Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Corrosion resistant and stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

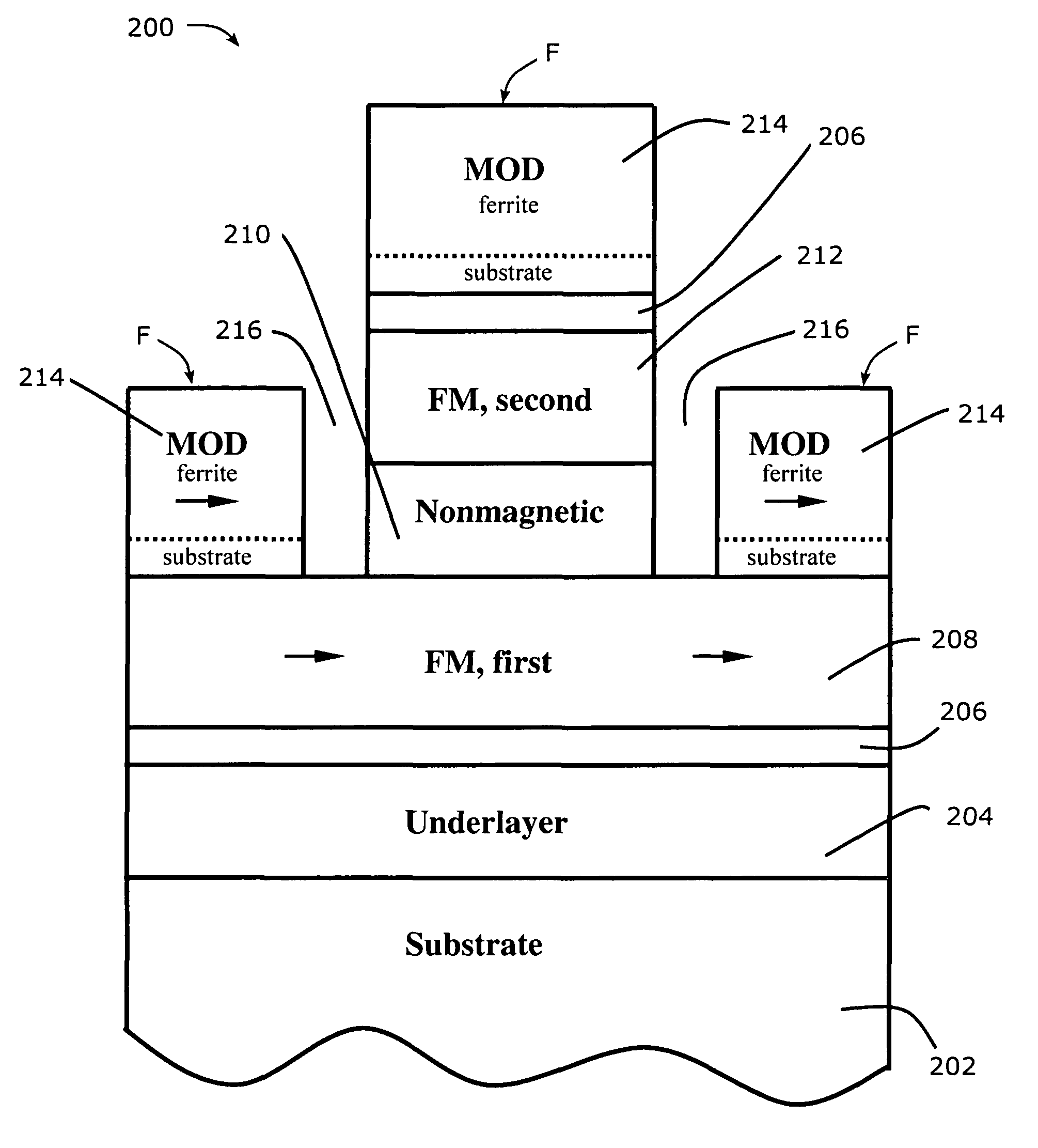

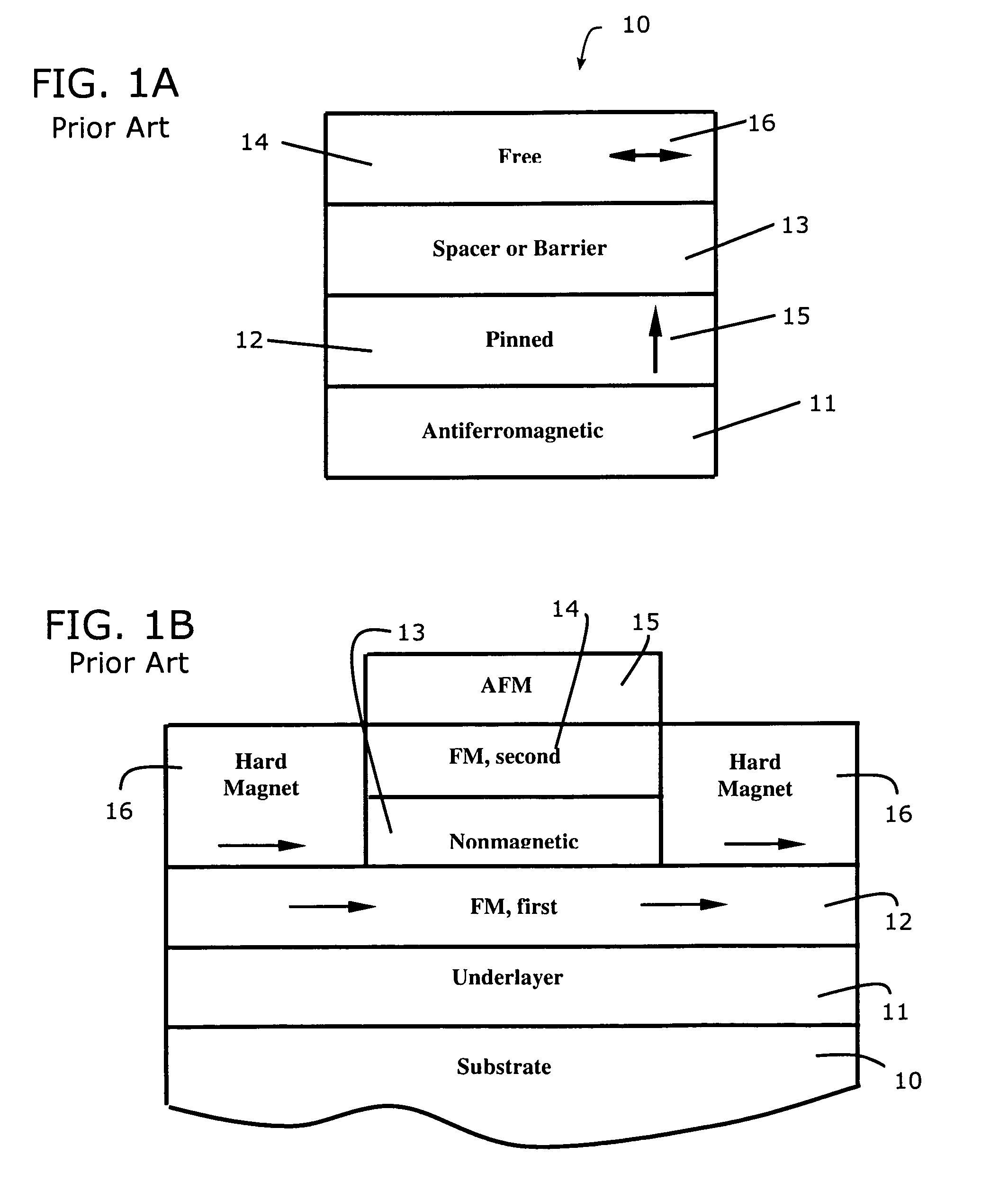

Magneto-optical device with an optically induced magnetization

ActiveUS8154957B1Total current dropEasy to manufactureCombination recordingDifferent record carrier formsMagnetic memoryMagnetization

A magneto-optical device (MOD) with optically induced magnetization for use in magnetic field sensors as a magnetic element pinning a magnetization in a preferred direction of a ferromagnetic layer as well as a magnetic memory cell for magneto-optical recording. The MOD comprises the Mg—Mg—Co ferrite film deposited on a magnesium oxide (MgO) substrate. The ferrite film is illuminated at room temperature with a circularly polarized light (CPL) in a static magnetic H-field (about of 3 kOe) normal to the illuminated ferrite film surface. At certain (“writing”) combinations of H, sigma (CPL helicity), the long-lived optically induced magnetization with a unidirectional anisotropy, stable to a conventional demagnetization occurs. For readout of information, conventional magnetoresistive sensors and MFM can be used. To erase information, the ferrite film should be illuminated with two field-light combinations, other than “writing”, or annealed at temperature higher than 530 degrees C.

