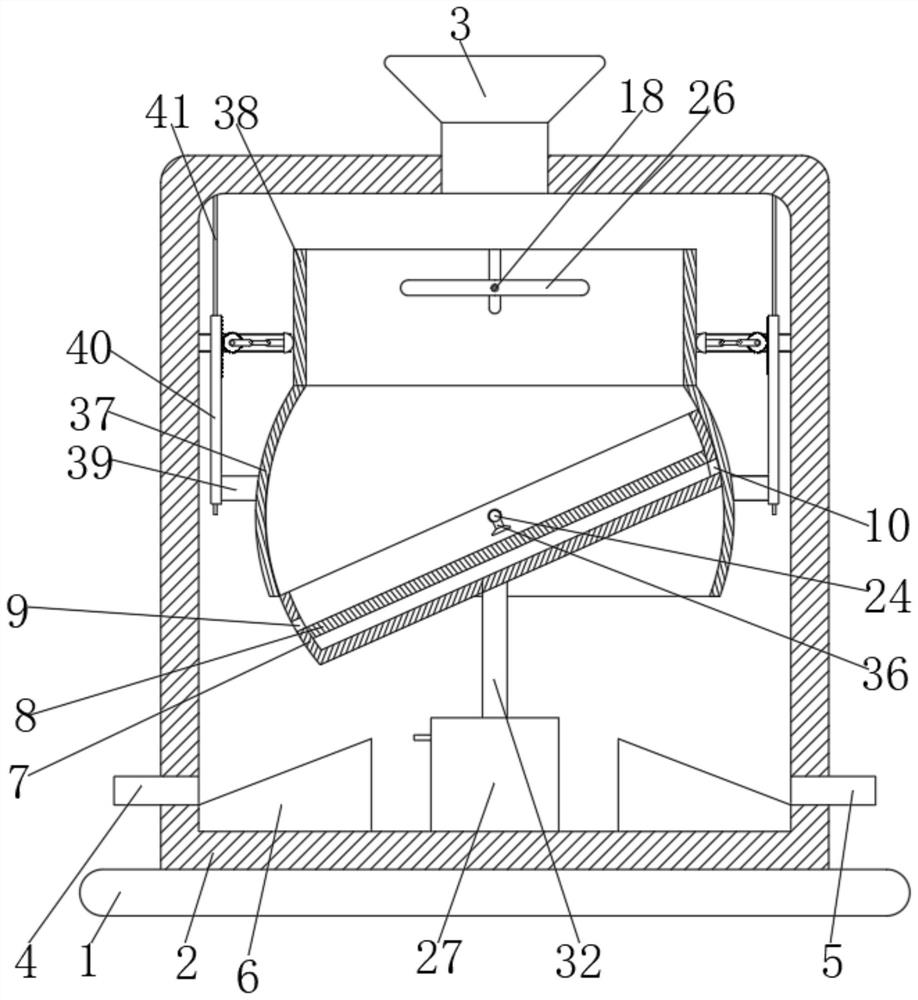

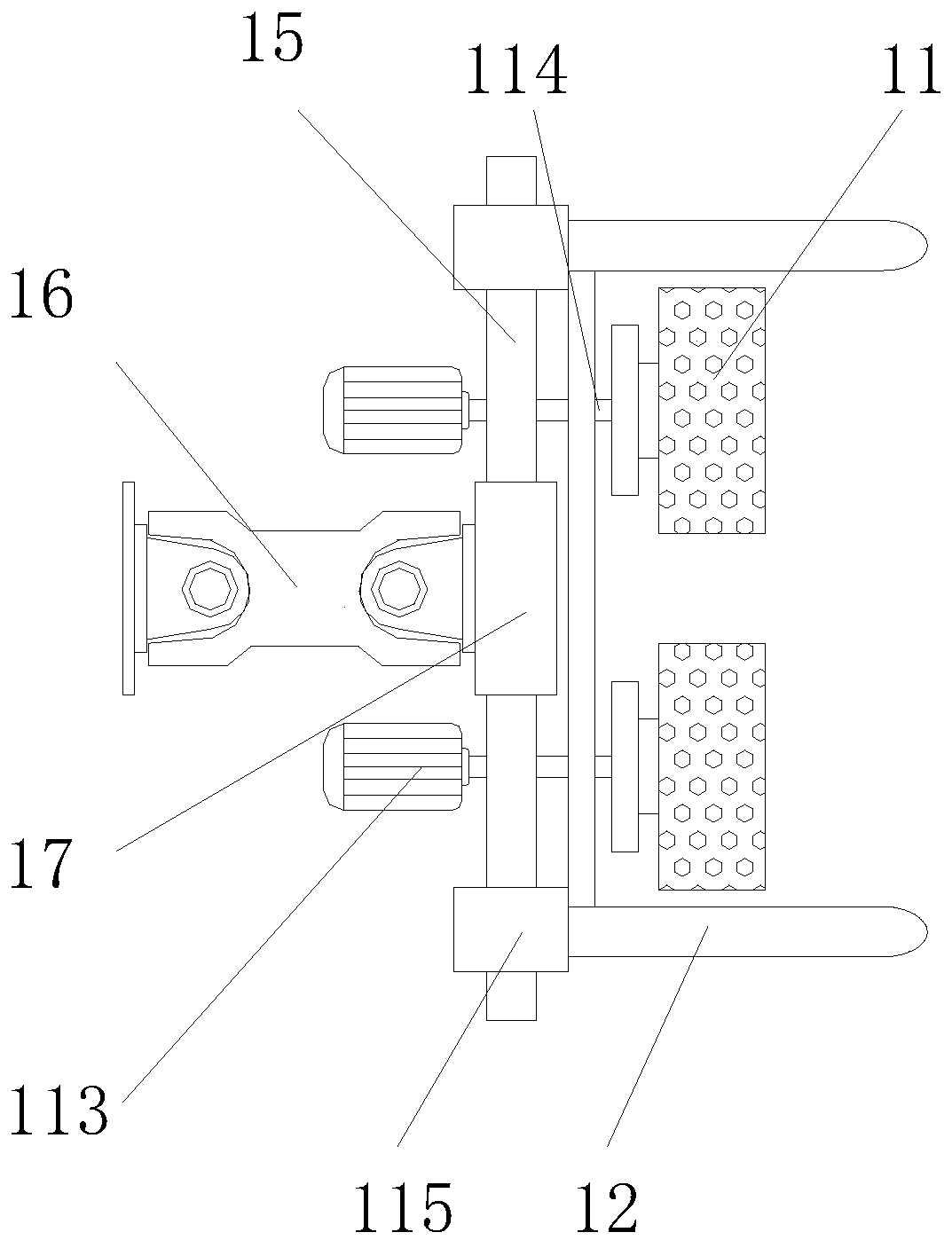

Vibrating type feed powder shaking device for livestock breeding and powder shaking method

ActiveCN113198723ASpeed up sievingEasy to separateSievingFeeding-stuffAnimal scienceLivestock breeding

The invention discloses a vibration type feed powder shaking device for livestock breeding and a powder shaking method, and relates to the technical field of feed powder shaking. Under the action of two vibration parts, feed in powder shaking parts continuously shakes, the inner wall of a powder shaking box is fixedly connected to a guide plate, the problems that an existing feed screening mode is generally simple in structure, so that a screen is only provided, a vibration mode matches and the feed is screened by inflow water, the mode possibly has many defects, the screening effect on impurities gathered together on the screen is possibly poor through the pure vibration mode, the quality of the feed obtained after screening is reduced due to the fact that the feed at the edge position of the screen cannot be effectively screened at the same time, and due to long-time screening, the impurities on the surface of the screen are too many and cannot be synchronously discharged, and the powder shaking efficiency and effect are poor are solved.

