Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Spring Test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1. A test used to differentiate between backward or forward sacral torsions/rotations. 2. A test used to differentiate bilateral sacral extension and bilateral sacral flexion. 3. A test used to differentiate unilateral sacral extension and unilateral sacral flexion.

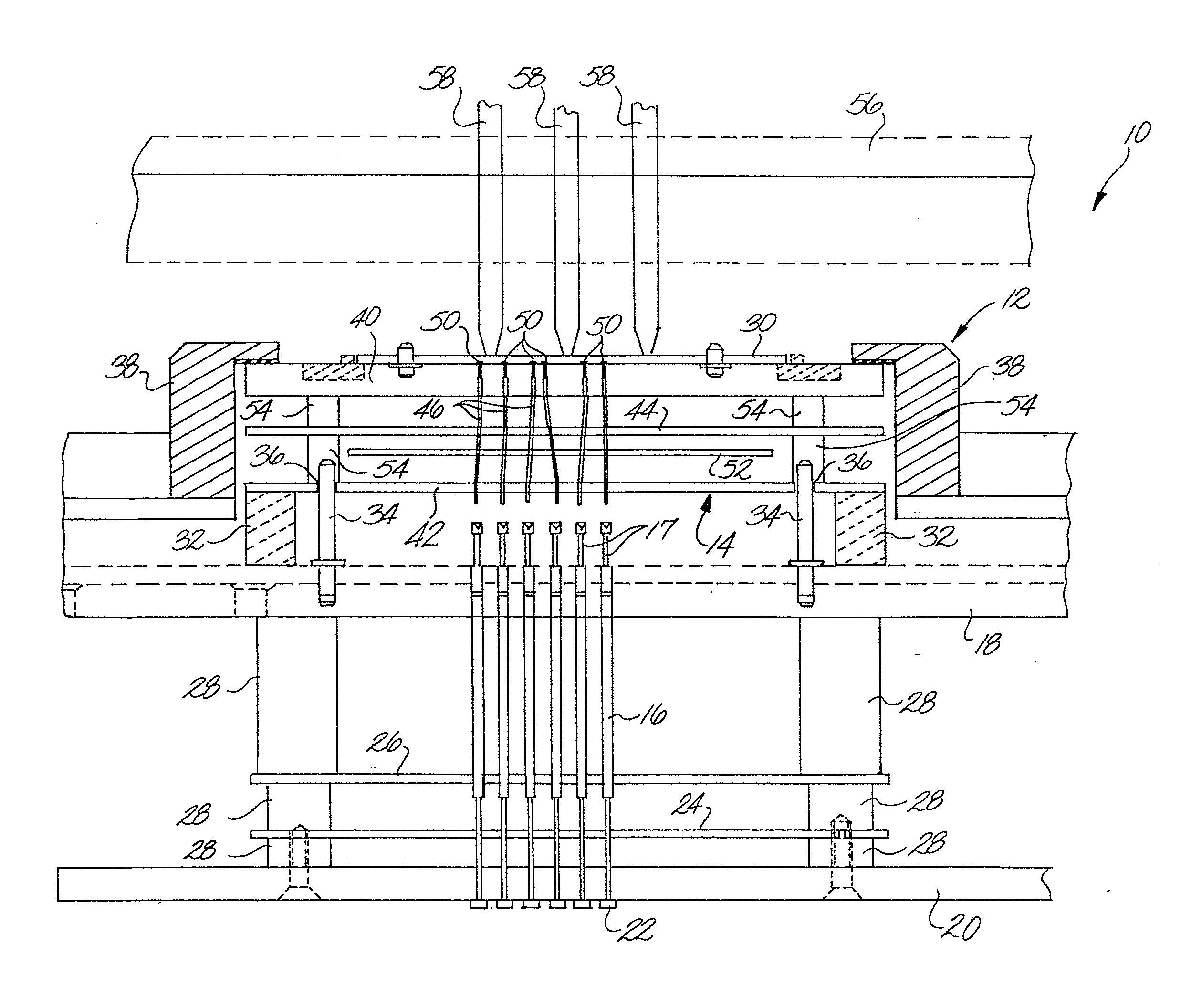

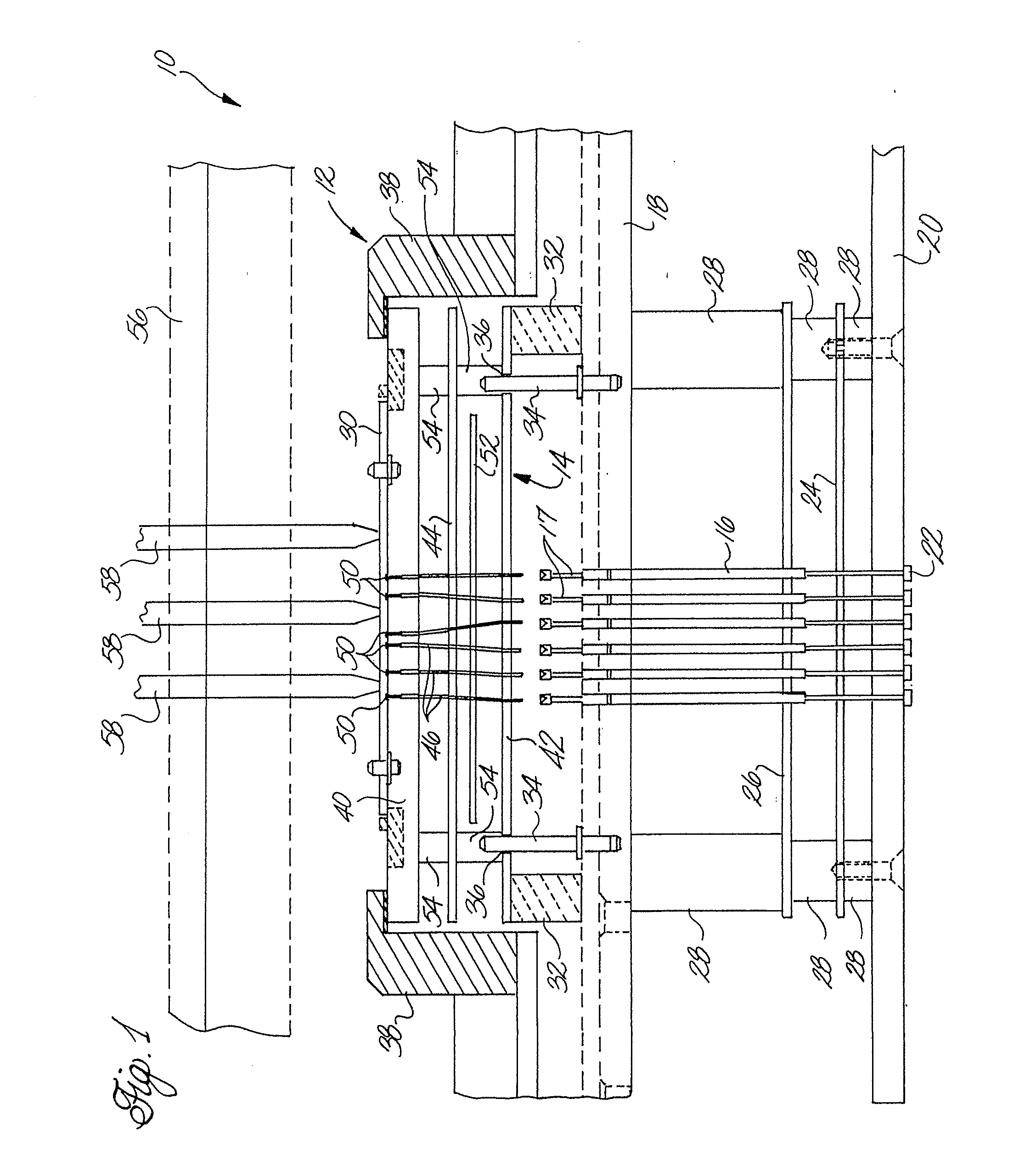

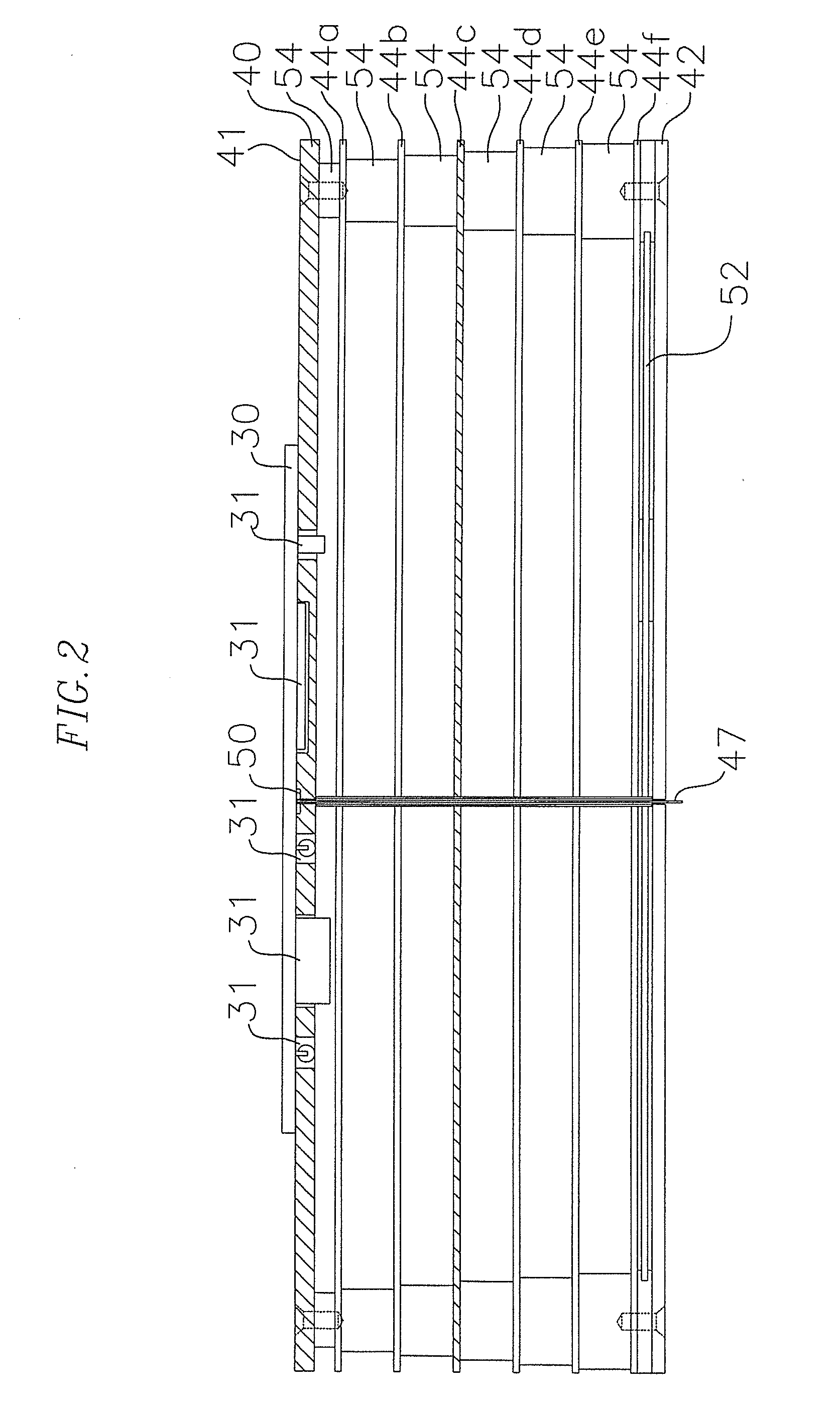

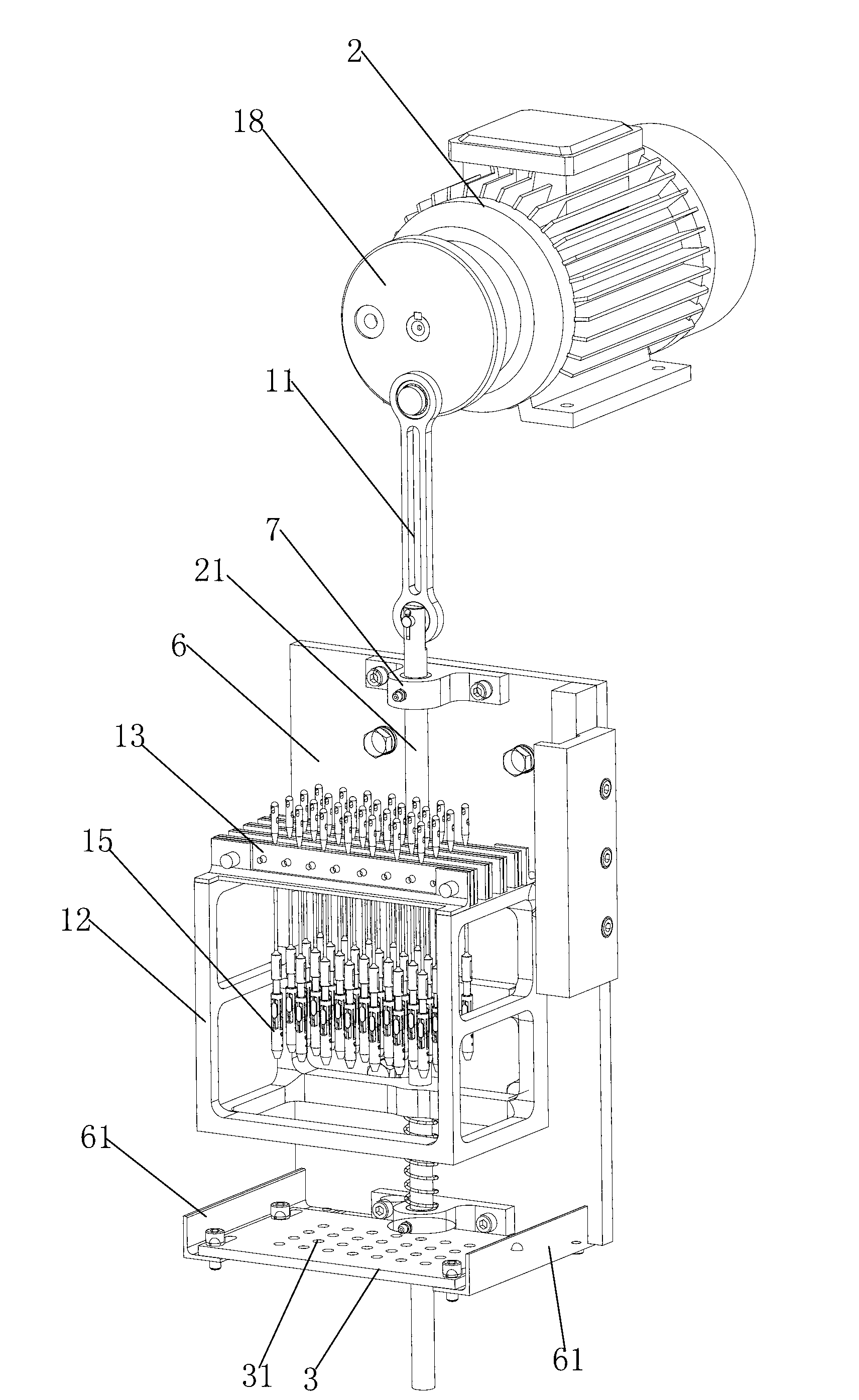

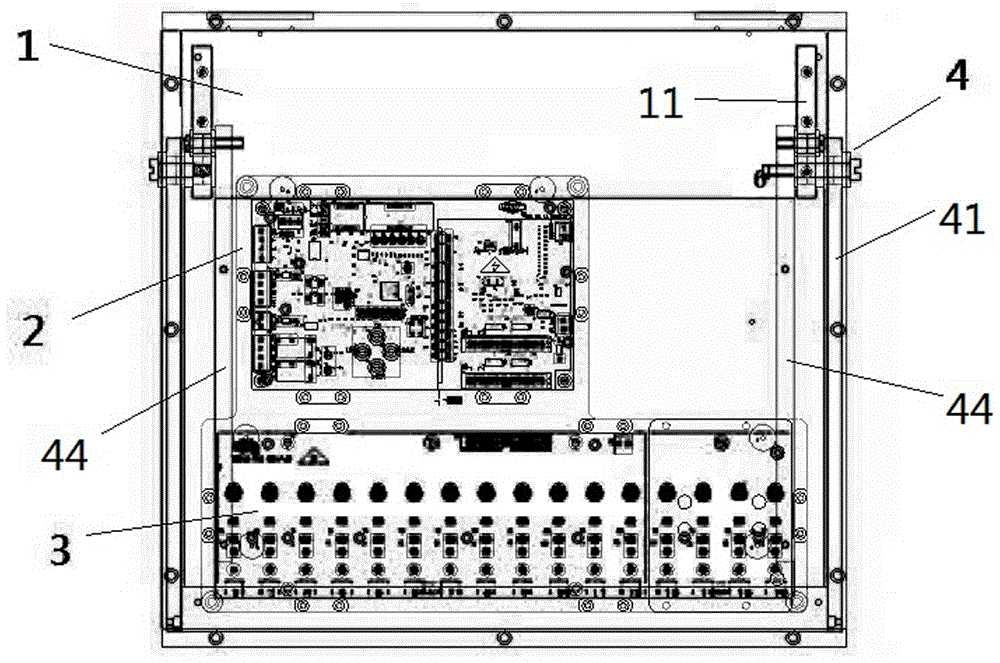

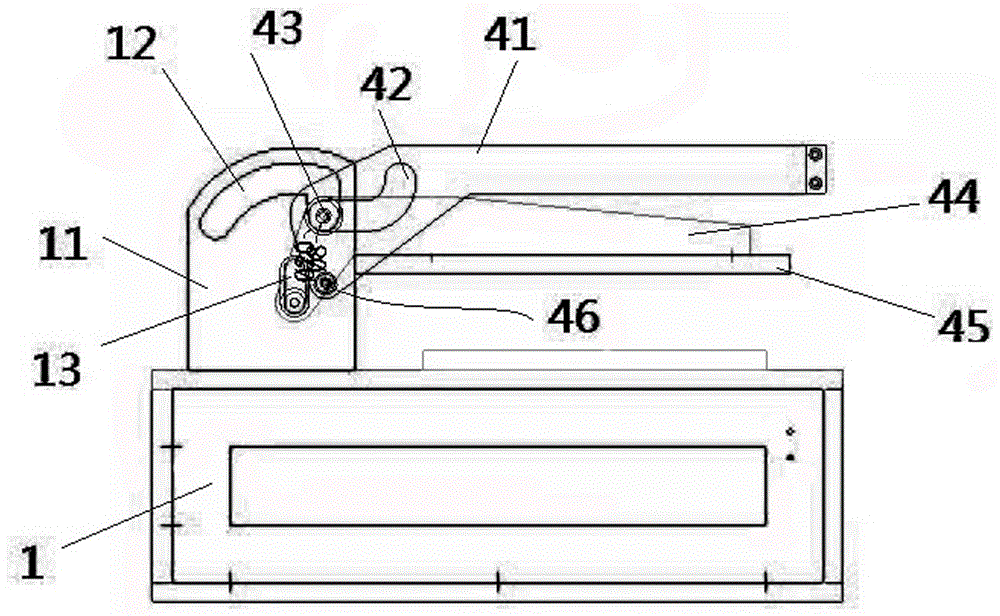

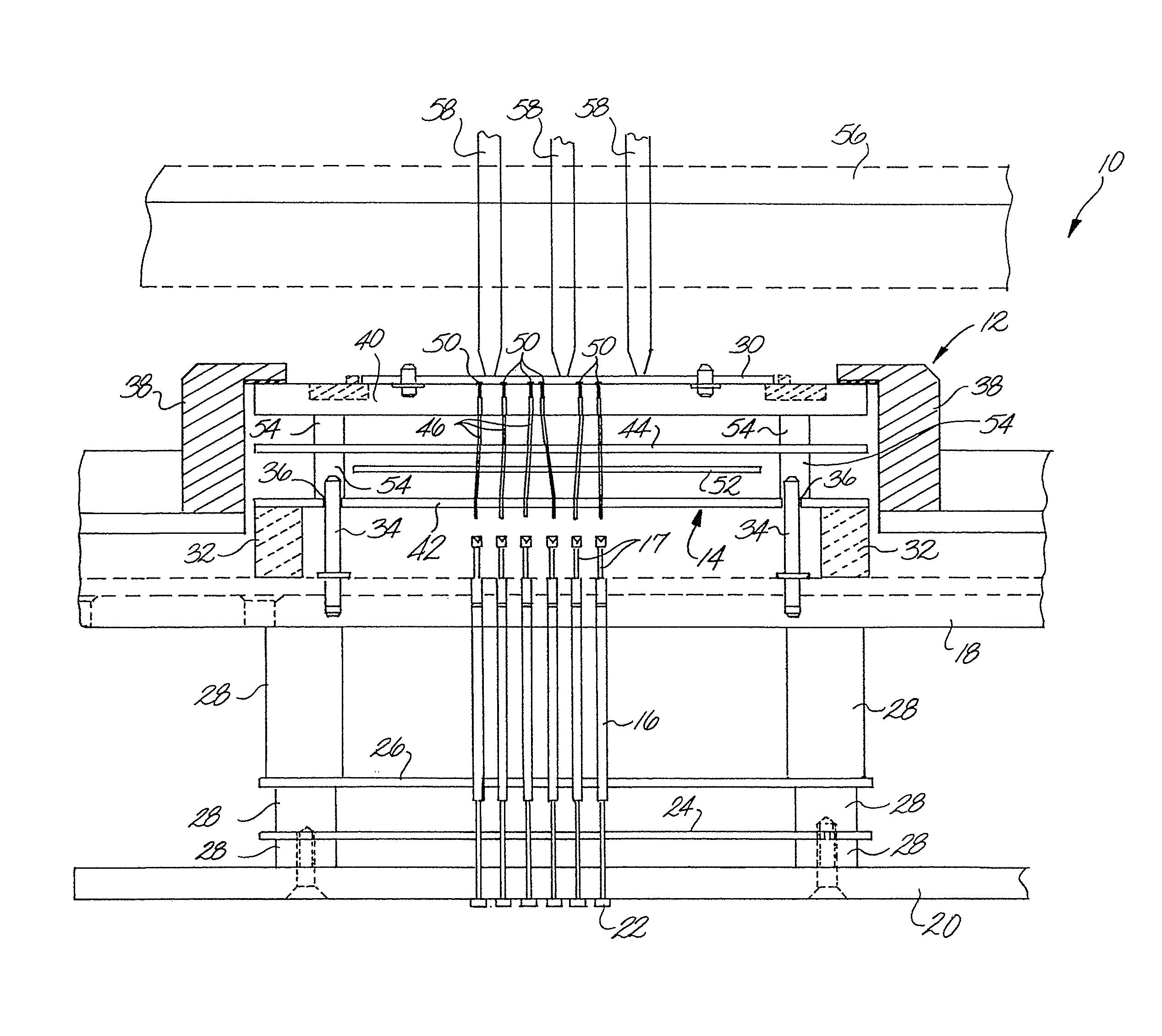

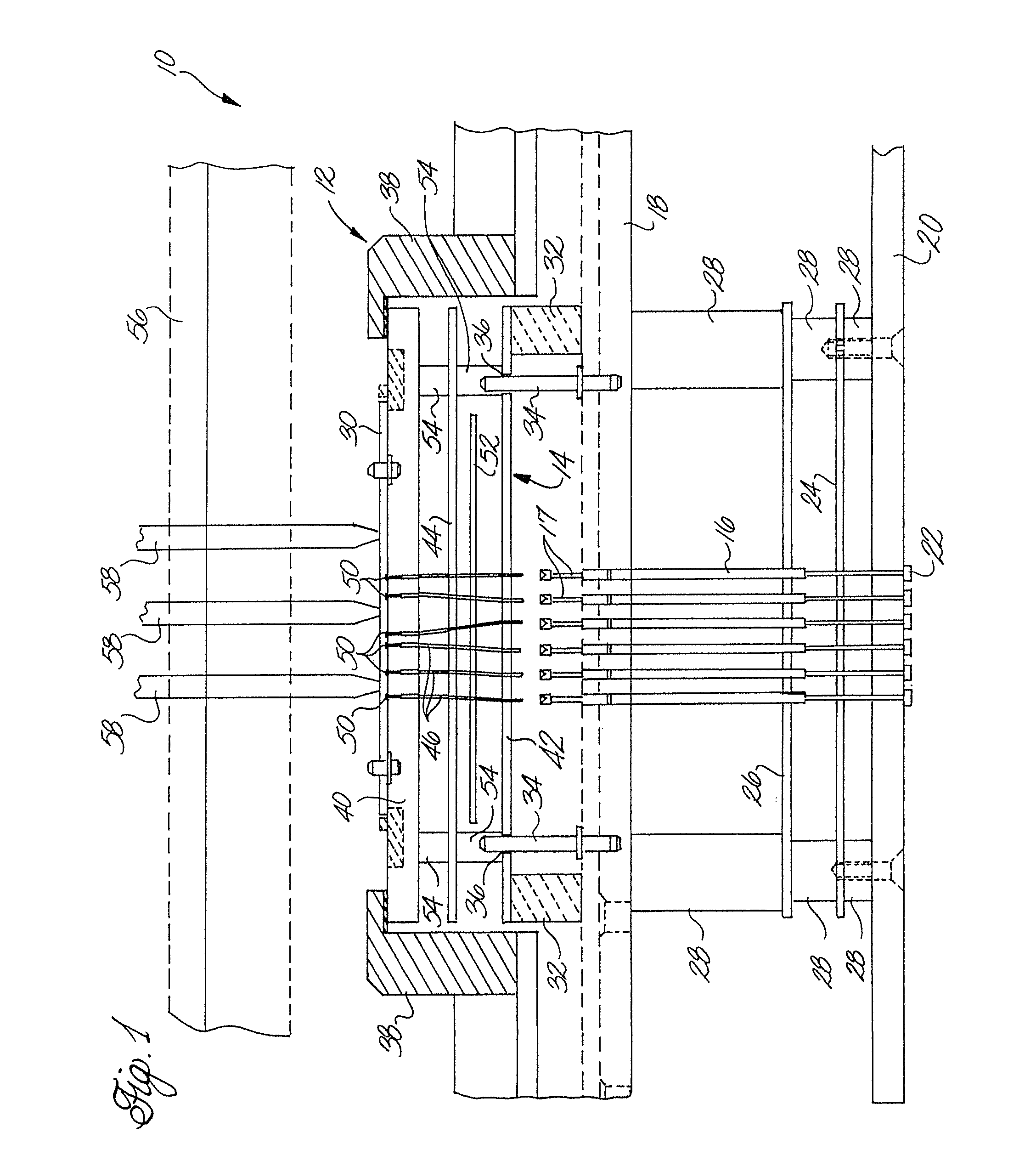

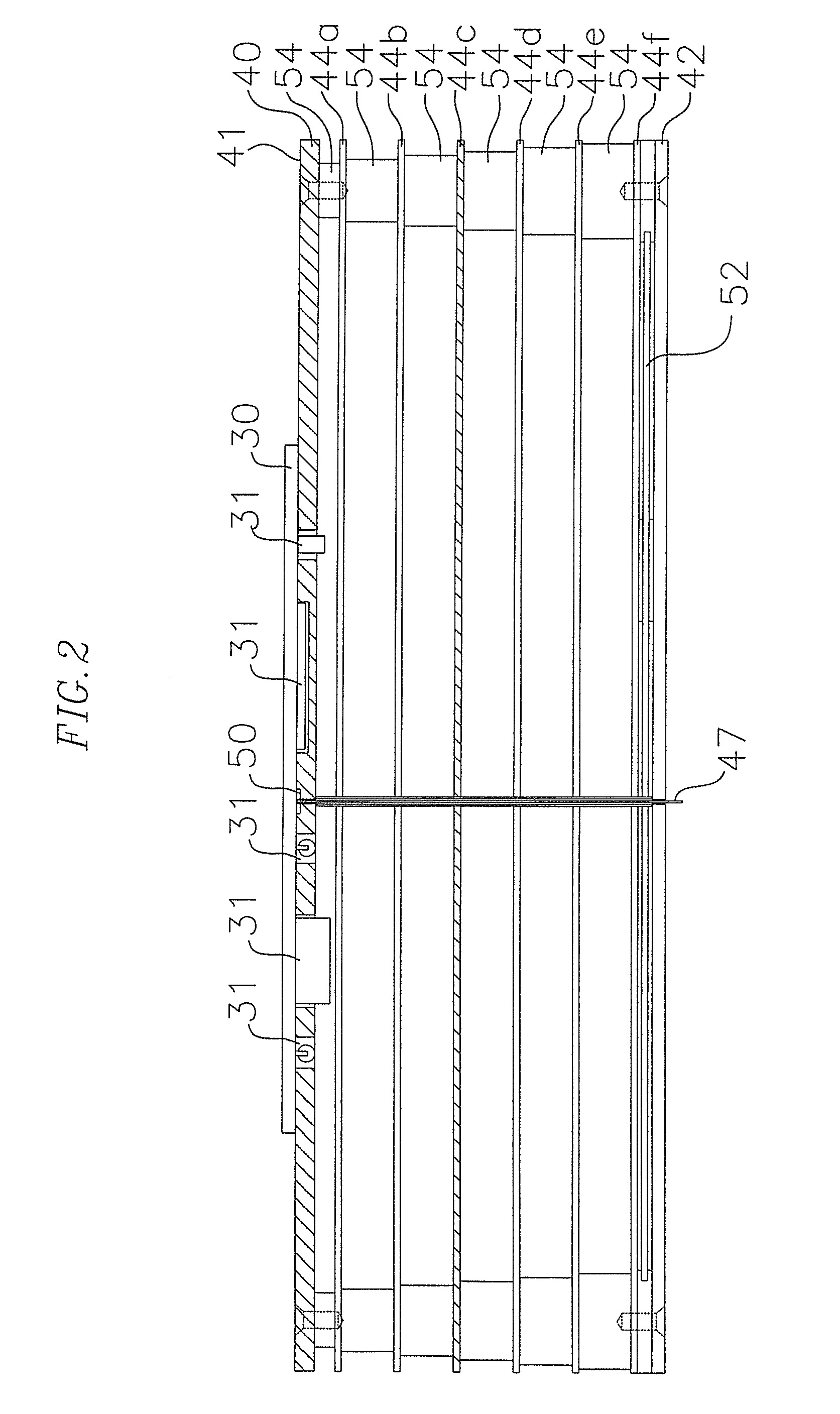

Loaded printed circuit board test fixture and method for manufacturing the same

ActiveUS20110148448A1Good electrical contactLow costElectrical measurement instrument detailsElectrical testingTest fixtureSpring Test

A test fixture for testing loaded printed circuit boards having a plurality of test points having a probe plate including an array of widely spaced high force spring test probes in compliant contact with solid translator pins located in a translator fixture removably positioned over the probe plate. The test fixture includes optimization software wherein translation of the test signals are optimized by providing the shortest interconnect distance in the x-y plane between the test points on the printed circuit board and the test probes in the probe plate. The fixture further includes an unpowered opens device for testing components on the loaded printed circuit board.

