Novel rapid repair cement based on magnesium oxysulfate cementing material and preparation method thereof

A magnesium oxysulfide glue, fast technology, applied in cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., to achieve good fluidity, simple operation, and reduce the effect of sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

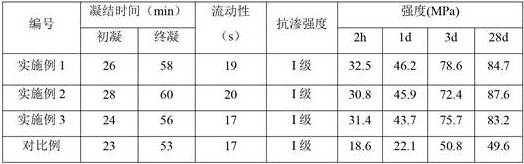

Examples

Embodiment 1

[0027] A kind of raw material ratio of the novel rapid repair cement based on magnesium oxysulfate cementitious material of the present invention is: light-burned magnesium oxide powder 150g, label is the aluminate cement clinker 15g of CA-50, magnesium sulfate heptahydrate 55g, water 65g, citric acid 0.8g.

[0028] The preparation method of the present invention specifically comprises the following steps:

[0029] (1) Put all the light-burned magnesia powder and the aluminate cement clinker labeled CA-50 in a mixer and stir for 2-3 minutes, stir and mix evenly to prepare a mixture;

[0030] (2) Put all the magnesium sulfate heptahydrate and water in a blender and stir for 3~4min, stir and mix evenly, so that the solute is fully dissolved to obtain a magnesium sulfate solution; put all the citric acid and magnesium sulfate solution in a blender and stir for 3~4min, After the citric acid is completely dissolved, set aside;

[0031] (3) Put the mixed material in step 1) and th...

Embodiment 2

[0035] A kind of raw material ratio of the novel rapid repair cement based on magnesium oxysulfide cementitious material of the present invention is: 150g of light-burned magnesia powder, 8g of aluminate cement clinker that label is CA-50, 55g of magnesium sulfate heptahydrate, water 65g, citric acid 0.8g.

[0036] The preparation method is the same as in Example 1.

Embodiment 3

[0038] A kind of raw material ratio of the novel rapid repair cement based on magnesium oxysulfide cementitious material of the present invention is: 150g of light-burned magnesia powder, 8g of aluminate cement clinker that label is CA-70, 55g of magnesium sulfate heptahydrate, water 65g, citric acid 0.8g.

[0039] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com