Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Constant velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

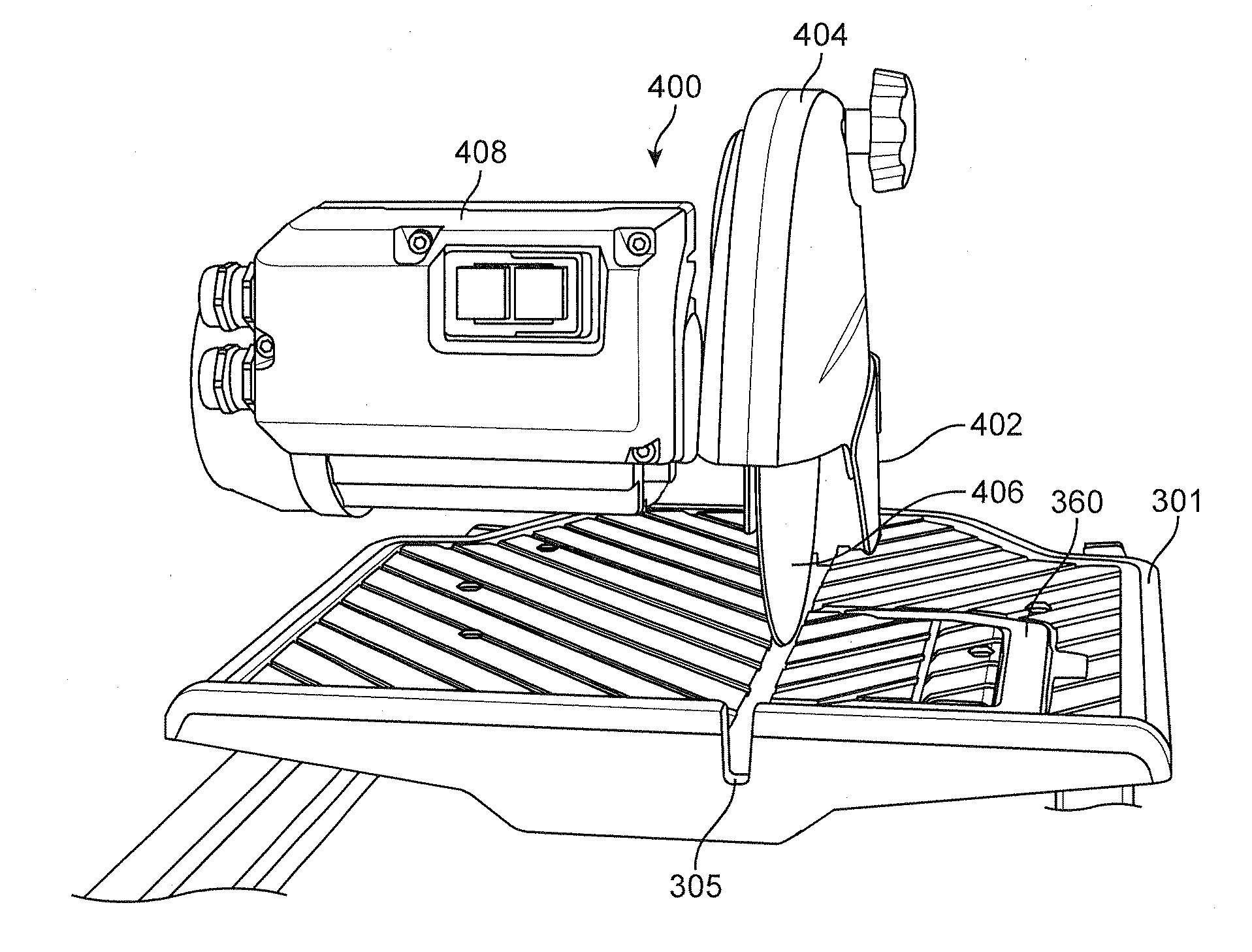

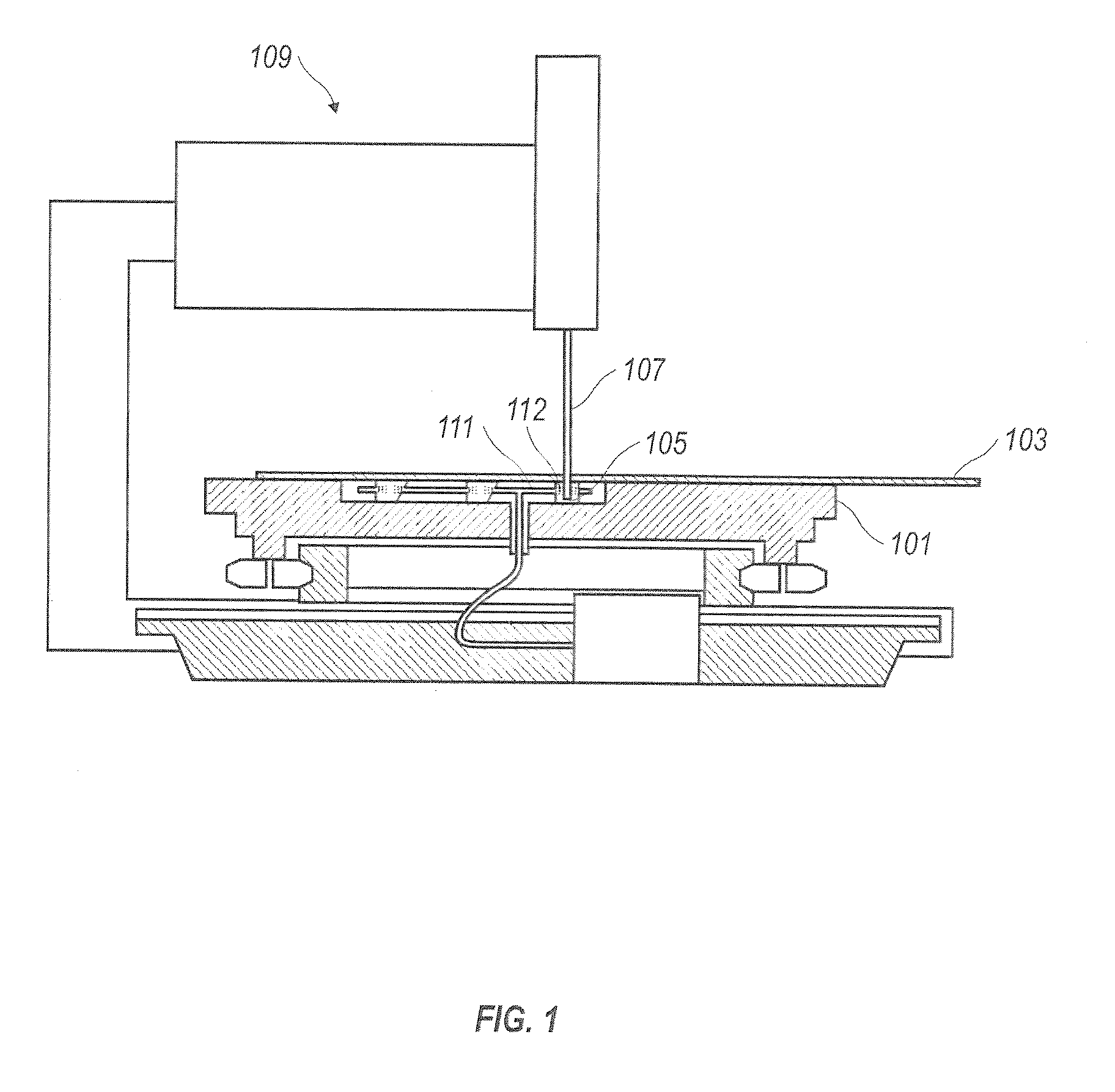

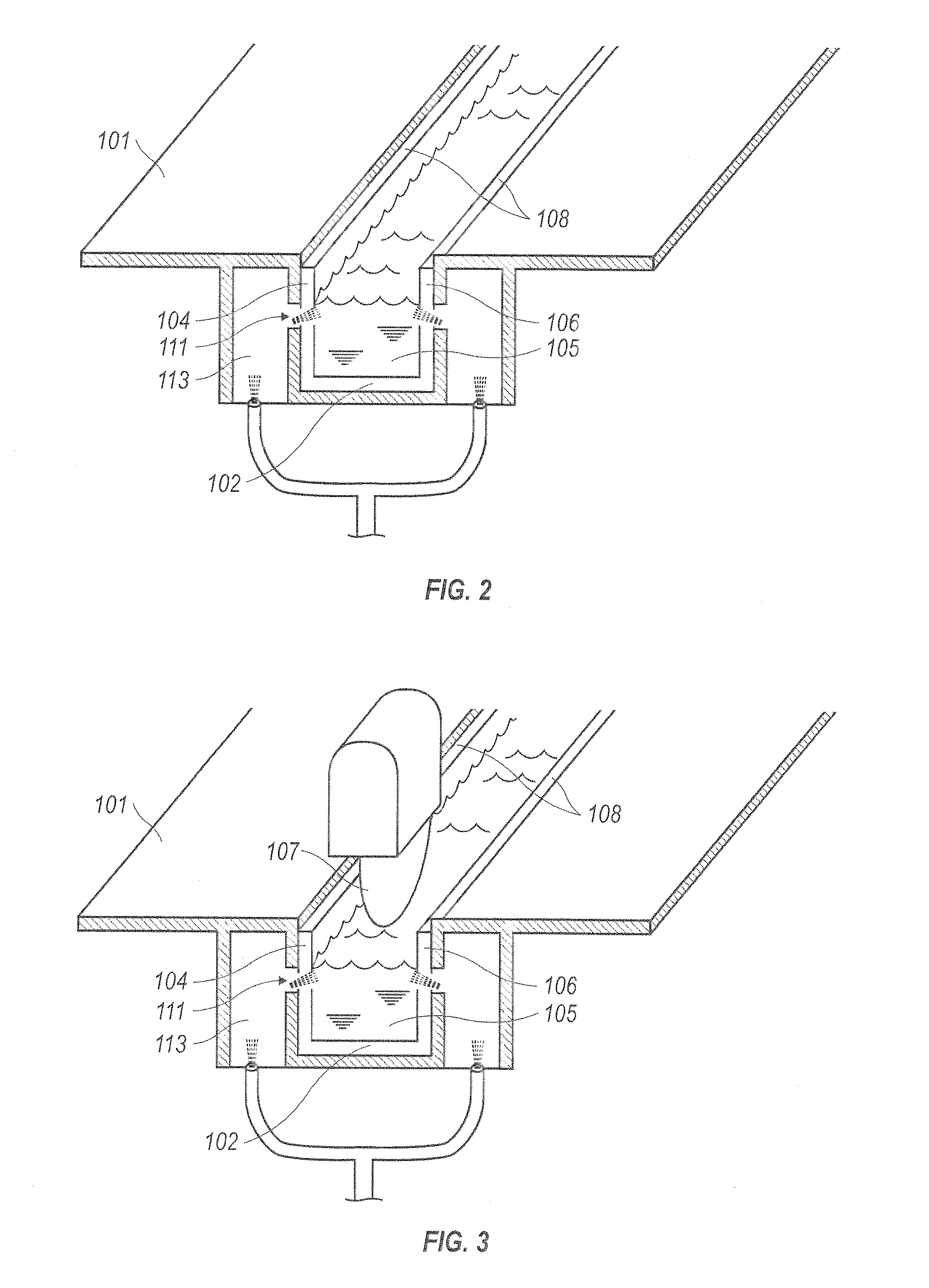

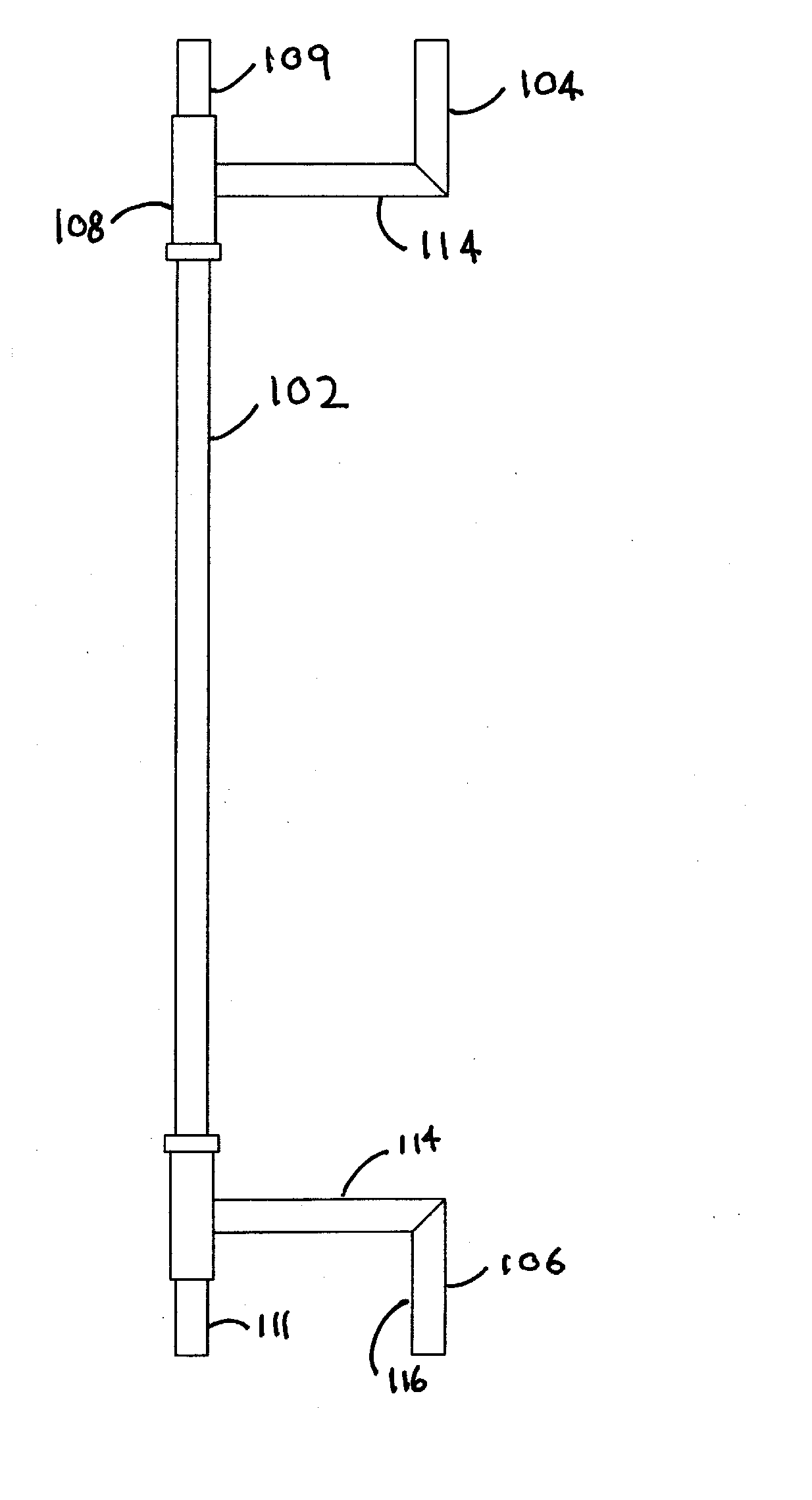

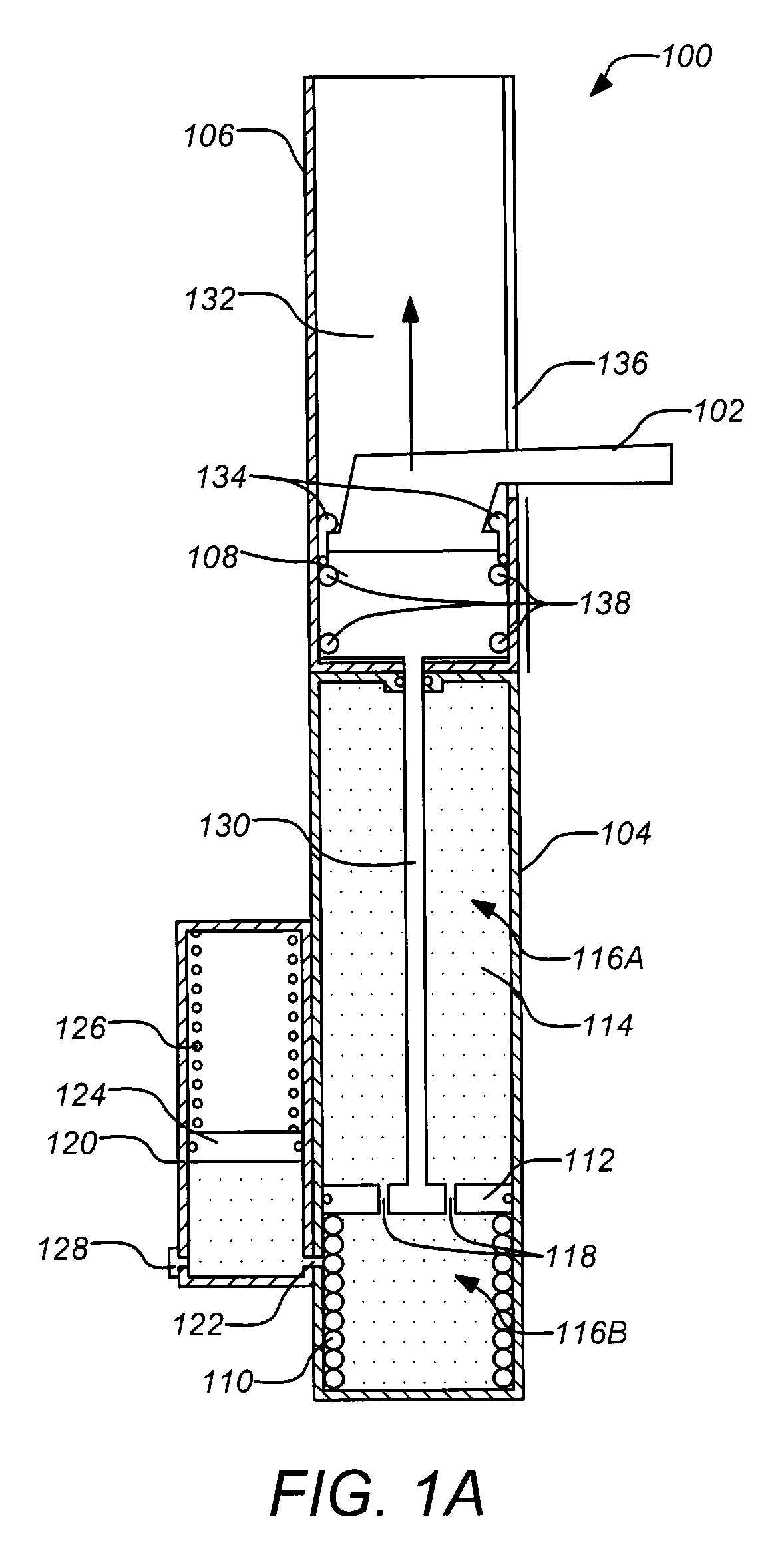

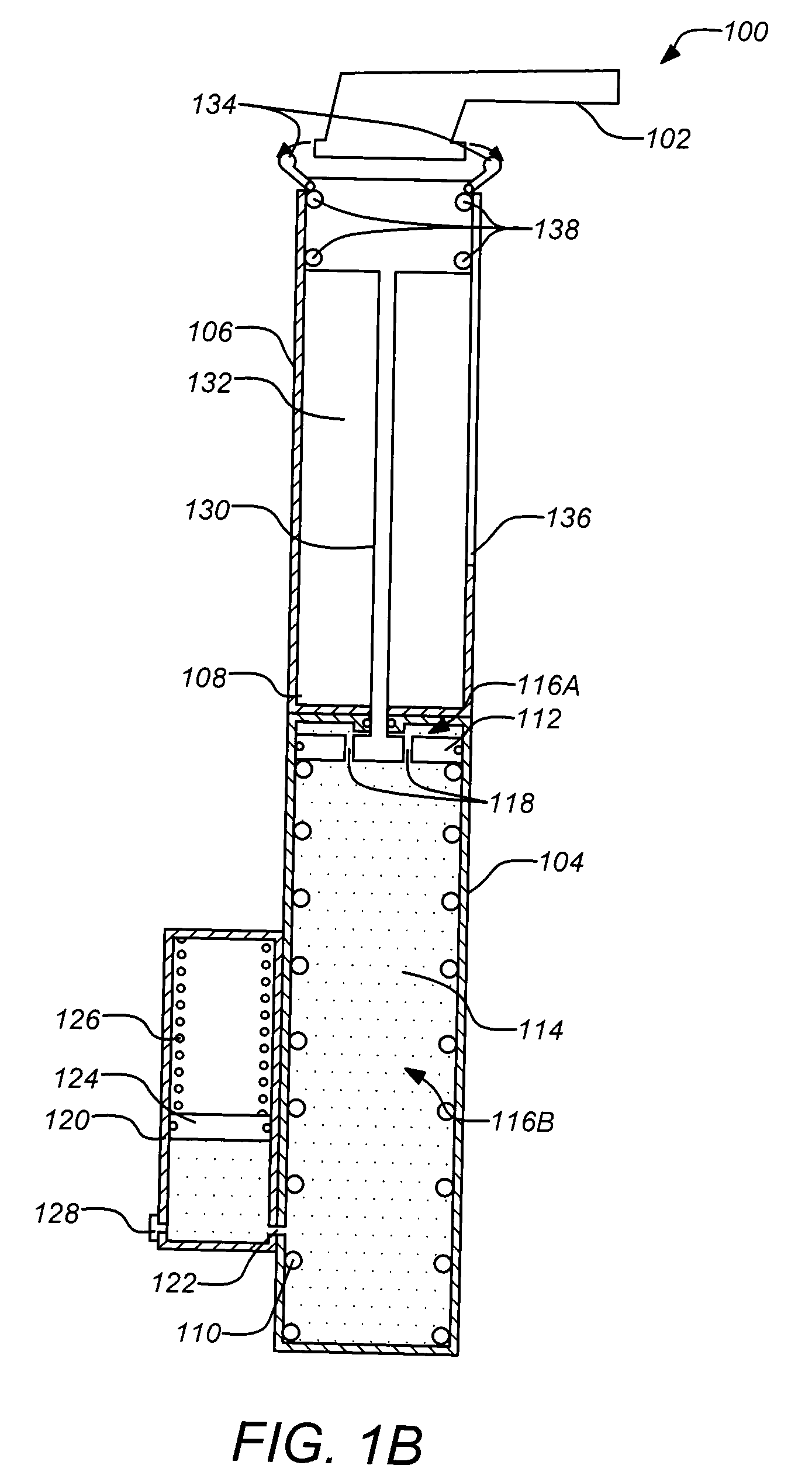

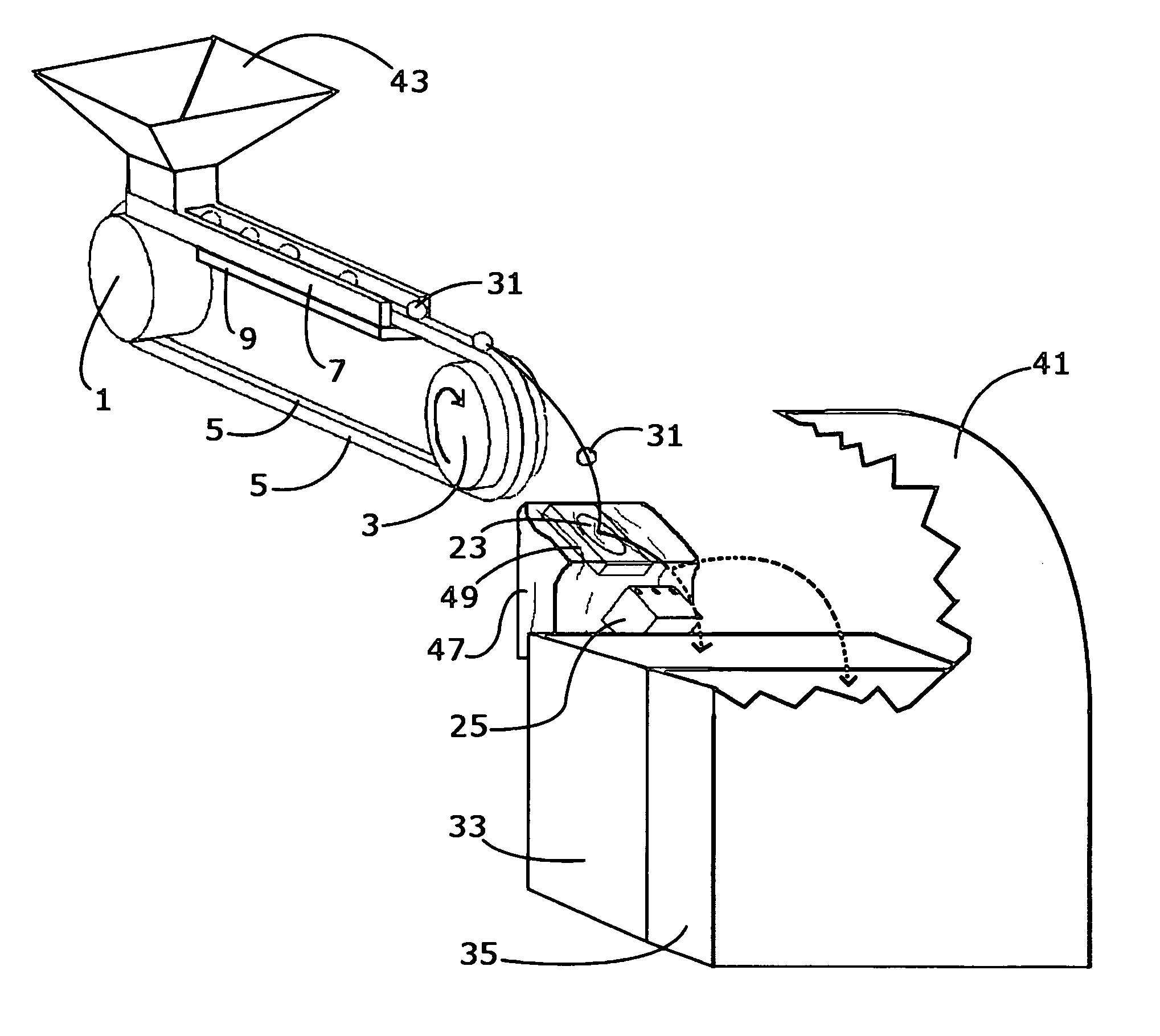

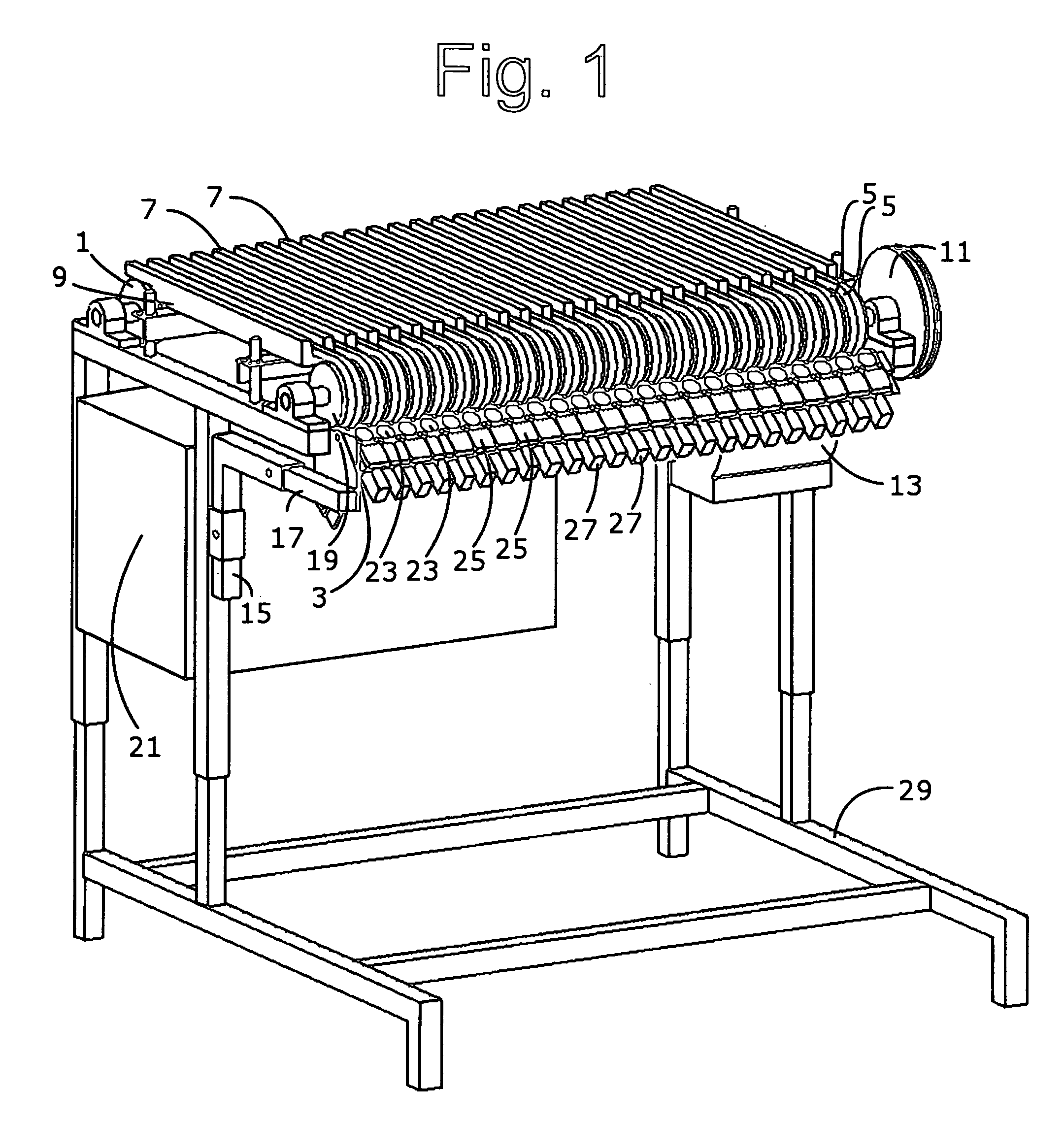

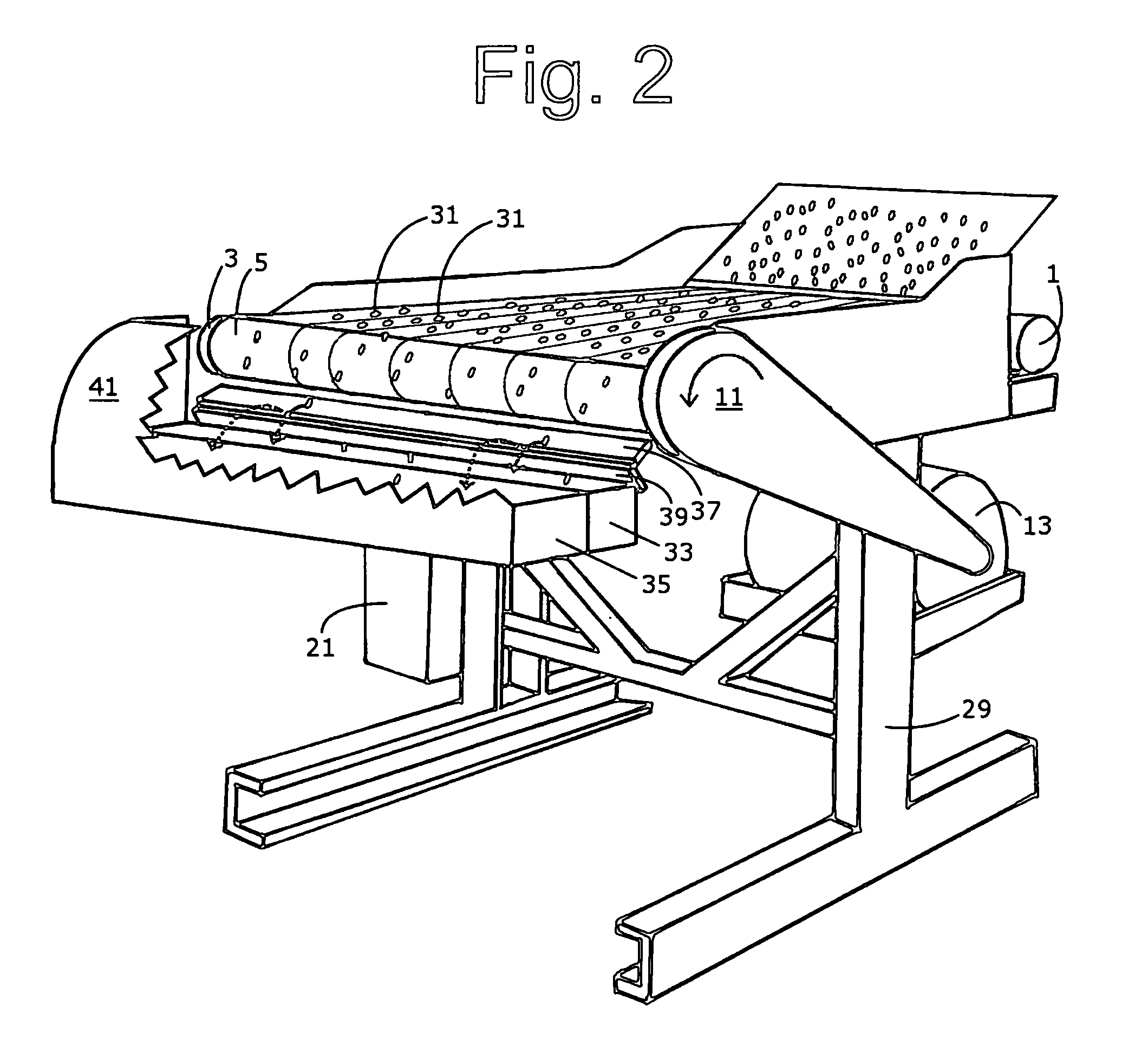

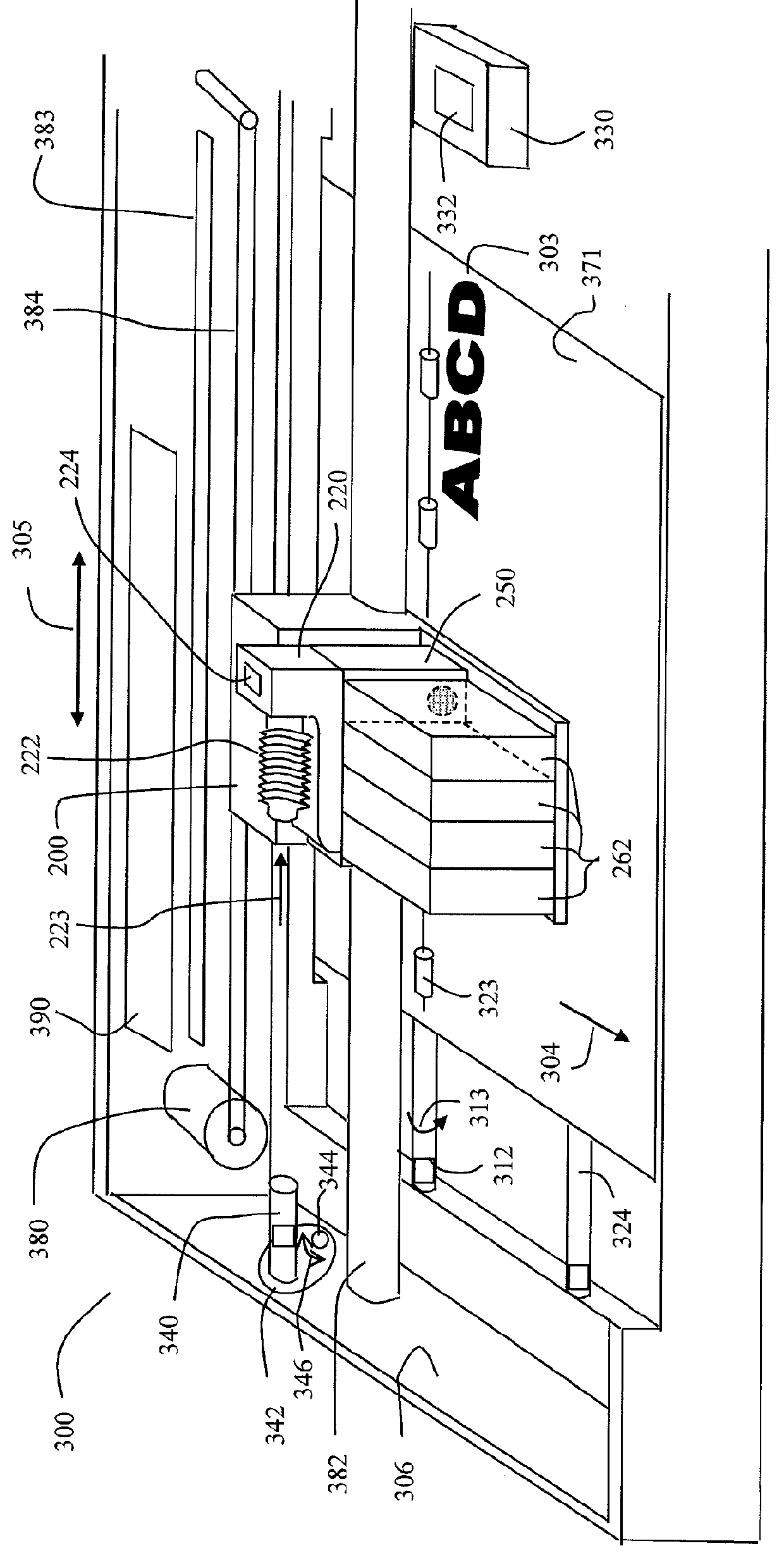

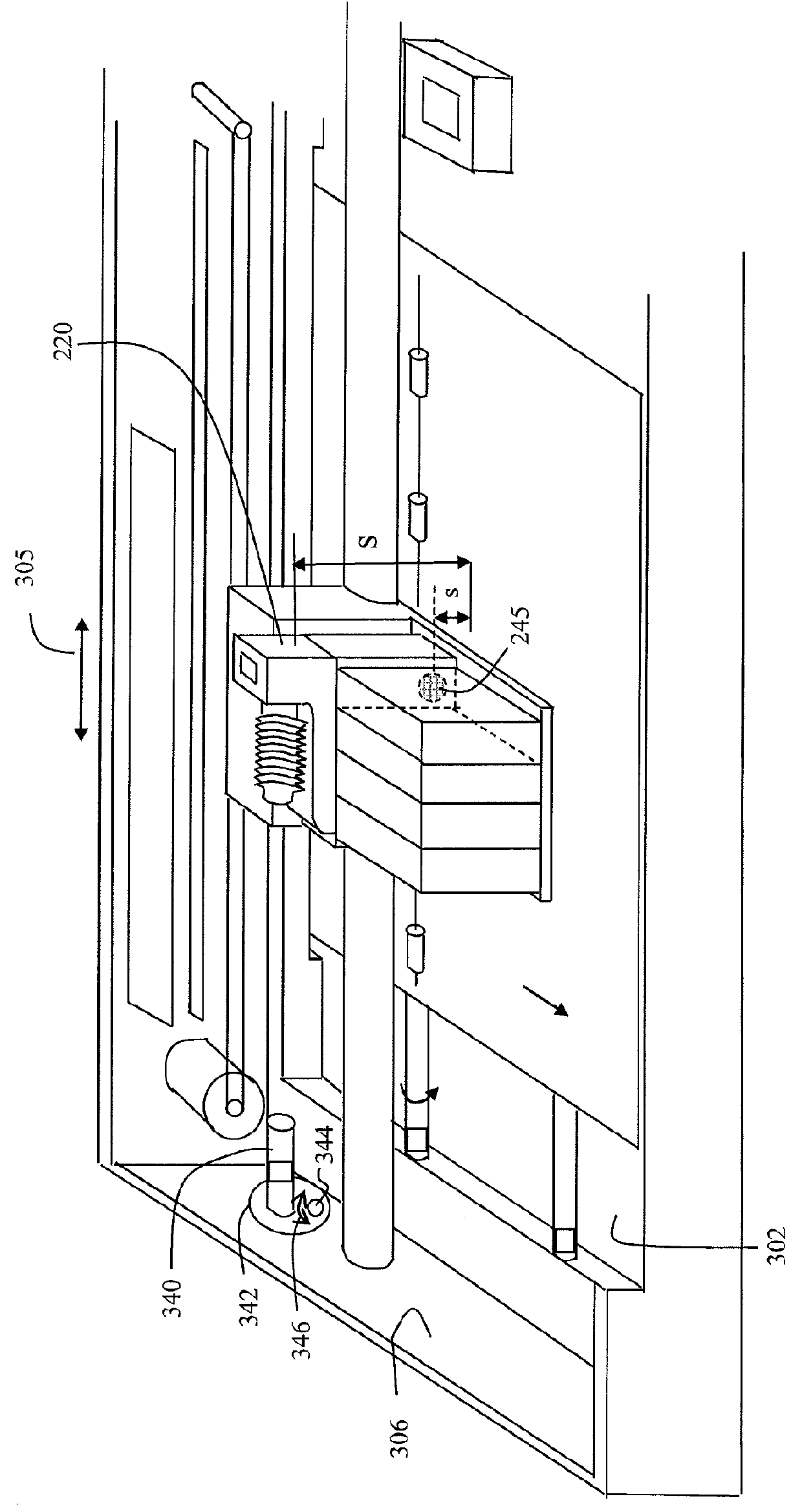

Cutting machine with a liquid lubrication delivery system having a controlled liquid level

ActiveUS20120118278A1Efficiently cool and lubricate and remove debrisImprove fluid flowMetal sawing devicesMetal sawing accessoriesMain channelEngineering

A cutting machine having a liquid lubrication delivery system. The machine includes a work-piece platform having an upper surface for supporting a work-piece thereupon. The work-piece platform can further include a main channel defining a recess in the upper surface. At least one liquid lubrication inlet for discharging liquid into the main channel can also be present on the work-piece platform. The at least one liquid lubrication inlet can be a plurality of liquid lubrication inlets.