Owner:XCERRA

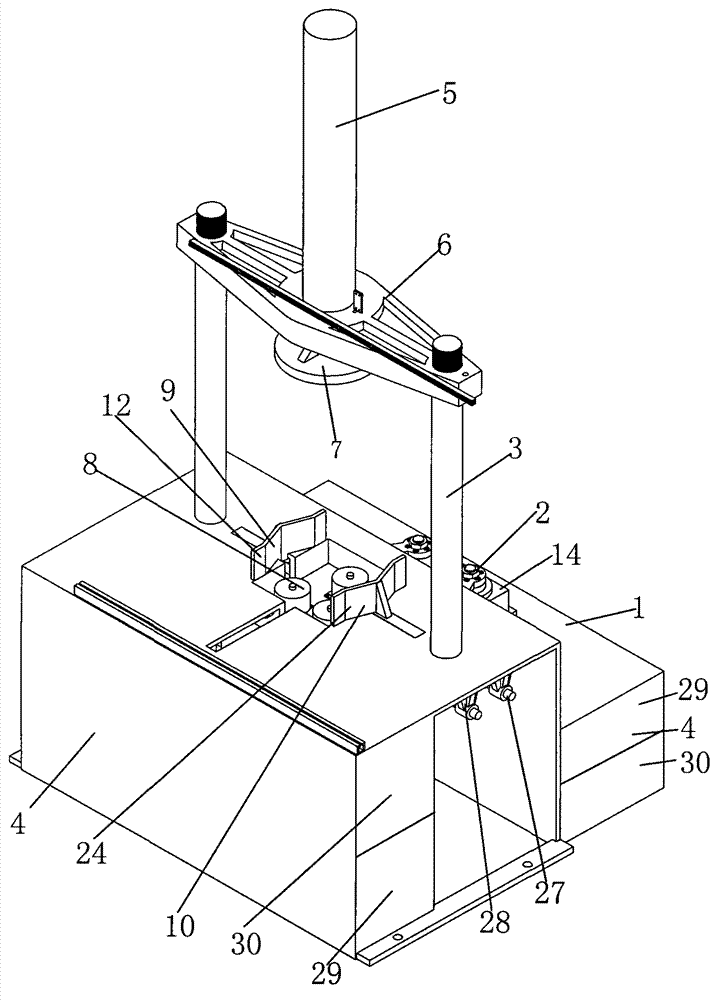

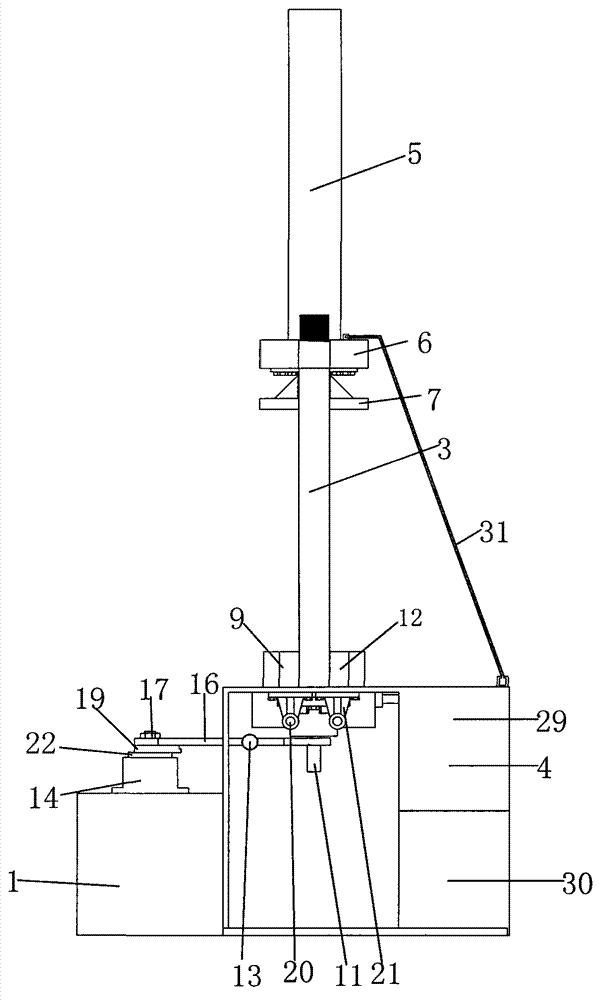

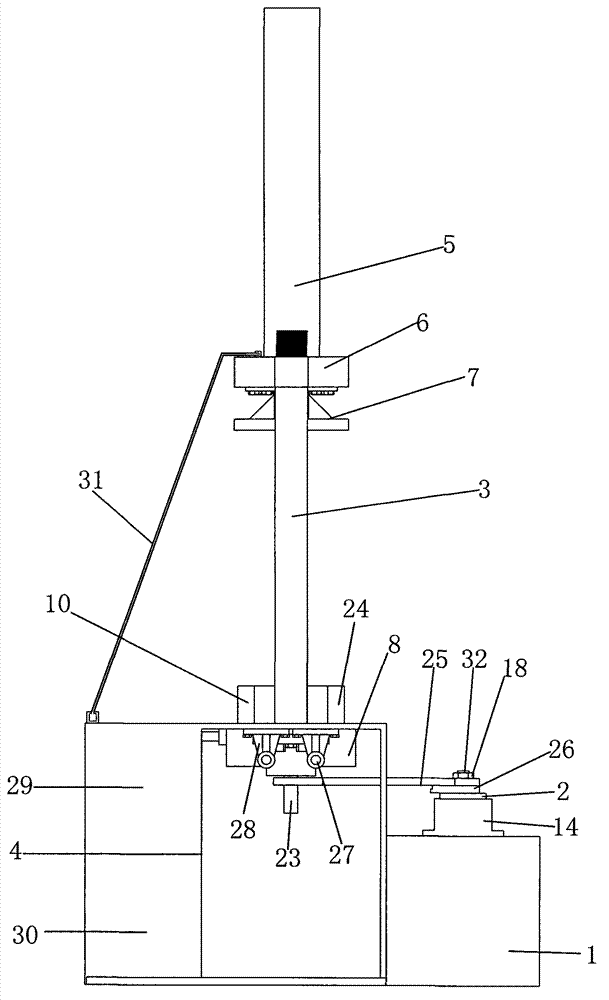

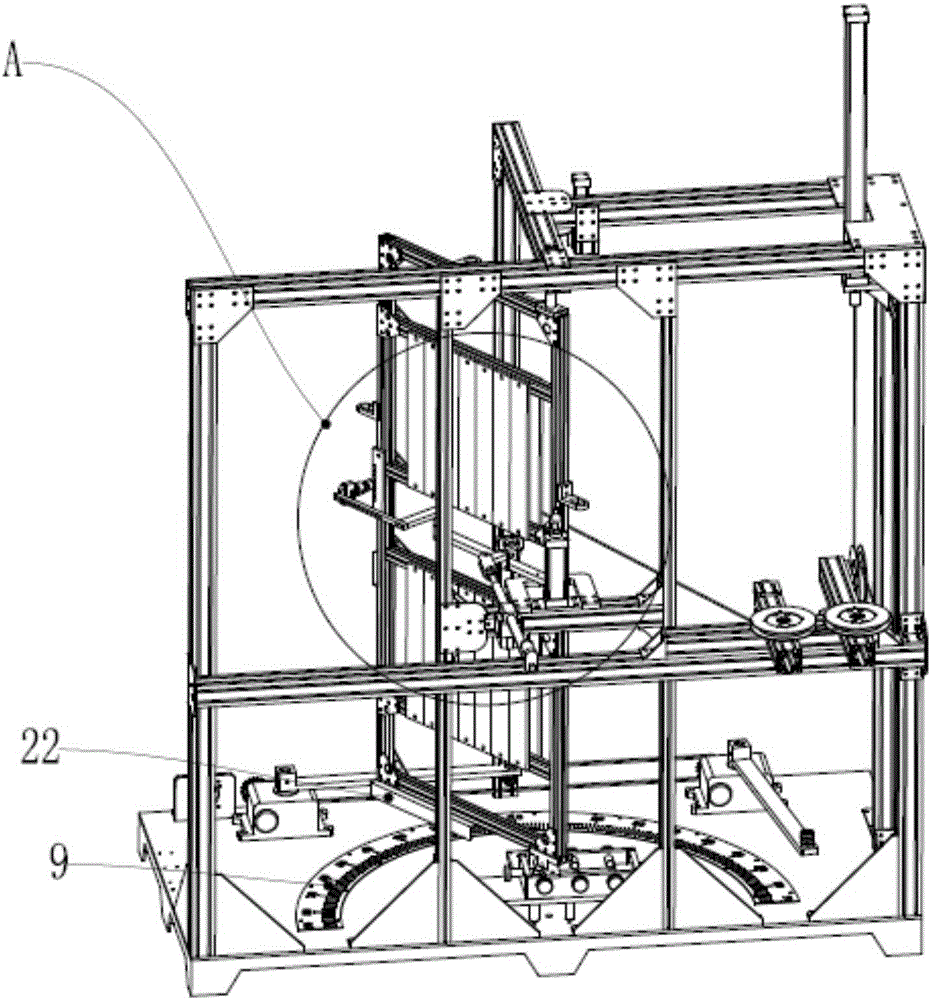

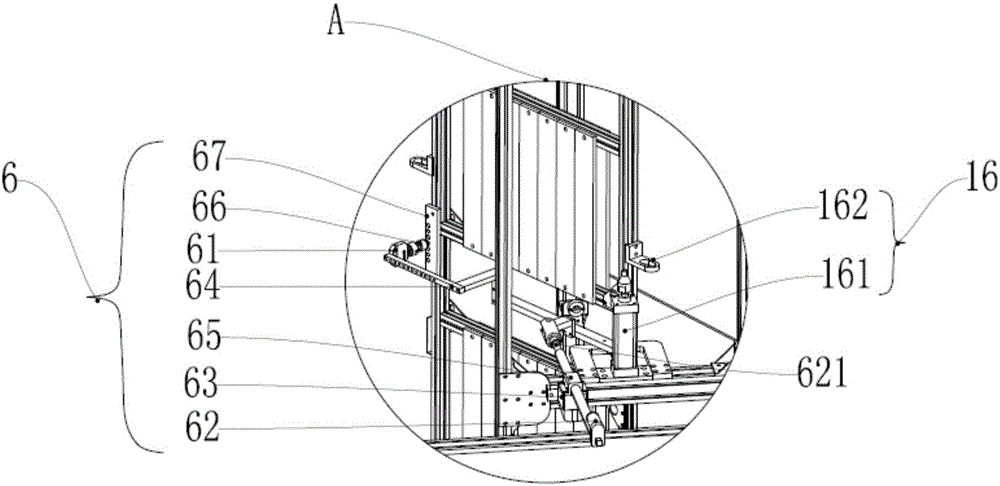

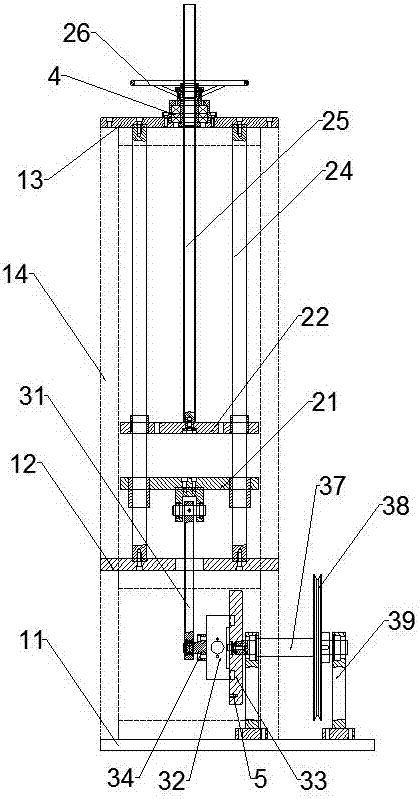

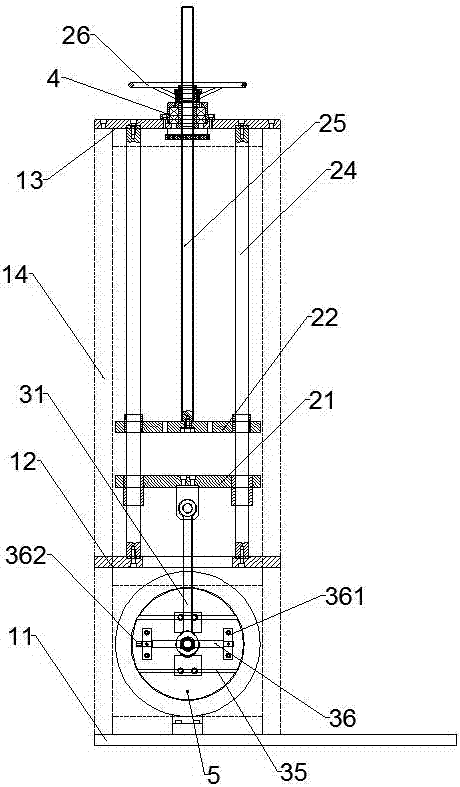

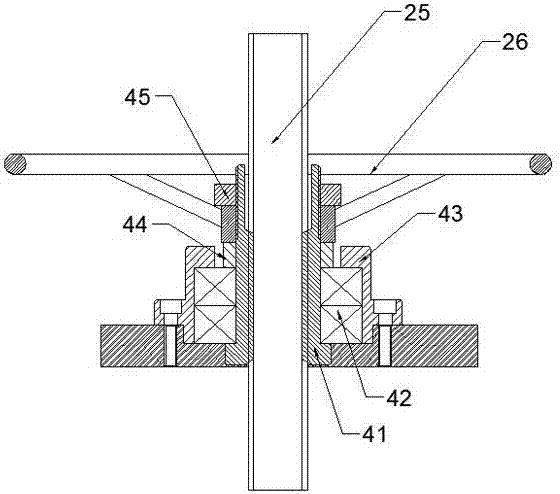

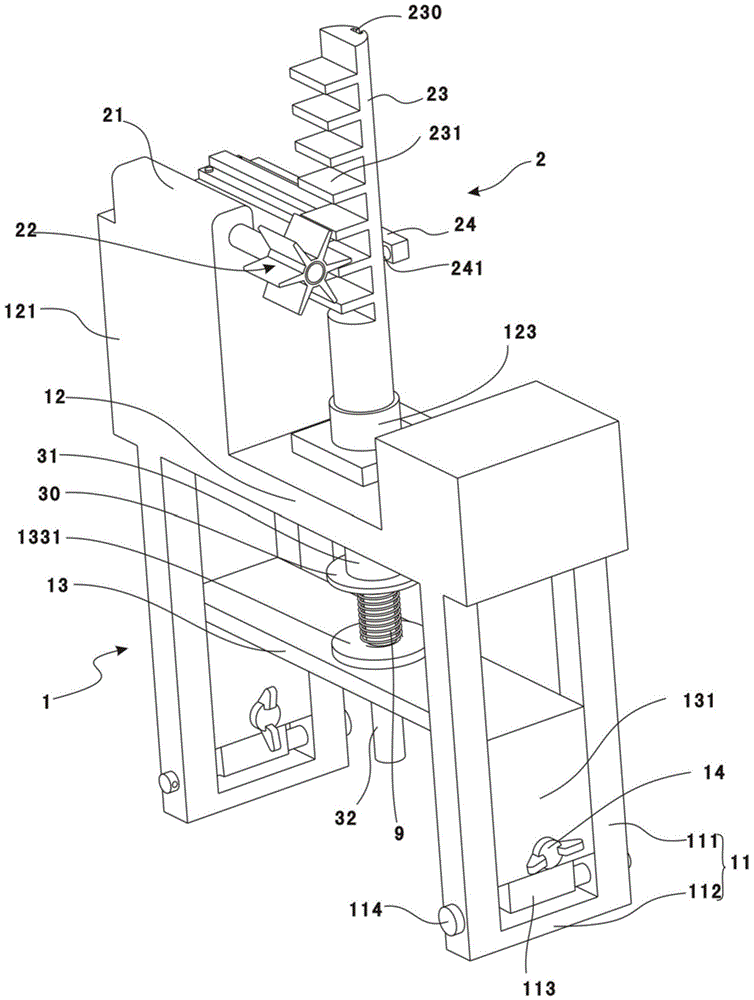

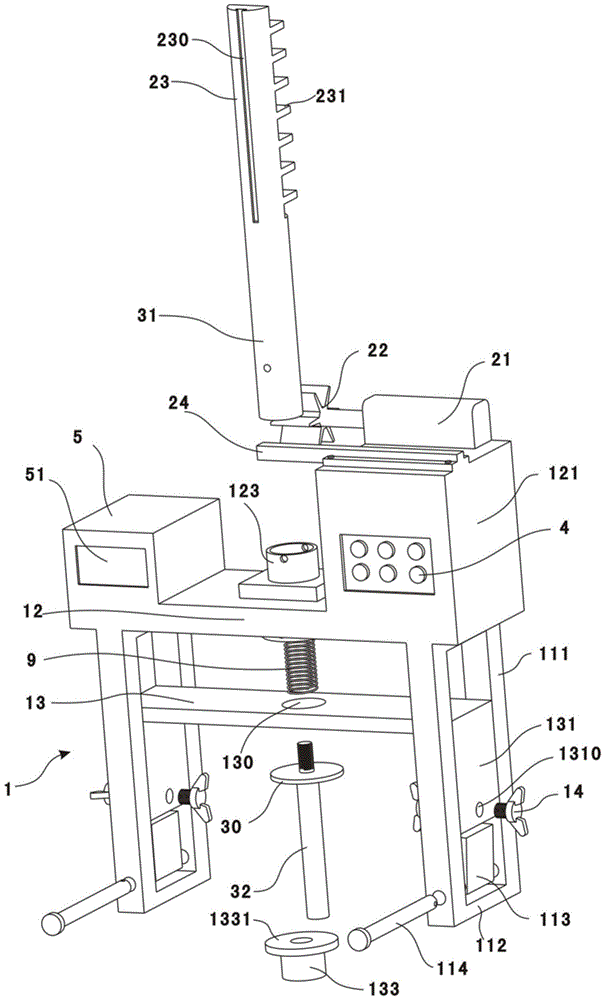

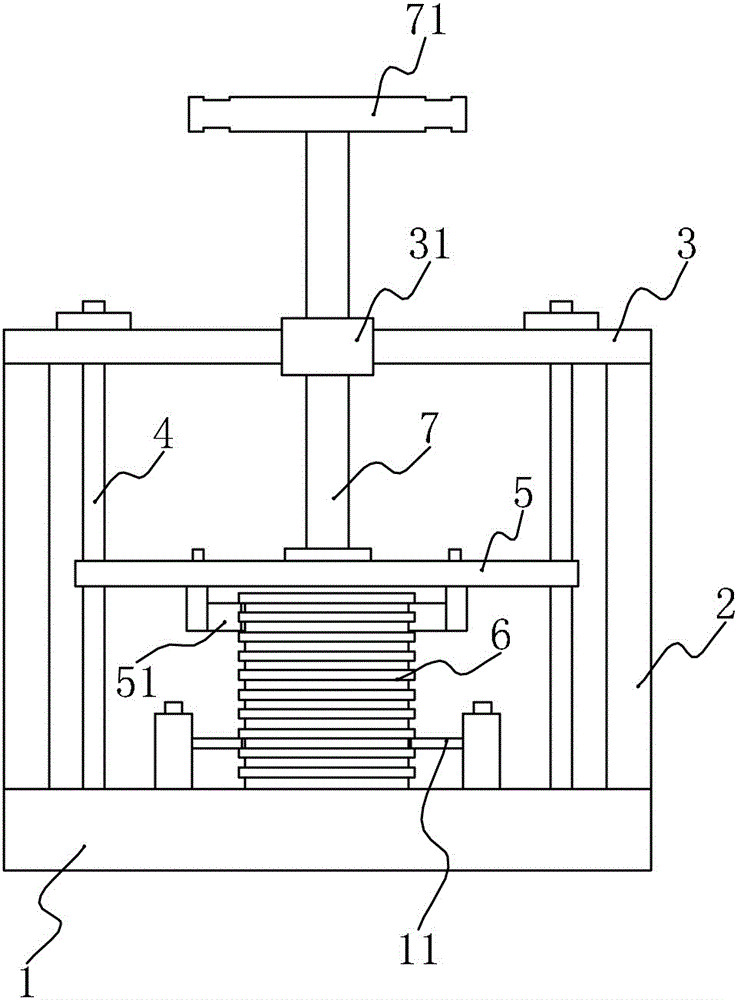

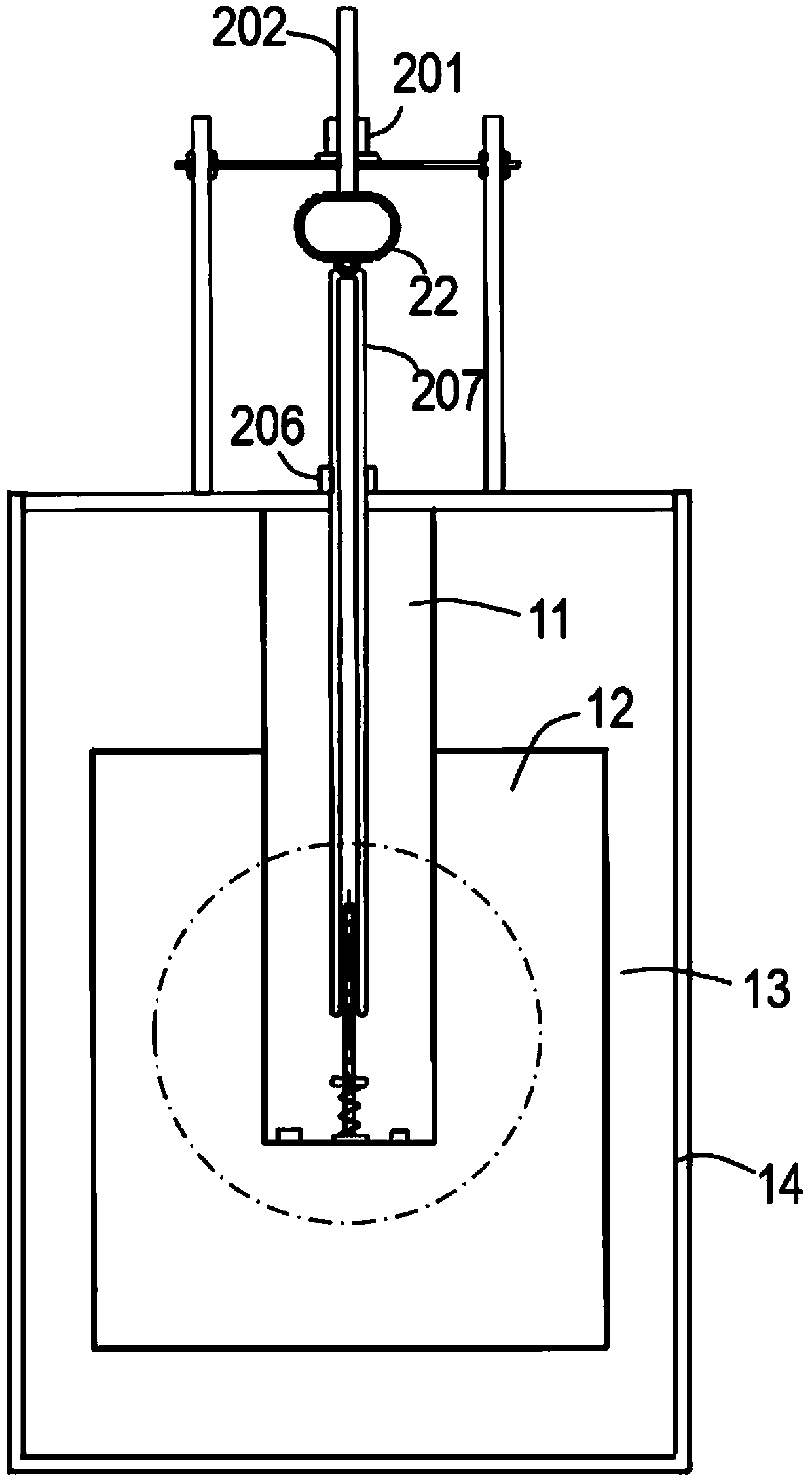

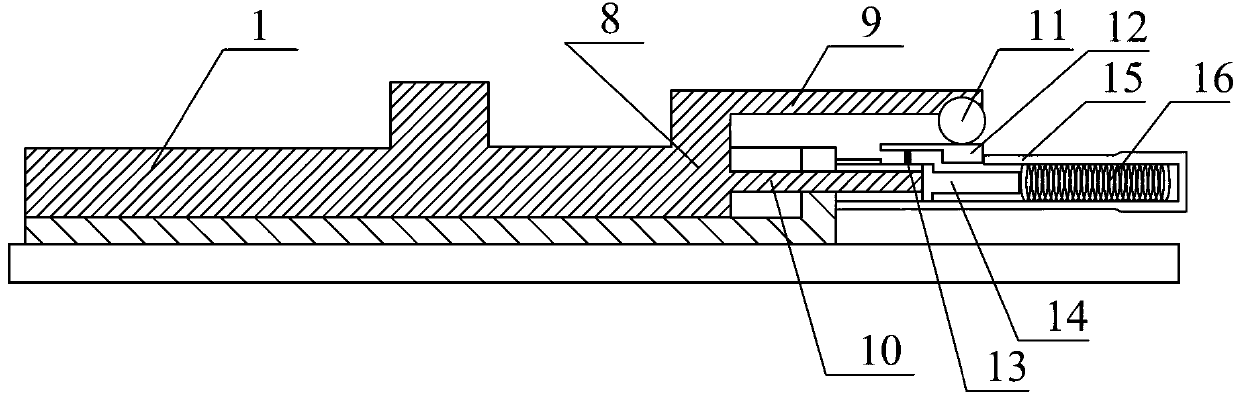

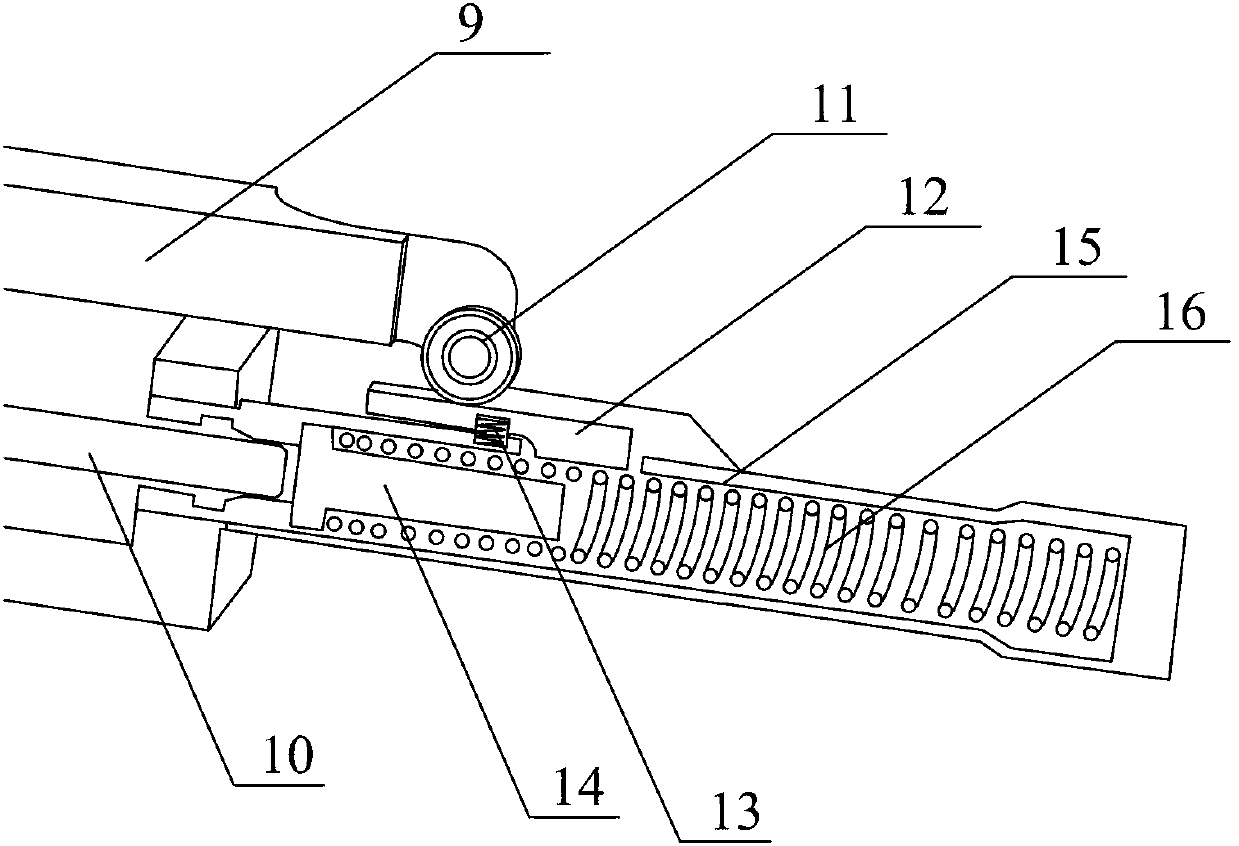

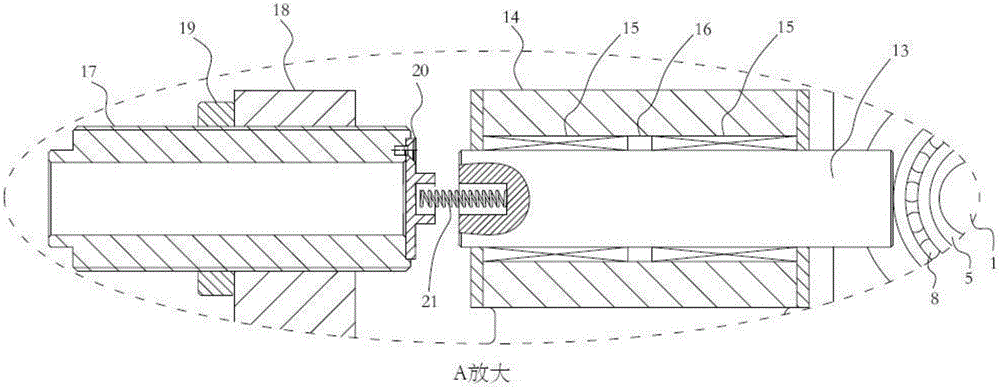

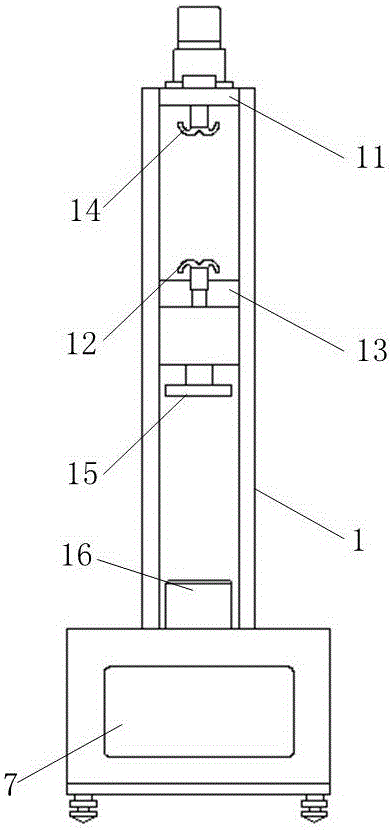

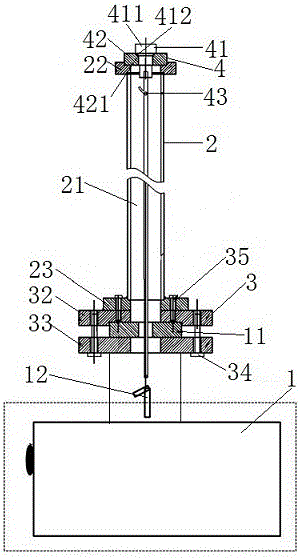

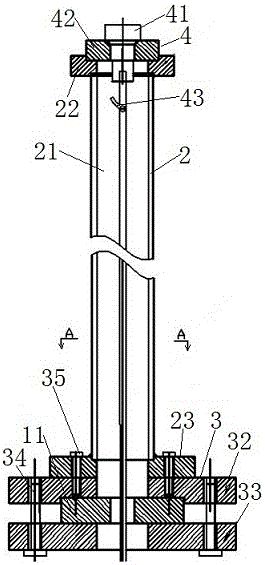

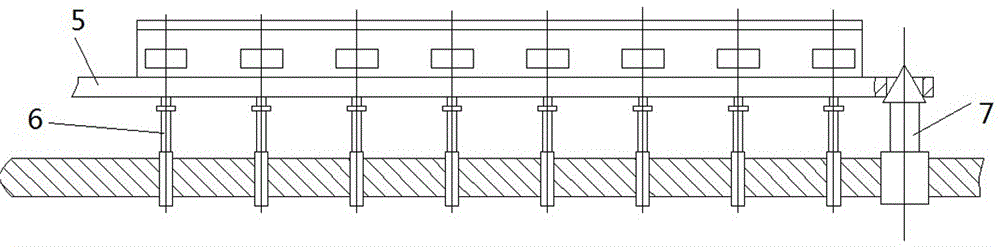

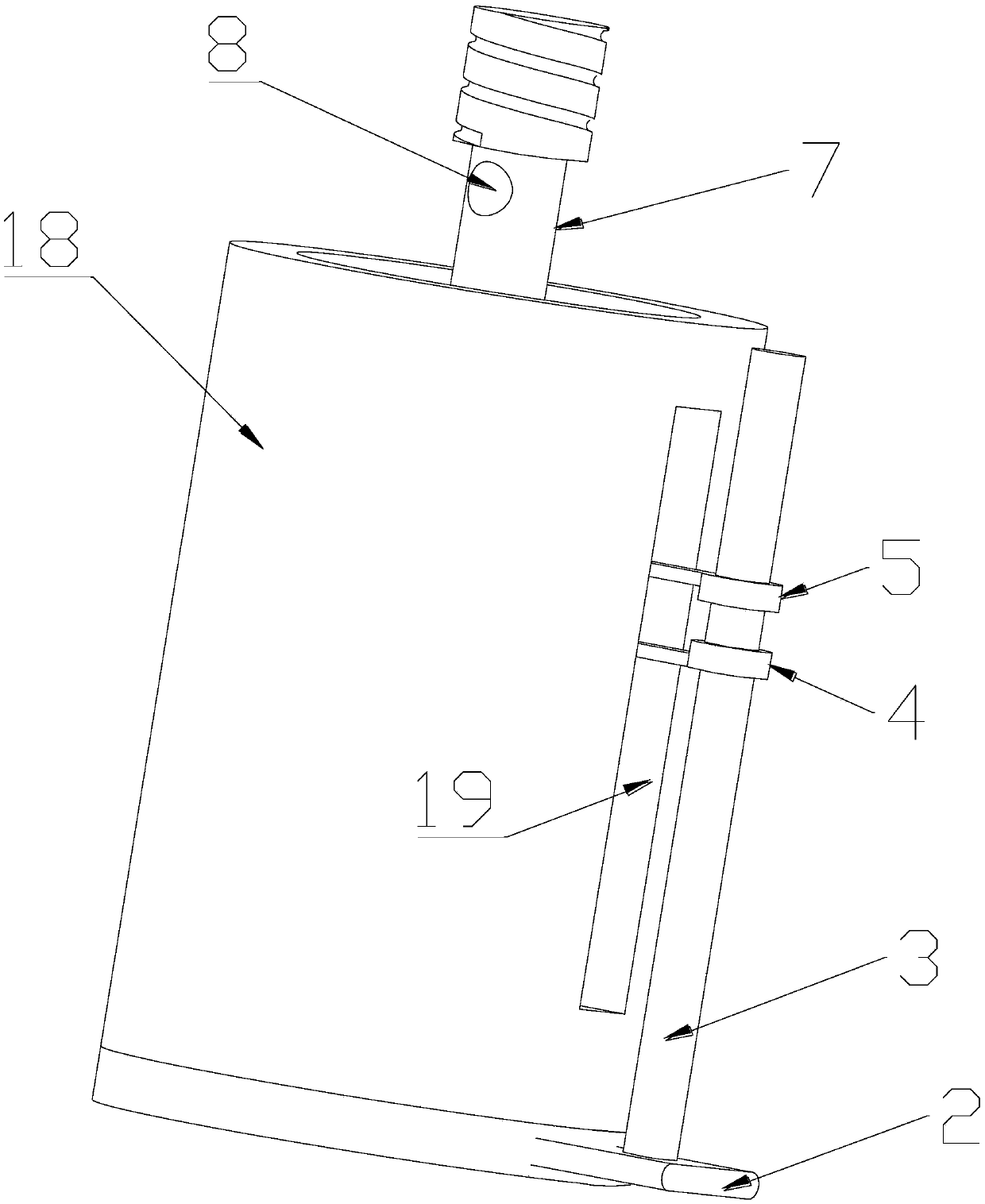

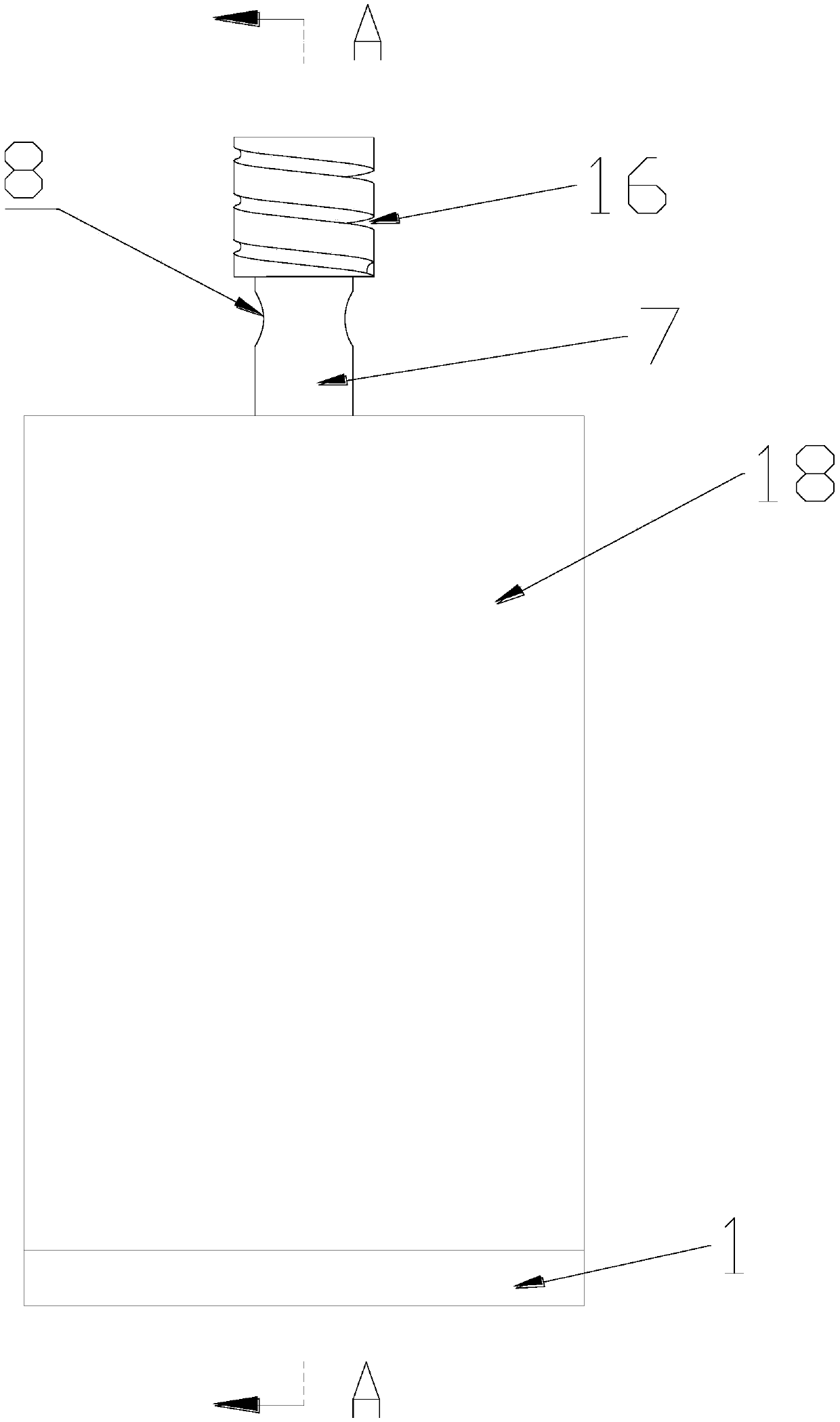

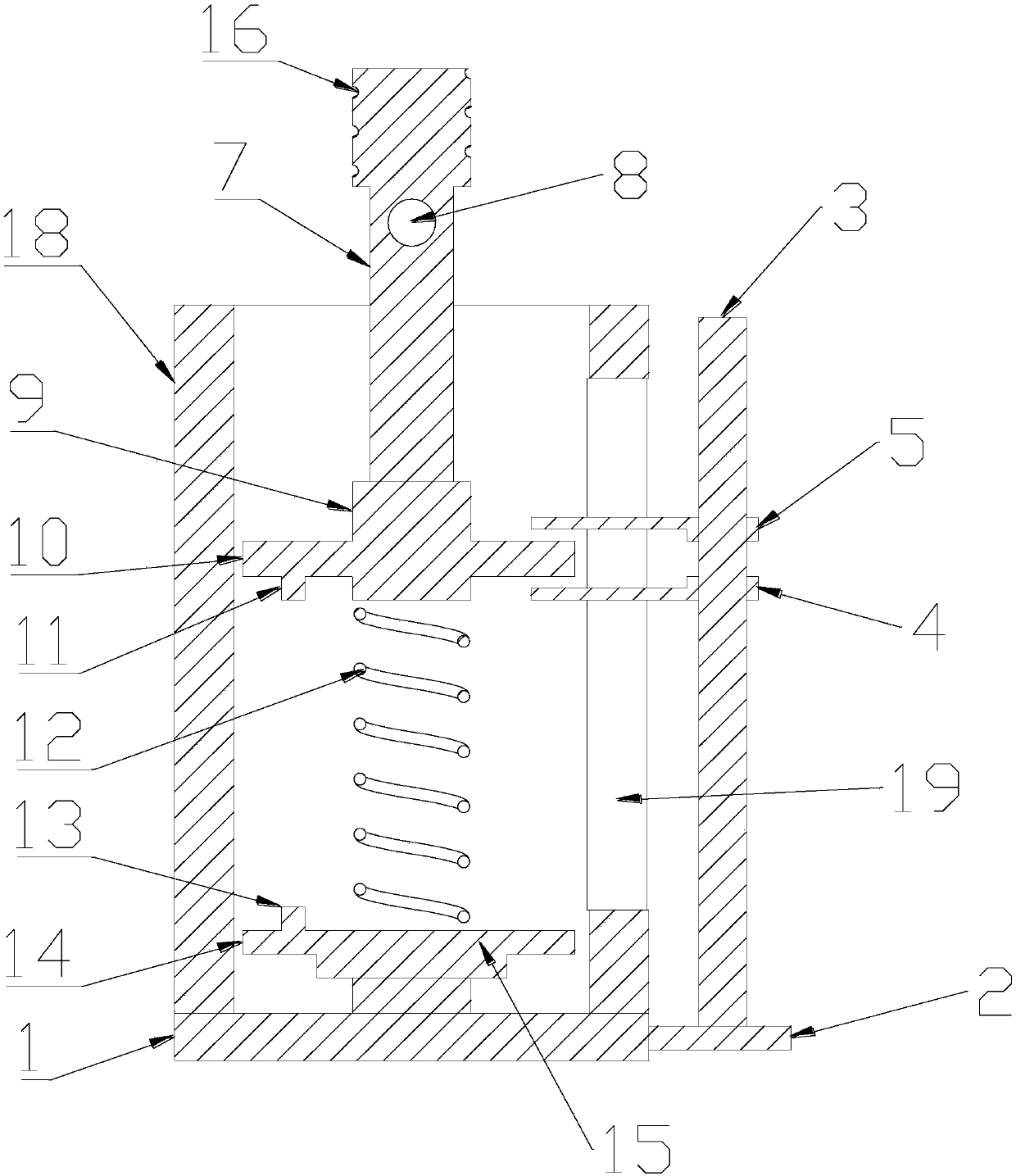

Round spring test device

ActiveCN103115758AImprove test efficiencyImprove test accuracyMachine part testingTest performanceHydraulic cylinder

The invention relates a test device of railway vehicle braking examine and repair technology, in particular to a round spring test device capable of testing performances of round springs such as axle-box spring and swing-bolster spring. The round spring test device comprises a base, a centering component, a support, a hydraulic system component, a main hydraulic cylinder and a top bar. The centering component is fixedly mounted on the base, the support and the hydraulic system component are fixedly mounted on one side of the base, the top bar is fixed on the support, the main hydraulic cylinder is fixed on the top bar, a displacement sensor is mounted on the main hydraulic cylinder, and a force sensor is mounted between the base and the centering component. The round spring test device is mainly used for testing the performances of the axle-box spring and the swing-bolster spring.

