Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Parts washer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces. Parts washers are used in new manufacturing and remanufacturing processes; they are designed to clean, degrease and dry bulk loads of small or large parts in preparation for assembly, inspection, surface treatment, packaging and distribution. Parts washers may be as simple as the manual "sink-on-a-drum" common to many auto repair shops, or they may be very complex, multi-stage units with pass-through parts handling systems. Parts washers are essential in maintenance, repair and remanufacturing operations as well, from cleaning fasteners, nuts, bolts and screws to diesel engine blocks and related parts, rail bearings, wind turbine gears boxes and automotive assemblies.

Parts washer

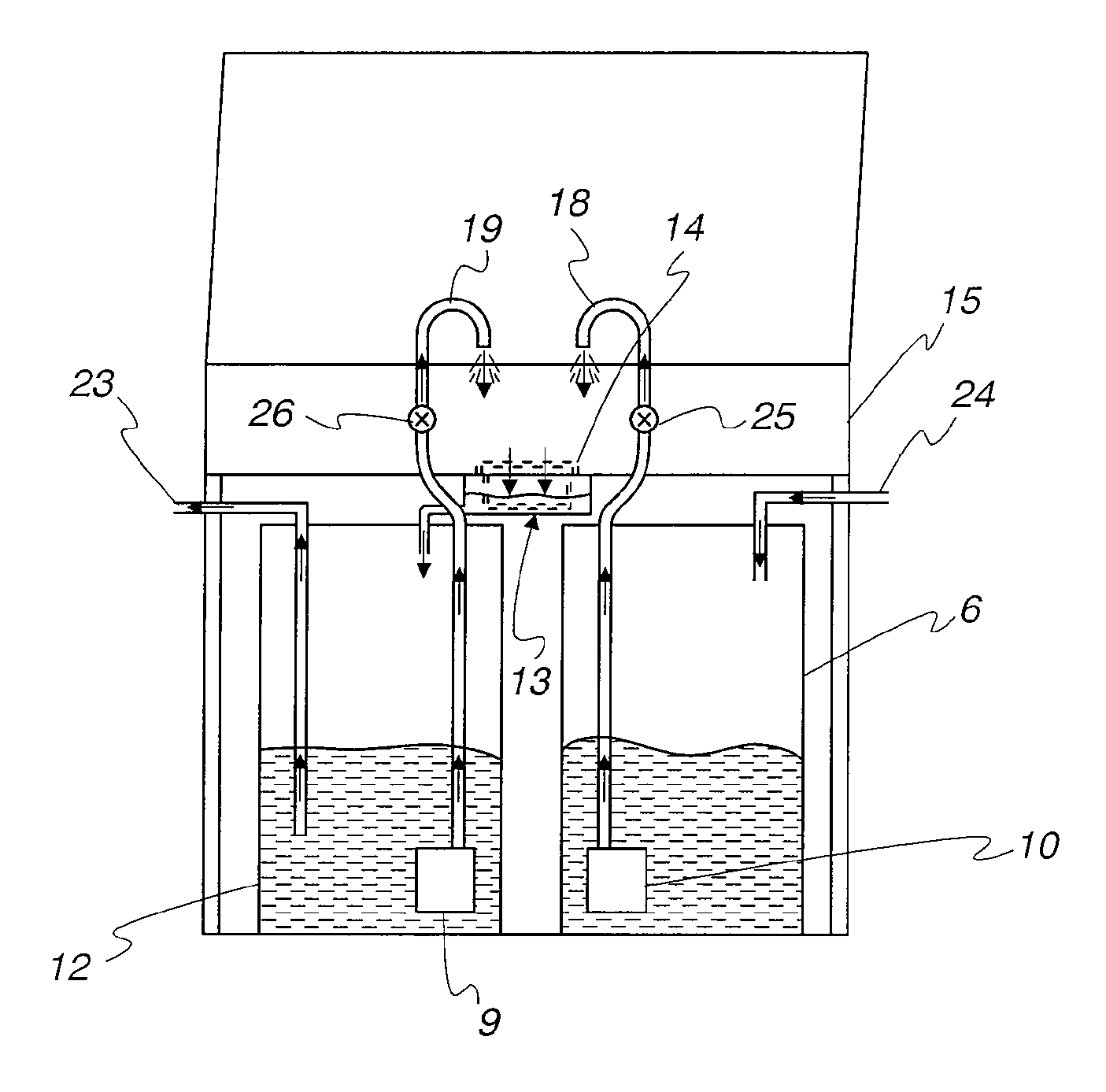

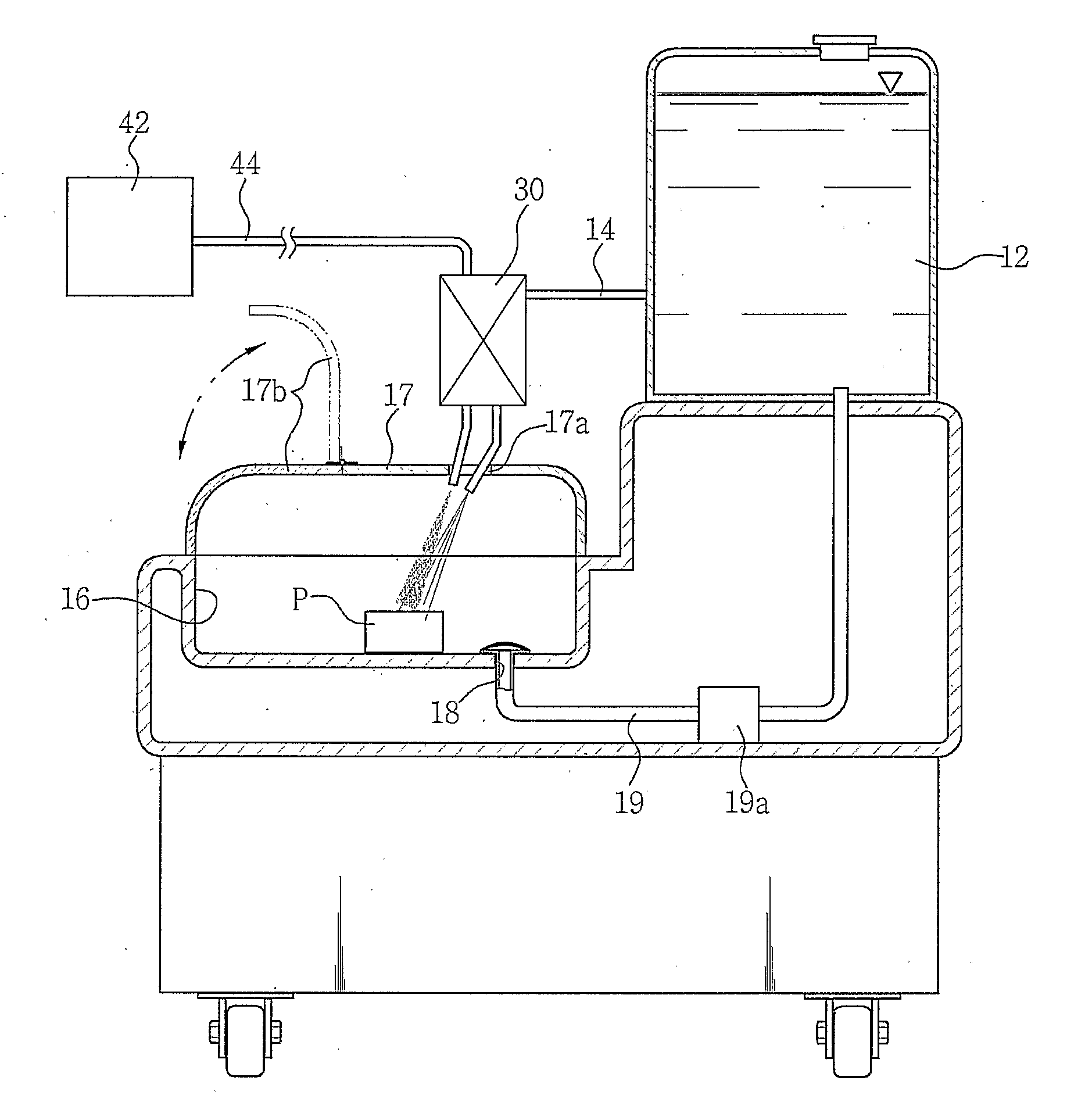

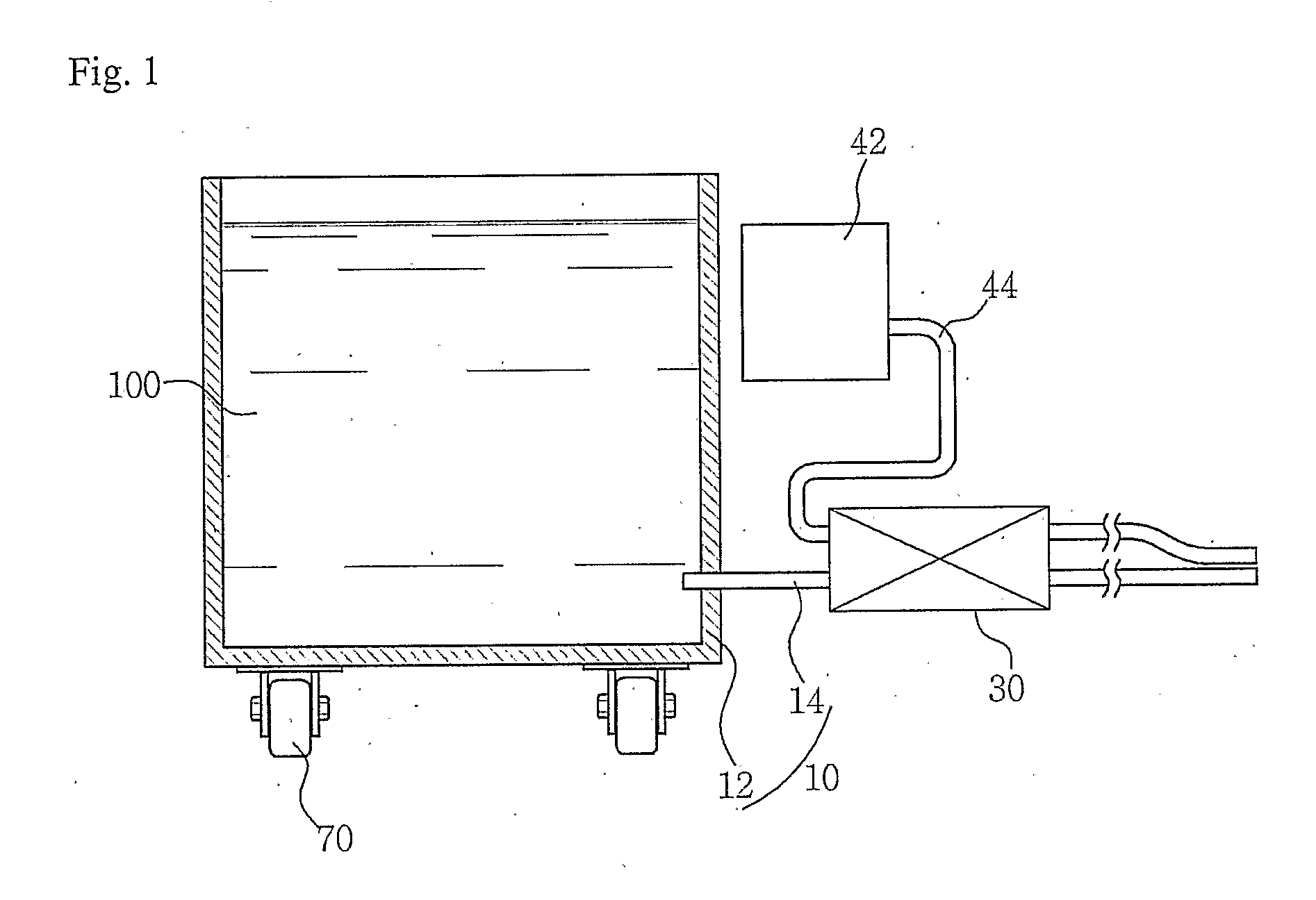

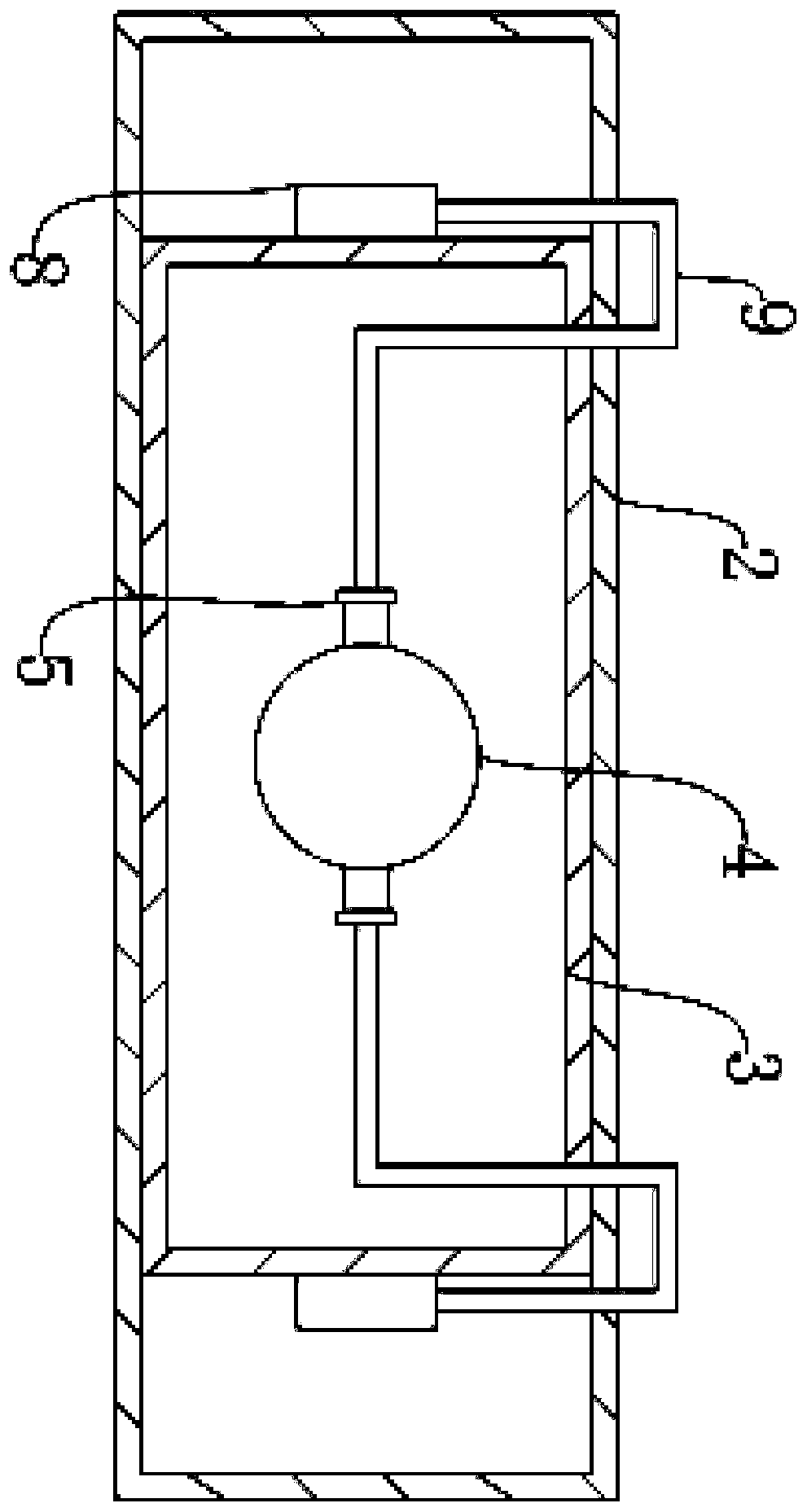

A parts cleaner for use in a process whereby solvent is preferred to always be available and is preferred to be as clean or pure as possible for use, comprising two containers respectively for clean solvent and for capture of used solvent or a single container having separate zones for clean and used solvent, said clean container having an outlet for supplying clean solvent for cleaning. The clean container may have an outlet for supplying clean solvent for cleaning and an inlet for clean recycled solvent, the used solvent container having an inlet for used solvent, an outlet for supplying used solvent for cleaning and an outlet for supplying used solvent for recycling. The used solvent container may have an outlet for supplying used solvent for cleaning and means for automatically switching between the outlets supplying said clean solvent and said used solvent for cleaning. The clean container may have an inlet for clean recycled solvent, the used solvent container having an inlet for used solvent, an outlet for supplying used solvent for cleaning and an outlet for supplying used solvent for recycling, the parts cleaner being adapted to draw first from the clean solvent container and drain into a separate used solvent container and when clean solvent is not available, to draw from the used solvent container, thus ensuring availability of solvent at all times. Also disclosed is a solvent recycler having a distillation chamber and a filling system for the distillation chamber or a distillation zone of the distillation chamber without the use of valves when filling the distillation chamber from a used solvent zone or a container for a batch or continuous system.