Owner:HUSQVARNA AB

An apparatus for reducing body stress on an exerciser

An apparatus used during weighted barbell exercises for reducing body stress on the wrists and lower back comprises identical assemblies mounted for rotation on the end sleeves of the barbell. Weights are suspended on the assemblies below the barbell. Each assembly comprises first horizontal tubular member having a sidewall defining an annulus adapted to receive the barbell end sleeves; a vertical extension member welded perpendicular to the first horizontal tubular member; and, a second horizontal member, parallel to the first horizontal tubular member welded to and suspended from the vertical extension member for carrying the weights. During the lift and recovery, the apparatus keeps the combined dynamic centers of gravity of the weights and apparatus close to the body reducing back stress. The apparatus reduces wrist stress by minimizing torque about the wrist.

Owner:LOGUE SCOTT

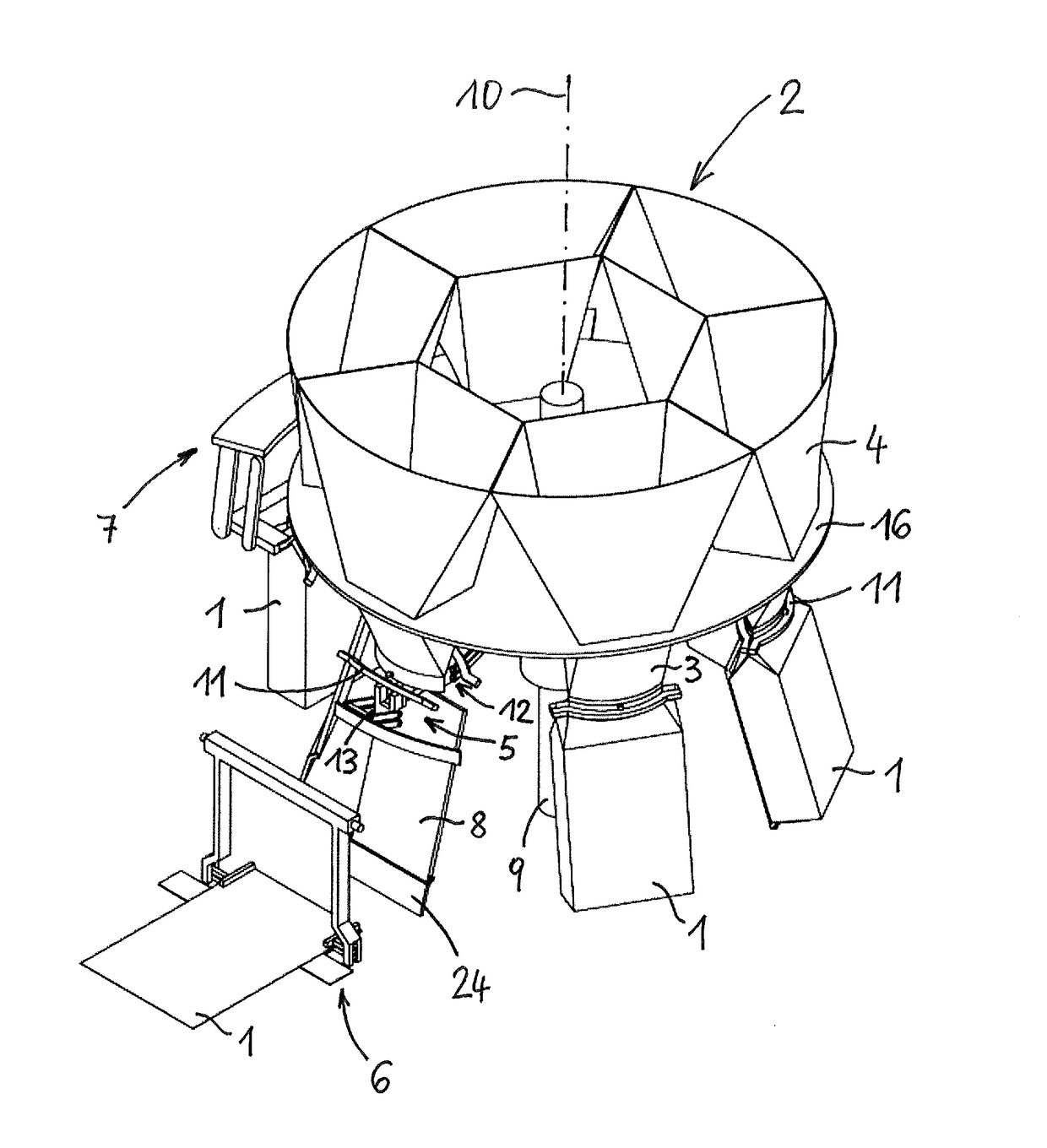

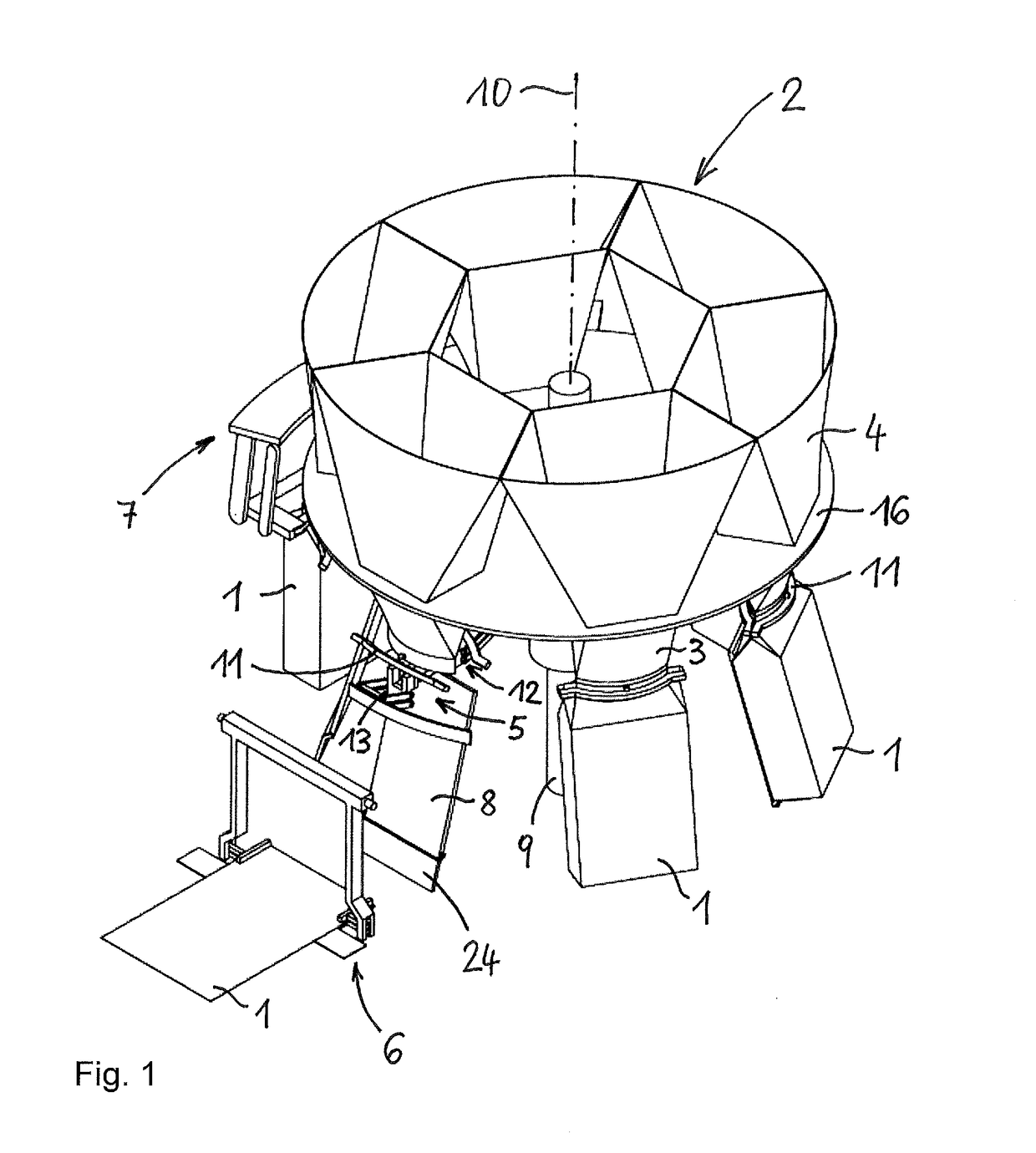

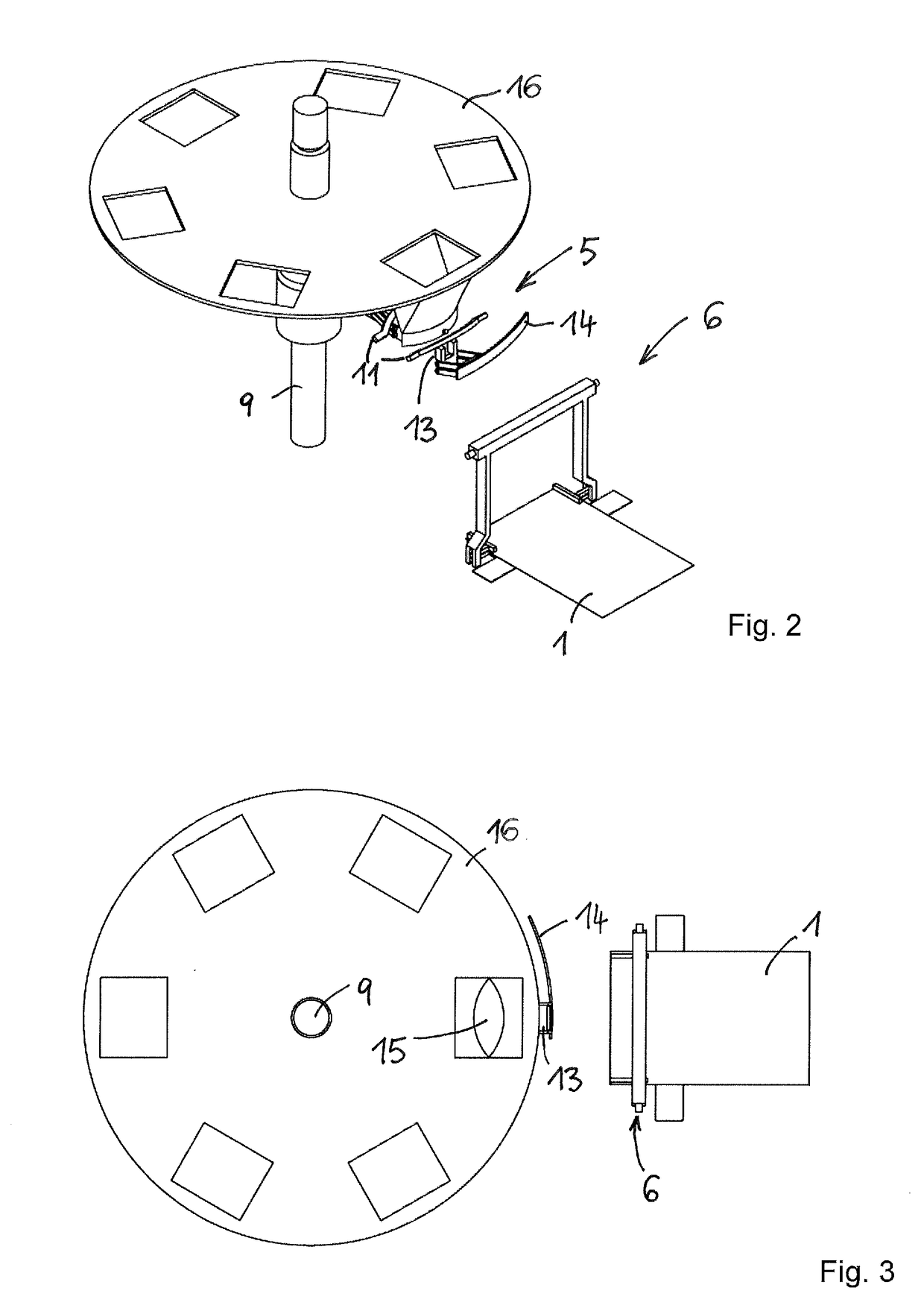

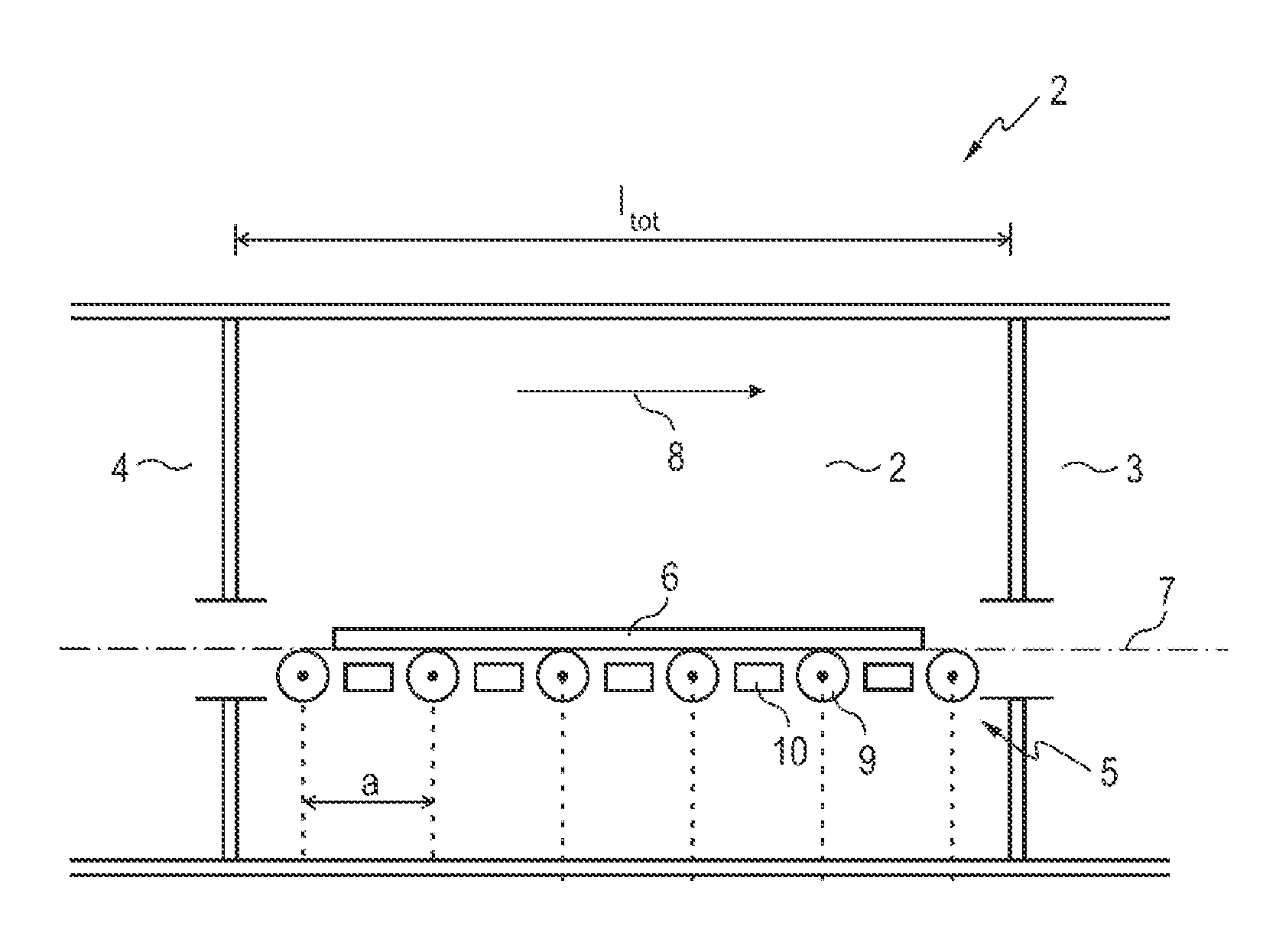

Device and method for transporting bags

ActiveUS20180215489A1Easy to open bagLess space requirementSolid materialMechanical engineeringEngineering

Owner:STATEC BINDER

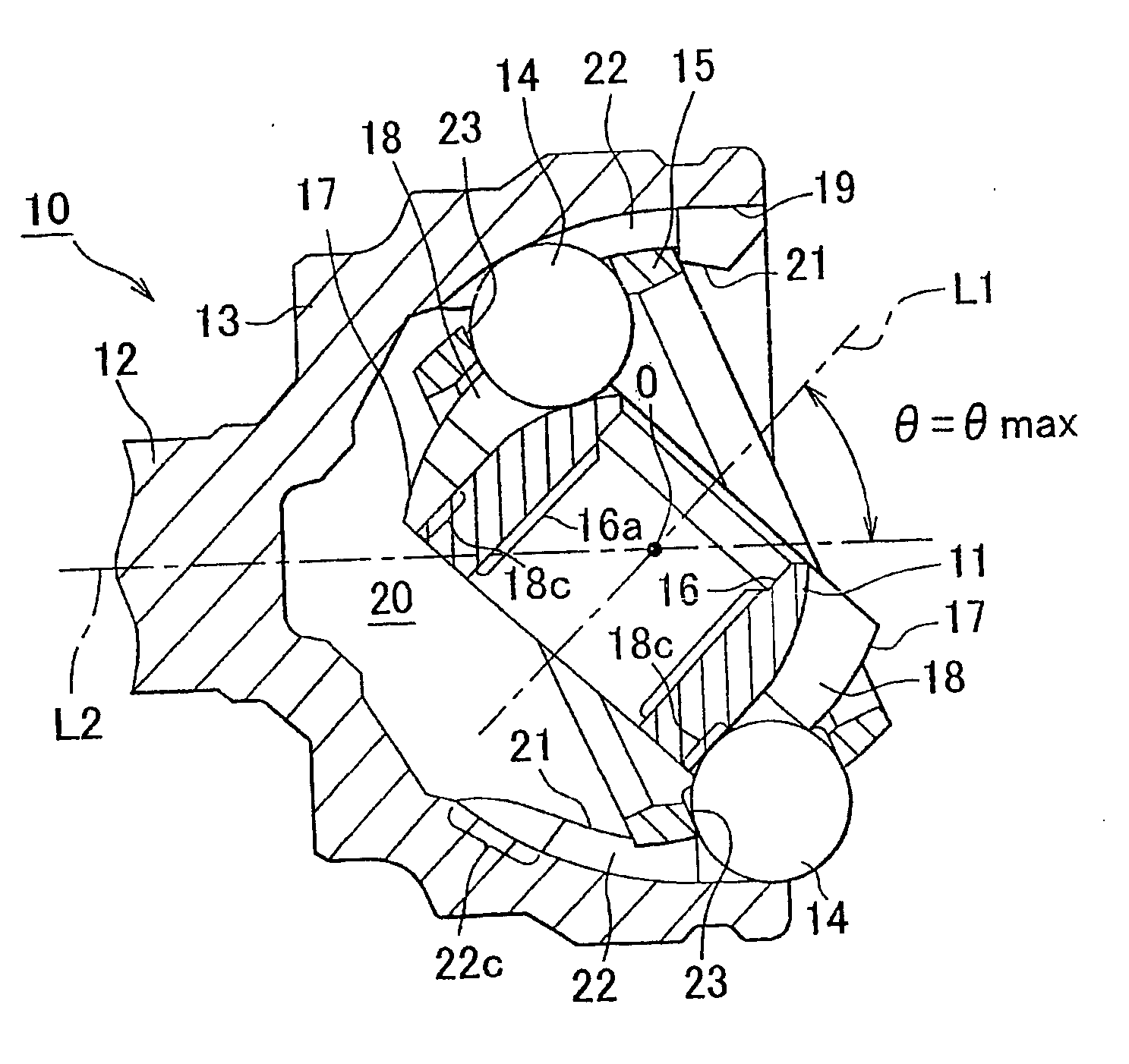

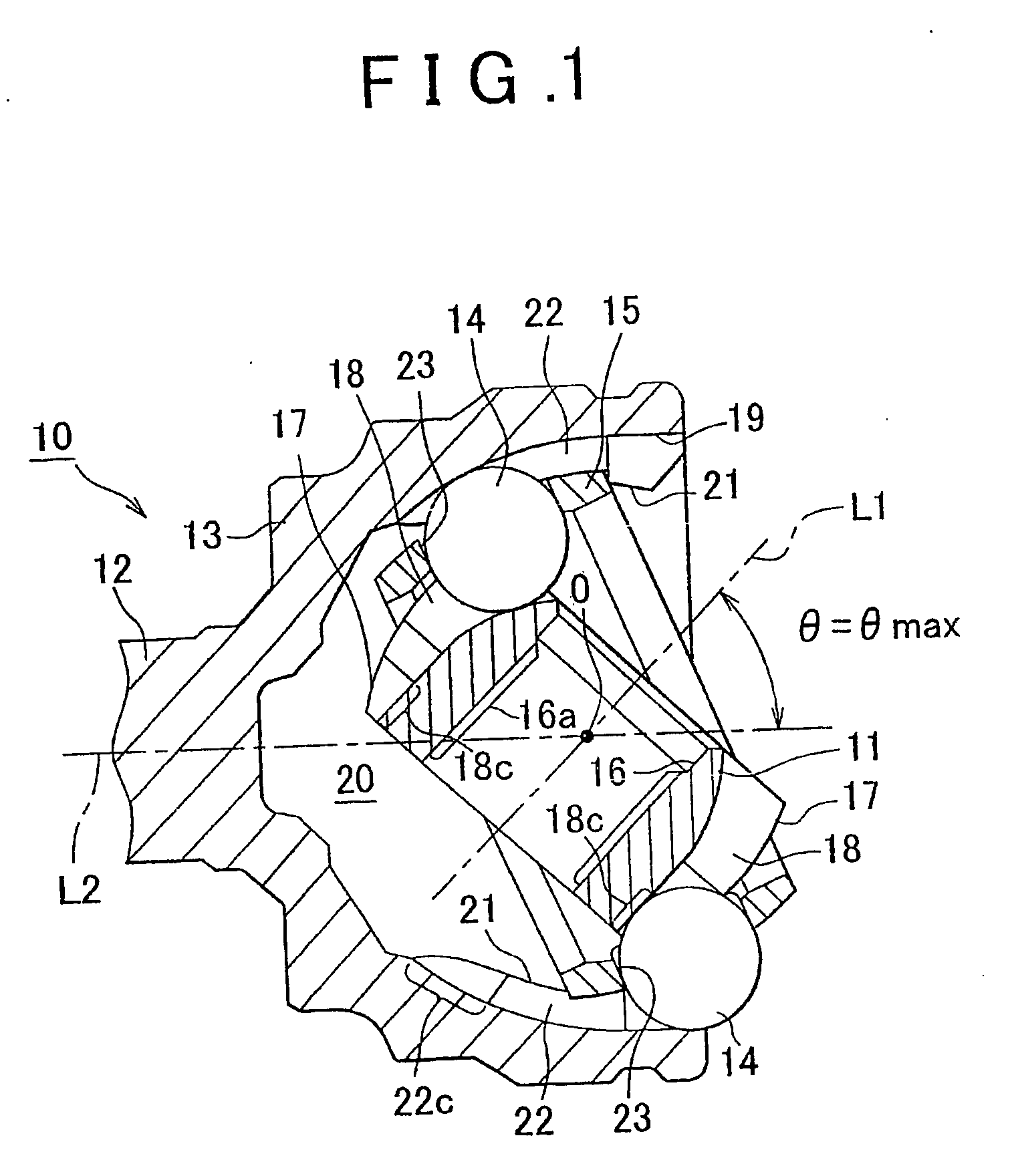

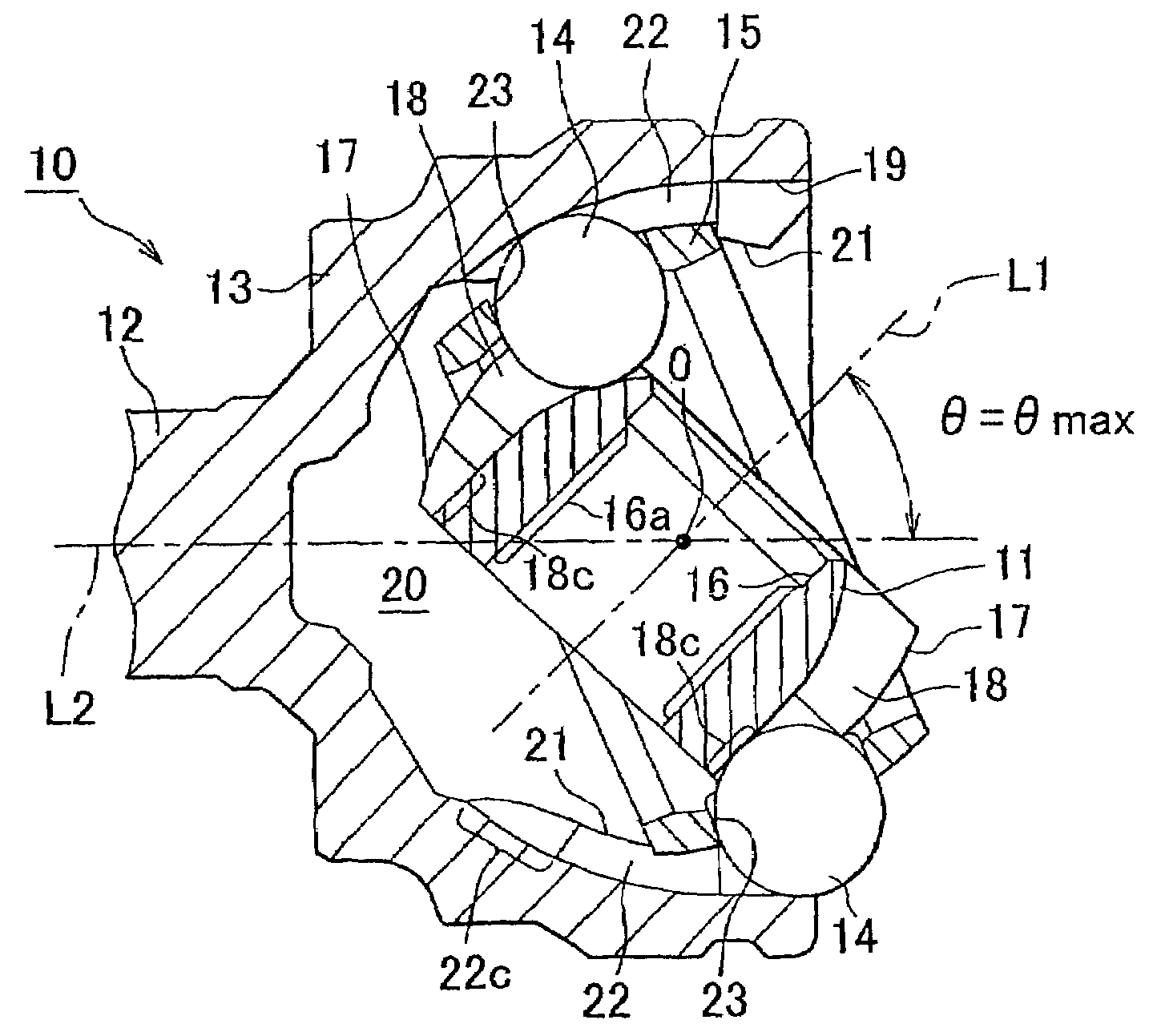

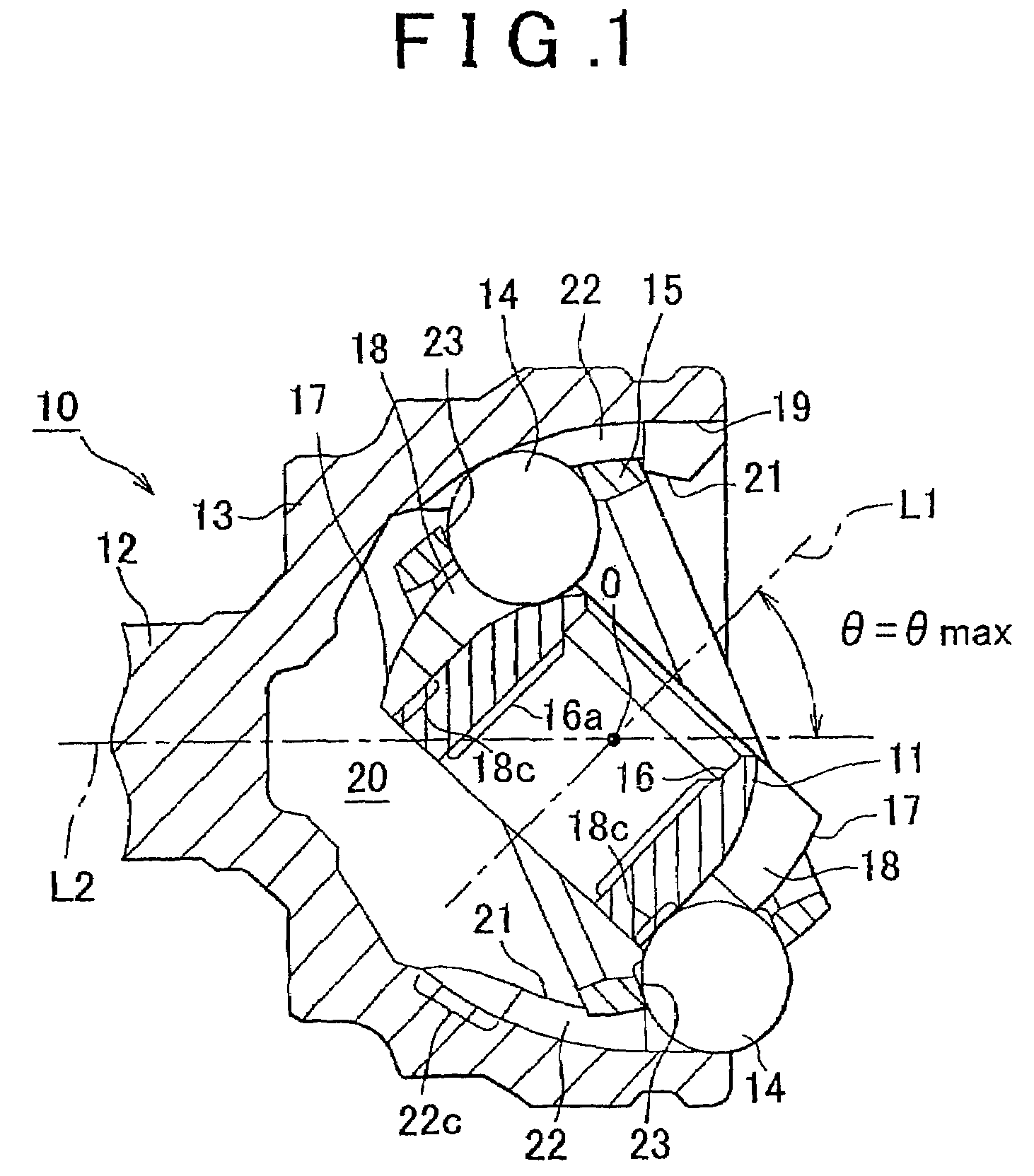

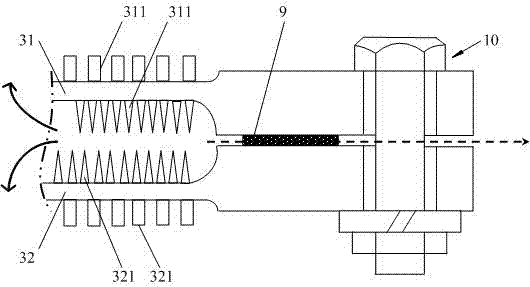

Constant velocity joint

InactiveUS20050070364A1Increased durabilityIncrease freedomYielding couplingRotary machine partsTorque transmissionEngineering

