Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Textile reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

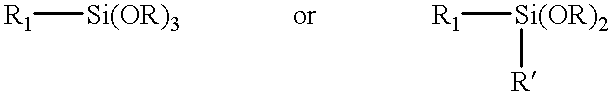

Composition for promoting adhesion between rubber and textiles

InactiveUS6046262ALimited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

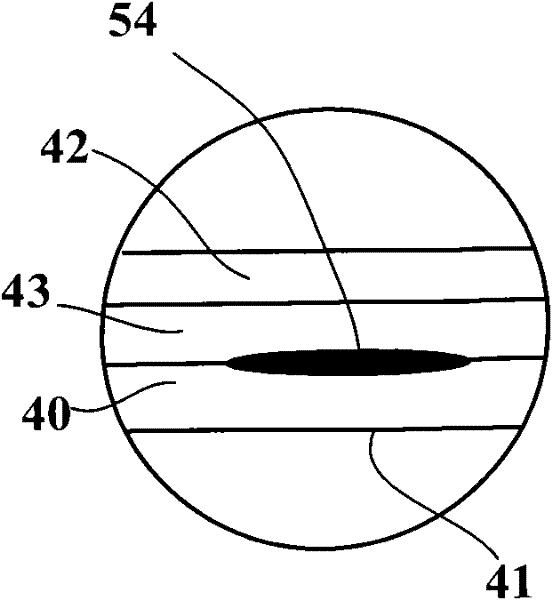

Tire that includes an electronic component

PendingUS20110226401A1Endurance is optimizedEasy to installTyresPneumatic tyre reinforcementsEngineeringElectronic component

An aeroplane tire that operates at an inflation pressure in excess of 12 bar includes a crown, two sidewalls, two beads, a carcass ply reinforcement anchored in the two beads and including at least one ply of textile reinforcements, a crown reinforcement, and an electronic component. The crown reinforcement includes, radially from inside outward, a working block that includes plies of textile reinforcement, and a protective block that includes reinforcements directed substantially circumferentially. The electronic component has elongate overall shape and includes a passive radio frequency identification device transponder equipped with two antennas forming a dipole. The electronic component is positioned in the tire under the crown, radially on an inside portion in relation to the carcass ply reinforcement, and directed in a substantially axial direction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