Owner:KATSNELSON ESFIR Z +1

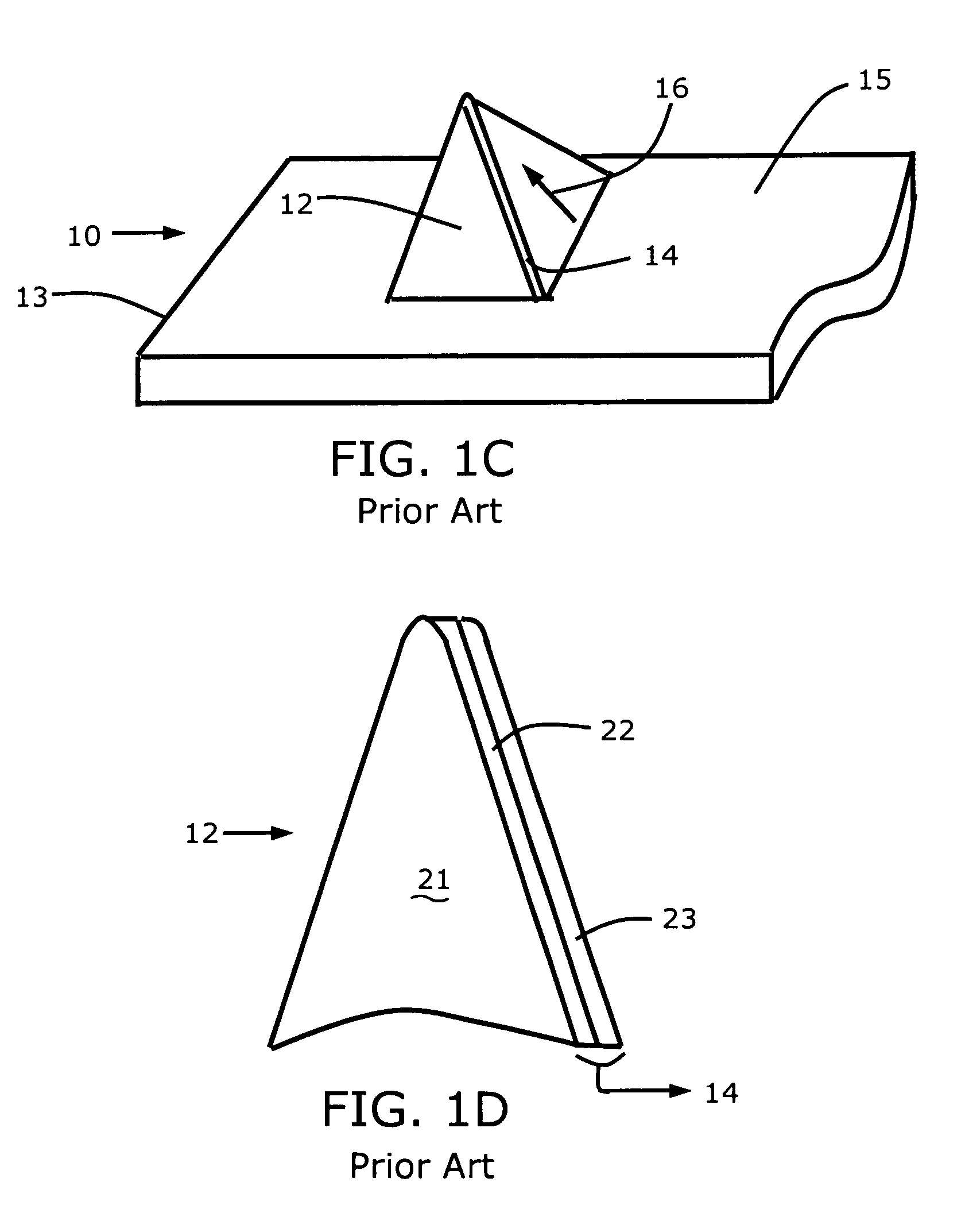

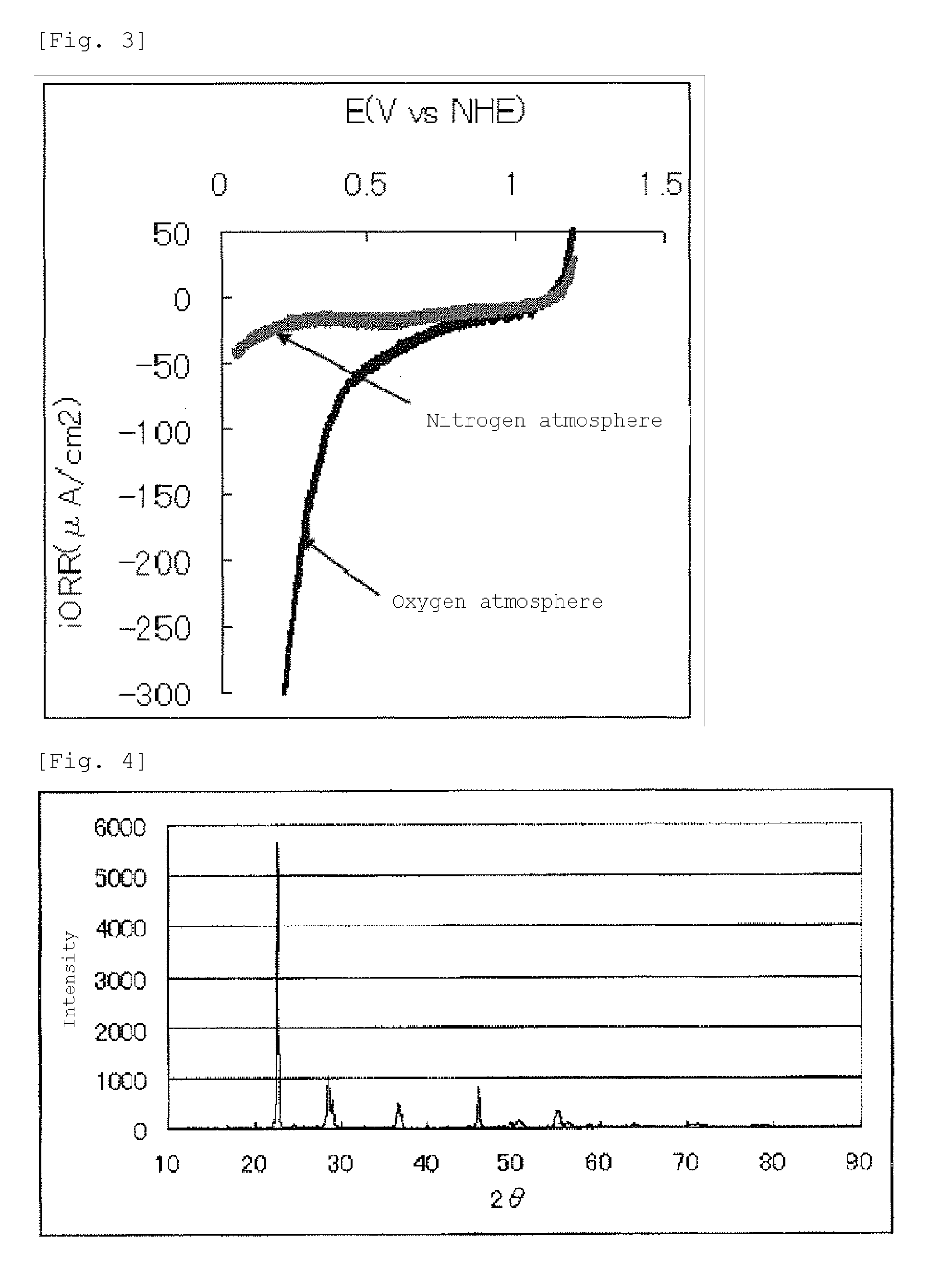

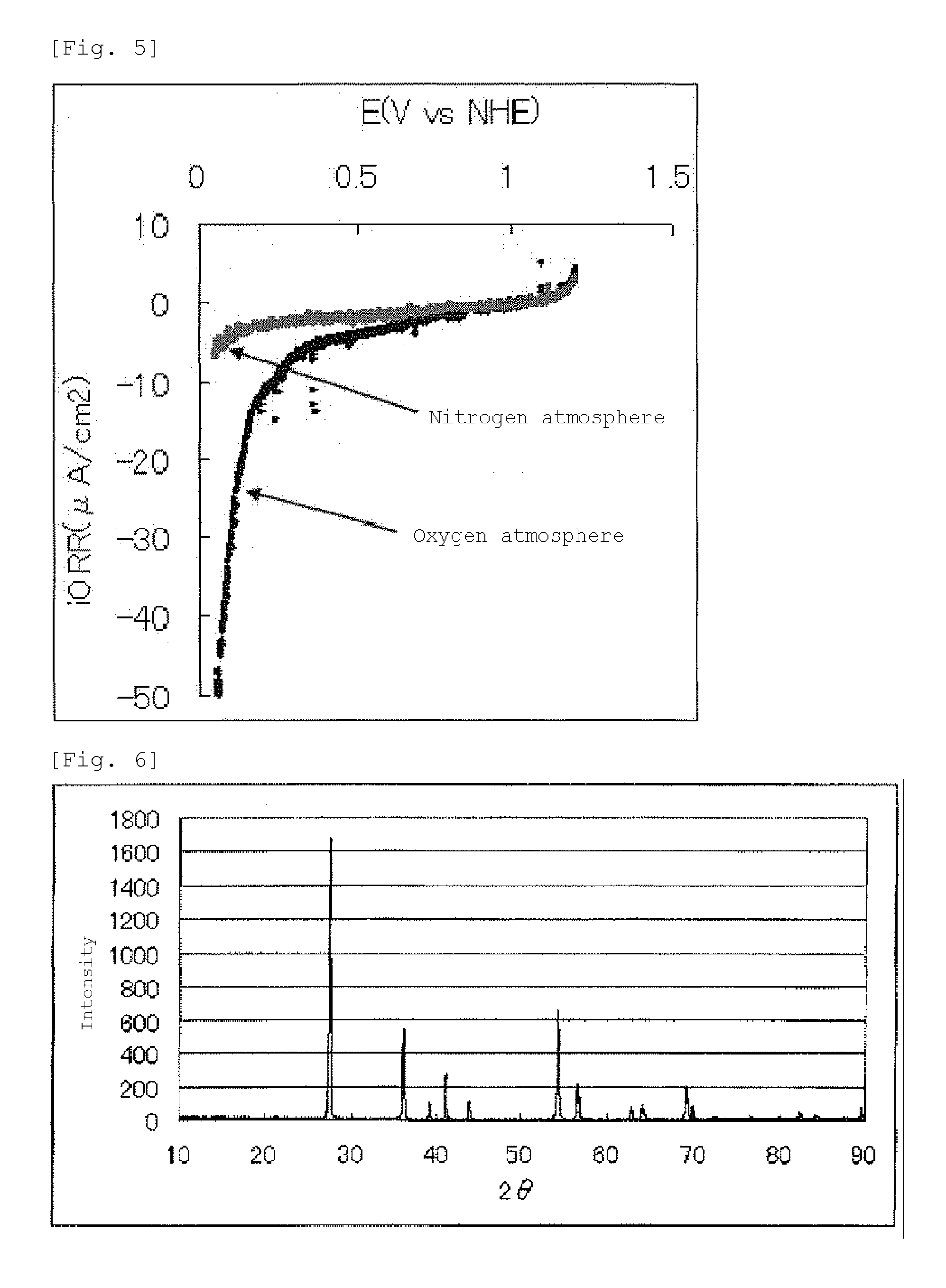

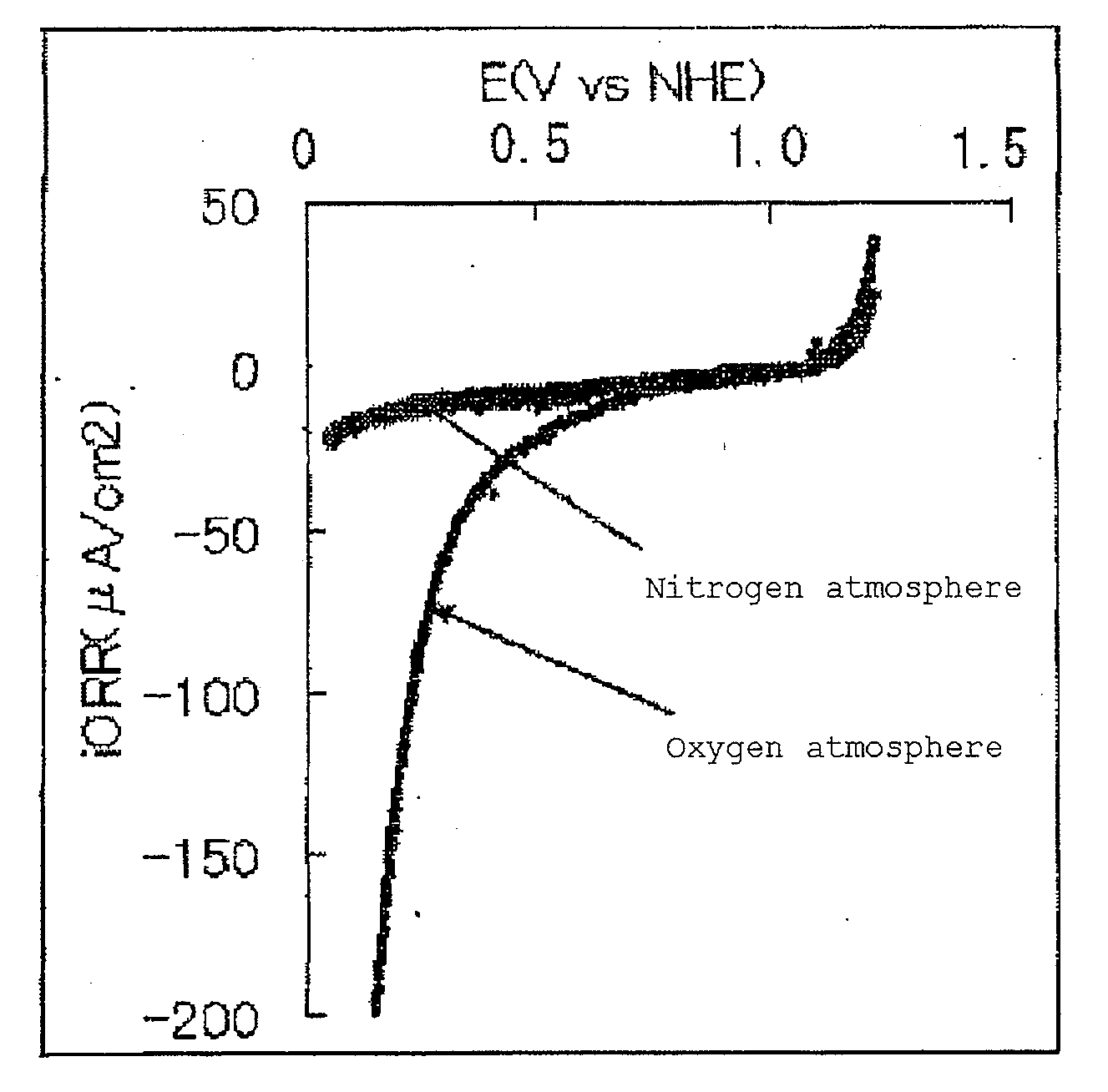

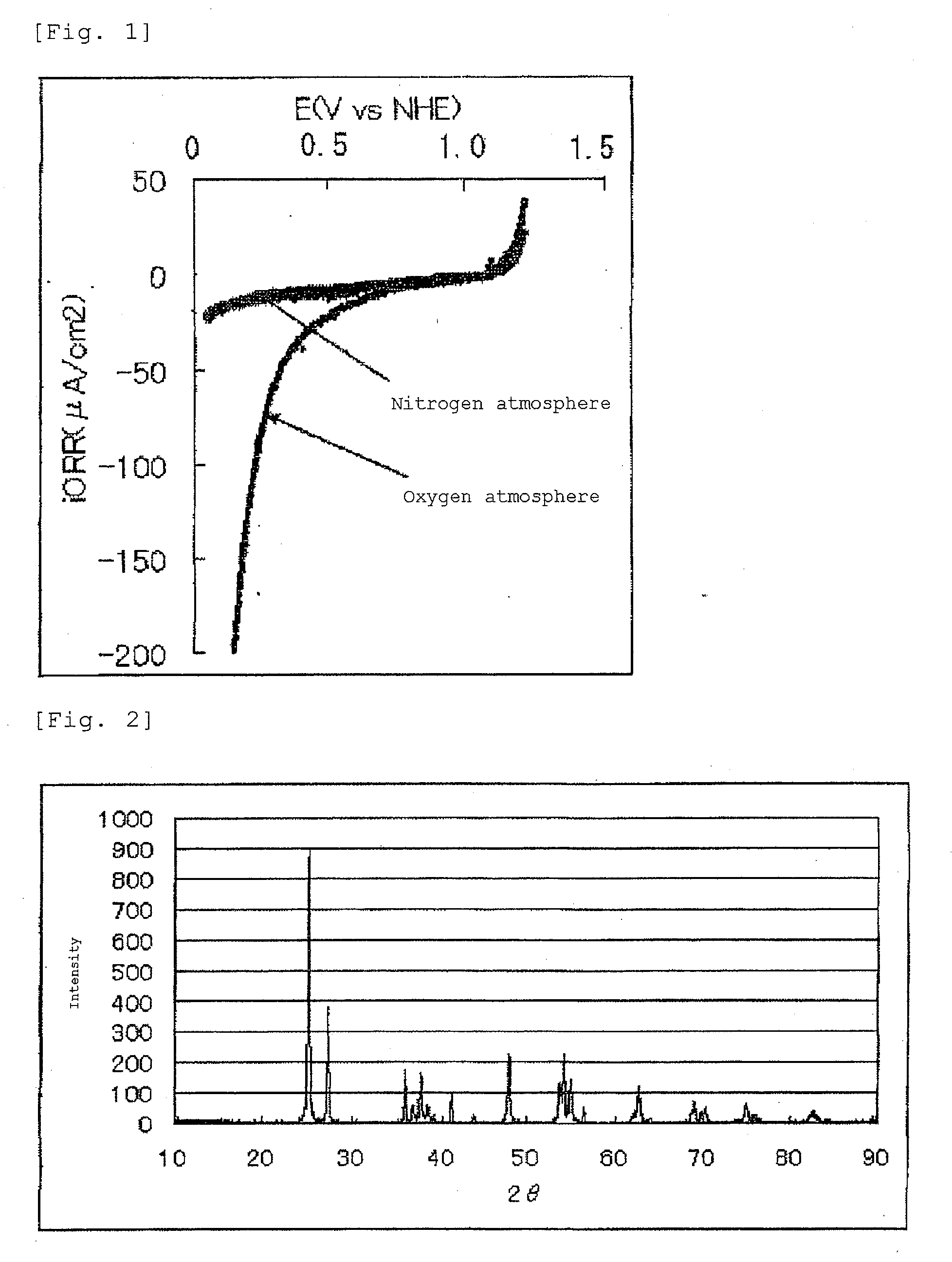

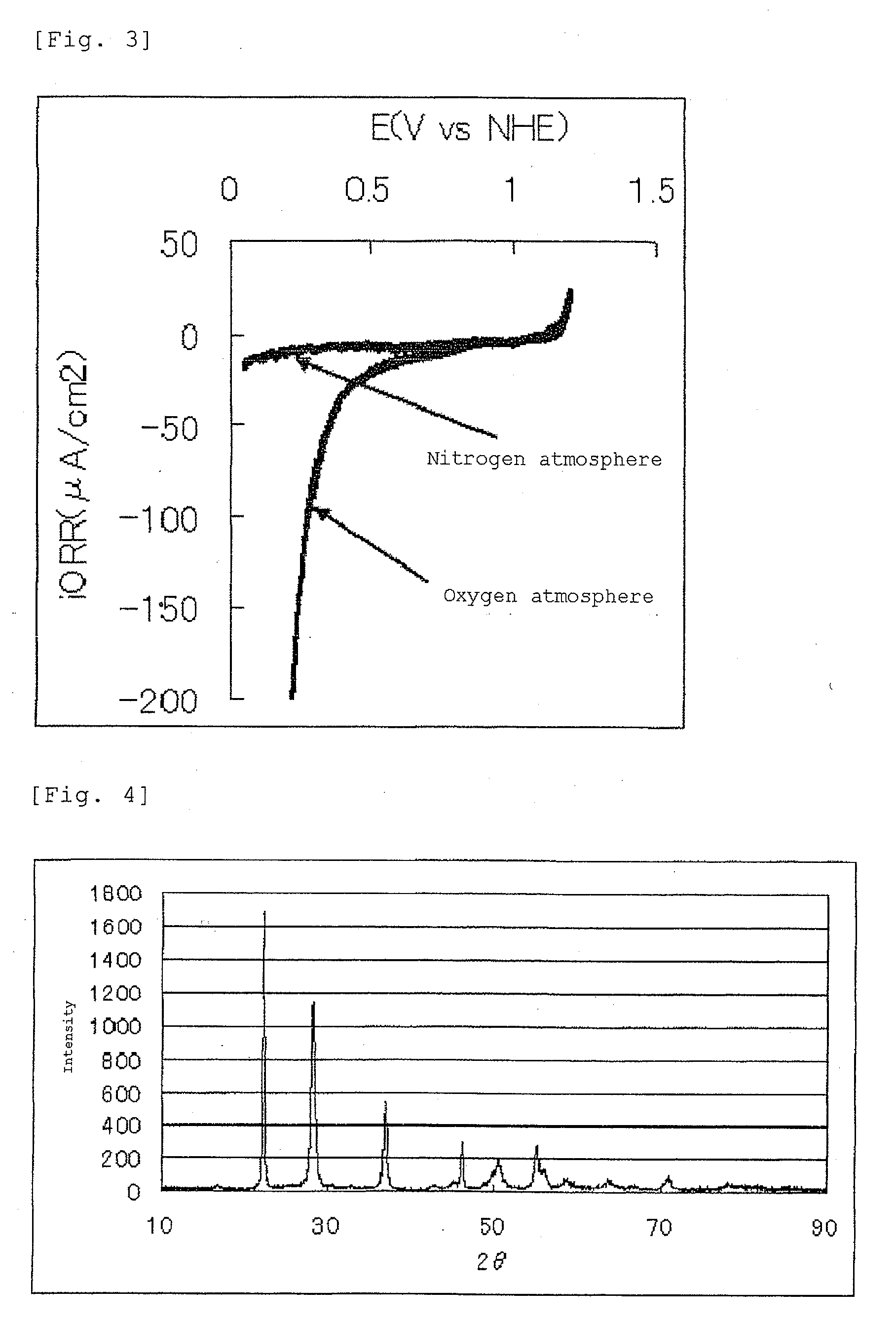

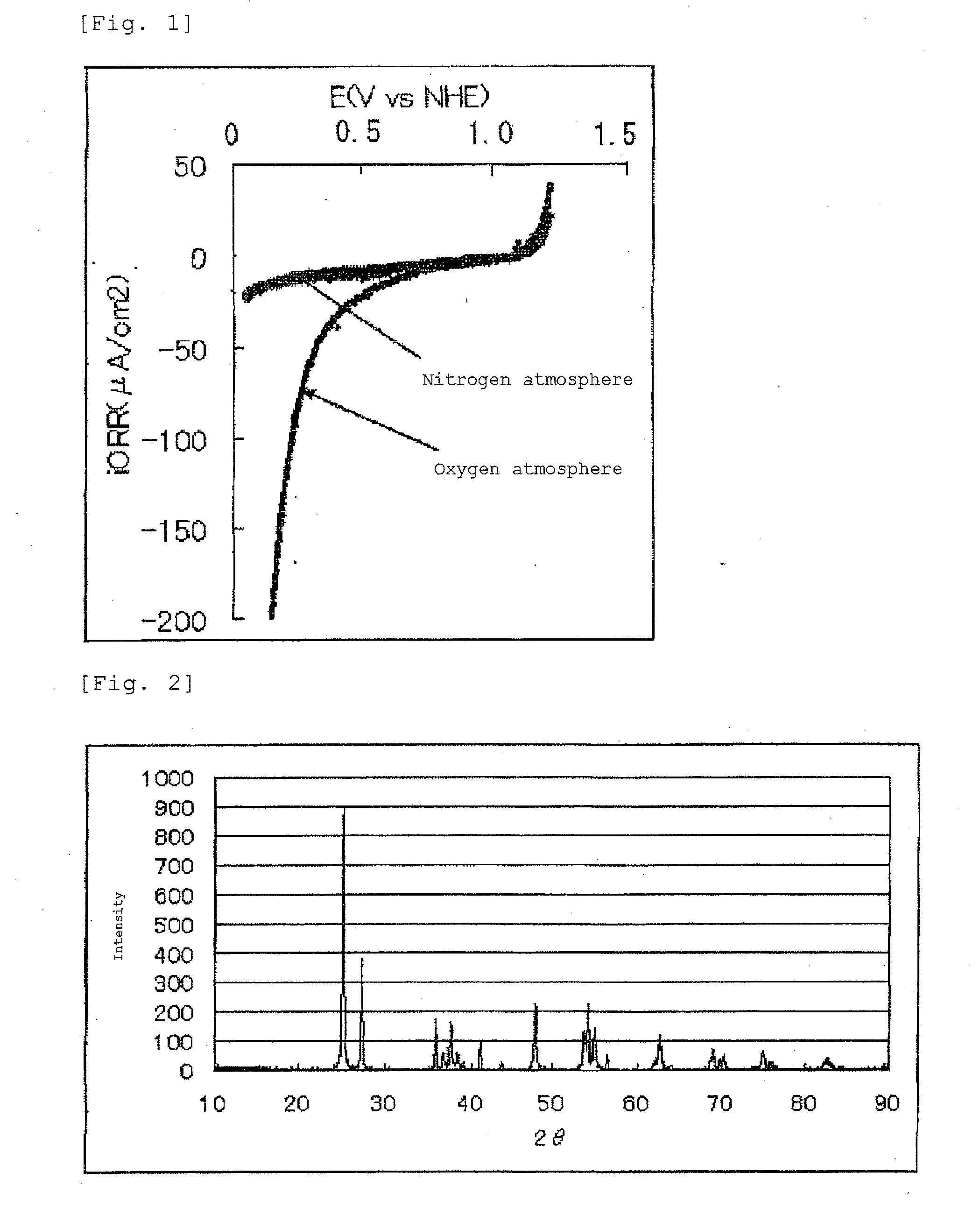

Metal oxide electrocatalyst, use thereof, and process for producing metal oxide electrocatalysts

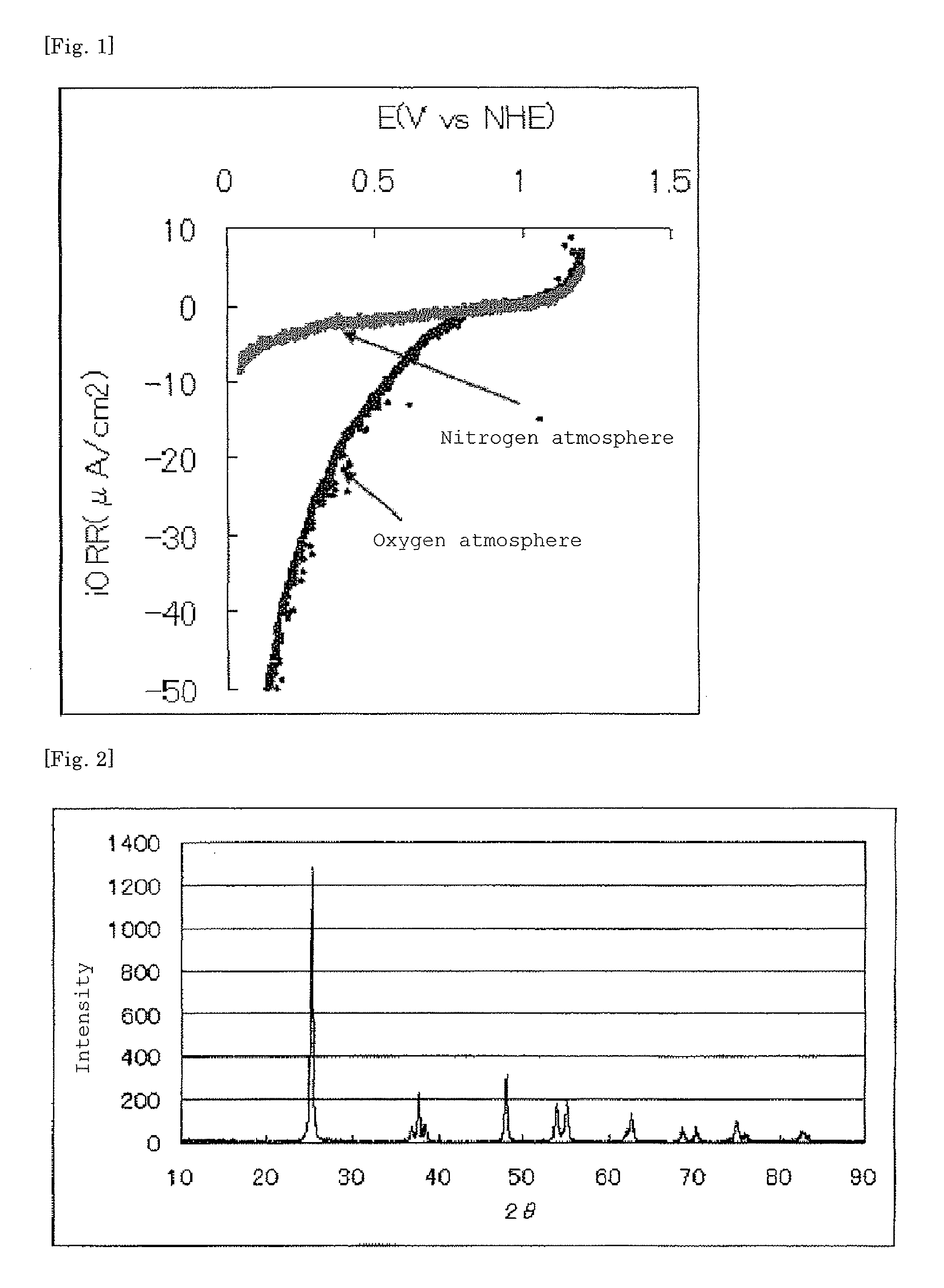

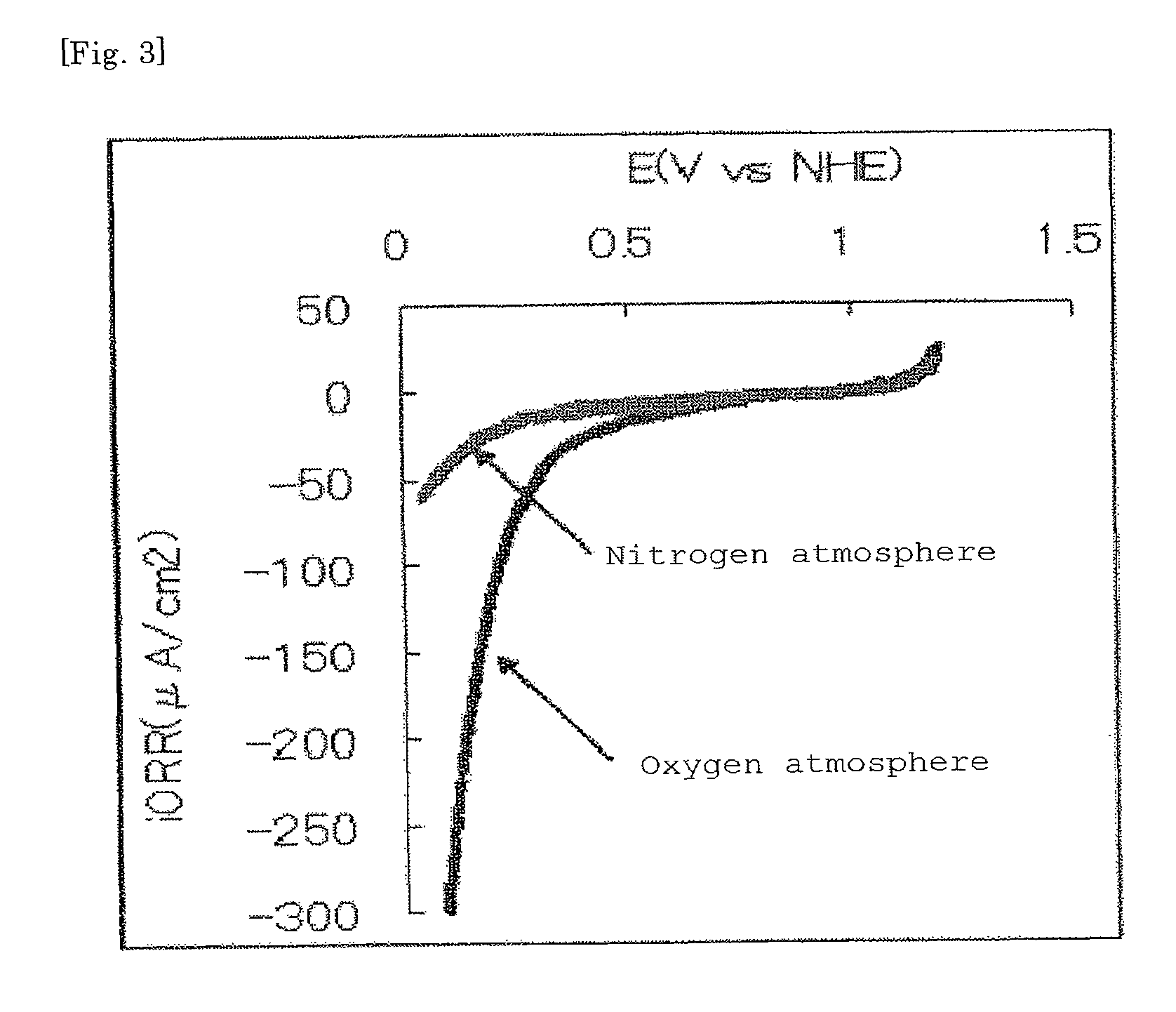

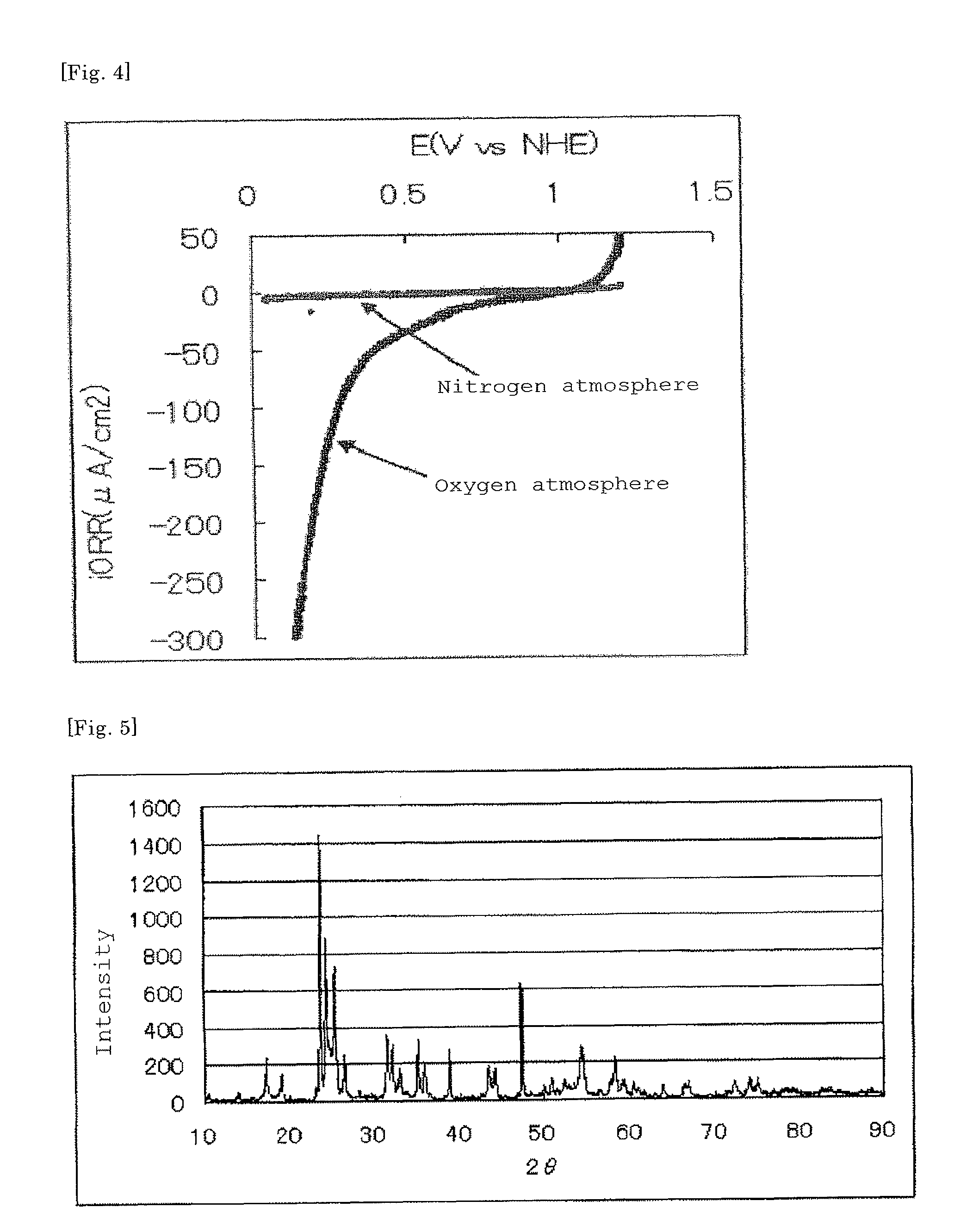

ActiveUS20110229793A1High oxygen reduction activityCorrosion resistant and stableOxide/hydroxide preparationTantalum compoundsIonizationMetal oxide electrode

A metal oxide electrode catalyst which includes a metal oxide (Y) obtained by heat treating a metal compound (X) under an oxygen-containing atmosphere. The valence of the metal in the metal compound (X) is smaller than the valence of the metal in the metal oxide (Y). Further, the metal oxide electrocatalyst has an ionization potential in the range of 4.9 to 5.5 eV.

Owner:SHOWA DENKO KK

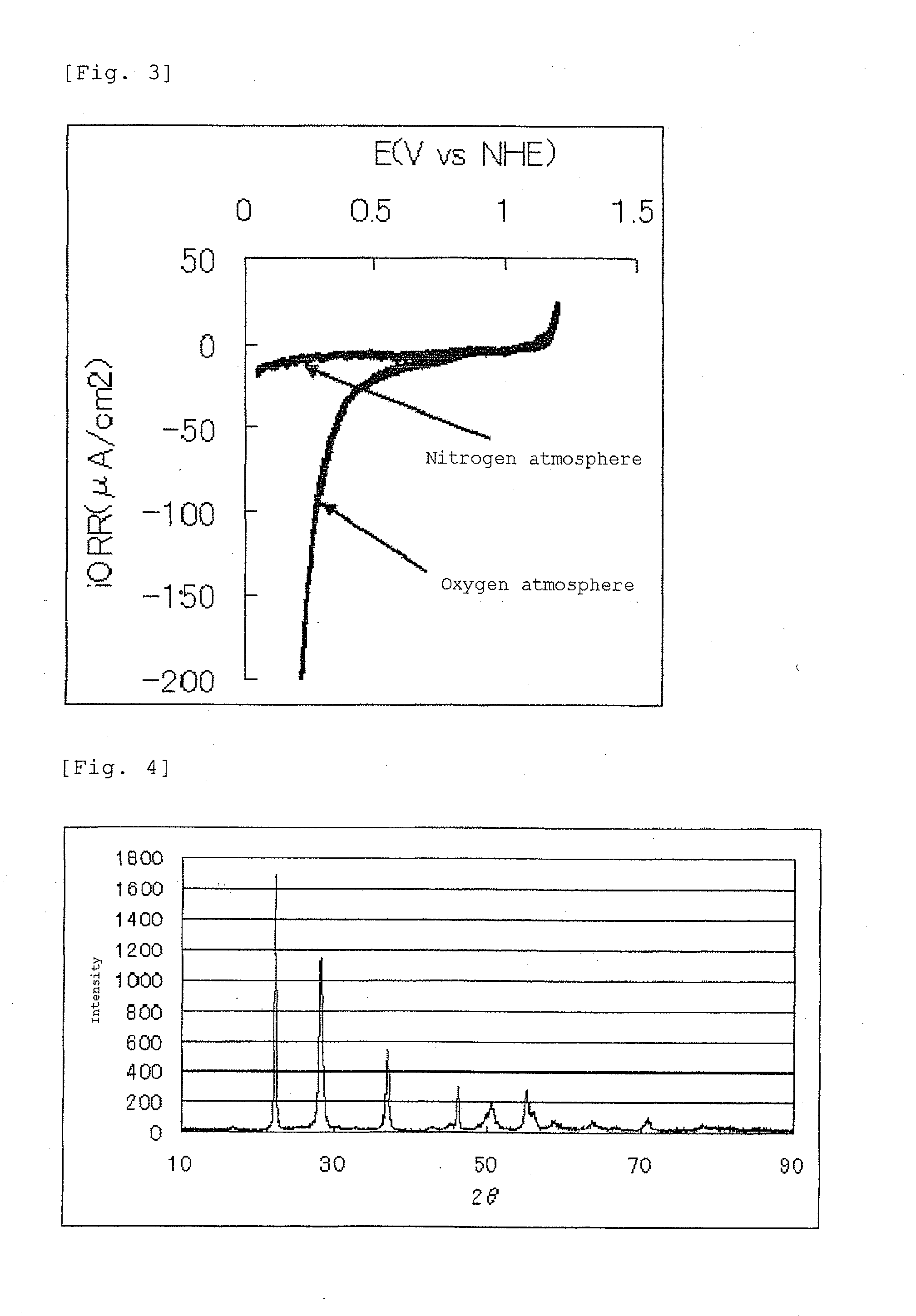

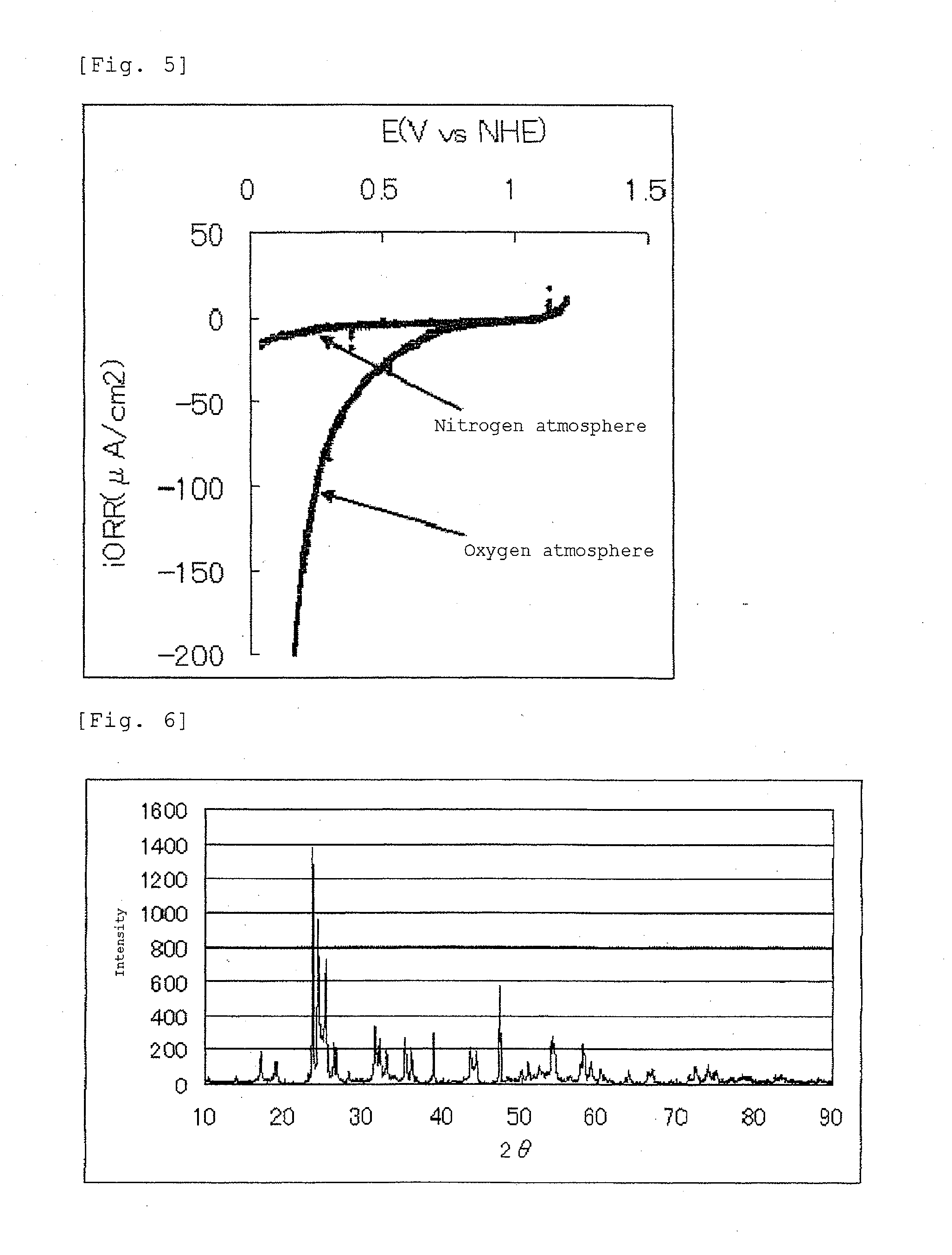

Electrocatalyst layer, memebrane electrode assembly and fuel cell

InactiveUS20100255404A1High oxygen reduction activityCorrosion resistant and stableOxide/hydroxide preparationOther chemical processesReduction ActivityNiobium

Electrocatalyst layers include an electrocatalyst having high oxygen reduction activity that is useful as an alternative material to platinum catalysts. Uses of the electrocatalyst layers are also disclosed.The electrocatalyst layer includes an electrocatalyst that is formed of a metal oxide obtained by thermally decomposing a metal organic compound. The metal element forming the electrocatalyst is preferably one selected from the group consisting of niobium, titanium, tantalum and zirconium.

Owner:SHOWA DENKO KK

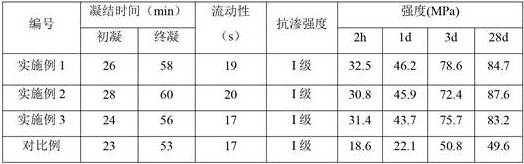

Novel rapid repair cement based on magnesium oxysulfate cementing material and preparation method thereof

InactiveCN111825418ANo pollution in the processImprove liquidityDischarging arrangementCement mixing apparatusAluminatePhysical chemistry

The invention provides novel rapid repair cement based on a magnesium oxysulfate cementing material and a preparation method thereof. The material is characterized by being prepared from the followingraw materials in parts by weight: 45 to 55 parts of light calcined magnesia powder, 30 to 40 parts of magnesium sulfate solution, 2 to 7 parts of aluminate cement clinker with the mark number of CA-50 or CA-70, and 0.2 to 0.7 part of citric acid. According to the novel rapid repair cement based on the magnesium oxysulfate cementing material, the cement has the advantages of simple preparation process, short setting time, high early strength, good stability, cost reduction and environmental protection on the premise of ensuring the use strength, impermeability, stability and other properties of the cement so the early-strength quick-repair cement has positive meanings for the development of magnesian resources and the preparation of quick-repair cement in the future.

