Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about "Testing/calibration for volume metering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

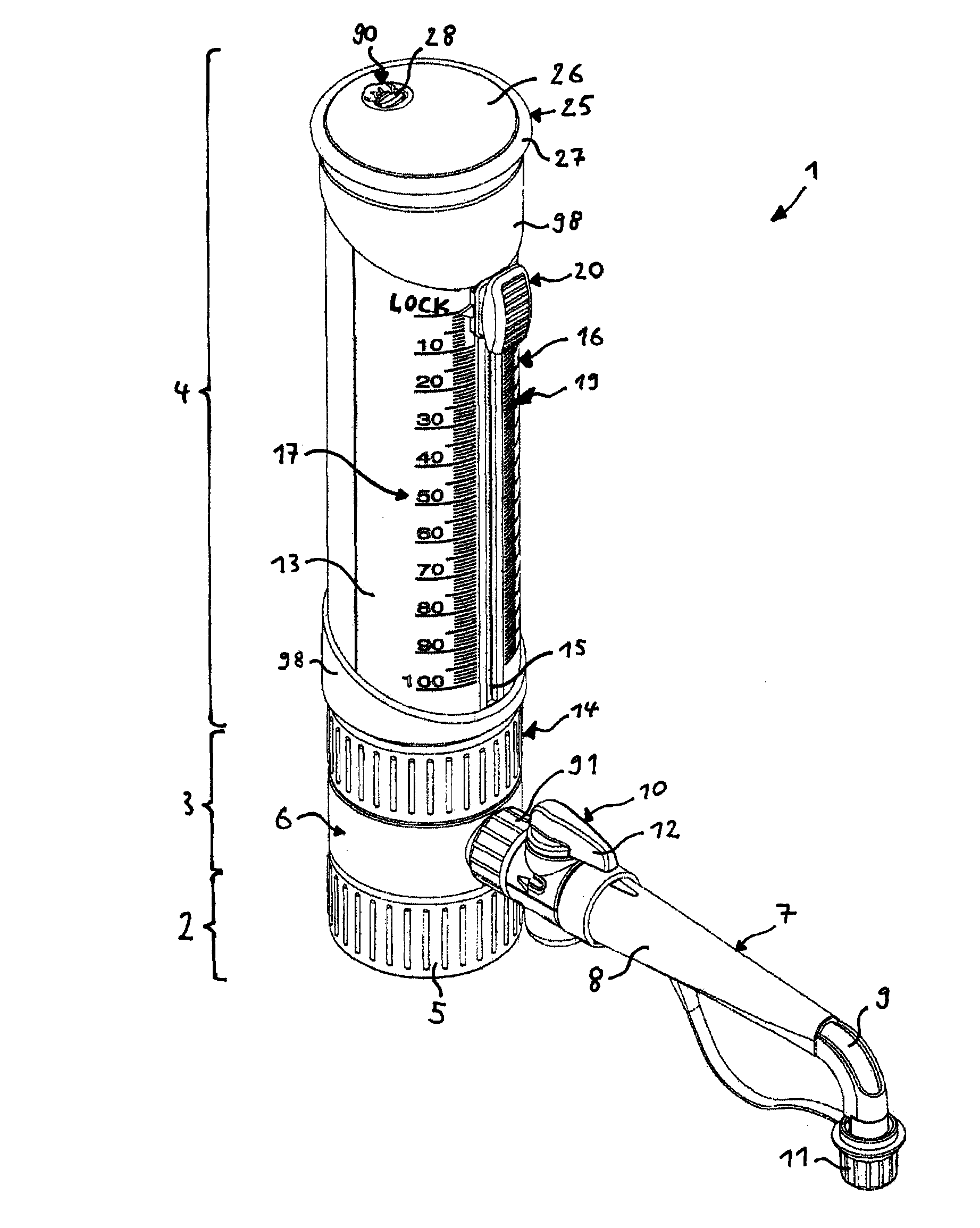

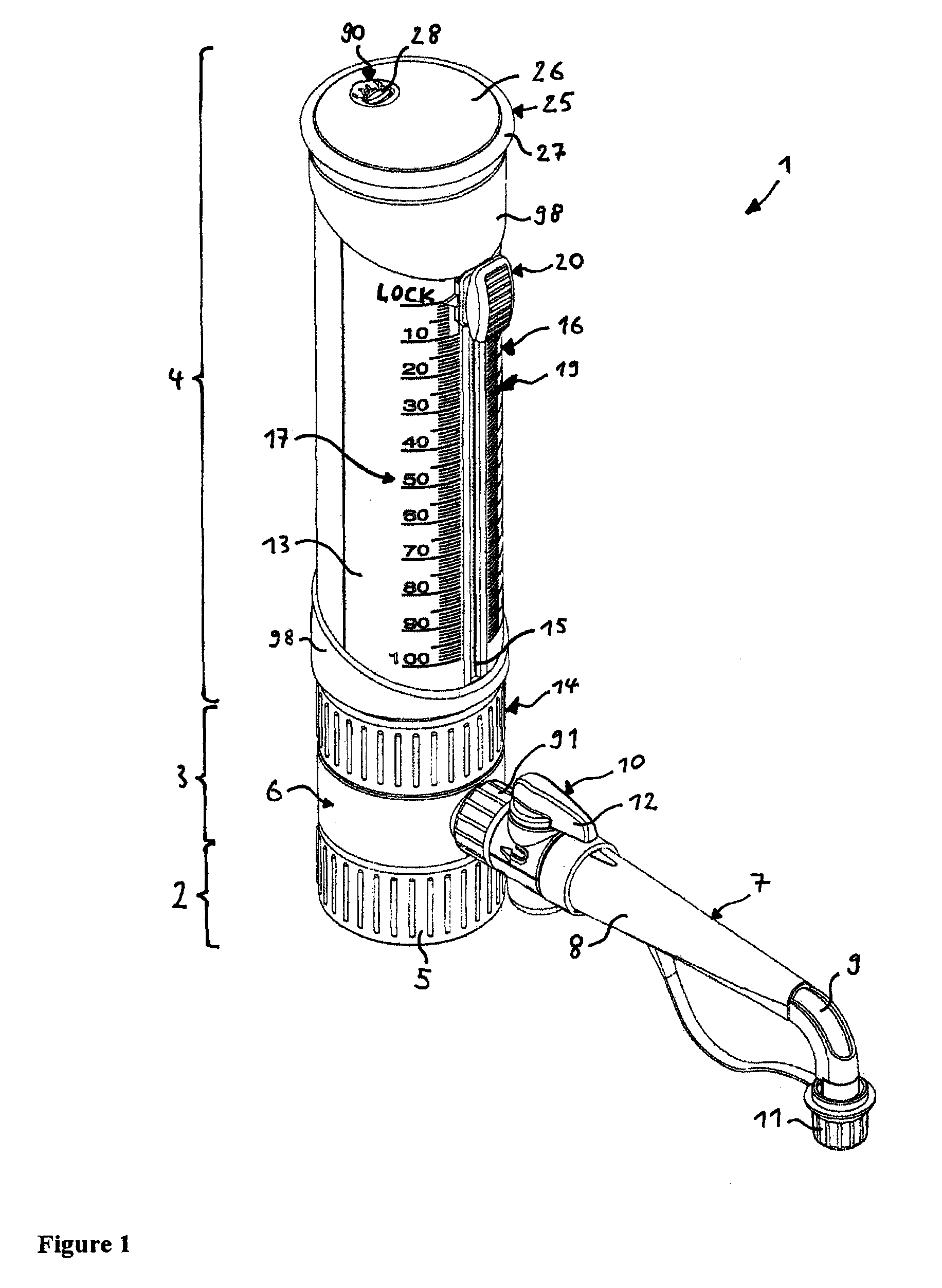

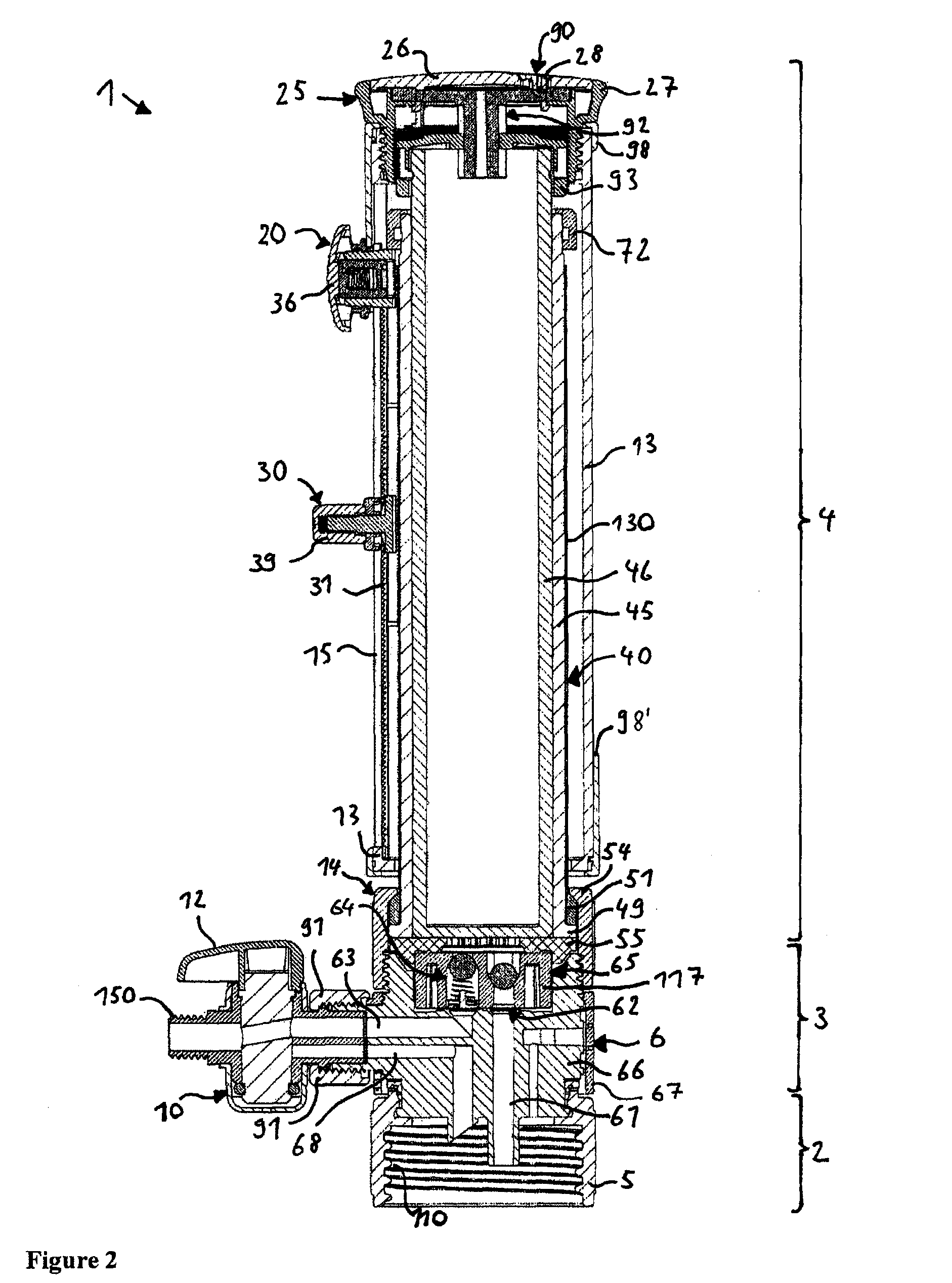

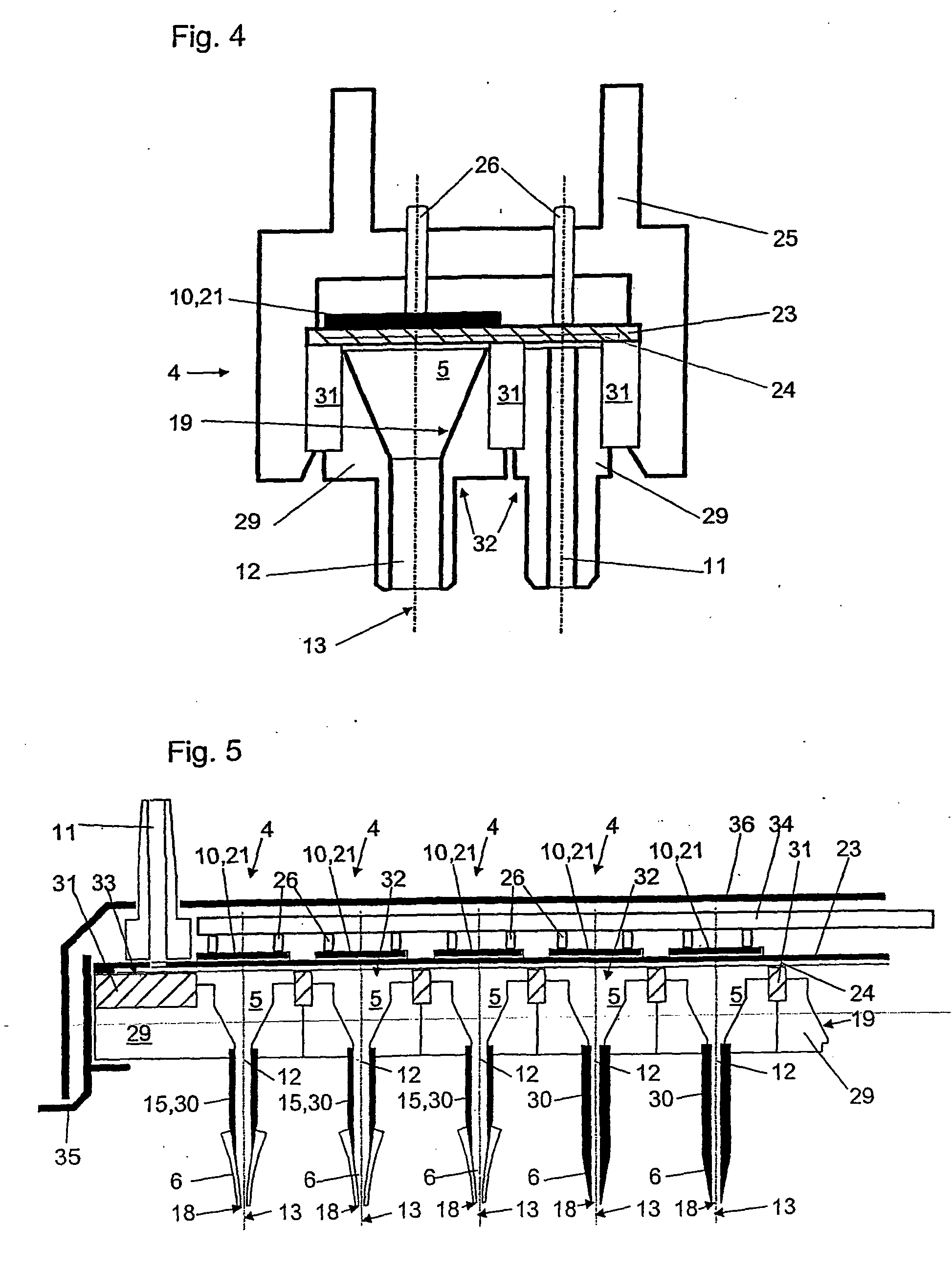

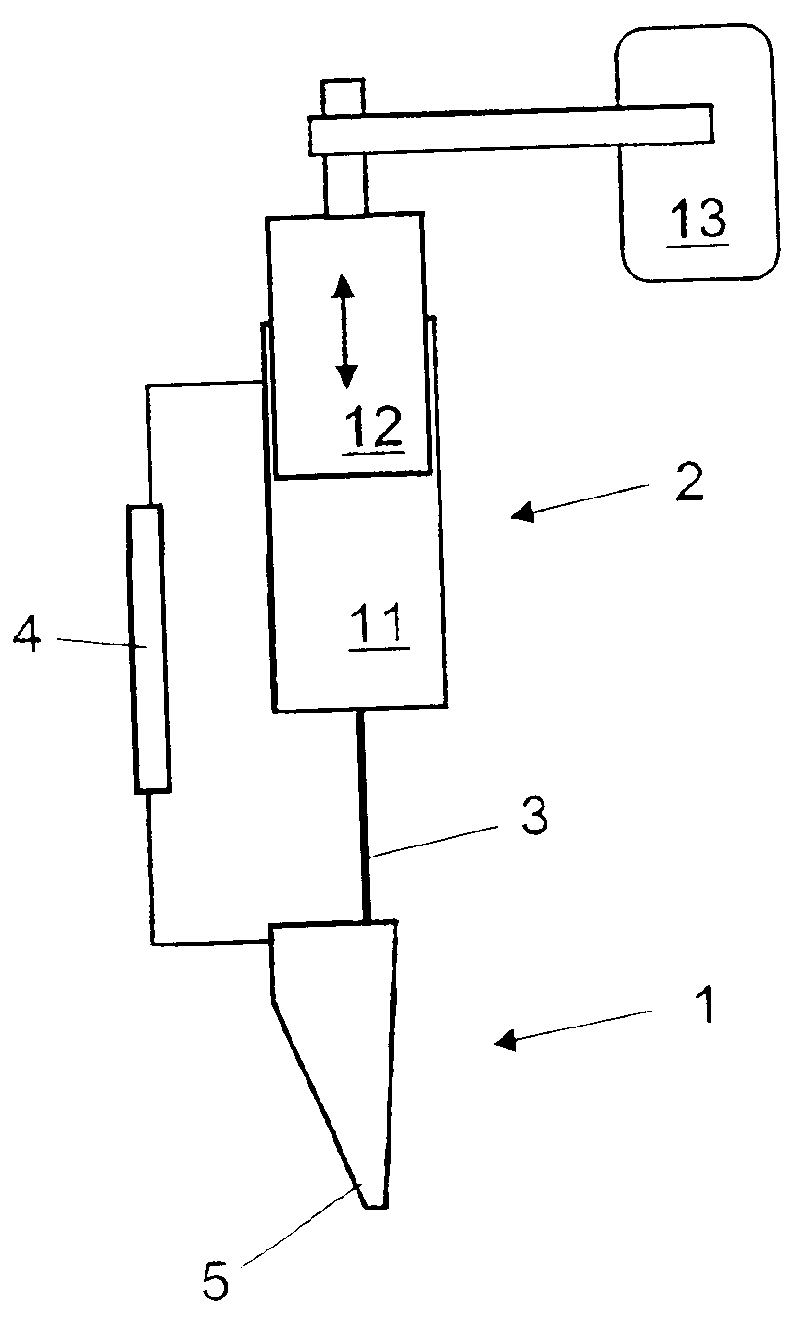

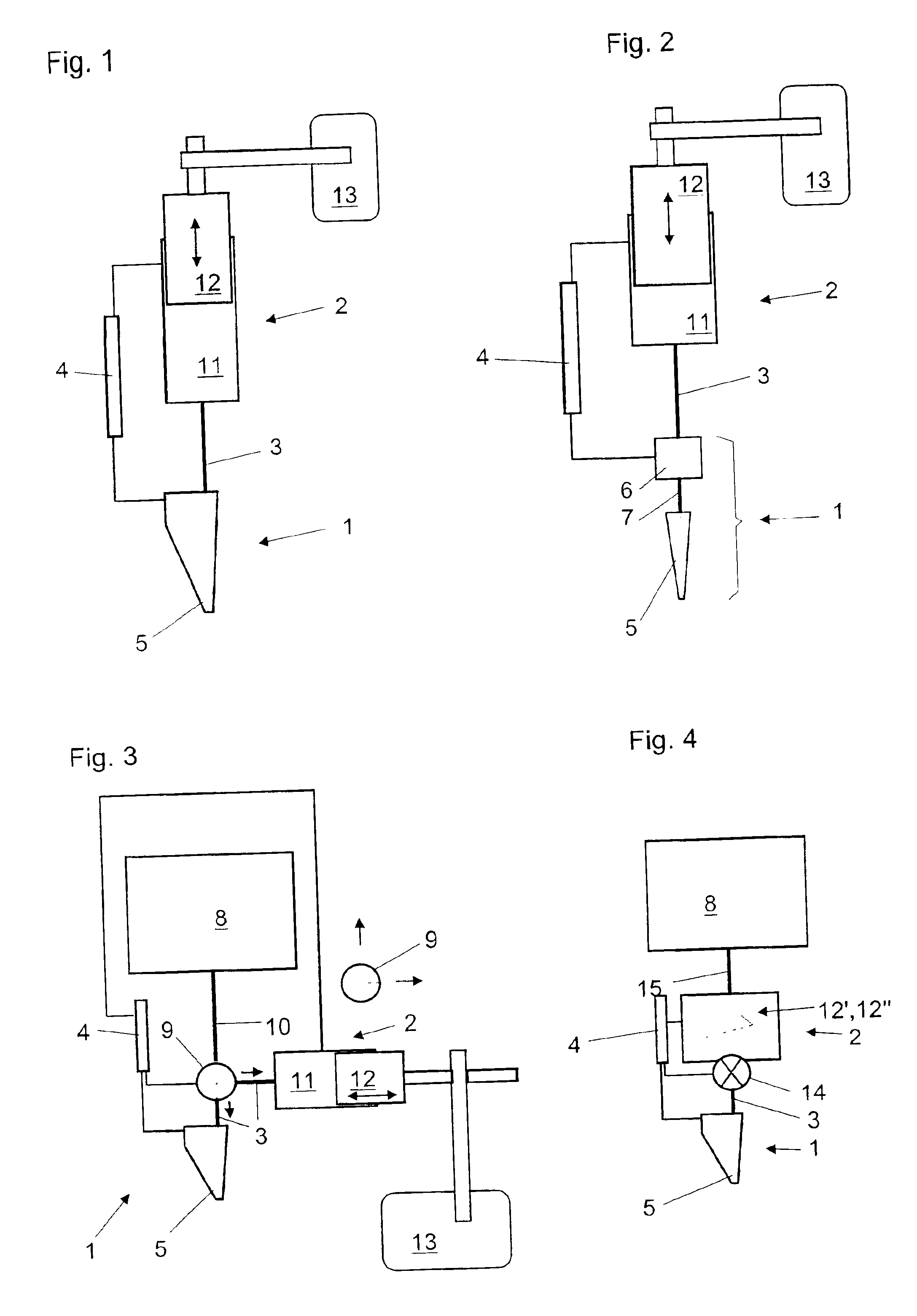

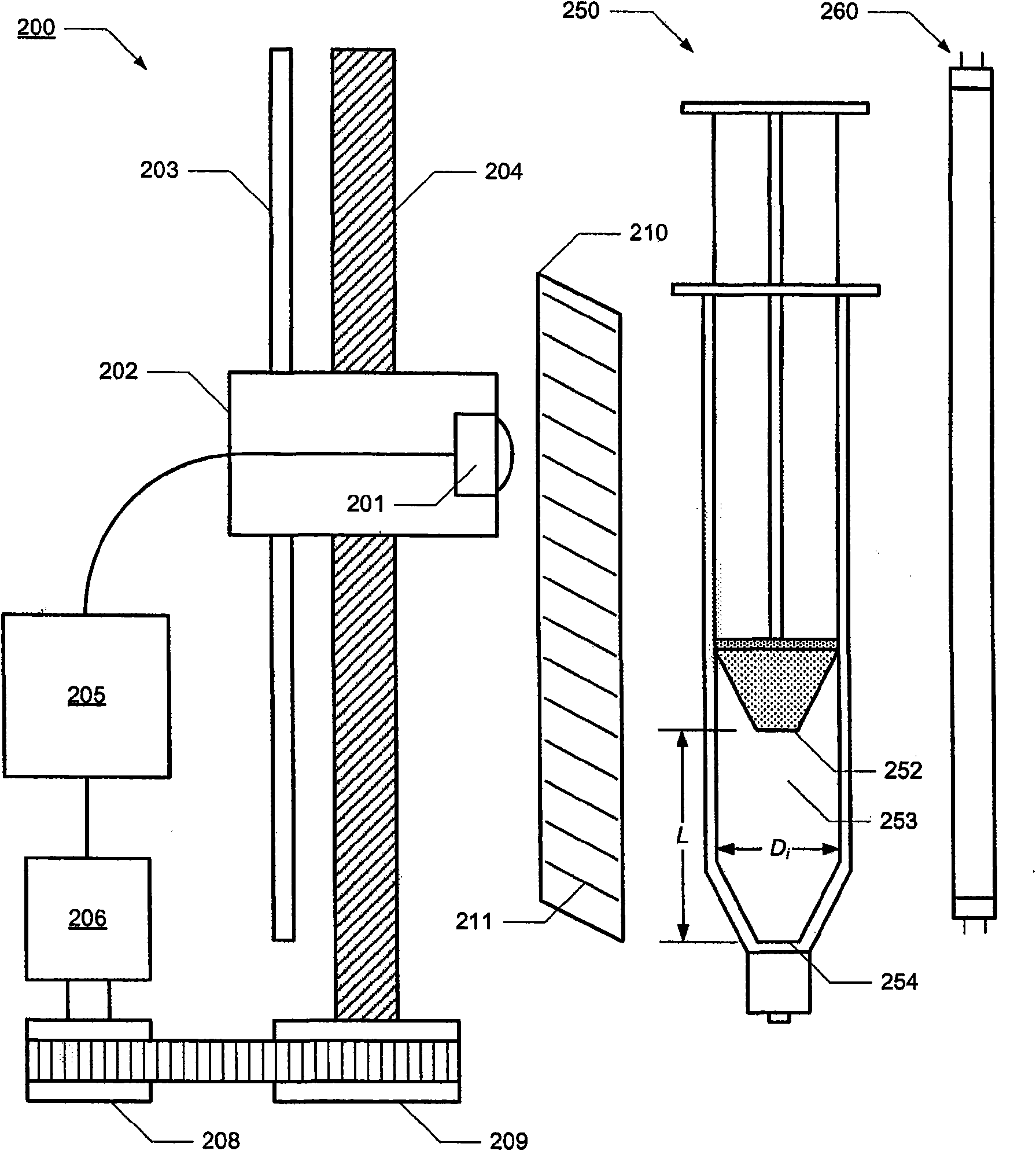

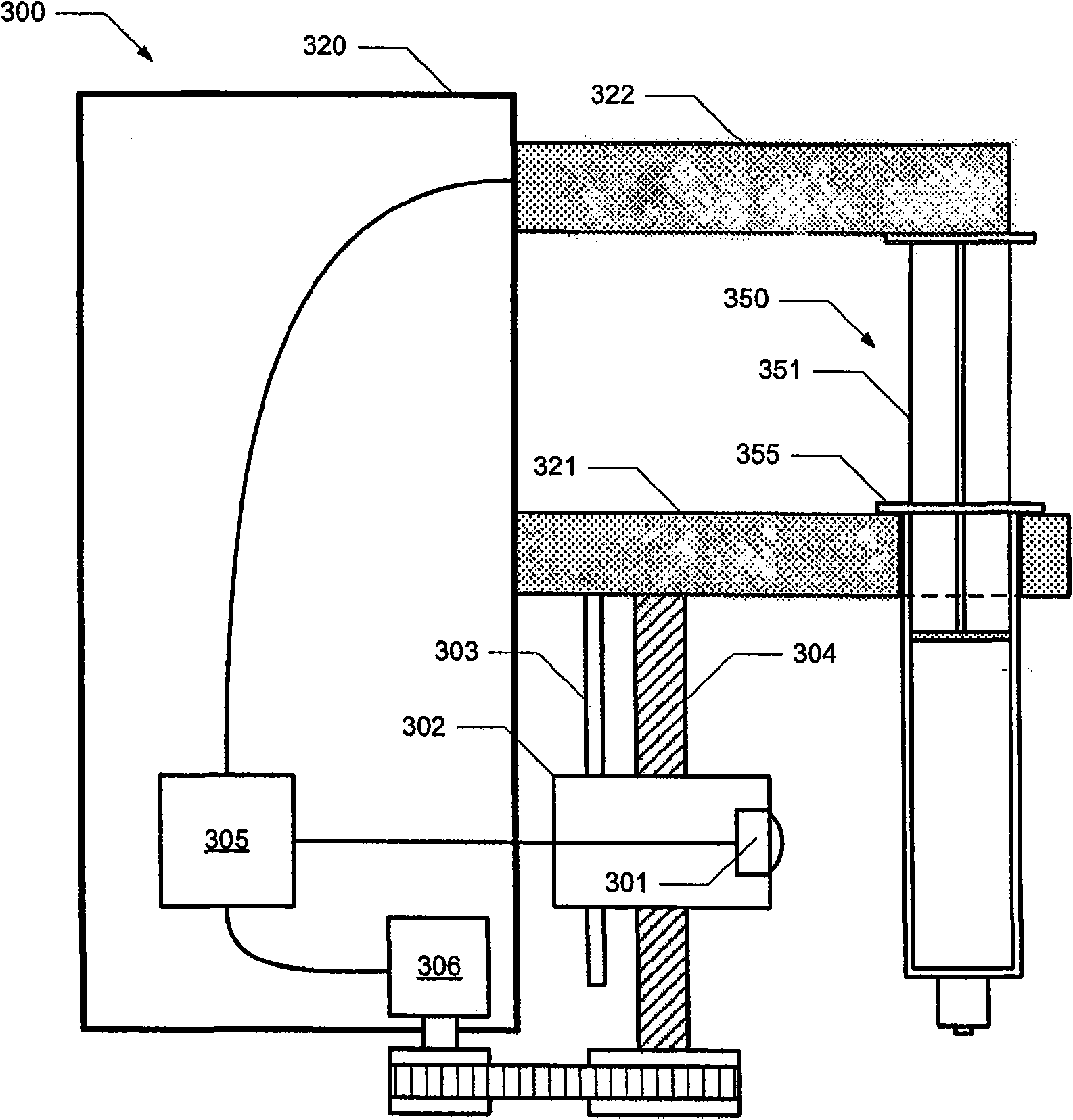

Device for aspirating and dispensing liquid samples

InactiveUS6869571B2Chemical analysis using titrationWithdrawing sample devicesEngineeringMechanical engineering