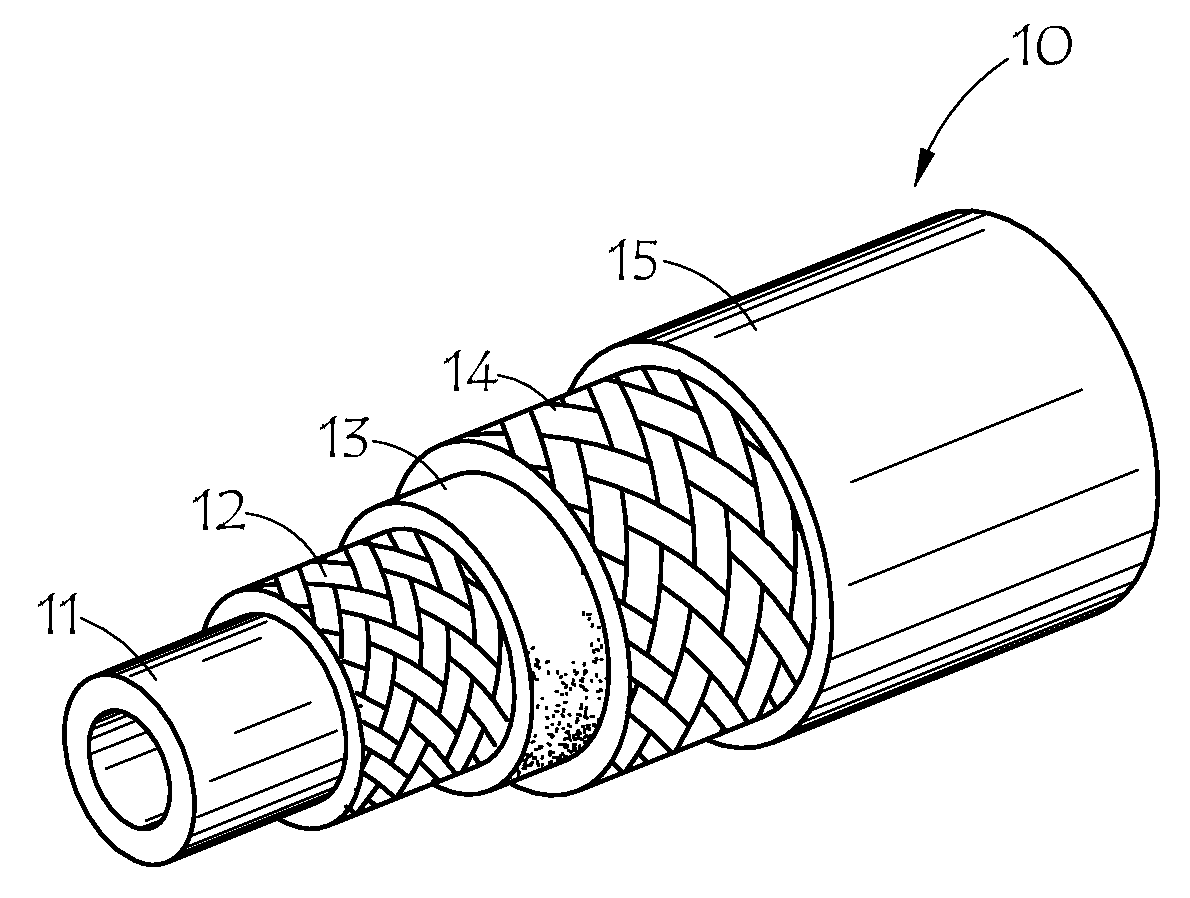

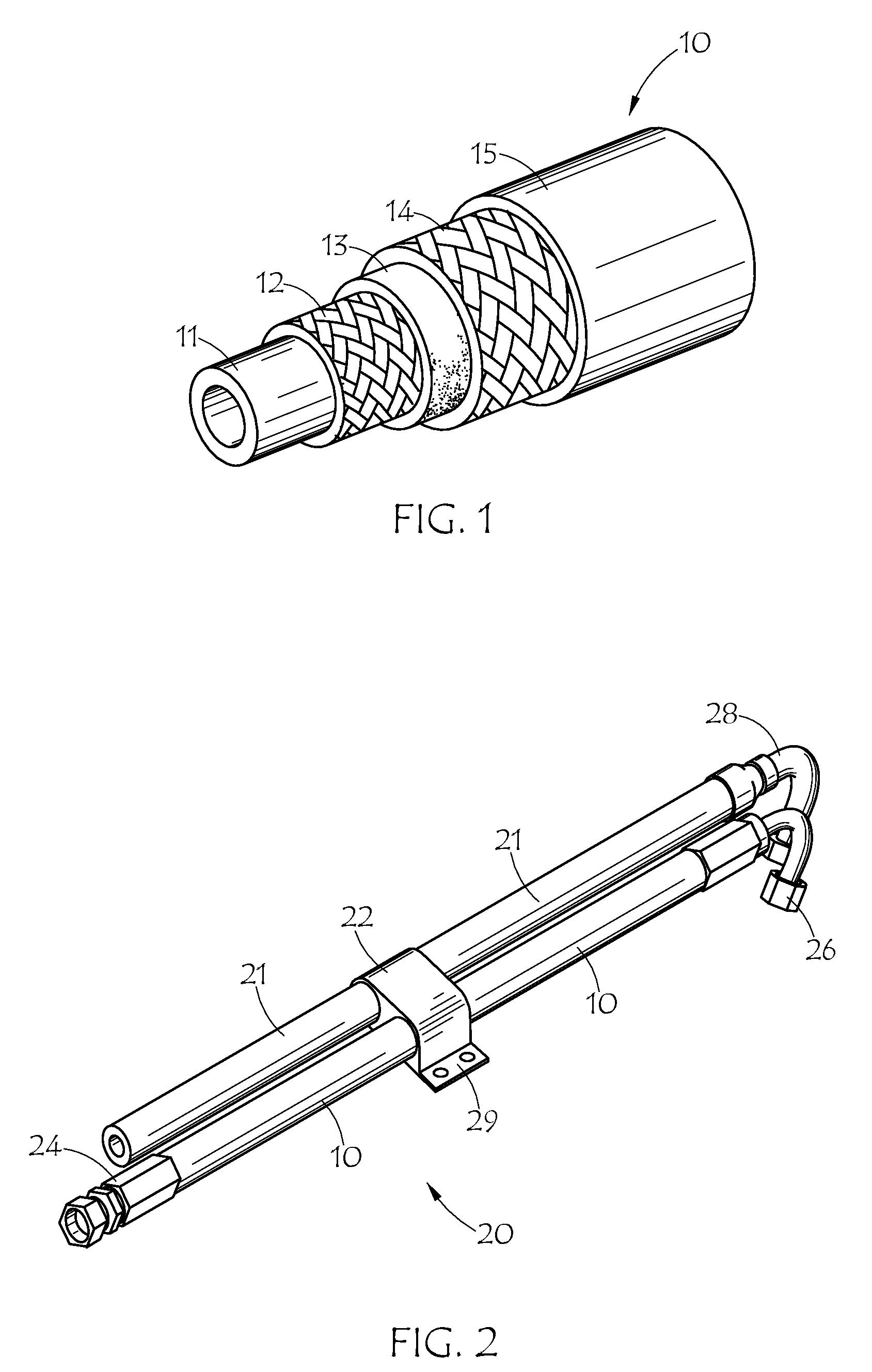

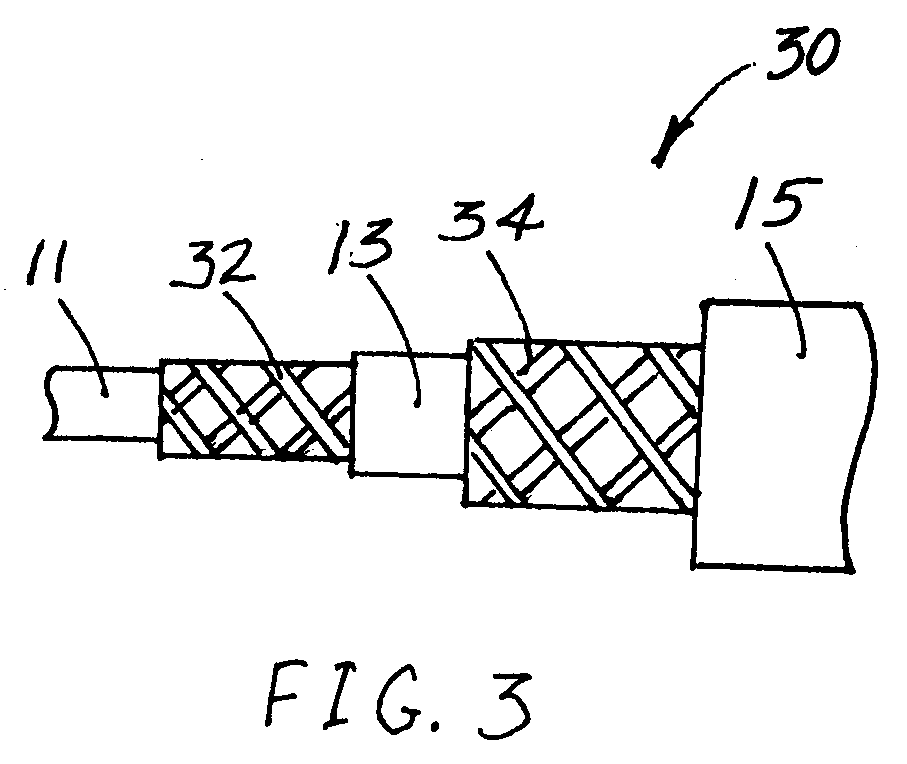

Controlled expansion hose

ActiveUS20090211660A1Reducing and smoothing pressure fluctuationImproved impulse fatigue resistance and burst pressureLayered productsPipe elementsYarnMaterial type

An expansion hose adapted for smoothing pressure fluctuations in a hydraulic system having an inner tube, a textile reinforcement, and an outer cover. The reinforcement includes a plurality of yarns, which in turn have a plurality of filaments of first fiber material type and a plurality of filaments of second fiber material type, with first fiber type having elongation at break higher than the second fiber type by at least about 4% elongation. The expansion hose may be part of an assembly including at least one fitting, coupling, bracket, hose clamp, or other hose.

Owner:THE GATES CORP

Low-Permeation Flexible Fuel Hose

A flexible hose having a non-fluorinated rubber inner tube, a non-fluorinated rubber outer cover, an intermediate barrier layer consisting essentially of ethylene-vinyl alcohol copolymer (EVOH) having an ethylene content less than 30 mole %, and preferably a textile reinforcement between said barrier layer and said outer cover. A non-fluorinated rubber tie layer may be included between the barrier and the reinforcement. Permeability to ethanol- and methanol-containing fuels is very low.

Owner:THE GATES CORP

Vehicular tire having a carcass with sidewalls and tread, process of making vehicle tire, and process of masking an overlapping portion of carcass ply needs

Vehicular tire and process of making the same. The tire includes a carcass made of rubber, sidewalls, and tread. The carcass, in a sidewall region, includes at least one carcass ply having parallel textile reinforcements embedded in the rubber and two carcass ply ends, and the two carcass ply ends are arranged to overlap in a circumferential direction, thereby forming an overlapping point. A sidewall rubber strip is positioned to cover the carcass in the sidewall region, and a moiré pattern is formed on the sidewall rubber strip. The process includes circumferentially overlapping the two carcass ply ends of the carcass, thereby forming an overlapping region, covering the overlapping region on the outside with a sidewall rubber strip, and forming a moiré pattern on the sidewall rubber strip.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Aircraft tire reinforcements

ActiveUS20070235116A1Reduce weightEasy to manufacturePneumatic tyre reinforcementsTyre beadsYarnEngineering

An aircraft tire, inflated to high pressure, with a tread (7), a crown reinforcement (6) and a radial carcass reinforcement (1) comprising at least two axially inner plies (1A and 1B) formed of textile reinforcement elements, said two plies being wound around at least one bead wire (3) within each bead (2) from the inside to the outside, forming upturns (10A and 10B) and at least one axially outer ply (1C, 1D) of textile elements which is superposed radially on the inner plies (1A and 1B) beneath the crown reinforcement (6) to extend along the upturns (10A and 10B) of said inner plies in the beads (2), characterized in that the radial reinforcement elements of all the plies (1A, 1B, 1C, 1D, . . . ) of the carcass reinforcement (1) are cables formed by plying at least one yarn having a modulus of elasticity in tension at least equal to 2000 cN / tex, with a yarn, whether overtwisted or not, having an modulus of elasticity in tension at most equal to 1500 cN / tex, said moduli of elasticity of said yarns being measured for a tensile force equal to 0.1 times the breaking load of a yarn.