Owner:CHEMCHAMP BARBADOS

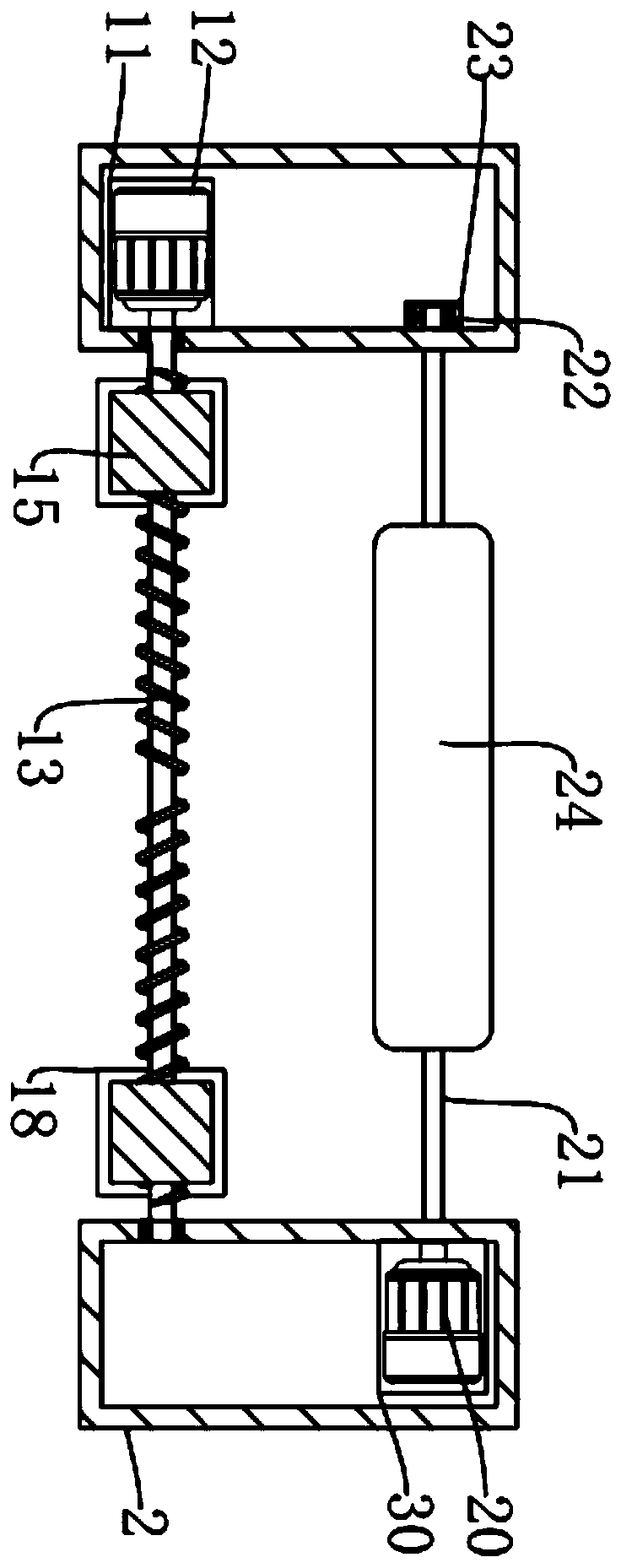

Combination agitating parts washer and sink washer

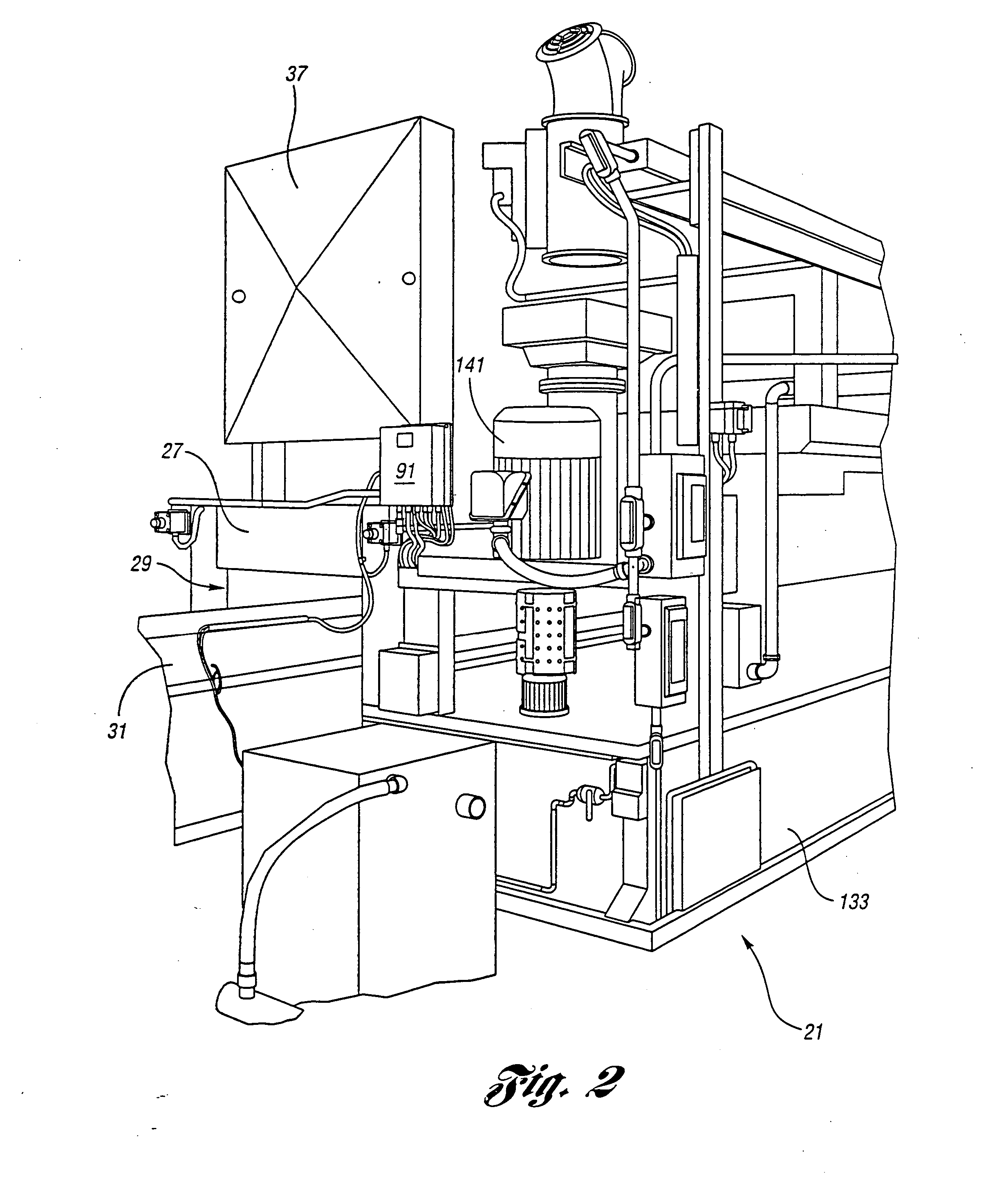

ActiveUS20100307544A1Easy to useReduce manufacturing costCleaning using liquidsHydraulic cylinderEngineering