Owner:UNIV OF SCI & TECH LIAONING

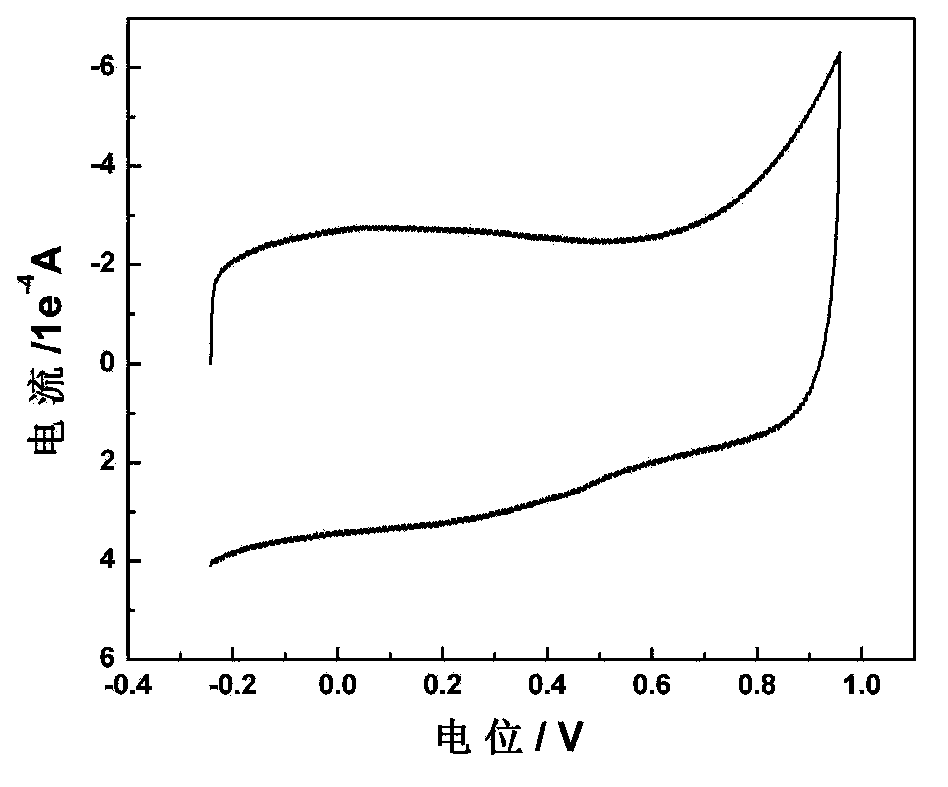

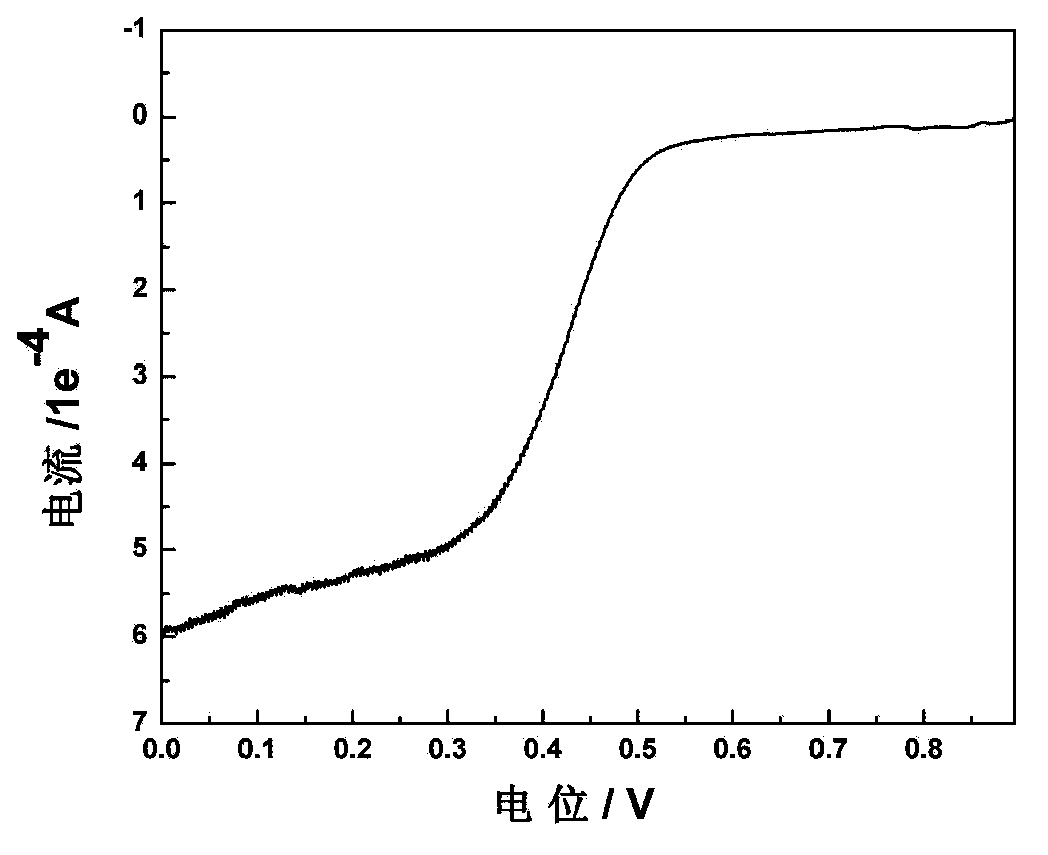

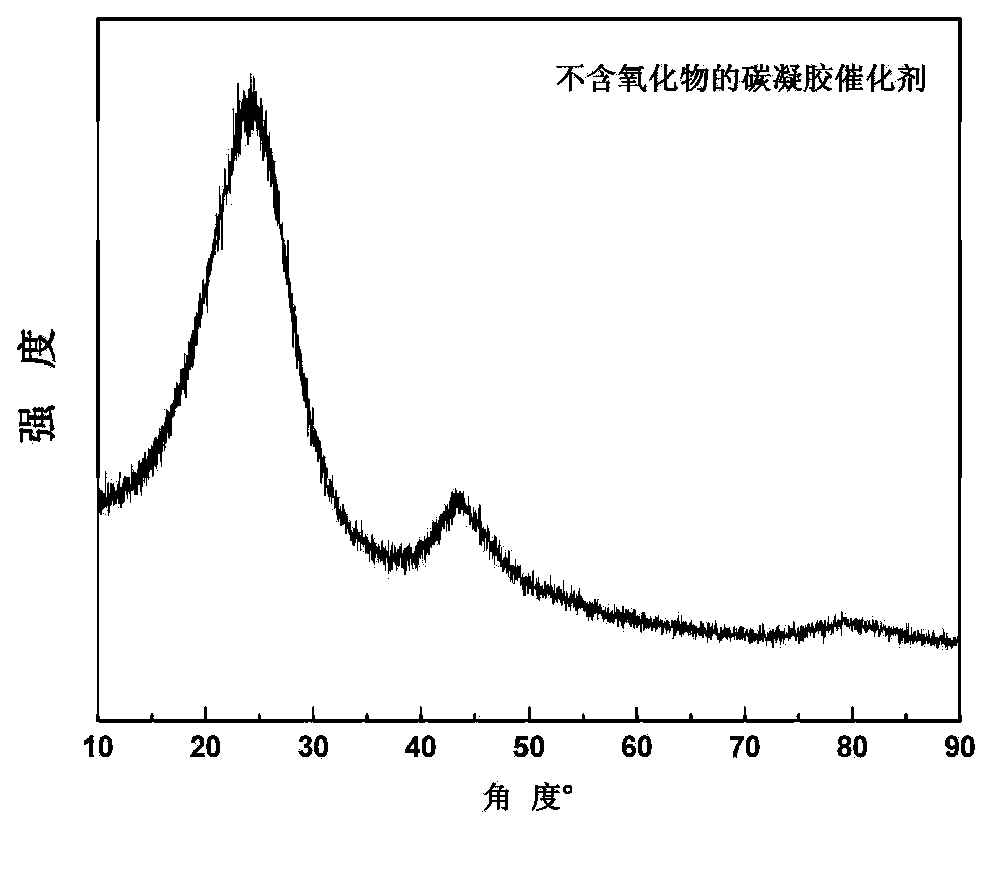

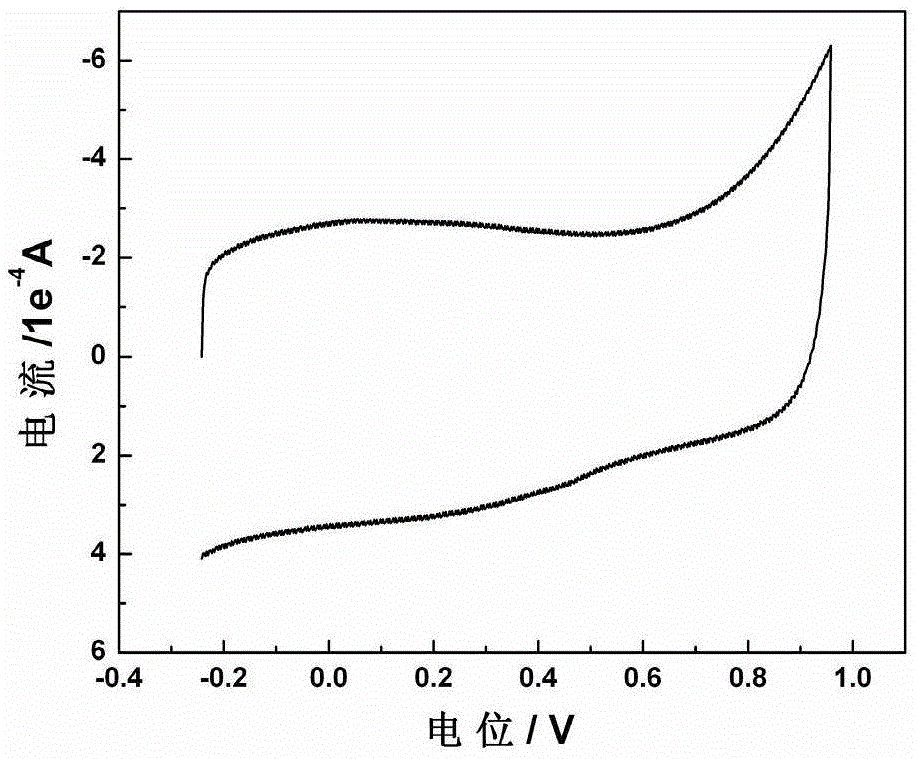

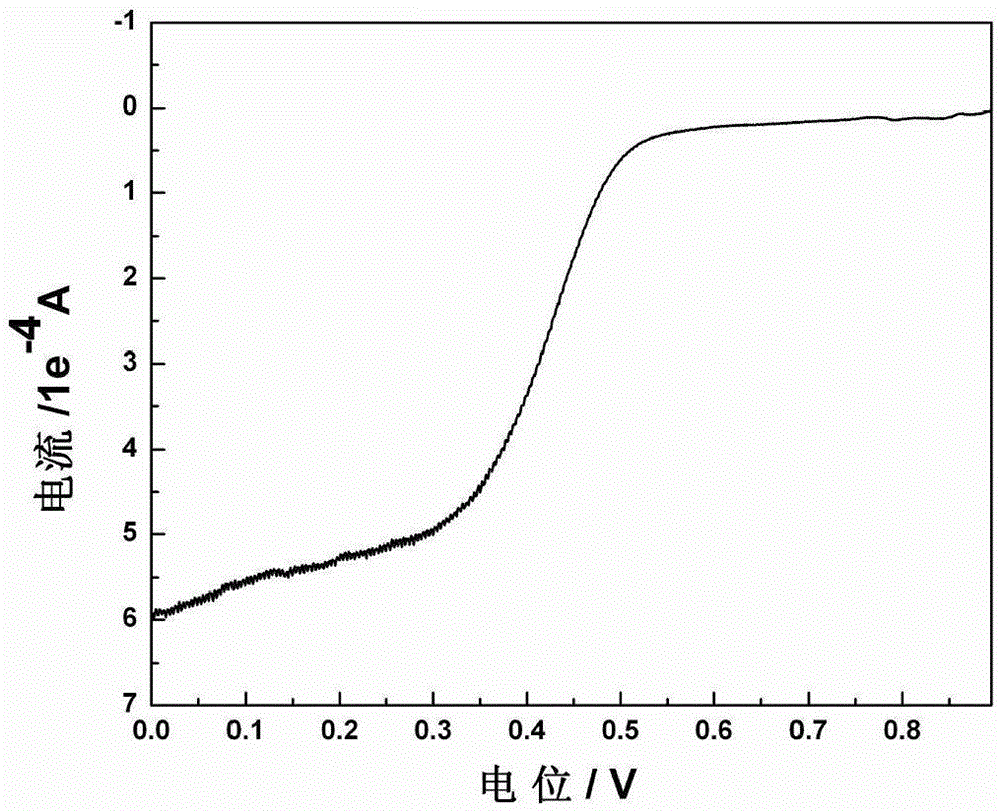

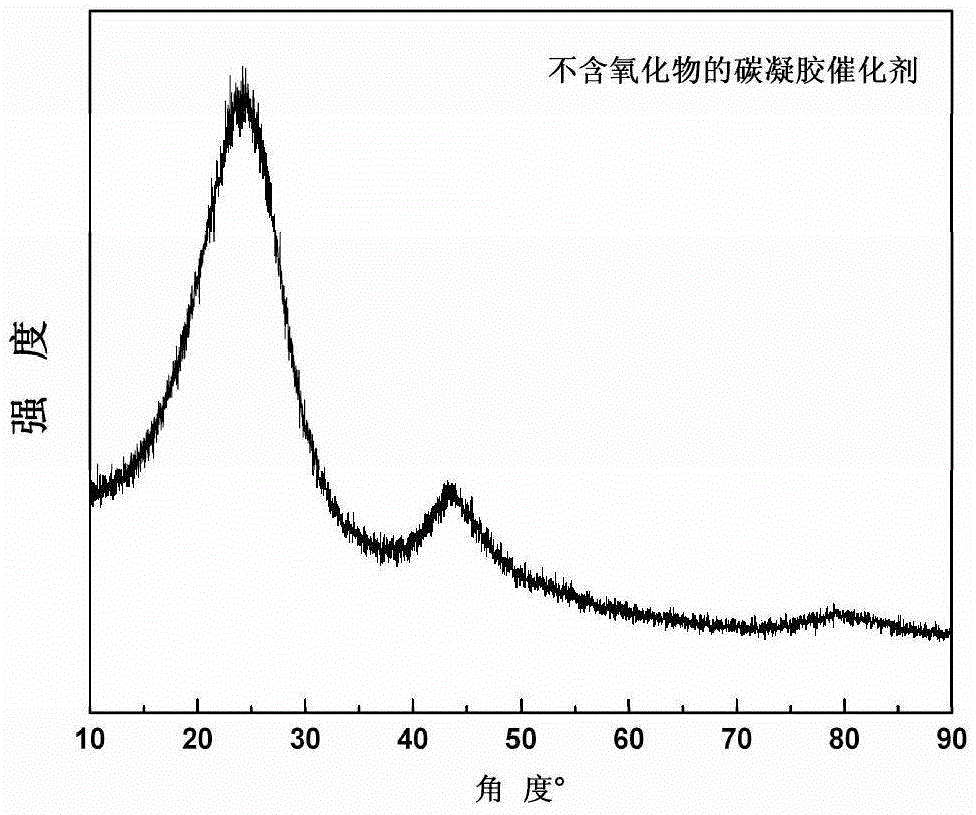

Carbon gel catalyst for fuel batteries and application thereof

ActiveCN103682378AGood application effectLarge specific surface areaPhysical/chemical process catalystsCell electrodesCarbonizationProton

The invention relates to a carbon gel catalyst for fuel batteries and application thereof. By adopting resorcinol, formaldehyde, a coordination compound, a metal salt and a metal organic compound as raw materials, the carbon gel catalyst which is controllable and adjustable in pore structure and specific surface area is prepared through controlling the adding of the metal salt of different amounts and adjusting the precursor solution concentration, the reaction environment temperature and the carbonization and nitridation treatment temperature. When serving as a nonmetal catalyst for a proton exchange membrane flue battery cathode catalyst, the carbon gel catalyst disclosed by the invention shows good corrosion resistance and stability after long-term use; the preparation process of the catalyst is simple in flow, short in period and friendly to environment; the catalyst is low in cost and wide in application range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spraying painting material for slide bearing

InactiveCN1163626CCorrosion resistant and stableExtended service lifeMolten spray coatingChemical compositionPlain bearing

A spray material for slide bearing is a self-fused hard alloy powder for the hot galvanizing machine set, and contains Cr (20-26 wt.%), Co (22.8-61), Mo (10-16), W (6-12), Si (1-4), B (2-5), F (less than 14) and C (less than 0.2). Its spayed layer has high anticorrosion and antiwear performance to elongate the service life of slide bearing up to 21-27 days with low cost.