Owner:MICHELIN RECH & TECH SA

Tyre comprising an electronic element

ActiveCN102189906AWill not damage the shapeDoes not limit the efficiency of passive RF transmissionTyresTyre measurementsEngineeringElectronic component

An aeroplane tire that operates at an inflation pressure in excess of 12 bar includes a crown, two sidewalls, two beads, a carcass ply reinforcement anchored in the two beads and including at least one ply of textile reinforcements, a crown reinforcement, and an electronic component. The crown reinforcement includes, radially from inside outward, a working block that includes plies of textile reinforcement, and a protective block that includes reinforcements directed substantially circumferentially. The electronic component has elongate overall shape and includes a passive radio frequency identification device transponder equipped with two antennas forming a dipole. The electronic component is positioned in the tire under the crown, radially on an inside portion in relation to the carcass ply reinforcement, and directed in a substantially axial direction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

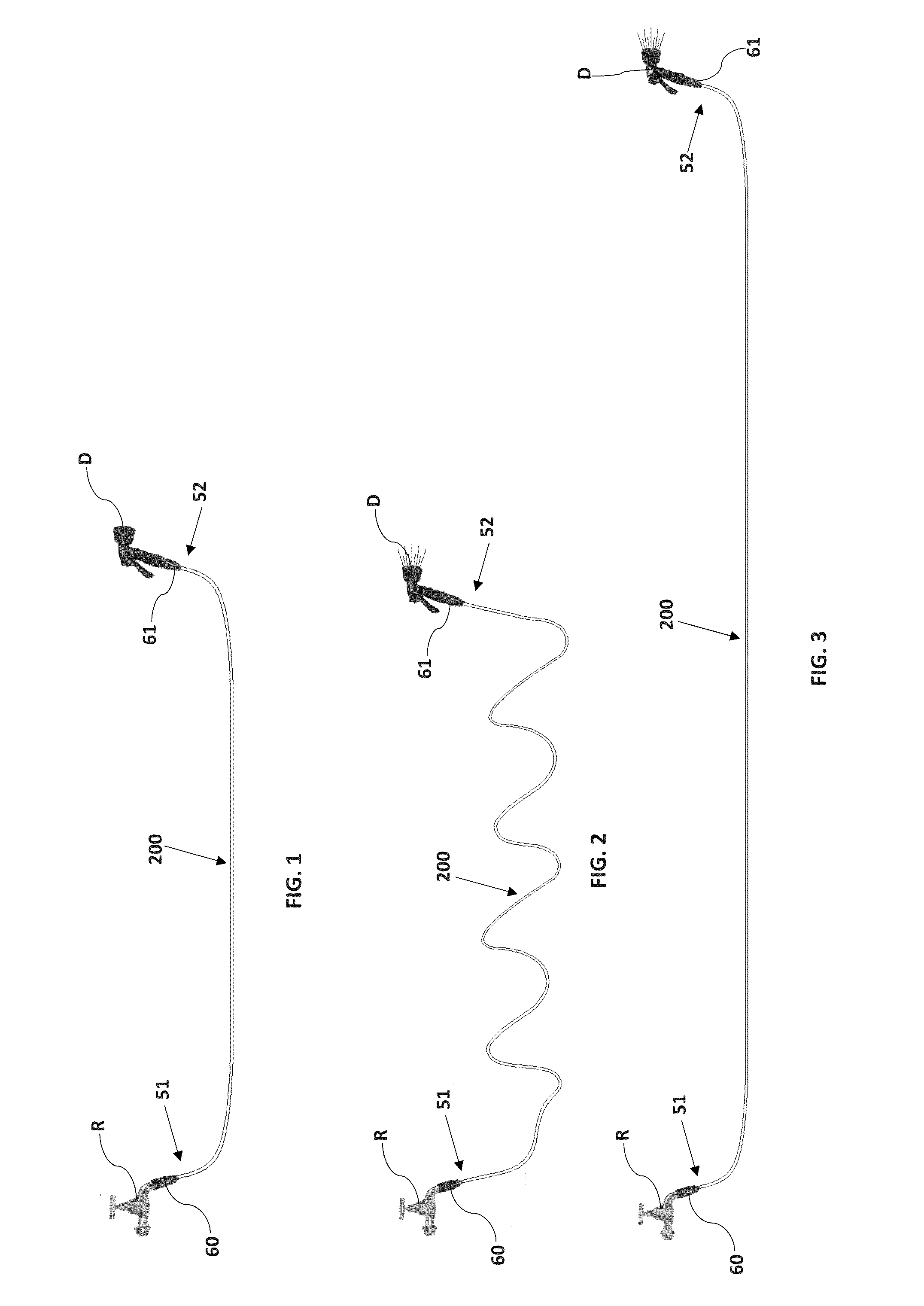

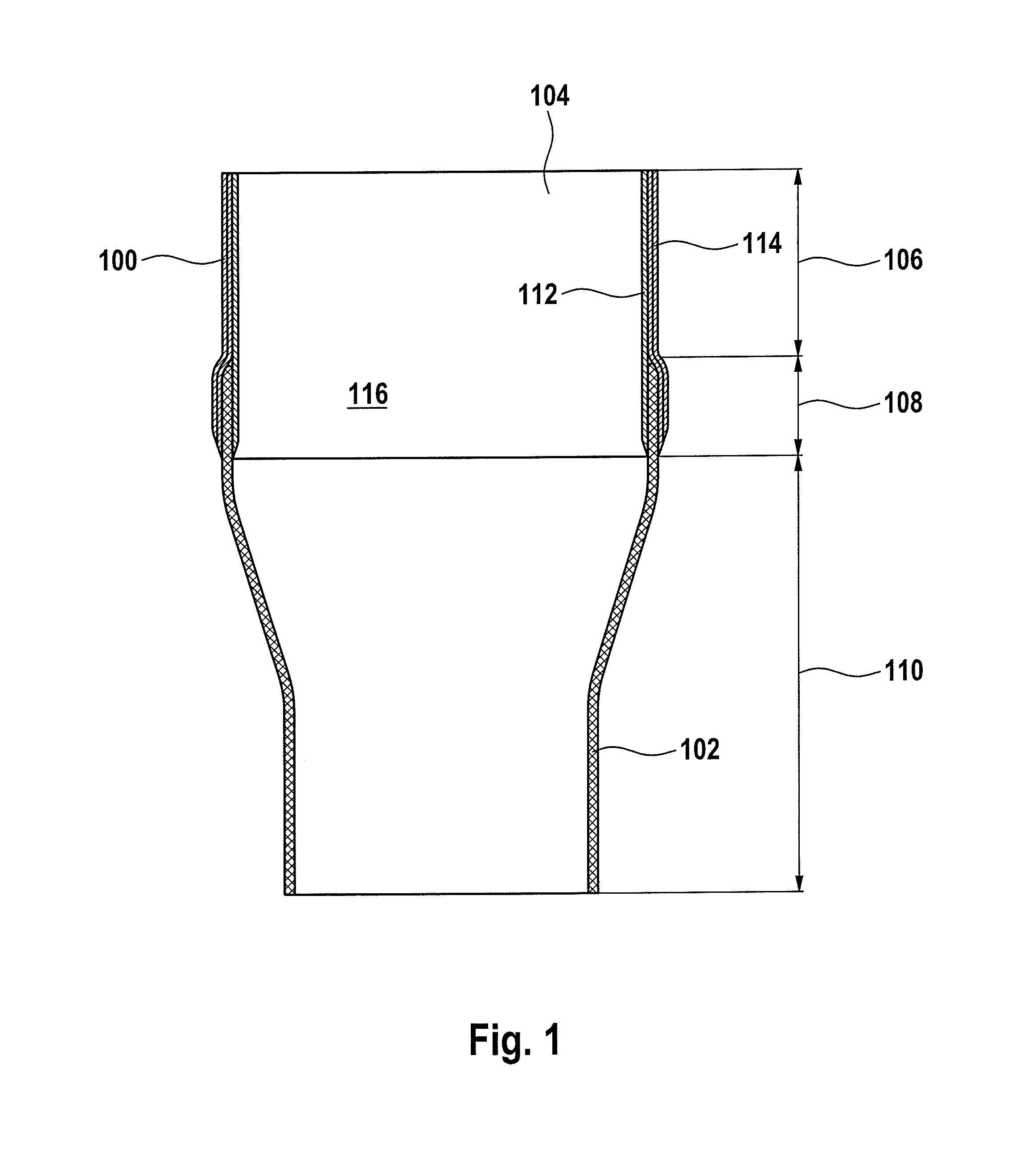

Extensible flexible hose

InactiveUS20160245430A1Improve efficiencyLow costAgricultural articlesWatering devicesWork pressureTextile reinforcement

A flexible hose for transporting a fluid, particularly a flexible garden hose for transporting water, includes an outer sheath and an inner tube. The inner tube has an inner layer made of a first elastic polymeric material and an outer layer made of a second elastic polymeric material with a textile reinforcement layer embedded within the inner tube to form a unitary tubular member. The elasticity of the unitary tubular member is such that it automatically elongates under the working pressure provided by a liquid flowing therethrough and automatically recovers its original length when the working pressure stops. The textile reinforcement layer is adapted to move from a rest configuration when there is no working pressure, to a working configuration when the unitary tubular member elongates under the working pressure.