Owner:中电科鹏跃电子科技有限公司

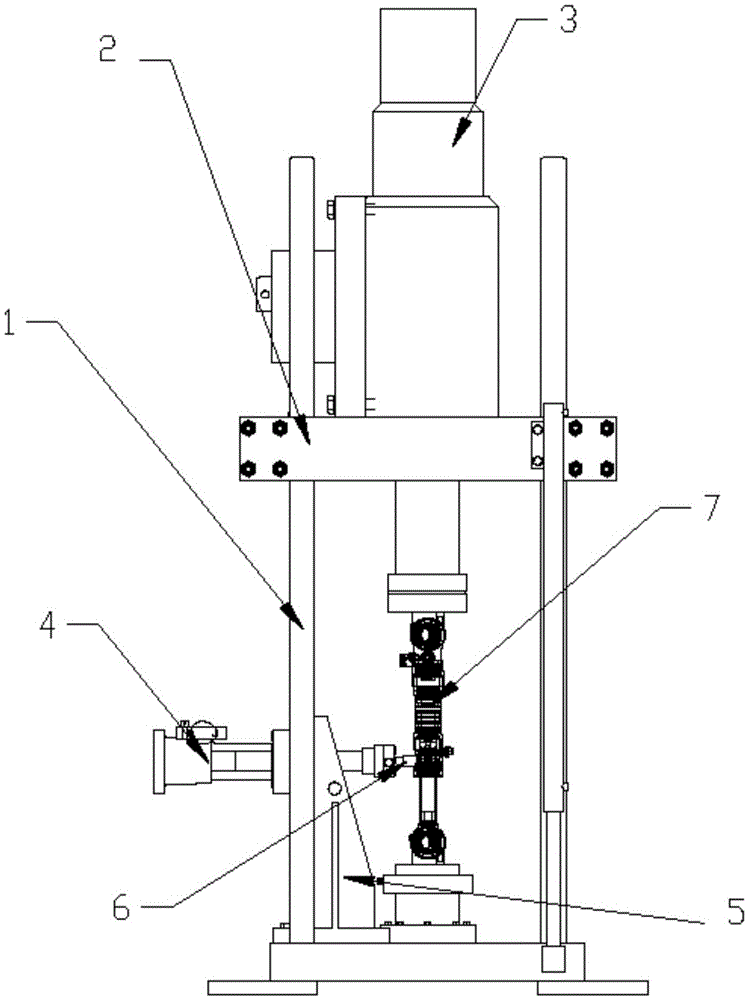

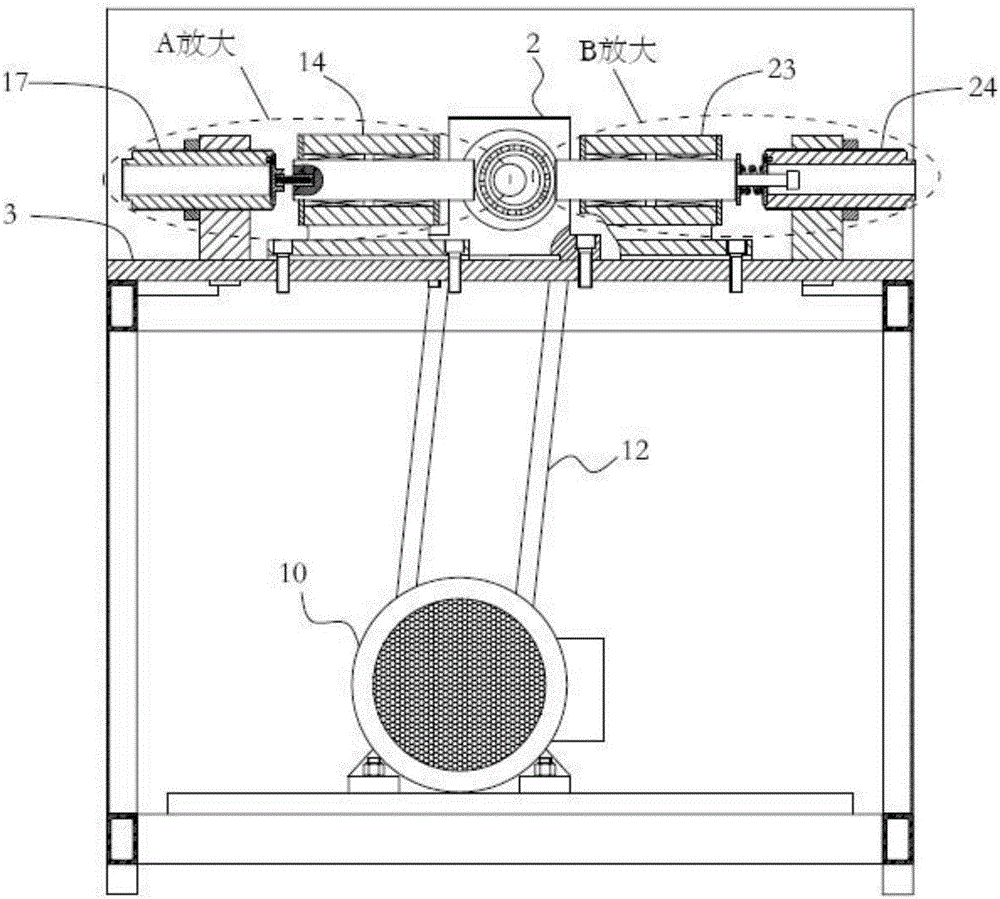

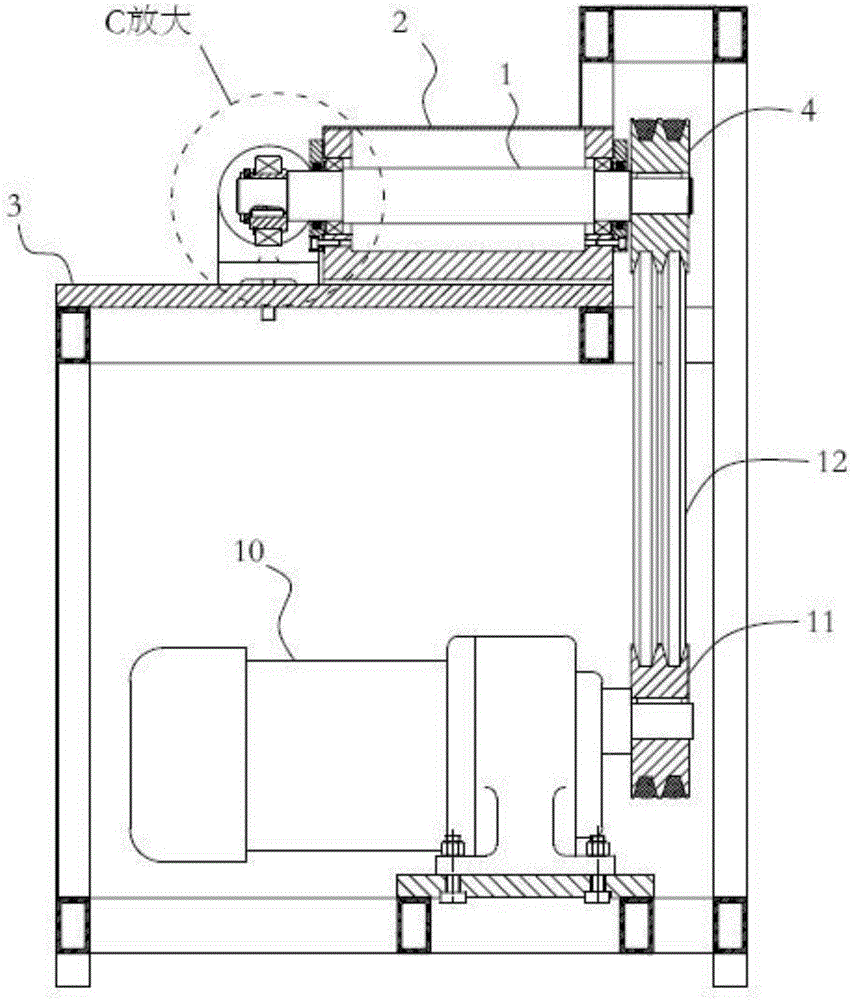

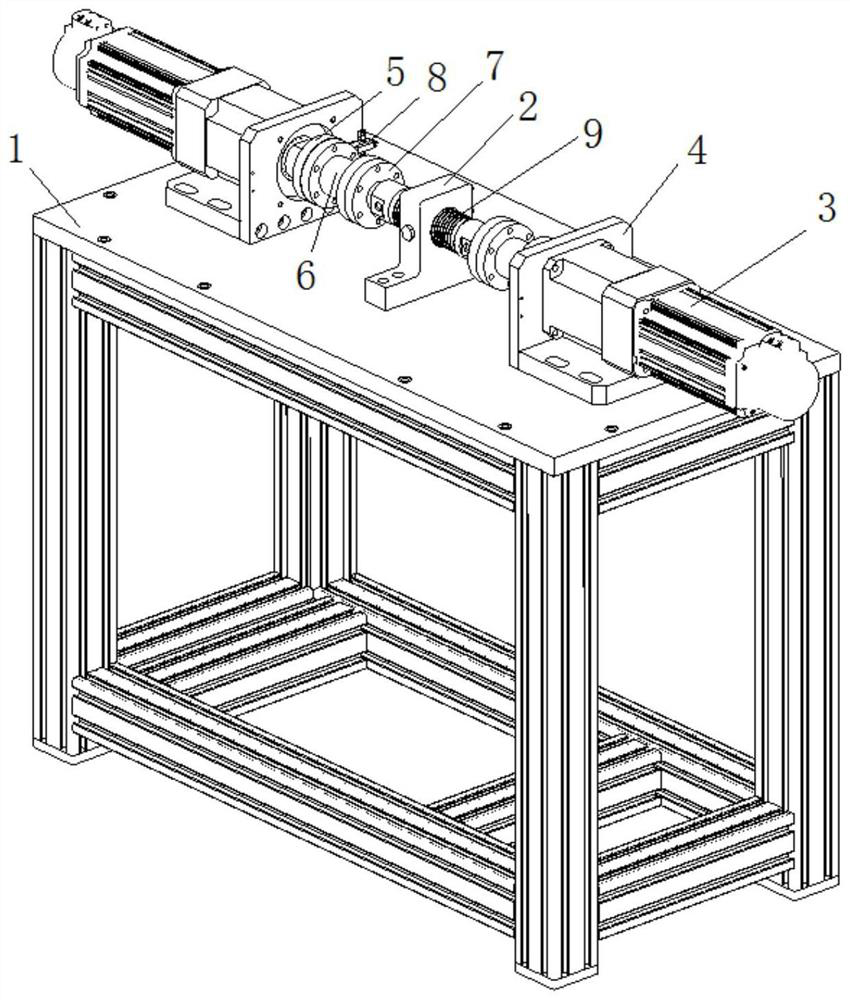

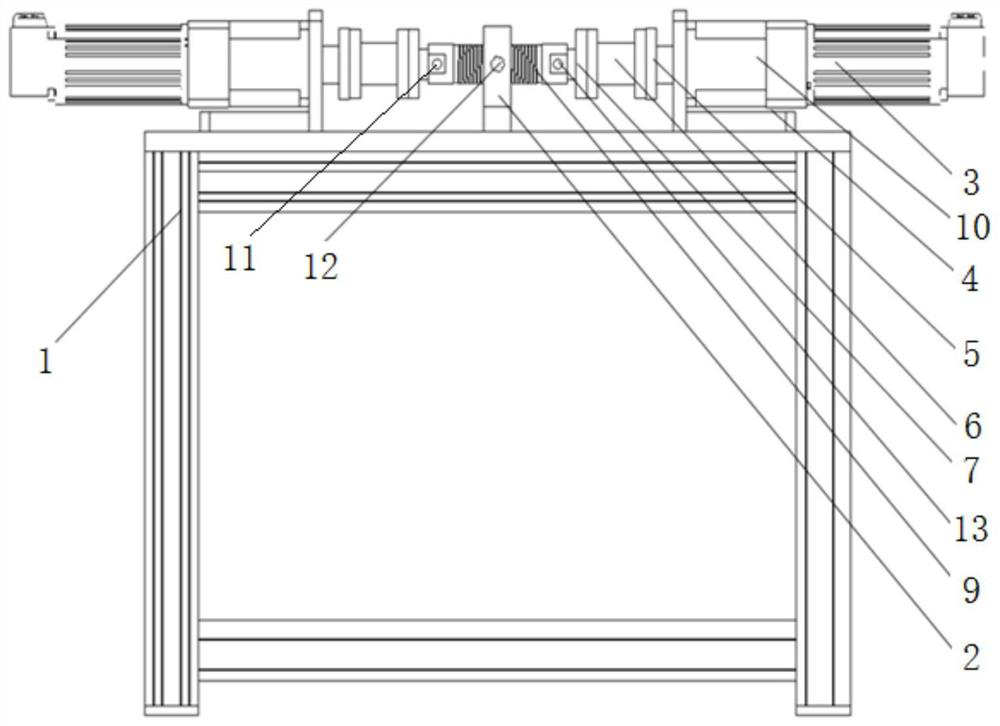

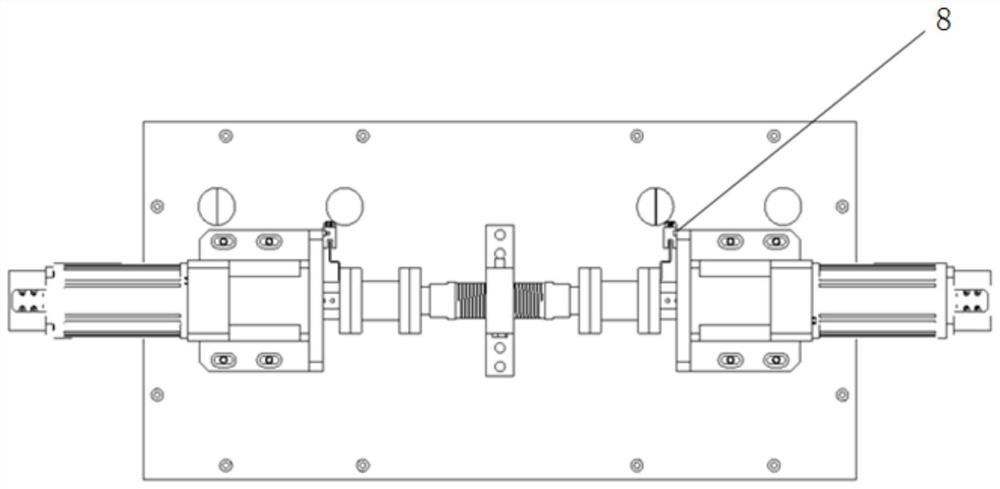

Hydro-pneumatic spring test bench with side force simulation device

The invention discloses a hydro-pneumatic spring test bench with a side force simulation device, and the test bench comprises a fixed rack with a function of damping, a movable rack, an axial load simulation hydraulic actuator, a side force simulation actuator, a side force simulation actuator support, side force loading tools, a hydro-pneumatic spring, a controller, and a hydraulic system. The test bench can achieve the testing of all items when a side force is applied to a tested hydro-pneumatic spring, simulates the load condition of the hydro-pneumatic spring in use more truly, and provides a hardware platform of scientific experimental verification for the research of the hydro-pneumatic spring. Moreover, there are various types of side force loading tools, thereby meeting the requirements of the testing of all items of different types of hydro-pneumatic springs under the action of the side force.

Owner:CHINA NORTH VEHICLE RES INST

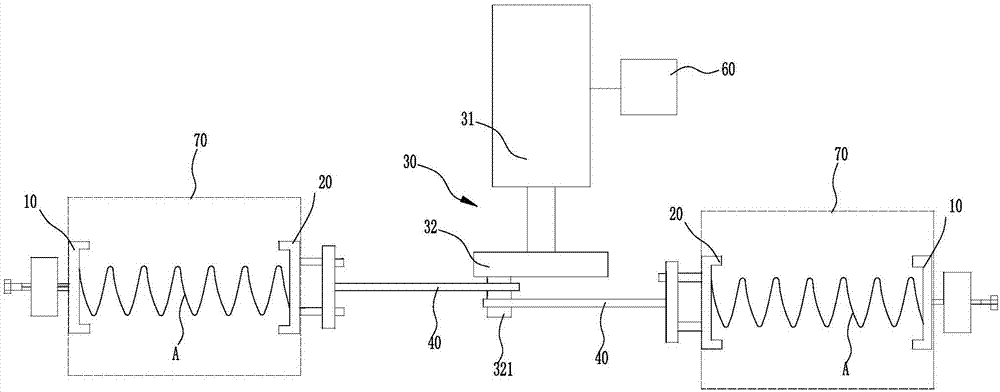

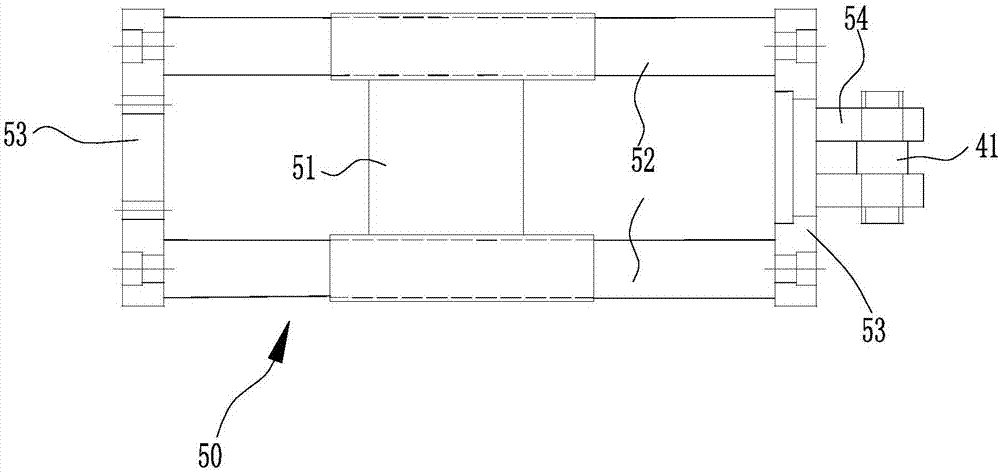

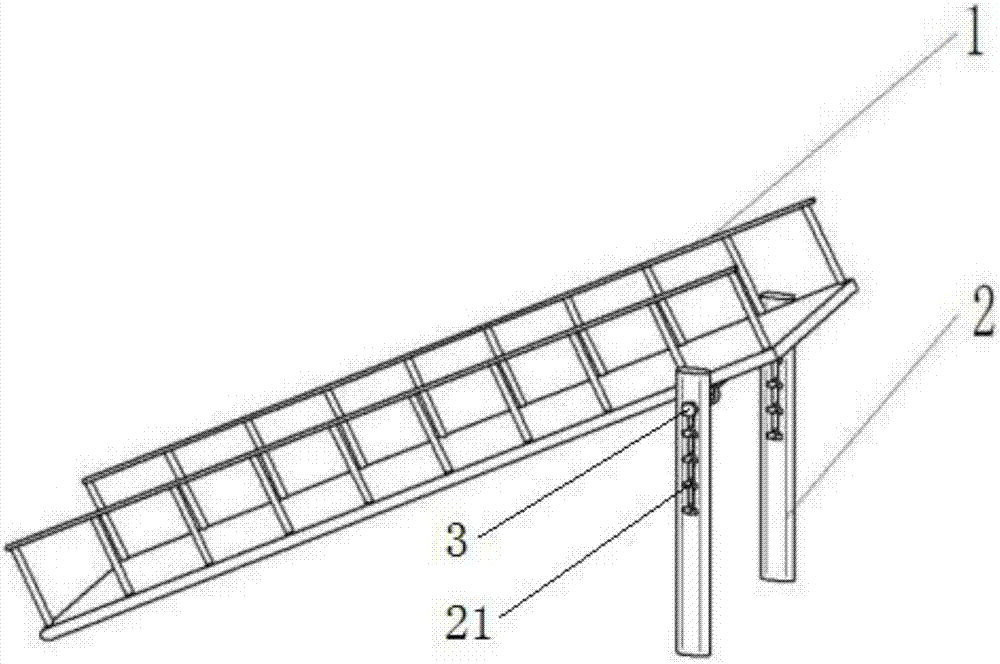

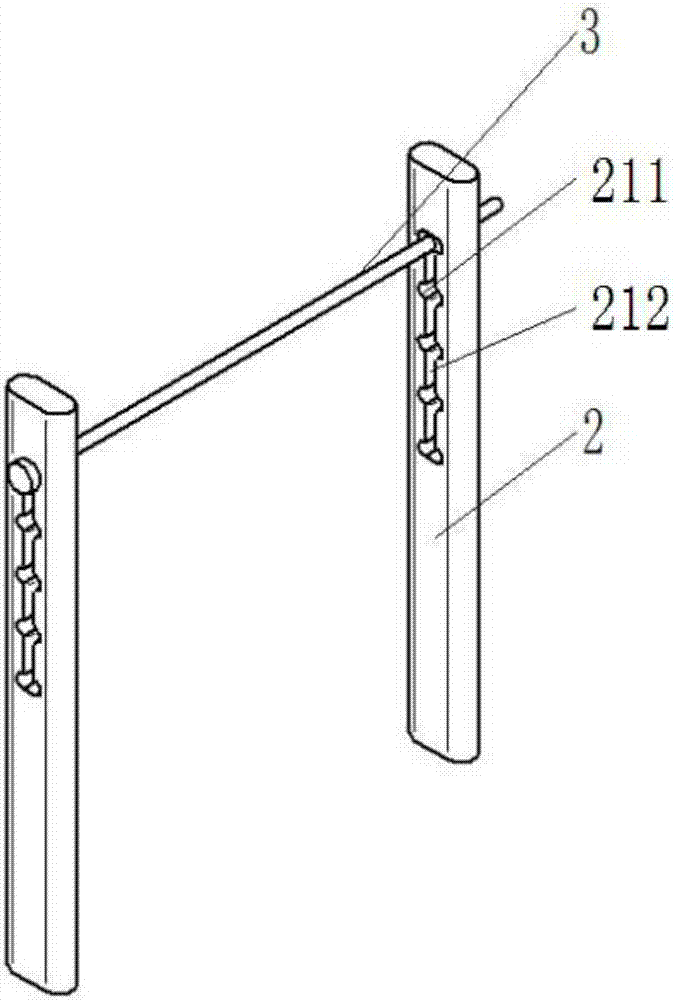

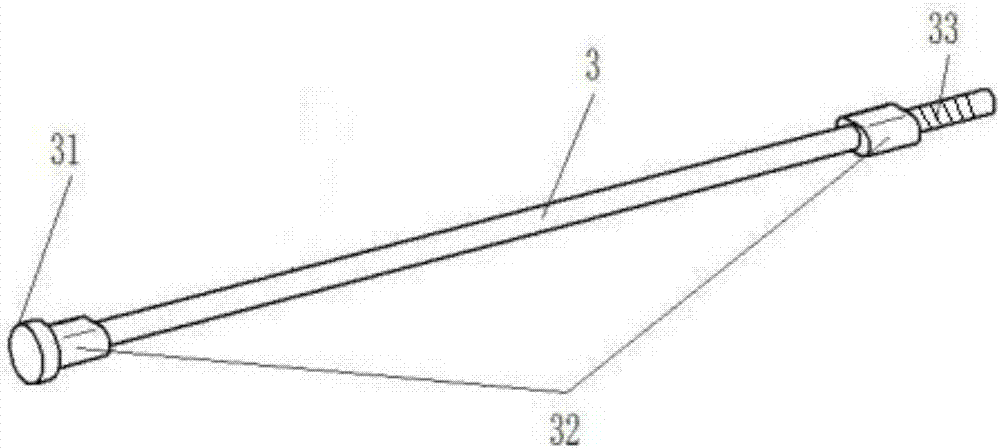

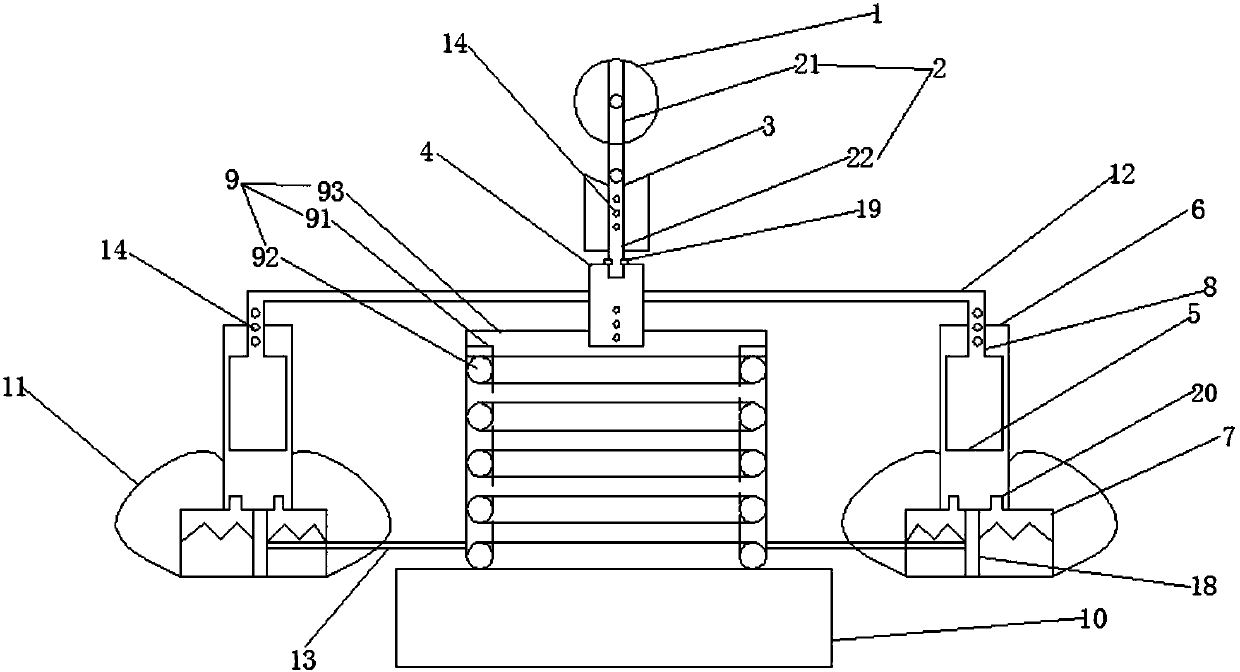

Automotive suspension spiral spring durability test device

The object of the present invention provides an automotive suspension spiral spring durability test device. The device shortens the test period and improves the test efficiency. Meanwhile, the cost is low. The device comprises a fixed bracket and movable brackets. The fixed bracket is connected with one end of a spiral spring A. The movable brackets are connected with the other end of the spiral spring A. The movable brackets are connected with a driving mechanism. The driving mechanism is connected with at least two groups of movable brackets and the spiral spring A. One part of the spiral spring A conducts the stretching movement, while the other part of the spiral spring A conducts the compression movement. According to the technical scheme of the invention, the spiral spring has the energy storage effect, and skillfully utilizes the energy conservation law and the acting force and counter-acting force principles. Meanwhile, a plurality of spiral spring tests can be conducted through a single test. Therefore, the test efficiency is almost doubled, and the test period is shortened. The cost is reduced.

Owner:CHERY AUTOMOBILE CO LTD

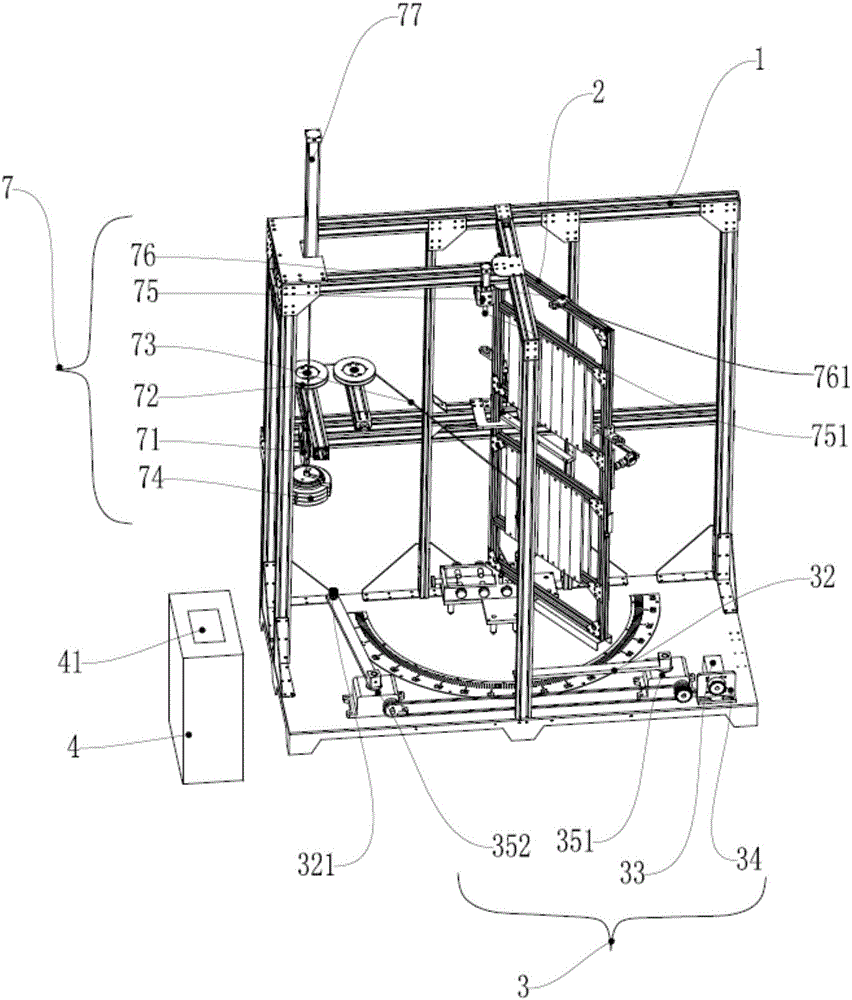

Floor spring test system

A floor spring test system comprises a frame body, a test door, an actuator, and an electric control box. The test door is hinged into the frame body and can swing in the frame body. The bottom of the test door is equipped with a swing slot. The actuator is mounted at the bottom of the frame body. The floor spring test system further comprises a swing rod which is mounted on the actuator. The actuator drives the swing rod to rotate and match the swing slot so as to pull the test door to be opened or closed. The floor spring test system further comprises a counting sensor which is mounted on the frame body. The electric control box is arranged at one side of the frame body. With the floor spring test system, the unidirectional life and bidirectional life of a floor spring can be measured. The floor spring test system accords with the test standard. The counting sensor is used for calculating the number of fatigue tests. The whole process is automated, the test precision is improved, and error caused by manual test is reduced.

