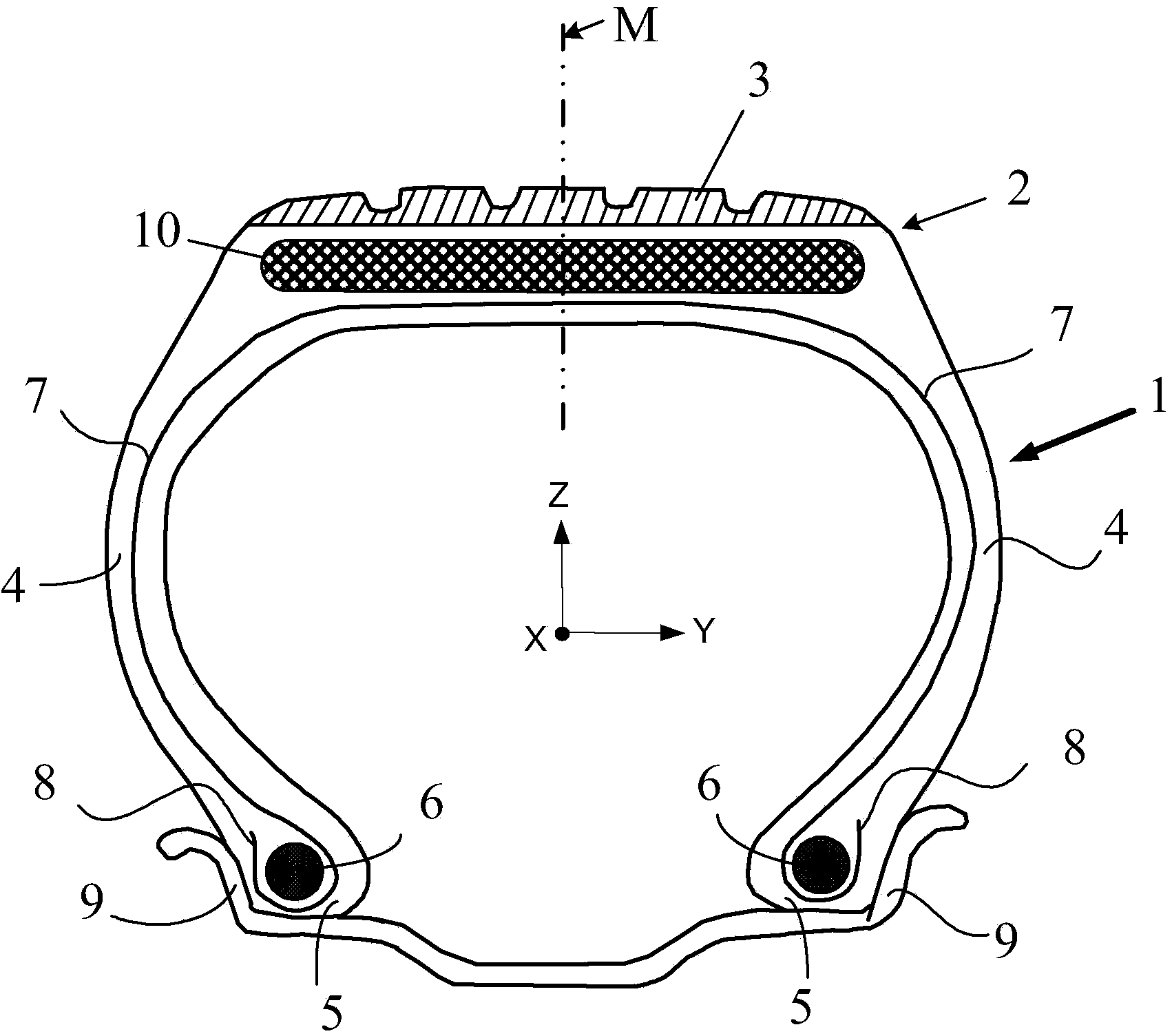

Radial tyre with lightened belt structure

A belt layer and tire technology, applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve problems such as difficult physical constraints, obstructions, adverse tire performance and overall durability, and achieve low drag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] definition

[0034] The terms in this application should be understood as follows:

[0035] - "rubber" or "elastomer" (these two terms are considered synonymous): elastomers of any type, whether diene or non-diene, such as thermoplastic types;

[0036] - "rubber compound" or "rubber-like compound": a compound containing at least one rubber and one filler;

[0037] - "layer": sheet, strip or any other element whose thickness is relatively small relative to its other dimensions, preferably wherein the ratio of thickness to the largest of the other dimensions is less than 0.5, more preferably less than 0.1;

[0038] - "axial" means a direction substantially parallel to the axis of rotation of the tyre;

[0039] - "circumferential": a direction substantially perpendicular to both the axial and radial directions of the tyre (in other words, tangent to a circle whose center lies on the tyre's axis of rotation);

[0040] - "radial": a direction along the radius of the tyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com