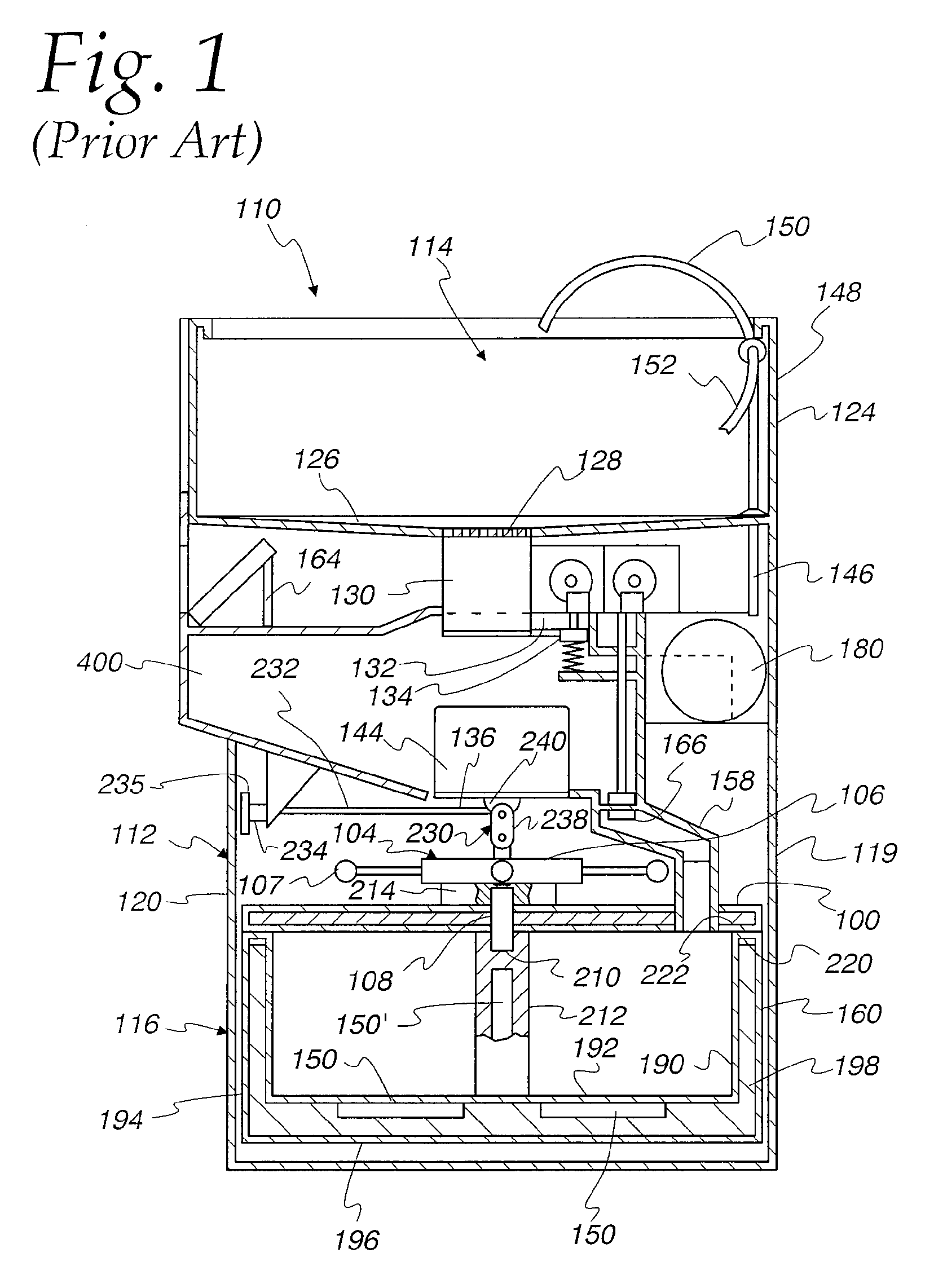

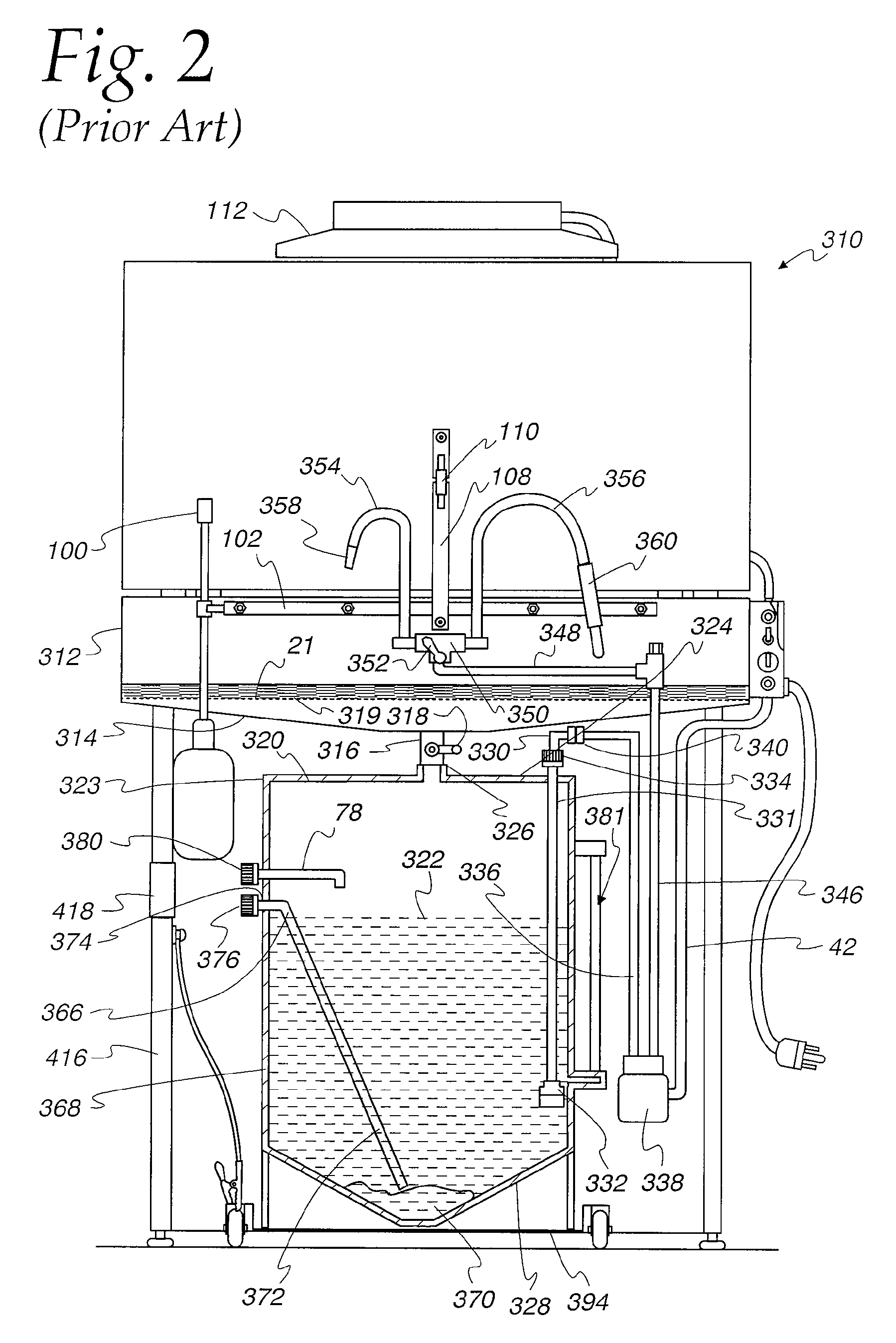

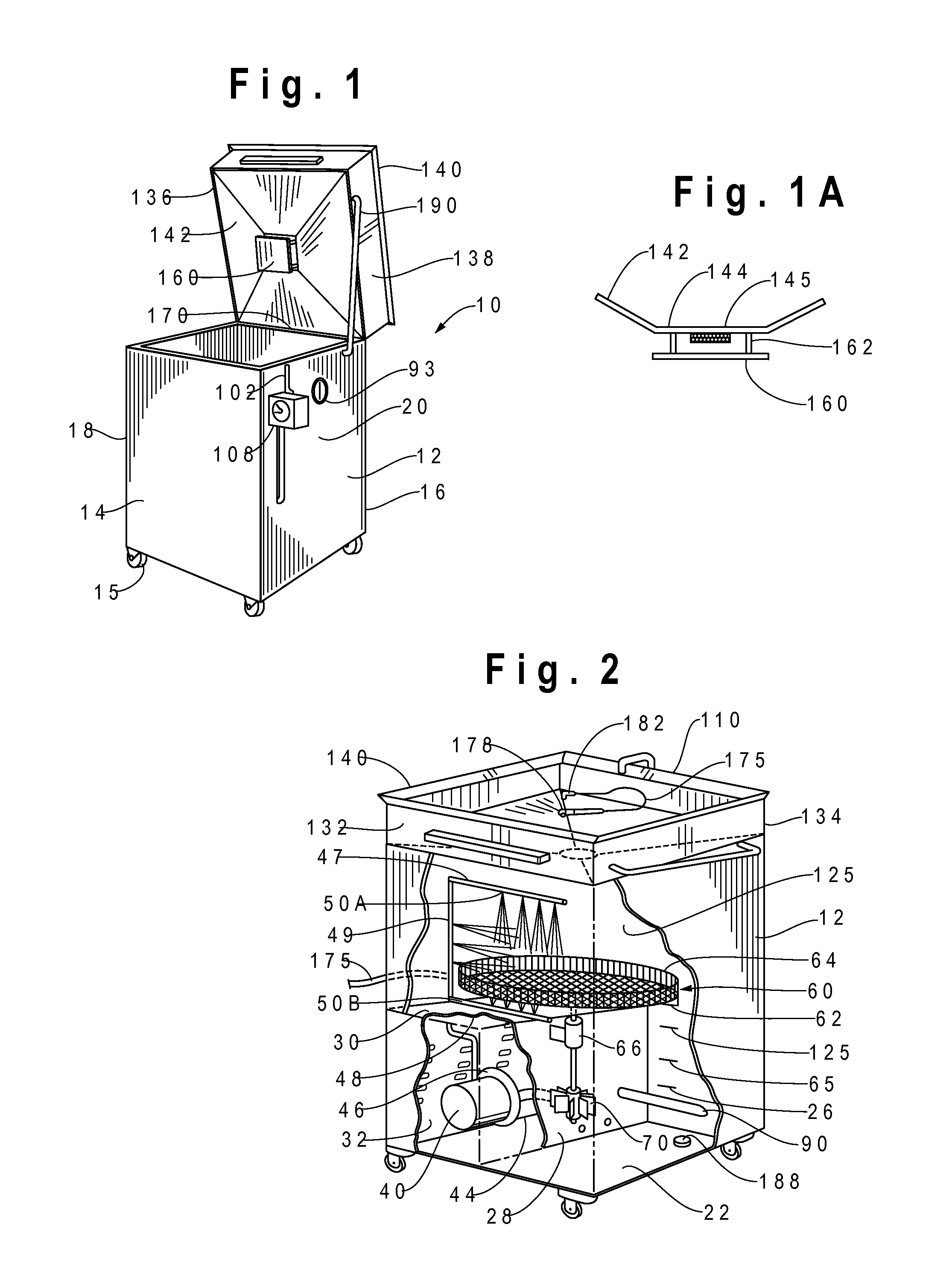

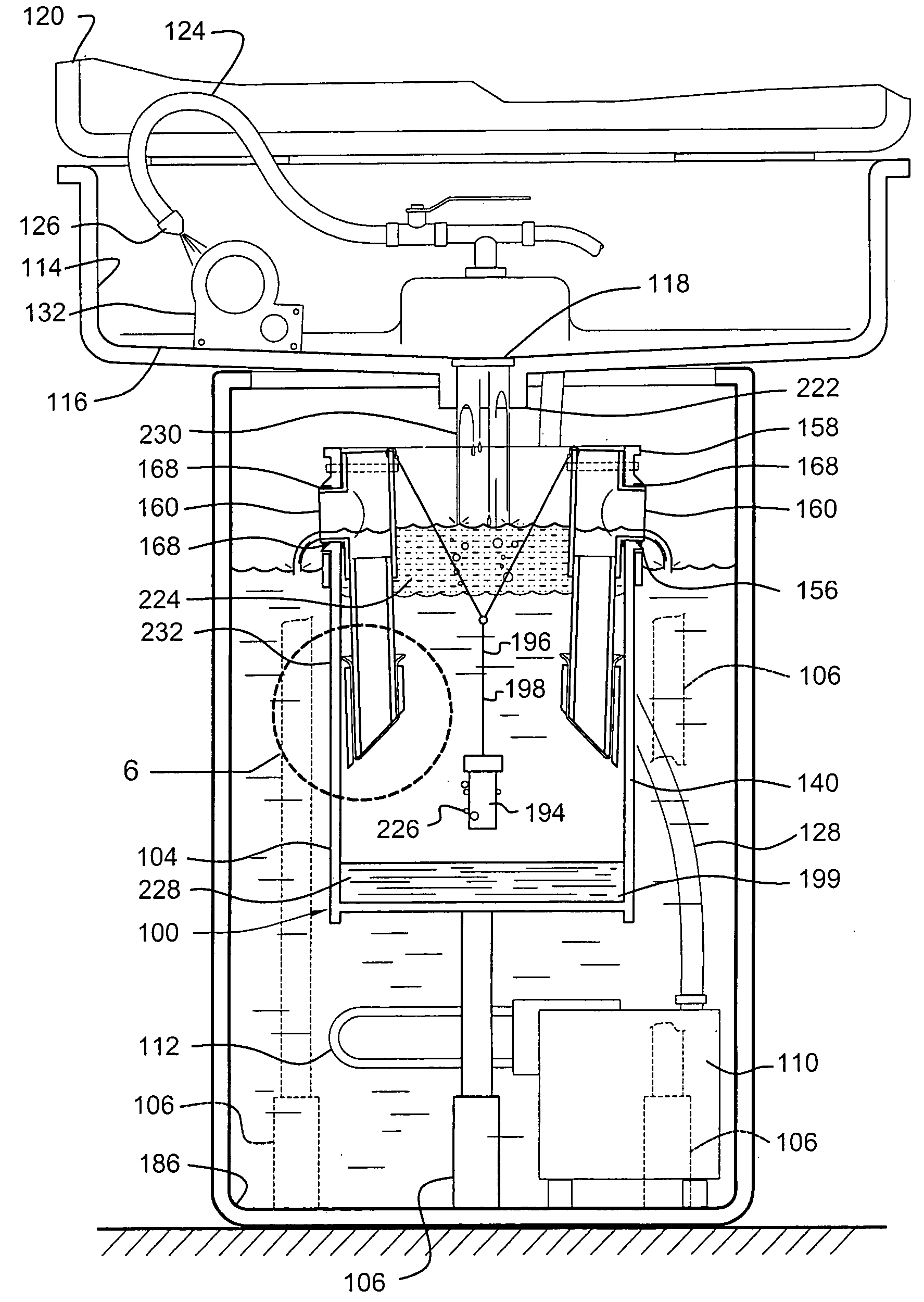

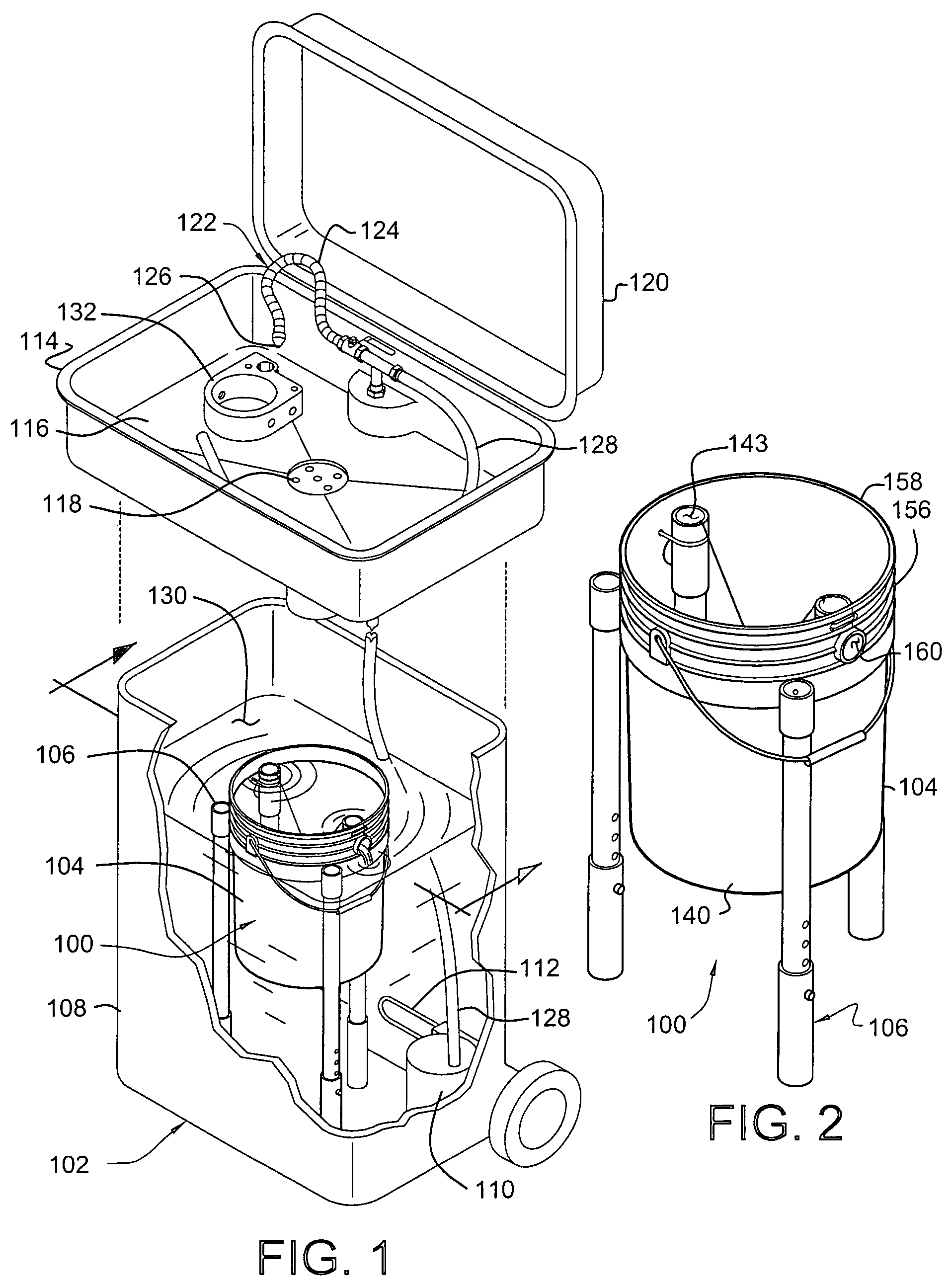

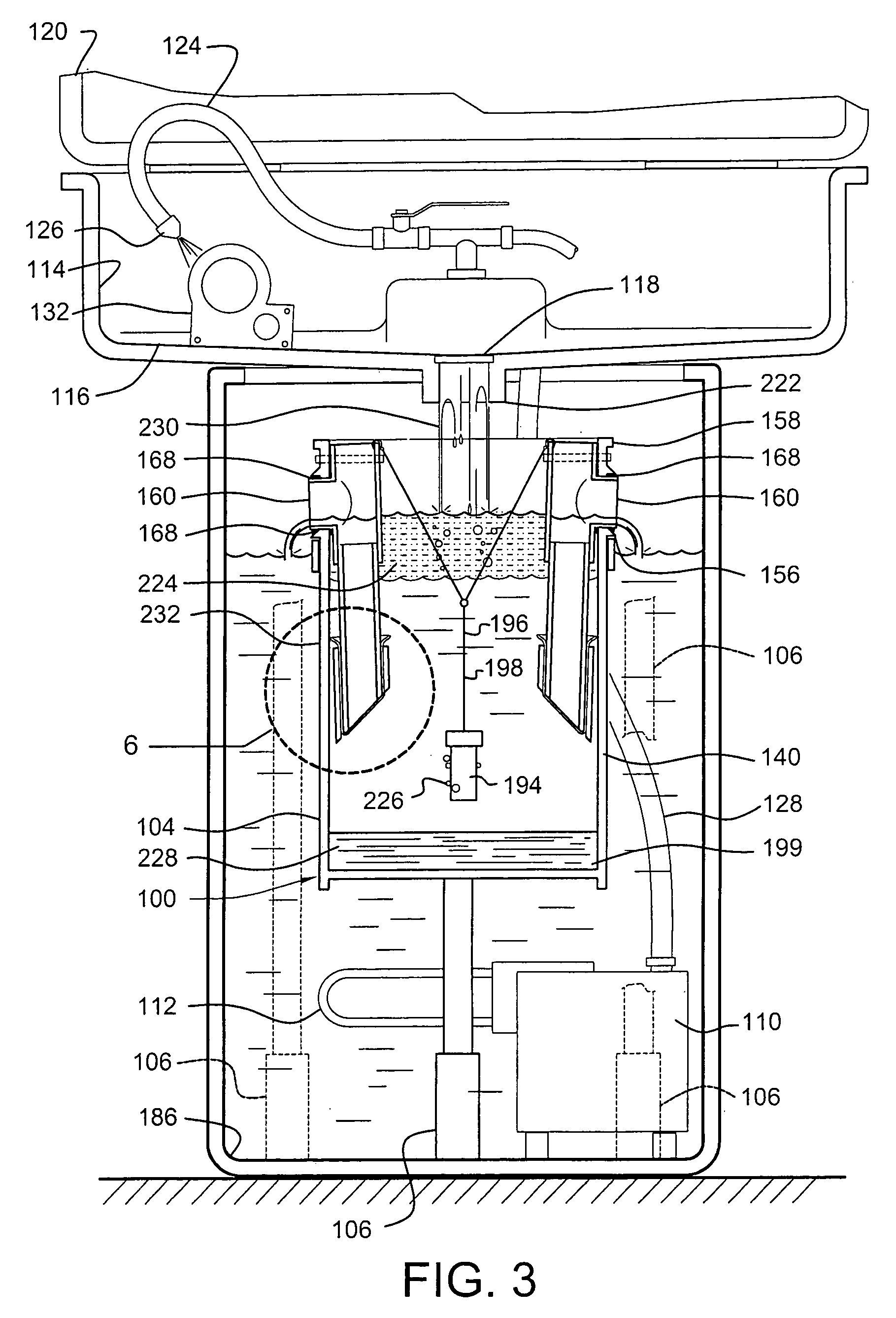

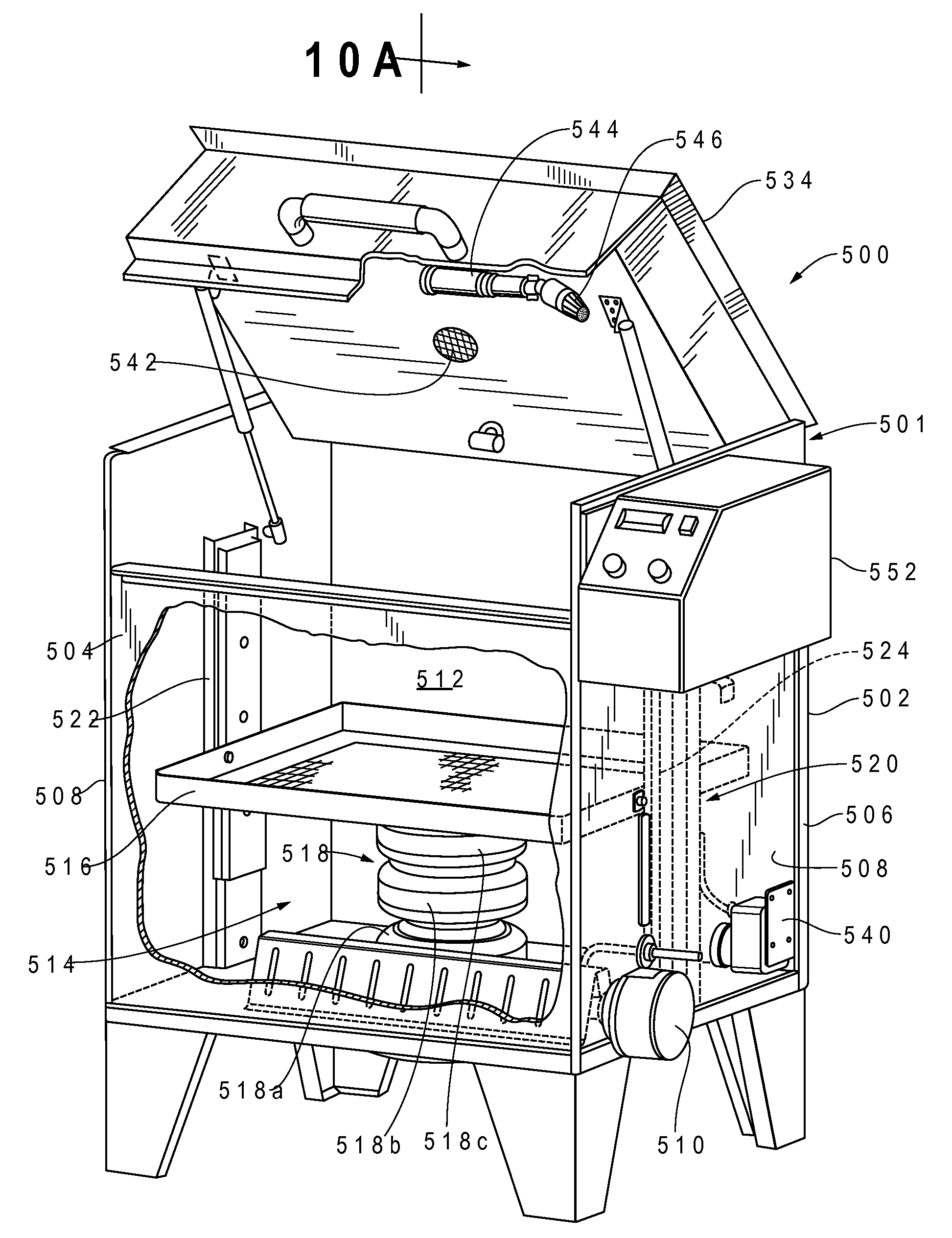

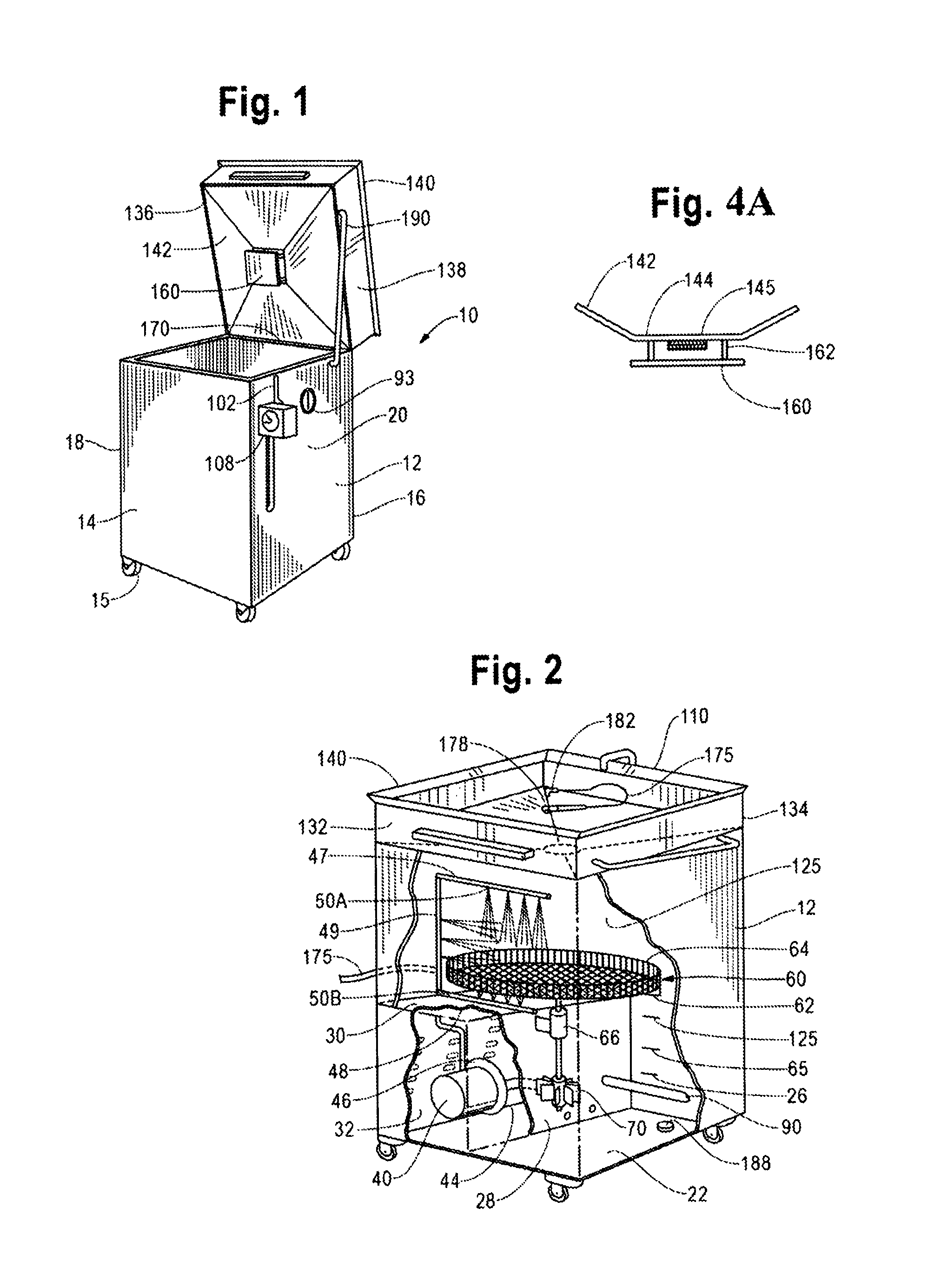

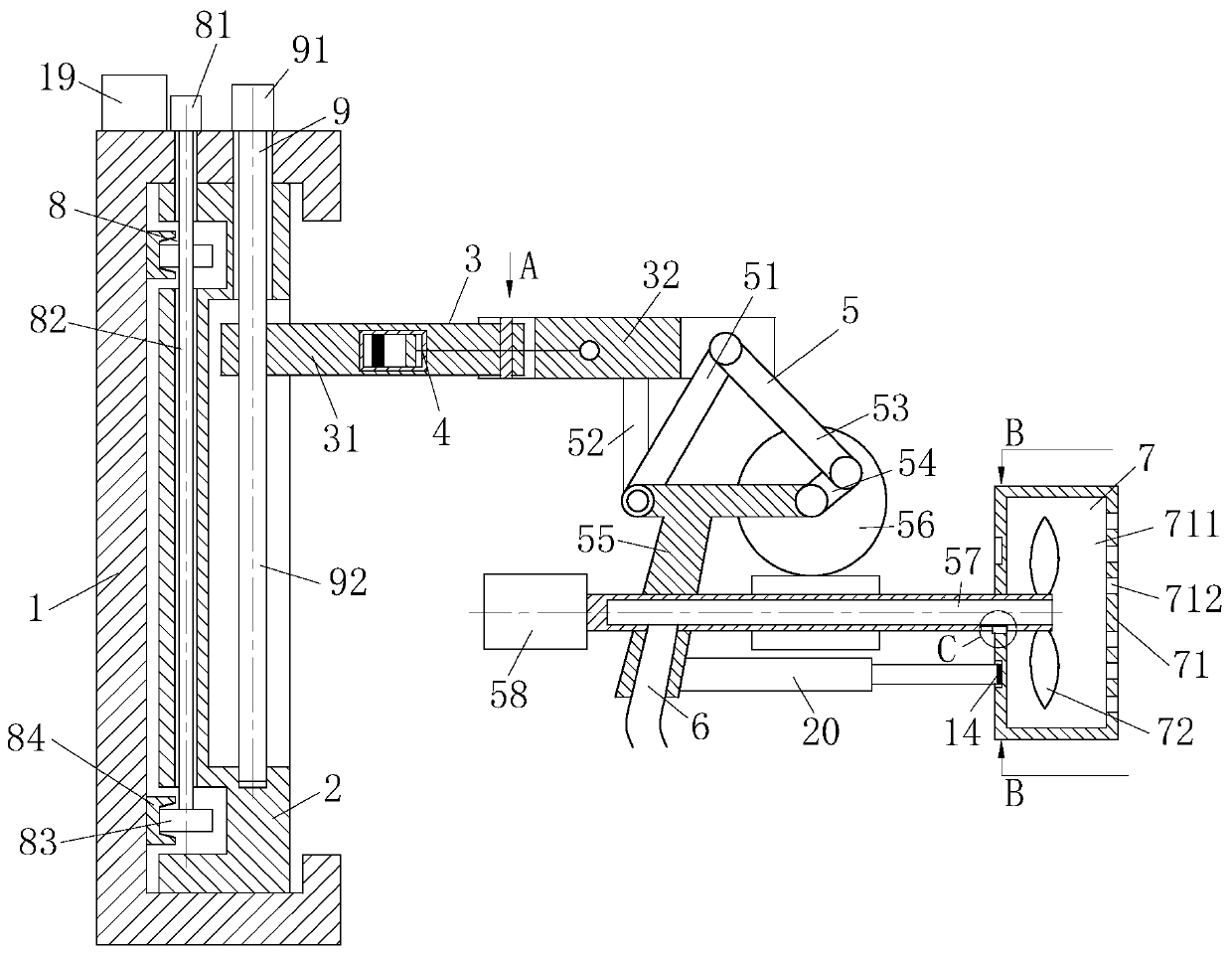

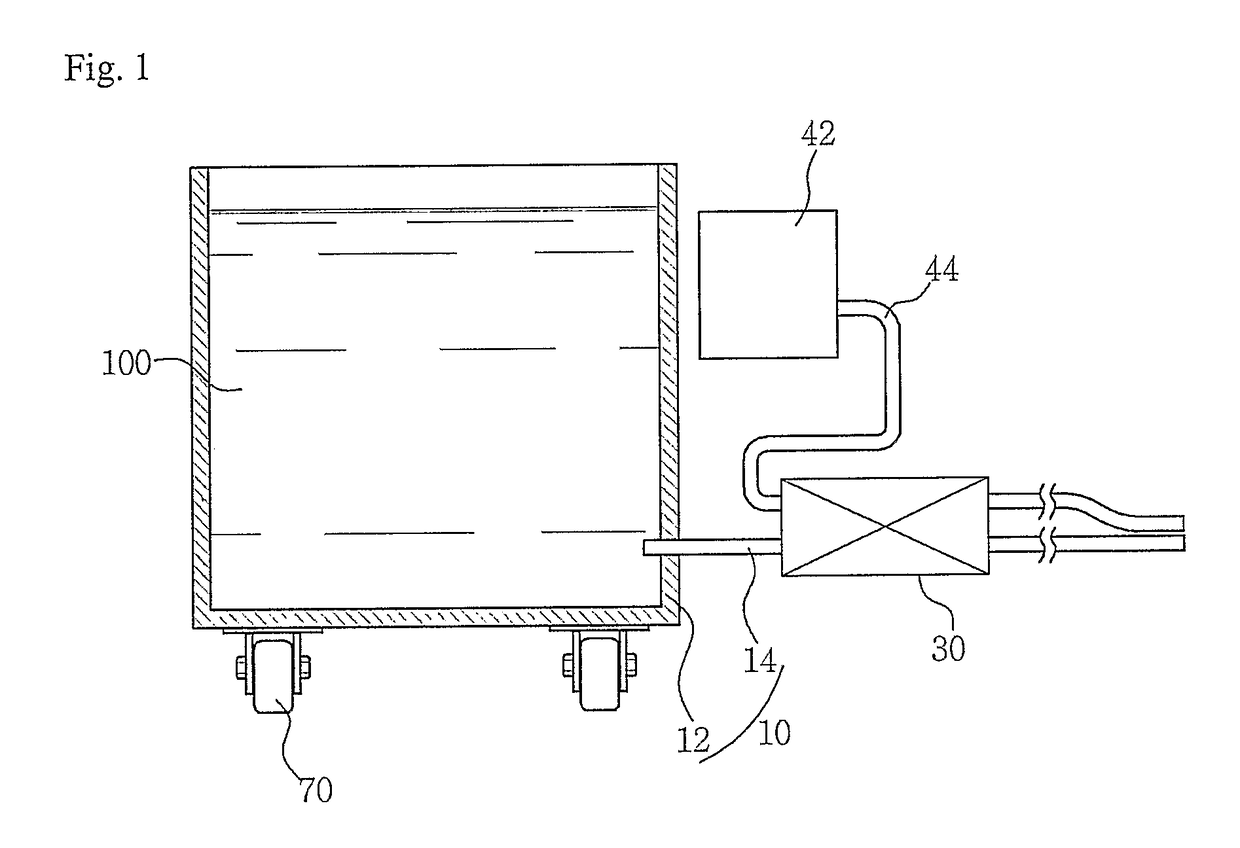

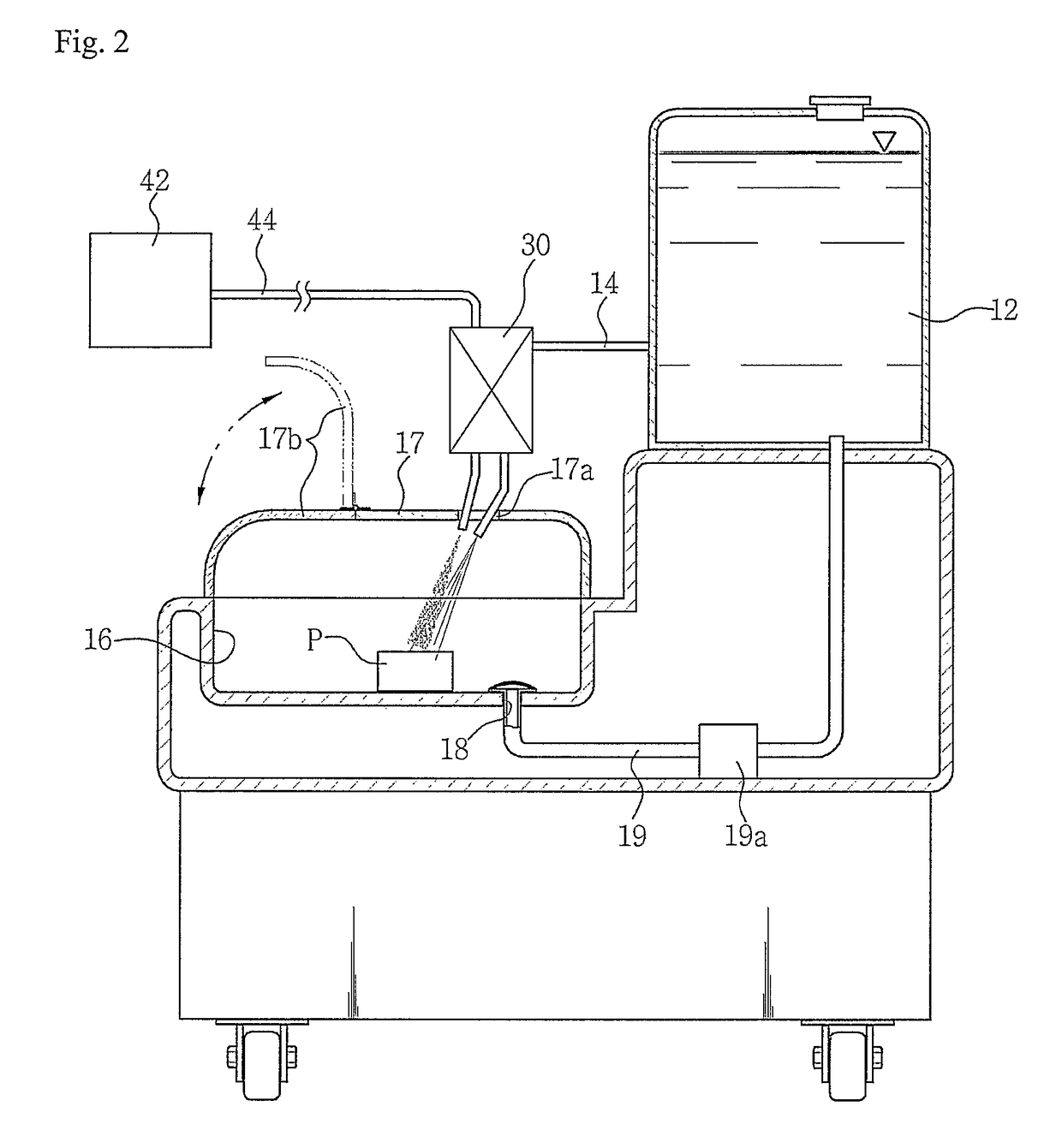

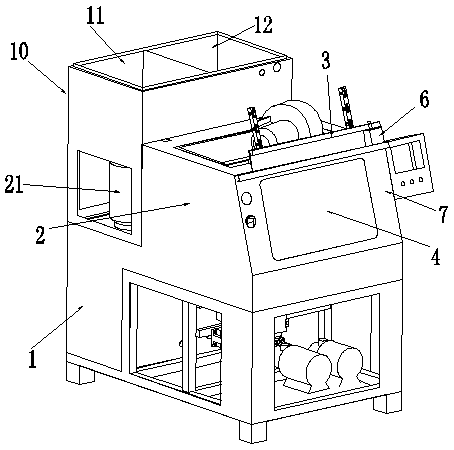

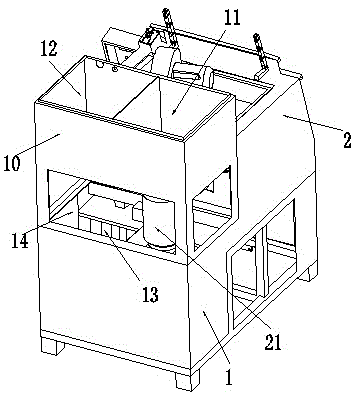

A multi-function parts washer for removing contaminants from parts either by hand or automatically using an aqueous cleaning fluid includes a base cabinet having sides, a floor and an open top defining a compartment. A parts receptacle is mounted in the compartment for receiving parts to be washed. The receptacle is mounted for reciprocating, vertical movement in the compartment. An agitator assembly includes one or more compressed gas bladders mounted to the parts receptacle. The bladder has an inlet for introducing compressed gas into the bladder and an outlet for discharge of the compressed gas from the bladder. As compressed gas is introduced into the bladder, the bladder inflates and the parts receptacle is raised, and as compressed gas is discharged from the bladder, the parts receptacle is lowered to provide an agitating motion of the parts receptacle and the parts thereon in the cleaning fluid. The agitator can include a hydraulic cylinder to effect movement of the parts receptacle.

Owner:HERITAGE CRYSTAL CLEAN

Part Washer

InactiveUS20080087306A1Increase cleansingImprove drying efficiencyFlow mixersTransportation and packagingEngineeringHigh pressure