Owner:FITT

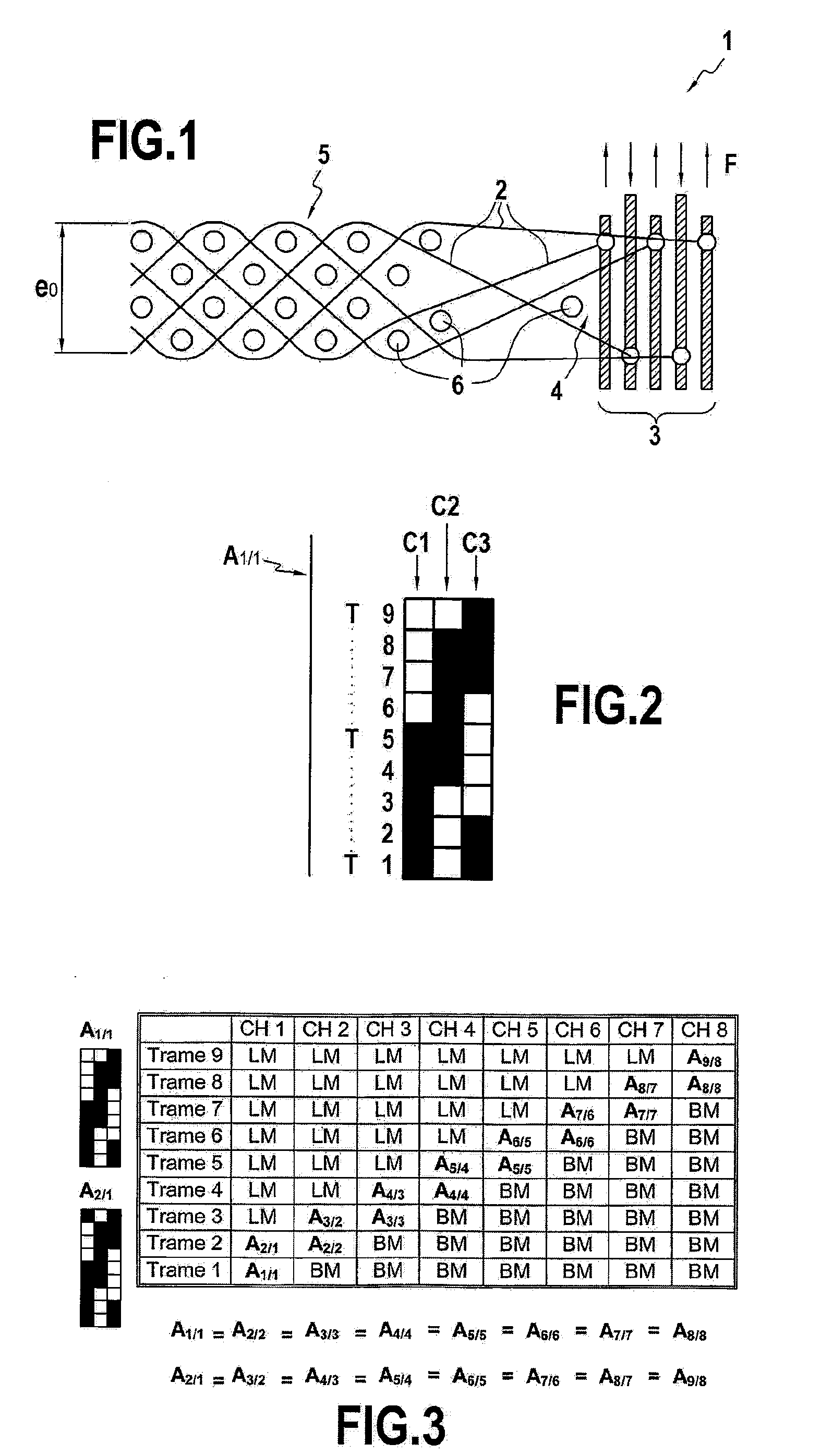

Method of manufacturing a composite, especially a bulletproof composite, and composite obtained

The subject of the present invention is a method of manufacturing a composite (8) comprising a textile reinforcement (7) and a polymer matrix, especially a bulletproof composite. Said method characteristically comprises: a step of forming the textile reinforcement (7) by 2.5D weaving of first yarns with second yarns in a defined weave (A1 / 1), said second yarns being of a thermosetting polymer and said first yarns being high-performance yarns, so as to obtain an interlock fabric (7); and then a heat treatment during which said interlock fabric (7) is subjected to specified temperature and pressure conditions so as to melt said second yarns in order to form the polymer matrix, without impairing the first yarns.

Owner:ENSAIT

Composition for promoting adhesion between rubber and textiles

InactiveUS6333281B1Limited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Method for promoting adhesion between rubber and textiles

InactiveUS6346563B1Limited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsPolyesterSilane compounds

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Controlled expansion hose

ActiveUS7694695B2Improved impulse fatigue resistance and burst pressureImprove fatigue resistanceLayered productsPipe elementsYarnFiber type

An expansion hose adapted for smoothing pressure fluctuations in a hydraulic system having an inner tube, a textile reinforcement, and an outer cover. The reinforcement includes a plurality of yarns, which in turn have a plurality of filaments of first fiber material type and a plurality of filaments of second fiber material type, with first fiber type having elongation at break higher than the second fiber type by at least about 4% elongation. The expansion hose may be part of an assembly including at least one fitting, coupling, bracket, hose clamp, or other hose.