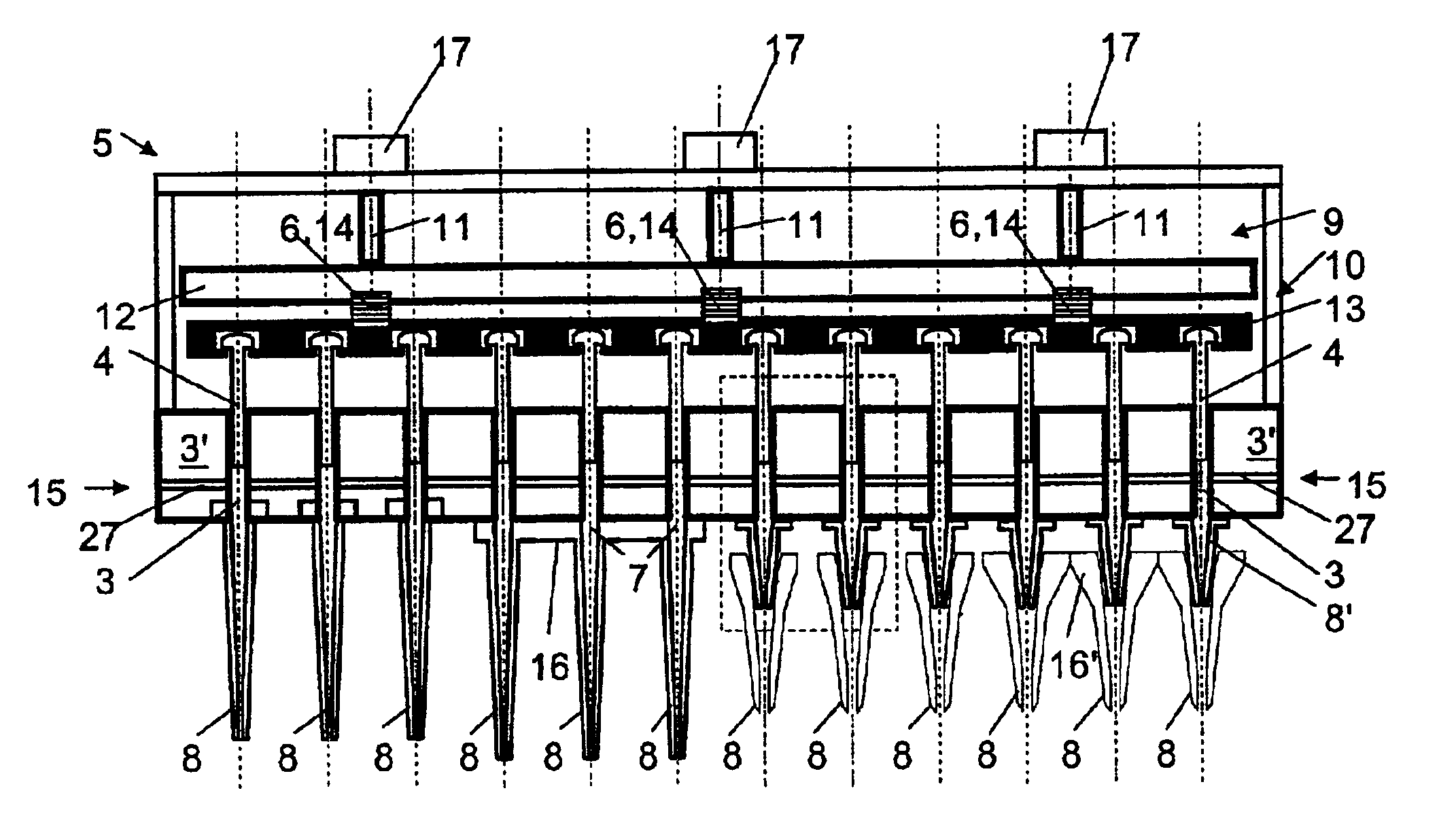

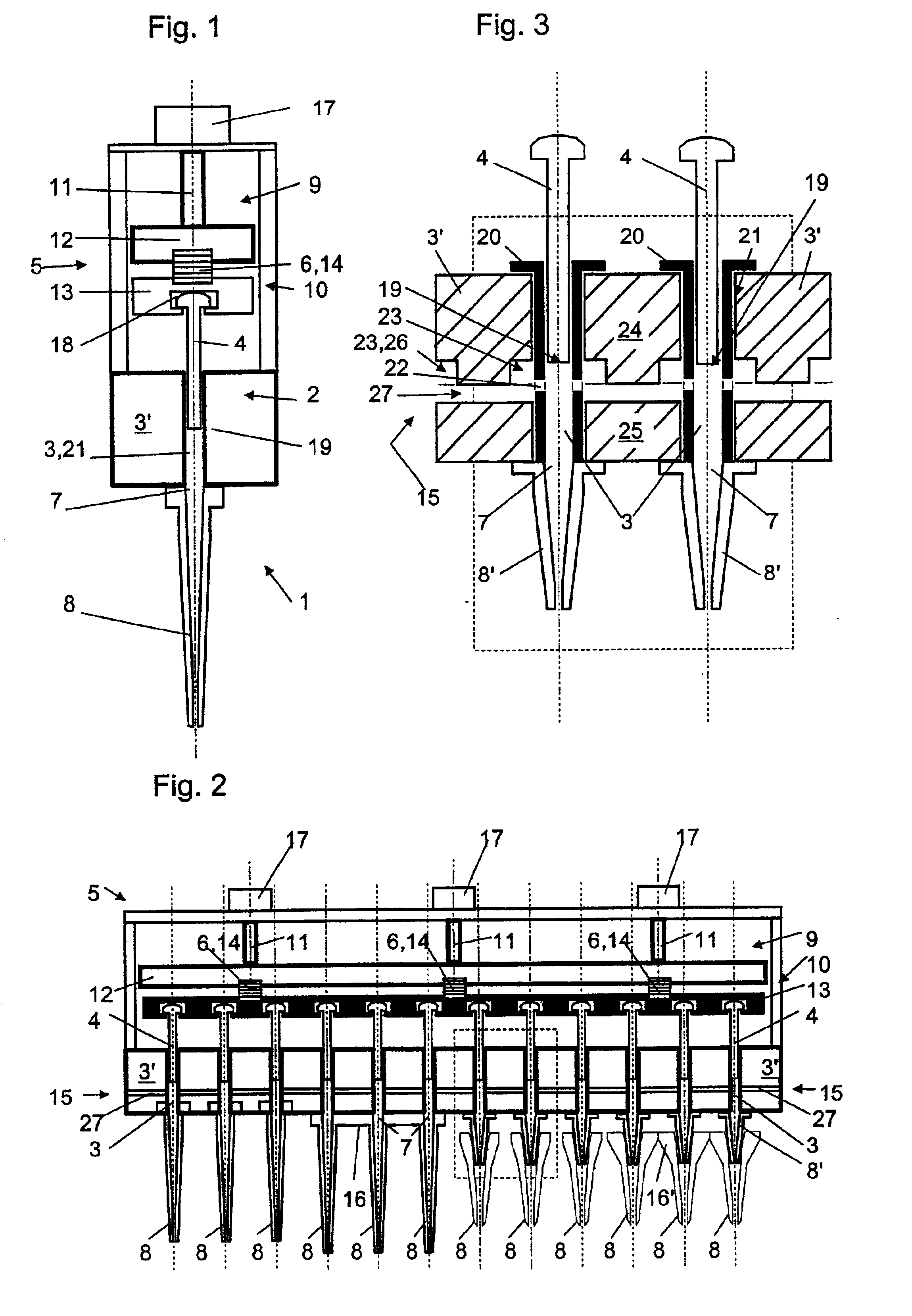

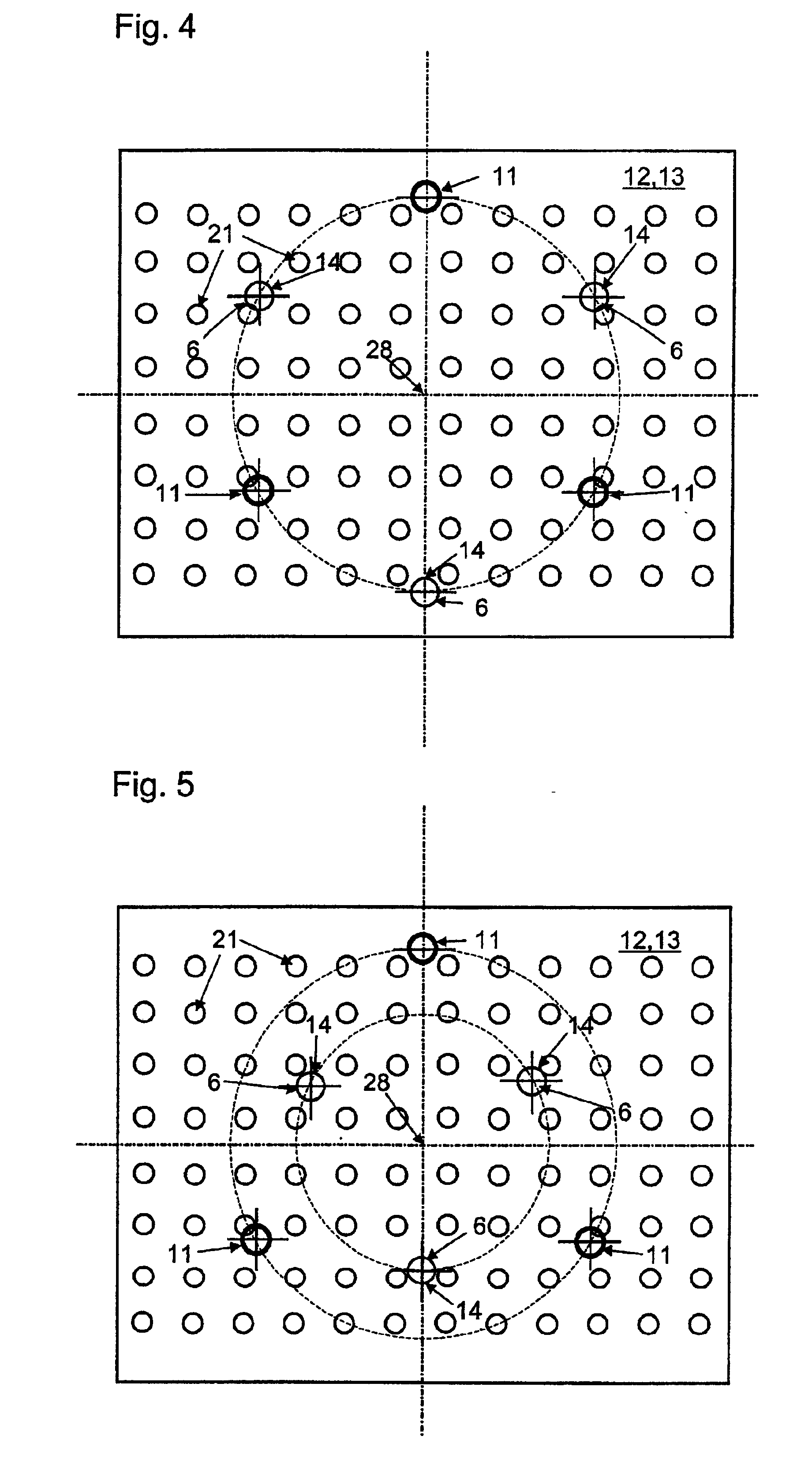

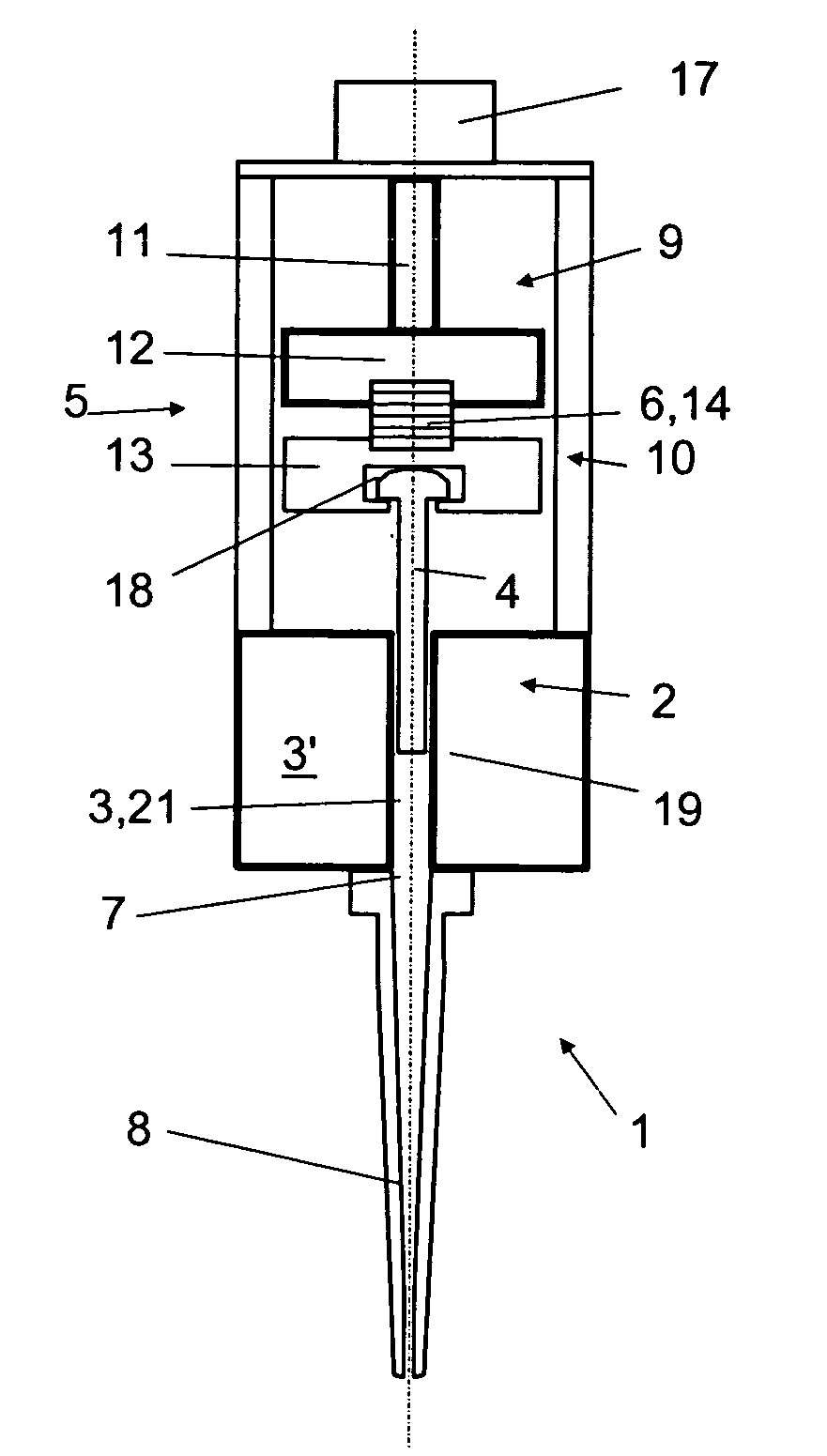

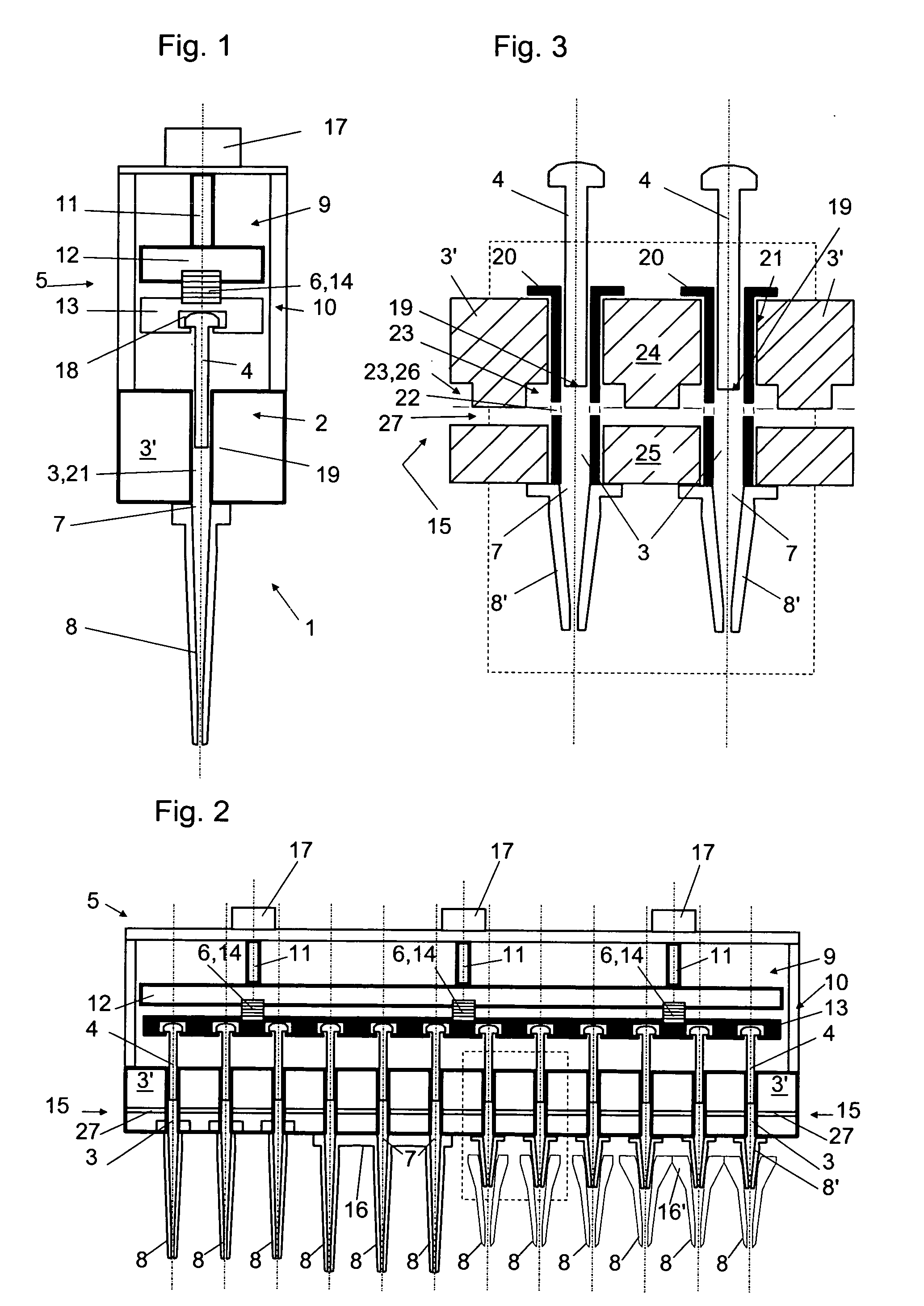

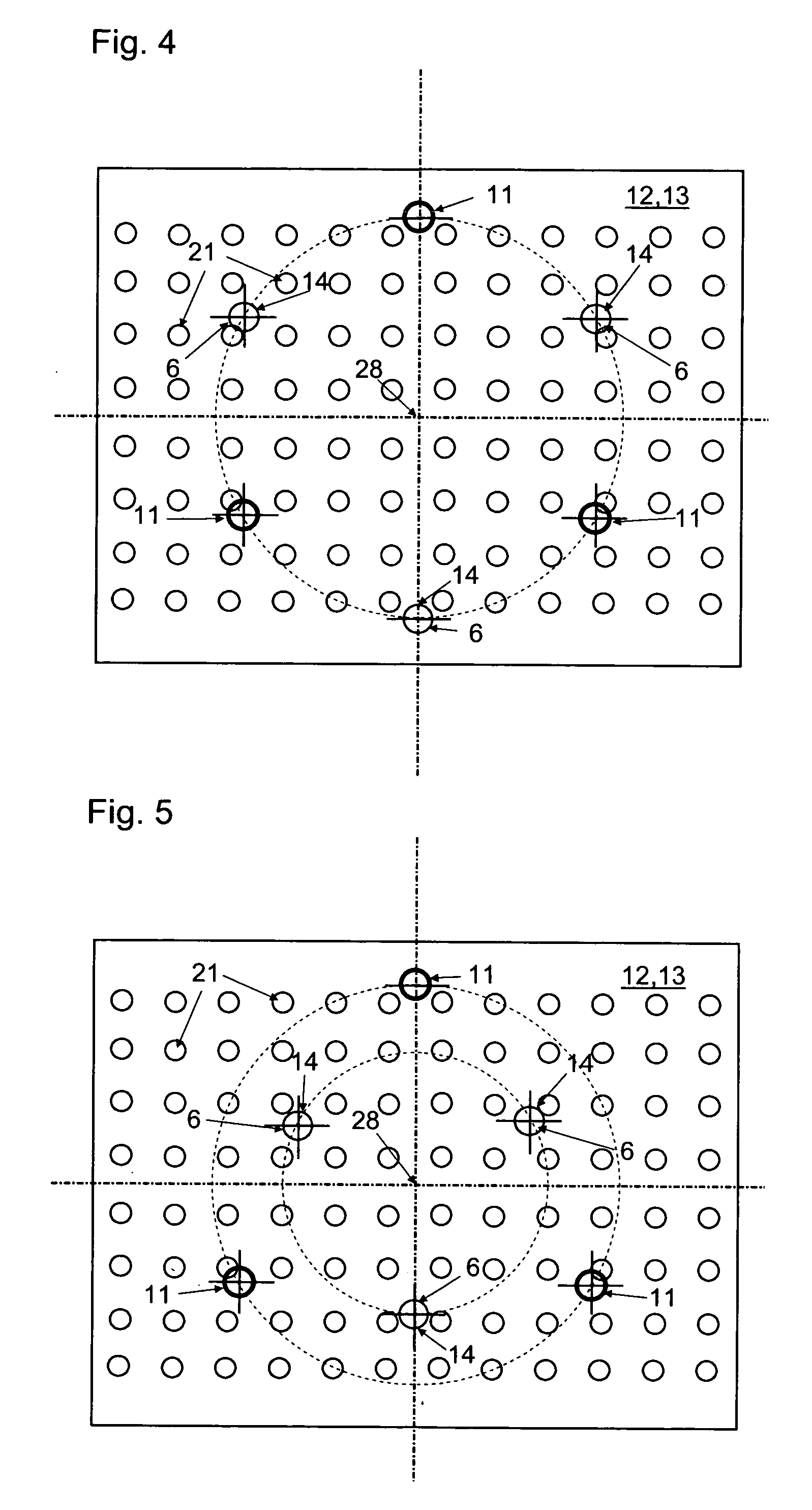

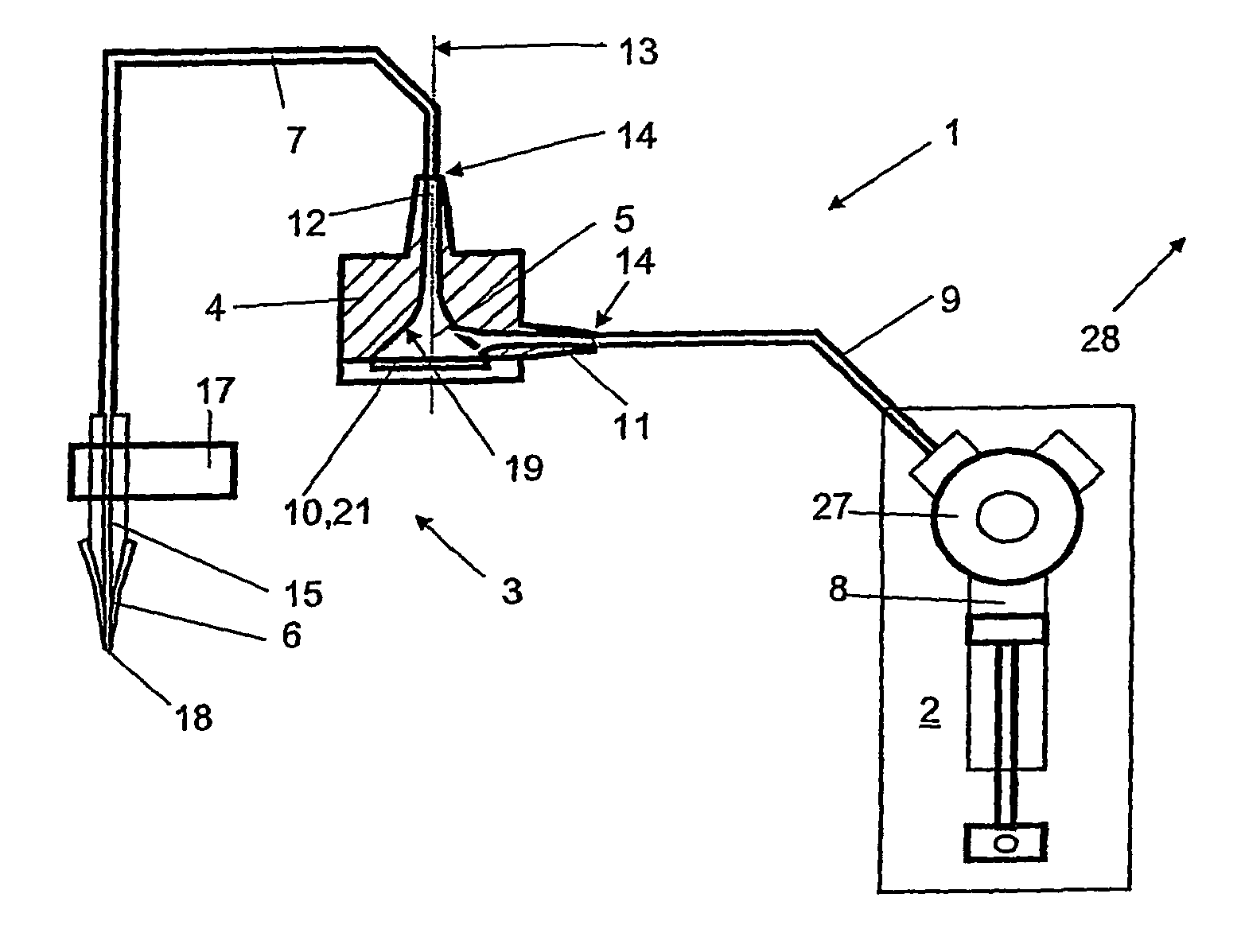

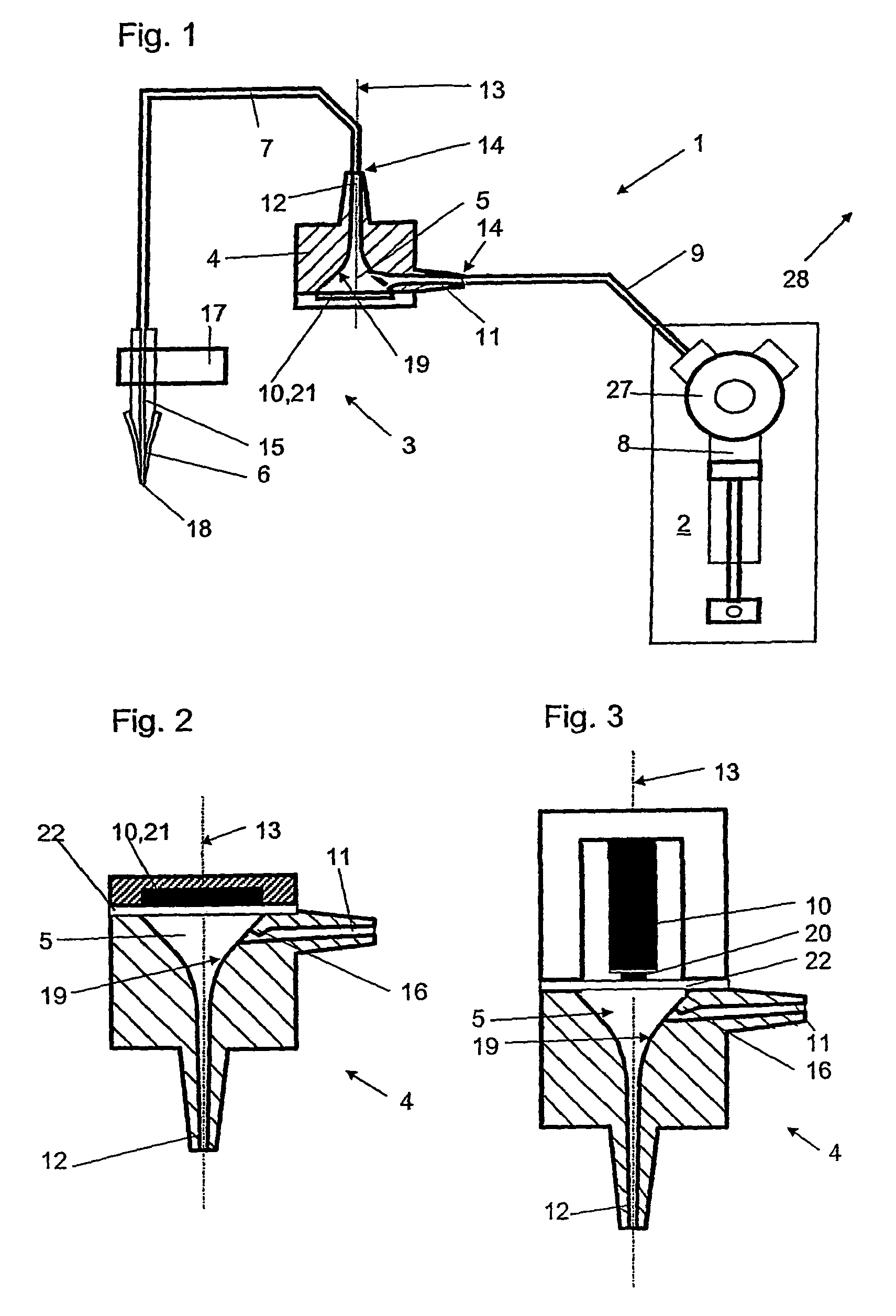

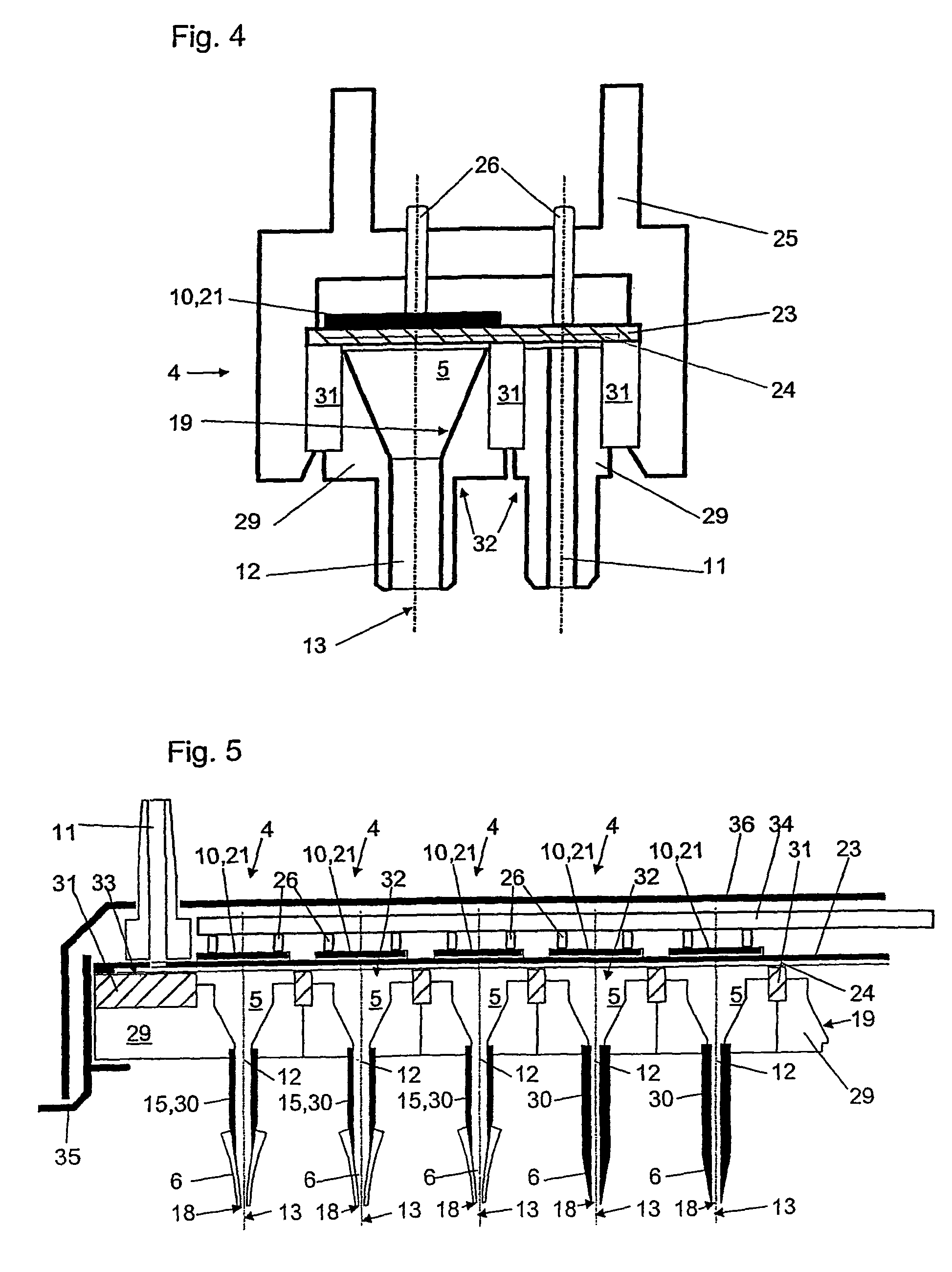

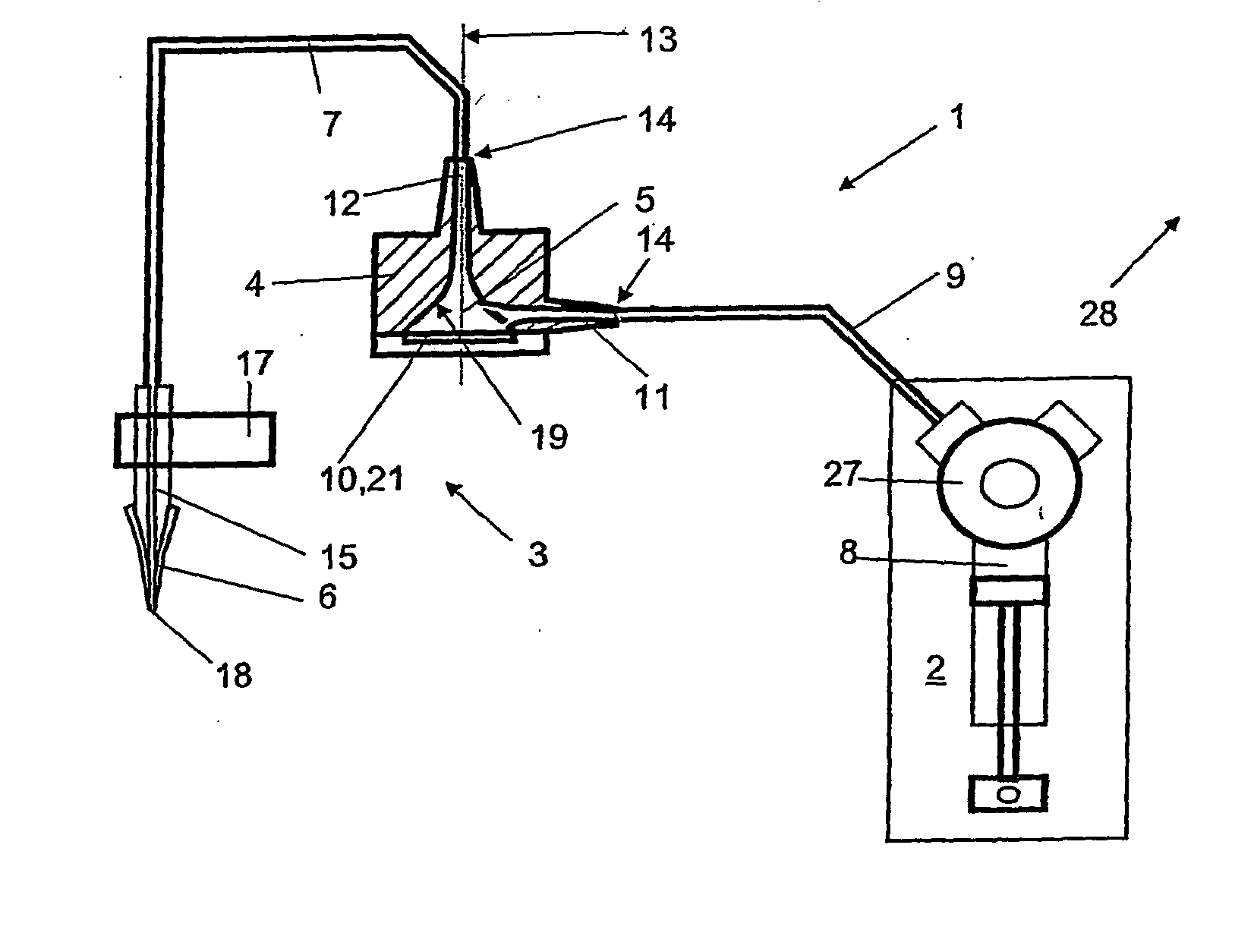

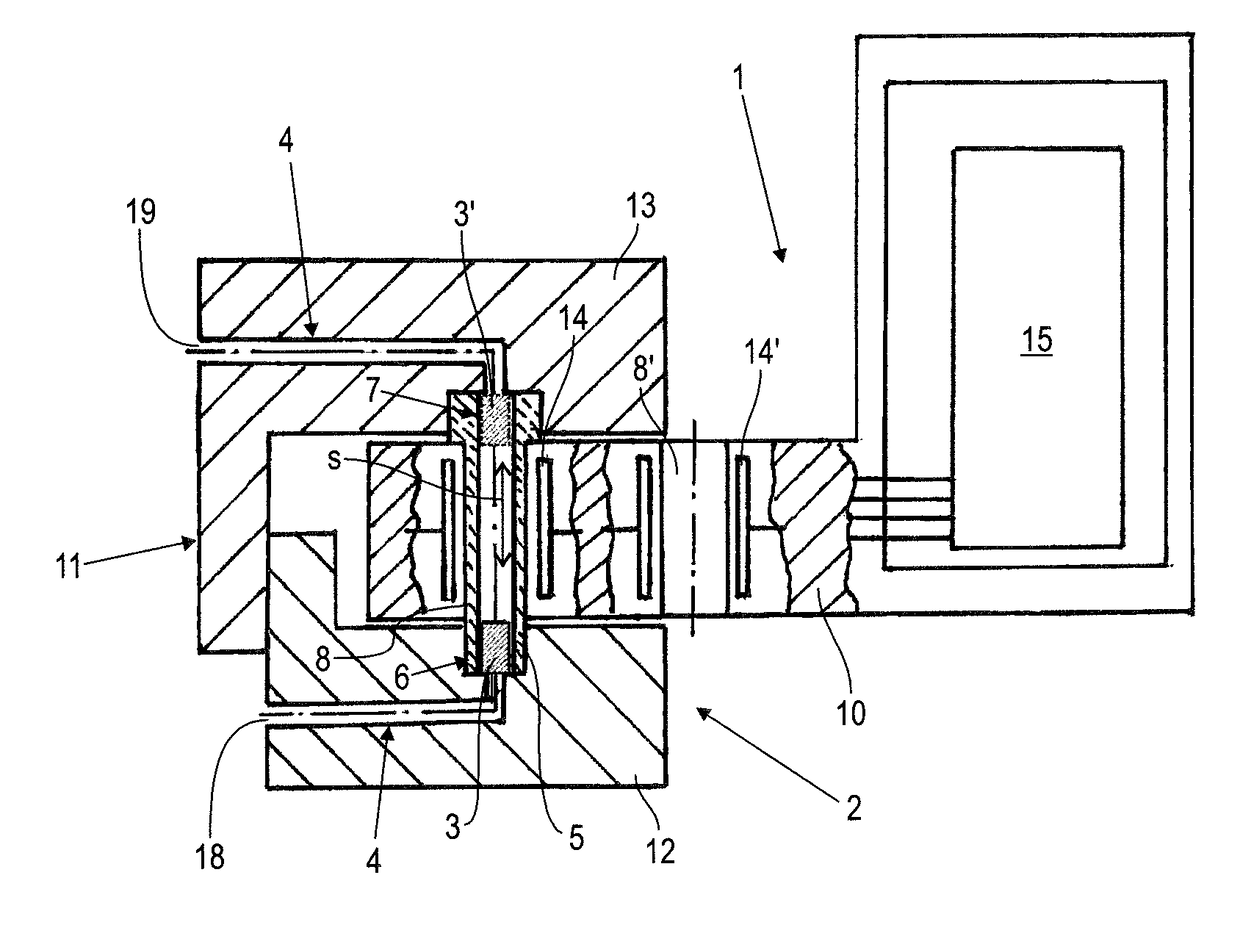

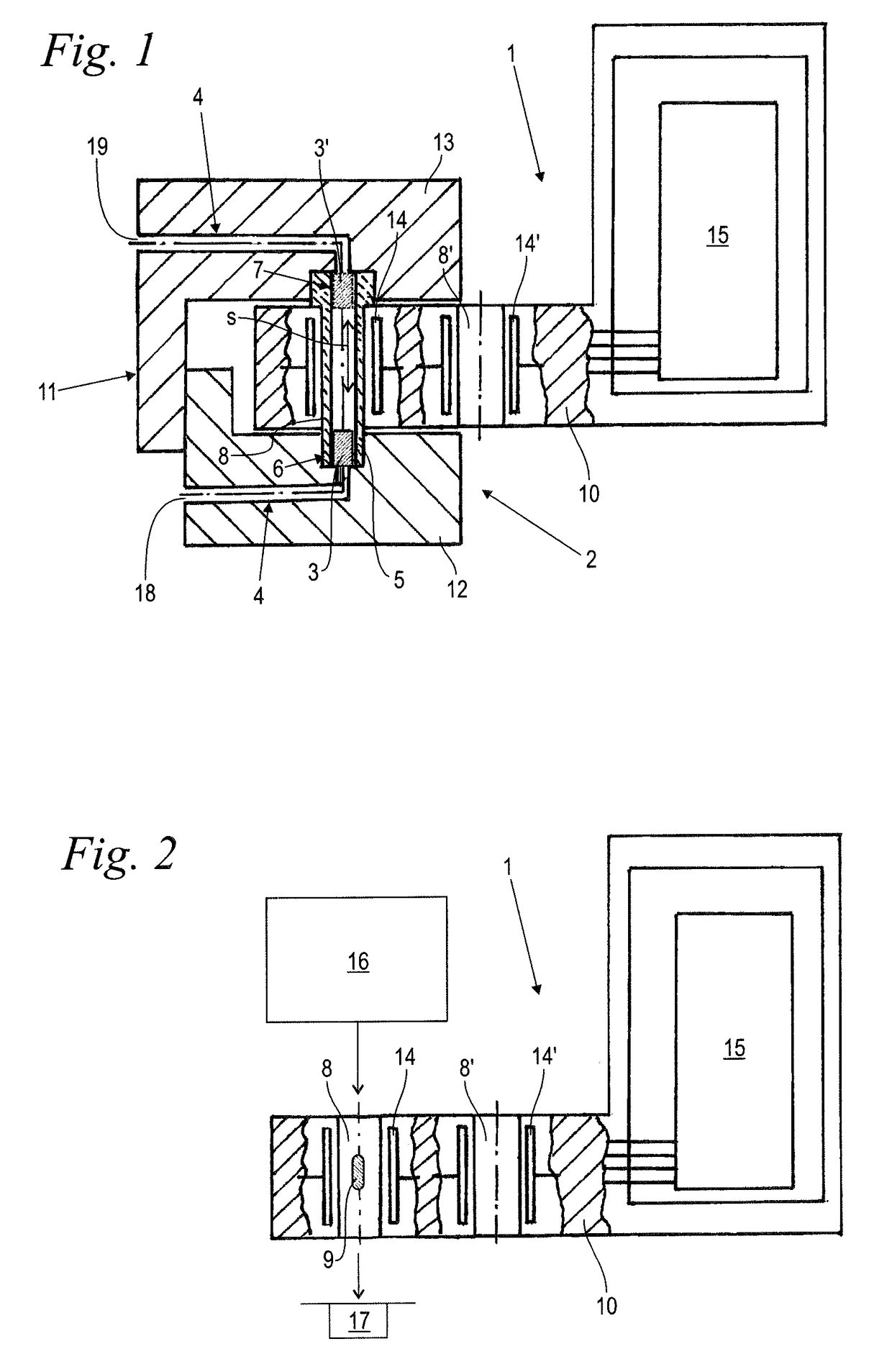

A device (1) for aspirating and dispensing liquid samples having a pump (2), which comprises a cylindrical chamber (3), a piston (4) movable in this cylindrical chamber, and a piston drive (5) engaging on the piston. The device additionally comprises a pulse generator (6), which effects dispensing of samples from a liquid by generating pressure waves in this liquid and a tip (8) connected via a line (7) with the cylindrical chamber (3), with the piston drive (5) comprising a first drive (9) and a second drive (10), implemented as a pulse generator (6). Such a device comprises a channel (27) for rinsing or flushing the cylindrical chamber (3), with the channel (27) discharging into the cylindrical chamber (3). Furthermore, the invention also concerns systems with, for example, 384 or more such devices that are arranged in an array.

Owner:TECAN TRADING AG

Device for aspirating and dispensing liquid samples

A device for aspirating and dispensing liquid samples comprising a pump that comprises a cylindrical chamber, a piston movable in this cylindrical chamber, and a piston drive that engages the piston. The device further comprises a tip connected to the cylindrical chamber with a line, and a channel system that discharges into the cylindrical chamber for flushing or rinsing the latter. The device is characterized in that the piston entirely seals this cylindrical chamber from the channel system, if the piston is positioned in the cylindrical chamber in such a way that a free piston end comes to rest between the channel system and the line. Preferably, the cylindrical chamber is located in a cylinder block, which comprises two parts that are separated by and enclosing an intermediate channel system. The channel system most preferably is implemented