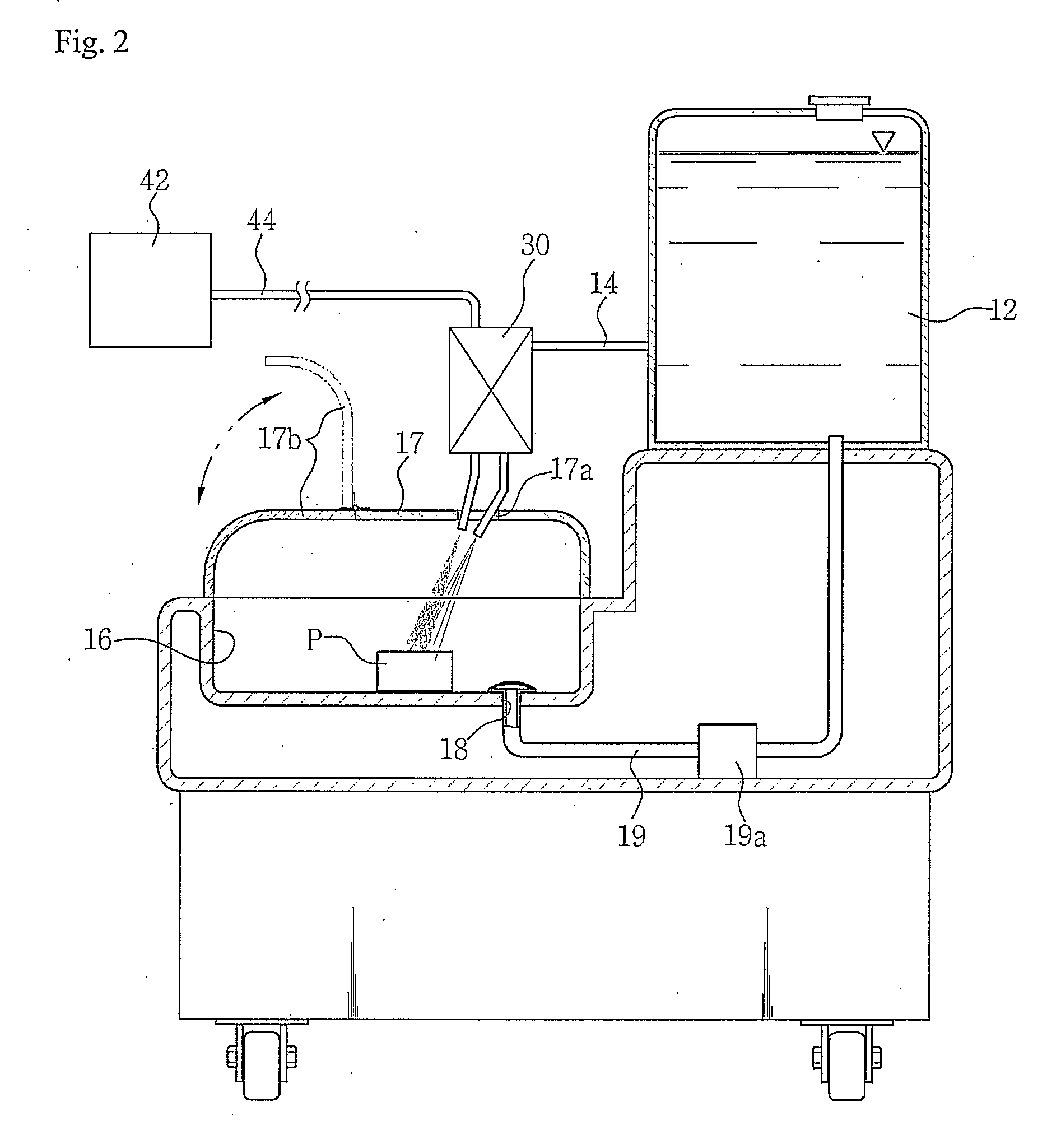

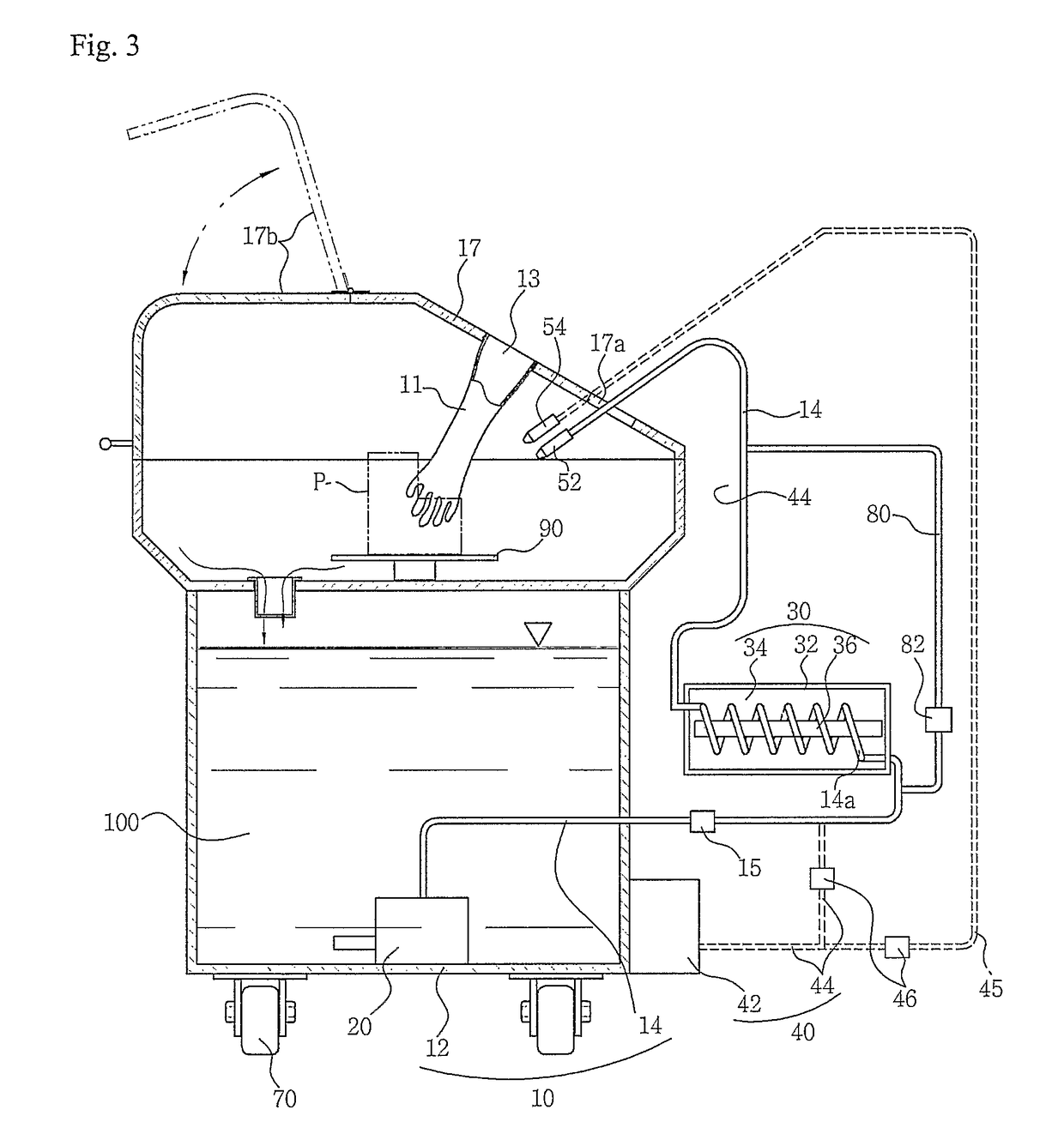

The present invention provides a part washer for cleansing various parts using cleansing solution, in particular to a part washer, which discharges the high-pressure air to be sprayed to the parts and the solution for cleansing the parts at the state where they are heated by means of heating means and heats the high-pressure air moving at high velocity smoothly, thereby improving cleansing and drying efficiencies in comparison with conventional art.

Owner:KIM SUNG IL

Part washer

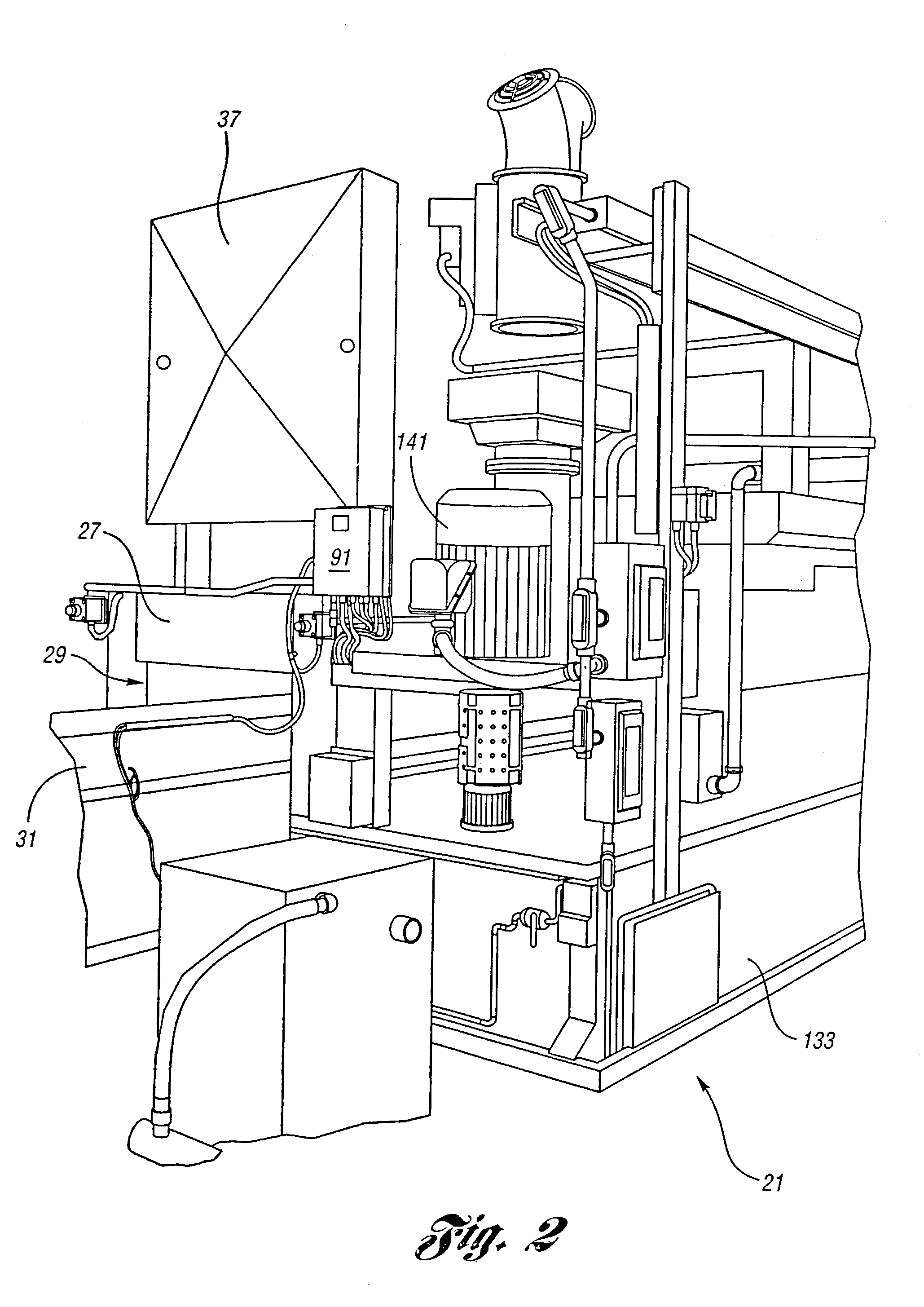

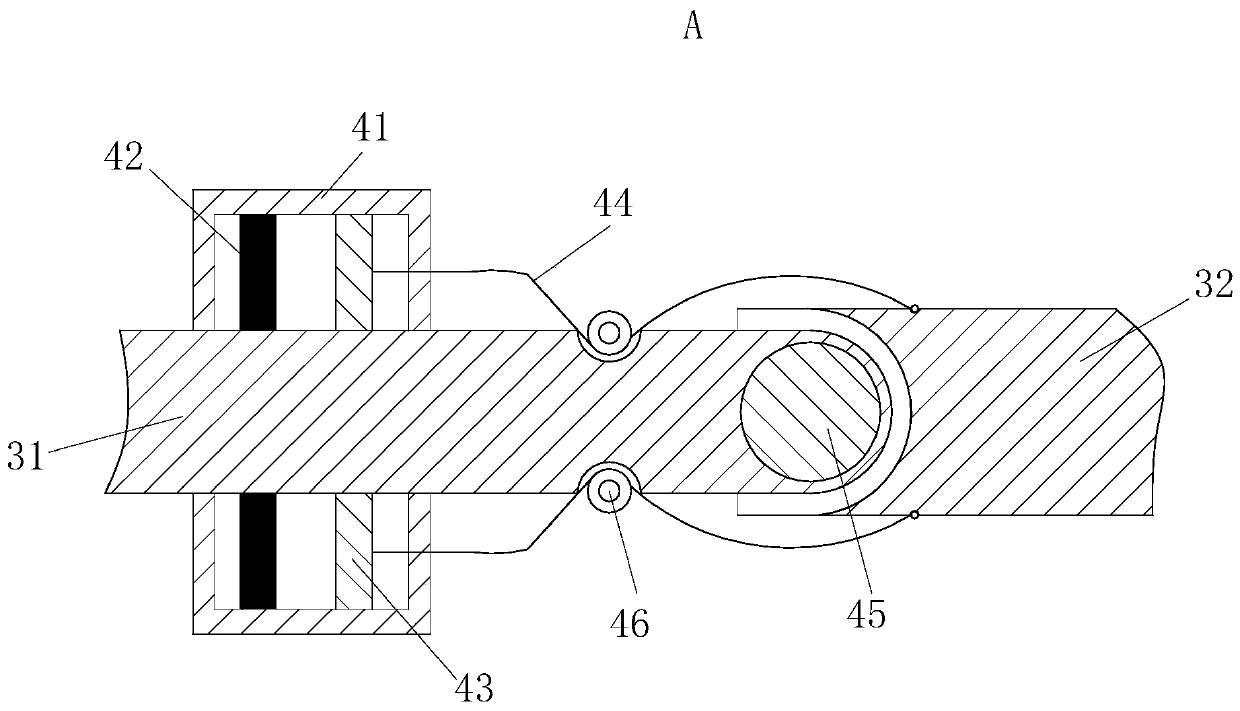

InactiveUS6073640AImprove sealingElectrostatic cleaningCleaning using liquidsClosed chamberEngineering

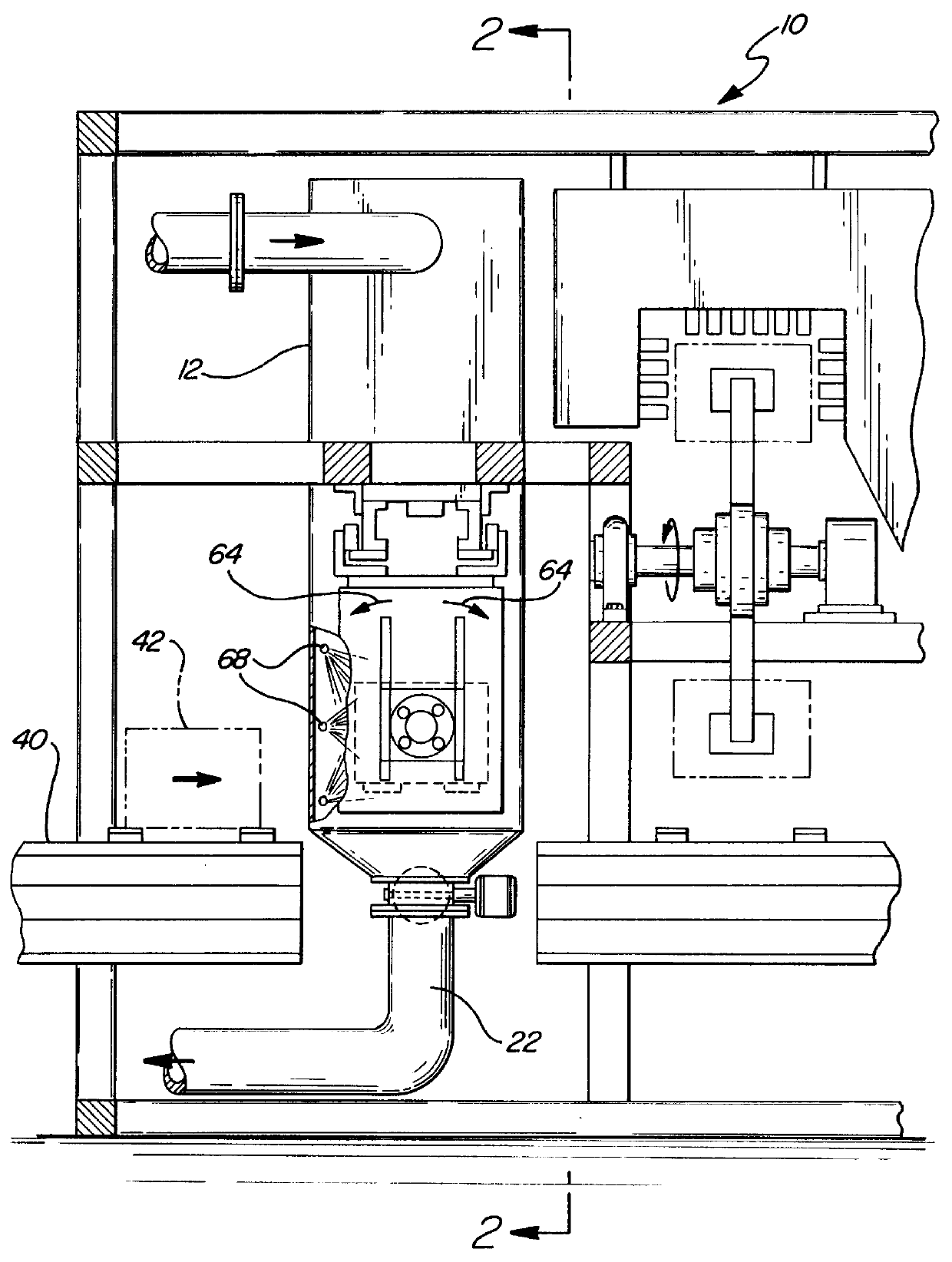

An industrial part washer is disclosed having a washer housing with an upper chamber, a lower chamber, and a fluid passageway connecting the chambers together. A fluid drain is connected to a lower chamber for draining fluid from it while a pump pumps a cleaning fluid into the upper chamber. A flood valve is positioned in the fluid passageway between the upper and lower chambers and this valve is movable between an open and a closed position. Parts are sequentially moved into a position adjacent the washer housing and are selectively loaded into the lower chamber, washed and, following completion of a wash cycle, subsequently unloaded from the lower chamber. A valve control closes the flood valve during the loading and unloading operations of the part into the lower chamber so that, during the loading and unloading portions of the wash cycle, the upper chamber at least partially and preferably completely fills with the cleaning fluid.

Owner:VALIANT CO LTD

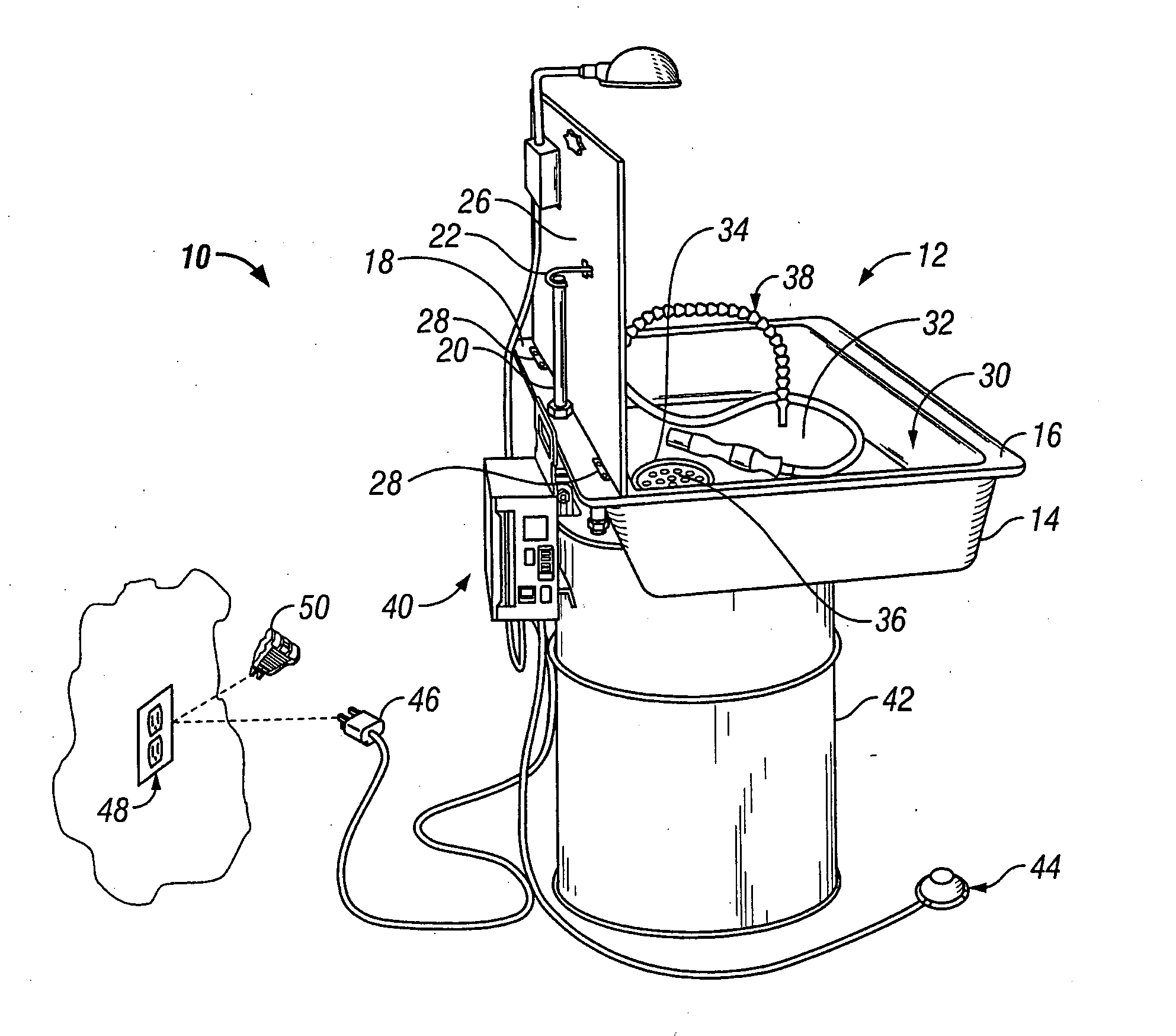

Portable purifying system

InactiveUS20040159597A1Prolong lifeEasy to cleanLiquid suspension thickening by filtrationSedimentation separationEngineeringVolumetric Mass Density