Owner:GUANGDONG OCEAN UNIVERSITY

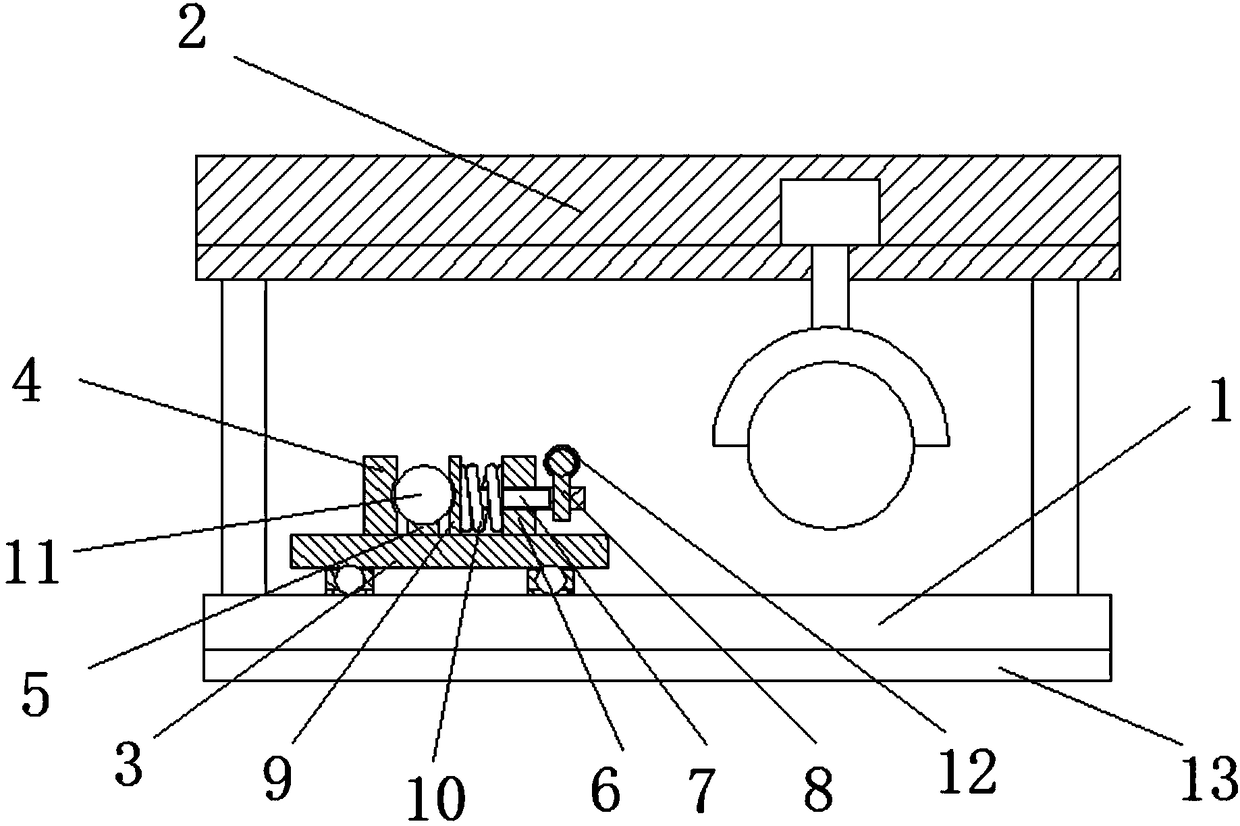

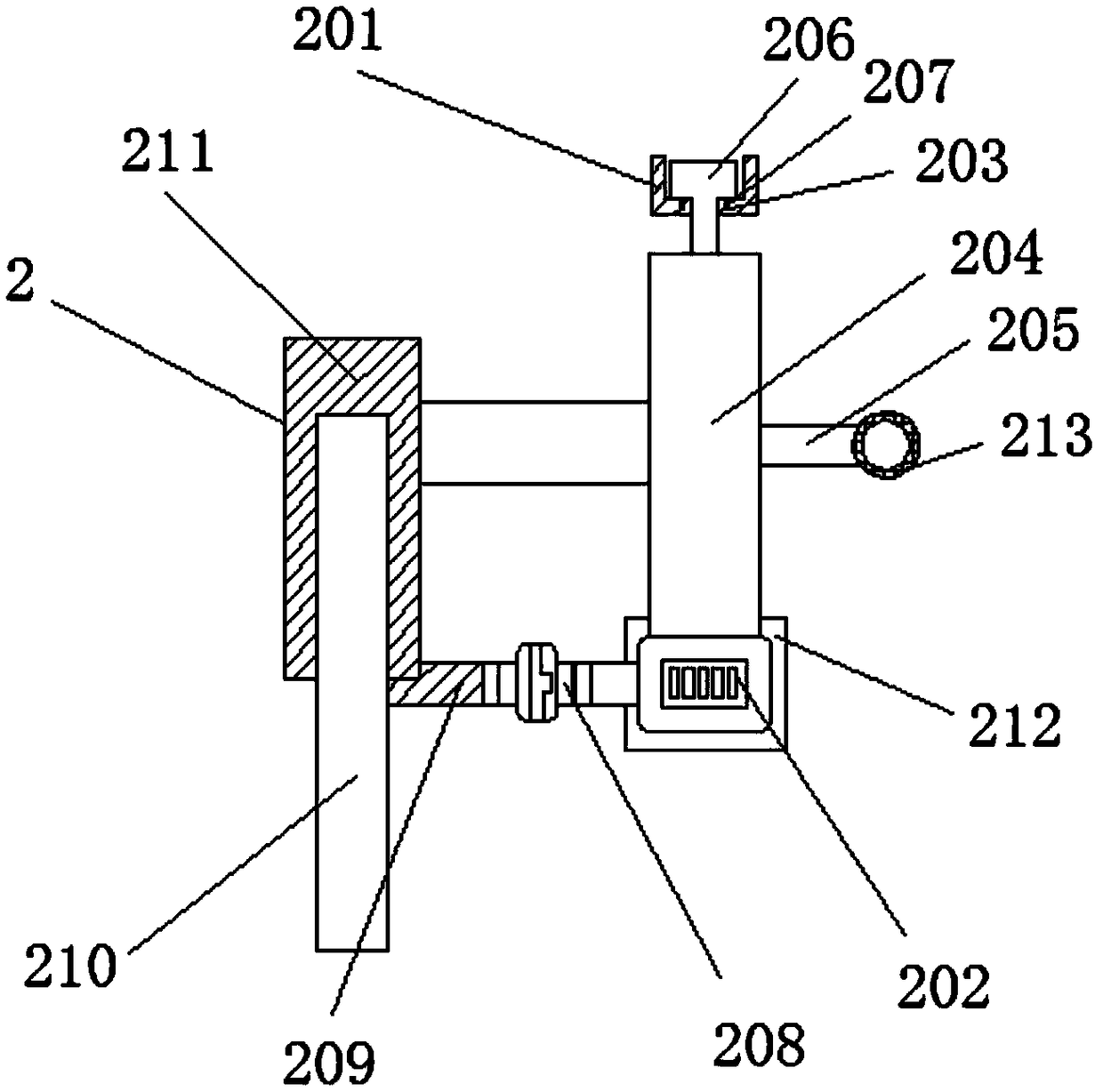

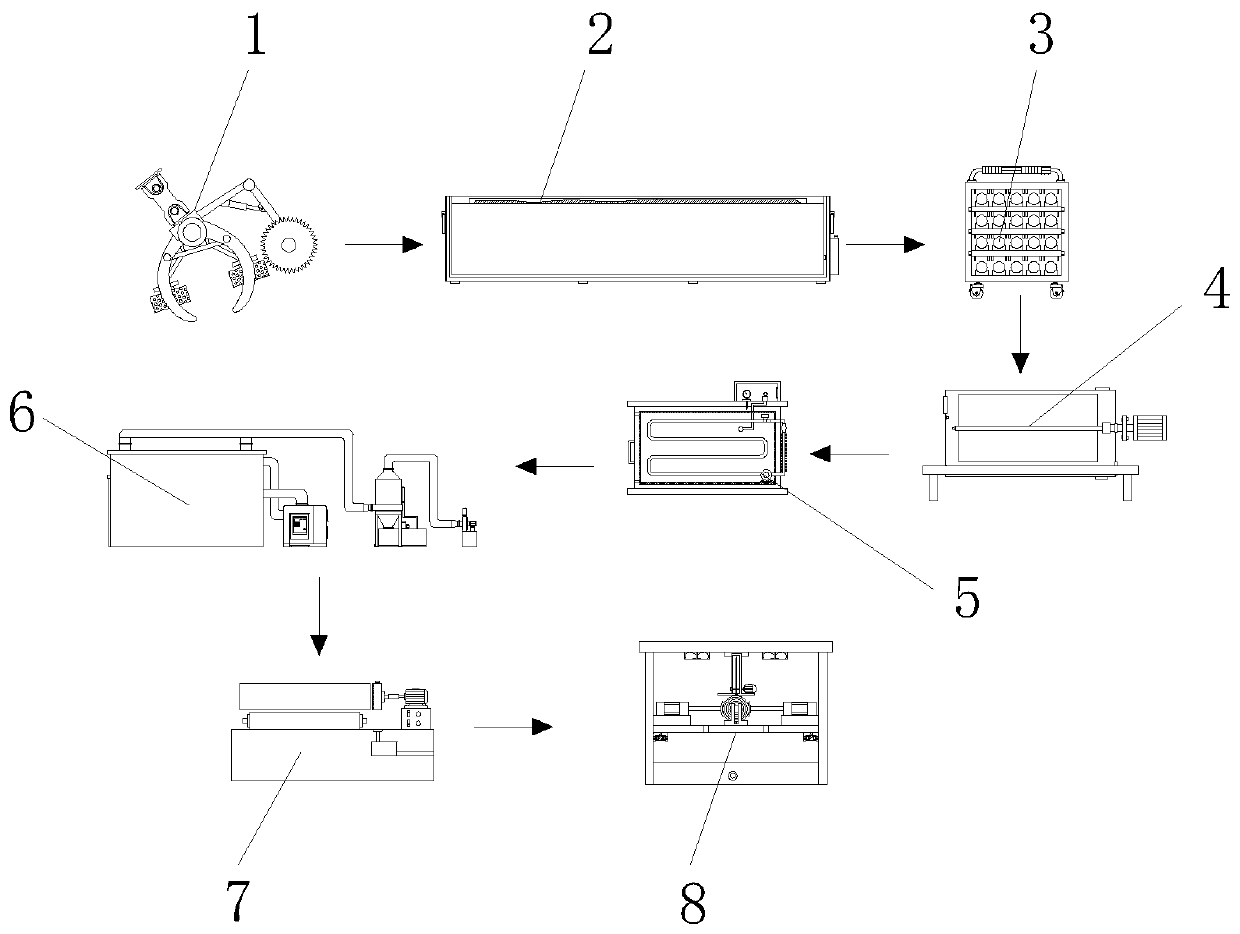

Low-energy-consumption high-environment-protection type denitration catalyst cutter

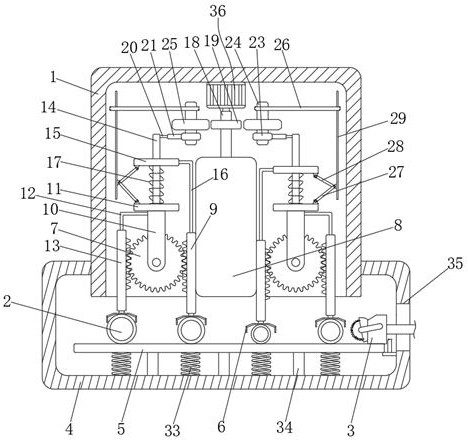

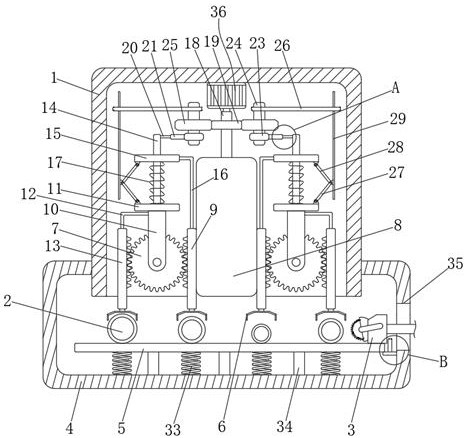

PendingCN106363818AEasy to cutFor precise cuttingWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a denitration catalyst cutter, in particular to a low-energy-consumption high-environment-protection type denitration catalyst cutter. In order to solve the technical problems, the invention provides the low-energy-consumption high-environment-protection type denitration catalyst cutter which is low in energy consumption, is precise in cutting and can be used for doing physical exercise. The low-energy-consumption high-environment-protection type denitration catalyst cutter comprises a table top, a first slide rail, a first slide block, a first spring, a rack, a gear, a flat belt, a first belt wheel, a first rotary rod, a bearing base, a first connecting rod and the like, wherein the first slide block is connected onto the first slide rail in a sliding mode; and the first slide block fits to the first slide rail. The low-energy-consumption high-environment-protection type denitration catalyst cutter achieves the effect of saving resources.

Owner:安陆鲸鱼嘴电子科技有限公司

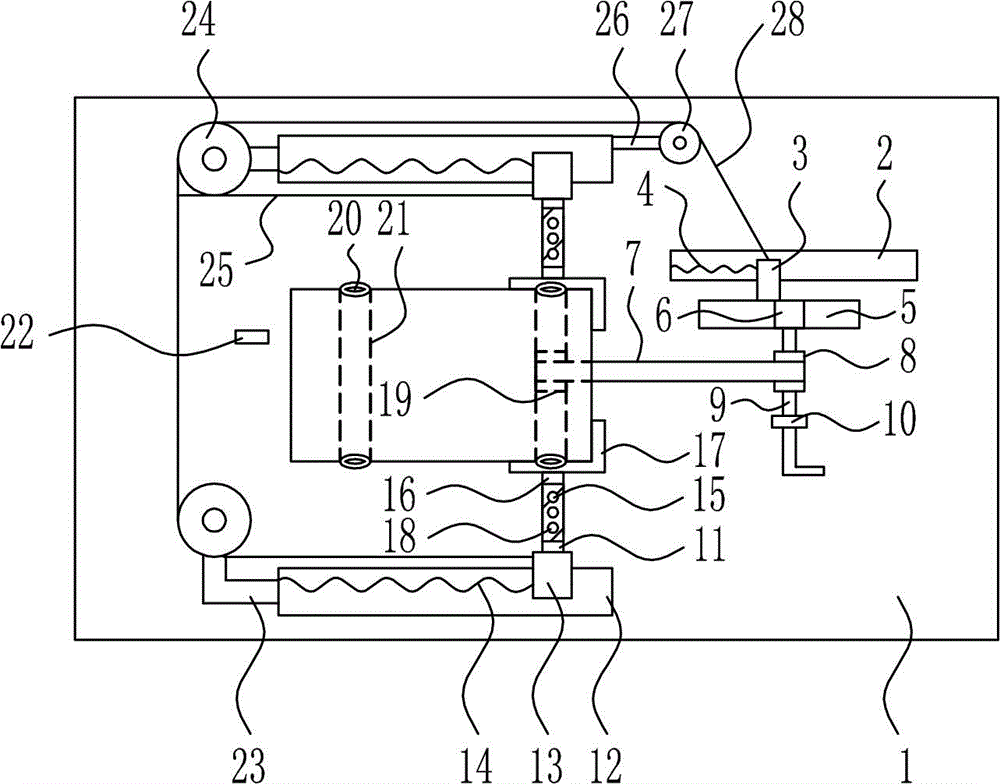

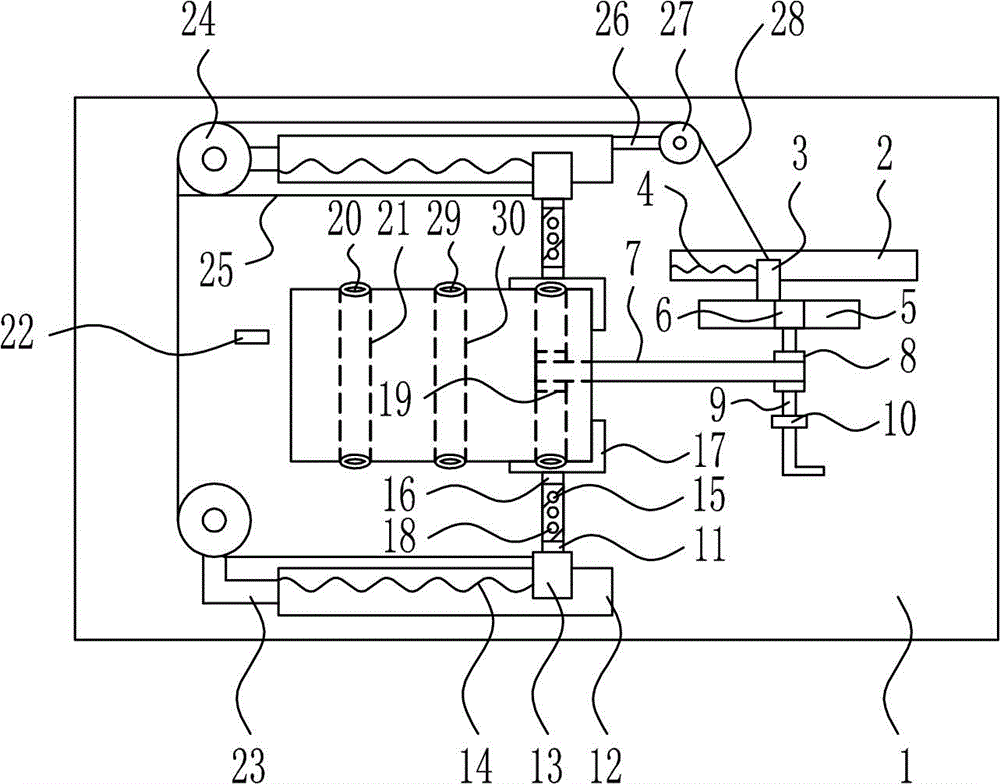

Non-woven fabric forming and cutting device

InactiveCN110293595ANo deviationEfficient cuttingMetal working apparatusArticle deliveryNonwoven fabricMechanical engineering