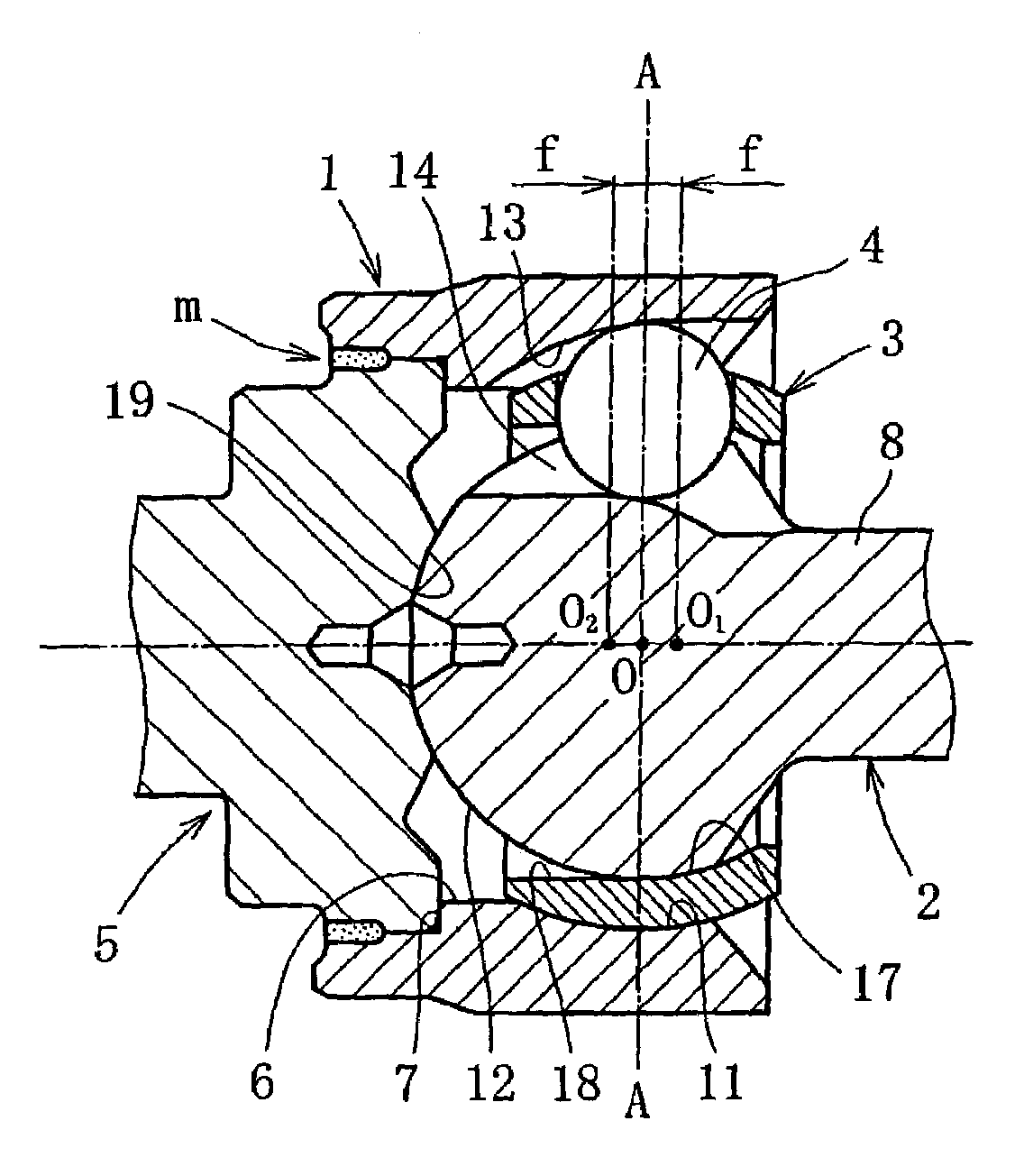

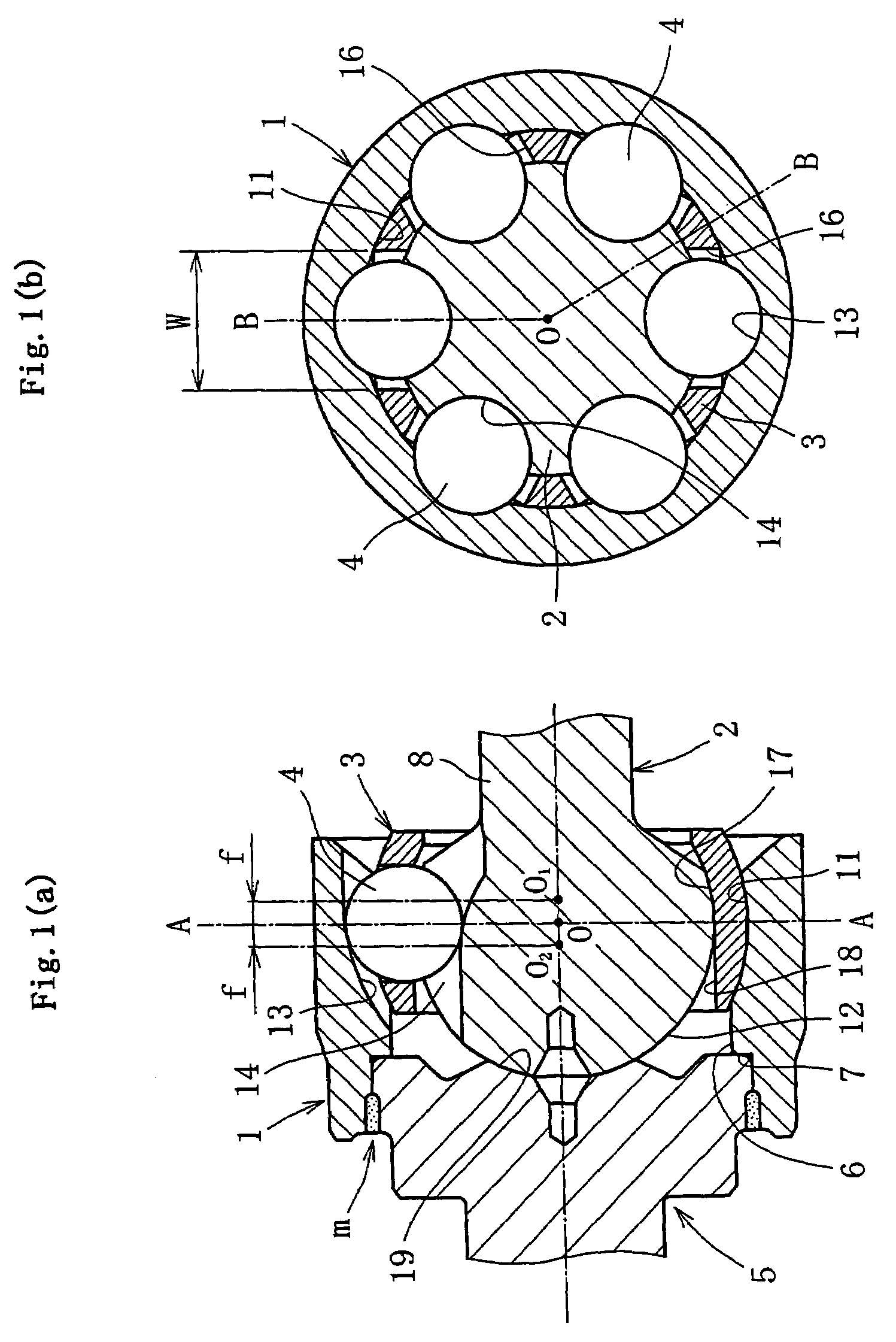

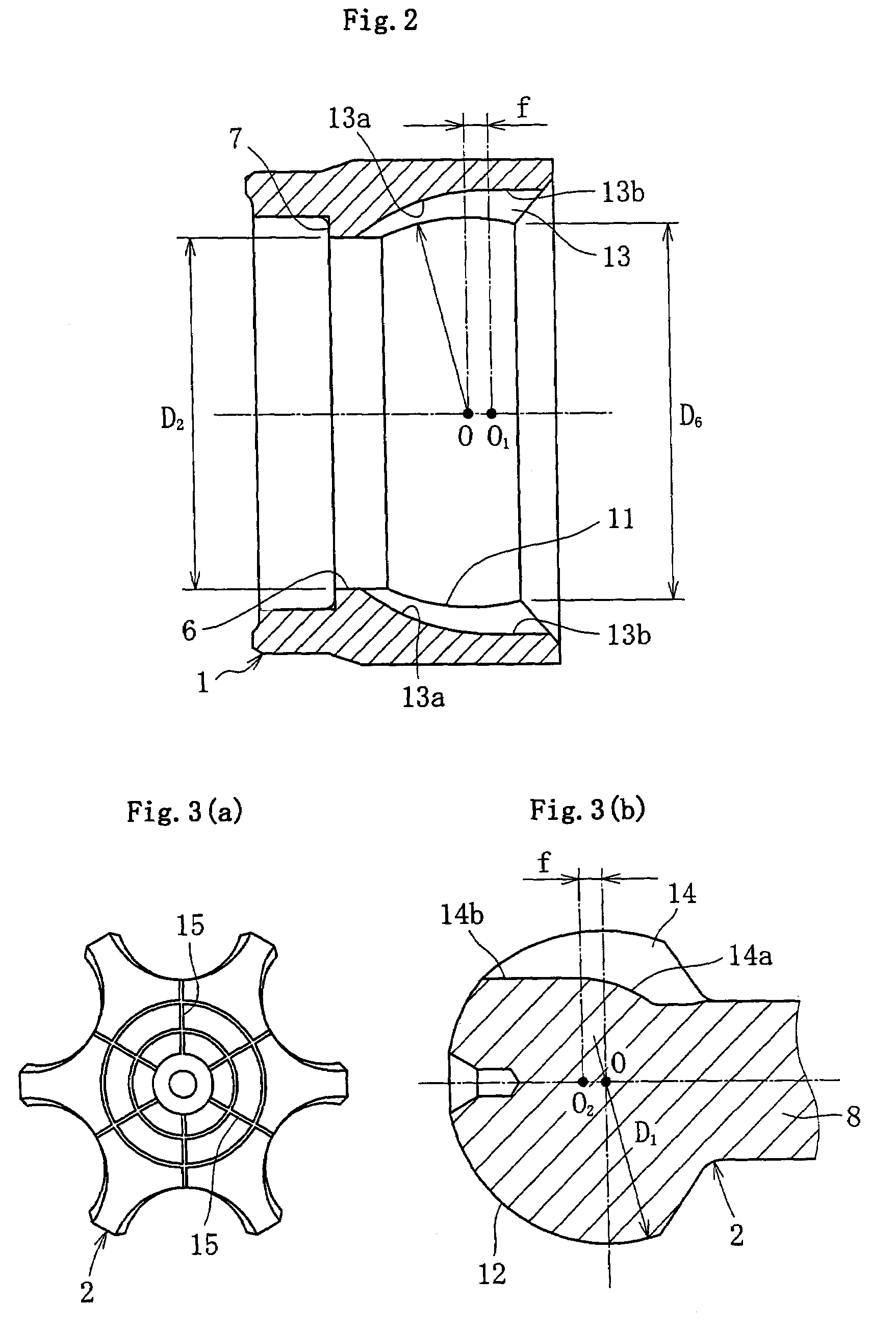

A constant velocity joint includes an outer race having a plurality of ball grooves formed in an inner spherical surface thereof, which ball grooves extend in a direction of a rotation axis of the outer race, an inner once having a plurality of ball grooves formed in an outer spherical surface thereof, which ball grooves extend in a direction of a rotation axis of the inner race and are paired with the ball grooves of the outer race, and a plurality of balls disposed between the ball grooves of the outer race and the hall grooves of the inner race. In the constant velicity joint, the hall grooves of at least one of the outer race and the inner race are partially formed wit relief profiles to provide a plurality of relief groove portions such that a load applied to each of the balls located in the relief groove portions during torque transmission between the inner race and the outer race is smaller than a load applied to each of the balls located in the other portions of the ball grooves.

Owner:TOYOTA JIDOSHA KK +1

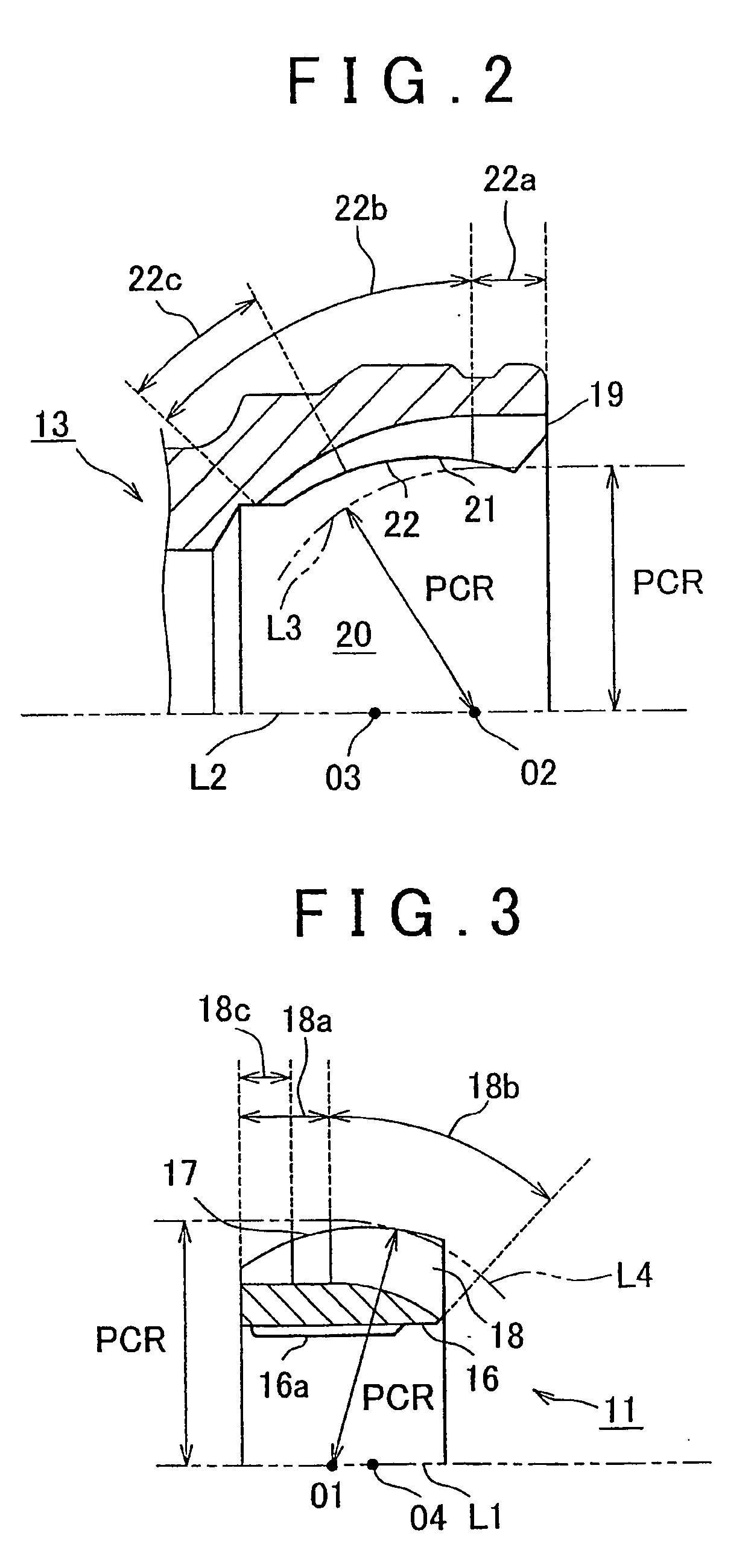

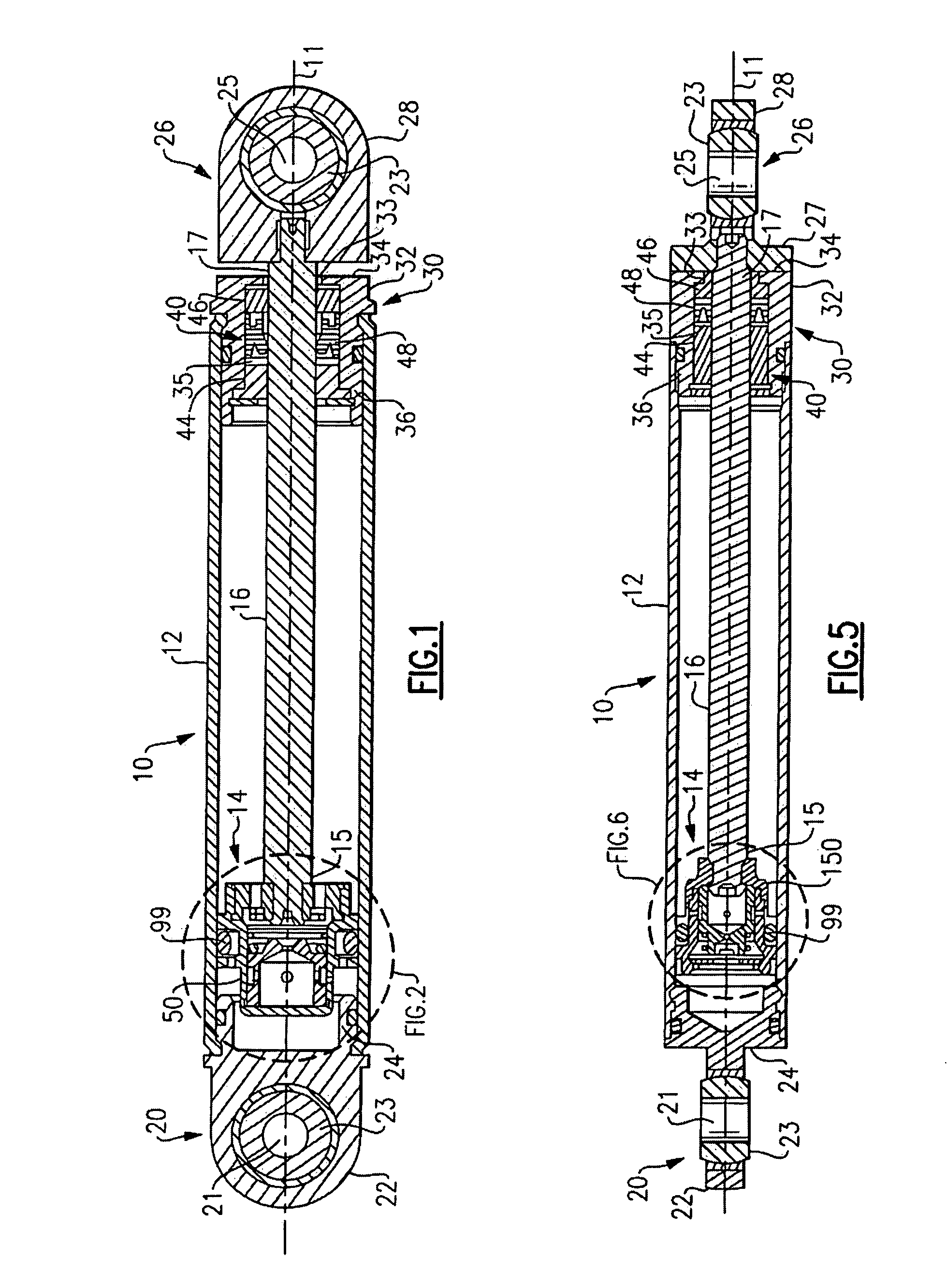

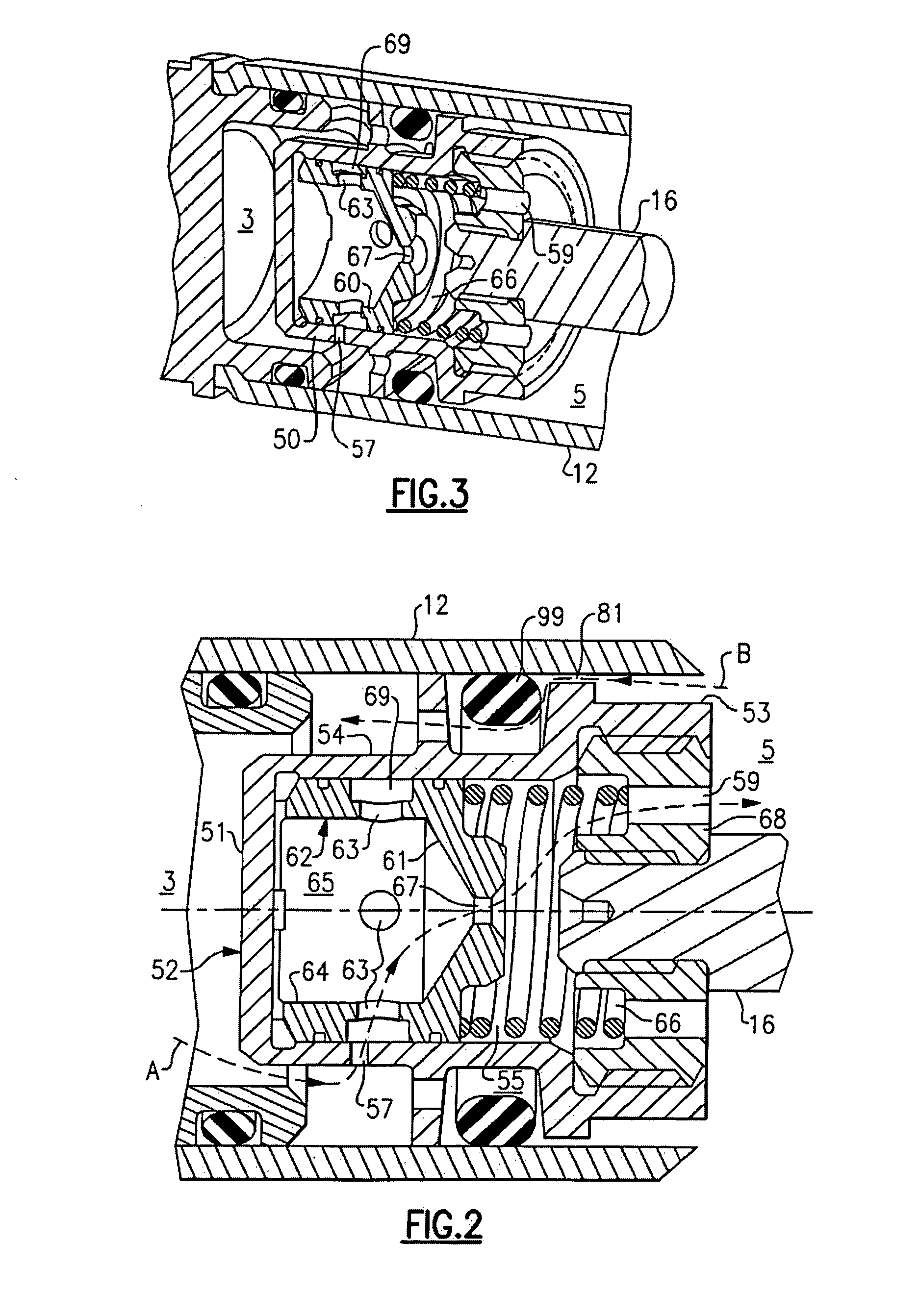

Load compensating hydraulic rate control

A rate control device includes an outer cylinder defining an interior chamber having a longitudinal axis and containing a hydraulic fluid. A piston head mounted to a proximal end or a piston rod is slidably positionable within the interior chamber. A rate control valve is disposed within an interior cavity of the piston head coaxially with the longitudinal axis of the interior chamber of the cylinder. The rate control valve includes a variable flow rate orifice and a fixed flow rate orifice disposed in series relationship with respect to fluid flow through the rate control valve.

