Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about "Electromagnet terminals/connectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

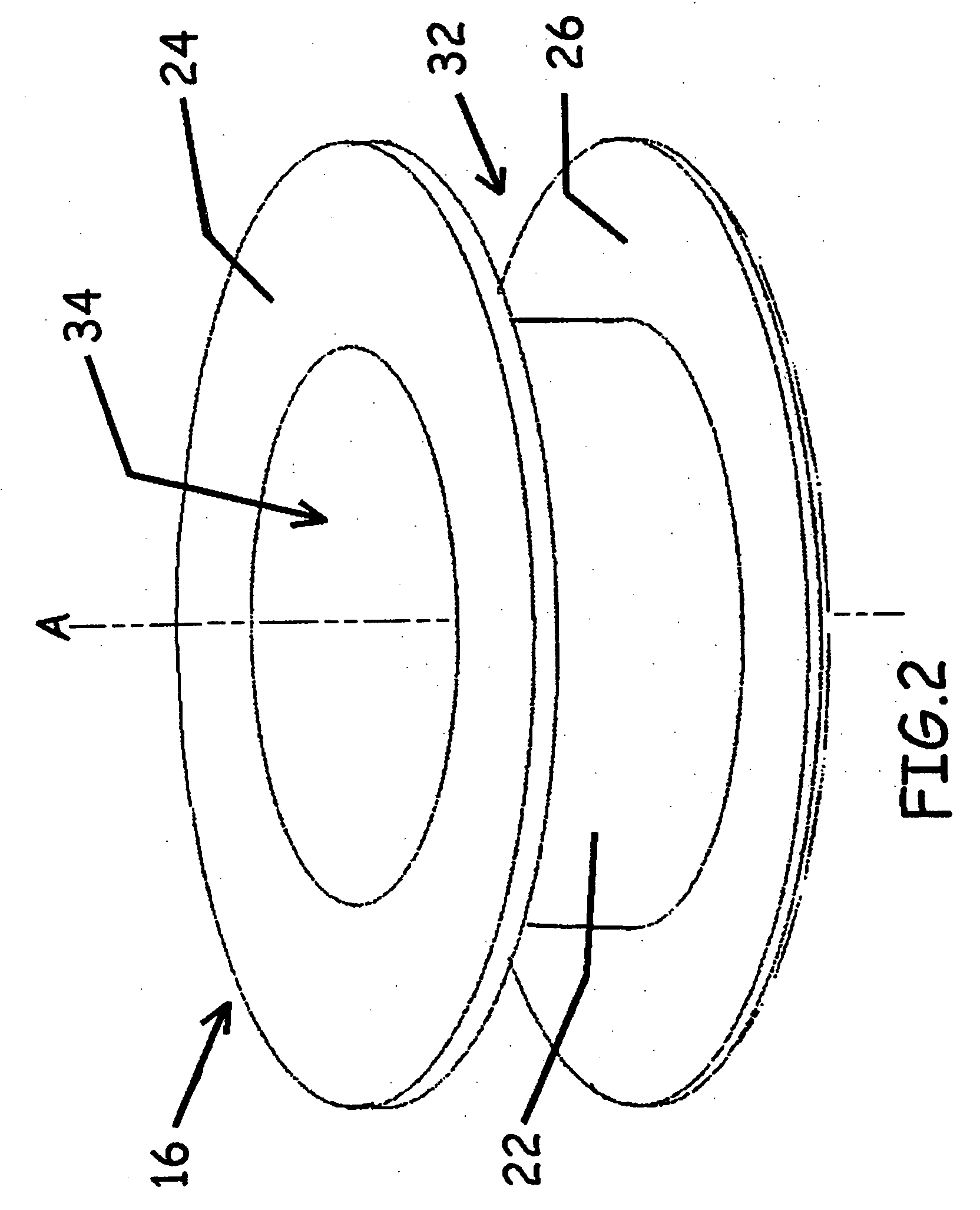

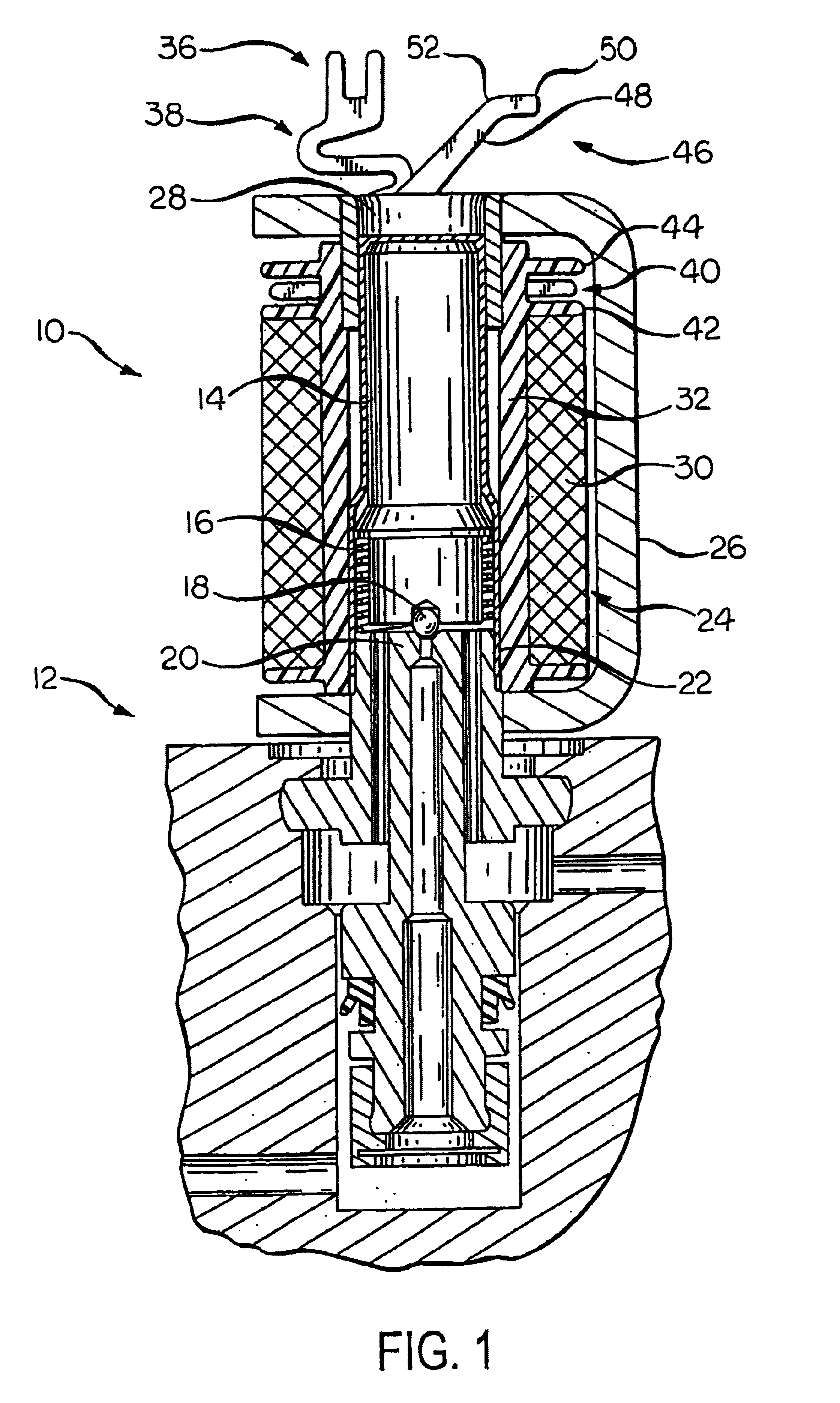

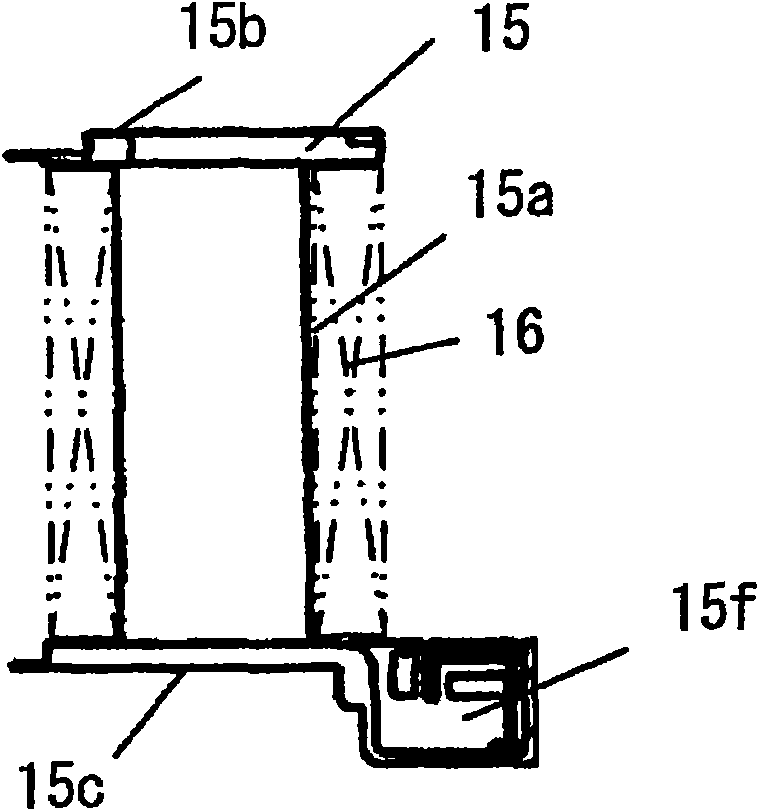

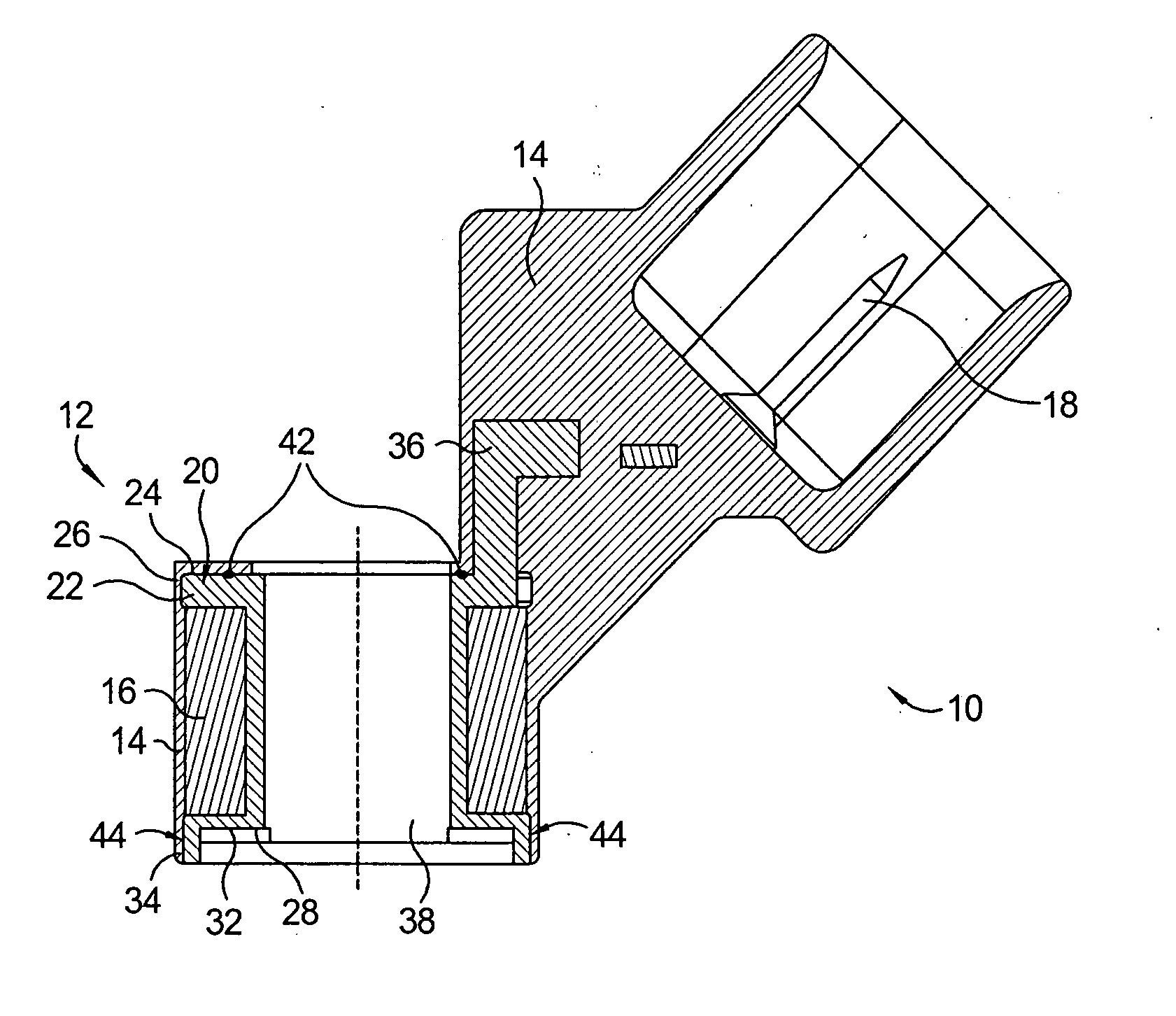

Electromagnetic coil assembly

InactiveUS20050225418A1Prevent exitTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinMagnet wire

An electromagnetic coil assembly is provided. The electromagnetic coil assembly includes a bobbin, a coil of magnet wire and a cover piece. The bobbin includes a hub, a first flange and a second flange. The hub has a longitudinal axis. The first and second flanges are spaced axially from each other. The hub and flanges together define a circumferential bobbin channel. The bobbin is made from a material that is an electrical insulator. The coil of magnet wire is positioned around the hub in the circumferential bobbin channel. The magnet wire has first and second ends. The cover piece is self-supporting and is sized to extend circumferentially around the coil of magnet wire. The cover piece is resilient and exerts a compressive force radially inwardly on the coil of magnet wire.

Owner:POLYMER TECH CORP

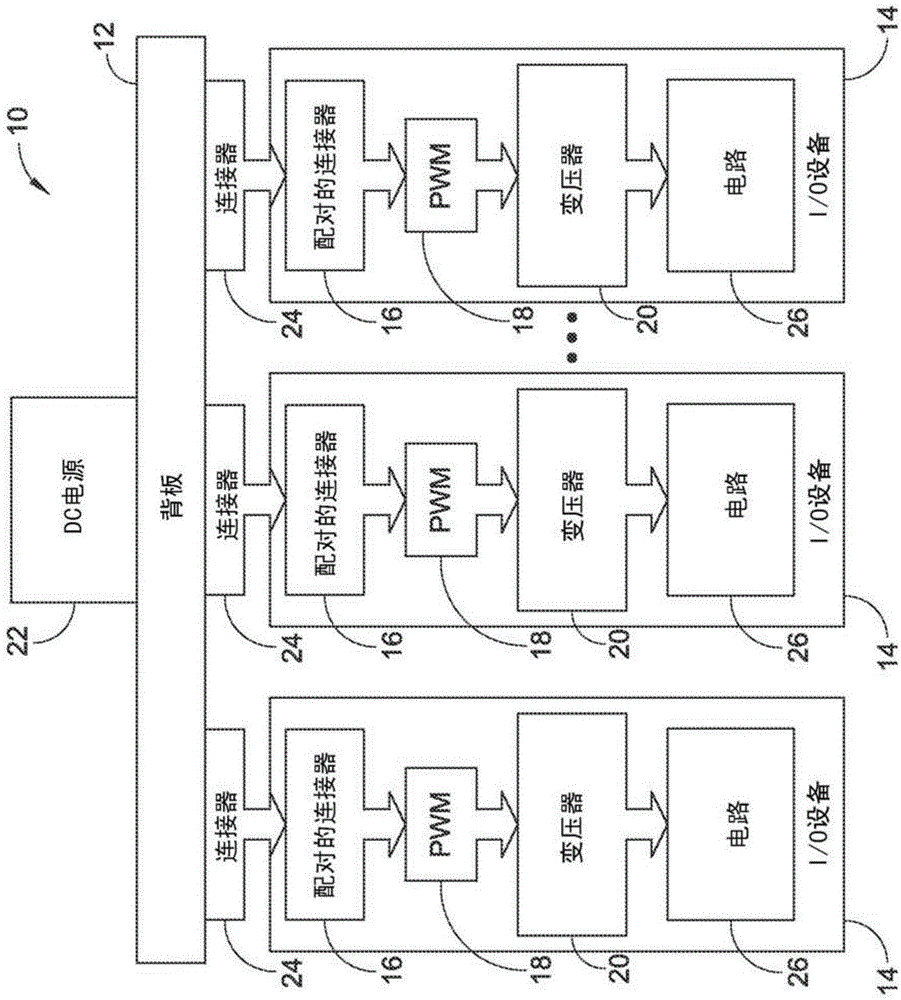

Electromagnetic connector and communications/control system/switch fabric with serial and parallel communications interfaces

ActiveCN104025387AEngagement/disengagement of coupling partsTransformers/reacts mounting/support/suspensionControl systemEngineering

An electromagnetic connector is disclosed that is configured to form a first magnetic circuit portion comprising a first core member and a first coil disposed of the first core member. The electromagnetic connector is configured to mate with a second electromagnetic connector. A communications control system / switch fabric is disclosed that includes a serial communications interface and a parallel communications interface (e.g., for coupling input / output modules with a control module). The serial communications interface is configured for connecting input / output modules / slave devices to a control module / master device in parallel, and the parallel communications interface is configured for separately connecting the input / output modules / slave devices to the control module / master device.