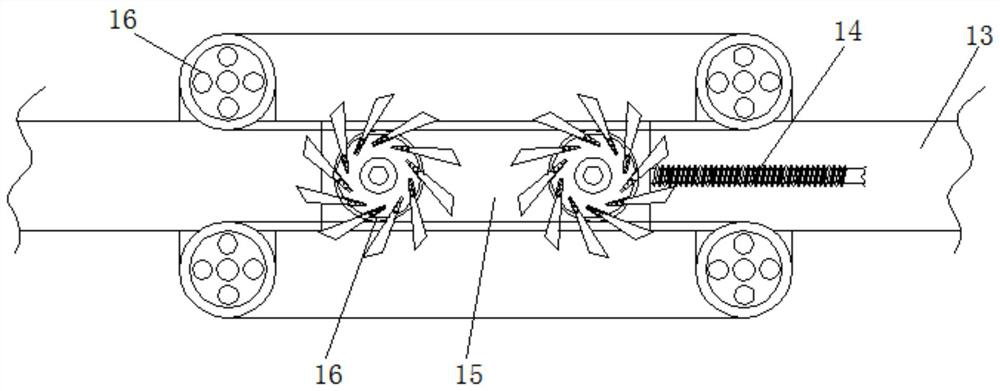

The invention discloses a non-woven fabric forming and cutting device which structurally comprises a lower side supporting frame of a frame type structure. A vertical supporting frame of a cuboid frame type structure is fixedly arranged on the upper end face of the lower side supporting frame. Textile fabric roller devices capable of winding textile fabric and ensuring that the textile fabric runsin a centering manner are arranged on the left side and the right side of the lower side supporting frame. A hob cutting device capable of efficiently cutting the textile fabric is arranged in the vertical supporting frame. The textile fabric roller devices and the hob cutting device are adopted, and by means of the textile fabric roller devices, a spring moving manner facilitating demounting isutilized so that the efficiency of winding the textile fabric on the outer surface of a roller is improved; meanwhile, a centering structure in the device is utilized, the textile fabric cannot be deflected during cutting, and the equipment cutting precision is improved; and the hob cutting device is adopted, hobs are static, a textile fabric moving manner is adopted, a threaded rod is used for adjusting the staggered position between the hobs, and therefore cloth strips with different specification sizes can be machined and formed.

Owner:沈文亮

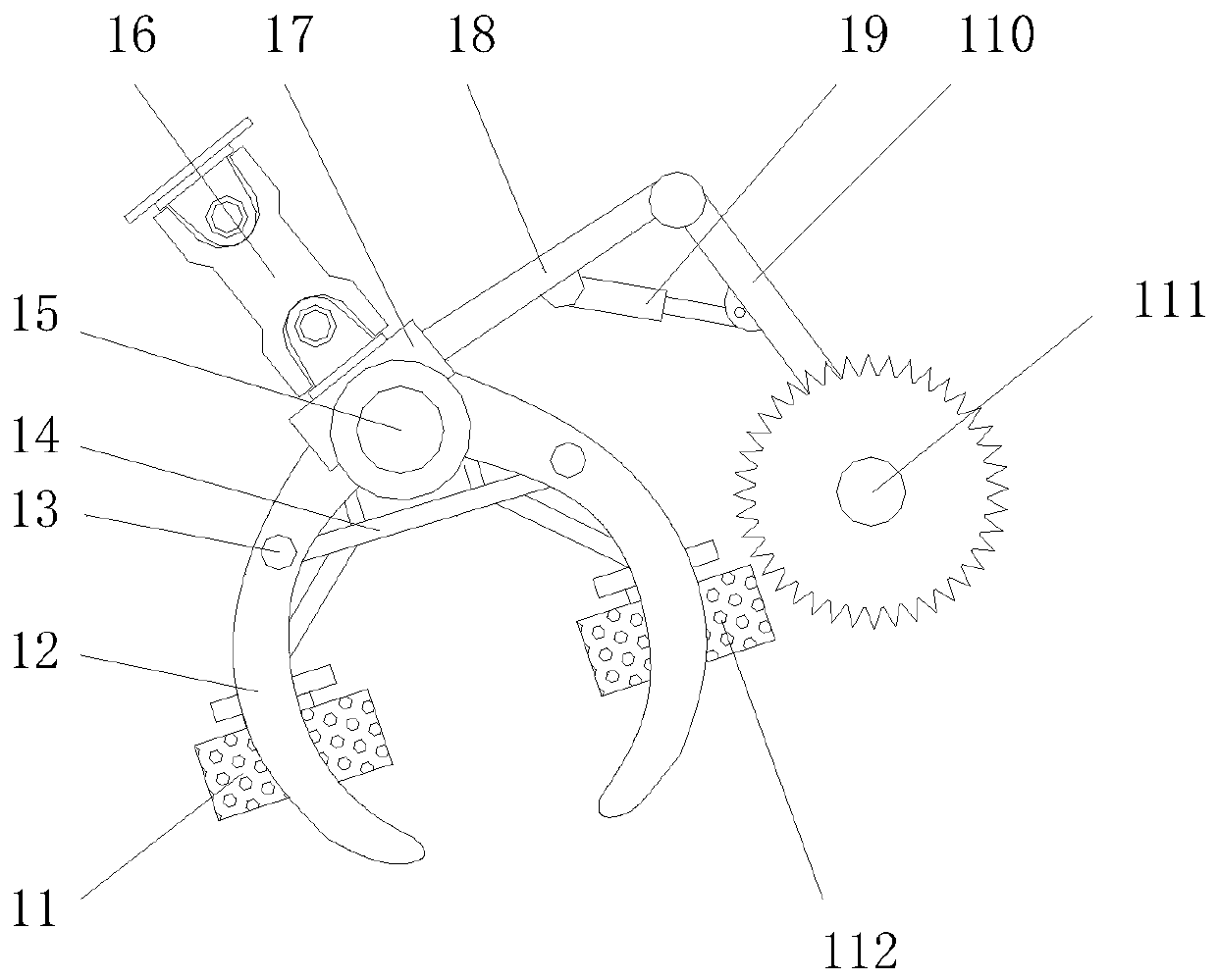

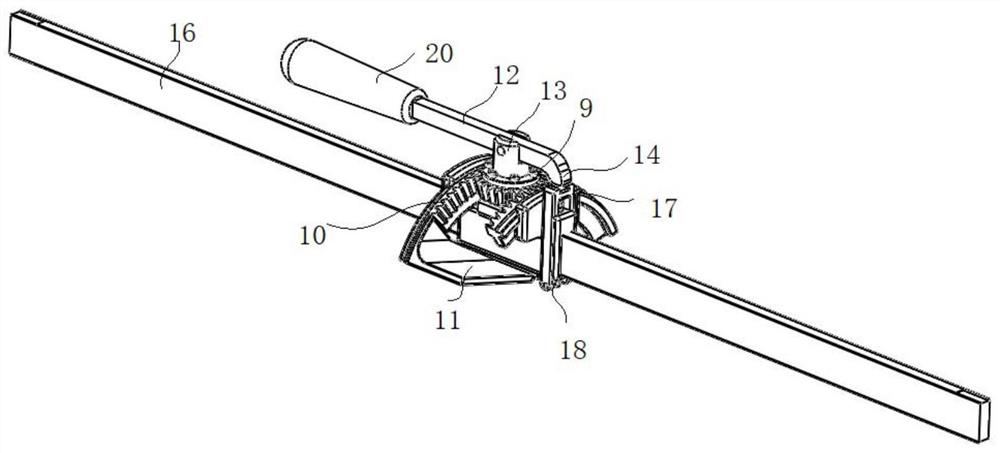

Small-size garment shearing cutter head for garment cloth local shearing

InactiveCN108755092AMany applicationsIncrease contact areaSevering textilesMechanical engineeringElastic rods

The invention discloses a small-size garment shearing cutter head for garment cloth local shearing. The small-size garment shearing cutter head comprises a screw rod, wherein one end of the screw rodis connected with an upper support frame; the bottom end of the upper support frame is movably connected with a lower support frame; an elastic rod is connected between the upper support frame and thelower support frame; a cutter wheel can realize the rotation between a cutter wheel frame and the lower support frame, and is used for trimming the circular arc-shaped cloth by a shearing machine; due to the effect of resistance, the cutter wheel can always be in contact with the cloth at the edge of the cutter head through the rotation between the cutter wheel frame and the bearing inside the lower support frame; the circular arc can be easily sheared; the cutter head is a little greater than the outer diameter of the outer wheels at the two sides; during the shearing, the pressing fixationof the outer wheels at the two sides on the edge of the cloth and the shearing on the cloth by the cutter head can be realized; in addition, the outer wheels and the cutter head are in concentric bonding connection and are connected with the cutter wheel frame through an installing shaft; the contact and the transmission are more reliable; the cutting effect is not influenced; the whole parts arefew; the use and the maintenance are convenient.