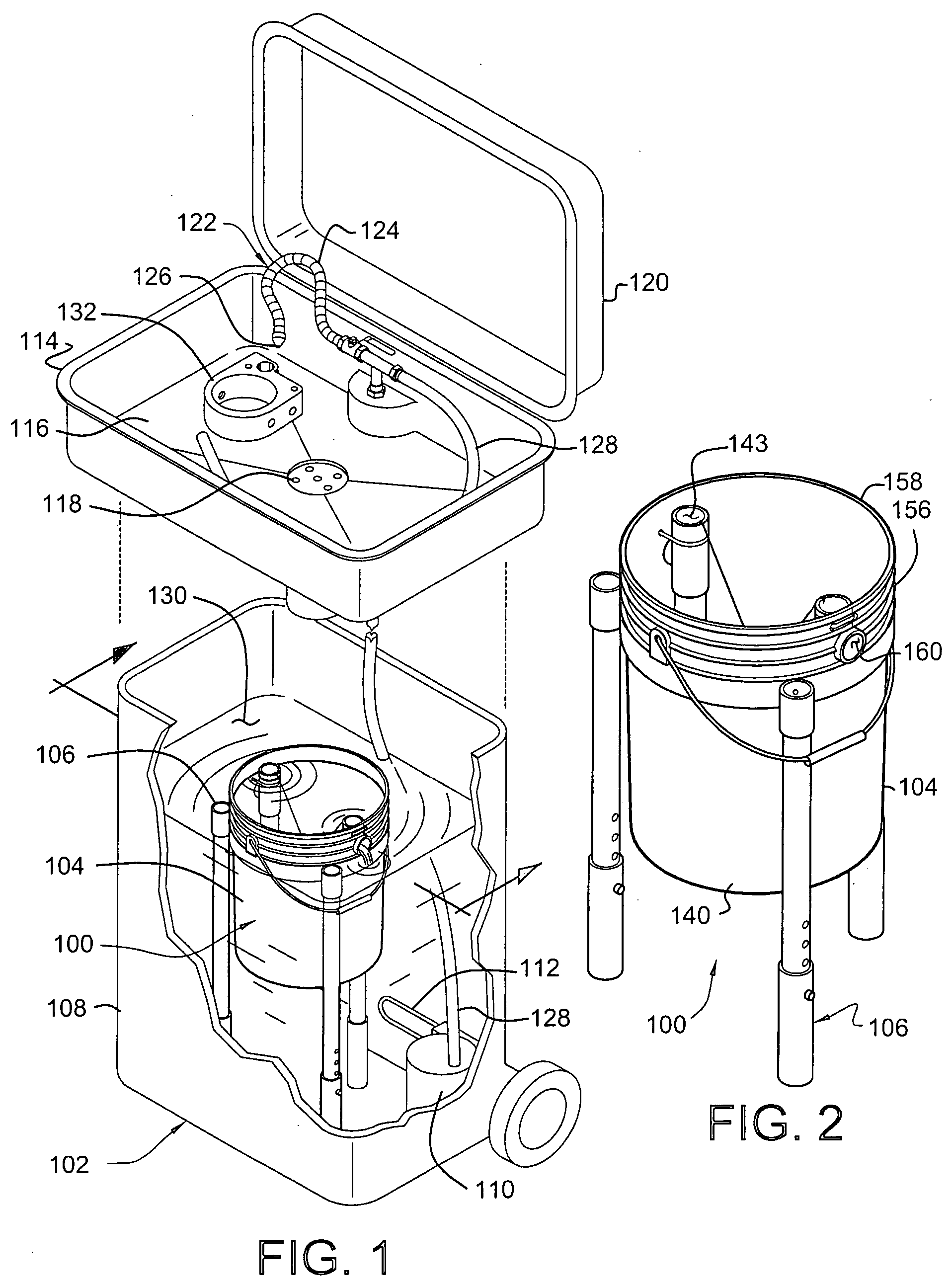

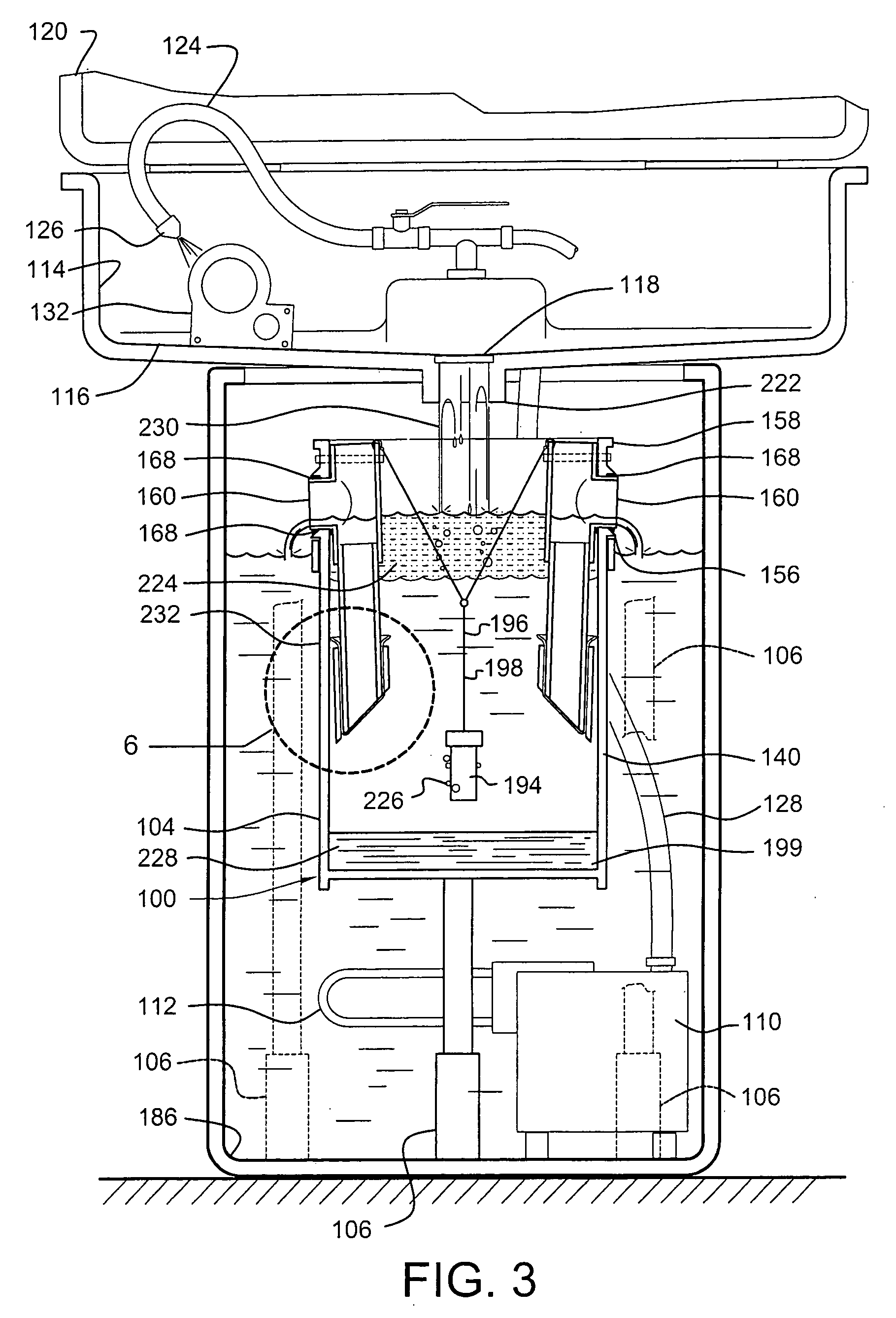

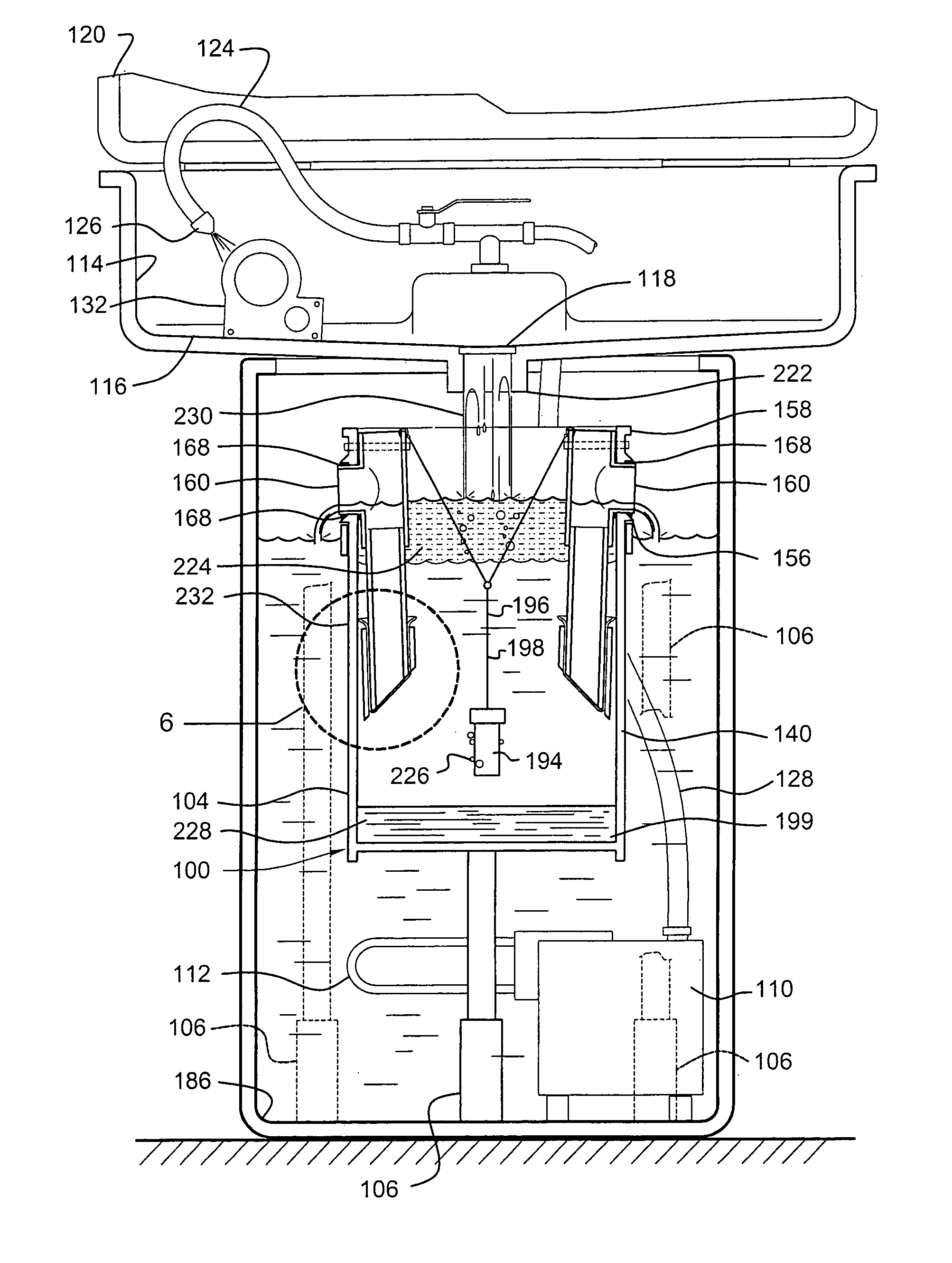

A portable purifying system for improved filtering and / or separating of cleaning solutions such as solvents, particularly those used in parts washers. The purifying system utilizes a removable reservoir to provide a smaller reservoir within a larger reservoir such as a parts washer. The portable purifying system provides an apparatus and method of use to perform the following steps: using re-circulating solvent from the larger reservoir, washing oily parts in such manner that oily residue from the washed parts is deposited in the smaller reservoir; separating cleaner portions of solvent from dirtier portions of solvent within the smaller reservoir using density differences to separate by gravity action cleaner portions from dirtier portions; moving the cleaner portions of solvent into the larger reservoir; and periodically emptying and cleaning the smaller reservoir.

Owner:LEE F DONALD

Portable purifying system

InactiveUS7018528B2Prolong lifeEasy to cleanLiquid suspension thickening by filtrationSedimentation separationVolumetric Mass DensitySolvent

A portable purifying system for improved filtering and / or separating of cleaning solutions such as solvents, particularly those used in parts washers. The purifying system utilizes a removable reservoir to provide a smaller reservoir within a larger reservoir such as a parts washer. The portable purifying system provides an apparatus and method of use to perform the following steps: using re-circulating solvent from the larger reservoir, washing oily parts in such manner that oily residue from the washed parts is deposited in the smaller reservoir; separating cleaner portions of solvent from dirtier portions of solvent within the smaller reservoir using density differences to separate by gravity action cleaner portions from dirtier portions; moving the cleaner portions of solvent into the larger reservoir; and periodically emptying and cleaning the smaller reservoir.