Owner:BAOSHAN IRON & STEEL CO LTD +1

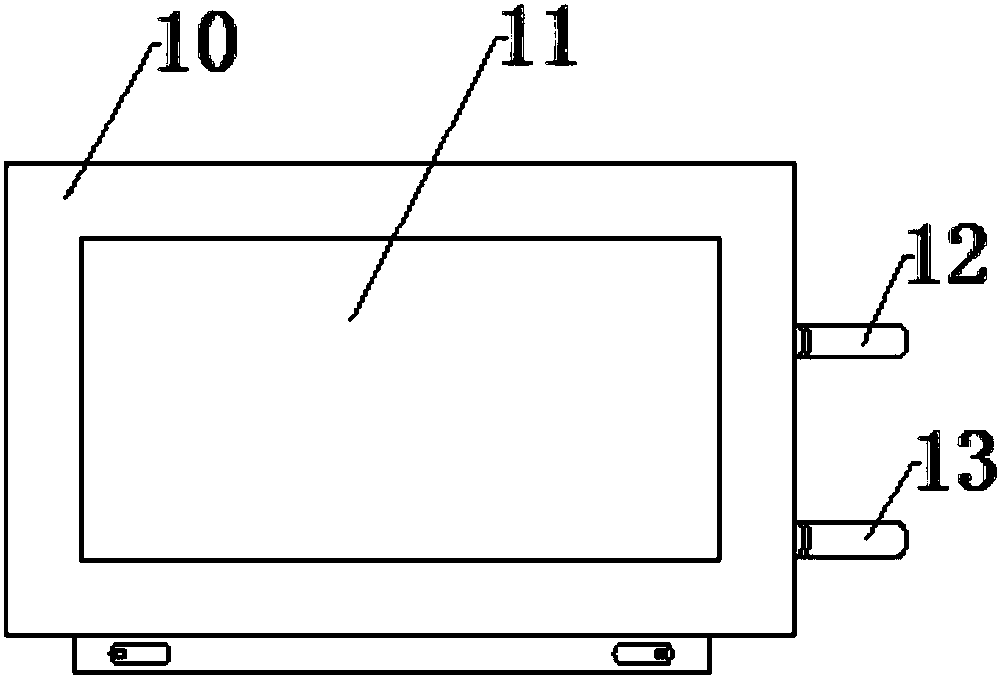

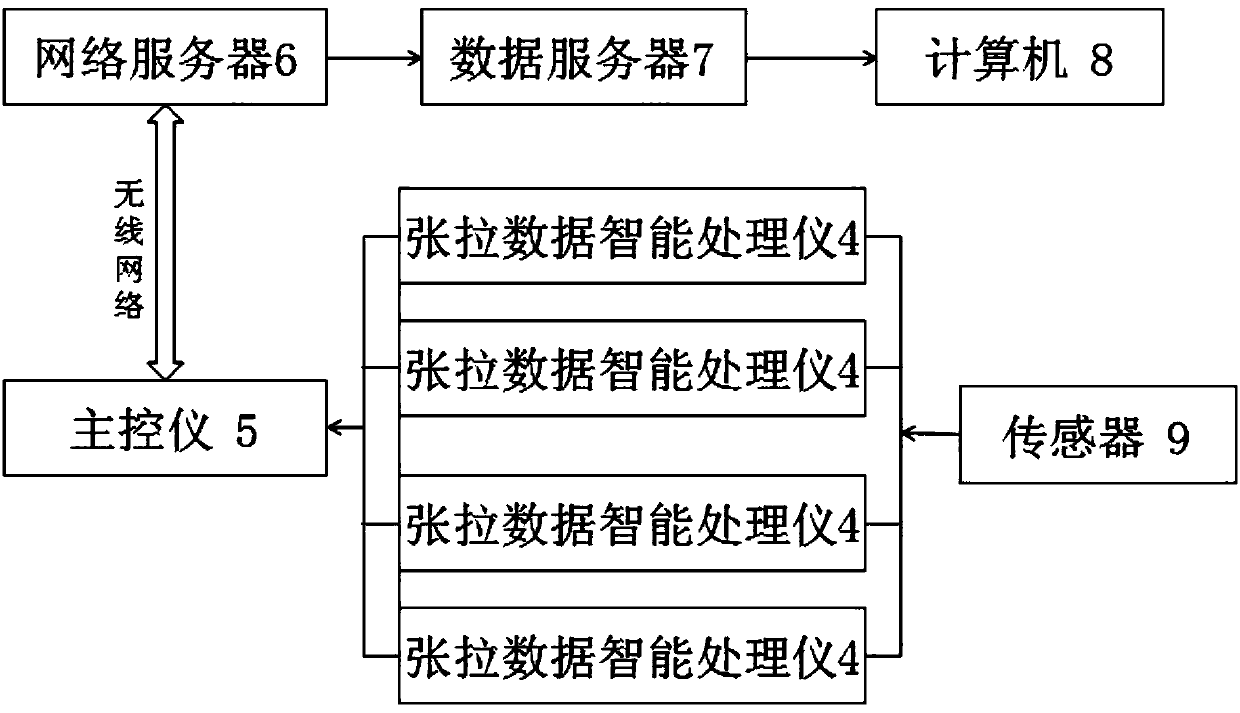

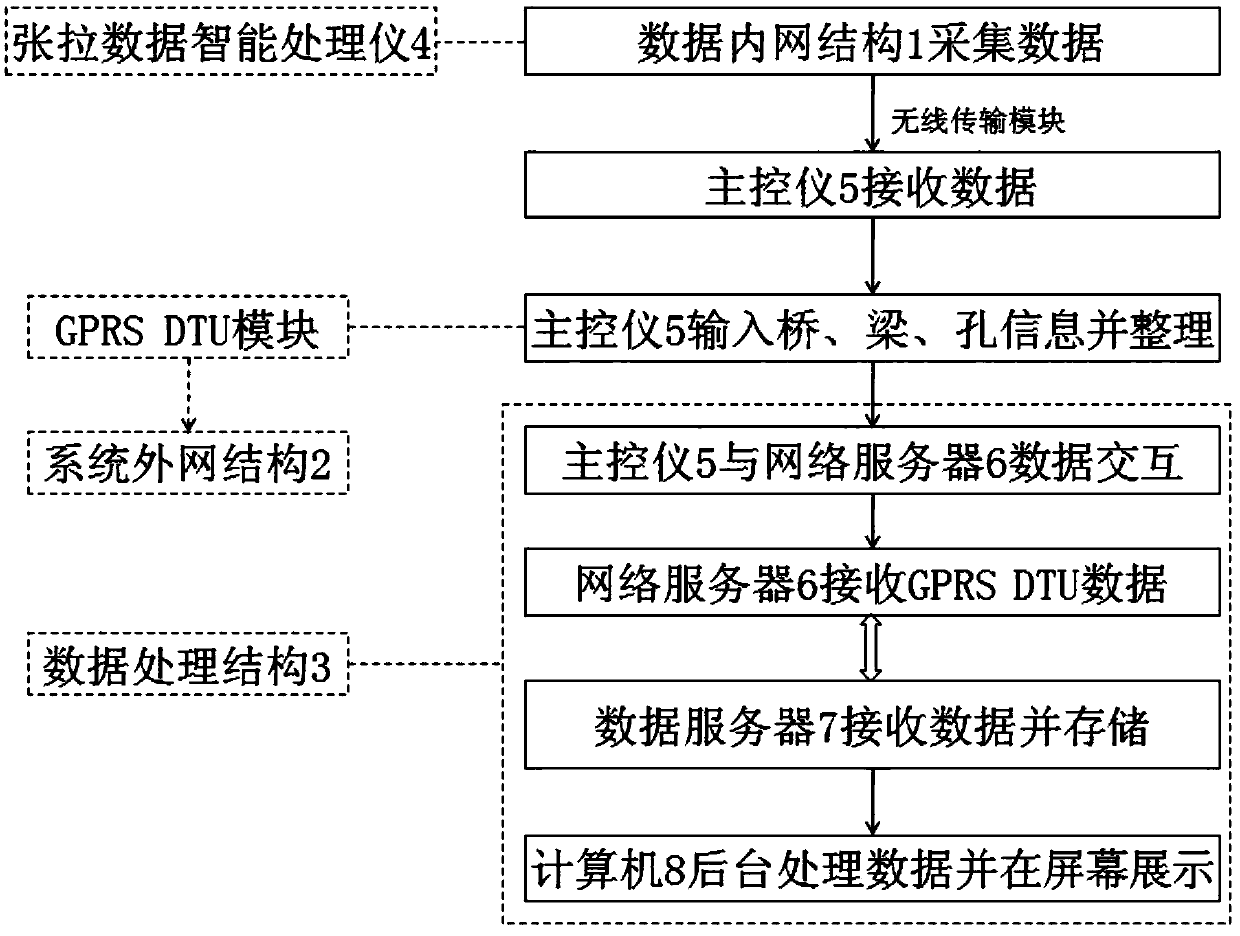

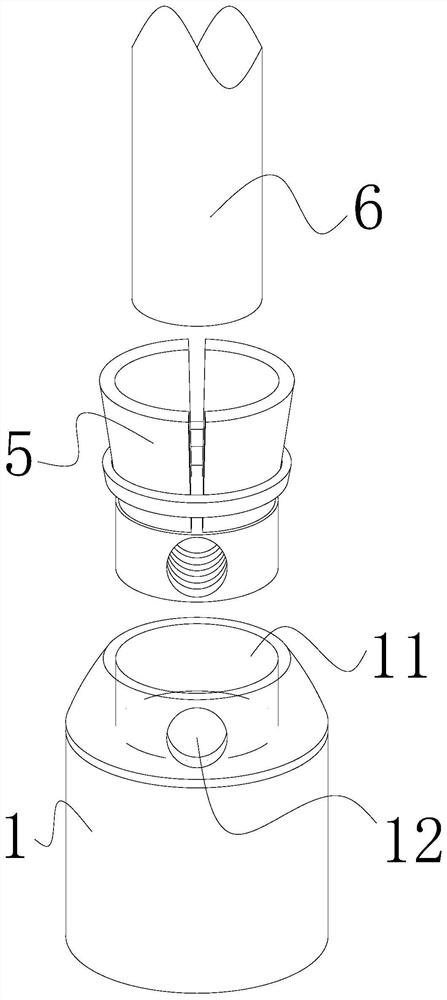

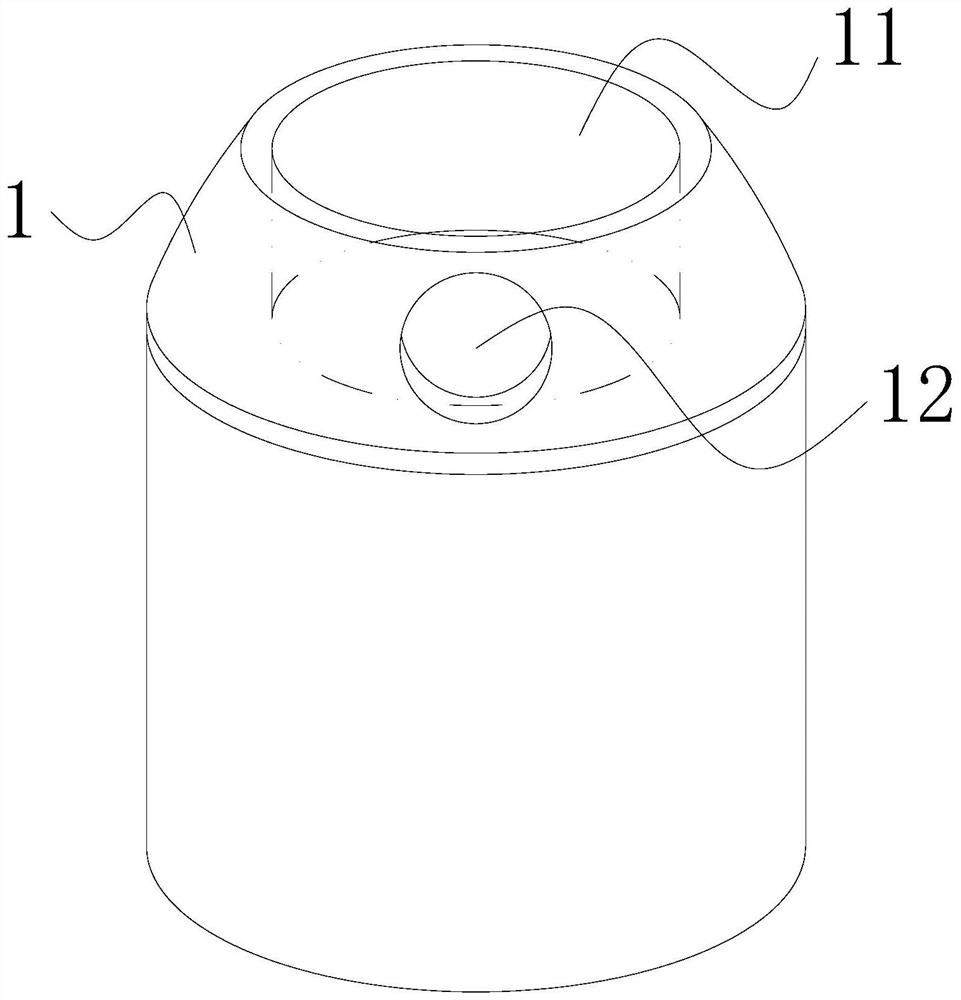

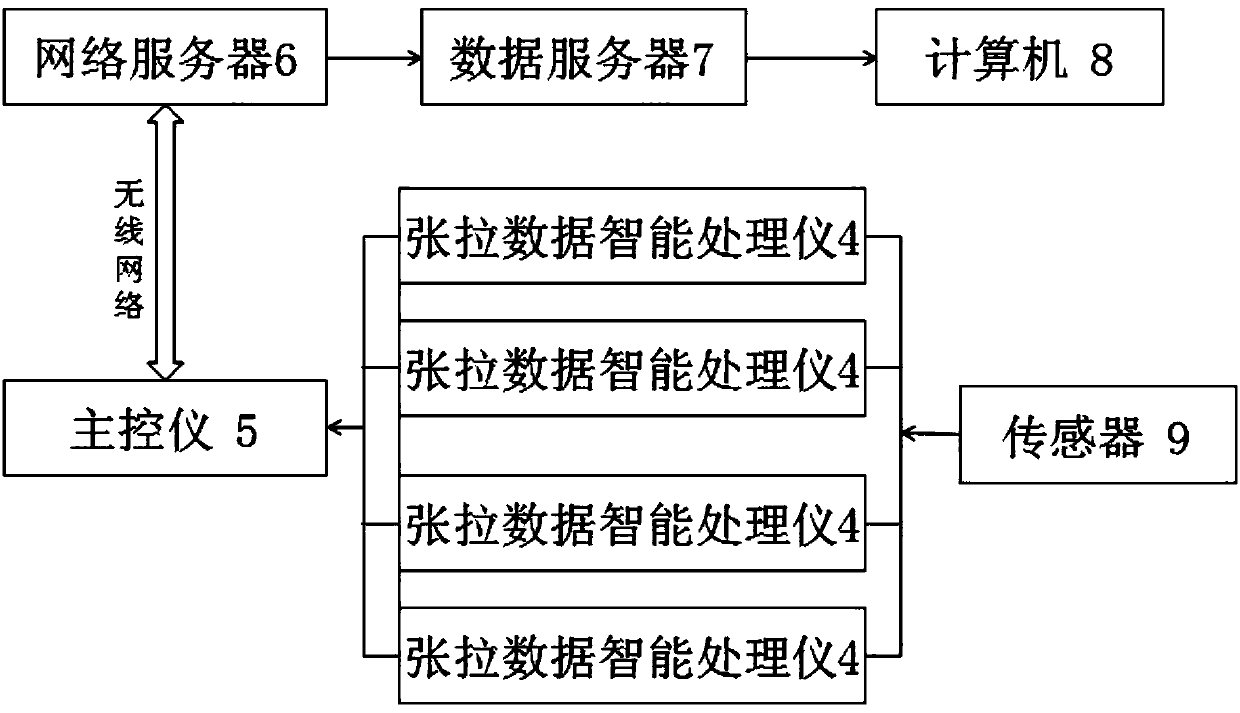

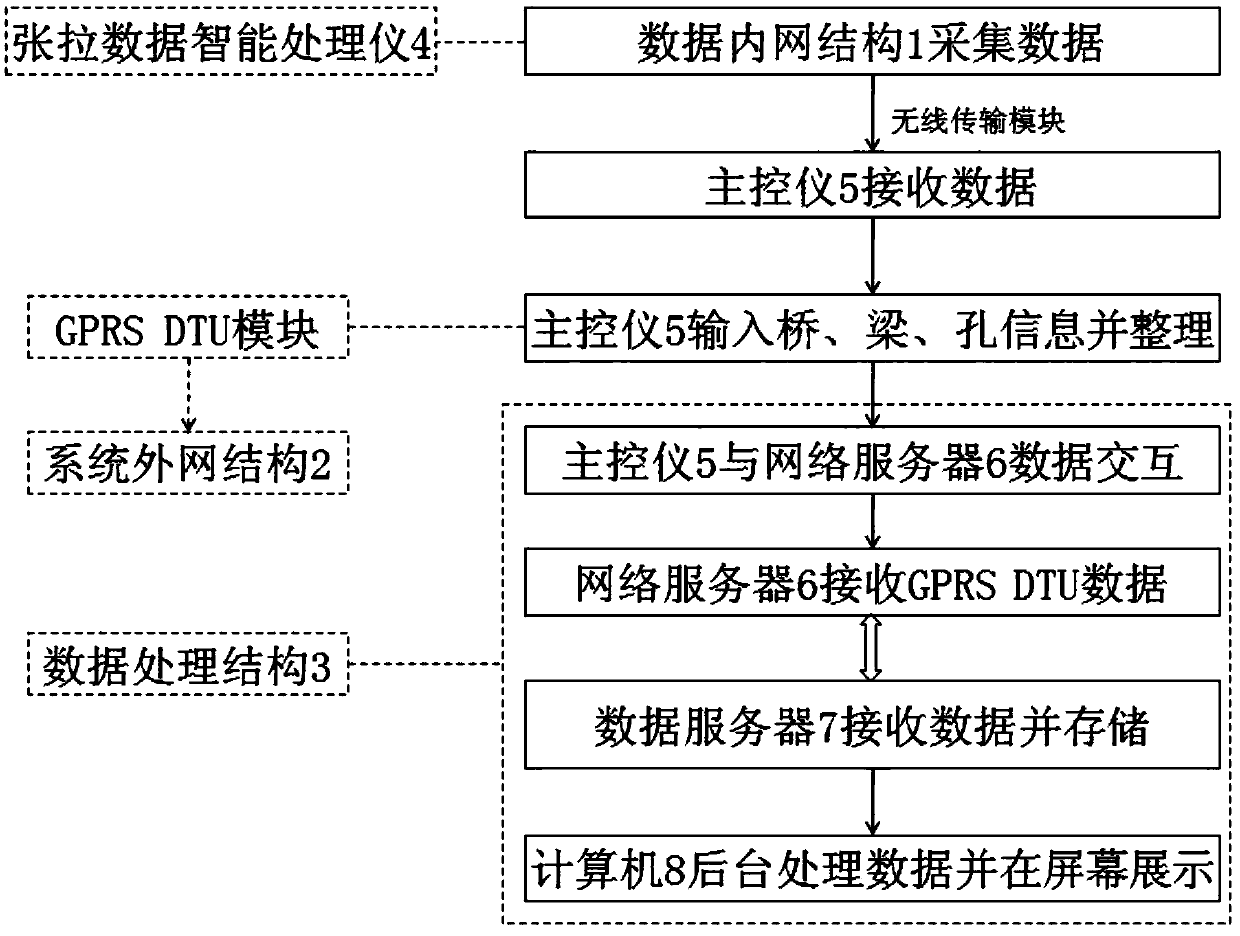

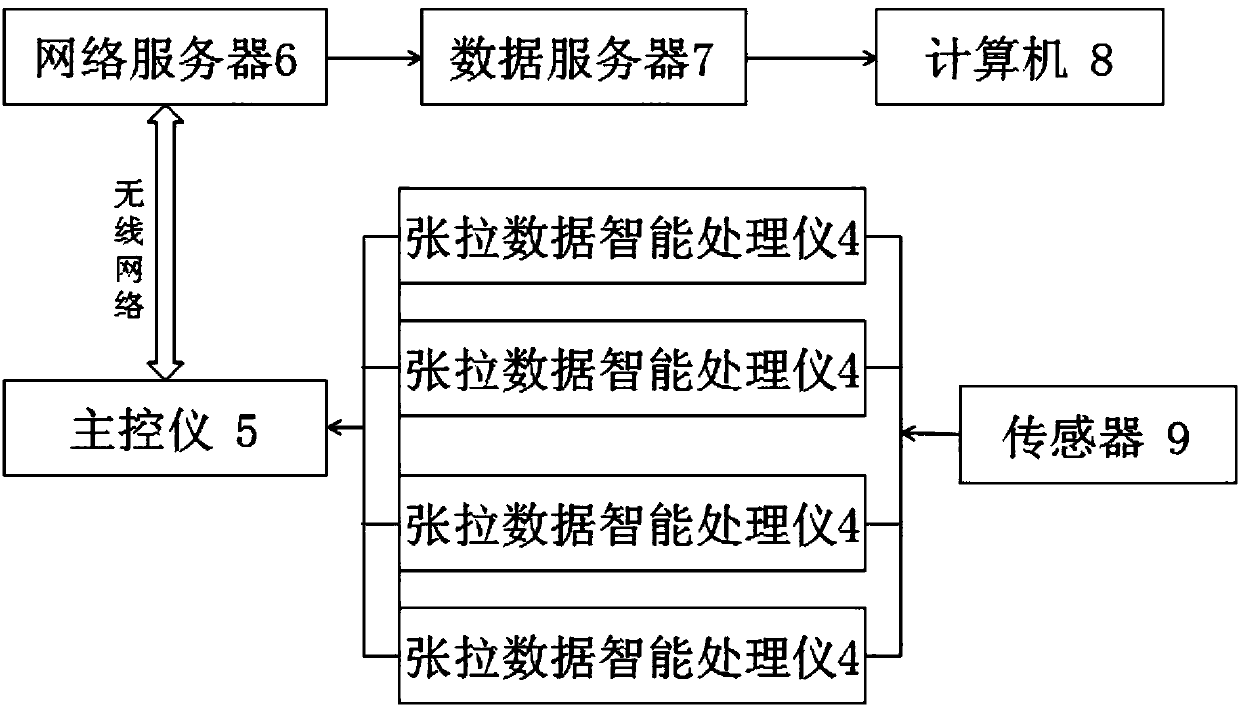

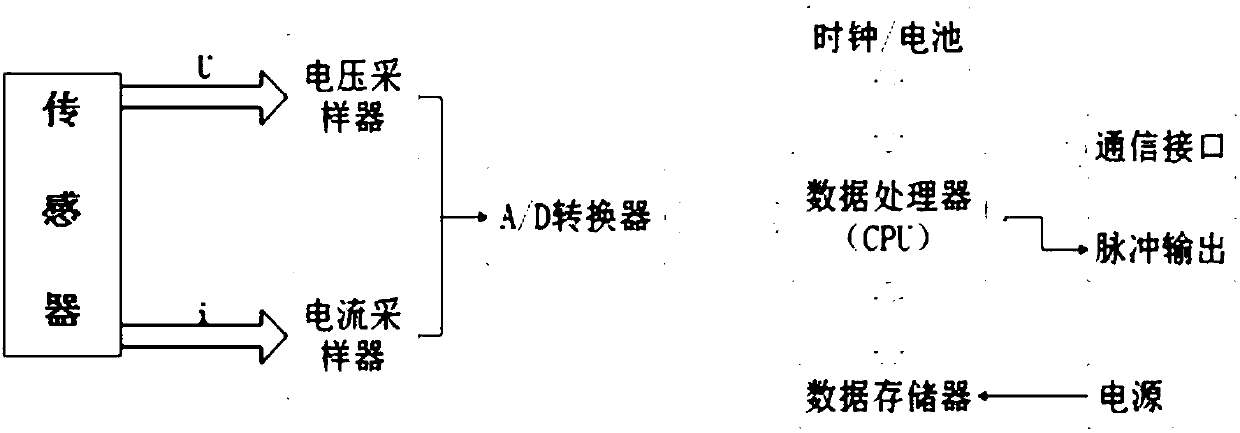

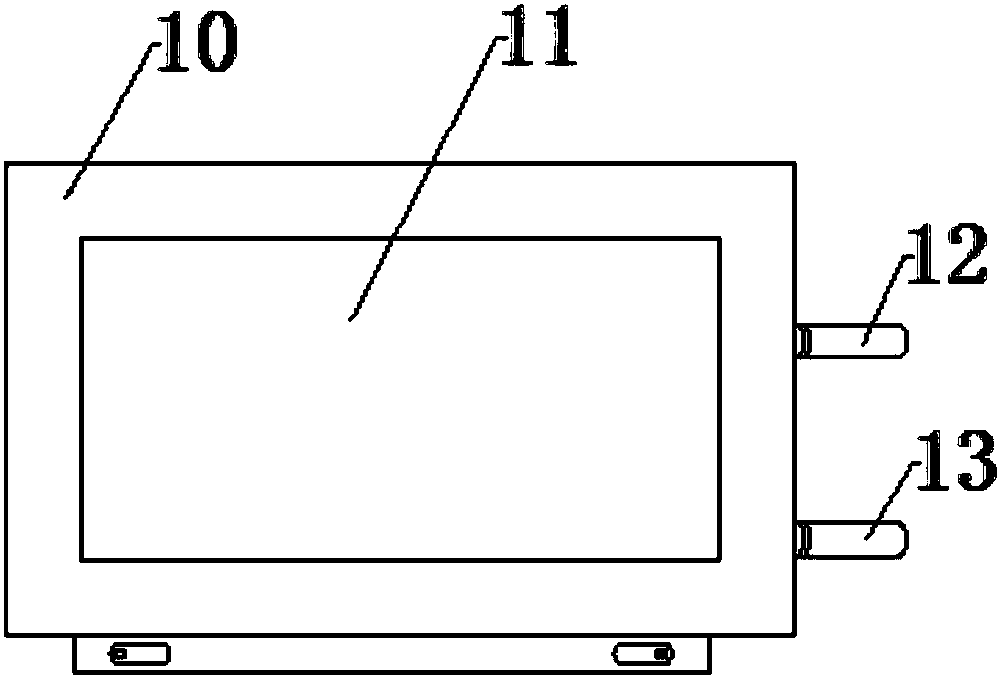

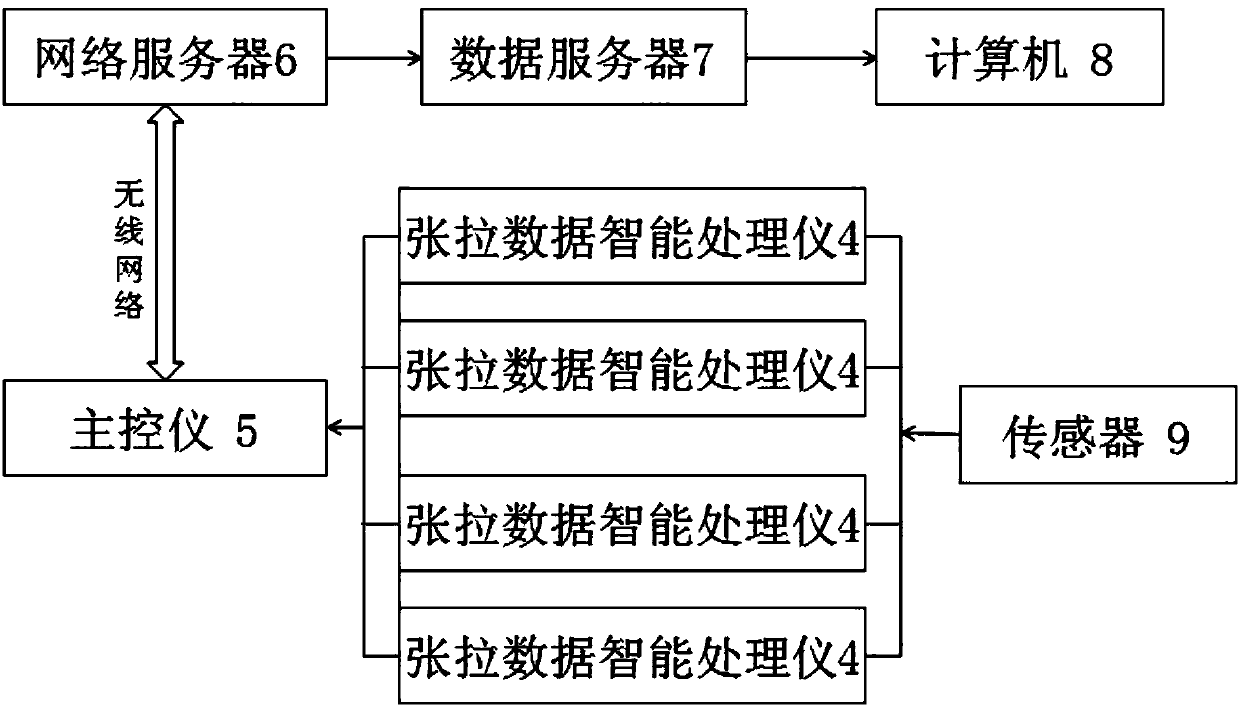

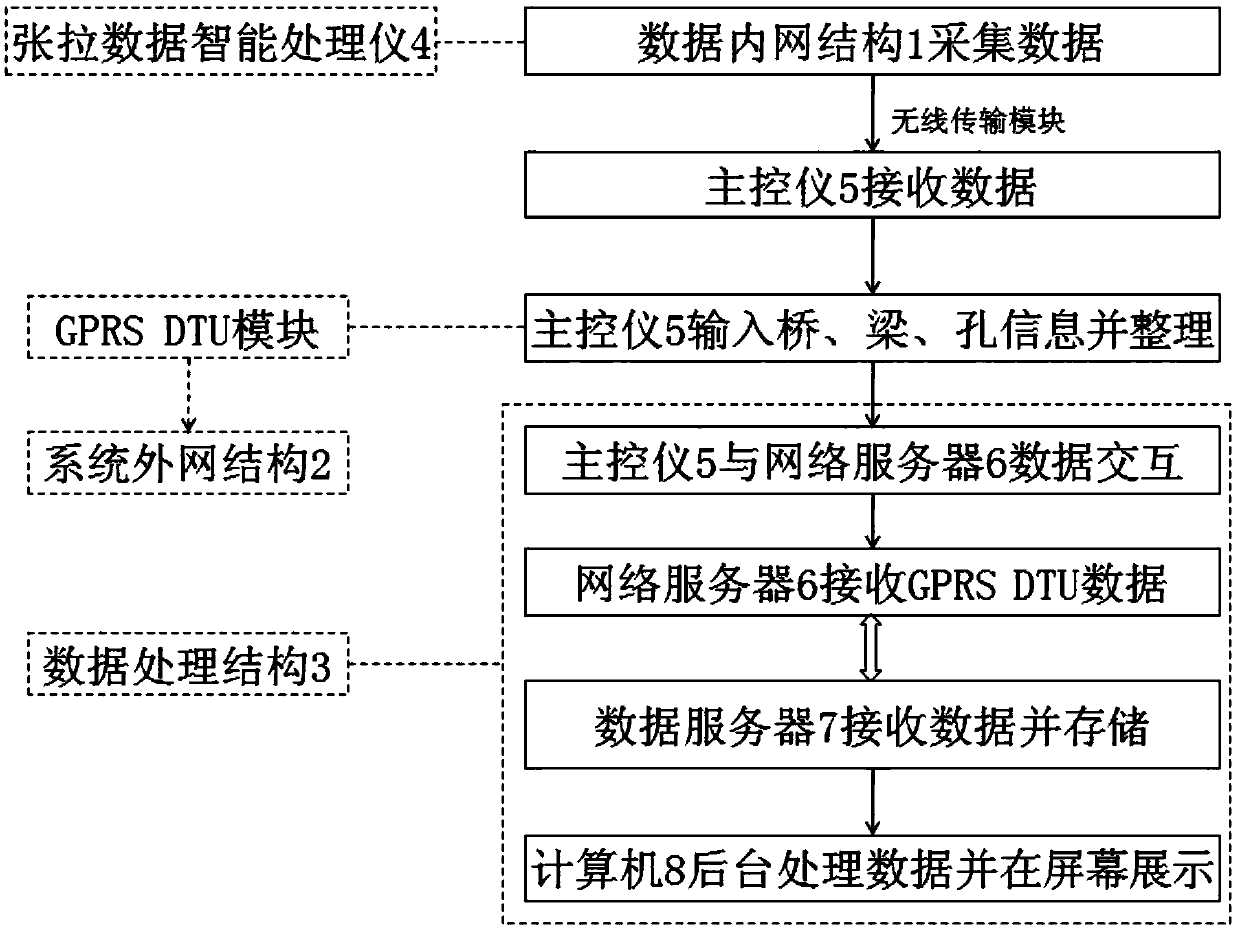

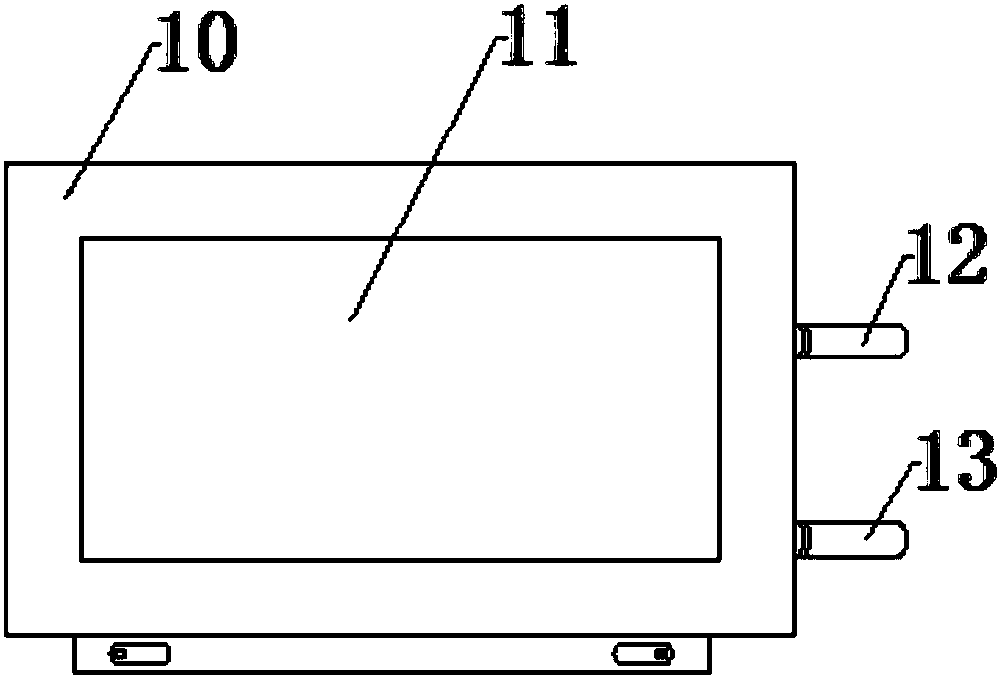

Engineering machinery equipment data remote monitoring system

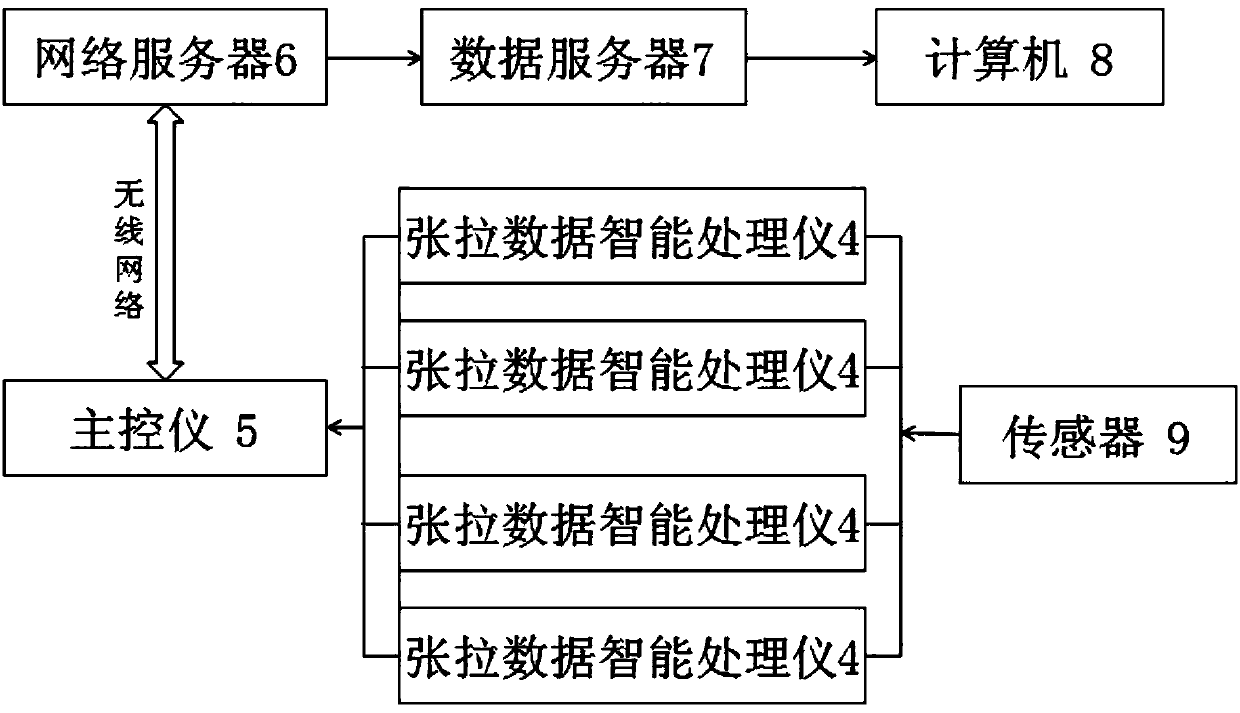

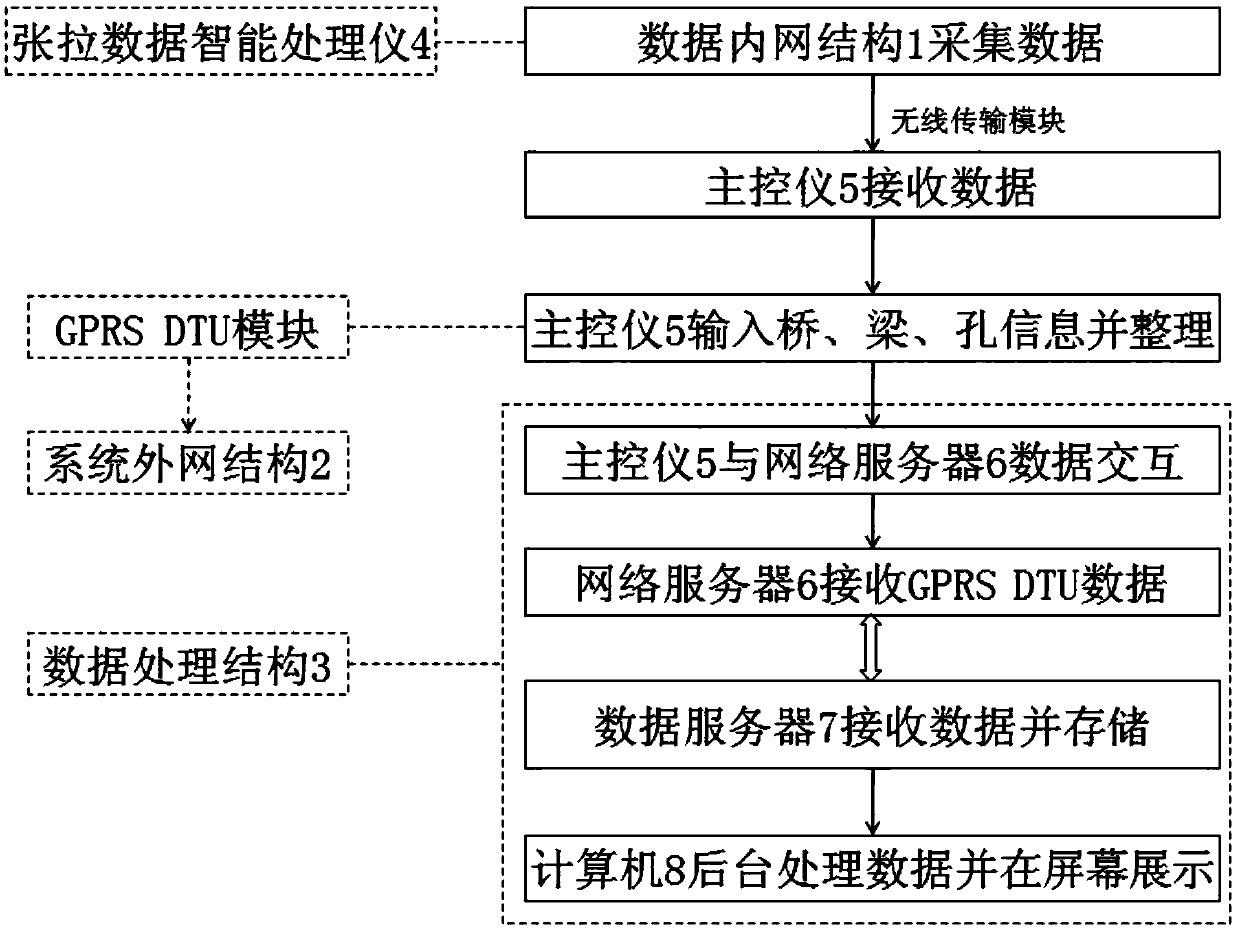

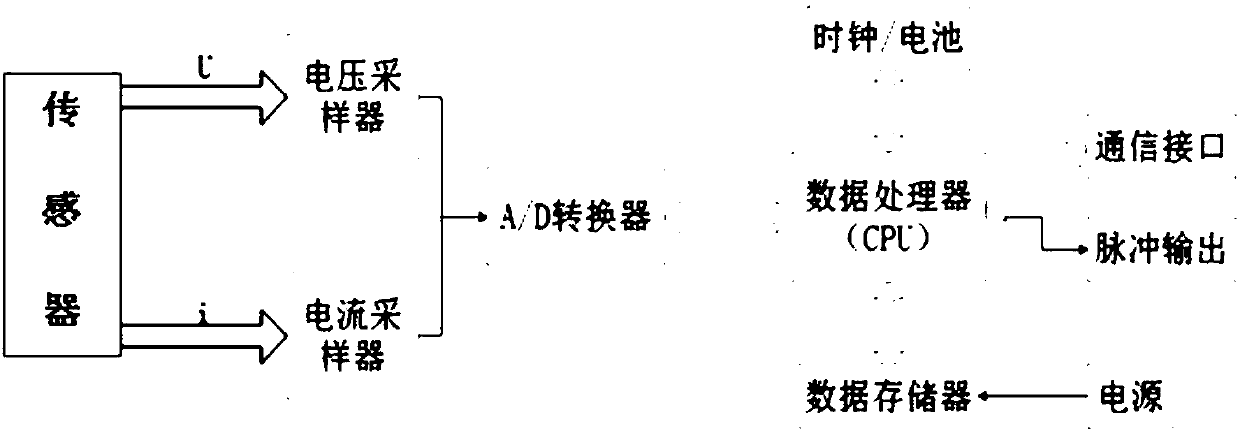

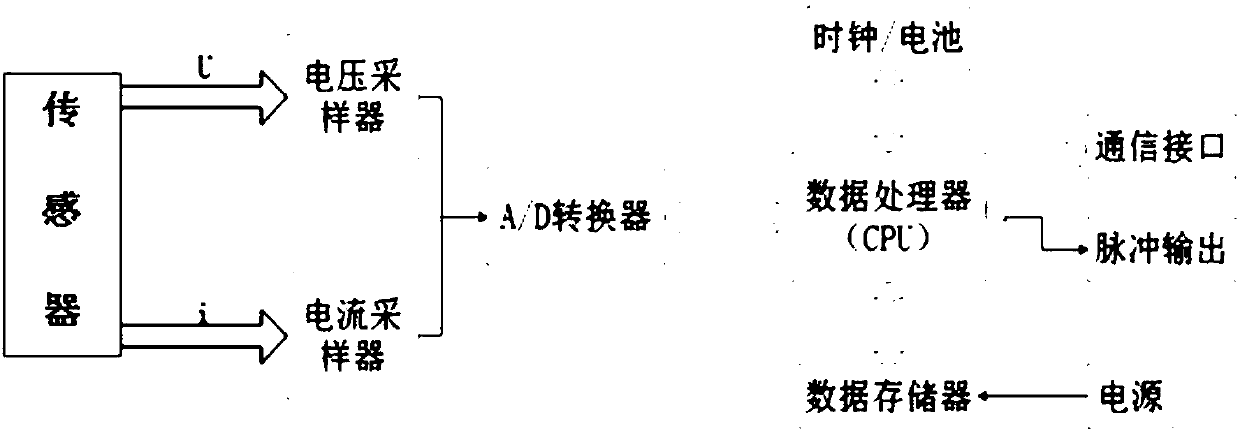

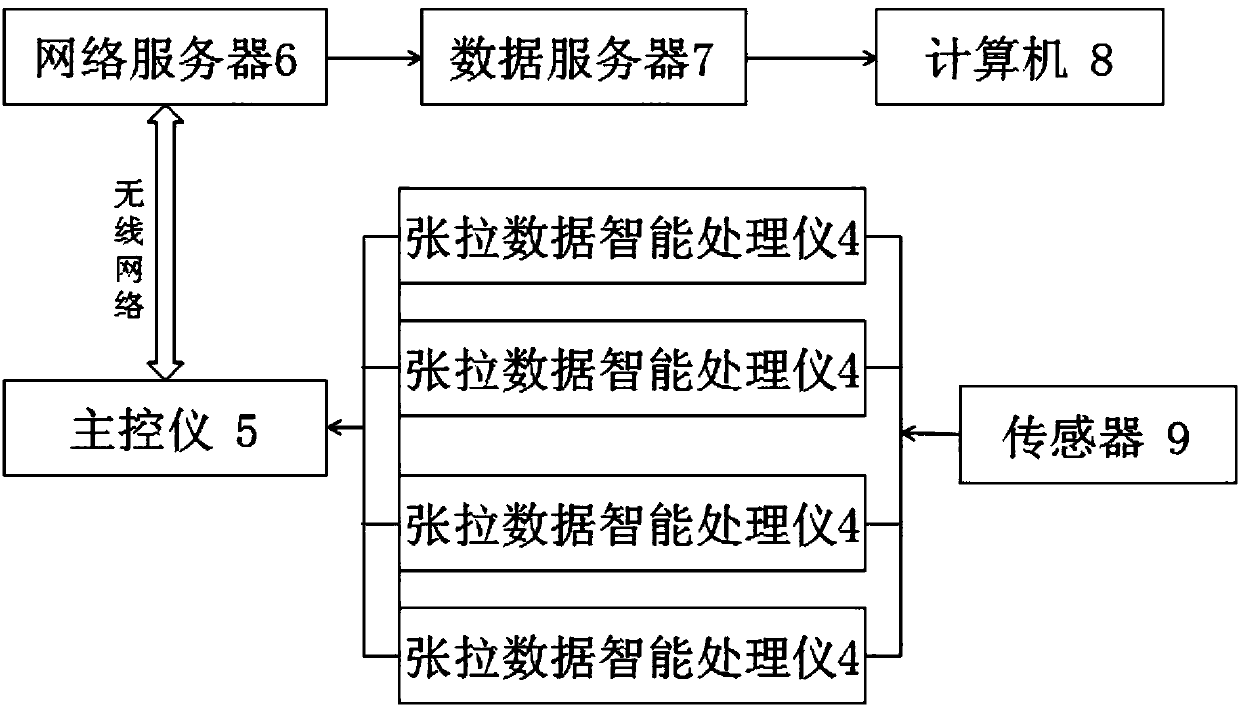

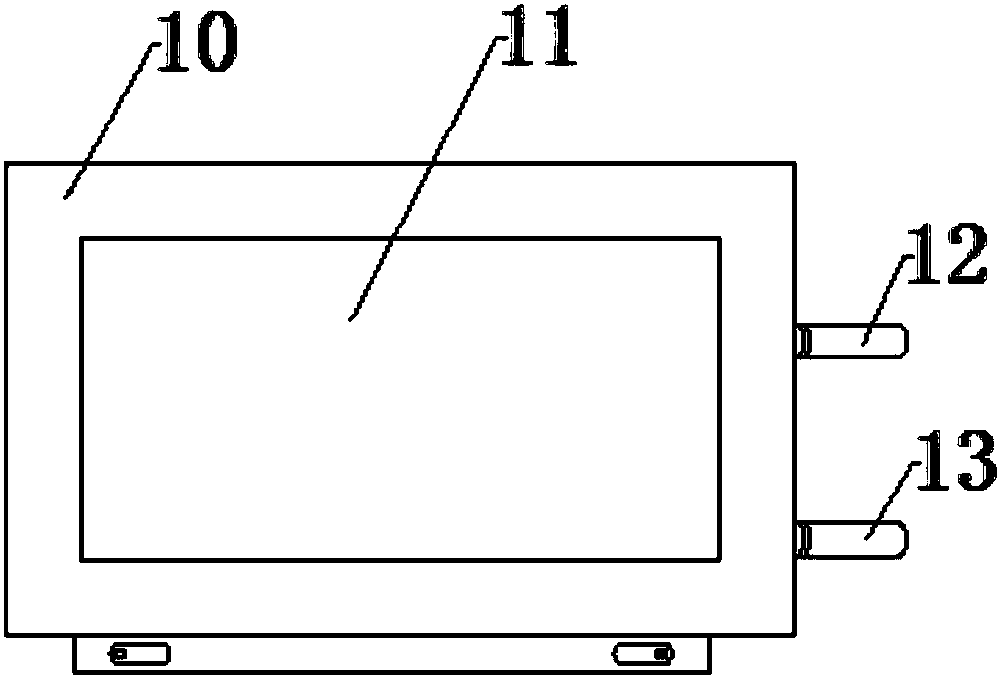

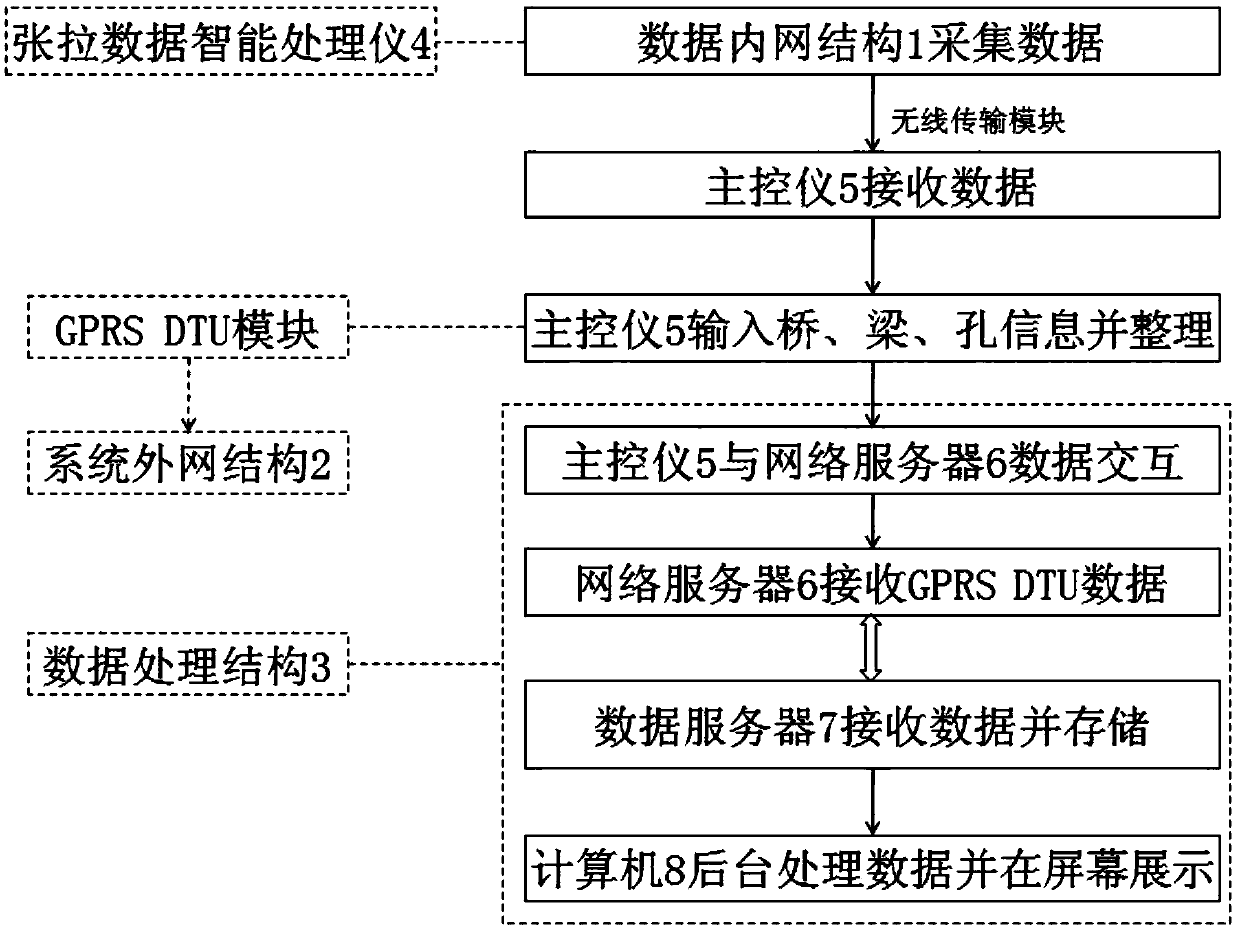

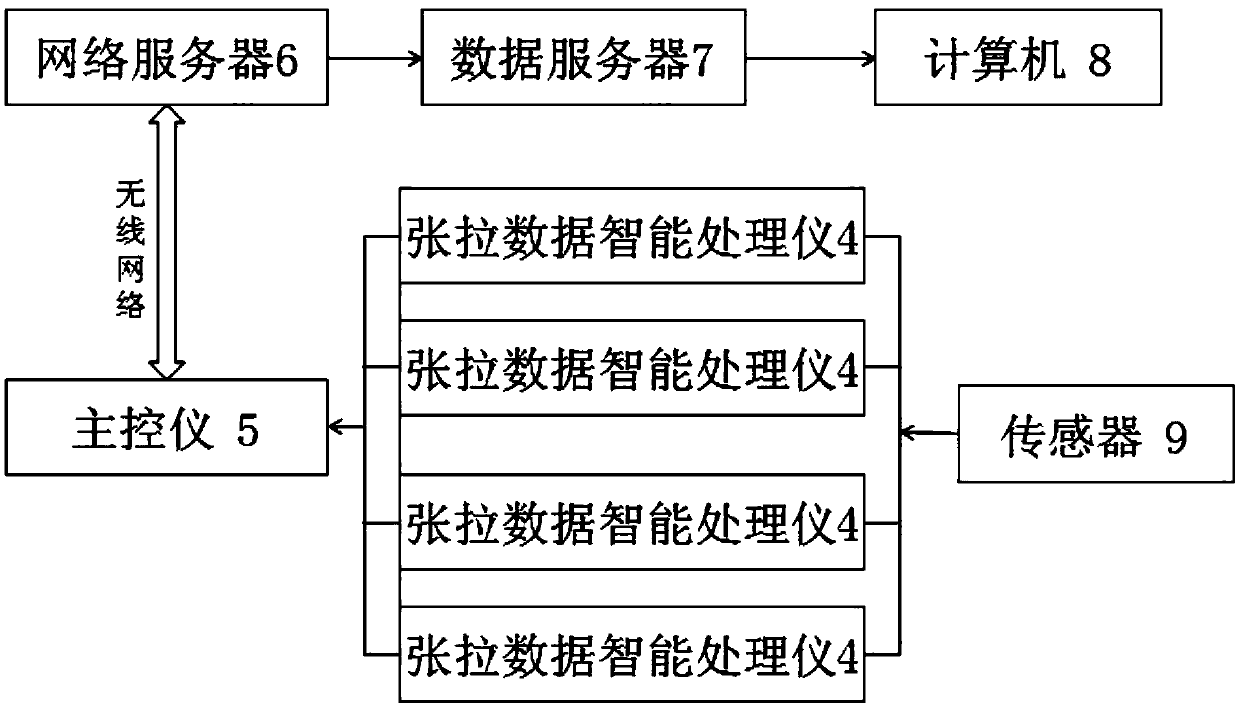

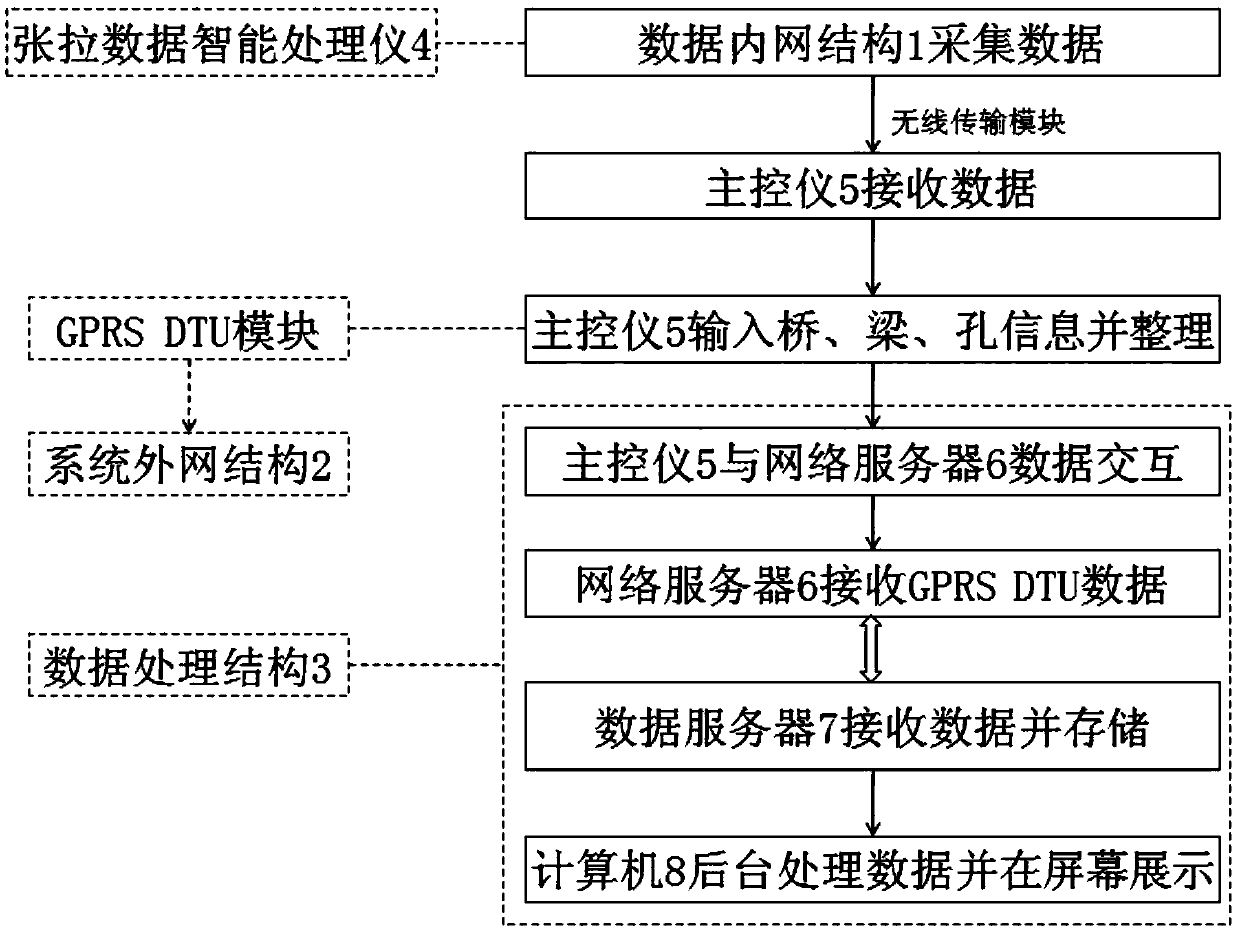

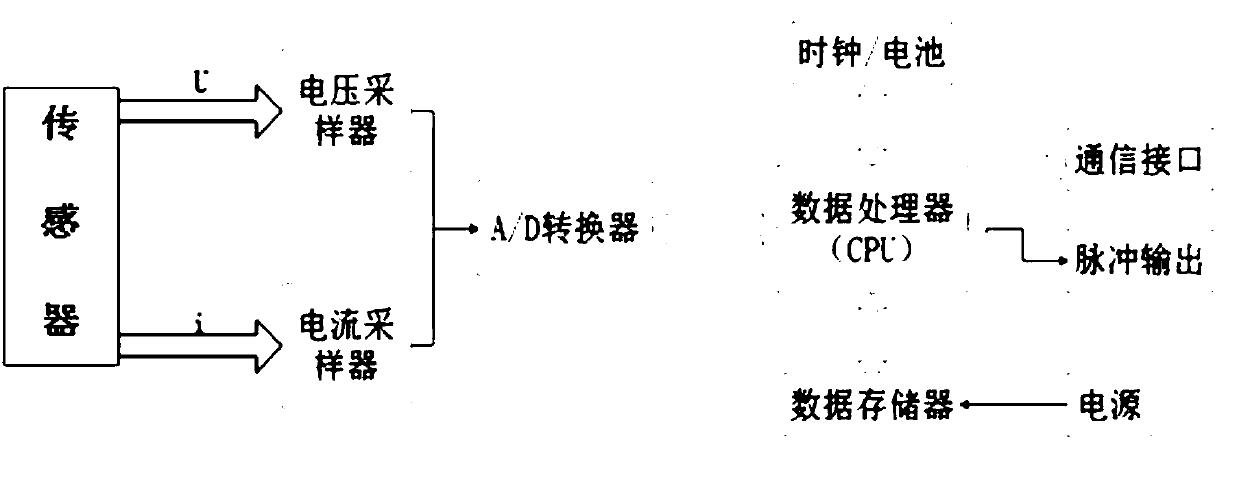

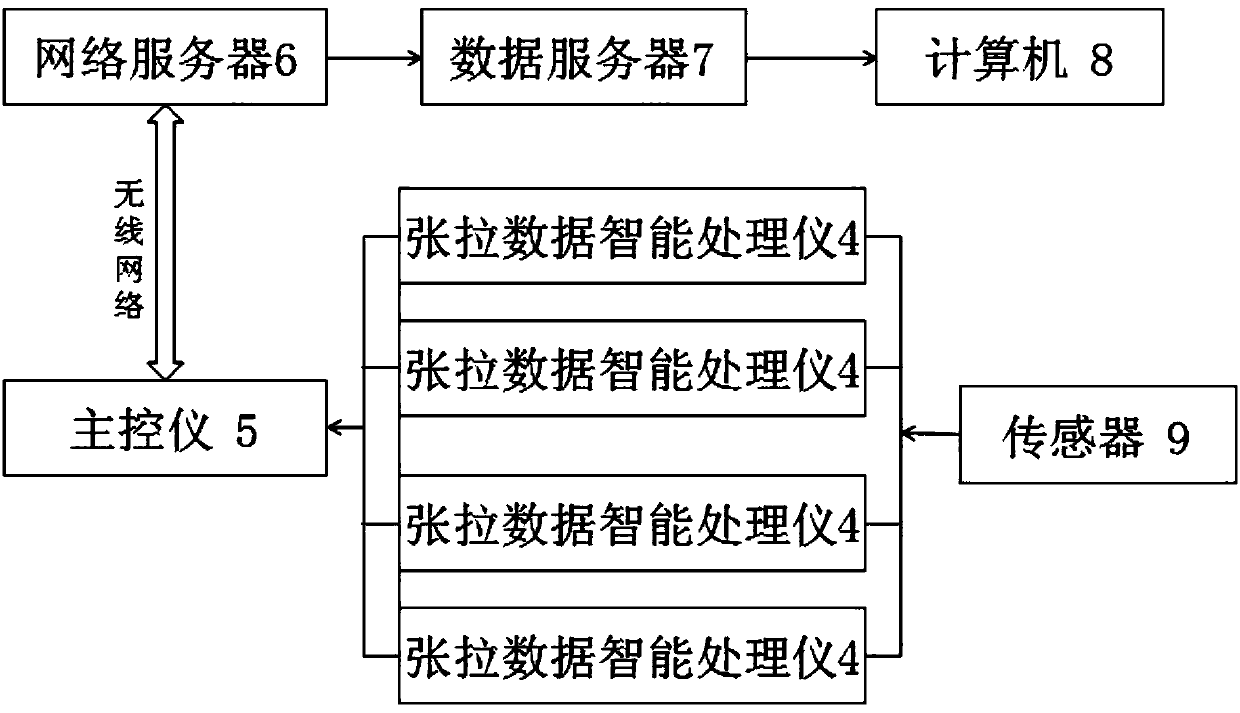

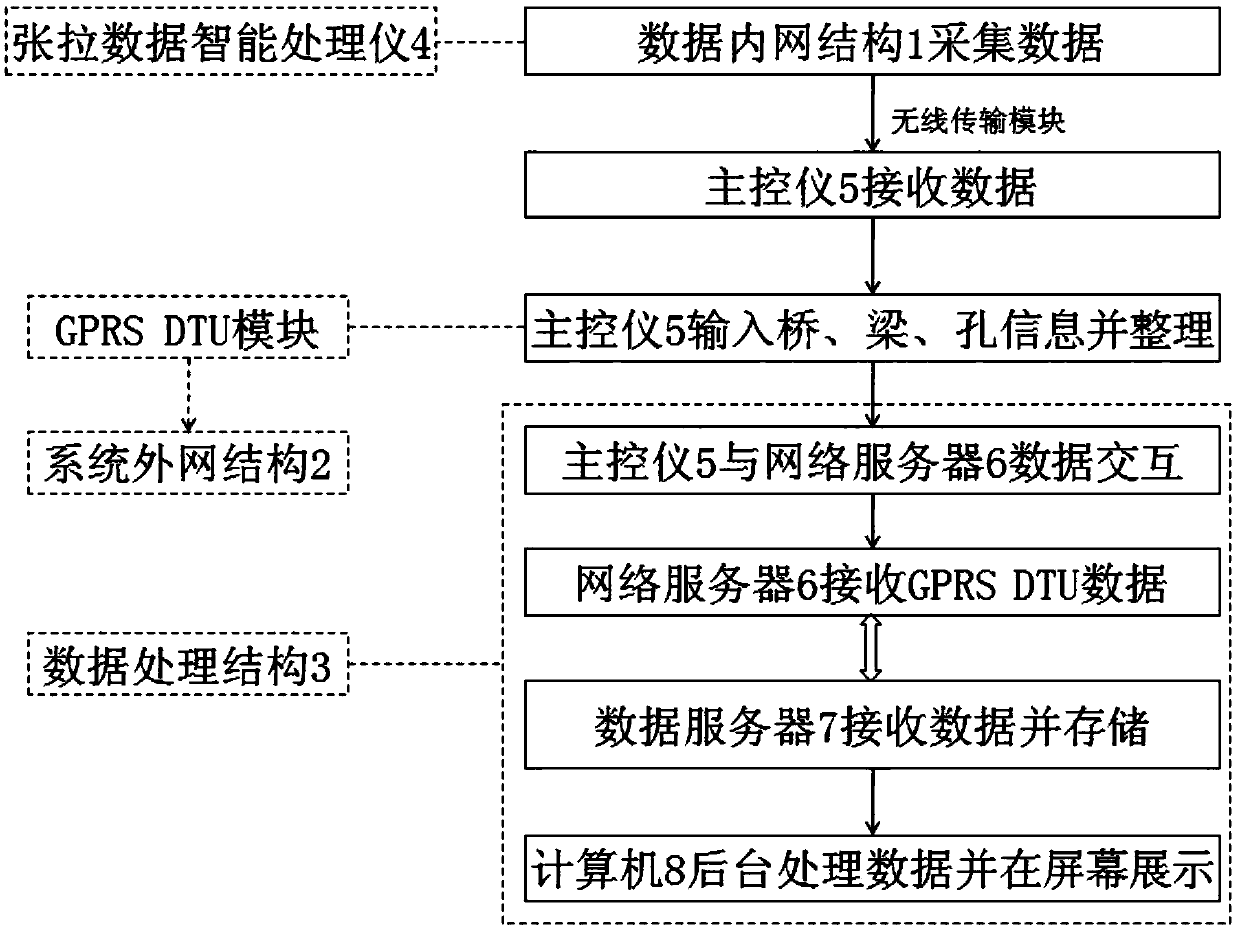

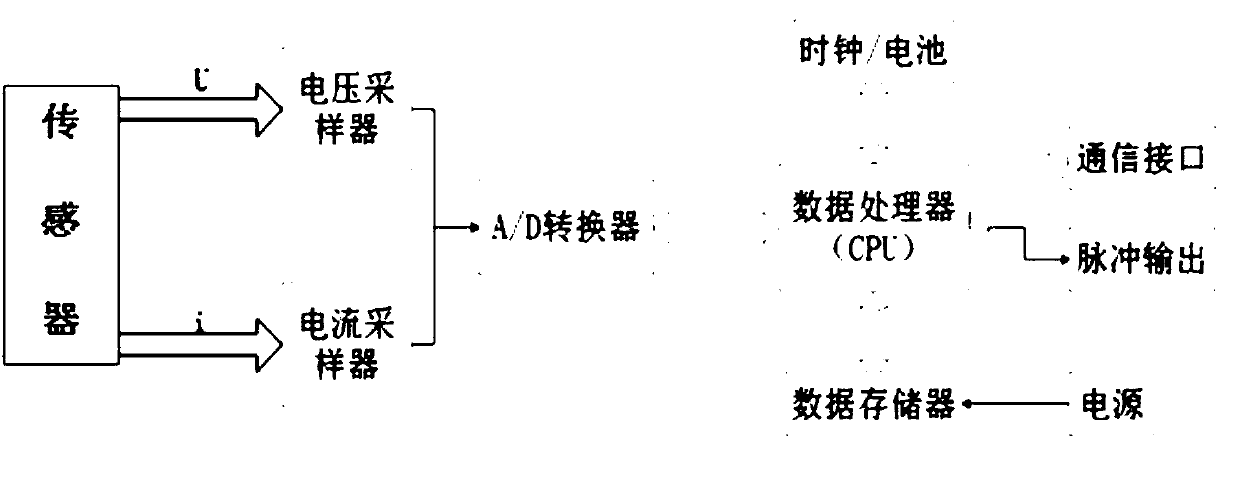

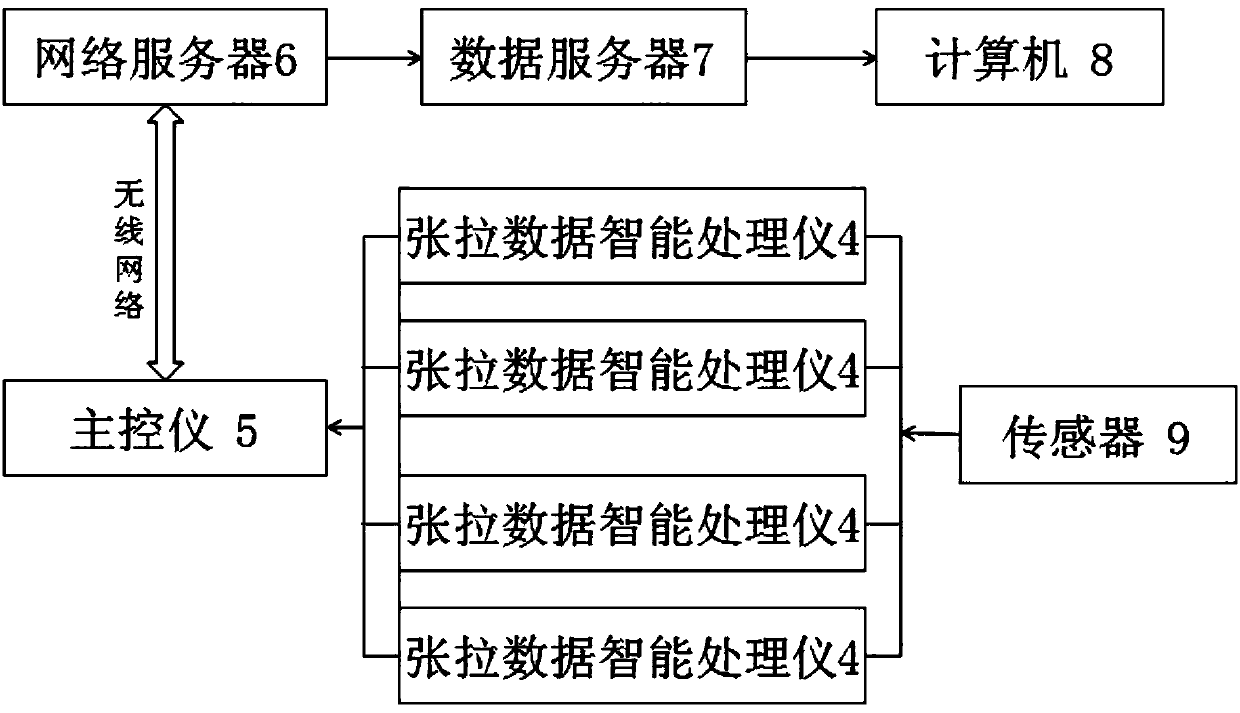

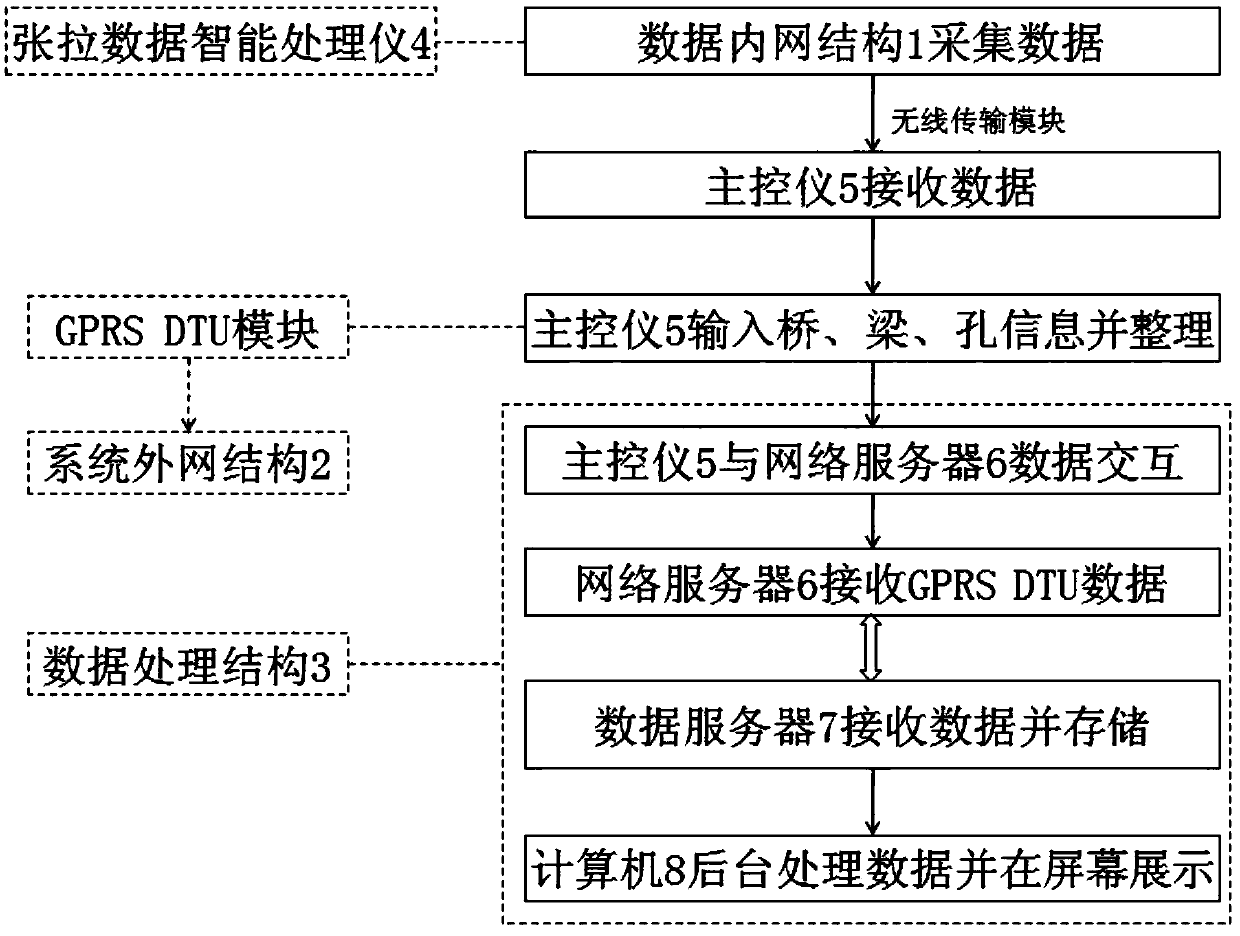

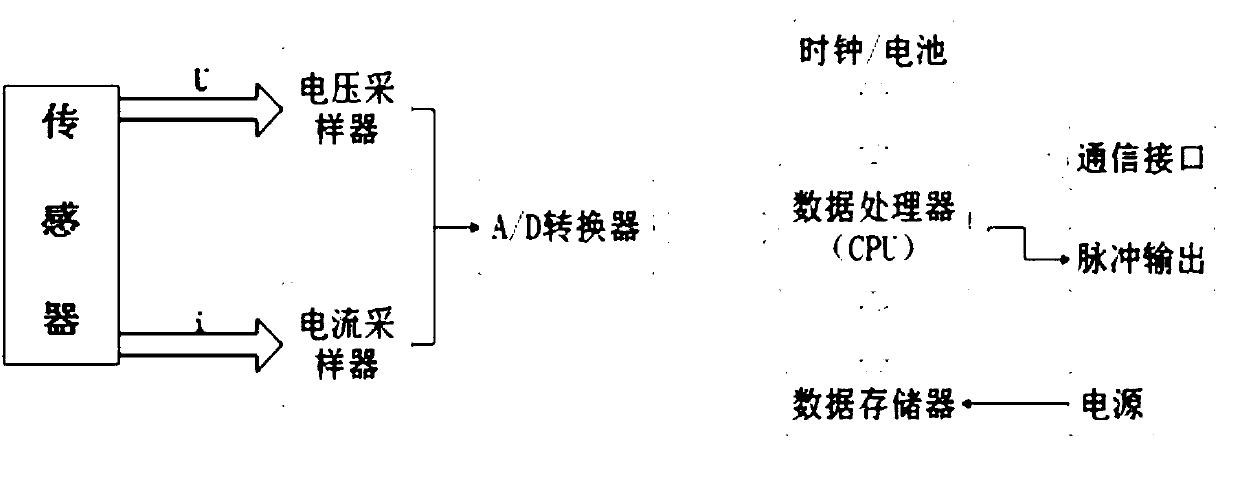

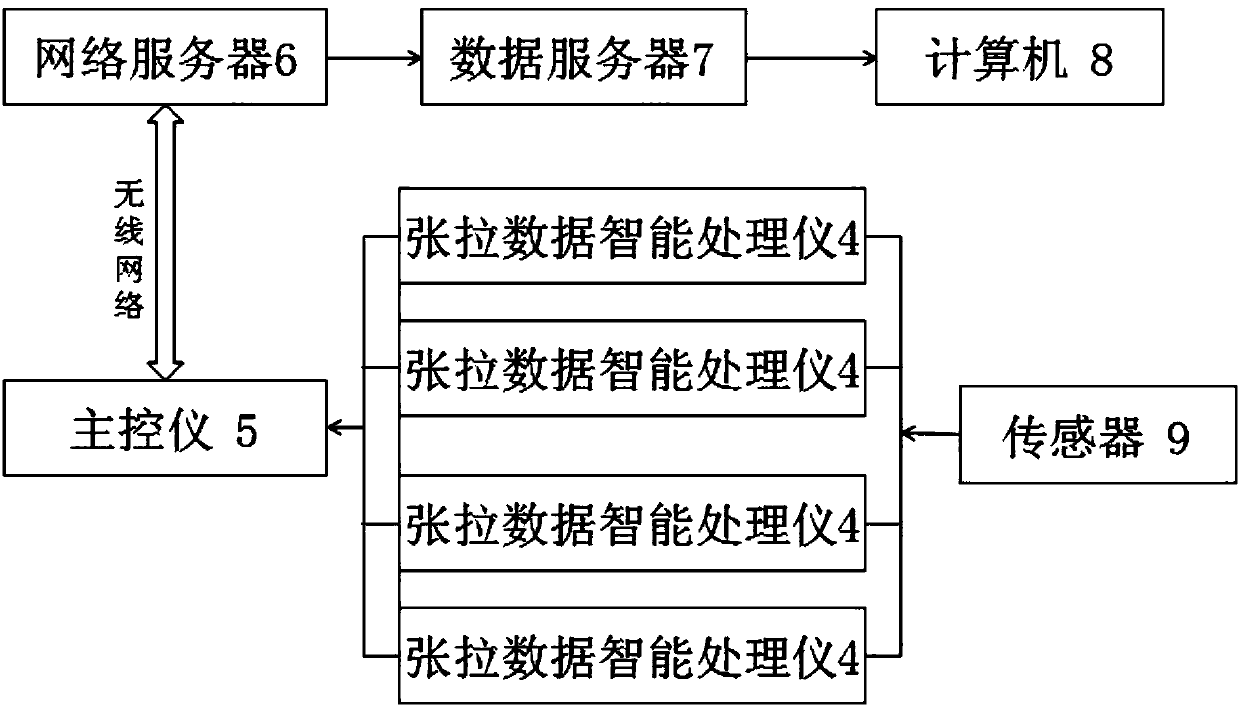

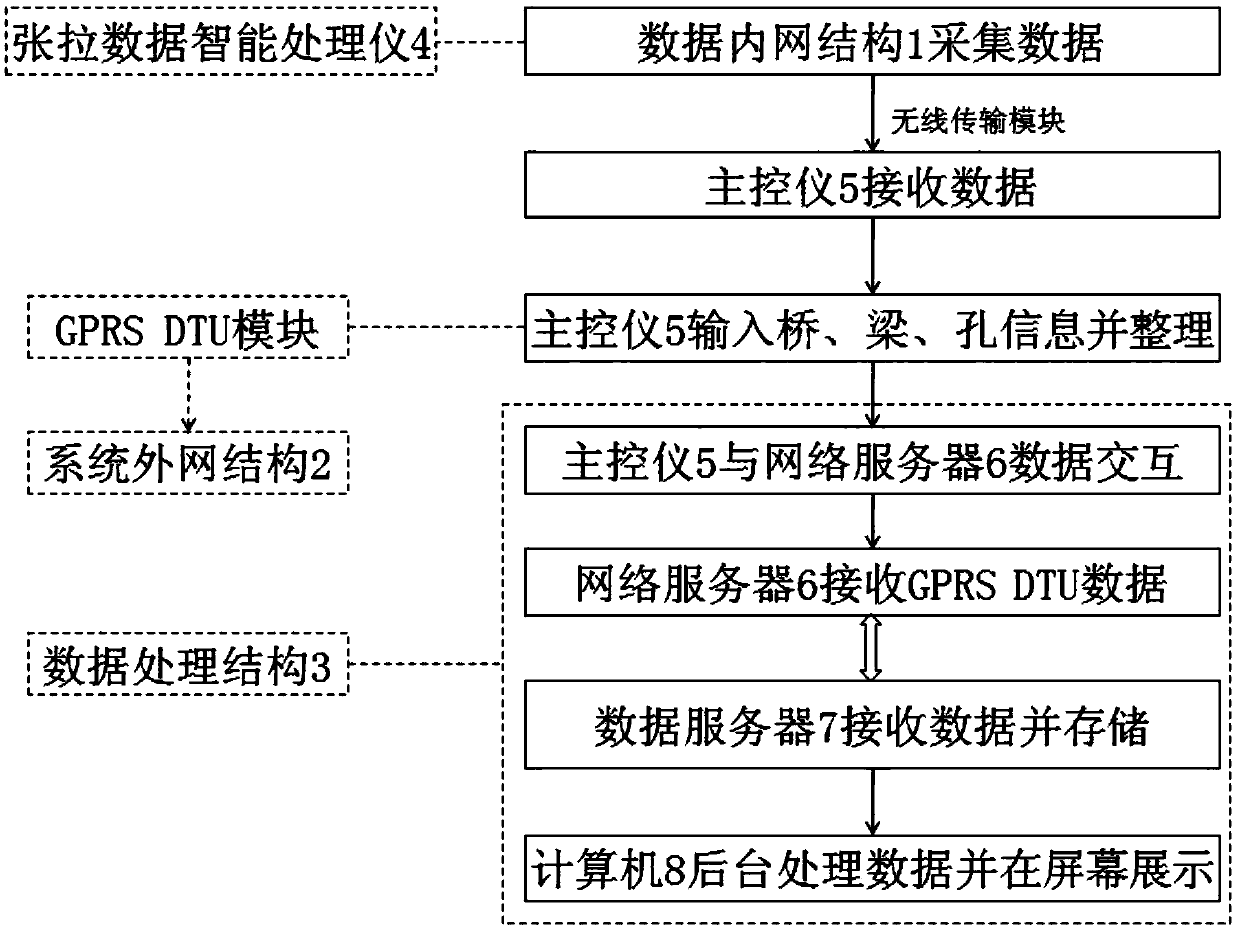

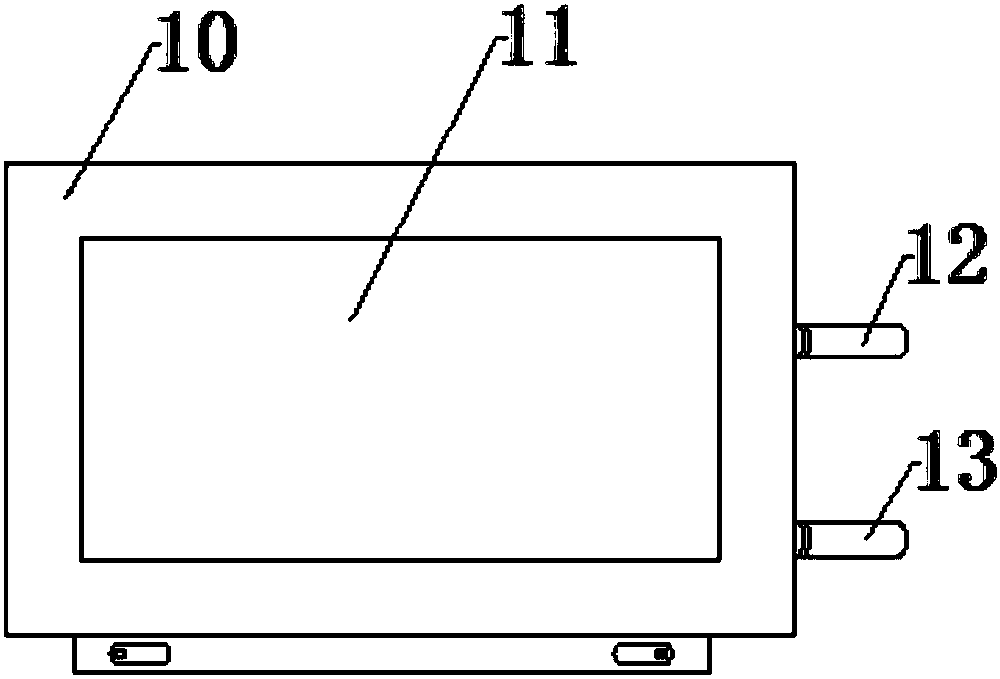

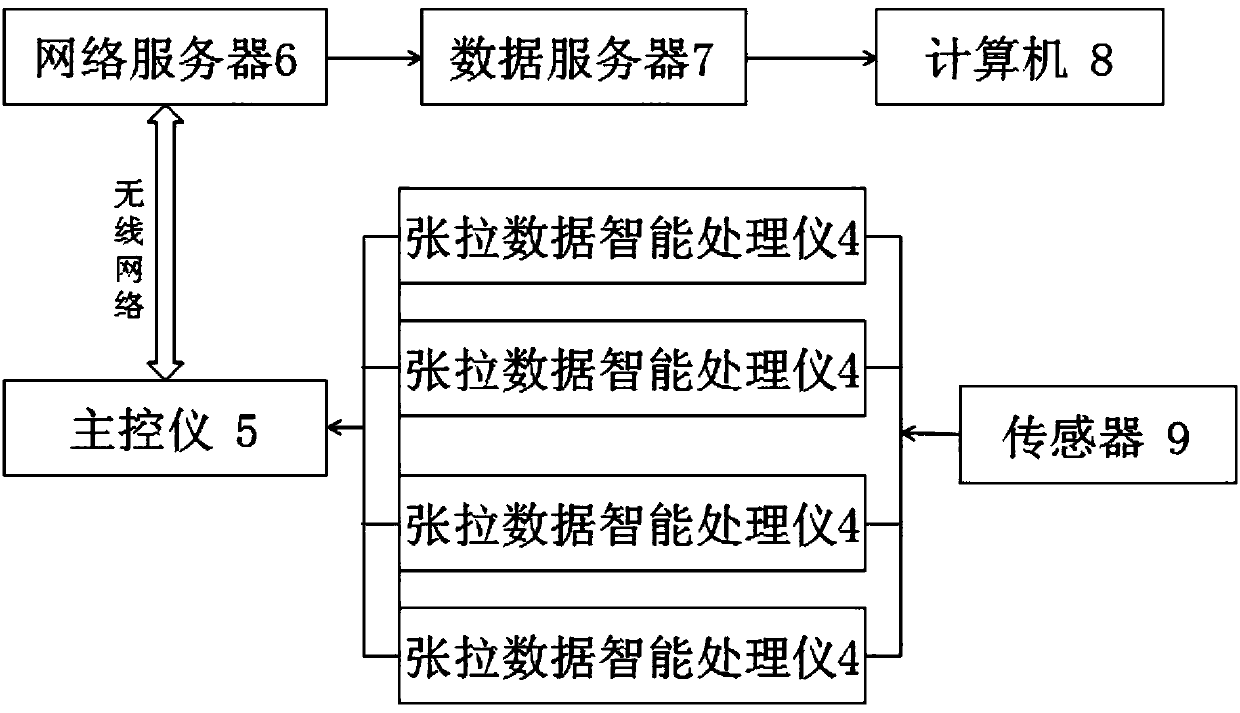

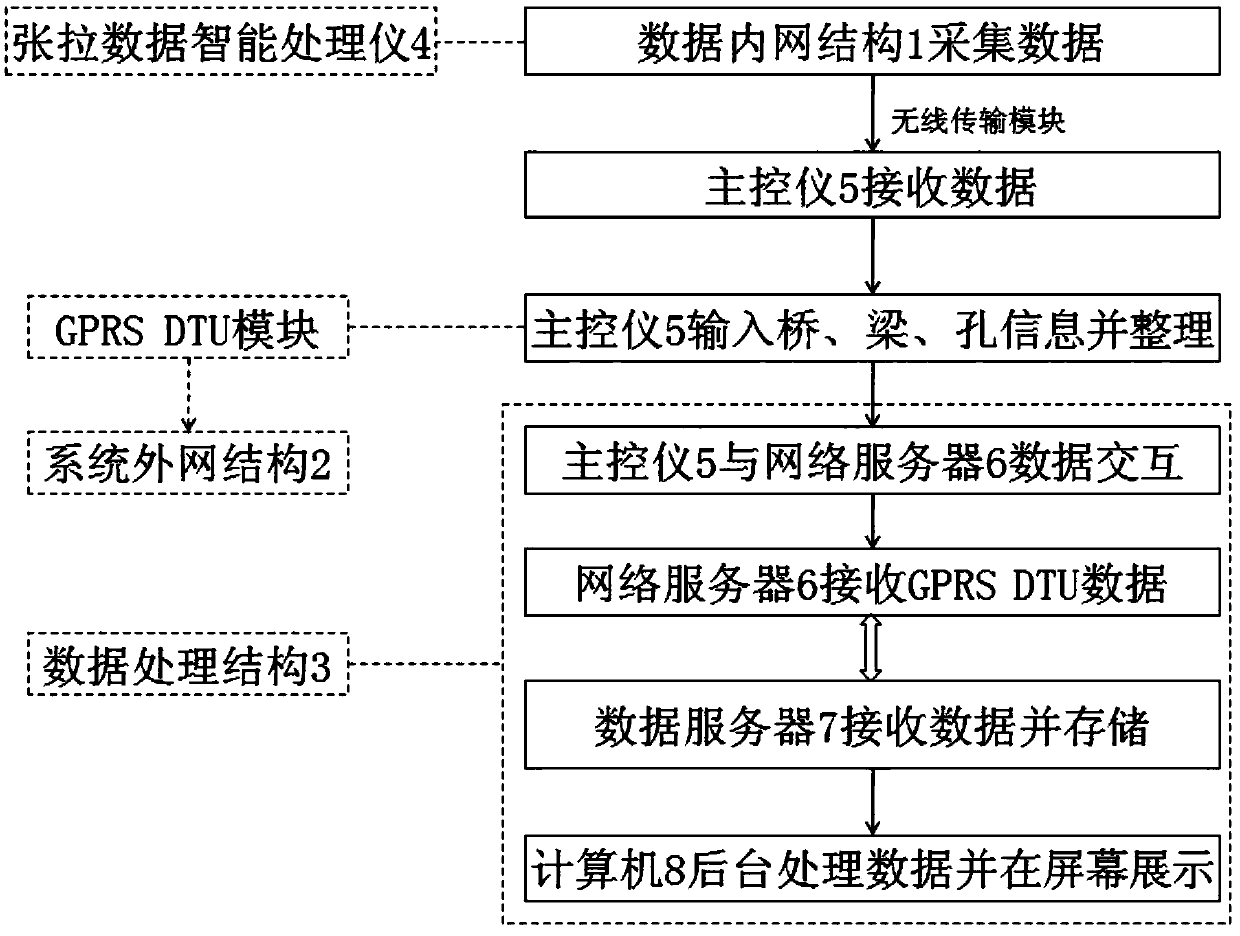

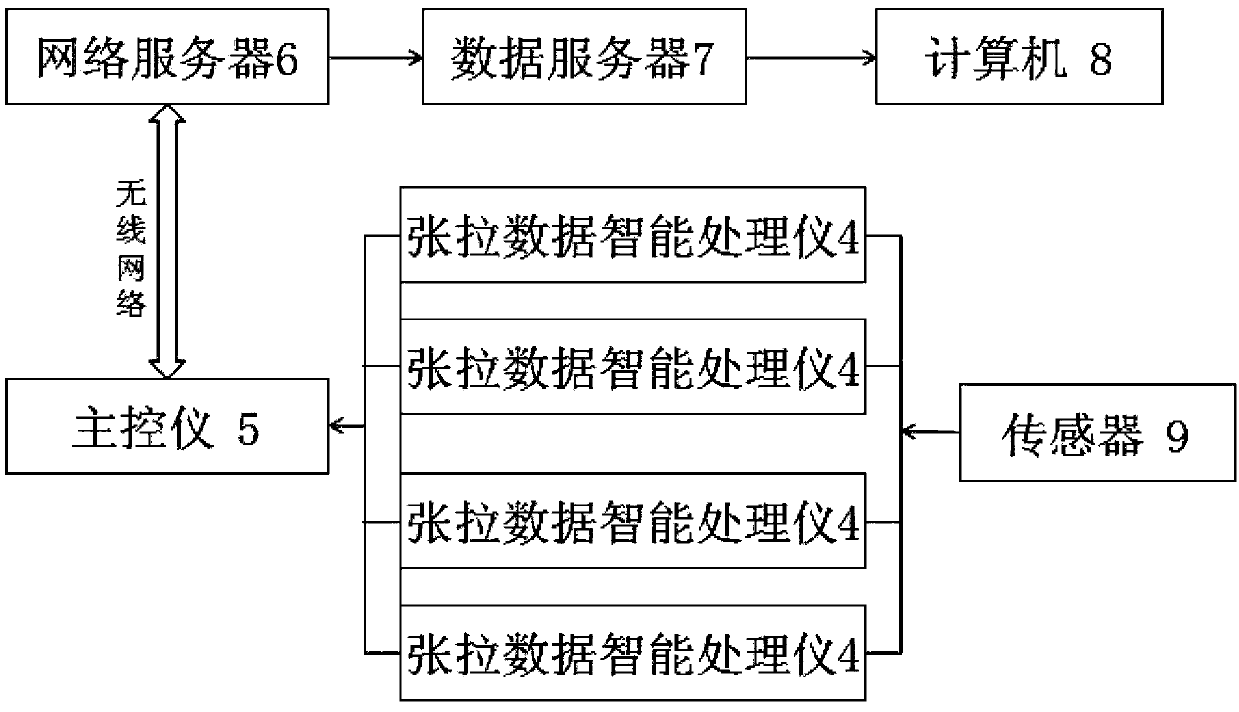

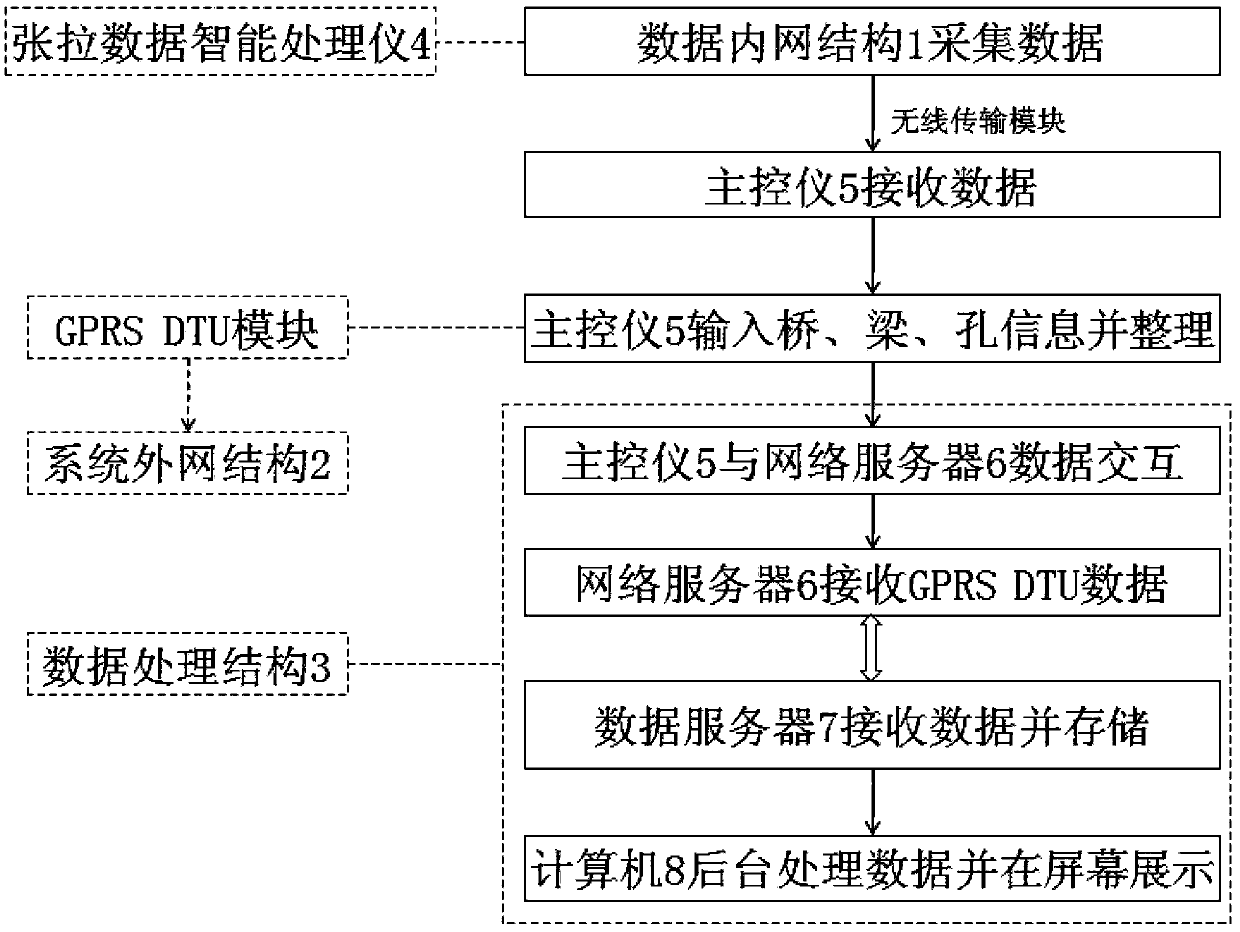

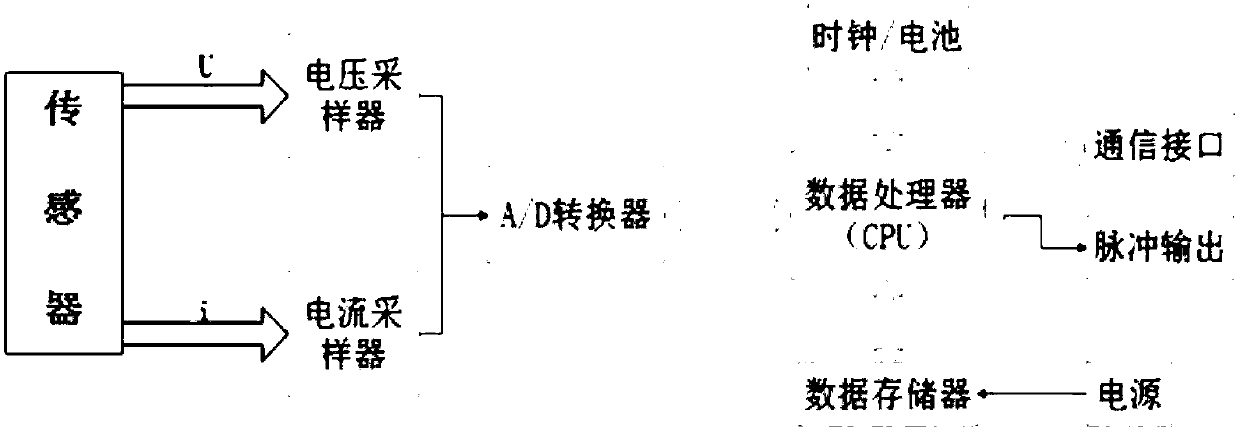

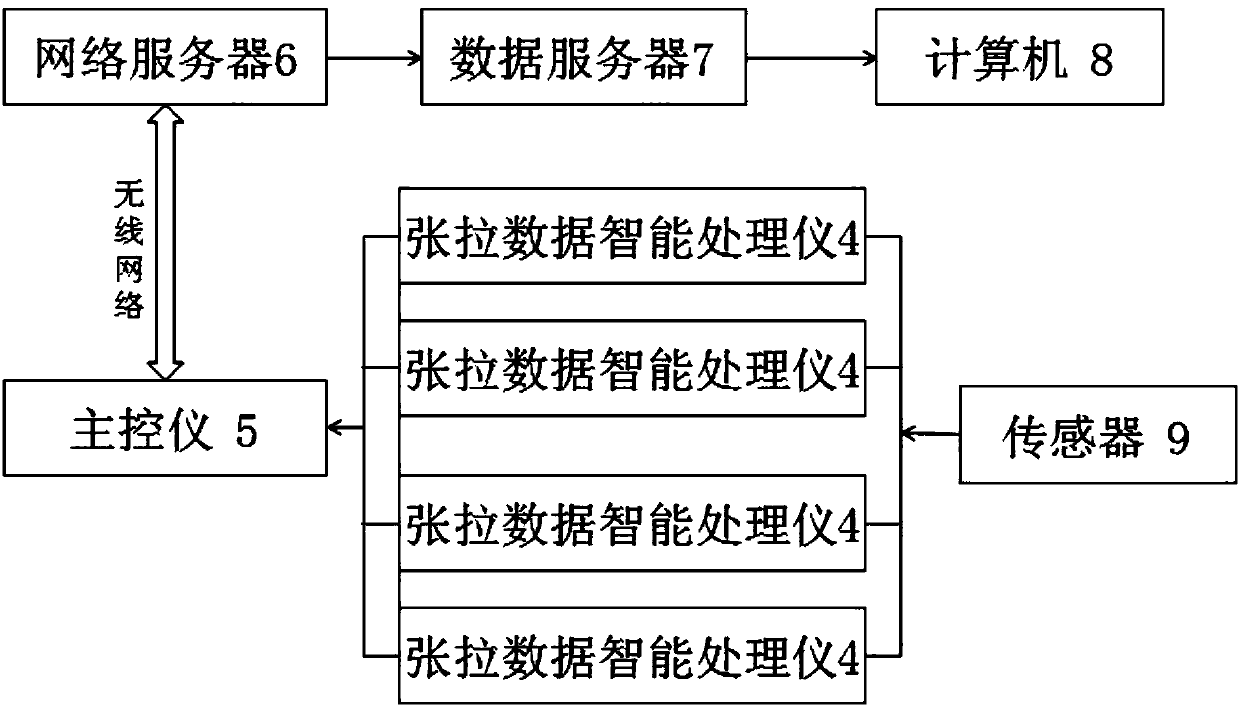

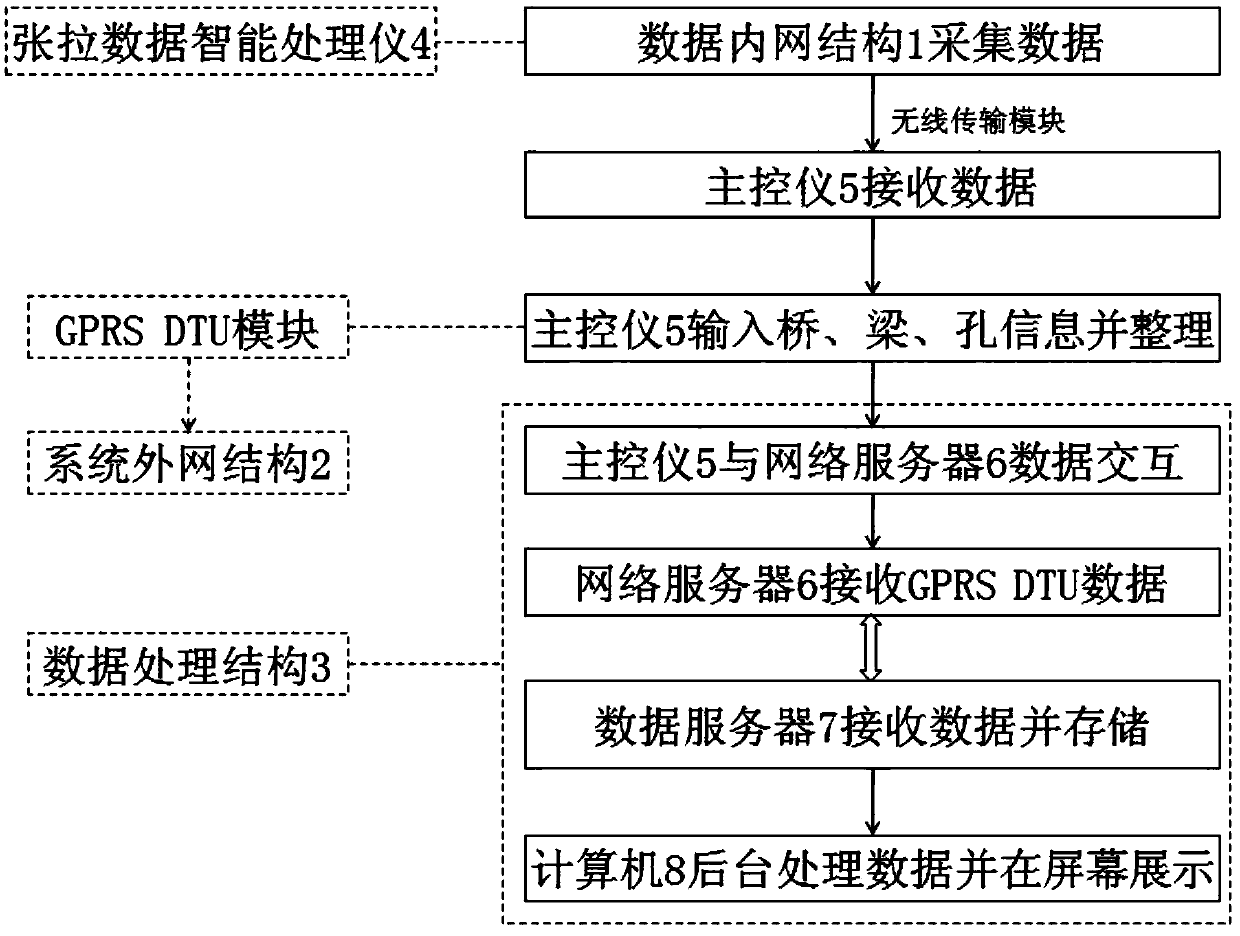

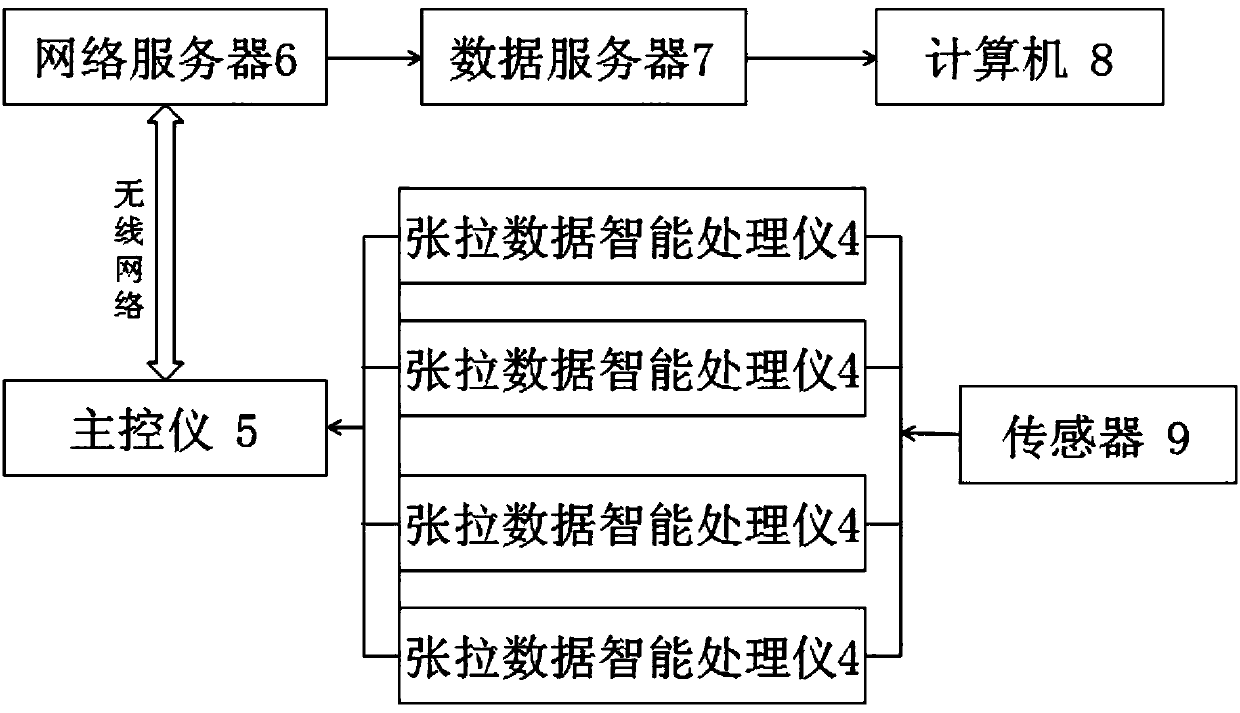

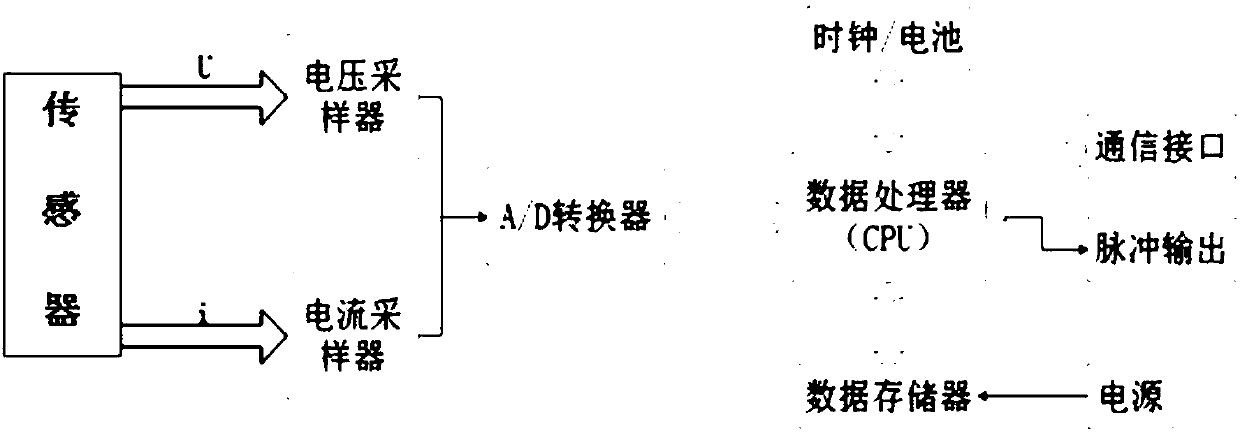

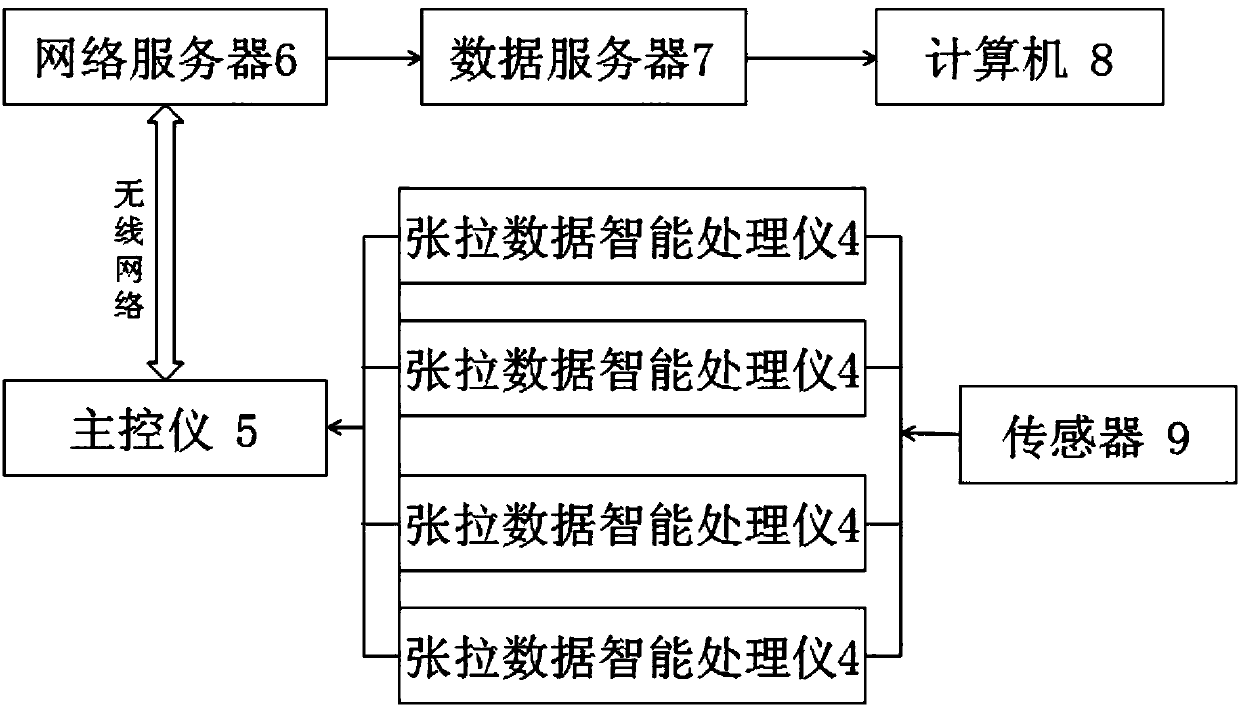

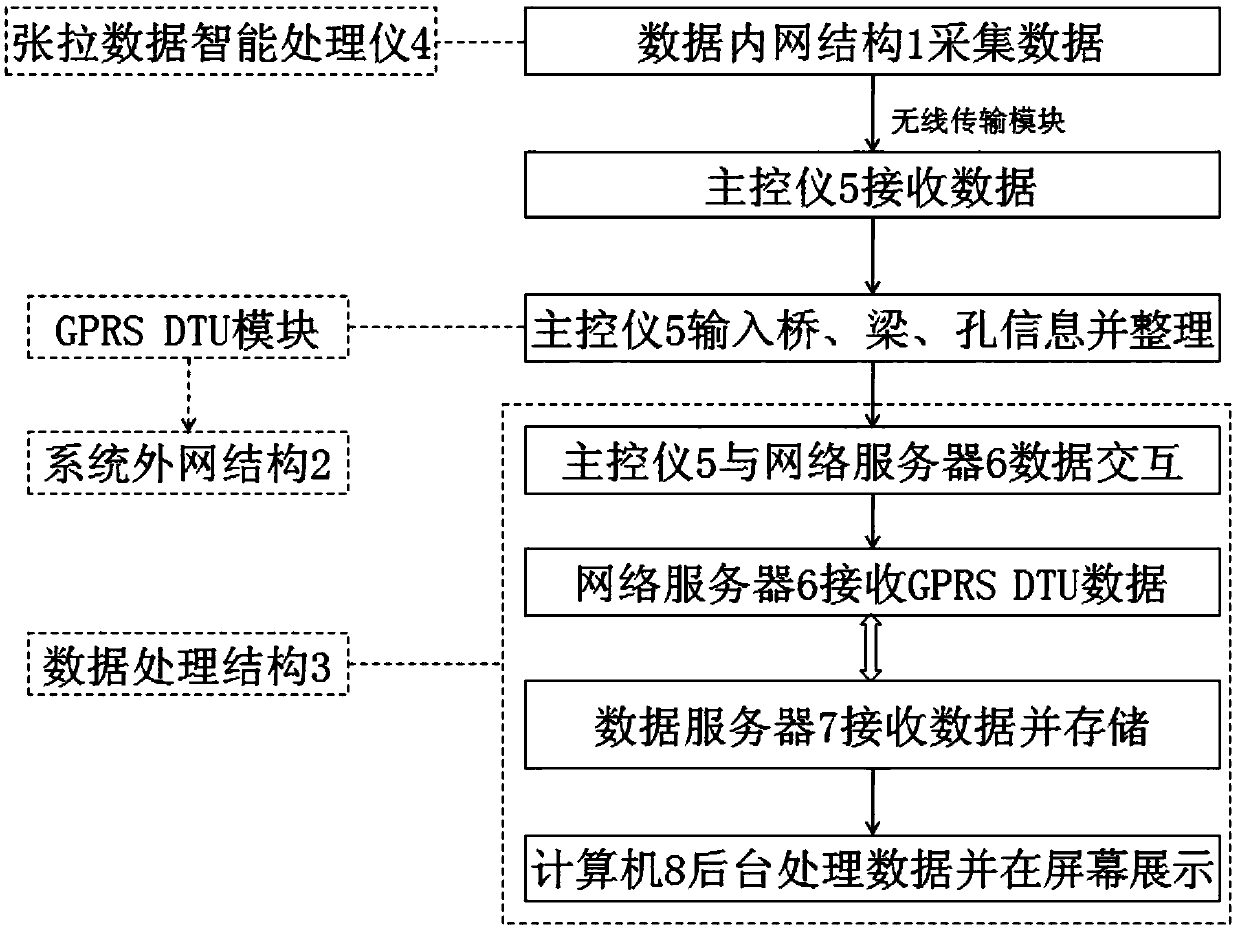

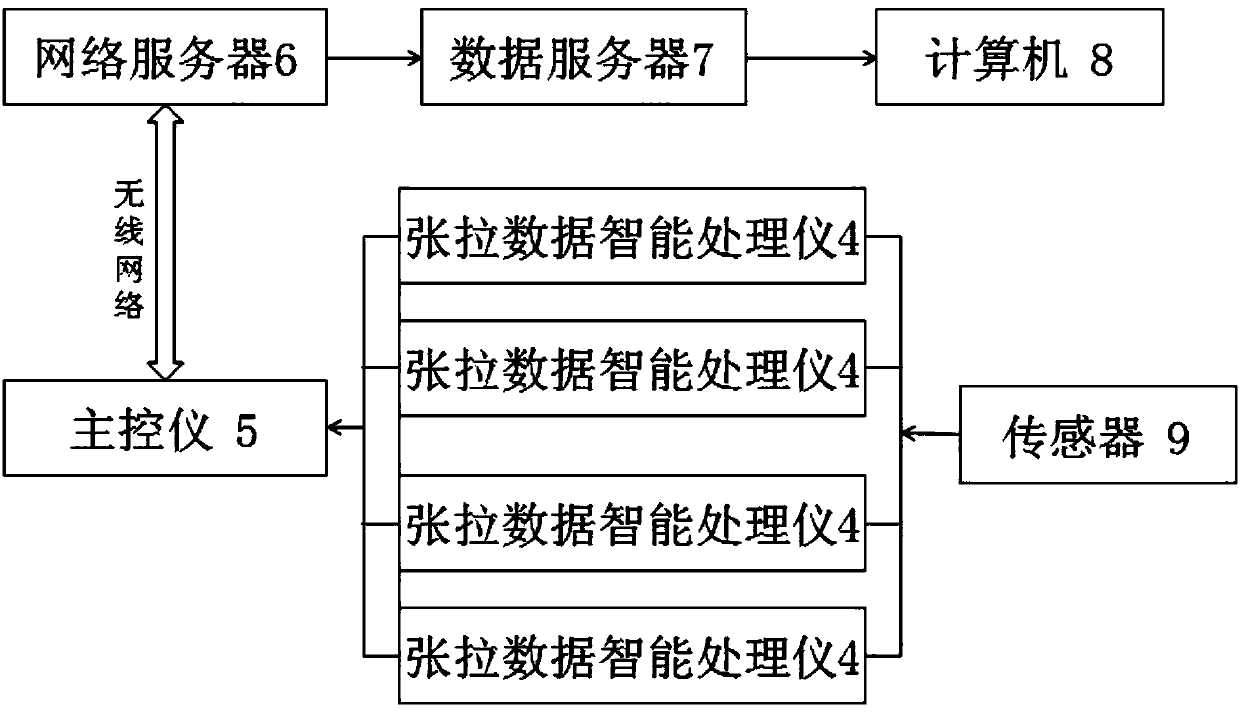

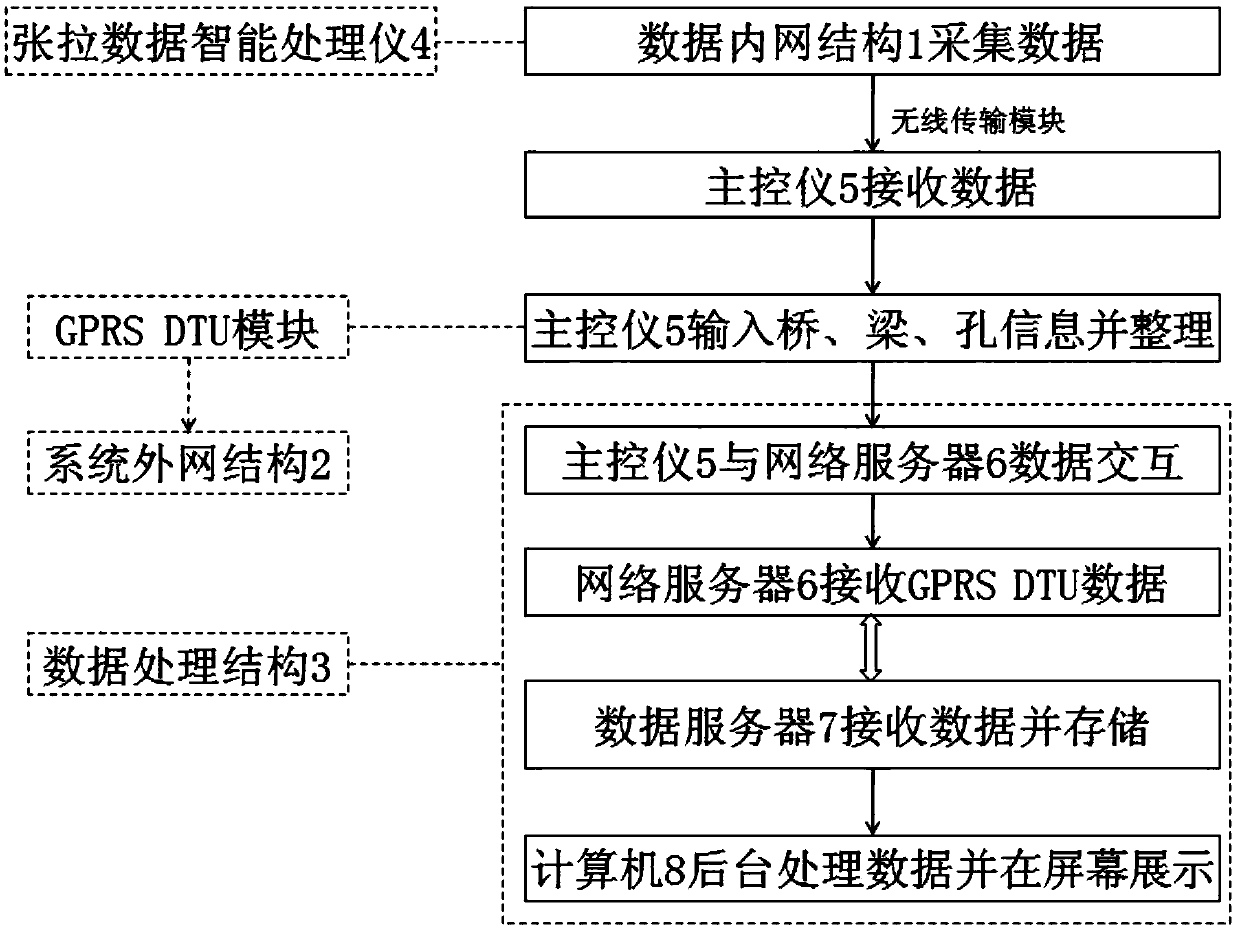

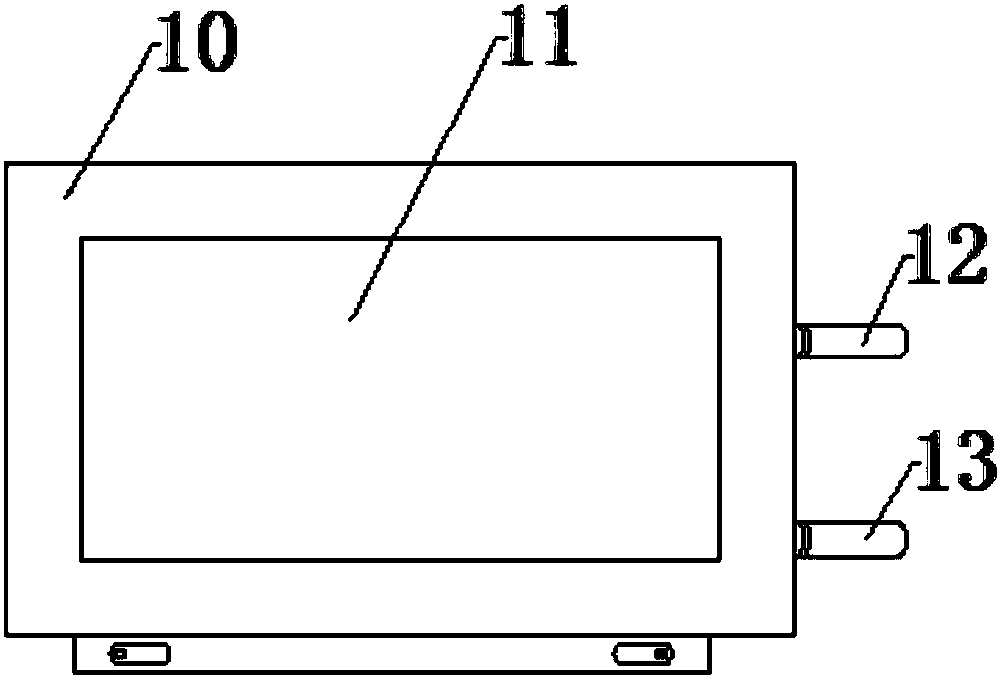

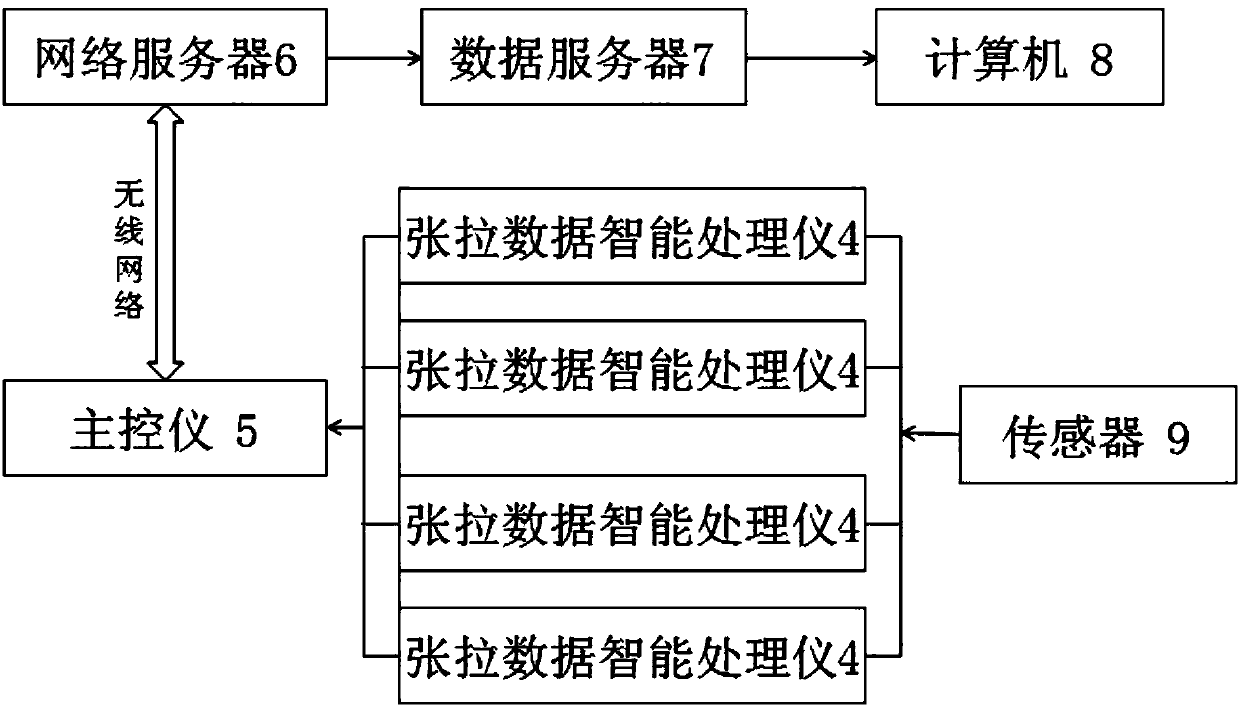

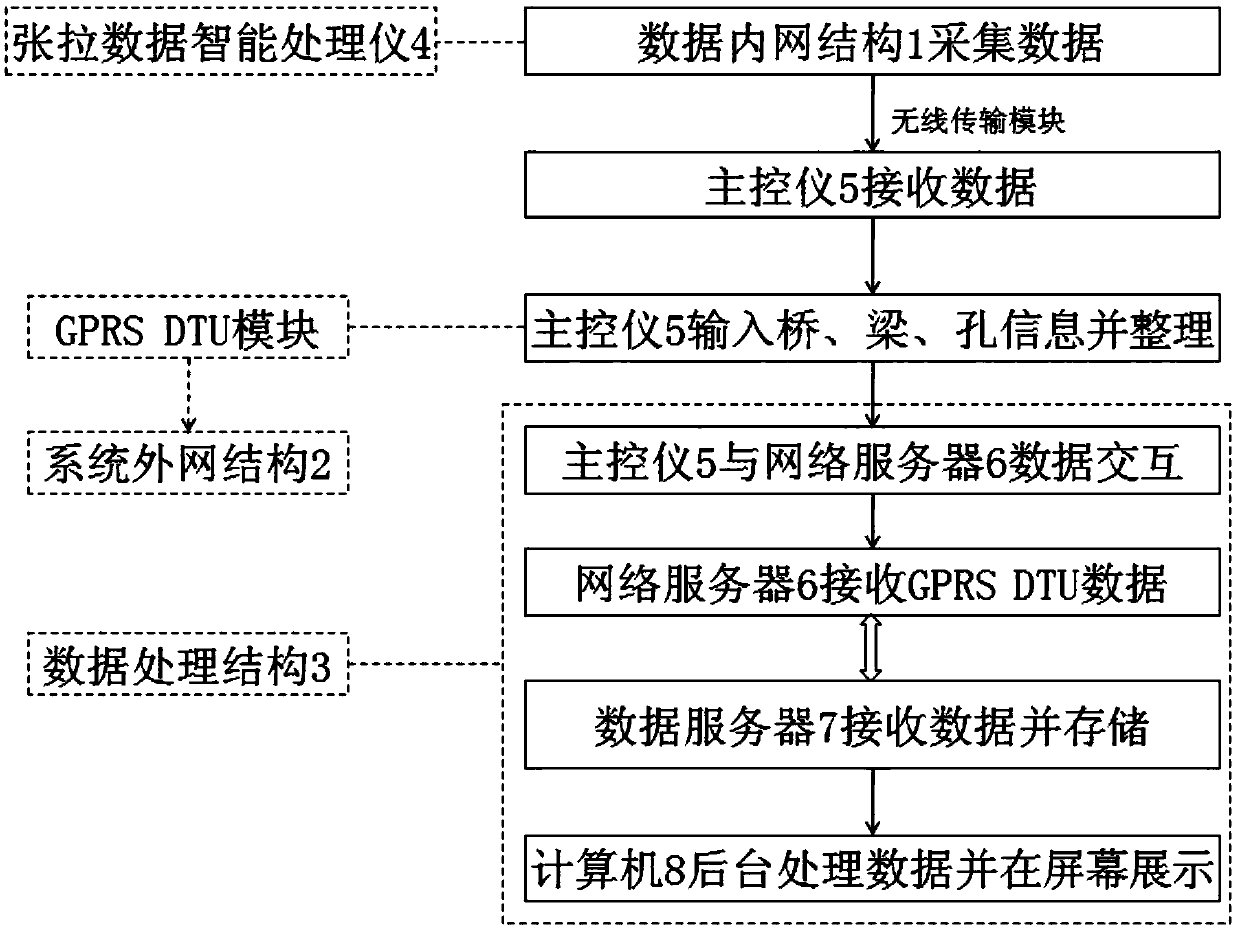

InactiveCN109839311AAbundant resourcesImprove execution efficiencyStrength propertiesMonitoring systemData treatment

The invention relates to a engineering machinery equipment data remote monitoring system, which comprises a data intranet structure used for acquiring data of a working process of the whole system, asystem extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The engineering machinery equipment data remote monitoring system has the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridgeprestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

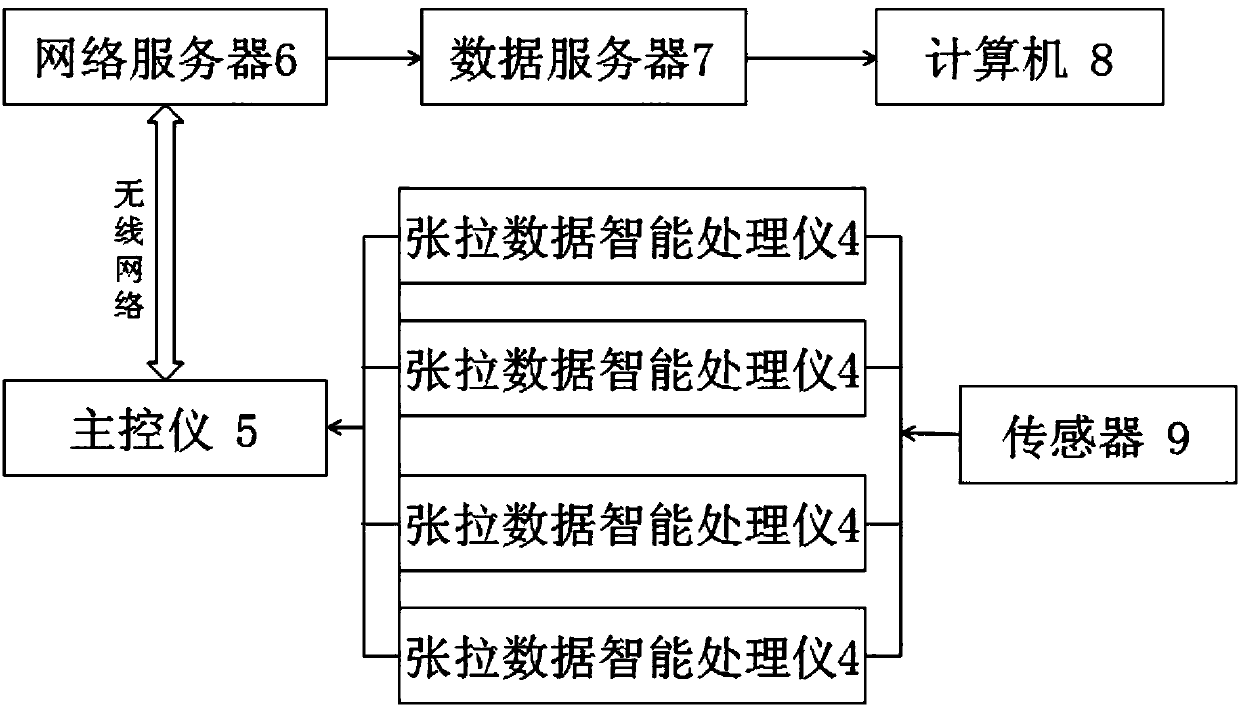

Prestress tension remote monitoring system

InactiveCN110318336AAbundant resourcesImprove execution efficiencyBridge erection/assemblyBuilding material handlingNetwork structureMonitoring system

The invention relates to a prestress tension remote monitoring system. The system includes a data internal network structure used for collecting data of a working process of a whole system, a system external network structure used for transmitting the data collected by the data internal network structure, and a data processing structure used for processing and displaying the data, wherein the datainternal network structure includes multiple tension data intelligent processing devices; the system is advantageous in that owner, supervisor, construction and detection units are unified on a sameInternet platform, real-time interaction is performed on the data, geographical restrictions are broken through, precast beam field and bridge prestressed tension construction quality conditions are timely grasped, and a management and control target of "real-time tracking, intelligent control, timely error correction" is achieved.

Owner:陕西云彩信息科技有限公司

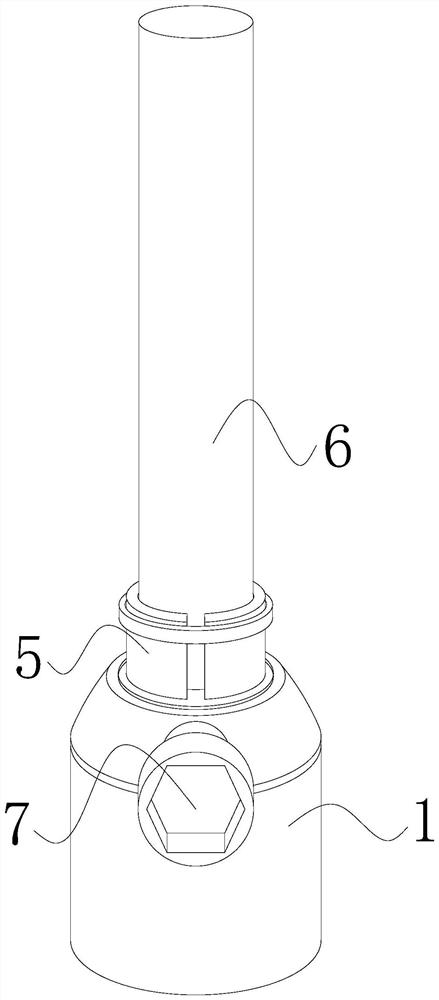

Stable corrosion-resistant material supporting jig

The invention is applicable to the technical field of jigs, and provides a stable and corrosion-resistant material supporting jig. The jig comprises: a stable base which is internally provided with a containing space, wherein a balancing weight is contained and fixed in the containing space, an opening communicated with the containing space is formed in the bottom of the stable base, and a base sealing cover is detachably and fixedly connected to the interior of the opening; a locking mechanism which is movably connected to the top of the stable base; and a guide rod. The balancing weight is stored and placed in a containing space formed in the stable base, and therefore the weight of the stable base can be increased so as to guarantee that the stable base is in a vertical state all the time and is not prone to toppling over. Besides, the base sealing cover is movably installed at the bottom of the containing space through mutual cooperation of threads, so that on one hand, supporting of the balancing weight can be achieved; and on the other hand, the invention guarantees that the balancing weight is located in the containing space and does not fall off, and the stability of follow-up work of the device is guaranteed.