Owner:安徽美裕集团有限公司

Cutting fixture and using method thereof

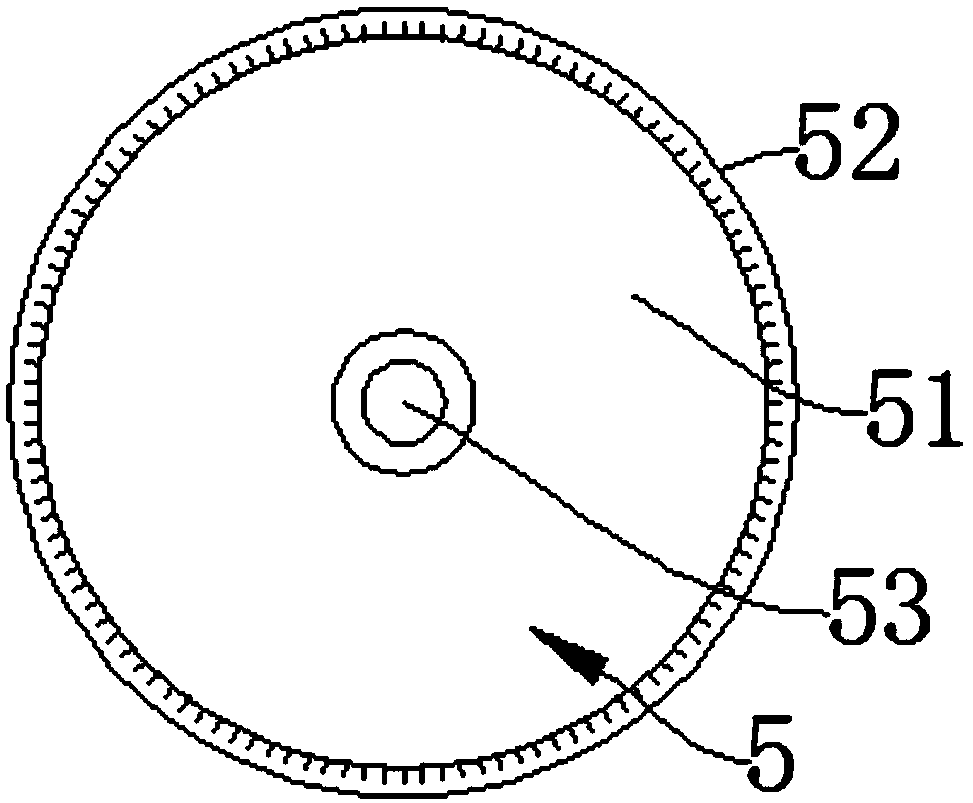

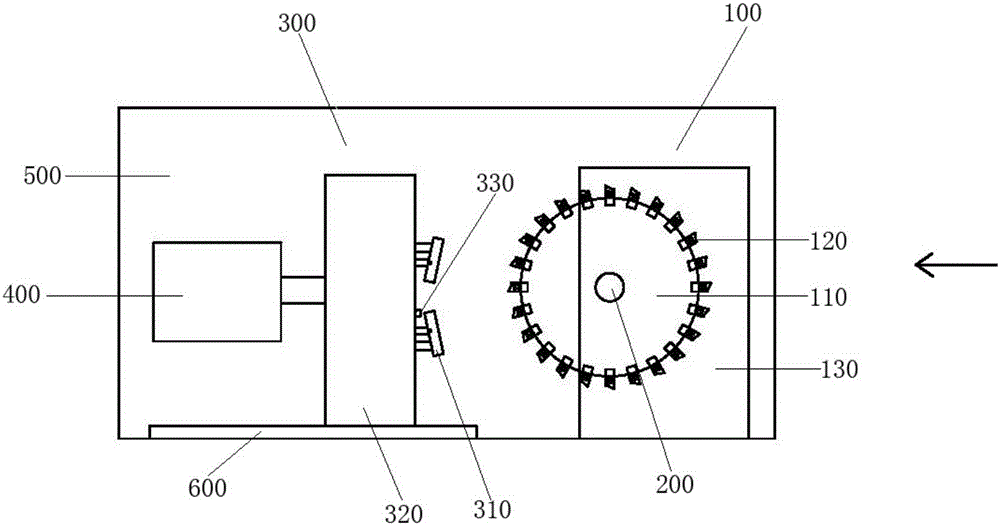

The invention discloses a cutting fixture. The cutting fixture comprises a cutting part, a first driving device, a workpiece fixing part and a second driving device. The cutting part comprises a disk-shaped knife rest and multiple blades installed on the outer circumference of the disk-shaped knife rest. The cutting edge of each blade is radially extended along the direction deviated from the circle center of the disk-shaped knife rest. The first driving device is connected with the circle center of the disk-shaped knife rest so as to drive the disk-shaped knife rest to be rotated by using the circle center as the axis. The workpiece fixing part comprises a clamp for fixing the workpiece. The to-be-cut face of the workpiece and the blades are positioned on the same plane. The second driving device is connected with the workpiece fixing part so as to push the workpiece fixing part to be close to or away from the cutting part. The cutting fixture is capable of effectively saving the cutting cost, and guaranteeing the cutting precision and the whole cutting quality. The invention further discloses a using method for the cutting fixture.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