Owner:ITT ENIDINE

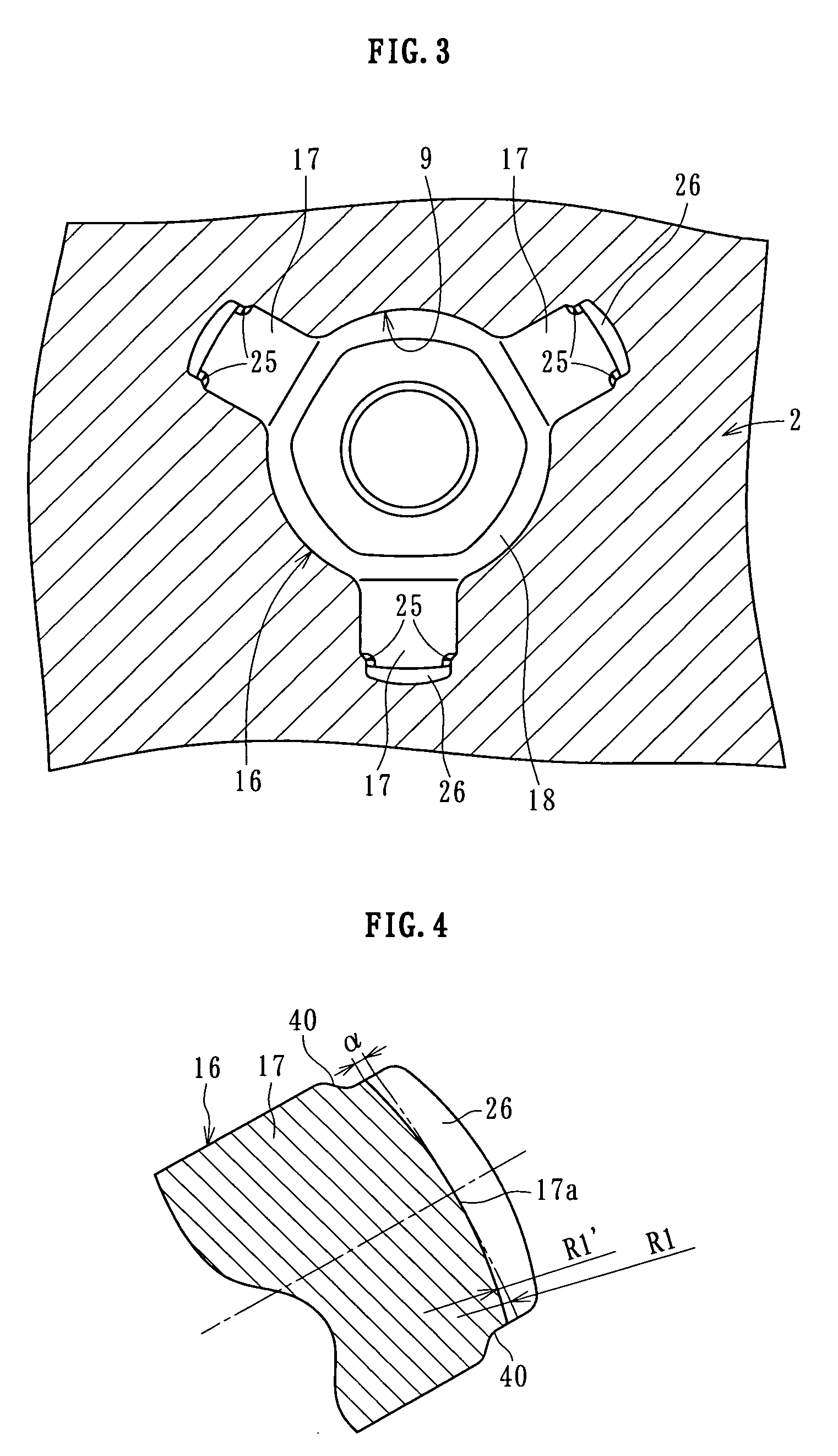

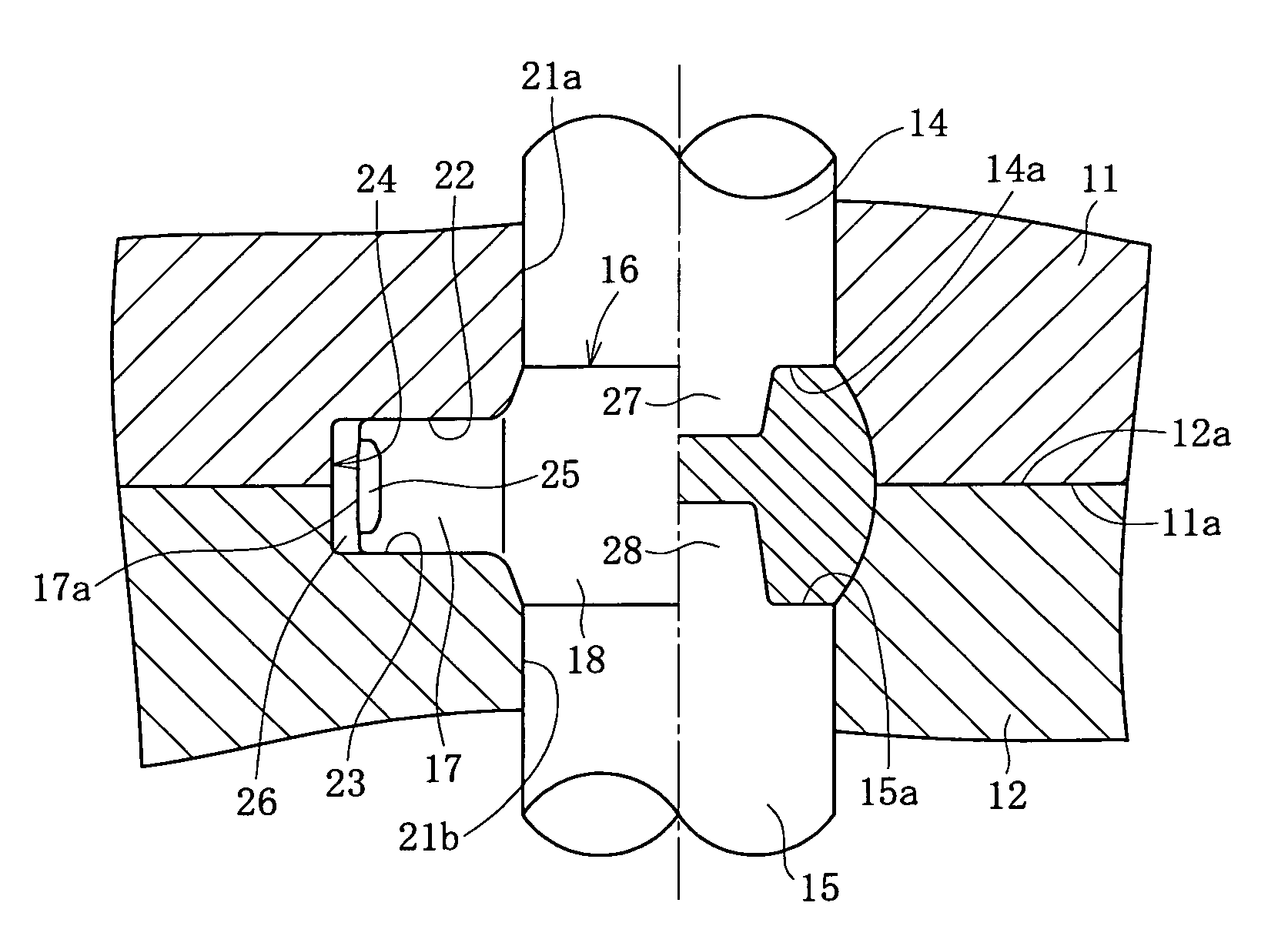

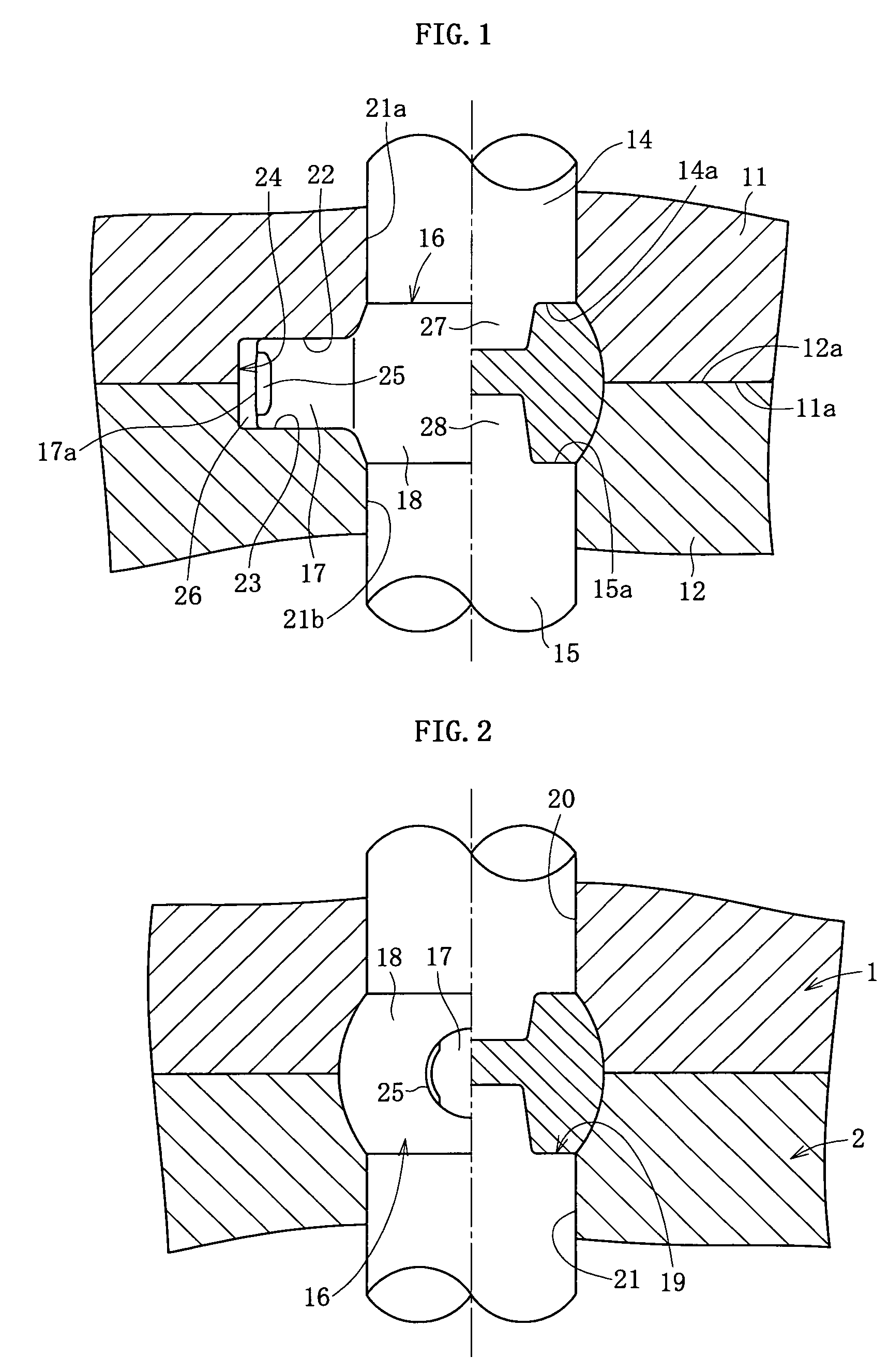

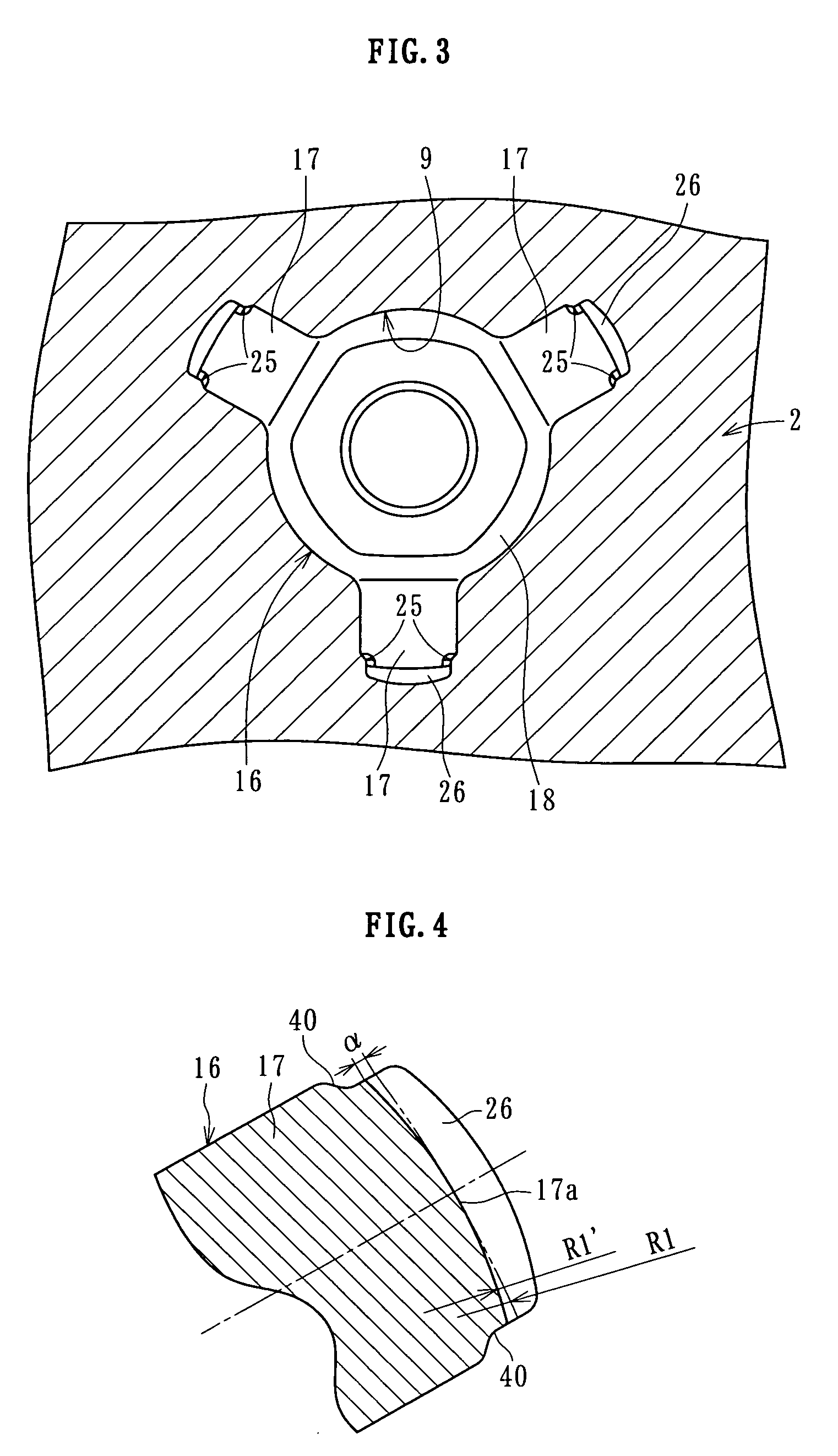

Closed forging die and forging method

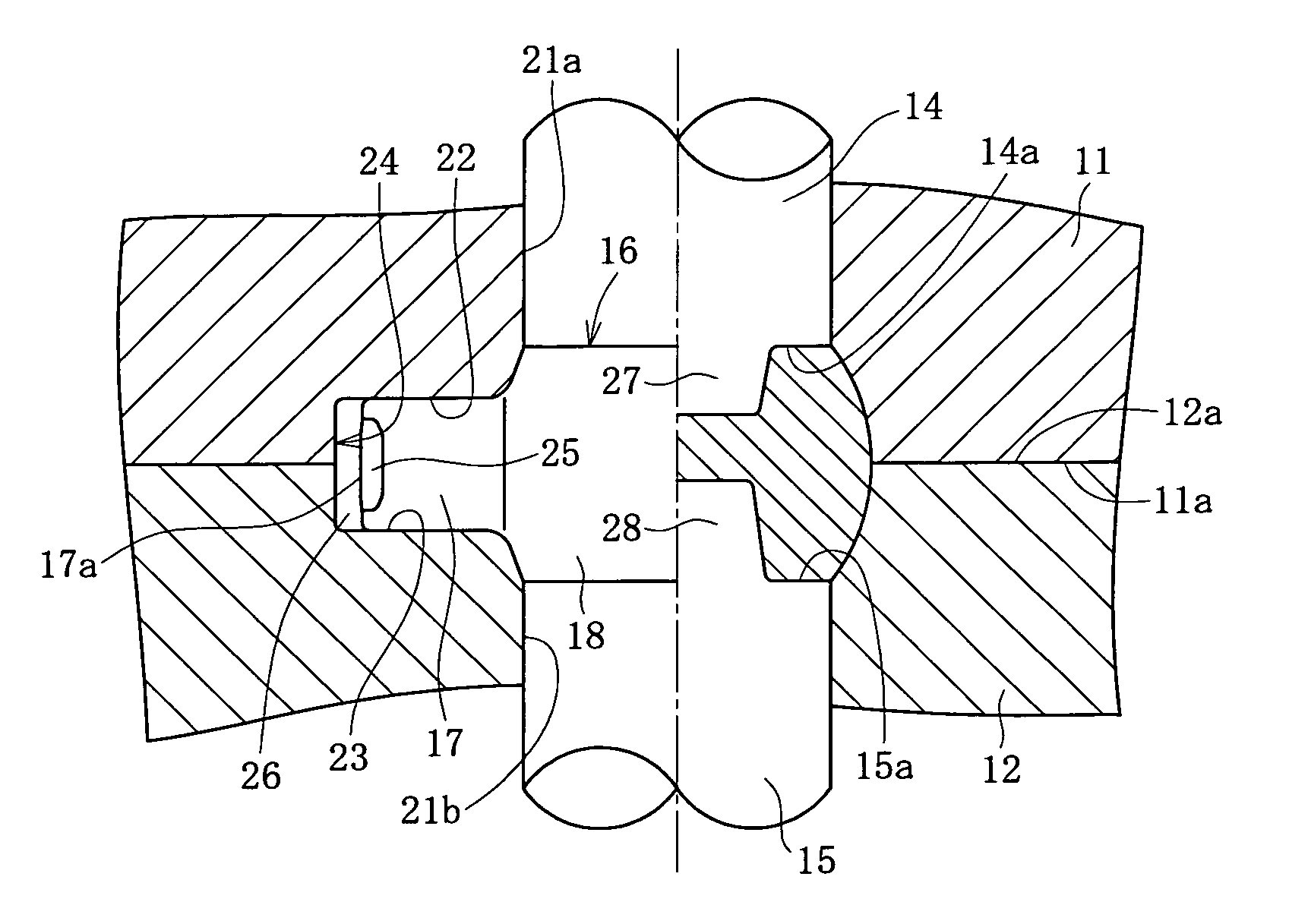

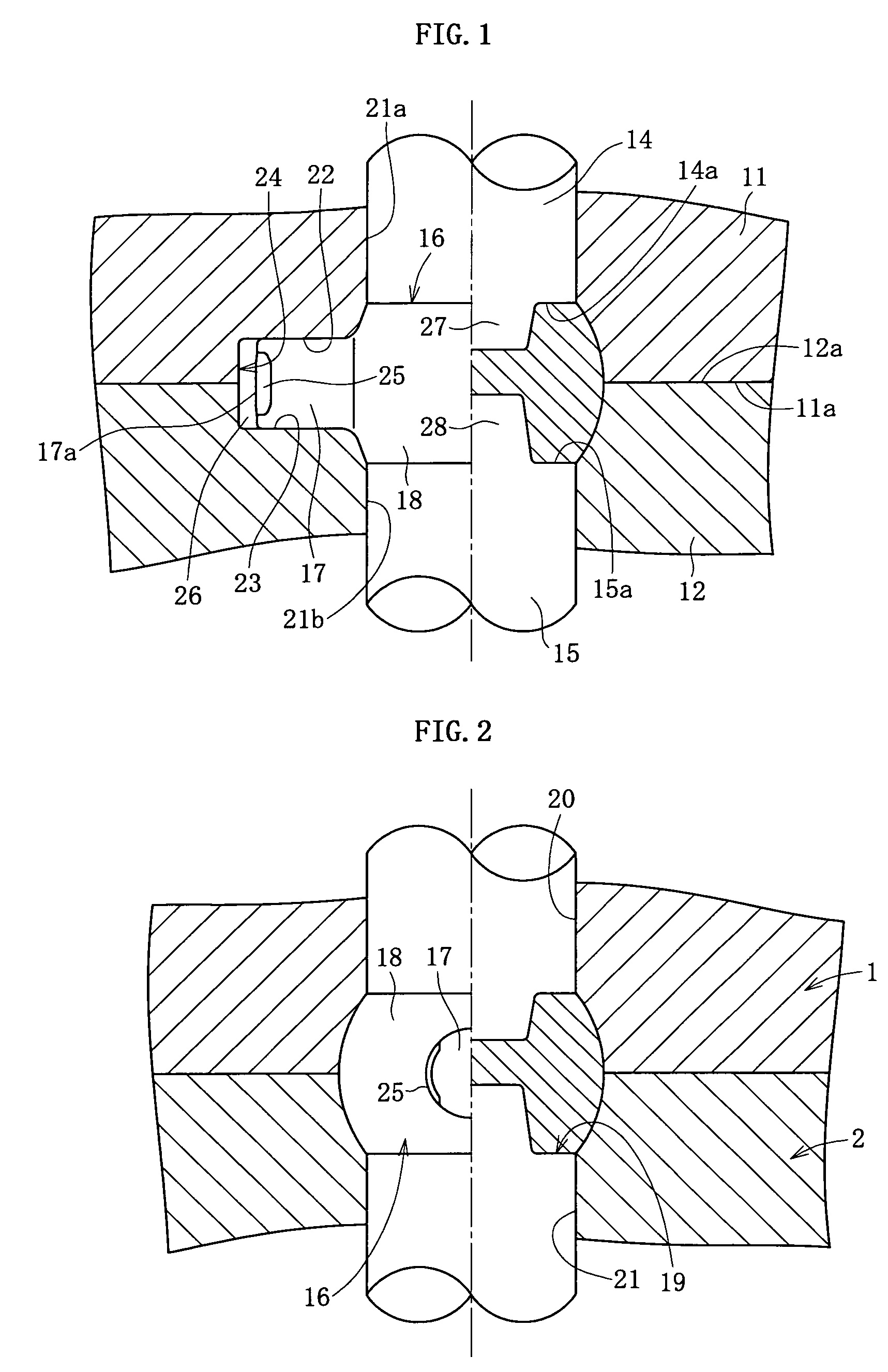

ActiveUS20080184765A1Speed up the flowReduce saggingForging/hammering/pressing machinesEngine componentsUniversal jointEngineering

The present invention provides a closed forging die and a forging method with which sagging can be reduced, a constant velocity joint and a universal joint can be made compact and lightweight, remove of a shaft tip thereof by machining prior to heat treatment is not required, and material costs and machining costs can be reduced. The closed forging die according to the present invention includes openable dies (11, 12), and punches (14, 15) that move in an opening / closing direction of the dies (11, 12) to pressurize a material in the dies (11, 12). By using the die, a product (16) having shaft portions (17) formed radially is manufactured. A clearance (26) is provided to each of the formed shaft portions (17) between a tip surface (17a), and abutting portions (25) are provided to the dies side abutting against at least a tip side of an outer circumferential surface of the shaft portions (17).

Owner:NTN CORP

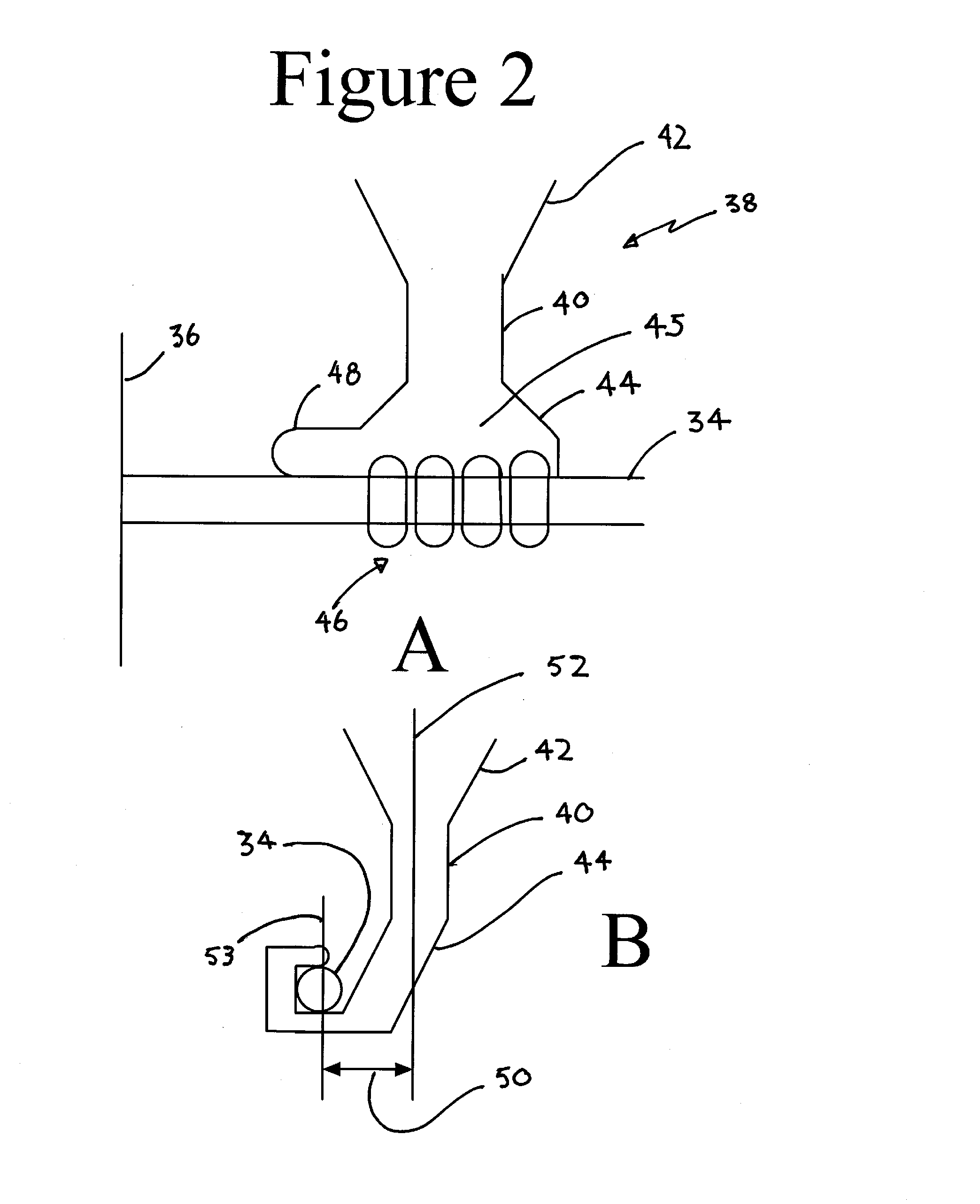

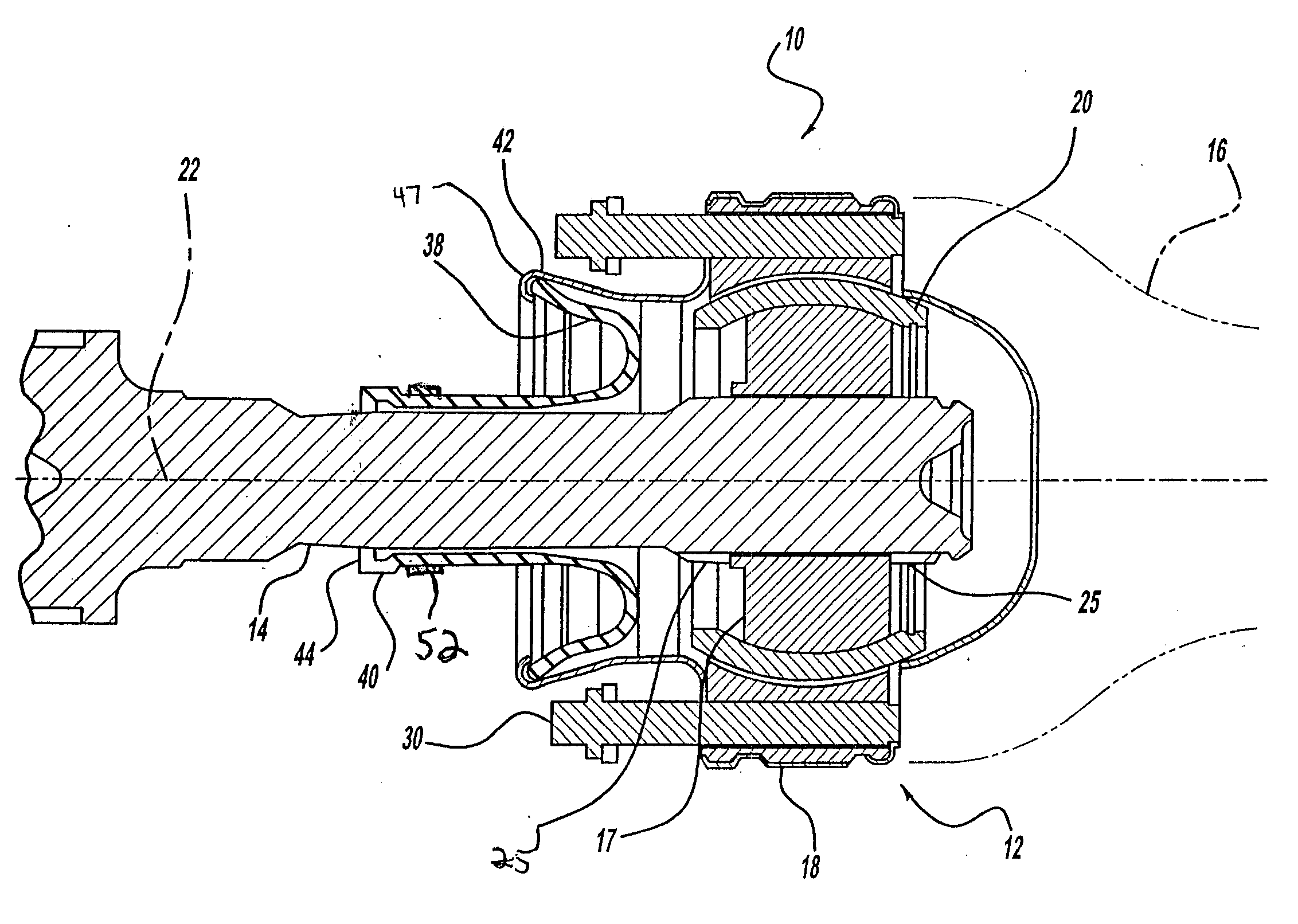

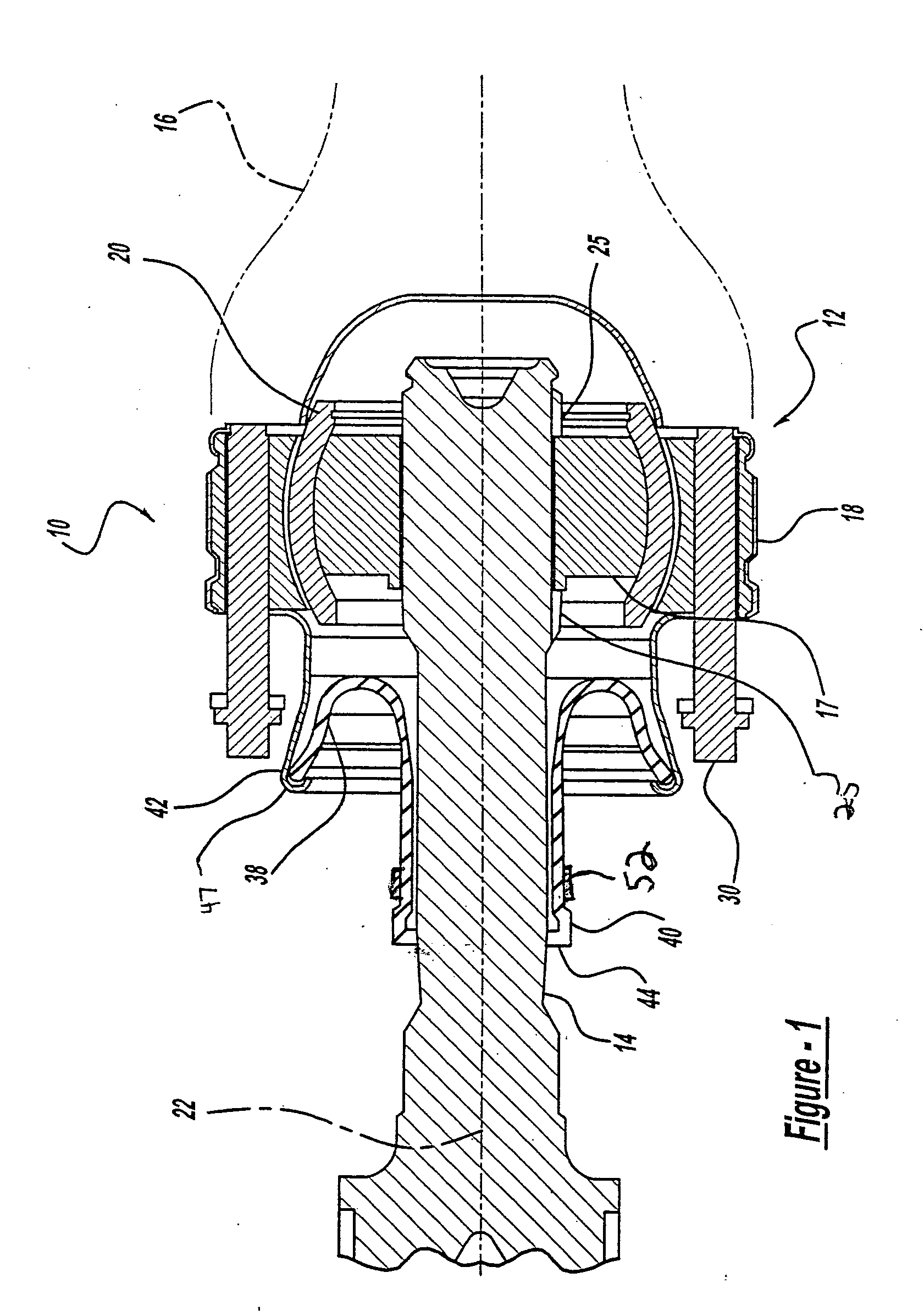

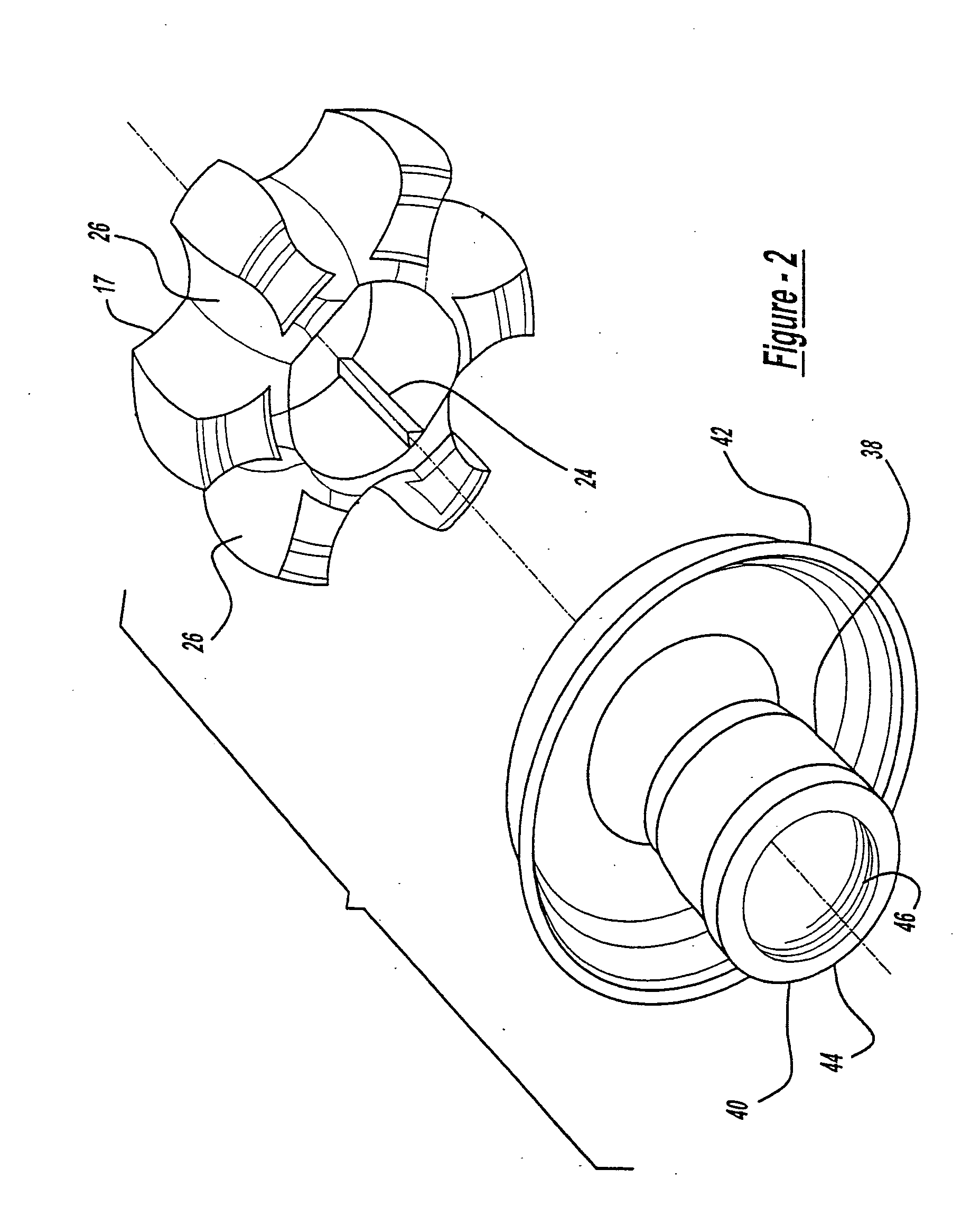

Constant velocity joint assembly and sealing boot

InactiveUS20050051972A1Improve sealingConstant velocityEngine sealsYielding couplingJoint componentEngineering

