A plastic extrusion film of renewable plastic and its production equipment

A technology of recycled plastics and plastics, which is applied in the field of plastic extrusion film pressing and its production equipment, which can solve the problems of inability to produce plastic film products, high production costs, and large resource consumption, so as to reduce the number of replacements, increase the utilization rate, and save energy. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0015] As shown in the figure, a plastic extrusion film made of renewable plastics is composed of polypropylene, and its characteristics are that: its composition also includes low-density polyethylene, high-density polyethylene, water-absorbing agent, white mother, polypropylene The weight of propylene is 1-10 grams, the weight of low-density polyethylene is 0.4-10 grams, the weight of high-density polyethylene is 0.4-10 grams, the weight of water-absorbing agent is 0.2-2 grams, and the weight of white mother is 0.2- 2 grams.

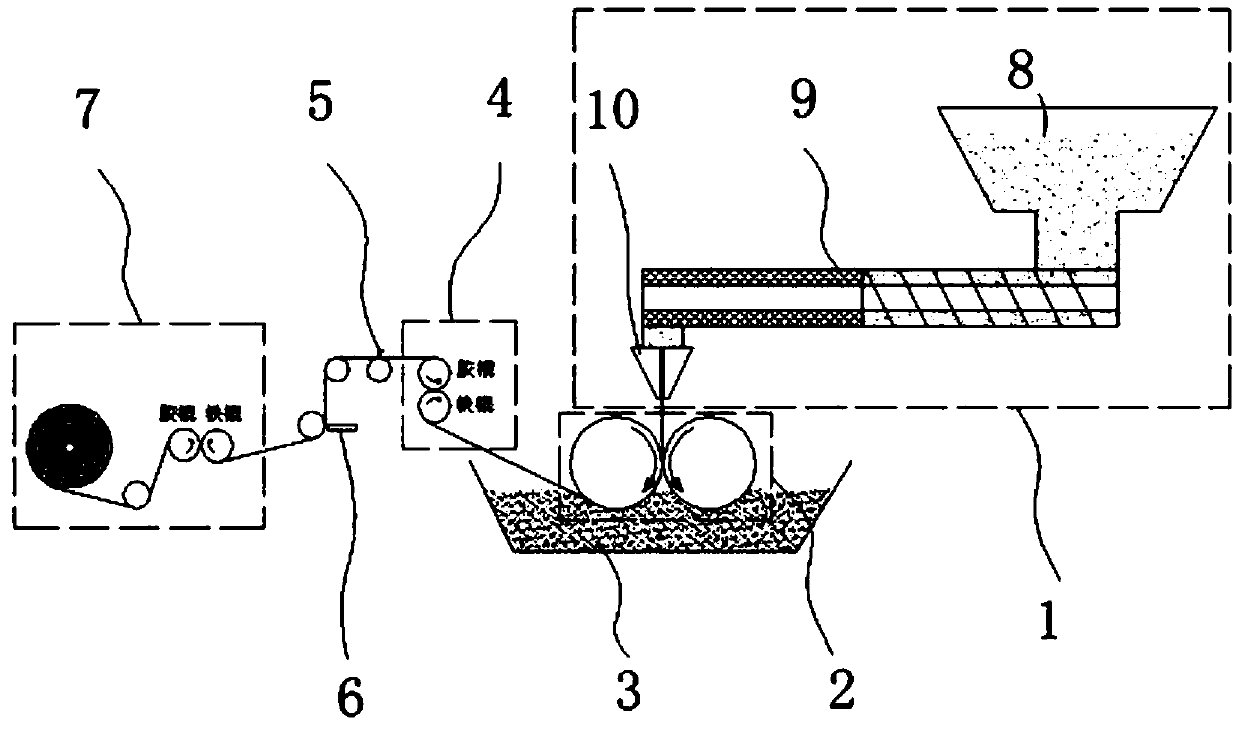

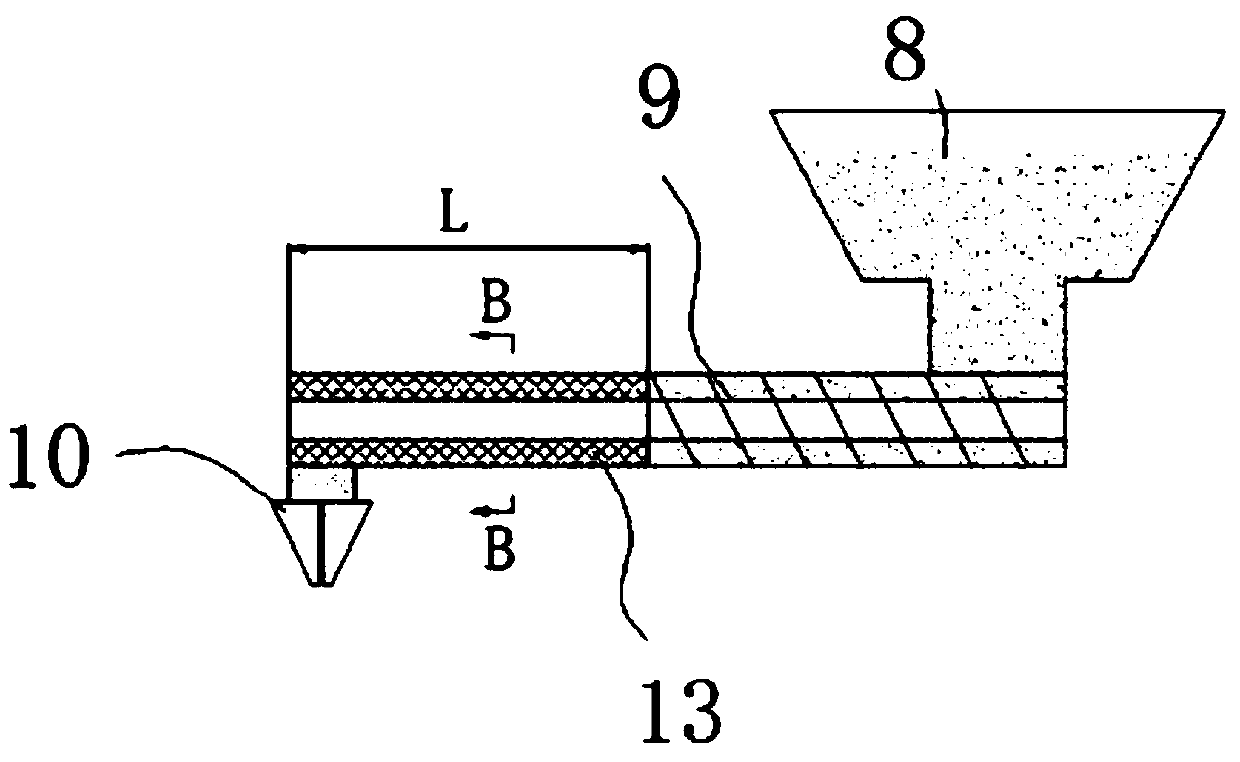

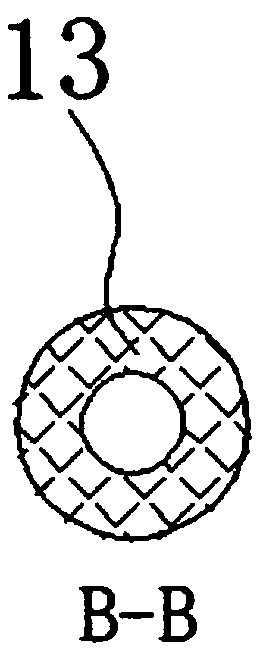

[0016] A plastic extrusion lamination equipment for producing recycled plastics, comprising an extruding device 1 and a shaping device 2 arranged at the lower part of the extruding device, wherein the extruding device 1 includes a feed port 8, and a screw transmission device arranged at the lower part of the feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com