Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about "Multiple 3D object manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

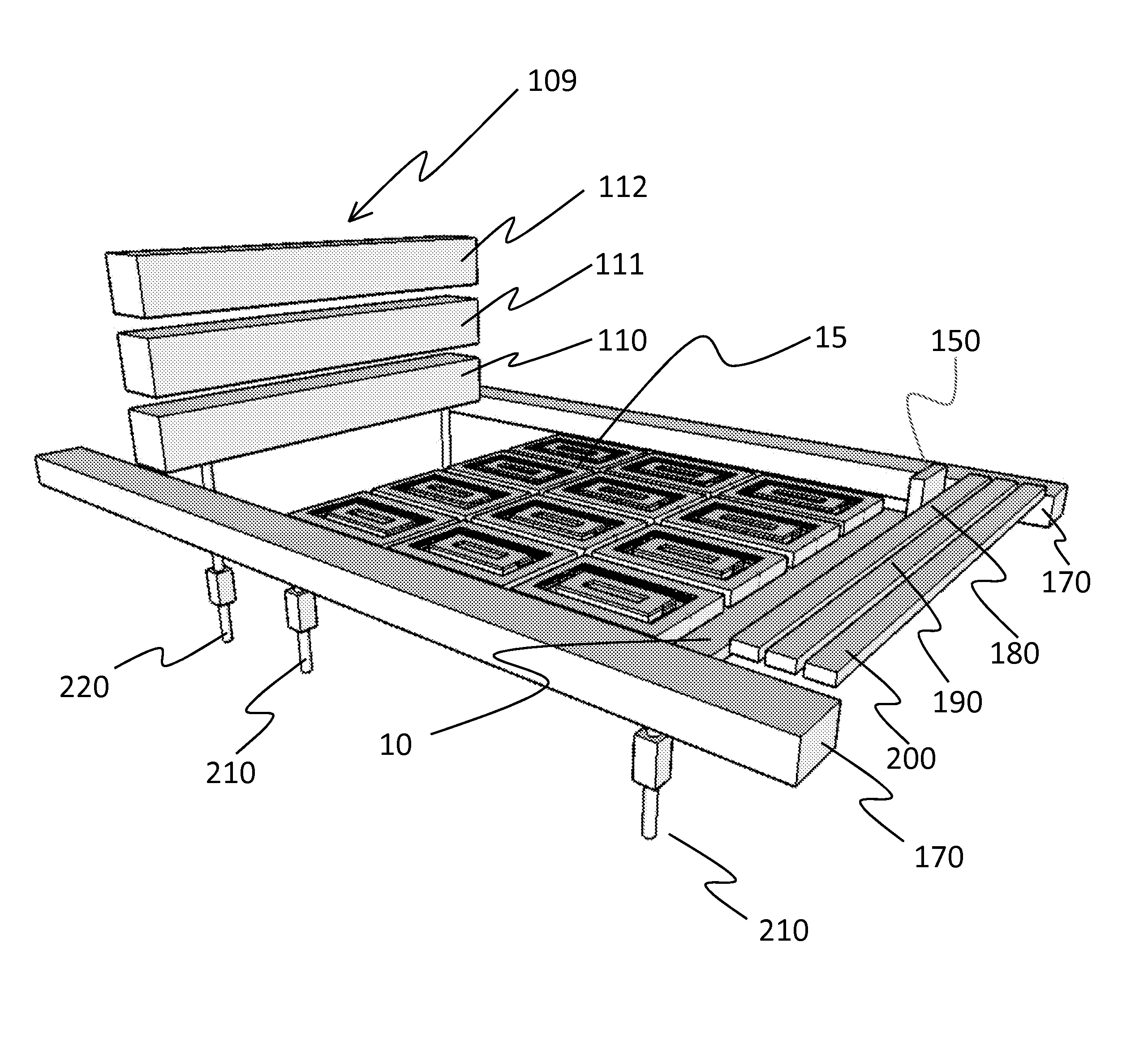

Systems and methods for 3D printing with multiple exchangeable printheads

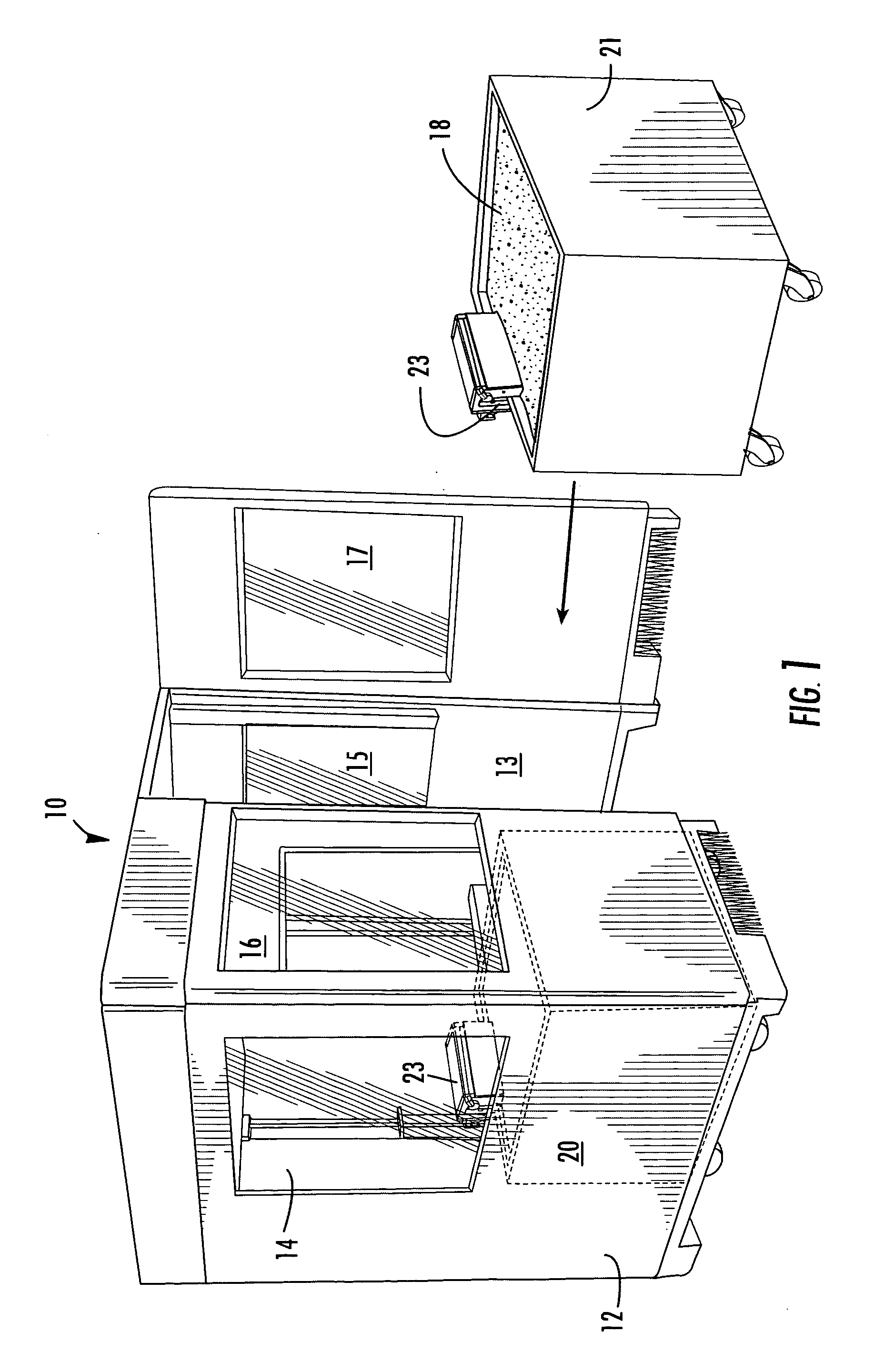

A modular 3D printer system can include a base subsystem and multiple exchangeable components. The base subsystem can have a 3D motion module, a printhead module and a platform module. The multiple exchangeable components can include printheads having different configurations and functionalities, which can be exchangeably installed in the printhead module. The multiple exchangeable components can include platform supports having different configurations and functionalities, which can be exchangeably installed in the platform module.