Owner:GKN AUTOMOTIVE INC

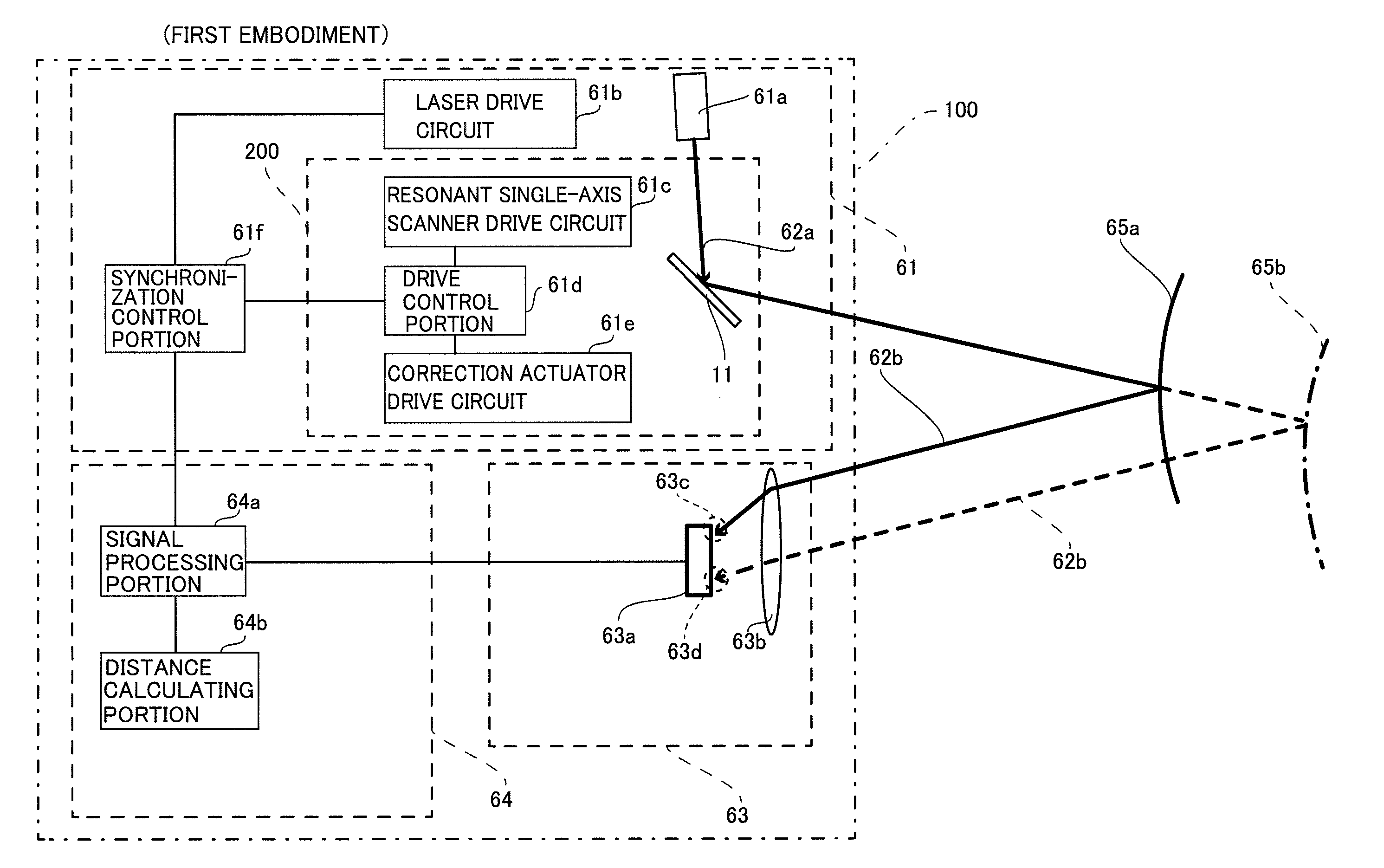

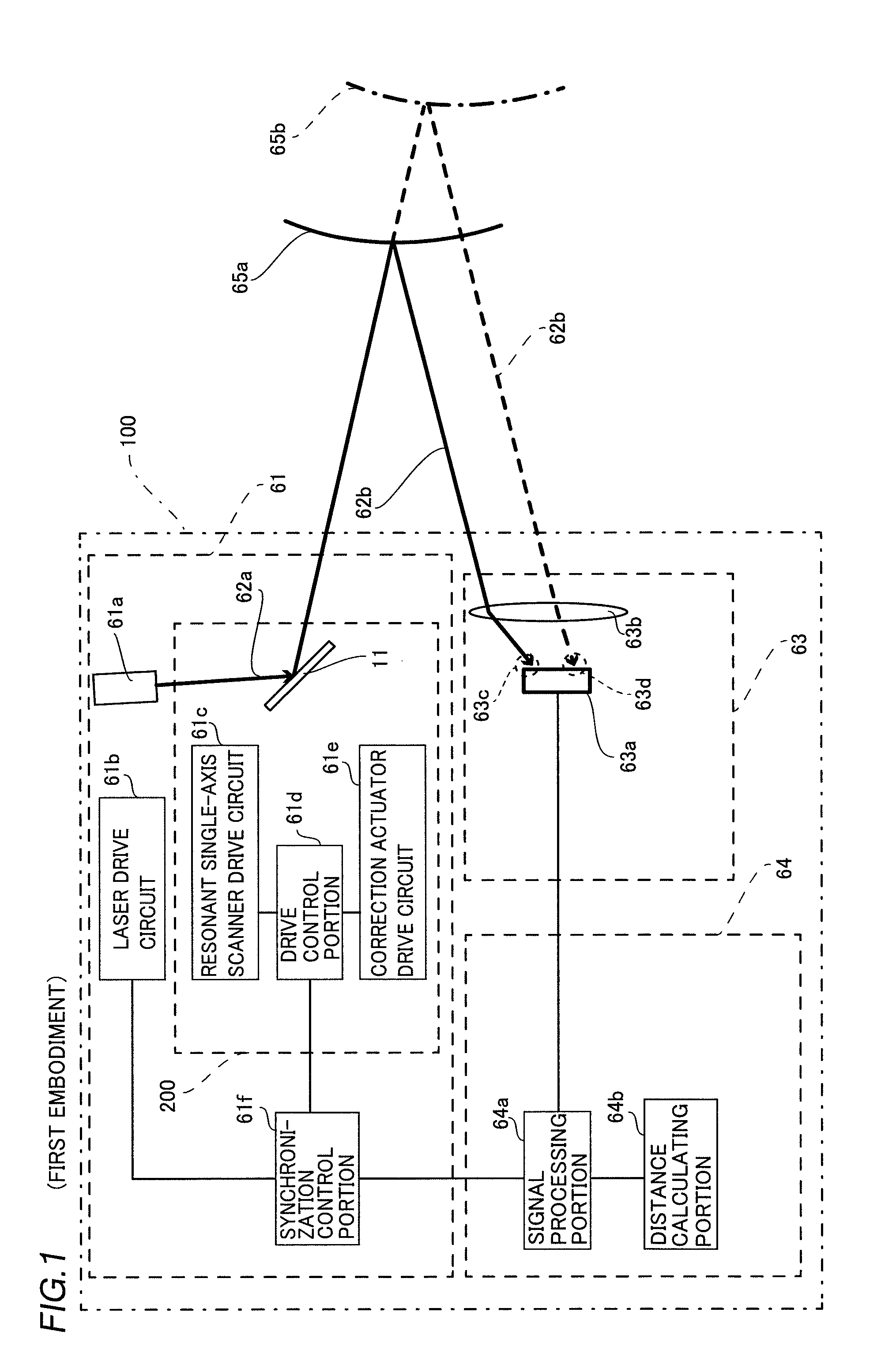

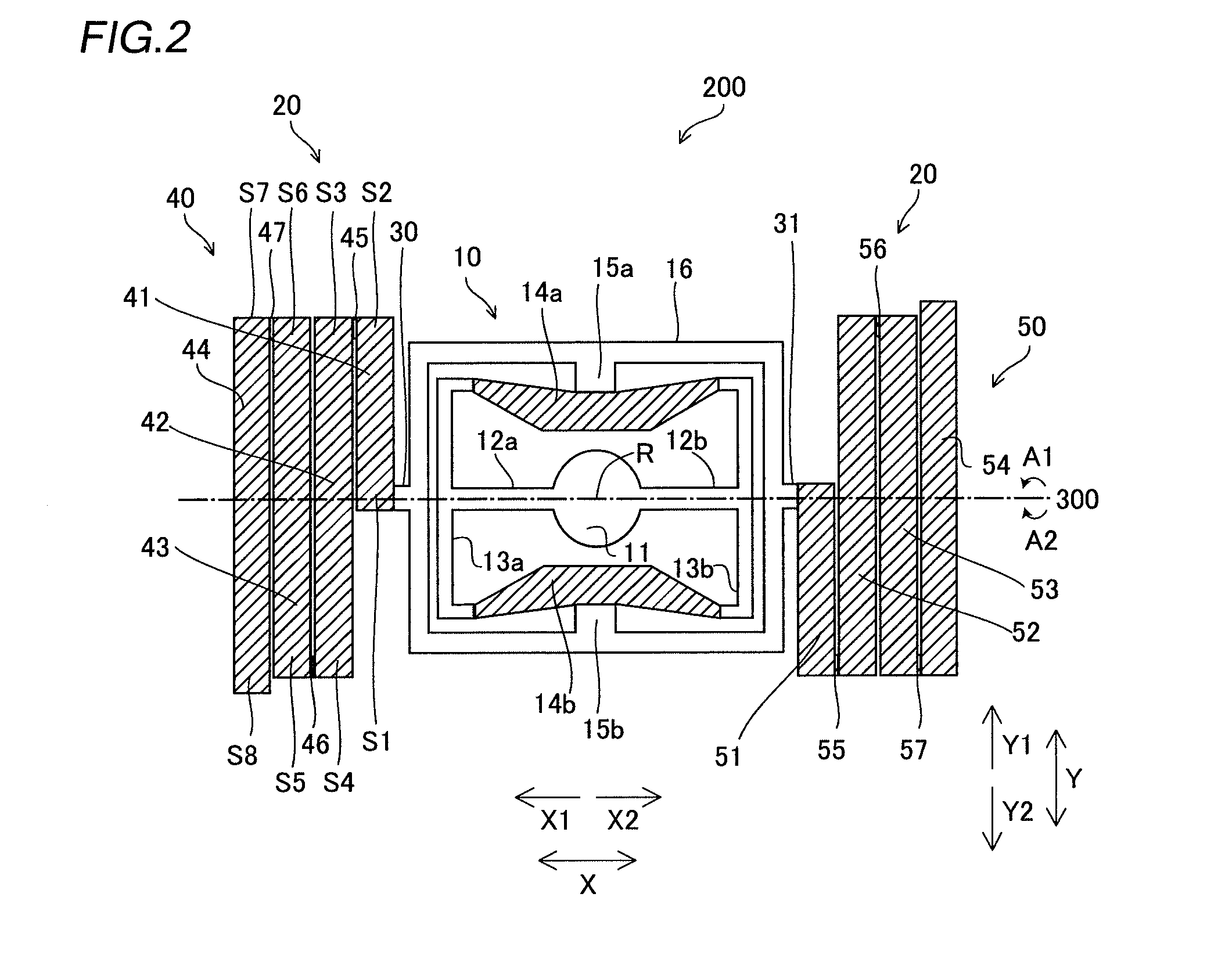

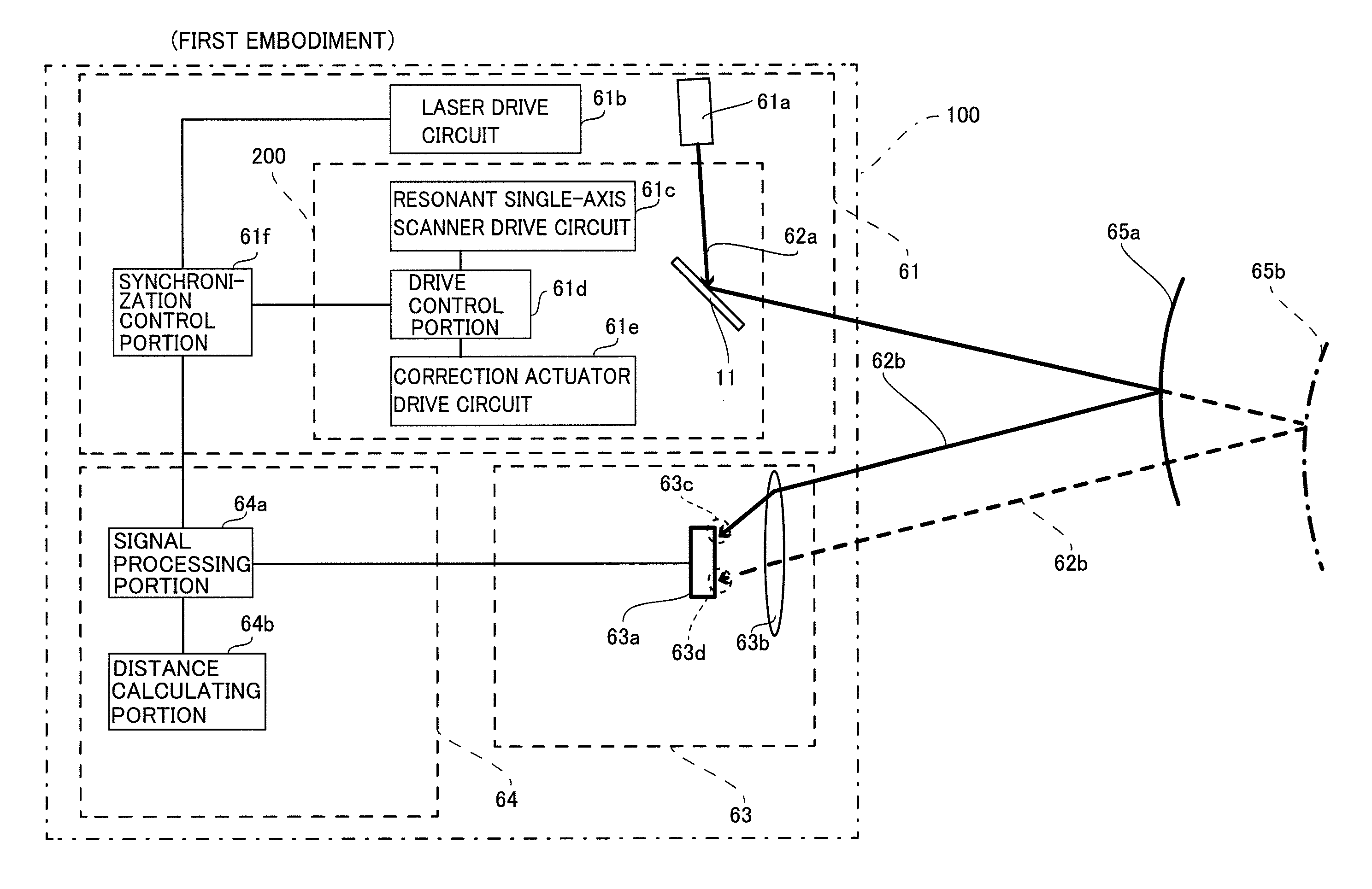

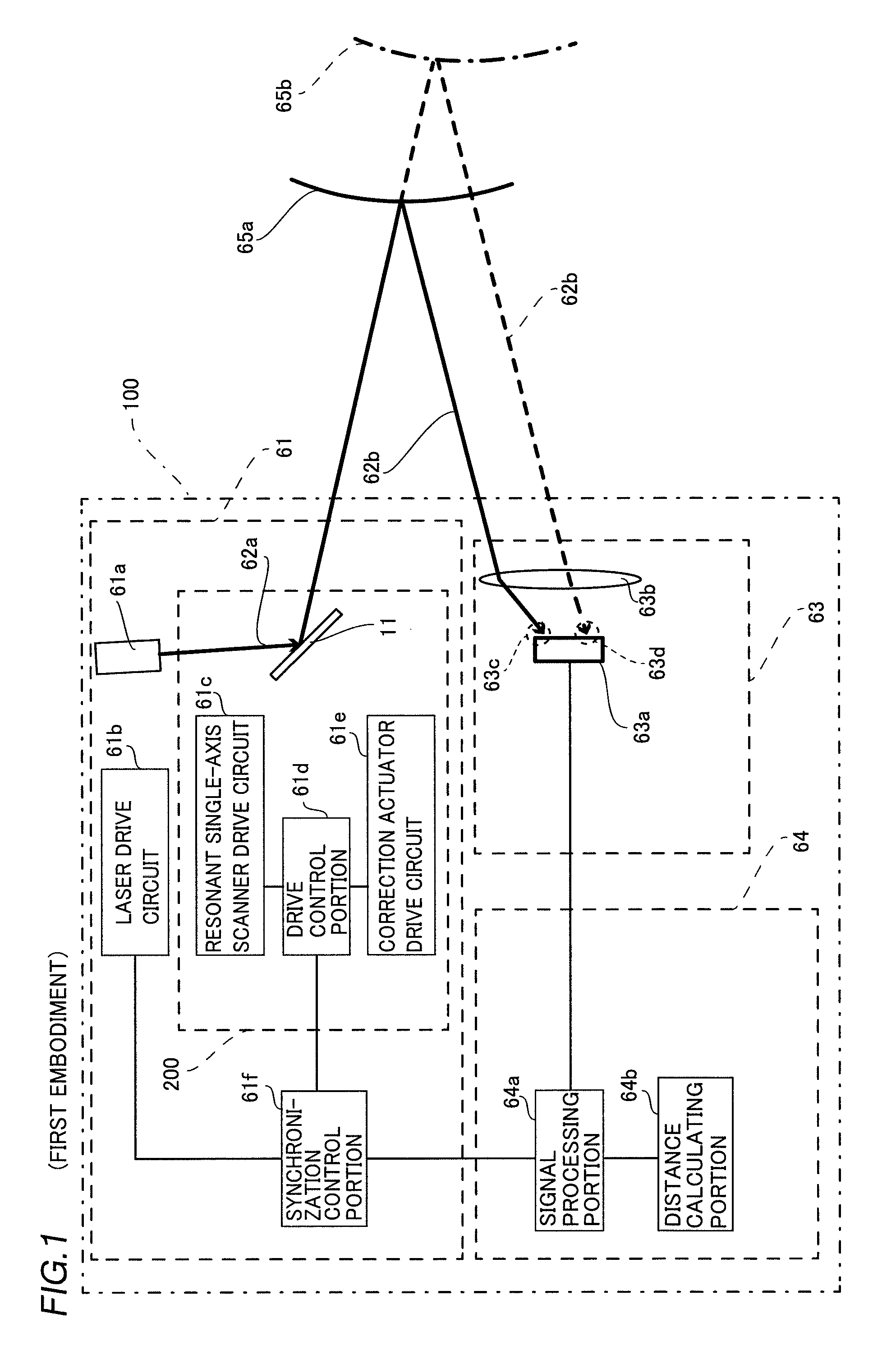

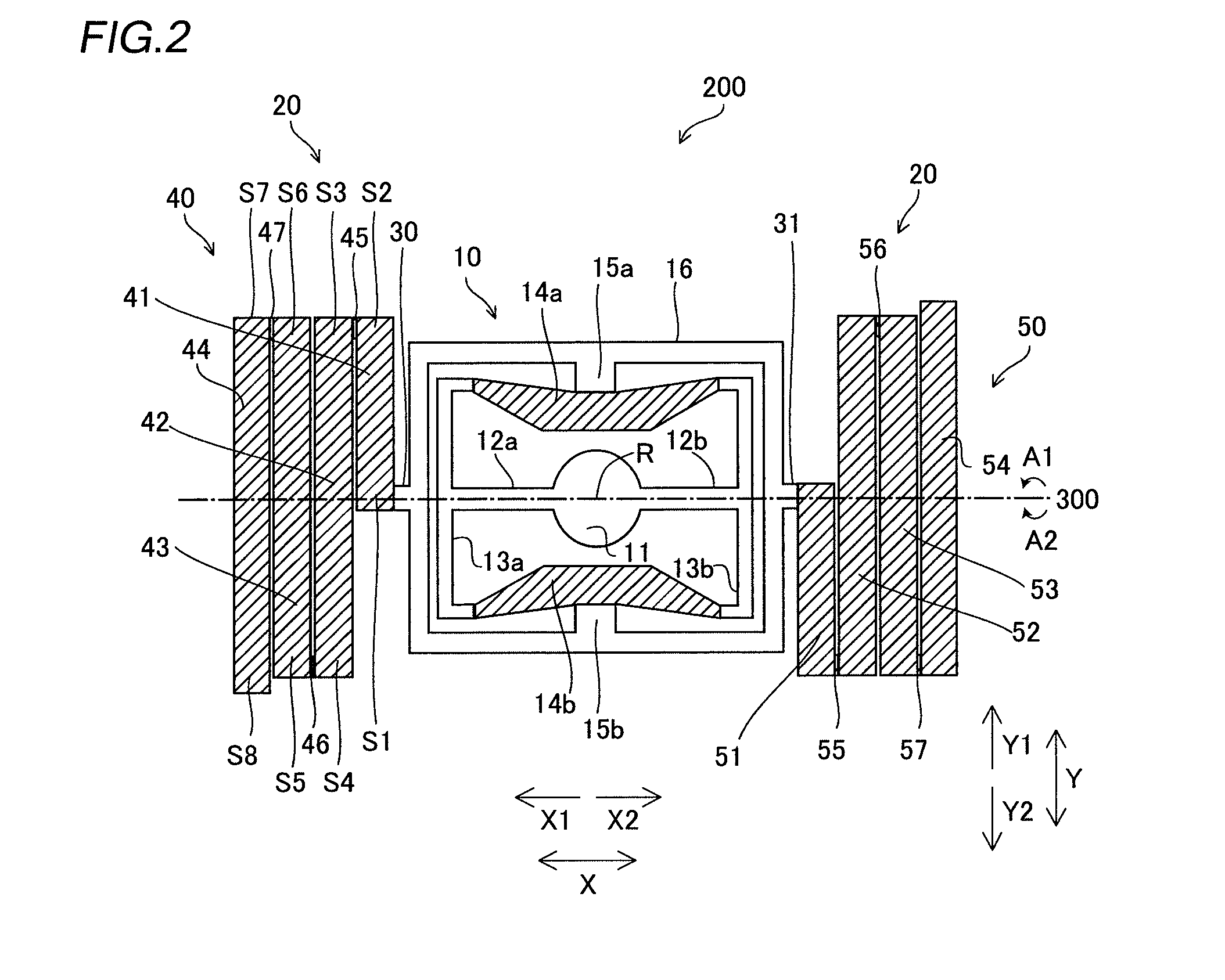

Vibrating Mirror Element, Distance Measuring Apparatus, and Projector

InactiveUS20150021483A1Simple structureIncrease freedomRadiation pyrometryMaterial analysis by optical meansTurn angleResonance

A vibrating mirror element includes a drive control portion configured to control the driving of a correction drive portion to keep the turning angle velocity of a mirror portion substantially constant by oscillating the mirror portion about an axis at a non-resonance frequency in a direction opposite to a direction in which a resonant drive portion oscillates the mirror portion.

Owner:FUNAI ELECTRIC CO LTD

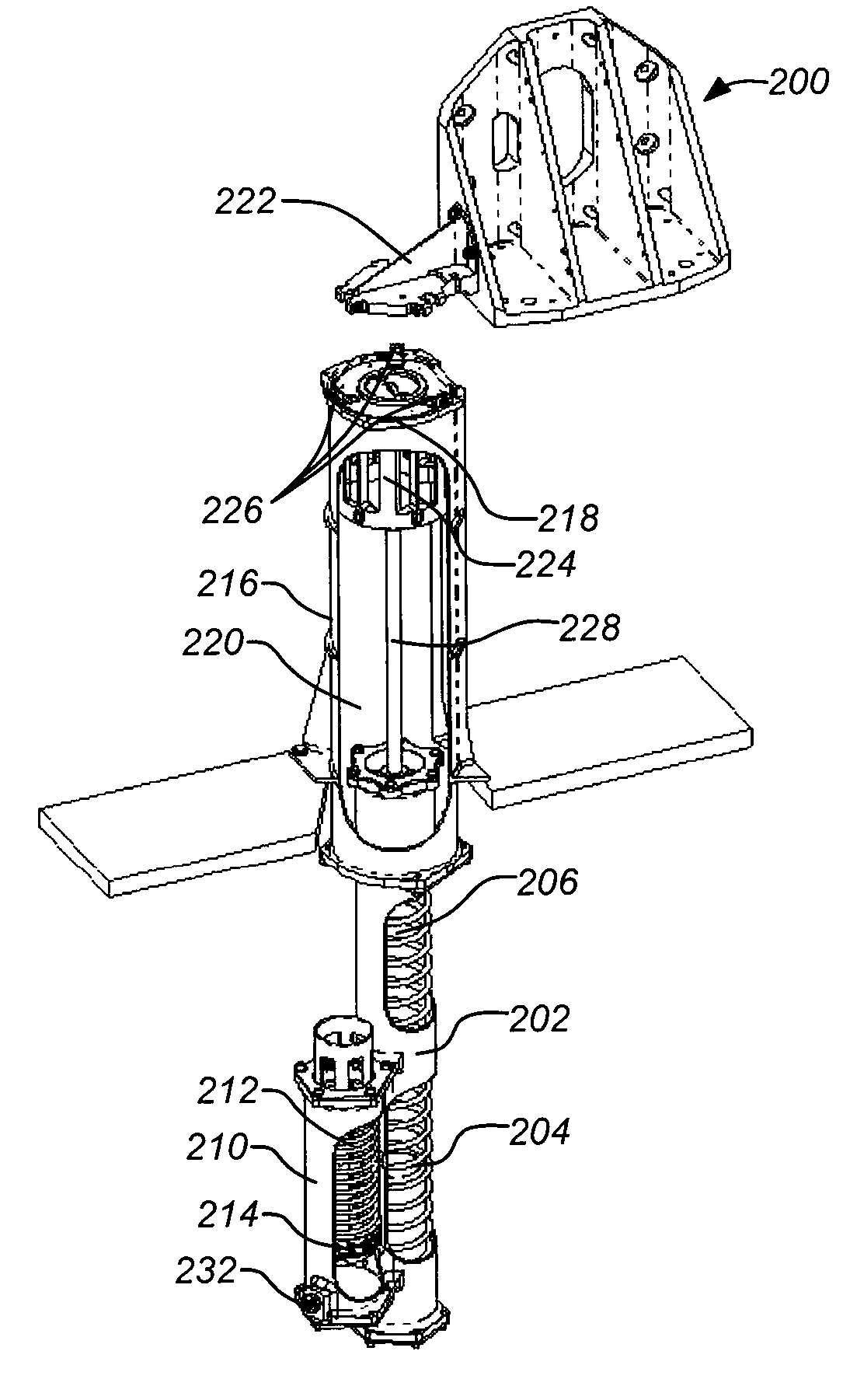

Spacecraft low tumble linear release system

ActiveUS20080290222A1Constant velocityCosmonautic vehiclesLaunching/towing gearLinear actuatorPiston

Systems and methods for releasing a spacecraft payload at a substantially constant velocity are disclosed. A linear actuator is used that includes a spring loaded and fluid filled chamber. The spring drives against a piston within the chamber that includes a control orifice that restricts the fluid flowing from one side of the piston to the other and results in a substantially constant damped motion of the piston. The piston drives a rod from the chamber that is attached to a capture device that holds a flange of the spacecraft payload. The capture device moves along a linear guide toward an open end. Spring loaded latches are held in a closed position by the side walls of the guide as the capture device moves. The latches release the flange as exit the open end of the guide.

Owner:THE BOEING CO

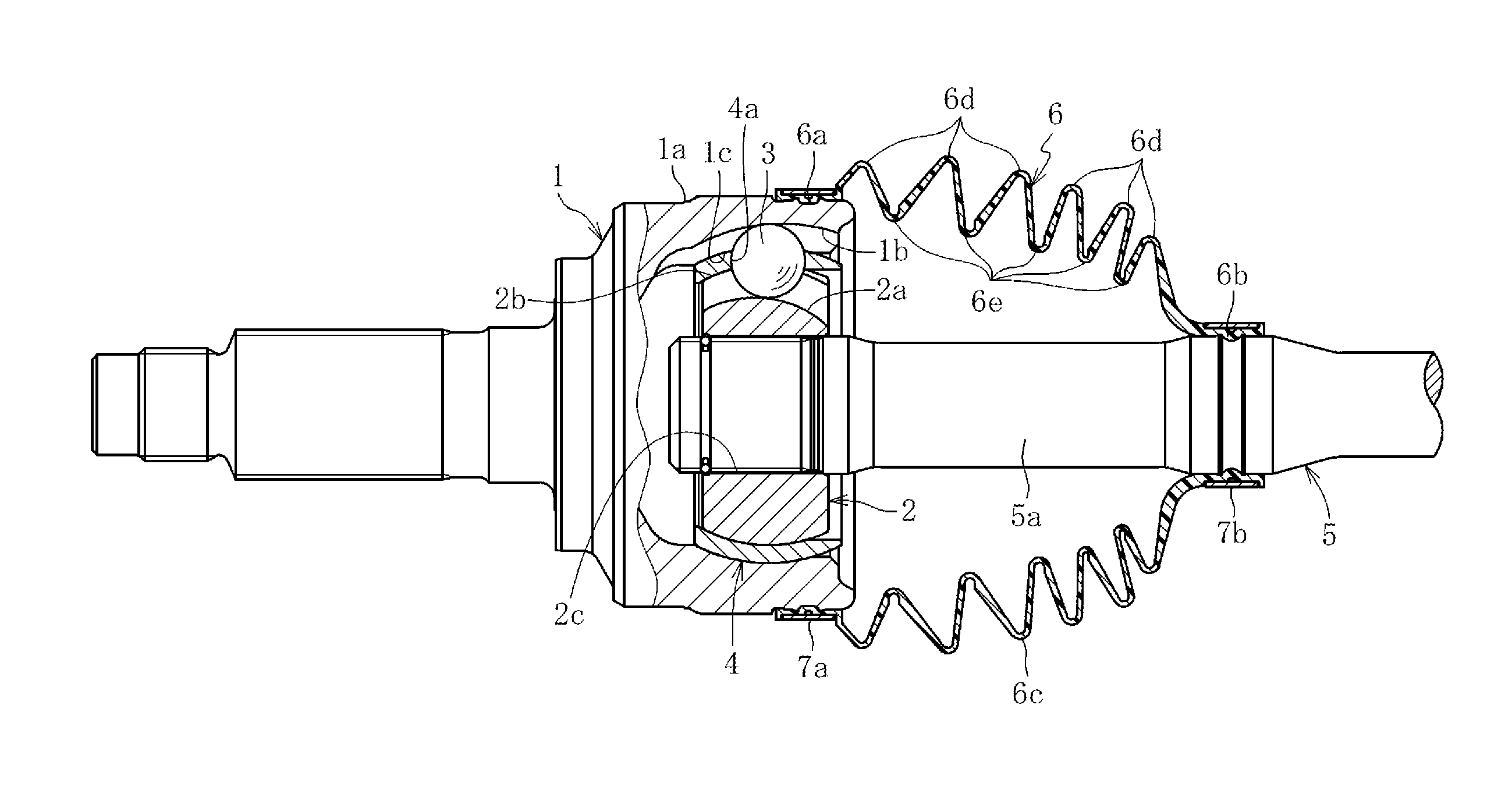

Constant velocity joint

InactiveUS7407441B2Increased durabilityIncreasing sizeYielding couplingRotary machine partsTorque transmissionEngineering

A constant velocity joint includes an outer race having a plurality of ball grooves formed in an inner spherical surface thereof, which ball grooves extend in a direction of a rotation axis of the outer race, an inner once having a plurality of ball grooves formed in an outer spherical surface thereof, which ball grooves extend in a direction of a rotation axis of the inner race and are paired with the ball grooves of the outer race, and a plurality of balls disposed between the ball grooves of the outer race and the ball grooves of the inner race. In the constant velicity joint, the ball grooves of at least one of the outer race and the inner race are partially formed with relief profiles to provide a plurality of relief groove portions such that a load applied to each of the balls located in the relief groove portions during torque transmission between the inner race and the outer race is smaller than a load applied to each of the balls located in the other portions of the ball grooves.

Owner:TOYOTA JIDOSHA KK +1

Closed forging die and forging method

ActiveUS7900493B2Sagging can be reducedConstant velocityForging/hammering/pressing machinesEngine componentsUniversal jointEngineering

A closed forging die and a forging method with which sagging can be reduced, a constant velocity joint and a universal joint can be made compact and lightweight, removal of a shaft tip thereof by machining prior to heat treatment is not required, and material costs and machining costs can be reduced by using a closed forging die includes openable dies, and punches that move in an opening / closing direction of the dies to pressurize a material in the dies. By using the die, a product having shaft portions formed radially is manufactured. A clearance is provided to each of the formed shaft portions between a tip surface, and abutting portions are provided to the dies side abutting against at least a tip side of an outer circumferential surface of the shaft portions.

Owner:NTN CORP

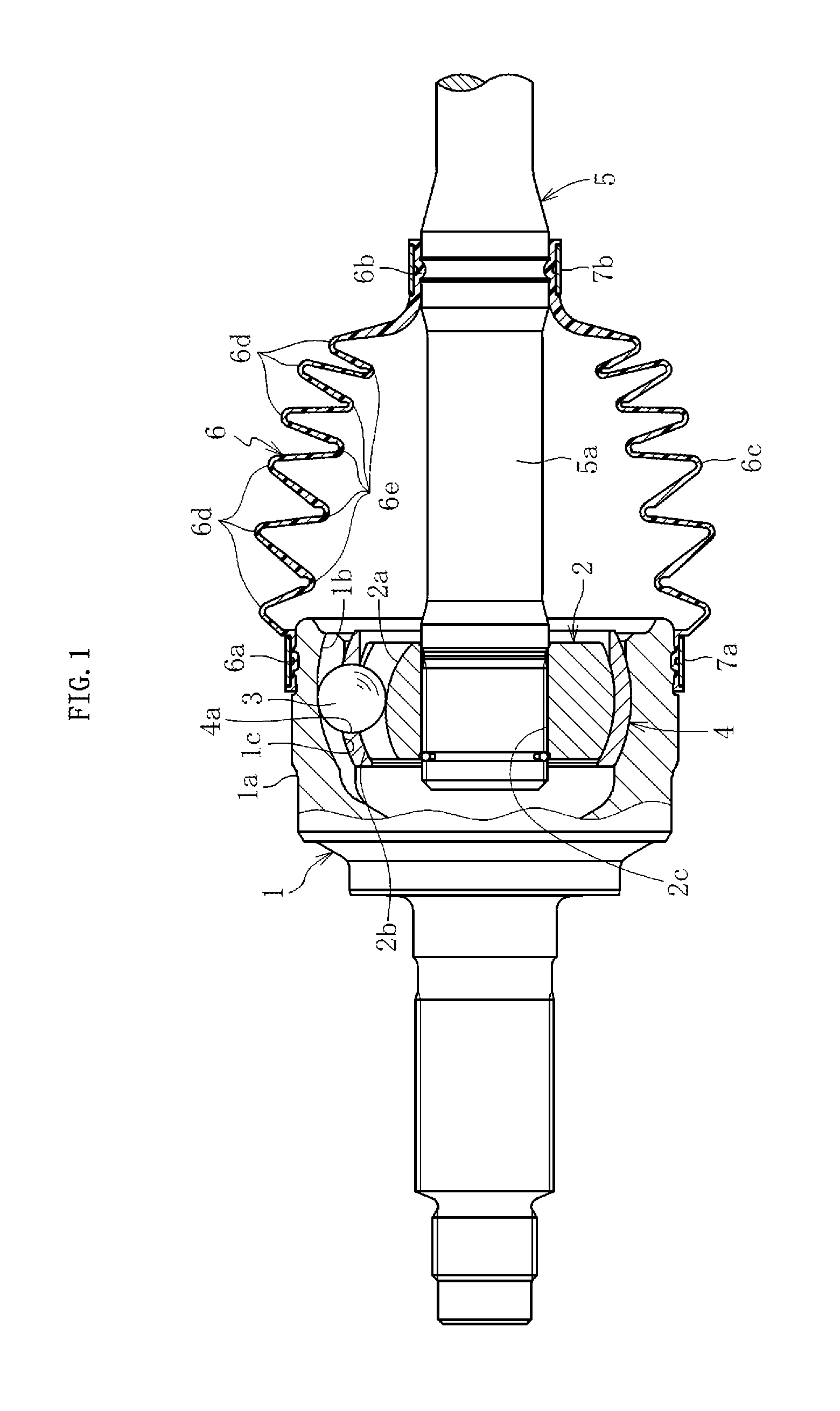

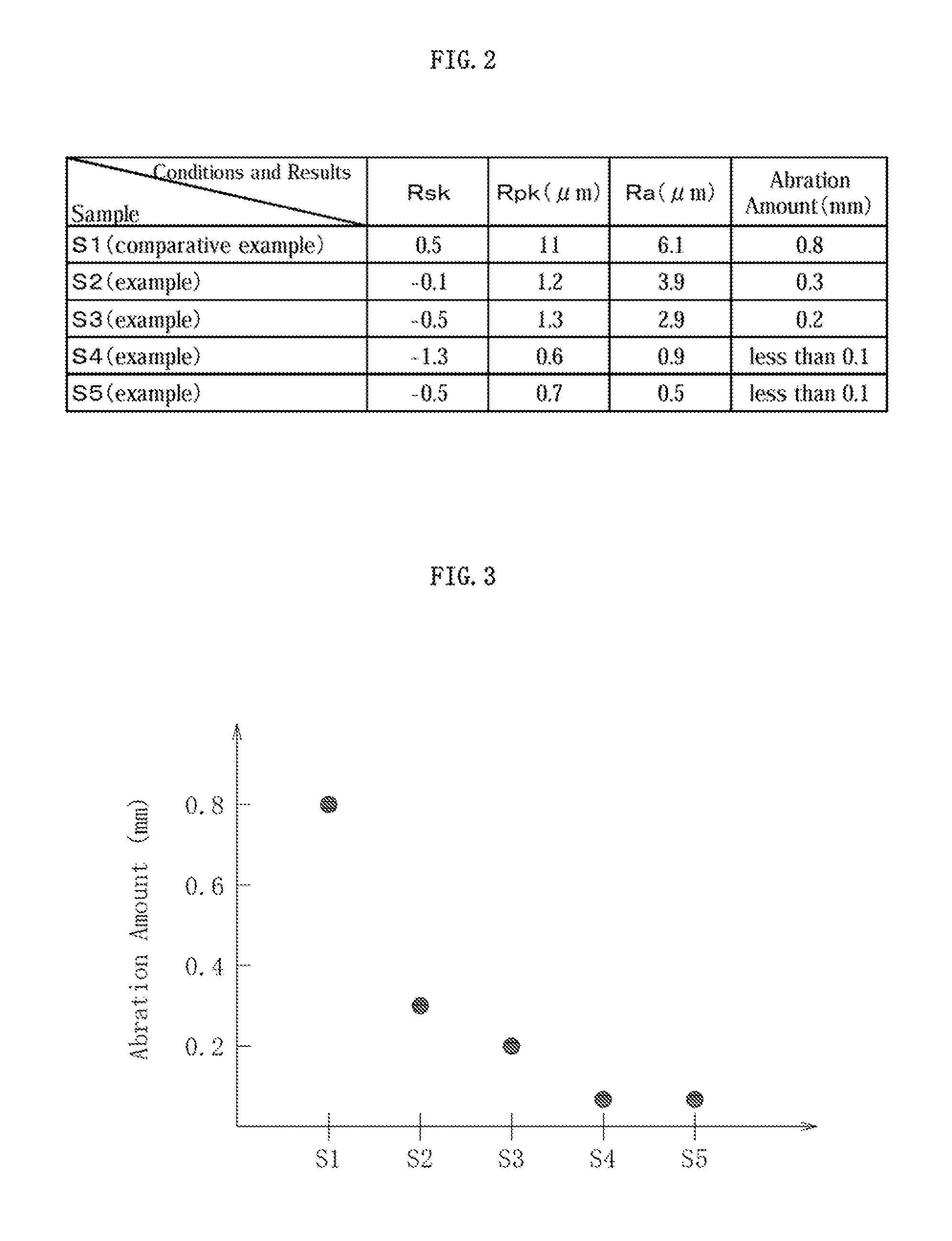

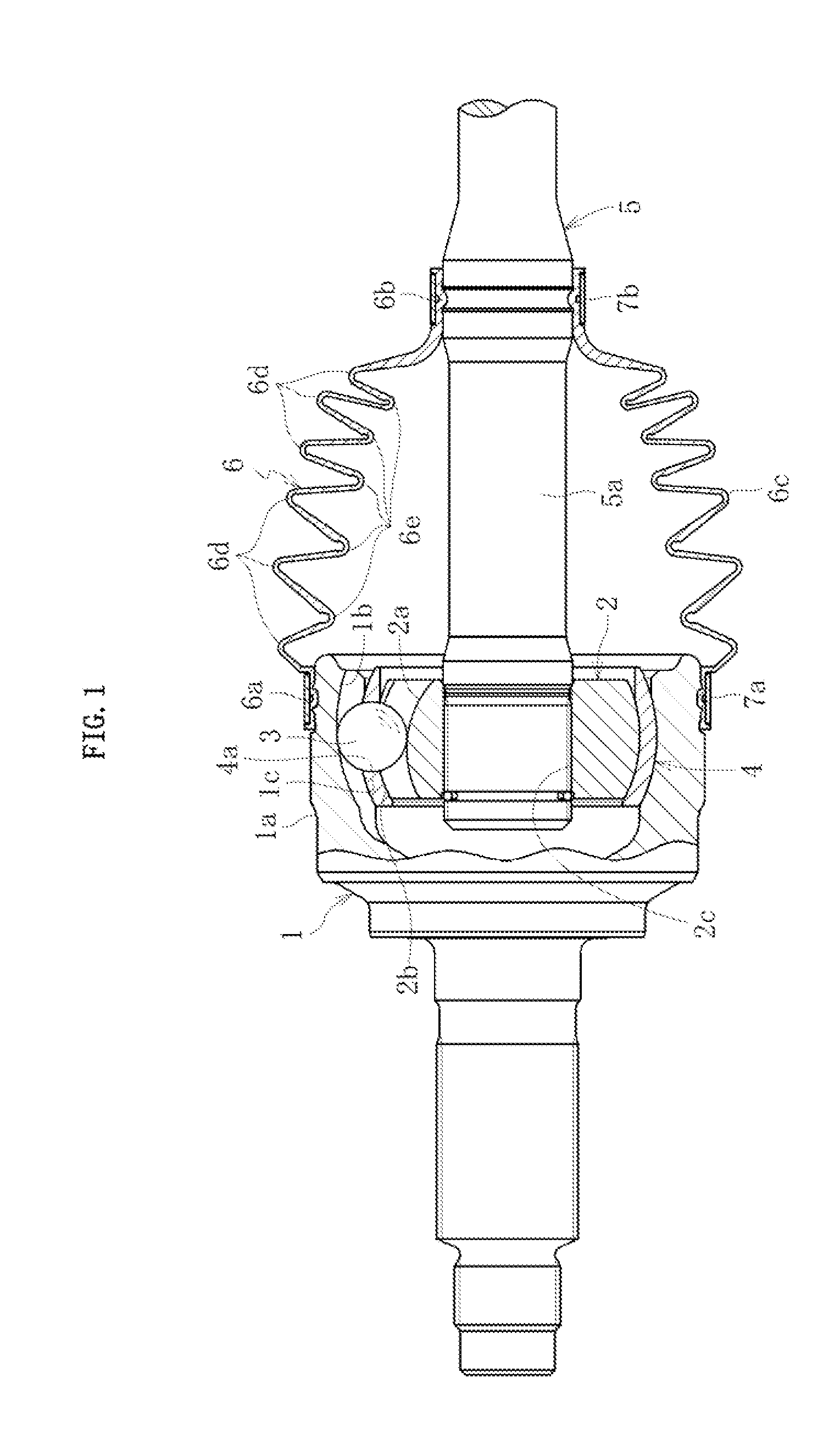

Constant velocity universal joint

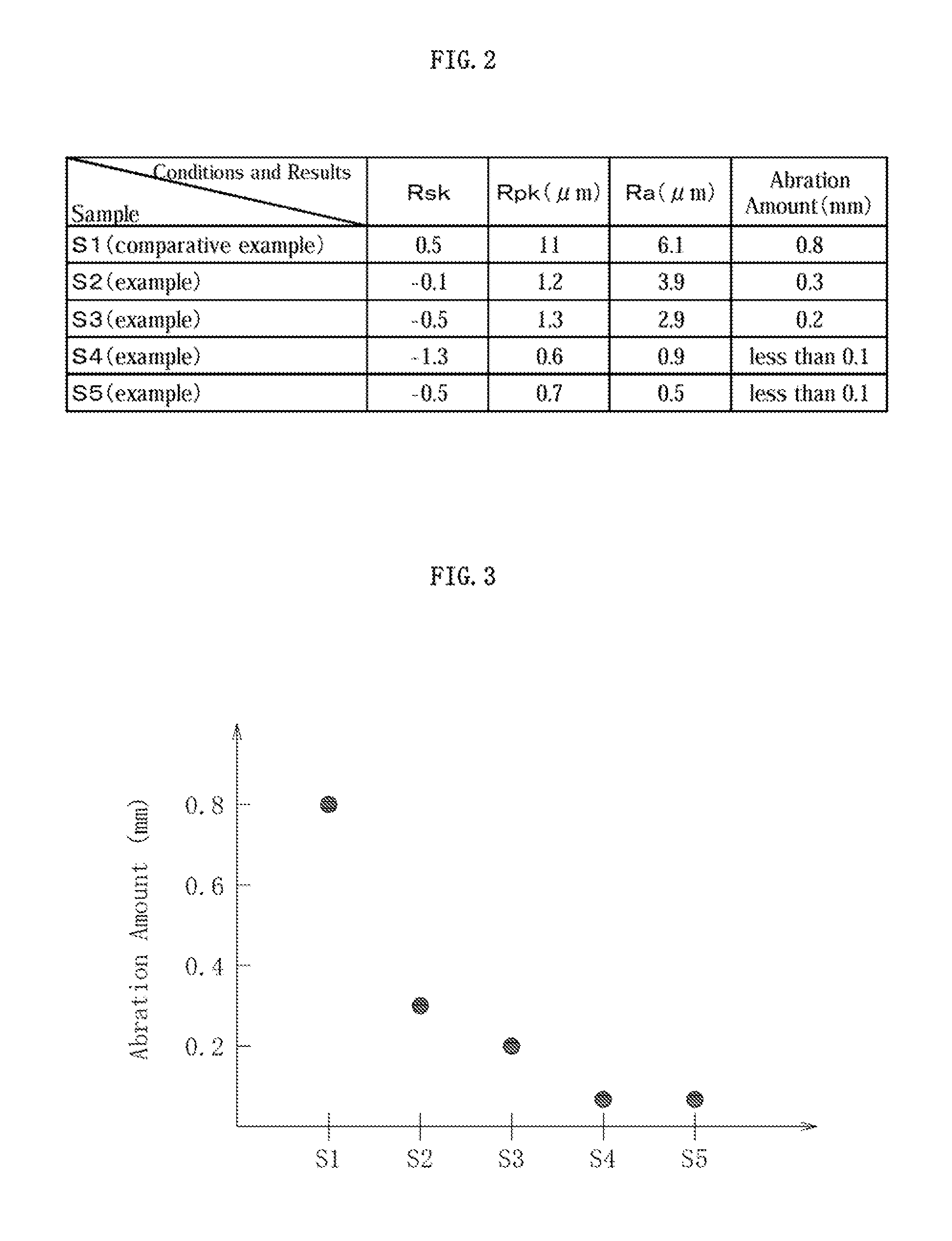

ActiveUS8398494B2Enhanced in durability and compactnessConstant velocityClutchesYielding couplingUniversal jointSurface roughness

A constant velocity universal joint has a boot with enhanced durability and compactness, which are achieved by suppressing abrasion of the boot. The constant velocity universal joint includes an outer joint member, an inner joint member, a torque transmitting member, a shaft, and a boot. The surface roughness of an outer peripheral surface of the shaft satisfies Rsk<0, Rpk<2 μm, and Ra<4 μm.

Owner:NTN CORP

System and method for automated tactile sorting

InactiveUS8346388B1Constant velocityAvoid grippingVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityContact time

A system and method for automated piezoelectric sensor-based tactile sorting of plurality of small objects. A high accuracy, high precision delivery system targets the sensor which accounts for softness and mass of individual objects by measuring a force exerted and total contact time for each object upon passing contact with a sensing surface of a piezo sensor, wherein a plurality of objects cascade onto the sensor in one-by-one fashion. The quantified force and contact time values are then analyzed and compared against two threshold values or a range of threshold values which are predetermined and preset based on data from optimal objects and undesirable objects or possibly a spectrum of objects which has been analyzed and recorded to assist in calibrating the system.