as a coherent cavity. According to a first embodiment, the cylindrical chamber is implemented as a sleeve that is inserted in a boring located in a cylinder block. According to a second embodiment, the cylindrical chamber is implemented as a boring located in a cylinder block. Furthermore, the invention also concerns systems with, for example, 384 or more such devices that are arranged in an array.

Owner:TECAN TRADING AG

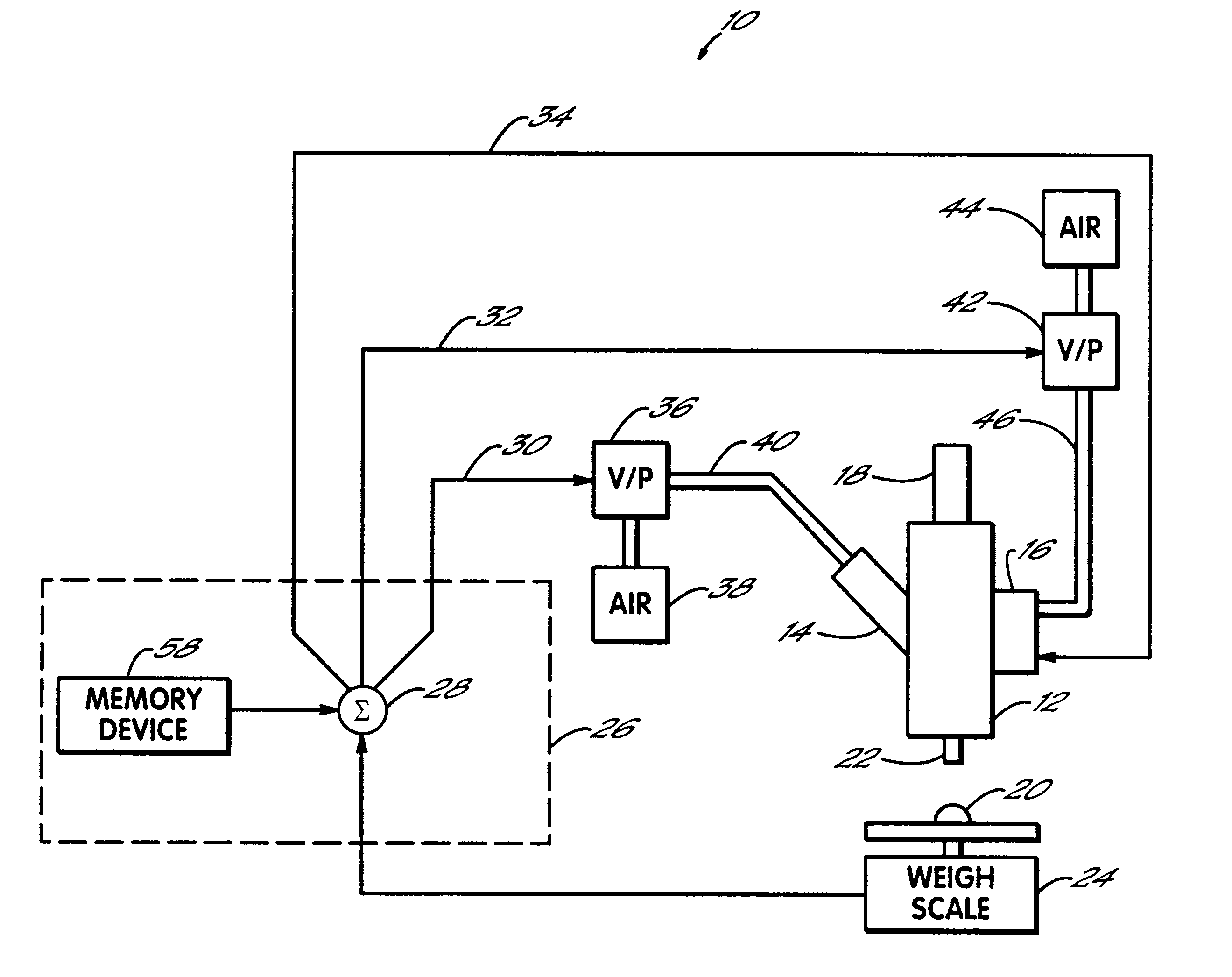

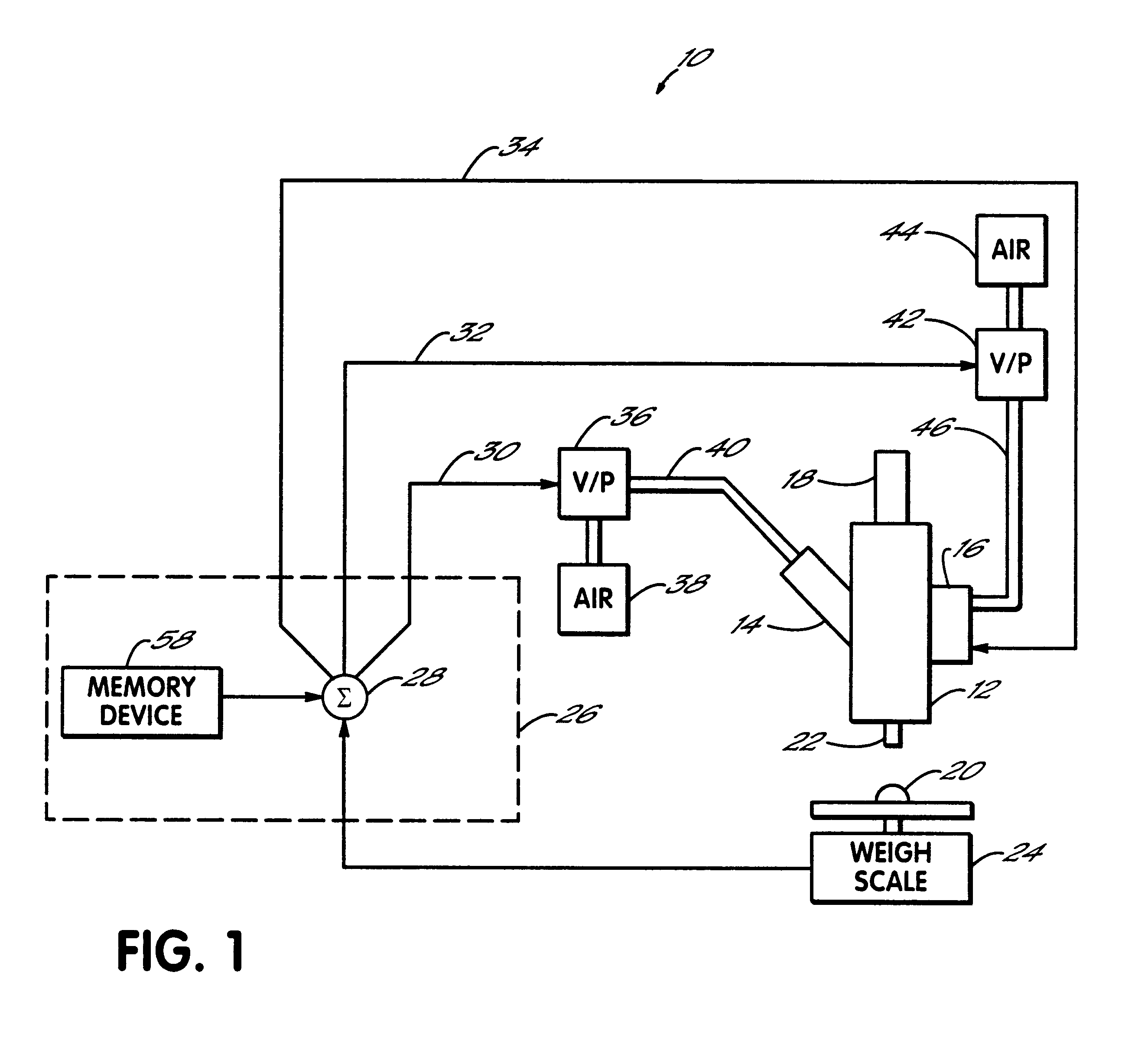

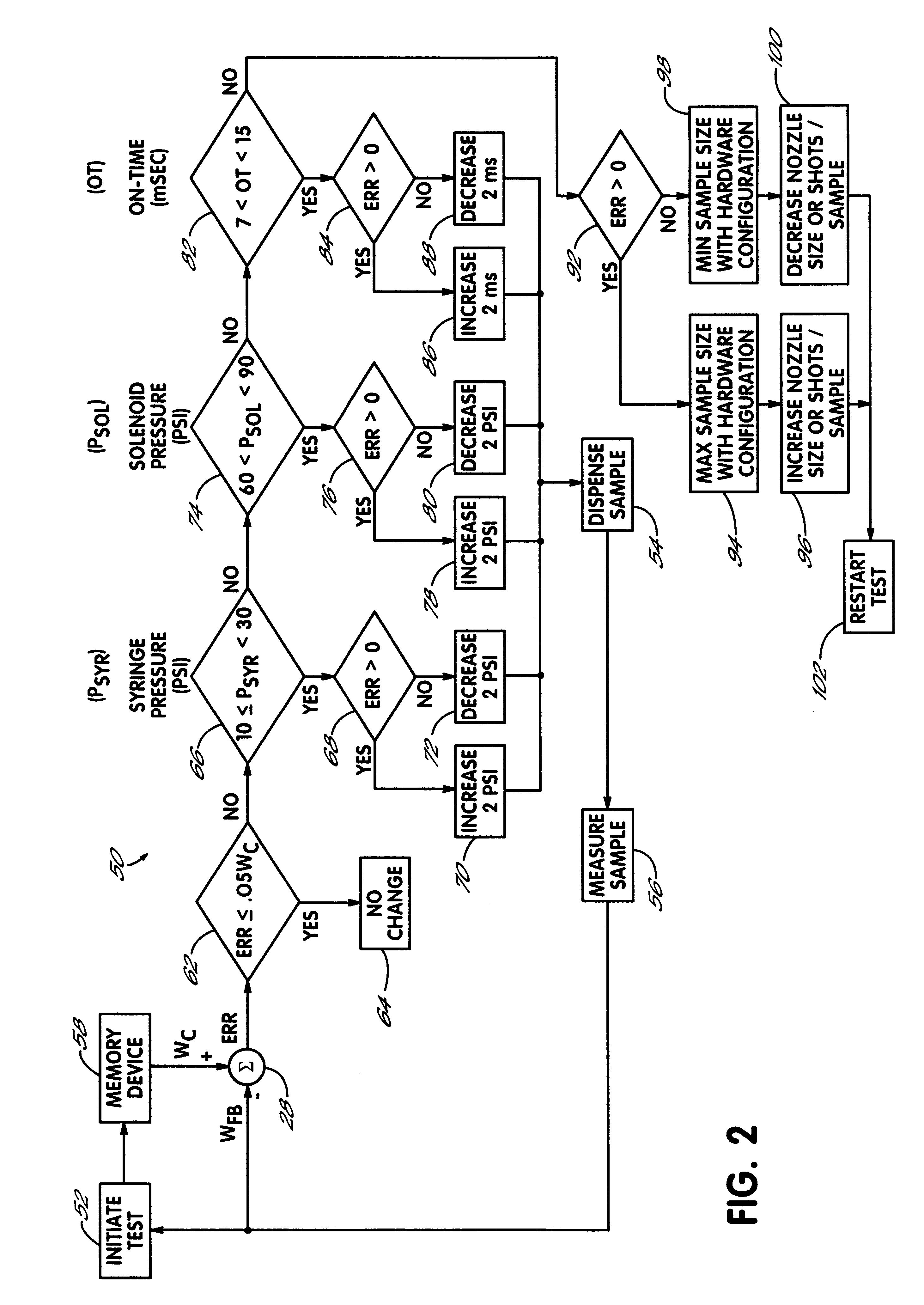

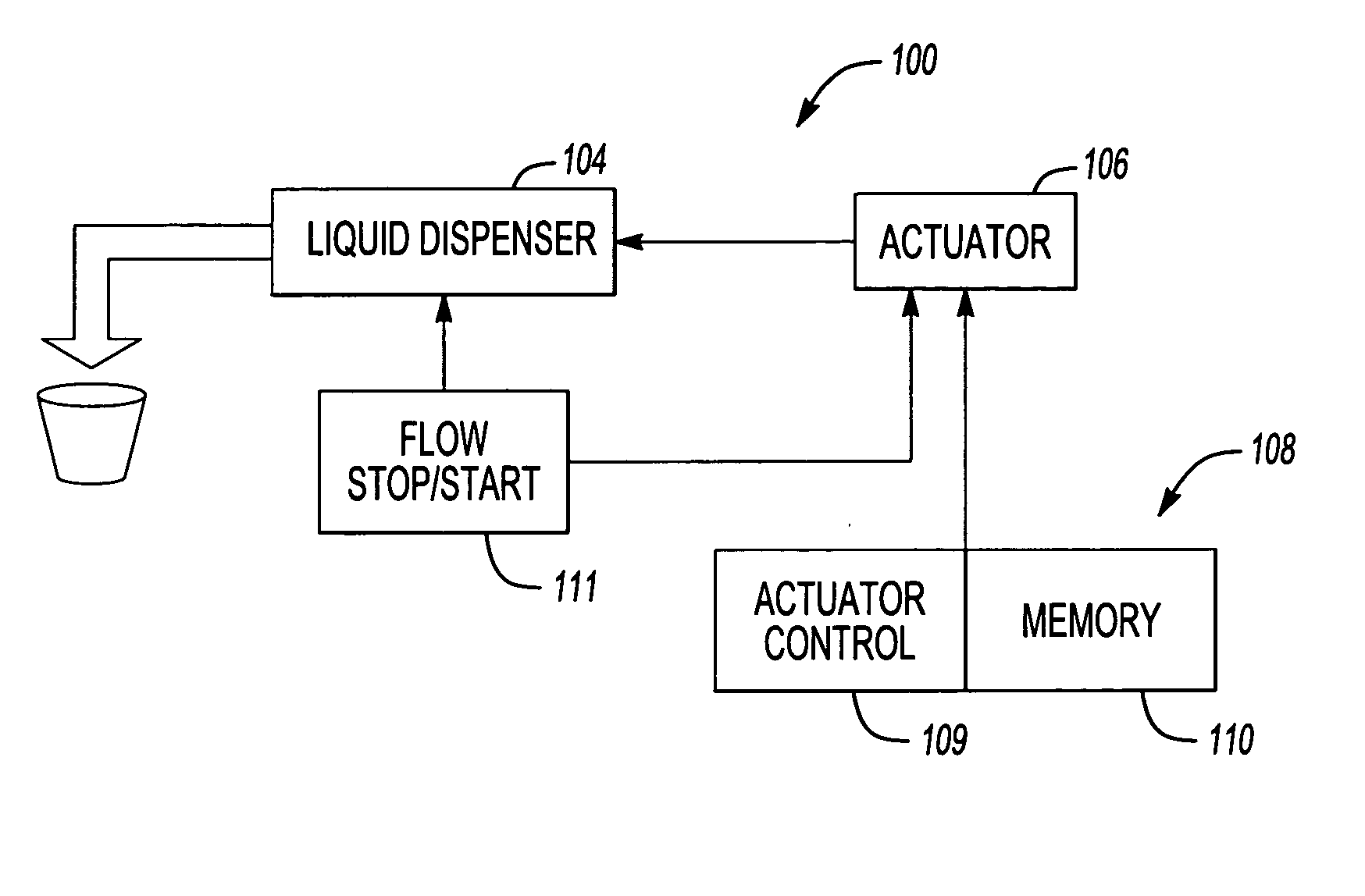

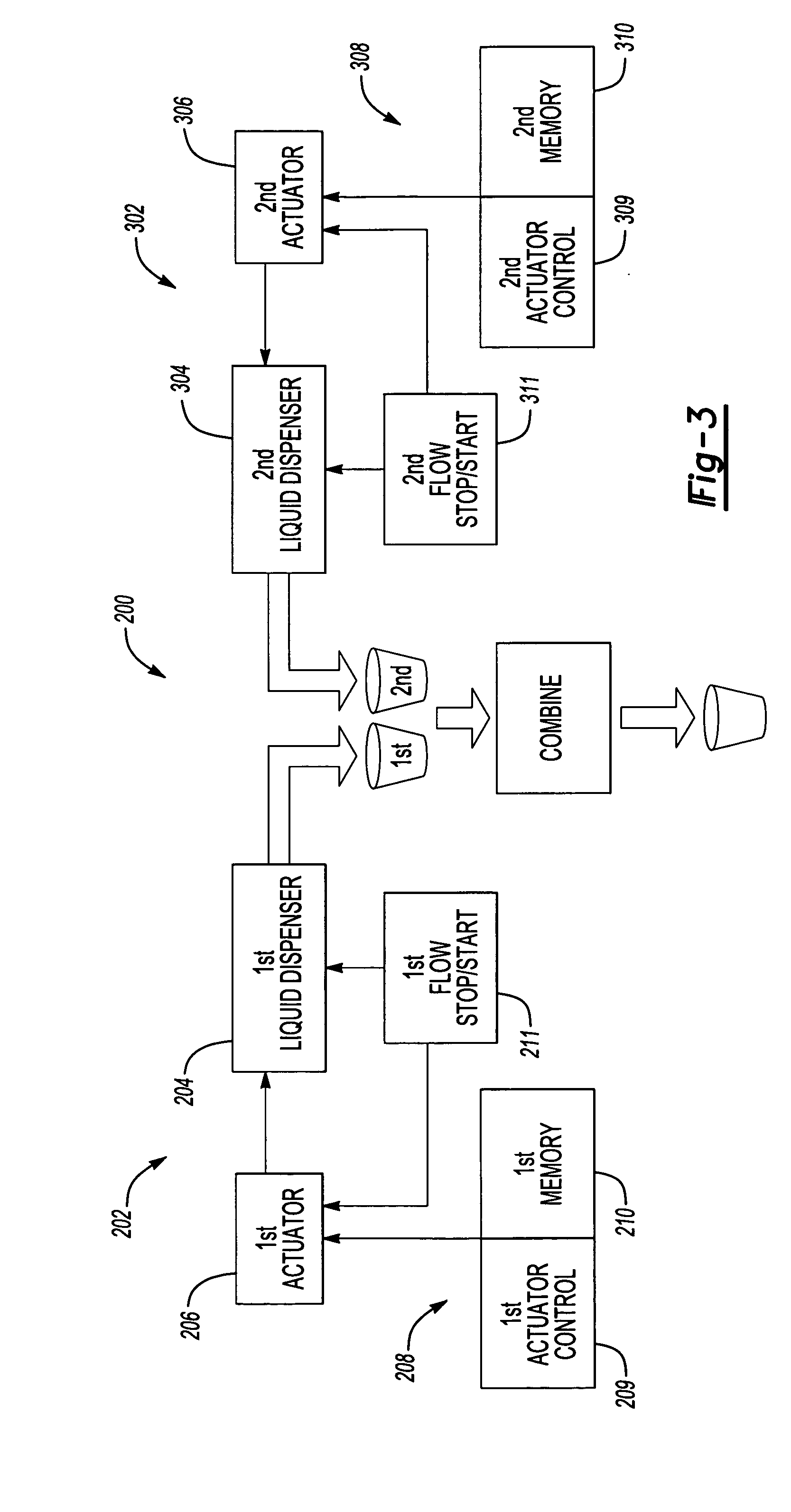

Viscous material dispensing system and method with feedback control

InactiveUS6173864B1Allocation is accuratePretreated surfacesLiquid transferring devicesFeedback controllerFeedback control

A system for accurately dispensing controlled amounts of viscous material. The system includes a pressurized supply of the viscous material, a dispenser connected with the pressurized supply and a feedback control for ensuring that a discrete dispensed amount corresponds closely to the desired dispensed amount for a particular application. The different methods of feedback control include changing pressure of the pressurized supply after measuring a dispensed amount and comparing the dispensed amount with a stored value representing the desired amount. Another manner of feedback control includes changing an air operating pressure associated with the dispenser. A third type of feedback control includes adjusting the duration that the dispenser is maintained on to dispense the viscous material. Each of these types of feedback control are preferably used in succession, as necessary, to ensure that the desired amount of viscous material is discharged from the dispenser. Methods of controlling an amount of viscous material discharged from a dispenser further include using one or more of the feedback controls described above.

Owner:NORDSON CORP

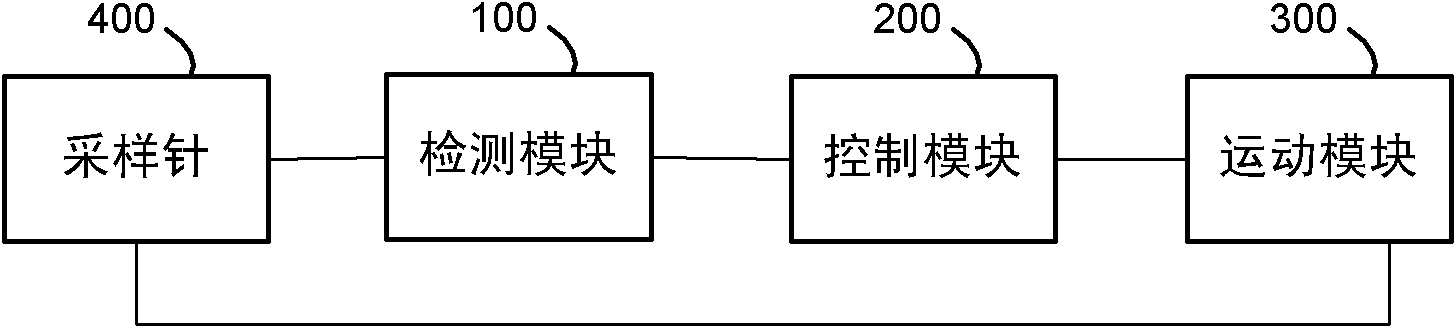

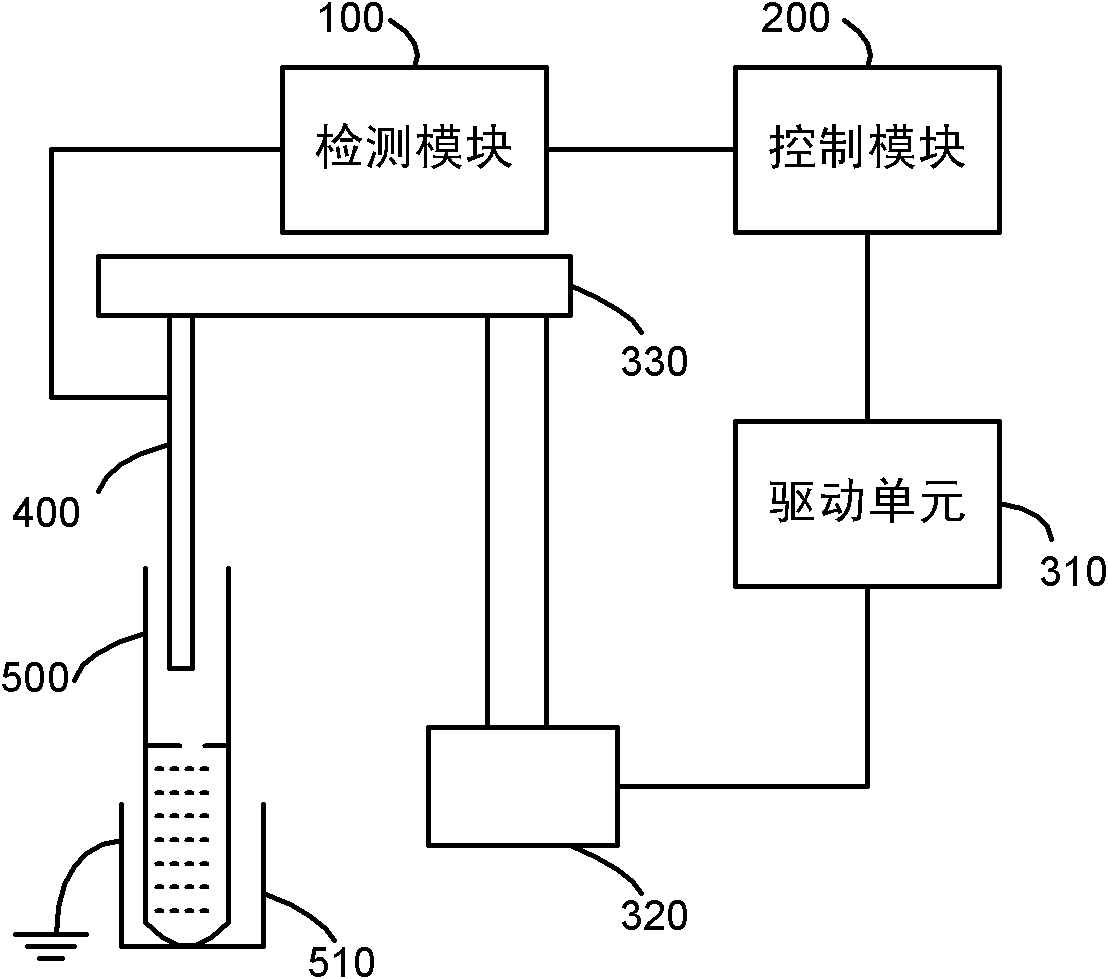

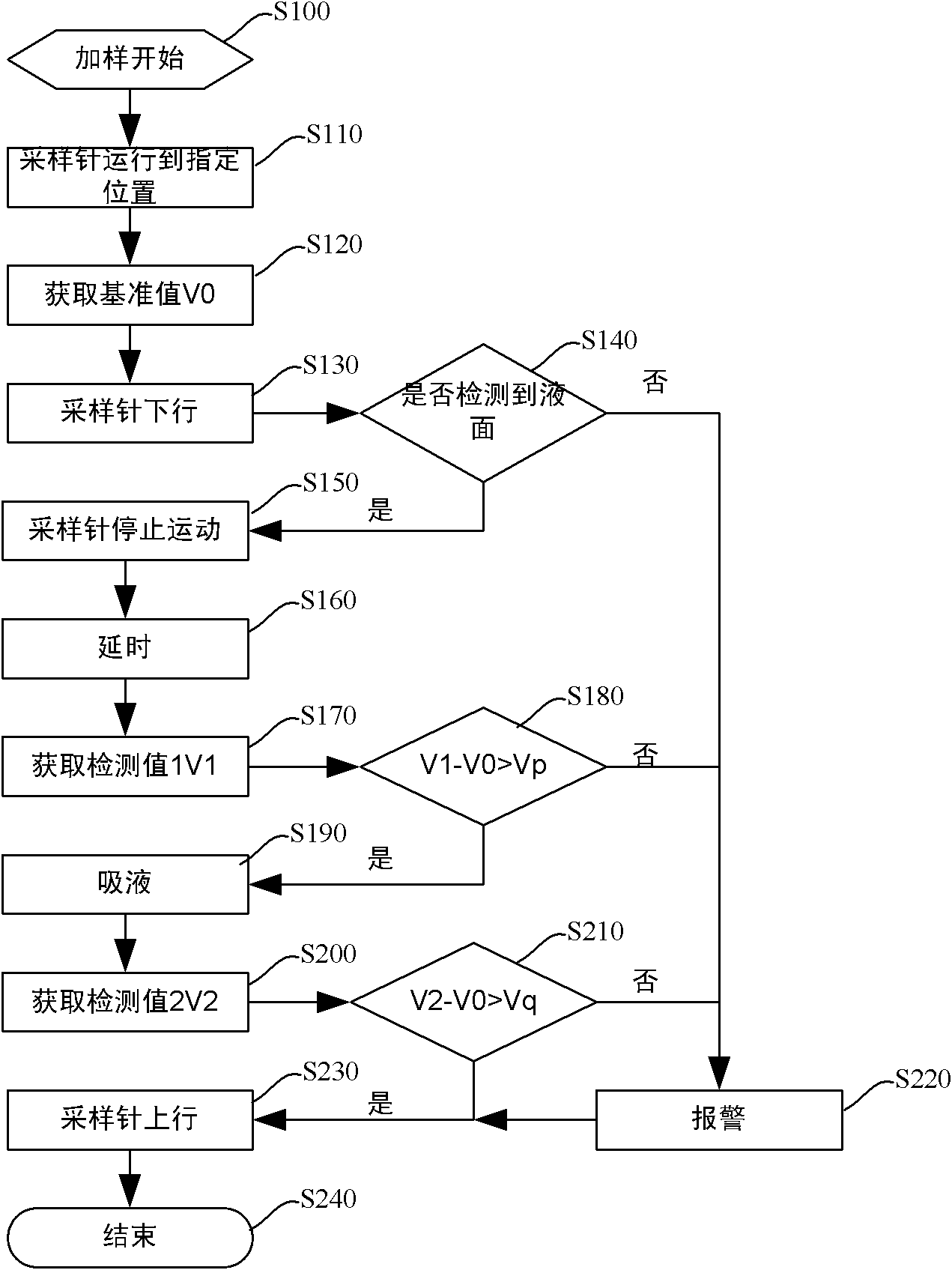

Sampling device and method

ActiveCN101881706AImplement samplingWithdrawing sample devicesTesting/calibration for volume meteringComputer scienceLiquid surfaces