Owner:KUNSHAN SOKAY AUTOMATION TECH CO LTD

Vehicle-mounted terminal of Internet of Things remote intelligent monitoring system of natural gas tank car

InactiveCN109916544AAbundant resourcesImprove execution efficiencyTransmission systemsBridge erection/assemblyIntelligent lightingStructure of Management Information

The invention relates to a vehicle-mounted terminal of an Internet of Things remote intelligent monitoring system of a natural gas tank car, which comprises a data internal network structure, a systemexternal network structure and a data processing structure, wherein the data internal network structure is used for acquiring data in the whole working process of the system; the system external network structure is used for transmitting the data acquired by the data internal network structure; the data processing structure is used for processing and displaying the data; the data internal networkstructure comprises a plurality of tension data intelligent processing instruments. The vehicle-mounted terminal has the advantages that proprietors and supervision, construction and detection unitsare unified on the same internet platform, data are interacted in real time, geographical restrictions are broken through, the quality conditions of the prestressed tension construction of the precastbeam field and the bridge are mastered in time, and the management and control objectives of real-time tracking, intelligent control and timely error correction are achieved.

Owner:胡海涛

Pipeline detection robot system based on visual technology

InactiveCN110493277AAbundant resourcesImprove execution efficiencyMetal casingsApparatus for force/torque/work measurementRobotic systemsVisual technology

The invention relates to a pipeline detection robot system based on a visual technology, and the system comprises a data intranet structure which is used for collecting the data of the whole system ina working process; a system external network structure for transmitting the data acquired by the data internal network structure; and a data processing structure for processing and displaying data. The data intranet structure comprises a plurality of tension data intelligent processors. Tthe system has the advantages that owners, supervision units, construction units and detection units are unified on the same internet platform, real-time interaction is conducted on data, geographical limitations are broken through, the prestress tensioning construction quality conditions of the precast beamfield and the bridge are mastered in time, and the management and control targets of real-time tracking, intelligent control and timely error correction are achieved.

Owner:陕西云彩信息科技有限公司

Oil well remote monitoring device and remote monitoring system

InactiveCN109839851AMaintain stabilityCorrosion resistant and stableProgramme controlComputer controlMonitoring systemYard

The invention relates to an oil well remote monitoring device and an oil well remote monitoring system. The oil well remote monitoring device and the oil well remote monitoring system comprise a dataintranet structure used for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and aprocessing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The oil well remote monitoring device and the oil well remote monitoring system have the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

Remotely controlling human body health monitoring system and method

InactiveCN109900412AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlHuman bodyMonitoring system

The invention relates to a remotely controlling human body health monitoring system and method. The system comprises a data intranet structure for collecting data of a working process of the whole system, a system extranet structure for transmitting the data collected by the data intranet structure, and a data processing structure for processing and showing the data, wherein the data intranet structure comprises a plurality of tensioning data intelligent processors. The system has the advantages of concentrating the owner, the supervisor, construction and the detection unit in the same internet platform, interacting data in real time, breaking through regional limitation, acquiring conditions of a prefabricated beam field and bridge prestressed tension construction quality timely, and achieving a control goal of 'real-time tracking, intelligent control and real-time correcting'.

Owner:徐司雨

Oil well remote monitoring device and system

InactiveCN110488668AAbundant resourcesImprove execution efficiencyProgramme controlMeasurement devicesPre stressPre stressing