Owner:GIFFORD KARL JOSEPH +3

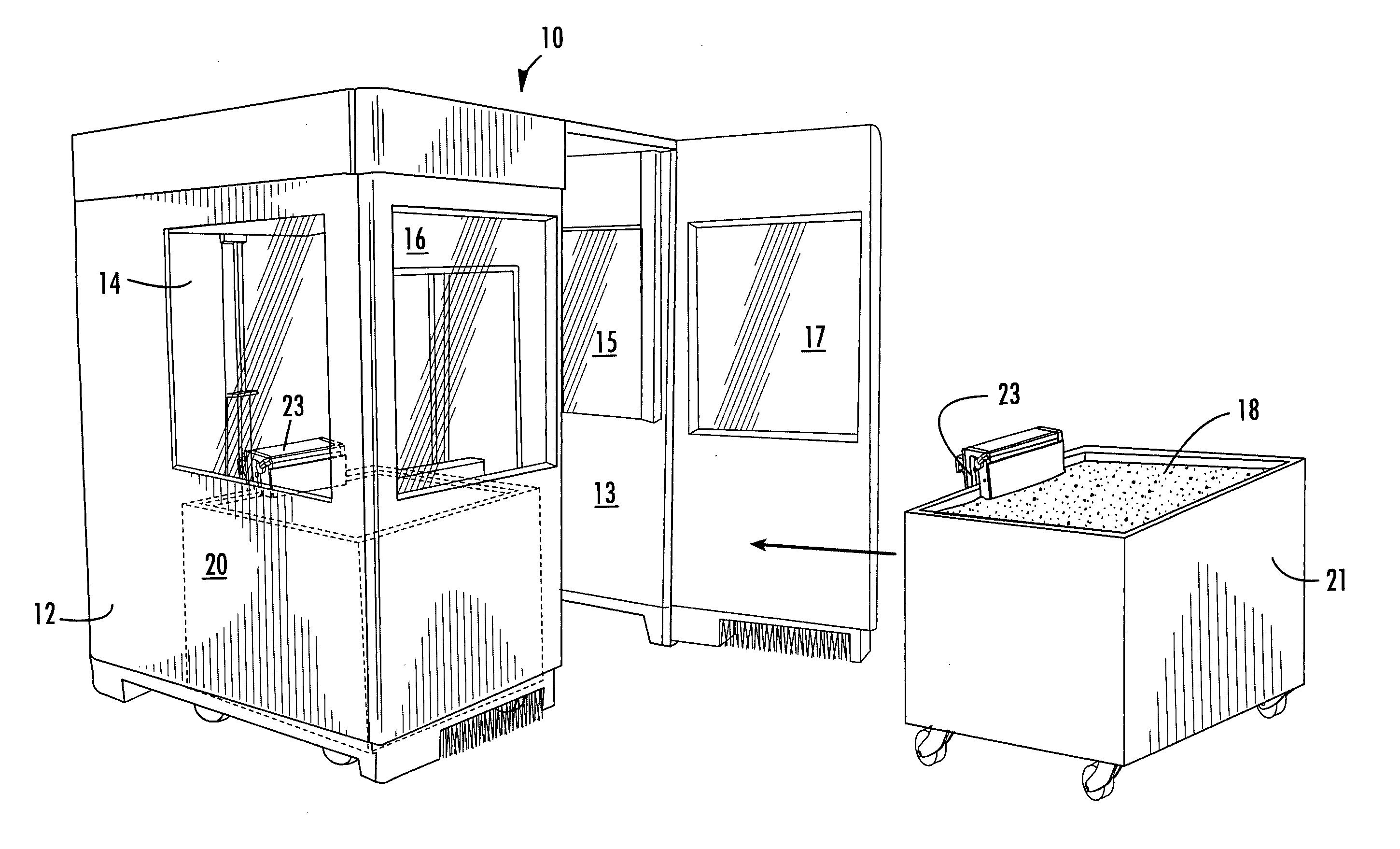

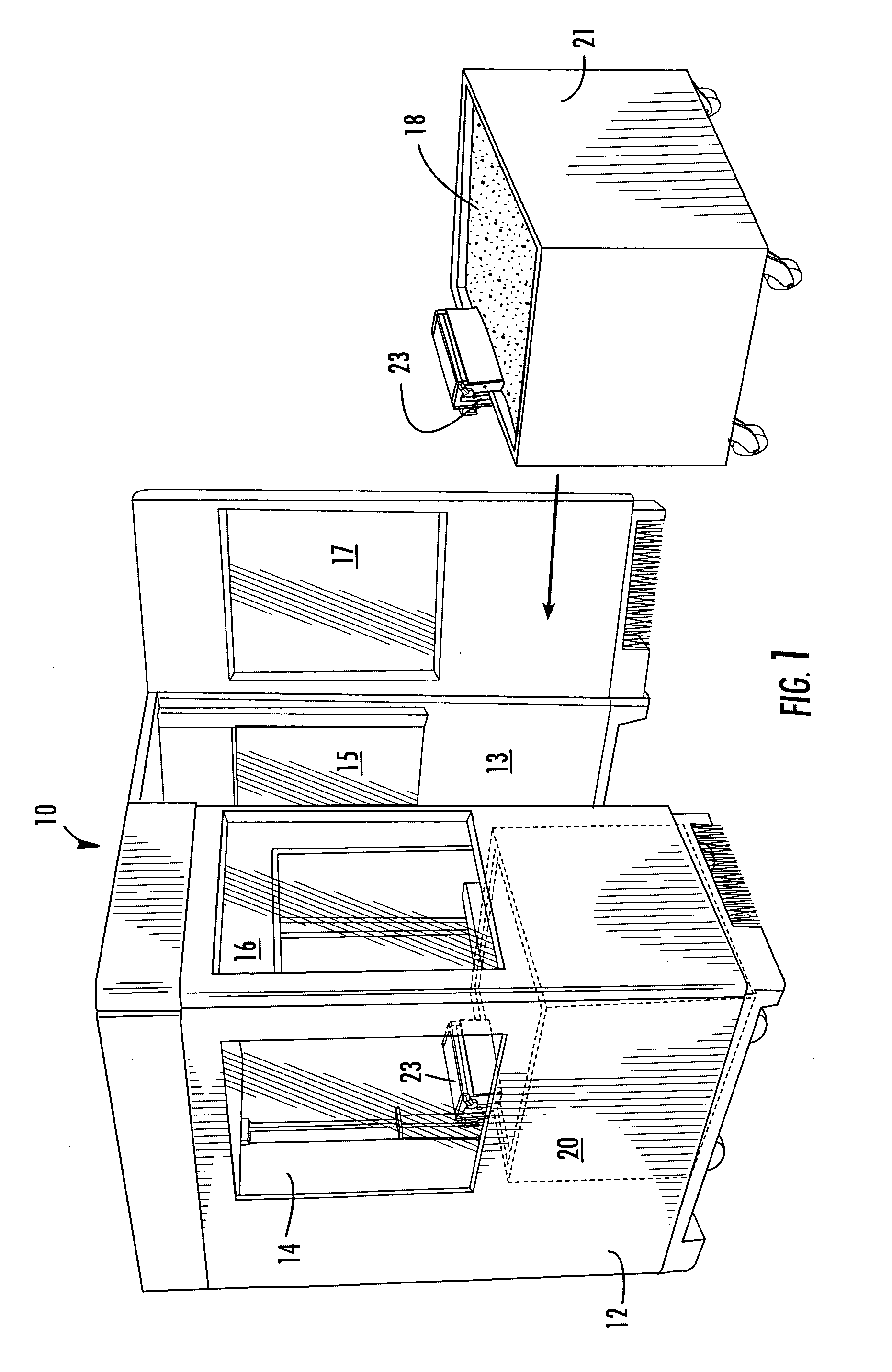

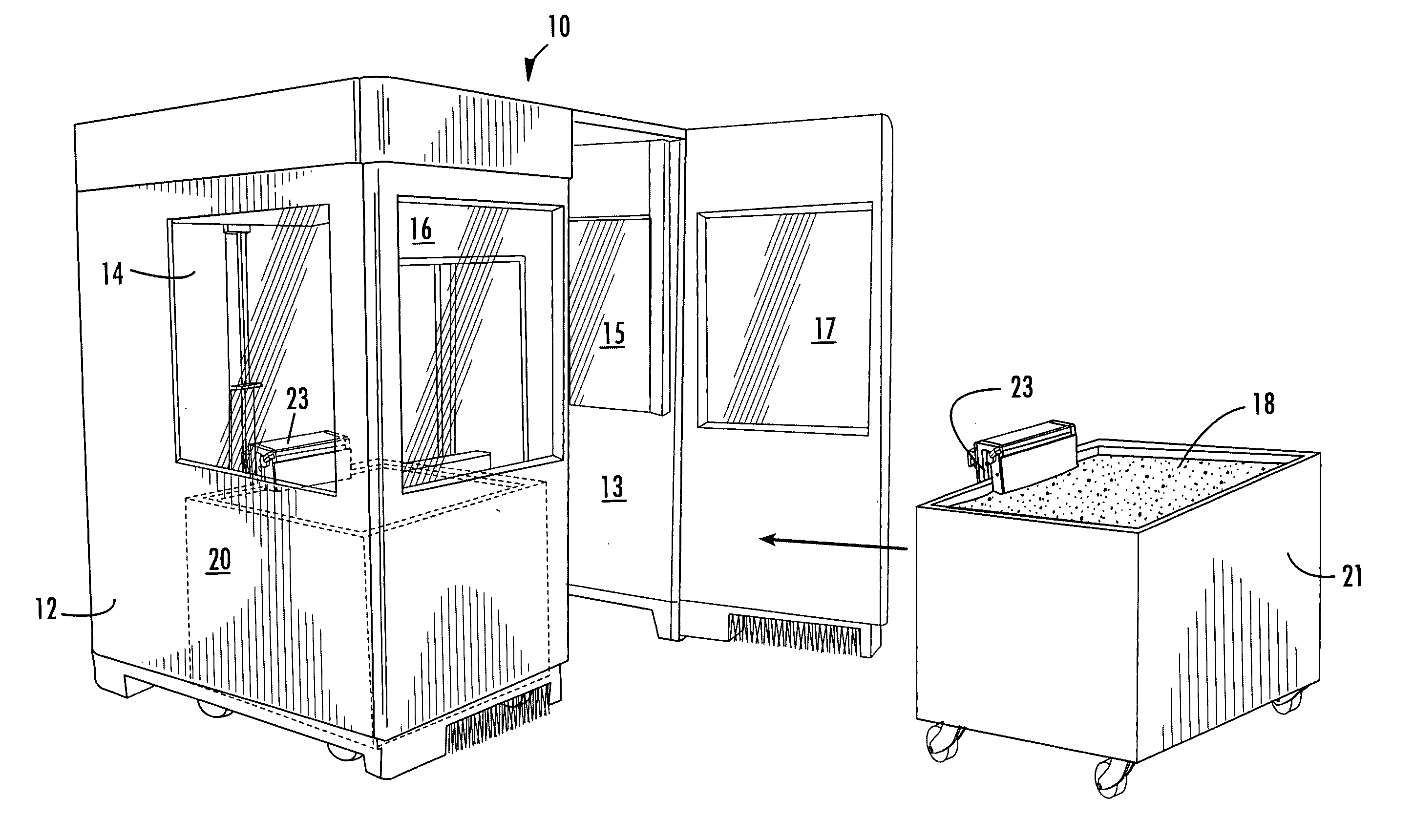

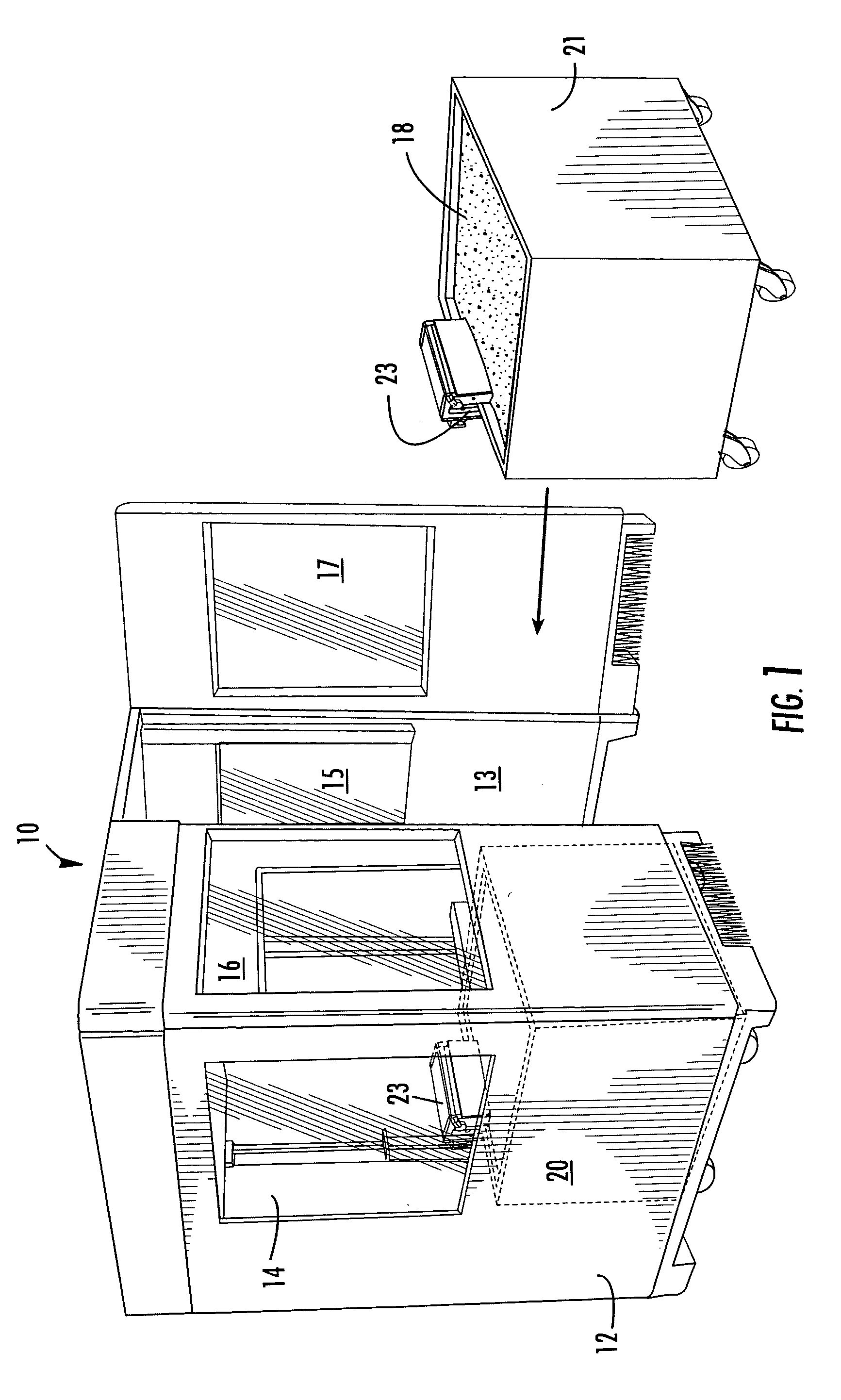

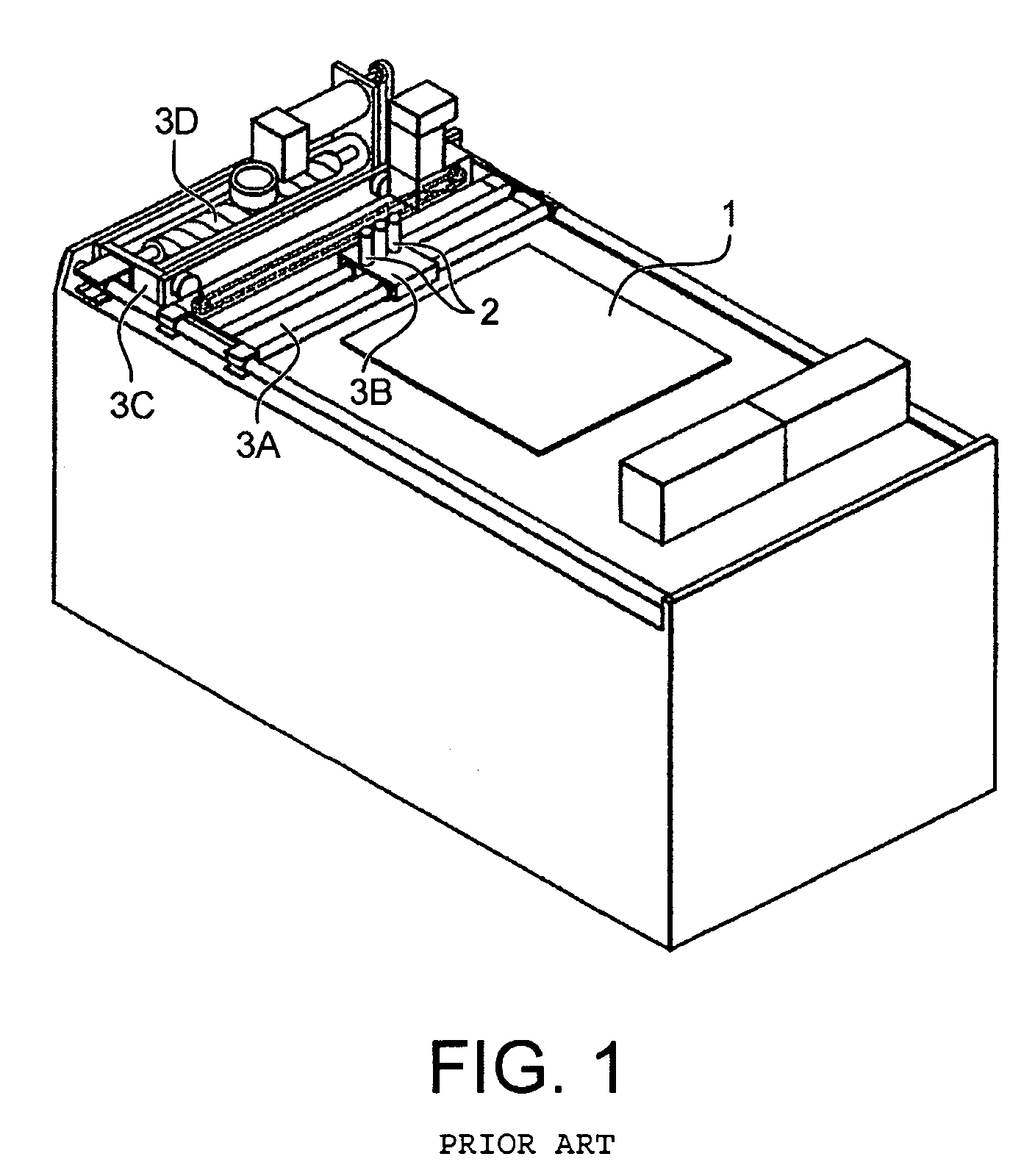

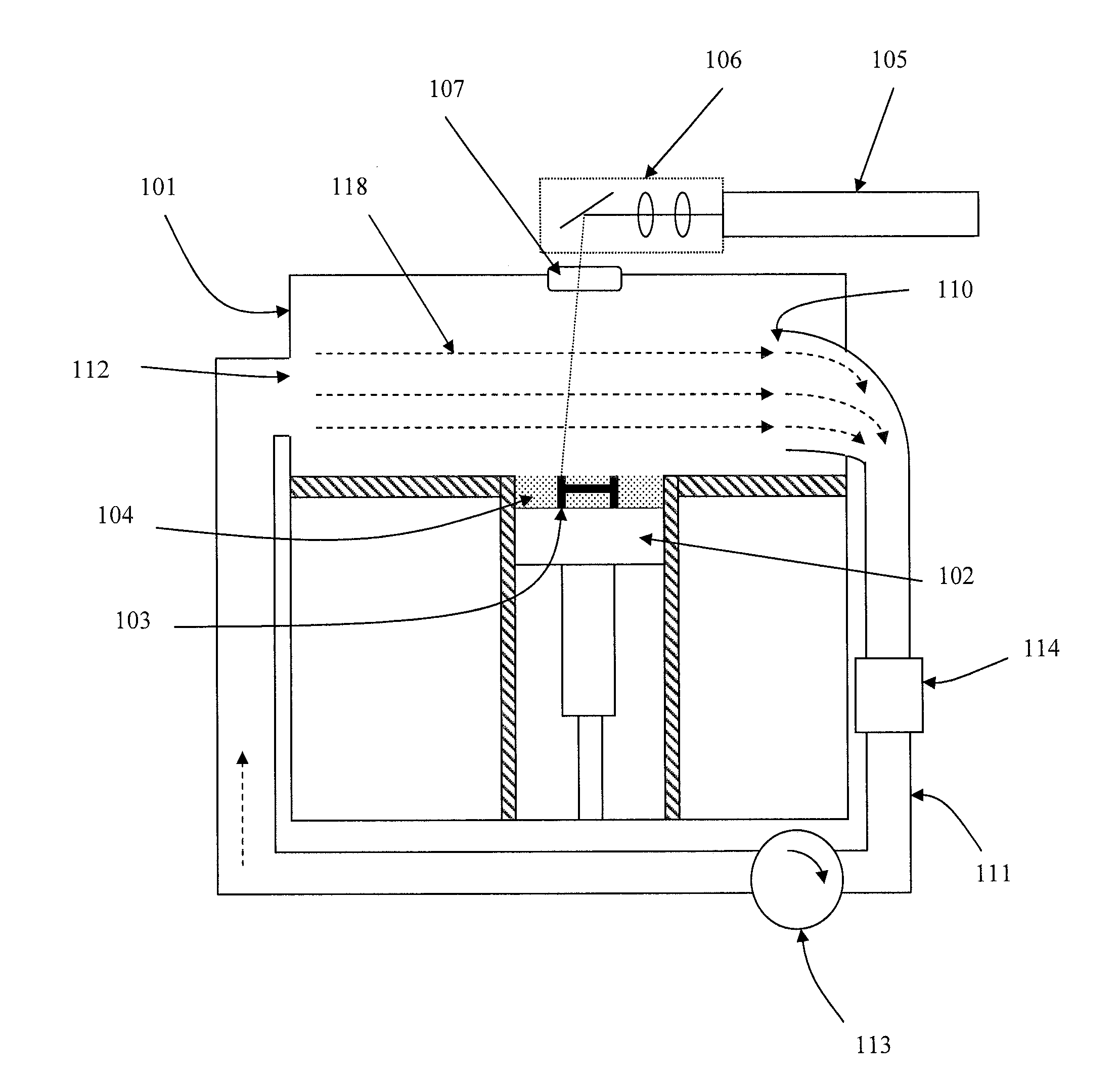

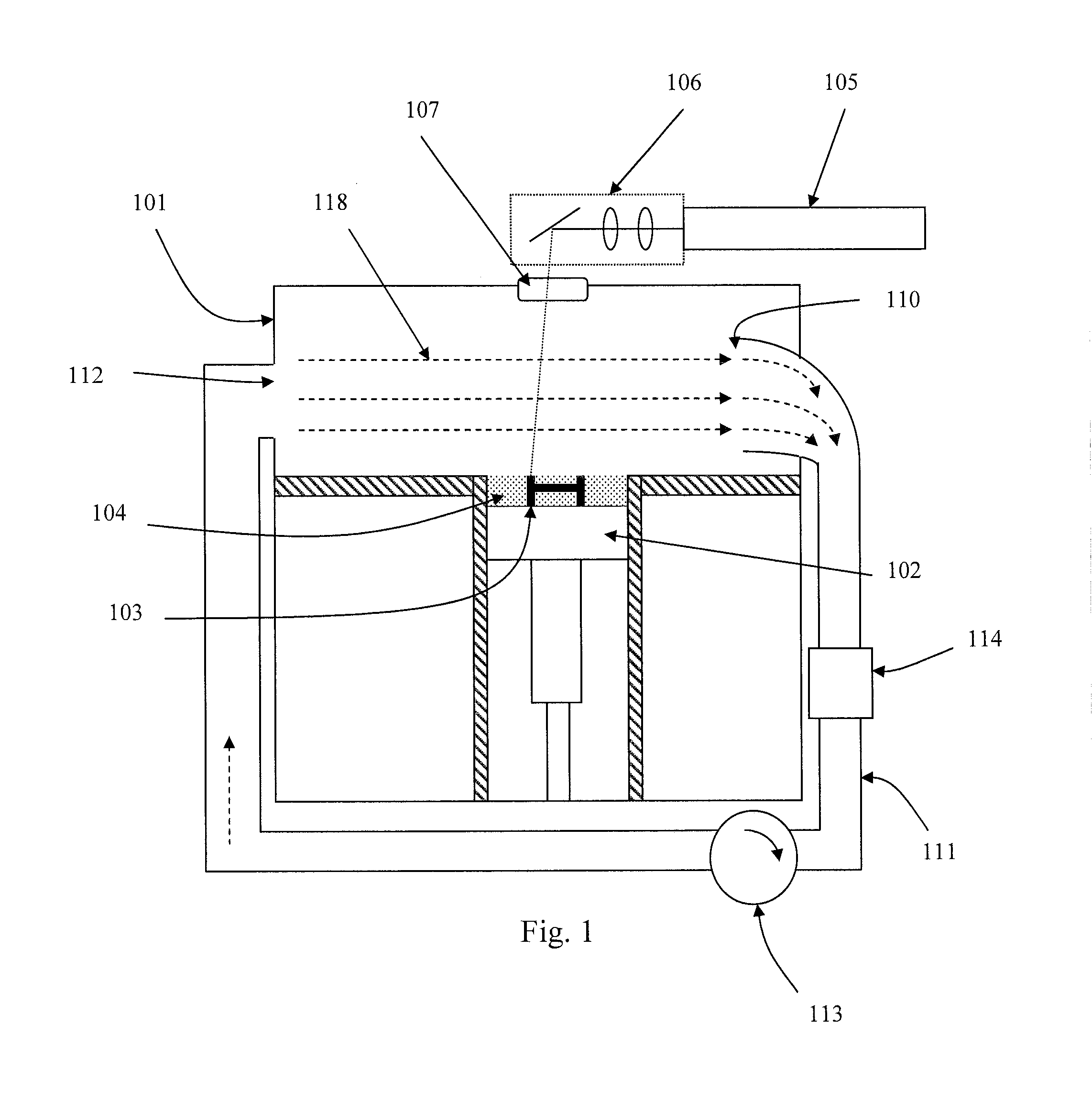

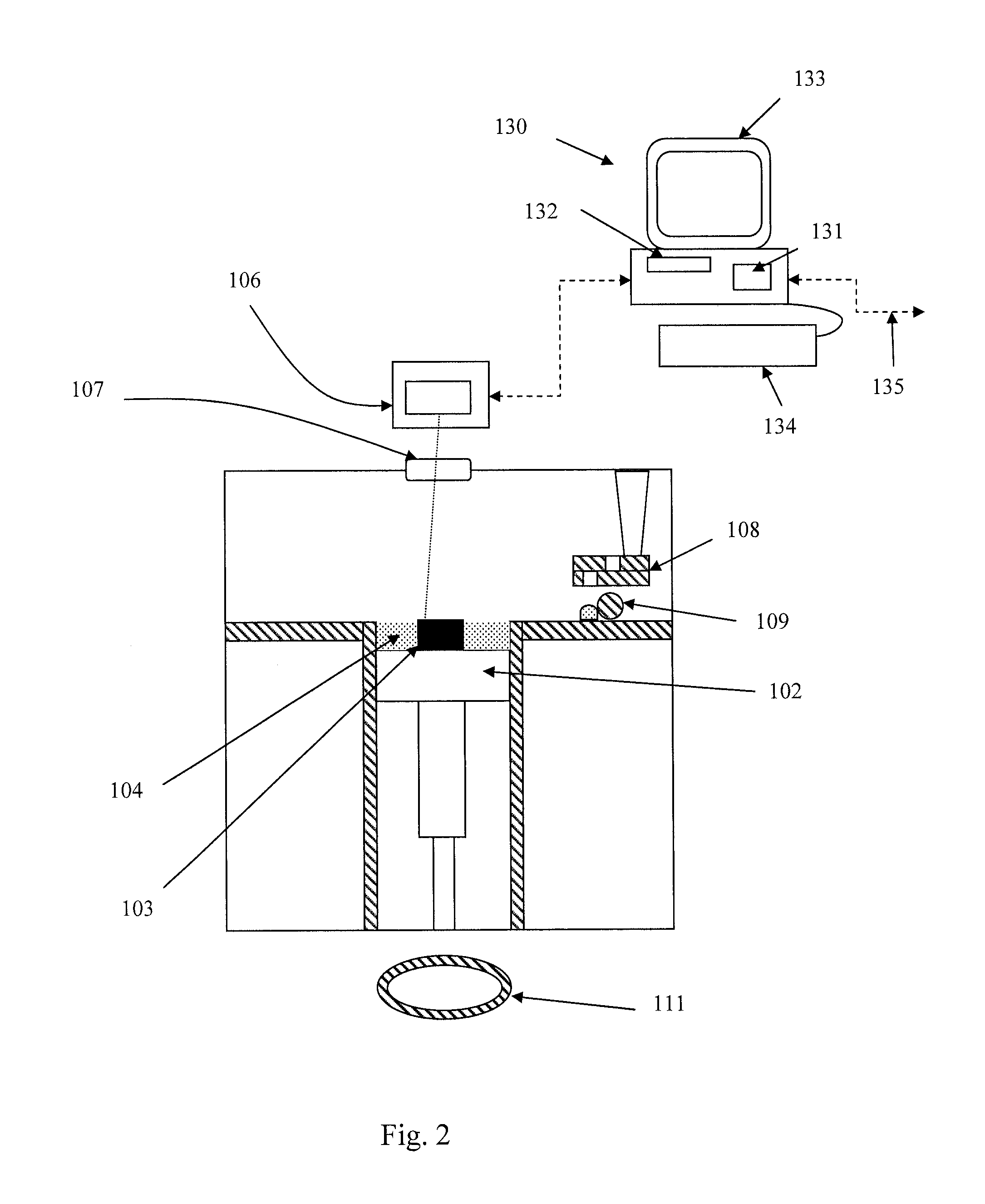

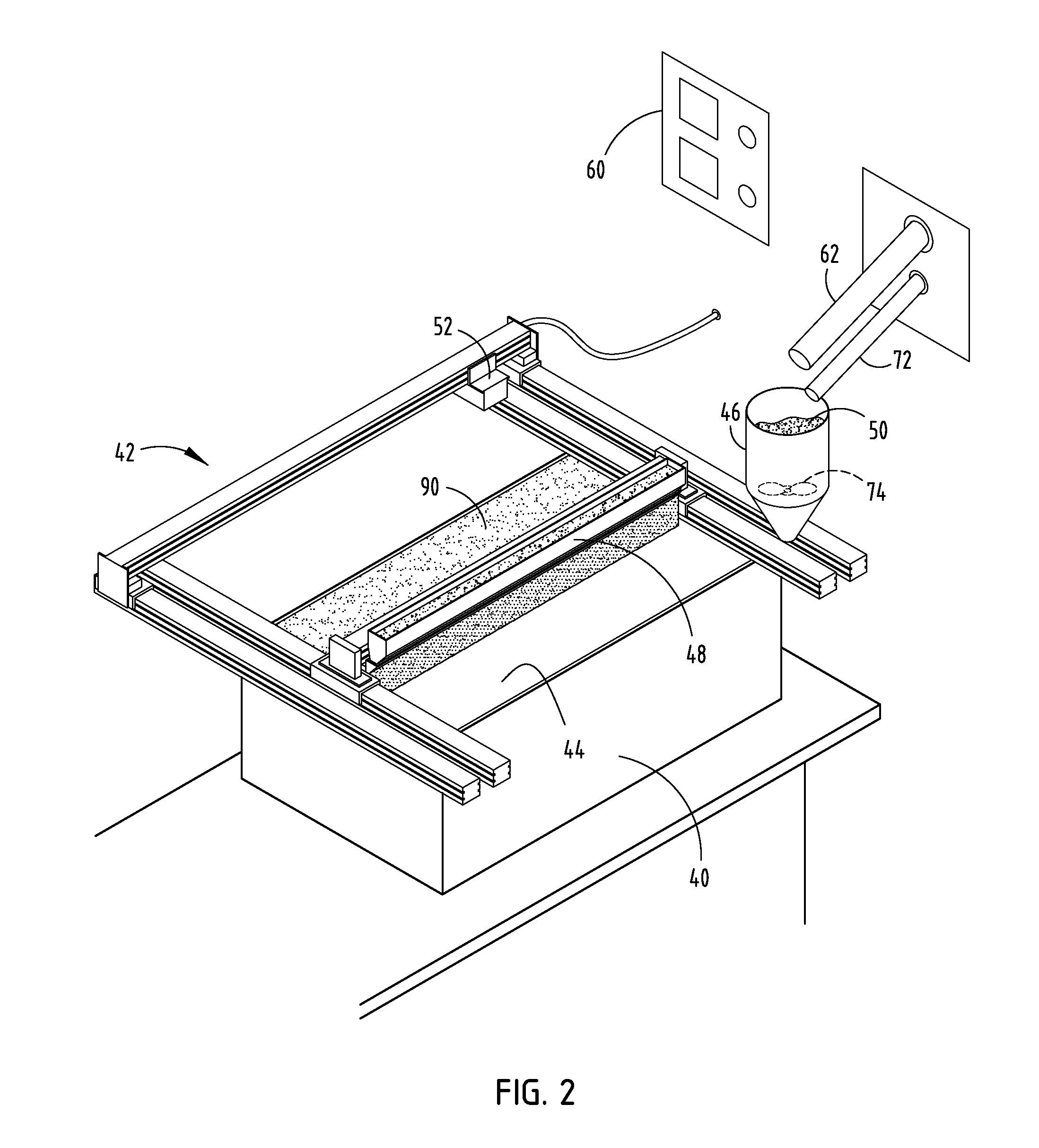

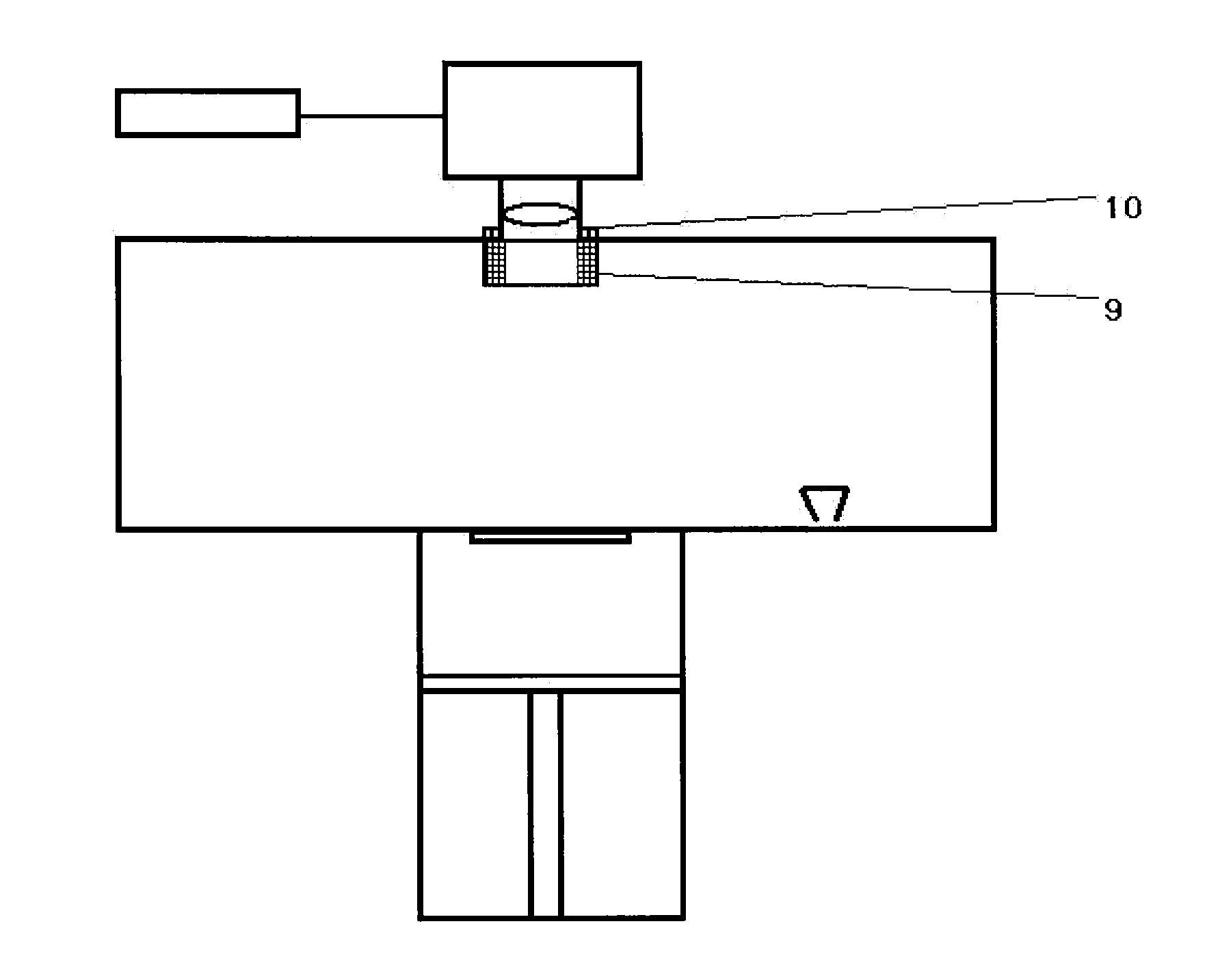

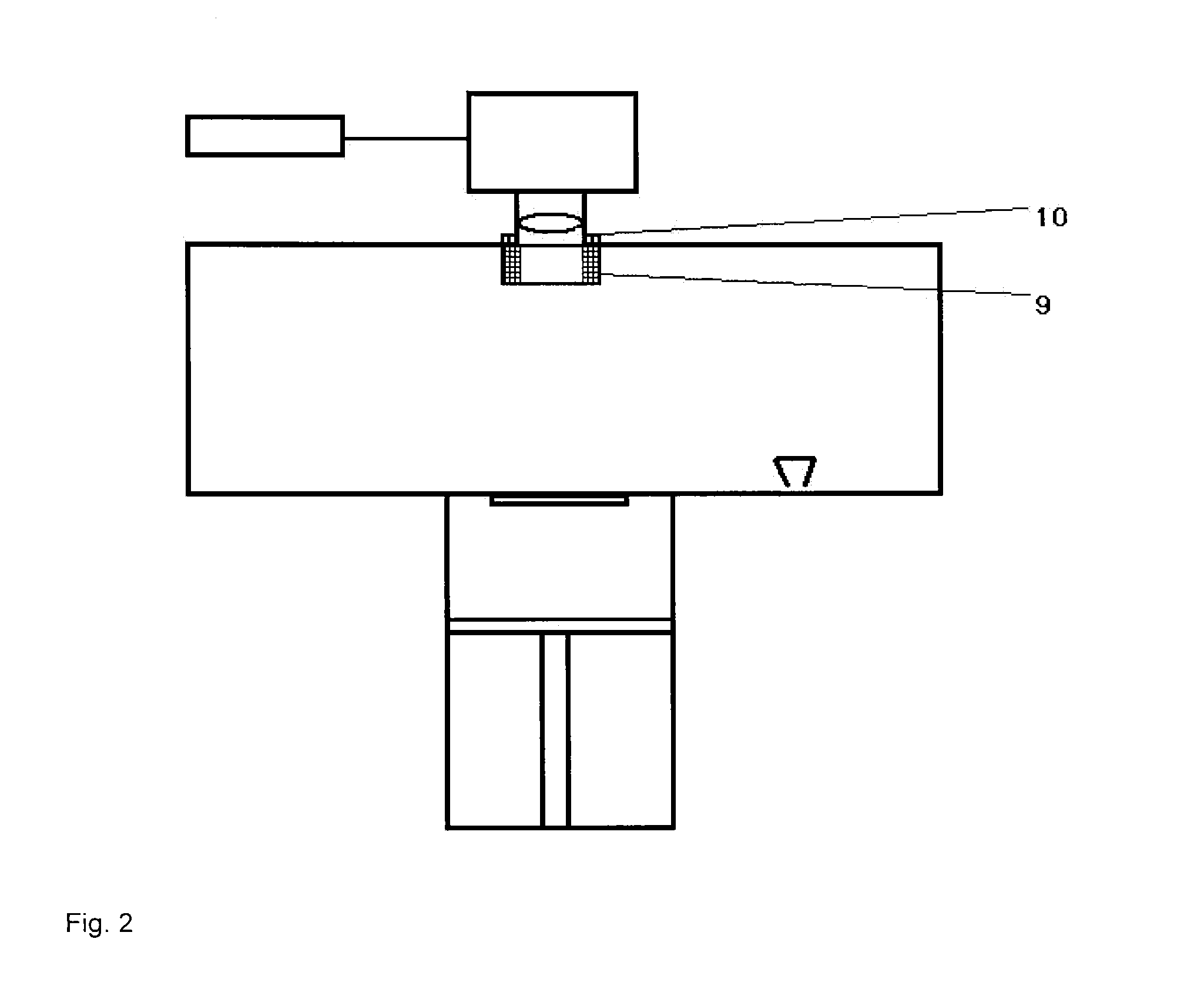

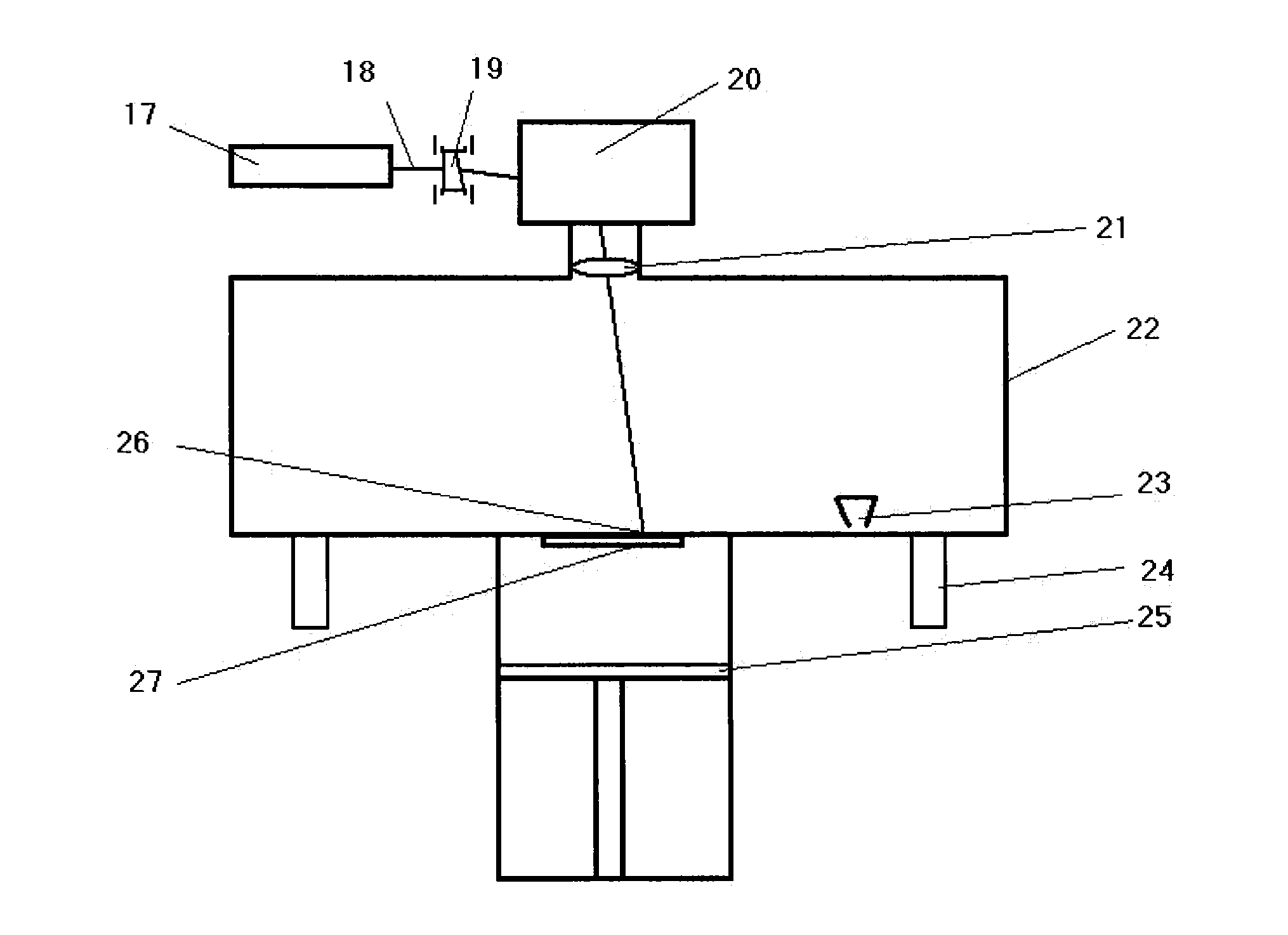

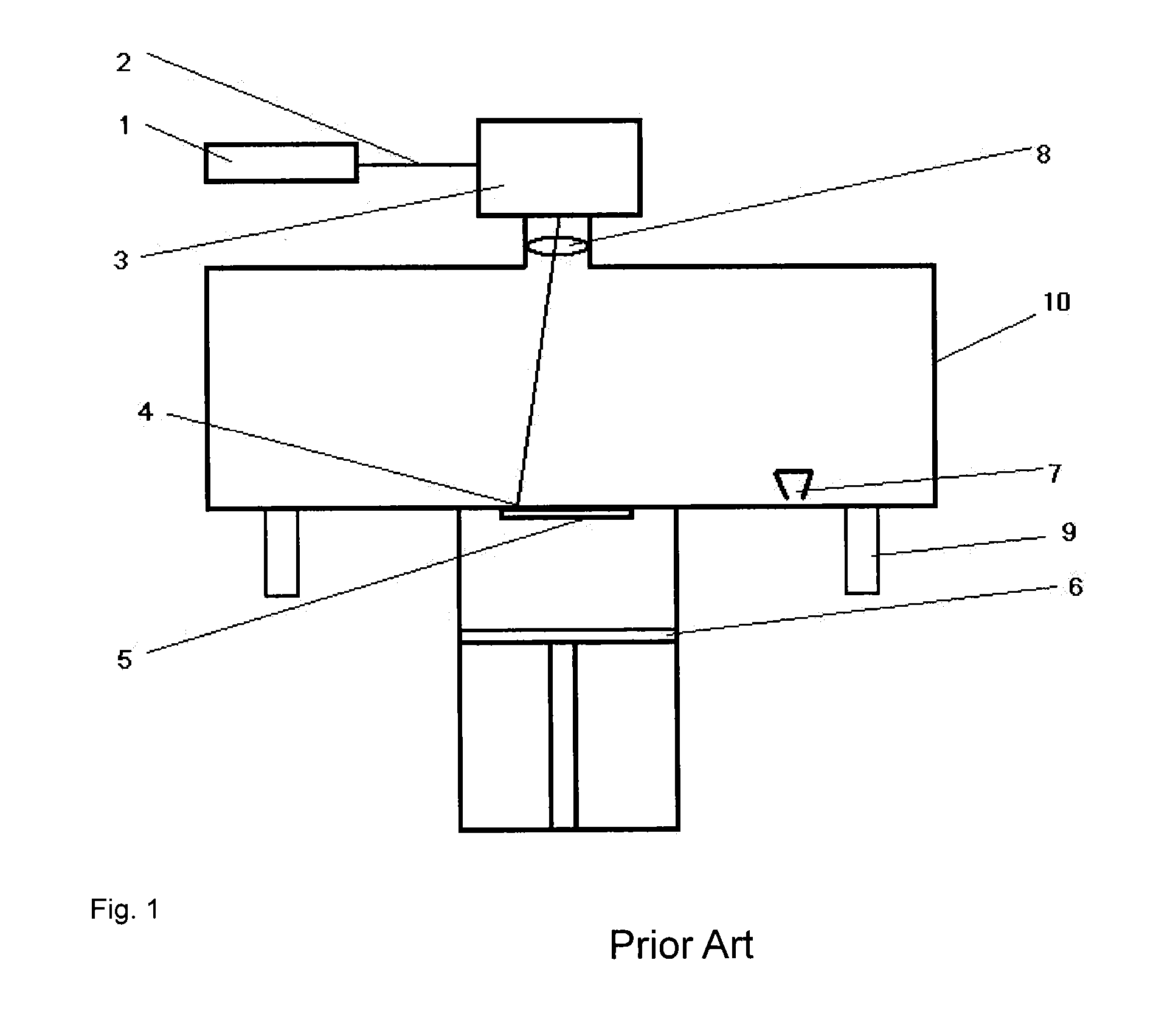

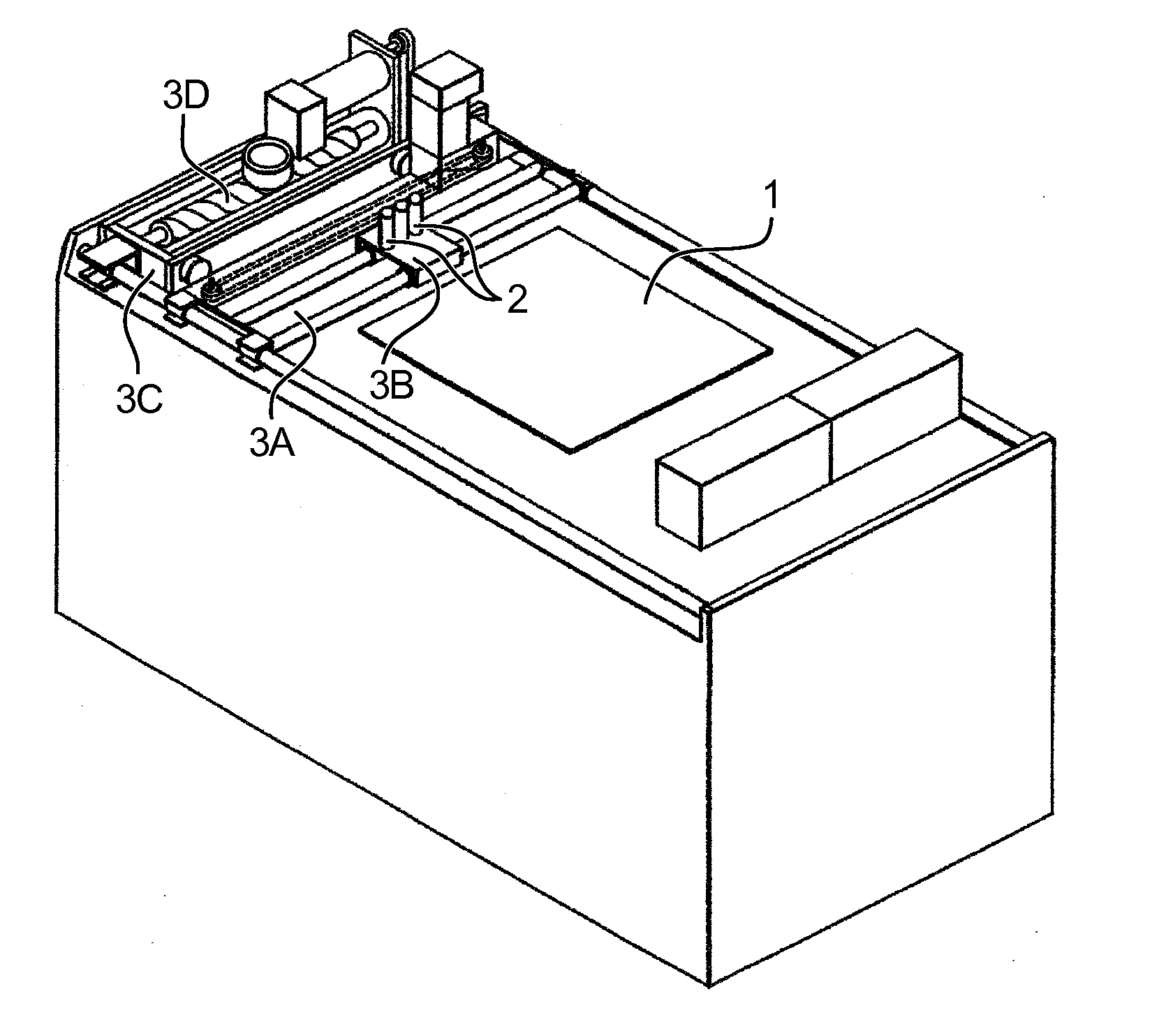

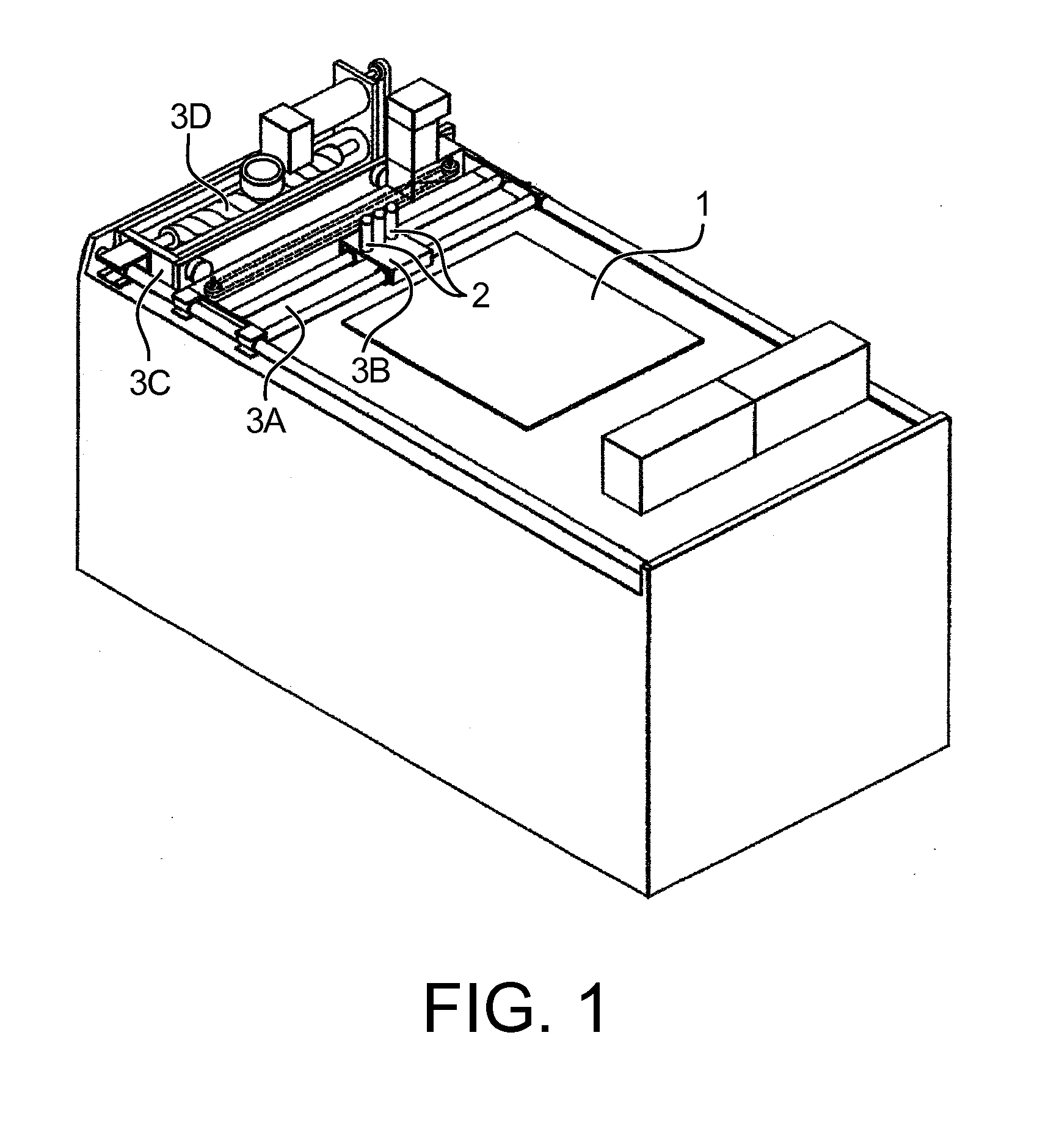

Rapid prototyping and manufacturing system and method

ActiveUS20070074659A1Simplify obtaining precisionFast preparationConfectioneryPretreated surfacesEngineeringRapid prototyping