The invention relates to a sampling device and a method. The sampling method comprises the following steps that: preparation of sampling: a sampling pin (400) acts towards a liquid surface until relevant physical quantity of the sampling pin (400) is mutated, and the sampling pin is judged to whether contact the real liquid surface; if the real liquid surface is contacted, sampling steps is carried out: the sampling pin (400) absorbs the liquid, variation of relevant physical quantity of the sampling pin (400) is detected so as to judge whether the liquid absorbed by the sampling pin (00) is sufficient or not. Compared with the prior art, the sampling method has the advantages that: abnormal liquid absorption situation can be judged, the interference and insufficient liquid absorption can be eliminated, and reliable sampling of the liquid can be realized.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

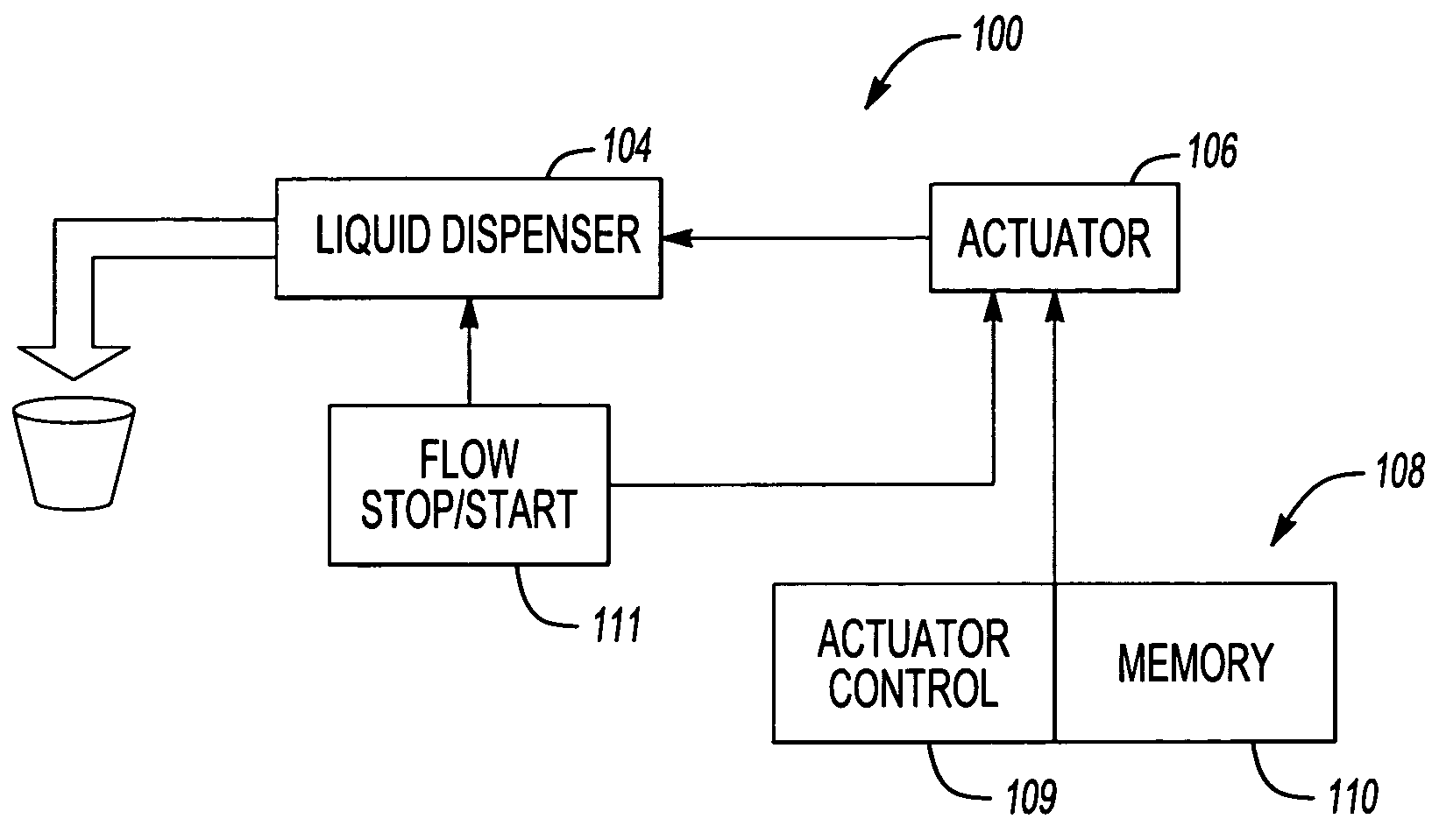

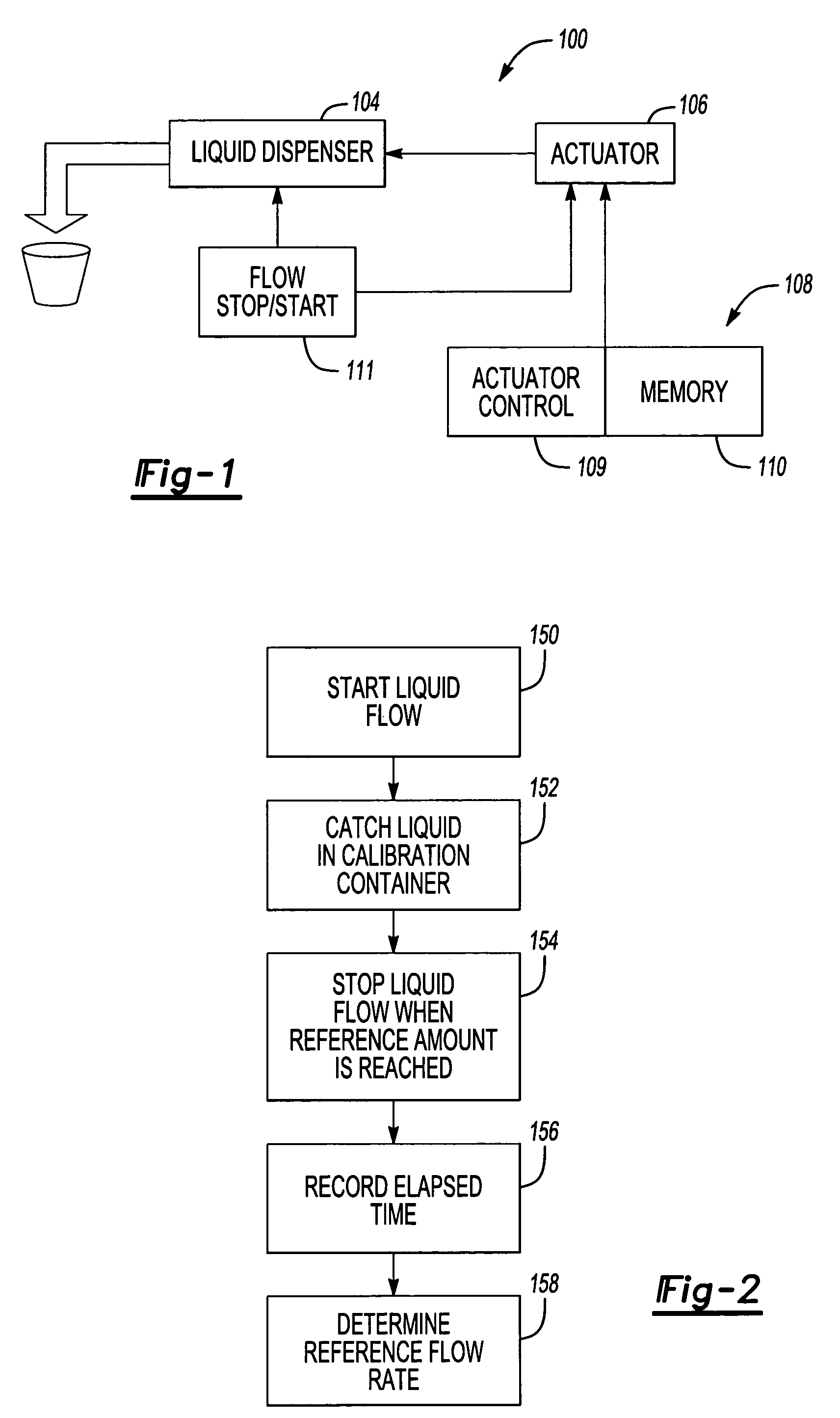

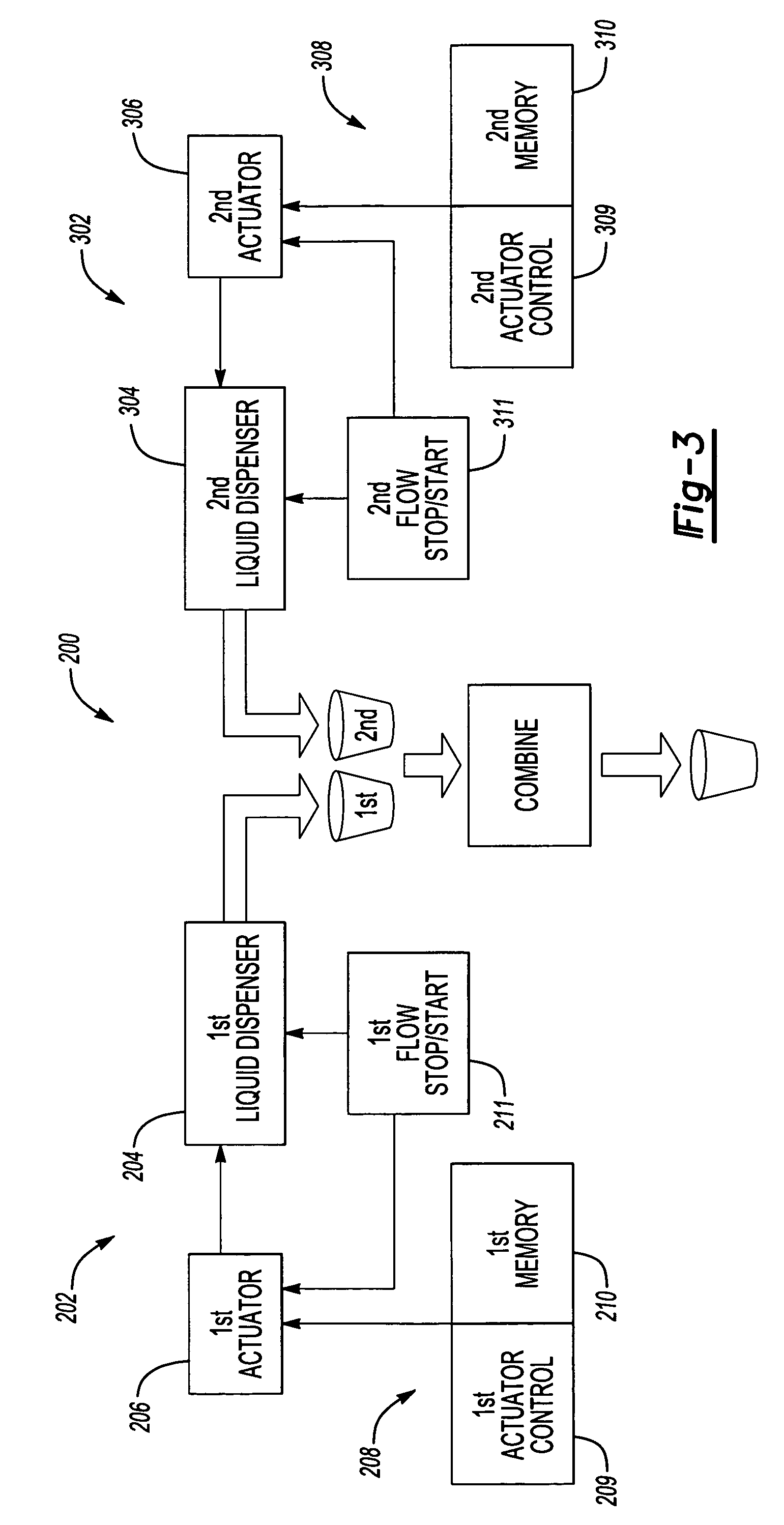

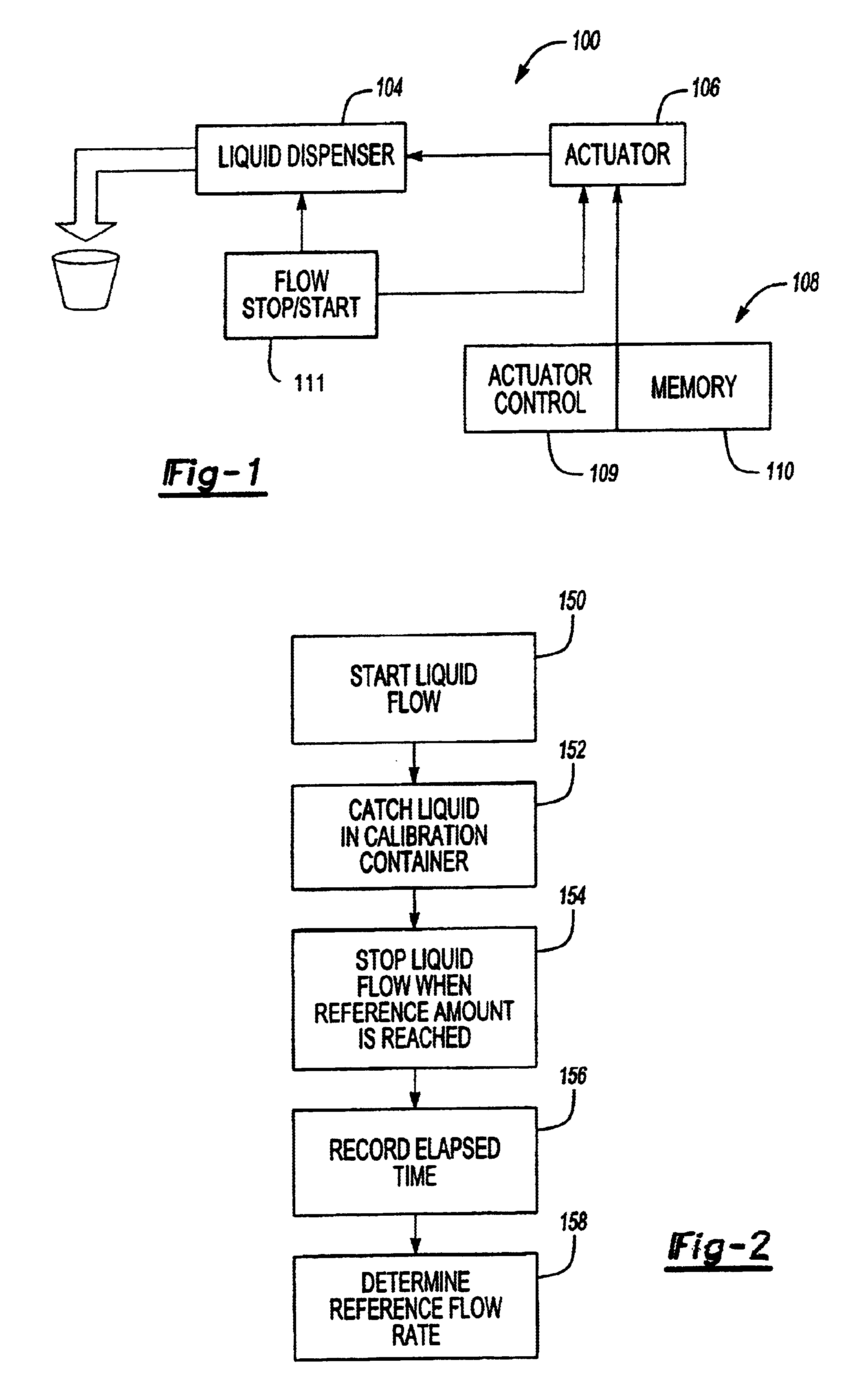

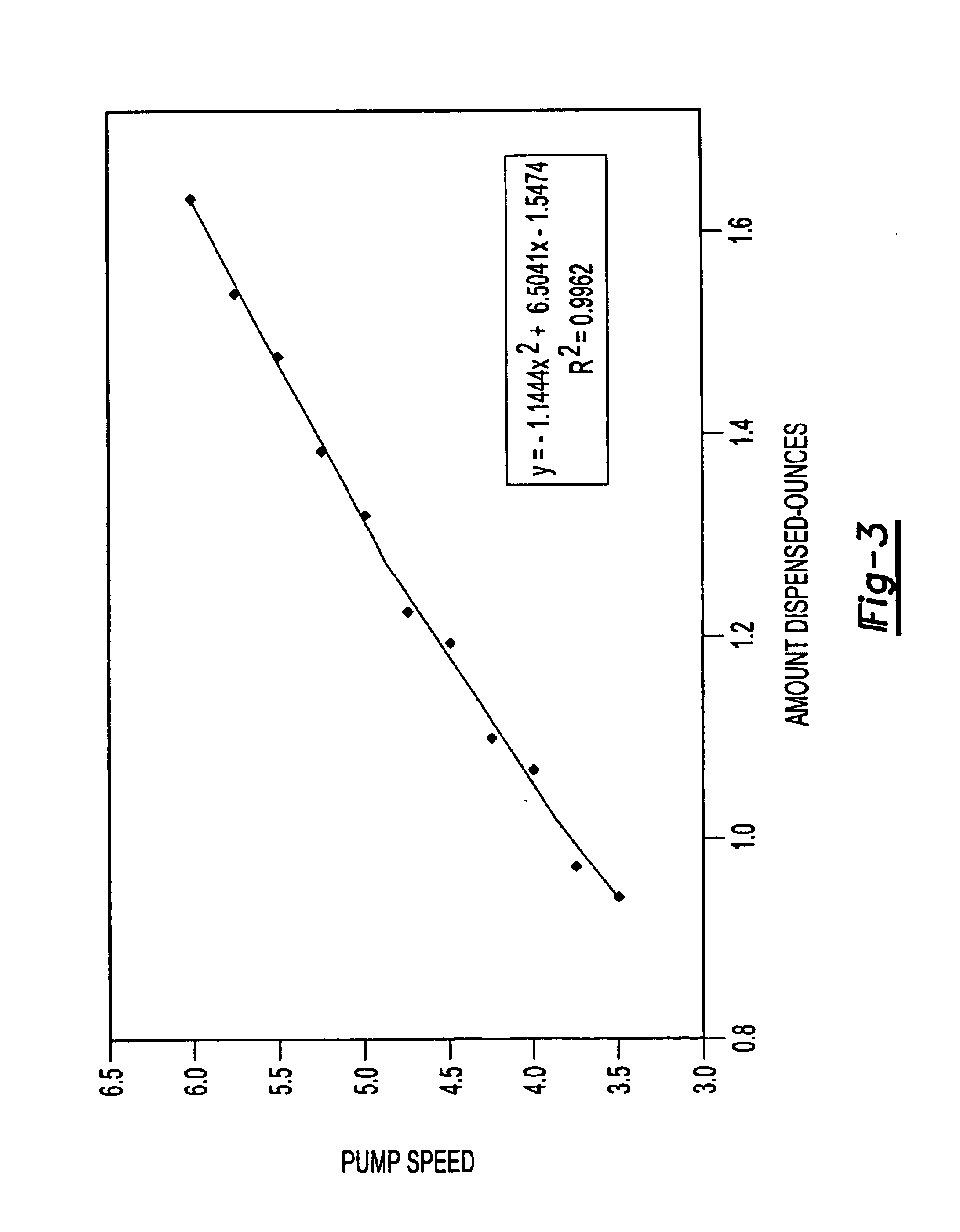

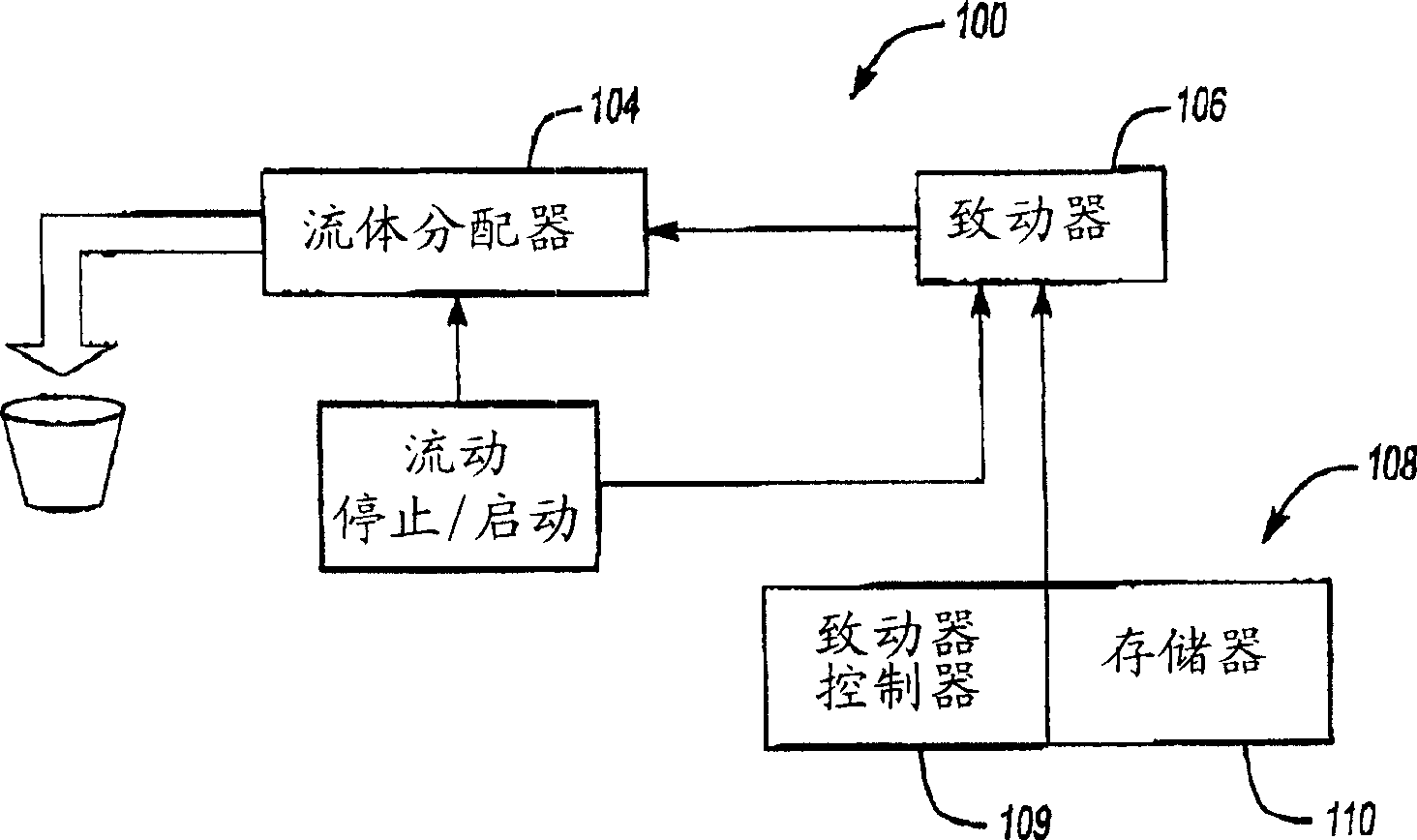

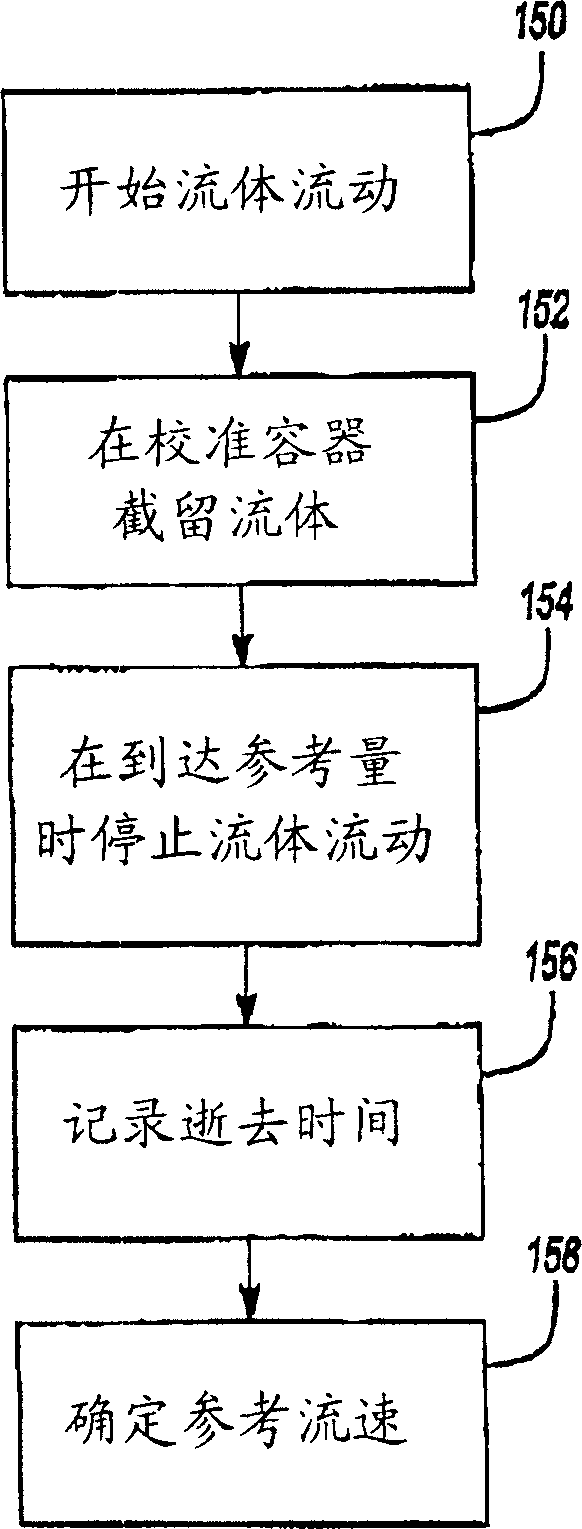

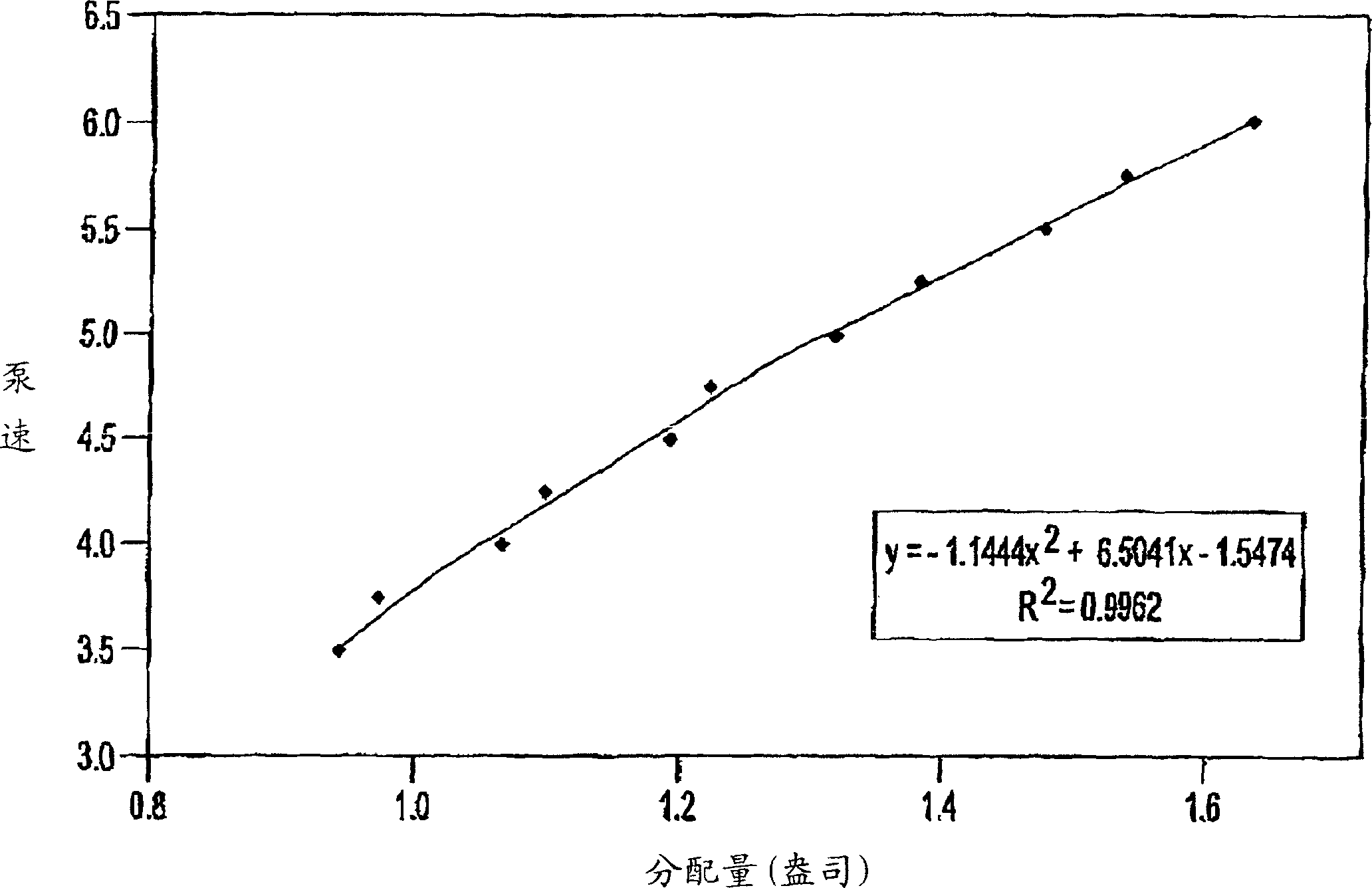

Fluid dispenser calibration system and method

ActiveUS7299944B2Opening closed containersBottle/container closureProcess engineeringIterative method

A system and method for calibrating fluid detects an actual fluid dispensing characteristic, such as dispensing speed, and automatically adjusts the dispensing characteristic to match an ideal dispensing characteristic. The adjustment is conducted by a controller that controls fluid dispensing based on a function that correlates dispensing speed, a dispensed volume, and a dispensing time. The function allows calibration to occur automatically by converging system operation to the ideal dispensing characteristic, without requiring a user to calibrate the system through manual iterative methods.

Owner:TAYLOR COMML FOODSERVICE LLC

Method and system for shape-memory alloy wire control

ActiveUS20110300001A1Volume/mass flow measurementVolume measurement and fluid deliveryShape-memory alloyAlloy

A method for controlling a device using a shape-memory alloy wire is disclosed. The method includes determining an ontime for the shape-memory alloy wire based on a target volume to be pumped by a pump plunger, determining the temperature of the shape-memory alloy wire and adjusting the ontime based on the temperature of the shape-memory alloy wire.