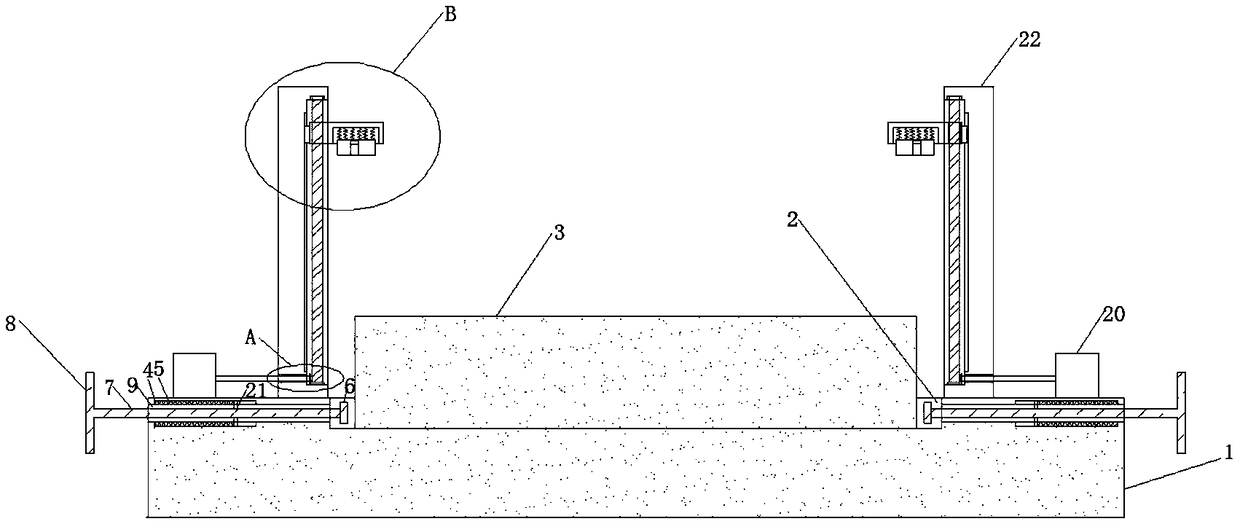

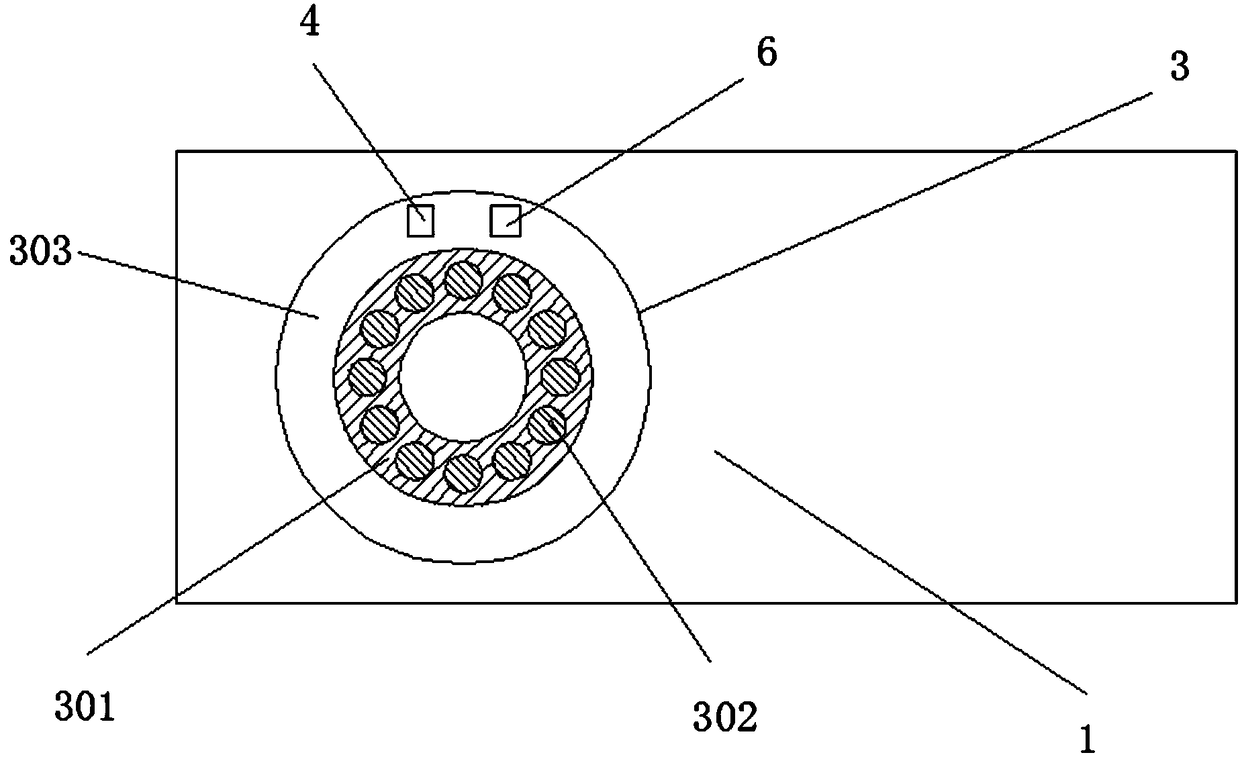

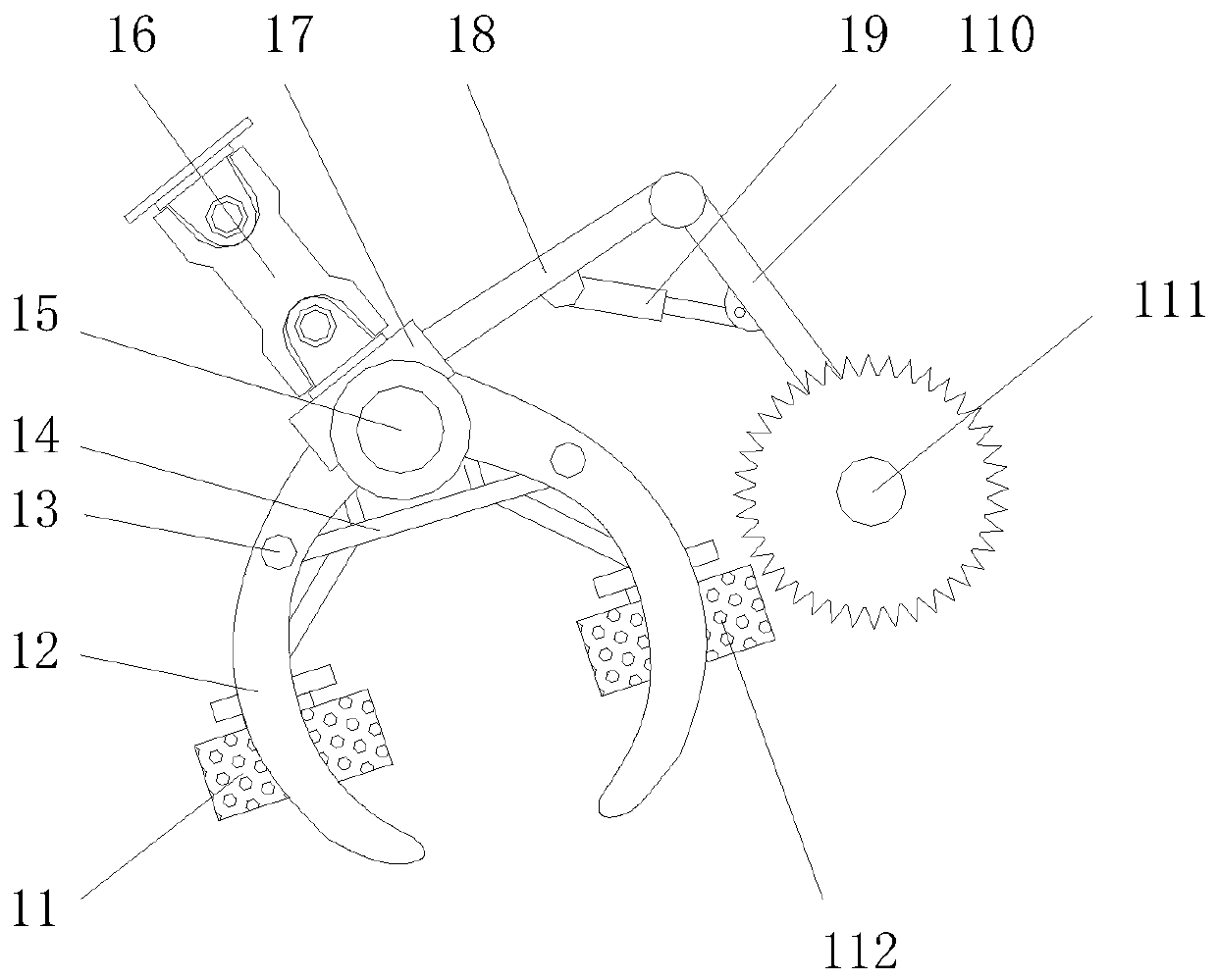

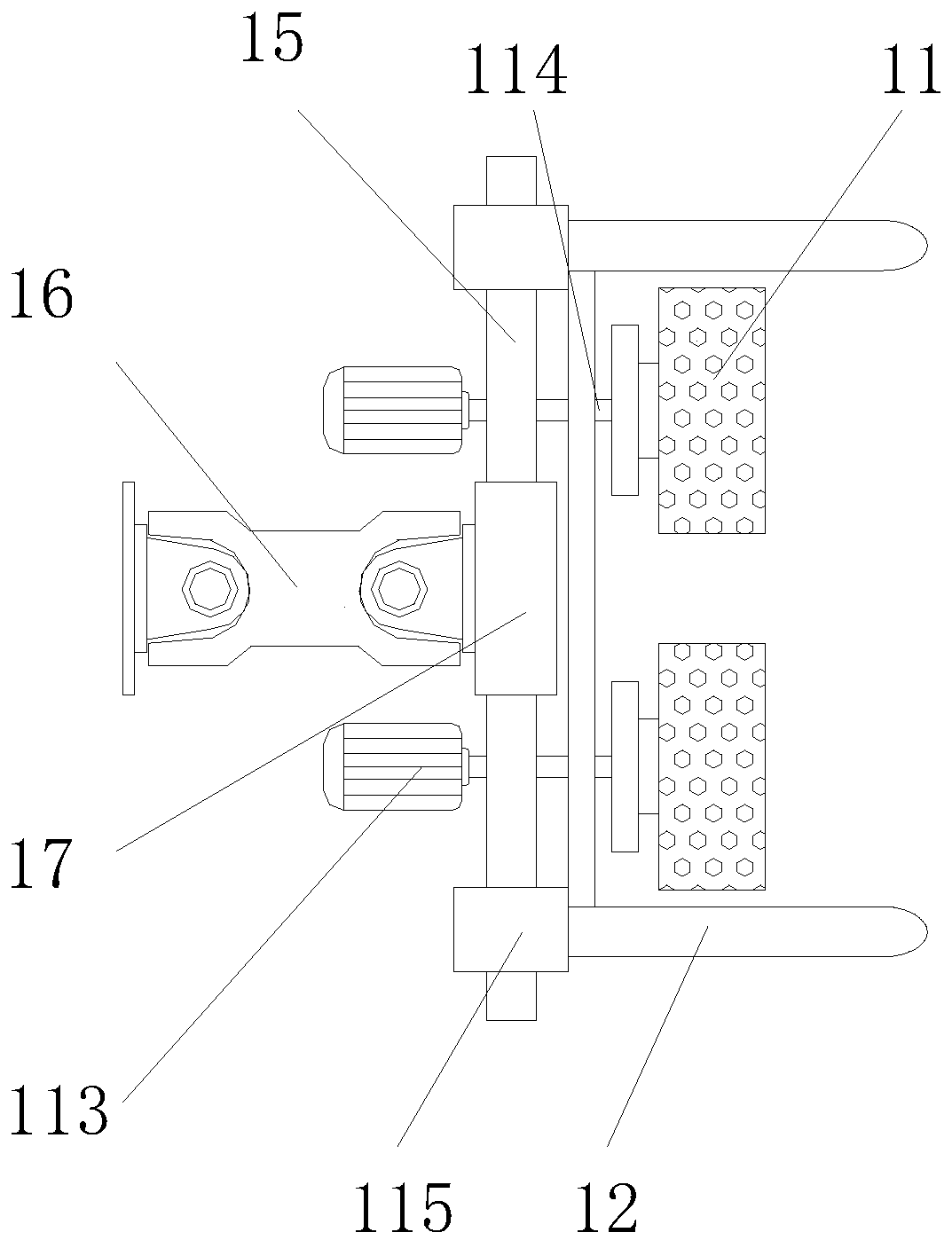

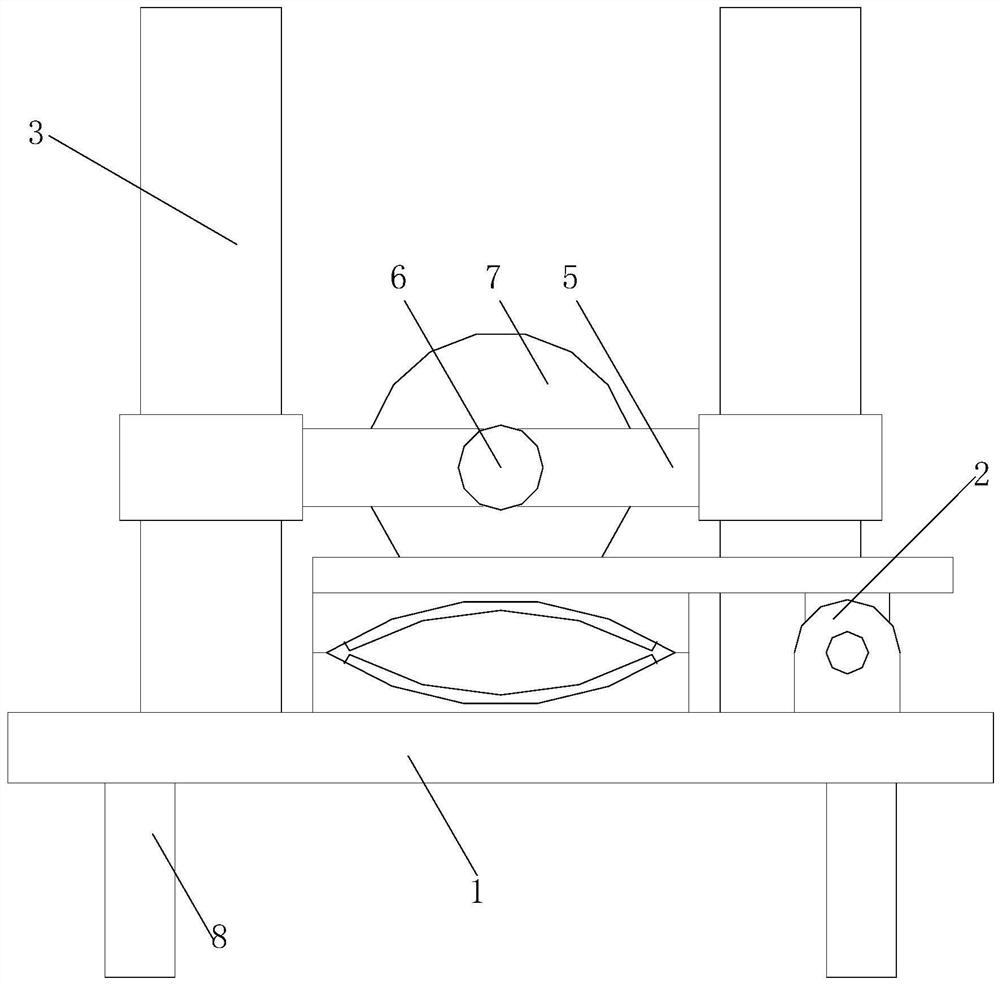

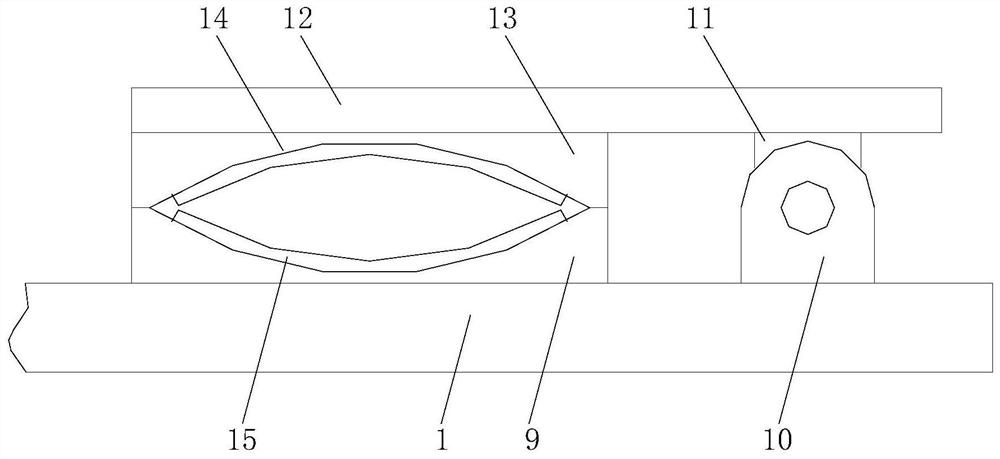

Fixing clamp used for log cutting

InactiveCN108437080AMeet the needs of useDoes not affect the cutting effectSawing componentsCircular sawsCircular discArchitectural engineering

The invention discloses a fixing clamp used for log cutting. The fixing clamp comprises a workbench. Cutting devices are fixedly mounted on the left side and the right side of the upper surface of theworkbench. A rotating device is fixedly mounted on the upper surface of the left end of the workbench. The rotating device comprises an isolation frame. The lower surface of the isolation frame is fixedly mounted on the upper surface of the left end of the workbench. Steel balls are arranged in the isolation frame, and the number of the steel balls is at least 12. The top ends of the steel ballsare slidably connected with a disc. According to the fixing clamp used for log cutting, through the cooperation of the cutting devices, the rotating device and a stud, the problems that according to an existing cutting method, large trees cannot be fixed, fixation is instable, only one cutting mode is available, log cannot be cut into long strips or oblique columns by one machine, subsequent processing is inconvenient, processing efficiency is low, and market requirements cannot be met are solved.

Owner:成都亚工电子科技有限公司

A dust-proof cutting device for wood processing

InactiveCN109015927BReduce dustReduce labor intensityProfiling/shaping machinesBark-zones/chip/dust/waste removalAgricultural engineeringWood machining

The invention belongs to the field of wood machining and particularly relates to a dustproof type cutting device for wood machining. The dustproof type cutting device for wood machining can reduce generated dust during wood cutting and lower the labor intensity of work personnel. The dustproof type cutting device for wood machining comprises a base plate, a side plate, a top plate, a first collecting frame, supporting seats, a second bearing seat, an air cylinder, first sliding rods, first sliding sleeves, a lifting plate and the like. The side plate is fixedly connected to one side portion ofthe base plate. A cutting platform is fixedly connected to the top of the base plate through the supporting seats. The first collecting frame is arranged between the corresponding supporting seat andthe side plate. A second collecting frame is arranged at the bottom of the cutting platform. The dustproof type cutting device for wood machining achieves the effects of reducing dust in the wood cutting process, collecting wood chips generated during cutting and lowering the labor intensity in the cutting process.

Owner:阜阳双乔木业有限公司

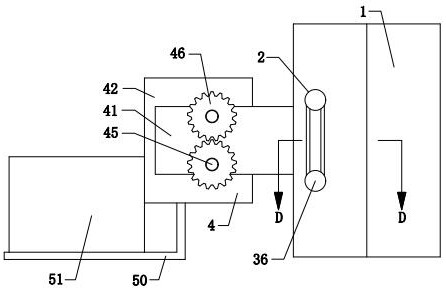

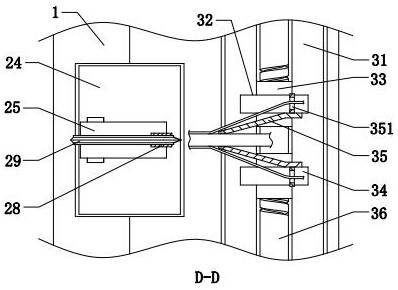

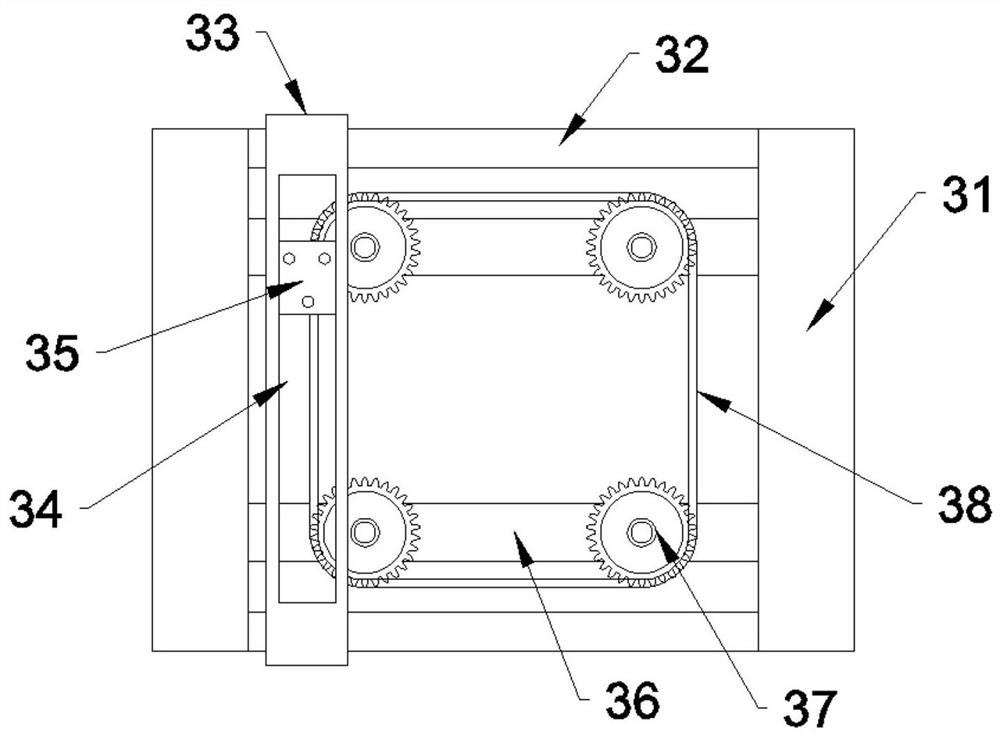

Office table and chair cutting device based on line drive

InactiveCN111844333ASolve the problem of manual feedingReduce labor intensityProfiling/shaping machinesGear wheelEngineering

The invention relates to the technical field of table and chair processing, and discloses an office table and chair cutting device based on line drive. The device comprises a bottom plate, wherein theside surface of the bottom plate is fixedly connected with a reversing block, the bottom surface of the bottom plate is meshed with a first gear, the inner part of the first gear is rotatably connected with a first connecting part, the inner part of the first gear is rotatably connected with an input shaft, the side surface of the bottom plate is rotatably connected with a first rotating wheel, the outer side of the first rotating wheel is connected with a belt in a transmission mode, and the outer side of the belt is connected with a second rotating wheel in a transmission mode. According tothe office table and chair cutting device based on line drive, through the connection of the bottom plate and the second rotating wheel, the problem of manual feeding of an existing cutting device inthe production process of tables and chairs is solved, the labor intensity of workers is effectively reduced, the problem of low safety of the existing cutting device in the production process of thetables and chairs, and in mass production, the cutting effect cannot be affected, plates of different lengths can be flexibly cut, and the cutting efficiency is high.