Owner:BEDROCK AUTOMATION PLATFORMS

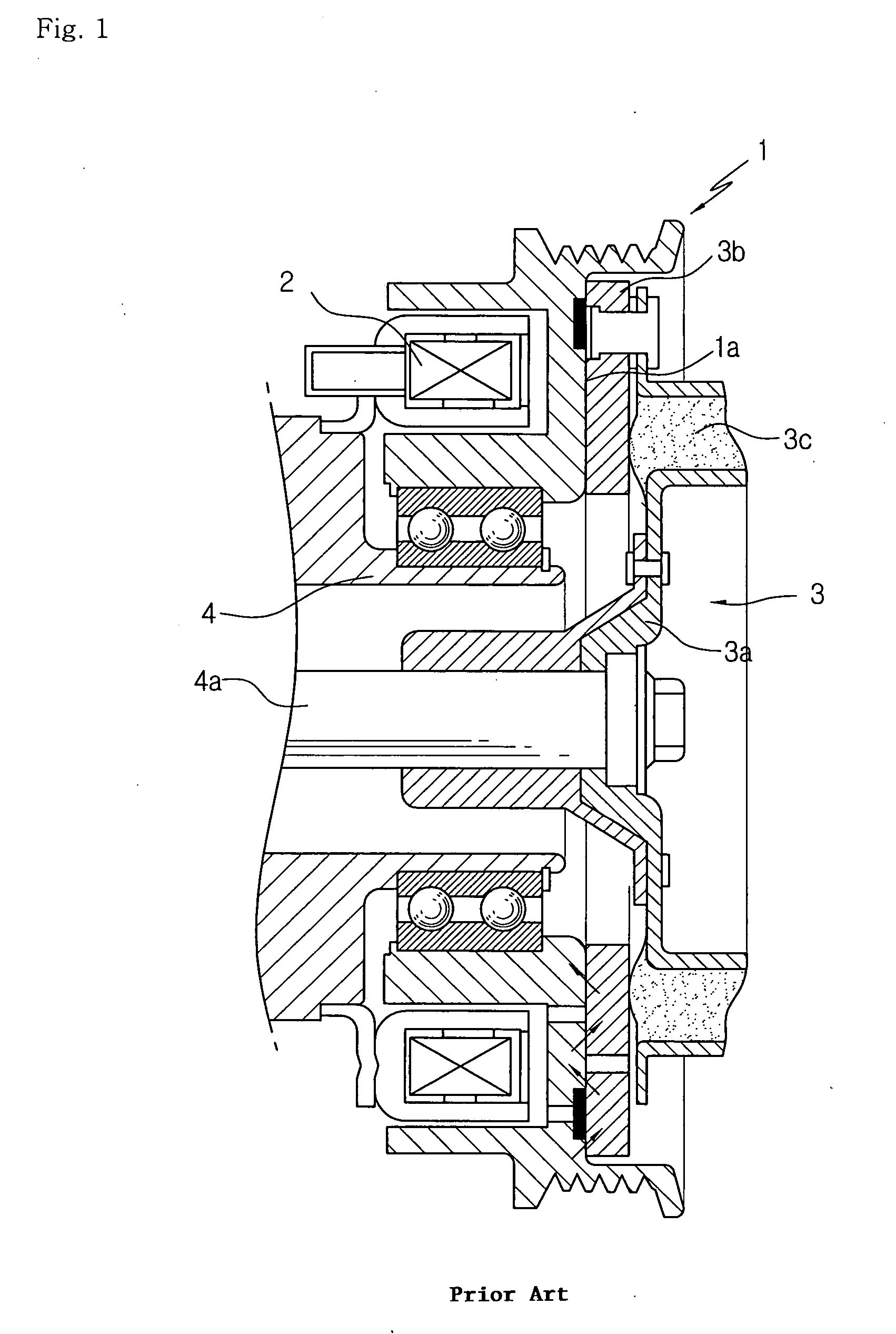

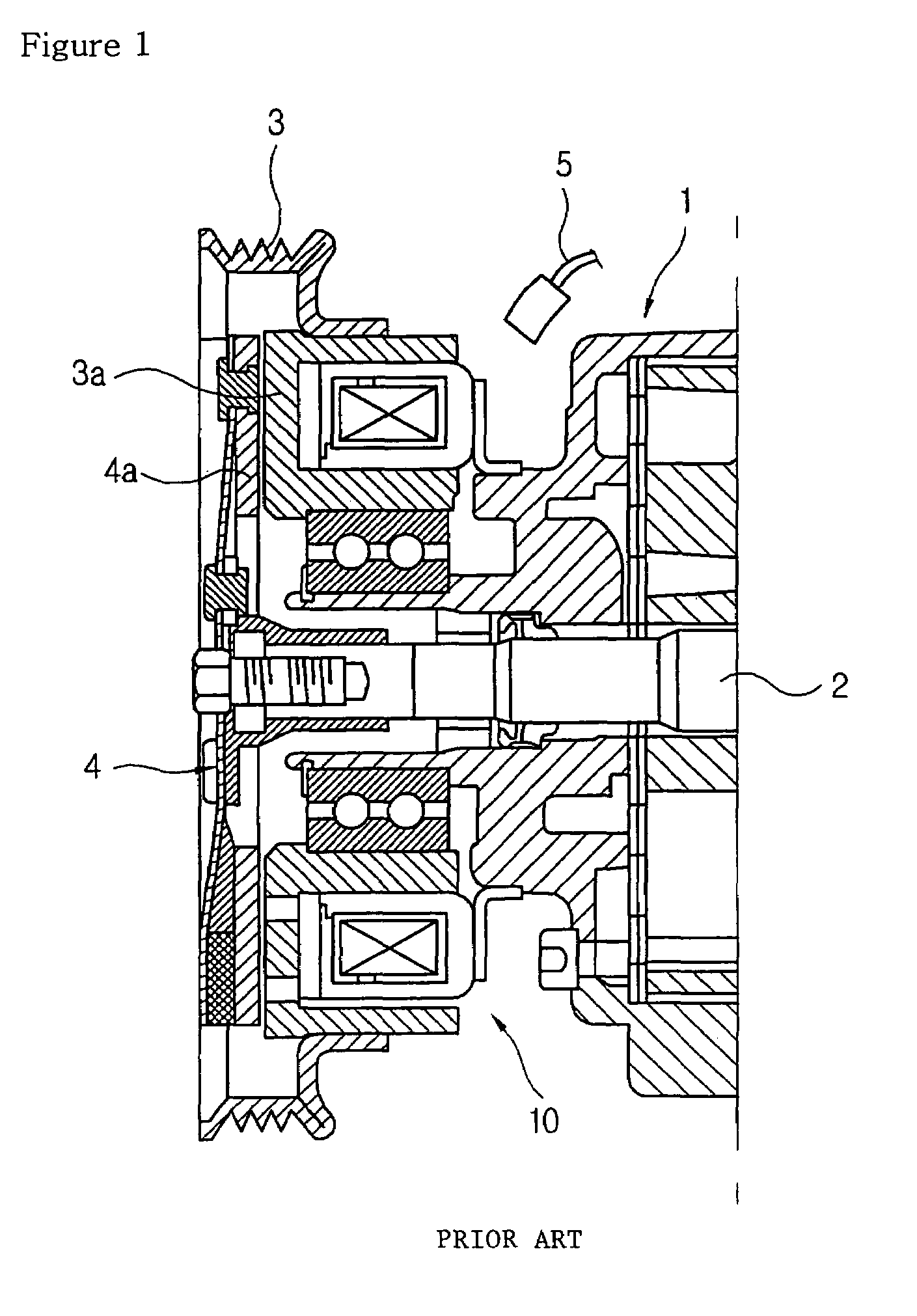

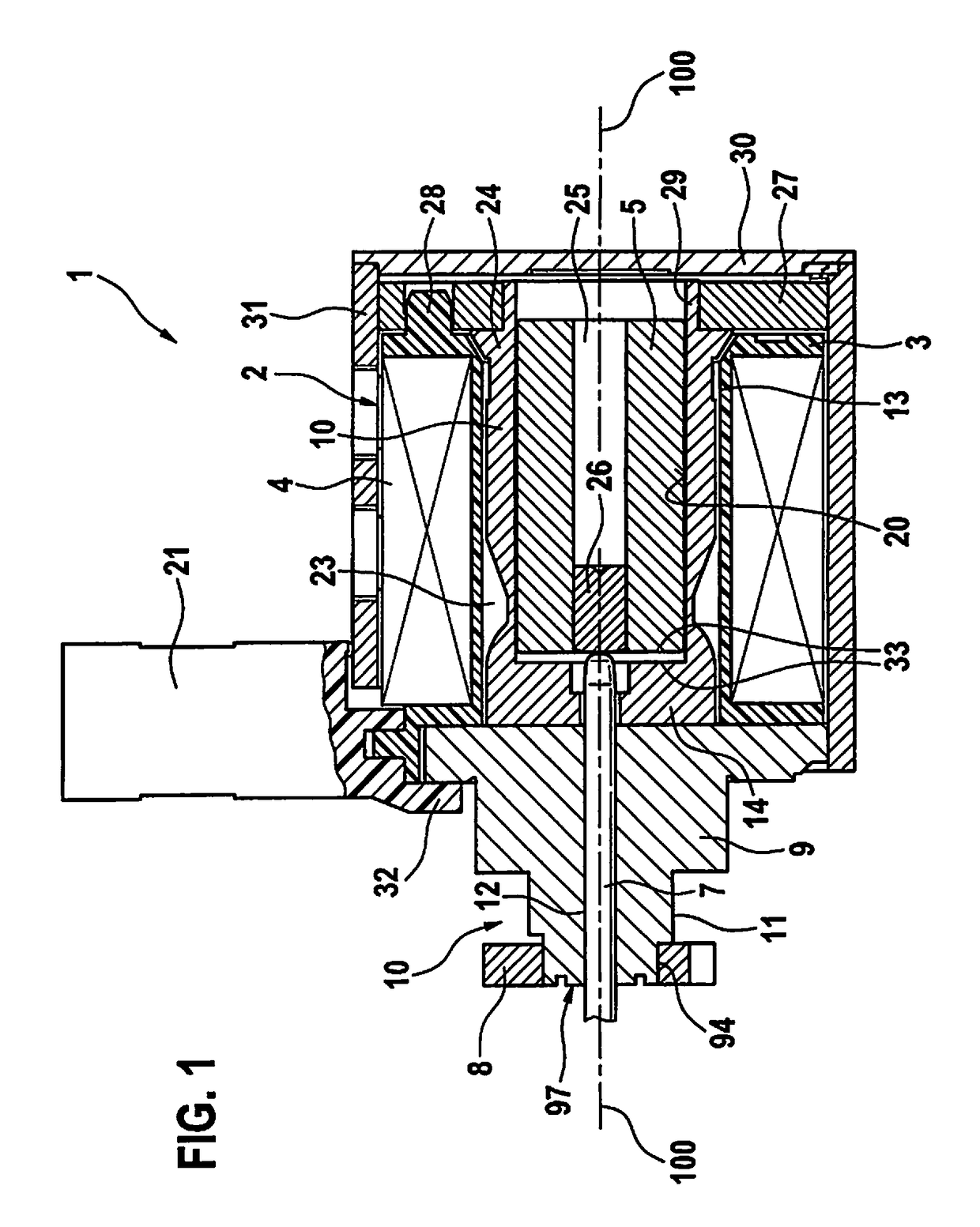

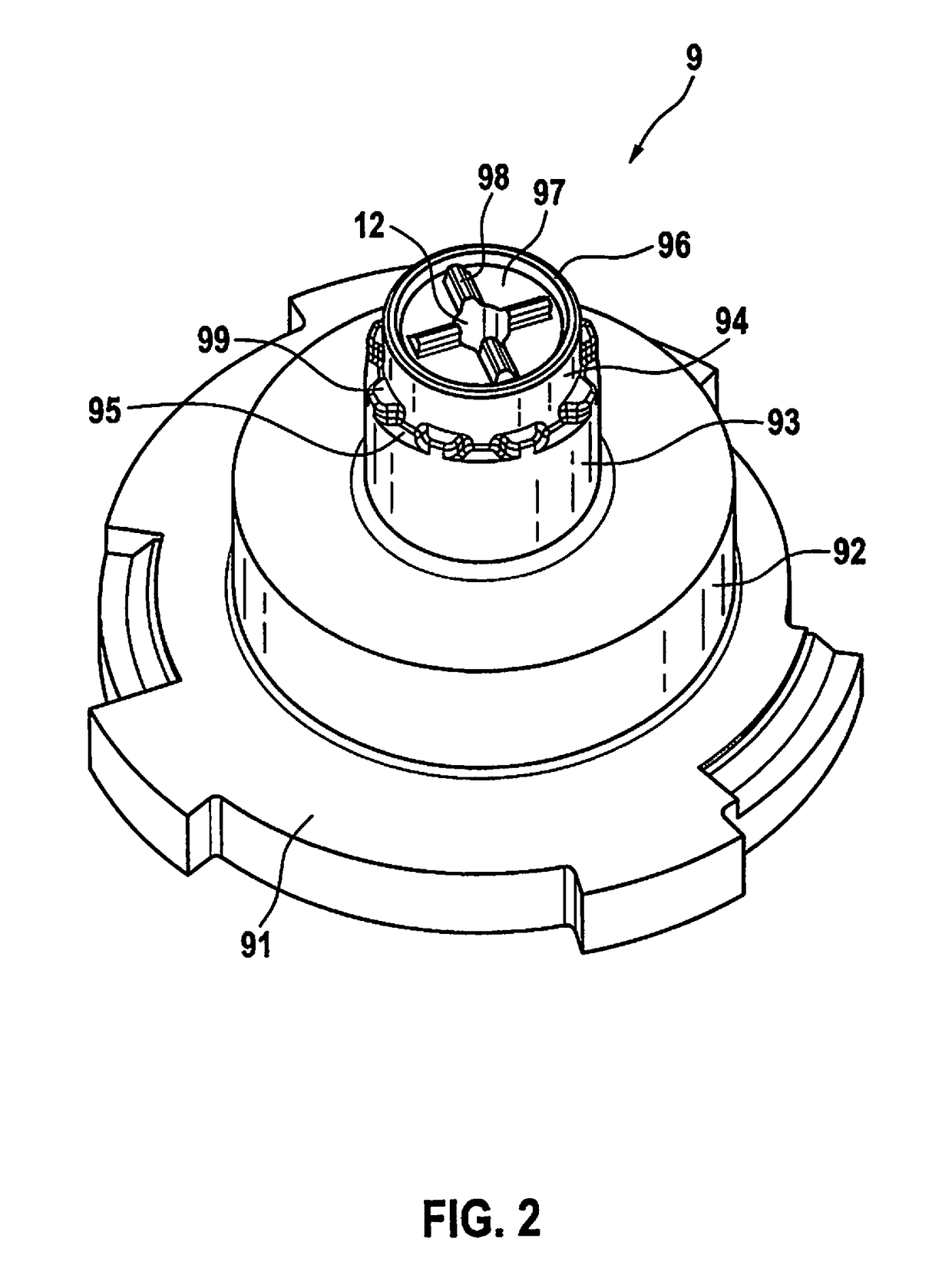

Control unit for vehicle brake system

A control unit having a circuit substrate mounted within a housing that is adapted to be mounted upon a hydraulic valve body with a coil spacer mounted upon said substrate. The coil spacer including at least one coil support ring having resilient member extending in a radial direction from the edge of the ring into the center of the ring. The control unit also including a solenoid coil and flux casing assembly mounted upon the coil spacer ring with the solenoid coil and flux casing assembly flexing the resilient member such that the resilient member urges flux casing away from the coil spacer.

Owner:KELSEY HAYES CO

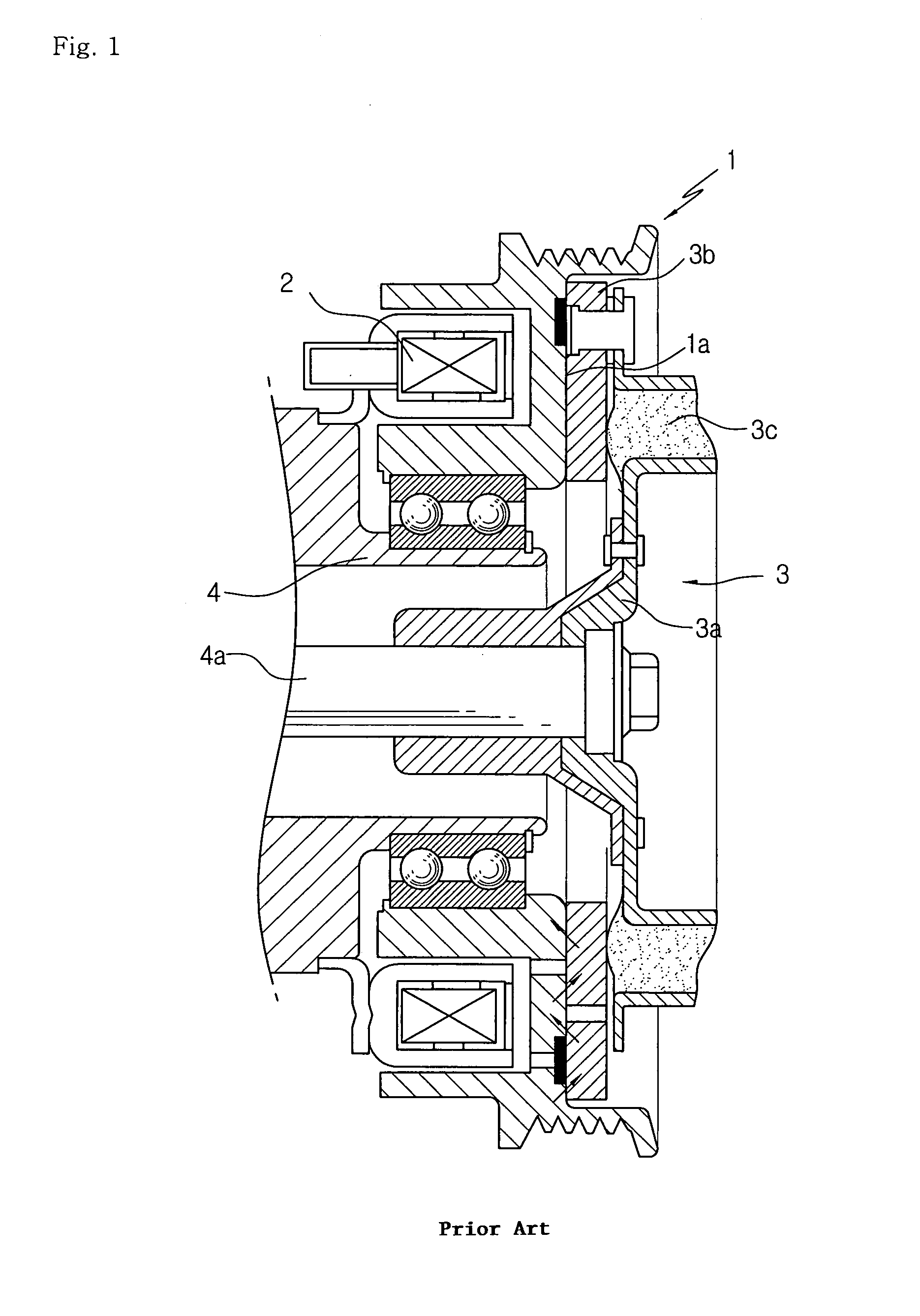

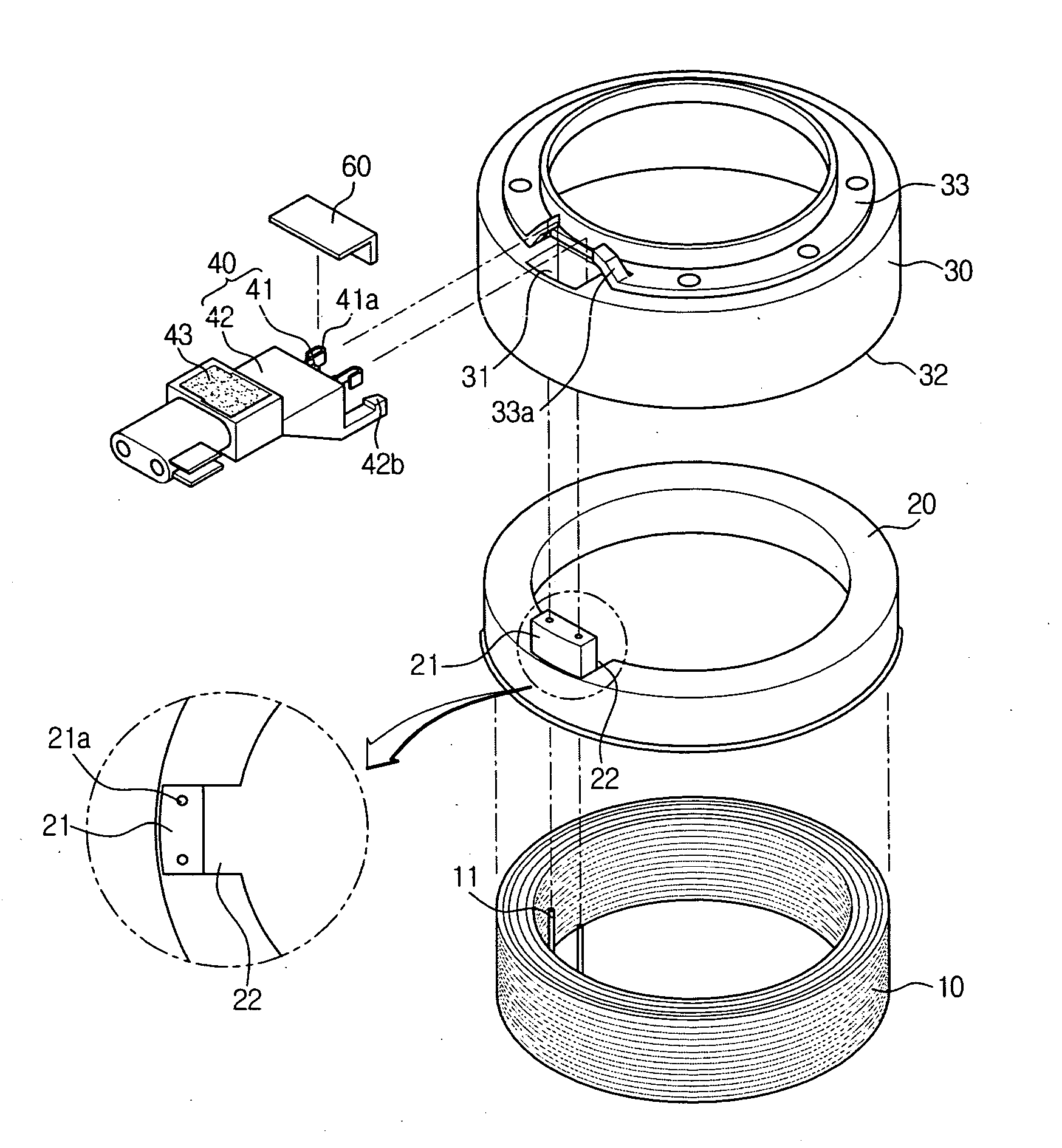

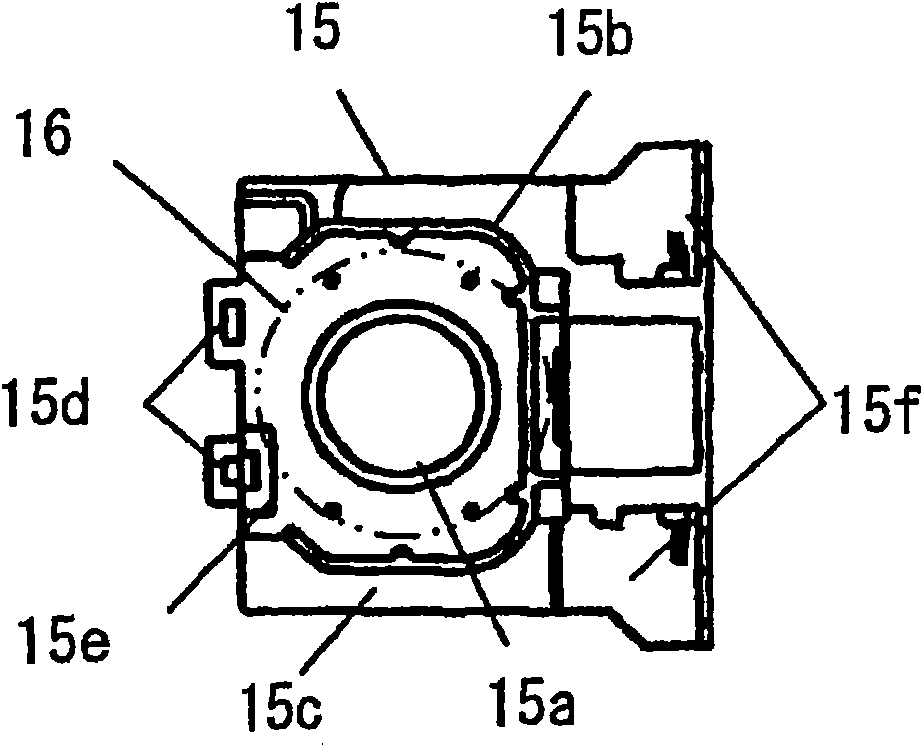

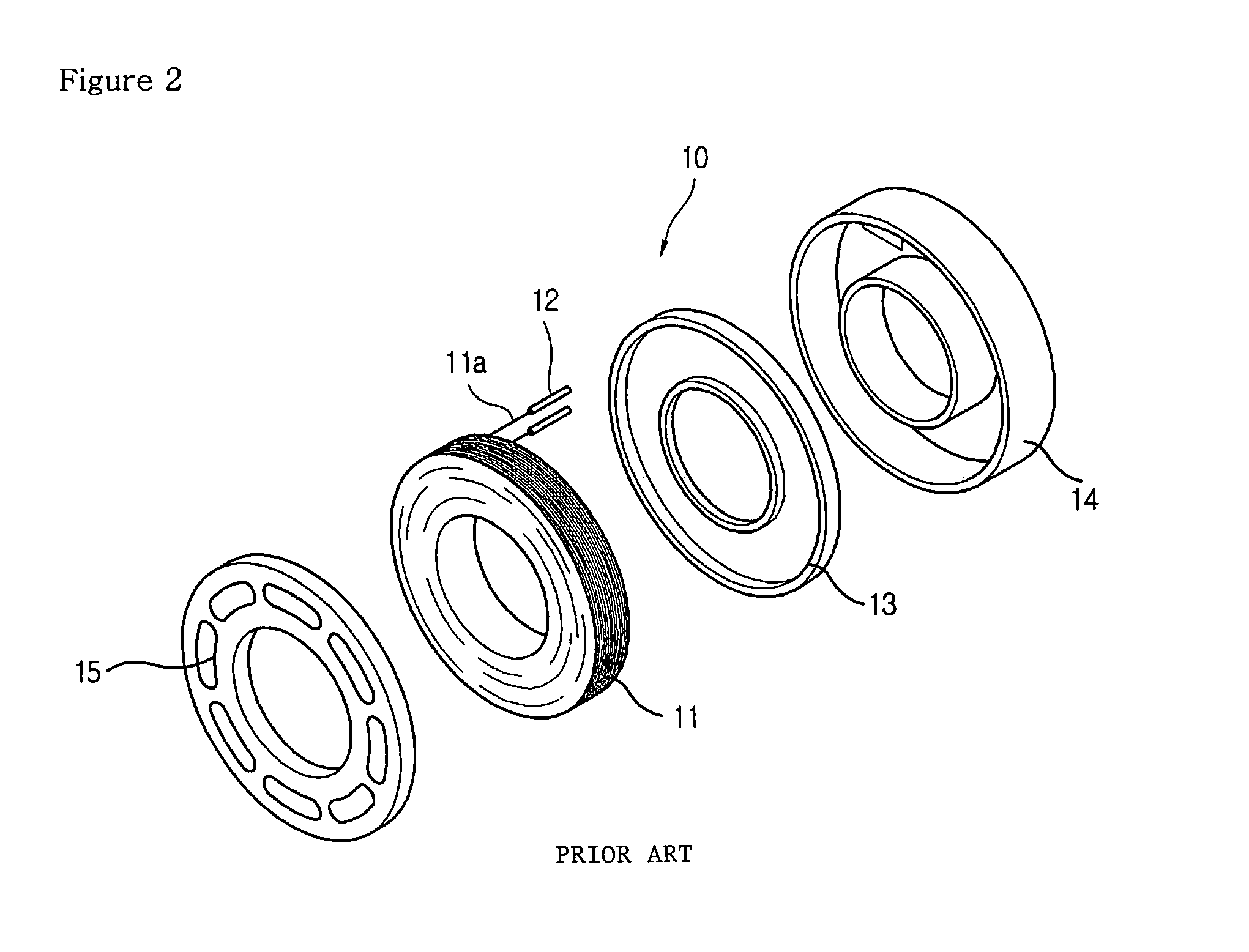

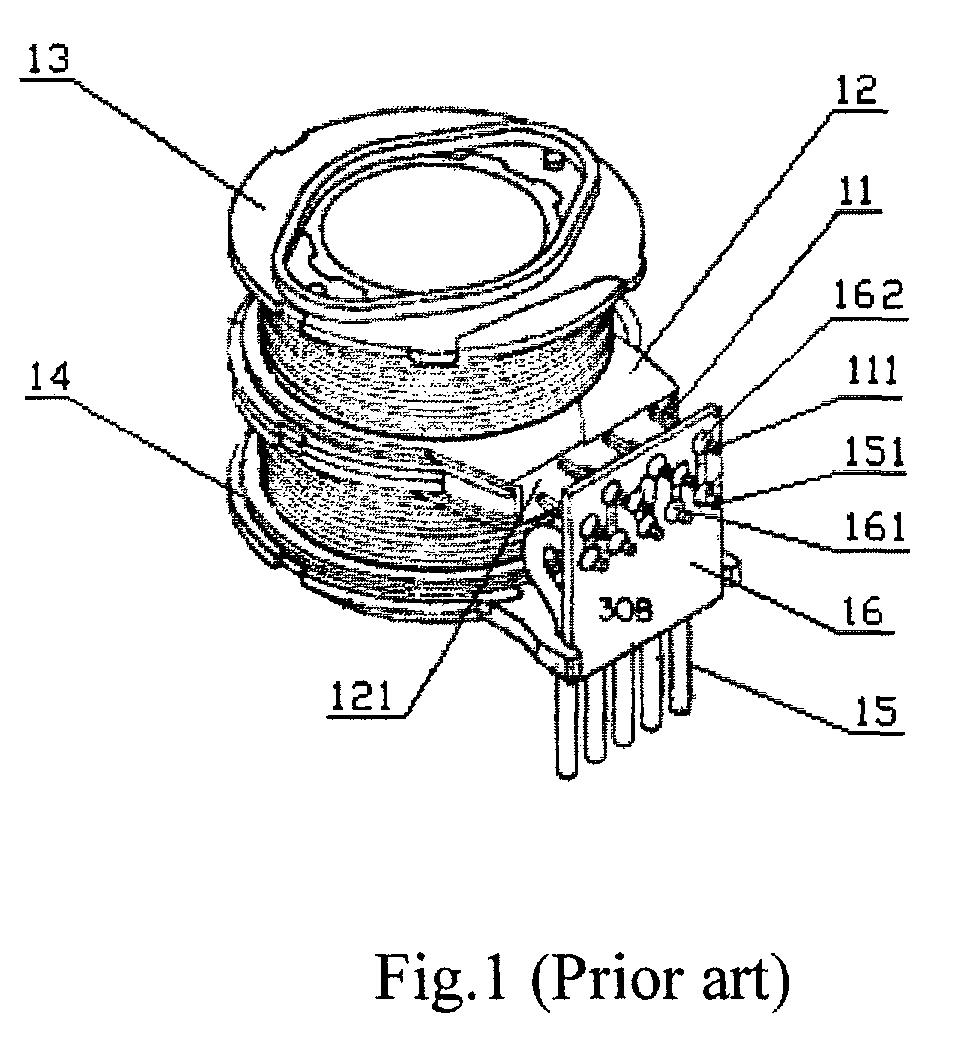

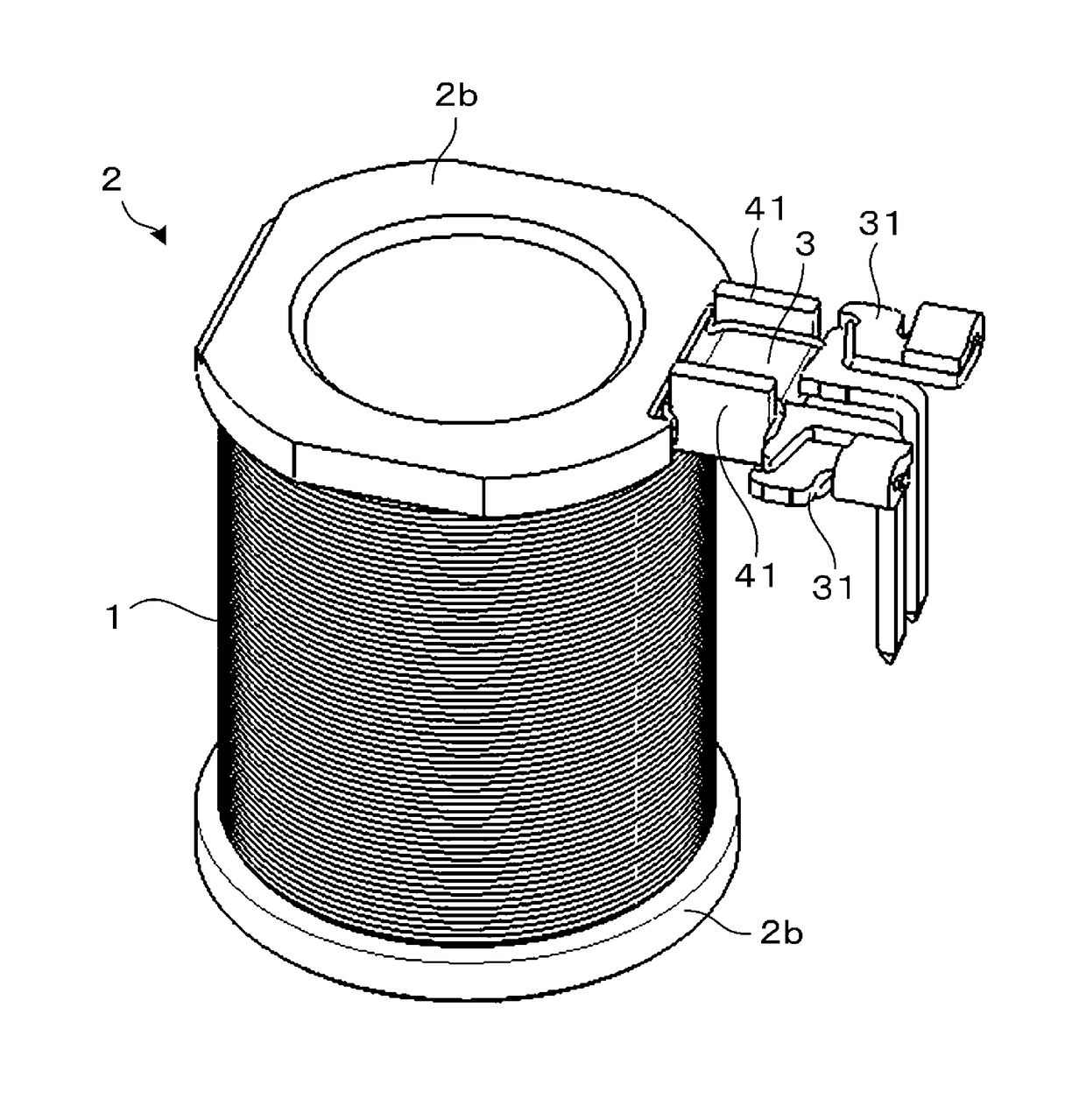

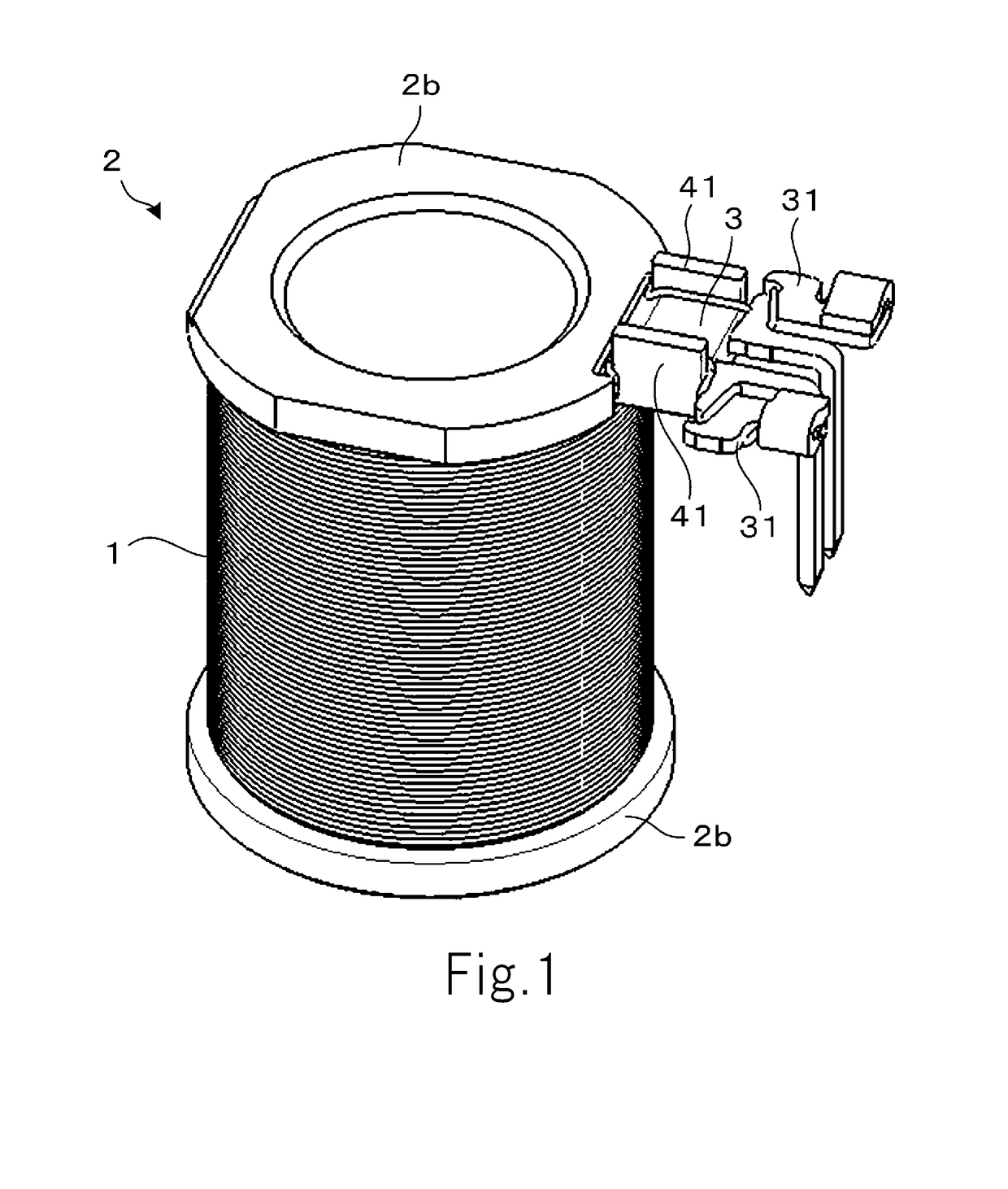

Field coil assembly for an electromagnetic clutch for a compressor

ActiveUS7138895B2Avoid disconnectionMechanical actuated clutchesTransformers/inductances casingsForeign matterElectricity

The present invention relates to a field coil assembly of an electromagnetic clutch for a compressor, in which a coil wire of an electromagnetic coil body exposed to a protrusion of a bobbin is electrically connected with a compressing portion of a coil wire formed at one side end portion of terminals mounted inside a sleeve, and the terminals and the electromagnetic coil body are molded with the resin, thereby preventing permeation of foreign matters from the outside, preventing disconnection of the coil wires due to vibration, and simplifying a manufacturing process.