Owner:DEKA PROD LLP

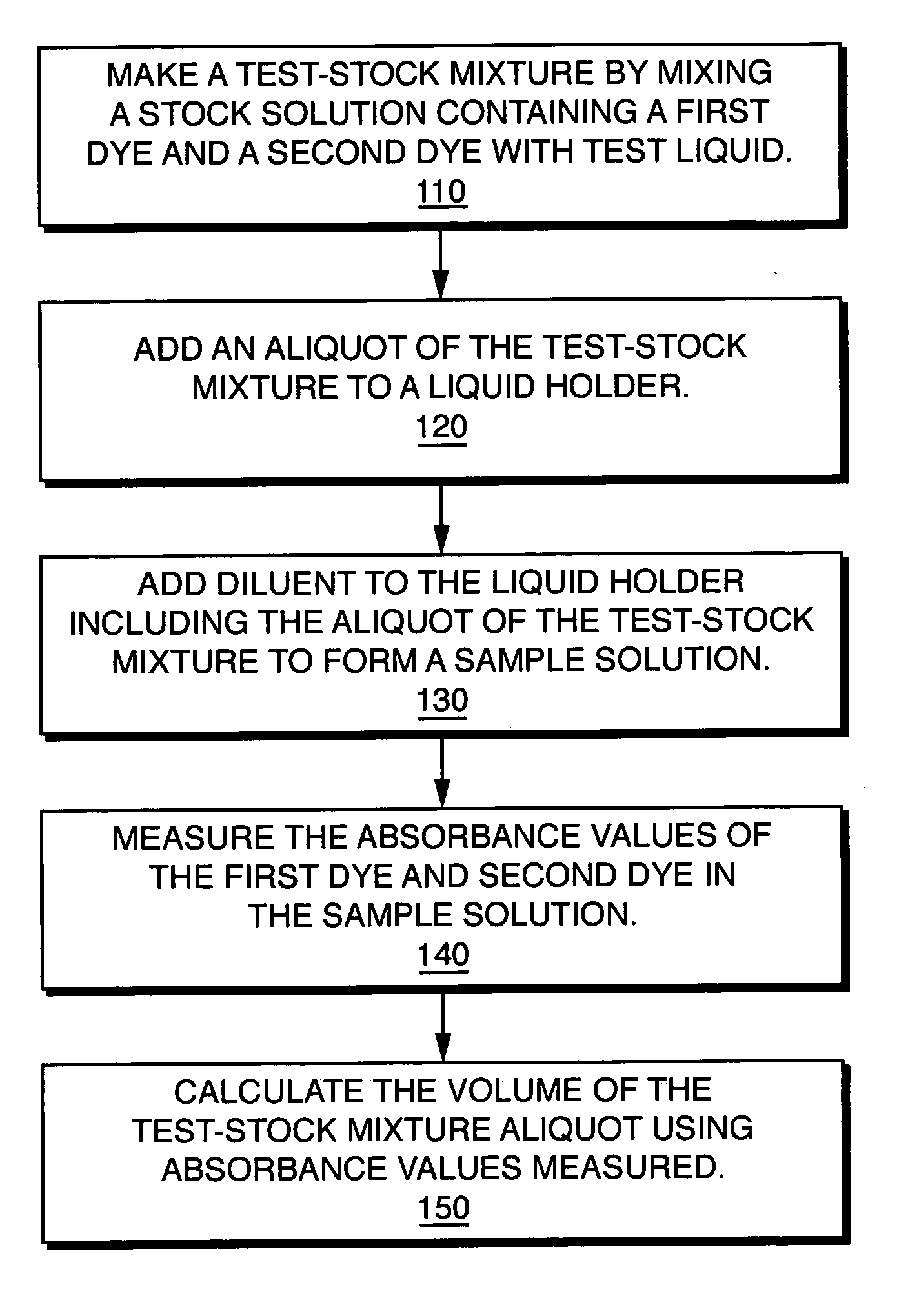

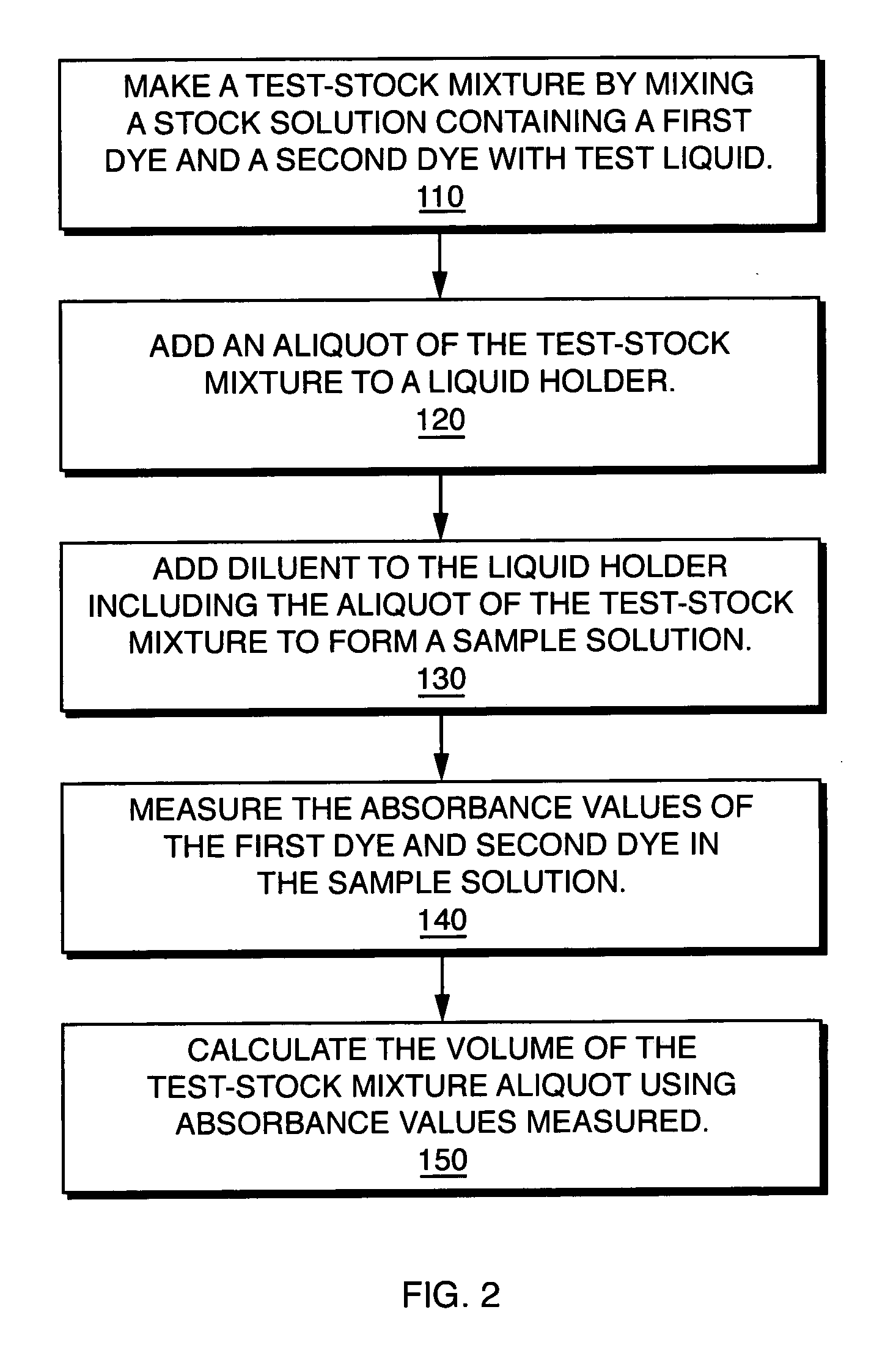

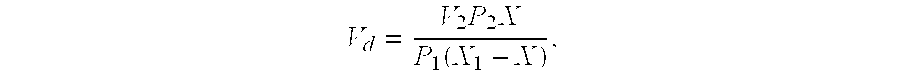

Calibrating dispensing device performance for complex and/or non-aqueous liquids

ActiveUS20070141709A1Accurate volumeWithdrawing sample devicesPreparing sample for investigationDiluentAbsorbance

A method for precisely and accurately determining the volume of a test liquid aliquot which can be used to calibrate a liquid delivery device. The method is particularly useful for determining the volume of an aliquot of a test liquid which is complex or non-aqueous, or is both complex and non-aqueous. The test-stock mixture contains at least the test liquid and a stock solution including a first dye, the first dye having absorbance characteristics which are measurably distinguishable from the absorbance characteristics of a second dye. The test-stock mixture is mixed with a diluent including the second dye to form a sample solution to be used to measure absorbances of the first dye and the second dye. The volume of the test-stock mixture aliquot is calculated by using a formula based on the Beer-Lambert law which incorporates the measured absorbance values and a dilution characteristic of the test-stock mixture. The test liquid and the stock solution are combined gravimetrically in a controlled ratio so that the flow characteristics of the test-stock mixture correspond to the flow characteristics of the test liquid and without affecting the ability to distinguish the absorbance characteristics between the first dye and the second dye.

Owner:ARTEL

Variable-Volume Dispenser for Accurately Dispensing of an Adjusted Amount of Liquid

The present invention relates to a bottle top dispenser. According to an embodiment, the dispenser comprises a swayable selector for convenient and rapid volume adjustment by a user. The dispenser further comprises a second selector for analogous volume adjustment, wherein a user may use one of the two selectors according to preferences. The dispenser further preferably comprises two different graduations for assisting a user in the rapid identification of a specific volume when adjusting the volume. The dispenser relates to further advantageous embodiments.

Owner:SOCOREX ISBA SA

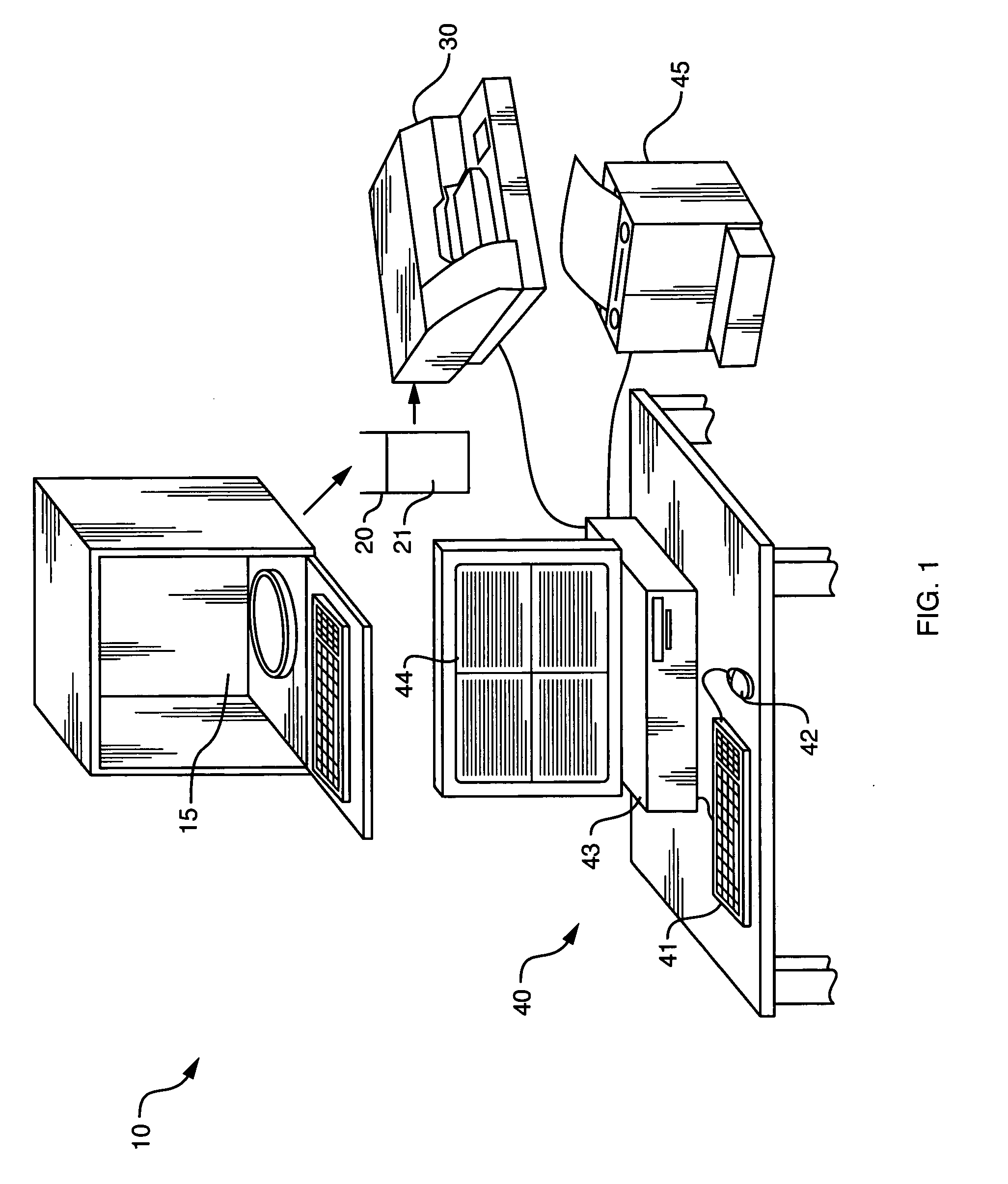

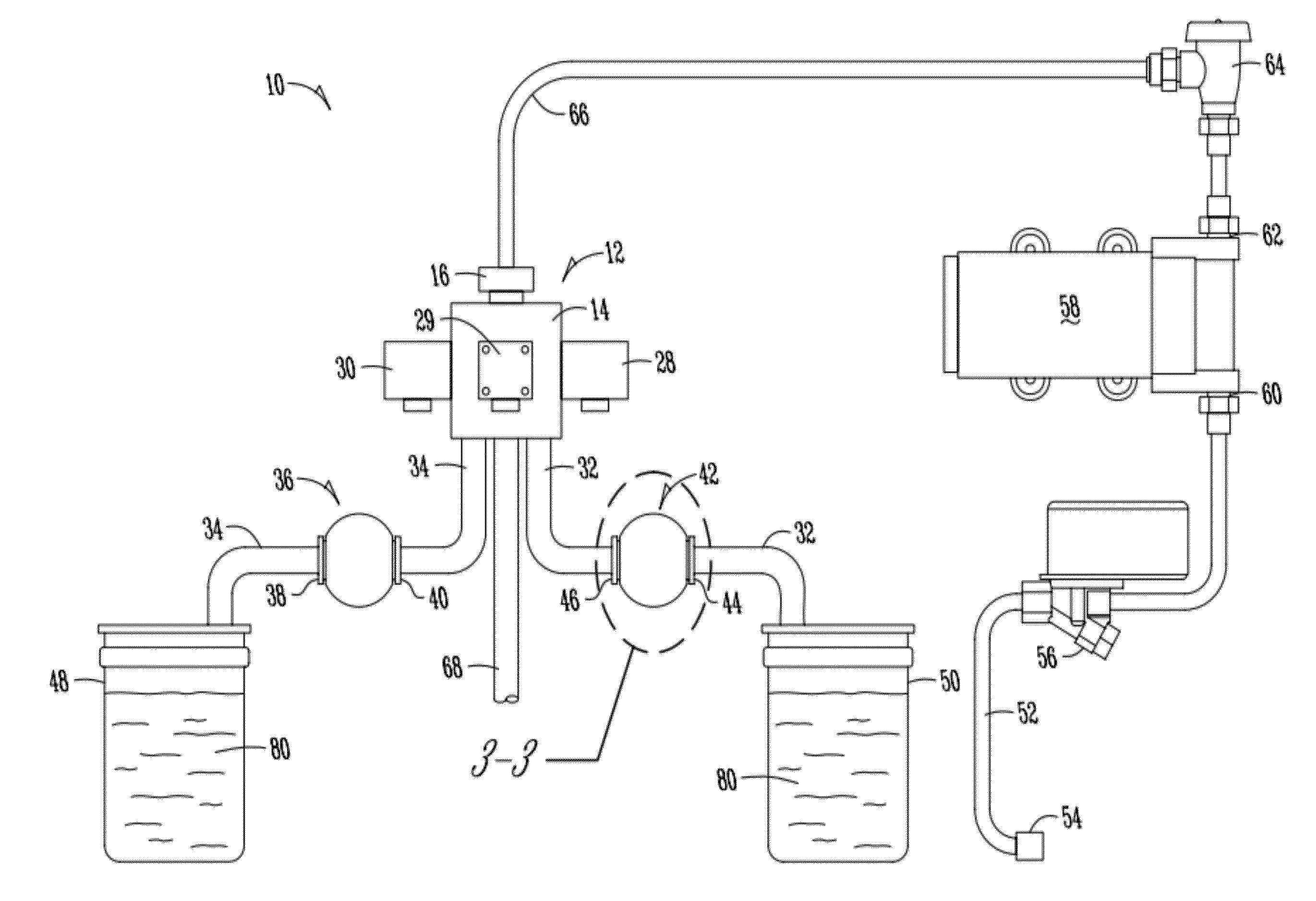

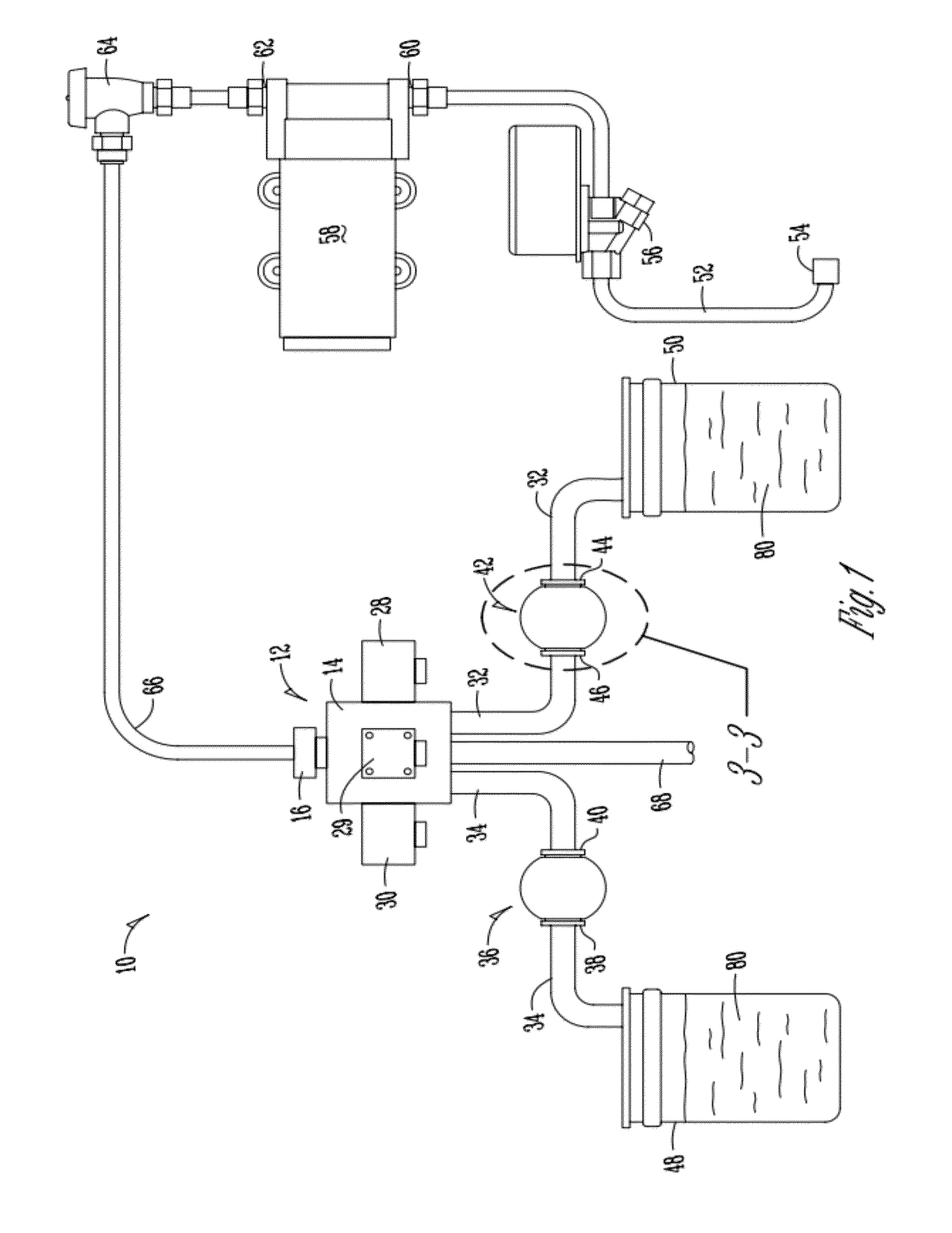

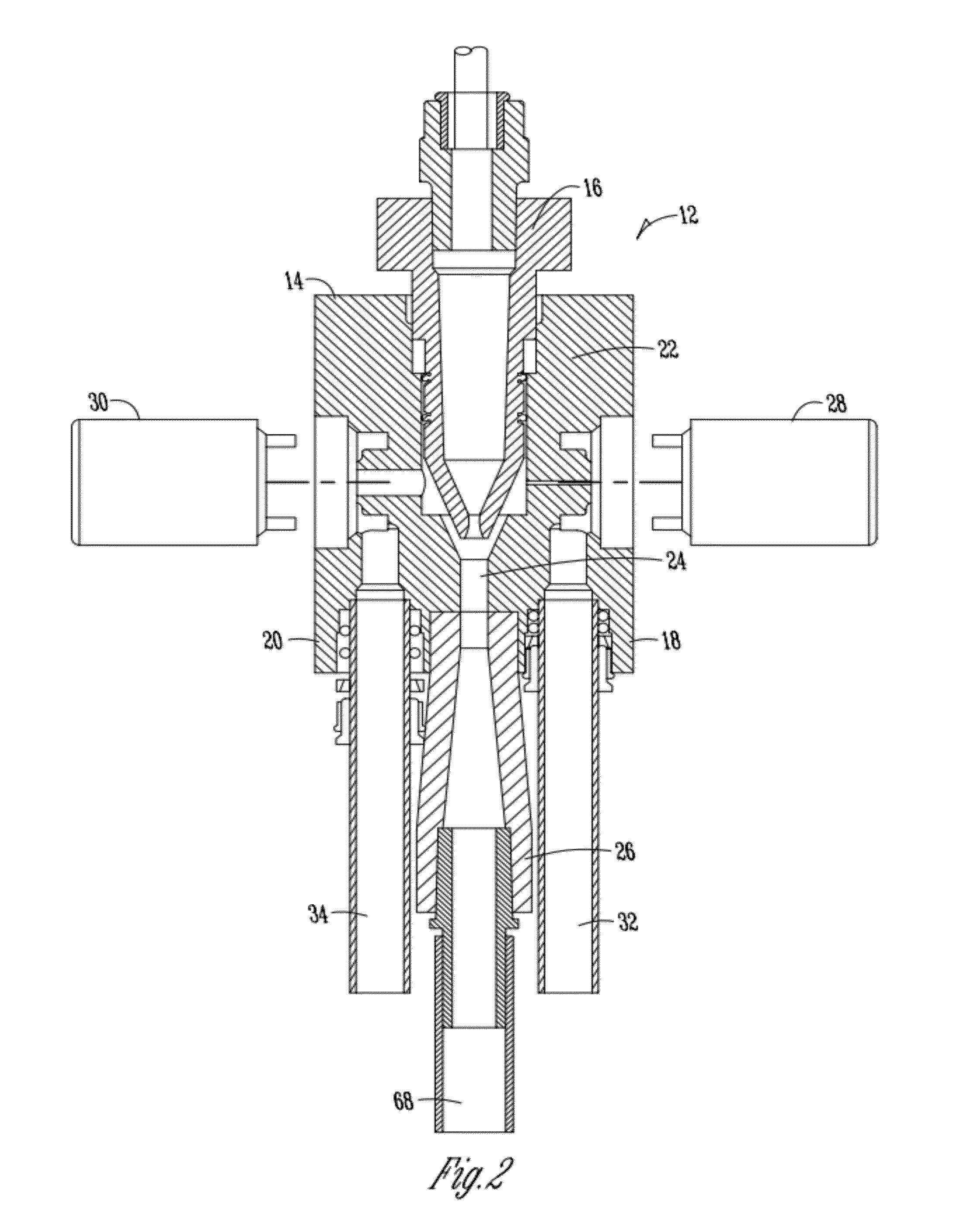

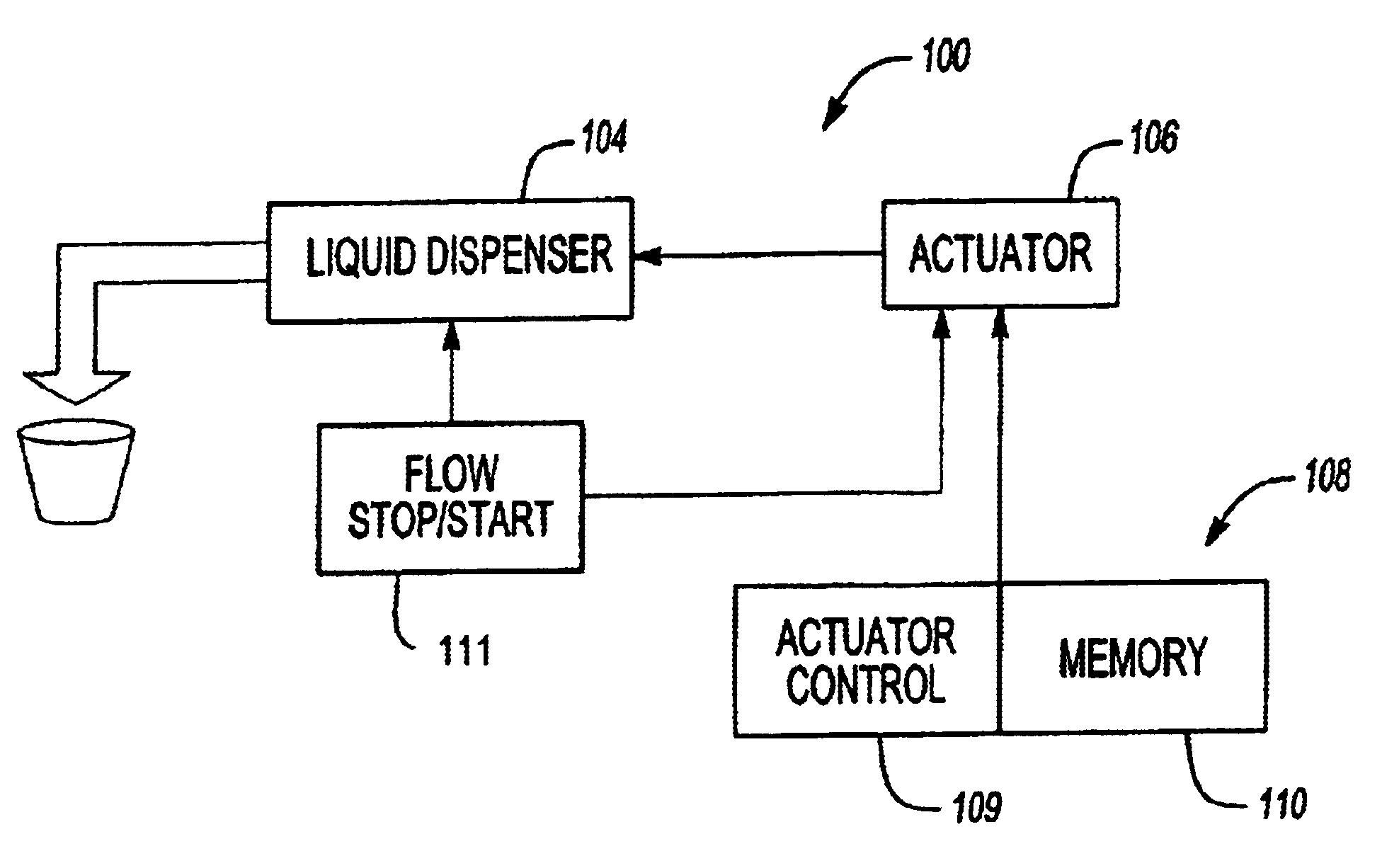

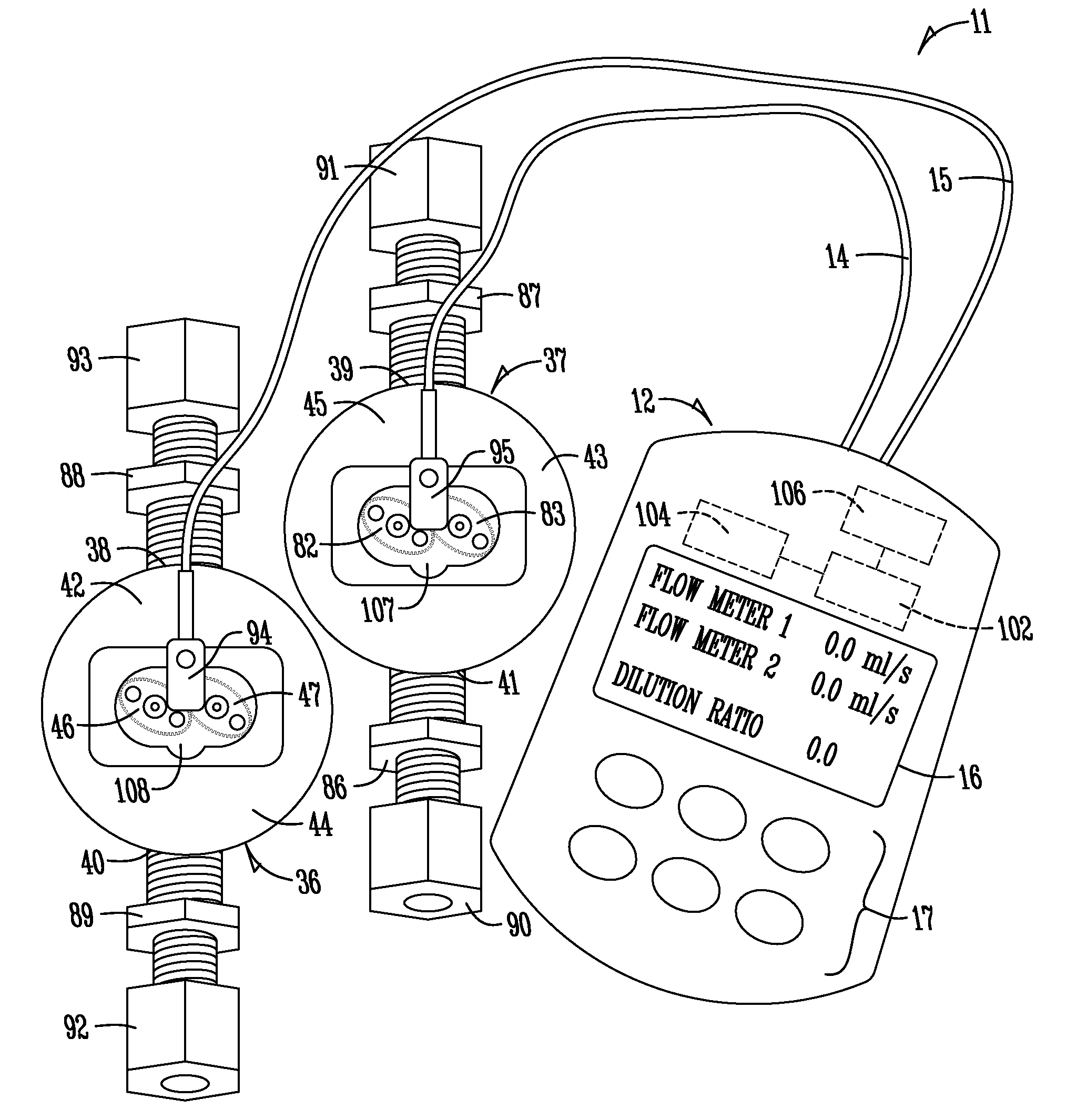

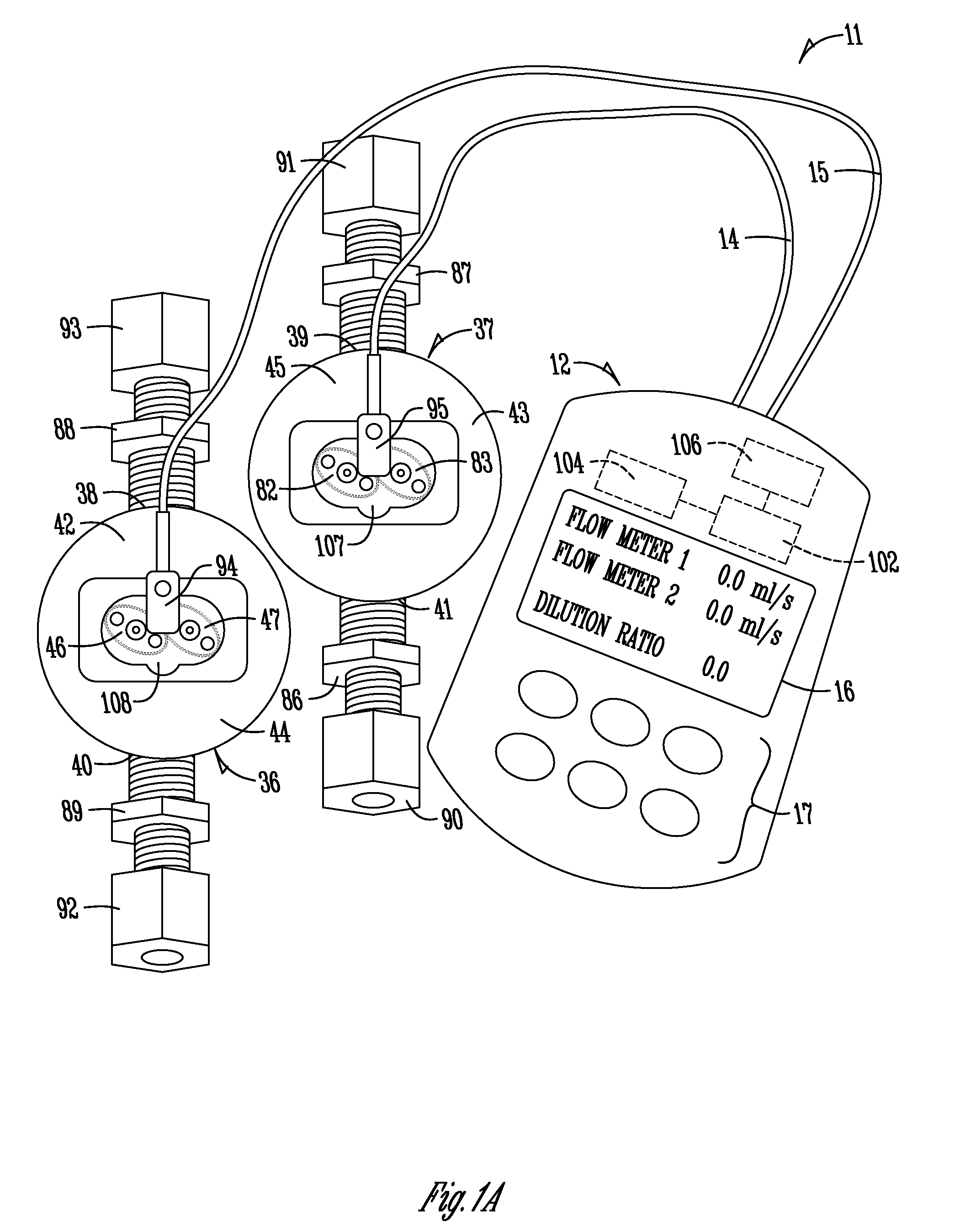

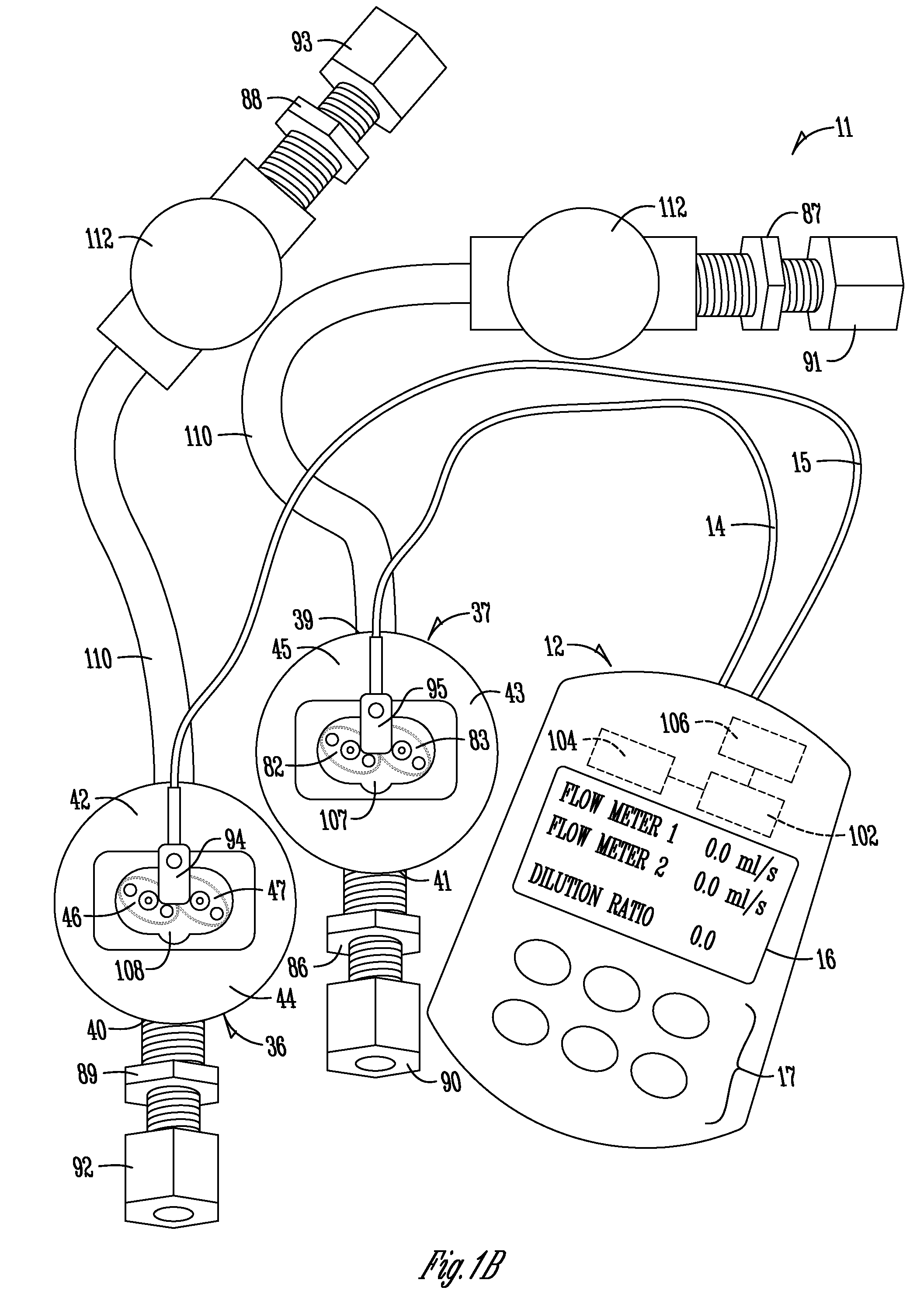

Method, apparatus and system for accurately measuring and calibrating liquid components dispensed from a dispenser

InactiveUS20120047988A1Accurate measurementAccurate CalibrationOpening closed containersBottle/container closureLiquid productDiluent

A method, apparatus and system provides for accurately measuring and calibrating liquid products dispensed from a dispenser. A liquid diluent enters an aspirator assembly (12). A liquid product is drawn from a product container through a flow meter (36) into the aspirator assembly (12), wherein liquid product and diluent are mixed to dispense at the outlet of the aspirator (14). The flow meter (36) monitors the amount of liquid product drawn into and dispensed from the aspirator (14).