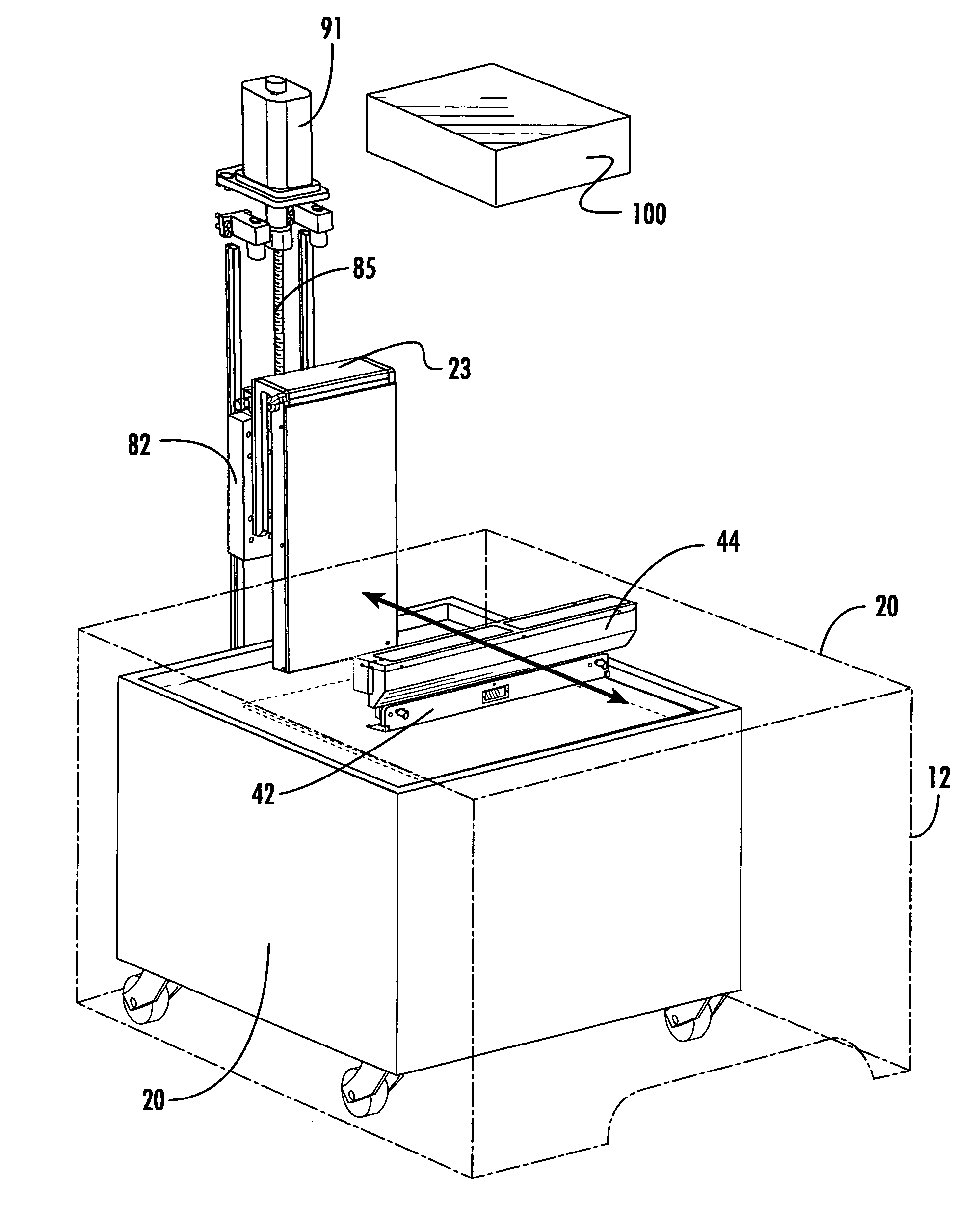

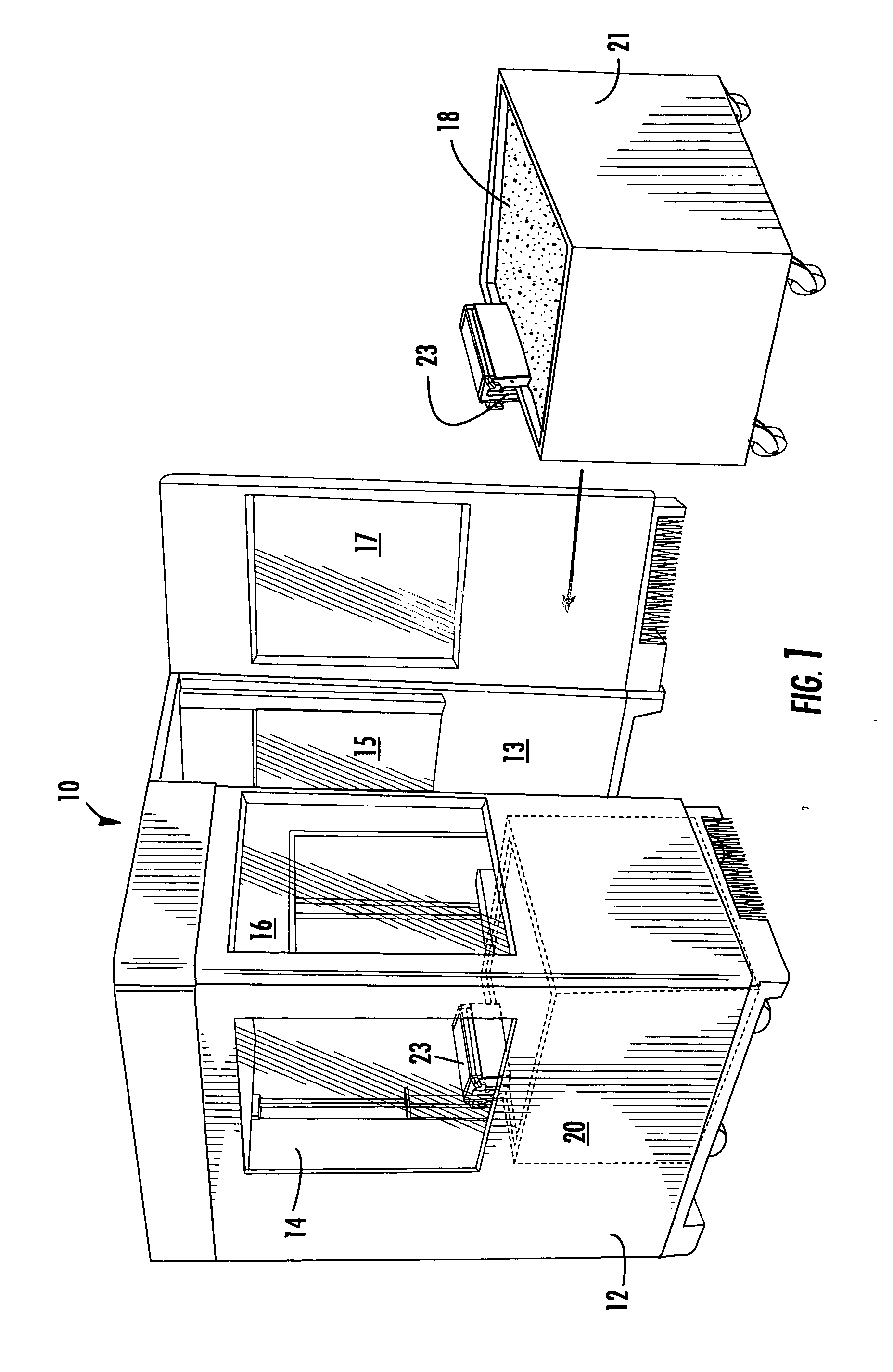

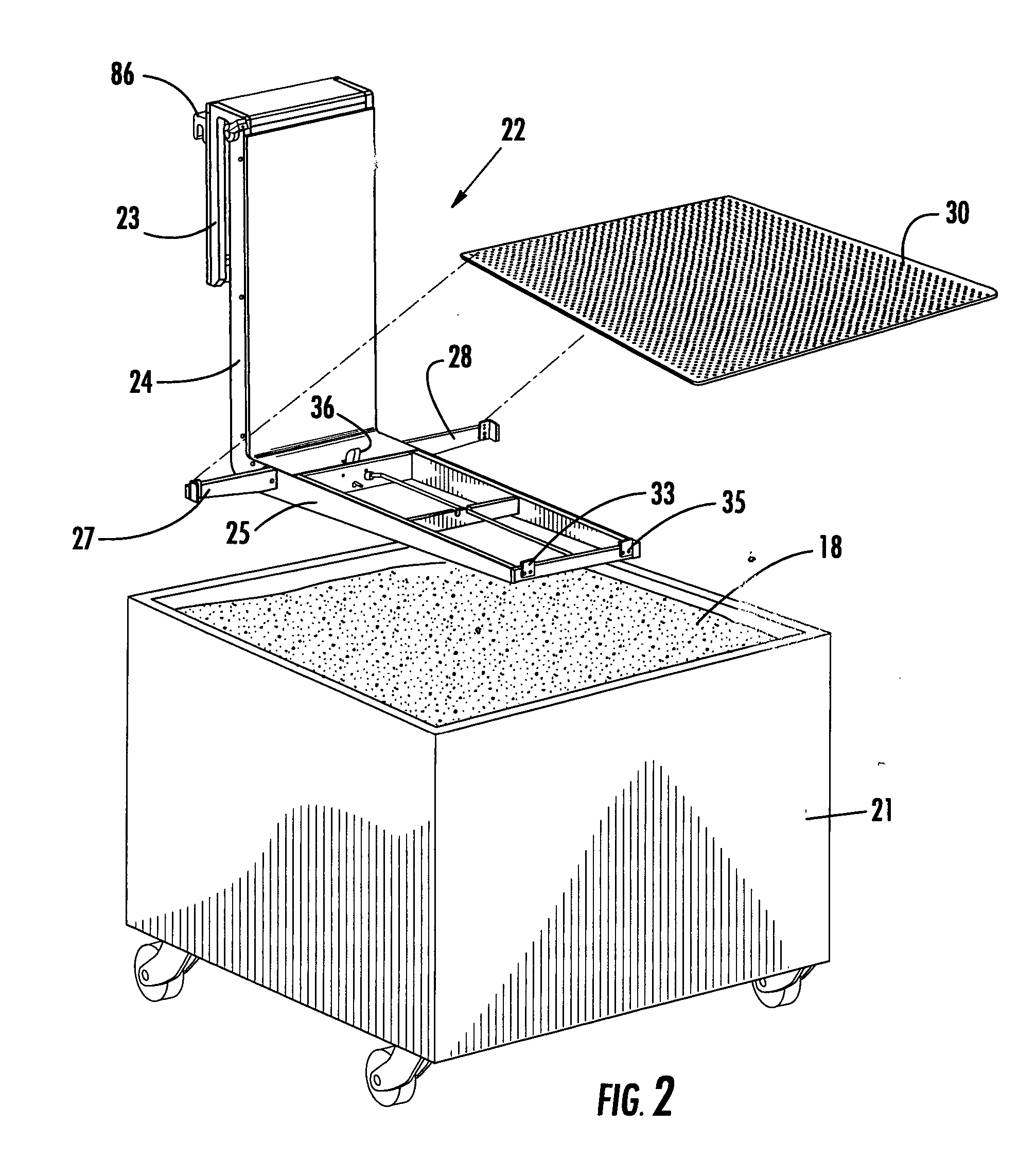

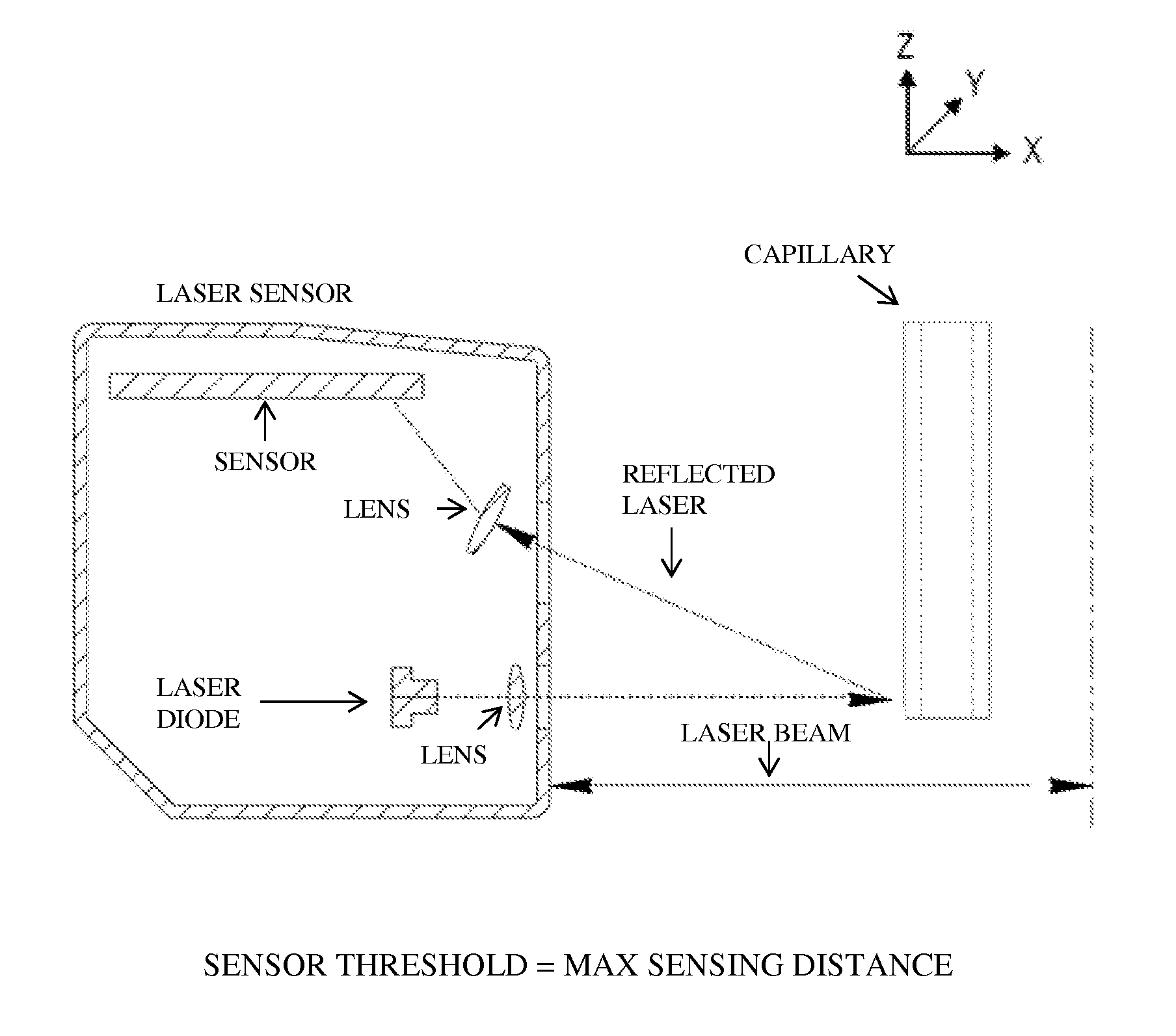

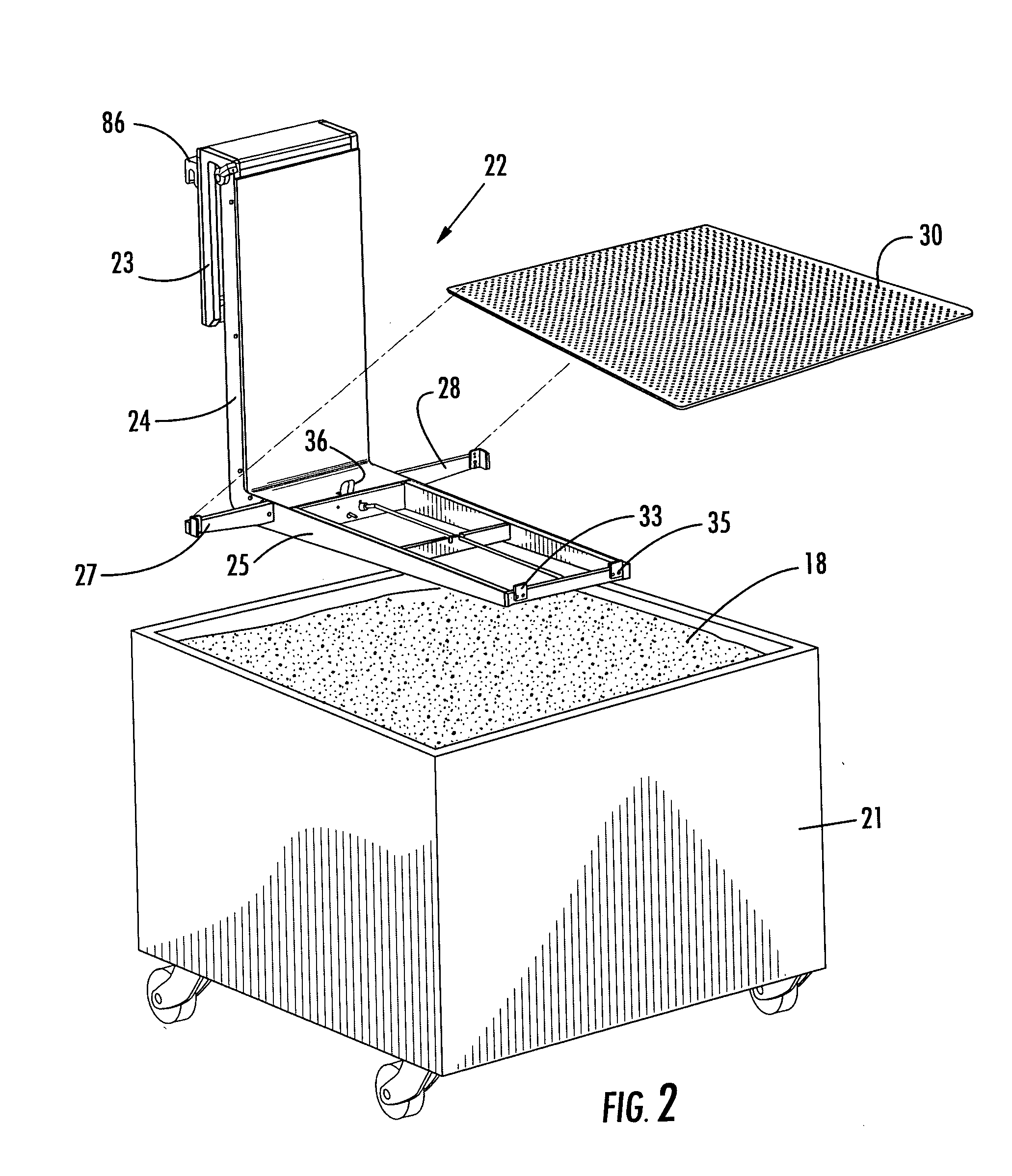

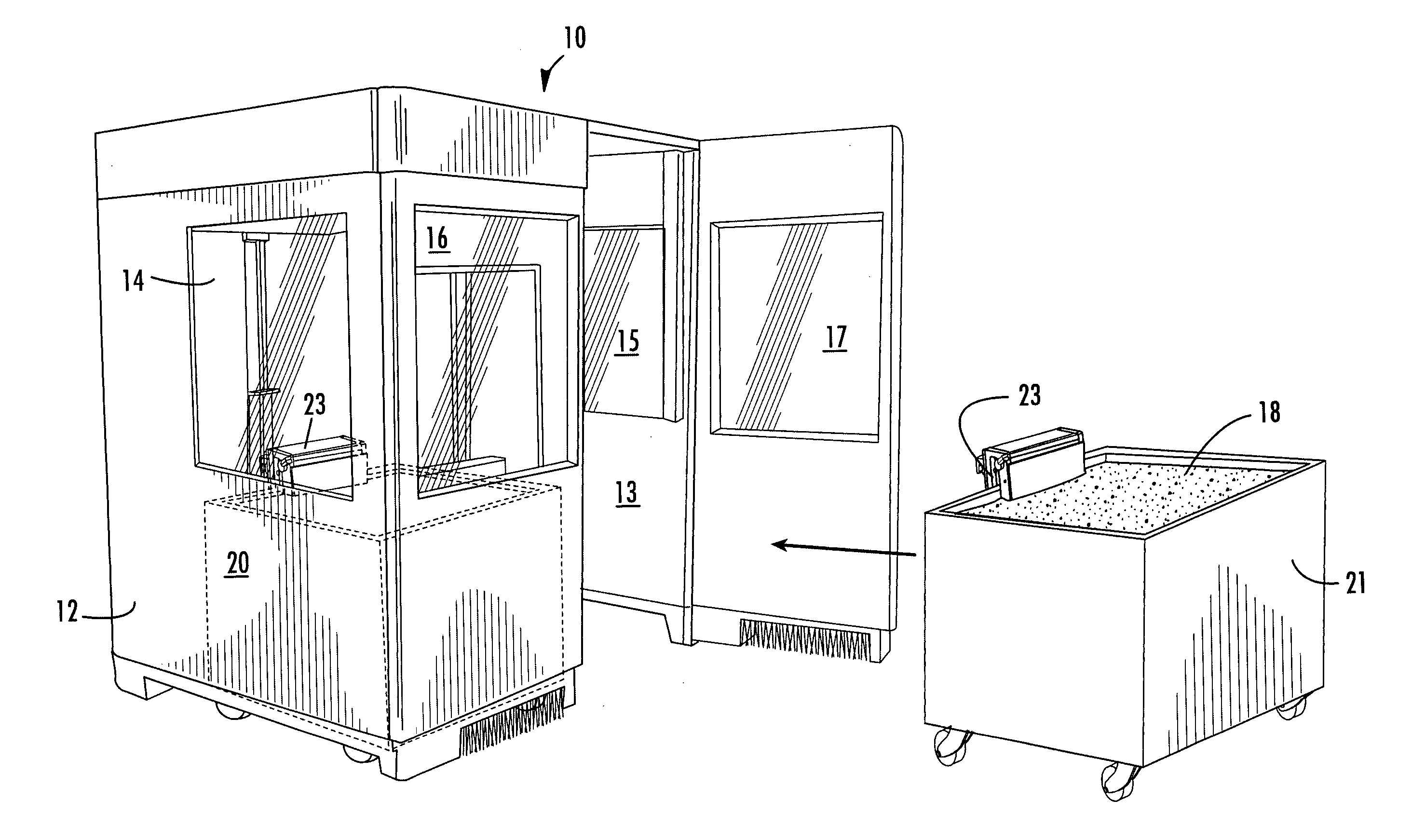

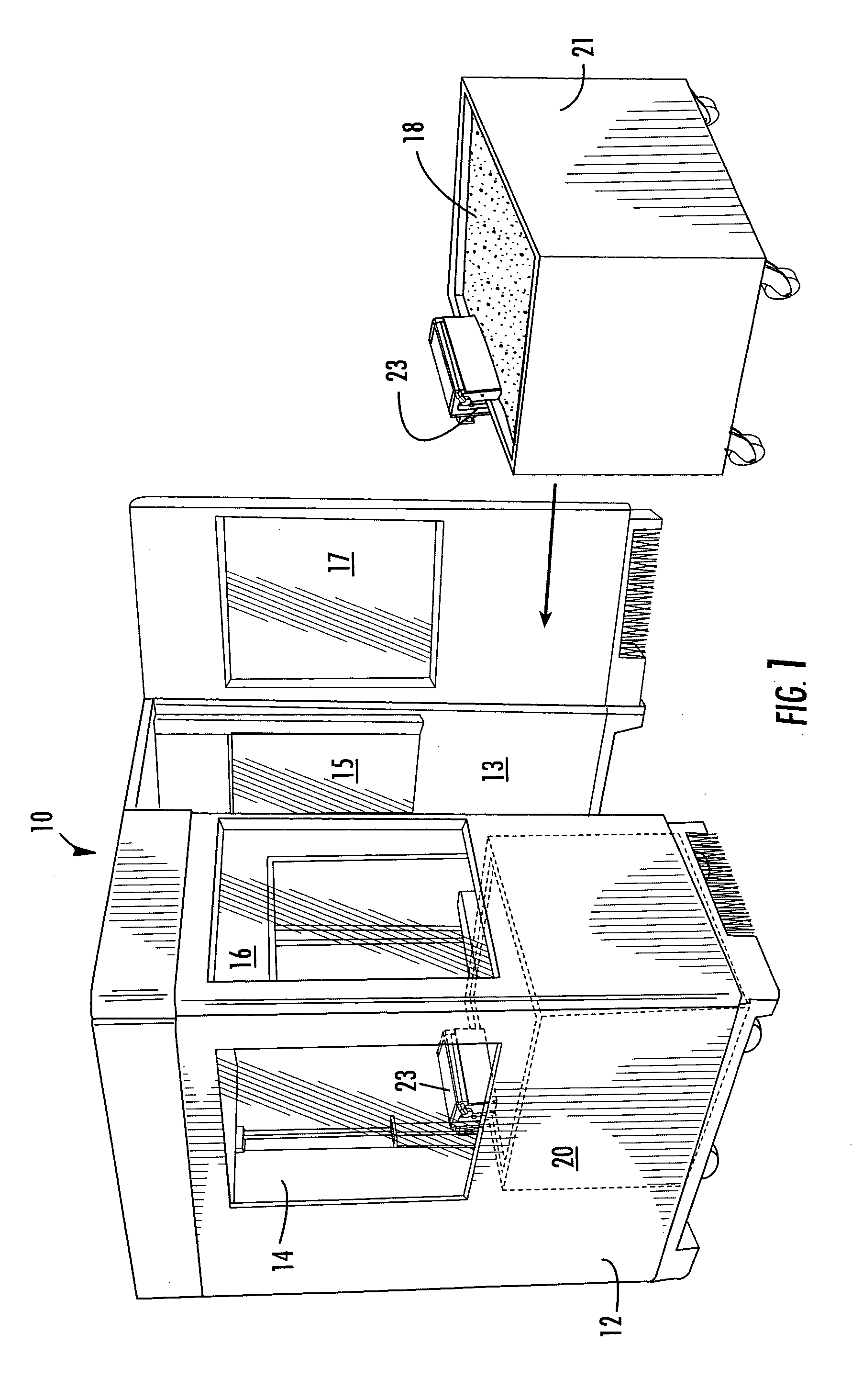

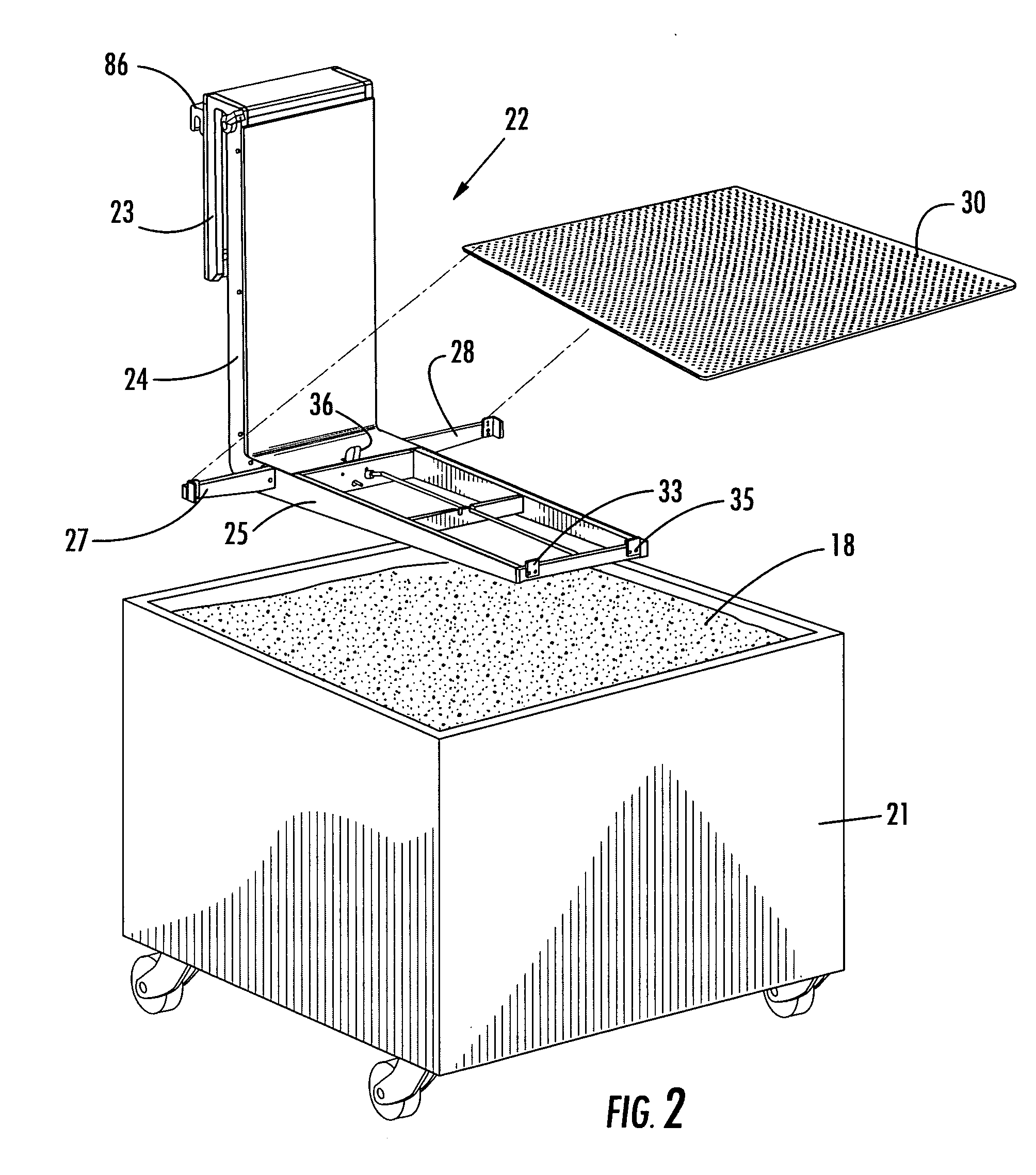

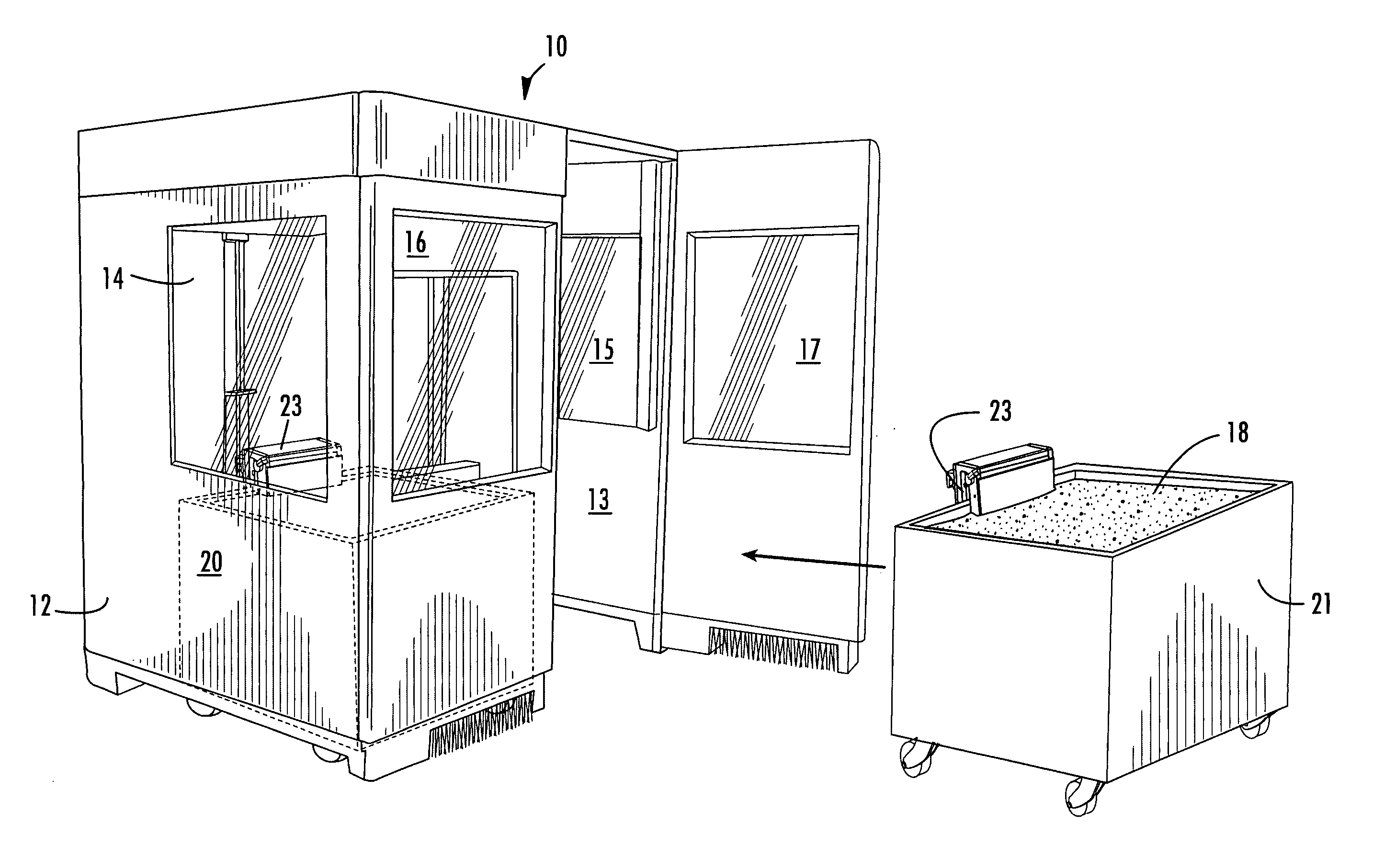

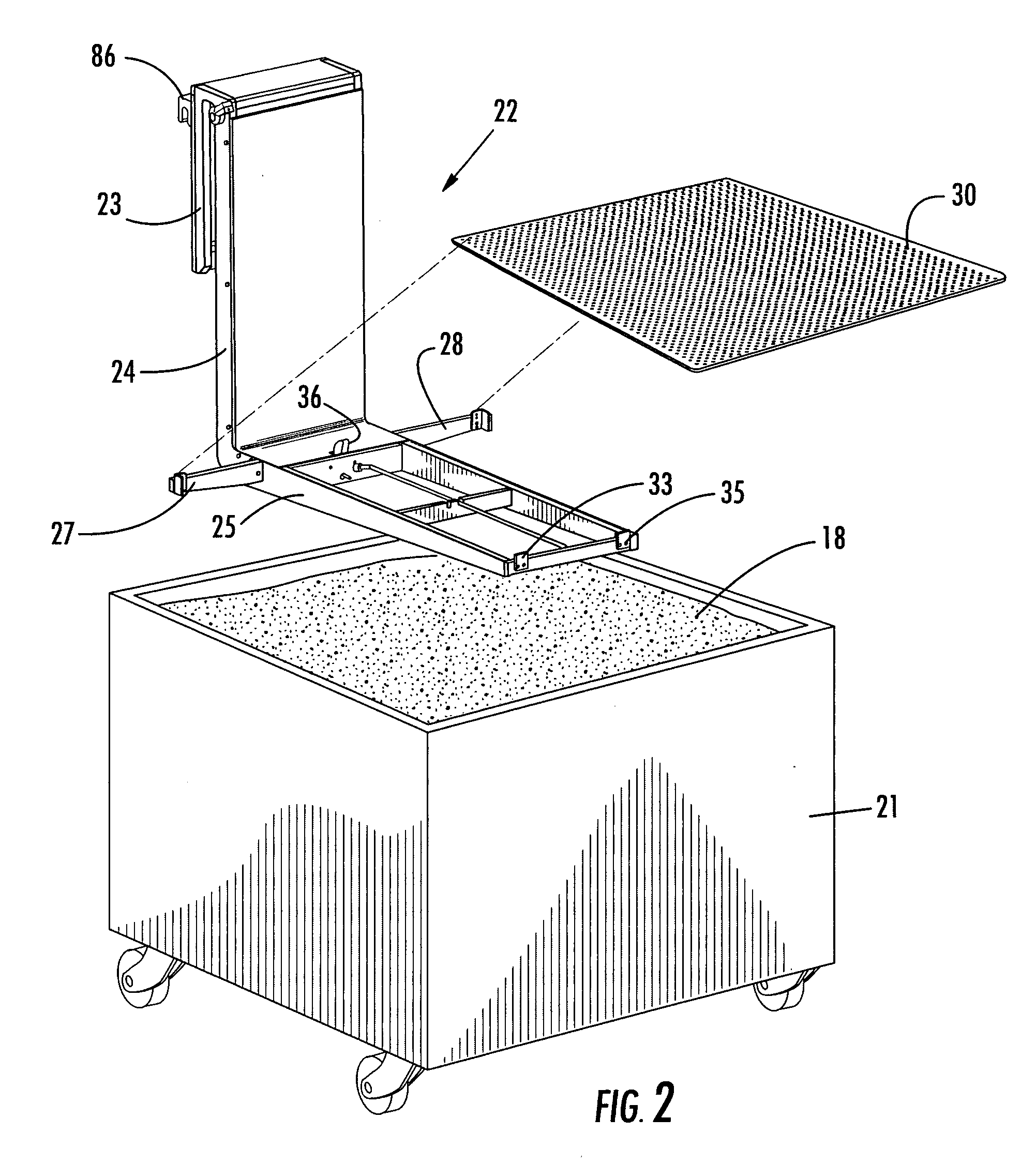

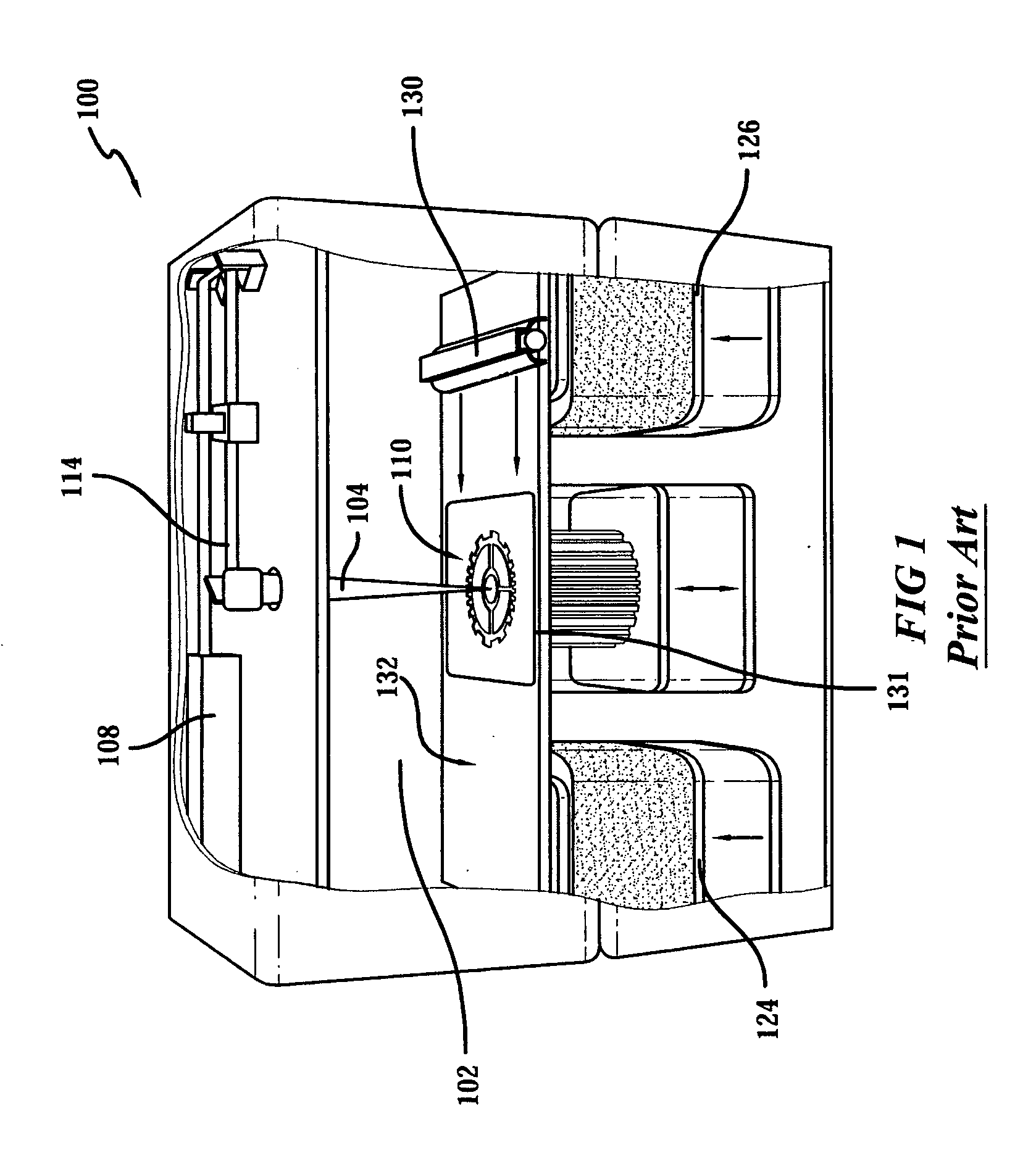

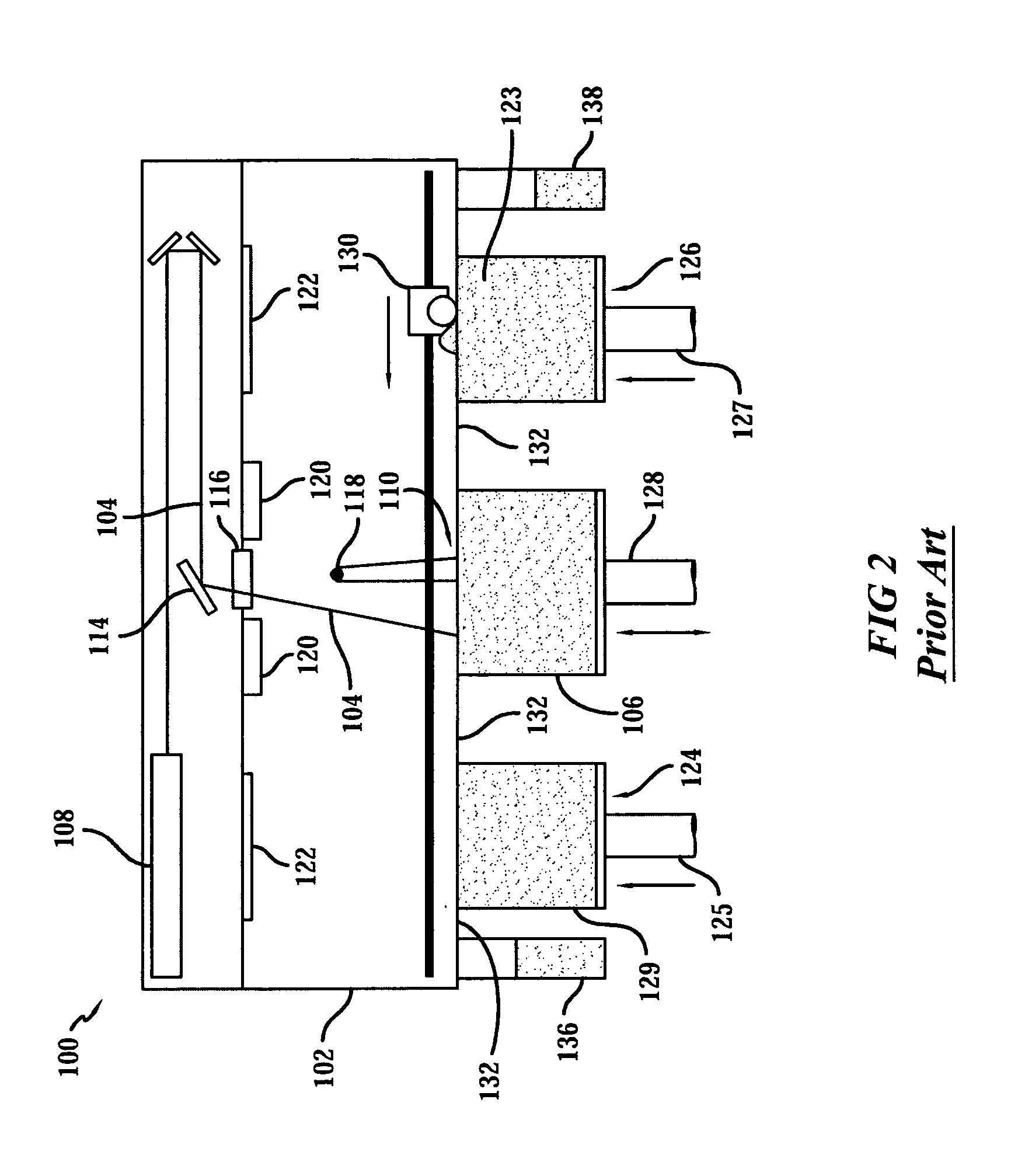

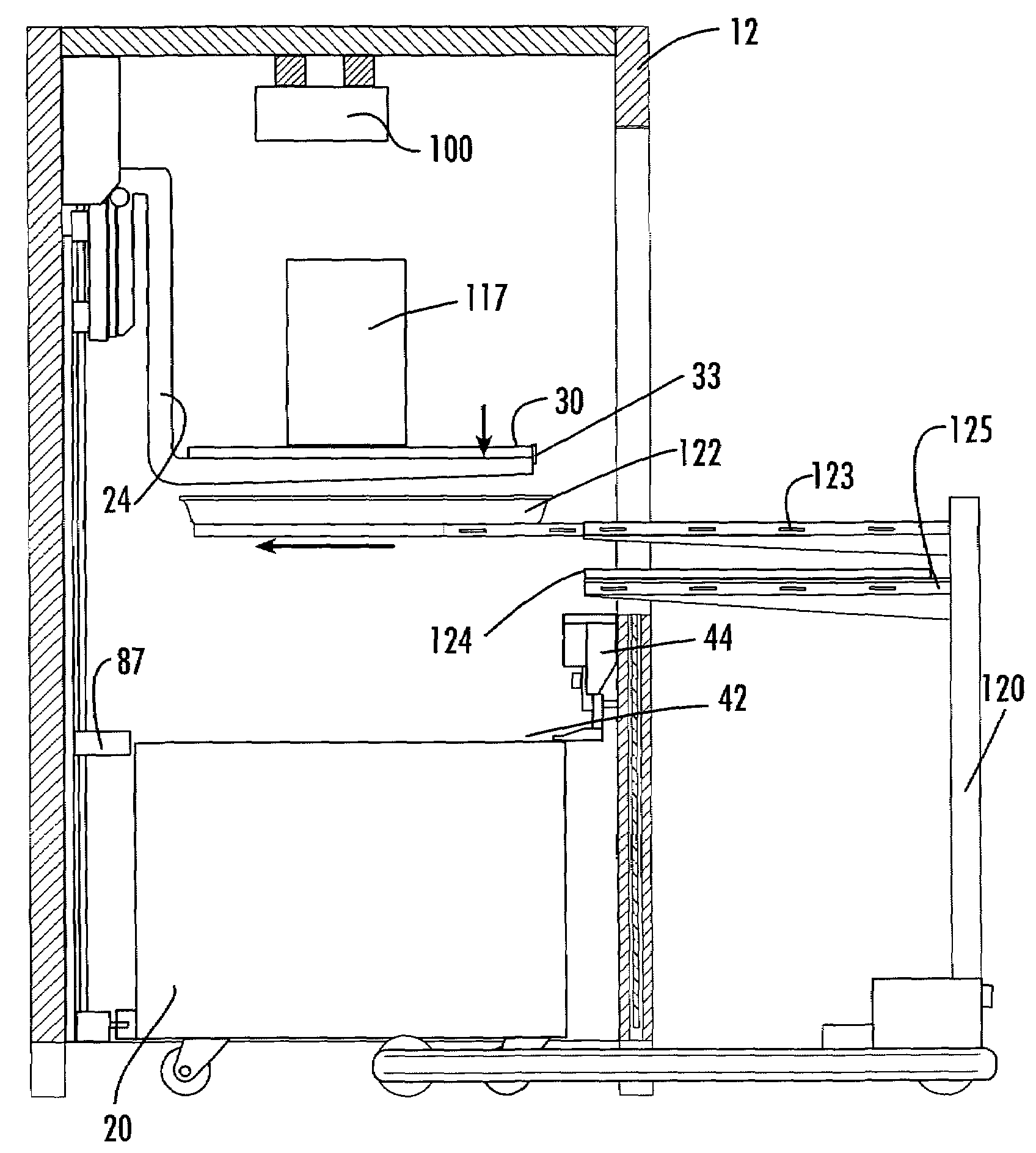

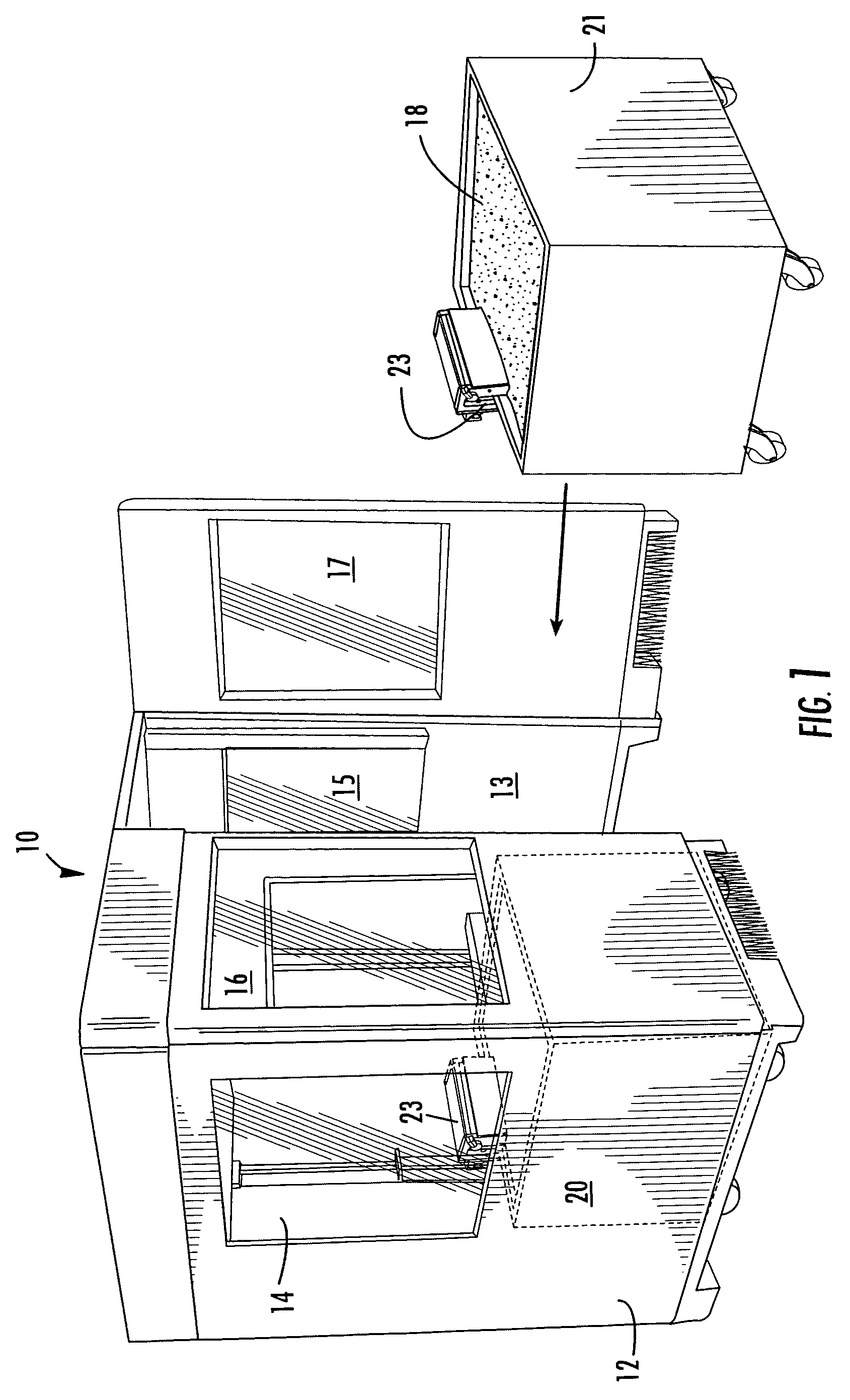

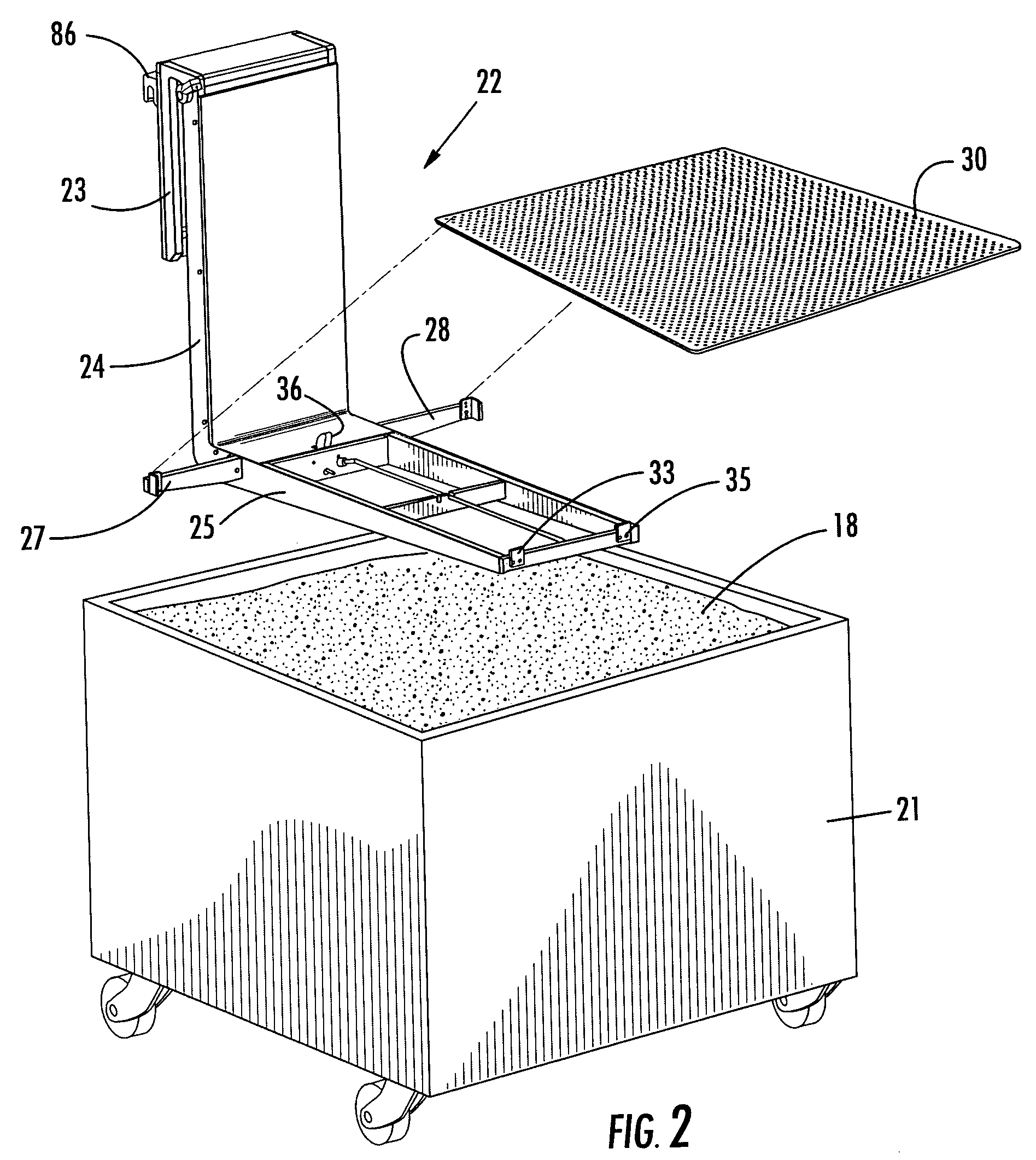

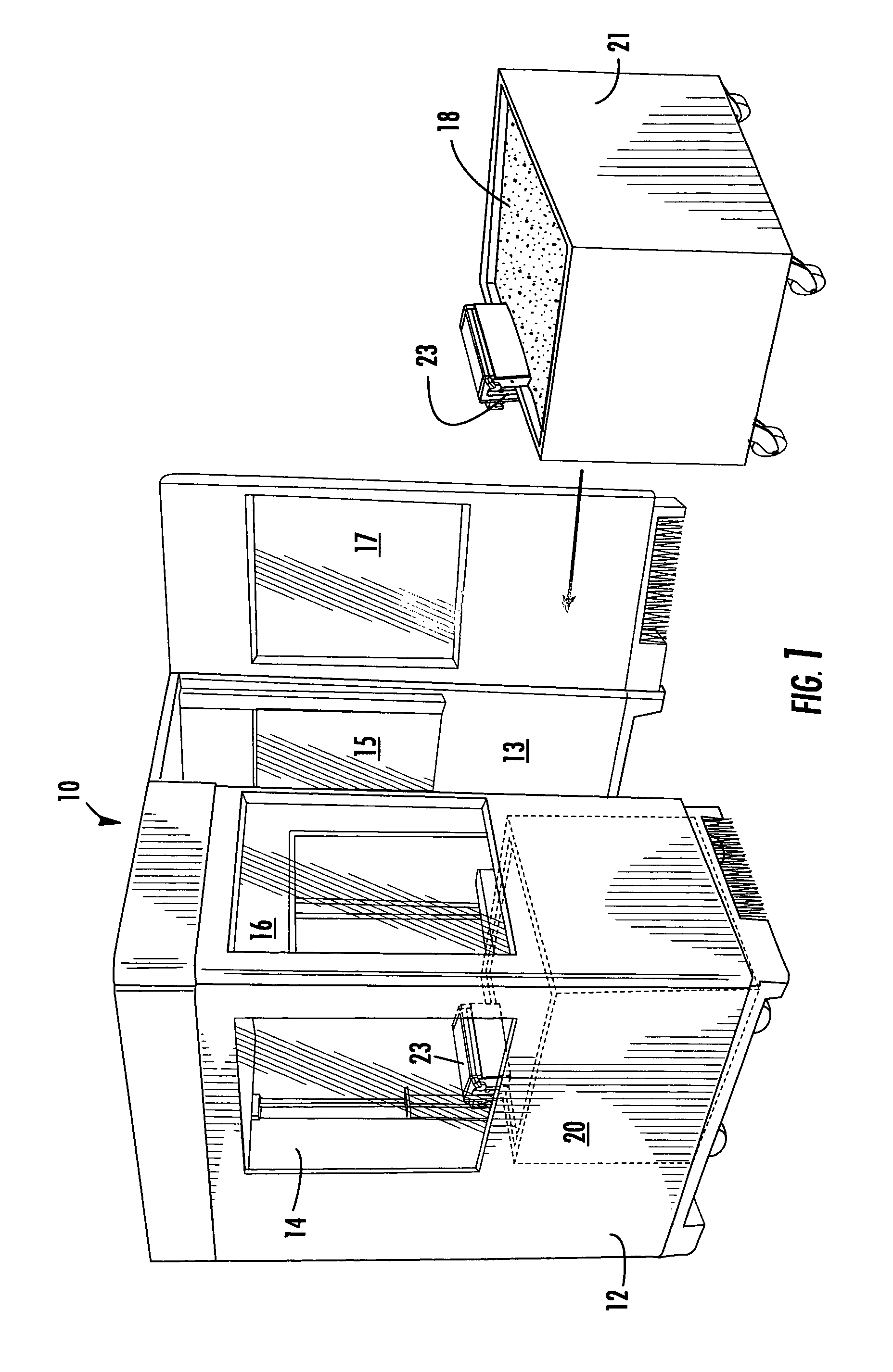

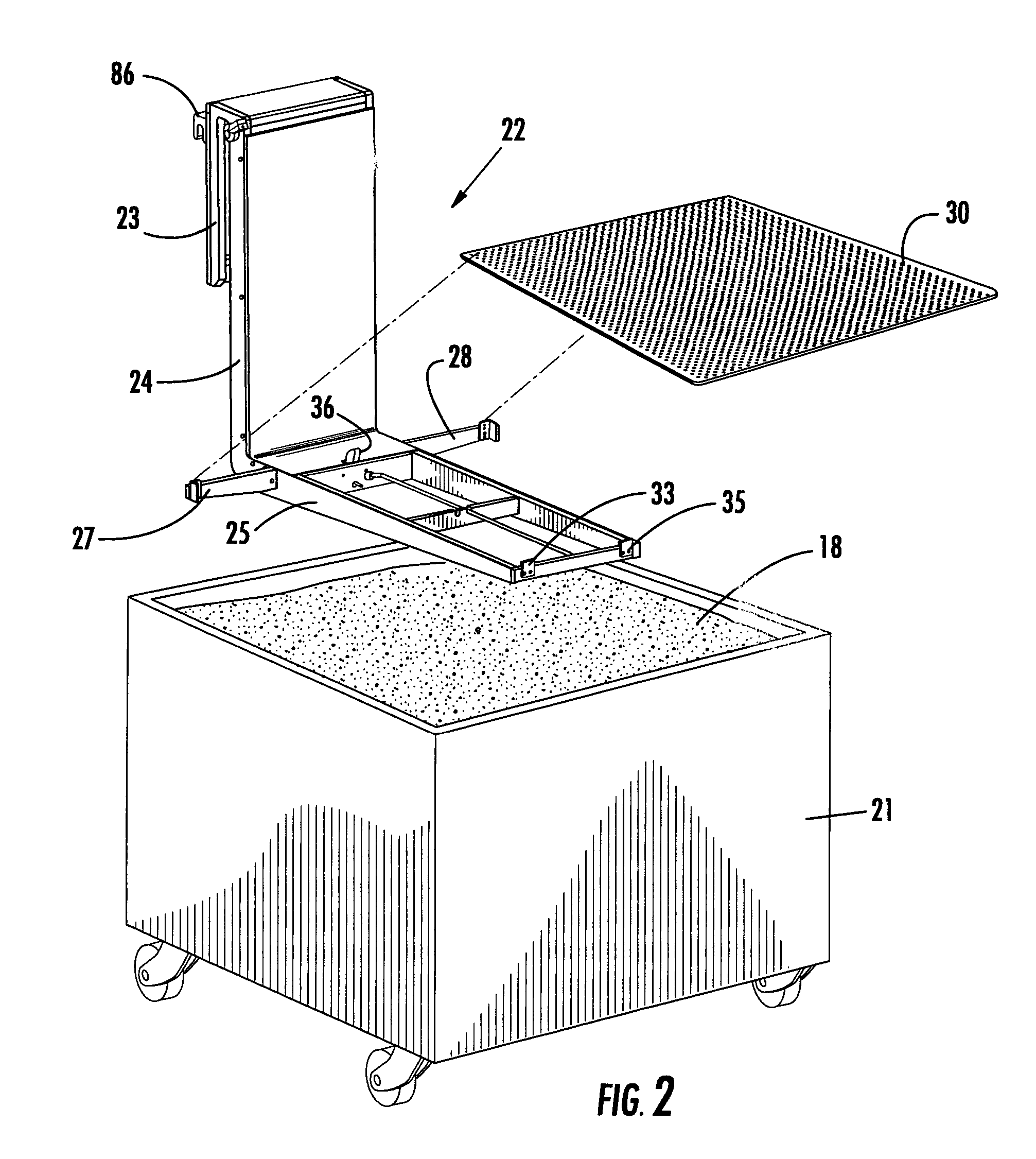

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

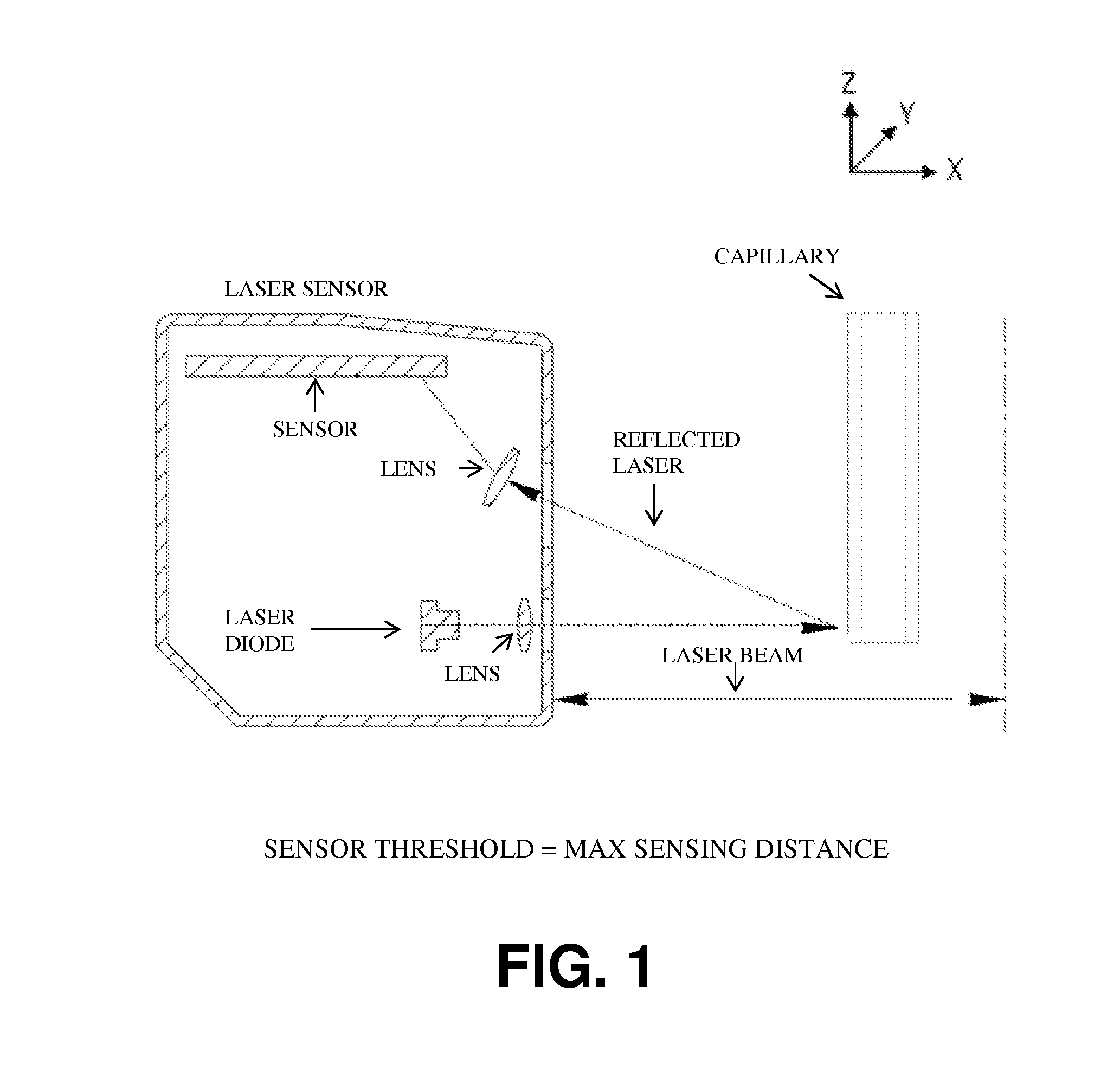

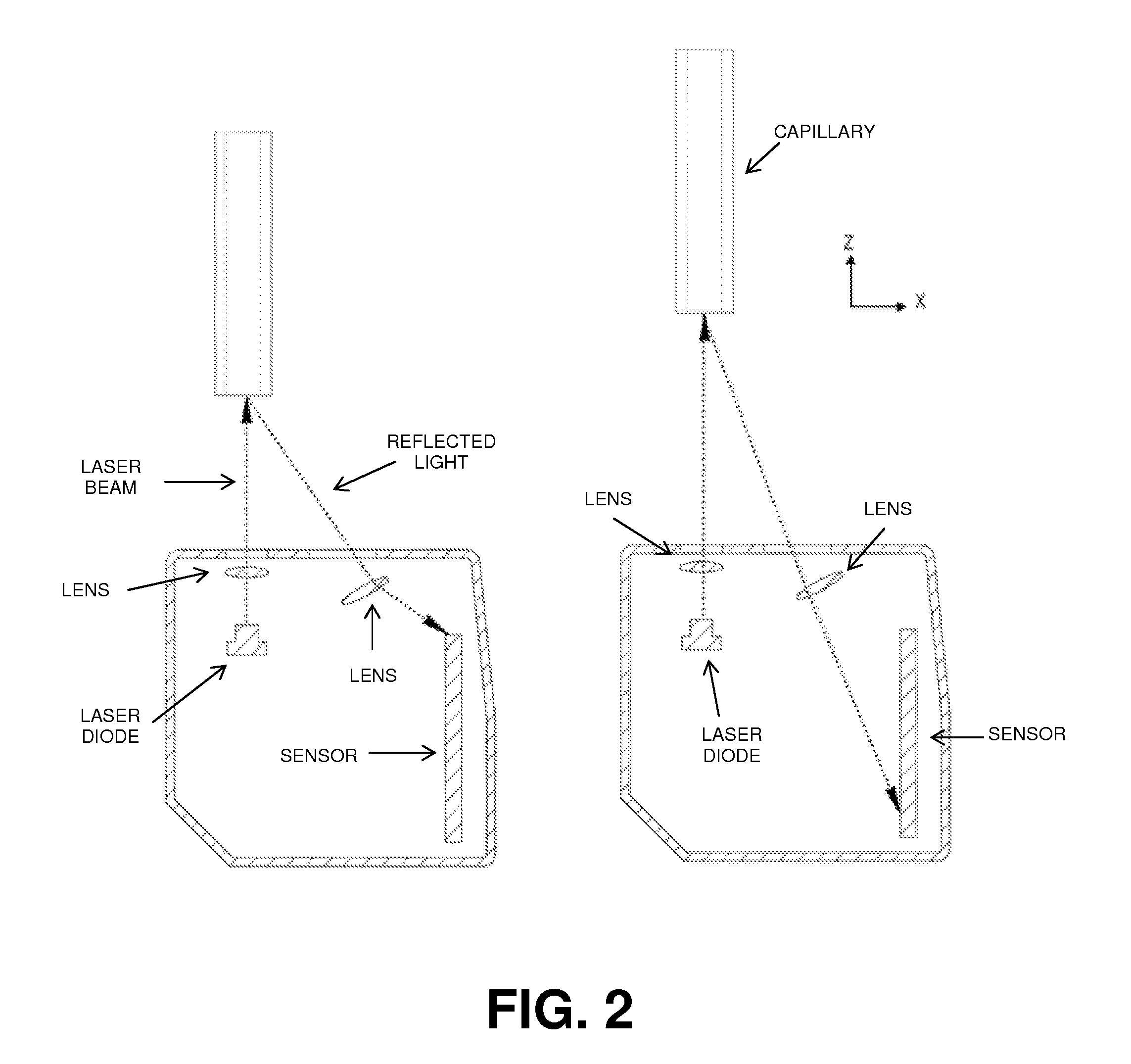

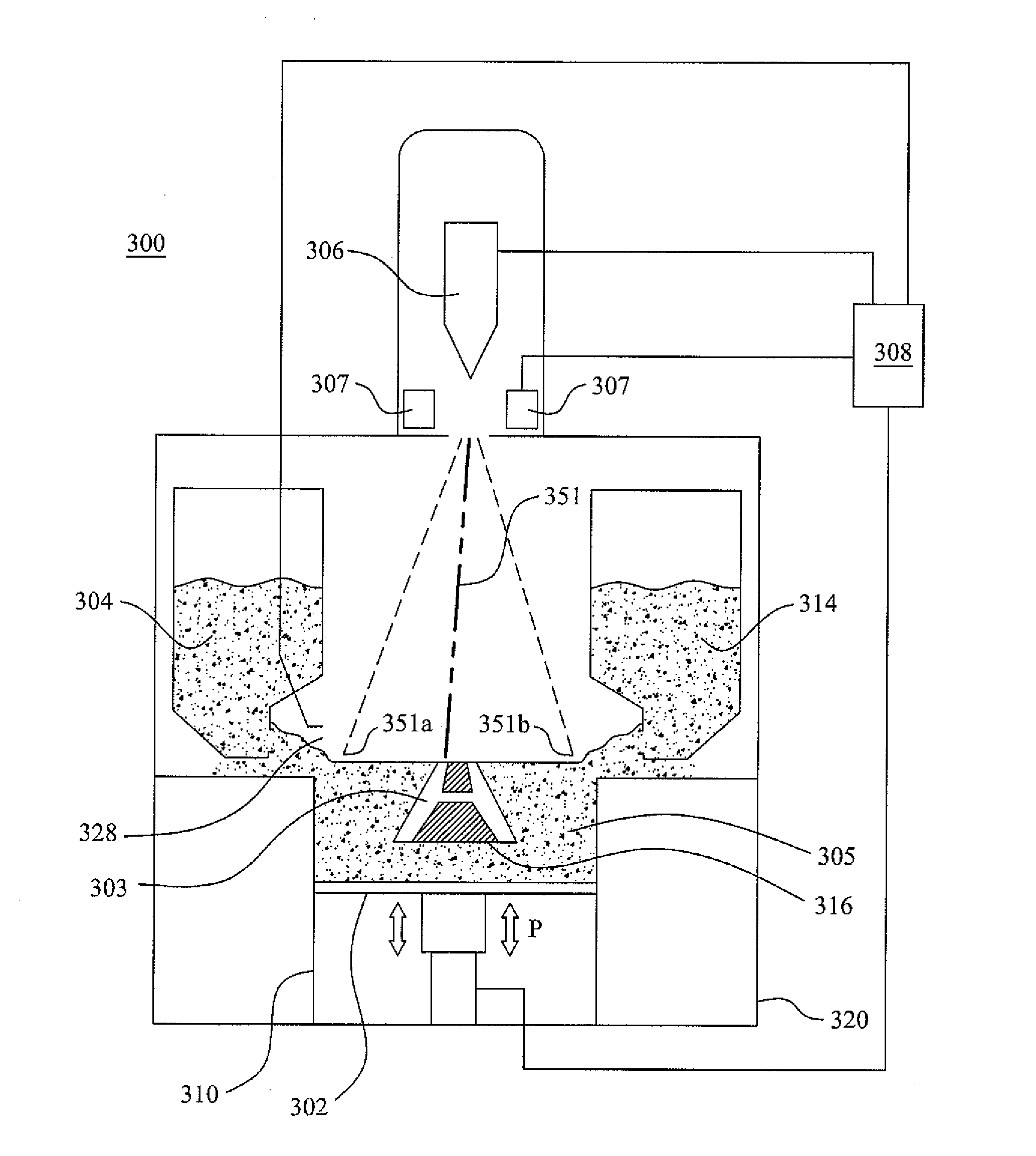

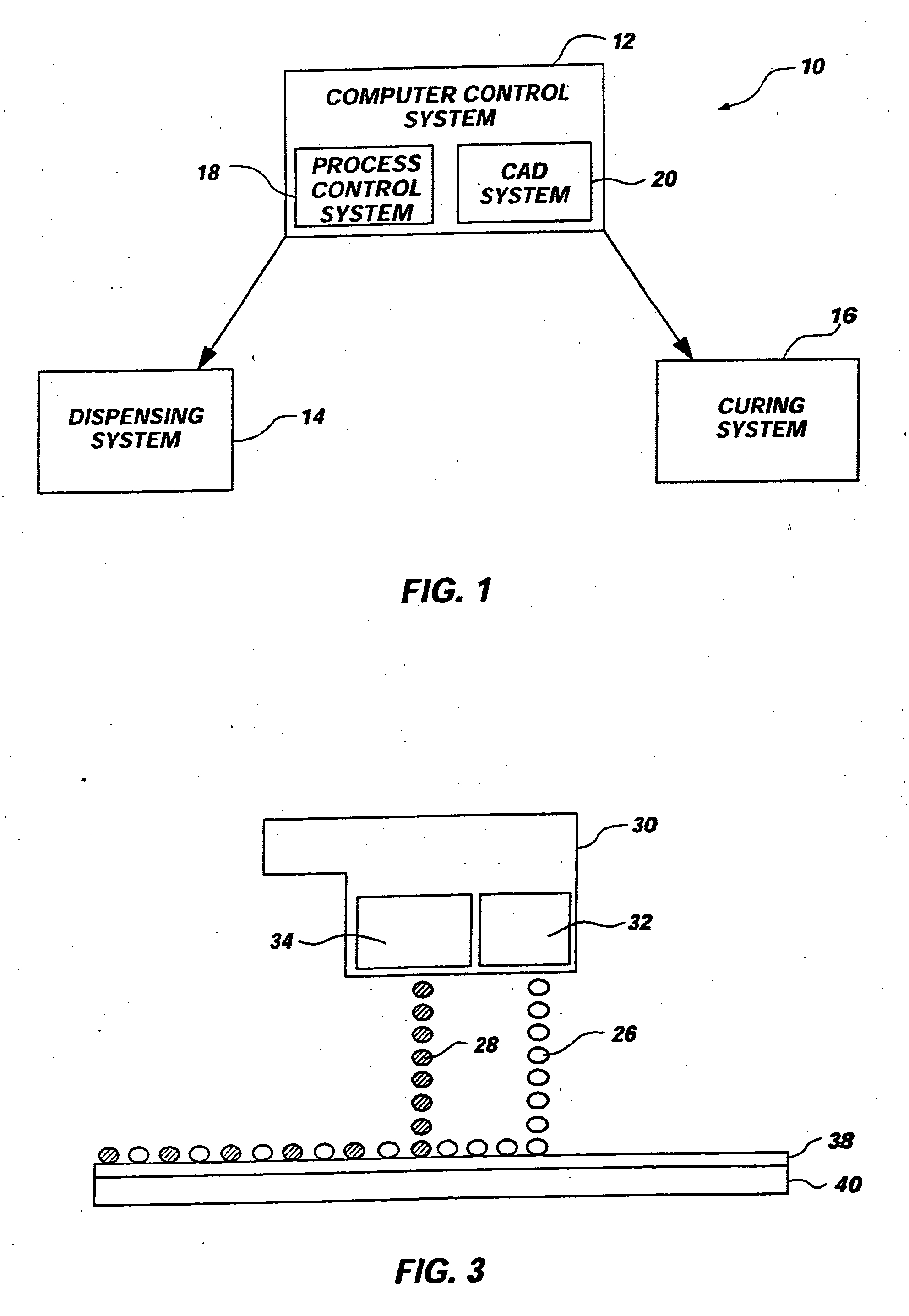

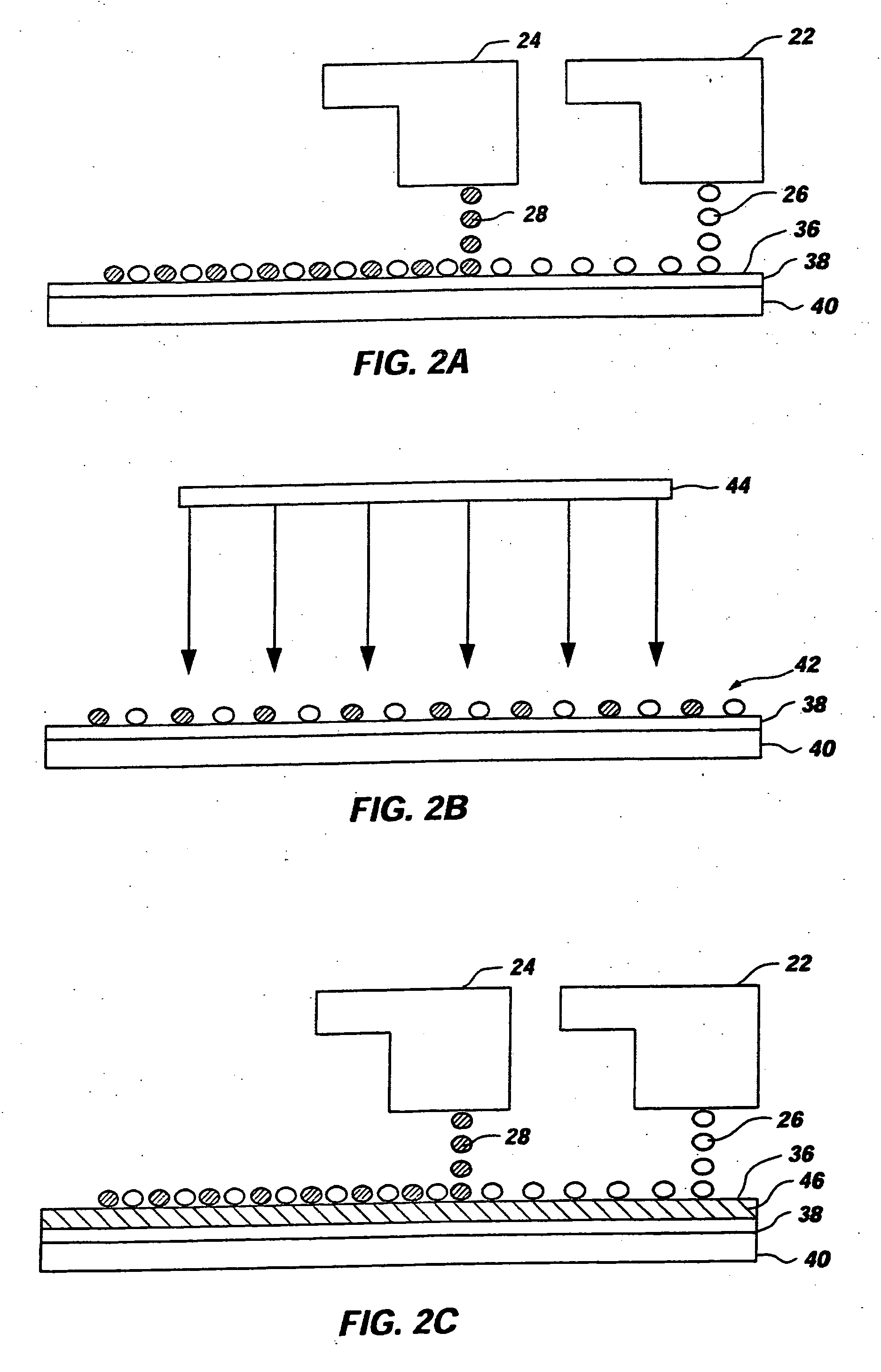

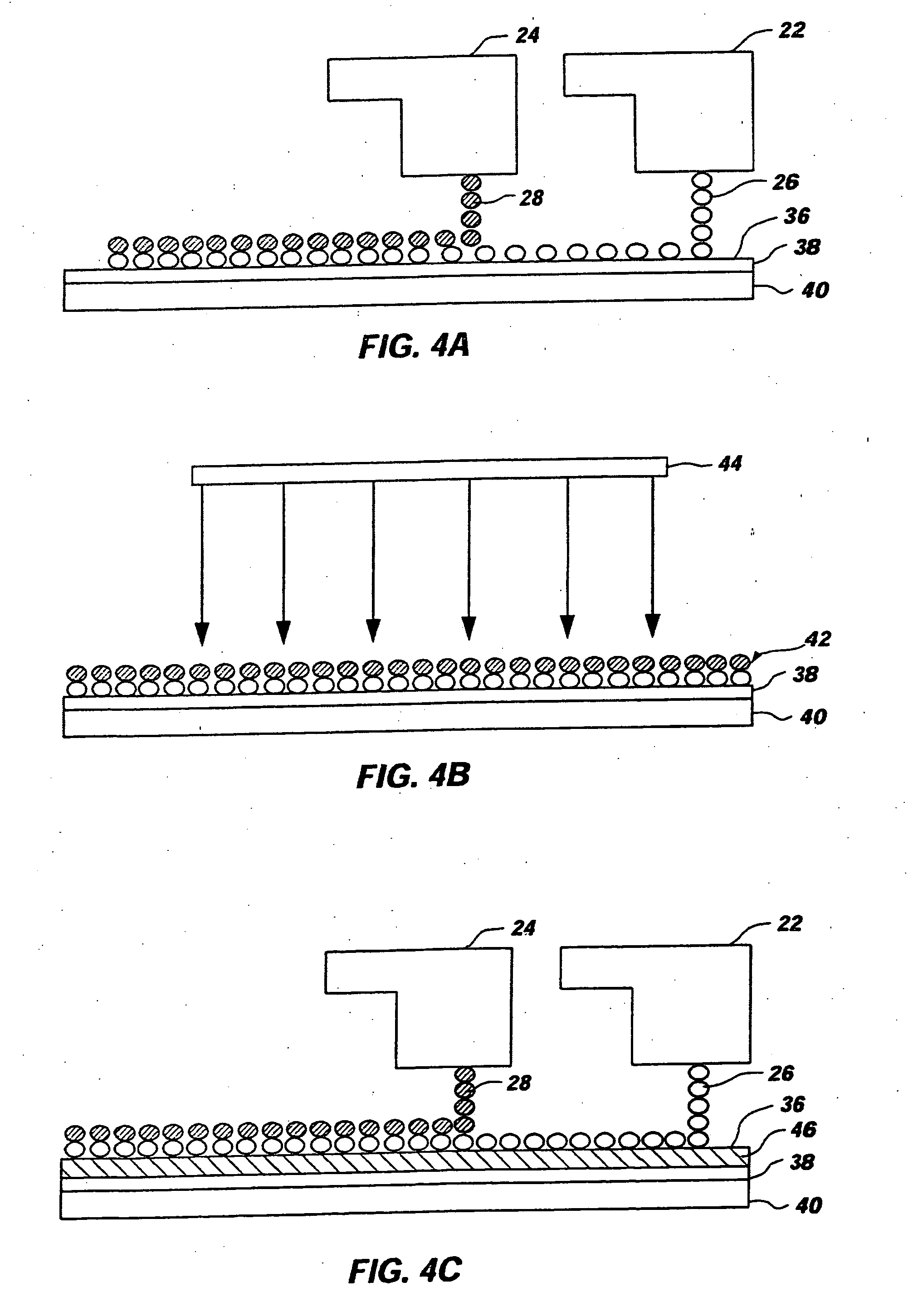

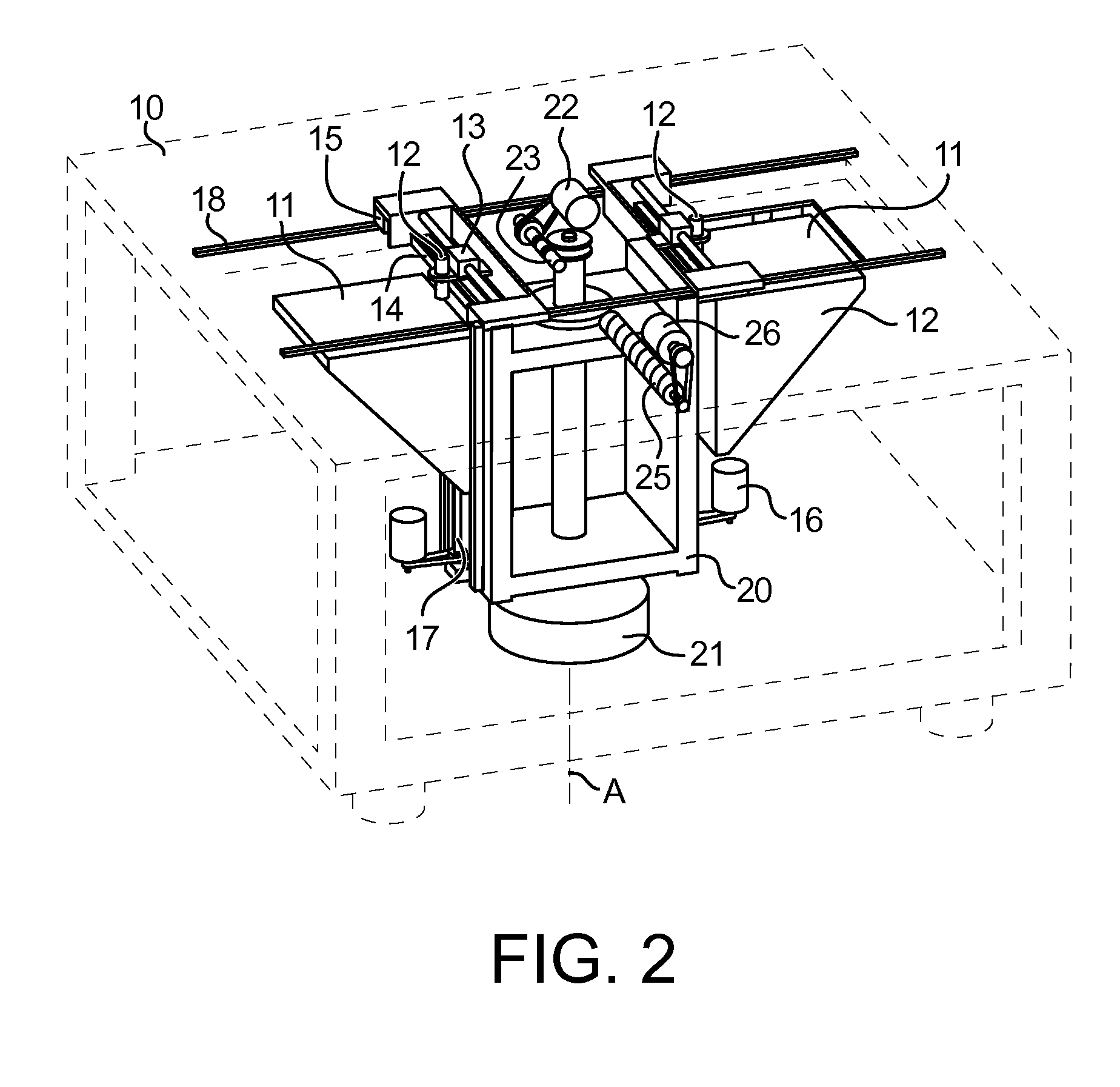

Automated devices, systems, and methods for the fabrication of tissue

InactiveUS20150037445A1Increase the number ofQuality improvementLiquid surface applicatorsConfectioneryBiomedical engineeringAutomation

Described herein are improvements to bioprinting technology that facilitate automation of tissue and organ fabrication processes.

Owner:ORGANOVO

Rapid prototyping and manufacturing system and method