Owner:LEE F DONALD

Parts washer system

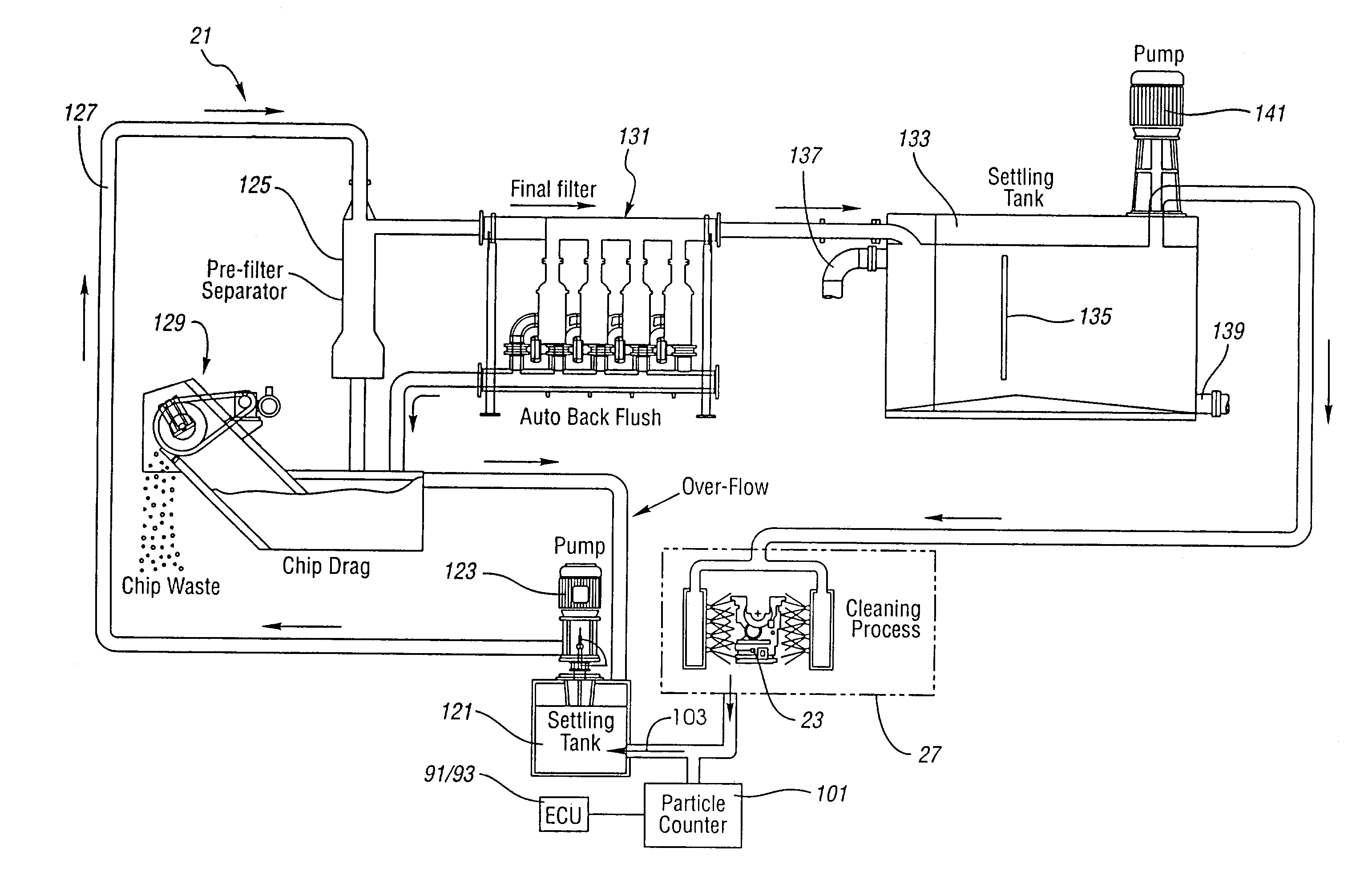

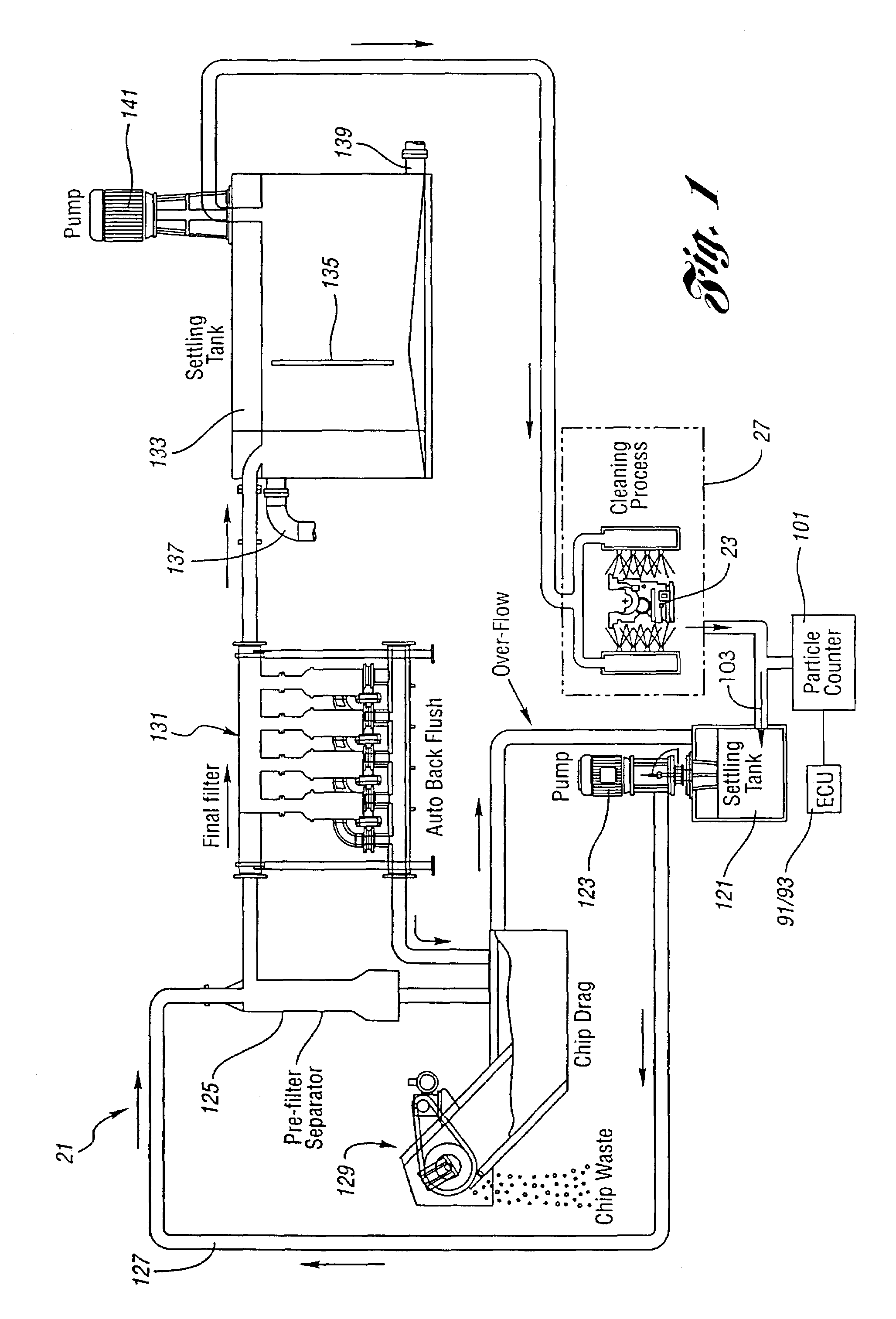

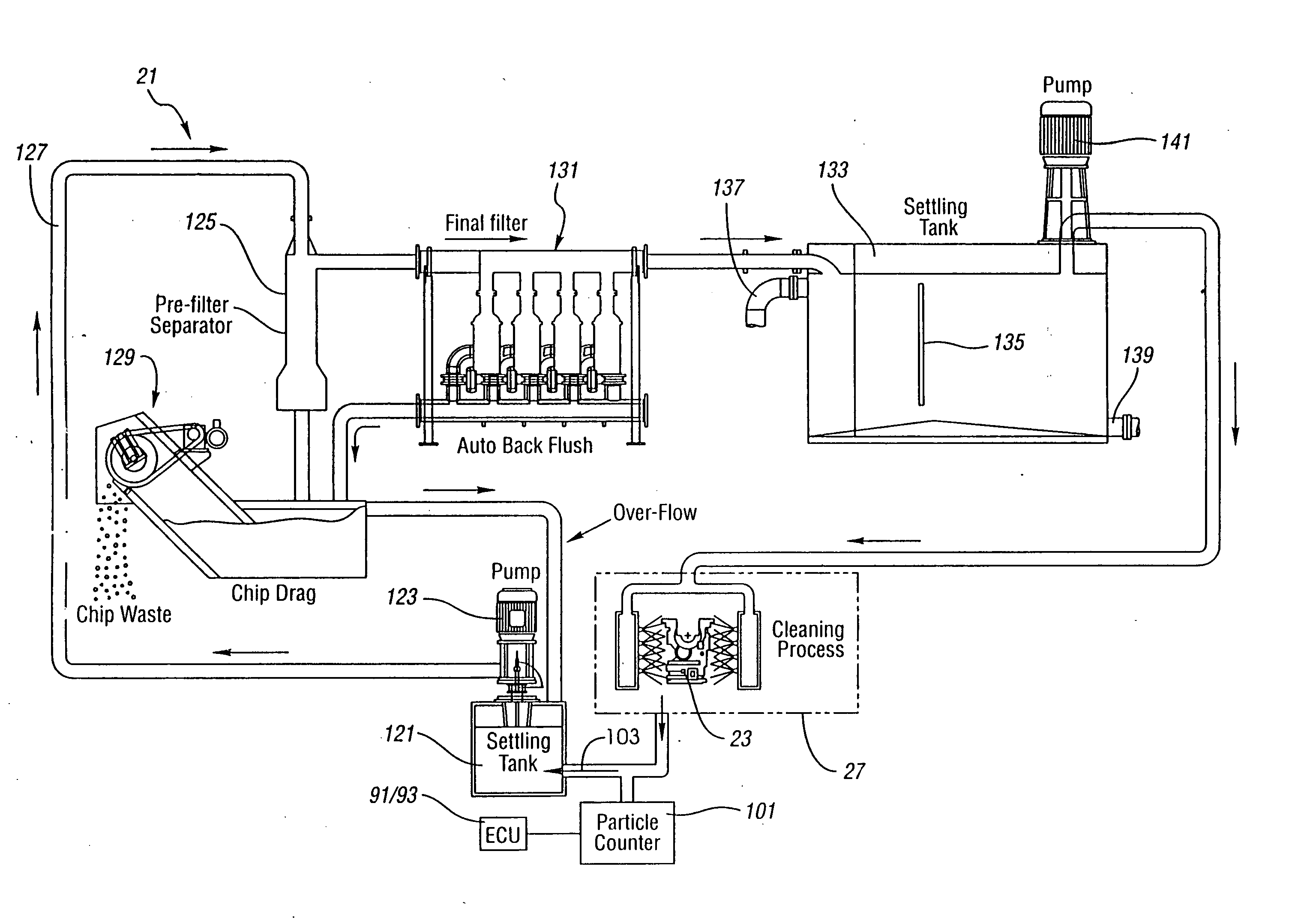

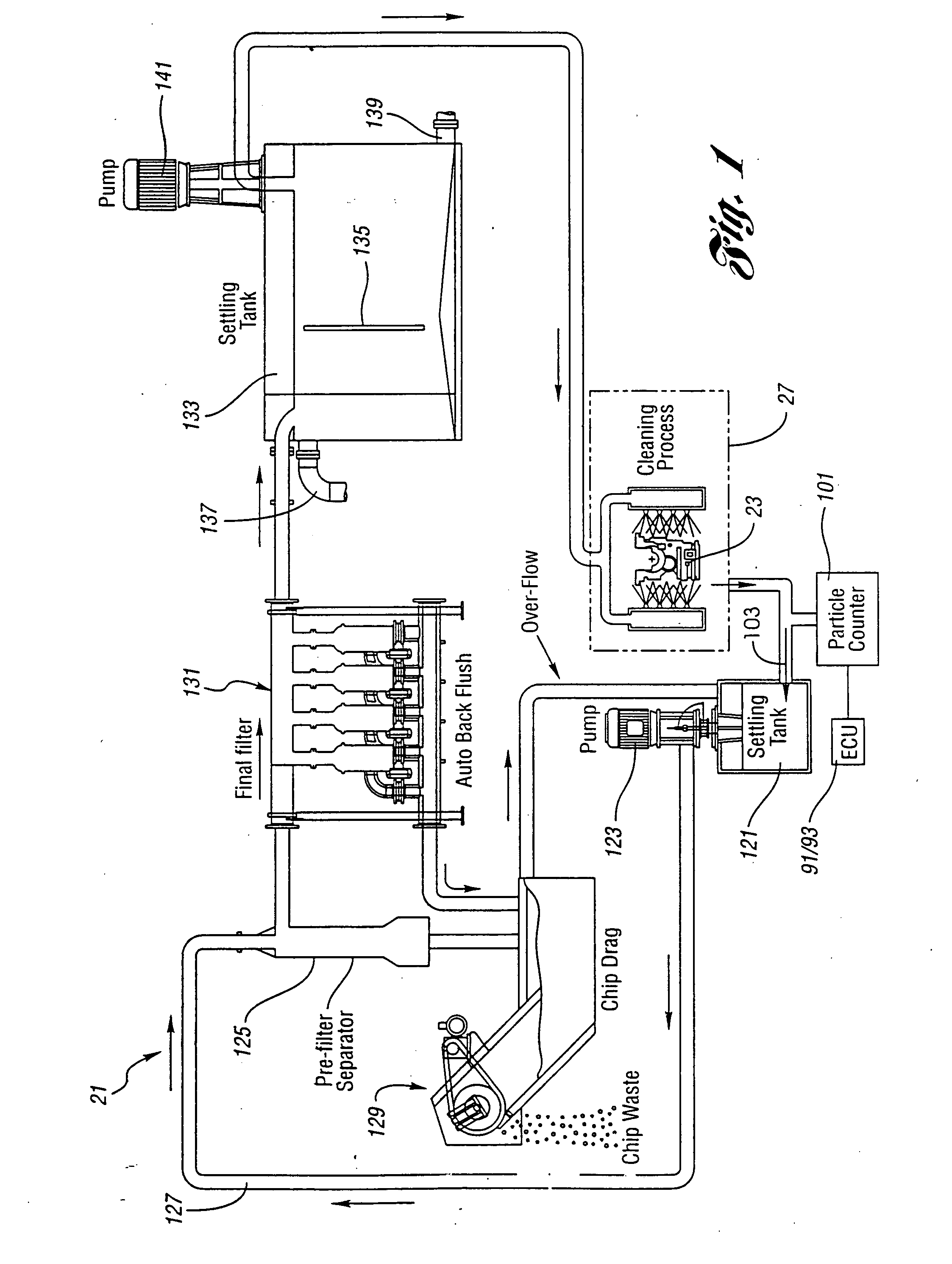

ActiveUS7146991B2Sure easyImprove processing speedHollow article cleaningElectrostatic cleaningTurbidityProcess engineering

An industrial parts washer system includes washing fluid, an assembly operable to apply the washing fluid to the part, a turbidity sensor coupled to the assembly operable to sense a condition of the washing fluid after the fluid washes the part, and a control unit connected to the sensor that compares the sensed condition of the washing fluid to a value and thereby determines whether the part should be washed further.

Owner:CINETIC AUTOMATION

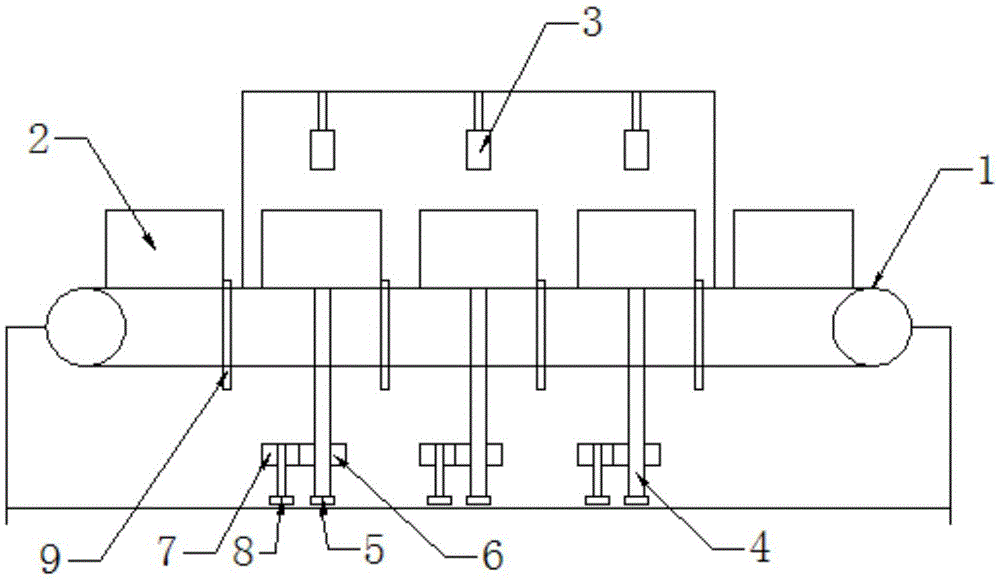

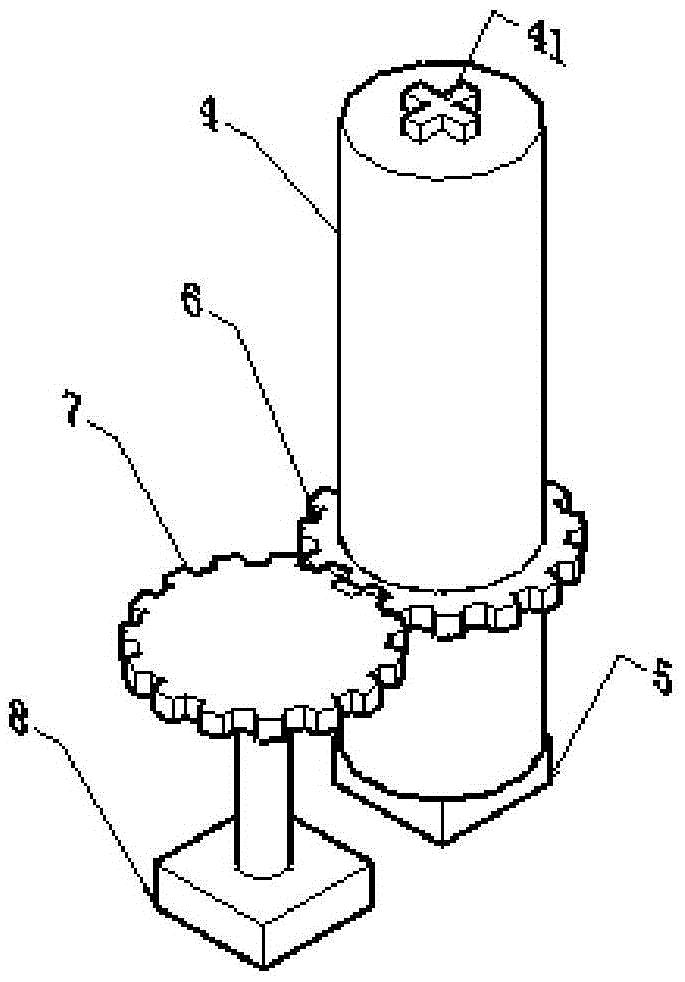

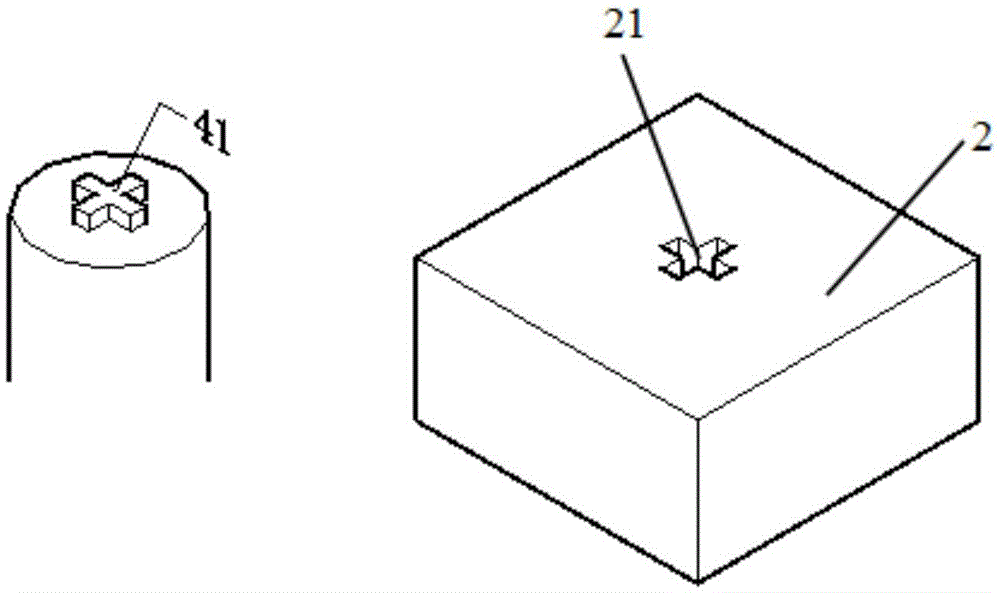

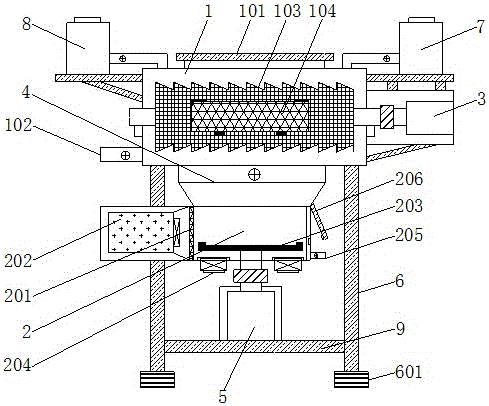

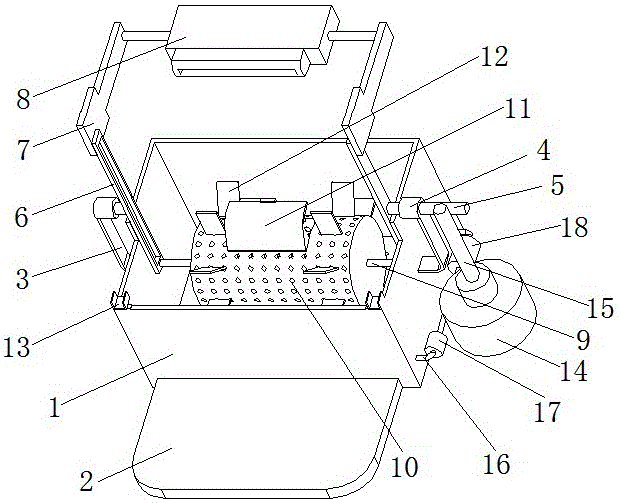

Part cleaning machine

The invention discloses a part cleaning machine. The part cleaning machine comprises a conveyor belt, material discs and rotary spray washing devices located above the conveyor belt. The spray washing devices are filled with cleaning liquid. Supporting rods are arranged under the parts, right below the spray washing devices, of the conveyor belt. The top ends of the supporting rods and the centers of the bottoms of the corresponding material discs are provided with mutually engaged locking mechanisms. The bottom of each supporting rod is provided with a pressure cylinder. The pressure cylinder can jack up the corresponding material disc conveyed to the position right below the corresponding spray washing device along the conveyor belt in the perpendicular direction. A gear is further fixedly arranged on each supporting rod, and each gear is engaged with another gear driven by a motor so as to drive the corresponding material disc to rotate. By the adoption of the part cleaning machine disclosed by the invention, the cleaning degree is high, and the cleaning efficiency is high.