Owner:ECOLAB USA INC

Fluid dispenser calibration system and method

InactiveUS6986441B2Opening closed containersBottle/container closureProcess engineeringIterative method

A system and method for calibrating fluid detects an actual fluid dispensing characteristic, such as dispensing speed, and automatically adjusts the dispensing characteristic to match an ideal dispensing characteristic. The adjustment is conducted by a controller that controls fluid dispensing based on a function that correlates dispensing speed, a dispensed volume, and a dispensing time. The function allows calibration to occur automatically by converging system operation to the ideal dispensing characteristic, without requiring a user to calibrate the system through manual iterative methods.

Owner:TAYLOR COMML FOODSERVICE LLC

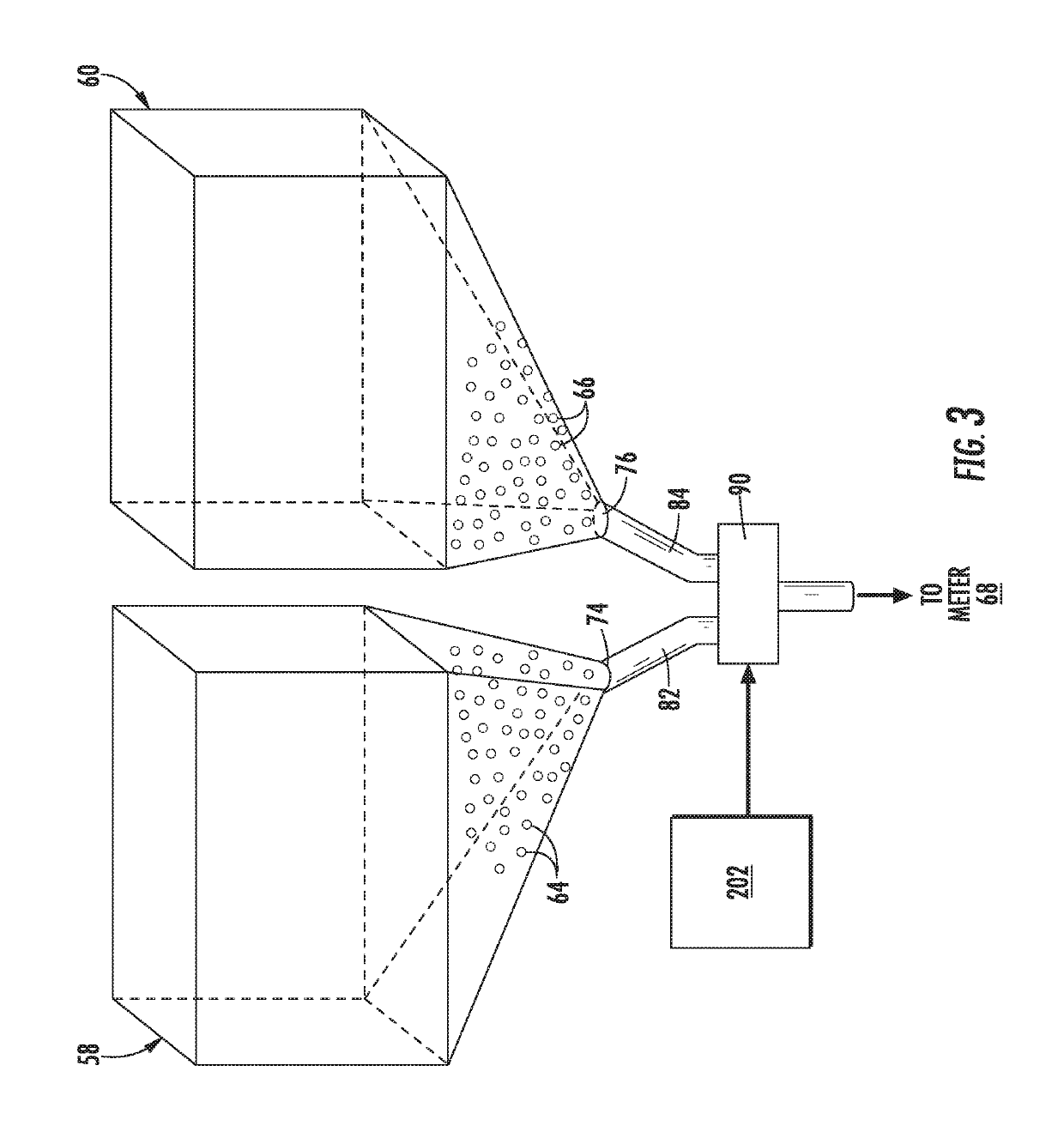

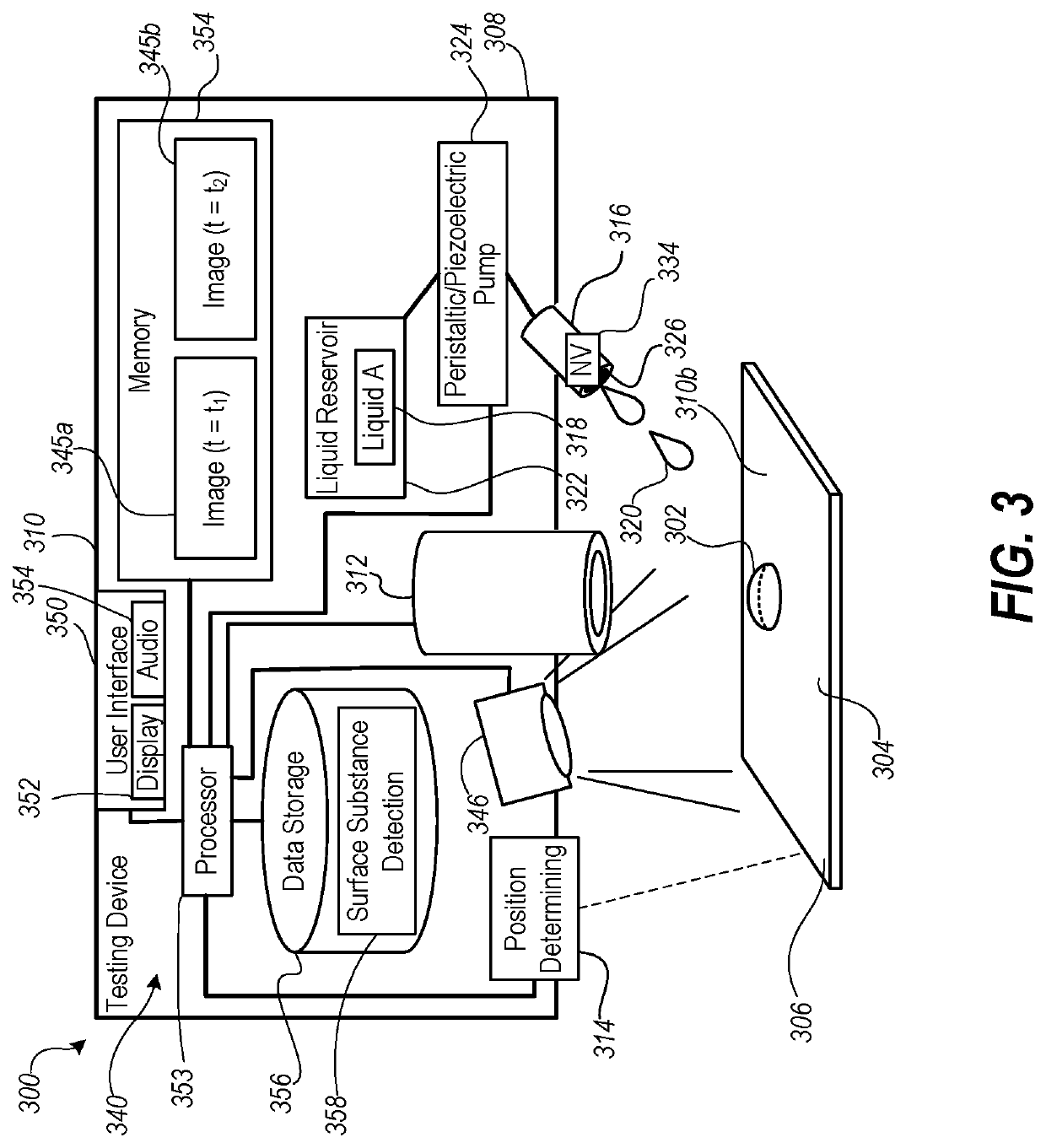

Apparatus, method and system for calibrating a liquid dispensing system

An apparatus, method and system providing for calibration and / or control of a liquid dispensing system is disclosed. The hand-held calibration auditing tool includes a flow meter (36-37) with inlets adapted for quick connection to one or more liquid inputs and / or liquid outputs of a liquid dispensing system (10). A sensor (94-95) having a data output of liquid flow information for a liquid input to the dispensing system (10) is operably connected to a controller (12) to receive the liquid flow information for the liquid input. The controller (12) provides a dilution rate and other liquid flow information for a liquid product input to a dispenser. The tool may include any number of flow meters, and may also include a flow meter connected to an outlet of a dispenser (22) for providing flow information.

Owner:ECOLAB USA INC

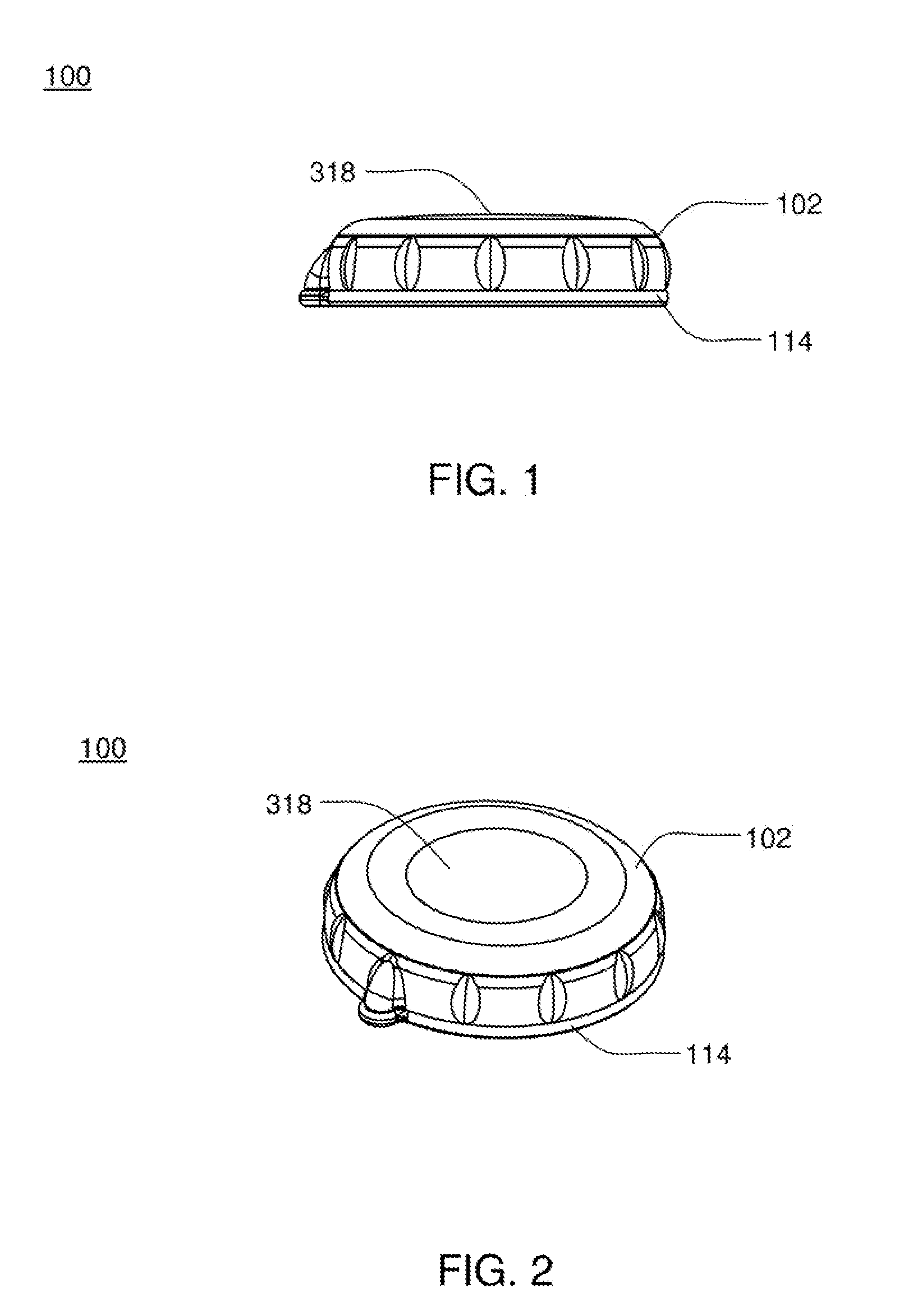

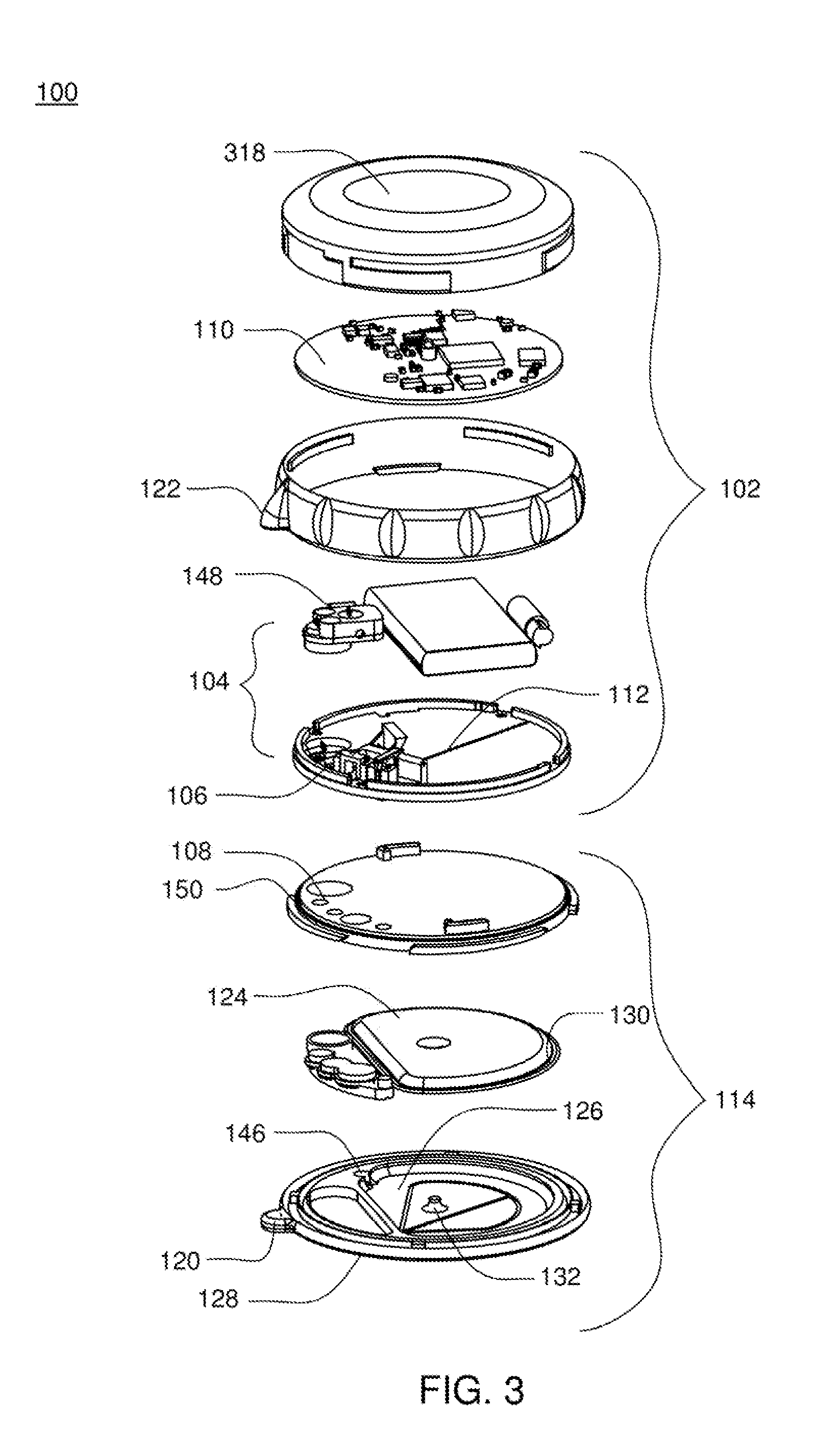

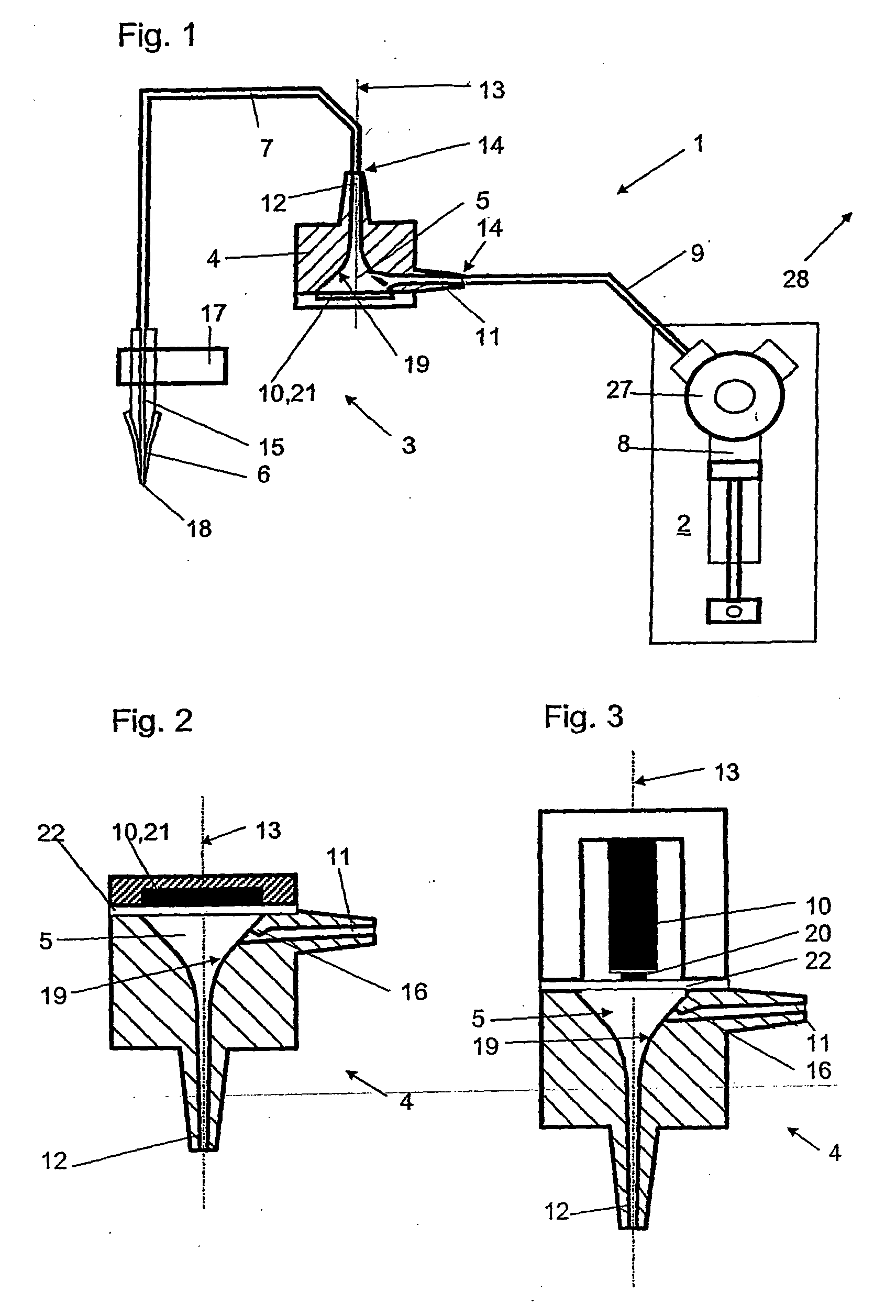

Device and system for dispensing or aspirating/dispensing liquid samples

Owner:TECAN TRADING AG

Fluid dispenser calibration system and method

A system and method for calibrating fluid detects an actual fluid dispensing characteristic, such as dispensing speed, and automatically adjusts the dispensing characteristic to match an ideal dispensing characteristic. The adjustment is conducted by a controller that controls fluid dispensing based on a function that correlates dispensing speed, a dispensed volume, and a dispensing time. The function allows calibration to occur automatically by converging system operation to the ideal dispensing characteristic, without requiring a user to calibrate the system through manual iterative methods.

Owner:TAYLOR COMML FOODSERVICE LLC

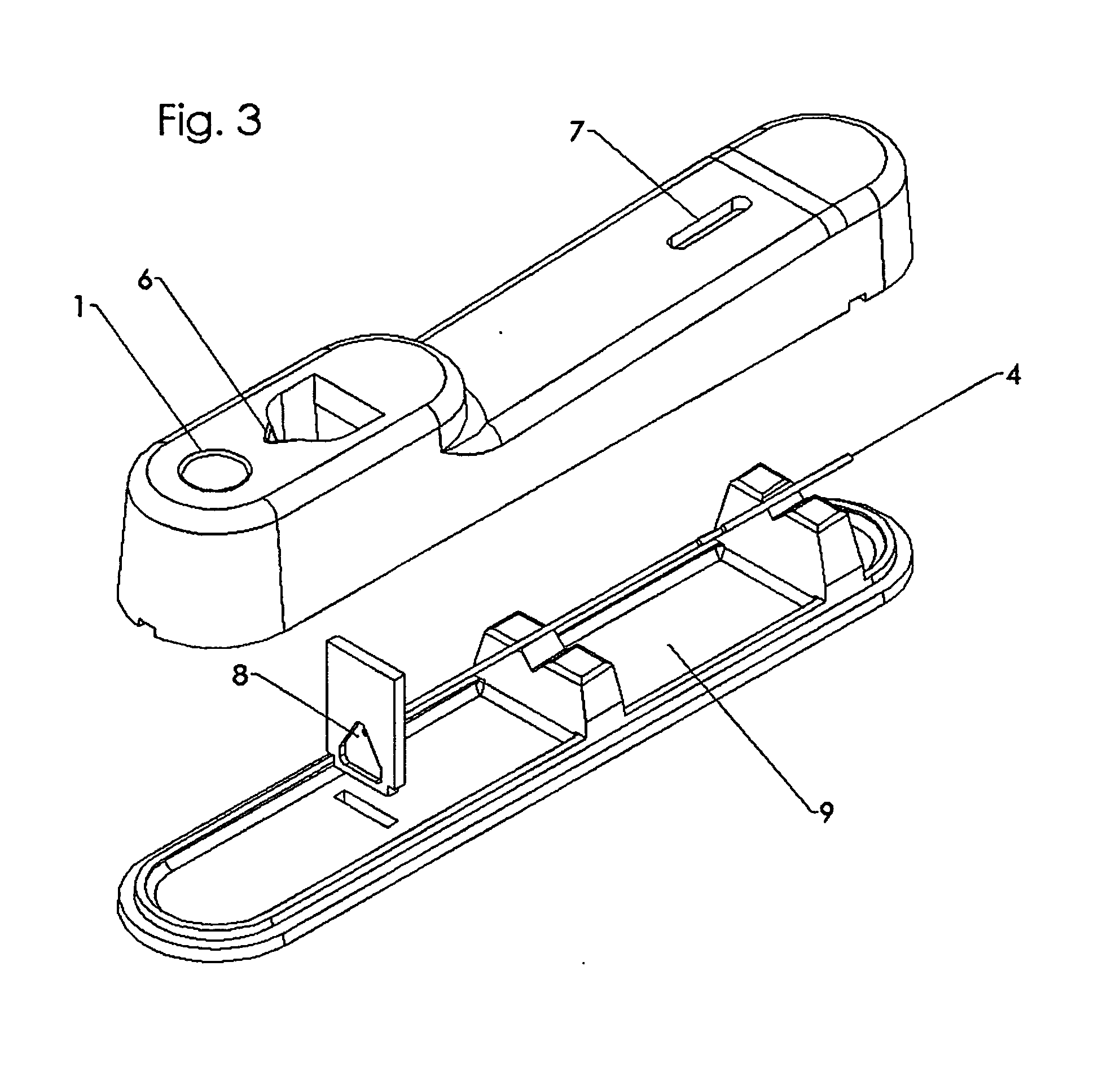

Dispensed Liquid Measurement Device

ActiveUS20140150522A1Accurately determineDisposable or reusableBurettes/pipettesTesting/calibration for volume measurementMeasurement deviceCapillary Tubing

A measurement device containing one or more capillaries to measure the volume of a dispensed fluid and determine the volumetric accuracy of the dispensing device. The measurement device can contain a reservoir containing the fluid to be measured and there may be an additional reservoir for a secondary fluid. A viewing window is necessary to complete a manual measurement and may include a magnifying lens. The liquid well by the capillary inlet may be shaped such that the measurement fluid is directed toward the capillary. The well may have features designed to position the dispensing device toward the capillary, or to position the well proximal to the capillary after it is filled. The well may also have surfaces or coatings which attract or do not attract various types of substances. The measurement device may interface with sensors to output measurement data.

Owner:FORWARD BIOTECH

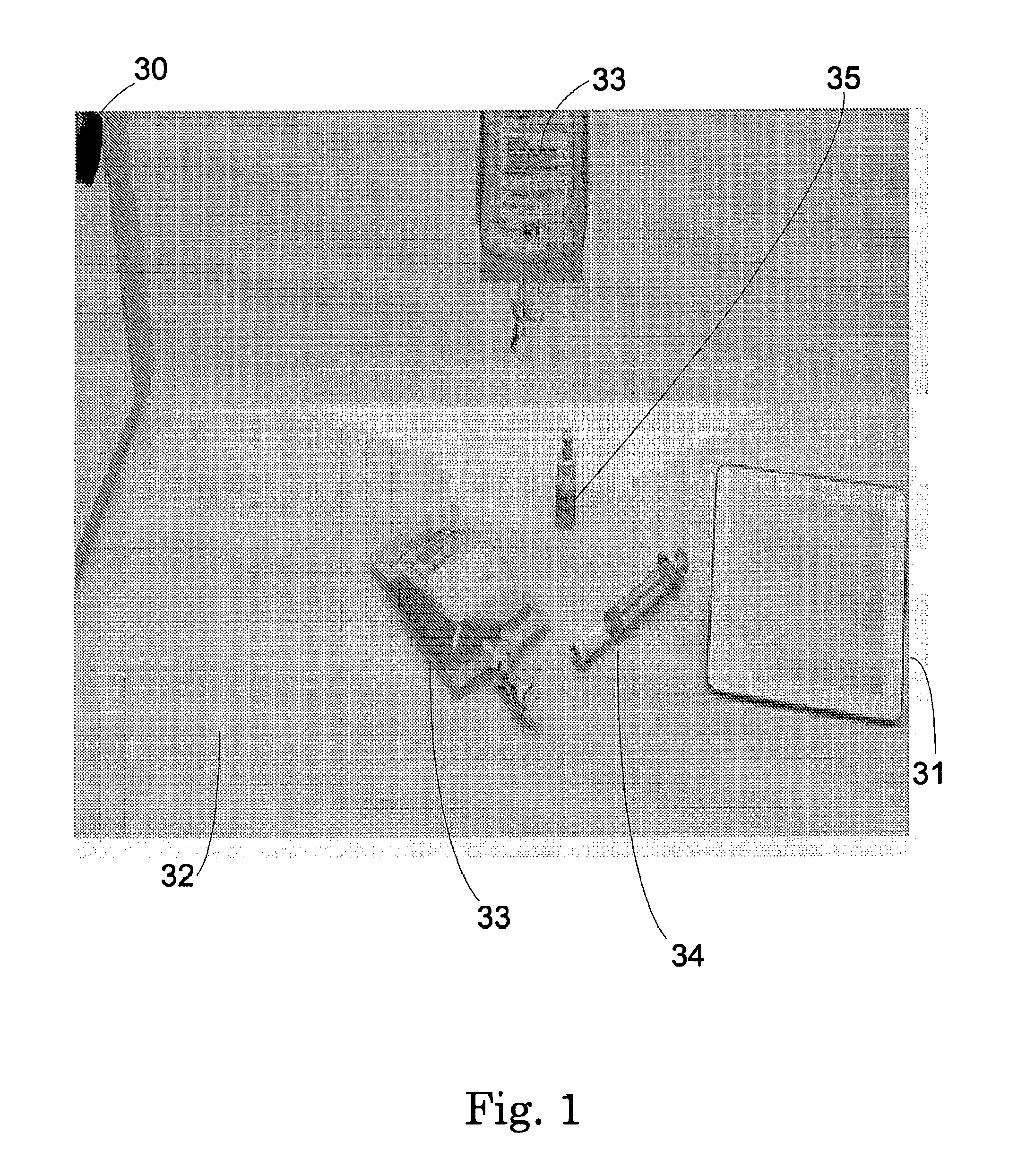

Method and apparatus for monitoring, documenting and assisting with the manual compounding of medications

The invention is a method and system for monitoring, documenting and assisting with the manual preparation and / or administration of medications. The invention accomplishes these goals via constant surveillance of the preparation / administration process using one or more digital cameras and software and hardware that processes the images and compares data from the processed images with information relative to the patient, to the drug components and composition of the medicament, and to non-drug items needed in the preparation that the system automatically or manually retrieves from various sources, e.g. internal or external data banks, from the technician / pharmacist, or by scanning the prescription.

Owner:EQUASHIELD MEDICAL

Device and system for dispensing or aspirating/dispensing liquid samples

The invention relates to a device (1) for dispensing or aspirating / dispensing liquid samples, comprising a pump (2) and a micro-ejection device (3), said micro-ejection device (3) having a pulse generator (4) with a chamber (5). Said pulse generator (4) is used to produce pressure waves in the liquid in order to cause the samples of a liquid to be dispensed. The micro-ejection device (3) also comprises an end piece (6) and a liquid line (7) which connects the pulse generator (4) to the end piece (6). The pulse generator comprises a micro-actuator (10) which is configured to function in the same direction as that in which the pressure wave leaves the chamber (5). The inventive devices are characterised in that the chamber (5), in the area of the end facing away from the end piece (6), or the corresponding connecting element (14) has a narrowed section (16) which restricts any expansion of the pressure waves in the direction of the pump (2). The invention also relates to systems with multiple devices of this type.

Owner:TECAN TRADING AG

Method and device for separating samples from a liquid

InactiveUS6926866B2Economical and highly reproducible separationLevel controlTemperatue controlPressure differenceComputer science

System, method, and computer program product for synchronizing a system for aspirating and / or dispensing of liquid samples that includes a microejection device and a pump, which are connected with one another via tubing, wherein a computer is capable of being loaded with an activatable computer program product for synchronizing operation of the microejection device and the pump. Embodiments are characterized in that the loaded and activated computer program product, directs the computer to control and synchronize the system: (a) to actively define a sample volume and dispense the defined sample volume using the microejection device, which is filled with sample liquid; and (b) to track a part of the pump that conveys liquid around a value, dependent on the sample volume, which is defined and is actively dispensed only by the microejection device, to prevent excessive pressure differences in the microejection device, tubing, and pump.

Owner:TECAN TRADING AG

Fluid dispenser calibration system and method

ActiveUS20050161469A1Automatically calibratingOpening closed containersBottle/container closureIterative methodBiomedical engineering

A system and method for calibrating fluid detects an actual fluid dispensing characteristic, such as dispensing speed, and automatically adjusts the dispensing characteristic to match an ideal dispensing characteristic. The adjustment is conducted by a controller that controls fluid dispensing based on a function that correlates dispensing speed, a dispensed volume, and a dispensing time. The function allows calibration to occur automatically by converging system operation to the ideal dispensing characteristic, without requiring a user to calibrate the system through manual iterative methods.