Owner:HANON SYST

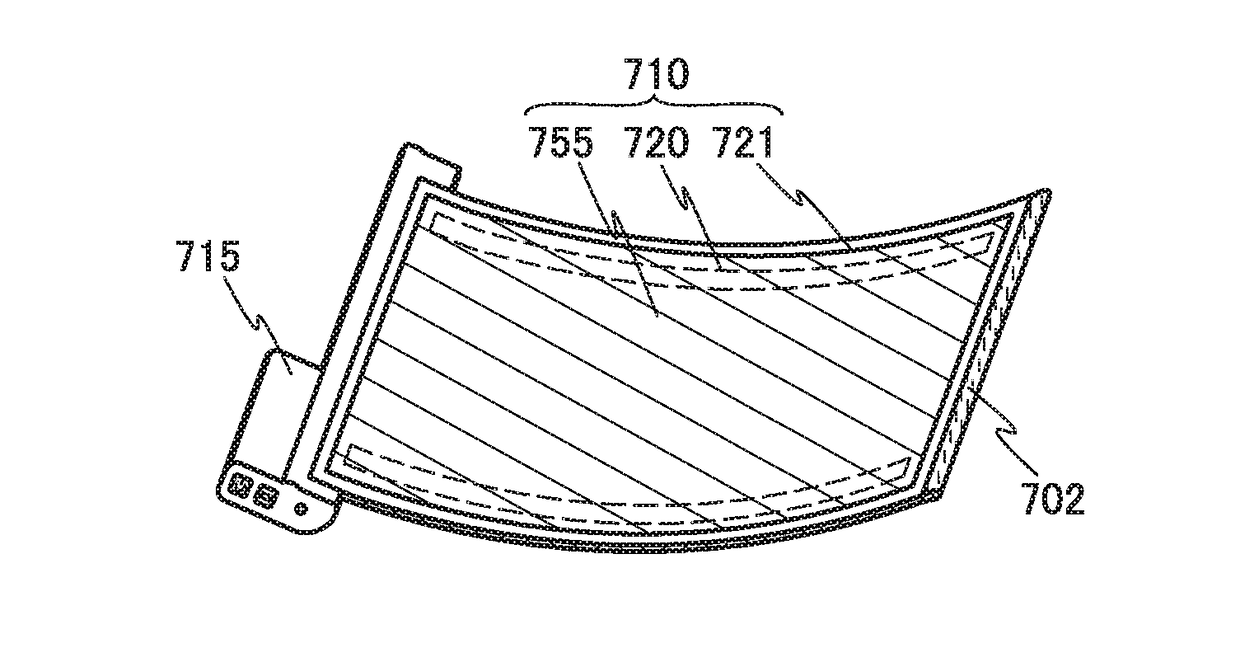

Circuit board and display system

ActiveUS20170092224A1Highly portable electronicImprove portabilityPorous dielectricsDigital data processing detailsEngineeringElectromagnet

To provide a circuit board in which a curvature of a display surface can be controlled, or to provide a highly portable circuit board. A circuit board includes a substrate with flexibility and a curvature control mechanism. The curvature control mechanism includes a first electromagnet and a second electromagnet provided over a first surface of the substrate, an insulating film provided over the first and second electromagnets, and wirings electrically connected to the first and second electromagnets.

Owner:SEMICON ENERGY LAB CO LTD

Field coil assembly for an electromagnetic clutch for a compressor

ActiveUS20060077026A1Prevent penetrationAvoid disconnectionMechanical actuated clutchesTransformers/inductances casingsForeign matterBobbin

The present invention relates to a field coil assembly of an electromagnetic clutch for a compressor, in which a coil wire of an electromagnetic coil body exposed to a protrusion of a bobbin is electrically connected with a compressing portion of a coil wire formed at one side end portion of terminals mounted inside a sleeve, and the terminals and the electromagnetic coil body are molded with the resin, thereby preventing permeation of foreign matters from the outside, preventing disconnection of the coil wires due to vibration, and simplifying a manufacturing process.

Owner:HANON SYST

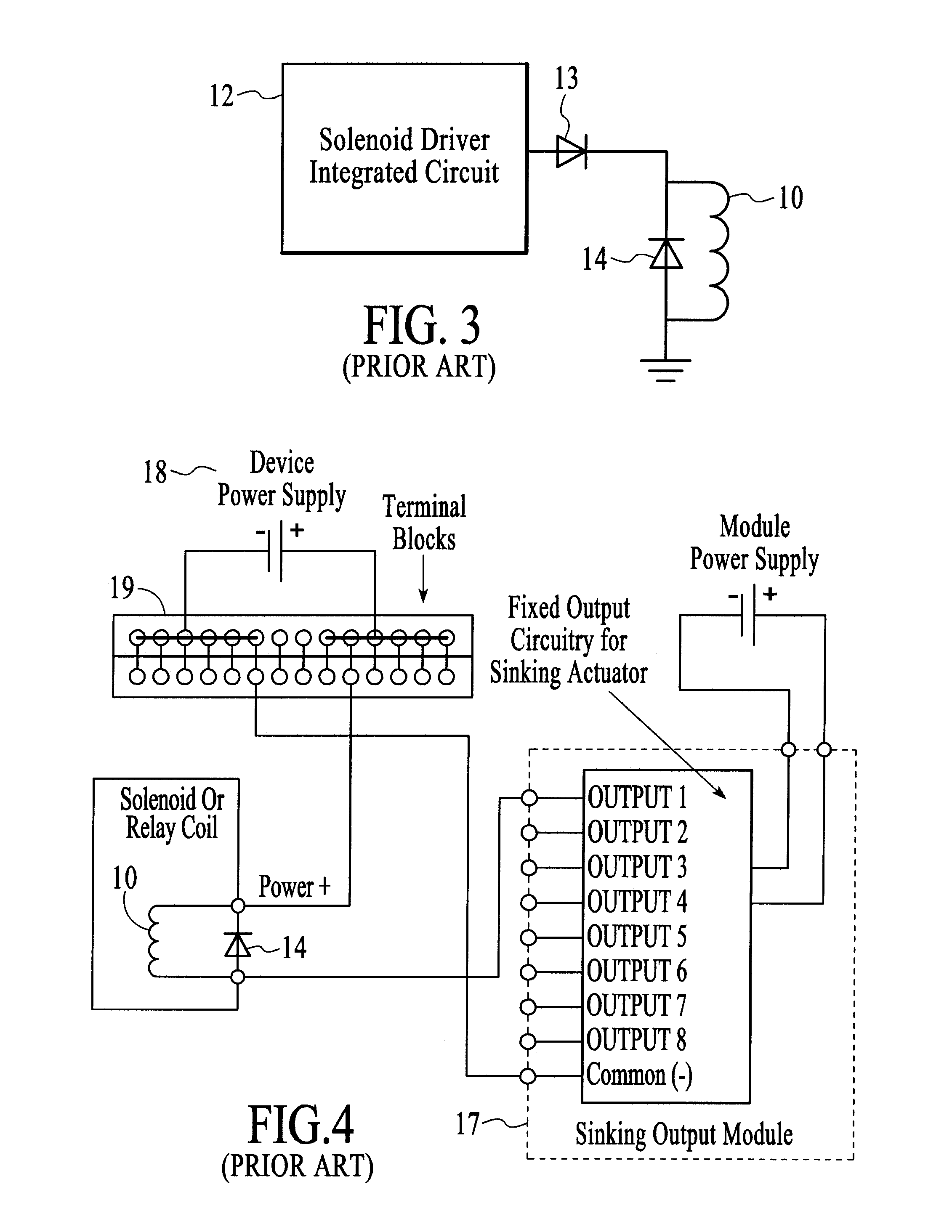

Configurable solenoid actuation method and apparatus

ActiveUS20120099239A1Reduces energy without continuous lossEasy to detectElectromagnet terminals/connectorsRelaysEnergy consumptionControl theory

A configurable, connectorized method and apparatus for driving a solenoid coil reduces energy consumption and heating of the solenoid coil, allows detection of the solenoid state, and simplifies connections to the solenoid.

Owner:X 10

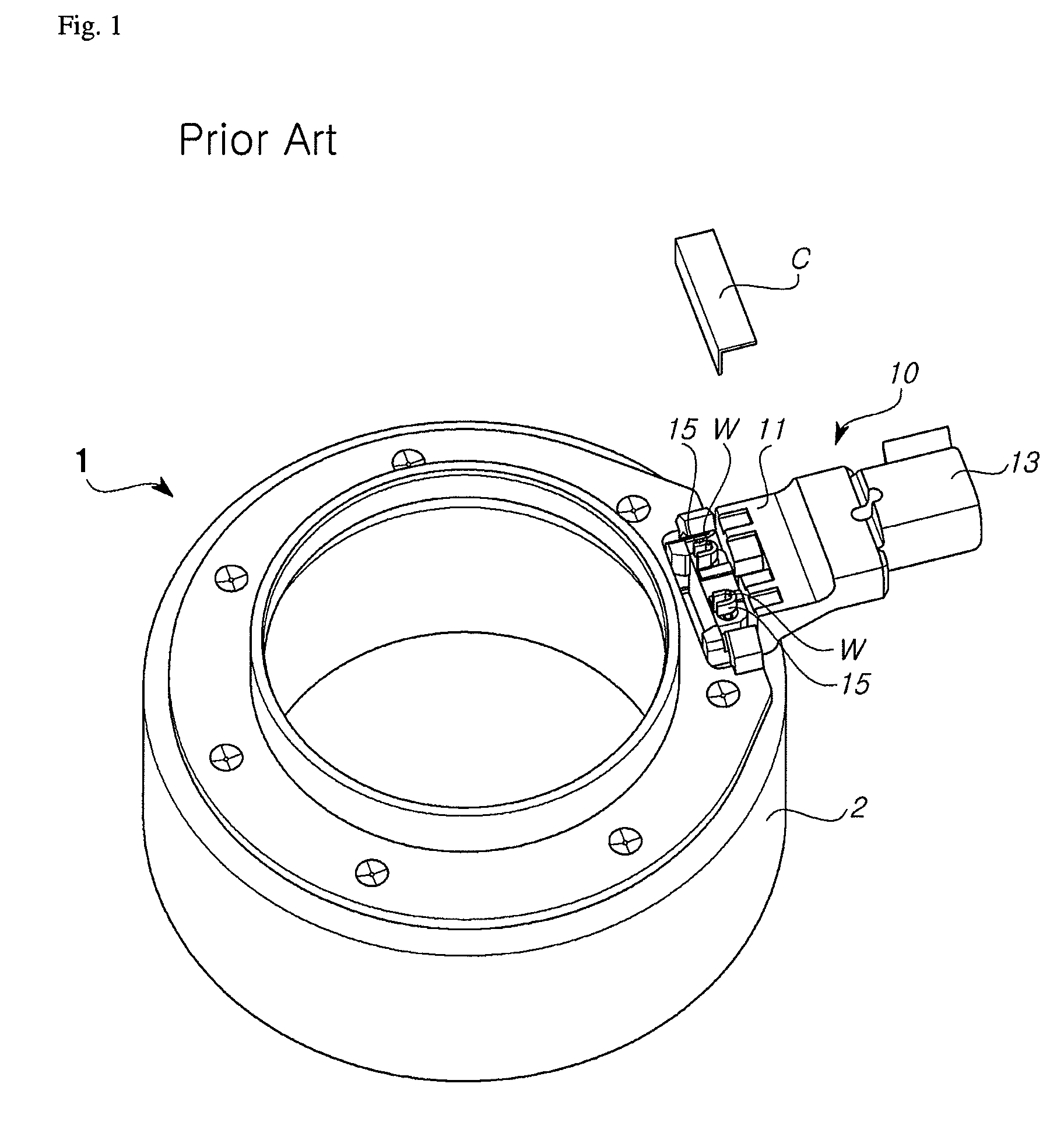

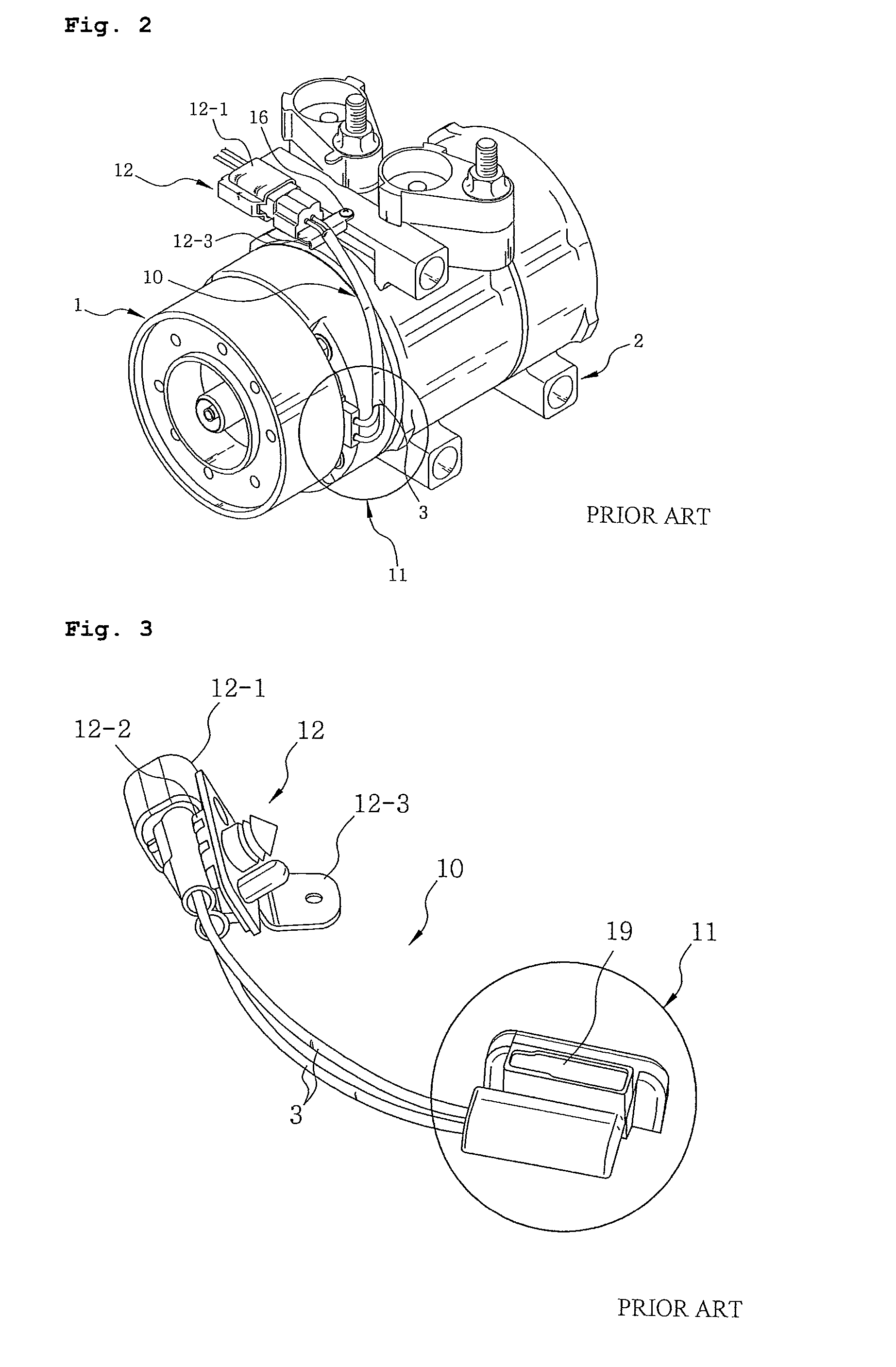

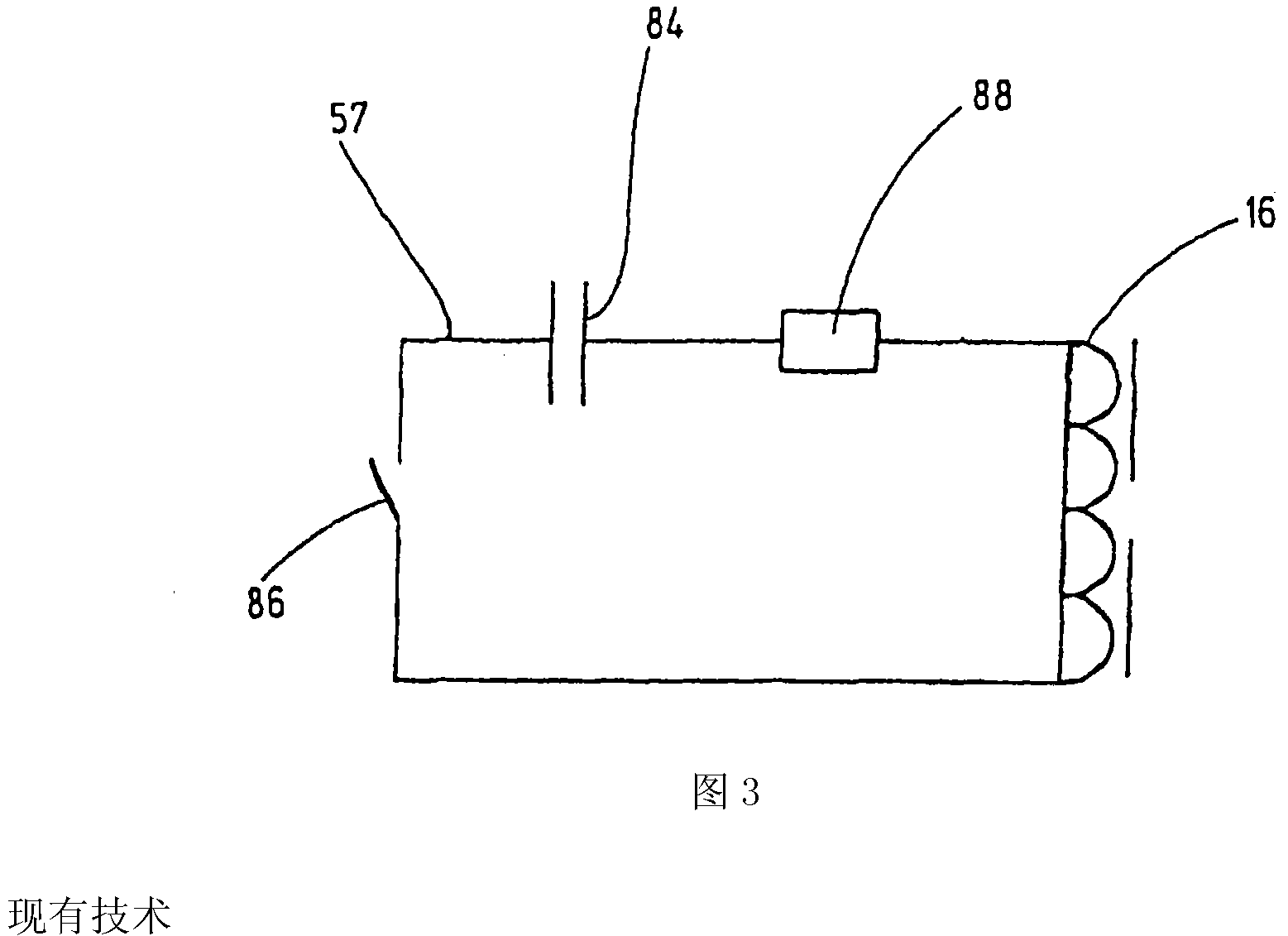

Electric power connection part of electromagnetic clutch field coil assembly

ActiveUS20070017770A1Reduce manufacturing costImprove productivityLine/current collector detailsMechanical actuated clutchesResidual magnetic fieldElectromagnetic clutch

An electric power connection part of an electromagnetic clutch field coil assembly connected with an electric power connector at a side of a vehicle engine includes a housing assembly connected to the field coil assembly with electric wires, which is extracted therefrom, interposed therebetween; a discharge device for absorbing a surge voltage; and a magnetic field elimination device for eliminating a residual magnetic field are injection molded and combonined within the housing assembly. Accordingly, on the electric power connection part has an advantage in that it is not directly influenced by heat radiated from a field coil assembly so that electric / electronic devices can be prevented from being damaged; since an epoxy applying process for attaching electric / electronic devices such as a discharge device and a magnetic field elimination device is omitted, a manufacturing process is greatly simplified; and the number of components are reduced so that manufacturing process thereby decreasing costs.

Owner:HANON SYST

Electromagnetic coil assembly

InactiveUS7289012B2Prevent exitTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinEngineering

Owner:POLYMER TECH CORP

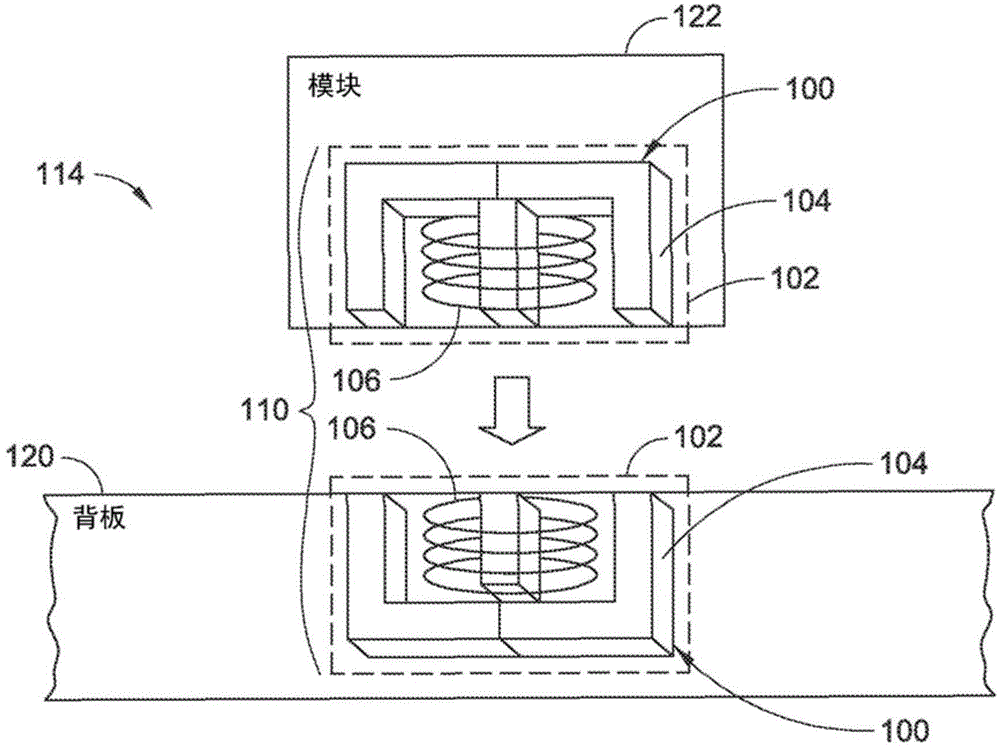

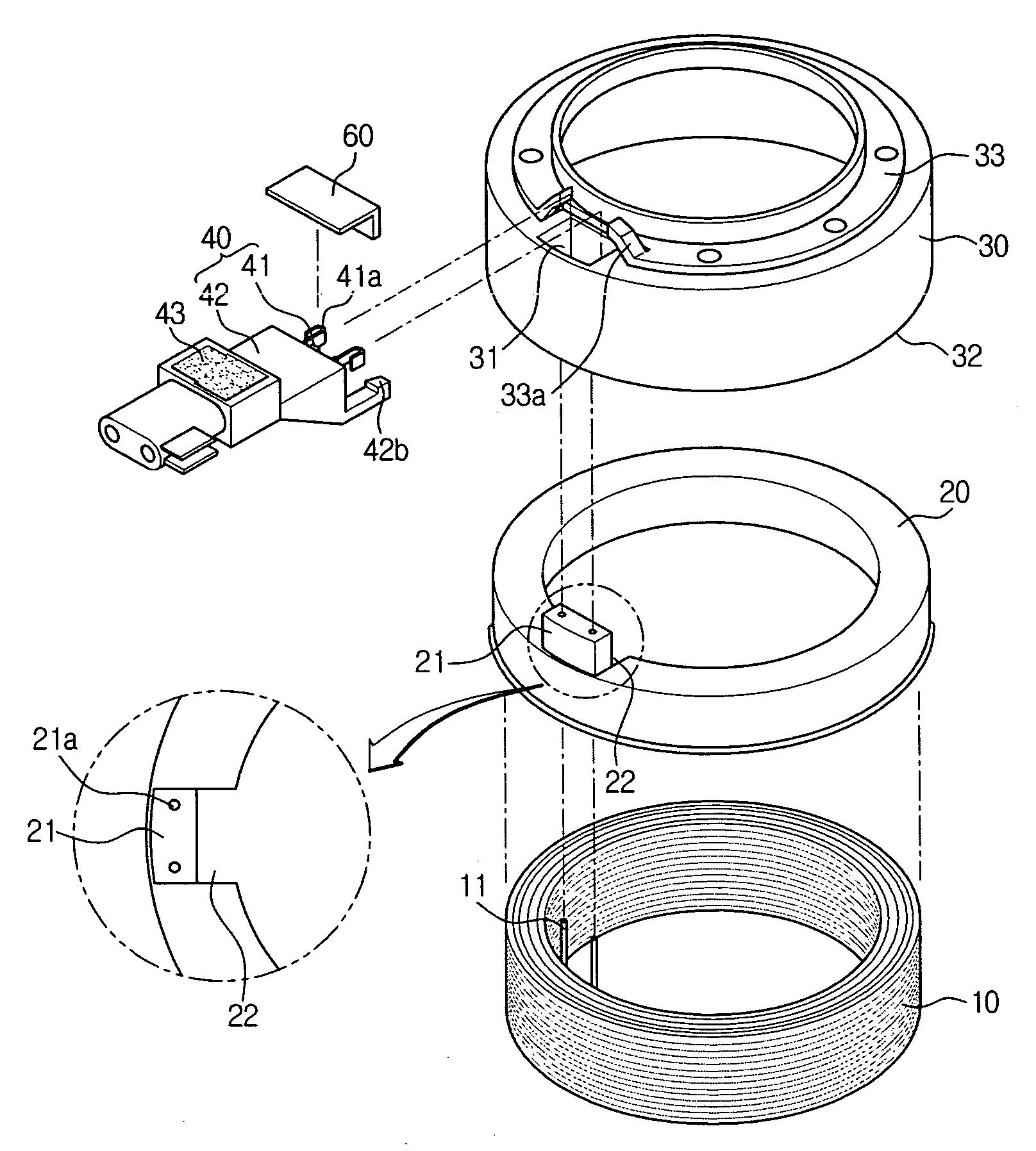

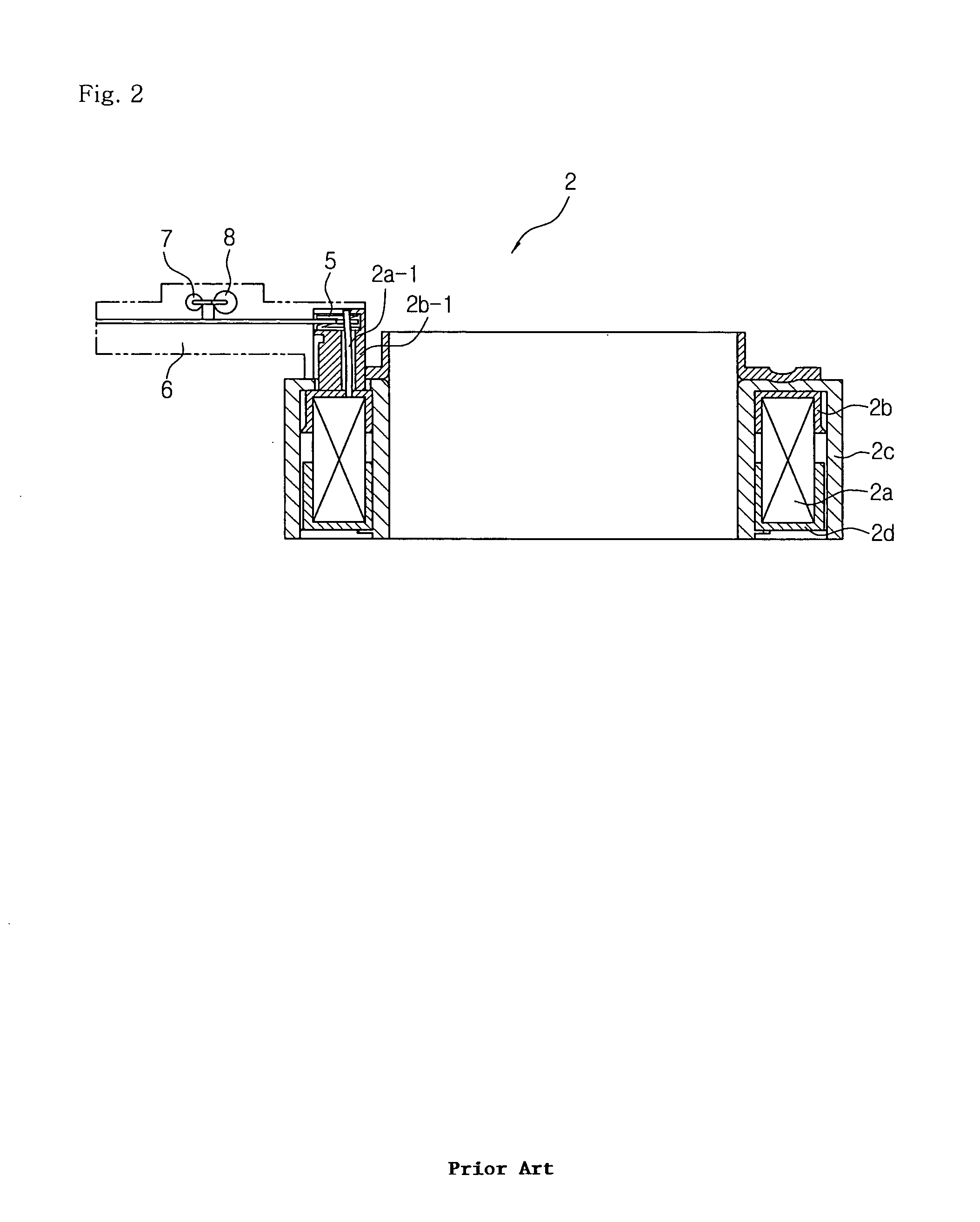

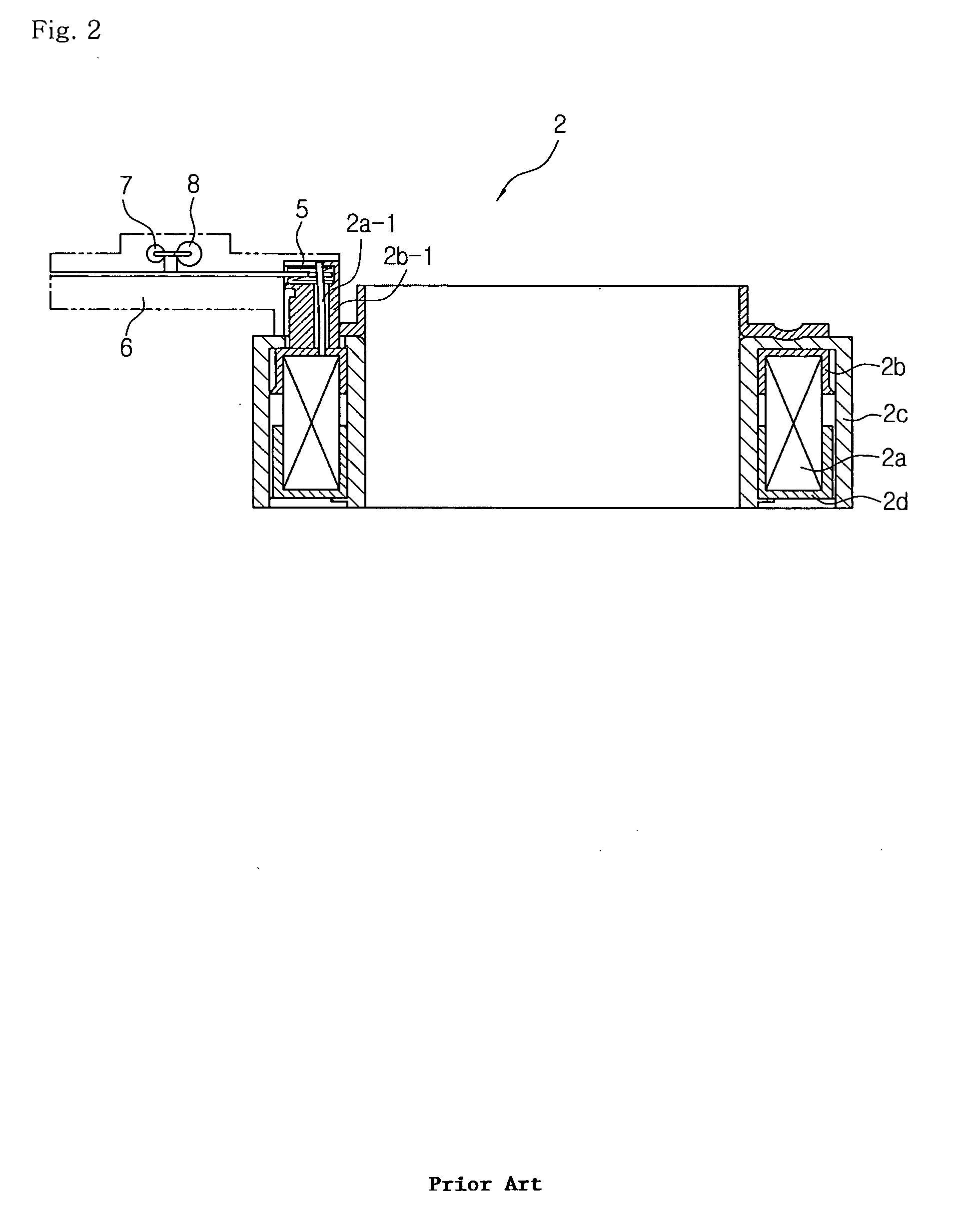

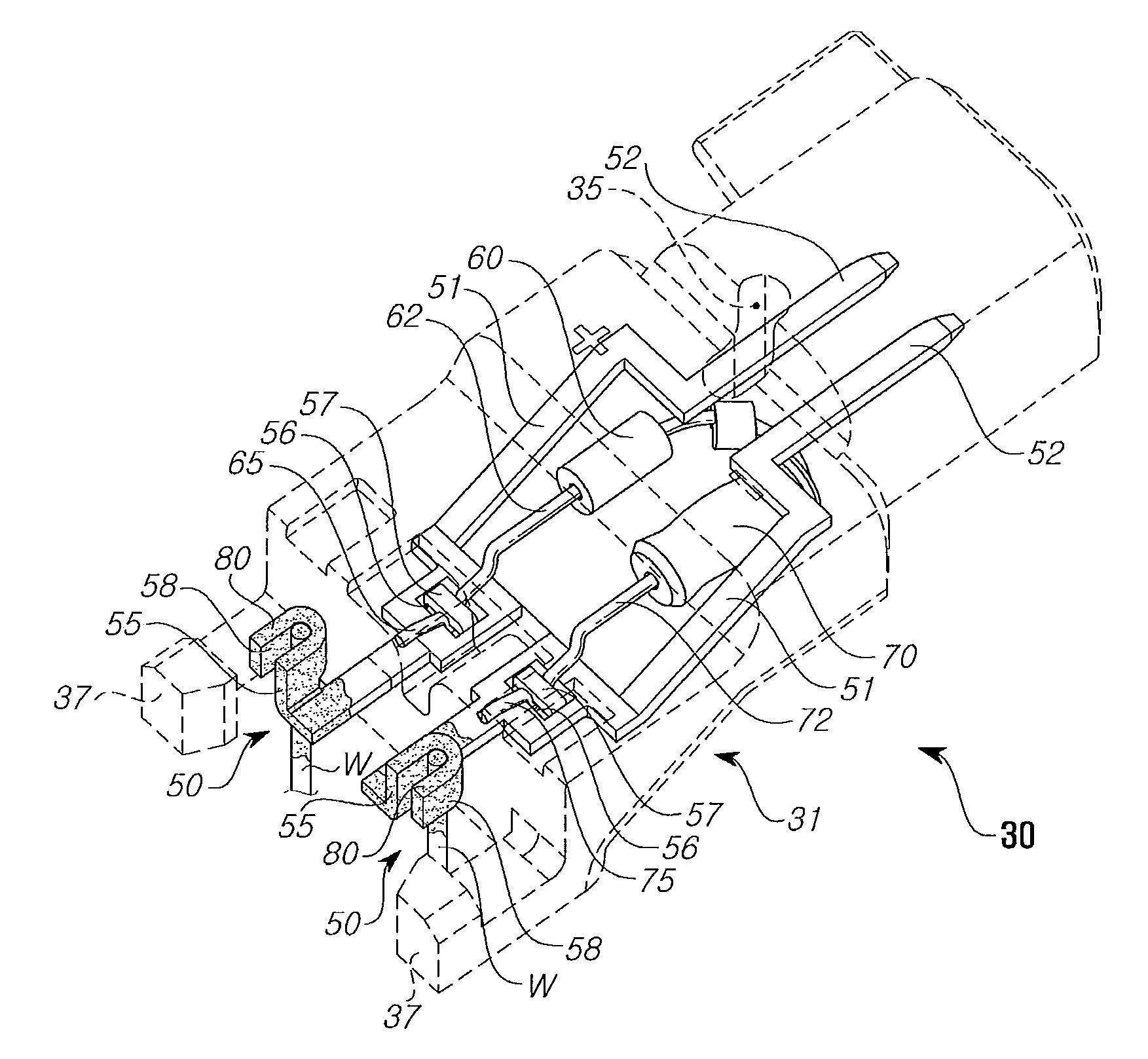

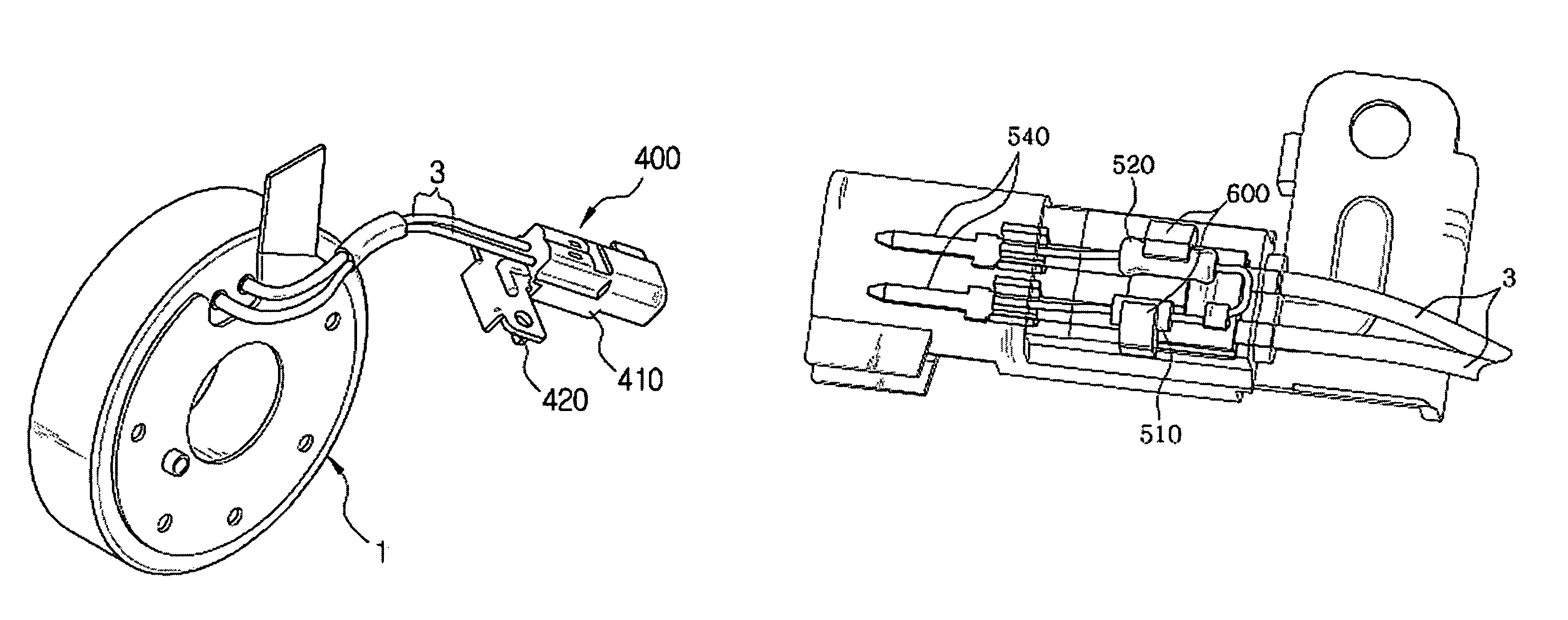

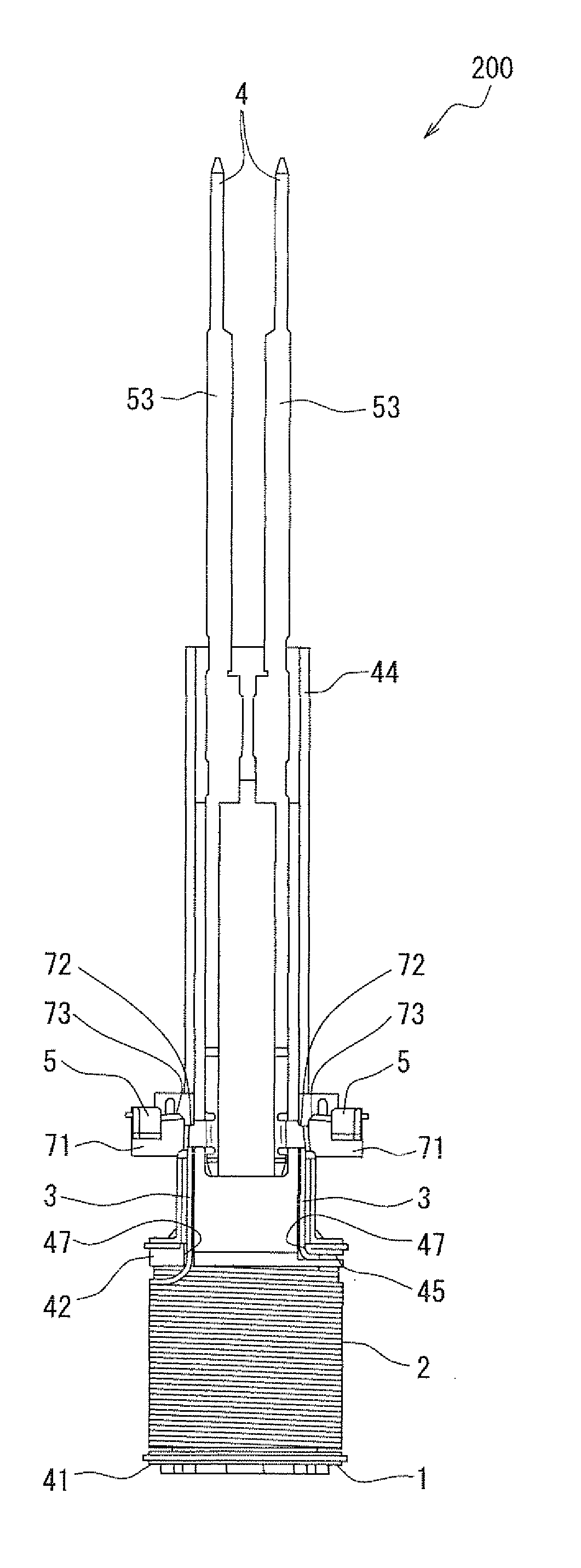

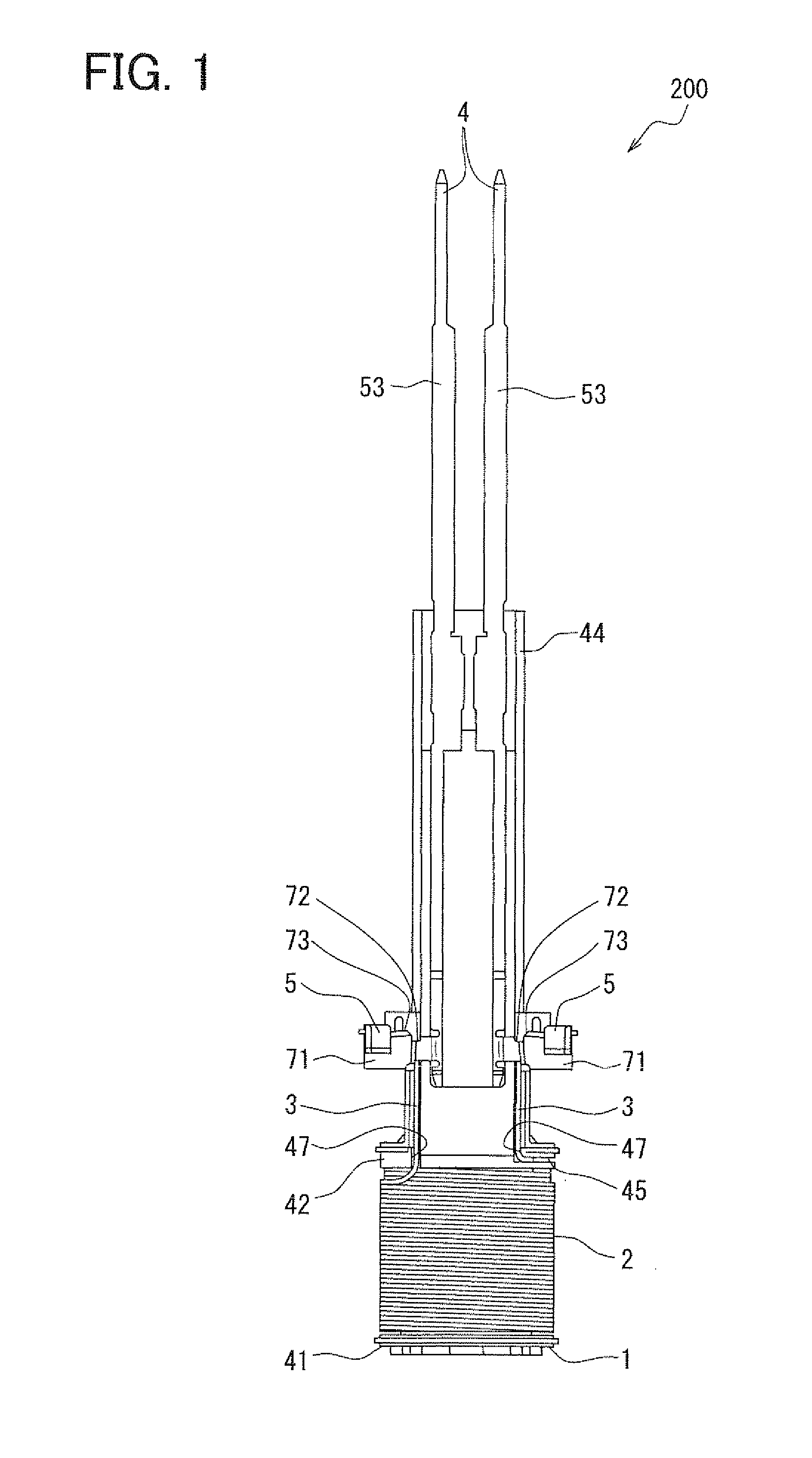

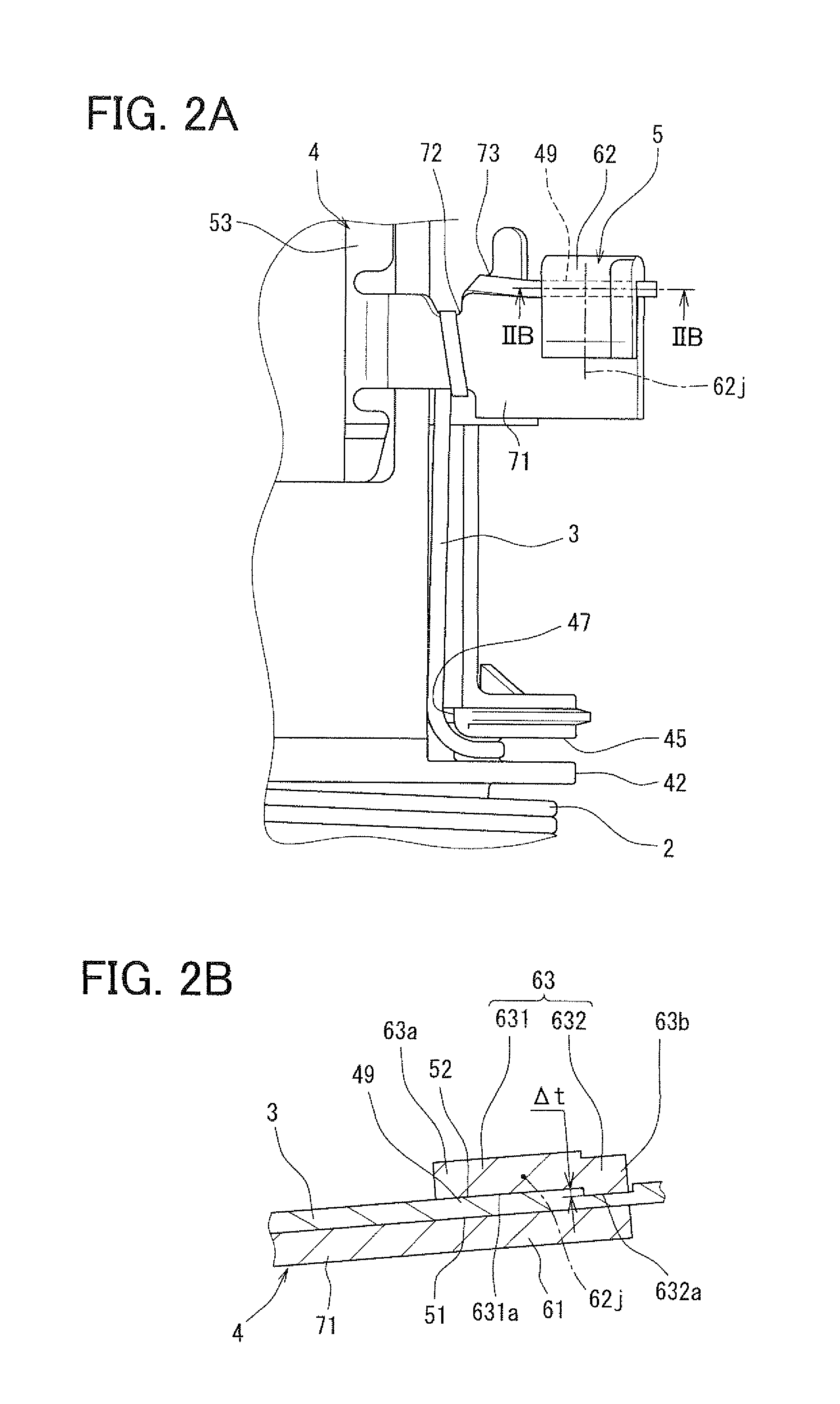

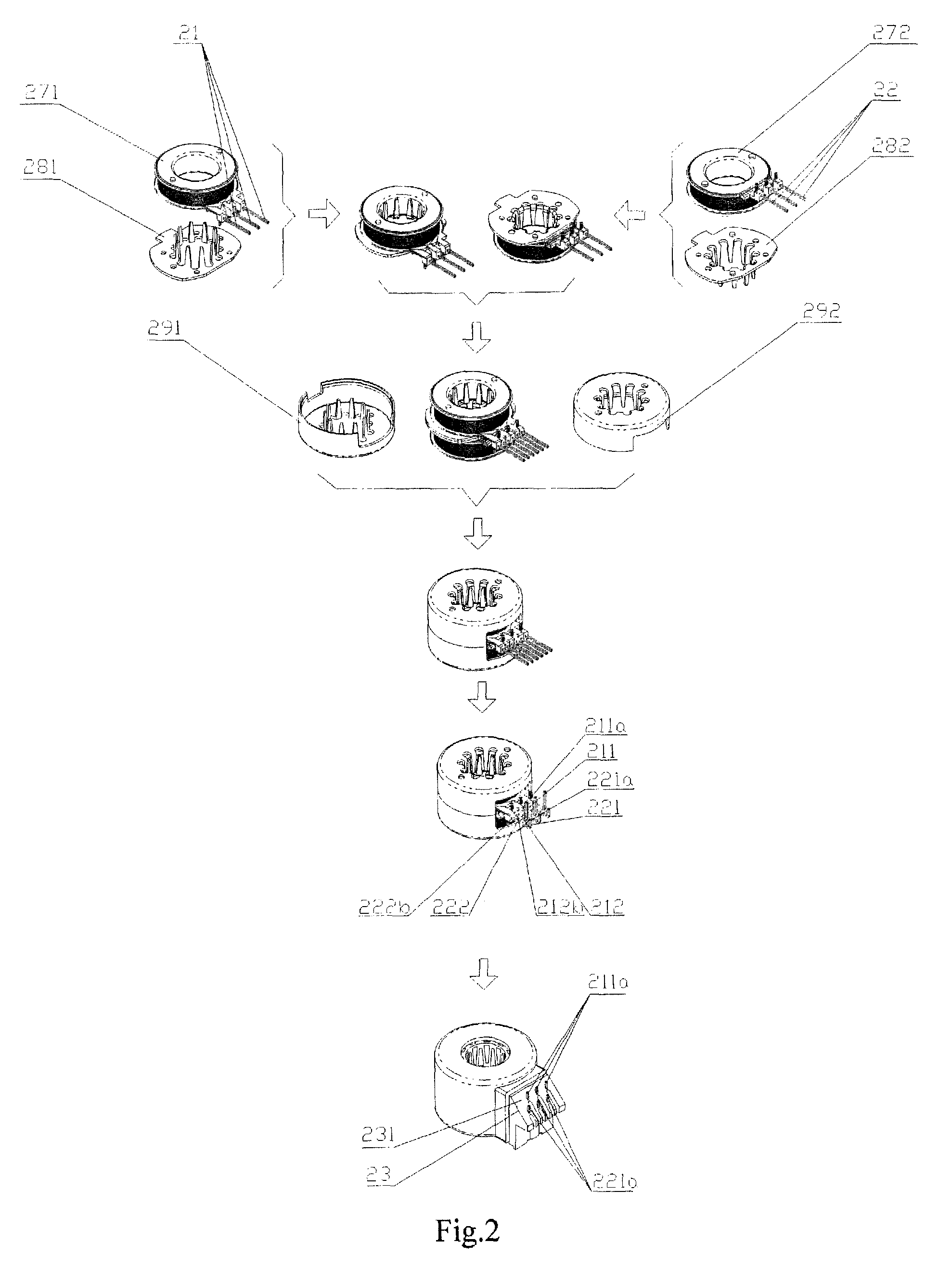

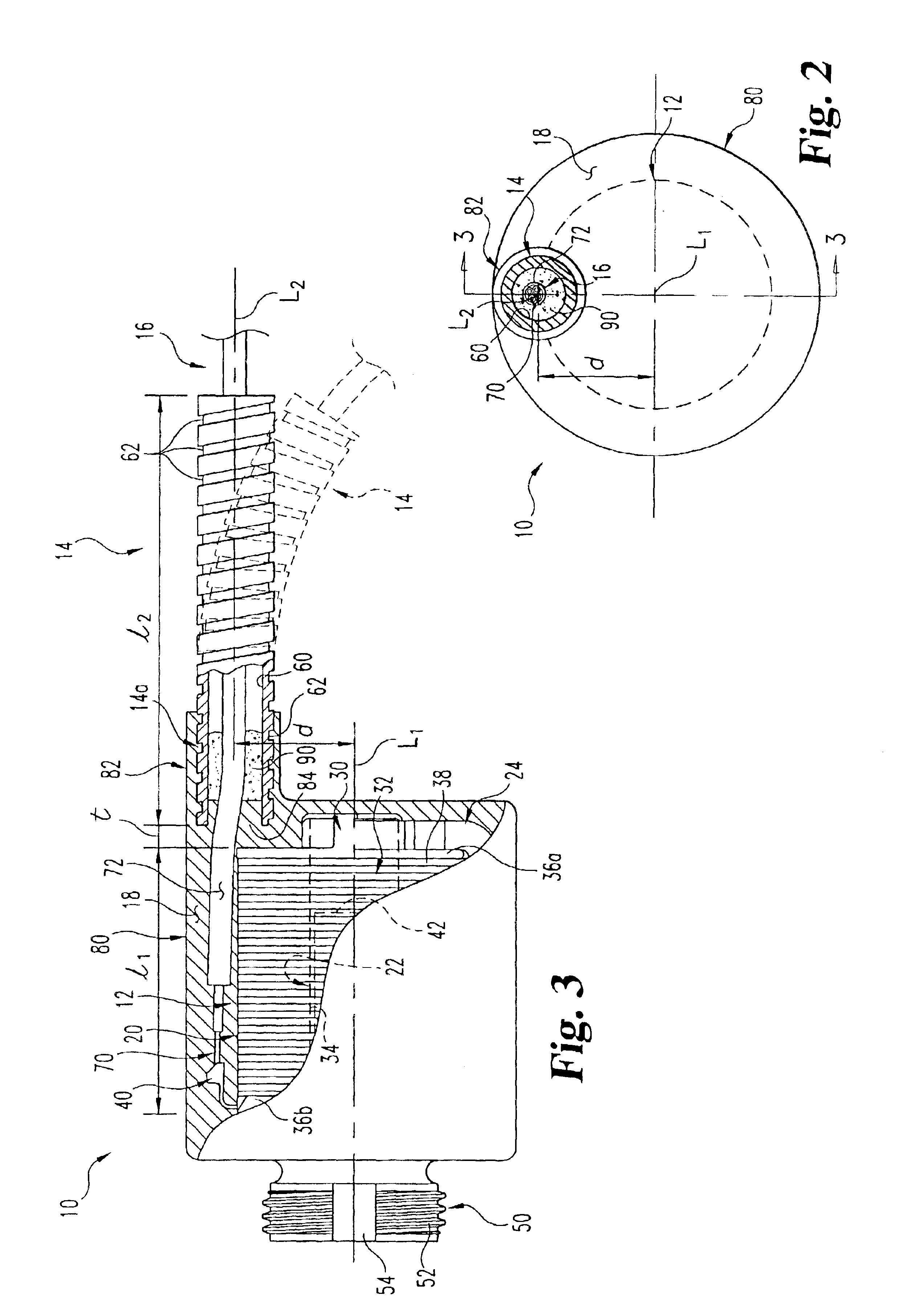

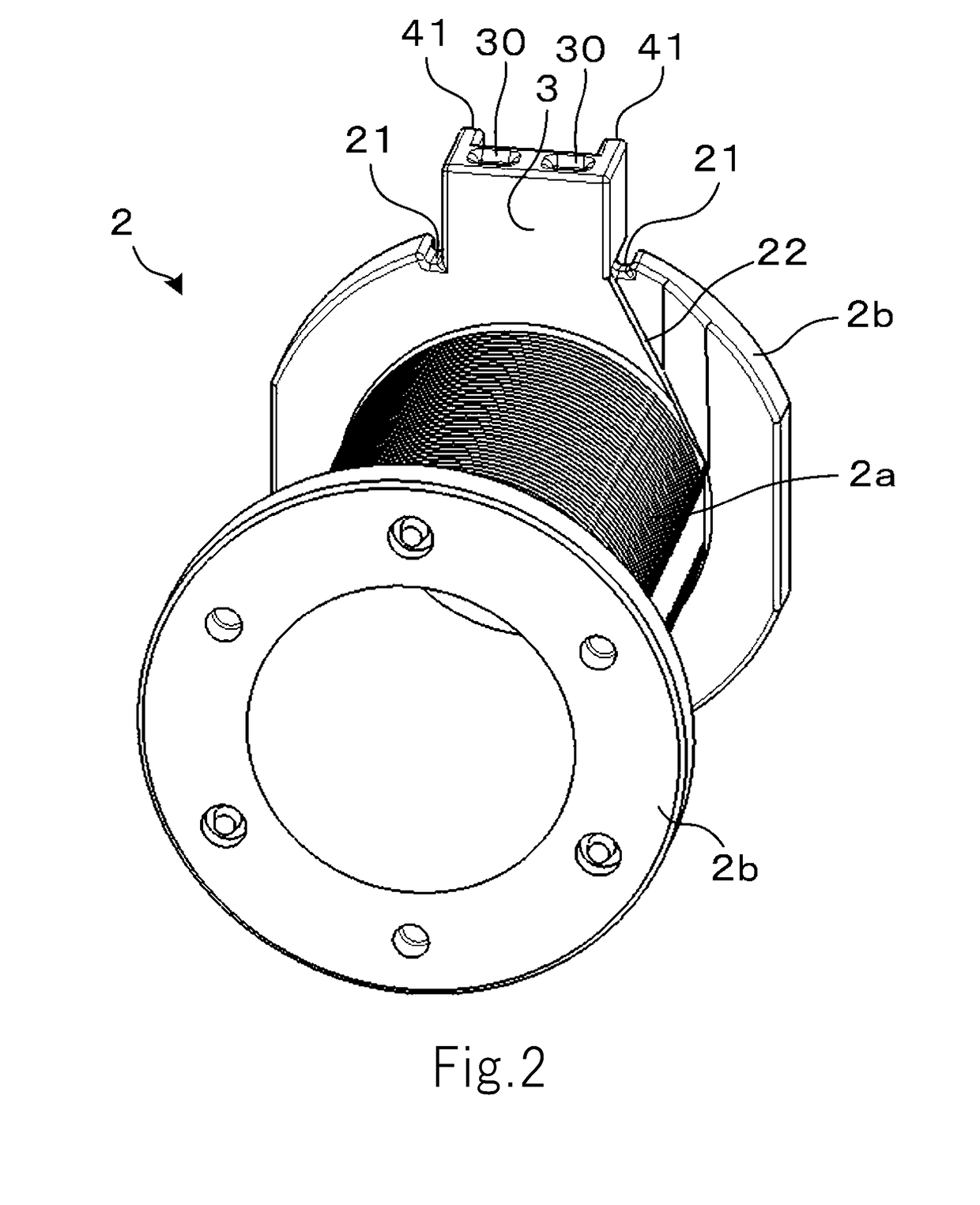

Field coil assembly of electromagnetic clutch for compressor and method for manufacturing the same

ActiveUS20090278640A1Avoid exposureMechanical actuated clutchesTransformers/inductances casingsElectromagnetic clutchEngineering

The present invention relates to a field coil assembly of an electromagnetic clutch for a compressor and a method for manufacturing the same. A field coil assembly 20 of the present invention includes a coil installed to a core 22 and made by winding a wire W to generate a magnetic flux, and a connector 30 coupled thereto. At this time, the connector 30 is provided at one side of the core 22 and has a terminal 50 therein, thereby being electrically connected to one end of the wire W. In addition, a protective coating portion 80 is formed at a connecting portion between the terminal 50 and the end of the wire W to thereby prevent the connecting portion of the wire W and the terminal 50 from being exposed to the outside. According to the present invention, the connecting portion between the terminal 50 and the coil is not exposed to moisture or air, thereby preventing electric short circuit from occurring by galvanic corrosion between the terminal 50 and the coil. As a result, there is an advantage in that the operation reliability and durability of the field coil assembly are improved.

Owner:HANON SYST

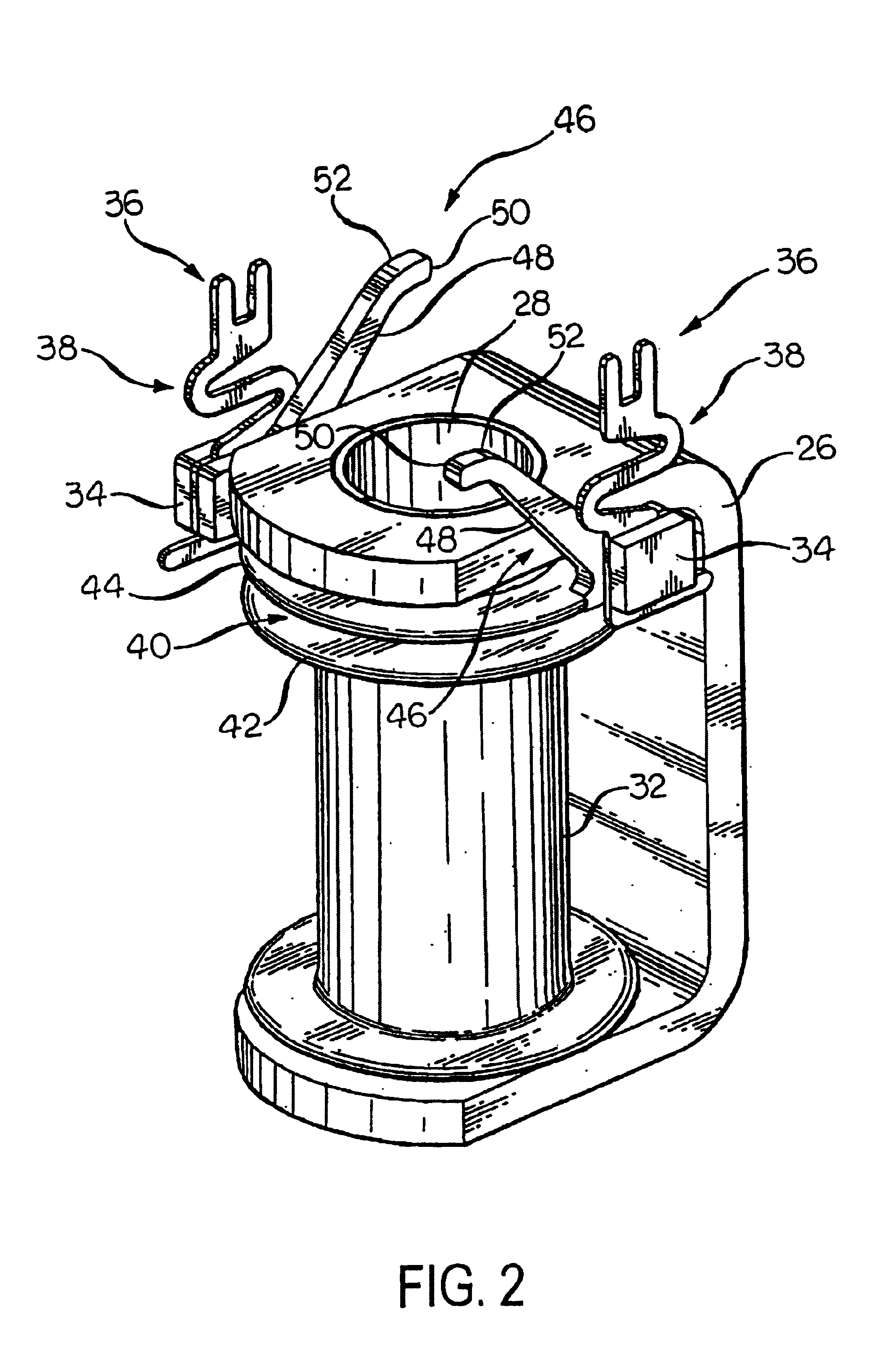

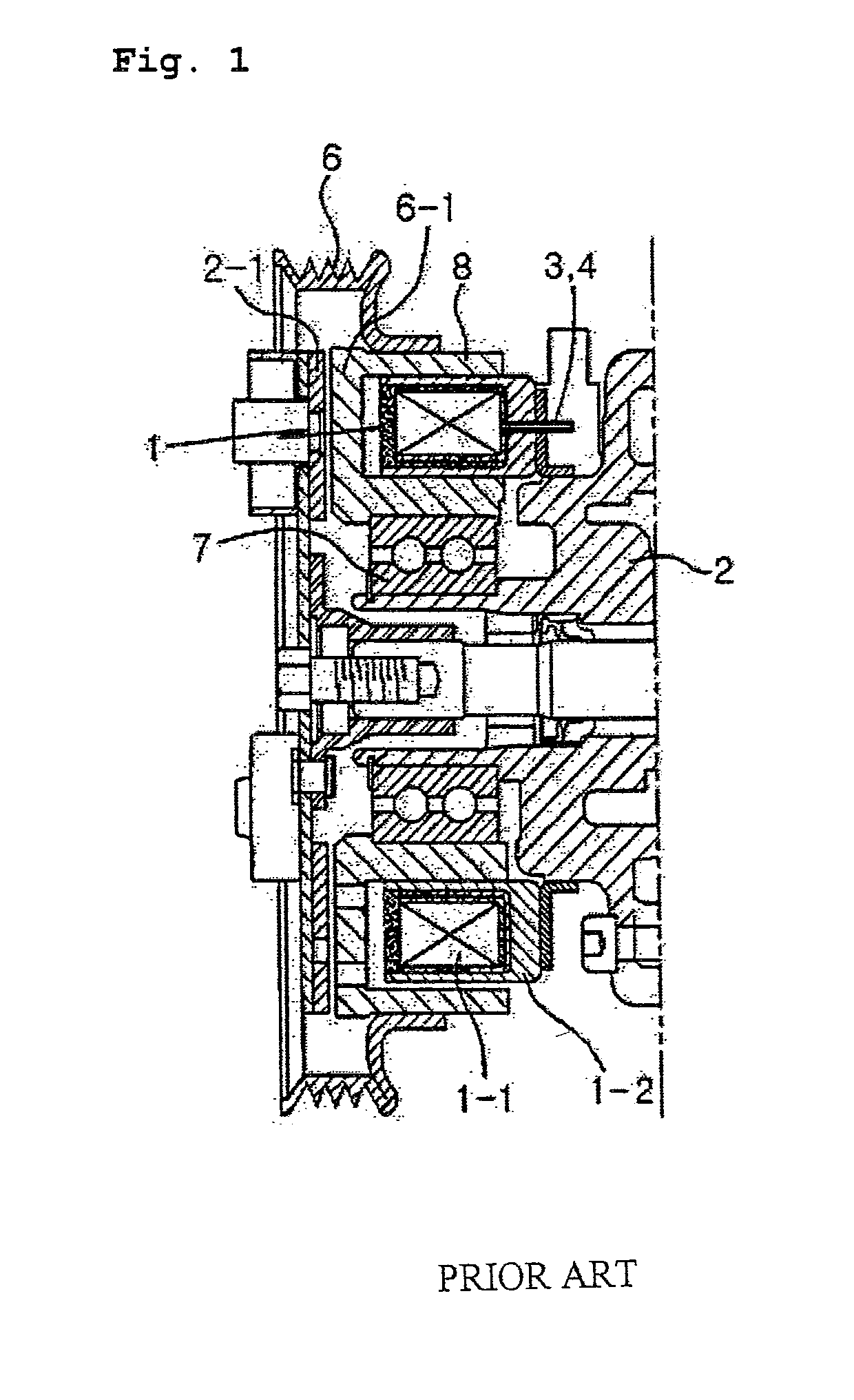

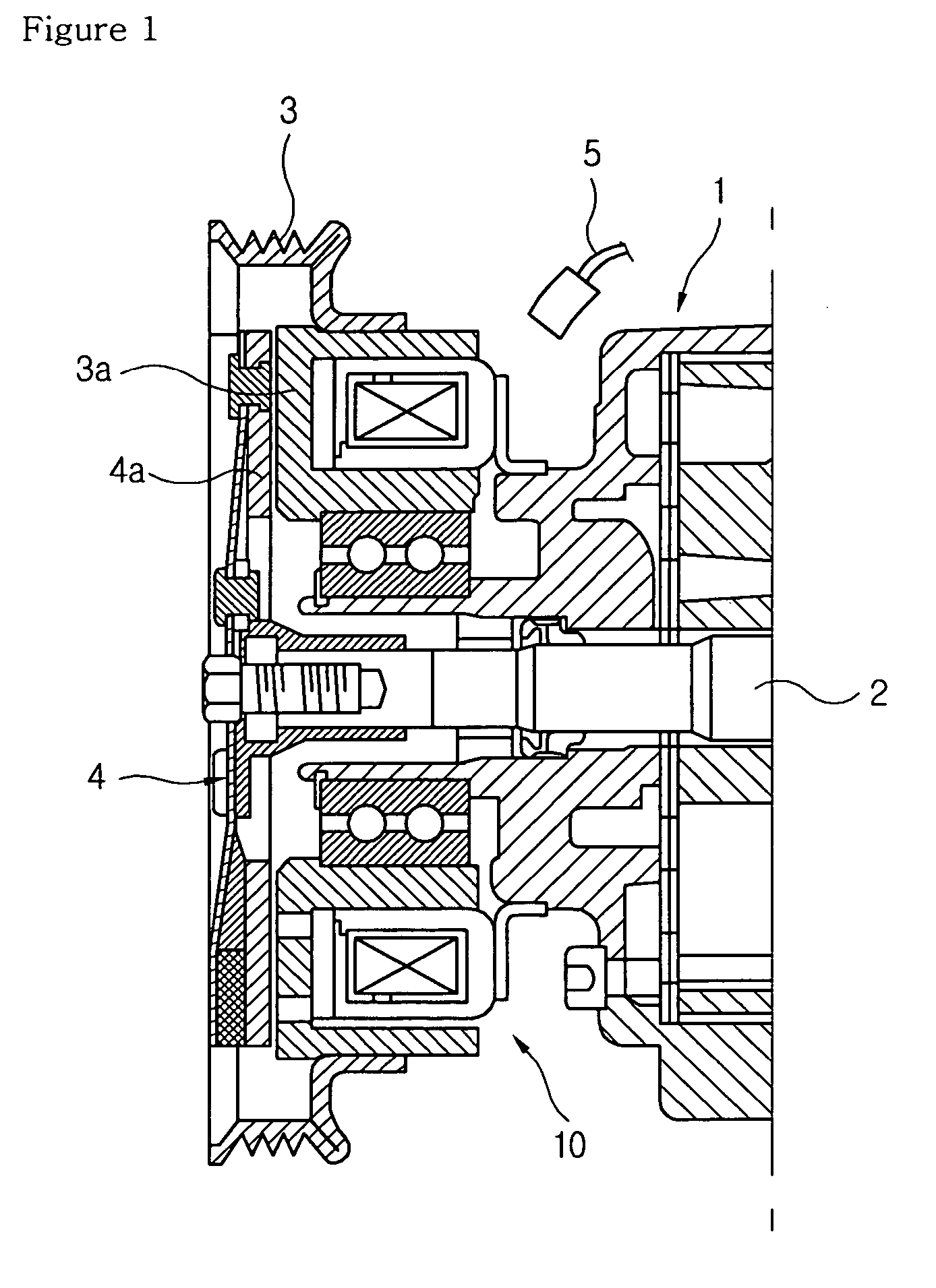