Owner:TRITZ JARED MICHAEL

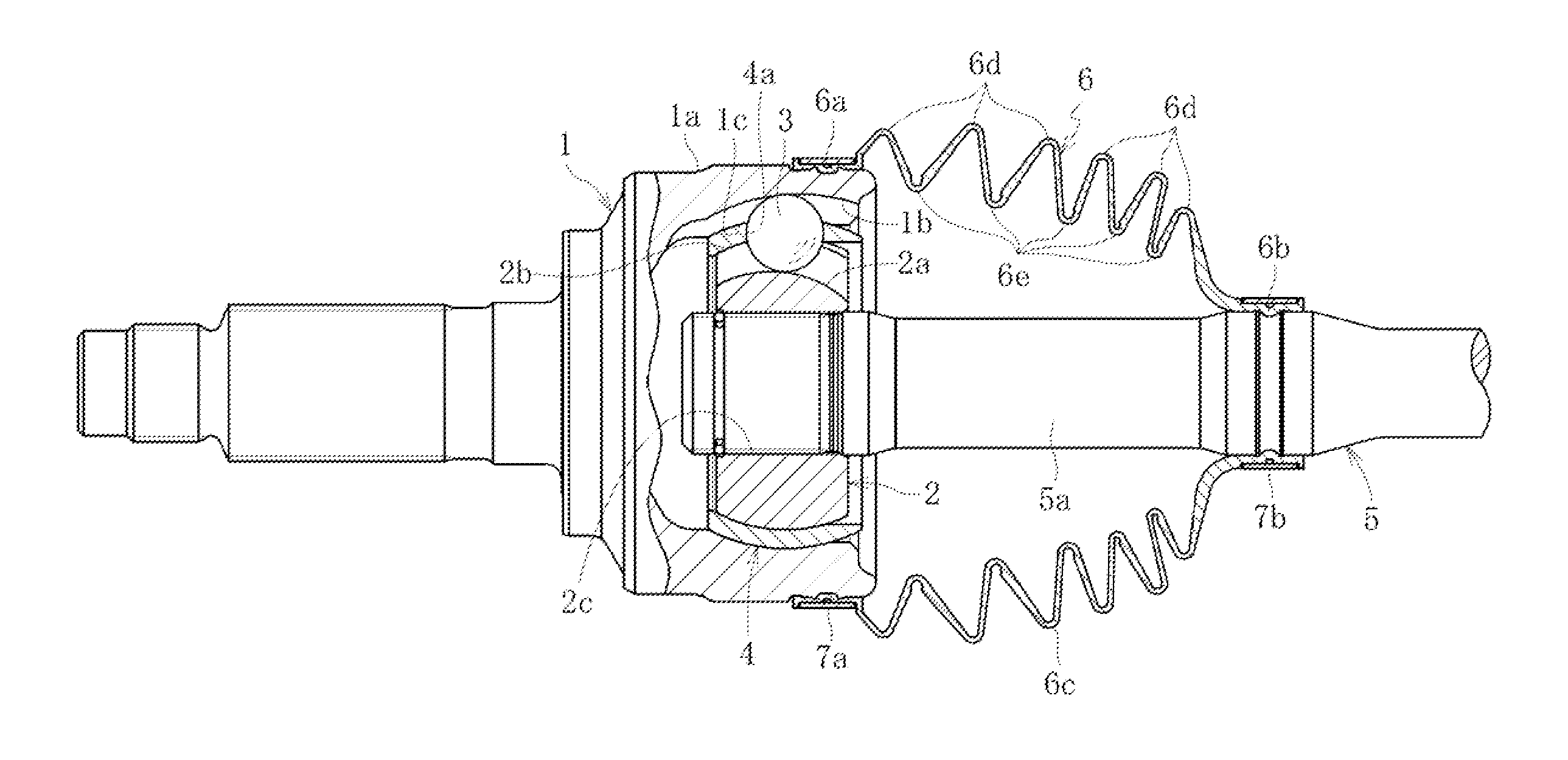

Constant velocity universal joint

ActiveUS20110092297A1Increased durabilityInhibit wearClutchesYielding couplingUniversal jointSurface roughness

Provided is a constant velocity universal joint in which a boot can be enhanced in durability and compactified, which are achieved by suppressing abrasion of the boot. In the constant velocity universal joint including: an outer joint member (1); an inner joint member (2); a torque transmitting member (3); a shaft (5); and a hoot (6), surface roughness of an outer peripheral. surface (5a) of the shaft (5) satisfies Rsk<0, Rpk<2 μm, and Ra<4 μm.

Owner:NTN CORP

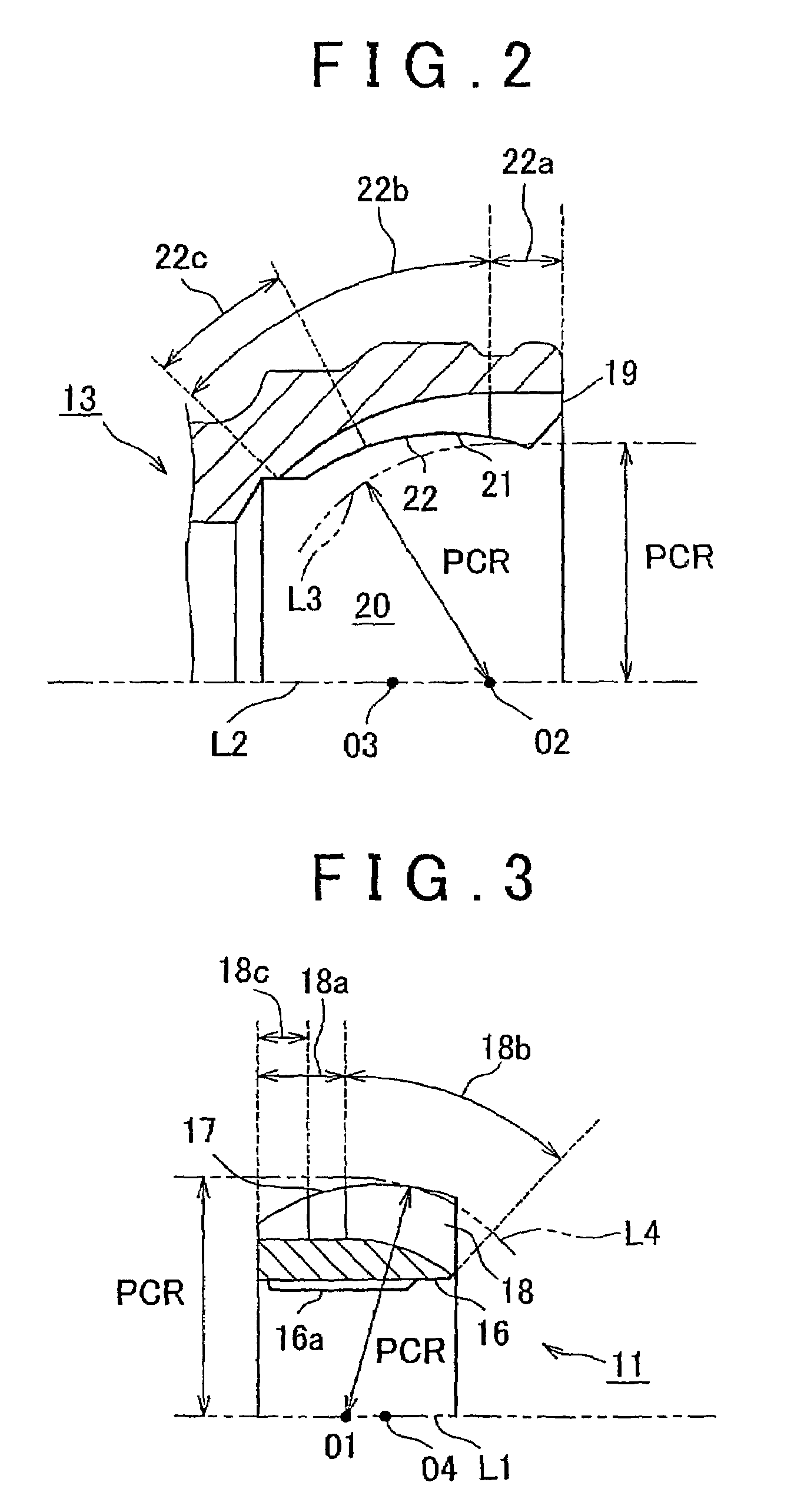

Fixed type constant velocity joint and method of producing the same

InactiveUS7153213B2Solve insufficient capacityConstant velocityYielding couplingRotary machine partsEngineeringSpherical form

A fixed type constant velocity joint includes a cylindrical joint outer ring having an inner spherical surface formed with circumferentially equispaced axially extending track grooves, a joint inner ring having an outer spherical surface formed with circumferentially equispaced axially extending track grooves, balls disposed in ball tracks defined by cooperation between the track grooves in the joint outer and inner rings, and a cage for holding the balls in the ball tracks. The rear open end of the joint outer ring has an inner diameter larger than the outer diameter of the joint inner ring, an inner diameter surface of said cage is a surface having a shape such that the region located forwardly of the axial center is capable of controlling the forward movement of the joint inner ring while the region located rearwardly of the axial center is capable of allowing the axial movement of the joint inner ring.

Owner:NTN CORP

Vibrating mirror element, distance measuring apparatus, and projector

InactiveUS9134115B2Simple structureIncrease freedomOptical rangefindersUsing optical meansResonanceClassical mechanics

Owner:FUNAI ELECTRIC CO LTD

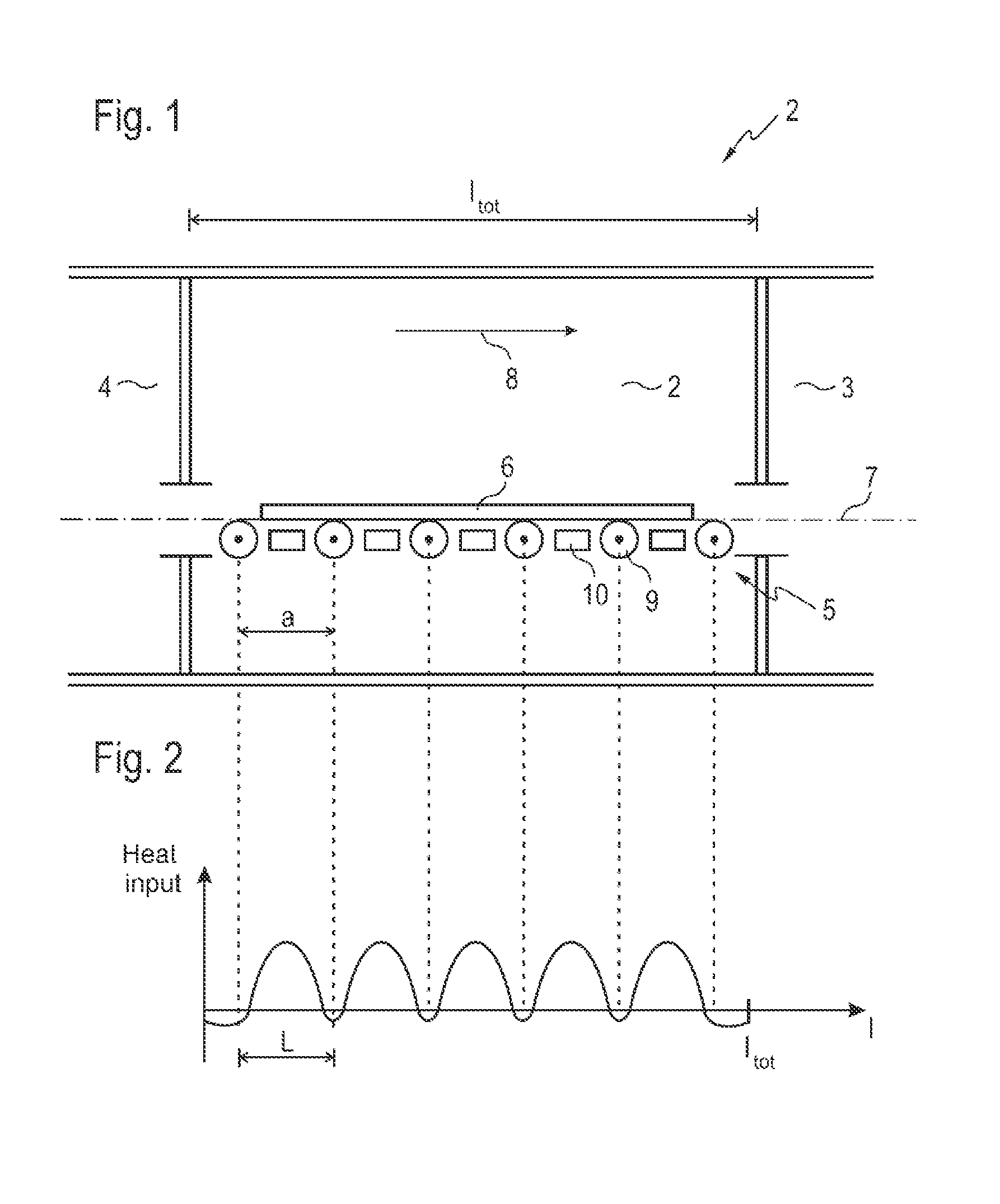

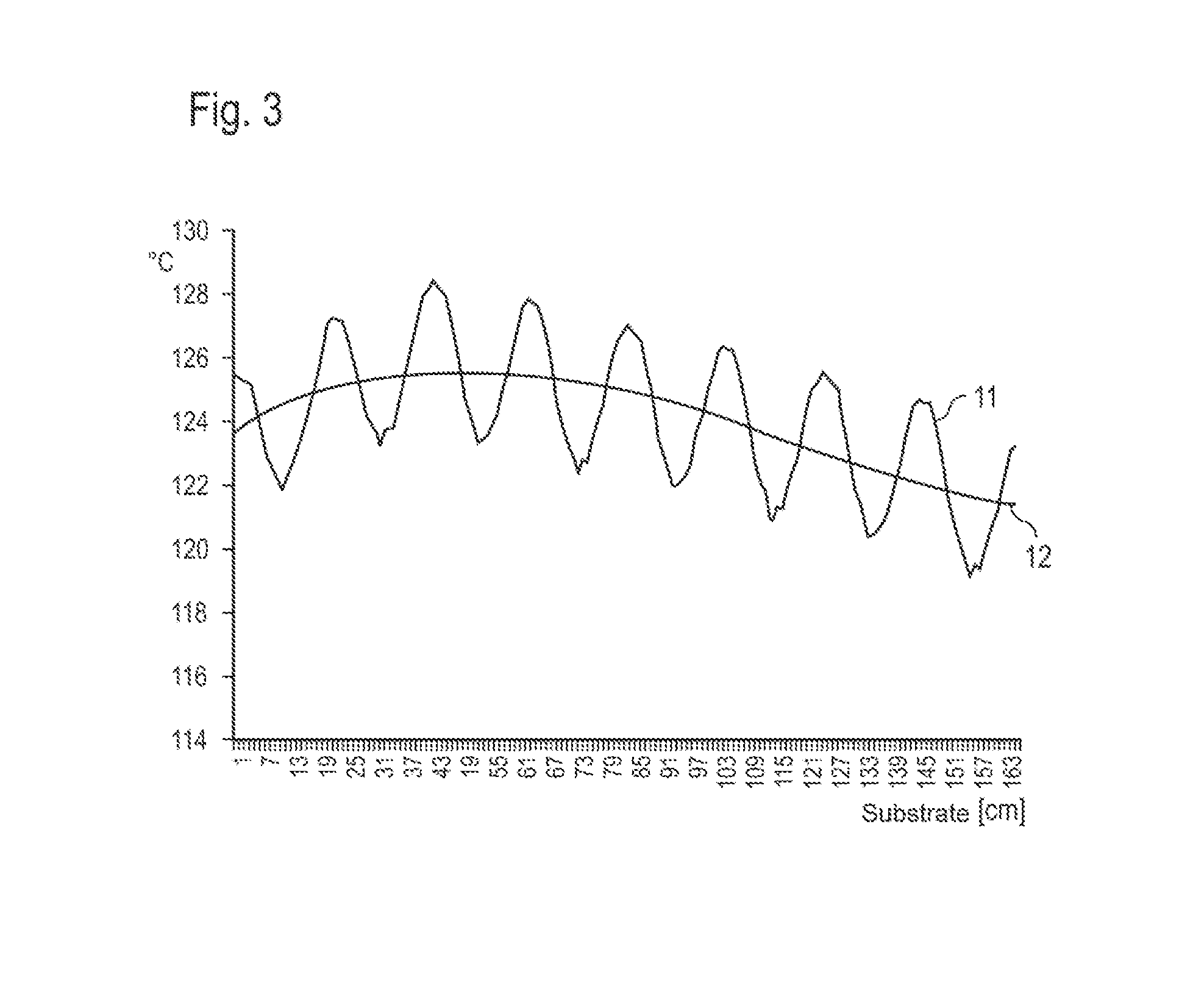

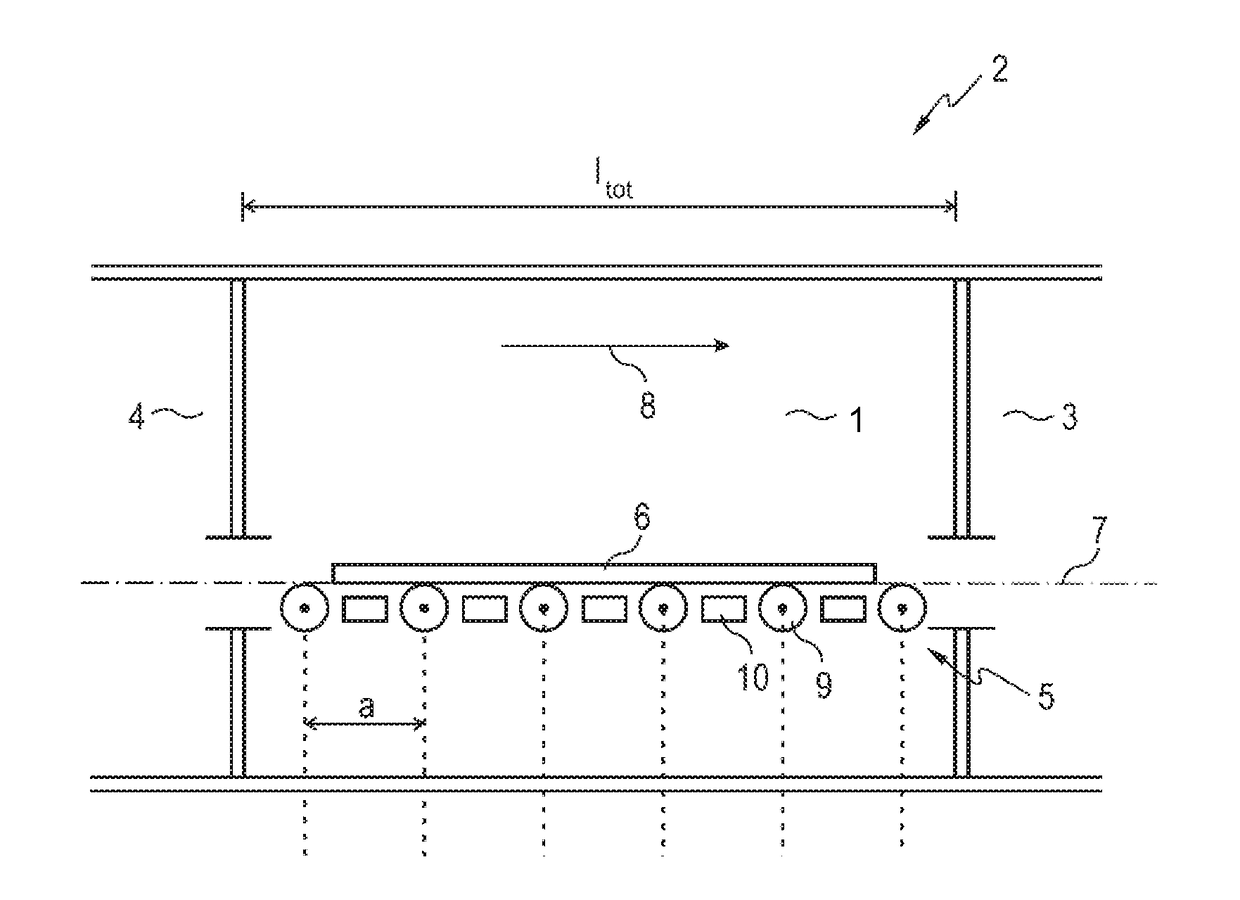

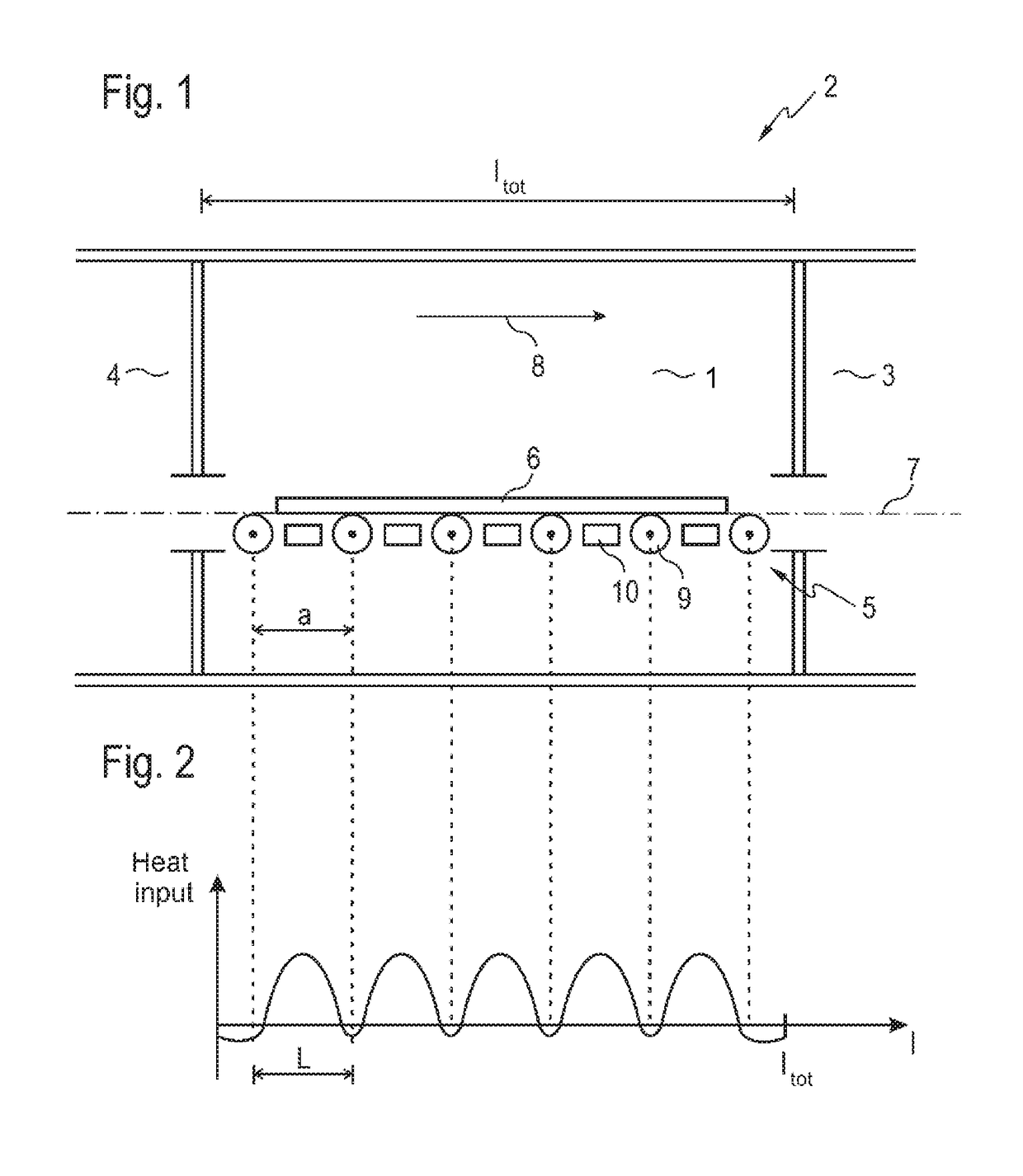

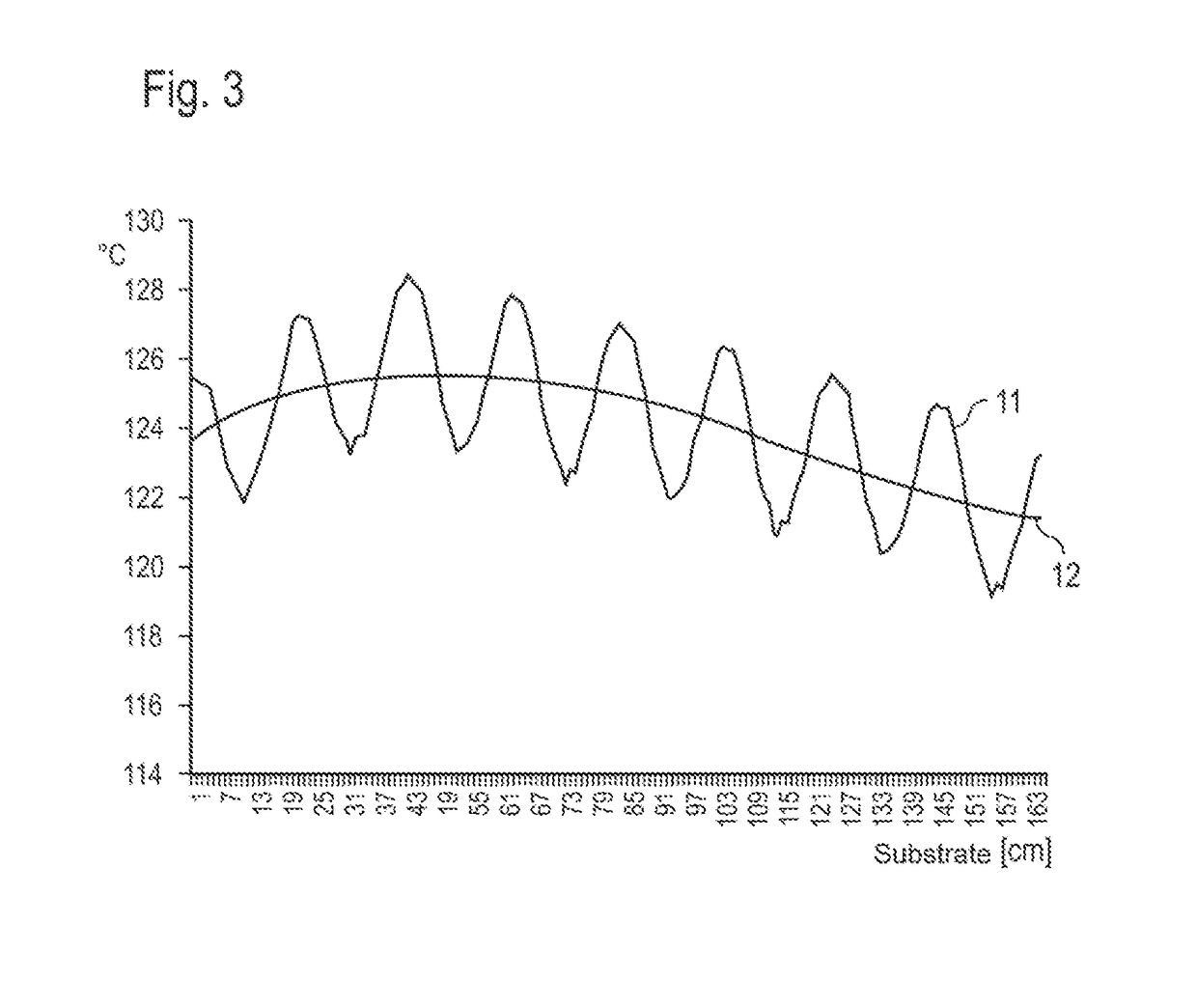

Substrate treatment process

ActiveUS20150044621A1Relieve stressConstant velocityCharge manipulationFurnace typesEngineeringMechanical engineering

Owner:VON ARDENNE ANLAGENTECHNIK GMBH

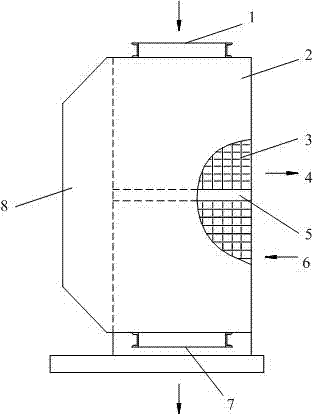

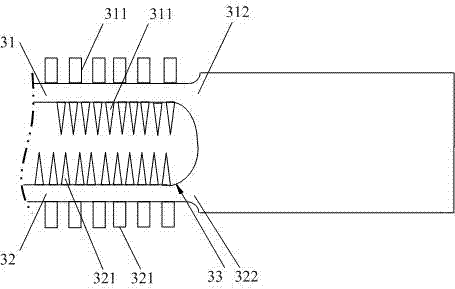

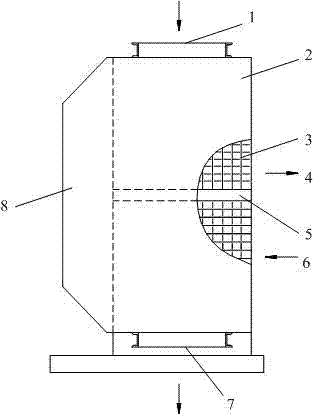

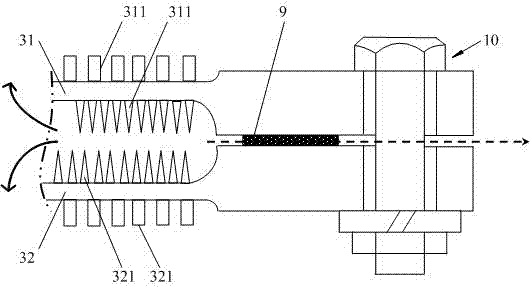

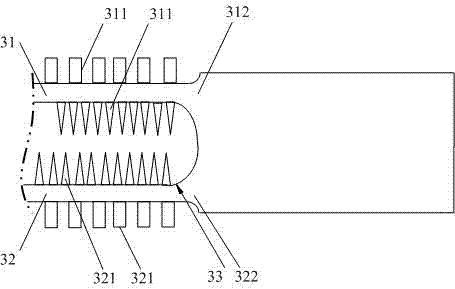

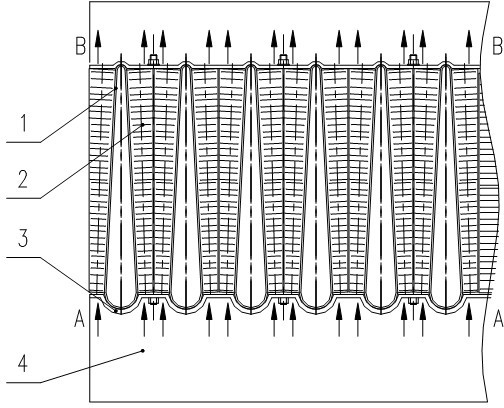

Self-closed integrally cast air preheater

ActiveCN102313294AOvercoming the problem of smoke leakage on the sealing surfaceImprove sealingCombustion processIndirect carbon-dioxide mitigationAir preheaterStructural engineering

The invention discloses a self-closed integrally cast air preheater, which comprises a shell body, a smoke inlet, a smoke outlet, an air inlet, an air outlet and a heat exchange component which is arranged in the shell body, wherein the heat exchange component comprises a plurality of cast fin heat exchange units; each cast fin heat exchange unit comprises a first matrix, a second matrix and finswhich are respectively arranged at the two sides of the middles of the first matrix and the second matrix; the two ends of the first matrixes and the second matrixes are connected and molded into onebody so that circular structures are formed; and main passageway structures are formed in the middle through the first matrixes and the second matrixes. Compared with the prior art, the problem of the seal surface smoke leakage of the heat exchange units, which exists in the cast air preheater formed by cast fin board heat exchange units in the prior art, is solved through the self-closed integrally cast air preheater disclosed by the invention, so that the self-closed integrally cast air preheater has the advantages of simple structure and light weight, is sealed reliably and is convenient to clean.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