Owner:TAYLOR COMML FOODSERVICE LLC

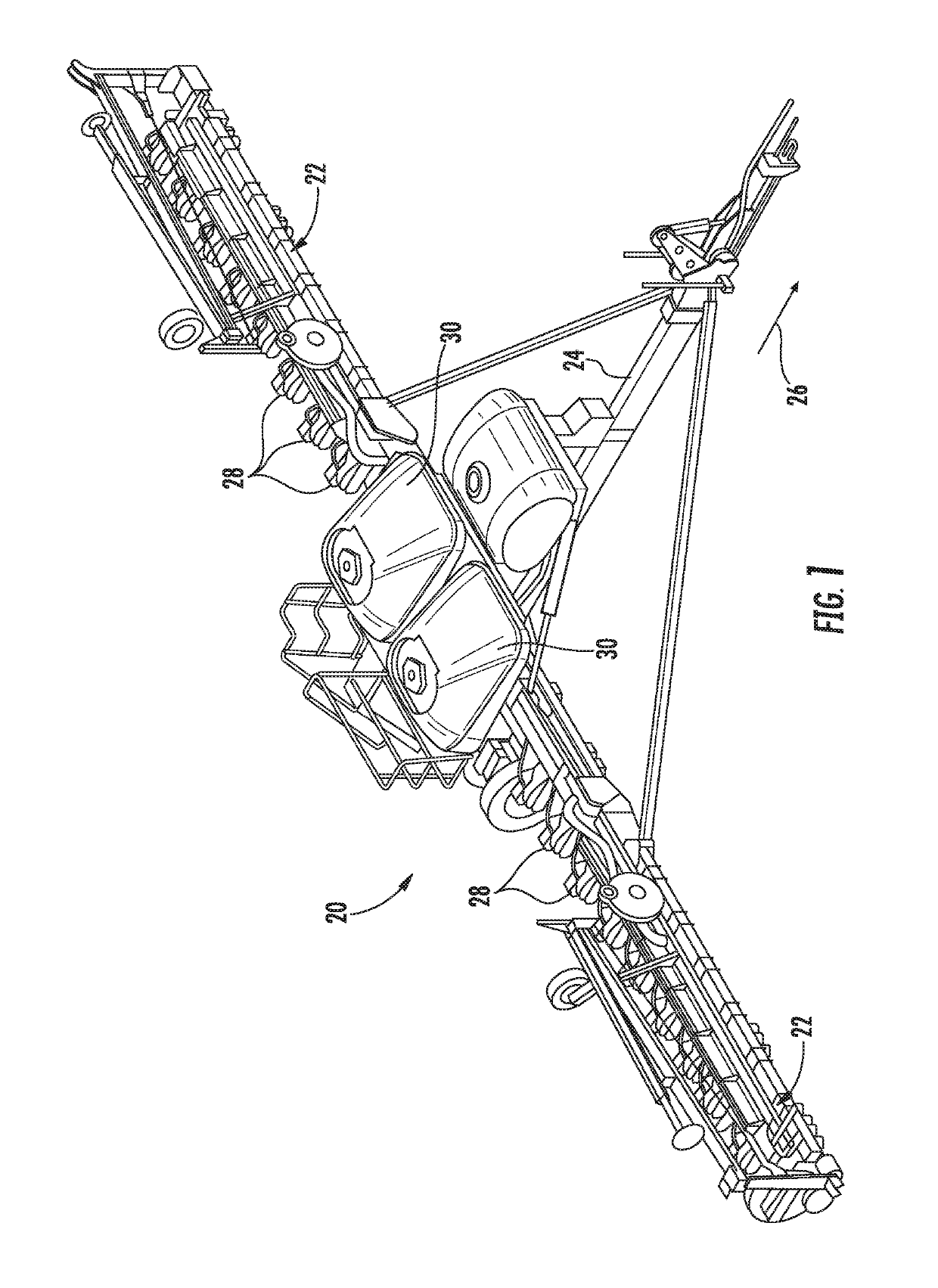

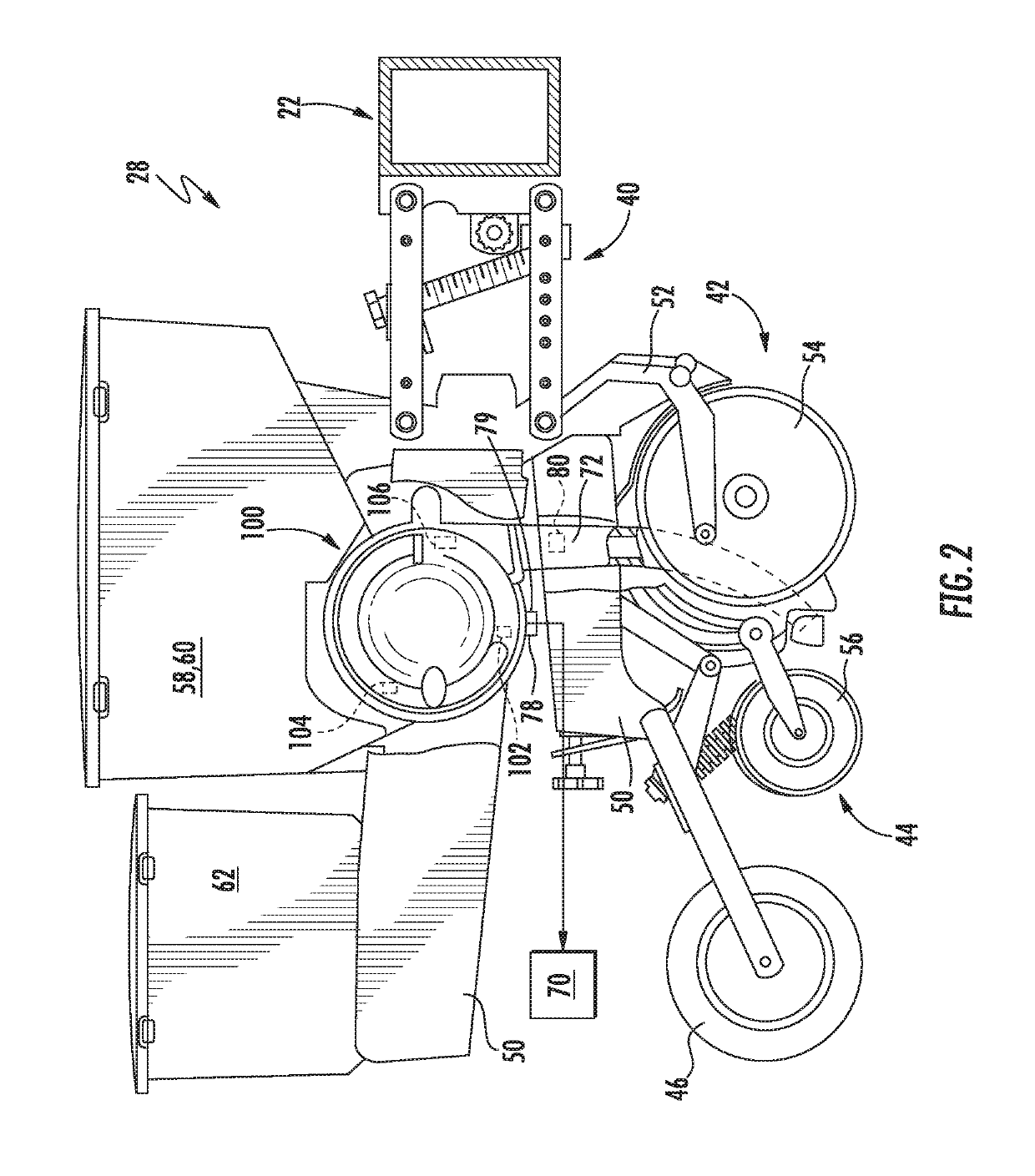

Calibration methods for multi-variety seed meters and related systems

Owner:BLUE LEAF I P INC

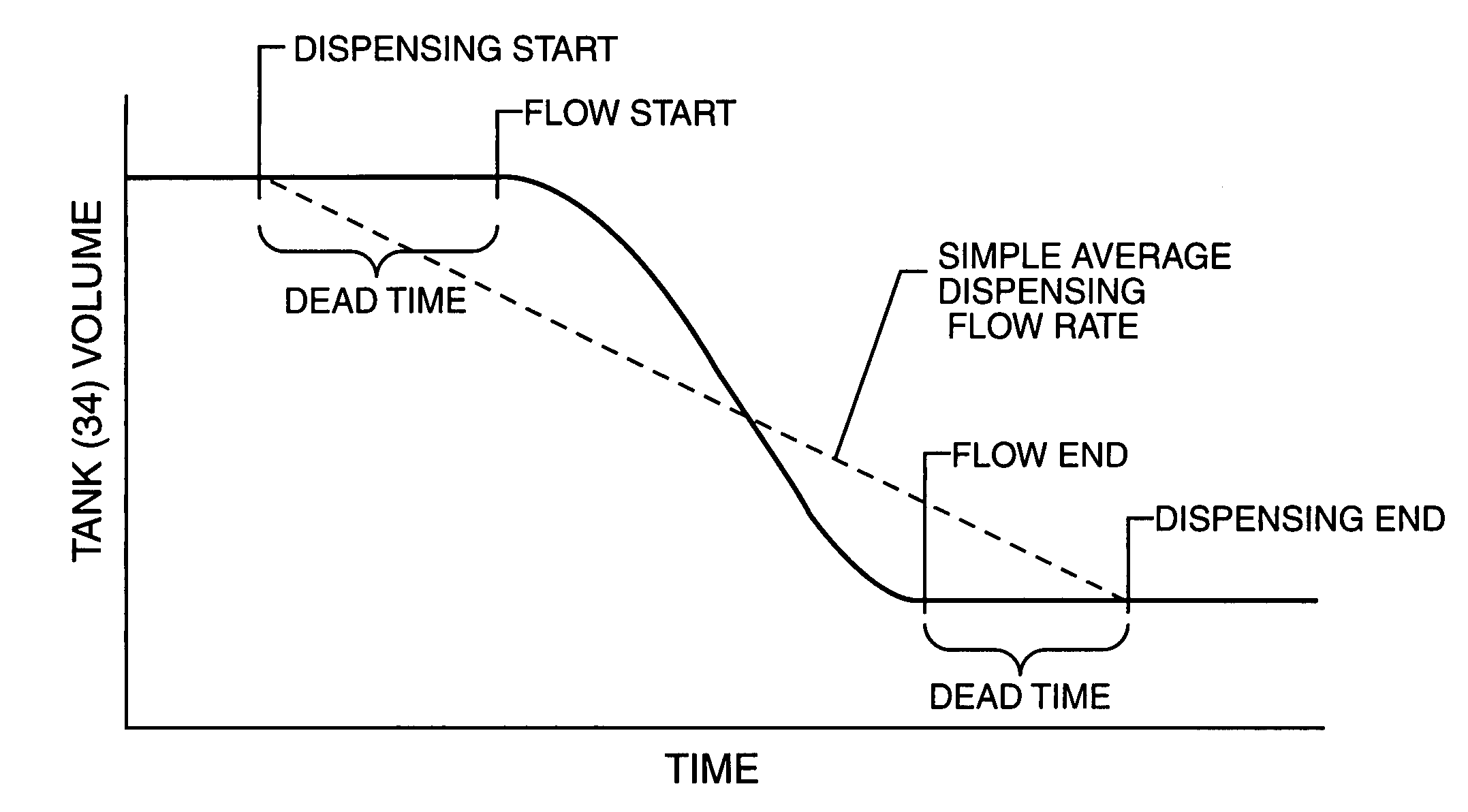

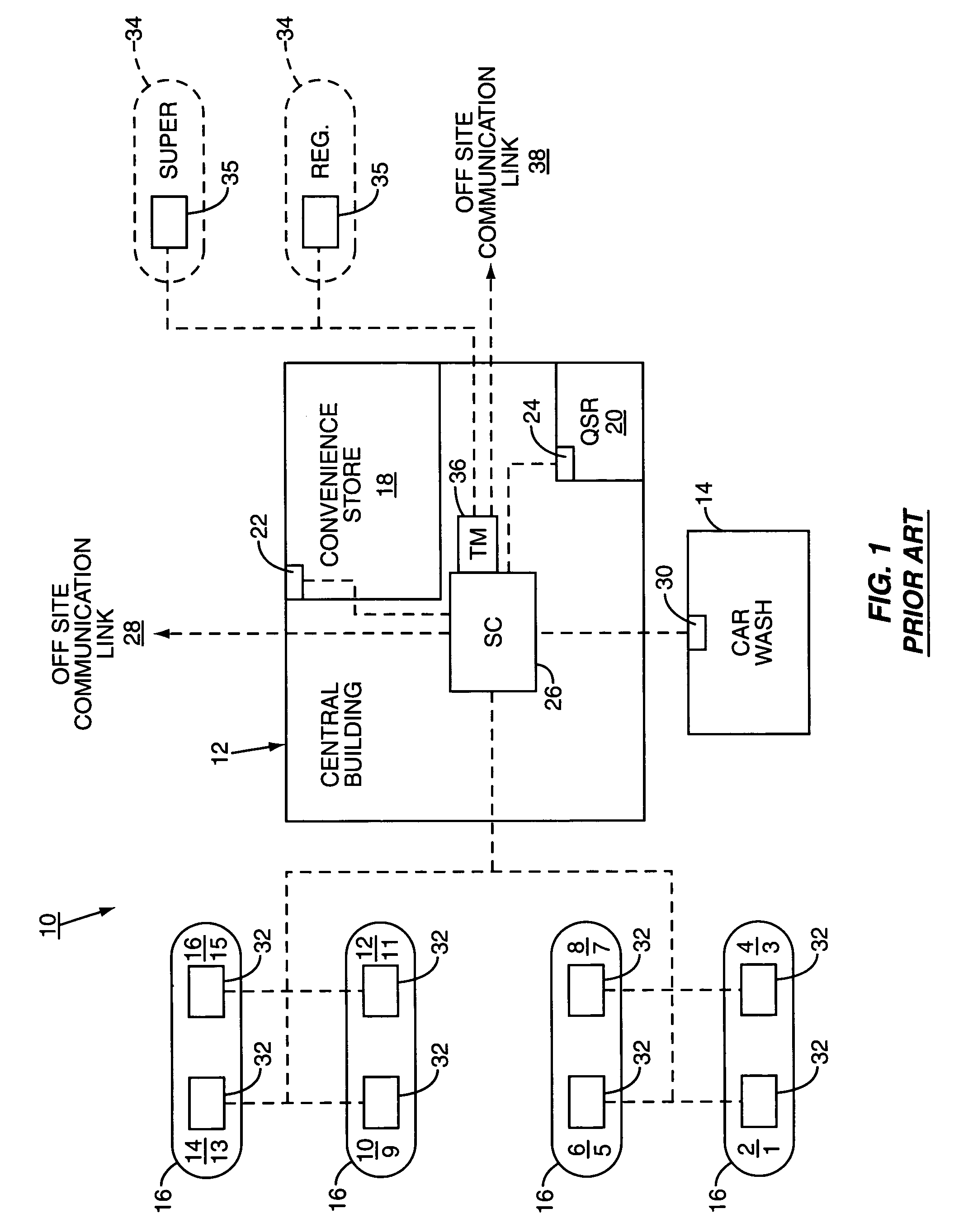

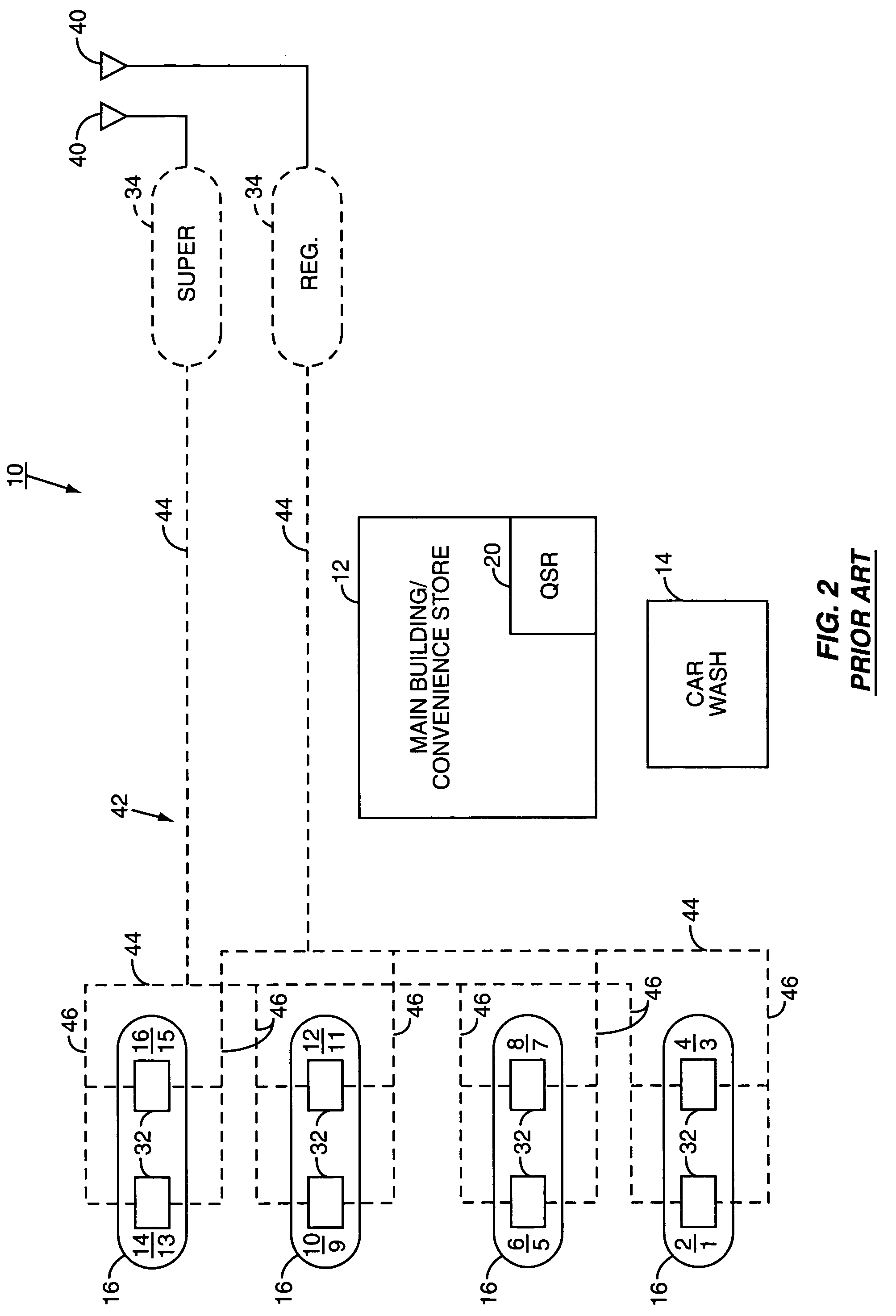

Method and system for determining and monitoring dispensing point flow rates and pump flow capacities using dispensing events and tank level data

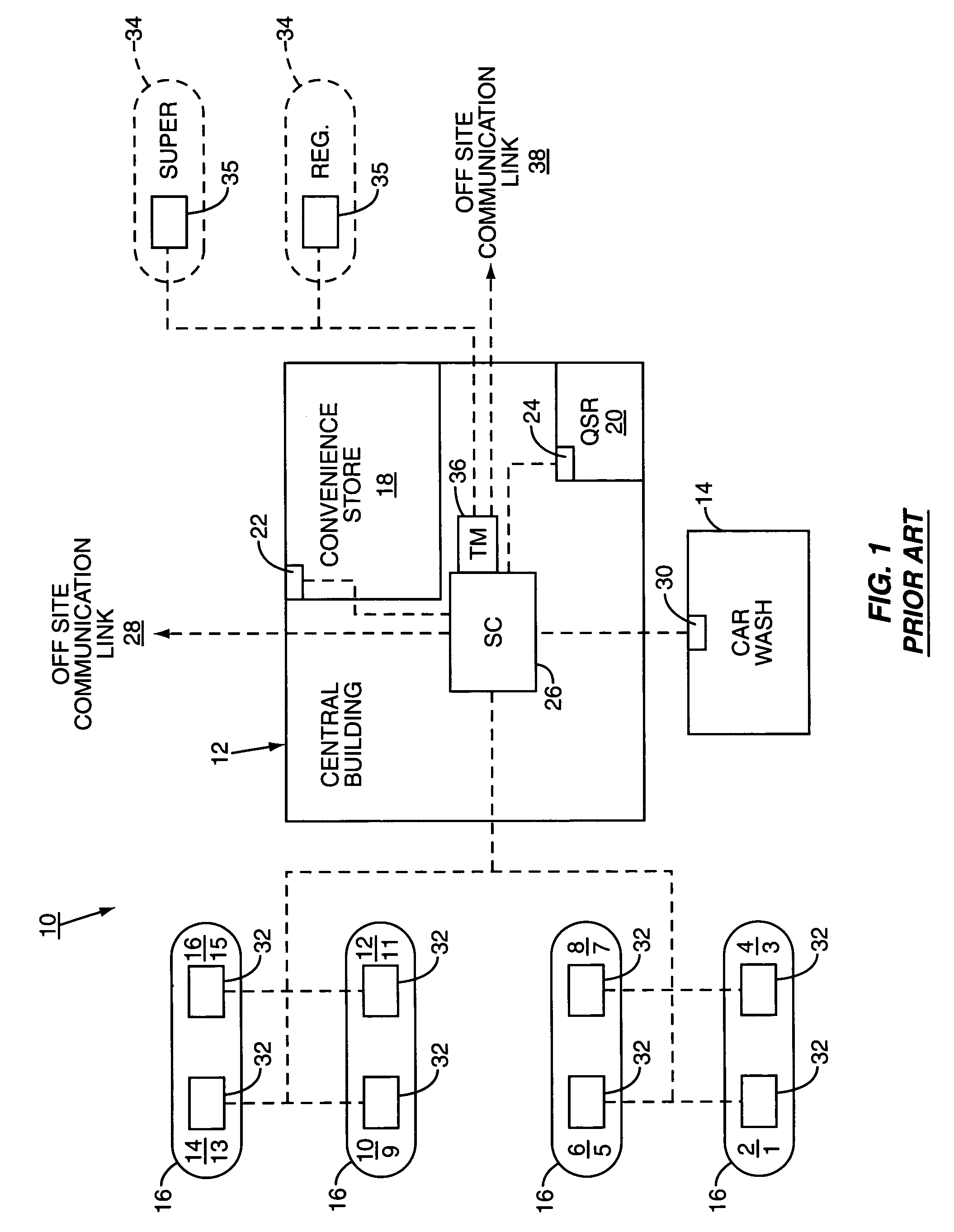

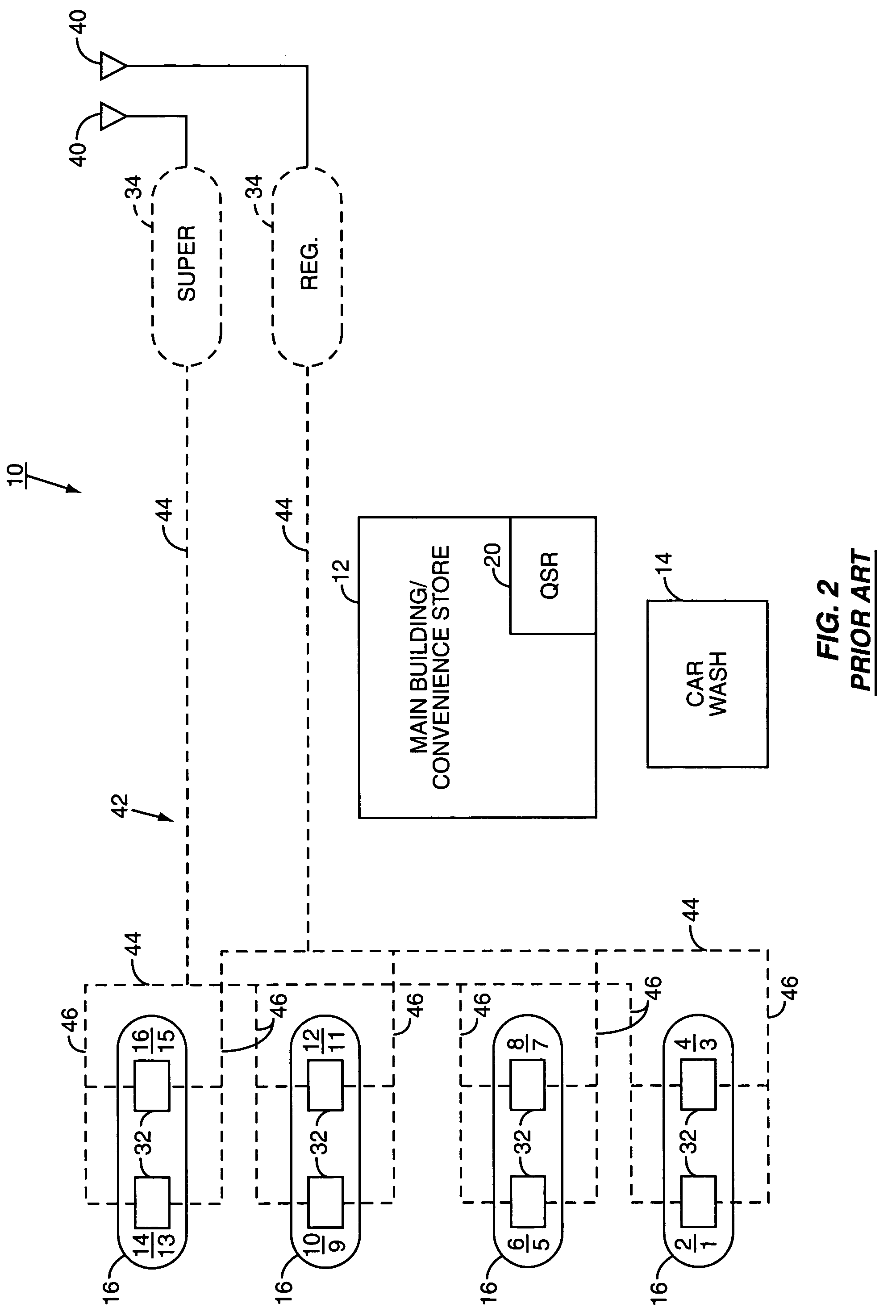

ActiveUS7152004B2Improve accuracyShorten the timeFlow propertiesVolume/mass flow measurementDead timeImage resolution

A system and method for calculating the flow rate of a dispensing point or flow capacity of a pump and fuel delivery system and determining if the dispensing point or fuel delivery system has a blockage and / or a performance problem if the calculated dispensing point flow rate is other than expected. The calculated dispensing flow rate is calculated by collecting fuel tank level data points for a dispensing point that fall within start and stop events of the dispensing event. The slope of a fitted line to the fuel tank level data points is used as the indication of the flow rate of the dispensing point. Different mathematical techniques may be used to improve the flow rate calculation to compensate for the minimum resolution of collecting fuel tank level data and the dead time included in the data of a dispensing transaction.

Owner:VEEDER ROOT

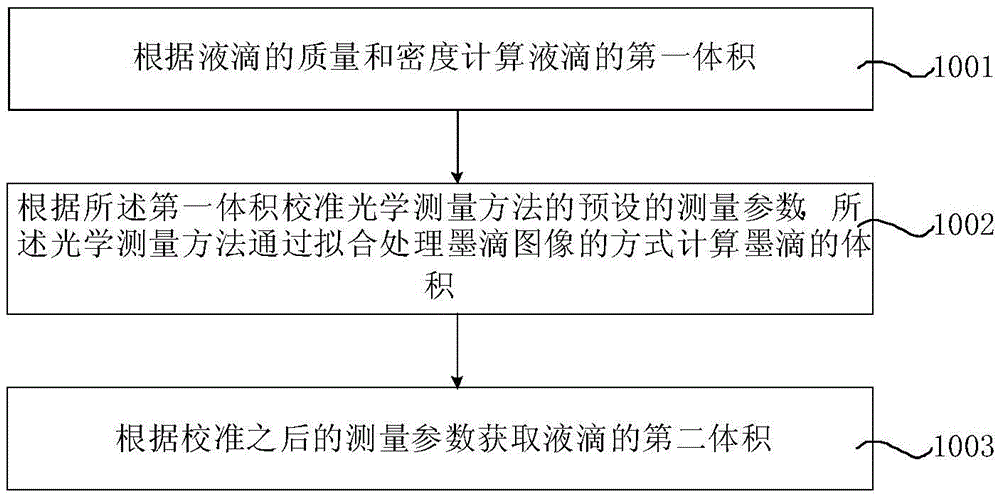

Ink droplet volume calibration method, calibration system thereof, and printing device

InactiveCN105459601AAccurate measurementHigh measurement accuracyVolume measurement apparatus/methodsTesting/calibration for volume meteringEngineeringOptical measurements

The invention discloses an ink droplet volume calibration method, a calibration system thereof, and a printing device. The ink droplet volume calibration method calculates the first volume of ink droplets according to ink droplet quality and density; according to the first volume, the preset measuring parameters of an optical measurement method are calibrated; the optical measurement method calculates the volume of ink droplets through a fitting processing ink droplet image mode; the second volume of ink droplets is obtained according to calibrated measuring parameters. In the technical scheme, a weighing measurement method and the optical measurement method are combined, and the measuring parameters of the optical measurement method are calibrated according to the result of the weighing measurement method, thereby improving ink droplet volume measurement precision. In addition, specific to different ink droplets, different optical fitting parameters are provided in the embodiment, thereby realizing accurate measurement of ink droplet volumes.