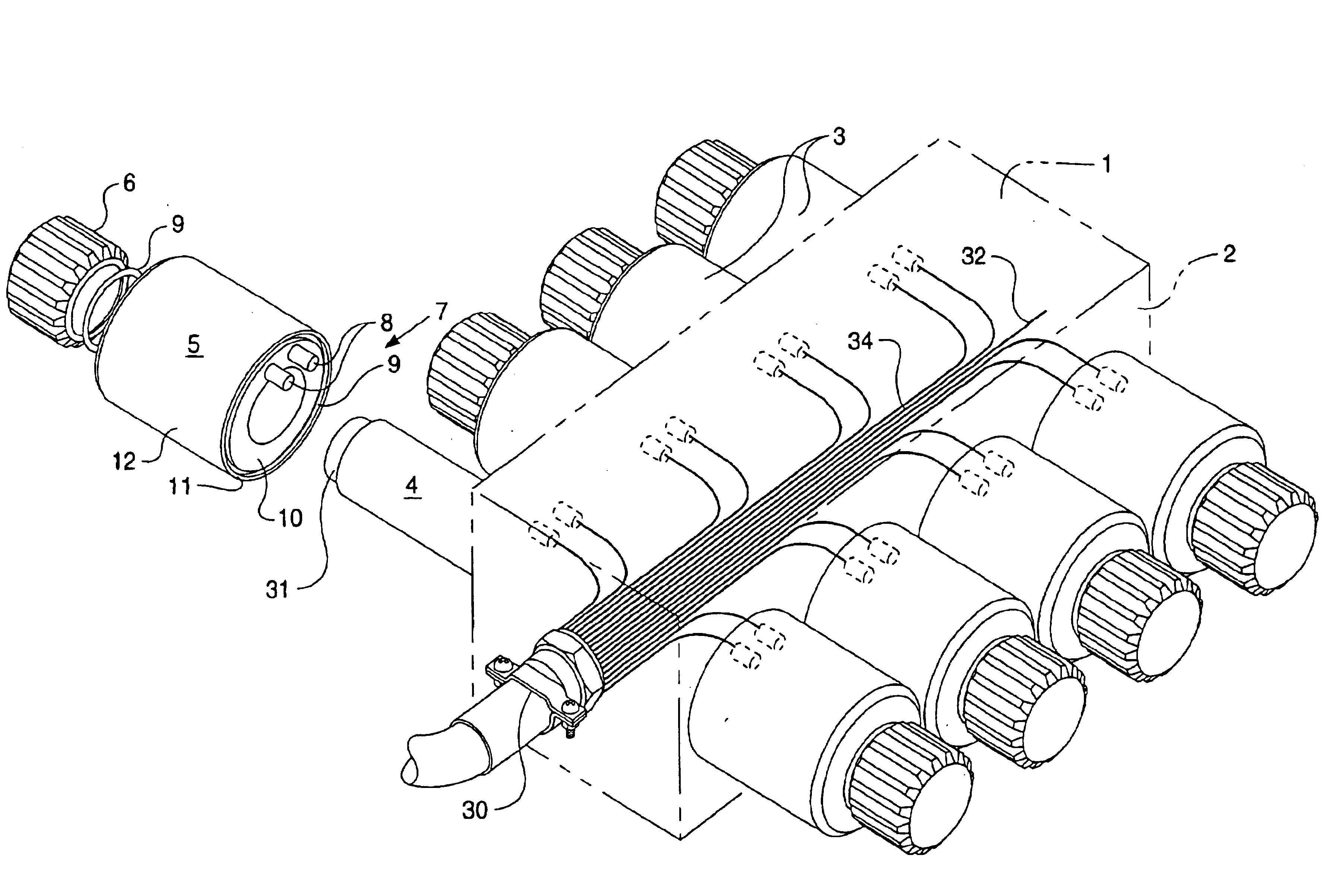

Coil unit of electromagnetic contactor and assembling method thereof

ActiveCN101677043AFirmly connectedReduce processing timeElectromagnetic relay detailsElectromagnet terminals/connectorsBobbinFlange

The invention provides a coil unit of electromagnetic contactor and assembling method thereof. In a coil unit of an electromagnetic contactor in which a coil having a coil strand as a conductor wire wound around a flanged bobbin is mounted on a leg of a stationary core of an operating electromagnet, into one flange of the bobbin are press fitted a pair of terminal metal pieces respectively corresponding to an initial side lead wire as an initial side conductor wire and a final side lead wire as a final side conductor wire of the coil, and each of the terminal metal pieces is formed with a press fitting base for making the terminal metal piece press fitted into the one flange, a coil connecting arm around which the lead wire as the conductor wire of corresponding side of the coil is wound and a tab terminal made to have a plug-in connection with a corresponding connector of an extension lead. The initial side conductor wire is wound on a coil connection arm 19b of a terminal metal piece19 and the coil strand is wound on the coil on the bobbin to form the coil. The final side connector wire is wound on the coil connection arm 19b of another terminal metal piece 19. Subsequently thelead wound on each coil connection arm is welded. In addition, the tab terminal is in plug-in connection with connector of the extension lead for external connection and serial connection, therefore the coil unit is assembled into double-coil unit.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

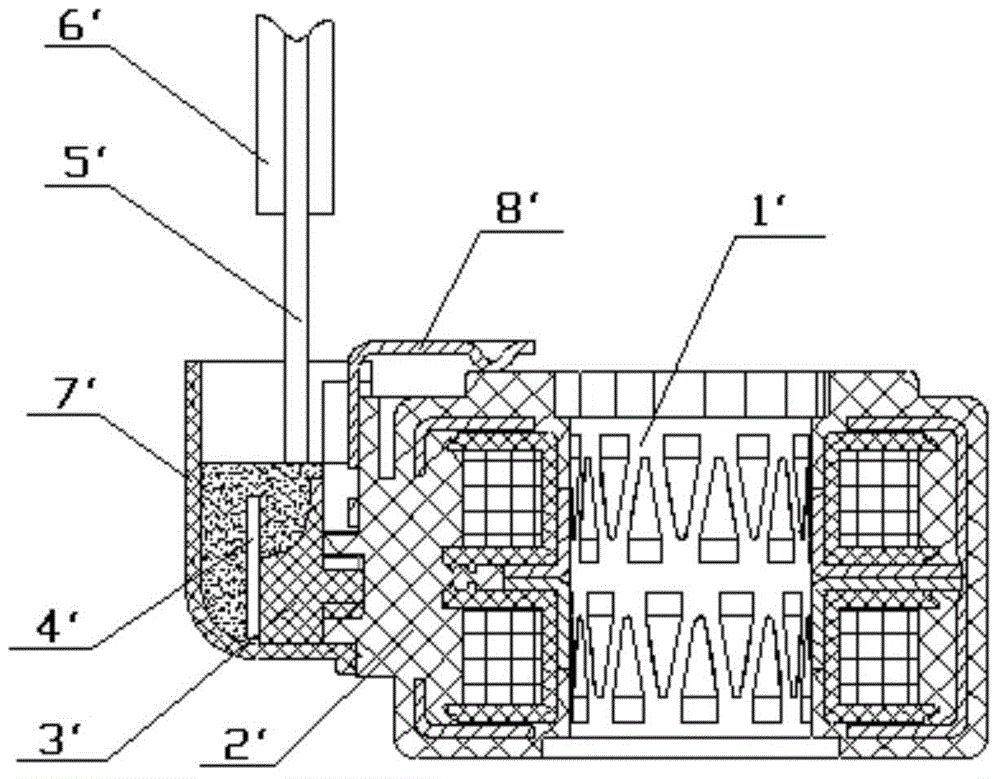

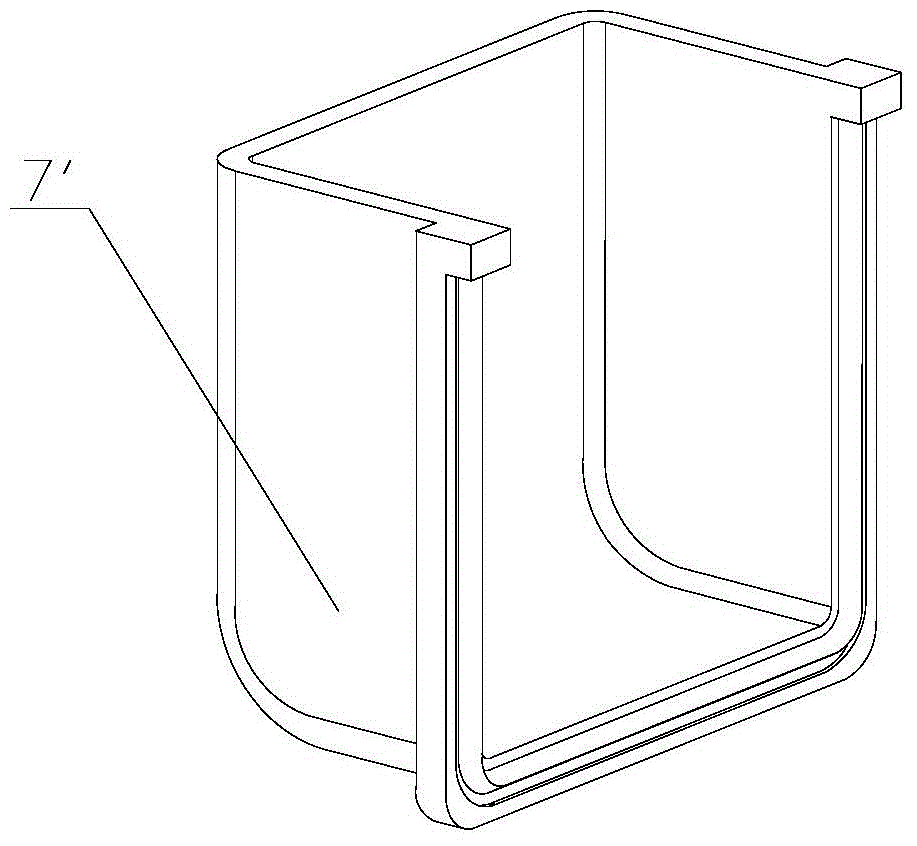

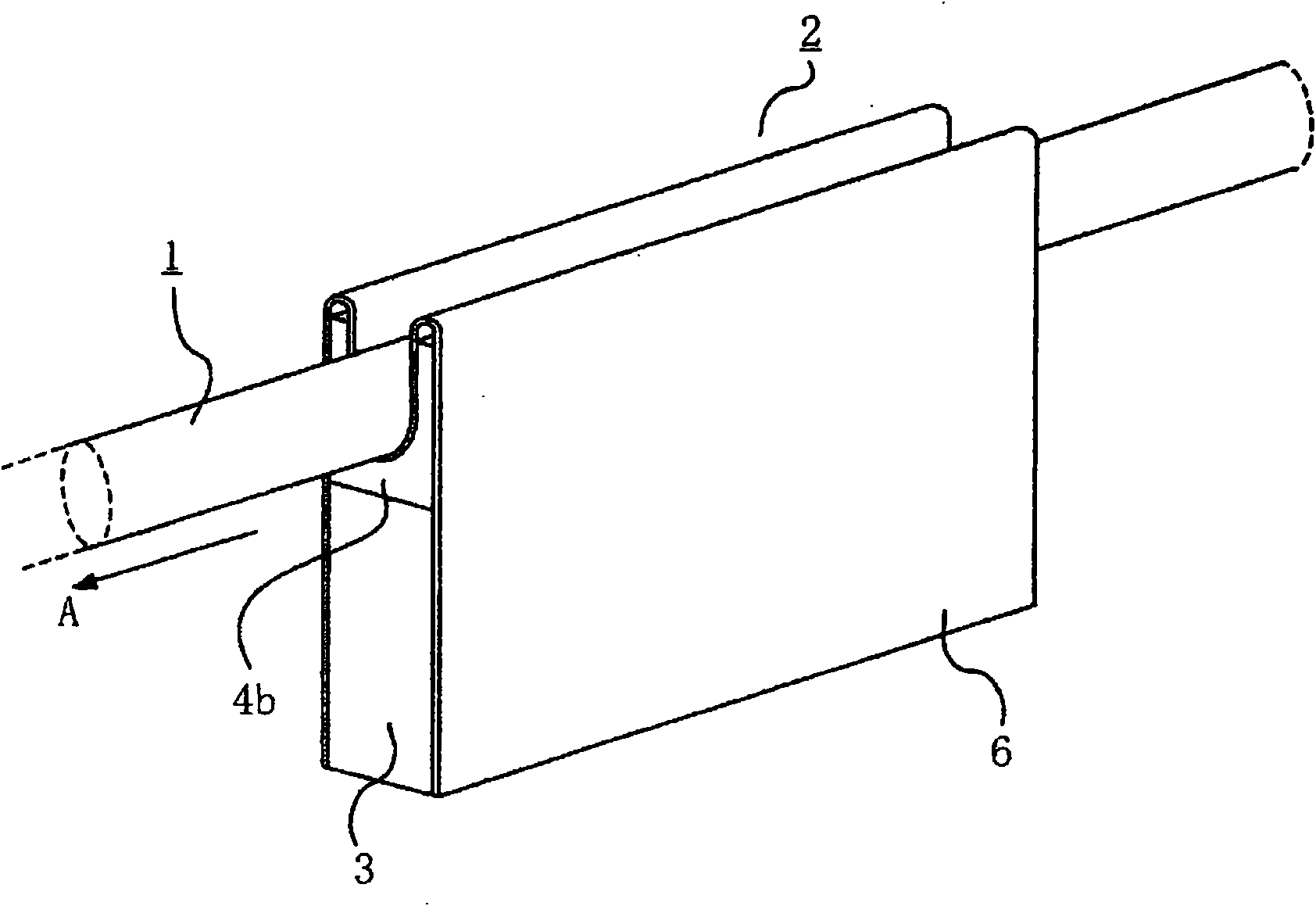

Explosion-proof coil, electronic expansion valve and machining method of explosion-proof coil