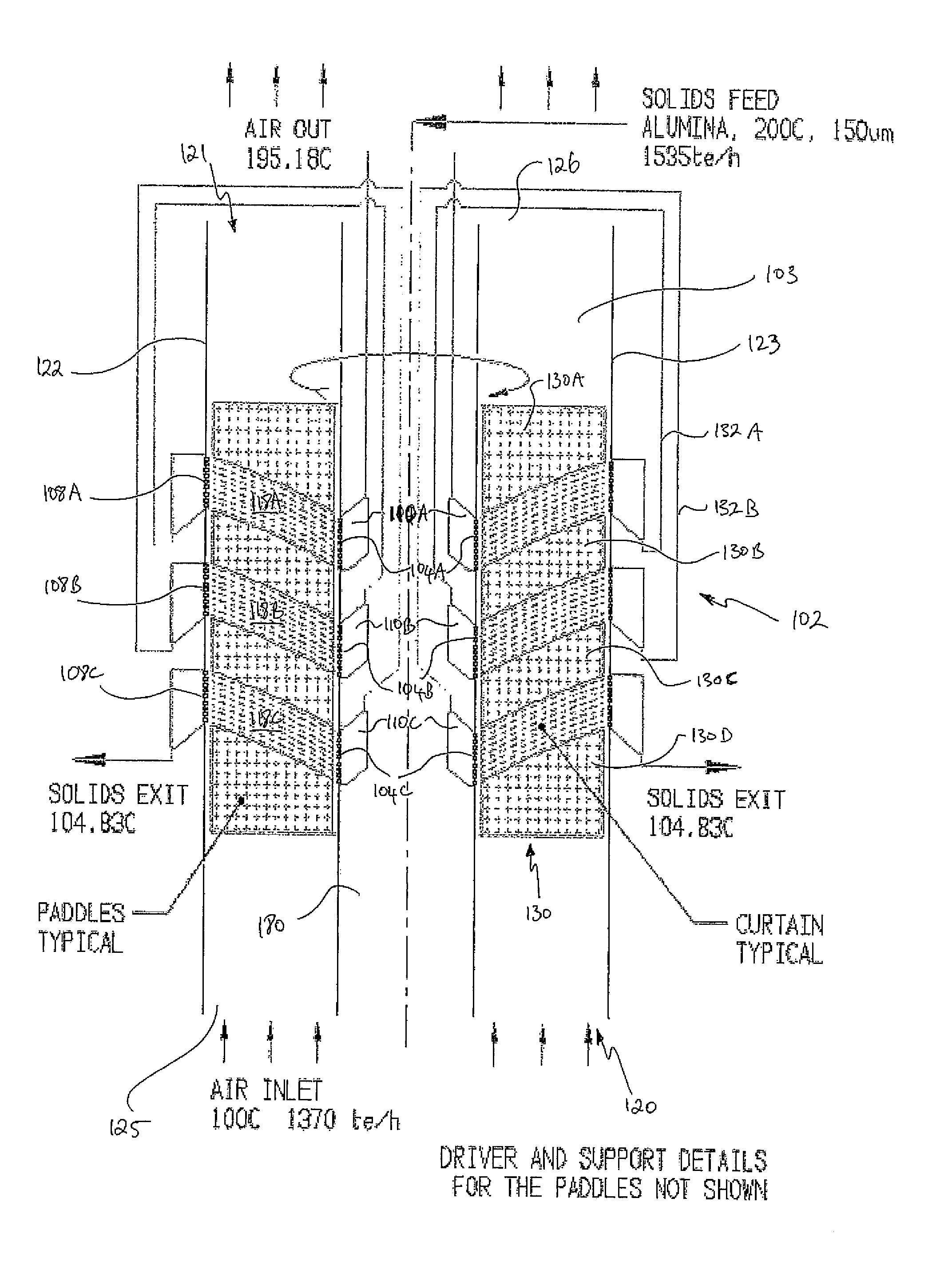

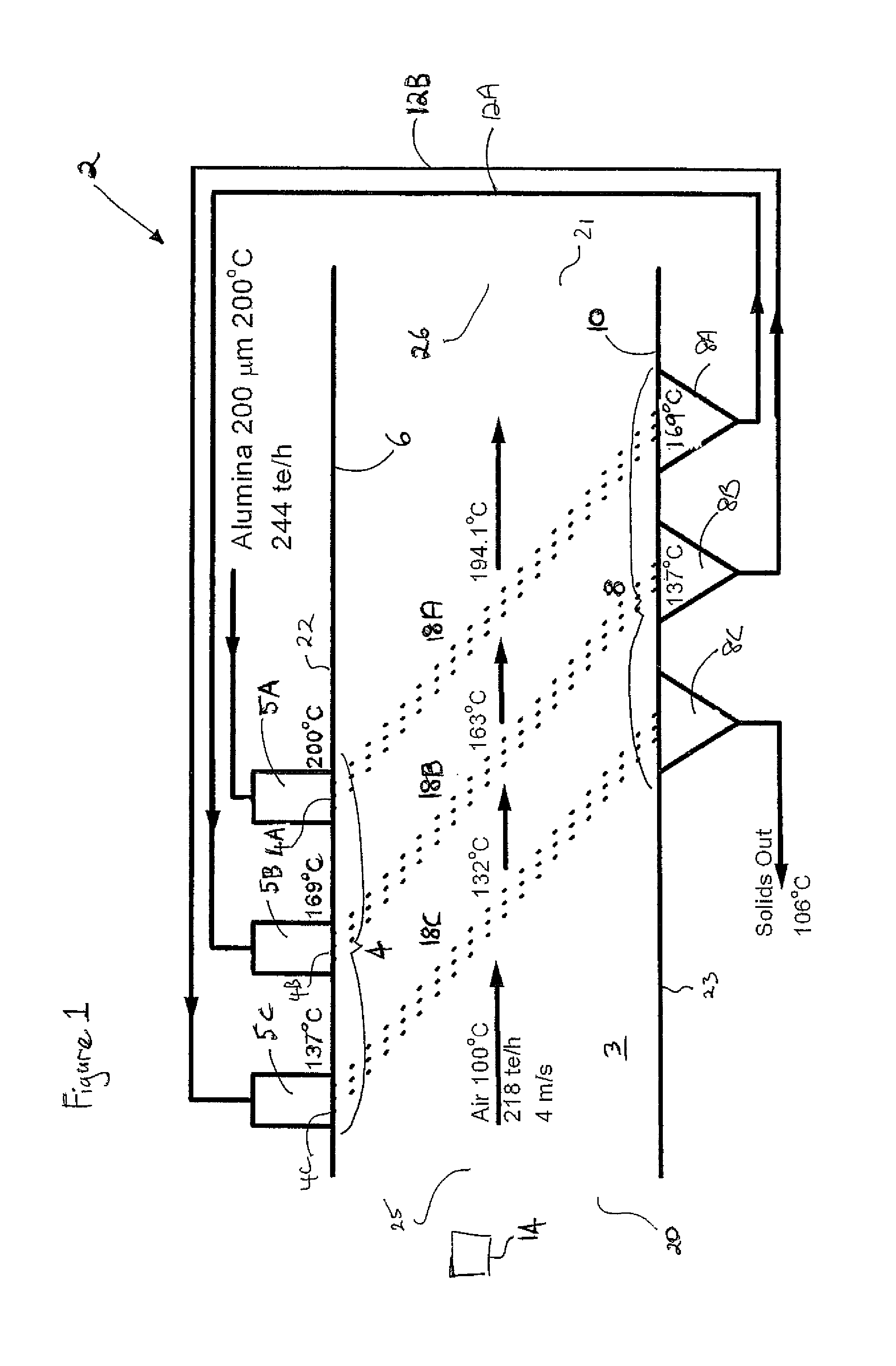

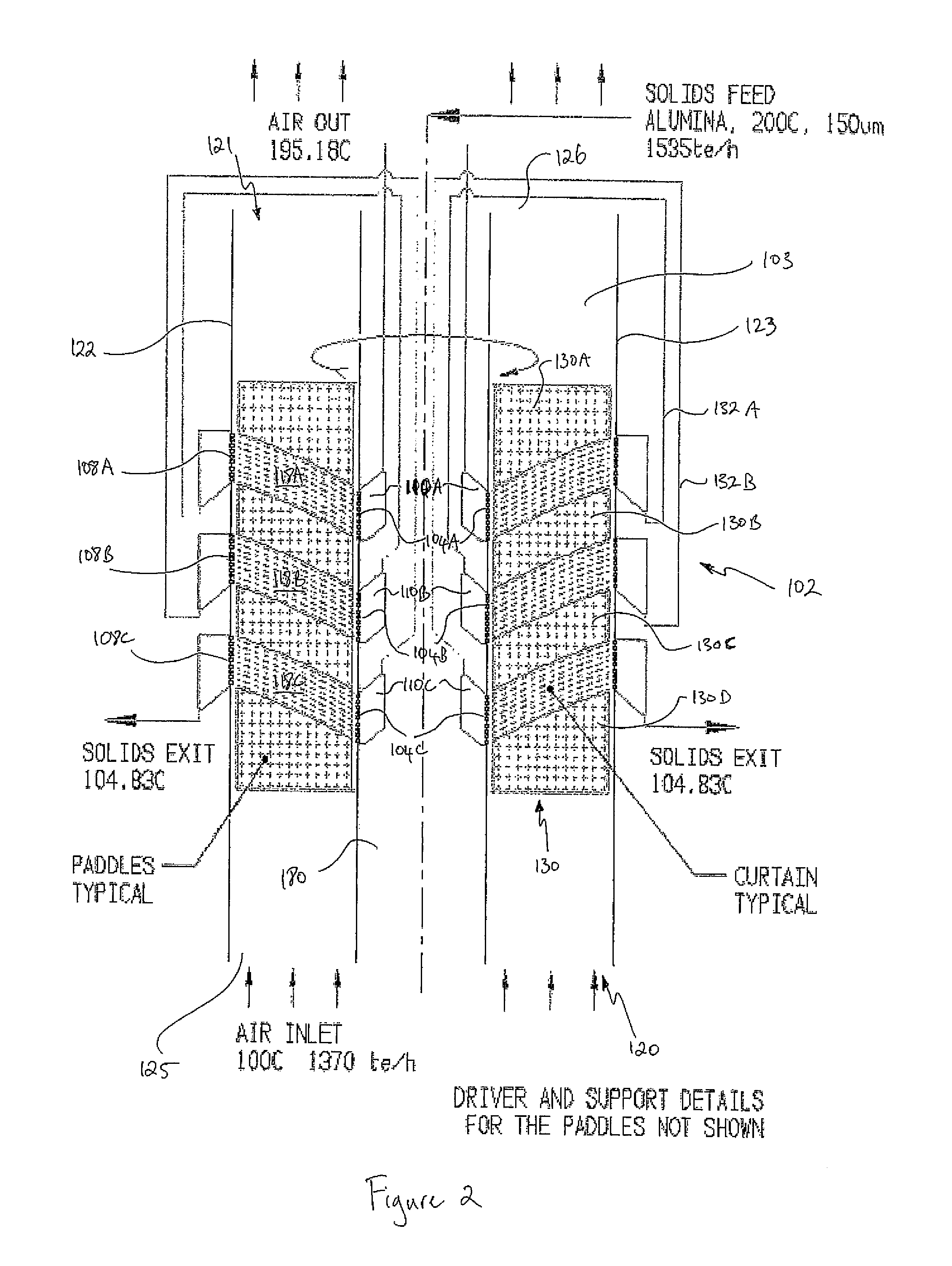

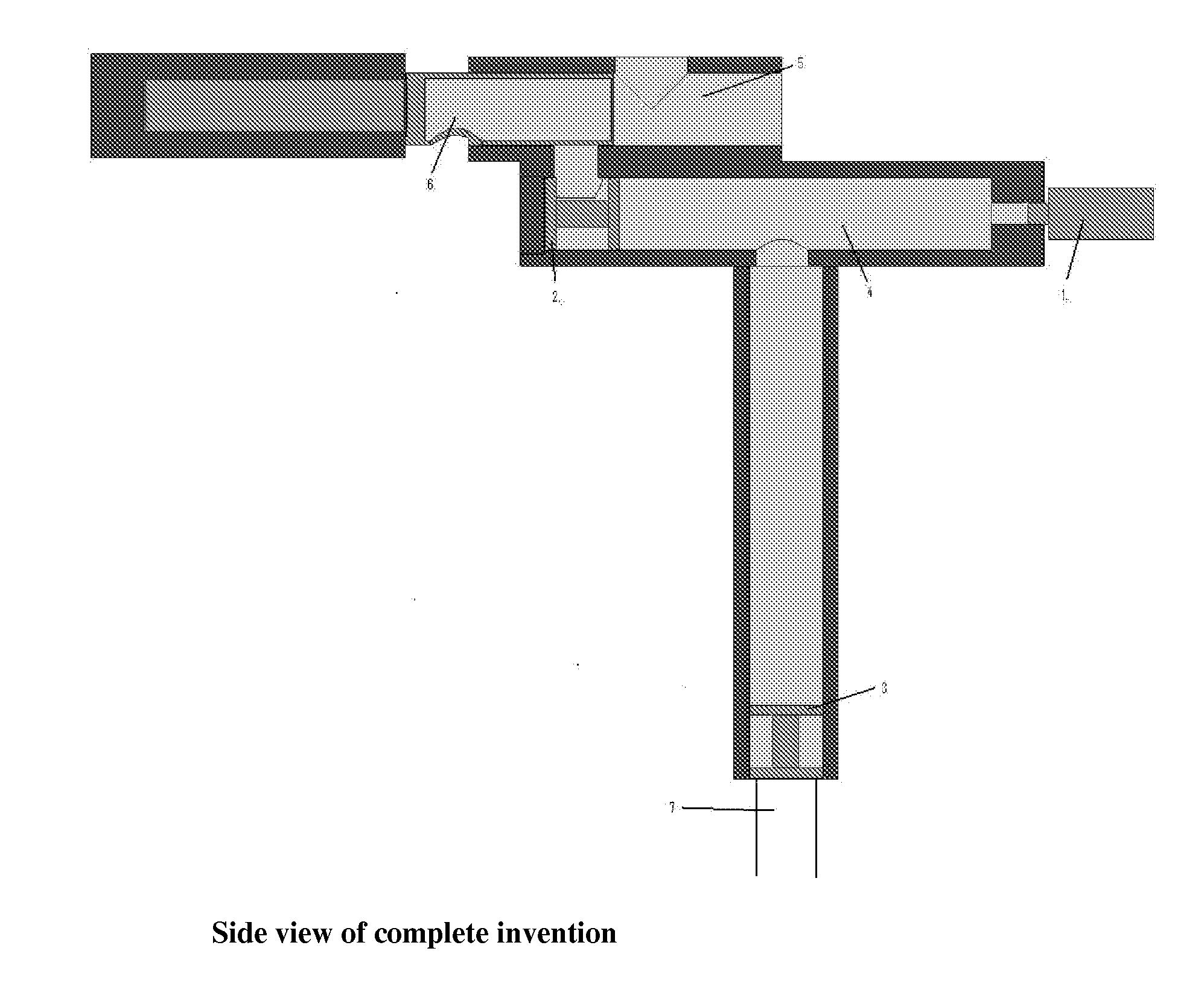

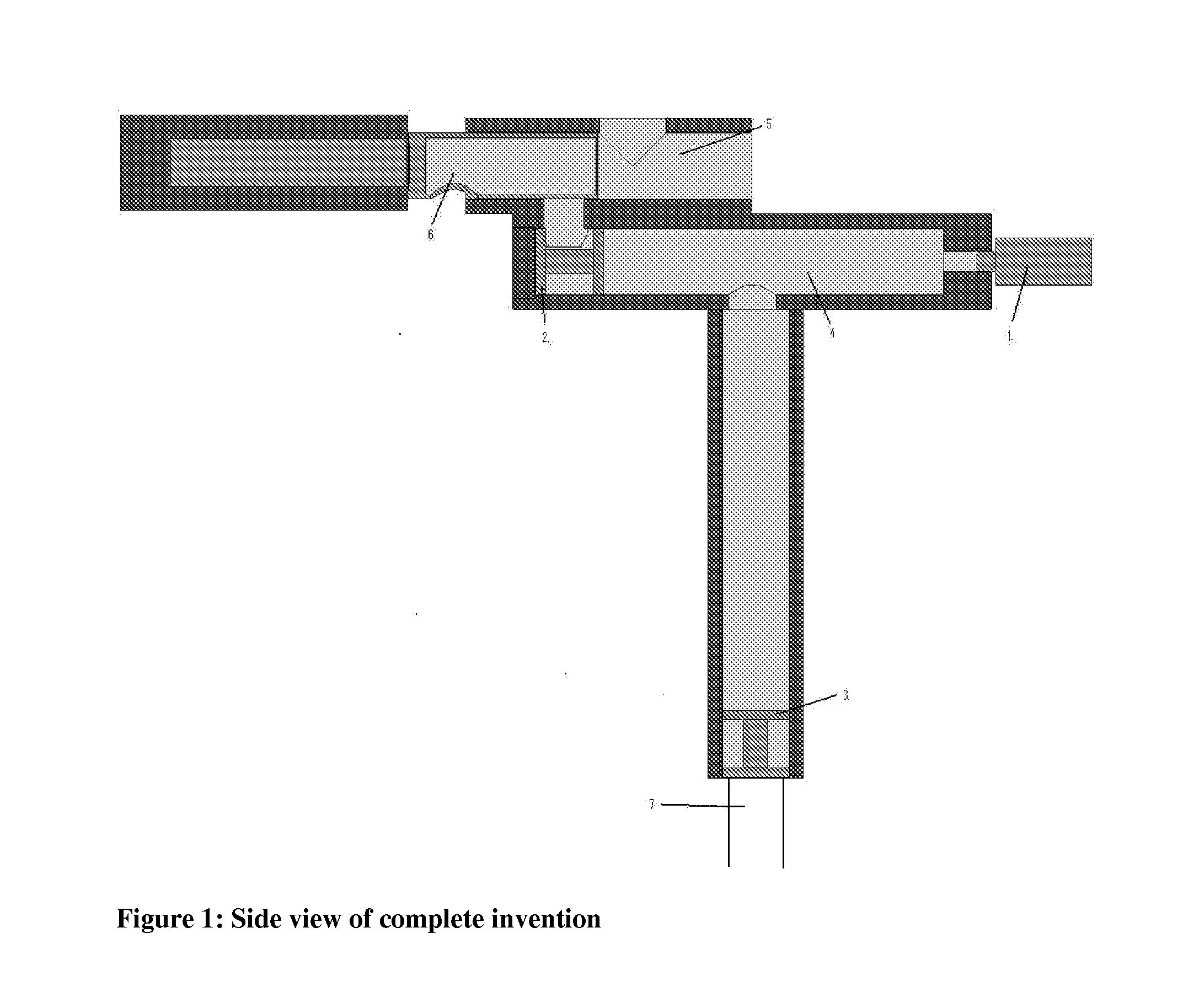

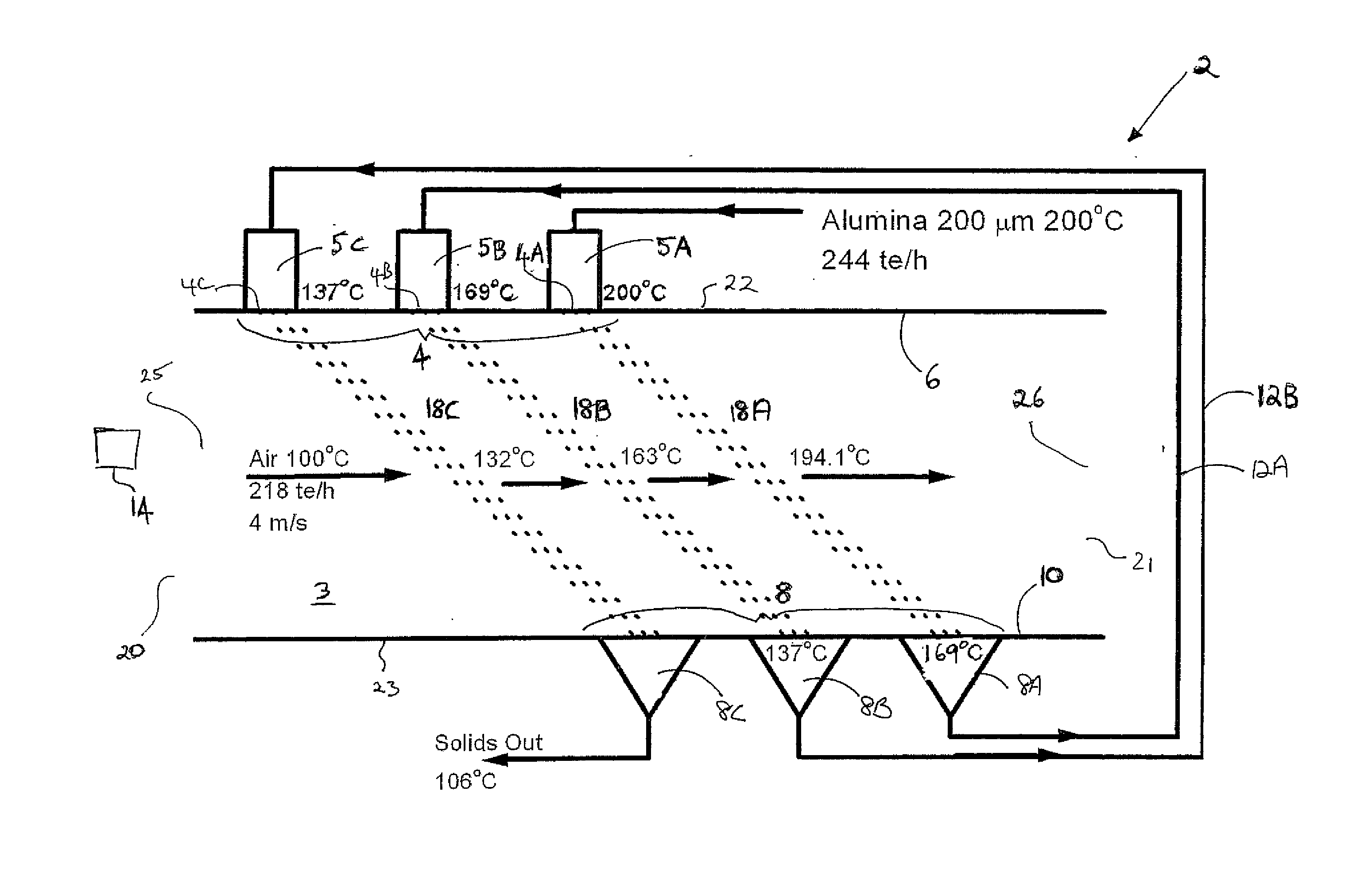

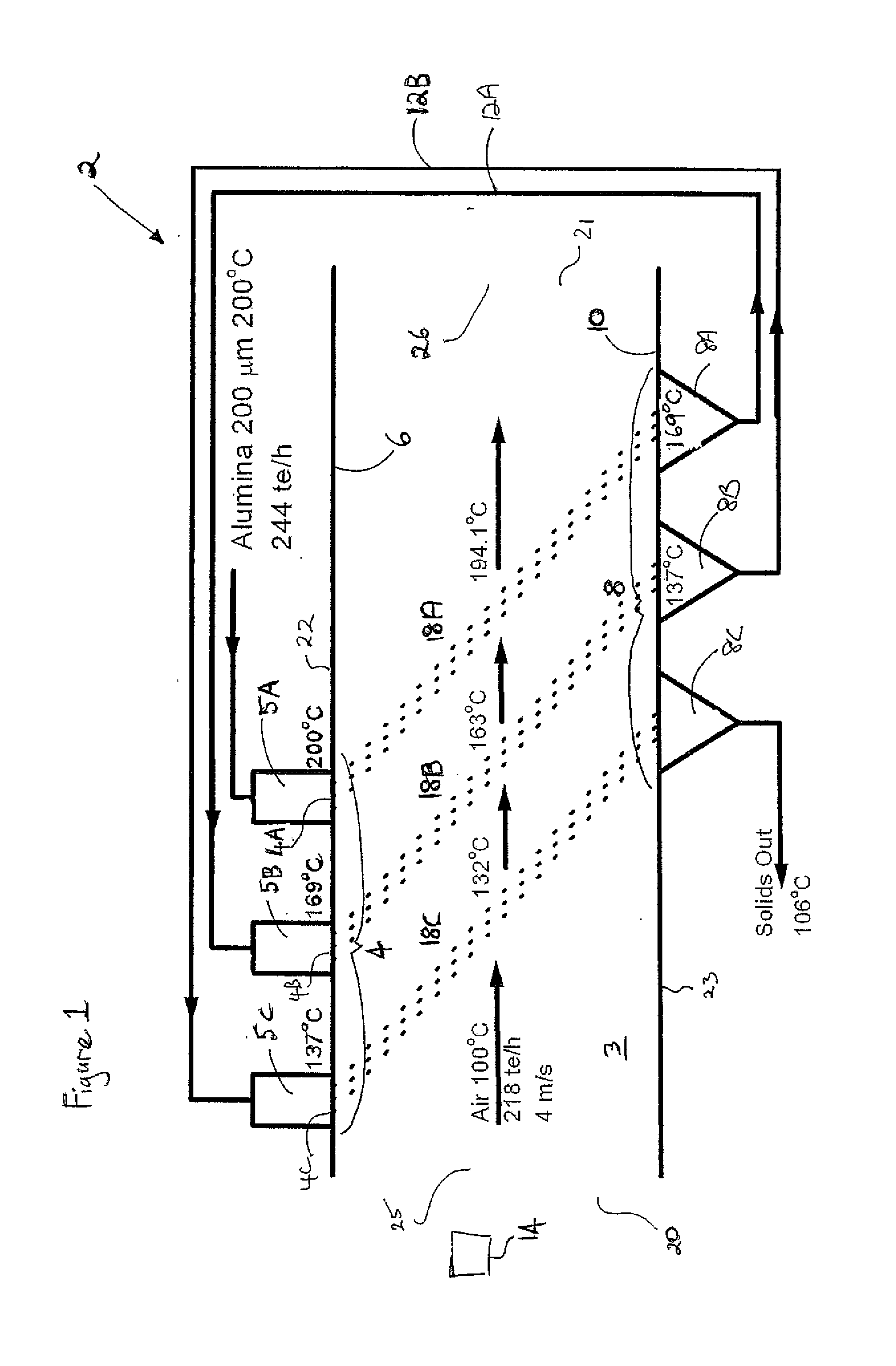

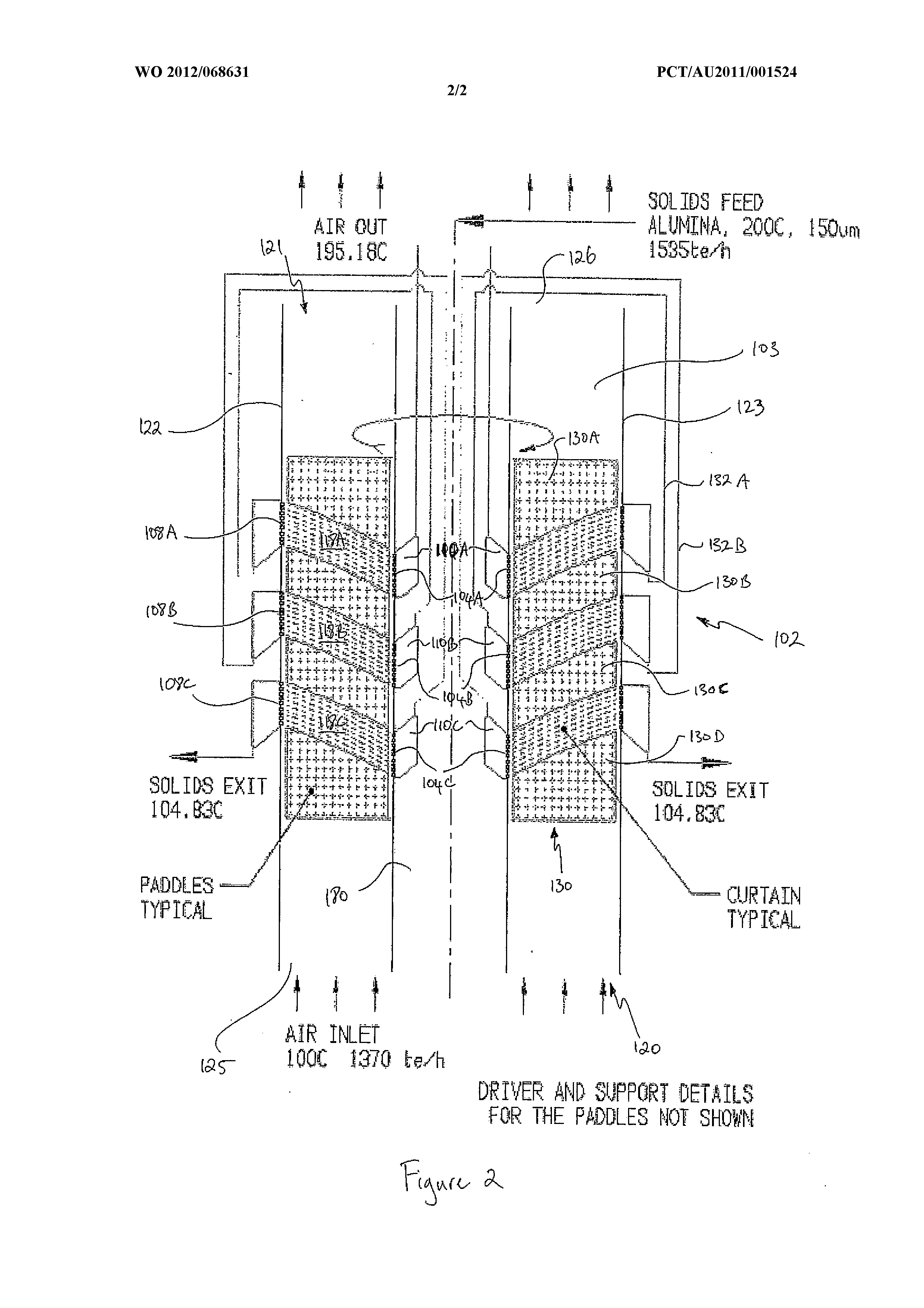

Gas-particle processor

ActiveUS9146055B2Expand accessConstant velocityDrying solid materials with heatDrying gas arrangementsParticle flowPorosity

A gas-particle processor comprising: a chamber having a gas inlet, a gas outlet and one or more particle inlets; a gas flow arrangement operable to flow gas through the chamber from the gas inlet to the gas outlet at a first controlled mass flow-rate; and a particle flow arrangement operable to introduce particles in one or more streams into the chamber at a second controlled mass flow-rate, each particle stream flowing through respective processing regions in the chamber, wherein the processor is operable to control the first and / or second controlled mass flow-rates to provide a gas-particle mixture porosity in a substantial portion of each processing region of 0.900-0.995.

Owner:APRIL PTY LTD

Precision Control of Operating Pressure for Pneumatic Guns

InactiveUS20100300420A1Improve accuracyConstant velocityFluid pressure measurement by mechanical elementsCompressed gas gunsTransducerEngineering

A pressure transducer or other means of measuring pressure inside a vessel is used to measure the pressure of a gas inside a pneumatic powered projectile gun. A valve is used to control the pressure inside the gun by controlling the amount of air entering from a compressed gas source at a higher pressure. Finally, a second valve is used to release the gas inside the gun into the barrel section, firing the projectile.

Owner:NELSON DANIEL ROBERT

Gas-particle processor

ActiveUS20130283636A1Expand accessConstant velocityDrying solid materials with heatDrying gas arrangementsParticle flowPorosity

A gas-particle processor comprising: a chamber having a gas inlet, a gas outlet and one or more particle inlets; a gas flow arrangement operable to flow gas through the chamber from the gas inlet to the gas outlet at a first controlled mass flow-rate; and a particle flow arrangement operable to introduce particles in one or more streams into the chamber at a second controlled mass flow-rate, each particle stream flowing through respective processing regions in the chamber, wherein the processor is operable to control the first and / or second controlled mass flow-rates to provide a gas-particle mixture porosity in a substantial portion of each processing region of 0.900-0.995.

Owner:APRIL PTY LTD

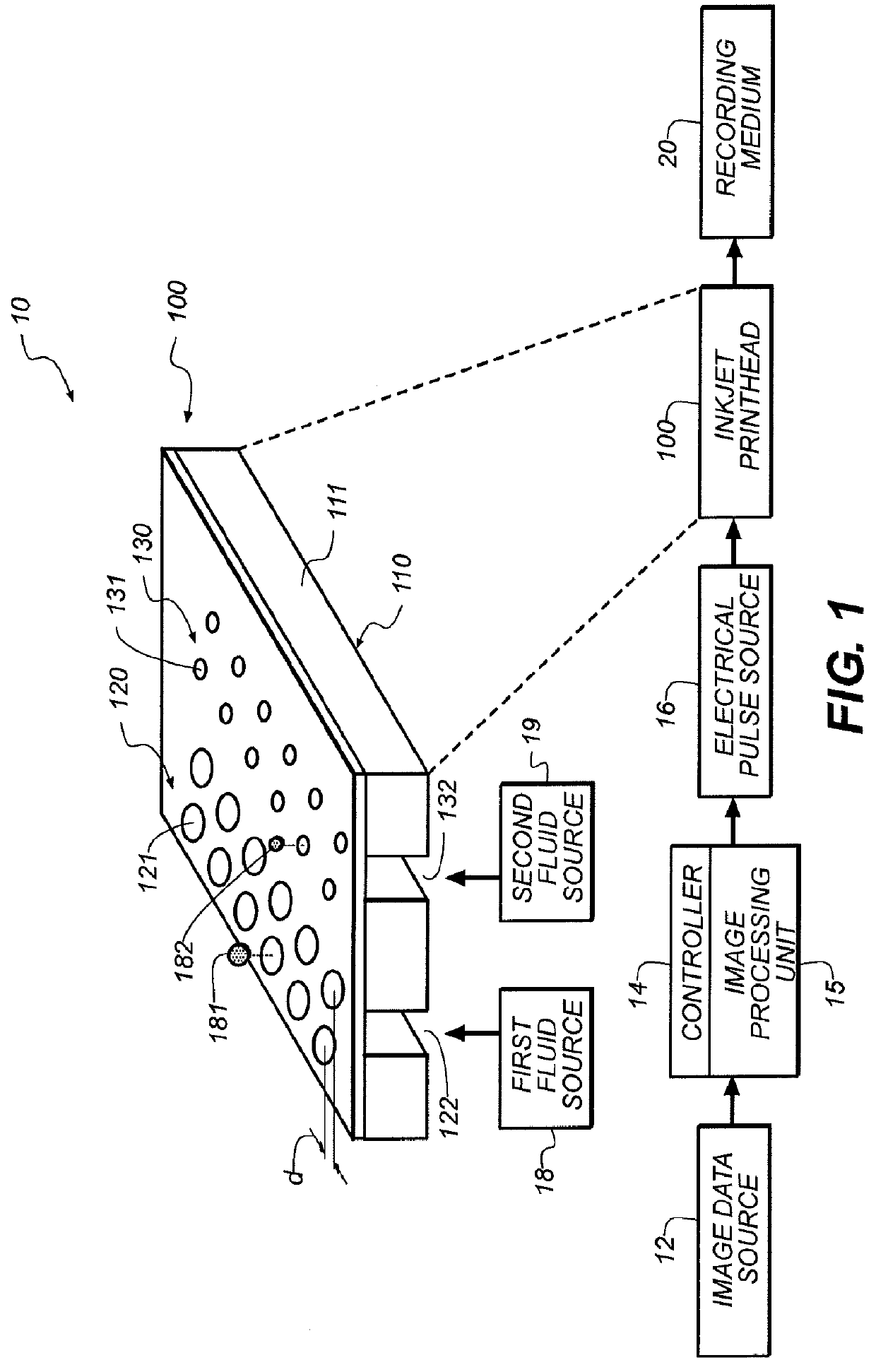

Dislodging and removing bubbles from inkjet printhead

InactiveUS20130050312A1Constant velocityEnhance vibrationSpacing mechanismsOther printing apparatusInkjet printingAir bubble

A method of operating an inkjet printer including an inkjet printhead having an ink inlet, the inkjet printhead mounted on a motor-driven carriage having an encoder sensor, the method including sending a signal from the encoder sensor to a controller to indicate a position of the motor-driven carriage; determining a velocity of the motor-driven carriage; implementing a first motion control mode during a period when the inkjet printhead is printing, wherein the first motion control mode includes a first signal for damping vibrations in order to provide a substantially constant velocity of the carriage; selectively implementing a second motion control mode when the inkjet printhead is not printing, wherein the second motion control mode includes a second signal for enhancing vibrations of the carriage in order to dislodge air bubbles in the printhead; and removing air corresponding to the air bubbles from the printhead.