Owner:佛山市质量计量监督检测中心 +1

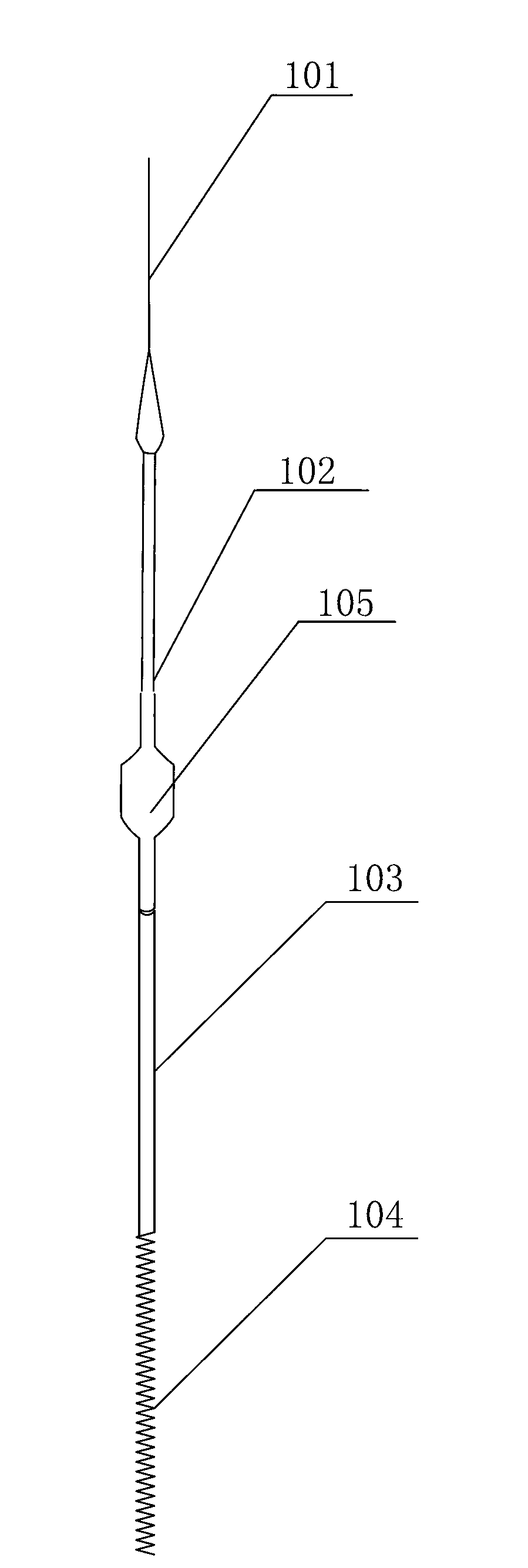

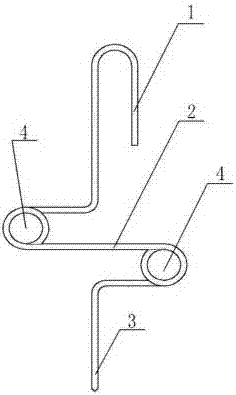

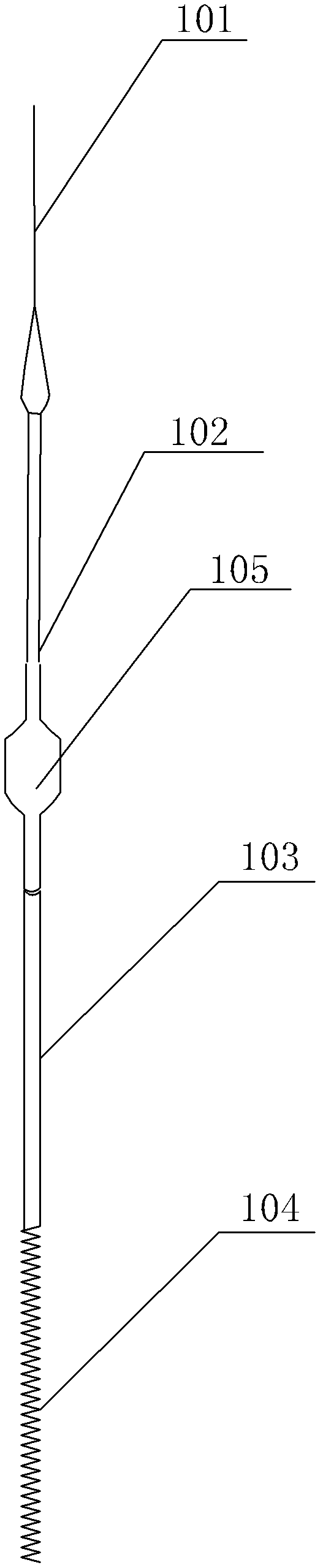

Solar cell spring testing probe

ActiveCN104702211ANo elastic deformationEffective cushioningPhotovoltaic monitoringPhotovoltaic energy generationElectrical resistance and conductanceElectrical performance

The invention discloses a solar cell spring testing probe and relates to matching members for solar cell testing, in particular to a probe member for testing electrical performance of solar cell. The solar cell spring testing probe sequentially comprises a connecting head, a spring portion and a contact from top to bottom, the connecting head, the spring portion and the contact are of an integral structure, the spring portion is a S-like spring, and the contact is linear. The connecting head, the spring portion and the contact are designed to be of the integral structure, the connecting head is fixed inside a testing device, and the spring portion and the contact are compressed through the testing device to realize testing. Due to the integral structure, production cost is lowered, jamming between the spring and the contact is reduced, the solar cell spring testing probe is less prone to being damaged and high in practicability, and testing resistance and light shading area are reduced.

Owner:陕西众森电能科技有限公司

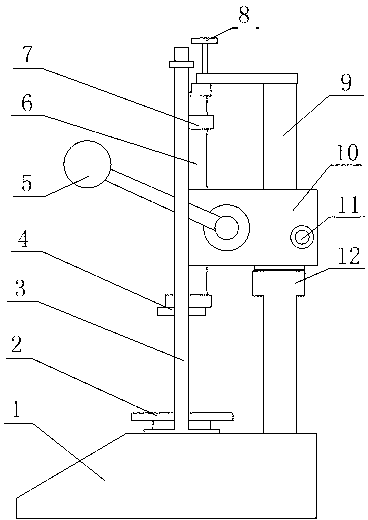

Multifunctional spring tester

ActiveCN106855455AEasy to observe the test situationAvoid injuryMachine part testingElasticity measurementFixed frameSpring force

The invention discloses a multifunctional spring tester, which comprises a fixing frame, an eccentric mechanism and a pressure test mechanism, wherein the fixing frame comprises a horizontally-arranged base, a first supporting plate, a second supporting plate and more than four vertically-arranged supporting columns; the lower ends of the supporting columns are fixed on the base; the second supporting plate is fixed at the upper end of the supporting column; the first supporting plate is located between the second supporting plate and the base and is fixed through the supporting columns; the eccentric mechanism is located between the first supporting plate and the base and is fixed on the base; the pressure test mechanism is fixed above the first supporting plate; and a perspex sheet is fixed between adjacent supporting columns. Spring fatigue test can be carried out, spring force test can also be carried out, the operation is simple, and due to the perspex sheet, the spring test condition can be observed, and the spring can be prevented from being broken and hurting a person in the case of spring fatigue test.

Owner:彭州市长庆全成技术开发有限公司

Spring deformation performance testing device

InactiveCN104677608AResize spaceImprove stabilityMachine part testingStrength propertiesReciprocating motionEngineering

The invention discloses a spring deformation performance testing device. The spring deformation performance testing device comprises a support, a driving assembly and a sliding rod, wherein the support comprises supporting pieces, a fixing piece and a bearing piece; the sliding rod slidably penetrates through the fixing piece and the bearing piece; each supporting piece is rectangular frame-shaped, and the supporting pieces comprise two long frame sides and two short frame sides; the bearing piece and the fixing piece are arranged at interval; sliding blocks are arranged on the bearing piece, and the sliding blocks are slidably arranged between the two long frame sides; the driving assembly is used for driving the sliding rod to linearly move back and forth. A spring to be tested can sleeve the sliding rod and be located between a pressing portion and the bearing piece, and a space for spring testing can be formed between the fixing piece and the bearing piece; by sliding the sliding blocks in the frame-shaped supporting pieces and locking the sliding blocks through locking bolts, the adjustment of the position of the bearing piece relative to the supporting pieces can be realized, and thus the space between the fixing piece and the bearing piece is adjusted to install springs with different length; since the supporting pieces are frame-shaped, the stability is good and the sliding fitting with the sliding blocks is facilitated.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

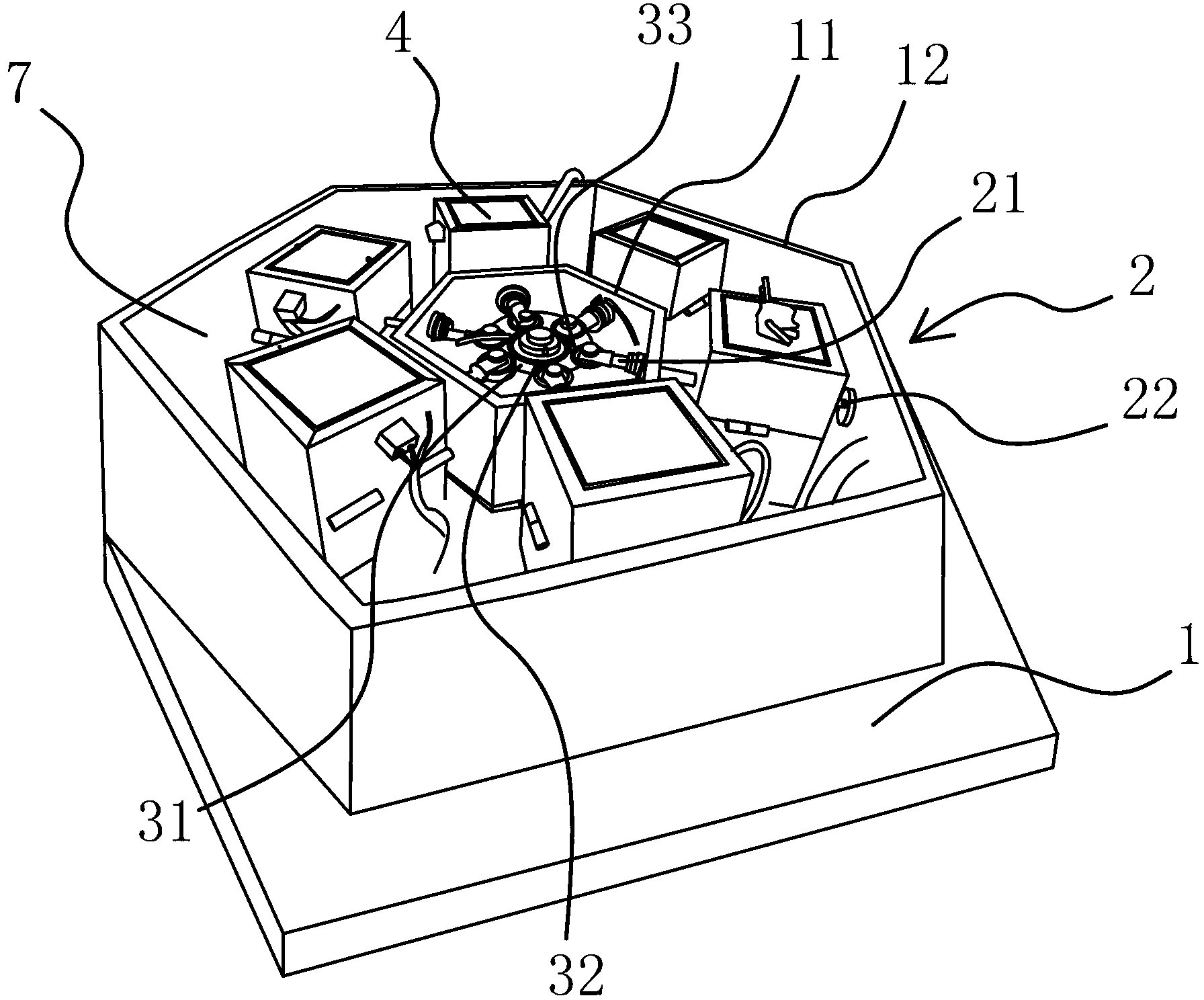

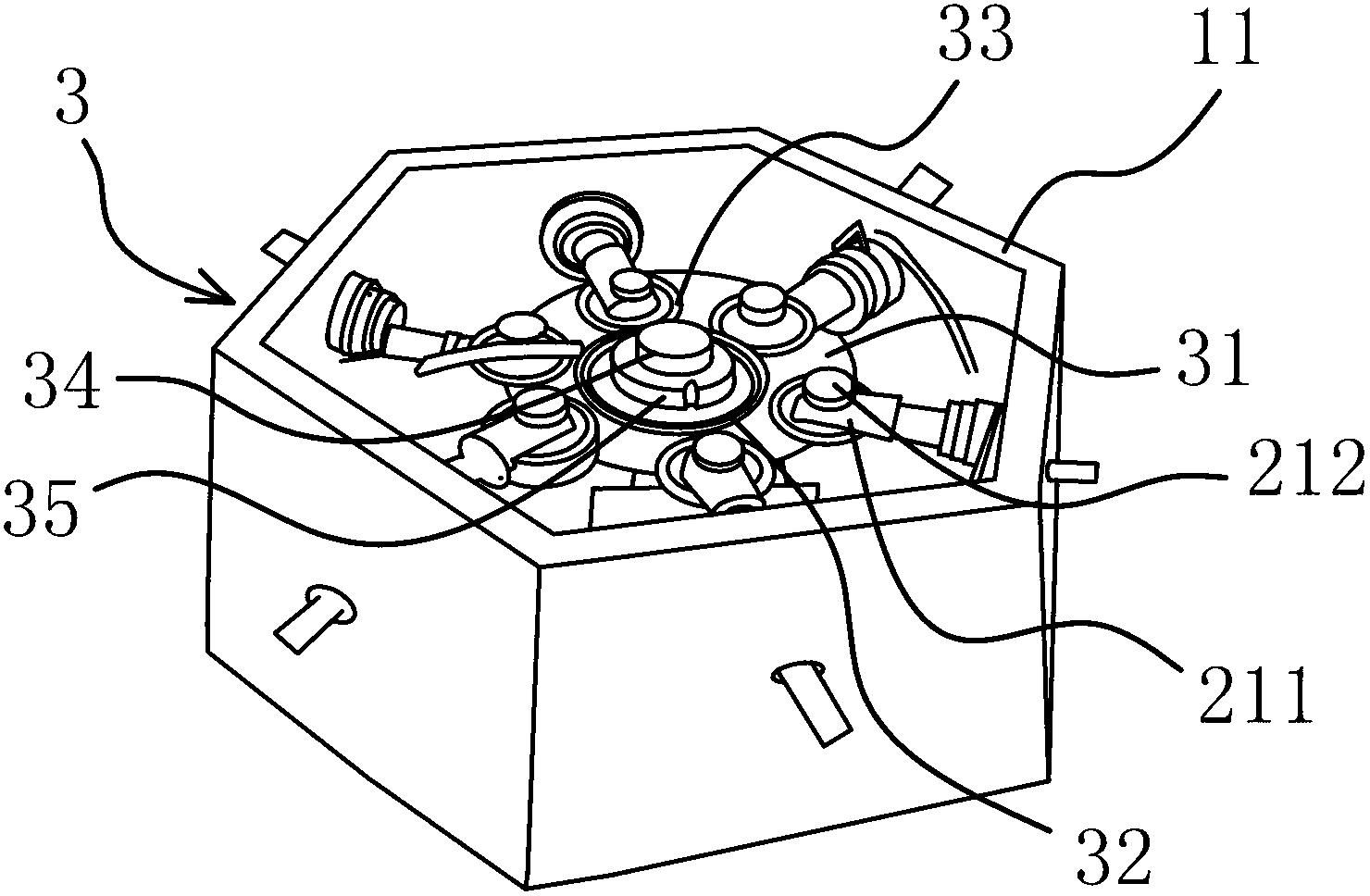

Temperature-controlled multiphase horizontal spring fatigue tester

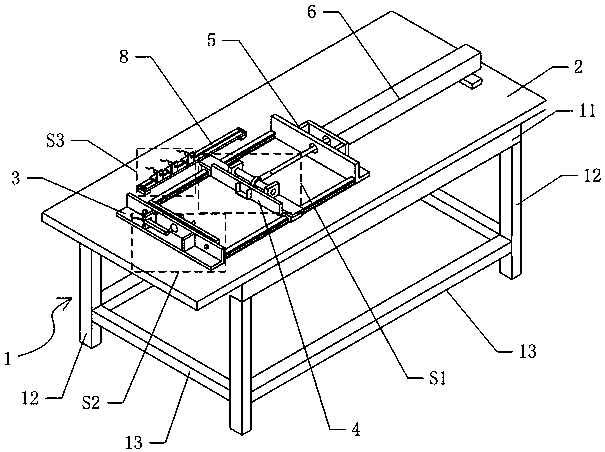

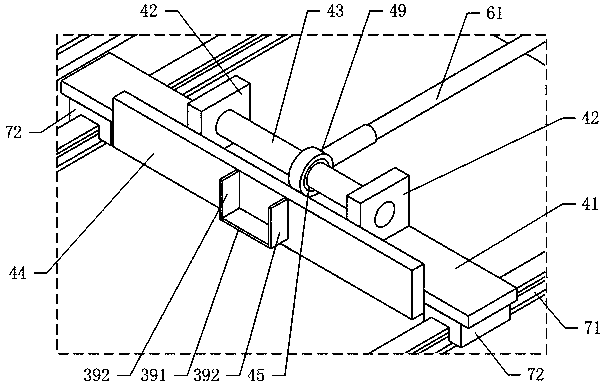

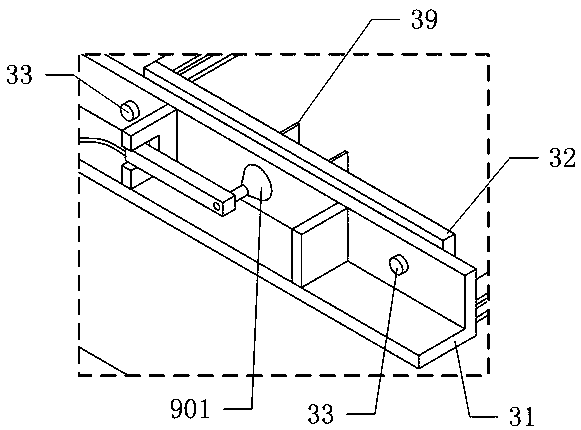

The invention provides a temperature-controlled multiphase horizontal spring fatigue tester, aiming to solve the problems like uneven stress during existing spring tests. The tester comprises a workbench and a driving mechanism. A plurality of spring horizontal mounting mechanisms are arranged on the workbench and evenly distributed in the peripheral direction. A transmission mechanism connected with the driving mechanism is arranged on the workbench and at the center of a circle formed by the spring horizontal mounting mechanisms in a surrounding manner. When being driven by the driving mechanism to move, the transmission mechanism sequentially drives to-be-tested springs to axially stretch back and forth. Heating and insulating devices are arranged on the peripheries of the spring horizontal mounting mechanisms. The temperature-controlled multiphase horizontal spring fatigue tester has the advantages of simple and reasonable structure, high stability, capability of testing fatigue properties of the springs at different temperatures, high testing accuracy, high working efficiency, capability of testing a plurality of springs at the same time, high safety, wide application range, convenience in mounting of the to-be-tested springs and high automation degree.

Owner:ZHEJIANG ISRI SHUANGDI SPRING

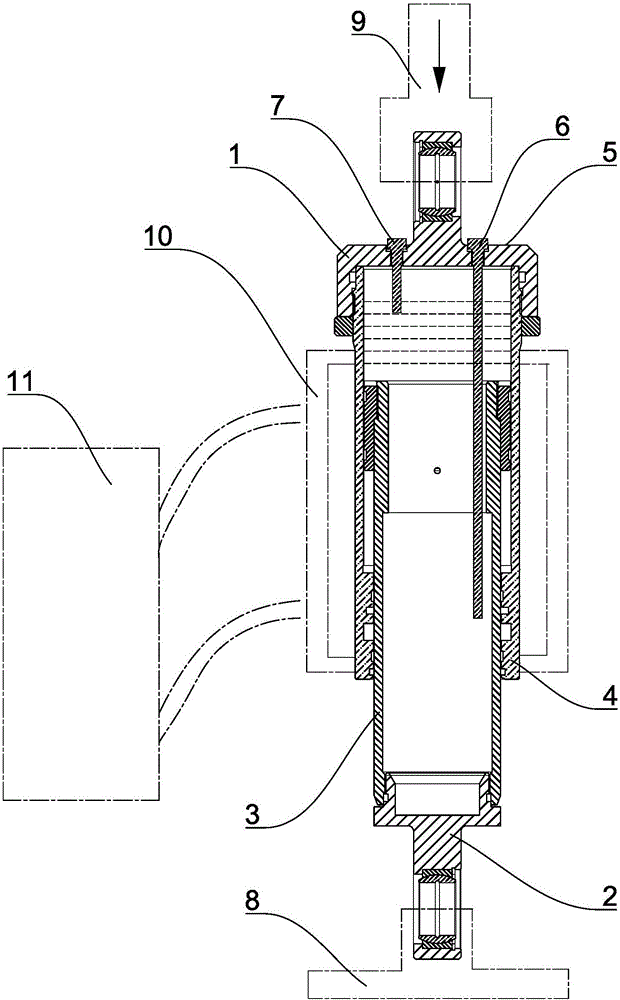

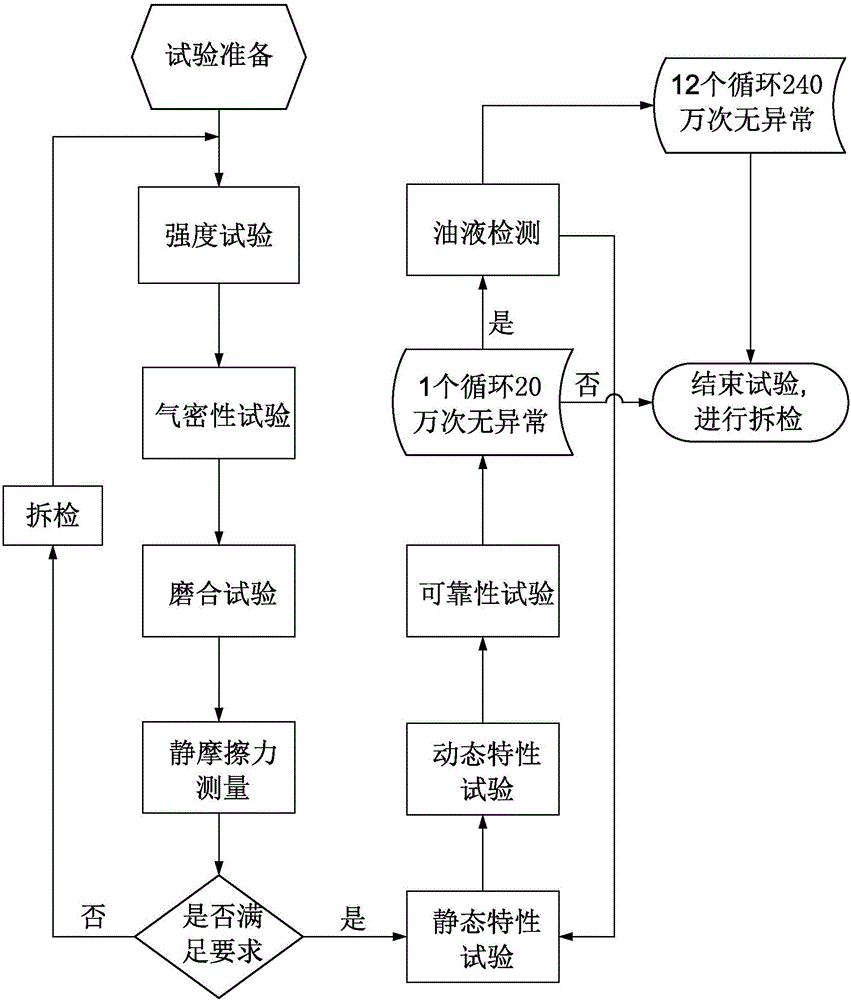

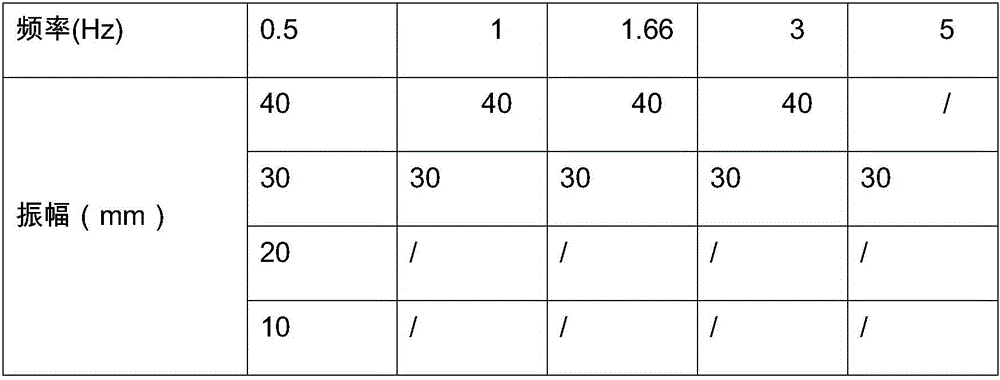

Test method for testing service life of hydro-pneumatic spring

ActiveCN105841904AMeet the special requirements of lifeResolve detectionMachine part testingVibration testingSpring TestNormal state

The invention discloses a test method for testing the service life of a hydro-pneumatic spring. The test method is conducted by means of a hydro-pneumatic spring test stand. The test method comprises the steps of 1, testing the static characteristics of a hydro-pneumatic spring; 2, testing the dynamic characteristics of the hydro-pneumatic spring; 3, testing the service life of the hydro-pneumatic spring; 4, returning to the step 1 when the oil liquid cleanliness of the hydro-pneumatic spring is in the normal state; 5, circularly executing the above process from the step 1 to the step 4. When the hydro-pneumatic spring conducts 240 million times of shock excitation after completing 12 cycles of the step 3, the test is terminated. When the leakage state, the sealing state and the oil liquid cleanliness state are normal, the hydro-pneumatic spring passes the test assessment on the service life of a corresponding mileage, wherein the 240 million times of shock excitation during 12 cycles corresponds to the vehicle travel of 6 ten thousand kilometers. The test method has the advantages of convenient implementation, scientific and reasonable properties, high reliability, and high practicability.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Spring test device

PendingCN107727389ARealize force measurementRealize fatigue testMachine part testingSpring TestEngineering

The invention discloses a spring test device. The device comprises an underframe, a bedplate fixed on the underframe, a fixed seat and an oil cylinder mounting seat which are fixed on the bedplate, amovable seat glidingly arranged on the bedplate, a force measurement sensor arranged on the fixed seat, an oil cylinder arranged on an oil cylinder mounting seat and an oil pump. The spring test device is simple in structure and easy to operate and can be used for testing the pressure condition of a spring and conducting a spring fatigue test.