InactiveUS20070077323A1Simplify obtaining precisionFast preparationAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringRapid prototyping

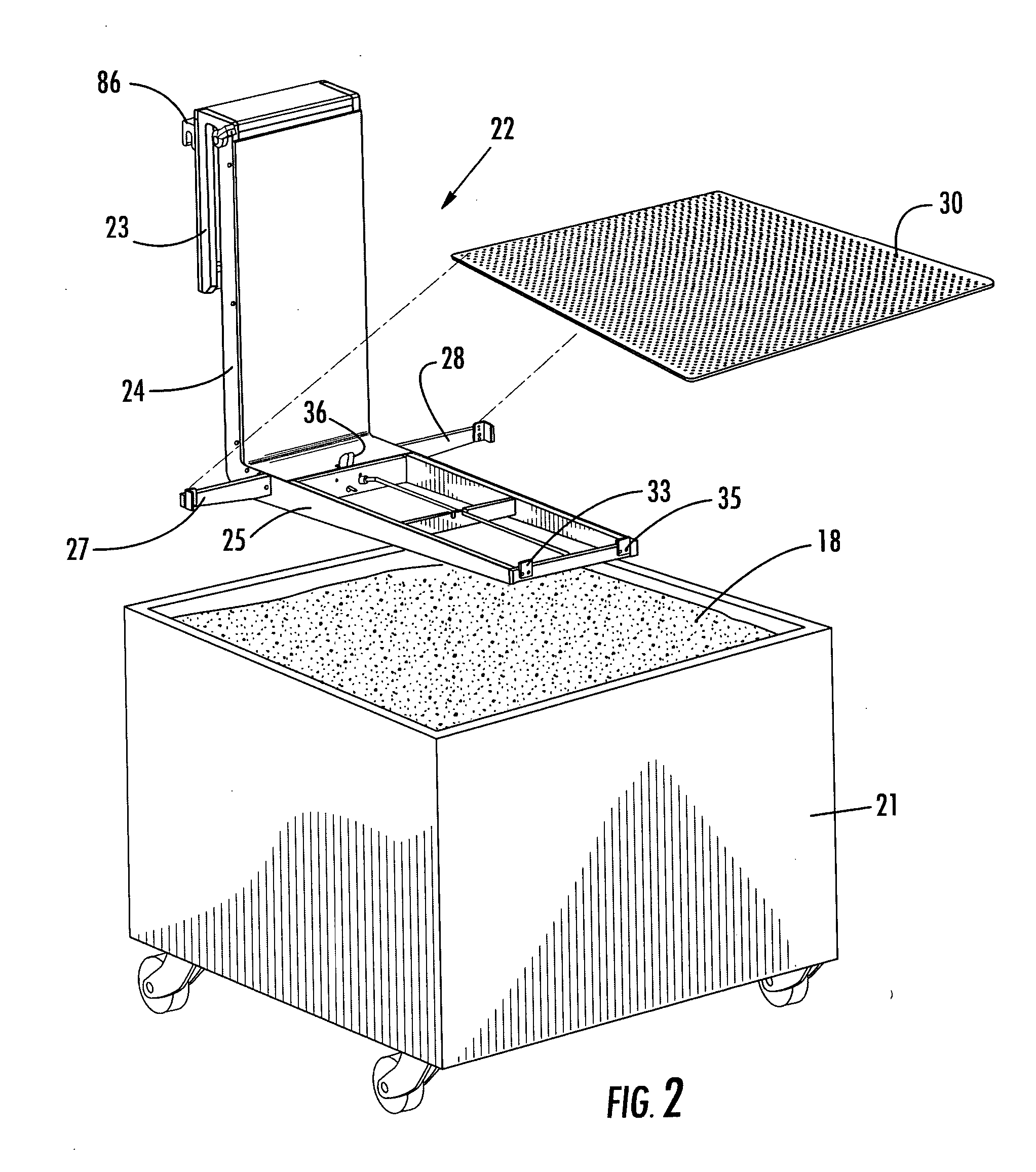

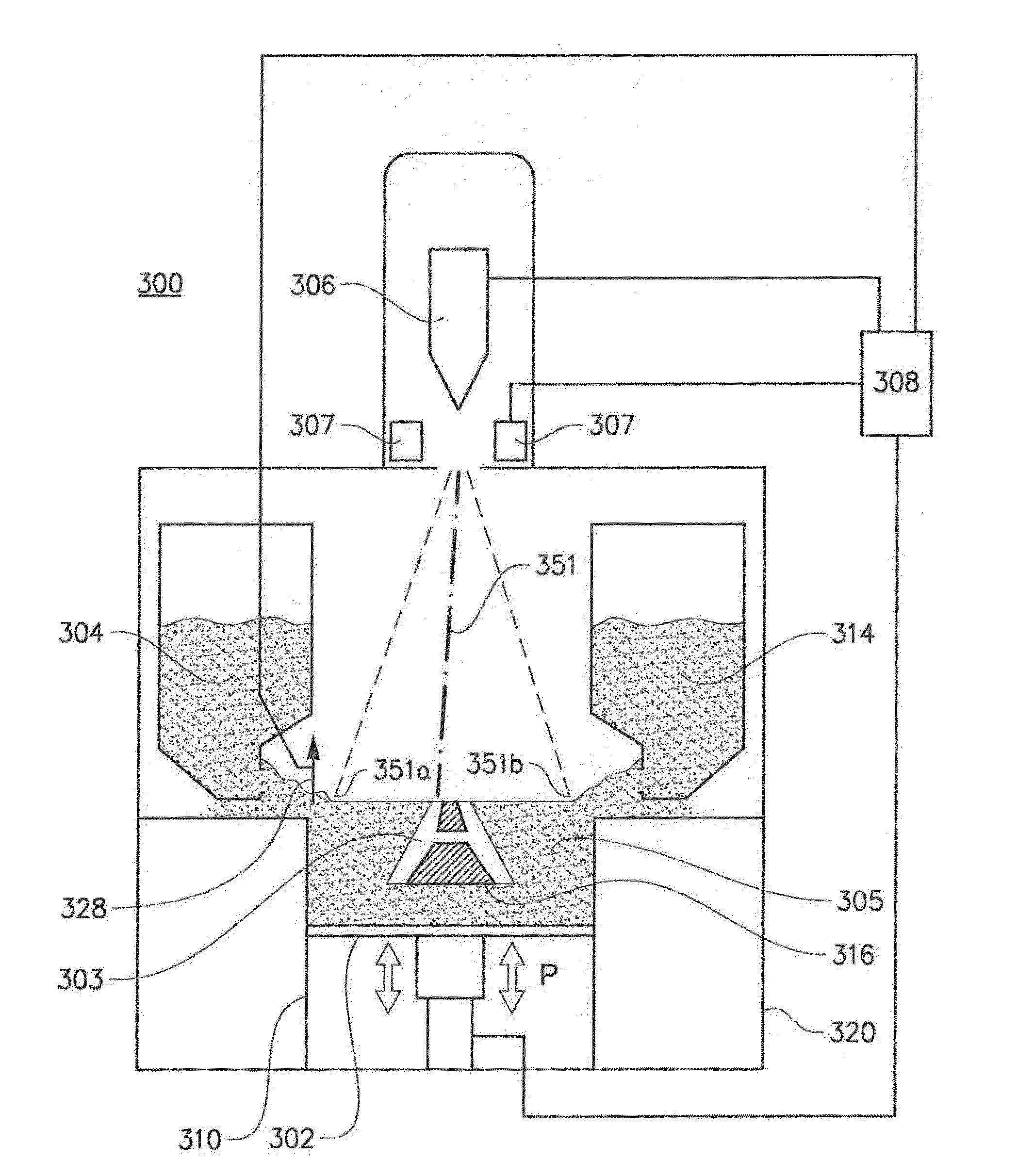

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

Method for additive manufacturing

ActiveUS20150174695A1Easy to controlImprove ductilityAdditive manufacturing apparatusIncreasing energy efficiencyScan lineBeam source

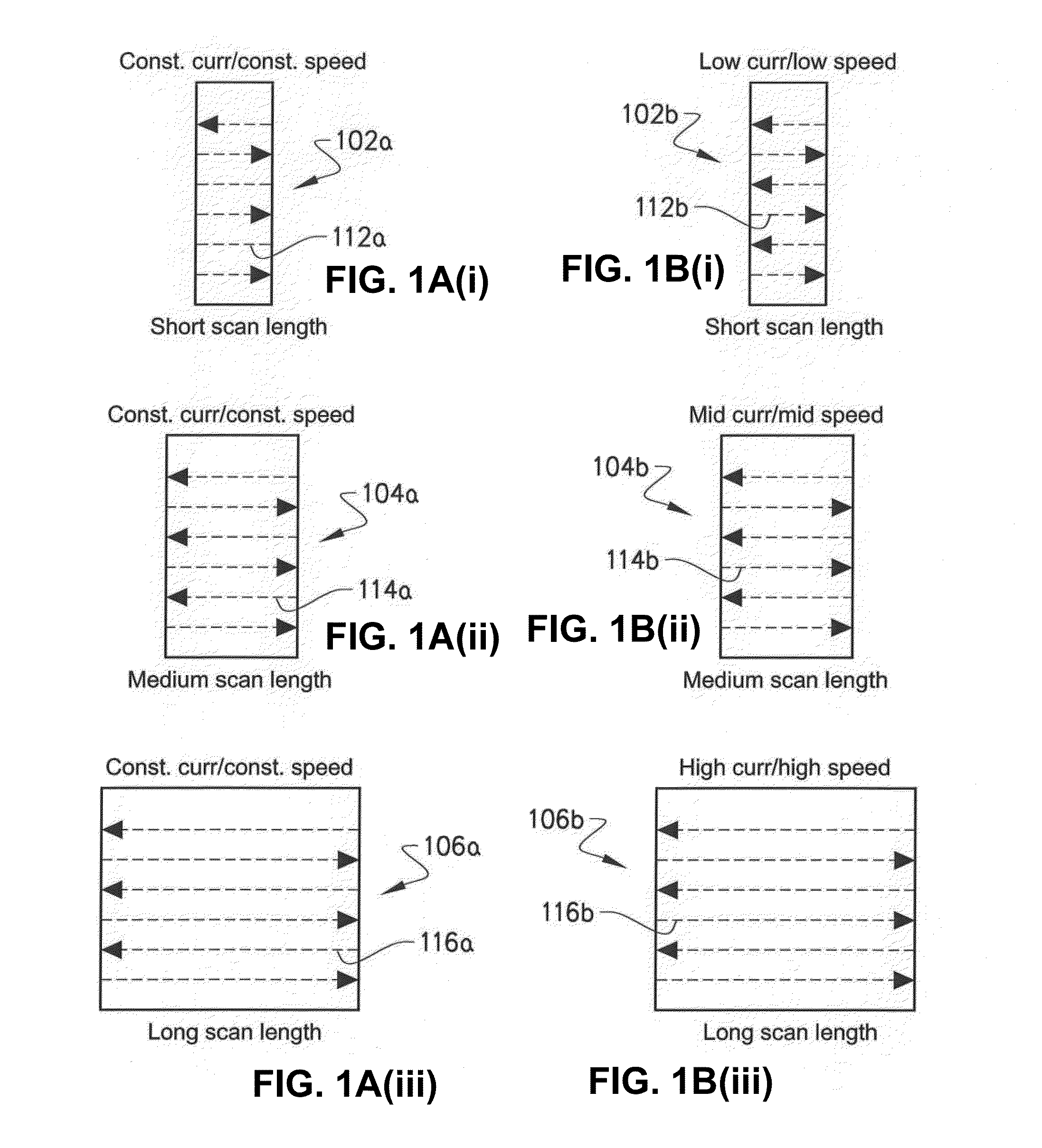

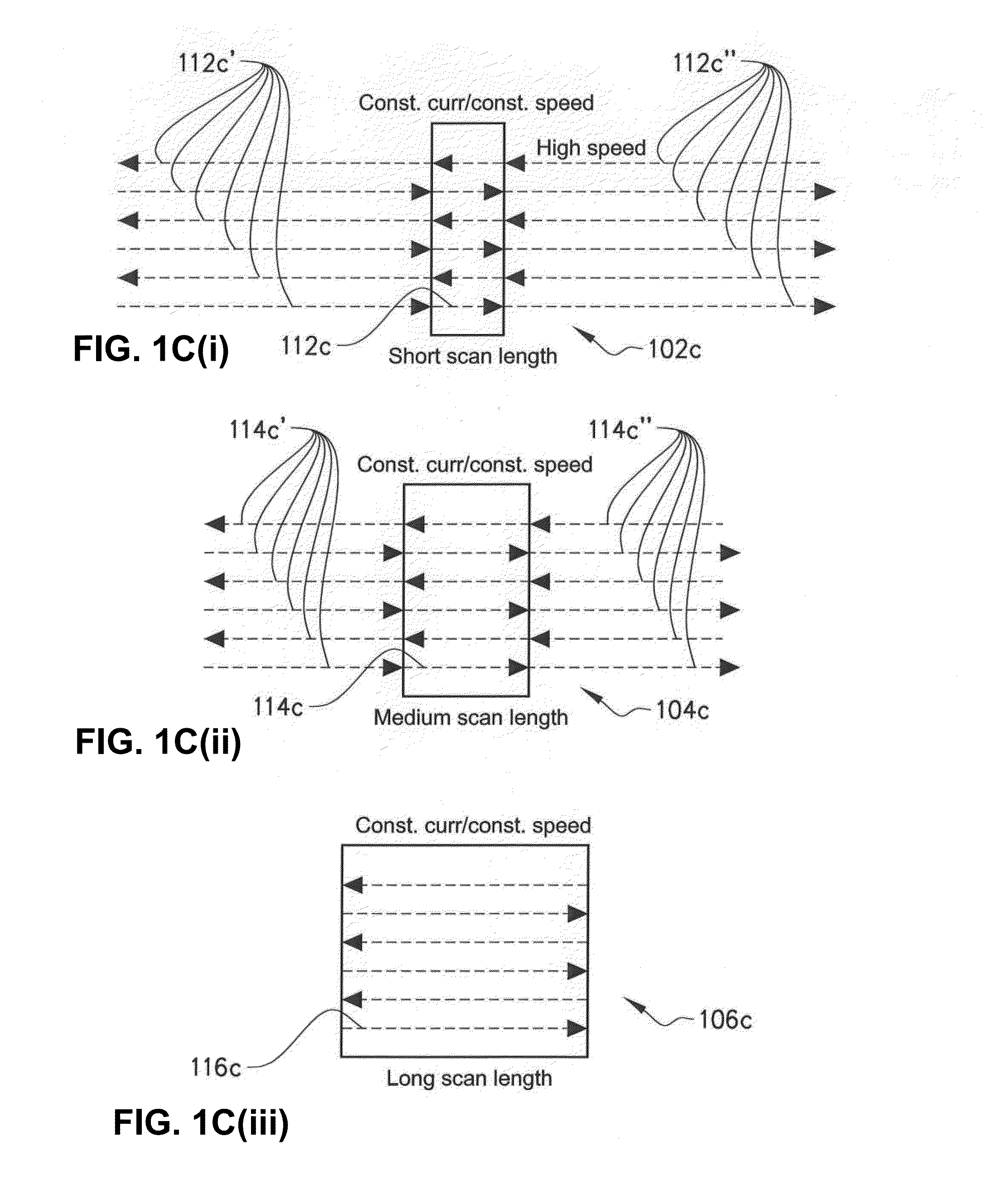

The invention relates to a method for forming a three-dimensional article through successive fusion of locations of a powder bed. The method comprising: providing a model of said three-dimensional article; applying a powder layer on a work table; determining a maximum scan length of an energy beam; directing said energy beam from a first energy beam source over said work table with constant energy causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, wherein locations with a shorter scan length than said maximum scan length is provided with a time sink before and / or after said scan line so that the time period between each two adjacent scan lines is constant throughout the manufacture of said three-dimensional article.

Owner:ARCAM AB

Method for additive manufacturing of three-dimensional articles

ActiveUS20150251249A1Line lengthAdditive manufacturing apparatusAuxillary shaping apparatusScan lineBeam source