ActiveCN106151646AImprove explosion-proof performanceMeet certification requirementsOperating means/releasing devices for valvesEfficient regulation technologiesElectronic expansion valveMachining

The invention discloses an explosion-proof coil which comprises a winding (1) and a winding shell (2). A cable mounting part (3) and a circuit board (4) are arranged on the winding shell (2). A leading wire (5) is installed on the circuit board (4). A protection sleeve (6) is arranged outside the leading wire (5). A housing (7) is further fixedly connected outside the winding shell (2). The top end of the housing (7) is higher than the bottom end of the protection sleeve (6). The housing (7), the cable mounting part (3), the circuit board (4), the leading wire (5) and part of the protection sleeve (6) are formed into a whole through encapsulation. Compared with the prior art, encapsulation of the bottom end of the protection sleeve (6) is achieved through the explosion-proof coil, the electric insulation performance of the joint of the circuit board (4) is guaranteed, the explosion-proof performance of the explosion-proof coil is improved, the explosion-proof coil is made to meet the national certification requirements for explosion-proof coils, and meanwhile, market requirements for the explosion-proof coil of an electronic expansion valve can also be met. The invention further provides the electronic expansion valve with the explosion-proof coil applied and a machining method of the explosion-proof coil.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

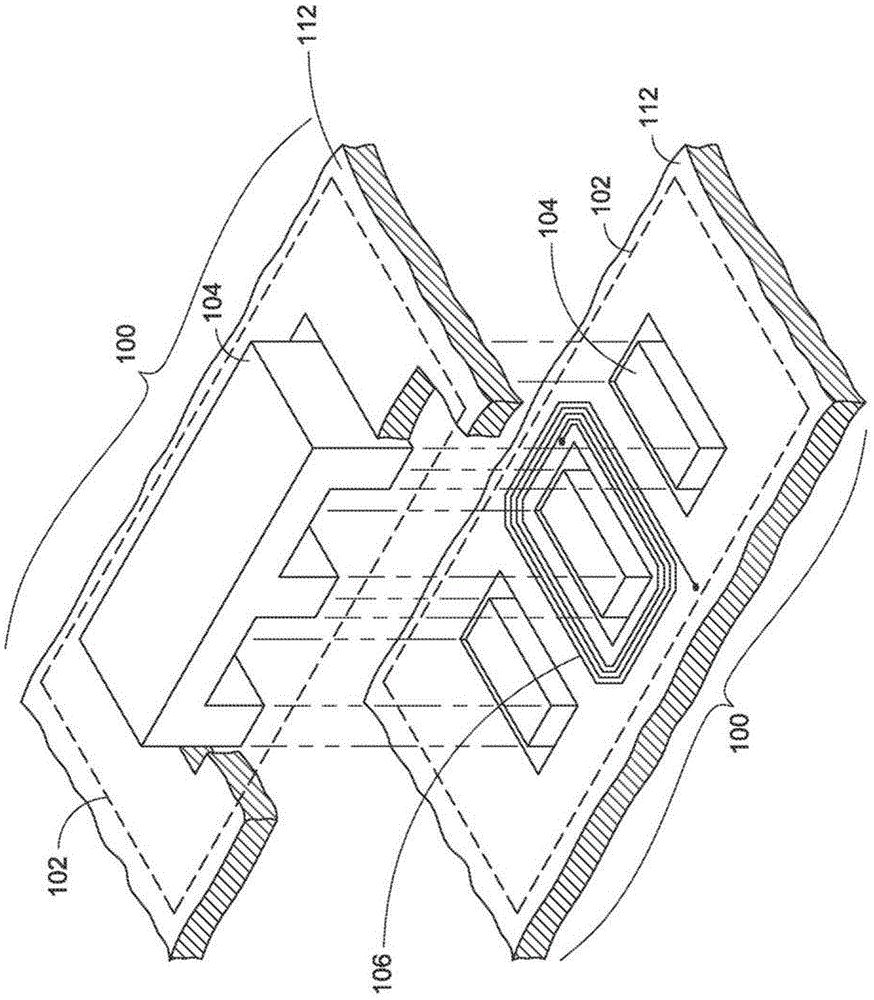

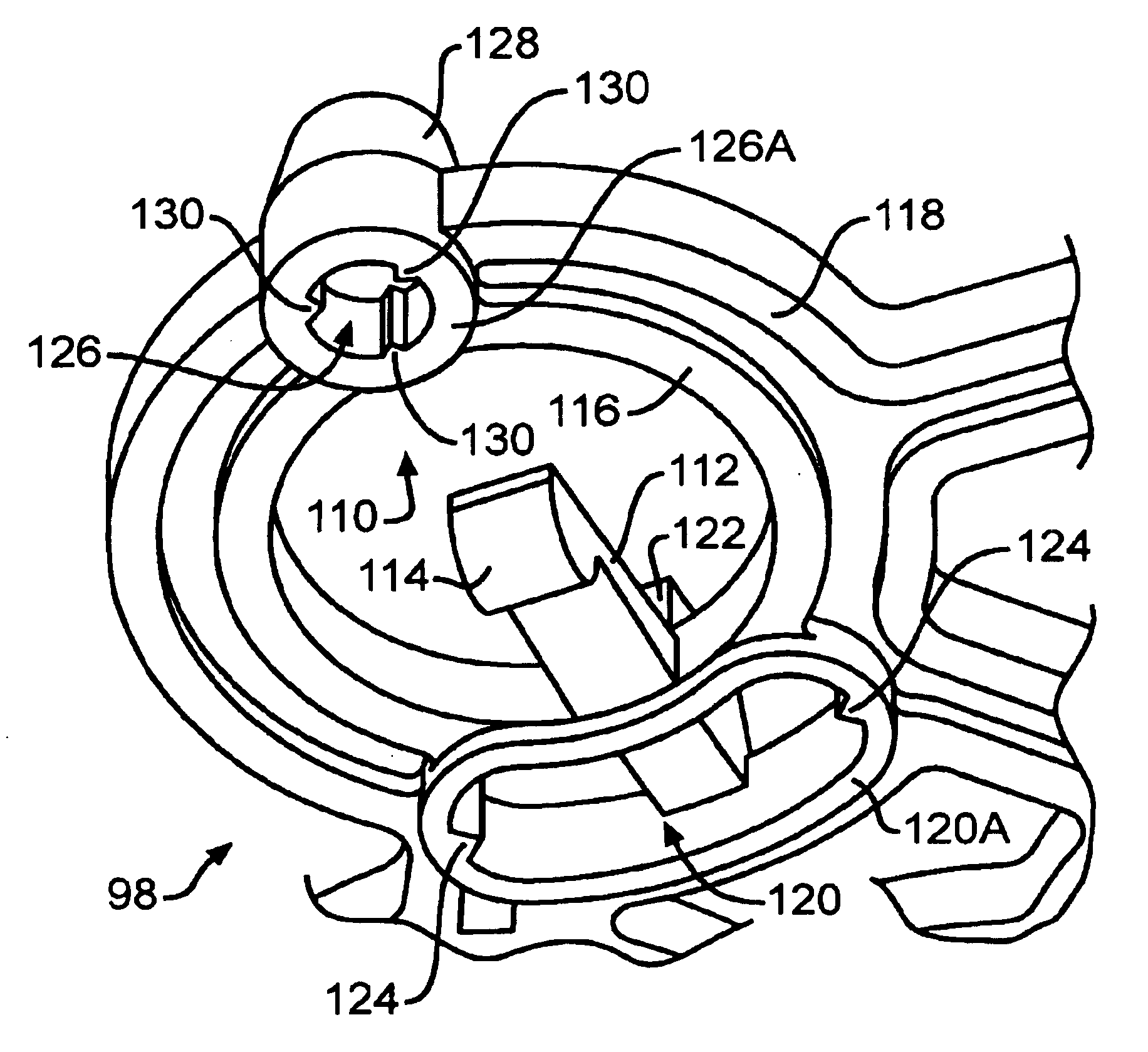

Assembling structure of field coil

ActiveUS7224253B2Simple structureImprove placement efficiencyElectromagnets without armaturesMechanical actuated clutchesManufacturing cost reductionElectromagnetic clutch

The present invention relates to an assembling structure of field coil, which has a simple mounting structure for a diode and a resistor to cut an off-noise of an electromagnetic clutch and to prevent damage of peripheral parts due to surge voltage generation when power source applied to an electronic coil body is cut off, thereby improving a mounting efficiency, reducing a manufacturing cost by reduction of the number of parts, and realizing an automatic production. The assembling structure of field coil includes an electronic coil body (101), a core ring (110) and a sleeve (120) having a first and second terminals (131) (132), and a case that has a receiving part (135) and a first and second connection parts (136) (137).

Owner:HANON SYST

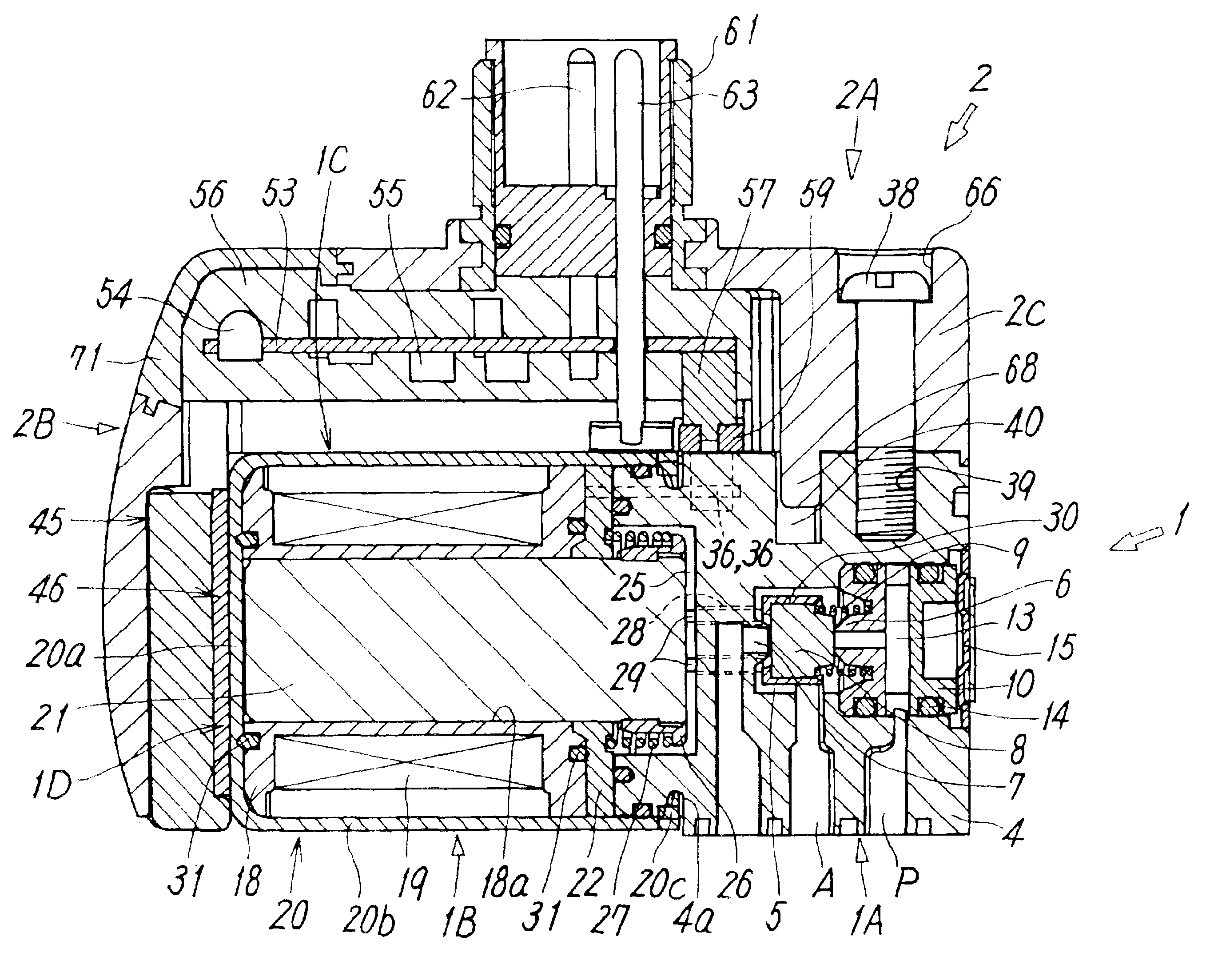

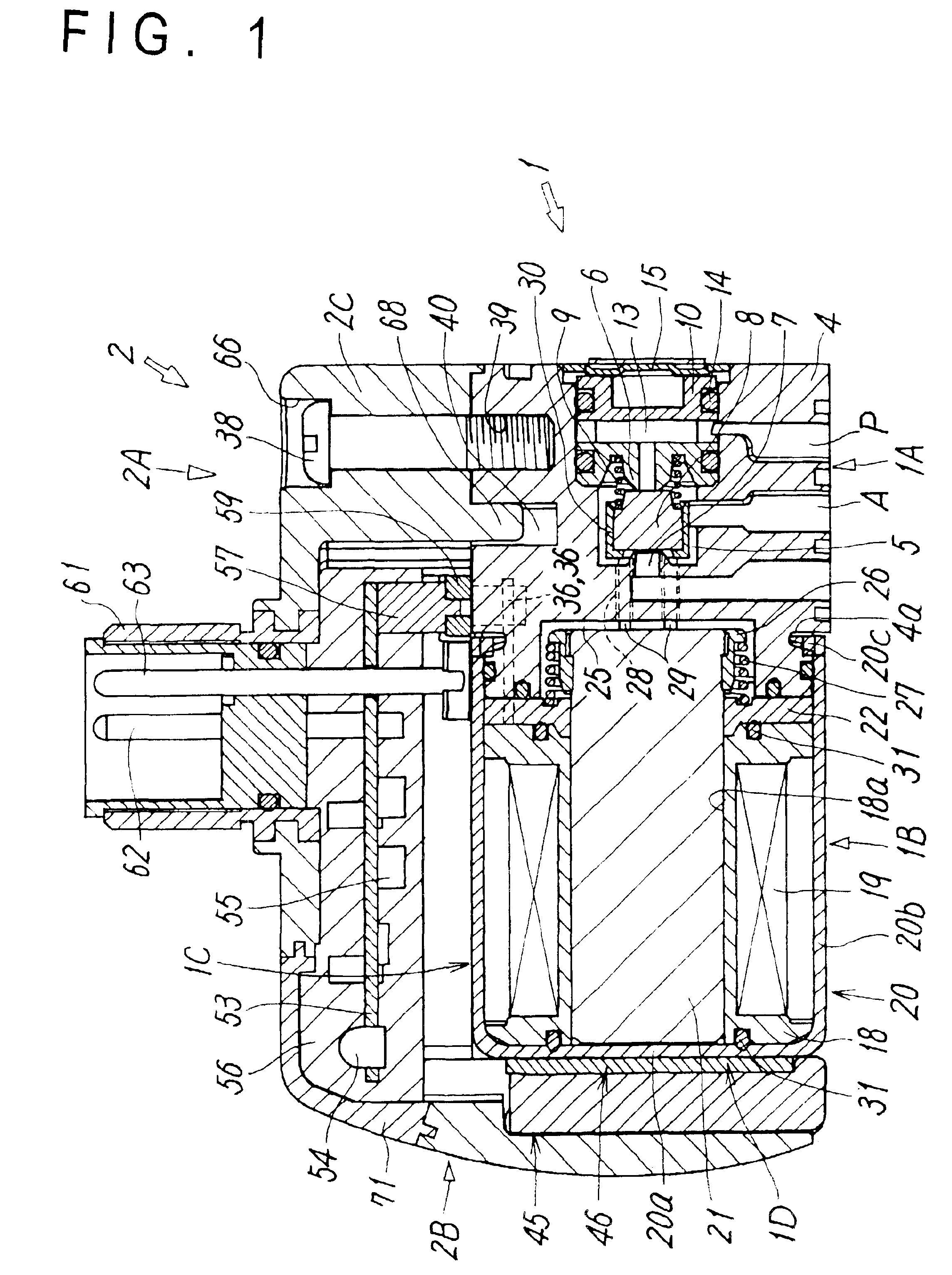

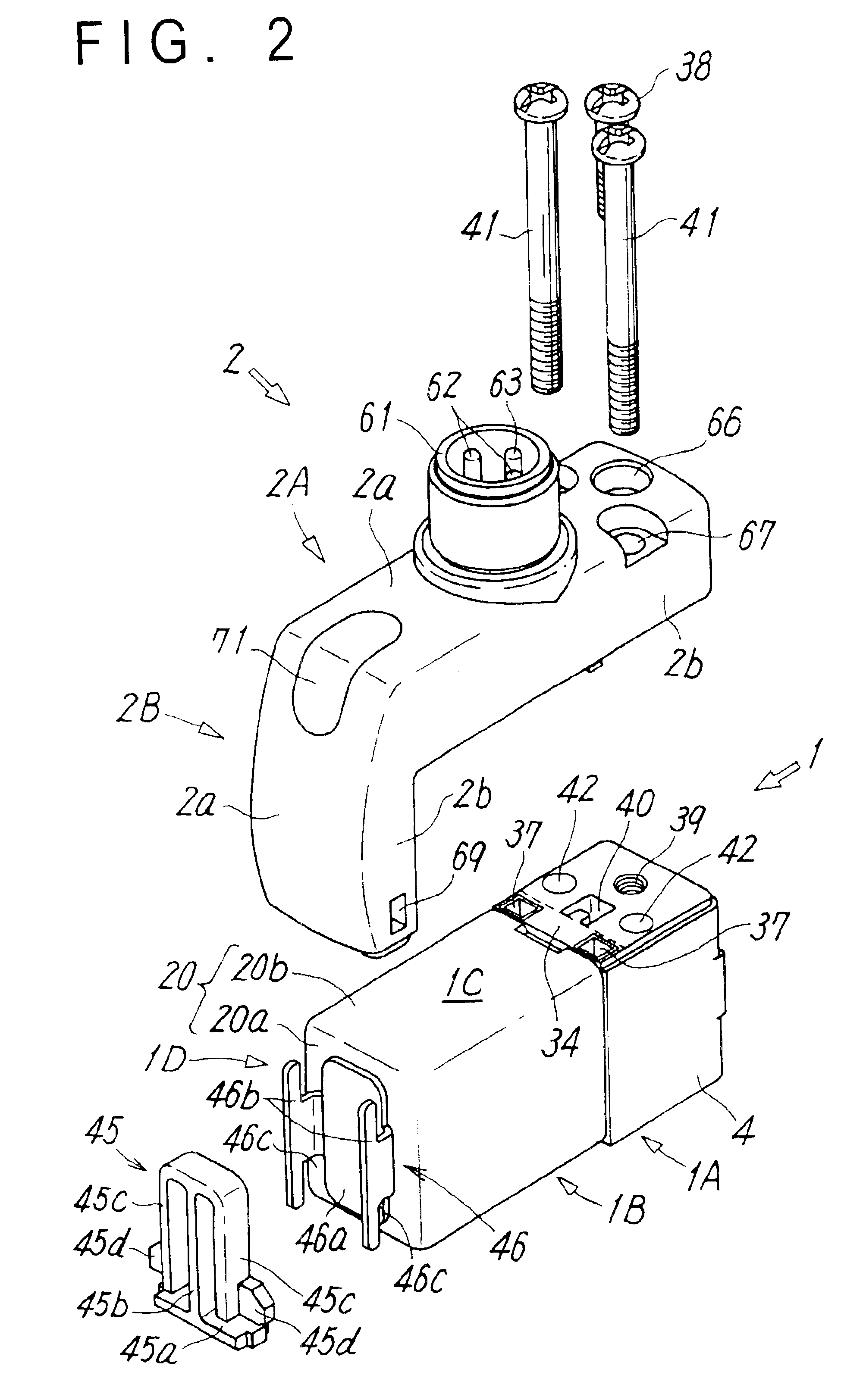

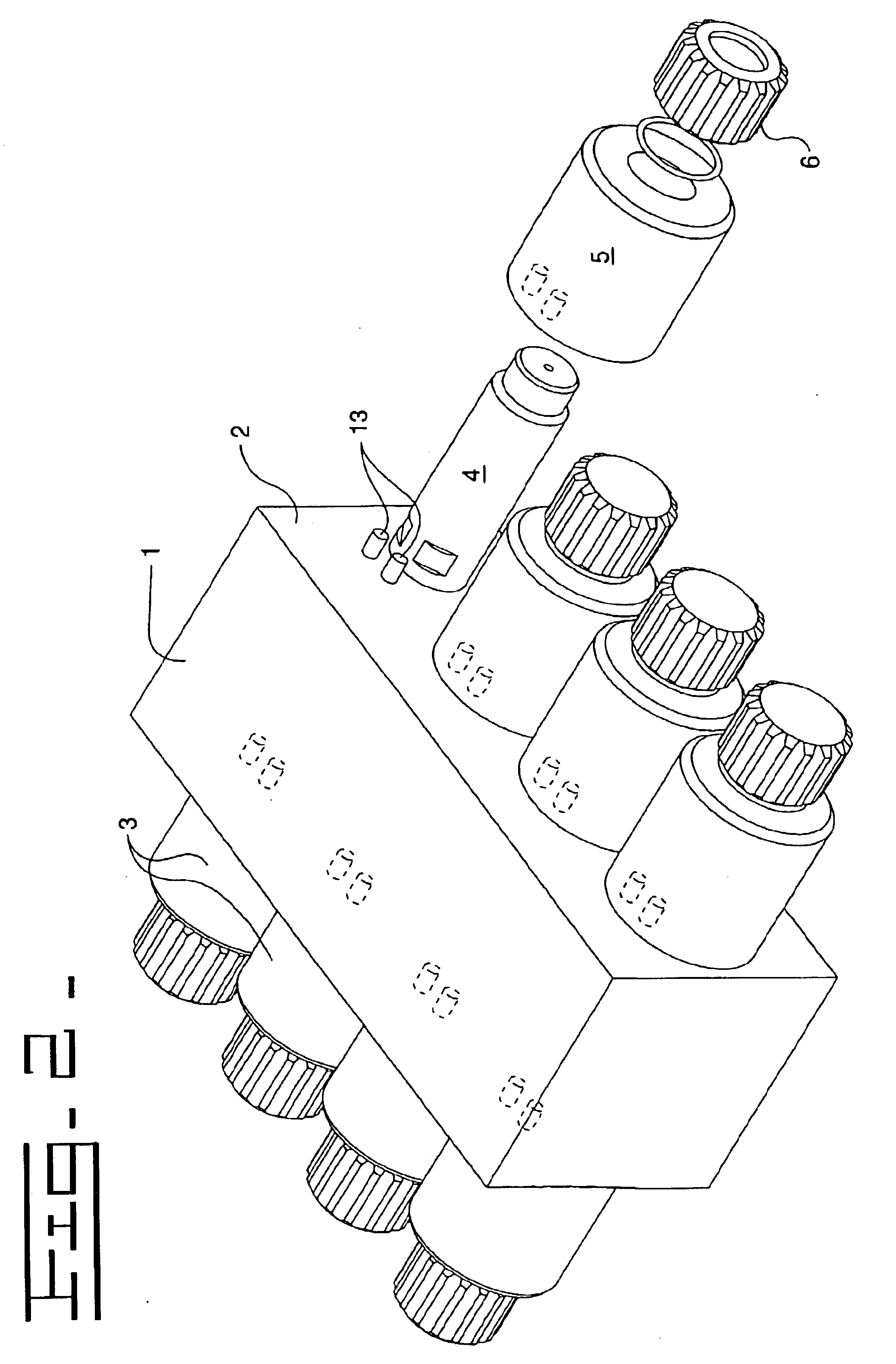

Solenoid valve with terminal box

InactiveUS6854707B2Simple structureEasy to separateOperating means/releasing devices for valvesTransformers/inductances casingsSolenoid valveElectronic component

A solenoid valve includes a first mounting face and a second mounting face for mounting of a terminal box. The first mounting face is formed with terminal holes in which coil terminals are housed and a screw hole for fixing. The second mounting face is provided with an elastic clip having hooks. The terminal box is in a substantially L shape. A first portion of the terminal box is provided with connecting terminals to be connected to the coil terminals, a connector to be brought into continuity with the connecting terminals, and a printed board mounted with an indicating lamp and electric components. A second portion of the terminal box is provided with locking holes into which the hooks of the elastic clip are locked.