Owner:佛山市子活力弹簧有限公司

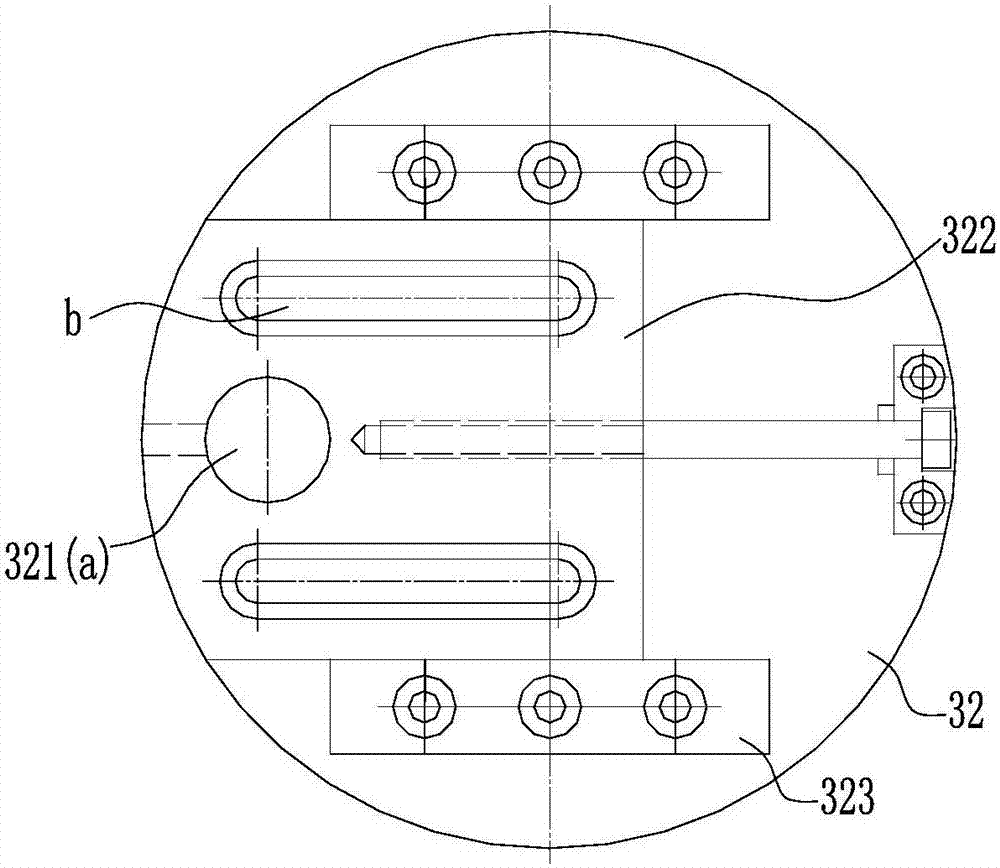

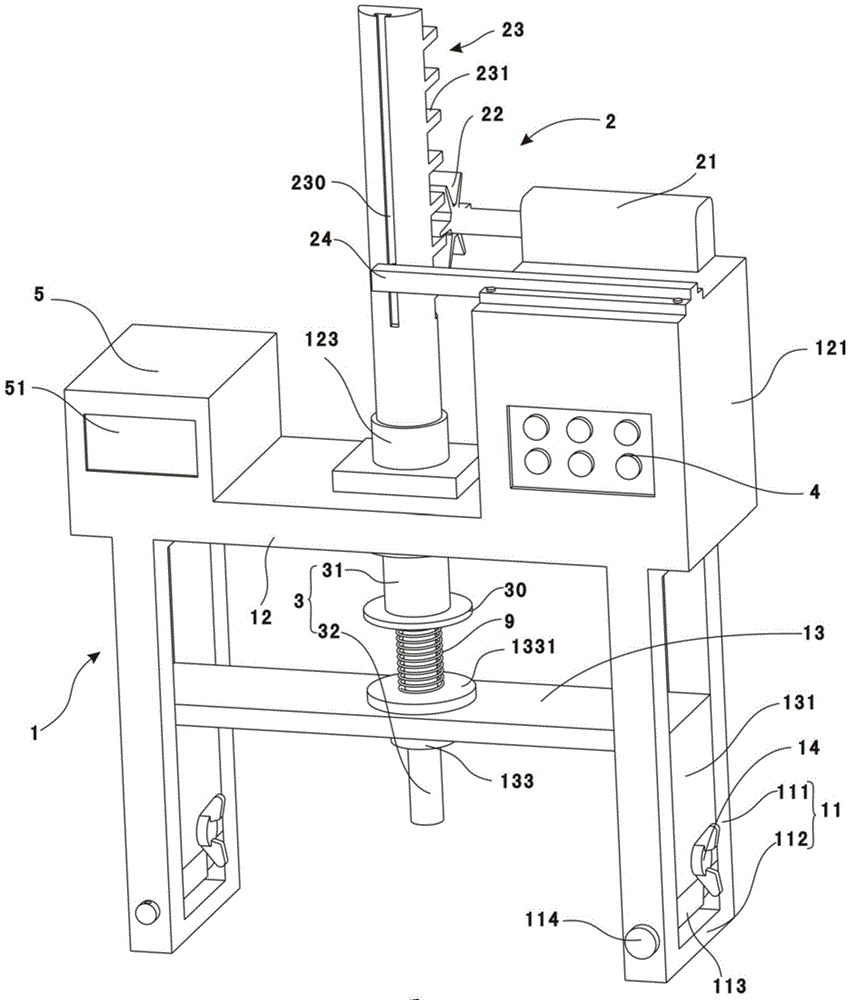

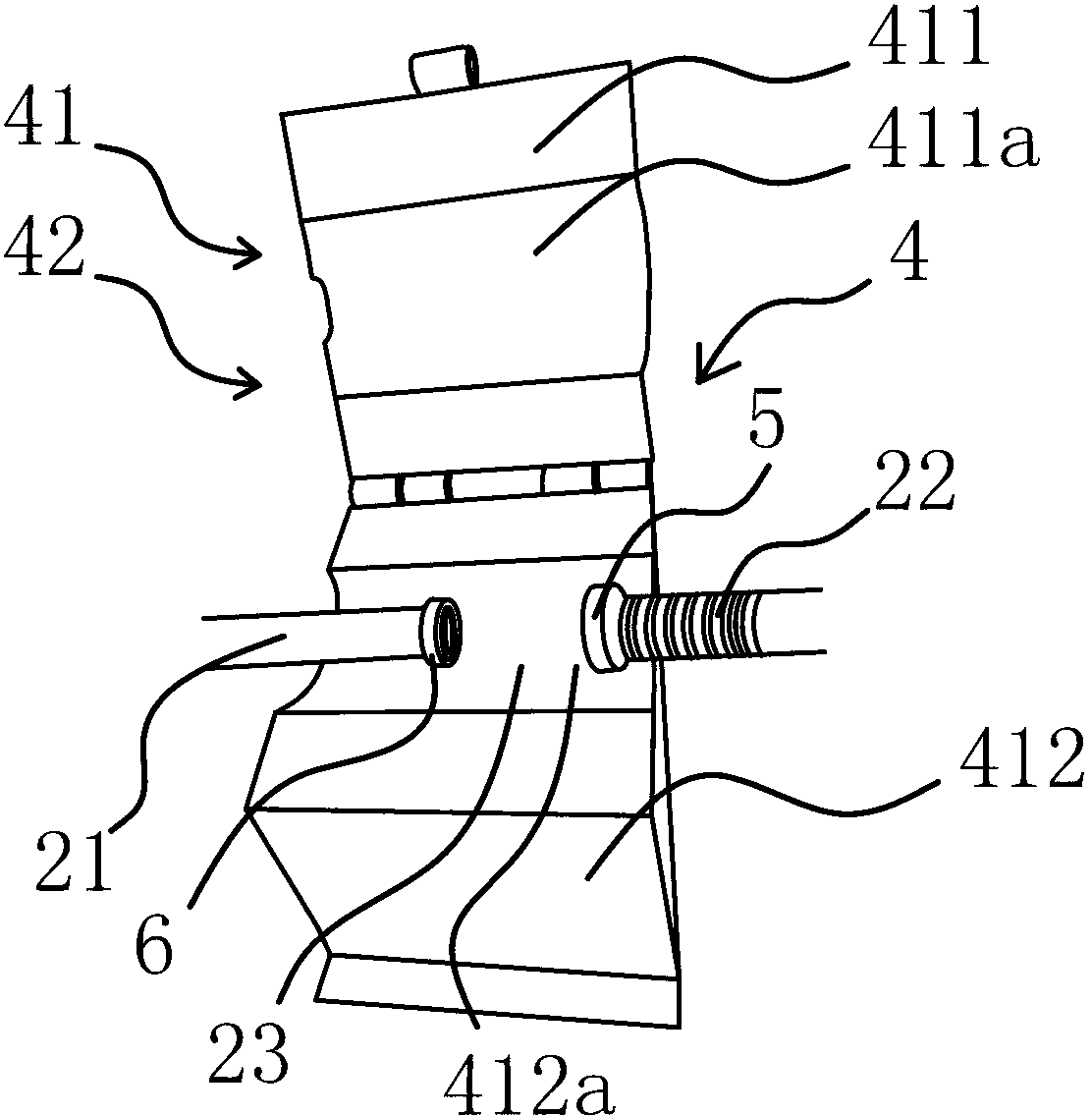

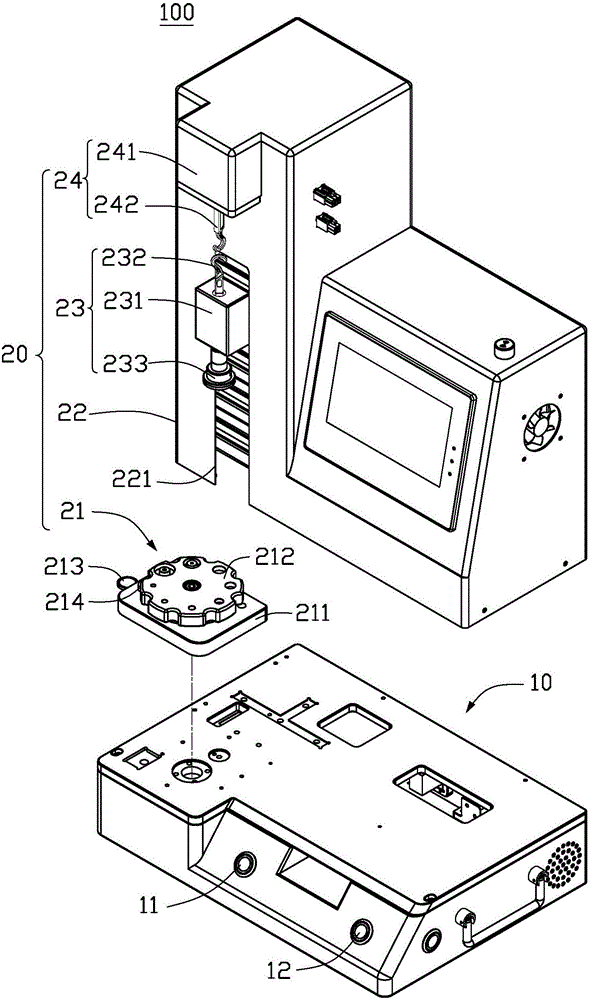

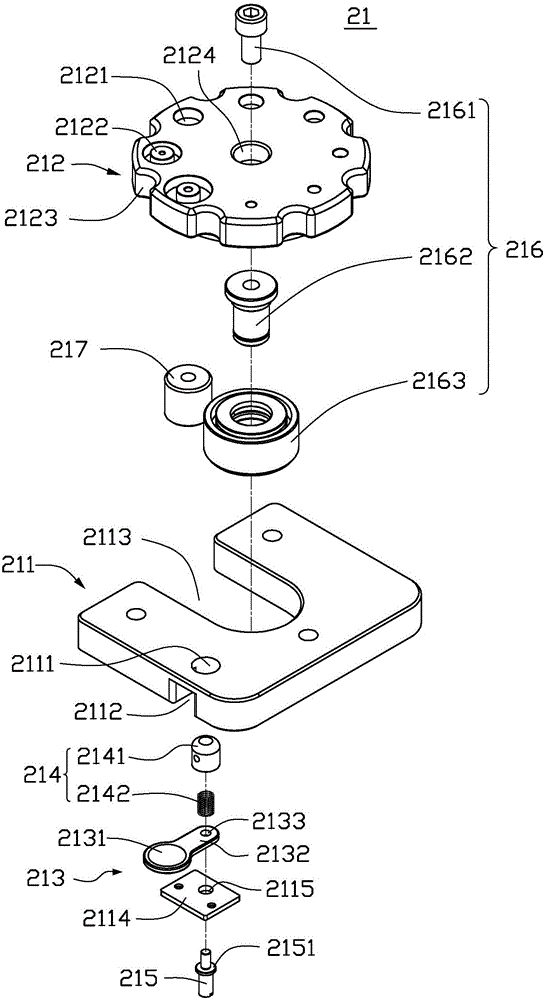

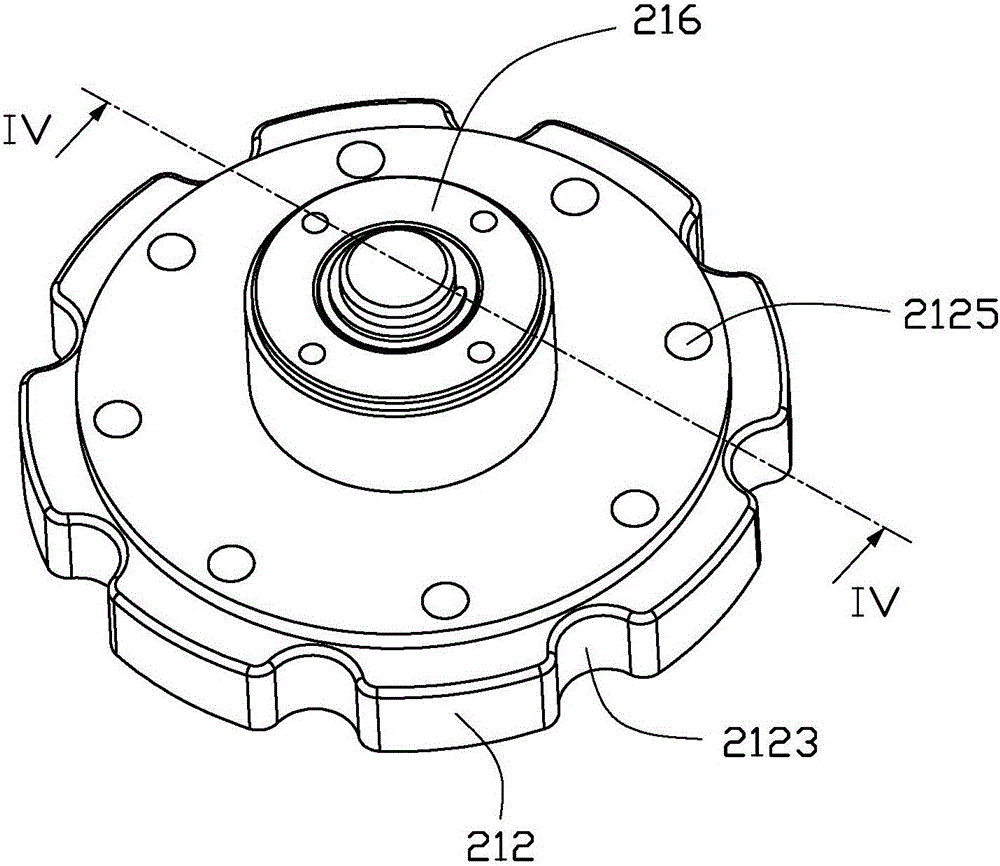

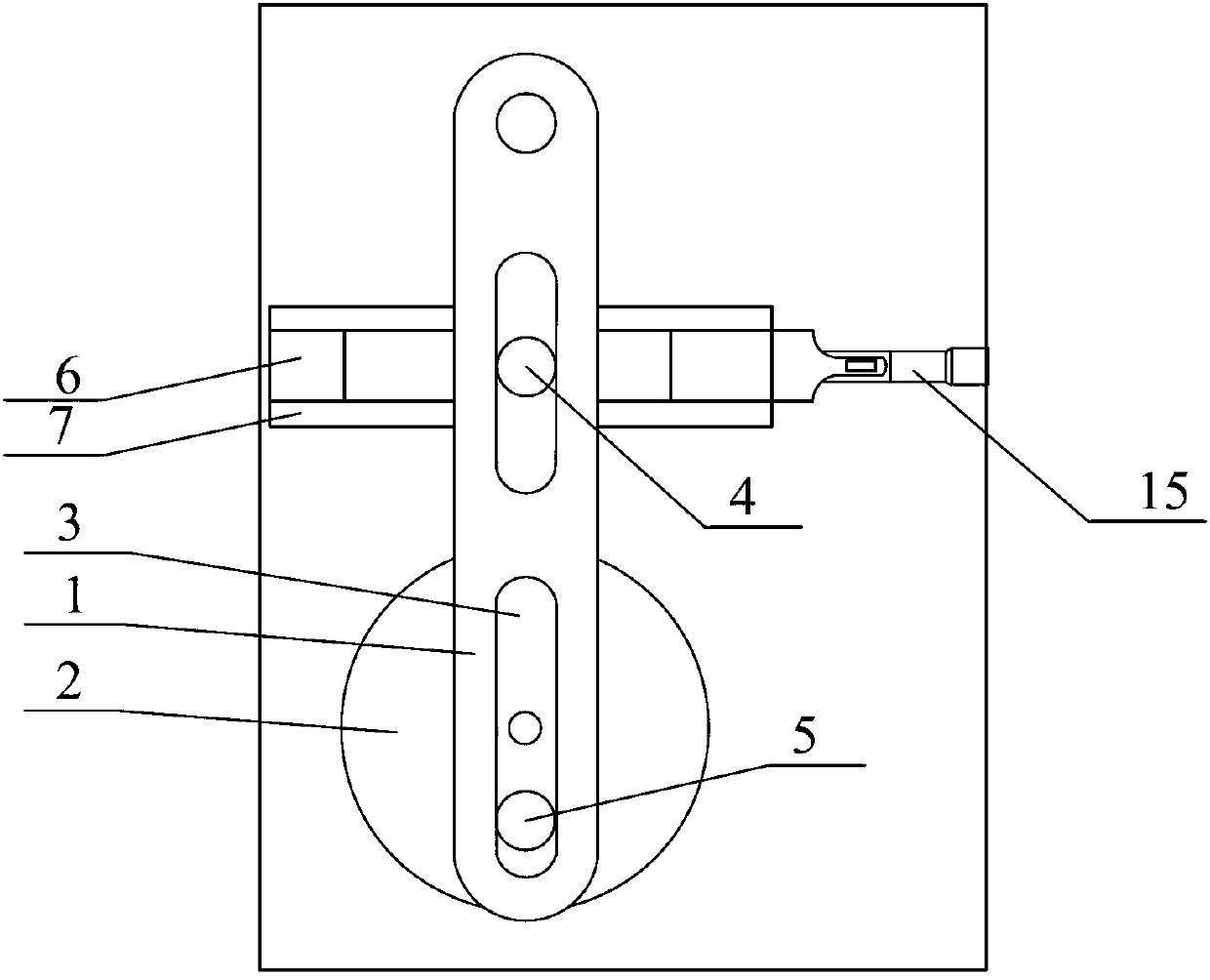

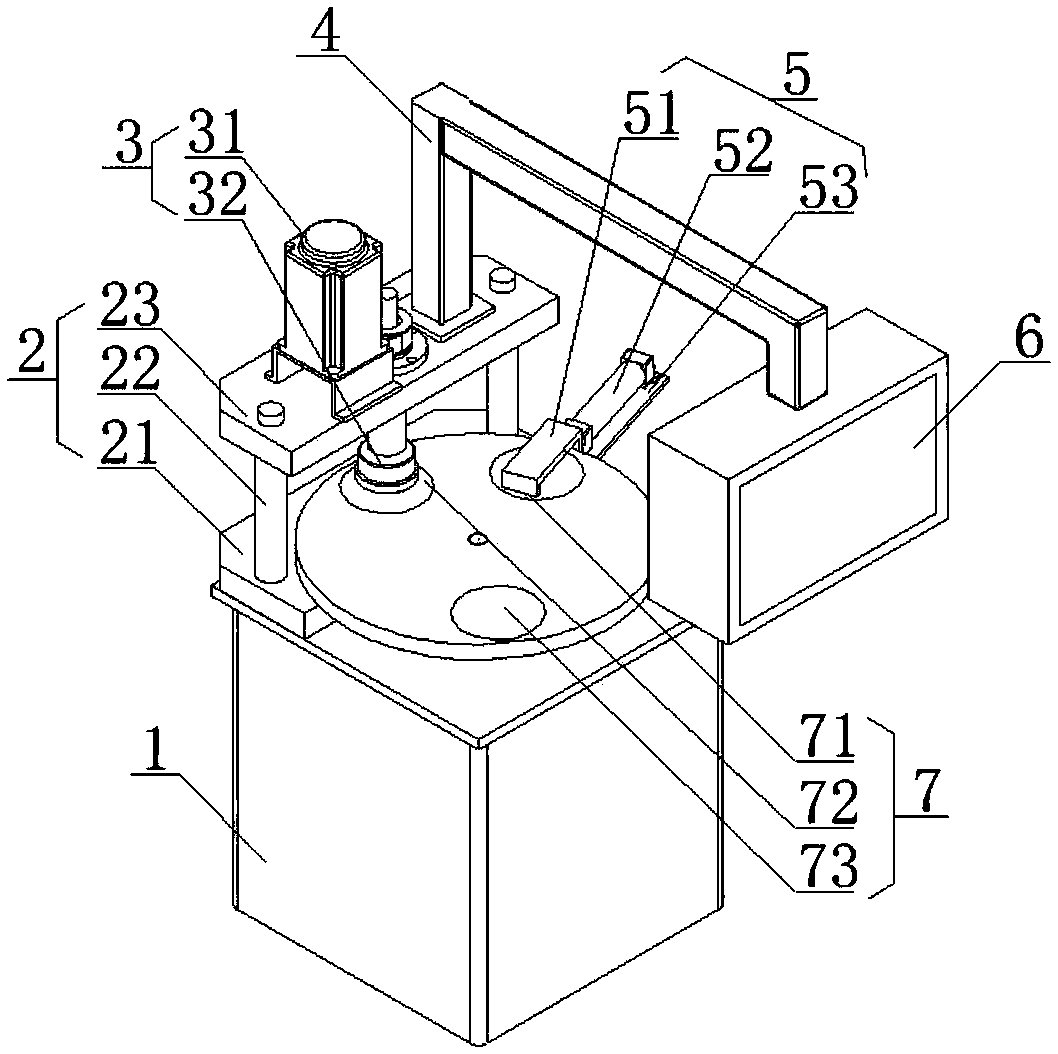

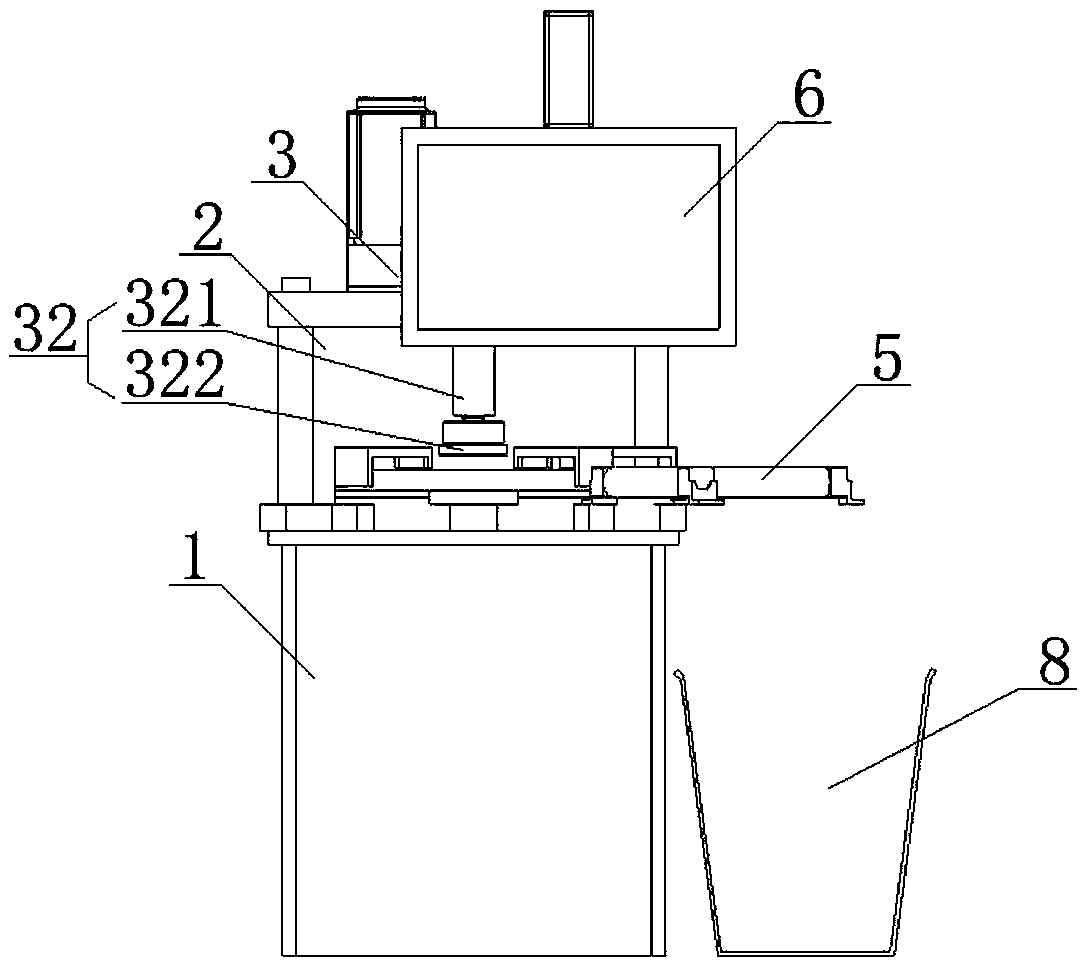

Spring fixing seat and spring test device using same

The invention provides a spring fixing seat, which comprises a base and a turntable, the turntable is rotatably arranged on the base, and the upper surface of the turntable is provided with several positioning grooves of different sizes along the outer periphery. The invention also provides a spring testing device using the spring fixing seat. The spring fixing seat and the spring testing device of the present invention can position the turntable to a proper testing position of the spring to be tested, thereby improving the accuracy of testing results.