Owner:广州思威耀家具有限公司

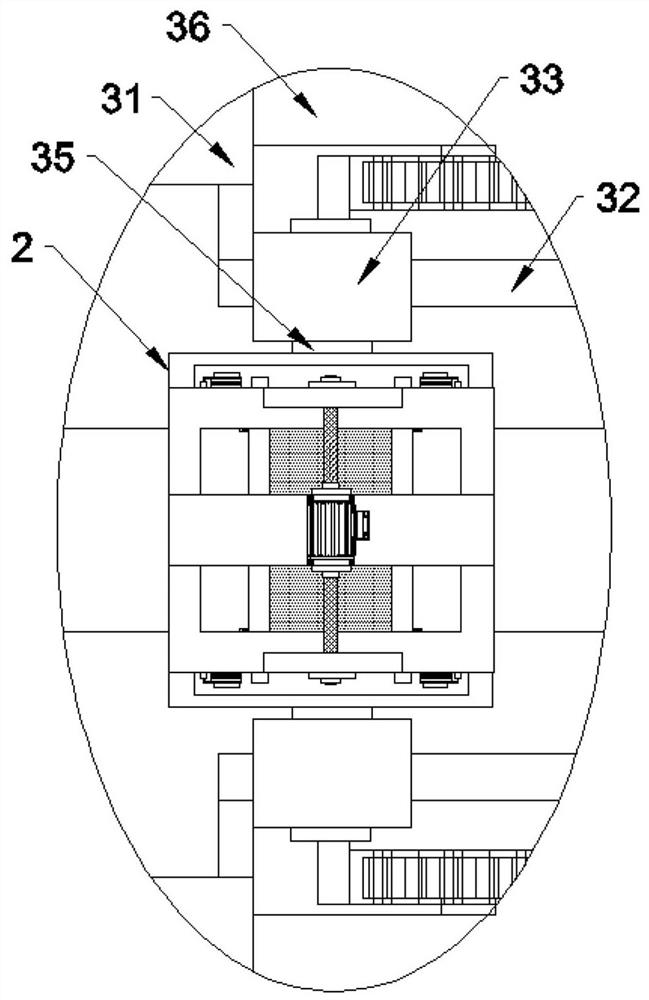

An automatic processing and forming device for welding grooves of welded elbows

ActiveCN113427073BAchieve a fixed effectUniform pressureFeeding apparatusTube shearing machinesPipe fittingStructural engineering

The invention discloses an automatic processing and forming device for welded grooves of welded elbows, which relates to the technical field of pipe fitting shearing, and includes a casing and a cutting device. The surface of the casing is fixedly connected with a working frame, and a There is a workbench on which the pipeline is placed, four splints for fixing the pipeline are arranged in the workframe, and four splints are arranged in the outer shell to control the displacement of the two splints so as to control the displacement of the four splints. The two sets of fixing parts for fixing the pipes with different sizes also include adjustment parts to keep the strength of the four pipes uniform when they are fixed, so as to avoid the force deviation from affecting the groove forming effect. The mutual cooperation of multiple pipe fittings with different sizes can be fixed at the same time, the fixing effect is good, and the effect of force is uniform, which solves the problem that each group of pipe fittings needs to be fixed separately in the traditional way, and the problem of low efficiency.

Owner:南通久鼎特种钢管有限公司

A kind of non-woven fabric forming and cutting equipment

InactiveCN110293595BNo deviationEfficient cuttingMetal working apparatusArticle deliveryNonwoven fabricThreaded rod

The invention discloses a non-woven fabric forming and cutting device which structurally comprises a lower side supporting frame of a frame type structure. A vertical supporting frame of a cuboid frame type structure is fixedly arranged on the upper end face of the lower side supporting frame. Textile fabric roller devices capable of winding textile fabric and ensuring that the textile fabric runsin a centering manner are arranged on the left side and the right side of the lower side supporting frame. A hob cutting device capable of efficiently cutting the textile fabric is arranged in the vertical supporting frame. The textile fabric roller devices and the hob cutting device are adopted, and by means of the textile fabric roller devices, a spring moving manner facilitating demounting isutilized so that the efficiency of winding the textile fabric on the outer surface of a roller is improved; meanwhile, a centering structure in the device is utilized, the textile fabric cannot be deflected during cutting, and the equipment cutting precision is improved; and the hob cutting device is adopted, hobs are static, a textile fabric moving manner is adopted, a threaded rod is used for adjusting the staggered position between the hobs, and therefore cloth strips with different specification sizes can be machined and formed.