A method for forming at least one three-dimensional article through successive fusion of parts of a powder bed, which parts correspond to successive cross sections of the three-dimensional article, the method comprising the steps of: providing a model of the at least one three-dimensional article; applying a first powder layer on a work table; directing a first energy beam from a first energy beam source over the work table causing the first powder layer to fuse in first selected locations according to corresponding models to form a first cross section of the three-dimensional article, where the first energy beam is fusing at least a first region of a first cross section with parallel scan lines in a first direction; varying a distance between two adjacent scan lines, which are used for fusing the powder layer, as a function of a mean length of the two adjacent scan lines.

Owner:ARCAM AB

Rapid prototyping and manufacturing system and method

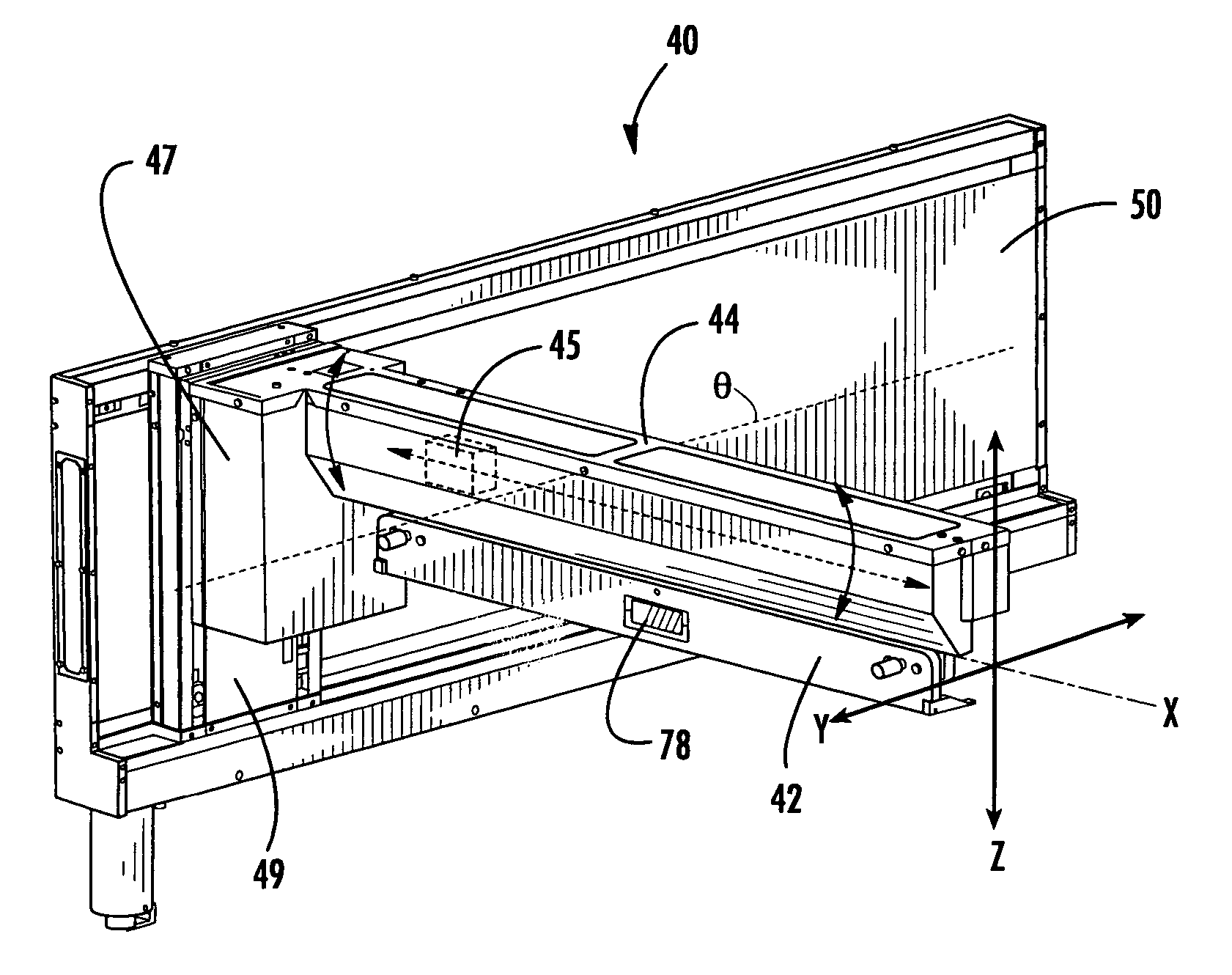

InactiveUS20070075461A1Simplify obtaining precisionShorten the timeManufacturing platforms/substratesAuxillary shaping apparatusElectrical resistance and conductanceEngineering

A stereolithography apparatus having a resin vat with computer controlled heating elements responsive to thermistors for controlled preheating of the resin vat, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater blade that can be removed and accurately installed by hand, thus providing that all wetted components can be quickly and efficiently removed and installed and enabling rapid changeover from spent resin to fresh resin and minimizing apparatus downtime between stereolithography operations.