Owner:SHENZHEN STRONG TECH

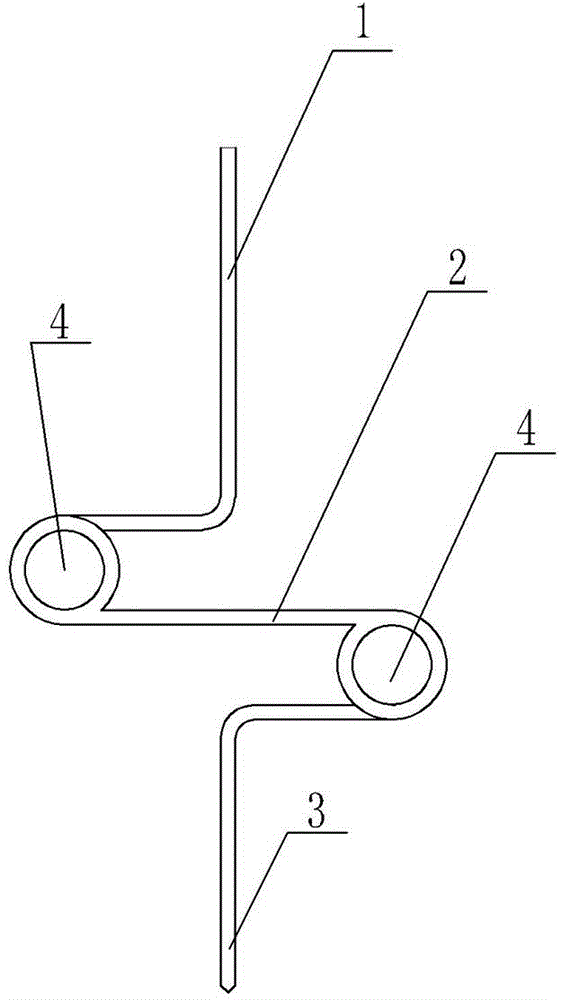

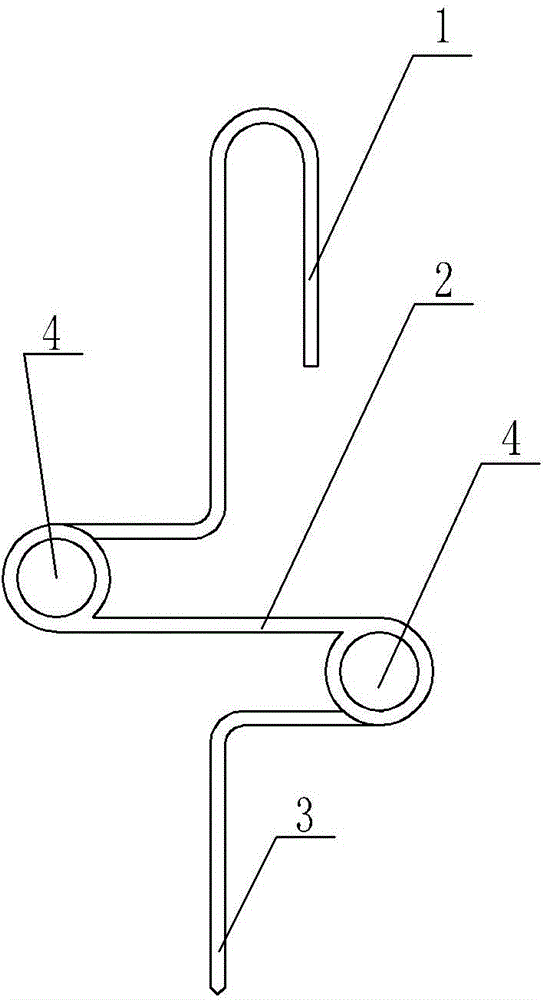

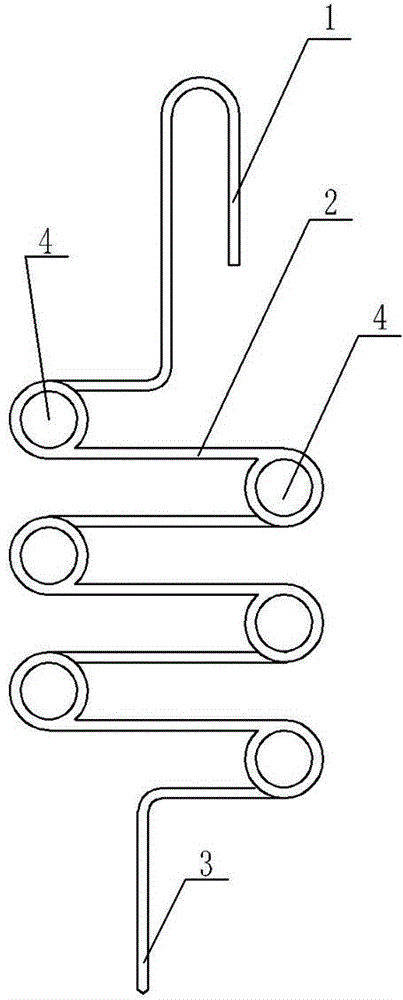

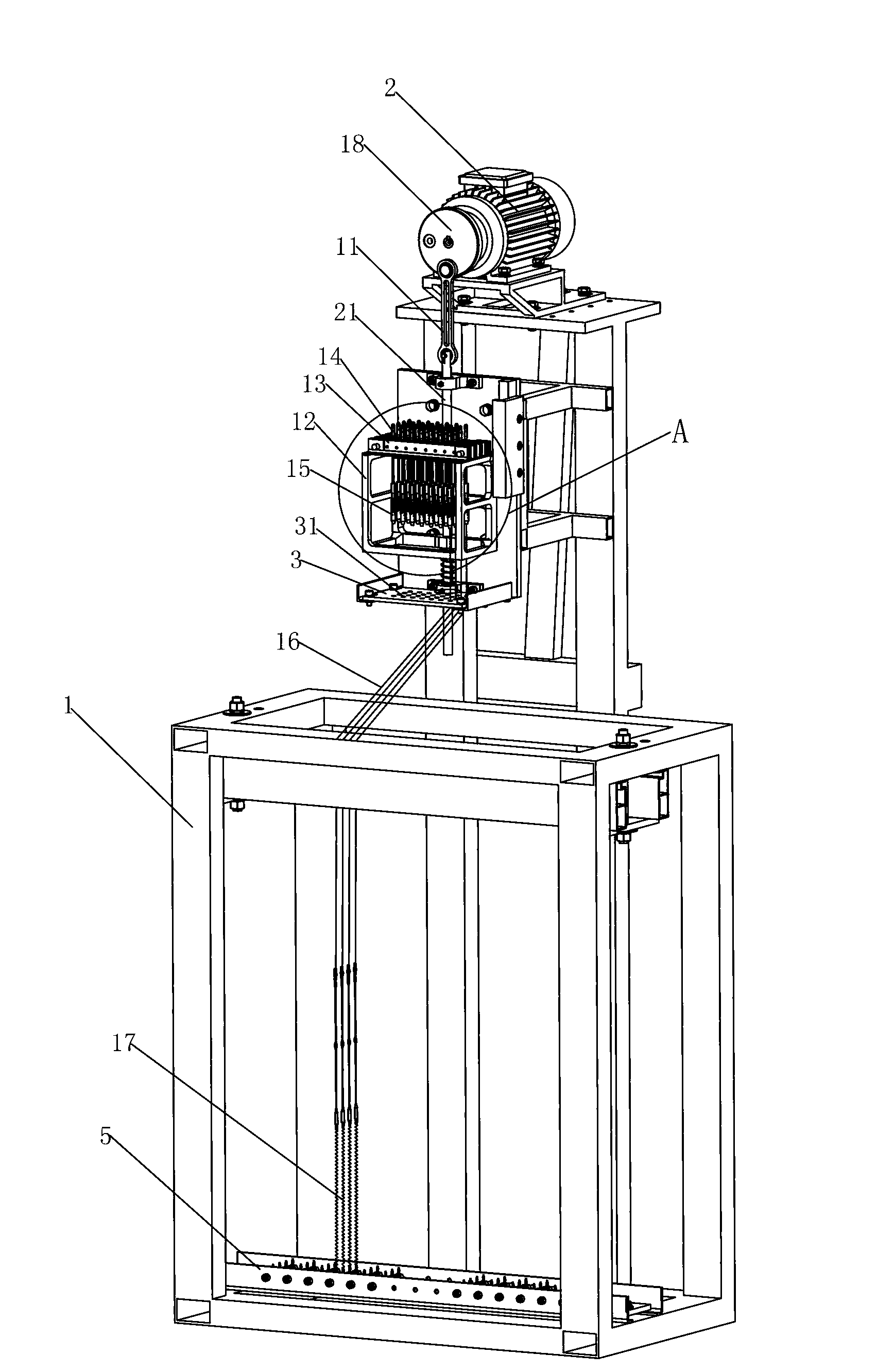

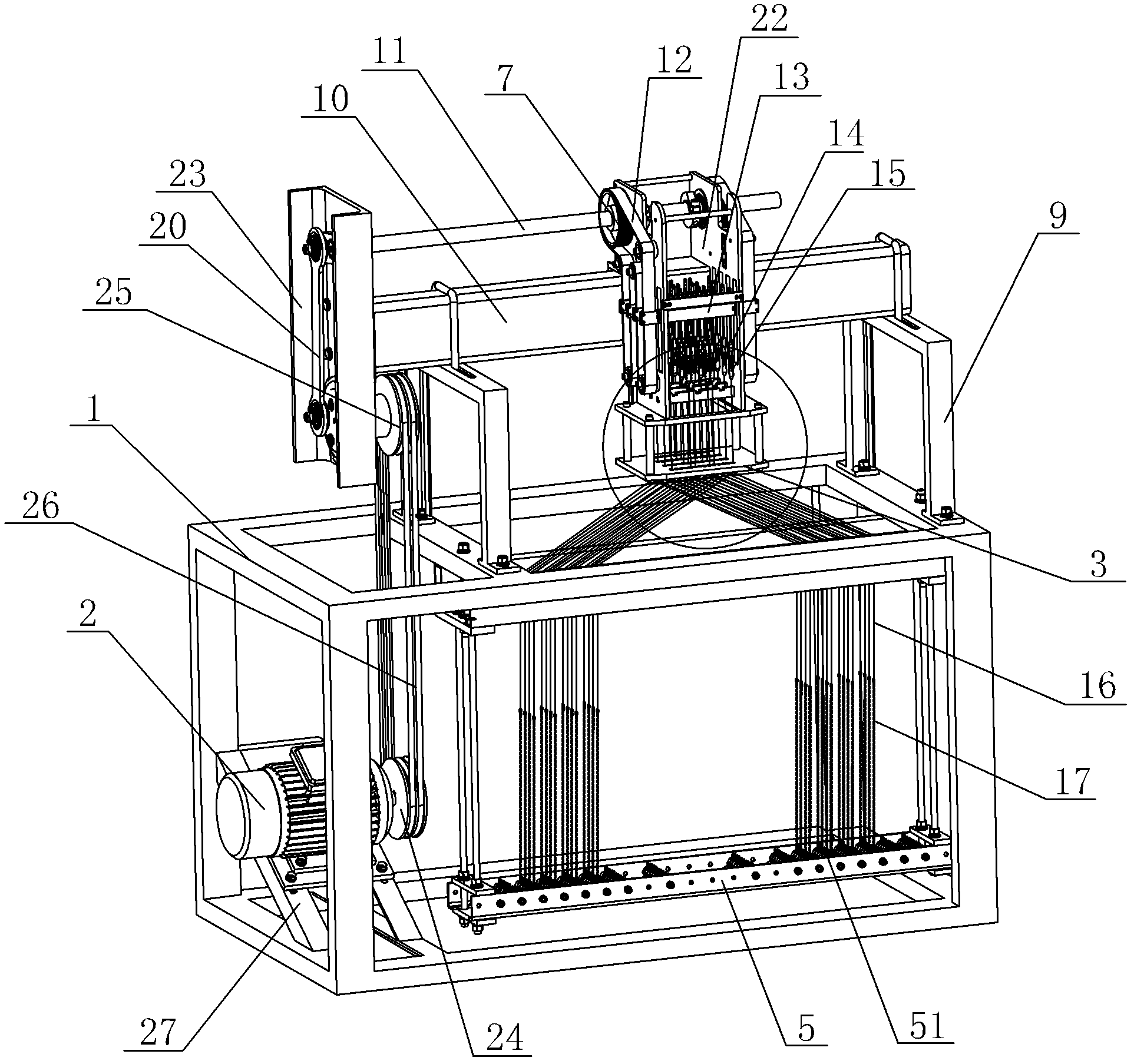

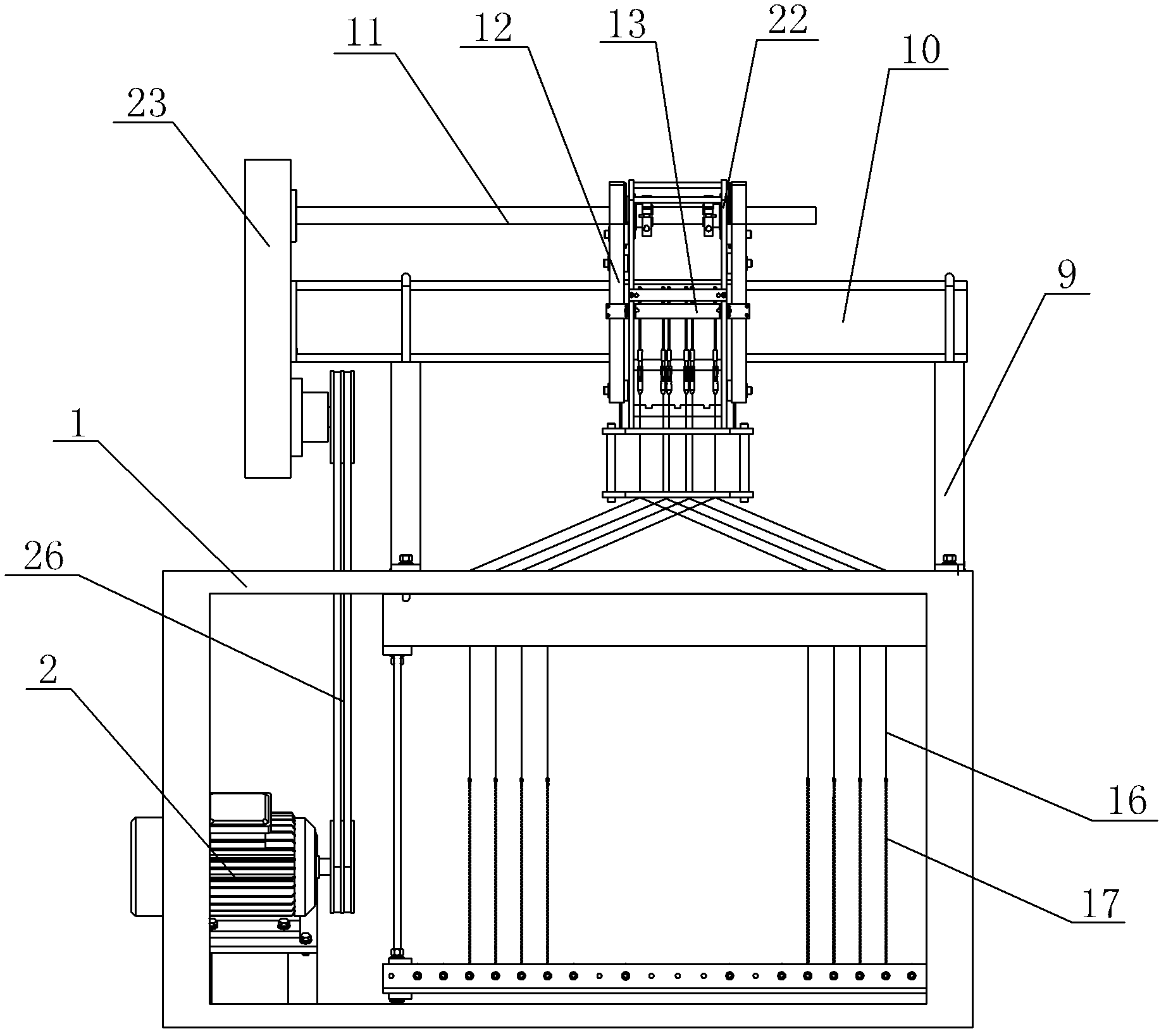

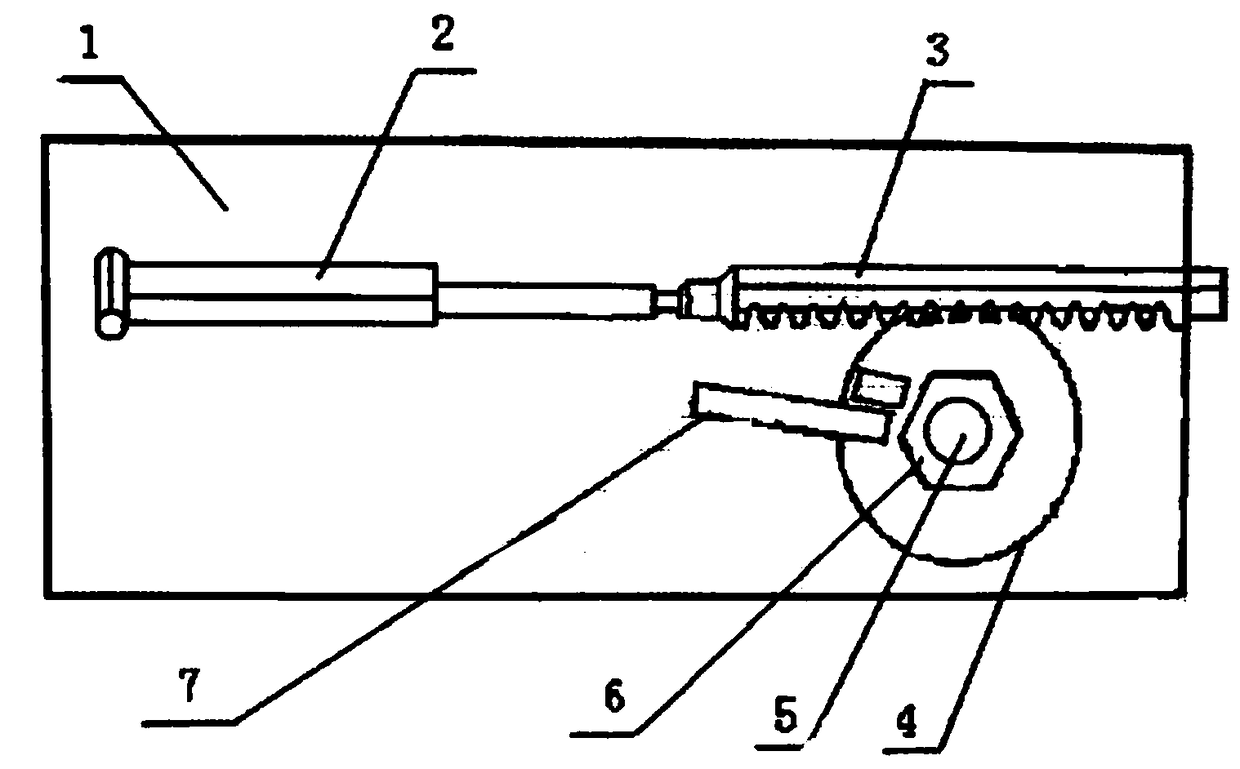

Harness string mounting apparatus and high-speed spring test equipment

InactiveCN103267694AEasy to chooseEasy to useMaterial strength using repeated/pulsating forcesFixed frameReciprocating motion

The invention discloses a harness string mounting apparatus on high-speed harness string spring test equipment. The harness string mounting apparatus comprises a harness string fixing frame; the harness string fixing frame is provided with a plurality of parallel hook clips; a joint hook is fixed on each hook clip; the joint hooks are connected with quick joints, and the quick joints are connected with harness strings; a threading plate allowing the harness strings to successively pass through is arranged below the quick joints and is provided with threading holes. The invention also discloses the high-speed spring test equipment of the harness string mounting apparatus. The harness string mounting apparatus firmly mounts the harness strings on the test equipment and can adapt to testing of a spring under the condition of high-speed motion, so selection and usage of the spring are optimized. Moreover, since a transmission mechanism of the high-speed harness string spring test equipment is simple and direct, high speed reciprocating motion of a harness string spring can be realized, time for obtaining a test result is greatly shortened, and selection of the spring can be carried out under the condition of high-speed operation.

Owner:ZHEJIANG KD TEXTILE MACHINERY

Fixing device for valve spring tests

InactiveCN106404528AReduce forceMaterial strength using tensile/compressive forcesWork holdersSpring Test

Owner:CHONGQING ANTAI SPRING IND

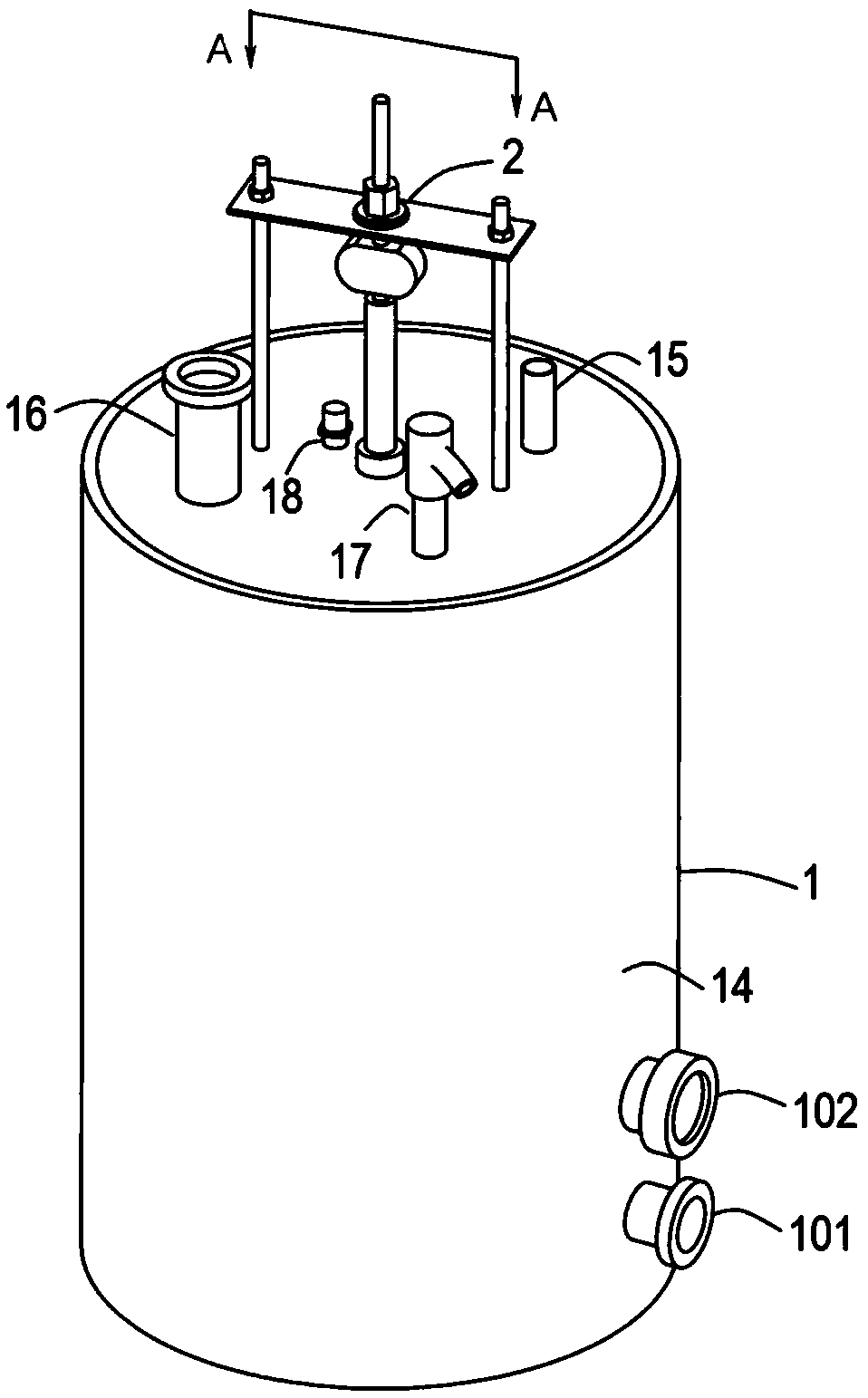

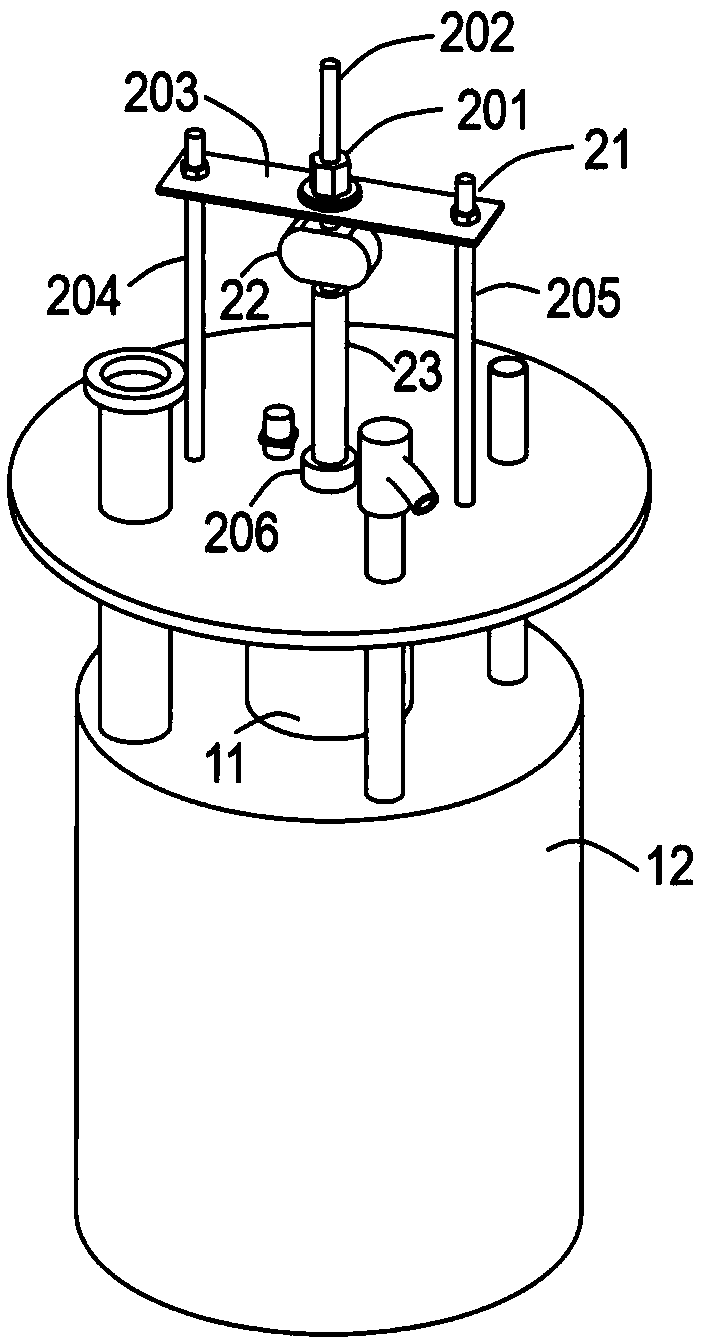

Device and method for measuring elastic properties of spring under low temperature