Owner:SMC CORP

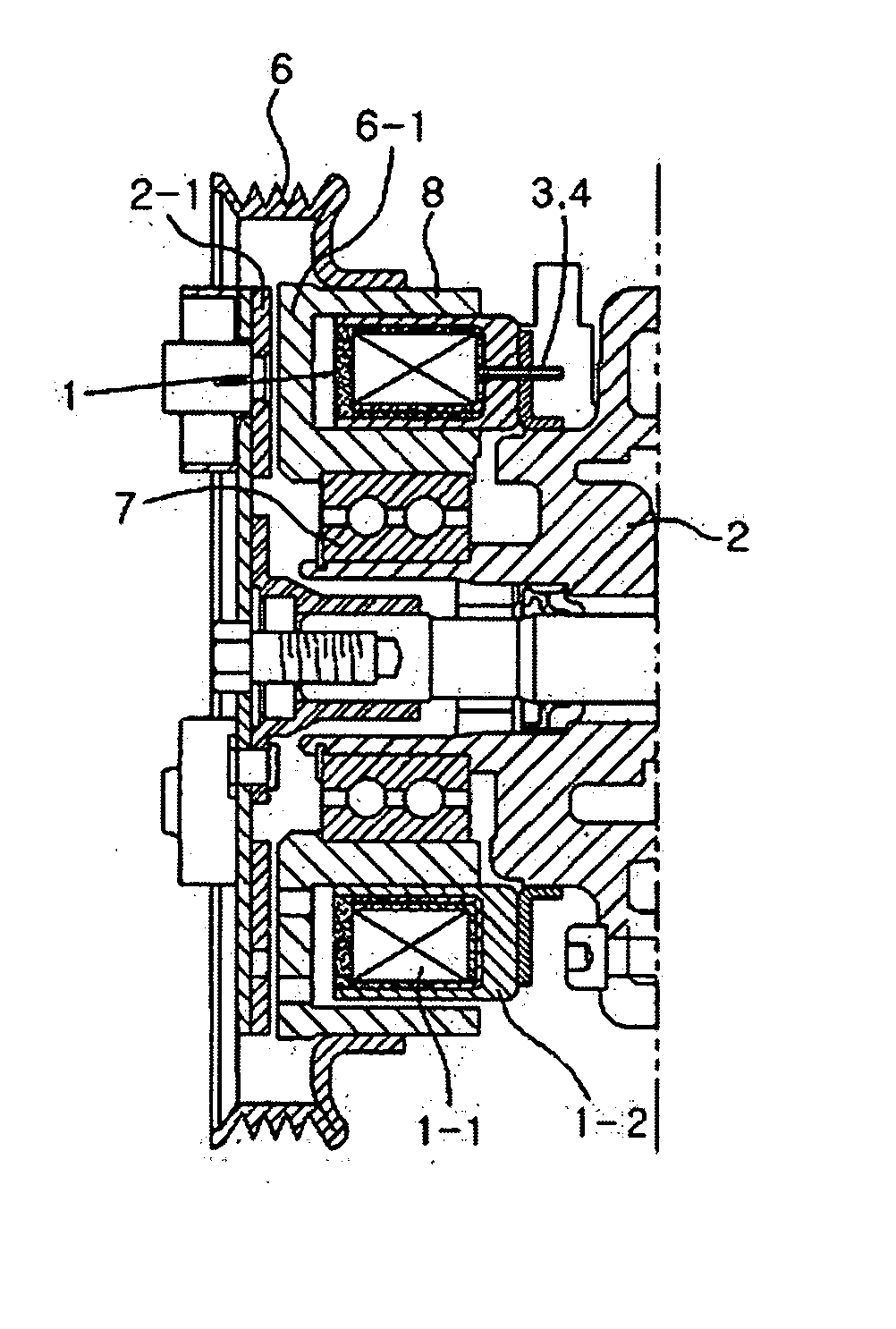

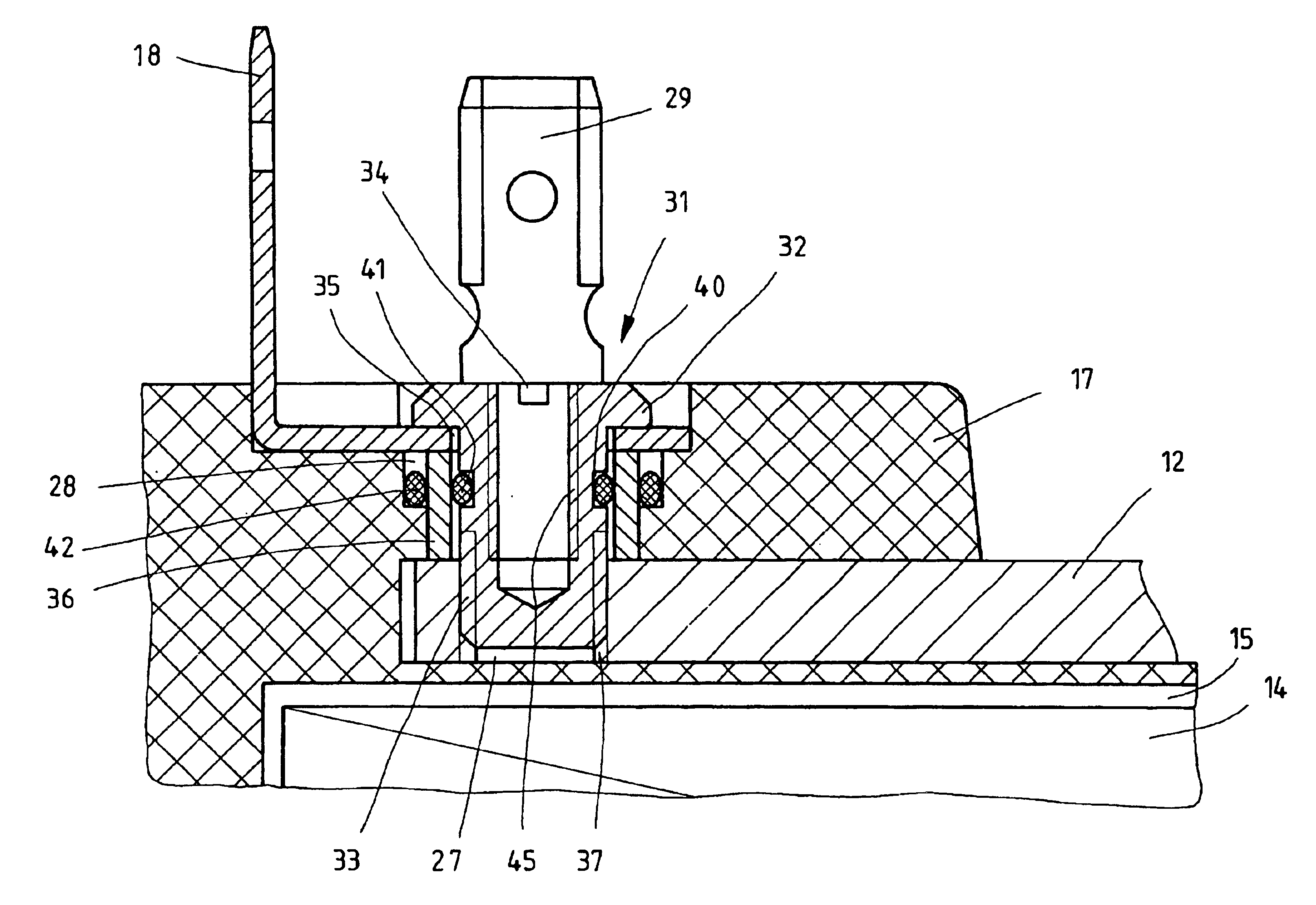

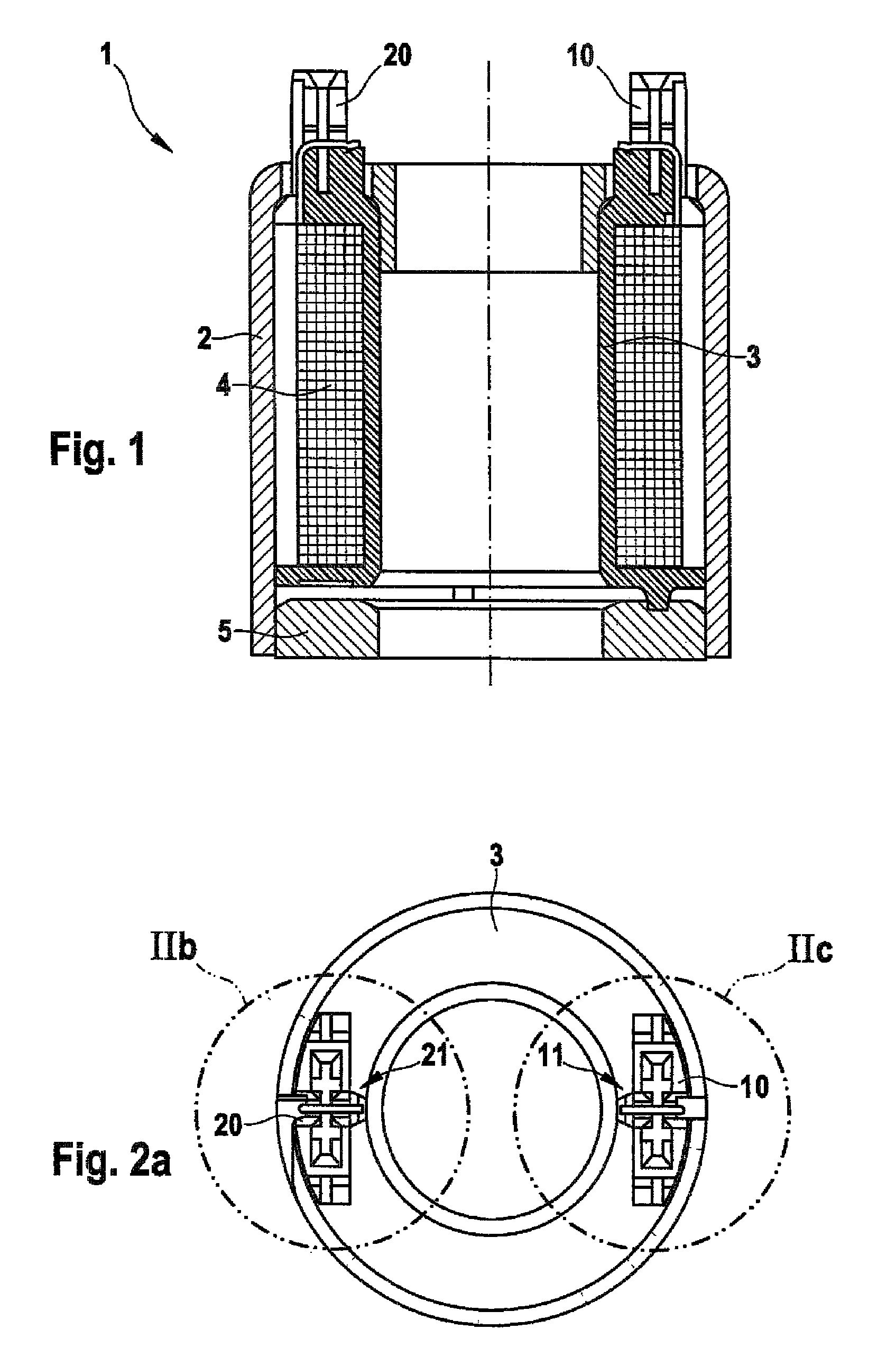

Magnet coil arrangement

InactiveUS6848919B2Fixed resistors with intervening connectorsTransformers/inductances casingsElectrical conductorElectrical connection

According to the invention, the coil of a magnet coil arrangement has a coil body which comprises a winding (14) and is extruded with plastic (17). A plug-in base with contact connectors is formed on the coil, wherein one of the connectors is used for connection of the grounding conductor (18). A metallic housing is placed over the coil. Connection of said metallic housing to the contact connector associated to the grounding conductor is achieved by means of a connection element which is guided through a recess of the plug-in base. A sealing element (42) disposed between the connection element and the recess prevents penetration of a fluid from a region between the metallic housing and the coil, into the region where a connector is connected to the contact connectors. In order to improve the electrical connection between the contact connector associated to the grounding conductor and the metallic housing, for a connection element (31) which is threaded in the metallic housing, a cylindrical metallic part is placed between the contact connector and the metallic housing. A respective sealing element (41, 42) is placed between the connection element and the metallic cylindrical part as well as between said part and the recess of the plug-in base. Such magnet coil arrangements are used in electromechanically-controlled hydraulic valves in which metallic parts accessible from outside must be connected to a grounding conductor.

Owner:BOSCH REXROTH AG

Electric power connection part of electromagnetic clutch field coil assembly

ActiveUS7772946B2Reduce manufacturing costImprove productivityLine/current collector detailsMechanical actuated clutchesElectromagnetic clutchResidual magnetic field

An electric power connection part of an electromagnetic clutch field coil assembly connected with an electric power connector at a side of a vehicle engine, includes a housing assembly connected to the field coil assembly with electric wires, which is extracted therefrom, interposed therebetween; a discharge device for absorbing a surge voltage; and a magnetic field elimination device for eliminating a residual magnetic field are injection molded and combonined within the housing assembly. Accordingly, the electric power connection part has an advantage in that it is not directly influenced by heat radiated from a field coil assembly so that electric / electronic devices can be prevented from being damaged; since an epoxy applying process for attaching electric / electronic devices such as a discharge device and a magnetic field elimination device is omitted, a manufacturing process is greatly simplified; and the number of components are reduced so that manufacturing process thereby decreasing costs.

Owner:HANON SYST

Electromagnetic actuator

ActiveUS20150332834A1Exact lengthOperating means/releasing devices for valvesElectromagnet terminals/connectorsEngineeringConductor Coil

An electromagnetic actuator includes: a magnetic coil, which has a coil form having a coil winding situated on it and a central clearance extending in an axial direction; an armature slidably situated in the central clearance; a terminal piece situated on an axial end of the coil form, in which an actuating element is slidably supported in the axial direction. The armature is movable by an actuation of the magnetic coil such that a force applied by the armature is transmitted to the actuating element. The actuating element is configured in two parts, including an actuating pin supported in the terminal piece and a separator fixedly connected to the actuating pin on an end section of the actuating pin protruding from the terminal piece in the direction of the armature and which is acted upon by the armature when the magnetic coil is actuated.

Owner:ROBERT BOSCH GMBH

Terminal structure of coil device

ActiveUS20100245010A1Transformers/inductances coils/windings/connectionsFuel injection apparatusEngineeringMechanical engineering

A terminal structure of a coil device includes a coil having a rectangular conductive wire covered with a dielectric film, and a terminal having a fusing part. An end portion of the wire from the coil has first and second flat surfaces, and the fusing part is electrically connected to these flat surfaces by fusing. The fusing part includes a planar portion surface-contacting a first flat surface, and a folded piece folded in a direction perpendicular to a plane of the planar portion. The end portion is clamped between the planar portion and the folded piece. The folded piece includes a contact surface portion contacting a second flat surface. The contact surface portion includes a stepped portion that increases a deformation amount of a contact area of the second flat surface contacting the stepped portion, compared to an adjacent area of the second flat surface adjacent to the contact area.

Owner:DENSO CORP

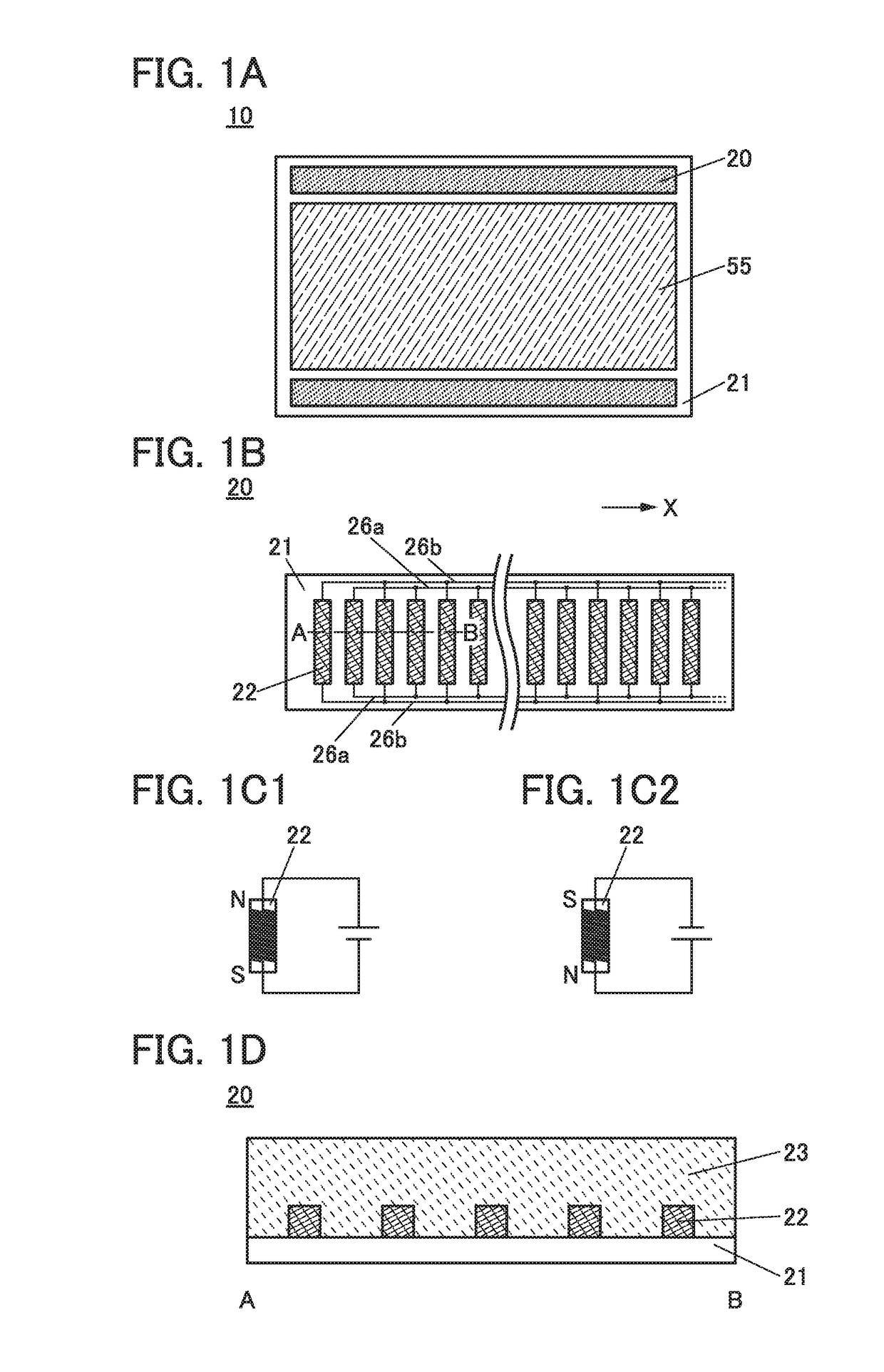

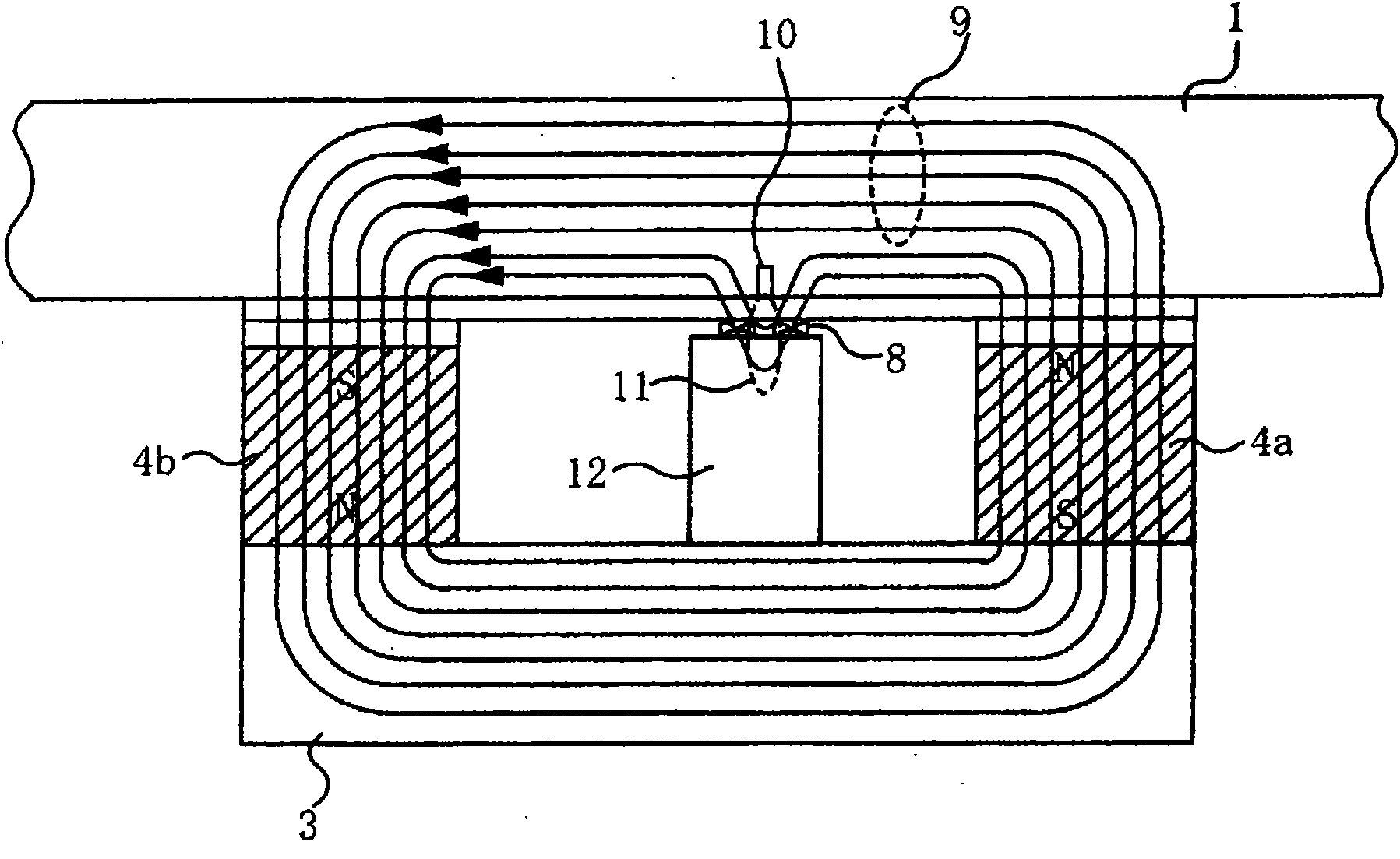

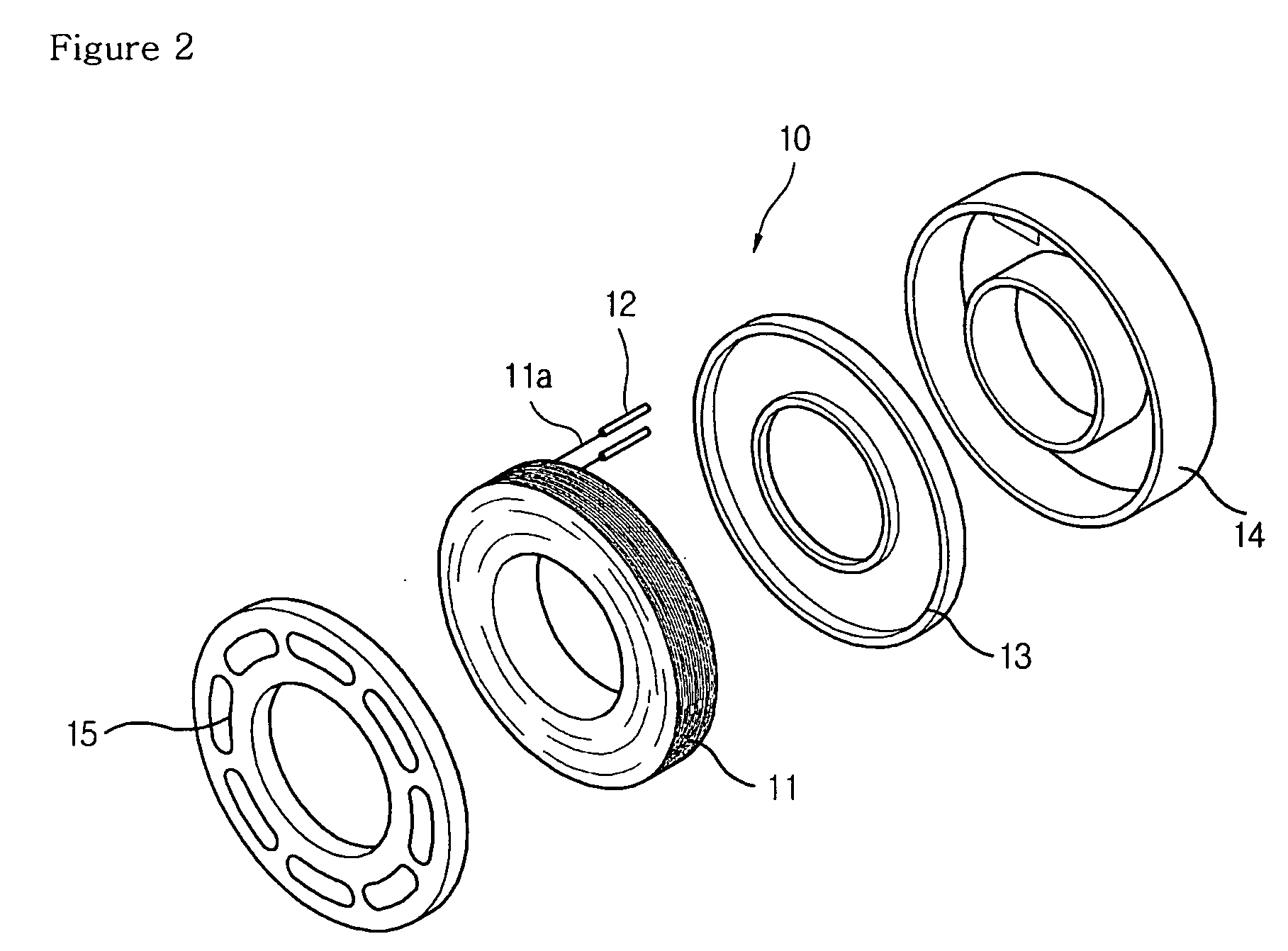

Wire rope flaw detector

InactiveCN101600961AReduce fluxLarge leakage fluxElevatorsElectromagnet terminals/connectorsMagnetic polesElectrical polarity

A wire rope flaw detector comprises a magnetizer having a pair of excitation magnets (4a, 4b) arranged on a back yoke (3) by reversing the polarities and forming a main magnetic path in a predetermined section of a wire rope (1) in the axial direction, and a detection coil (8) arranged in the predetermined section in the axial direction and detecting leakage flux generated from a damaged part (10) of the wire rope. The excitation magnets (4a, 4b) have such a shape as the cross-section intersecting the wire rope (1) perpendicularly surrounds the wire rope (1), and has orientations of magnetic pole directing toward the wire rope (1) from at least two directions on this cross-section.

Owner:MITSUBISHI ELECTRIC CORP

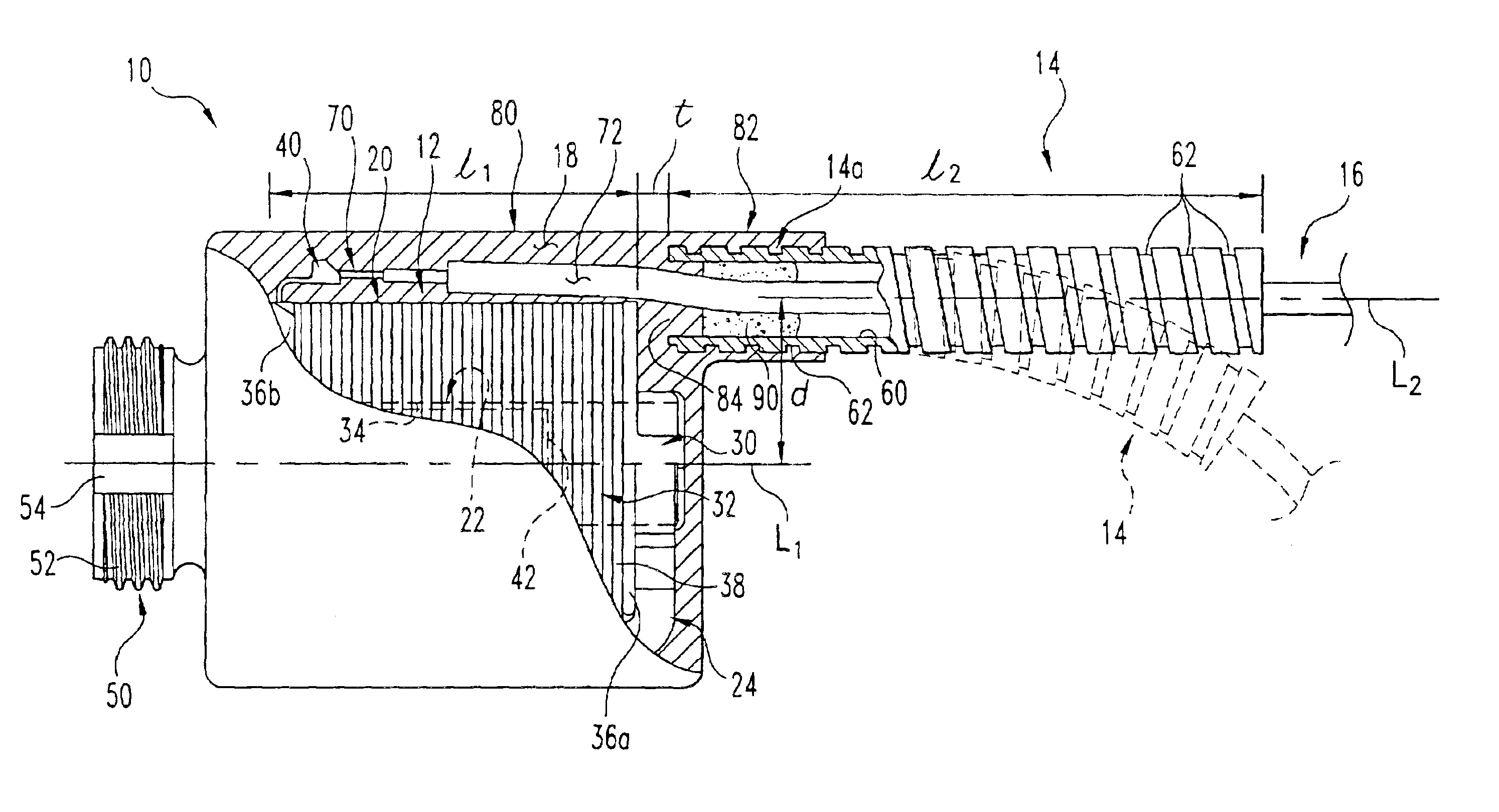

Laser sealing of injector solenoids

InactiveUS20090291575A1Efficiently meltedImprove performance and durabilityInductances/transformers/magnets manufactureElectromagnet terminals/connectorsBobbinPlastic materials

A solenoid coil / connector assembly includes a coil assembly having coil wires wound around a bobbin, an overmold encapsulating the coil assembly, and a plurality of seals formed between the bobbin and the overmold using laser light, the seals hermetically sealing the coil wires. By using a laser welding process for plastic materials directed at an internal interface between the bobbin and overmold the coil wires become hermetically sealed and moisture is thus prevented from gaining access to coil wires during use of the solenoid coil / connector assembly.