Owner:3D SYST INC

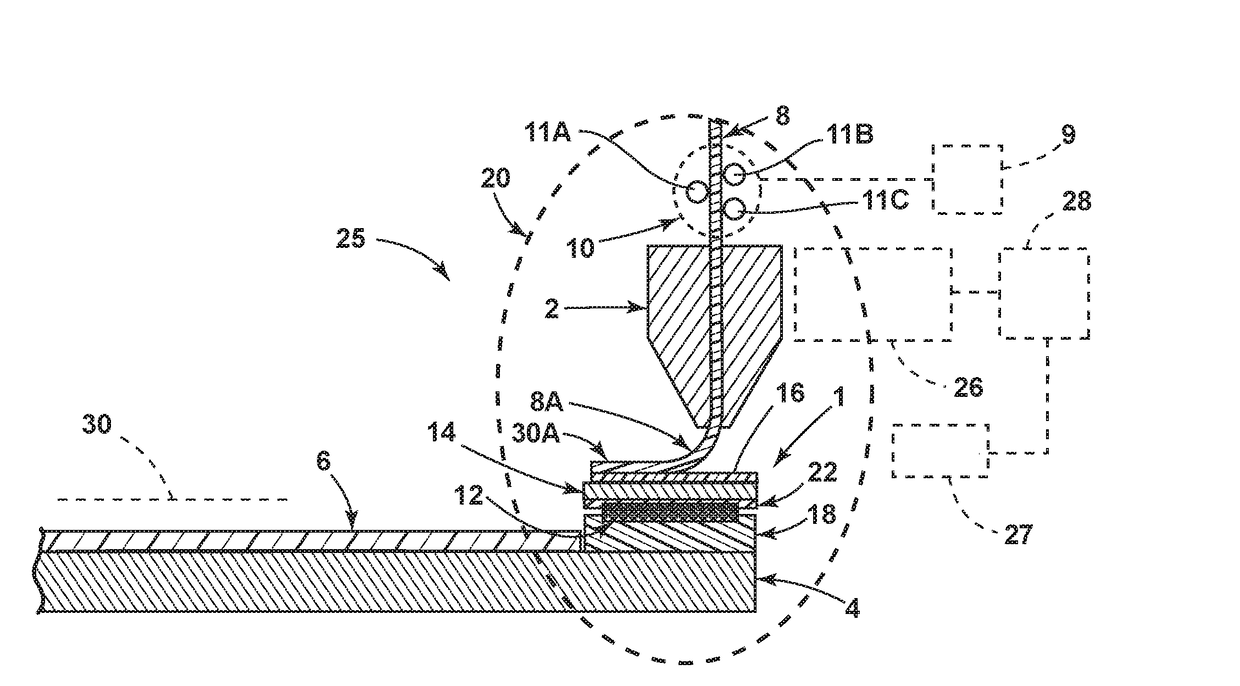

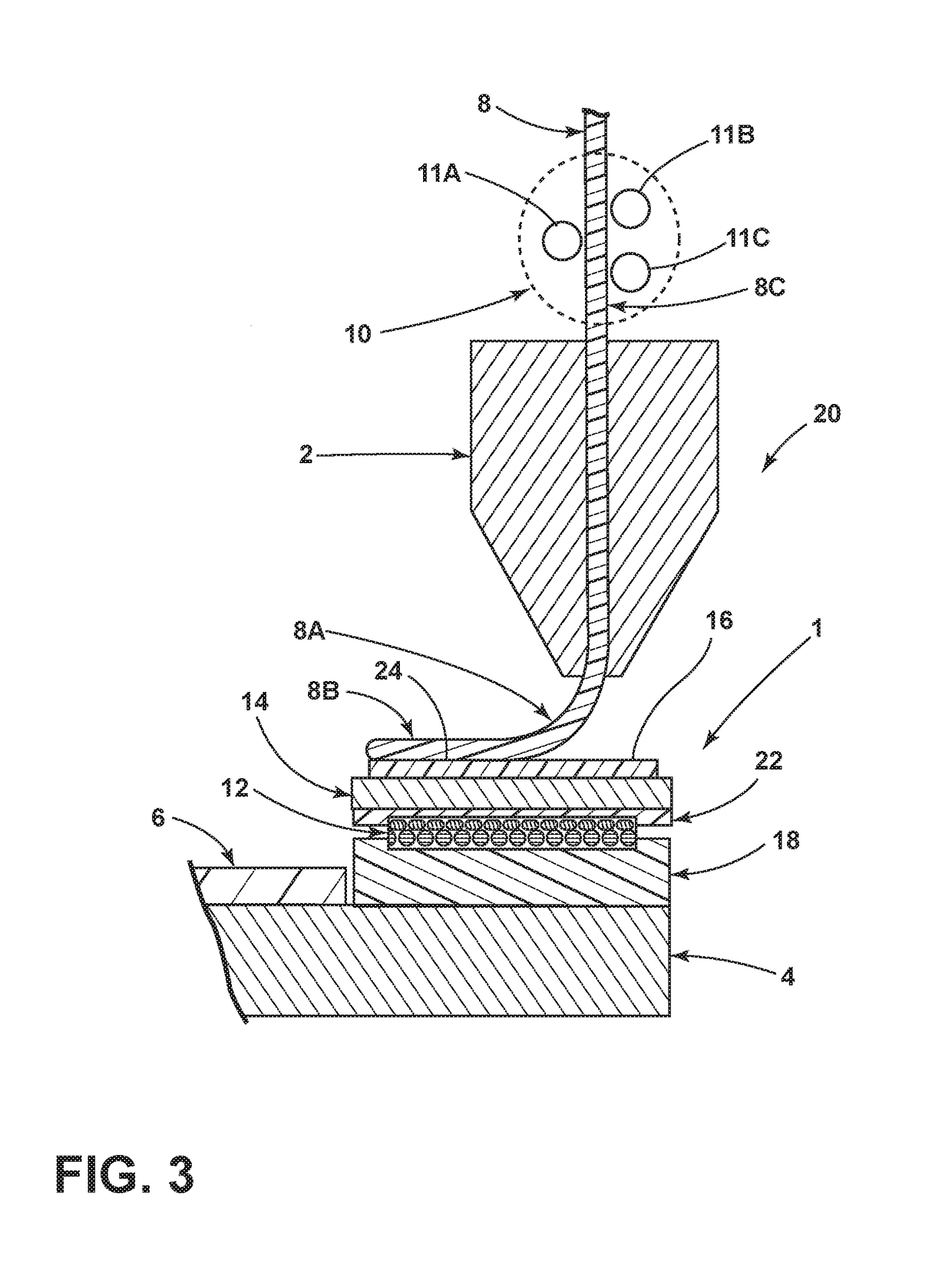

Adhesion test station in an extrusion apparatus and methods for using the same

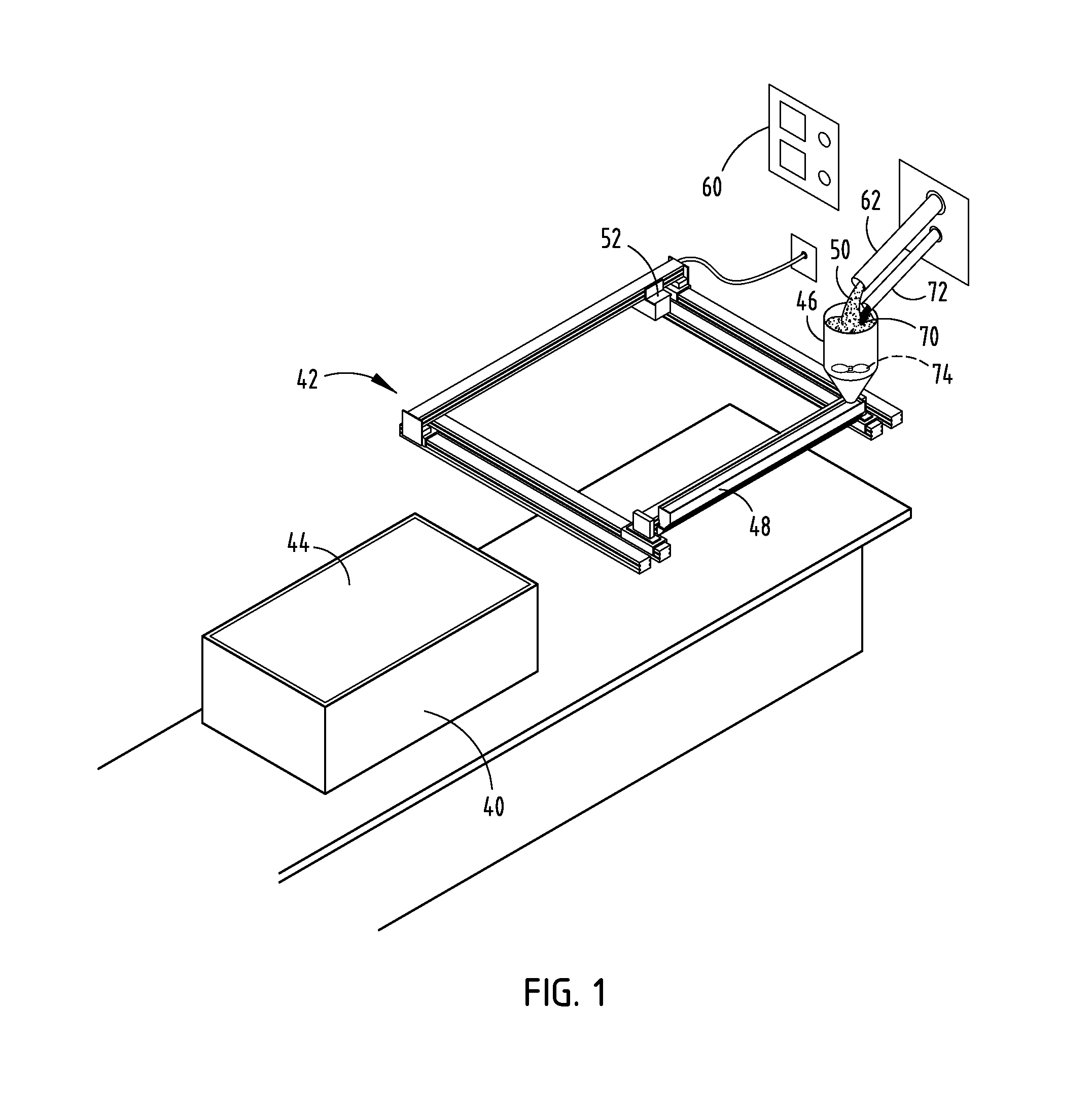

ActiveUS20170129186A1Small and accurate loadEasy to adjustManufacturing platforms/substratesAdditive manufacturing with liquidsEngineeringTest material

A method of controlling an additive fabrication process includes providing a primary substrate and a test substrate. Polymer test material is extruded onto the test substrate utilizing an extrusion head. The extrusion head is moved relative to the test substrate, and a force required to move the extrusion head relative to the test substrate is measured to thereby generate test data. A part is fabricated by extruding polymer material onto the primary substrate utilizing the extrusion head. The test data is utilized to control at least one process parameter associated with extruding polymer material onto the primary substrate.

Owner:NASA

Rapid prototyping and manufacturing system and method

ActiveUS20070075460A1Fast preparationAvoid pollutionConfectionerySweetmeatsEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

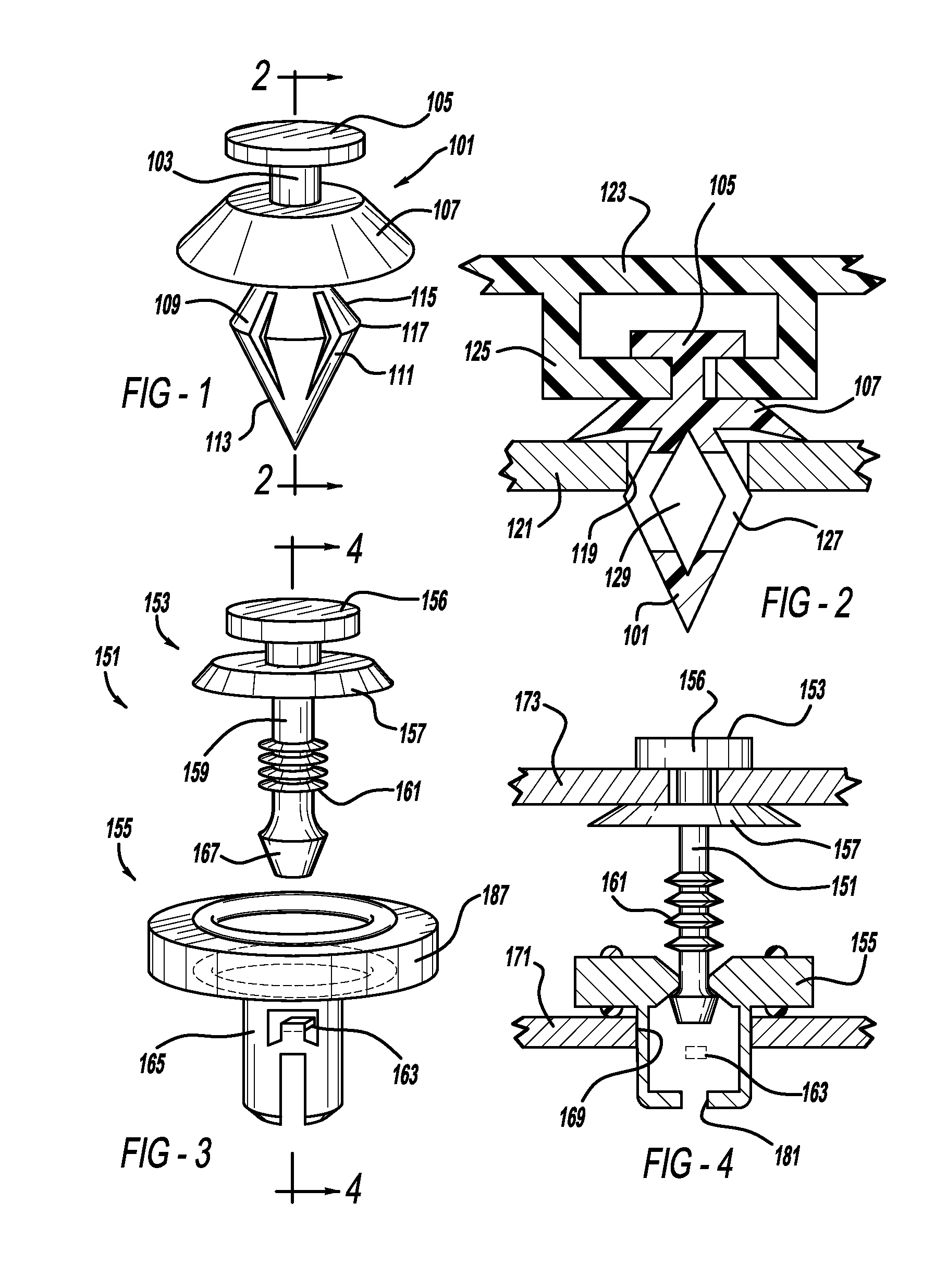

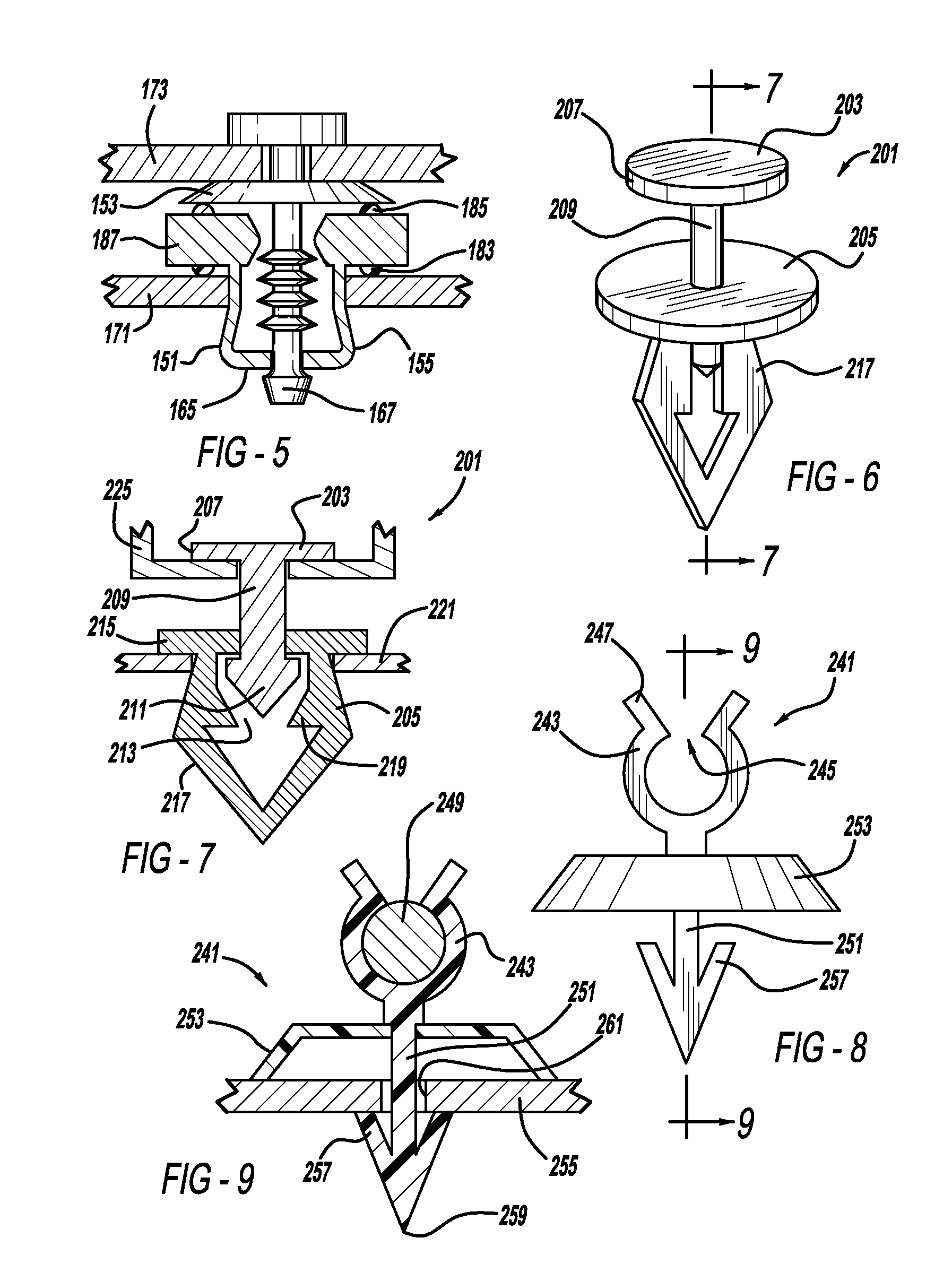

Fasteners manufactured by three-dimensional printing

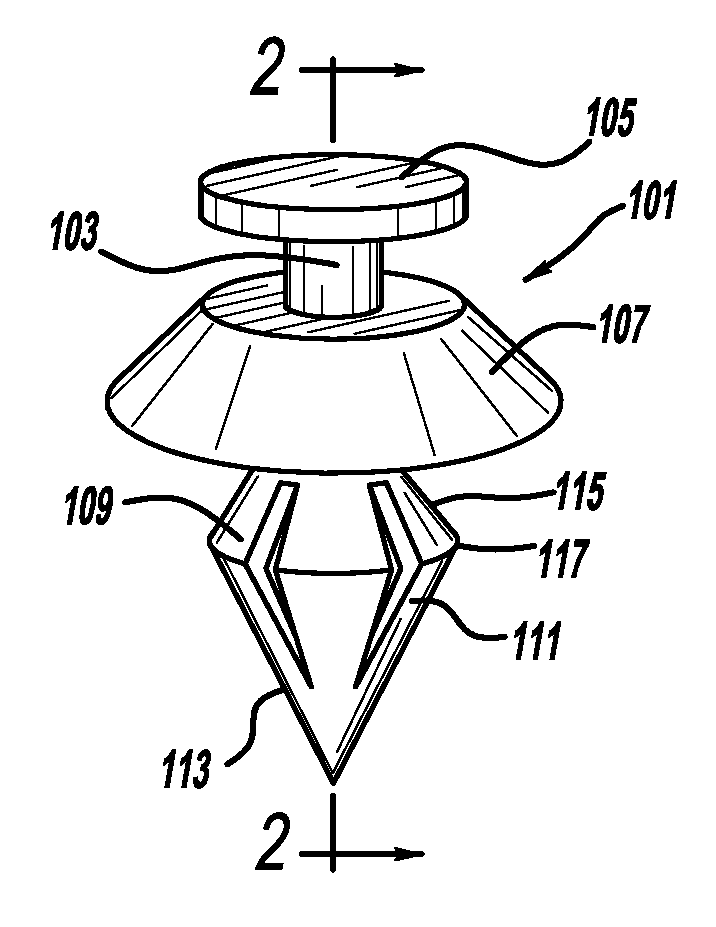

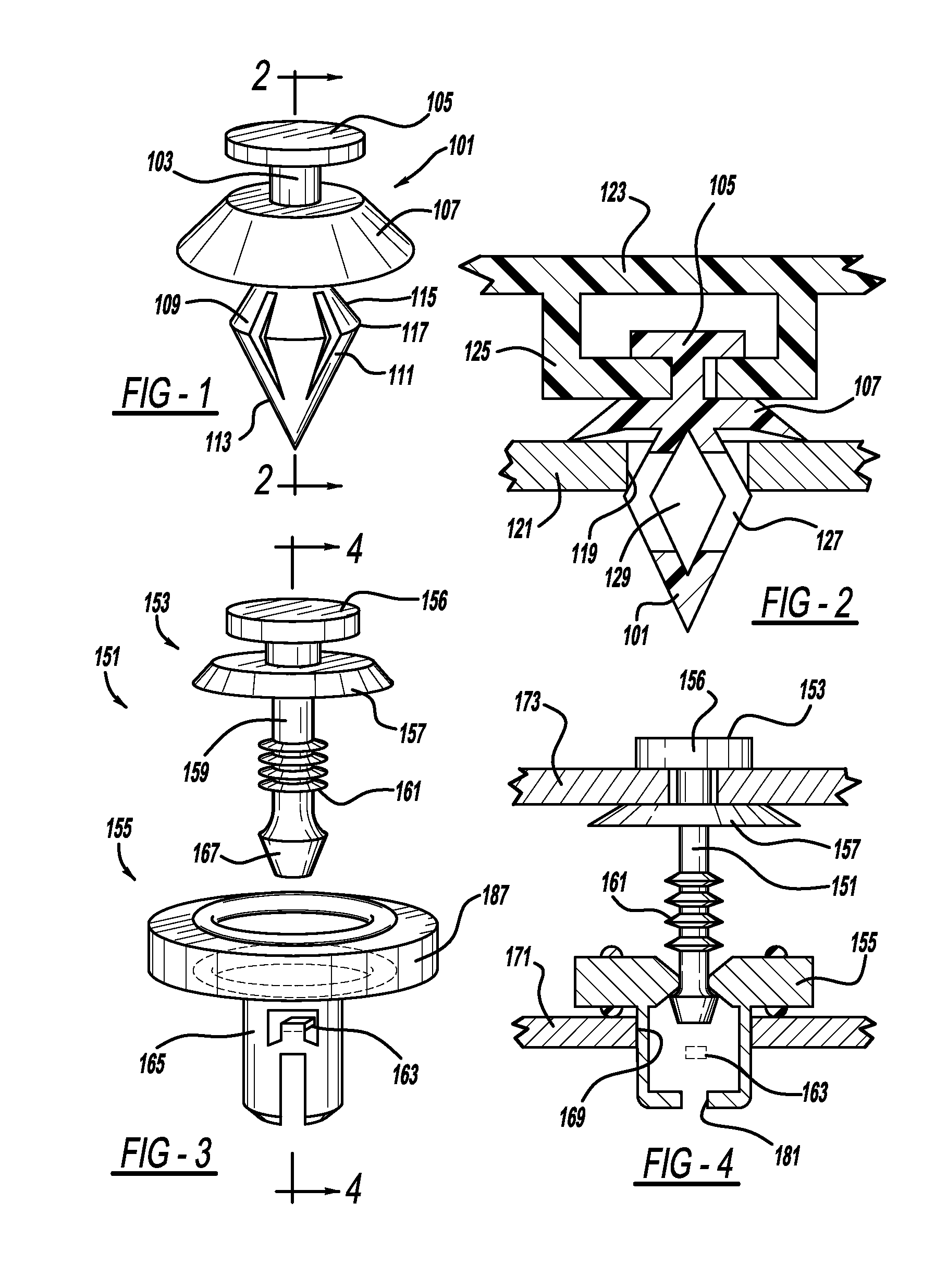

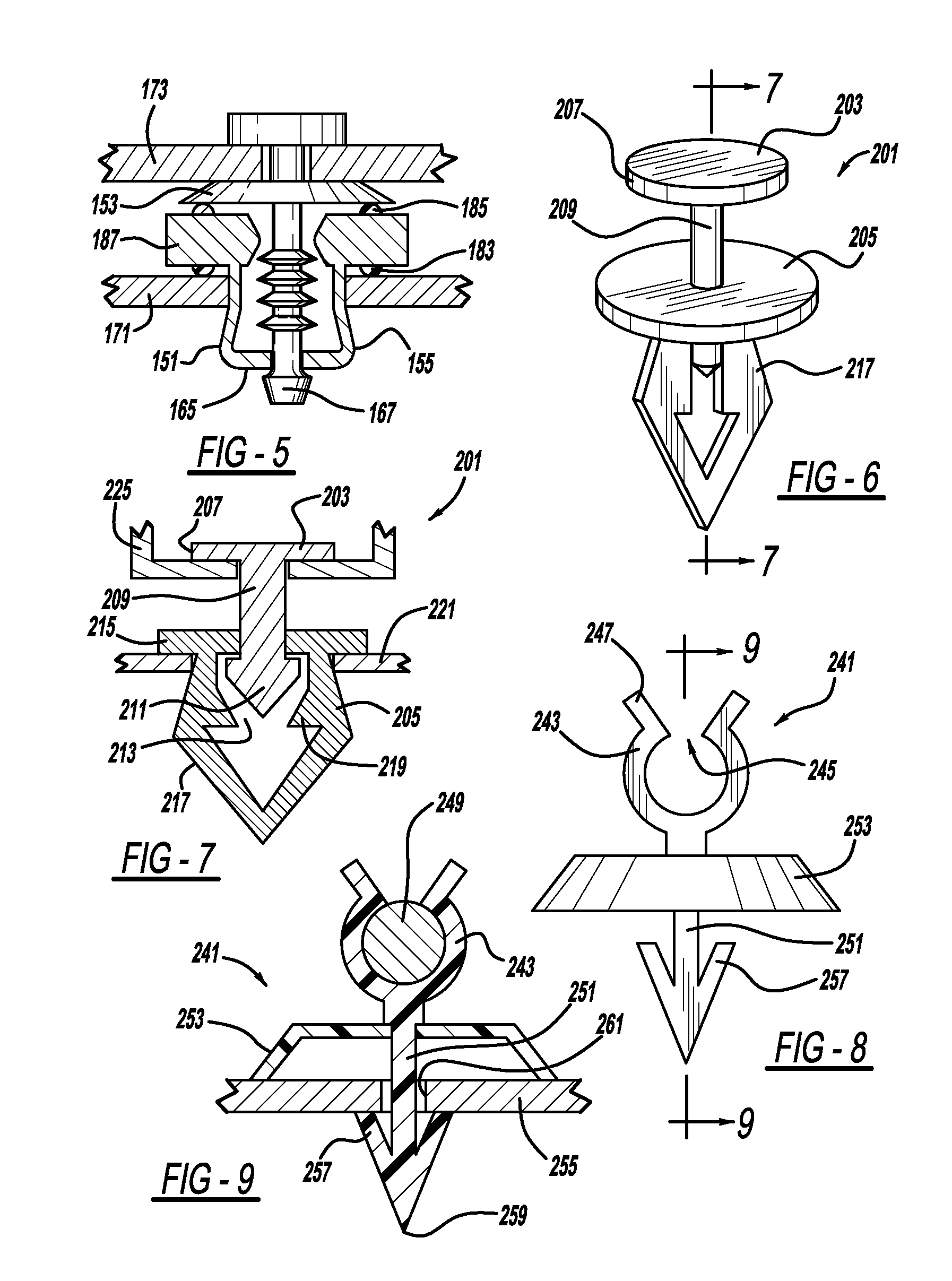

InactiveUS20140086704A1Many timesQuick and inexpensive designDeformable pinsPinsEngineeringPrinting press

