Spring test machine and spring detection method thereof, control device and storage medium

A detection method and technology of a testing machine, applied in the field of spring detection methods, spring testing machines, readable storage media, and control devices, can solve problems such as large measurement errors, consistency, and non-uniform positions of test fixtures, and achieve force application Consistent, reduced measurement error, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

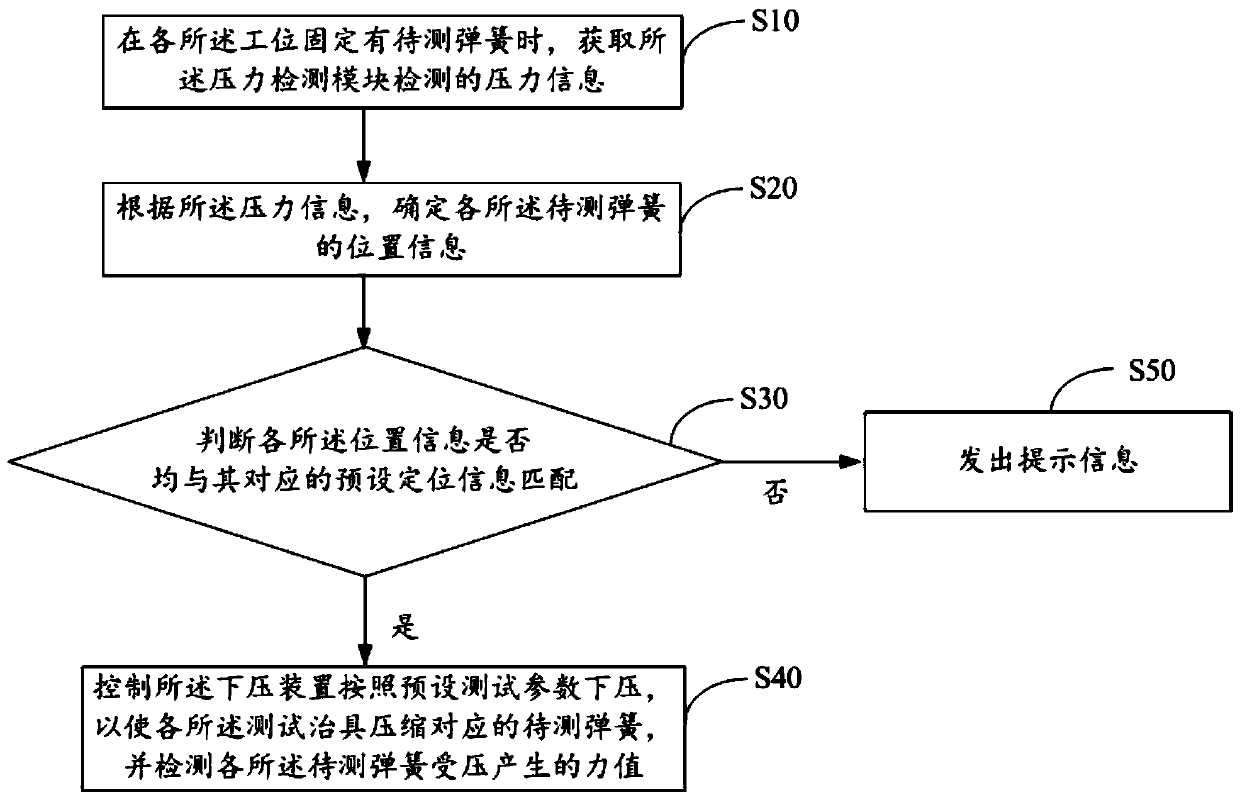

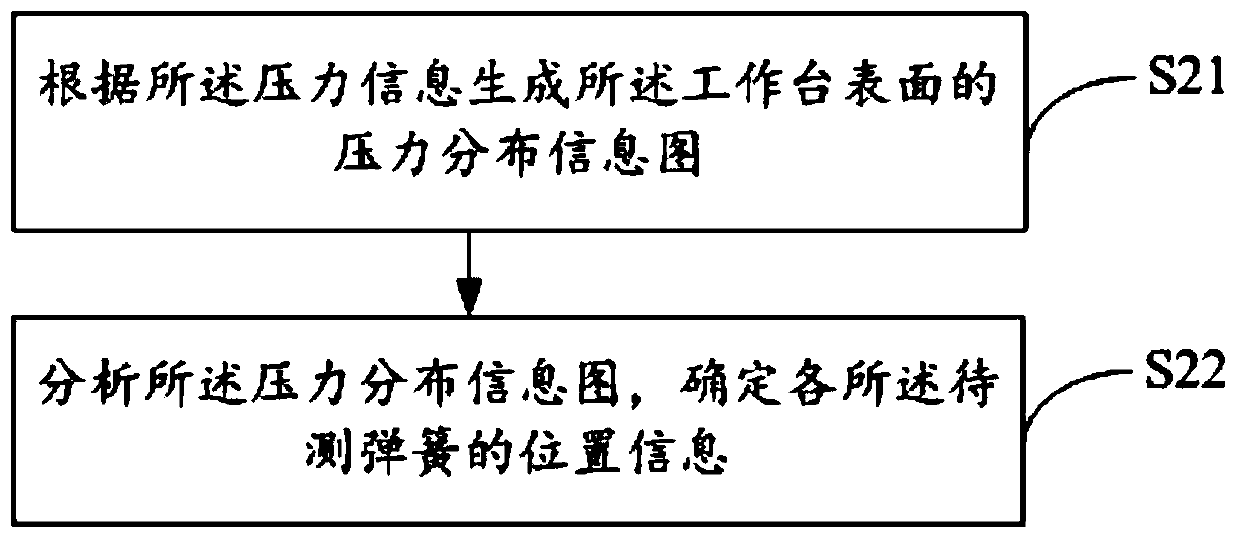

[0060] refer to figure 2 , the first embodiment of the spring detection method of the present invention is proposed, and the spring detection method includes:

[0061] Step S10, when each station is fixed with a spring to be tested, the pressure information detected by the pressure detection module is obtained;

[0062] Specifically, it can be determined whether each station is fixed with a spring to be tested through infrared induction or according to an instruction input by the user.

[0063] Wherein, when each station is fixed with a spring to be tested, before the step of obtaining the pressure information detected by the pressure detection module, it also includes: controlling the pressing device to press down a preset stroke, so that each station The spring to be tested corresponds to the compression of the test fixture. The preset itinerary can be set according to actual needs. In this way, it can be ensured that the spring to be tested can generate a sufficiently l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com