The invention relates to an oil well remote monitoring device and system, and the device comprises a data intranet structure which is used for collecting the data of the whole system in a working process; a system extranet structure which is used for transmitting the data acquired by the data intranet structure; a data processing structure which is used for processing and displaying data, whereinthe data intranet structure comprises a plurality of tension data intelligent processors. The device has the advantages that owners, supervision units, construction units and detection units are integrated on the same internet platform, the real-time interaction is conducted on data, the geographical limitations are broken through, the pre-stress tensioning construction quality conditions of the precast beam field and the bridge are mastered in time, and the management and control targets of real-time tracking, intelligent control and timely error correction are achieved.

Owner:孙彦斌

A geopolymer grout

ActiveCN106699037BThere is stable and adjustable performanceLow costCement productionAlkaneDimethylaniline N-oxide

Owner:CHENGDU JIAXIN TECH +3

Coal mine video remote monitoring system based on SOA

InactiveCN109901448AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlCoalSmart control

The invention relates to a coal mine video remote monitoring system based on SOA, comprising a data internal network structure for collecting data of working process data of the whole system; a systemexternal network structure for transmitting the data collected by the data internal network structure; and a data processing structure for processing and displaying the data, wherein the data internal network structure comprises a plurality of tension data intelligent processing instruments; and the coal mine video remote monitoring system based on SOA provided by the invention has the advantagesthat owner, supervision, construction and detection departments in the same Internet platform, and the data are interacted in real time, the geographical restriction is broken through, the prestresstension construction quality conditions of prefabricated beam yards and bridges are mastered in time, and the management and control targets of "real-time tracking, intelligent control and timely error correction" are achieved.

Owner:张永春

A kind of carbon gel catalyst for fuel cell and application thereof

ActiveCN103682378BLarge specific surface areaGood electrical and thermal conductivityPhysical/chemical process catalystsCell electrodesCarbonizationProton

The invention relates to a carbon gel catalyst for fuel batteries and application thereof. By adopting resorcinol, formaldehyde, a coordination compound, a metal salt and a metal organic compound as raw materials, the carbon gel catalyst which is controllable and adjustable in pore structure and specific surface area is prepared through controlling the adding of the metal salt of different amounts and adjusting the precursor solution concentration, the reaction environment temperature and the carbonization and nitridation treatment temperature. When serving as a nonmetal catalyst for a proton exchange membrane flue battery cathode catalyst, the carbon gel catalyst disclosed by the invention shows good corrosion resistance and stability after long-term use; the preparation process of the catalyst is simple in flow, short in period and friendly to environment; the catalyst is low in cost and wide in application range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Remote monitoring equipment for fire-fighting water

InactiveCN110488667AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlPre stressPre stressing

The invention relates to remote monitoring equipment for fire-fighting water, and the equipment comprises a data intranet structure which is used for collecting the data of a whole system in a workingprocess; a system extranet structure which is used for transmitting the data acquired by the data intranet structure; a data processing structure which is used for processing and displaying data, wherein the data intranet structure comprises a plurality of tension data intelligent processors. The equipment has the advantages that owners, supervision units, construction units and detection units are unified on the same internet platform, the real-time interaction is conducted on data, the geographical limitations are broken through, the pre-stress tensioning construction quality conditions ofa precast beam field and a bridge are mastered in time, and the management and control targets of real-time tracking, intelligent control and timely error correction are achieved.

Owner:孙彦斌

Prestressed tension remote monitoring system

InactiveCN109839237AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlMonitoring systemYard

The invention relates to a prestressed tension remote monitoring system, which comprises a data intranet structure used for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The prestressed tension remote monitoring system has the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension constructionquality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

Remote monitor and remote monitoring system for vehicle

InactiveCN109839852AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlStructure of Management InformationMonitoring system