Owner:A RAYMOND & CO

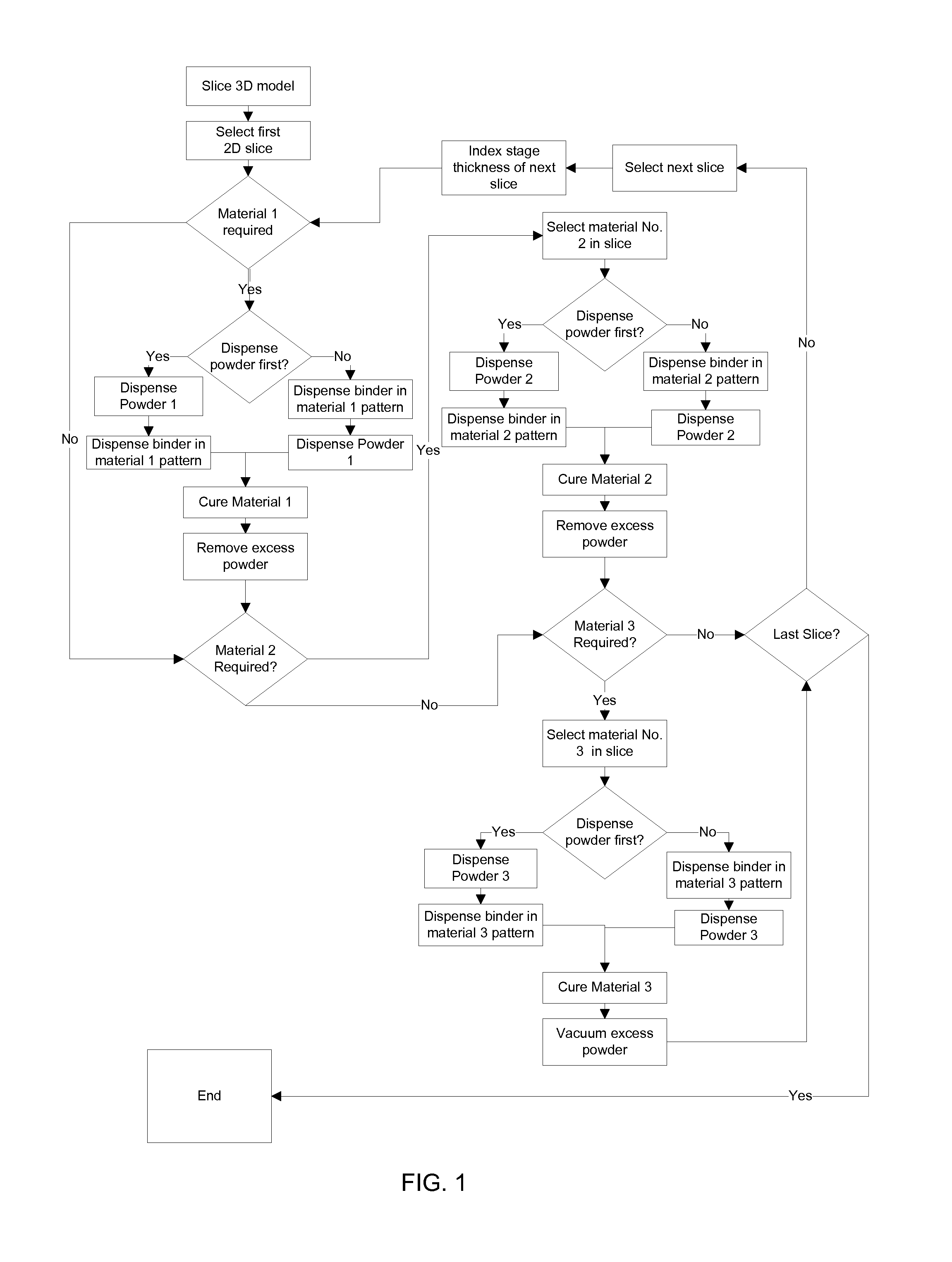

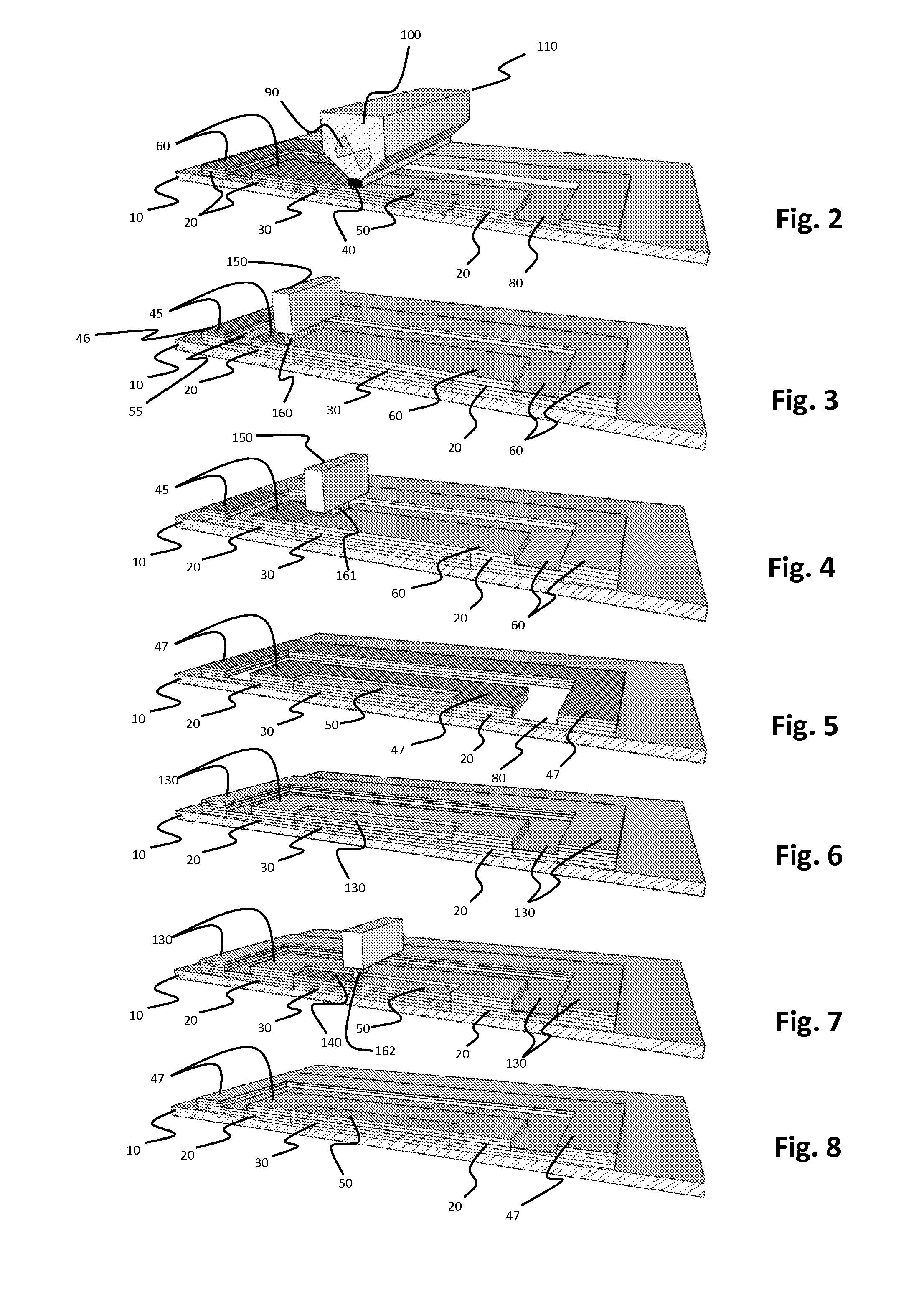

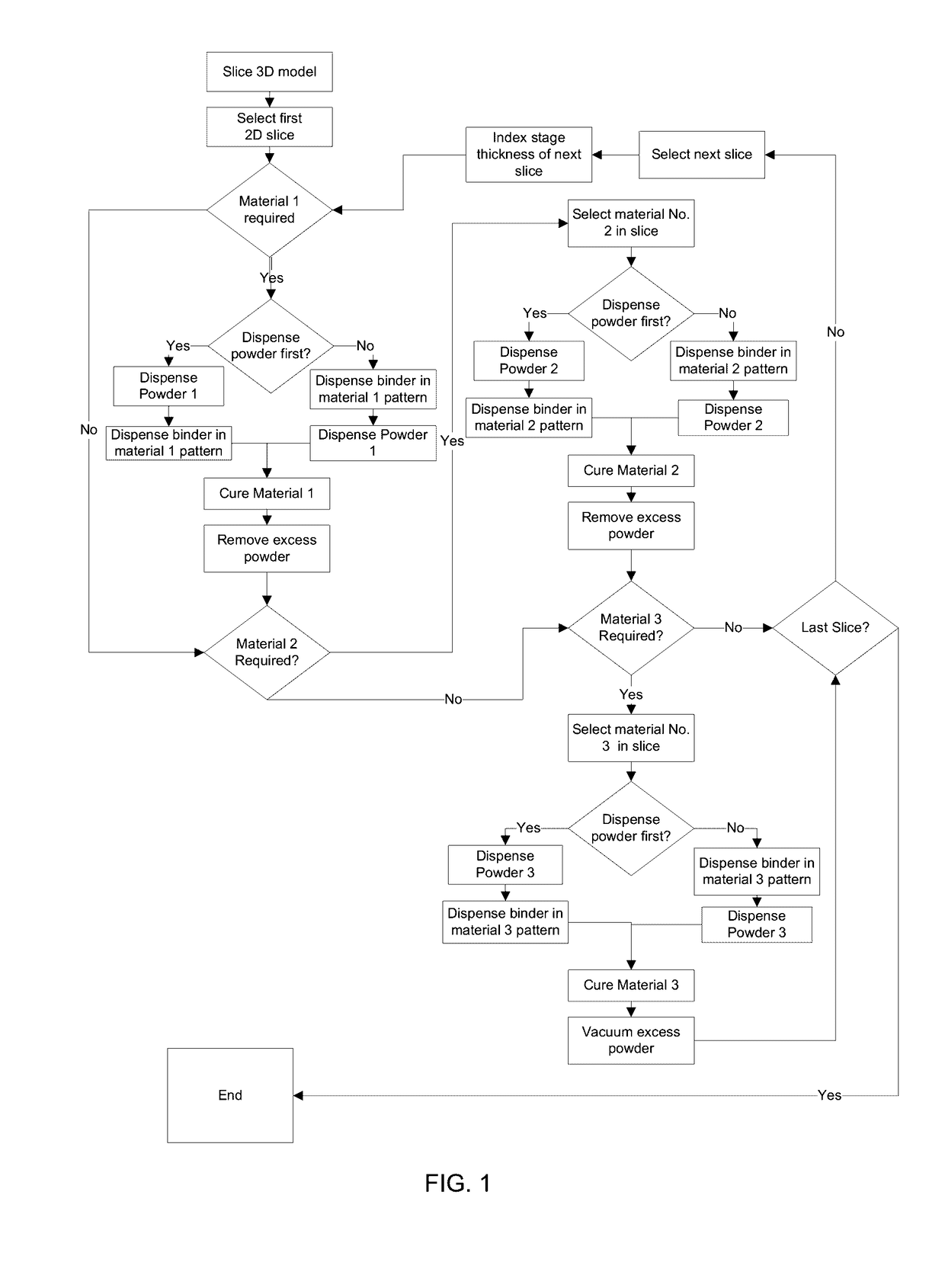

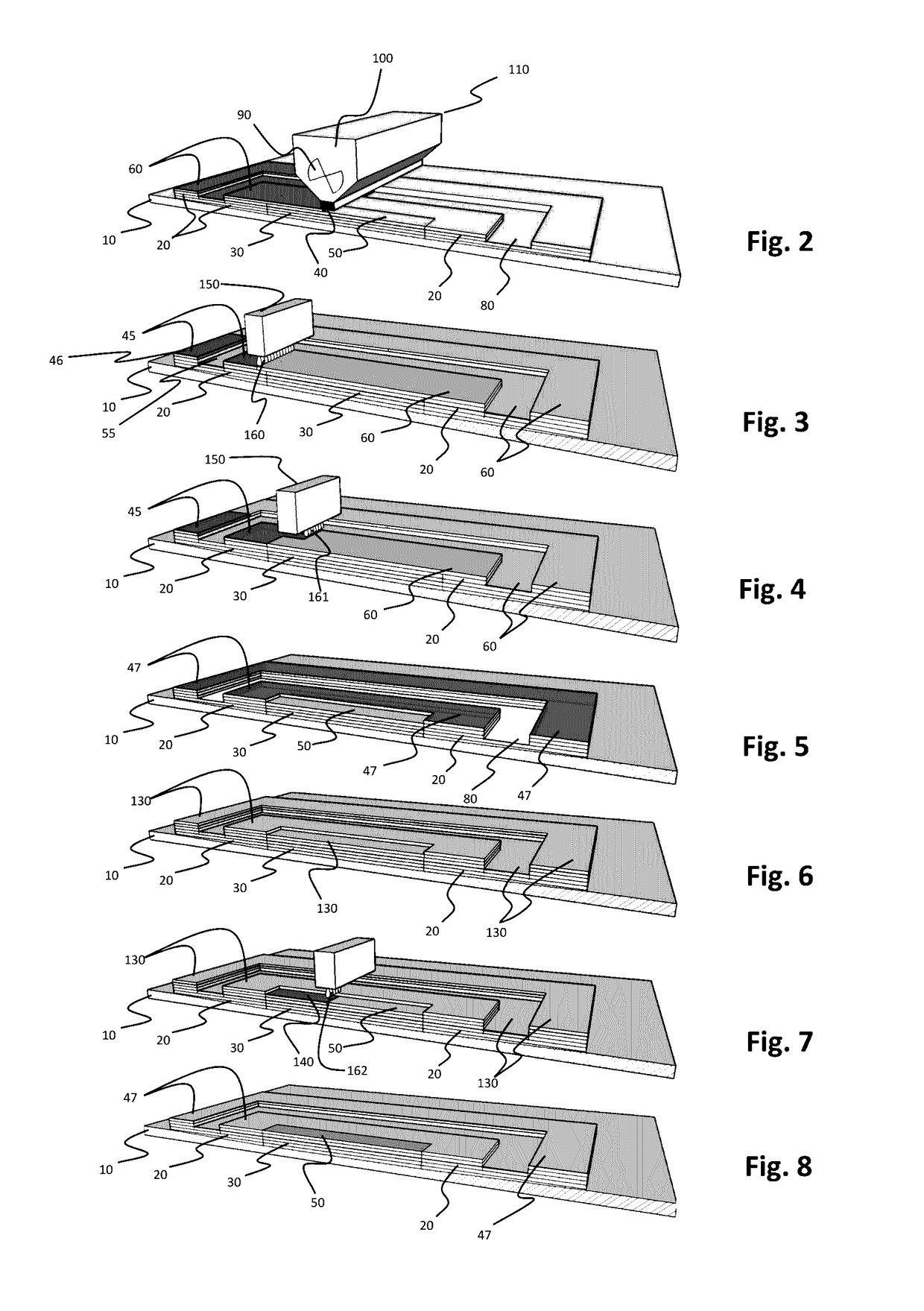

Multi-material three dimensional printer

A layer of a first powder is dispensed in a layer over a build plate. Binder is then selectively applied to hold portions of the layer of first powder together. Unbound first powder is then removed. A second powder is then dispensed in a layer over the build plate and portions of the bound first powder above the build plate. Binder is then selectively applied to hold portions of the second powder together. Unbound second powder is then removed. A third or more different powders can be similarly dispensed and bound to complete a multi-material layer. The process is then be repeated on a next subsequent layer. A curing radiation source can accelerate binding of powder together. Voids can be formed in portions of the layers by dispensing a fugitive material in portions of each multi-material layer. Mechanisms for implementing the printing process are also disclosed.

Owner:EOPLEX

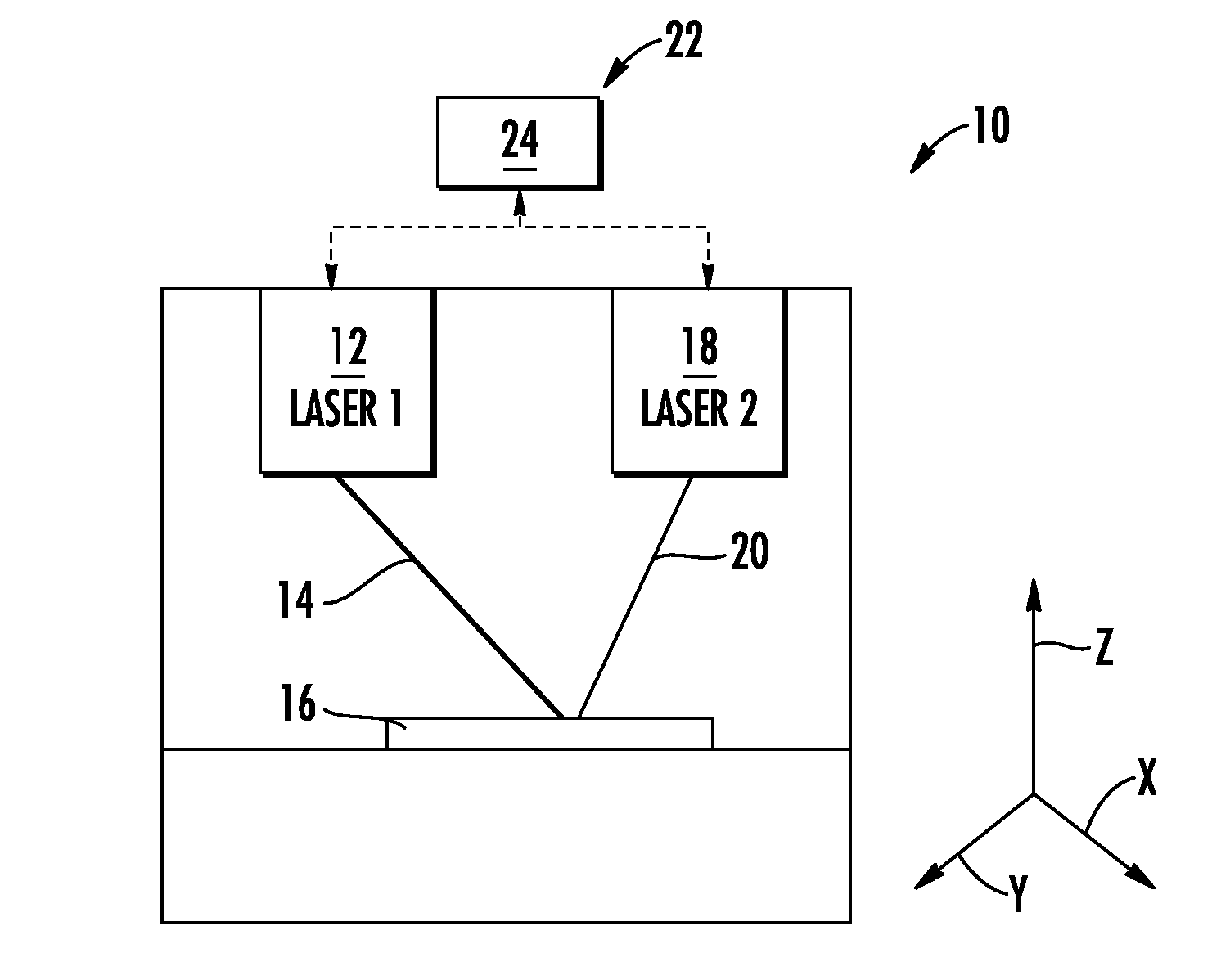

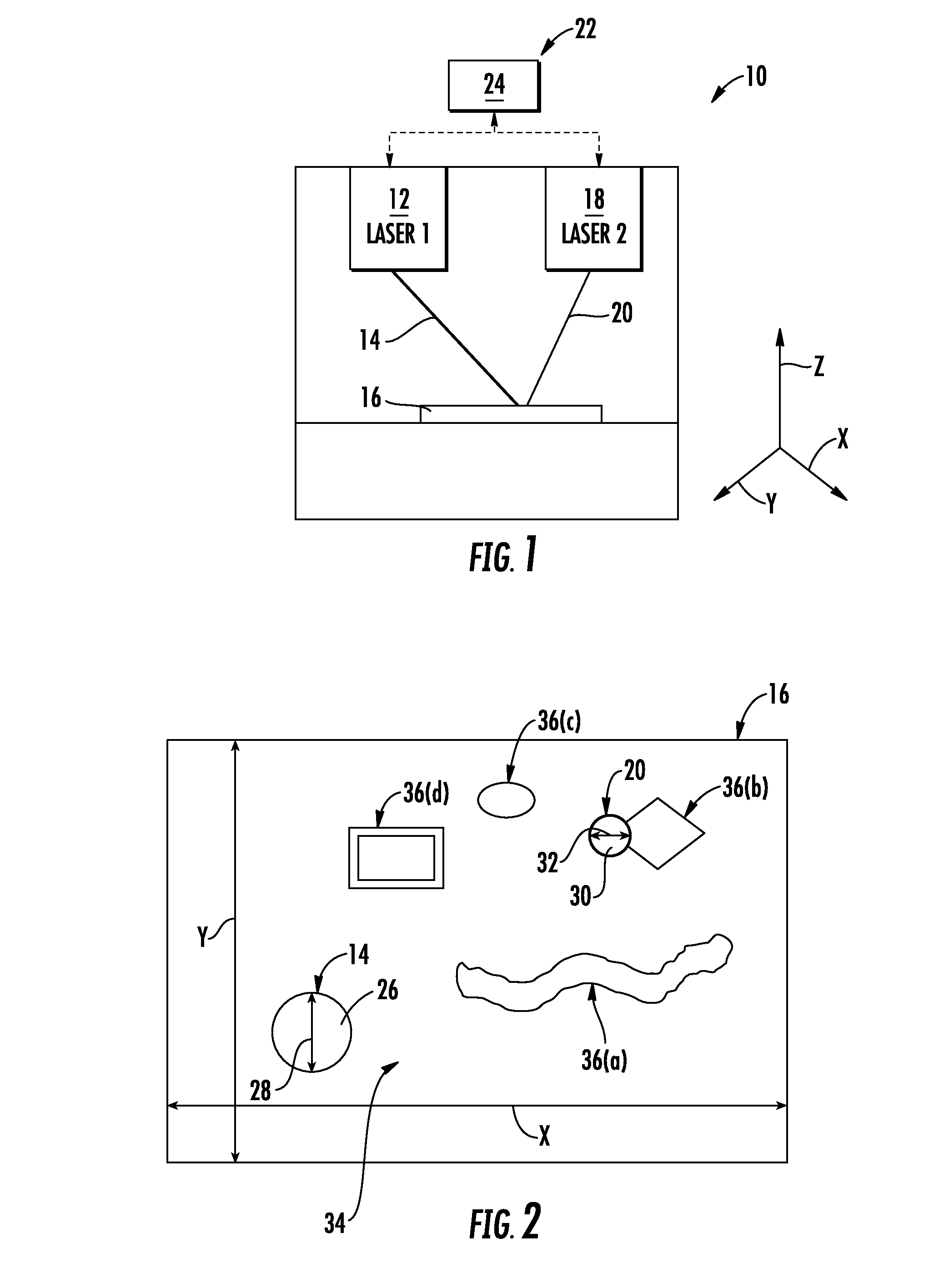

System and method for multi-laser additive manufacturing

InactiveUS20160318129A1Additive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser additive manufacturing

A system and method for additive manufacturing an object using multiple lasers is disclosed herein. The system includes a first laser generating a first focused laser beam having a first surface area where the first focused laser beam is directed onto a first quantity of a powder material on a substrate so as to fuse particles of the powder material in a first layer of the substrate. A second laser generating a second focused laser beam having a second surface area where the second laser beam is directed onto a second quantity of the powder material on the substrate so as to fuse particles of the powder material in the first layer of the substrate. The first surface area of the first focused laser beam is greater than the second surface area of the second focused laser beam.

Owner:GENERAL ELECTRIC CO

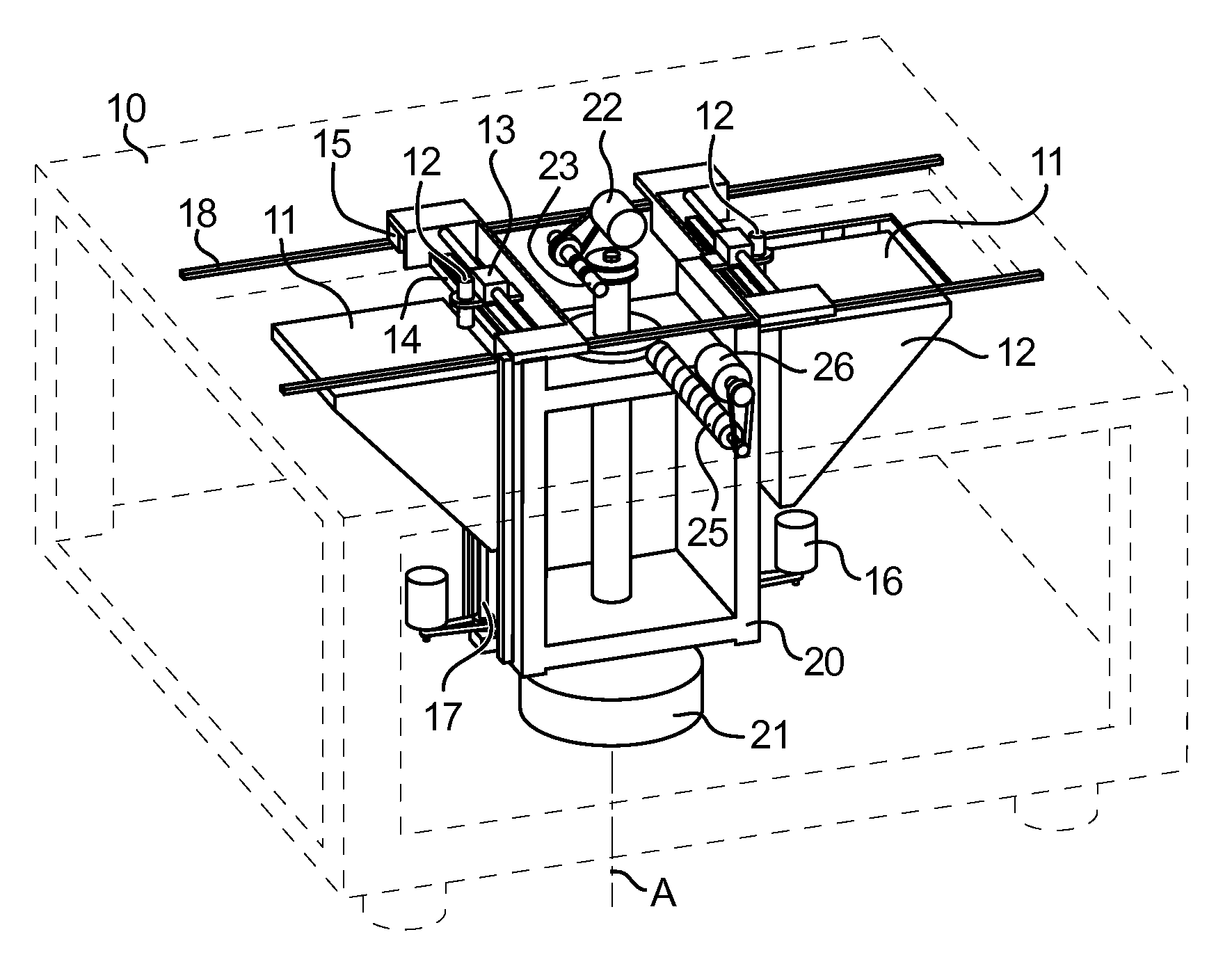

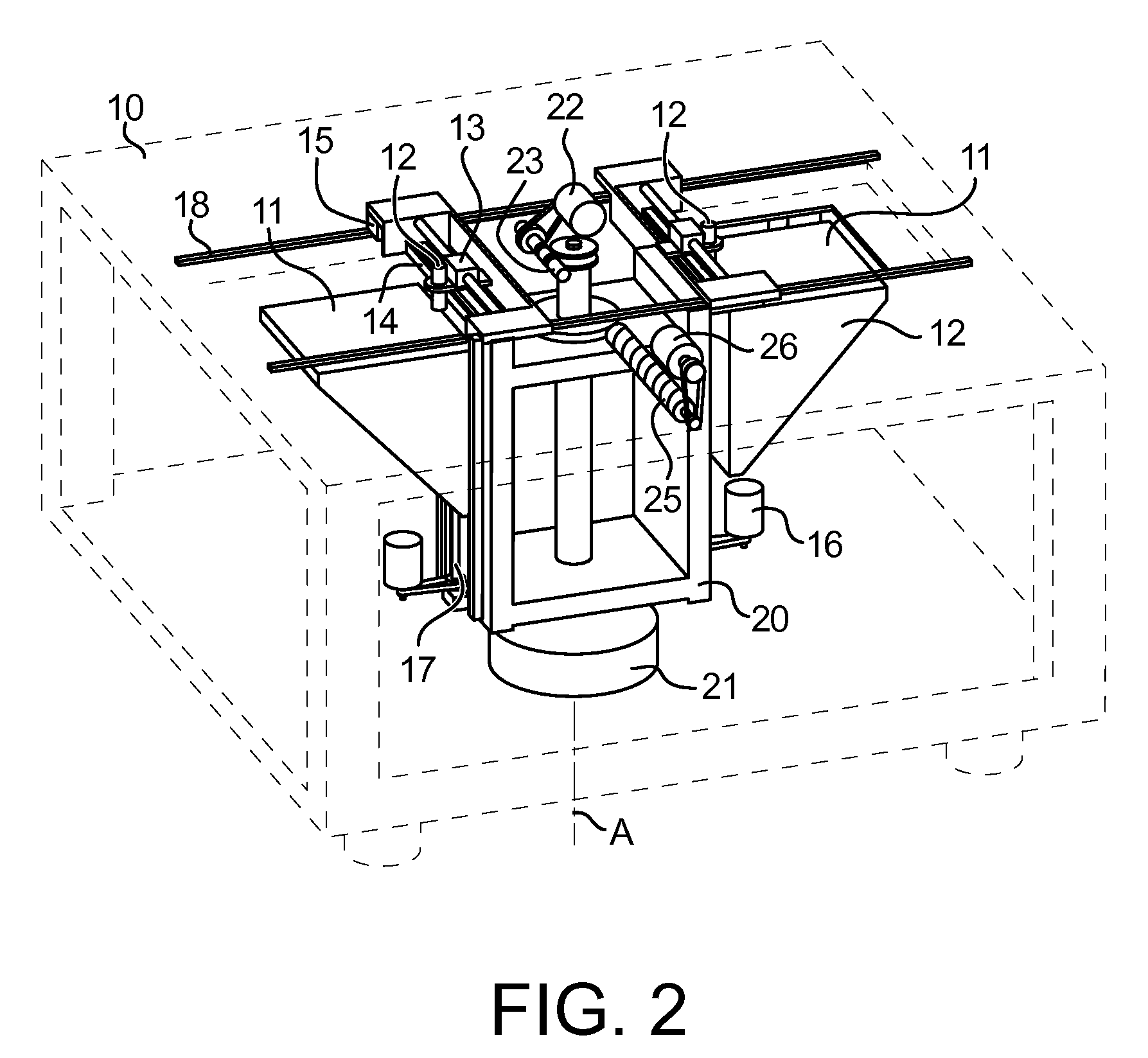

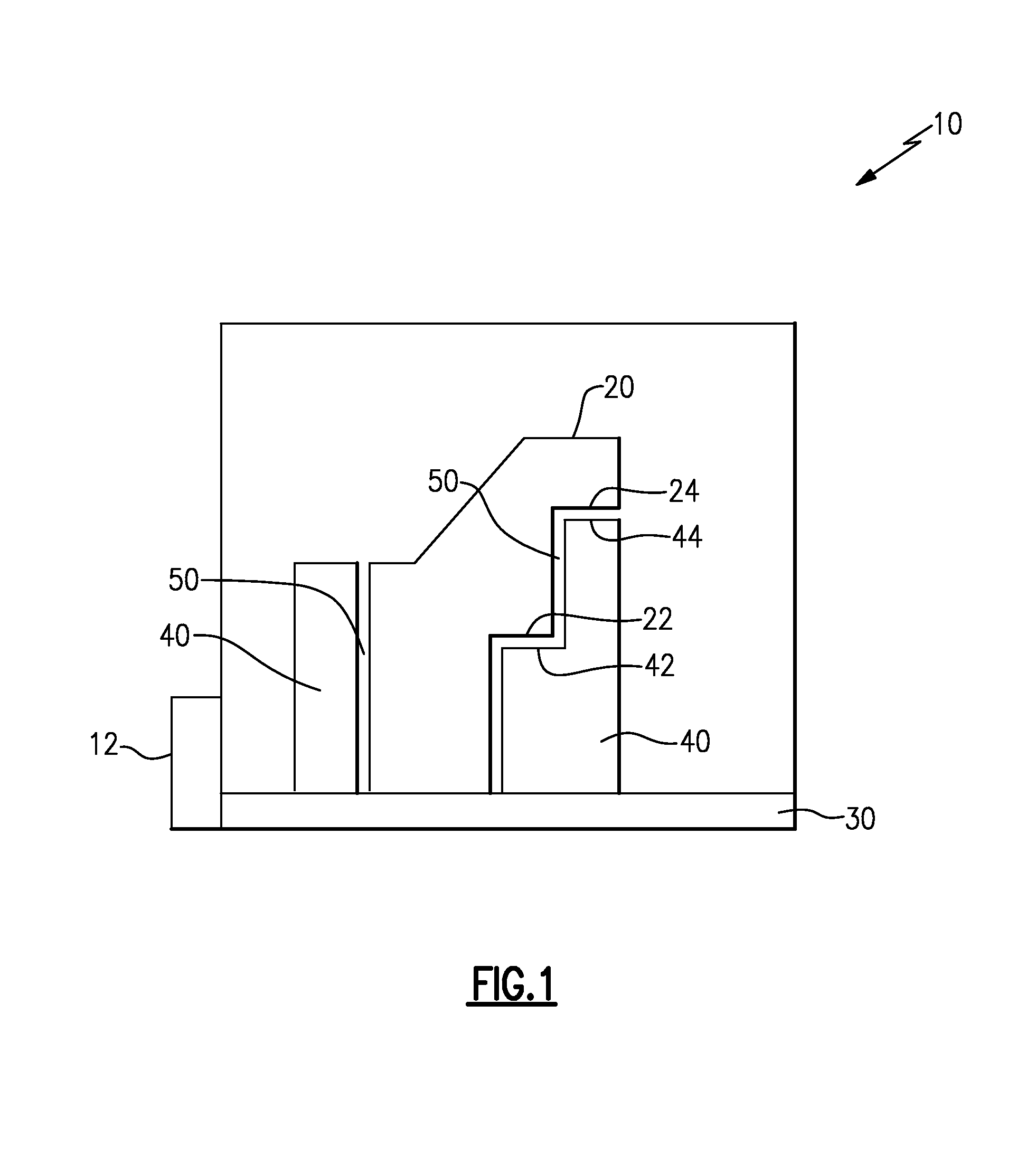

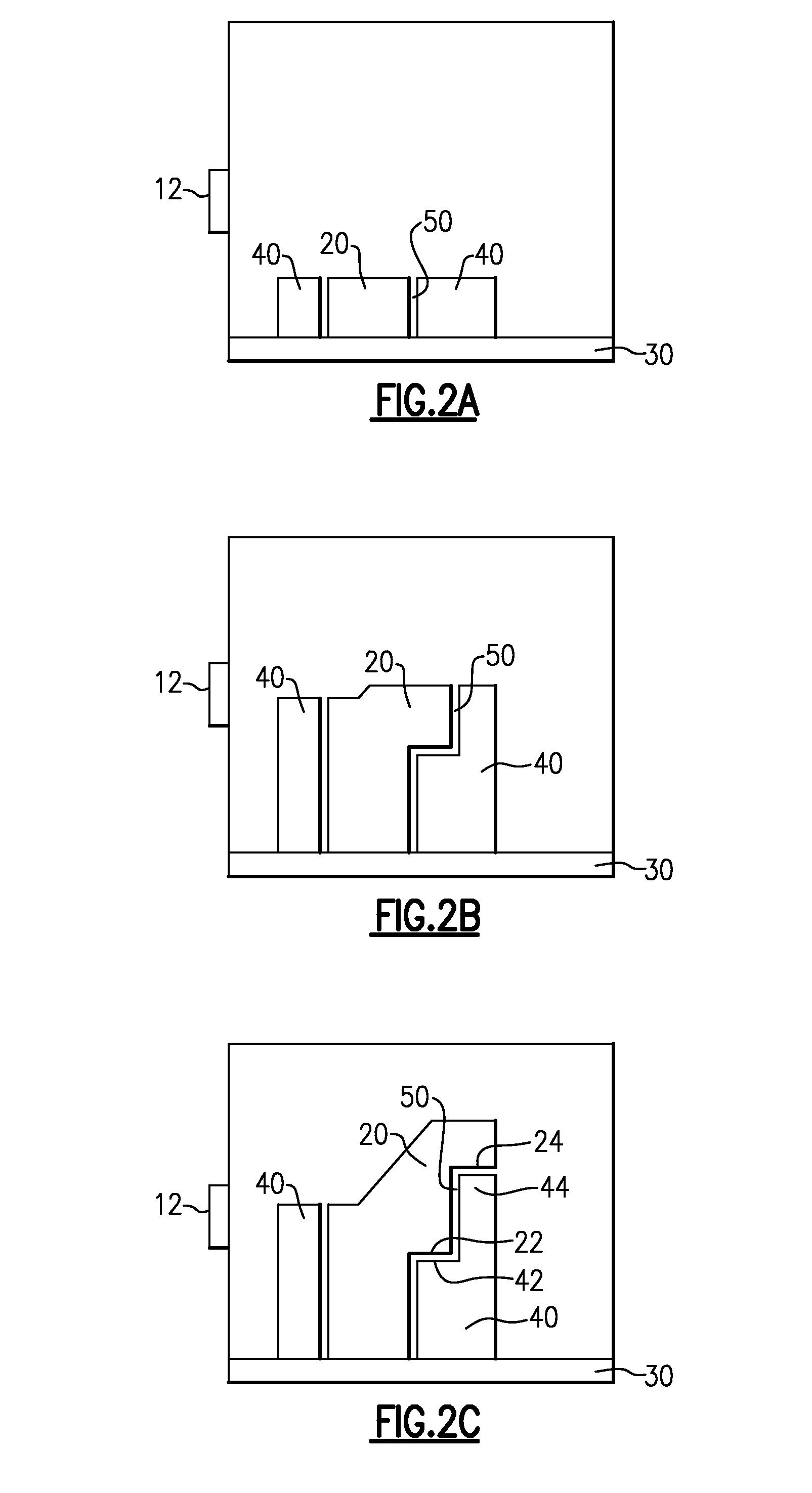

Method and machine for producing three-dimensional objects by means of successive layer deposition

Inventive machine allowing the simultaneous fabrication of several objects by a method of “rapid prototyping” type, by depositing a succession of layers of heat-fusible fluid.It chiefly comprises a crossbar (20) carrying two platforms (11) on each of which an object is fabricated by deposition. Two fixed work stations are arranged diametrically opposite each other so that the jet (12) of each of these fixed stations can perform a depositing operation at the same time as the other jet (12). After each deposit, the crossbar is rotated 180° to alternate the depositing operations of the two different materials.Particular application to prototyping jewellery models.