Owner:沈文亮

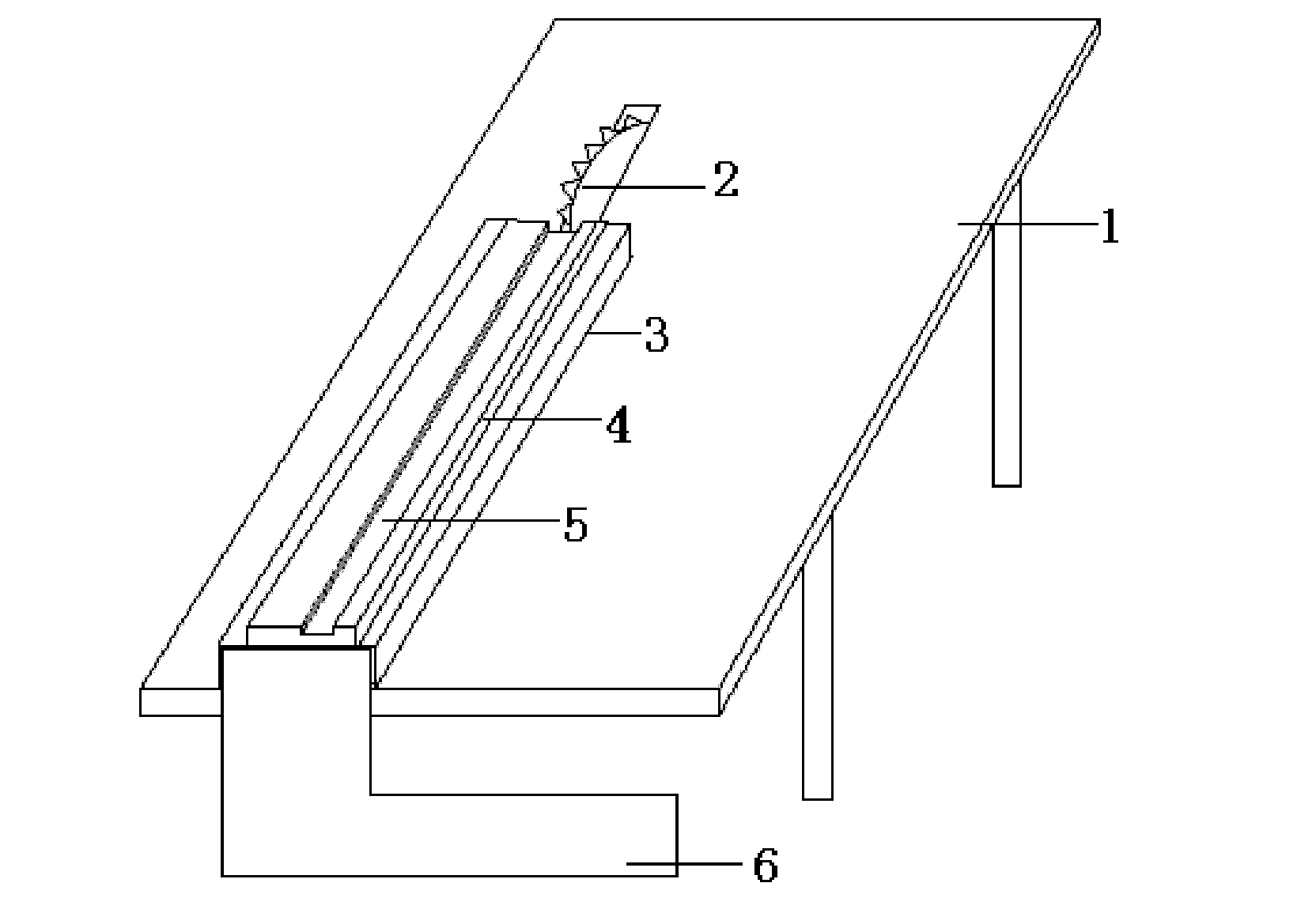

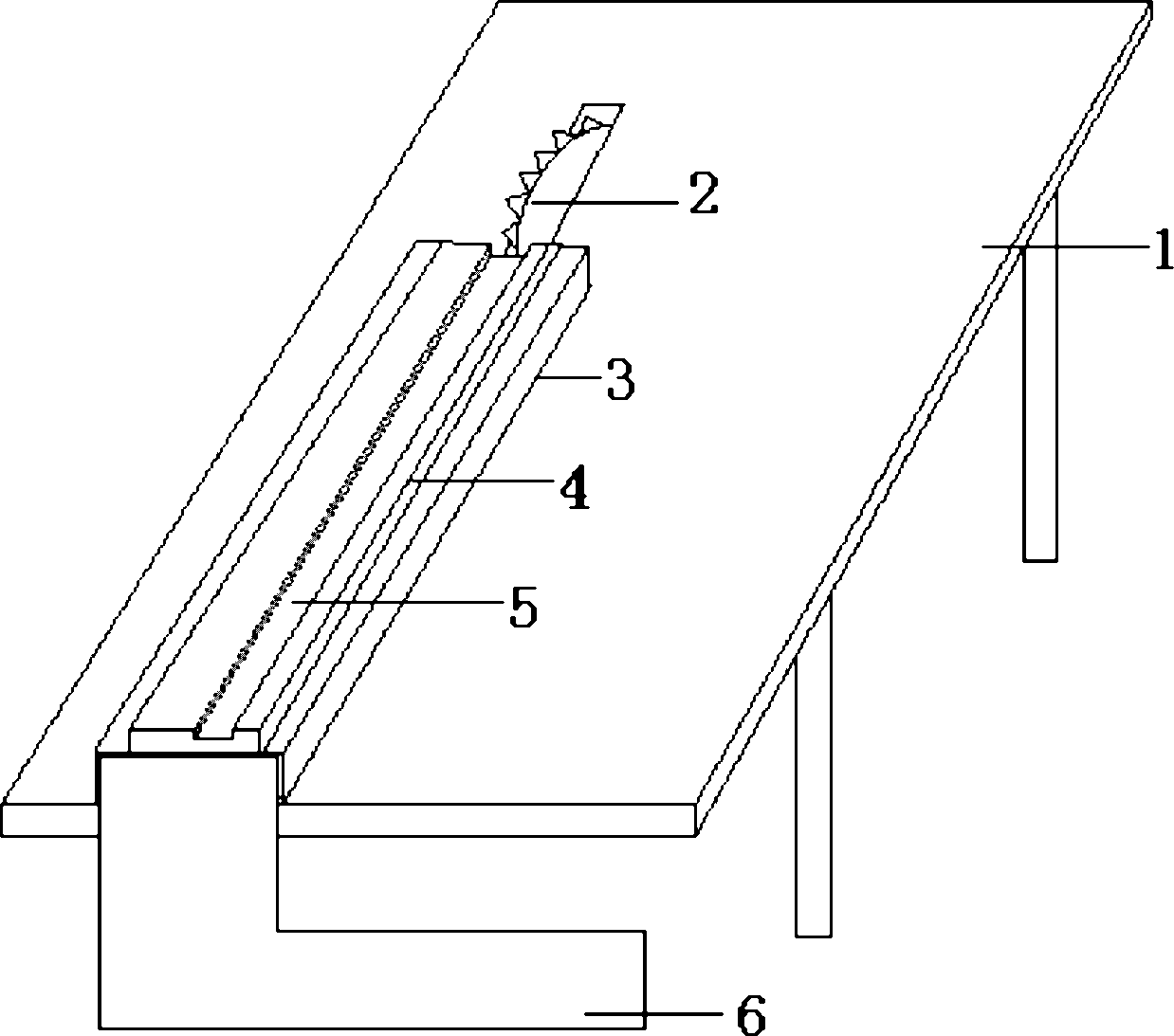

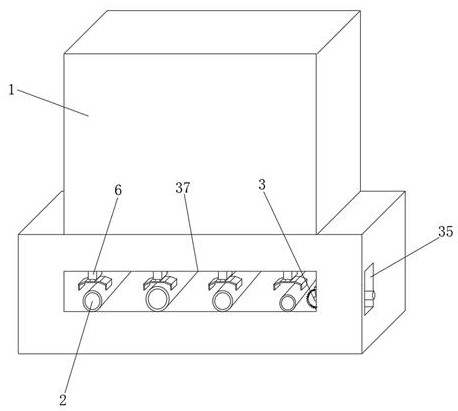

Synchronous stripping device for multiple strands of wires and cables

ActiveCN114268055AEasy to cutAvoid secondary cuttingApparatus for removing/armouring cablesElectronic waste recyclingStructural engineeringElectric wire

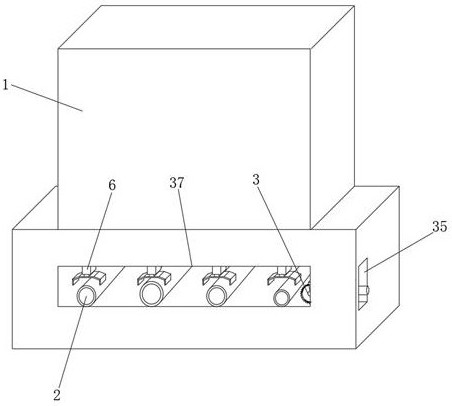

The invention relates to the technical field of wires and cables, in particular to a multi-strand wire and cable synchronous stripping device which comprises a processing box, a stripping part and a wire core conveying part, feeding ports are formed in the left end of the processing box at equal intervals in the front-back direction of the processing box, the stripping part is arranged in the processing box, and the wire core conveying part is installed at the right end of the processing box; an existing electric wire stripping machine has the following problems that the existing stripping machine cannot carry out transmission and stripping treatment on electric wires with different diameters, so that limitation exists; the stripping machine cannot segment a wire core, and the wire core needs to be subjected to secondary cutting through special cutting equipment, so that the working procedures are increased; the electric wires with different diameters can be cut through the cutting knives located on the upper and lower sides of the electric wires; according to the invention, intermittent pressing and cutting segmentation processing can be carried out on the peeled wire core while the wire is peeled, and secondary cutting of the wire core can be avoided, so that processes can be reduced.

Owner:徐州华创电子有限公司

A wood processing and processing integrated system and processing method thereof

ActiveCN108501124BAvoid damageHigh degree of automationWood treatment detailsProfiling/shaping machinesThermal insulationPulp and paper industry

The invention discloses a wood processing treatment integrated system. The system comprises wood sectional acquisition equipment, wood thermal insulation and moisturizing transportation equipment, wood collision preventing storage equipment, automatic temperature-adjusting wood soaking equipment, layered freezing equipment, wood standing and drying equipment, end part oiling sealing equipment andwood section slitting equipment. The invention also discloses the wood processing treatment integrated system and a treatment method thereof. The automation degree is high, wood cannot be damaged, thesystem and the method have broad market competitiveness, the wood quality can be effectively guaranteed, atmosphere pollution is avoided, the production cost is saved, and the production environmentis effectively improved.

Owner:新沂市超华木业有限公司

Manufacturing technique of blade for blood bag

The invention discloses a manufacturing technique of a blade for a blood bag. The manufacturing technique includes the following steps that an aluminum oxide material serves as a base material, and silicon oxide, silicon nitride and graphene are added to be mixed to prepare suspension liquid; the suspension liquid is poured into a ball-milling tank, continuous drying is carried out in a vacuum drying oven after ball milling, and dried mixed powder is screened; the powder is poured into a mold needing to be molded, a hot pressed sintering manner is adopted, and a blade base is obtained after sintering; a heating resistor and an electrode pin which are connected are printed on the upper portion and the lower portion of the blade base through electric conduction raw materials to serve as controllers for heating the blade base; zirconium oxide, aluminum oxide and rare earth oxide containing titanium powder are mixed to prepare slurry, the slurry is coated to the upper portion of the blade base to cover the controllers, and a knife edge part at the lower portion of the original blade base is exposed; staged sintering molding is carried out; and the knife edge part is ground and polished. The blade has the good heat-conducting property, and heating is even and easy to control.

Owner:KUNSHAN YULI METAL PROD

A multi-strand wire and cable synchronous stripping device

ActiveCN114268055BEasy to cutAvoid secondary cuttingApparatus for removing/armouring cablesElectronic waste recyclingStructural engineeringElectric wire

The invention relates to the technical field of electric wires and cables, in particular to a synchronous peeling device for multi-strand electric wires and cables, which includes a processing box, a peeling part and a wire core conveying part. There is a peeling part in the box, and a wire core delivery part is installed at the right end of the processing box; the existing wire stripping machine has the following problems: the existing stripping machine cannot transmit and strip the wires of different diameters, so there are limitations; The stripping machine cannot segment the wire core, and needs to use special cutting equipment to cut the wire core twice, thereby increasing the process; the invention can cut wires of different diameters through the cutting knives located on the upper and lower sides of the wire; The invention can intermittently press and cut the stripped wire core into sections while stripping the wire, avoiding secondary cutting of the wire core, thereby reducing the process.

Owner:徐州华创电子有限公司

Rapid segmentation cutting equipment for circuit board for electrical engineering

InactiveCN113601034ADoes not affect the cutting effectImprove clamping effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPressure sensor

The invention discloses rapid segmentation cutting equipment for a circuit board for electrical engineering. The rapid segmentation cutting equipment for the circuit board for electrical engineering comprises a base, a circuit board mounting table, a graduated scale, a controller, a first sliding groove, a second sliding groove, a third vertical rod, a first vertical rod, a first air cylinder, a first transverse rod, a first connecting rod, a third air cylinder, a second air cylinder, a pneumatic suction cup, a second vertical rod, a positioning block, a first positioning emitter, an L-shaped fixing frame, a third sliding groove, an L-shaped moving frame, a first positioning receiver, a fourth air cylinder, a pressure sensor, a second positioning emitter, a second transverse rod, a seventh sliding groove, a second connecting rod, a seventh air cylinder, a fifth air cylinder, a sixth air cylinder and an eighth air cylinder, wherein a piston rod of the fifth air cylinder penetrates through the second connecting rod and then is connected with a cutter; a fixing base is connected onto a piston rod of the sixth air cylinder; an inverted-U-shaped support is connected to the lower part of the fixing base; a displacement sensor is arranged on the side edge of the second connecting rod; and a second positioning receiver is arranged at the end of the lower part of the second connecting rod. The structure is beneficial to improving the working efficiency.

Owner:沈宇

An aerated concrete block cutting device

ActiveCN109049367BQuality improvementImprove functionalityWorking accessoriesStone-like material working toolsHydraulic cylinderClassical mechanics

The invention discloses an aerated concrete block cutting device. The aerated concrete block cutting device comprises a device main body; the top of the device main body is provided with a hydraulic cylinder; the output end of the hydraulic cylinder is connected with a piston rod penetrating into the device main body; the output end of the piston rod is provided with a fixing block; first screw holes are formed in the four corners of the fixing block; and the bottom of the fixing block is provided with a mounting base. Different mounting bases can be replaced through the screw holes and bolts,thus, blocks in different sizes and different shapes can be cut according to actual needs, the functionality is improved, by arranging a scraper under a cutter, when the cutter retracts after cuttingis completed, concrete residue at the edge of the cutter can be removed through a through hole, and the next cutting effect is not affected, so that the quality of finished products is improved.

Owner:HENGYANG HENGYU LIGHTWEIGHT INSULATION MATERIAL CO LTD

Vibrating Feed Powder Shaking Device and Powder Shaking Method for Livestock Breeding

ActiveCN113198723BSpeed up sievingEasy to separateSievingFeeding-stuffAnimal scienceAgricultural science

The invention discloses a vibrating feed powder shaking device and a powder shaking method for livestock breeding, and relates to the technical field of feed powder shaking. Under the action of two vibrating parts, the feed in the powder shaking parts is continuously shaken. The inner wall of the shaking powder box is fixedly connected with a material guide plate. It solves the existing feed screening method, usually because of its relatively simple structure, only the screen is set, and then the vibration is used to screen the feed water. This method may have many deficiencies. Through the simple vibration method, it may affect the The sieving effect of the aggregated impurities on the sieve is not good, and at the same time, the feed at the edge of the sieve cannot be screened effectively, resulting in a reduction in the quality of the sieved feed. There are too many impurities on the surface of the screen, and the impurities on the surface of the screen cannot be discharged synchronously, which makes the efficiency and effect of powder shaking poor.

Owner:GUANGDONG OCEAN UNIVERSITY

Environmental protection cutting liquid

The present invention relates to an environmental protection cutting liquid, which is prepared from ethylene glycol, sodium metasilicate, sodium phosphate and water according to a certain weight part ratio. The environmental protection cutting liquid has good stability, does not generate precipitating or layering, oil precipitating, soap graining, aging and other phenomena during storage and use, provides a certain resistance ability for bacteria and fungi, and is not easily subjected to mould generation and biodegradation so as not to cause odor generation and deterioration. In addition, the environmental protection cutting liquid has characteristics of no damage on painted parts, no harm on human body, no irritating odor, no smoke, no fog or less smoke during a use process, easy recovery, and low pollution.