Owner:BOE TECH GRP CO LTD

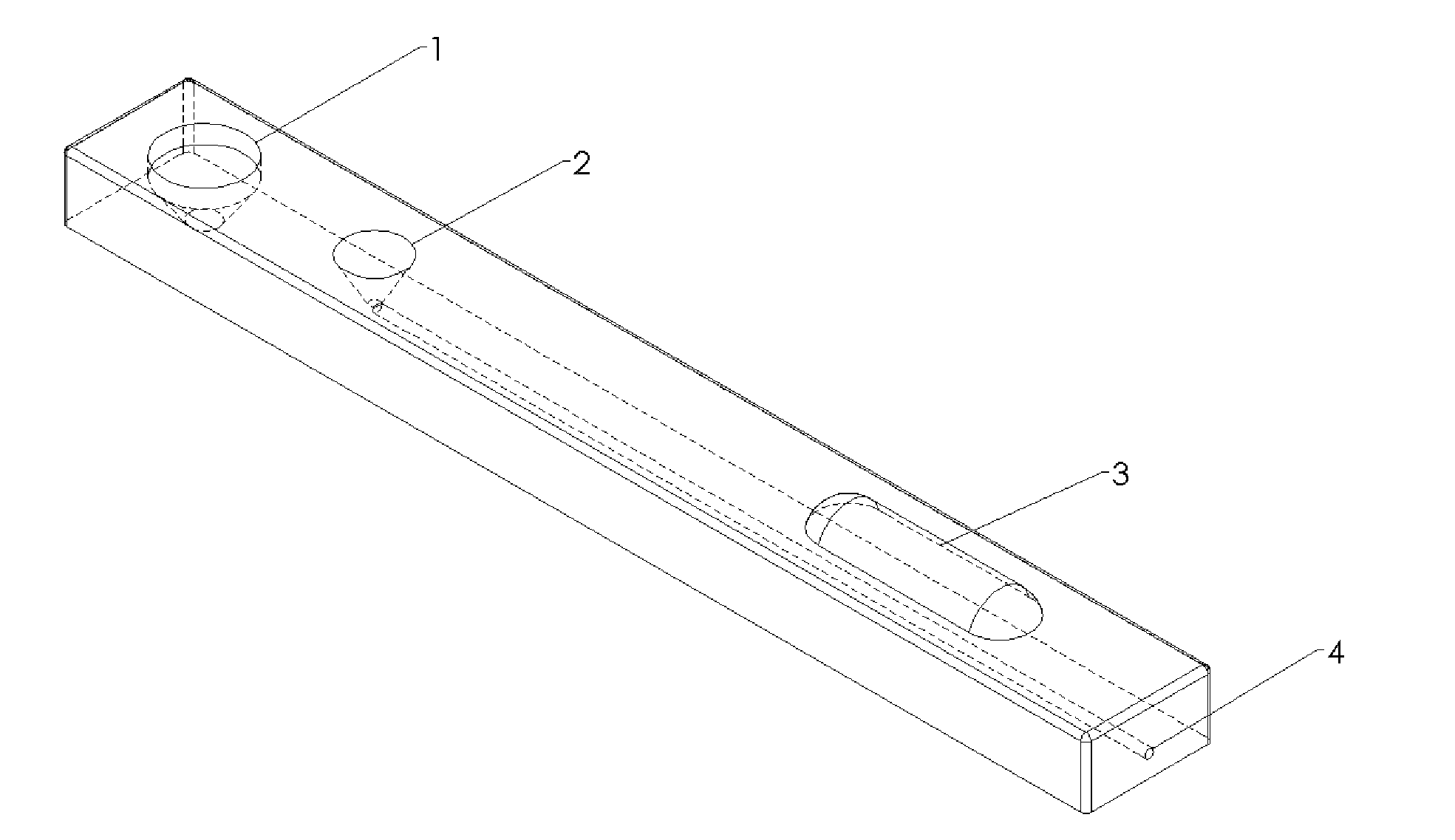

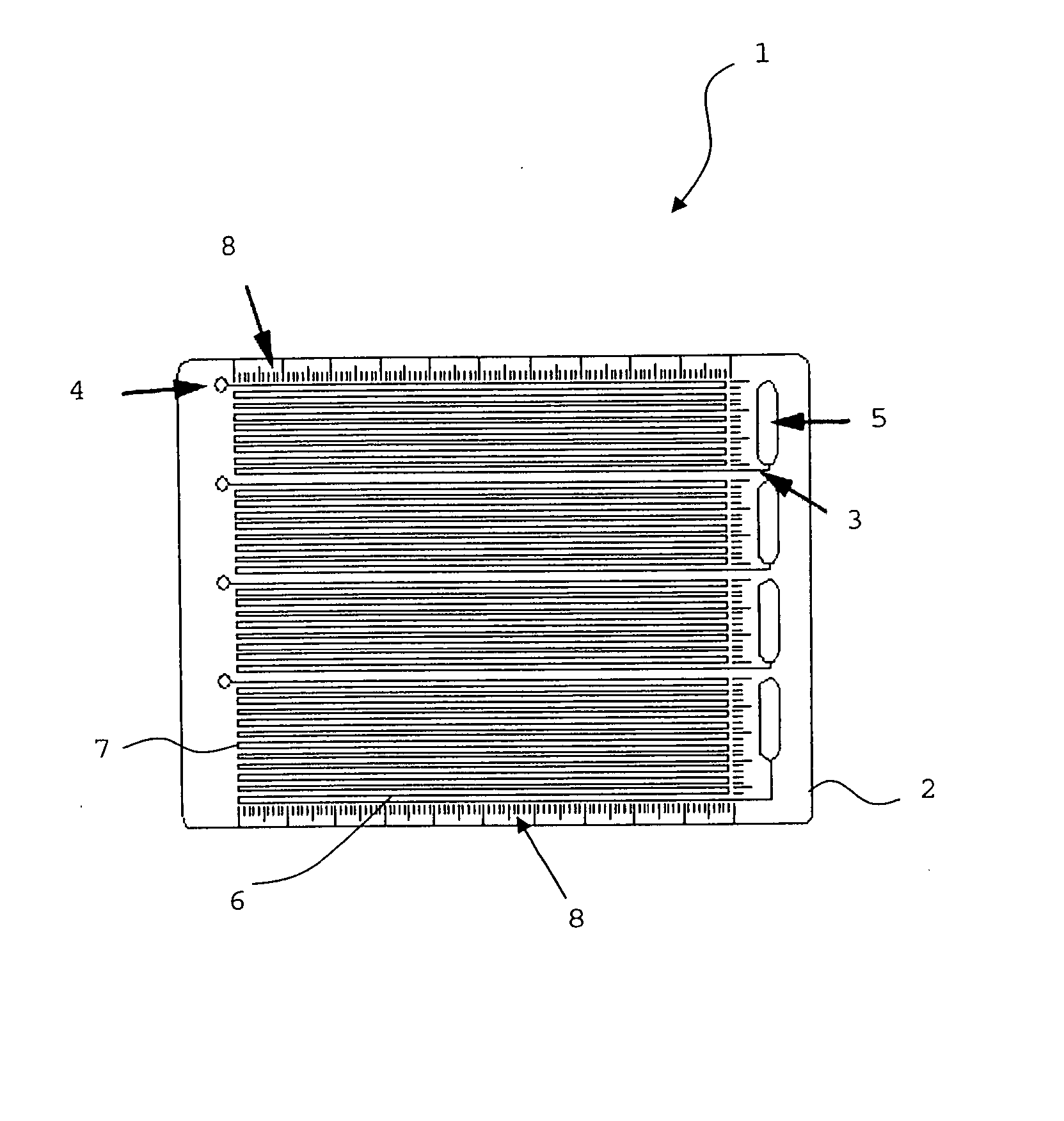

Device and method for calibrating a pipette or a dispensing system

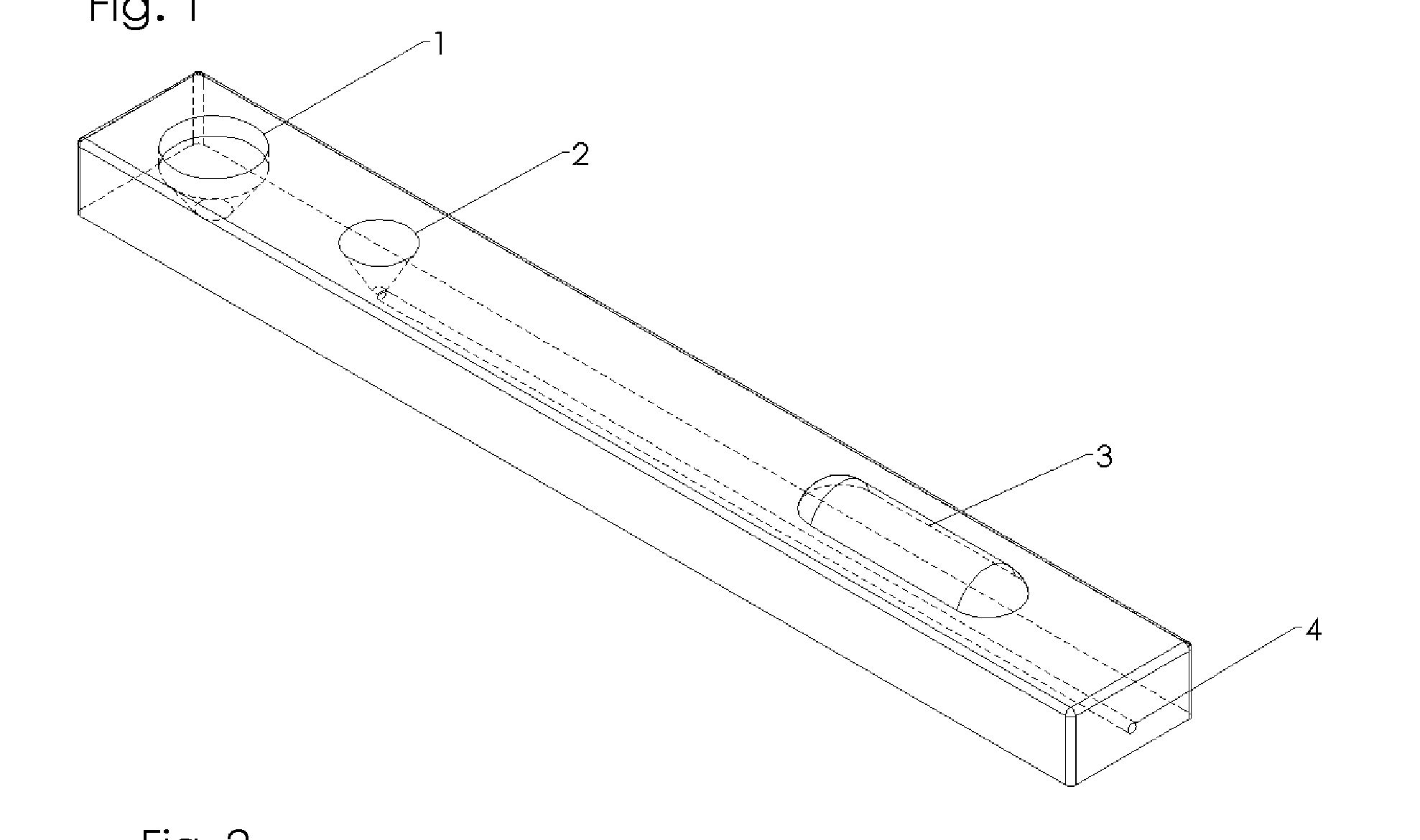

ActiveUS20080066523A1Economically manufacturedManufacturedLaboratory glasswaresTesting/calibration for volume meteringPipetteBiomedical engineering

The present invention relates to a device (1) for calibrating a pipette or a dispensing system comprising a plate (2), said plate (2) comprising at least one channel (3) with a loading port (4) for receiving a test volume of a fluid at one end of the at least one channel and an opening (5) at the other end of the at least one channel, wherein the at least one channel (3) is constructed as a capillary. Furthermore, the invention relates to a method for calibrating a pipette or a dispensing system, comprising the steps of introducing a first volume of a fluid into a loading port (4) of a device (1), recording a first length of the fluid column in a channel (3) of the device (1), introducing a second volume of a fluid from the pipette or the dispensing system to be calibrated to the same loading port (4), recording a second length of the fluid column in the channel (3), and computing the volume dispensed by the pipette or the dispensing system by calculating the distance between the second length and the first length and multiplying said distance with the cross-section of the channel (3).

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Method and system for determining and monitoring dispensing point flow rates and pump flow capacities using dispensing events and tank level data

ActiveUS20050102112A1Improve accuracyShorten the timeFlow propertiesVolume/mass flow measurementDead timeImage resolution

A system and method for calculating the flow rate of a dispensing point or flow capacity of a pump and fuel delivery system and determining if the dispensing point or fuel delivery system has a blockage and / or a performance problem if the calculated dispensing point flow rate is other than expected. The calculated dispensing flow rate is calculated by collecting fuel tank level data points for a dispensing point that fall within start and stop events of the dispensing event. The slope of a fitted line to the fuel tank level data points is used as the indication of the flow rate of the dispensing point. Different mathematical techniques may be used to improve the flow rate calculation to compensate for the minimum resolution of collecting fuel tank level data and the dead time included in the data of a dispensing transaction.

Owner:VEEDER ROOT

Calibration unit and method for metering a dosage unit

ActiveUS20180031410A1Reliable and repeatable determinationReliable and repeatableSievingCapacitance measurementsDosage Form UnitEngineering

A calibration unit is for a capacitive measuring system in a metering installation, or a metering installation for in particular solid pharmaceutical dosage units, and to an associated method for metering. The calibration unit includes a test body, a drive for the test body, and a guide for the test body. The guide has a first terminal position, a second terminal position, and a guided section that runs between the two terminal positions. The drive is configured for moving the test body along the guided section in a reciprocating manner between the two terminal positions. The capacitive measuring system is calibrated via the calibration unit. The dosage units are then metered via the metering installation and checked for a properly metered mass via the calibrated capacitive measuring system.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

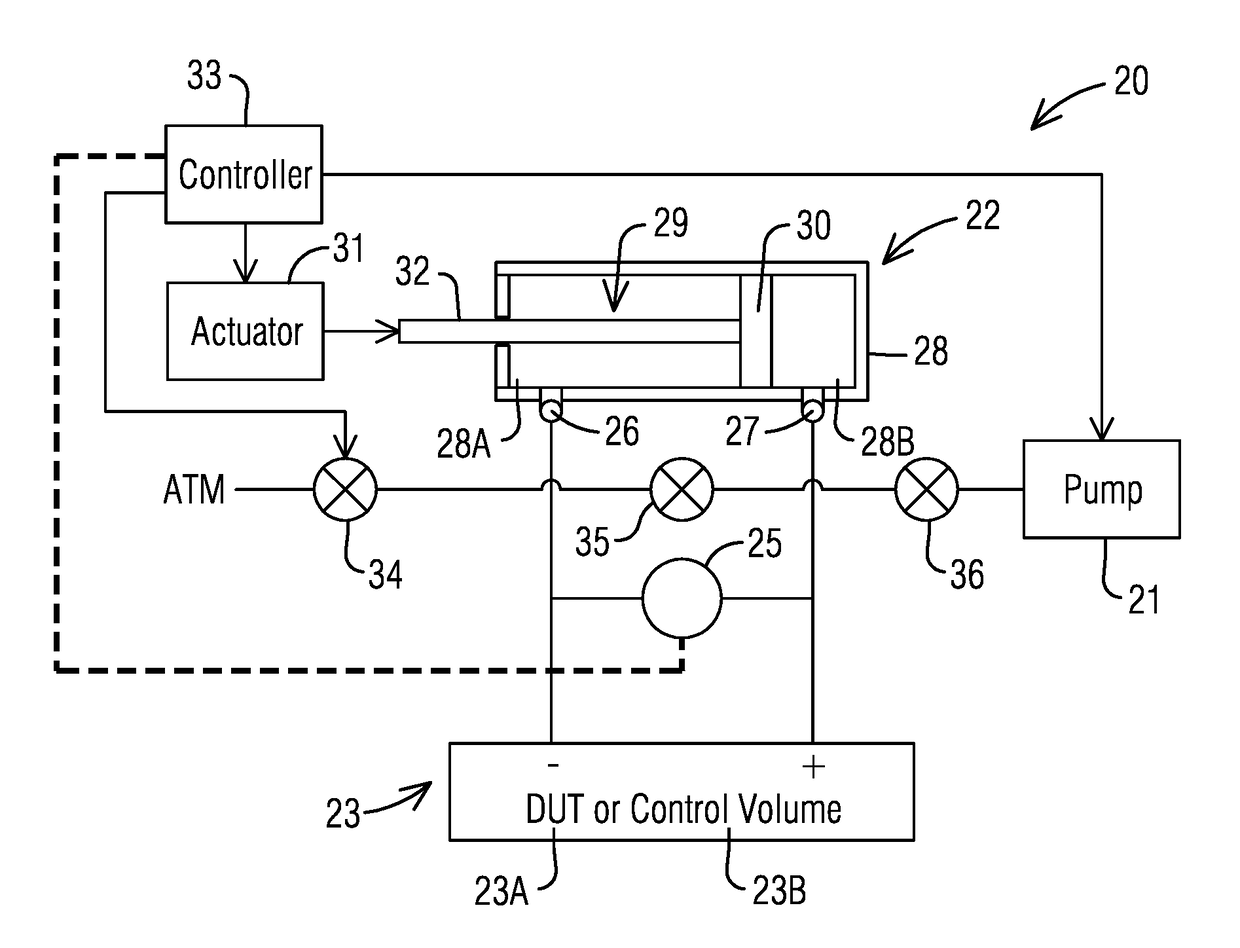

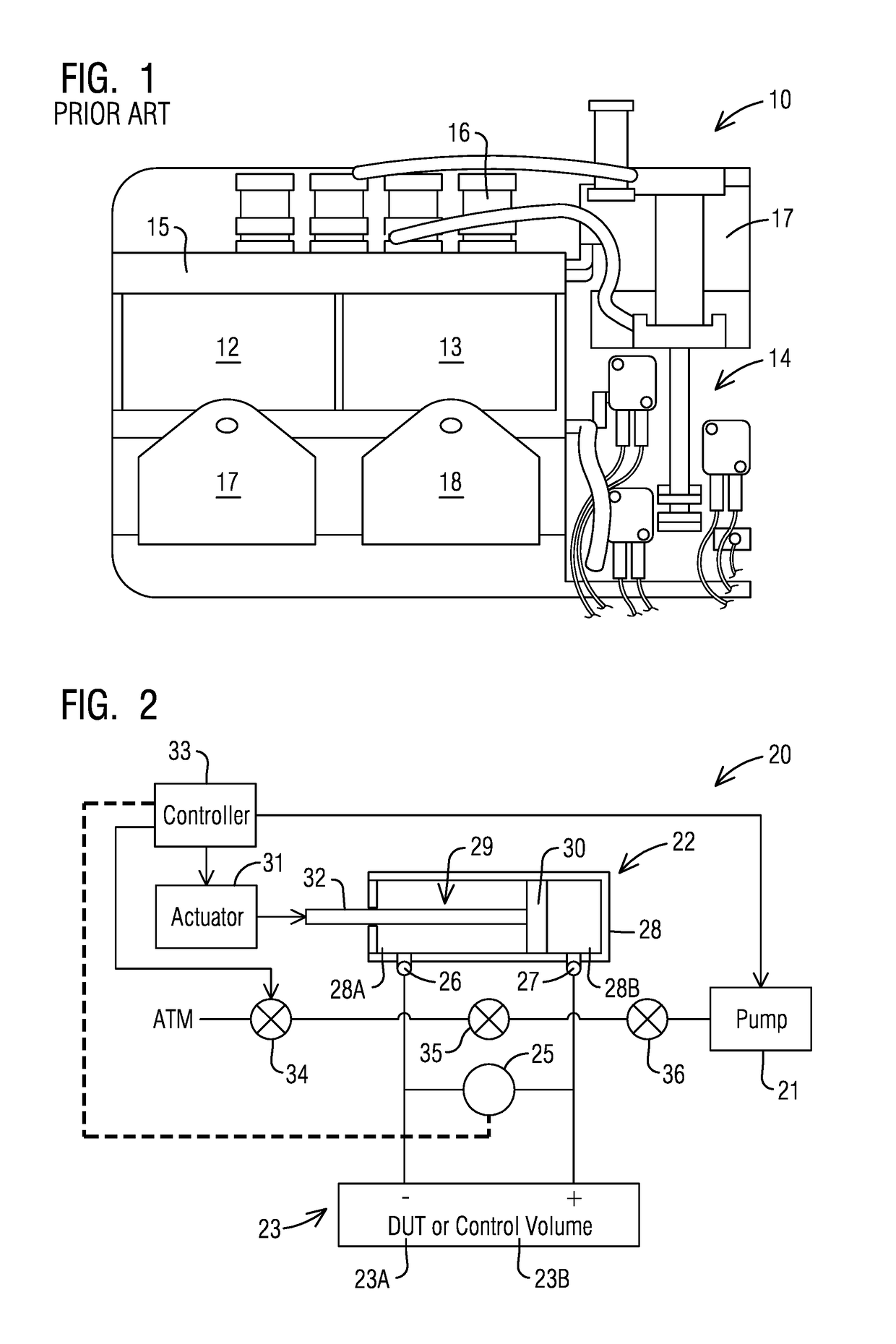

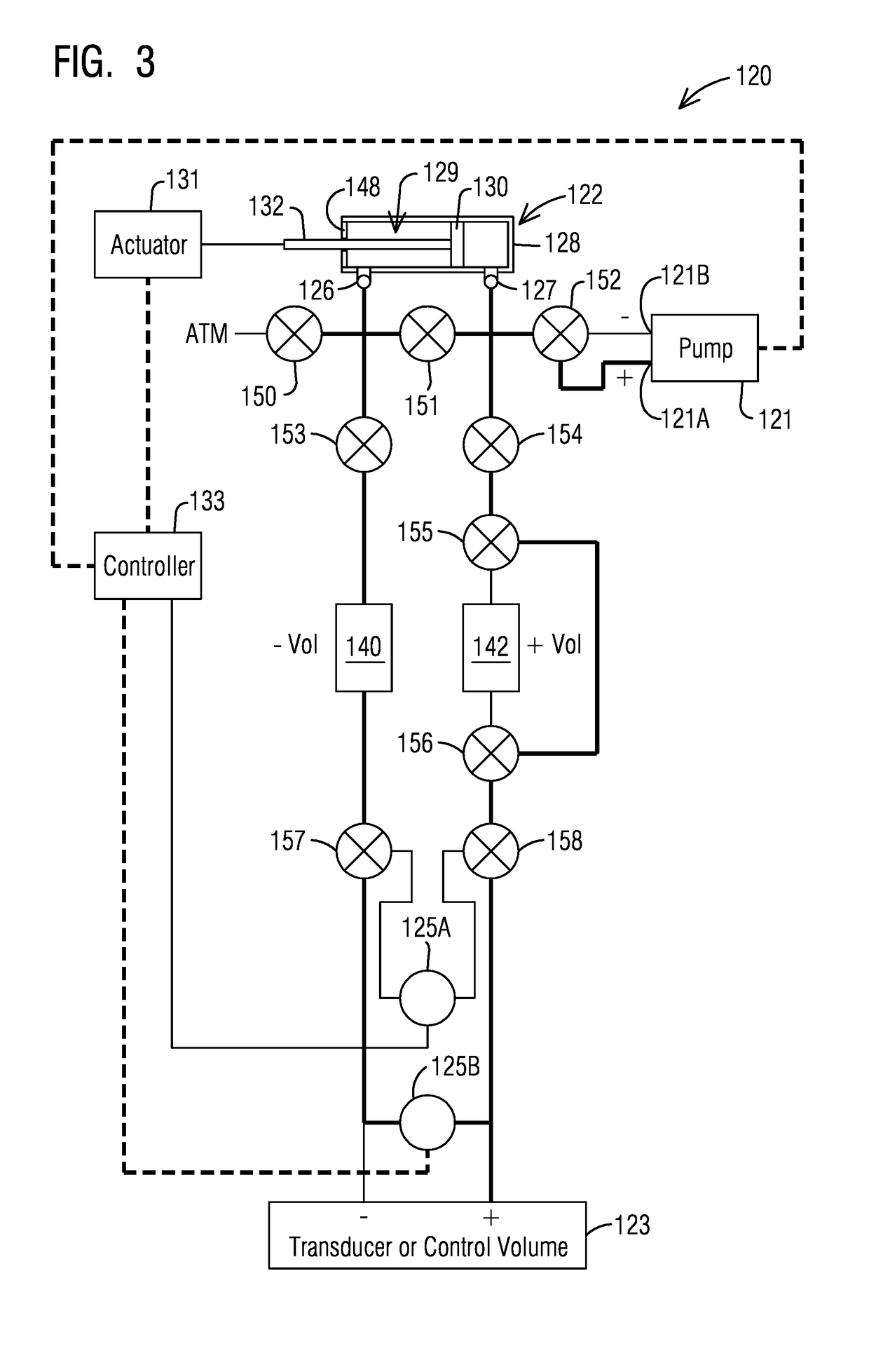

A system and method for callibrating and controlling pressure

InactiveUS20180017460A1Reduce in quantityFluid-pressure actuator testingFluid pressure measurementEngineeringPressure difference

A system for controlling pressure associated with a volume may comprising a pump and piston / cylinder assembly, both in fluid communication with a volume of a closed fluid system. In addition, the system may comprise an actuator operatively connected to the actuator and pump to control fluid flow and pressurization or depressurization of the volume and / or fluid flow system. The pump is activated to generate a first pressure level of the closed fluid system and when this first pressure level is reached the actuator is activated to drive the piston / cylinder assembly to reach a pressure set point from the first pressure level. The system may be used as a calibrator or a pressure controller for pressure differentials, gauge pressure or absolute pressure.

Owner:SETRA SYST

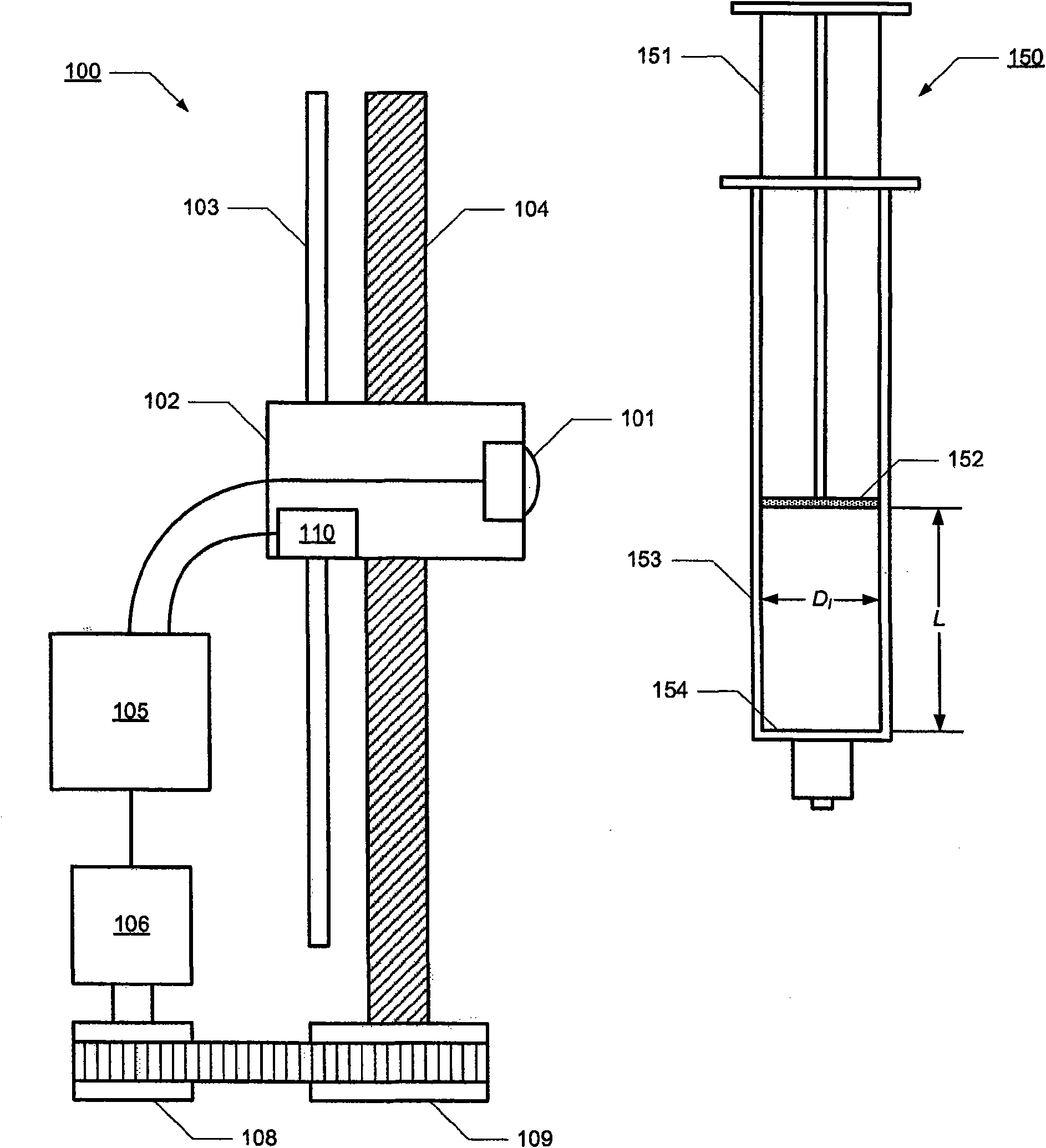

Syringe imaging systems

A syringe imaging system for a syringe infusion pump is provided. The system comprises an imaging device configured to capture one or more images of a syringe, and a processor, which is configured to determine, based on the one or more captured images, an internal diameter of the syringe and a distance between a bung and a bottom of the syringe, and to calculate a remaining volume of the syringe based upon the determined internal diameter and distance. A syringe infusion pump is also provided. The pump comprises a housing having a bracket configured to receive a syringe, a syringe driver configured to actuate a plunger of the syringe, an imaging device configured to capture one or more images of the syringe, and a processor. The processor is configured to determine, based on the one or more captured images, an internal diameter of the syringe and a distance between a bung and a bottom of the syringe, and to calculate a remaining volume of the syringe based upon the determined internal diameter and distance.

Owner:CAREFUSION 303 INC

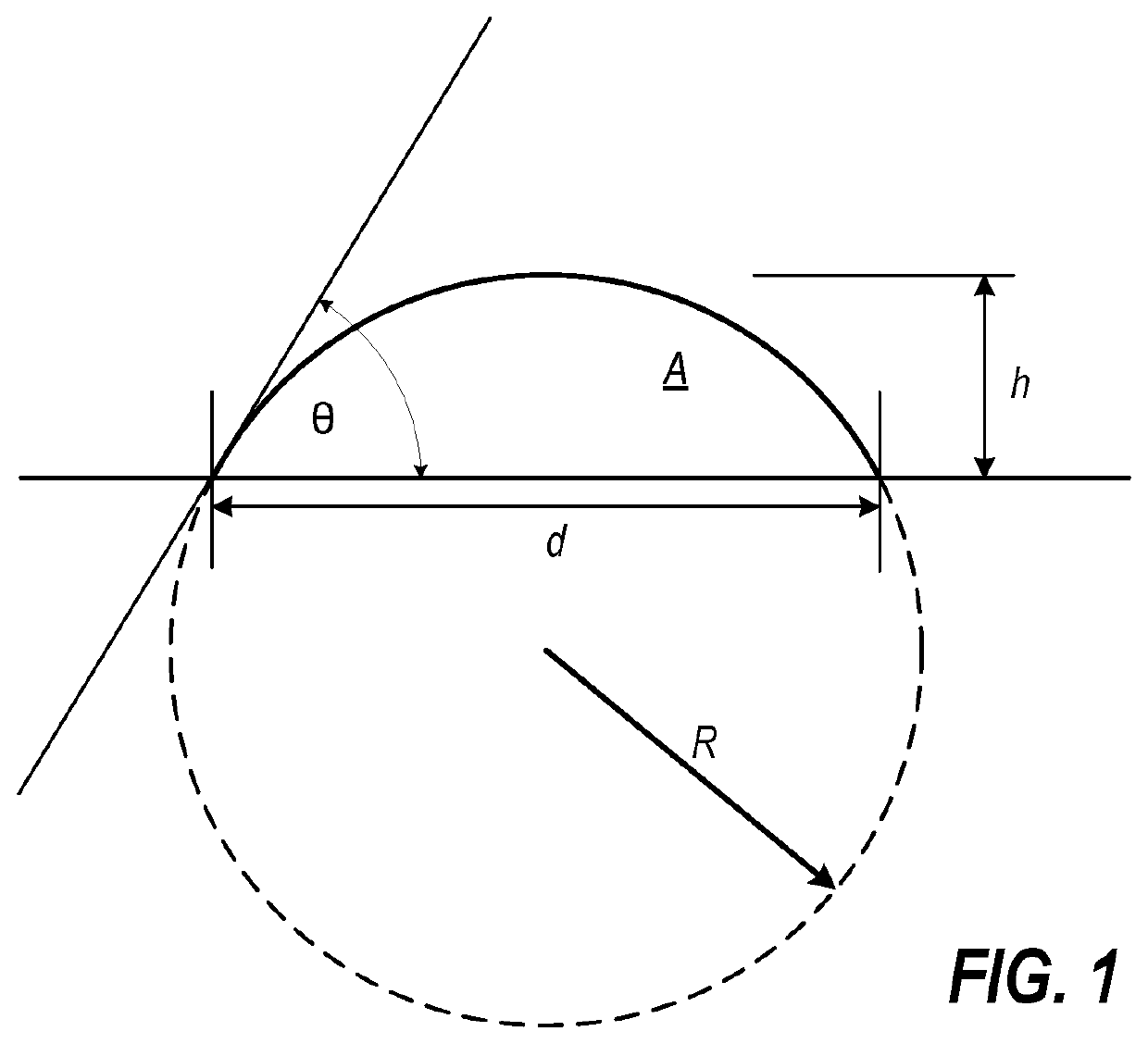

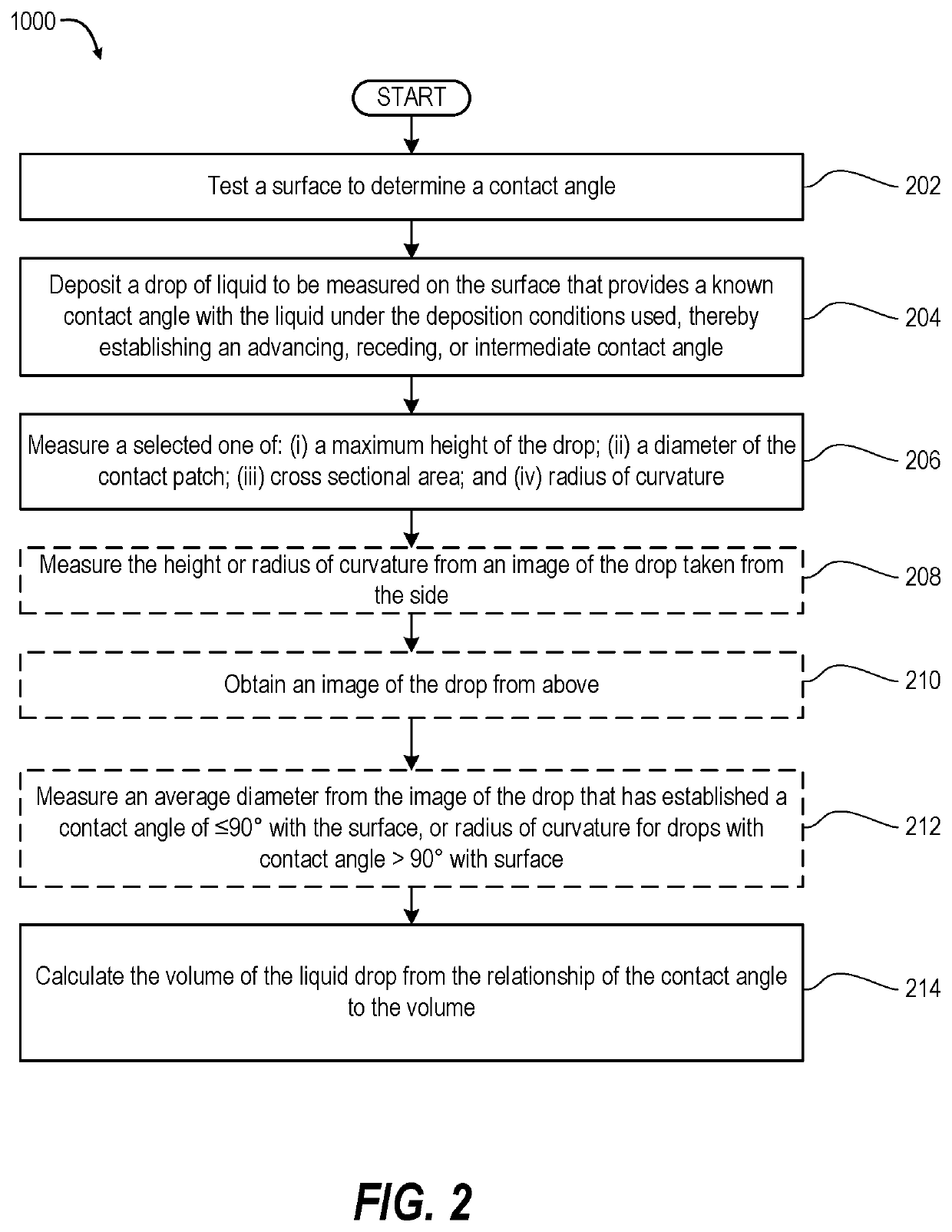

Method and device for measuring minute volume of liquid

InactiveUS20200080880A1Limit scopeVolume measurement apparatus/methodsImage analysisRadius of curvatureMechanical engineering

A method and test apparatus determines a volume of a droplet of liquid. The test apparatus deposits a drop of liquid to be measured on a surface that provides a known contact angle with the liquid under the deposition conditions used, thereby establishing one of: (i) an advancing, (ii) a receding, and (iii) an intermediate contact angle. The test apparatus images the drop. The test apparatus measures a dimension of height or diameter of the drop. In one embodiment, the test apparatus calculates a volume of the drop of liquid from the relationship of the contact angle to one or more parameters selected from the maximum height, the diameter of the contact patch, the radius of curvature, or the cross sectional area of the drop.

Owner:BRIGHTON TECH

Dispenser volume determination method

InactiveUS7270013B2Volume measurement and fluid deliveryFluid pressure measurementMeasurement testMedicine

The present invention includes methods of determining the volume of liquid dispensed by a dispenser. Initially, a refractive index analysis is preformed on a first liquid that has been dispensed from the dispenser in question. From the refractive index analysis, information is obtained about the volume of first liquid dispensed. The invention also includes methods for verifying the volumetric accuracy of a dispenser. The methods include dispensing a first liquid having a known refractive index into a vessel having a second liquid with a known volume and a known refractive index to form a test mixture. The refractive index of the test mixture is measured and then correlated with the refractive index of the first liquid to obtain information about the volume of first liquid dispensed. The dispensed volume is then compared to the theoretical volume of liquid dispensed by the dispenser.

Owner:STRECK INC

Method and apparatus for a bidirectional meter proving system

ActiveUS8505355B2Lower overall pressure dropLess-expensive to operateTesting/calibration for volume meteringTesting/calibration of speed/acceleration/shock measurement devicesGasolineEngineering

A bidirectional sphere prover is used to check the accuracy of a custody transfer meter when fluids, such as crude oil or gasoline are bought and sold. The bidirectional sphere prover of the present invention uses a straight calibrated section of pipe between the detection switches, the straight calibrated section of pipe being free of welds, flanges and elbows.

Owner:WFMS

Method and device for detecting gyration period of diaphragm gas meter based on image acquisition

ActiveCN106153158ASolve acquisition problemsImprove test efficiencyTesting/calibration for volume meteringTemplate matchingSonic nozzle

Provided are a method and a device for detecting a gyration period of a diaphragm gas meter based on image acquisition. Based on an original diaphragm gas meter calibrating device which is based on a sonic nozzle, a camera and an image acquisition and processing module are added. The camera and the image acquisition and processing module are fixed on a meter clamping component of the diaphragm gas meter calibrating device which is based on a sonic nozzle. The camera is on the right upper end of a diaphragm gas meter air inlet. An image in which an oscillating bar and a connecting rod are exposed is acquired and is used as a comparison template. After the image acquisition and processing module identifies the camera, and when the shot image in which the oscillating bar and the connecting rod are exposed can be matched with the comparison template, the interval of acquisition time is the gyration period of the diaphragm gas meter. The identification processing steps of the image acquisition and processing module comprise: (1) converting a grey-scale map; (2) performing image binaryzation; (3) and identifying images based on template matching. The detection method solves a problem that detection difficulty of to-and-fro movement period of reciprocating pieces in a diaphragm gas meter is large.

Owner:ZHEJIANG UNIV CITY COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com