Owner:THE GATES CORP

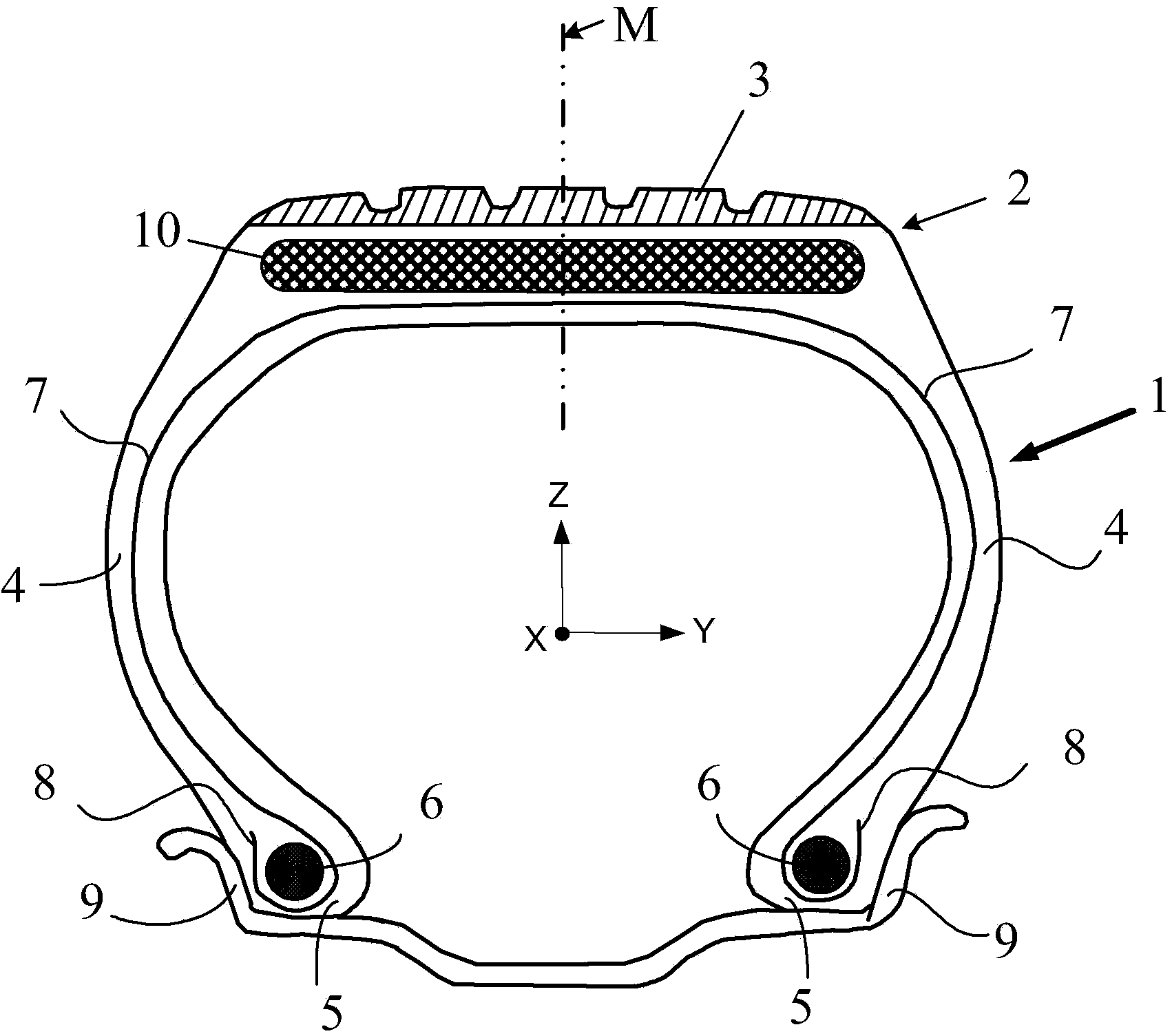

Radial tyre with lightened belt structure

Radial tyre, notably for a passenger vehicle or light van, with a lightened belt structure (10) comprising a multilayer composite laminate (10a, 10b, 10c) of specific construction, with a first layer (10a) of rubber (Cl) containing circumferential textile reinforcements (110) which are weakly heat-shrinkable, for example made of nylon or of polyester, this first layer radially (in the direction Z) surmounting two other layers (10b, 10c) of rubber (respectively C2, C3) reinforced with monofilaments (120, 130) of high strength steel; this multilayer composite laminate makes it possible to reduce the weight and rolling resistance of tyres without adversely affecting the cornering stiffness and therefore road holding, while at the same time offering road running endurance that is at least equal if not improved.

Owner:SOCIETE DE TECH MICHELIN

Gymflextor Training Device

InactiveUS20080032876A1Operational securityReduce distortionResilient force resistorsBiomedical engineeringVALVE PORT

The invention relates to gymnastic and exercise equipment and can be used for physical exercises to develop and strengthen body muscles, for carrying out sports events and in leisure activities. Said invention makes it possible to increase the durability of the training device, the elasticity of the surface thereof and to extend the possibilities for modifying the shape of training device as a result of its structure, comprising a pressurized torus-shaped sealed reinforced chamber which is provided with a flush-mounted valve and means for modifying the shape of the chamber. Said reinforced chamber consists of an internal hermetic chamber and multilayer textile reinforcement, located on screw line around hermetic internal chamber, wherein the coils of the textile reinforcement of adjacent layers are oppositely oriented with angle between coils of 30 to 150°, and of an outer sheath made of an elastic cloth.

Owner:MUKENEV YERZHAN KARYMGAZY ULY

Material for shoe upper

The present invention relates to a material for a shoe upper, in particular for soccer shoes, with a particularly low weight and improved tensile strength. According to an aspect of the invention, a material for a shoe upper, in particular for soccer shoes, is provided, that comprises a first foil layer and a textile reinforcement layer which is at least partially laminated with the first foil layer. The textile reinforcement layer comprises a first textile material with at least three axes, each axis defining an orientation of a set of essentially parallel yarn-portions in the textile material.