The invention relates to a remote monitor and a remote monitoring system for a vehicle. The remote monitoring system comprises a data intranet structure used for acquiring data of a working process ofthe whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data,wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The remote monitor and the remote monitoring system have the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' areachieved.

Owner:田晓枫

Remote monitoring system and remote monitoring method of communication base station power supply

InactiveCN110485735AMaintain stabilityCorrosion resistant and stableBuilding material handlingTransmissionStructure of Management InformationMonitoring system

The invention relates to a remote monitoring system and a remote monitoring method of a communication base station power supply. The remote monitoring system of the communication base station power supply comprises a data intranet structure, a system outer net structure and a data processing structure, wherein the data intranet structure is used for acquiring data in the whole system working process; the system outer net structure is used for transmitting the data acquired by the data intranet structure; the data processing structure is used for processing and displaying the data; and the dataintranet structure comprises multiple intelligent tension data processors. The remote monitoring system and the remote monitoring method of the communication base station power supply provided by theinvention have the advantages that proprietors, supervisors, constructors and detection departments are unified into one same internet platform, data is interacted in real time, the geographical limitation is broken, the prestress tension construction quality situations of a precast beam field and a bridge are grasped in time, and the management and control goals of real-time tracking, intelligent control and timely correction are achieved.

Owner:孙彦斌

Remote monitoring method of high-temperature and high-pressure rheometer

InactiveCN109900312AMaintain stabilityCorrosion resistant and stableProgramme controlMeasurement devicesStructure of Management InformationNetwork structure

The invention relates to a remote monitoring method of a high-temperature and high-pressure rheometer. The remote monitoring method refers to a data intranet structure for collecting data in the working process of a whole system, a system outer network structure for transmitting the data collected by the data intranet structure, and a data processing structure for processing and displaying the data; and the data intranet structure comprises a plurality of tension data intelligent processing instruments. The remote monitoring method has the advantages that an owner, supervision, construction and a detection unit are integrated in the same Internet platform, the data are subjected to real-time interaction, the geographical limitation is broken through, precast beam field and bridge prestresstension construction quality conditions are timely grasped, and the management and control targets of real-time tracking, intelligent control and timely error correction are achieved.

Owner:王龙

Catalyst layer, membrane electrode assembly and fuel cell

ActiveUS8268490B2Corrosion resistant and stableReduced activityTantalum compoundsCell electrodesReduction ActivityFuel cells

Catalyst layers include an electrocatalyst having high oxygen reduction activity that is useful as an alternative material to platinum catalysts. Uses of the catalyst layers are also disclosed. A catalyst layer of the invention includes an electrode substrate and an electrocatalyst on the surface of the electrode substrate, and the electrocatalyst is formed of a metal compound obtained by hydrolyzing a metal salt or a metal complex.

Owner:SHOWA DENKO KK

Remote monitoring method for high-temperature and high-pressure rheometer

InactiveCN109839251AAbundant resourcesImprove execution efficiencyElasticity measurementHigh pressureComputer science

The invention relates to a remote monitoring method for a high-temperature and high-pressure rheometer. The remote monitoring method adopts a data intranet structure used for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The remote monitoring method has the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

Remote monitoring device and remote monitoring system for vehicle

InactiveCN109932114AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlReal time trackingPre stressing

The invention relates to a remote monitoring device and a remote monitoring system for a vehicle. A data internal network structure for collecting data of the whole working process of the system, a system external network structure for transmitting the data collected by the data internal network structure, and a data processing structure for processing and displaying data are arranged. The data internal network structure includes a plurality of intelligent tension data processing instruments. The remote monitoring device and a remote monitoring system have the following advantages: the owner,the supervisor, the construction side, and the testing unit are unified at one same Internet platform; the data are interacted in real time; the geographical restrictions are eliminated; the pre-stress tension construction quality situations of the prefabricated beam field and the bridge can be obtained timely; and the control objectives of real-time tracking, intelligent control, and timely errorcorrection are achieved.