Owner:EASTMAN KODAK CO

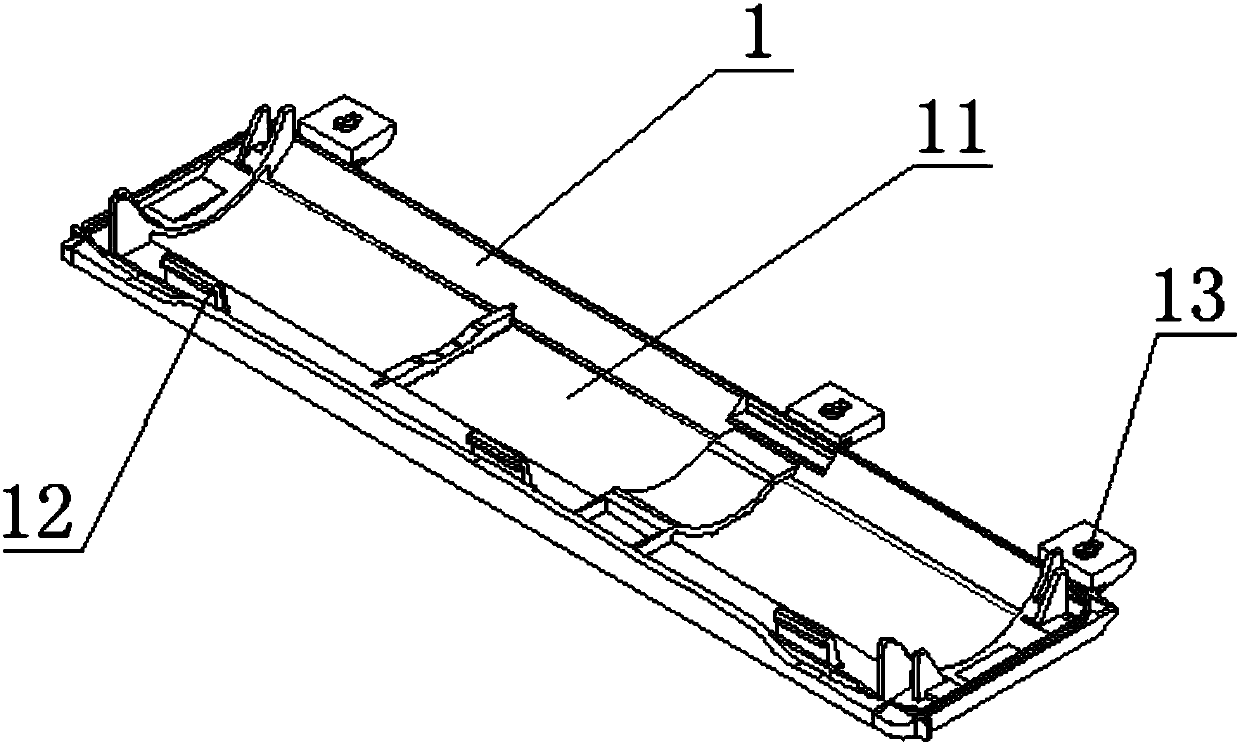

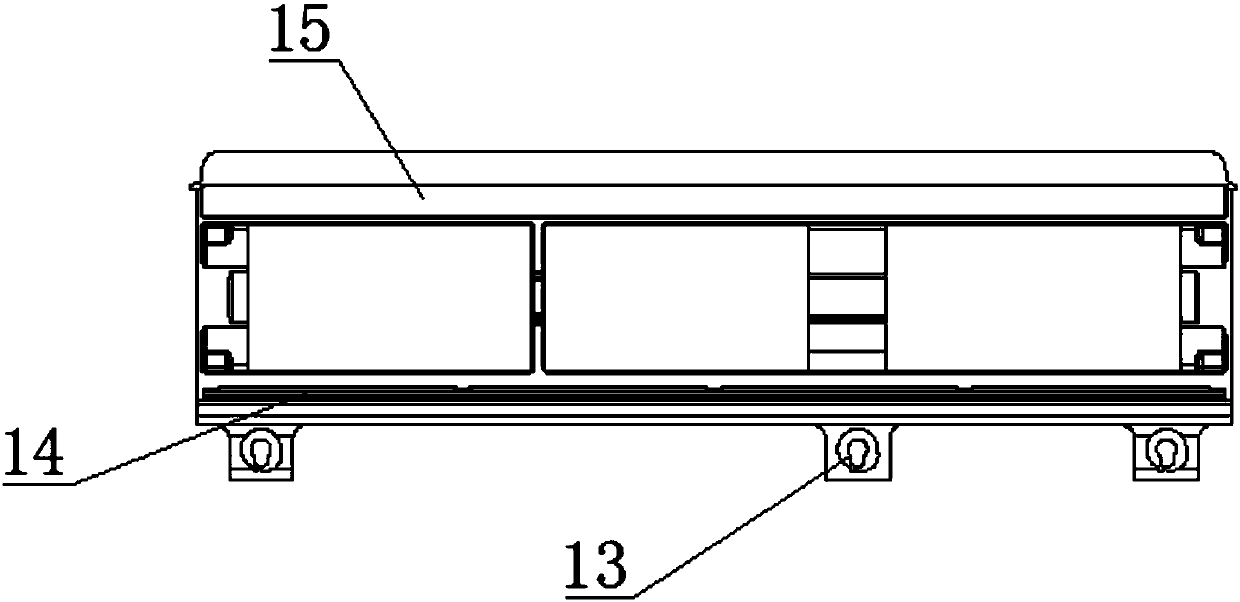

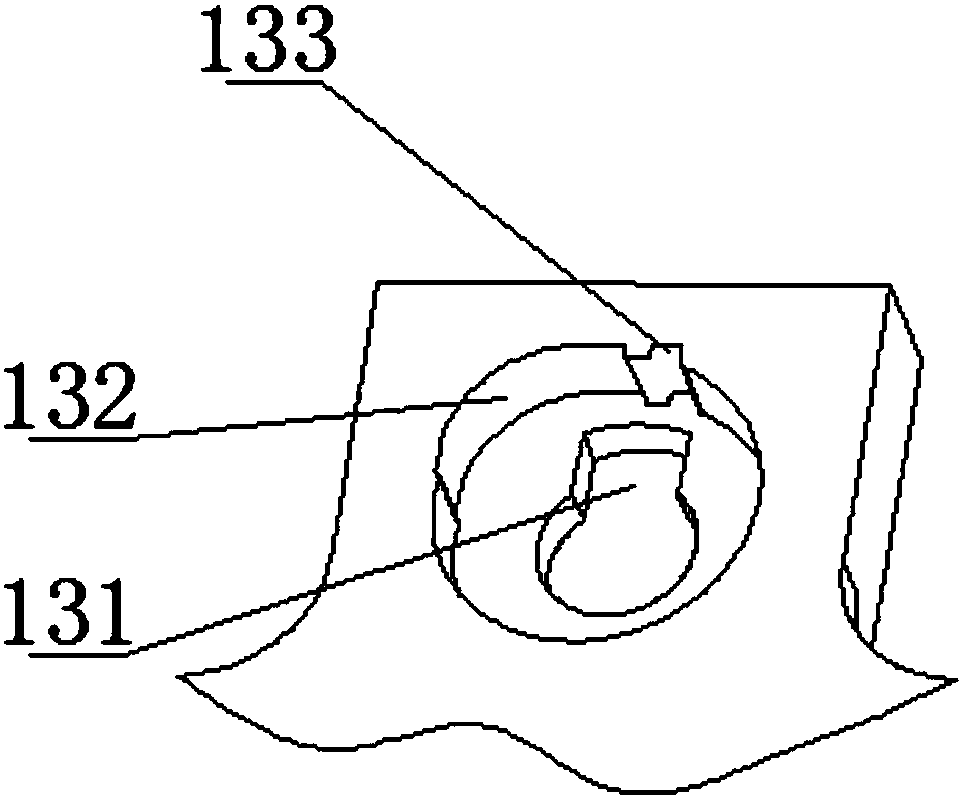

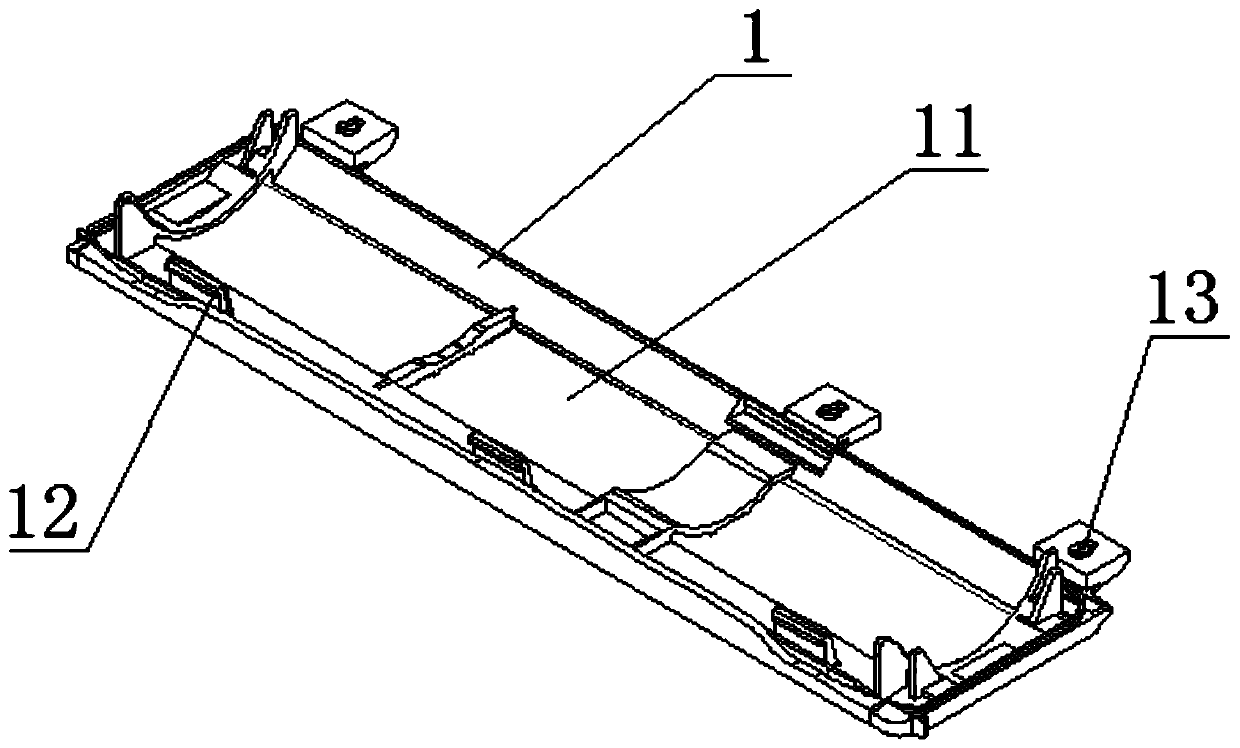

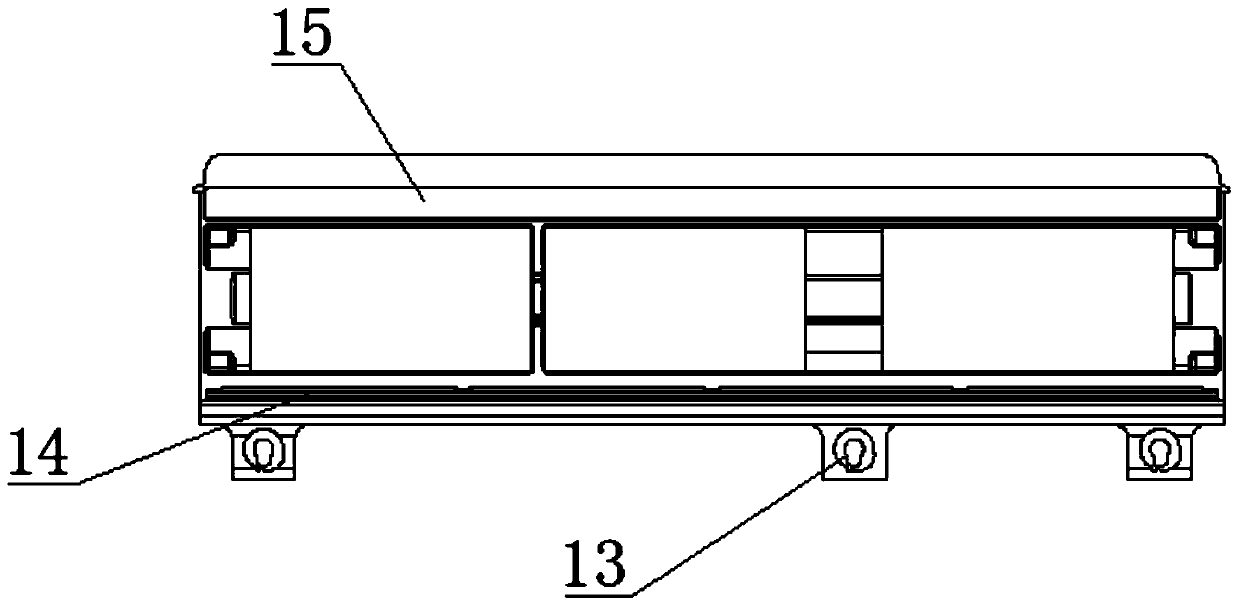

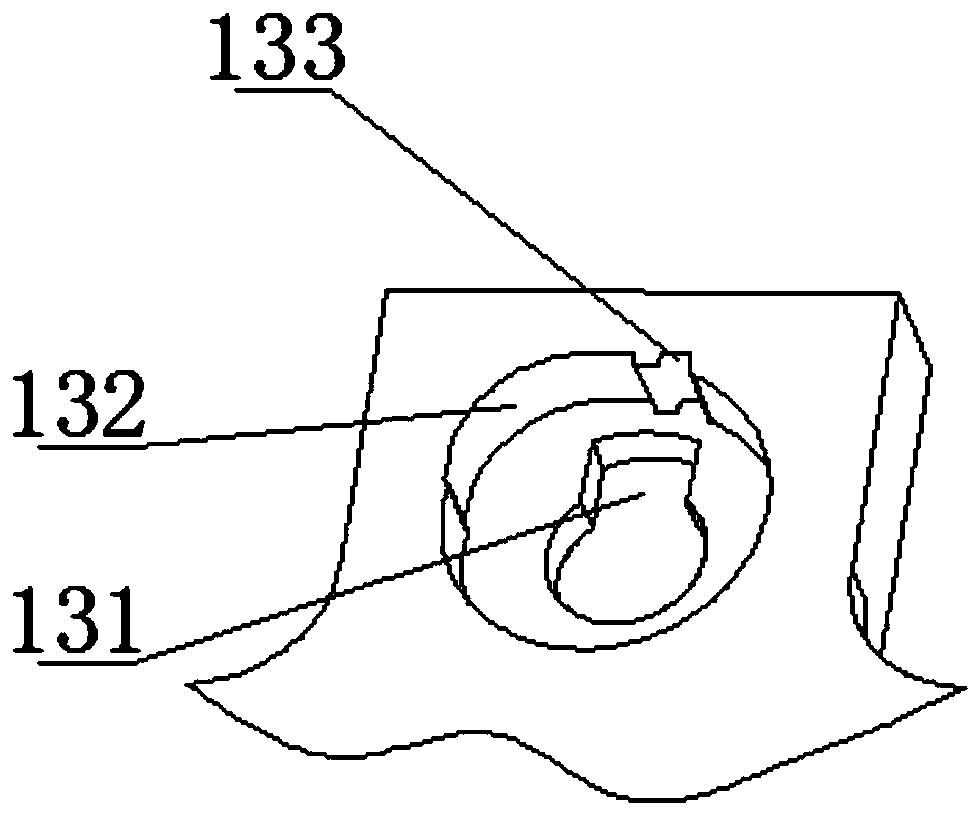

Detachable floor-brush bottom plate and dust-collector electric floor brush

ActiveCN107736841ASame cross-sectional areaGreat suctionMechanical suction controlSuction nozzlesSuction forceEngineering

The invention provides a detachable floor-brush bottom plate and a dust-collector electric floor brush. The floor-brush bottom plate is arranged on the bottom surface of the dust-collector electric floor brush. The floor-brush bottom plate includes a plate body, the middle of the plate body is provided with a dust absorbing opening, and the plate body is provided with a connection structure used for rapid disassembly. Compared with the prior art, the floor-brush bottom plate can be dismantled, floor-brush bottom plates different in shape and structure can be replaced for dust collectors different in power, the dust absorbing pressure and the suction-force flow velocity between the dust absorbing opening of the floor brush and the ground are adjusted, the universality of the floor brush isimproved, and the manufacturing cost is saved.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

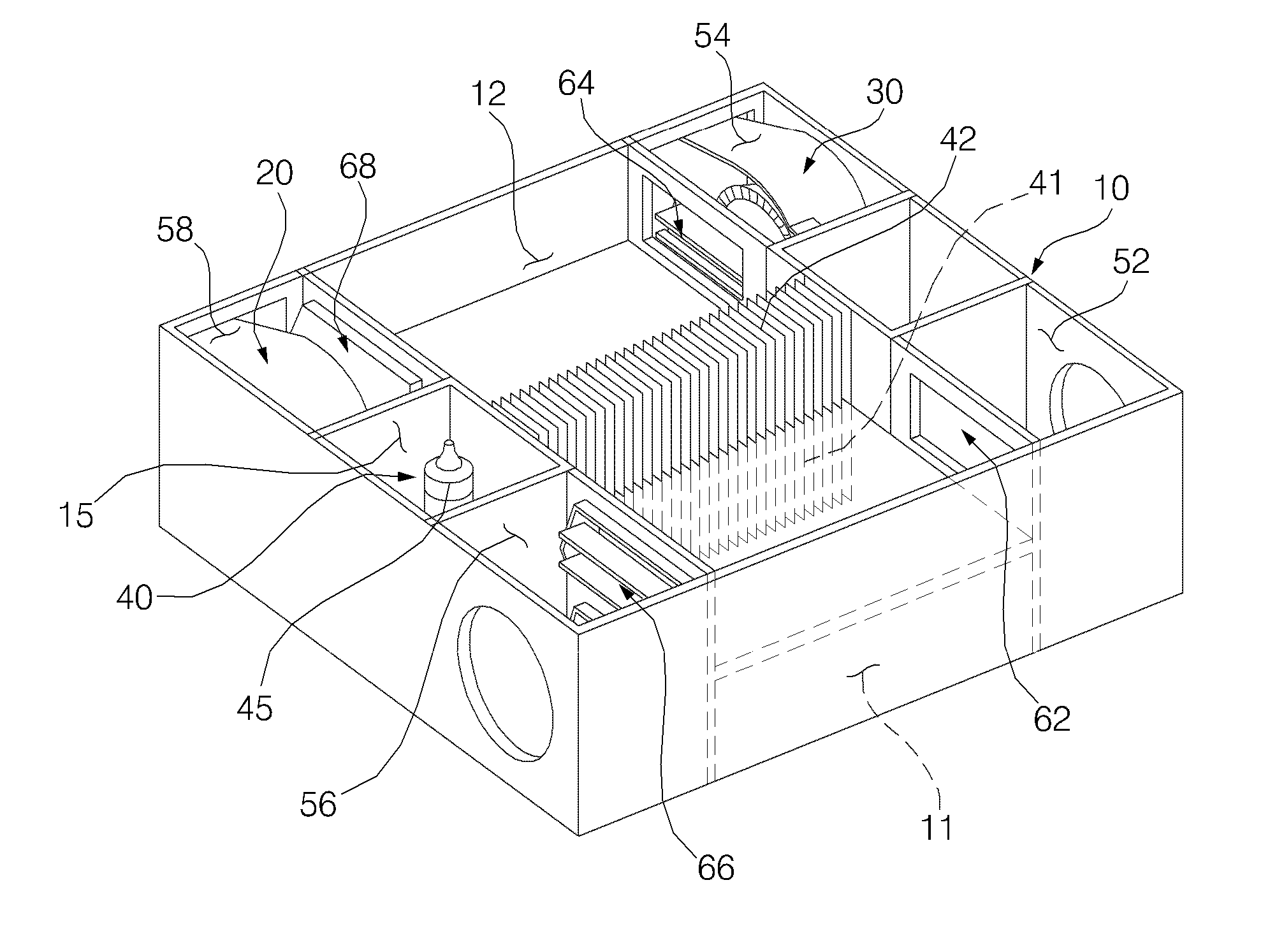

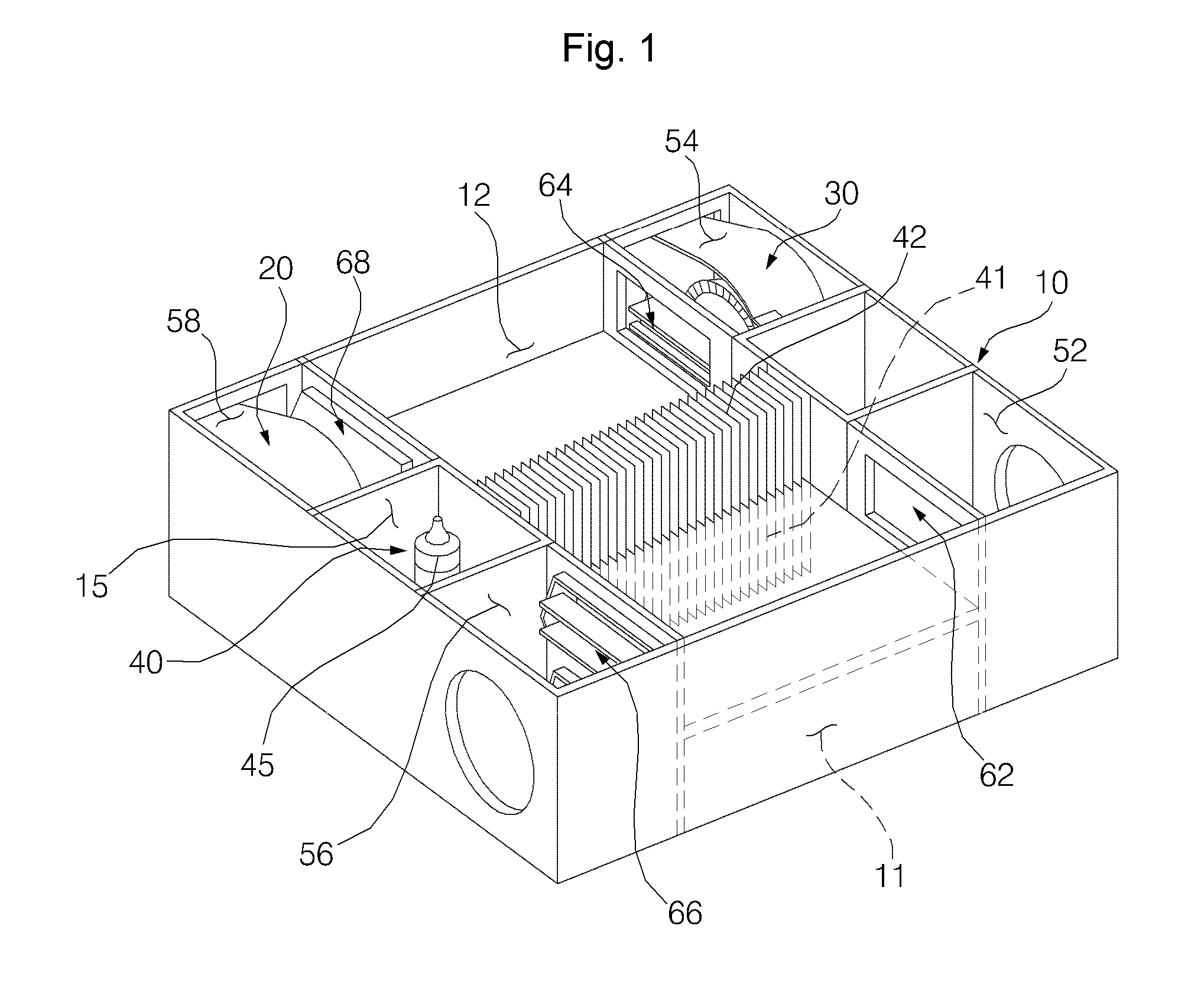

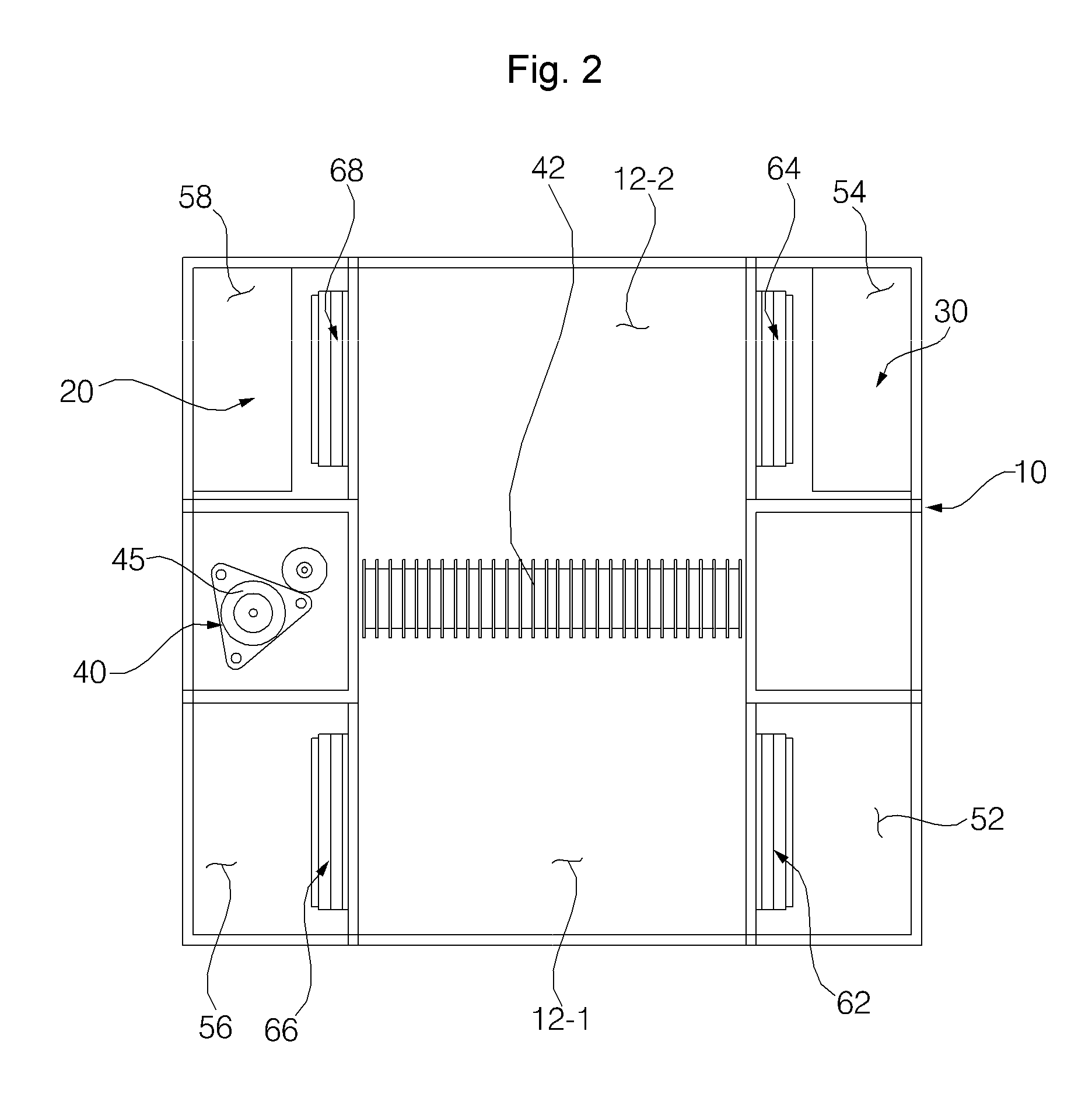

Ventilation Appartus

InactiveUS20160201942A1Air resistance is minimizedDrag minimizationEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringIndoor air

A ventilation apparatus includes a casing having the inside partitioned into a first floor and a second floor. A first sharing duct is formed in the first floor and configured to suck one of indoor air and outdoor air and to have the sucked air horizontally moved. A second sharing duct is formed in the second floor and configured to suck the other of indoor air and outdoor air and to have the sucked air horizontally moved. First and second heat exchangers are disposed in the first and second sharing ducts, respectively. The ventilation apparatus is advantageous in that air resistance is minimized, horizontally moving air is subject to heat exchange with the entire area of the heat exchanger, and efficiency of heat exchange between air and the heat exchanger is improved because air is divided into the first floor and the second floor and horizontally moved.

Owner:LG ELECTRONICS INC

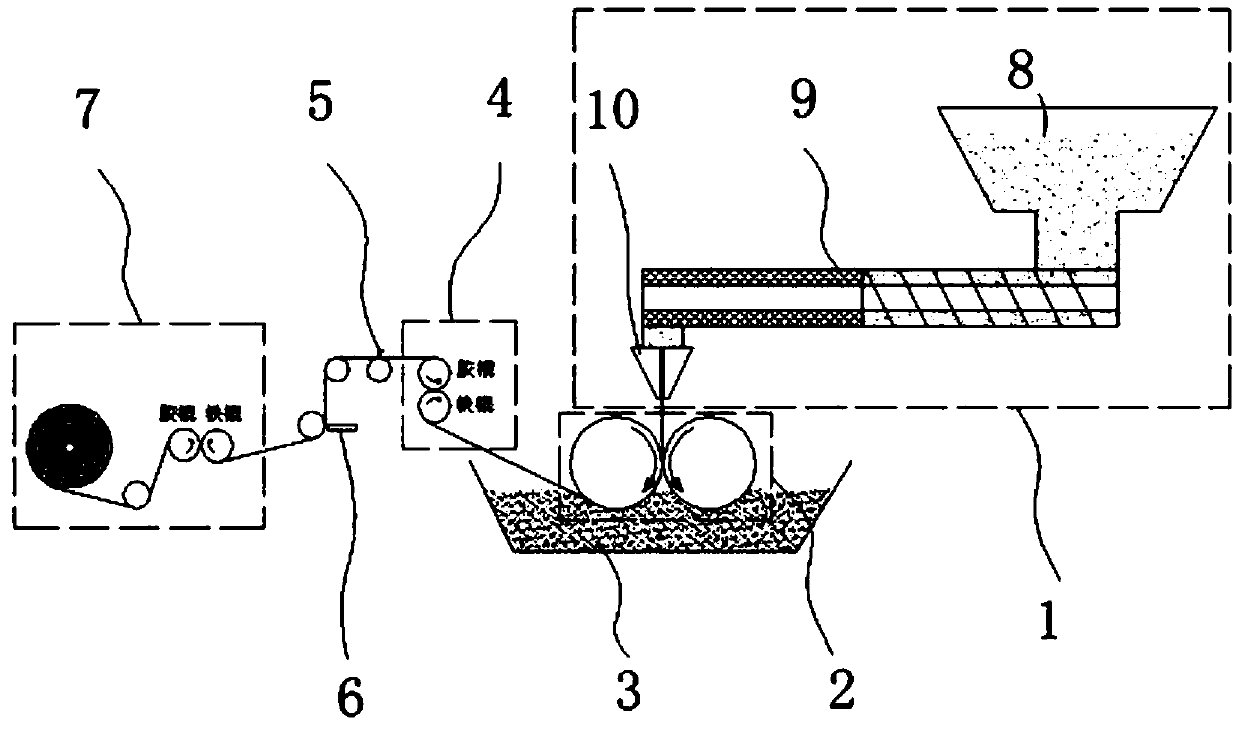

A plastic extrusion film of renewable plastic and its production equipment

The invention discloses a plastic extruded and pressed film of renewable plastics and its production equipment. Its composition is polypropylene, and it is characterized in that: its composition also includes low-density polyethylene, high-density polyethylene, water-absorbing agent, white Mother, the weight of polypropylene is 1-10 grams, the weight of low-density polyethylene is 0.4-10 grams, the weight of high-density polyethylene is 0.4-10 grams, the weight of water-absorbing agent is 0.2-2 grams, and the weight of white mother It is 0.2-2 grams, and the present invention is mainly used in the production equipment of plastic extrusion film pressing.

Owner:吕英炜

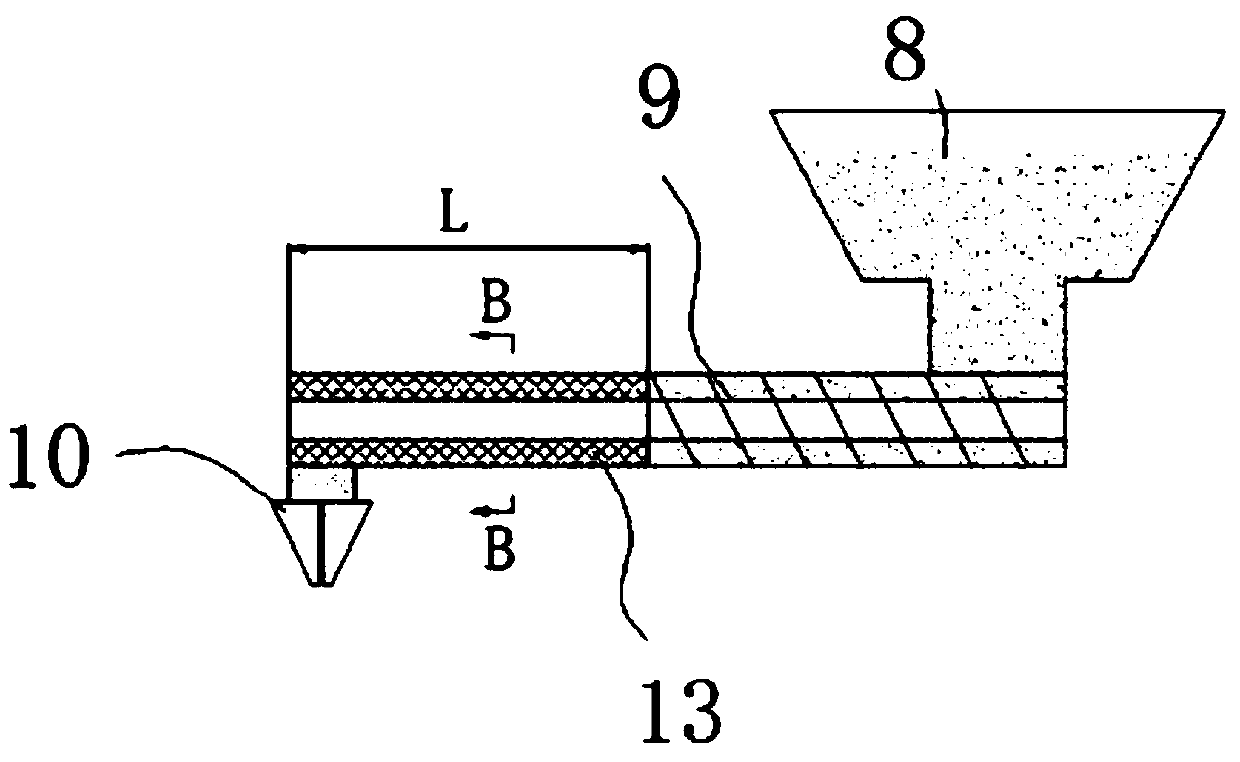

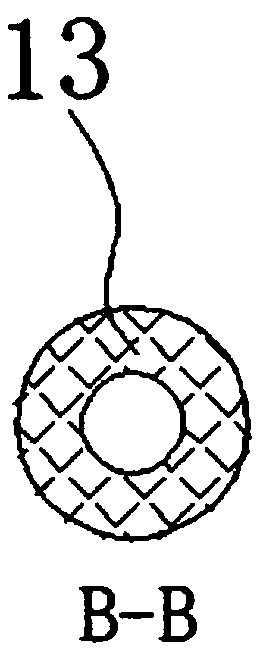

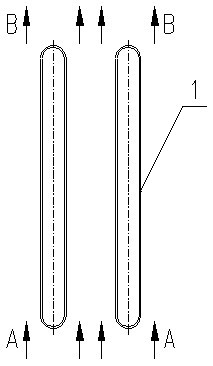

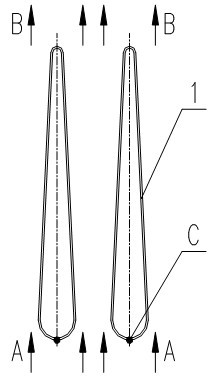

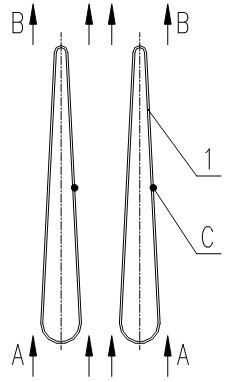

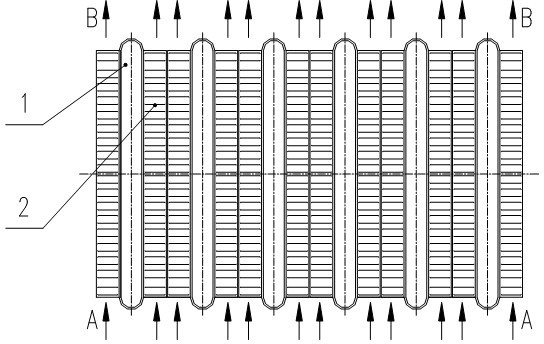

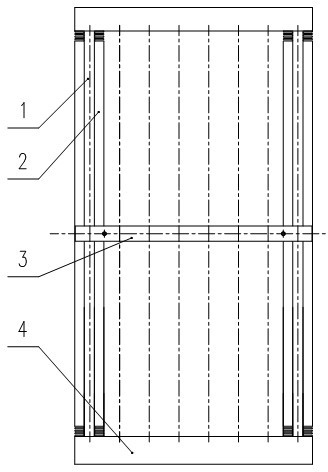

Heat exchange base tube for direct air-cooling condenser

InactiveCN102607311AConstant velocityReduce energy consumptionTubular elementsAir separationSteam condensation

The invention relates to a heat exchange base tube for a direct air-cooling condenser, which is applied to the exhaust-steam condensation field of turbines of thermal power plants, steam turbines in chemical and air separation industries and the like. The cross section of the heat exchange base tube (1) is shaped like a wedge and the size of the heat exchange base tube (1) is decreased along the flow direction of air. The heat exchange base tube for the direct air-cooling condenser is shaped like a wedge, the volume of hot air subjected to the air expansion is contained and the flow velocity of the air remains unchanged when the air flows through the heat exchange base tube, so that the resistance at the air side of the heat exchange base tube for the condenser can be decreased to achieve the purpose of reducing the energy consumption of a fan. When the heat exchange base tube for the direct air-cooling condenser is applied to direct air-cooling condensers of large-scale thermal power plants, the advantage of low resistance is more prominent.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Substrate treatment process

Owner:VON ARDENNE ANLAGENTECHNIK GMBH

Self-closed integrally cast air preheater

ActiveCN102313294BOvercoming the problem of smoke leakage on the sealing surfaceImprove sealingCombustion processIndirect carbon-dioxide mitigationAir preheaterStructural engineering

The invention discloses a self-closed integrally cast air preheater, which comprises a shell body, a smoke inlet, a smoke outlet, an air inlet, an air outlet and a heat exchange component which is arranged in the shell body, wherein the heat exchange component comprises a plurality of cast fin heat exchange units; each cast fin heat exchange unit comprises a first matrix, a second matrix and finswhich are respectively arranged at the two sides of the middles of the first matrix and the second matrix; the two ends of the first matrixes and the second matrixes are connected and molded into onebody so that circular structures are formed; and main passageway structures are formed in the middle through the first matrixes and the second matrixes. Compared with the prior art, the problem of the seal surface smoke leakage of the heat exchange units, which exists in the cast air preheater formed by cast fin board heat exchange units in the prior art, is solved through the self-closed integrally cast air preheater disclosed by the invention, so that the self-closed integrally cast air preheater has the advantages of simple structure and light weight, is sealed reliably and is convenient to clean.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Tube bundle for direct air cooling condenser

The invention relates to a tube bundle for a direct air cooling condenser, which consists of a tube plate, a finned tube and finned tubes, the area of an air flow channel outside the tube, which is formed among between the finned tubes, enlarges step by step, seen from the direction of the cross section of a base tube, the air flow channel from an air inlet to an air outlet appears in V shape. According to the tube bundle for the direct air cooling condenser, the cross section of the base tube (1) is wedge-shaped and changes from large to small along the air flow direction in size; and the cross section of a fin (2) is ladder-shaped and changes from small to large in size, the tube bundle for the direct air cooling condenser has the function of lowering the air side resistance and reducing the energy consumption of a fan, and the advantage of small resistance can be more obvious when the tube bundle is used in the direct air cooling condenser of a large-scale thermal power plant.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

A detachable ground brush bottom plate and electric ground brush of vacuum cleaner

ActiveCN107736841BGreat suctionMake sure to enterMechanical suction controlSuction nozzlesSuction forceStructural engineering

The invention provides a detachable floor-brush bottom plate and a dust-collector electric floor brush. The floor-brush bottom plate is arranged on the bottom surface of the dust-collector electric floor brush. The floor-brush bottom plate includes a plate body, the middle of the plate body is provided with a dust absorbing opening, and the plate body is provided with a connection structure used for rapid disassembly. Compared with the prior art, the floor-brush bottom plate can be dismantled, floor-brush bottom plates different in shape and structure can be replaced for dust collectors different in power, the dust absorbing pressure and the suction-force flow velocity between the dust absorbing opening of the floor brush and the ground are adjusted, the universality of the floor brush isimproved, and the manufacturing cost is saved.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com