Owner:ADIDAS

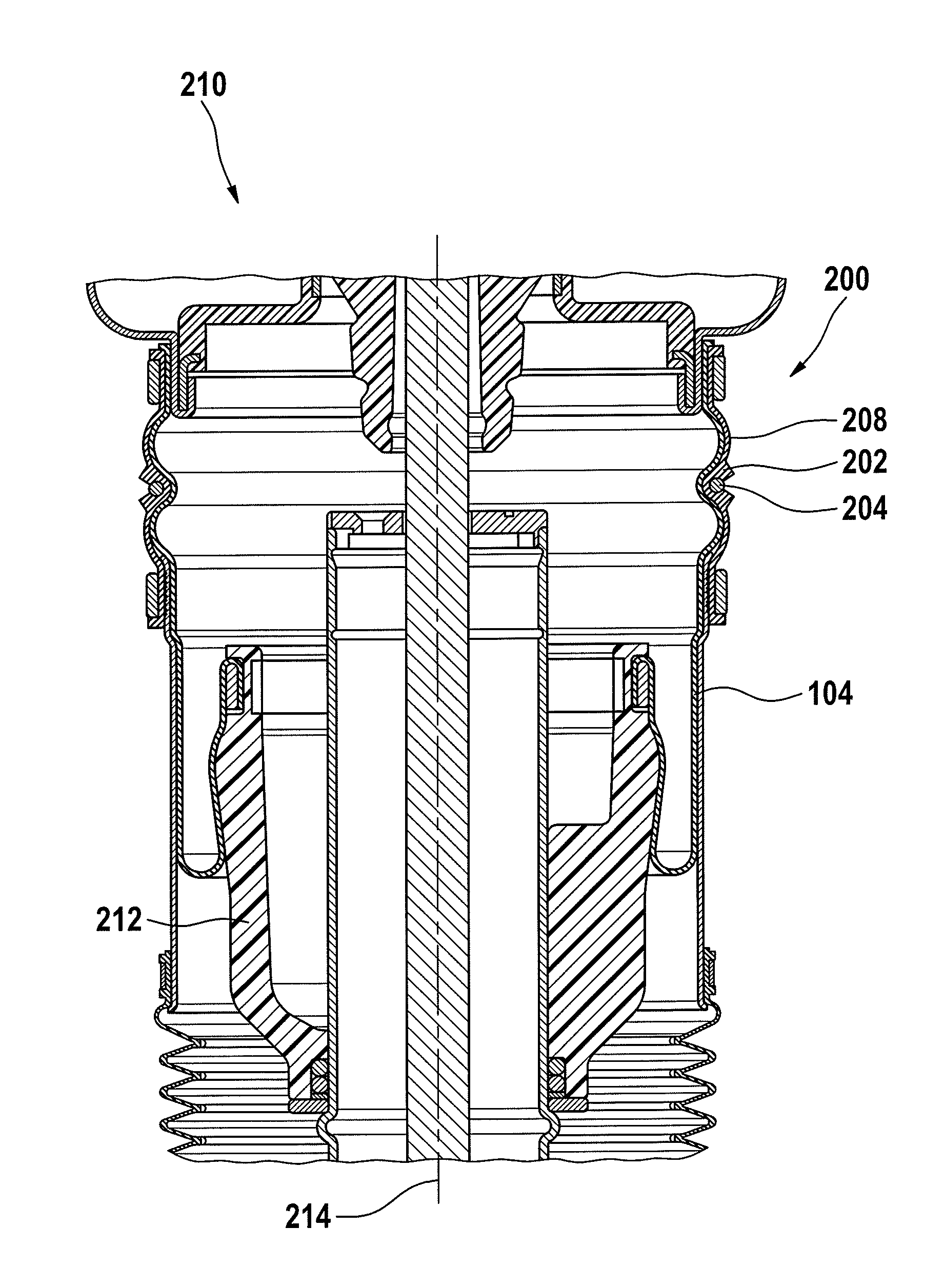

Air spring having hybrid bellows

An air spring assembly for a motor vehicle, including an air spring, a rolling piston, a tubular rolling air spring bellows arranged concentrically about a central longitudinal axis of the air spring, and an air spring cover. A first partial air spring bellows has a first embedded textile reinforcement and a second partial air spring bellows has a second embedded textile reinforcement The first textile reinforcement has first reinforcing threads, the preferred axis of which extends parallel or nearly parallel to the axis of the central longitudinal axis of the air spring The second textile reinforcement has second reinforcing threads, the first preferred axis of which extends obliquely to the longitudinal axis of the air spring and the second preferred axis of which extends obliquely to the longitudinal axis of the air spring, wherein the first and the second preferred axis are at an angle to each other.

Owner:CONTINENTAL TEVES AG & CO OHG

Flexible hose for high pressures and temperatures including a charge-air hose and a cooling-water hose

InactiveUS20110023988A1Minimizing expansionDistribute pressureCombustion-air/fuel-air treatmentMachines/enginesEngineeringHigh pressure

Owner:CONTITECH MGW GMBH

Material for shoe upper

ActiveUS10182618B2Provides breathabilityImprove stabilitySynthetic resin layered productsUpperYarnEngineering

Described are materials for a shoe upper, in particular for soccer shoes, with a particularly low weight and improved tensile strength. The material includes a first foil layer and a textile reinforcement layer, which is at least partially laminated with the first foil layer. The textile reinforcement layer includes a first textile material with at least three axes, each axis defining an orientation of a set of essentially parallel yarn-portions in the textile material.

Owner:ADIDAS

Binder-consolidated textile fabric, method for producing it, and use thereof

ActiveCN105385380ANon-macromolecular adhesive additivesFibre treatmentInterliningTextile reinforcement

The invention relates to a binder-consolidated textile fabric, a method for producing it, and use thereof. The invention relates to a novel binder system and its use for bonding textile fabrics as well as products containing such bonded textile fabrics. The materials according to the invention are suitable for the manufacture of base interlinings, optionally in combination with at least one further textile fabric, for coated sarking membranes, roofing sheets and water-proof sheetings, as a textile backing or a textile reinforcement in floorings, in particular in carpets and PVC floorings, or in facer, wall coating inside and outside of buildings as well as fabric backing and fabric reinforcement in furniture.

Owner:JOHNS MANVILLE EUROPE GMBH

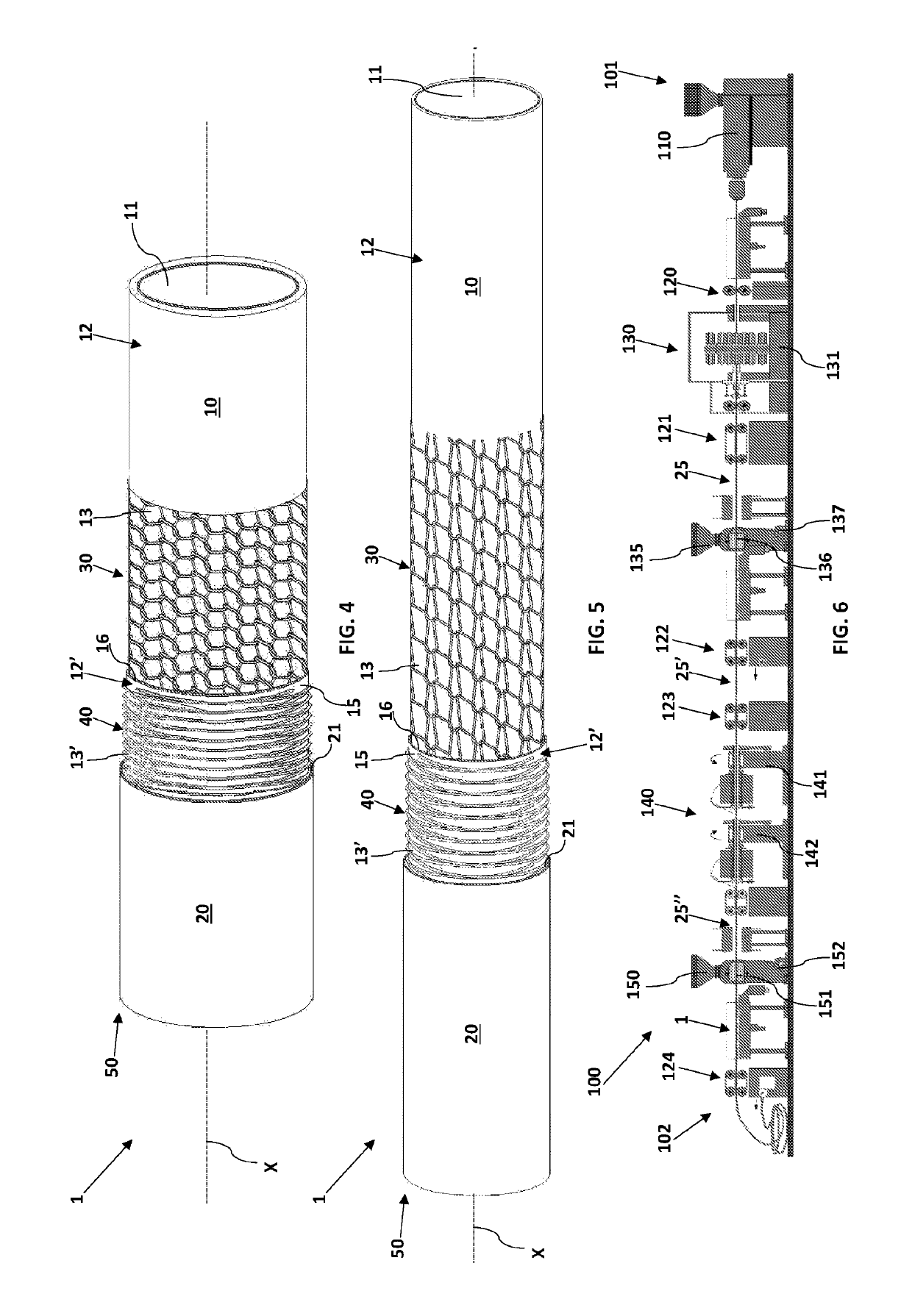

Extensible flexible hose, and method and production line for continuously manufacturing thereof