Owner:DELPHI TECH INC

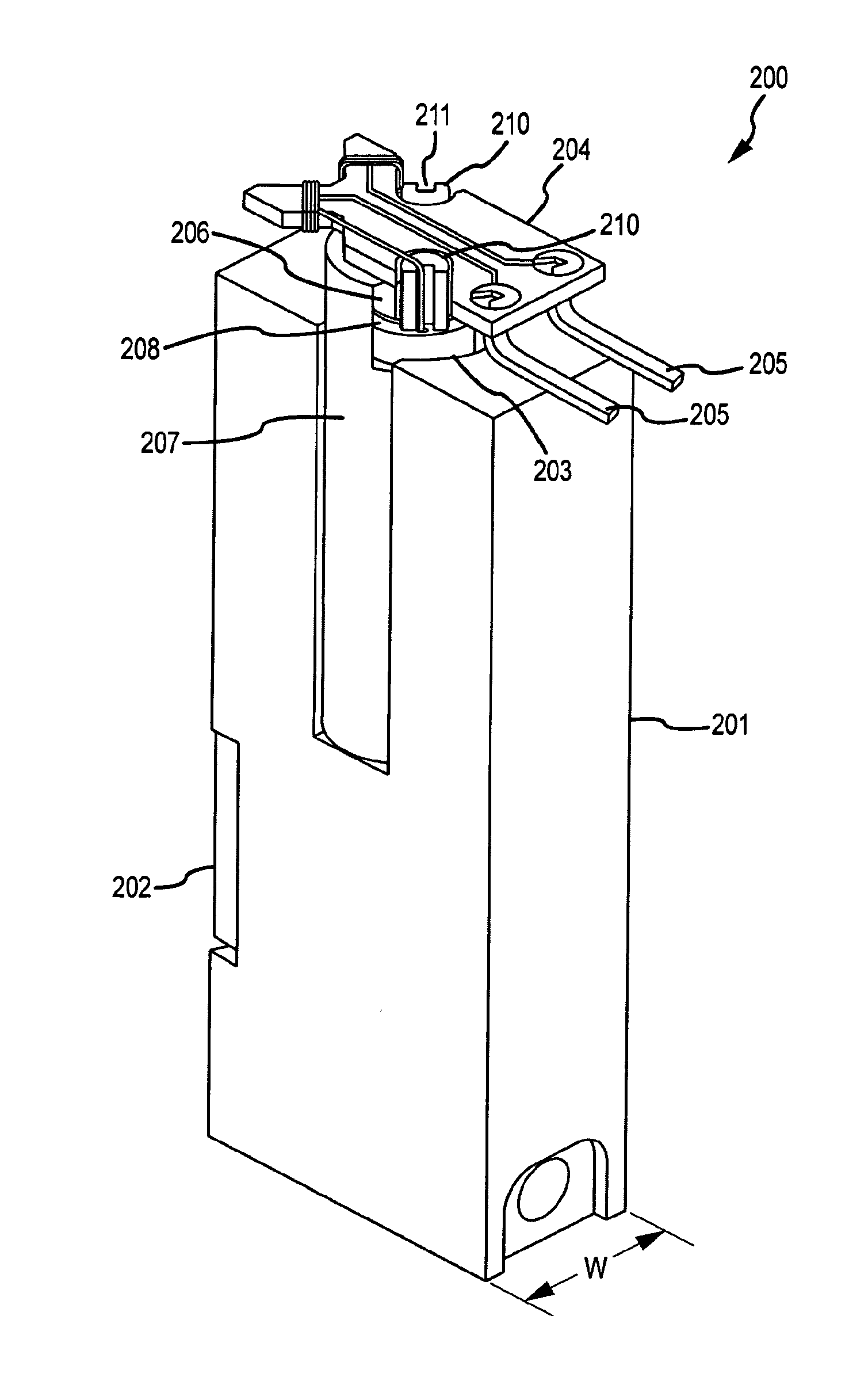

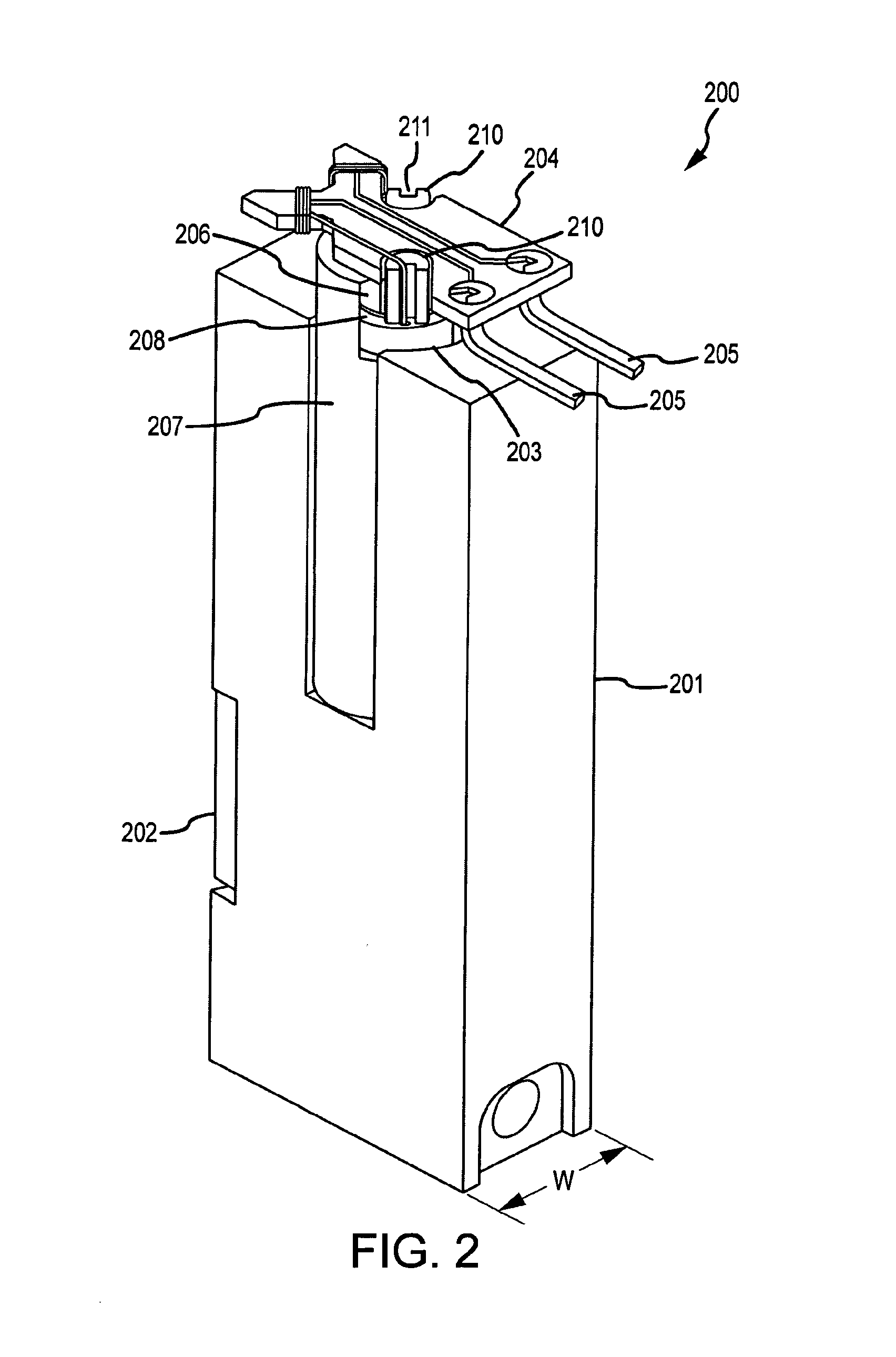

Solenoid valve with a metallic tube bobbin

InactiveUS20140239210A1Operating means/releasing devices for valvesTransformers/inductances detailsLine tubingBobbin

A solenoid valve (200) is provided. The solenoid valve (200) comprises a fixed core (206) and a movable armature (420). The solenoid valve (200) further comprises a metallic tube bobbin (308) surrounding at least a portion of the fixed core (206) and / or the movable armature (420). A wire coil (203) is wrapped around the metallic tube bobbin (308).

Owner:FAS MEDIC SA

Electromagnetic coil means

ActiveUS8305180B2Improve insulation performanceEnsure stability and reliabilityWindingsTransformers/inductances coils/windings/connectionsElectromagnetic coilStator

The present invention discloses an electromagnetic coil means, comprising a terminal part and pins passing through the terminal part, wherein the pins are divided into a first group of pins connected with an upper coil stator and a second group of pins connected with a lower coil stator which are spaced apart from each other; the first group of pins comprises first outer sections with first head portions and first inner sections with first root portions; the second group of pins comprising second outer sections with second head portion and second inner sections with second root portions; the first and second head portions extend out from a pin leading-out surface of the terminal part, characterized in that, at least one group of the first and second groups of pins are bent, and a distance between adjacent said first and second head portions is larger than that between adjacent said first and second root portions. By this electromagnetic coil means, the distance of solder joints between adjacent head portions of pins is increased, thus the insulation performance between the solder joints is improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

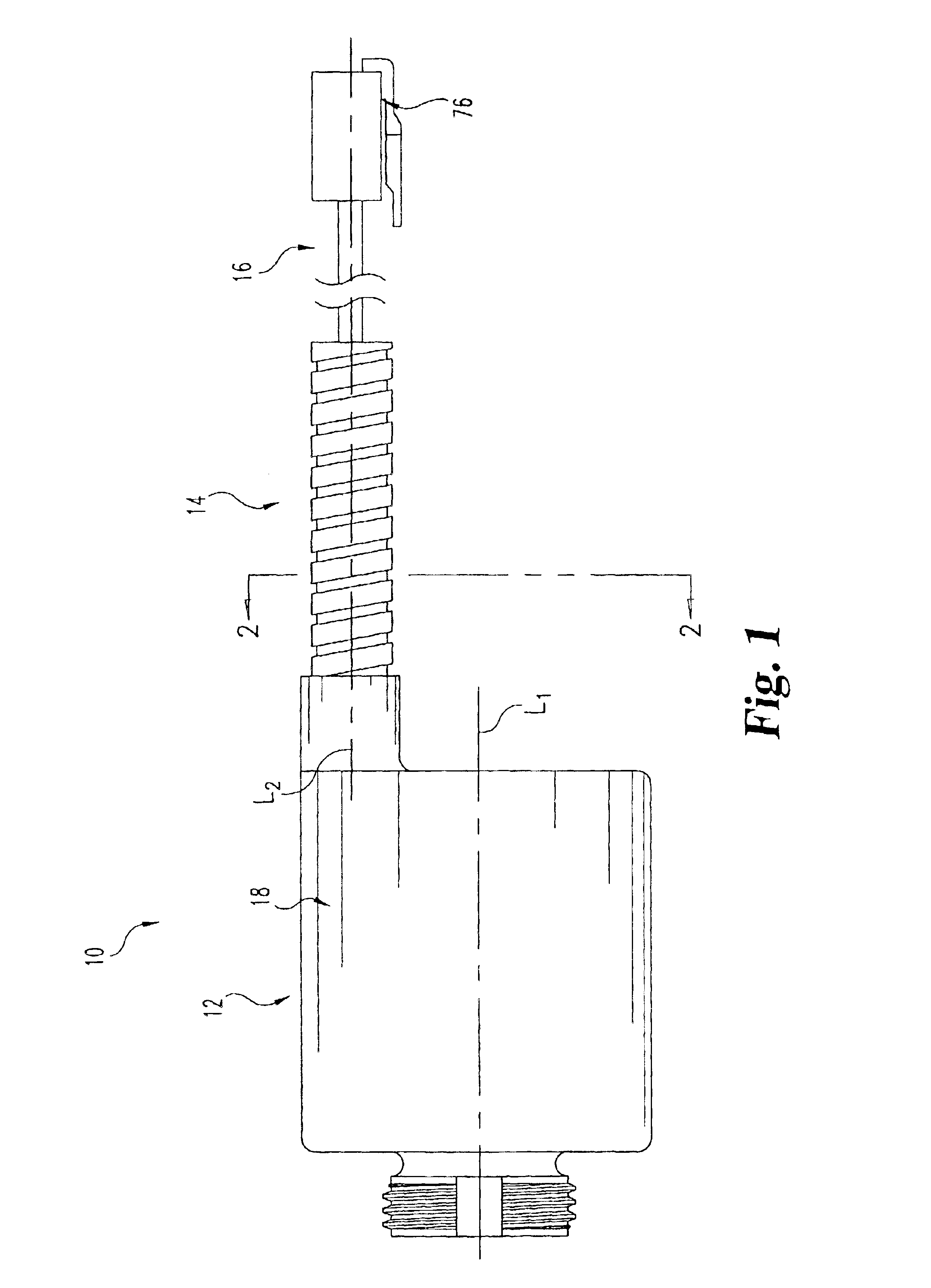

Safety apparatus

The invention relates to a safety apparatus for avoiding a possible fire risk in an operating magnet which can be supplied with electric current, having at least one coil former (14) which is arranged in a housing (76, 82) and on which a coil winding (16) is fitted, and having an operating part (20, 36) which is at least partially guided in the coil former (14). As a result of at least parts of the operating magnet being equipped with active and / or passive safety means of the apparatus in order to effectively counteract the risk of fire, the safety means are no longer arranged remote from the actual event, for example in the form of a fuse in the electrical supply circuit, but rather directly at the location of the event where the possible fire or scorching situation can directly occur.

Owner:HYDAC ELECTRONICS GMBH

Encapsulated solenoid assembly having an integral armor tube cable protector

InactiveUS6864772B2Operating means/releasing devices for valvesTransformers/inductances casingsElectrical conductorActuator

An encapsulated solenoid assembly including an electronic actuator and an elongate metallic armor tube for receiving an electrical conductor therethrough which is electrically connected to the electronic actuator. The electronic actuator and an end portion of the armor tube are encapsulated within an outer casing of encapsulation material to integrally couple the armor tube with the electronic actuator without the use of additional connection components or complex attachment arrangements. In one embodiment, the armor tube is corrugated to facilitate bending and to aid in maintaining engagement with the encapsulation material. In another embodiment, the electronic actuator includes a magnetic plunger that is displaceable along an actuation axis, with the armor tube extending along a longitudinal axis laterally offset from the actuation axis. In a further embodiment, the electrical conductor extends alongside a substantial length of the electronic actuator so as to become embedded within the outer shell of encapsulation material.

Owner:KURZ KASCH

Assembling structure of field coil

ActiveUS20060145803A1Simple structureImprove placement efficiencyElectromagnets without armaturesMechanical actuated clutchesManufacturing cost reductionElectromagnetic clutch

The present invention relates to an assembling structure of field coil, which has a simple mounting structure for a diode and a resistor to cut an off-noise of an electromagnetic clutch and to prevent damage of peripheral parts due to surge voltage generation when power source applied to an electronic coil body is cut off, thereby improving a mounting efficiency, reducing a manufacturing cost by reduction of the number of parts, and realizing an automatic production. The assembling structure of field coil includes an electronic coil body(101), a core ring(110) and a sleeve(120) having a first and second terminals(131)(132), and a case that has a receiving part (135) and a first and second connection parts(136)(137).

Owner:HANON SYST

Solenoid of electromagnetic valve

ActiveUS9746097B1Prevent a short circuitElectromagnets without armaturesOperating means/releasing devices for valvesBobbinEngineering

The present disclosure relates to a solenoid of an electromagnetic valve where the number of processes can be reduced and breaking of a conductive wire can be suppressed in a simple structure, and the solenoid of the electromagnetic valve according to the present disclosure comprises a conductive wire; a bobbin having a tubular winding portion where the conductive wire is wound around in a coil shape and a flange portion disposed on both end portions of the winding portion; a terminal portion which is disposed on the flange portion and protrudes in a planar shape in a direction perpendicular to the central axis of the bobbin on a radially outer side than the winding portion relative to the central axis, and in which two terminals are provided on a distal end portion side; and two wall portions which are disposed on both sides of the terminal portion in a width direction, stand upright in a central axis direction and face each other, wherein both end portions of the conductive wire are drawn out from the bobbin to the terminal portion, directed toward a radially outer side from a winding portion side of the two wall portions and electrically connected to the terminals.

Owner:NIDEC TOSOK CORP

Electromagnetic device and conductive structure thereof

ActiveUS20150116063A1Improve cooling effectElectromagnets without armaturesTransformers/inductances detailsElectrical connectionEngineering

A conductive structure for an electromagnetic device includes a conductive sheet and a plurality of protrusions. The conductive sheet includes two electrical connection terminals. The protrusions are arranged between the electrical connection terminals. The protrusions include a support. The support is connected to the conductive sheet. Adjacent two of the protrusions define a first heat dissipation passage.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

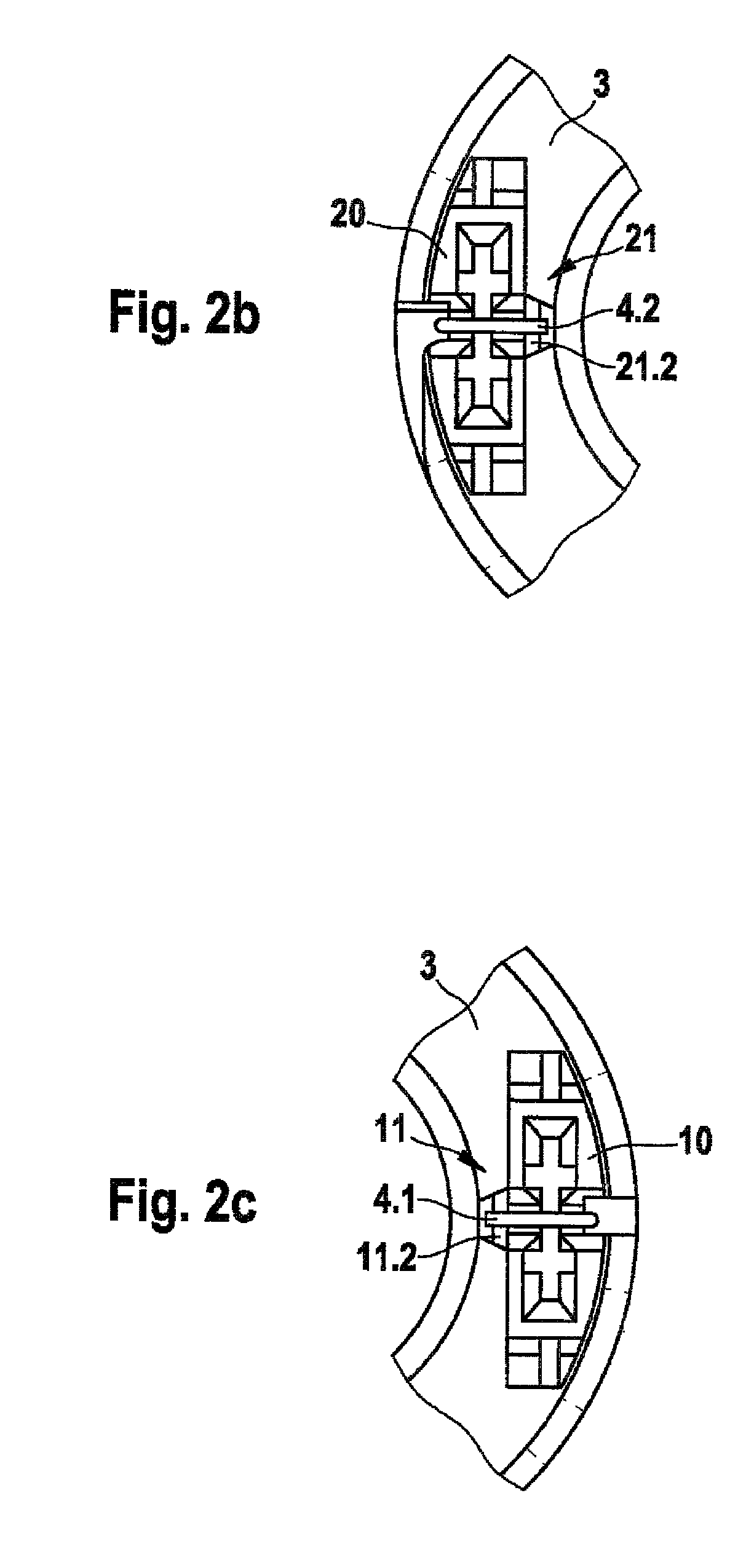

Connection device and associated process

InactiveUS6840265B2Compact structureShort processOperating means/releasing devices for valvesServomotor componentsEngineeringContact element

The invention relates to a device for making contact between a solenoid and an electronic control unit arranged neighboring a valve block, wherein the solenoid projects away from a side wall of the valve block by a magnetic coil and a magnetic core, contact elements being arranged in an end face region of the solenoid facing towards the valve block in such a way that the contact elements can be directly electrically connected to corresponding contact elements arranged on a wall of the electronic control unit or of the valve block.

Owner:CLAAS INDTECHN

Method and arrangement for winding a winding wire onto a winding body and associated magnet assembly for a solenoid valve

ActiveUS8193890B2Less in cross-sectionEasy to testOperating means/releasing devices for valvesTransformers/inductances coils/windings/connectionsElectricitySolenoid valve

The invention relates to a method and an arrangement for winding a winding wire onto a winding body, and to an associated magnet assembly. The start of the winding wire is threaded into a first wire-receiving slot of a first electrical connection dome. By a winding operation a predefinable number of turns are then wound onto the winding body, and one end of the winding wire is threaded into a second wire-receiving slot of a second electrical connection dome and cut off. According to the invention, the start of the winding wire which has been threaded into the first wire-receiving slot is placed on a first wire support which is arranged downstream of the first wire-receiving slot. The winding wire is shaped and held before the winding operation such that the diameter of the winding wire is increased at one region positioned on the first wire support, in the direction of the width of the first wire-receiving slot, and the start of the winding wire is prevented from slipping back into the first wire-receiving slot.

Owner:ROBERT BOSCH GMBH

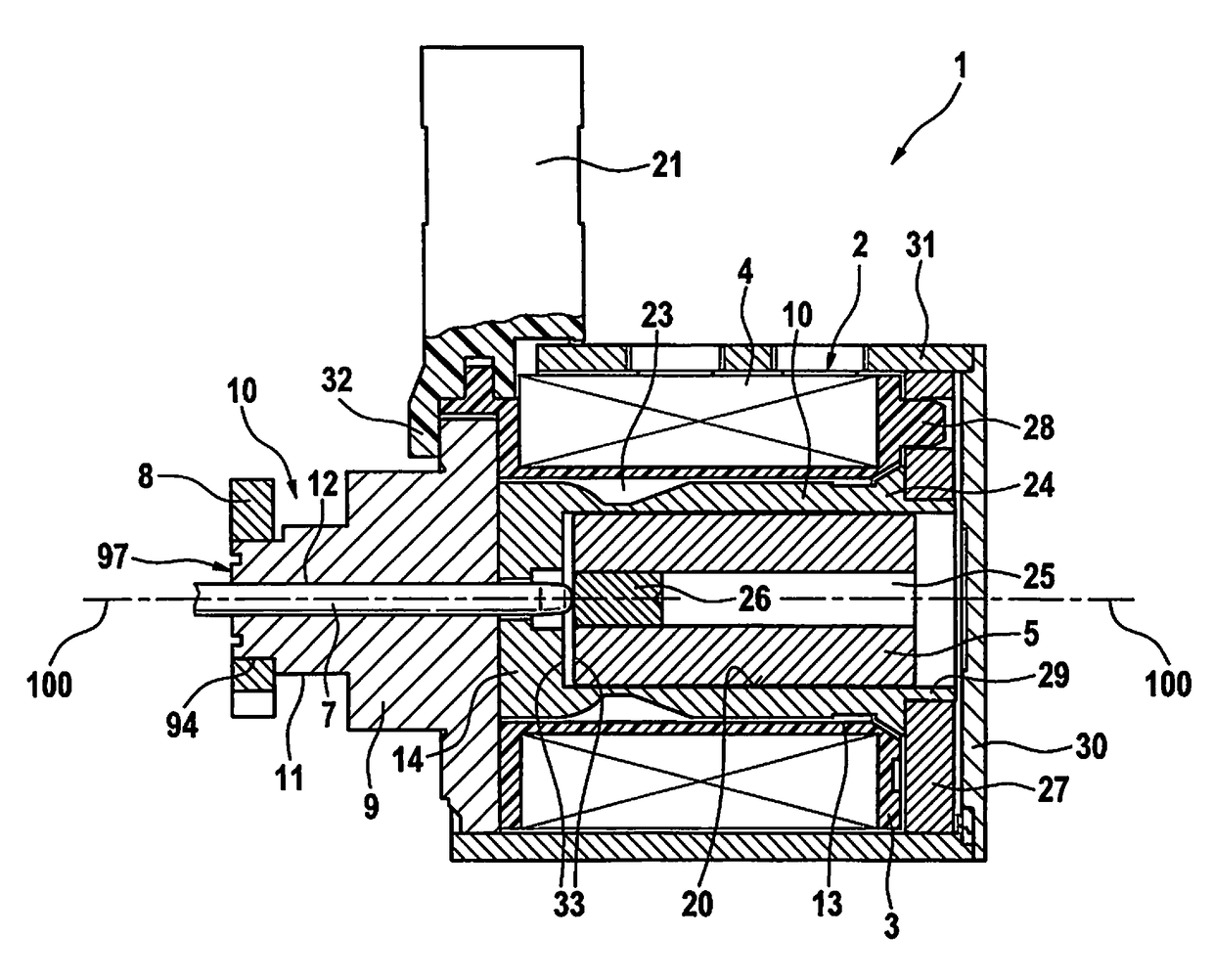

Electromagnetic actuator, flux washer body for an electromagnetic actuator, and method for manufacturing an electromagnetic actuator

ActiveUS20180156348A1Inexpensively manufacturableKeep strongOperating means/releasing devices for valvesElectromagnet terminals/connectorsMechanical engineeringElectromagnetic actuator

An electromagnetic actuator, including an armature movable along a longitudinal axis in an armature chamber, a solenoid coil extending around the longitudinal axis for generating a magnetic field for moving the armature, an actuating element coupled to the movements of the armature, and a flux washer body which is situated at an axial end of the solenoid coil and has a recess extending in the direction of the longitudinal axis in which the actuating element is displaceably mounted. It is provided that the flux washer body has a two-piece design and includes a base body made of sintered soft magnetic material, which faces the solenoid coil and in which the recess for the actuating element is situated, and a metal washer pressed onto an end of the base body facing away from the solenoid coil.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com