Owner:赵珠峰

Remote monitoring system and remote monitoring method for communication base station power supply

InactiveCN109916543AAbundant resourcesImprove execution efficiencyProgramme controlTransmission systemsReal time trackingControl objective

The invention relates to a remote monitoring system and a remote monitoring method for a communication base station power supply, and the system comprises a data intranet structure which is used for the data collection of the whole system working process; a system external network structure which is used for transmitting the data acquired by the data internal network structure; and a data processing structure which is used for processing and displaying the data; wherein the data intranet structure comprises a plurality of tensioning data intelligent processing instruments. The system has the advantages that proprietor, supervision, construction and detection units are unified on the same internet platform, data are interacted in real time, geographical restrictions are broken through, thequality conditions of the prestressed tension construction of the precast beam field and the bridge are mastered in time, and the management and control objectives of real-time tracking, intelligent control and timely error correction are achieved.

Owner:胡海涛

Electrocatalyst layer, membrane electrode assembly and fuel cell

InactiveUS20160276675A1High oxygen reduction activityCorrosion resistant and stableCell electrodesTitanium dioxideReduction ActivityNiobium

Electrocatalyst layers include an electrocatalyst having high oxygen reduction activity that is useful as an alternative material to platinum catalysts. Uses of the electrocatalyst layers are also disclosed.The electrocatalyst layer includes an electrocatalyst that is formed of a metal oxide obtained by thermally decomposing a metal organic compound. The metal element forming the electrocatalyst is preferably one selected from the group consisting of niobium, titanium, tantalum and zirconium.

Owner:RESONAC HOLDINGS CORPORATION

Firefighting water remote monitoring equipment

InactiveCN109839848AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlReal time trackingData processing

The invention relates to firefighting water remote monitoring equipment, which comprises a data intranet structure used for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The firefighting water remote monitoring equipment has the advantage that owners, supervisors, construction units and detectionunits are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

Human health monitoring system and method for remote monitoring

InactiveCN109839236AAbundant resourcesImprove execution efficiencyApparatus for force/torque/work measurementStructure of Management InformationHuman health

The invention relates to a human health monitoring system and a human health monitoring method for remote monitoring. The human health monitoring system comprises a data intranet structure used for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used forprocessing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The human health monitoring system and method for remote monitoring has the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timely error correction'' are achieved.

Owner:田晓枫

Vehicle-mounted terminal of natural gas tank car Internet of Things remote intelligent monitoring system

InactiveCN109839849AAbundant resourcesImprove execution efficiencyProgramme controlComputer controlIntelligent lightingStructure of Management Information

The invention relates to a vehicle-mounted terminal of a natural gas tank car Internet of Things remote intelligent monitoring system. The vehicle-mounted terminal comprises a data intranet structureused for acquiring data of a working process of the whole system, a system extranet structure used for transmitting the data acquired by means of the data intranet structure, and a processing structure used for processing and displaying the data, wherein the data intranet structure comprises a plurality of tension data intelligent processing instruments. The vehicle-mounted terminal has the advantage that owners, supervisors, construction units and detection units are unified on the same Internet platform, the data is exchanged in real time, the geographical restrictions are broken through, the precast beam yards and bridge prestressed tension construction quality situations are grasped timely, and the management and control purposes of ''real-time tracking, intelligent control, and timelyerror correction'' are achieved.

Owner:田晓枫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com