ActiveUS20180299038A1Remarkable efficiencyRemarkable cheapnessAgricultural articlesSynthetic resin layered productsEngineeringTextile reinforcement

A hose that includes an inner layer and an outer layer made of an elastic polymeric material, and a textile reinforcement layer interposed between the inner and the outer layers. The inner layer and the outer layer are reciprocally coupled to form a unitary tubular member, within which the textile reinforcement layer is embedded. The unitary tubular member has an elasticity such to automatically elongate under the working pressure given by the liquid flowing therethrough to increase its original length and to automatically recover once the working pressure stops. The textile reinforcement layer is adapted to move from a rest configuration when the working pressure stops to a working configuration when the unitary tubular member elongates under the working pressure, and vice versa.

Owner:FITT

Reinforced hose

InactiveCN101925454AImprove hydrolytic stabilityFlat surfaceMachines/enginesFlexible pipesElastomerFiber

Owner:POLYAMIDE HIGH PERFORMANCE

Drive belt

Owner:CONTITECH ANTRIEBSSYST

Structural element and method for producing a structural element

ActiveUS9388577B2Efficient and economical manufactureIncrease impressionConstruction materialFloorsGlass fiberCarbon fibers

Owner:GROZ BECKERT KG

Low-permeation flexible fuel hose

A flexible hose having a non-fluorinated rubber inner tube, a non-fluorinated rubber outer cover, an intermediate barrier layer consisting essentially of ethylene- vinyl alcohol copolymer (EVOH) having an ethylene content less than 30 mole %, and preferably a textile reinforcement between said barrier layer and said outer cover. A non-fluorinated rubber tie layer may be included between the barrier and the reinforcement. Permeability to ethanol- and methanol-containing fuels is very low.

Owner:THE GATES CORP

Enlargeable flexible hose

ActiveUS20190145553A1Improve efficiencyThe process is simple and fastFlexible pipesEngineeringPolymer

A flexible hose for transporting a fluid, particularly a flexible garden hose for transporting water, includes an inner layer made of a first elastic polymeric material; an outer layer made of a second elastic polymeric material; and a textile reinforcement layer interposed therebetween. The inner and outer layers are reciprocally coupled to form a unitary tubular member, internally to which the textile reinforcement layer is embedded. The elasticity of the unitary tubular member causes it to automatically enlarge under the working pressure given by the liquid flowing therethrough to increase its original diameter and to automatically recover to assume again its original diameter once the working pressure stops. The textile reinforcement layer is susceptible to move from a rest configuration, when there is no working pressure, to a working configuration, when the unitary tubular member enlarges upon under the working pressure.

Owner:FITT

Reinforced bead for a radial tire

InactiveUS6491078B2Easy to manufactureLow costWithout separate inflatable insertsSpecial tyresEngineeringHeavy load

A tire for heavy loads and having beads intended to be mounted on flat rim seats or rim seats which are inclined at 5°, including at least one radial carcass ply formed of inextensible reinforcement elements and anchored in each bead to a bead wire to form an upturn, the end of which is located at a radial distance HRNC from the base of the bead. Each bead is reinforced by at least two additional reinforcement armatures, at least one first armature formed of at least one ply of radial textile reinforcement elements which is located axially to the outside of a second armature formed of at least one ply of inextensible elements forming an angle alpha with the circumferential direction such that 0°<=alpha<=45°.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Extensible flexible hose, and method and production line for continuously manufacturing thereof

ActiveUS10359130B2Improve efficiencyThe way is simple and fastAgricultural articlesSynthetic resin layered productsProduction lineWork pressure

A hose that includes an inner layer and an outer layer made of an elastic polymeric material, and a textile reinforcement layer interposed between the inner and the outer layers. The inner layer and the outer layer are reciprocally coupled to form a unitary tubular member, within which the textile reinforcement layer is embedded. The unitary tubular member has an elasticity such to automatically elongate under the working pressure given by the liquid flowing therethrough to increase its original length and to automatically recover once the working pressure stops. The textile reinforcement layer is adapted to move from a rest configuration when the working pressure stops to a working configuration when the unitary tubular member elongates under the working pressure, and vice versa.

Owner:FITT

Enlargeable flexible hose

ActiveUS10927983B2Improve efficiencyThe process is simple and fastFlexible pipesPolymerTextile reinforcement

A flexible hose for transporting a fluid, particularly a flexible garden hose for transporting water, includes an inner layer made of a first elastic polymeric material; an outer layer made of a second elastic polymeric material; and a textile reinforcement layer interposed therebetween. The inner and outer layers are reciprocally coupled to form a unitary tubular member, internally to which the textile reinforcement layer is embedded. The elasticity of the unitary tubular member causes it to automatically enlarge under the working pressure given by the liquid flowing therethrough to increase its original diameter and to automatically recover to assume again its original diameter once the working pressure stops. The textile reinforcement layer is susceptible to move from a rest configuration, when there is no working pressure, to a working configuration, when the unitary tubular member enlarges upon under the working pressure.