ActiveCN109580136AContinuous adjustment of test temperatureEasy and quick temperature adjustmentElasticity measurementRoom temperatureEngineering

The invention discloses a device and a method for measuring elastic properties of a spring under a low temperature. The device comprises a cryostat and a test system for the elastic properties of thespring. The test system for the elastic properties of the spring is longitudinally arranged above the interior of the cryostat. The cryostat comprises a sample chamber, a low-temperature cavity, an insulating interlayer, and an outer wall of an insulating container. The sample chamber, the low-temperature cavity, and the outer wall of the insulating container are all hollow cylindrical structures,and the low-temperature cavity is longitudinally sleeved inside the outer wall of the insulating container. According to the device and the method for measuring elastic properties of the spring underthe low temperature, the device and the method have the beneficial effects that: the device for measuring elastic properties of a spring under the low temperature, which can realize a continuous adjustment of the test temperature from a room temperature to a liquid nitrogen temperature range, by using liquid nitrogen as a cooling medium to reduce the spring test temperature, and changing the gaspressure in the liquid nitrogen storage tank; and the device can carry on a replacement or an installation of the sample to-be-tested, is more convenient and easy to operate, and is suitable for testing a large number of samples.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

Spring test probe

InactiveCN107478872AImprove buffering effectReduce connectorsElectrical measurement instrument detailsElectrical testingElectrical performanceSpring Test

The invention relates to a spring test probe, particularly to a probe element for testing the electrical performance of a solar cell slice. The spring testing probe having an integrated structure is composed of a connecting head, a buffer part and a contact successively from top to bottom. The buffer part has a multi-stage spring structure; and the basic spring is a torsion spring. And the contact is in a shape like a straight line. When the probe is in use, the connecting head is fixed inside a testing device and the testing device compresses the buffer part and the contact for testing. With the multi-stage spring and the torsion spring of the buffer part, the flexibility and adaptability as we as the ability to repair of the probe are improved; and thus the probe is not easy to damage.

Owner:浙江德清众鑫盛五金弹簧有限公司

Spring tester providing stretching test function

InactiveCN103245497AReduce testing costsImprove efficiencyMachine part testingSoftware engineeringSpring Test

The invention discloses a spring tester providing stretching test function. The spring tester comprises a base, wherein a portal frame is arranged on the base; the bottom of the portal frame is fixed on the base; and a measuring disc is arranged between support pillars of the portal frame, and is fixed on the base. According to the invention, the portal frame and relevant equipment are arranged on the spring tester, so that the spring tester can perform pressure test and tension test at the same time, the test cost is saved, and the efficiency is increased.

Owner:CHENGDU CHENHUI SPRING MFG

Spring fatigue testing machine

InactiveCN103278407ATest accurateReasonable designMaterial strength using repeated/pulsating forcesSpring TestCompression test

The invention relates to a spring fatigue testing machine used for simulating actual spring fatigue tests. The spring fatigue testing machine is characterized by comprising a swing connecting rod, wherein the swing connecting rod is connected with a slide rail in a cross shape, the tail end of the slide rail is connected with a spring compression mechanism, and the spring compression mechanism is arranged in a spring sleeve. The spring fatigue testing machine provided by the invention is reasonable in design and convenient to use, a smart structure combination is used for performing compression test on the spring, accurately simulating the application environment of the spring and ensuring more accurate spring test.

Owner:SHANGDONG ZHONGBAOKANG MEDICAL DEVICES

Spring testing machine

PendingCN106840631ASimple structureThe distance is easy to adjustMachine part testingClassical mechanicsElectric machinery

The invention discloses a spring testing machine. The spring testing machine mainly comprises a main shaft, a motor, an eccentric wheel, a left shaft for compression, a left limiting stopper, a right shaft for compression, a right limiting stopper and a counter. The motor drives the eccentric wheel to rotate through the main shaft, the left shaft for compression and the right shaft for compression are installed at the two sides of the eccentric wheel respectively, a left testing spring is installed between the left shaft for compression and the left limiting stopper, and a right testing spring is installed between the right shaft for compression and the right limiting stopper; the rotating eccentric wheel drives the left shaft for compression and the right shaft for compression to periodically compresses the left testing spring and the right testing spring, and the left testing spring and the right testing spring are respectively independently installed, and conduct fatigue tests synchronously. In this way, the spring testing machine can not only test two springs simultaneously, but also support tests on springs with different types simultaneously.

Owner:NINGBO POLYTECHNIC

Threading silk yarn lifting mechanism used on threading silk yarn spring test equipment

The invention discloses a threading silk yarn lifting mechanism used on threading silk yarn spring test equipment. The threading silk yarn lifting mechanism comprises a driving belt which is connected with a driving wheel and a plurality of driven wheels, the driving wheel is fixedly connected with a driving shaft, the driven wheels are arranged up and down respectively, the driving belt is divided into a plurality of sections which are arranged in parallel, and a hook clamp is fixedly arranged on each section. According to the threading silk yarn lifting mechanism used on the threading silk yarn spring test equipment, the driving belt is arranged to be a plurality of sections, the hook clamp is fixedly arranged on each section and is used for fixing a threading silk yarn by a joint, the driving wheel on the driving belt is connected with a power mechanism by the driving shaft, the power mechanism drives the driving shaft to move up and down in a reciprocating manner through a crank rocker mechanism, so that the multiple sections of driving belt are staggered up and down to simulate the movement of the spinning of a textile machine so as to drive the threading silk yarn to move up and down, so that the property of a spring can be tested, and the time for obtaining the test result is shortened greatly.

Owner:ZHEJIANG KD TEXTILE MACHINERY

Double-torsion-spring fatigue test device and test method thereof

InactiveCN113237642AFatigueCompact structureMachine part testingMaterial strength using repeated/pulsating forcesReduction driveElectric machinery

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Spring testing machine

InactiveCN106017892AImprove operational safetyMachine part testingMaterial strength using tensile/compressive forcesProtection mechanismSpring Test

The invention relates to a spring testing machine to solve the problem in the prior art that the spring is easy to fall out and hurt people when the spring testing machine performs tension and compression tests on the spring. The spring testing machine of the present invention is provided with protective structure on frame, so in carrying out tensile test or compression process to the spring, when the tested spring appears eccentric and falls off from the testing machine, the spring that falls off will be in the horizontal direction. The movement can be stopped by the protective structure without flying out from the side of the rack to injure the operator, which improves the operating safety of the spring testing machine.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

Butterfly spring destructive testing machine

PendingCN107941498AHigh degree of automationIncrease productivityMachine part testingEngineeringUltimate tensile strength

The invention relates to the technical field of spring testing equipment, in particular to a butterfly spring destructive testing machine, comprising a rack. A drive bracket is arranged on one side ofthe upper end of the rack, the upper end of the driving bracket is provided with a drive press-down device, the drive press-down includes a driving mechanism and a press-down mechanism, a rotary table is arranged in the middle of the upper end of the rack, one end of the rotary table is located directly below a press-down head, and the other side of the upper end of the rack is also provided witha pushing mechanism; a cantilever arm is also arranged at the upper end of the driving bracket, and a control console is arranged at one end of the cantilever arm. The automation degree of the testing machine is improved, the labor intensity and the production cost are lowered, the production efficiency is improved and the usage is convenient.

Owner:黄石佳鼎自动化科技有限公司

Combiner box automatic pairing testing system and testing tool thereof

ActiveCN106093667AEasy to operateImprove test efficiencyPhotovoltaic monitoringElectrical testingTest efficiencyEngineering

The invention discloses a combiner box automatic pairing testing system and a testing tool thereof. The combiner box automatic pairing testing system comprises a direct voltage testing part, a direct voltage testing part, and a testing tool used for fixed installation of tested work pieces constituted by measuring plates and manifolds. The testing tool comprises a base, which is provided with a group of spring testing needles used for conductive inserted connection with terminals of tested work pieces during the test. Each spring testing needle comprises an input spring testing needle and an output spring testing needle. The base is also provided with a pressing mechanism used for pressing the tested work pieces tightly, after the tested work pieces are disposed on the spring testing needles. During the use, the to-be-tested work pieces are directly connected with the spring testing needles disposed on the base in an inserted manner, and the conductive connection between the corresponding terminals of the to-be-tested work pieces and the spring testing needles is completed. The bottom parts of the spring testing needles are connected with a voltage source or a current source by leads, and then during the test, the tested work pieces are only required to be connected with the spring testing needles in an inserted manner, and wiring operation is saved, and therefore testing efficiency is improved.

Owner:XUJI GRP +2

Damping spring testing device

The invention discloses a damping spring testing device. The damping spring testing device comprises a damping testing structure, and the damping testing structure comprises a damping spring, a damping spring guiding seat and a damping spring fixing seat; one end of the damping spring is fixedly connected with the damping spring guiding seat, and the other end of the damping spring is fixedly connected with the damping spring fixing seat; a sliding rod fixing seat is further fixed to the damping spring fixing seat; the sliding rod fixing seat further comprises a sliding rod and further comprises a first sliding rod bulge and a second sliding rod bulge which can move on the sliding rod; the damping spring guiding seat further comprises a first bulge capable of enabling the first sliding rodbulge and / or the second sliding rod bulge to move on the sliding rod; the first sliding rod bulge is located below the first bulge; and the second sliding rod bulge is located above the first bulge.The damping spring testing device can test the pull-up or compression length of the damping spring and can also conduct high-precision measurement through a linear displacement sensor, and the precision of the testing device is improved.

Owner:重庆巨九磊汽车零部件制造有限公司

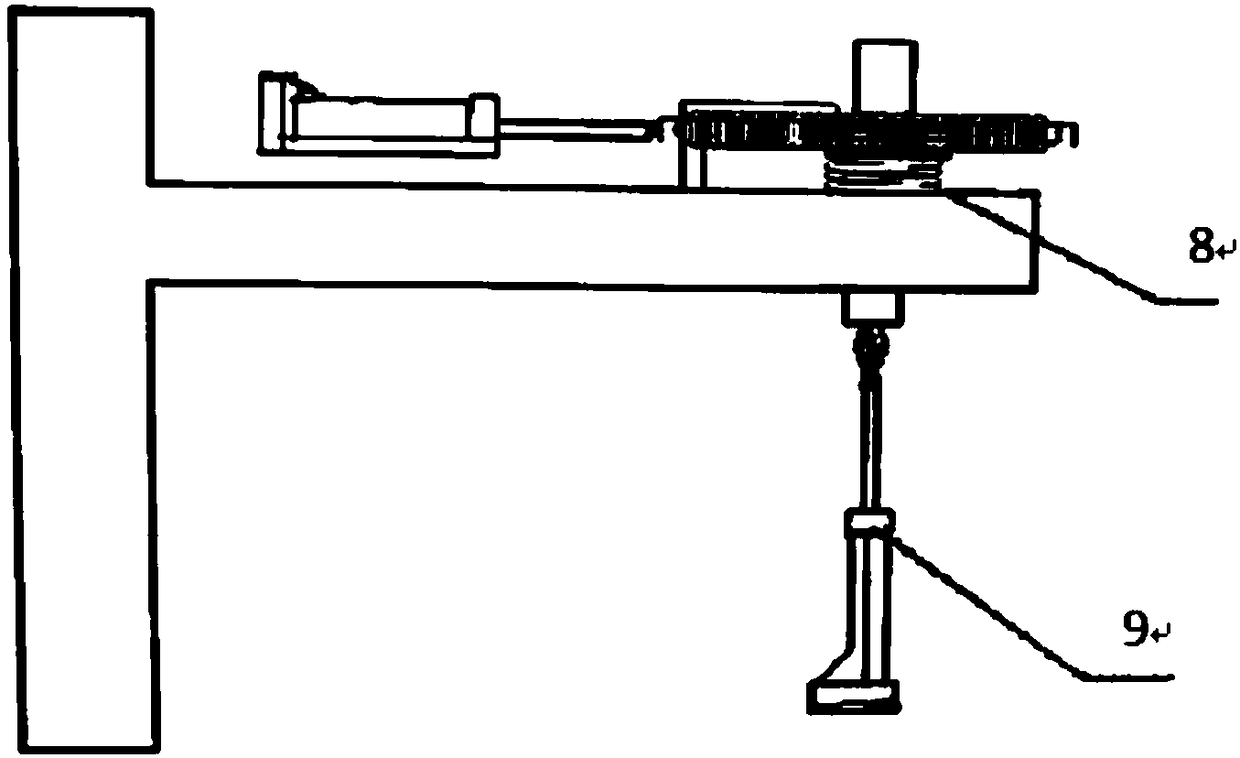

Spring stiffness measurement test device

ActiveCN109029883AMeasurement hasWith compressive forceElasticity measurementMeasurement testEngineering

The invention discloses a spring stiffness measurement structure, and relates to the field of spring test machinery, in particular to a spring stiffness measurement test device. The spring stiffness measurement structure comprises a test table and a hollow cylindrical gear type torsion spring fixer located on the test table; a shaft is coaxially arranged in the gear type torsion spring fixer; theshaft is connected with a power loader, and a force in an axial direction is applied; a gear is arranged on the outer wall of the gear type torsion spring fixer; the gear is meshed with a rack; the rack is connected with another power loader, and a force in a radial direction is applied; and during test, a spring of a test piece is arranged on the shaft in a sleeving mode, and a nut is used for limiting the displacement of the axial end of the test piece, and the other end of the test piece is connected to the test table. The device disclosed by the invention can be used for simultaneously detecting the conversion of the torsion and the compression amount of the spring of the test piece, and also can be used for performing measurement separately.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Compressor de-spring test device and test method thereof

ActiveCN107191365ALow failure ratePump testingPositive-displacement liquid enginesEngineeringSpring Test

The invention discloses a compressor de-spring test device. The device comprises a slide device, fixing piles and a positioning rod; the number of the fixing piles is set to be two; the fixing piles are provided with through grooves in the vertical direction; the positioning rod penetrates through the through grooves of the two fixing piles; the height of the positioning rod relative to the ground can be adjusted freely, the positioning rod is fixed, and when the positioning rod and the fixing piles are kept in a fixed state, the positioning rod is parallel to the horizontal plane; hooks are arranged at the bottom of the slide device; and the slide device is fixed on the positioning rod through the hooks. A compressor de-spring test method comprises the steps that a compressor to be tested is thrown away from the top end along a slope and is thrown away repeatedly for 2-30 times; the installation height of the positioning rod is increased, and the throwing stage is repeated; and shell opening treatment is carried out on the compressor to be tested, whether de-spring occurs or not is checked, and therefore whether the de-spring situation exists in the compressor or not under different centripetal acceleration conditions can be checked conveniently.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

Spring test device

The invention discloses a spring test device, which comprises a driving module, a hydraulic loop module and a loading stress module. The driving module is connected with the hydraulic loop module through a connecting rod; and the hydraulic loop module is connected with the loading stress module through a stretching rod. The hydraulic loop module is driven by the driving module, and thus a spring realizes a purpose of spring quality and life test under the function of the loading stress module.

Owner:SOUTH CHINA UNIV OF TECH

Loaded printed circuit board test fixture and method for manufacturing the same

ActiveUS8648616B2Good electrical contactLow costElectrical measurement instrument detailsElectrical testingEngineeringSpring Test

A test fixture for testing loaded printed circuit boards having a plurality of test points having a probe plate including an array of widely spaced high force spring test probes in compliant contact with solid translator pins located in a translator fixture removably positioned over the probe plate. The test fixture includes optimization software wherein translation of the test signals are optimized by providing the shortest interconnect distance in the x-y plane between the test points on the printed circuit board and the test probes in the probe plate. The fixture further includes an unpowered opens device for testing components on the loaded printed circuit board.

Owner:XCERRA

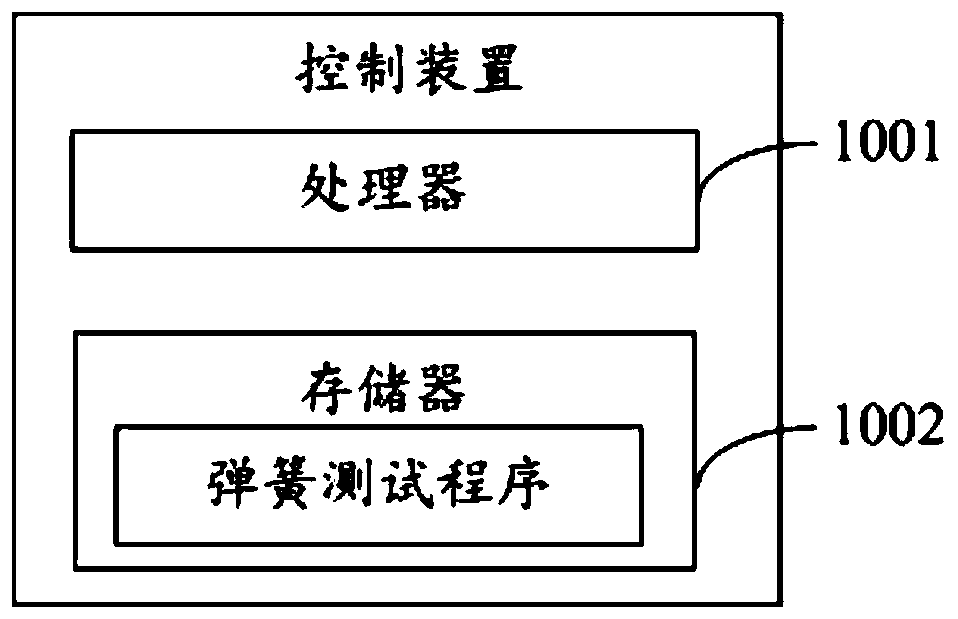

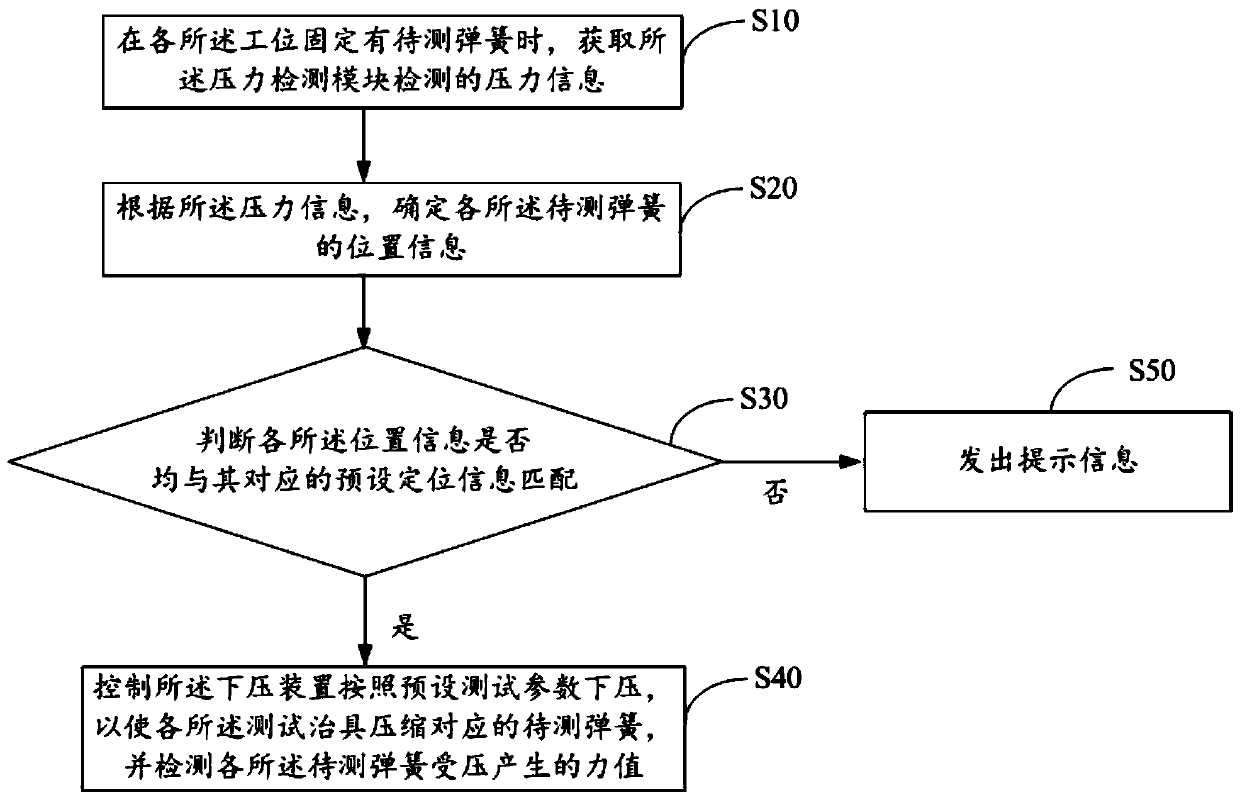

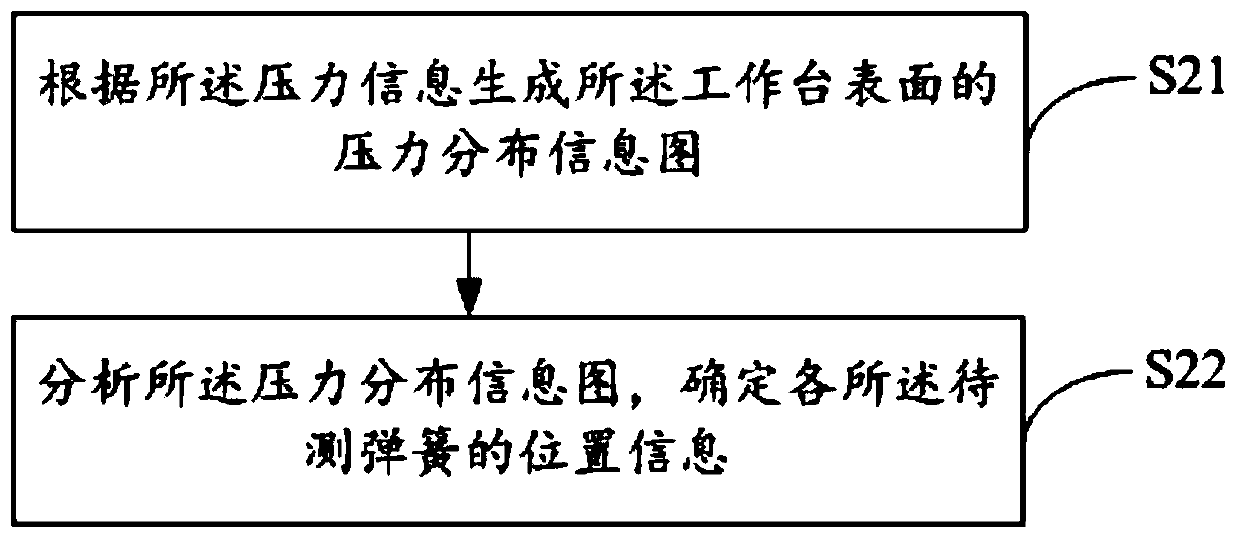

Spring test machine and spring detection method thereof, control device and storage medium

ActiveCN110243561AReduce measurement errorImprove reliabilityMachine part testingElasticity measurementObservational errorSpring Test

The invention discloses a spring detection method which is applied to a spring test machine. The spring detection method comprises following steps of: when a to-be-tested spring is fixed in each work station, acquiring pressure information detected by a pressure detection module; according to the pressure information, determining position information of each to-be-tested spring; determining whether each piece of position information matches corresponding preset position information; if yes, controlling the press device to press down according to preset test parameters, so as to enable each test jig to compress corresponding to-be-tested spring and detect force generated when the to-be-tested spring is pressed. The invention further discloses a control device, a spring test machine and a readable storage medium. The method aims to reduce measurement errors of spring tests and improve reliability of spring test results.

Owner:SHENZHEN ZHONGSHEN AIDE BEDDING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com