Owner:MARSAC NICOLAS

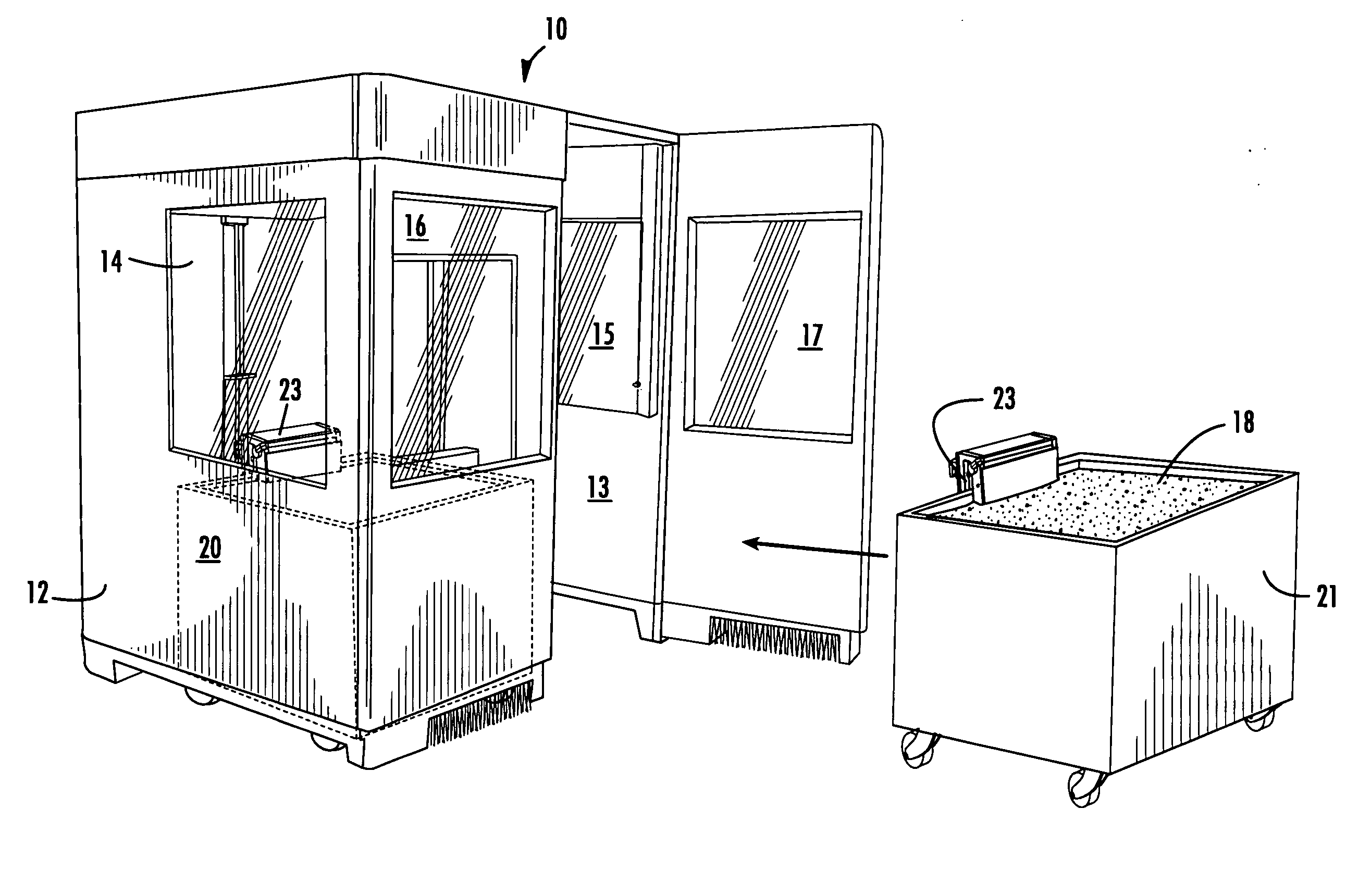

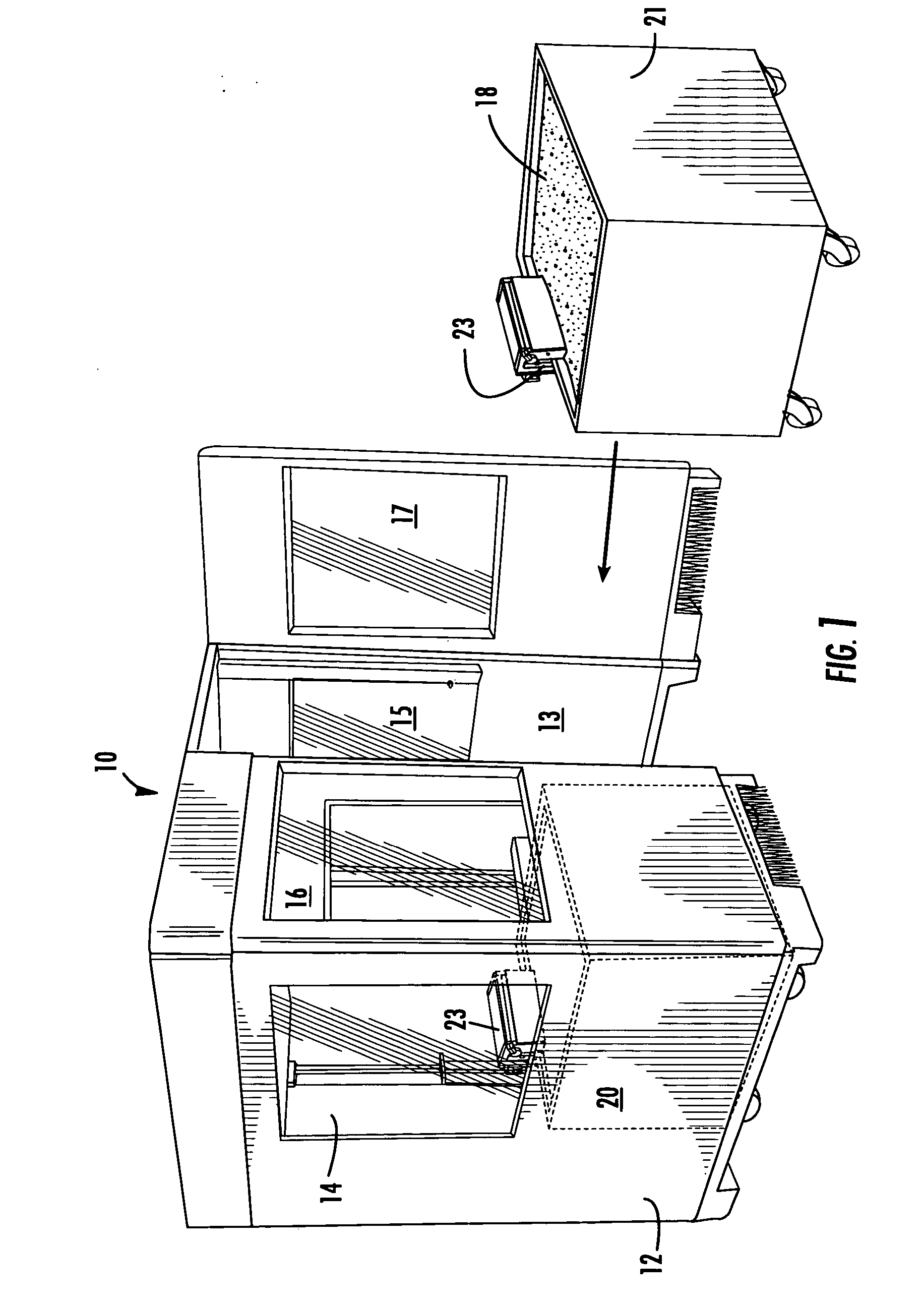

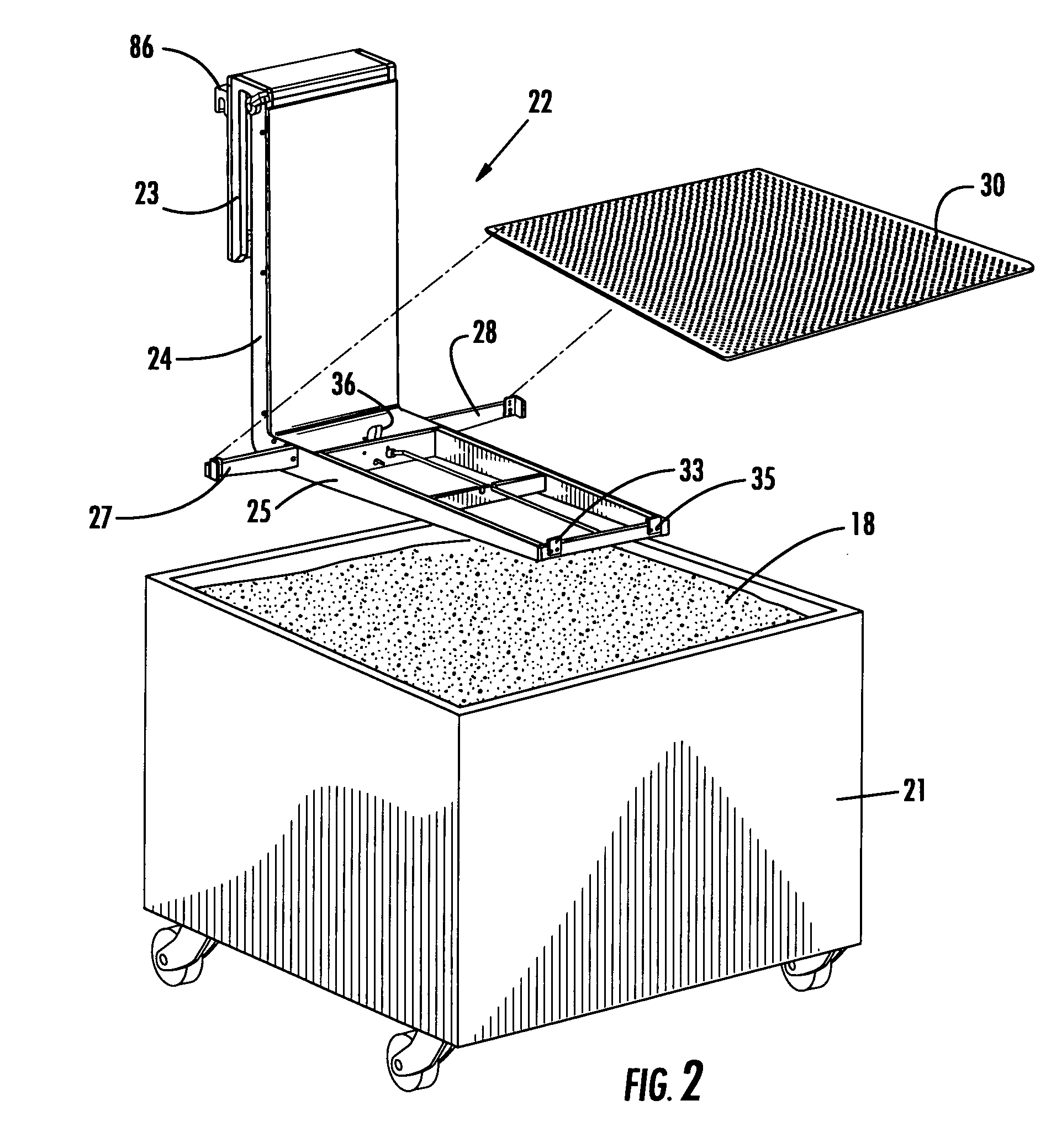

Rapid prototyping and manufacturing system and method

ActiveUS20070075459A1Simplify obtaining precisionFast preparationAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

Rapid prototyping and manufacturing system and method

ActiveUS20070075458A1Fast preparationAvoid pollutionAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

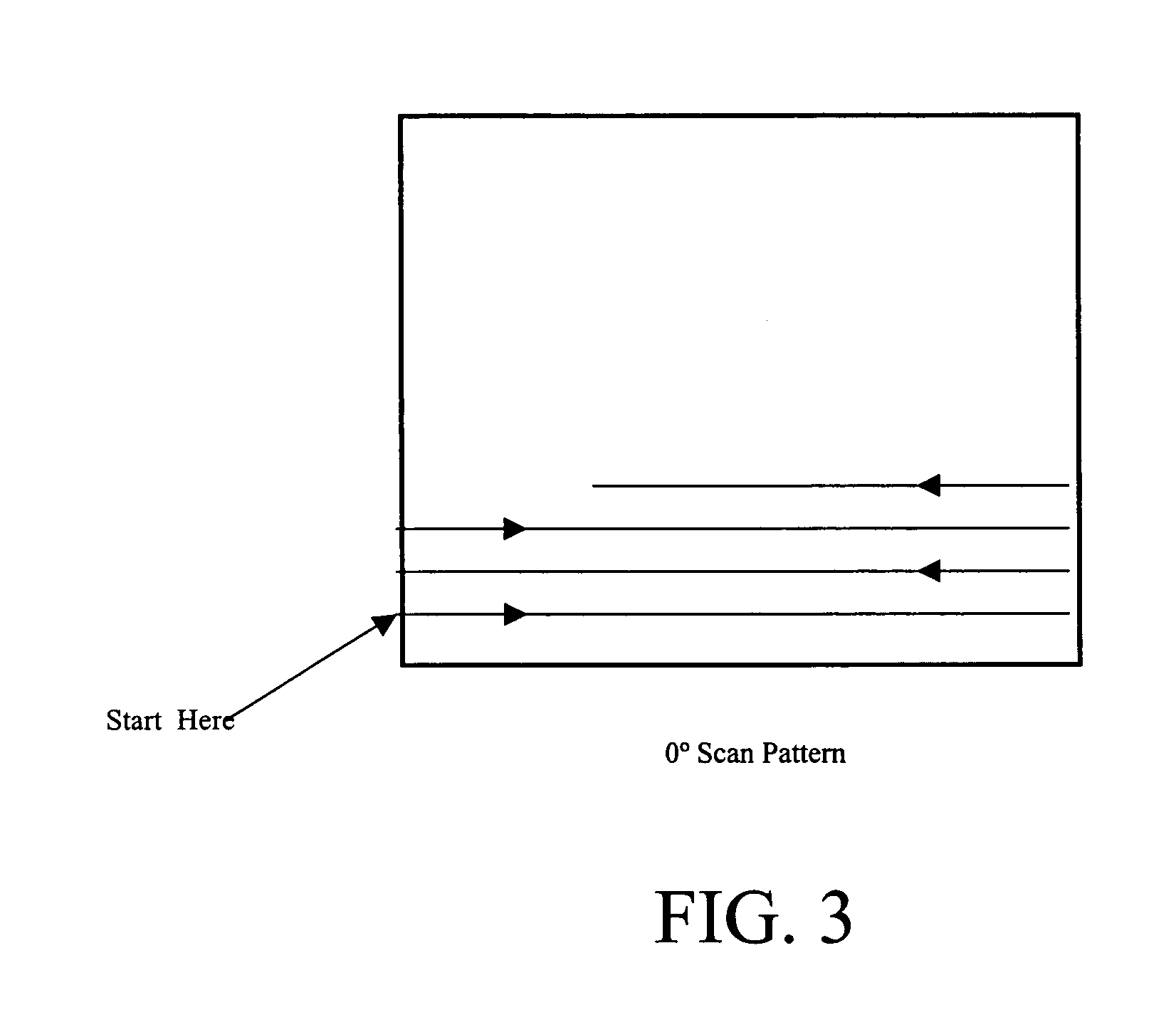

Uniform thermal distribution imaging

InactiveUS20050242473A1Uniform physical propertiesSimple technologyAuxillary shaping apparatusCoatingsImproved methodMaterials science

A method of obtaining uniform thermal distribution imaging in a thermally initiated and thermally based laser sintering process whereby a three-dimensional object is formed layer-by-layer in which the scanning sequences in successive layers is varied to more uniformly control the build up of heat within a three-dimensional object being formed. An improved method of image scanning multiple parts in a single build process is also employed.

Owner:3D SYST INC

Selective laser solidification apparatus and method

ActiveUS20140271965A1Uniform heightAdditive manufacturing apparatusAuxillary shaping apparatusLaser scanningLaser beams

A selective laser solidification apparatus including: a powder bed onto which a powder layer can be deposited, a gas flow unit for passing a flow of gas over the powder bed along a gas flow direction, a laser scanning unit for scanning a laser beam over the powder layer to selectively solidify at least part of the powder layer to form at least one object and a processing unit for selecting a scanning sequence of the laser beam based on the gas flow direction.

Owner:RENISHAW PLC

Rapid prototyping and manufacturing system and method

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

Additive fabrication technologies for creating molds for die components

InactiveUS20130220570A1Additive manufacturing apparatusFoundry mouldsStamping processAdditive layer manufacturing

Owner:FORD MOTOR CO

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

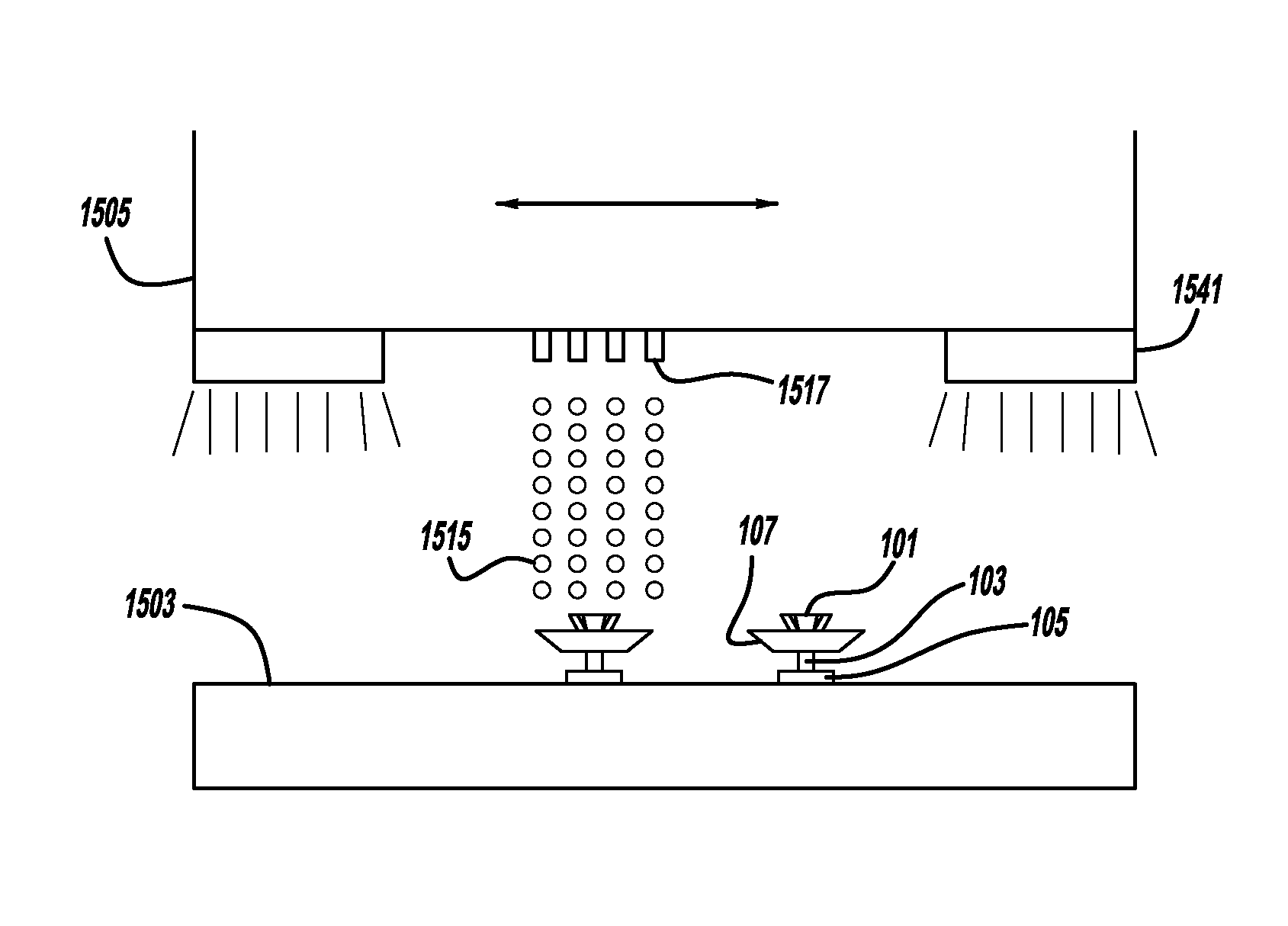

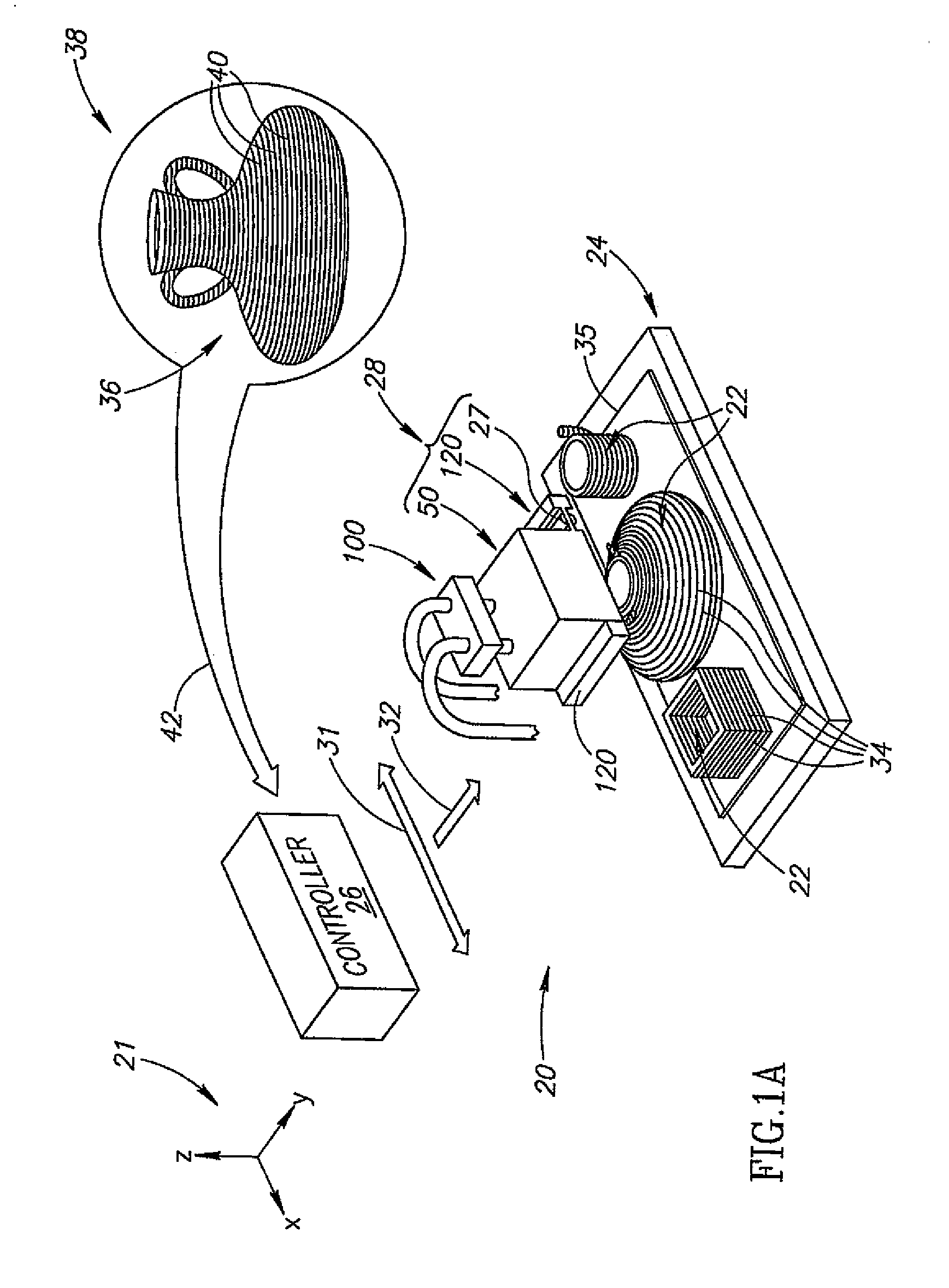

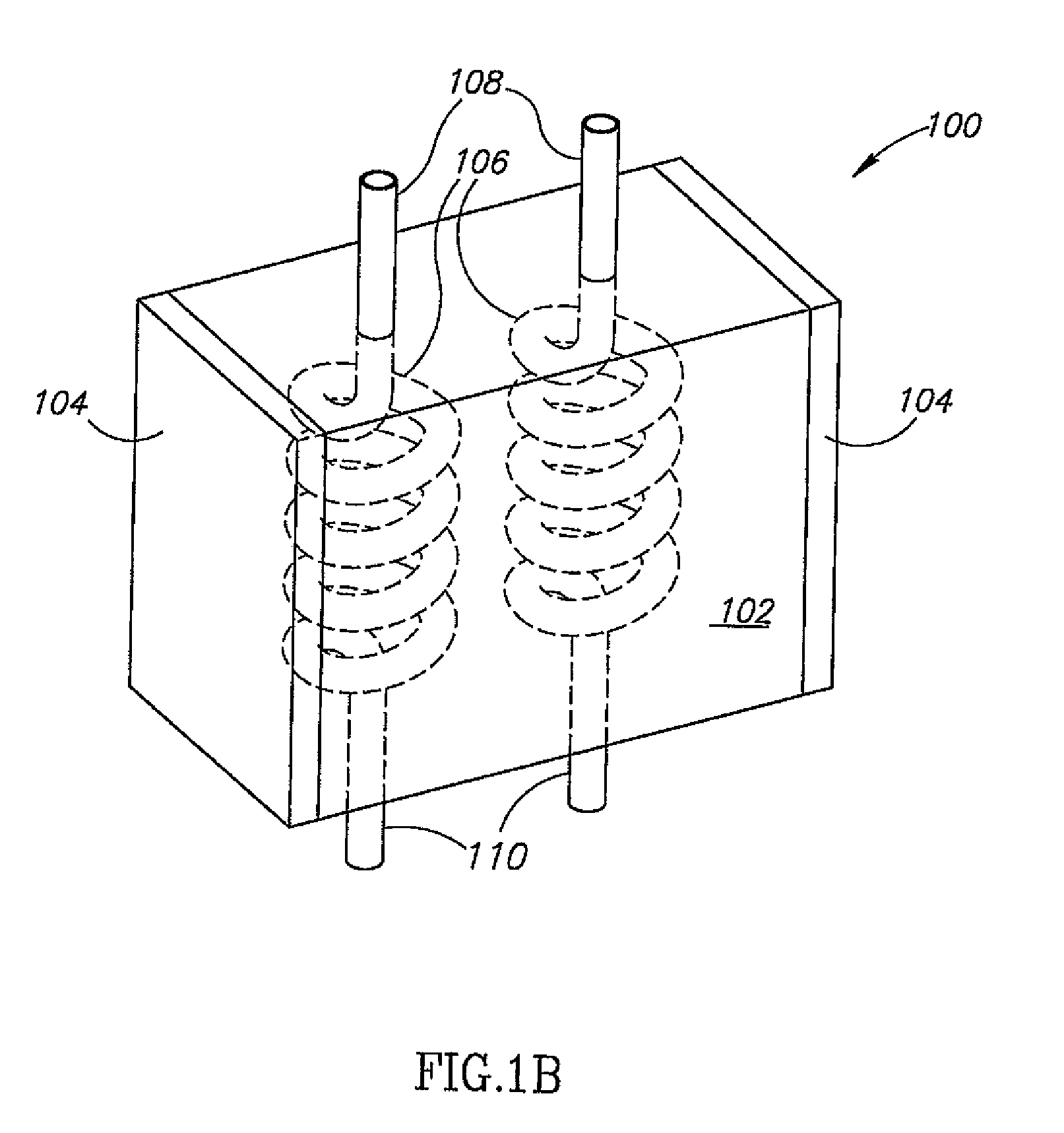

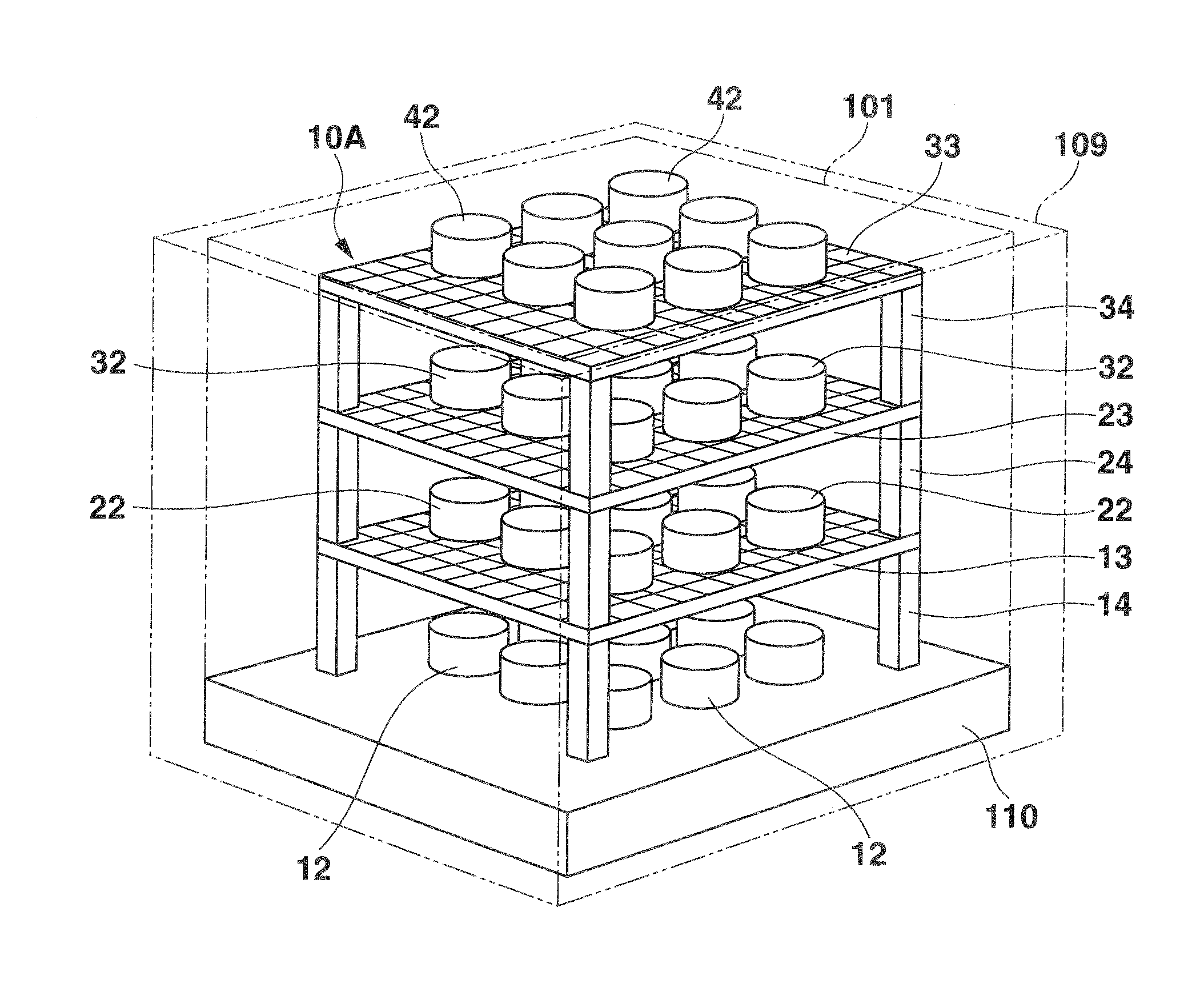

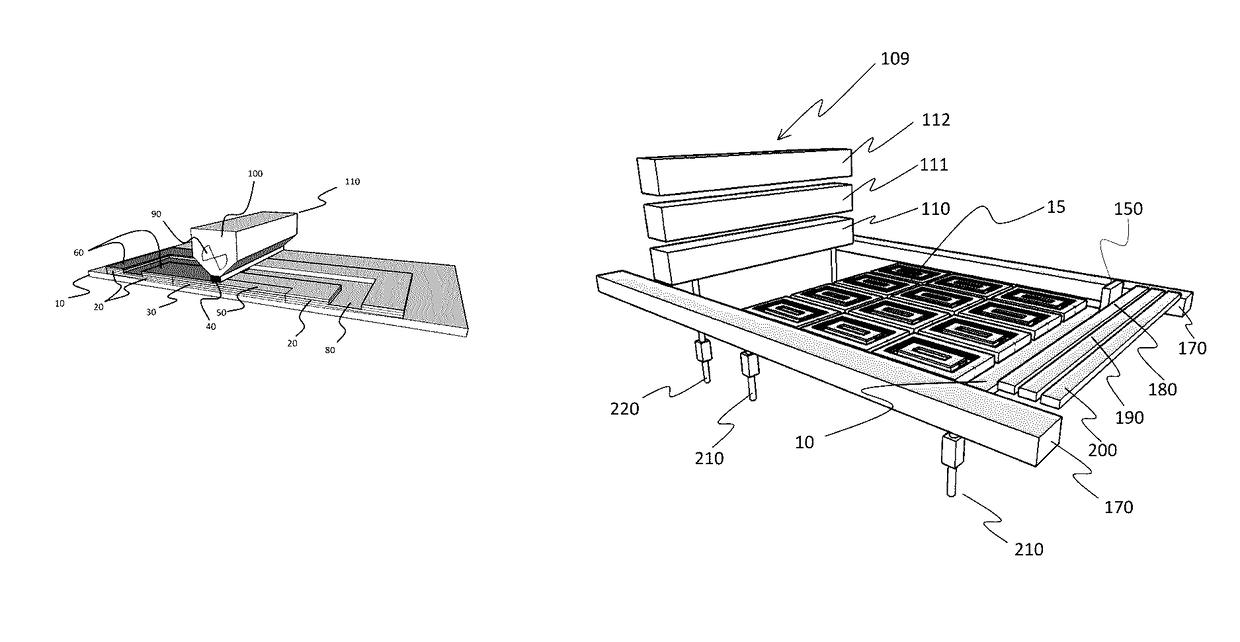

Fabrication of 3D objects via multiple build platforms

ActiveUS20160200084A1Shorten cycle timeImprove productivityMechanical working/deformationManufacturing driving meansProduction rateMultiple platform

A method is disclosed for improving the productivity of digitally fabricated 3D objects with the same or different shape and material composition. The improved productivity is enabled by the incorporation of multiple build platforms and multiple objects per build platform within a 3D object fabrication apparatus. Some 3D manufacturing processes such as those based on electrophotography require a wait time to condition the build object before the next layer of build and support material can be applied. Under these fabrication conditions, the utilization of multiple build platforms in the 3D object manufacturing process effectively minimizes the wait time between layer deposition so that the productivity for fabricating 3D objects is improved. Furthermore, the incorporation of an additional adjacent set of multiple platforms enables rapid changeover when the fabrication of one set of 3D objects is completed on an adjacent set of build platforms.

Owner:XACTIV

Rapid production apparatus

ActiveUS20100217429A1Easy temperature controlEasy to controlComputer controlSimulator controlLayer wiseBuilding material

A method of producing an object by sequentially printing layers of construction material one on top of the other, the method comprising: providing the construction material at a first lower temperature; flowing the construction material through a heated flow path in a flow structure to heat the construction material and delivering the heated construction material to a heated reservoir in a printing head; and dispensing the heated construction material from the reservoir to build the object layer by layer.

Owner:OBJET

Method and system for providing thermal support in an additive manufacturing process

ActiveUS20160221264A1Additive manufacturing apparatusIncreasing energy efficiencyEngineeringAdditive layer manufacturing

An additive manufacturing process includes simultaneously constructing a component and a non-contacting thermal support for the component. The non-contacting thermal support includes a three dimensional negative of the component. The non-contacting thermal support transfers heat from the component into a heat sink.

Owner:RAYTHEON TECH CORP

Rapid prototyping and manufacturing system and method

ActiveUS7690909B2Fast preparationAvoid pollutionConfectioneryPretreated surfacesEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

Three-dimensional shaping method and shaped object complex as well as three-dimensional shaping apparatus

A three-dimensional shaping method includes forming a combination to be each level of a three-dimensional shaped object and also forming a combination to be each level of a shaped object support member in each of a plurality of powder material layers having an uncured powder material in accordance with hierarchical shape data corresponding to each of the powder material layers.

Owner:CASIO COMPUTER CO LTD

Apparatus for avoiding deposits on optical components in the laser sintering process

ActiveUS20130101803A1Avoid condensationAvoid depositionManufacturing platforms/substratesLayered productsLaserSintering

The present invention provides a process and an apparatus for the layer-by-layer production of three-dimensional objects, wherein material vapours formed during processing in the construction chamber are prevented from deposition on apparatus components by exposing the gases to deposition surfaces where the materials condense and deposit.

Owner:EVONIK OPERATIONS GMBH

Process for melting/sintering powder particles for the layer-by-layer production of three-dimensional objects

ActiveUS20130216836A1Shorten the timeWithout reduction in qualityAdditive manufacturing apparatusLayered productsElectromagnetic radiationMaterials science

A process for melting / sintering powder particles for layer-by-layer production of three-dimensional objects wherein a layer of powder particles is irradiated by a nonlinear path of an electromagnetic radiation is provided. Also provided are an apparatus to conduct the process and three dimensional objects obtained by the process.

Owner:EVONIK OPERATIONS GMBH

Reactive materials systems and methods for solid freeform fabrication of three-dimensional objects

Systems and methods which utilize a plurality of reactive build compositions differing from one another in at least one material property and which may be applied, individually and / or in combination, layer upon layer to form solid three-dimensional objects having regions which vary in the at least one material property are provided. Further provided are systems and methods which utilize a plurality of reactive build compositions differing from one another in at least one material property and which may be applied, individually and / or in combination, layer upon layer to form a plurality of three-dimensional objects in a single solid freeform fabrication build, at least one object of the plurality of objects having a material property which differs from the same material property of at least one other object fabricated in the same build. Further provided are three-dimensional objects formed utilizing the disclosed systems and methods.

Owner:HEWLETT PACKARD DEV CO LP

Method and machine for producing three-dimensional objects by means of successive layer deposition

Inventive machine allowing the simultaneous fabrication of several objects by a method of “rapid prototyping” type, by depositing a succession of layers of heat-fusible fluid.It chiefly comprises a crossbar (20) carrying two platforms (11) on each of which an object is fabricated by deposition. Two fixed work stations are arranged diametrically opposite each other so that the jet (12) of each of these fixed stations can perform a depositing operation at the same time as the other jet (12). After each deposit, the crossbar is rotated 180° to alternate the depositing operations of the two different materials.Particular application to prototyping jewellery models.

Owner:MARSAC NICOLAS

Multi-material three dimensional printer

Owner:EOPLEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com