Owner:FITT

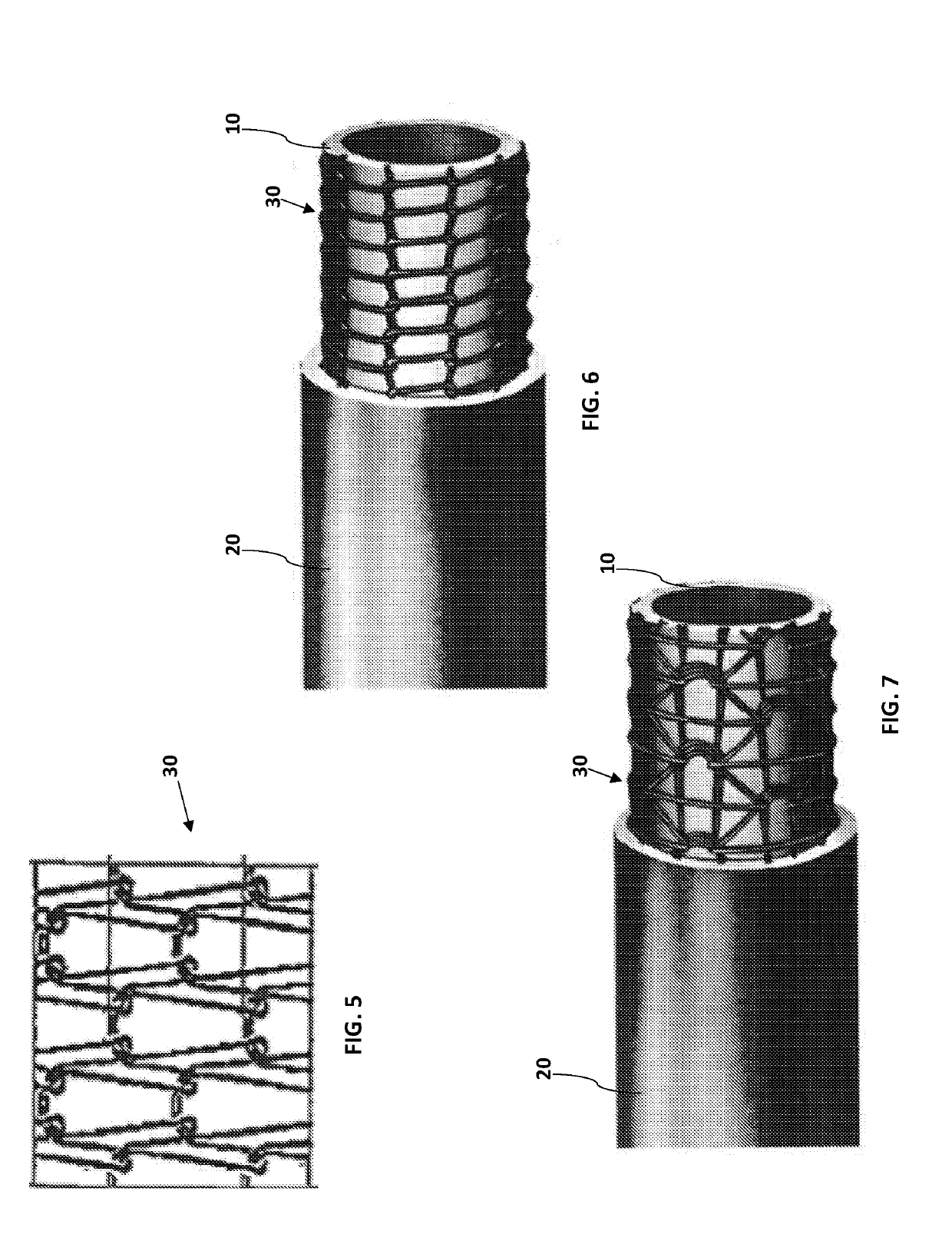

Composite system and consolidation method, in particular for structures made from reinforced concrete or masonry hardenable or hardened matrix and textile reinforcing mesh forming this system

ActiveUS20180230050A1Ensure dimensional stabilityMeet the requirements of mechanical propertiesBuilding repairsGauze-woven fabricsReinforced concreteRebar

The invention concerns a composite system for reinforcing, in particular, structures made from reinforced concrete or masonry comprising a curable or cured matrix and a textile reinforcement grid, and said two elements taken as such. The aim of the invention is for this system to make it possible to produce a cured composite structure having improved mechanical properties, both in the short term and in the long term (e.g. flexing behaviour, hardness, bending / compression resistance, durability, cohesion). This aim is achieved by the system of the invention in which the grid comprises at least one layer formed: —both from a framework consisting of flat warp yarns and weft yarns; —and from a network binding the framework; characterised in that the binding network is such that it ensures the geometric regularity and dimensional stability of the meshes of the framework, before the grid is applied to the structure to be reinforced. The invention also concerns a method for reinforcing, in particular, structures made from reinforced concrete or masonry, the composite structure obtained from this method, the dry and wet formulations of the curable matrix, and consolidated structures, in particular made from reinforced concrete or masonry.

Owner:PAREXGROUP SA

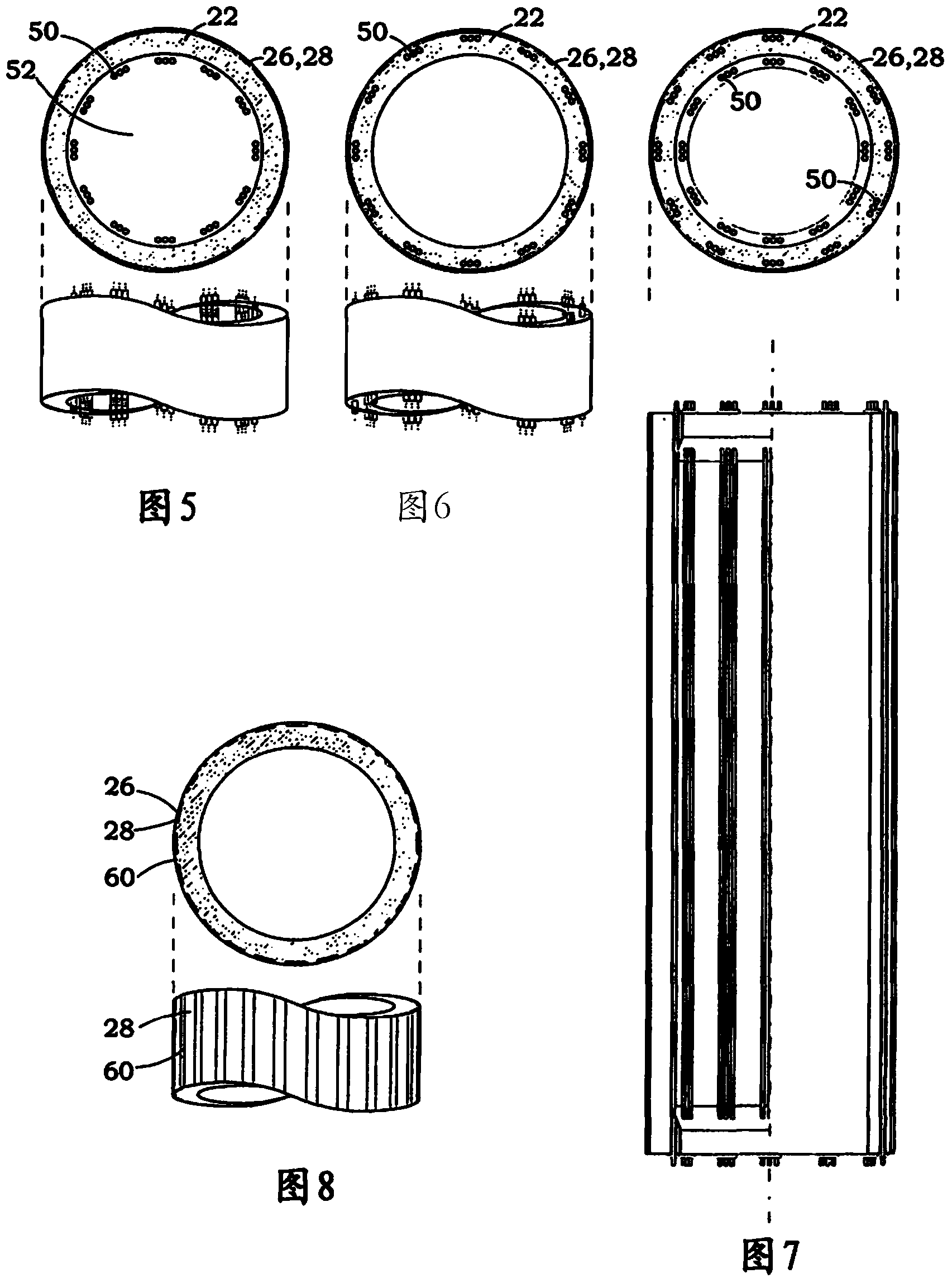

Method and sliding form for producing a structure and corresponding structure

ActiveCN103732368ALarge slendernessImprove the exterior surfaceEngine manufactureShaping reinforcementsEngineeringTower

The invention relates to a load-bearing structure and to a method for producing a load-bearing structure, in particular of wind turbine towers, which provides for a concrete hollow body having an outer wall which is produced by several wet in wet produced layers (22, 26). The outer layer (26) is a layer of fine grained concrete, provided with a textile reinforcement (28), and the inner layer (22) is made from mass concrete.

Owner:X TOWER CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com