Owner:张军辉

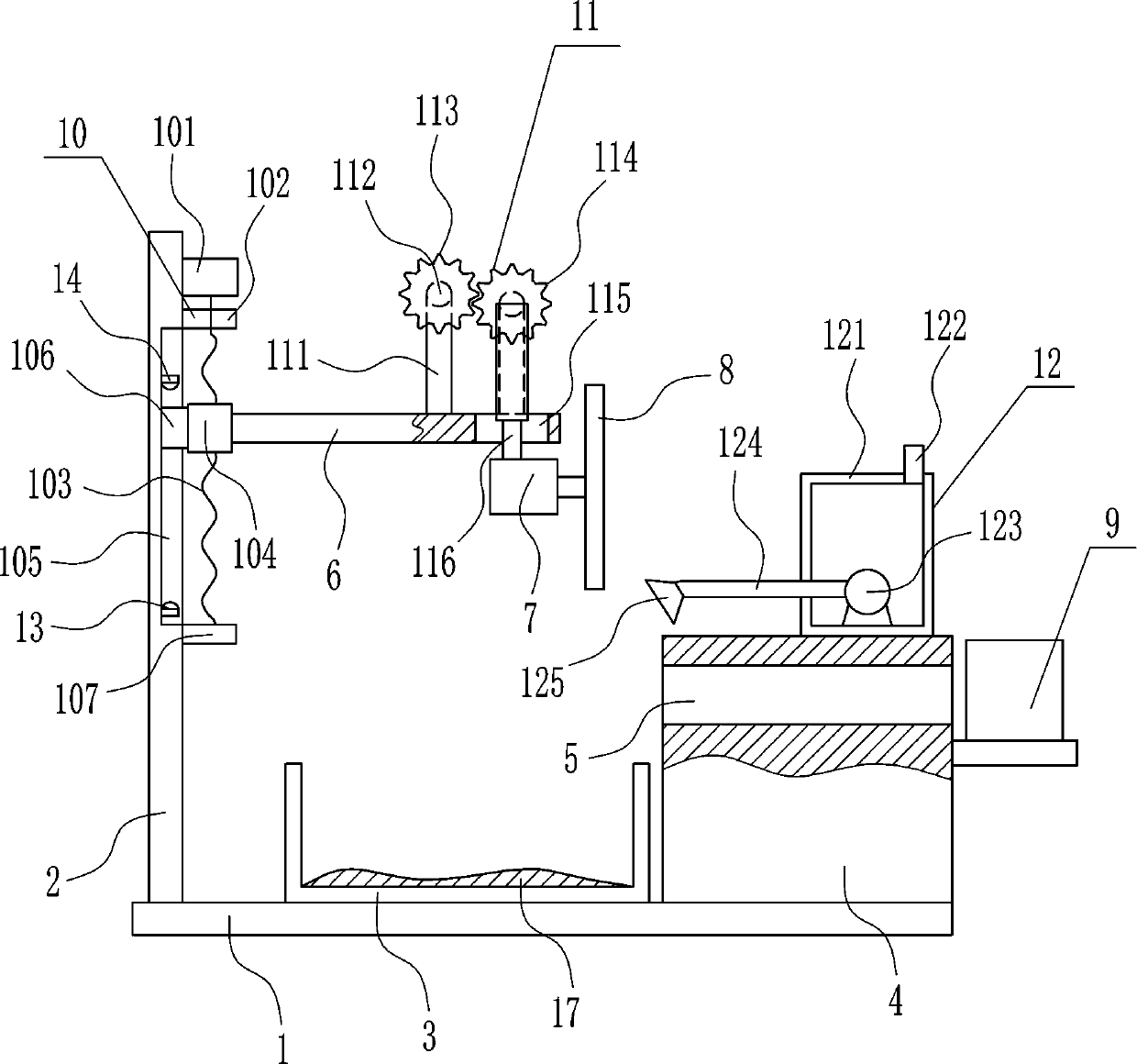

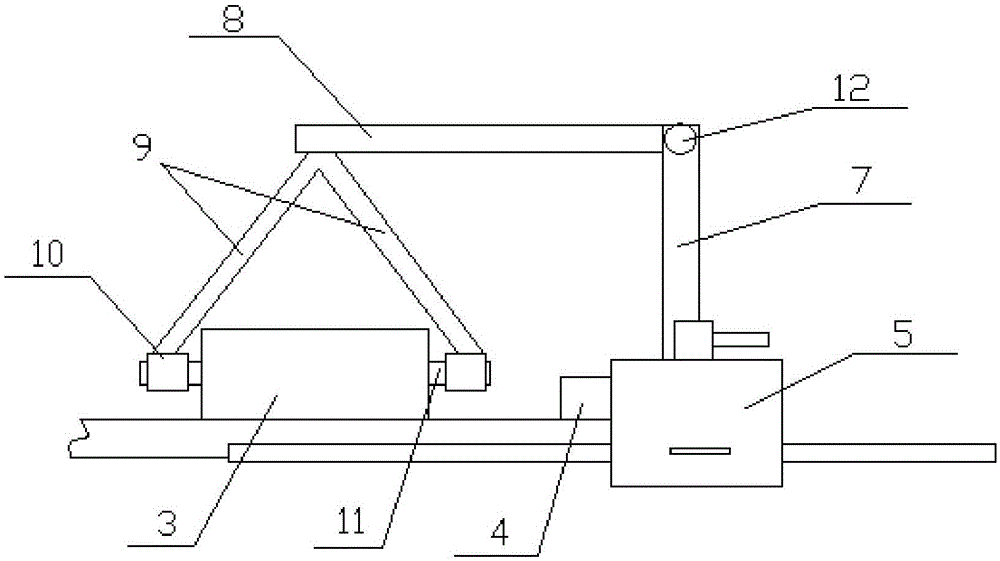

Mechanical part machining device in mechanical field

InactiveCN112238247AAvoid shakingAvoid displacementTube shearing machinesShearing machine accessoriesHydraulic cylinderSprocket

The invention relates to the technical field of part machining, and discloses a mechanical part machining device in the mechanical field. The mechanical part machining device comprises an operation table, a lifting mechanism is arranged in the middle of the upper surface of the operation table, and the lifting mechanism comprises a lifting frame, a sliding groove, a rotating shaft, a chain wheel,a sliding block, a chain, a hydraulic cylinder, a connecting block and a movable sleeve; the lifting frame is fixedly arranged on the operation table, the movable sleeve is connected to the outer partof the lifting frame in a sleeving mode, the hydraulic cylinder is fixedly arranged at the bottom of the interior of the lifting frame, the sliding block is fixedly arranged at the top of the hydraulic cylinder, and the sliding block is rotationally connected with the chain wheel through the rotating shaft; and the two ends of the rotating shaft are connected in the sliding groove in a sliding mode, the sliding groove is formed in the side face of the interior of the lifting frame, the chain wheel is in transmission connection with the chain, and one end of the chain is fixedly connected to the bottom surface of the lifting frame. According to the mechanical part machining device, the problems that a mechanical part machining device in the prior art cannot fix a steel pipe and the cuttingstroke is too small are solved, and the practicability of the mechanical part machining device is improved.

Owner:湖州数越智能科技有限公司

Cutting device for noodle production

PendingCN112056346AGood cutting uniformityLess breakageDough shaping and cutting apparatusGear wheelEngineering

The invention provides a cutting device for noodle production. The cutting device comprises a conveying table, wherein rotating modules are arranged on the two sides of the conveying table; a cuttingmodule is connected between the two rotating modules; the cutting module is located on the upper side of the conveying table; each rotating module comprises two vertical frames; two transverse framesand two guide rods are connected between the two vertical frames; two gears are installed on the two transverse frames; vertical plates are fixed on the two sides of a cutting support; cam moving units are installed on the vertical plates; a rotating shaft penetrates through the interior of a mounting plate; a cam is installed at the end part of the rotating shaft; two guide rings are fixed on themounting plate; movable shafts are embedded into the two guide rings; springs are embedded into the outer parts of the movable shafts; the upper ends of the springs abut against the tops of the movable shafts; the lower ends of the springs abut against the guide rings; the cam abuts against the tops of the movable shafts; and a cutter is fixedly connected between the lower ends of the two movableshafts located on the two sides of the cutting support. The cutting device for noodle production has the advantages of being good in cutting uniformity, less in breakage and high in cutting efficiency.

Owner:湖北十星杂粮食品有限公司

Cambered surface cutting device for aluminum alloy frame

InactiveCN102205442AClear in timeMeet the needs of useMetal sawing devicesMetal sawing accessoriesEngineeringStructural engineering

The invention discloses a cambered surface cutting device for an aluminum alloy frame. The cambered surface cutting device comprises a workbench; a rotary saw is arranged below the workbench; the rotary saw extends out of a bar-shaped open slot on the workbench; a slag guide barrel is arranged on the workbench; the slag guide barrel is positioned on one side of the rotary saw; a guide plate is fixedly arranged on the slag guide barrel; a guide slot is formed in the middle of the guide plate; and the guide slot and the rotary saw are positioned on the same plane. The cambered surface cutting device has a simple structure and perfect design; by the slag guide function of the slag guide barrel, slag produced during cutting can be removed immediately, so a cutting effect cannot be influenced; therefore, the using requirement of an enterprise is met.

Owner:安徽省美佳家俱装饰有限公司

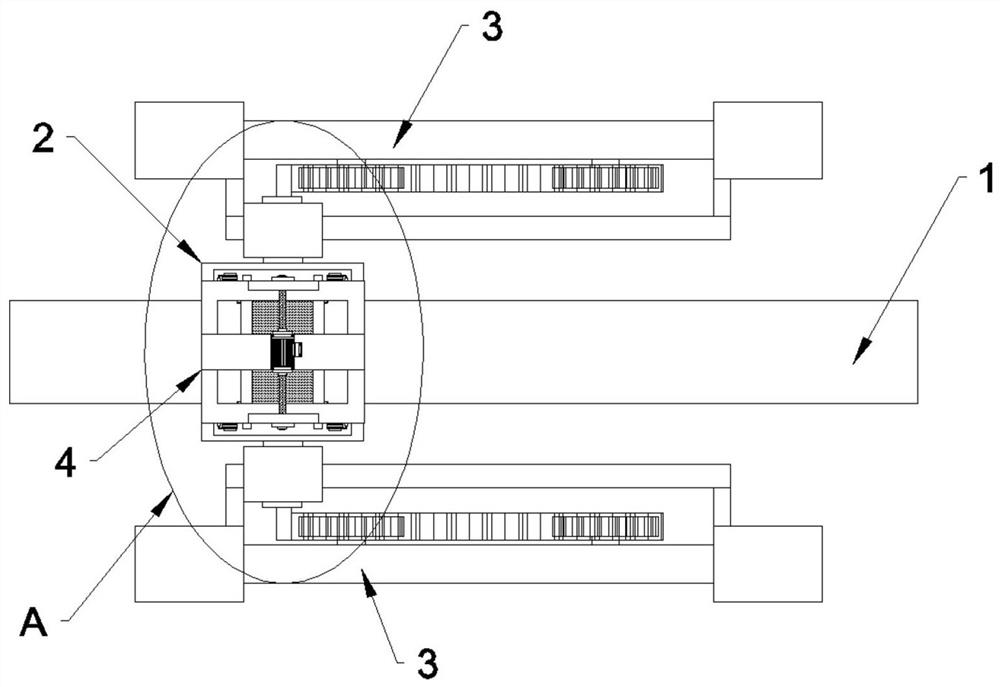

Automatic machining and forming device for welding groove of welded bent pipe

ActiveCN113427073AAchieve a fixed effectUniform pressureFeeding apparatusTube shearing machinesPipe fittingEngineering

The invention discloses an automatic machining and forming device for a welding groove of a welded bent pipe, and relates to the technical field of pipe shearing. The automatic machining and forming device comprises a shell and further comprises a cutting device, a working frame is fixedly connected to the surface of the shell, a working table is arranged in the working frame, pipelines are placed on the working table, four clamping plates used for fixing the pipelines are arranged in the working frame, two sets of fixing components used for controlling the two clamping plates to move so as to fix the four pipelines different in size are arranged in the shell, and the device further comprises adjusting components for keeping the force of the four pipes uniform when being fixed, and preventing the force deviation from affecting the forming effect of the groove. According to the device, through mutual cooperation of the structures, the effects that multiple pipe fittings with different sizes are fixed at the same time, the fixing effect is good, stress is uniform are achieved, and the problems that in a traditional mode, each set of pipe fittings need to be fixed independently, and efficiency is low are solved.

Owner:南通久鼎特种钢管有限公司

An integrated system for wood processing

ActiveCN108544583BAvoid damageHigh degree of automationPressure wood treatmentDispersed particle separationPulp and paper industryAir pollution

The invention discloses a wood processing and treating integration system. The system comprises a wood segment obtaining device, a wood heat-insulating, moisturizing and transporting device, a wood anti-collision storage device, an automatic-temperature adjustment wood immersing device, a layered refrigeration device, a wood standing and drying device, an end part oiling sealing device and a woodsegment cutting device. The invention also discloses a realization method of the wood processing and treating integration system. The system has the advantages of high automatic degree, ensuring of nodamages of wood, wide market competiveness, effectiveness in ensuring the quality of wood, avoiding of air pollution, production cost saving, and effectiveness in improvement of the production environment.

Owner:江苏七巧工艺木制品股份有限公司

Metal plate cutting equipment with noise reduction function

PendingCN113894347AEnsure stabilityNo noiseMetal-working feeding devicesShearing machinesStructural engineeringMechanical engineering

The invention relates to the technical field of metal part machining, and discloses metal plate cutting equipment with a noise reduction function. The metal plate cutting equipment with the noise reduction function comprises a lifting base capable of lifting, an auxiliary breaking structure installed on the lifting base and provided with a to-be-cut metal plate, an extrusion mechanism installed above the lifting base, a cutting mechanism capable of cutting the metal plate and an operating mechanism capable of driving the extrusion mechanism to abut against the metal plate; and when the extrusion mechanism abuts against the metal plate, the operation mechanism can drive the cutting mechanism to move towards the metal plate so as to complete cutting of the metal plate. According to the metal plate cutting equipment, a fixing piece and a cutting knife can be linked, the whole structure can cut only under the fixed condition, misoperation is avoided, and noise in the cutting process is reduced.

Owner:WUHU TIANHANG TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com