Owner:DONGGUAN QINGMAITIAN DIGITAL TECH

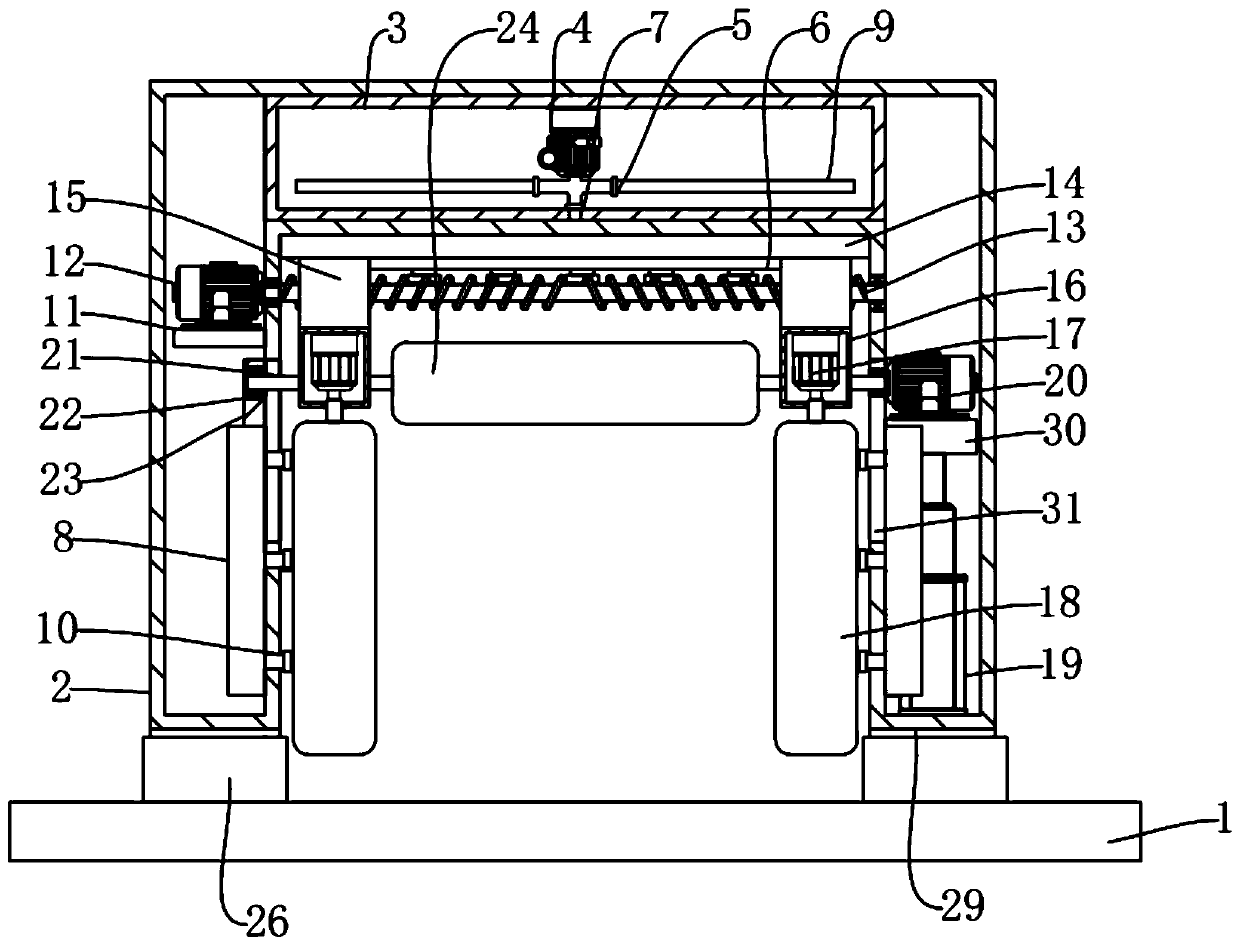

Hardware part cleaning machine

ActiveCN105689317AEasy to operateEasy to cleanDrying gas arrangementsCleaning using liquidsCouplingEngineering

The invention discloses a hardware part cleaning machine. The hardware part cleaning machine comprises a cleaning box and a drying box; a first cover plate is arranged on an inlet at the top of the cleaning box; a first dirt removing pipe is arranged on one side surface of the cleaning box; a waveform net cylinder is movably mounted in the cleaning box through a first rotating shaft, and is provided with a net cover; a first chassis is arranged on one side surface of the cleaning box; a first driving motor is arranged in the first chassis; and a first rotating shaft on one side of the waveform net cylinder is fixedly connected with a second rotating shaft of a first driving motor through a coupling. The hardware part cleaning machine can dry hardware parts after cleaning, is convenient for operation, excellent in cleaning effect, high in reliability, high in operation efficiency and simple in structure, can achieve better cleaning adaptability to various hardware parts, reduces the labor intensity, saves the labor cost, and improves the cleaning effect; and the drying box is unique in internal structure, reasonable in layout, simple and practical, can perform quick drying, and is high in working efficiency.

Owner:无锡锡东新农村投资发展有限公司

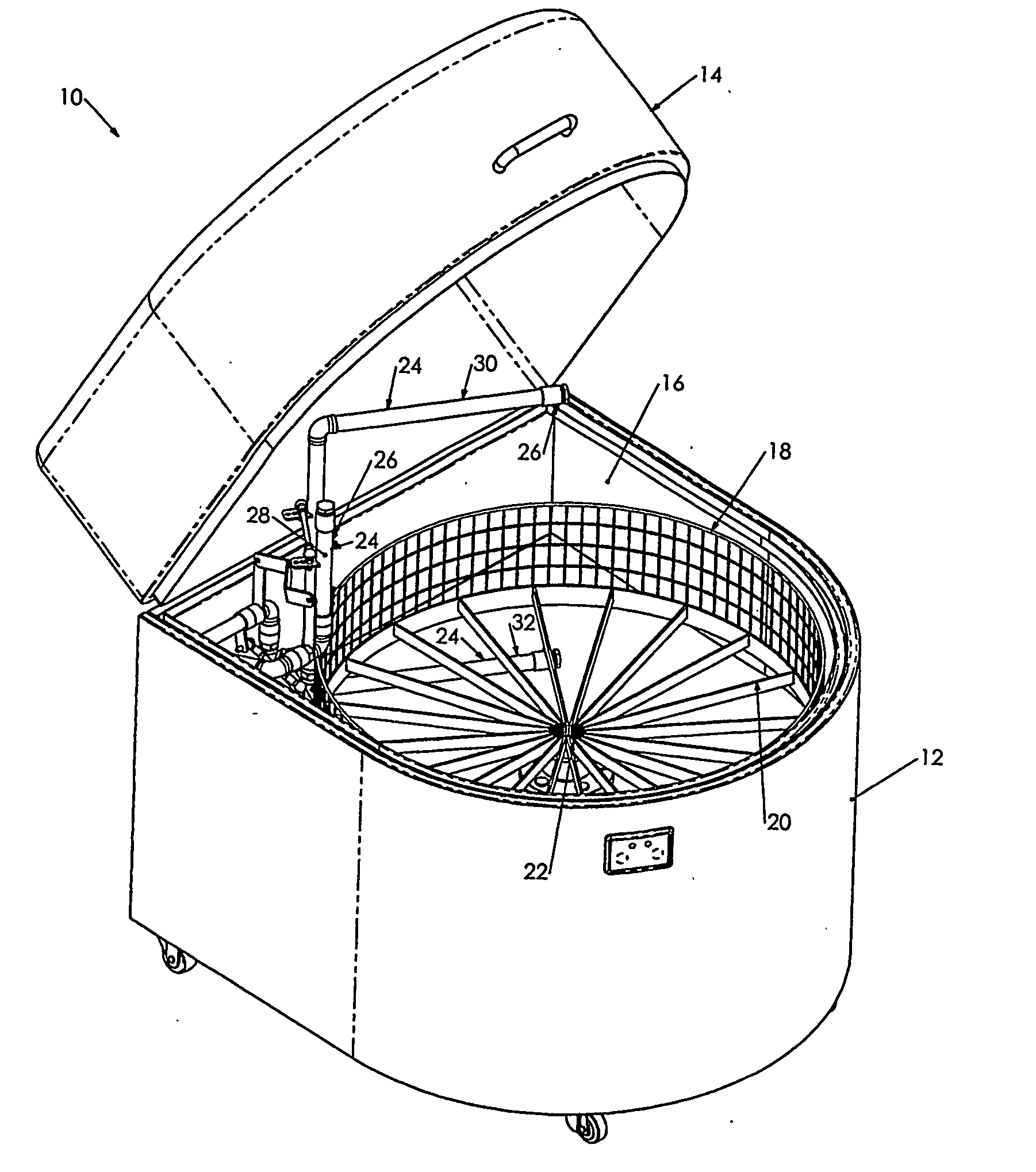

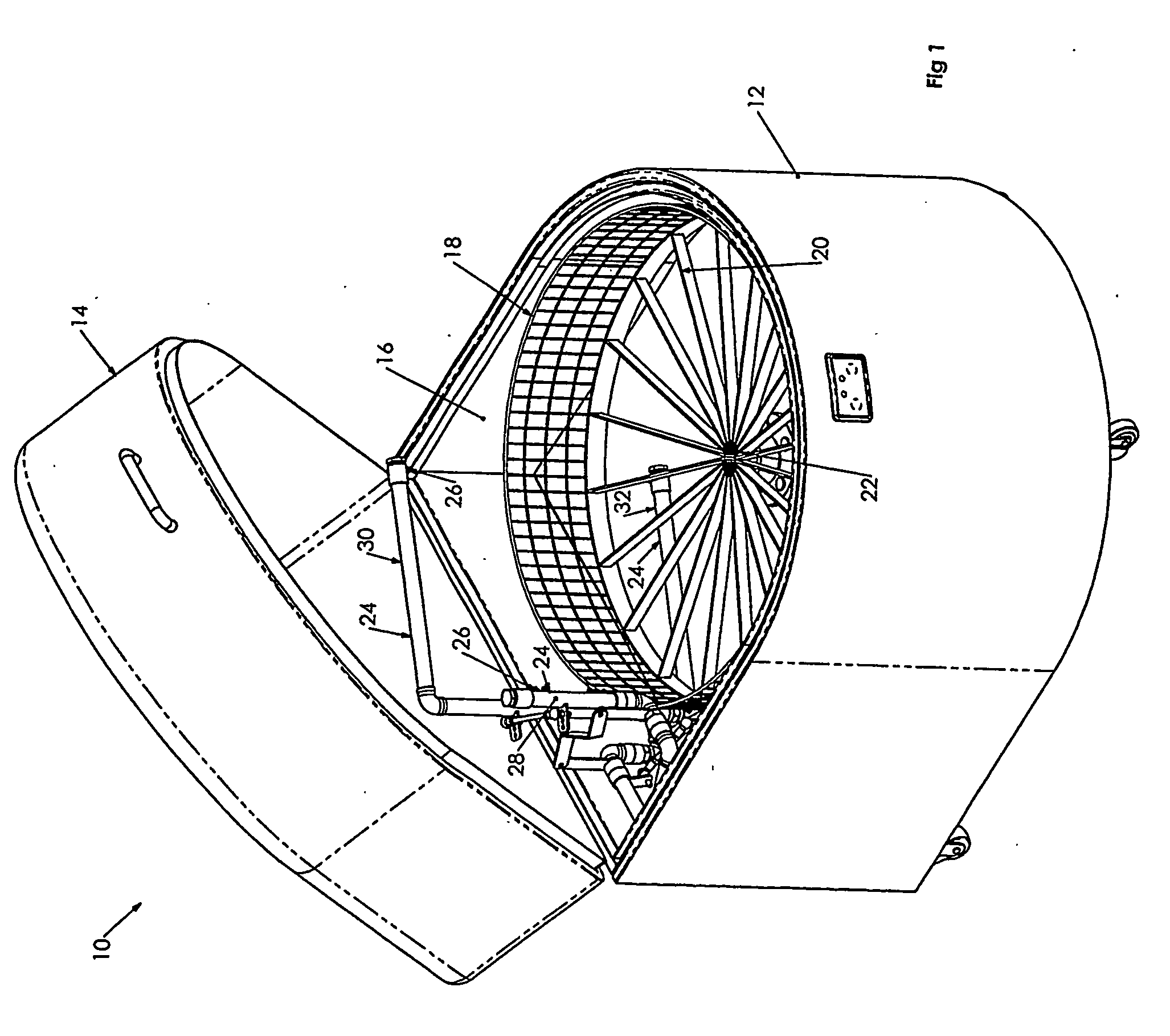

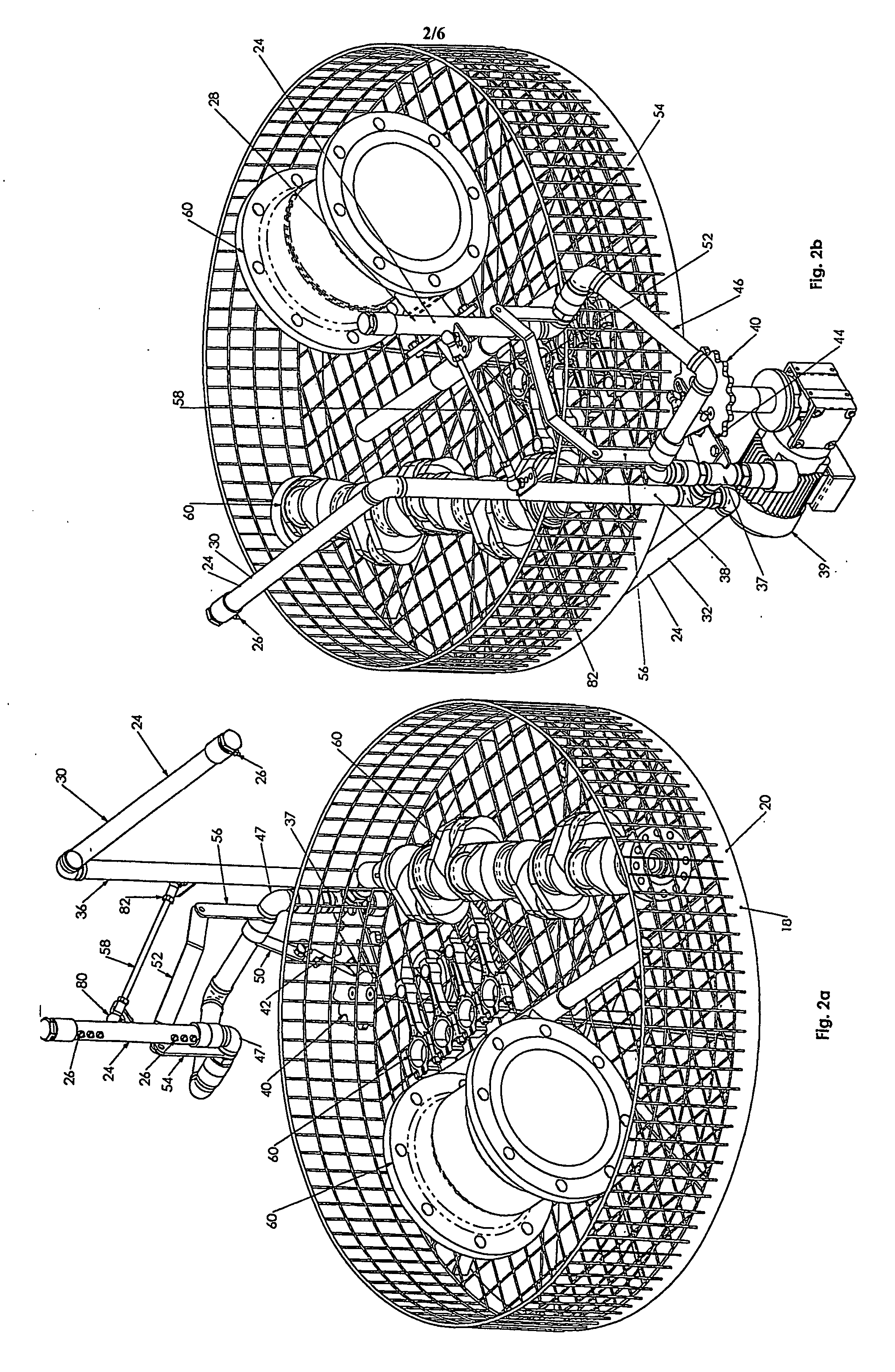

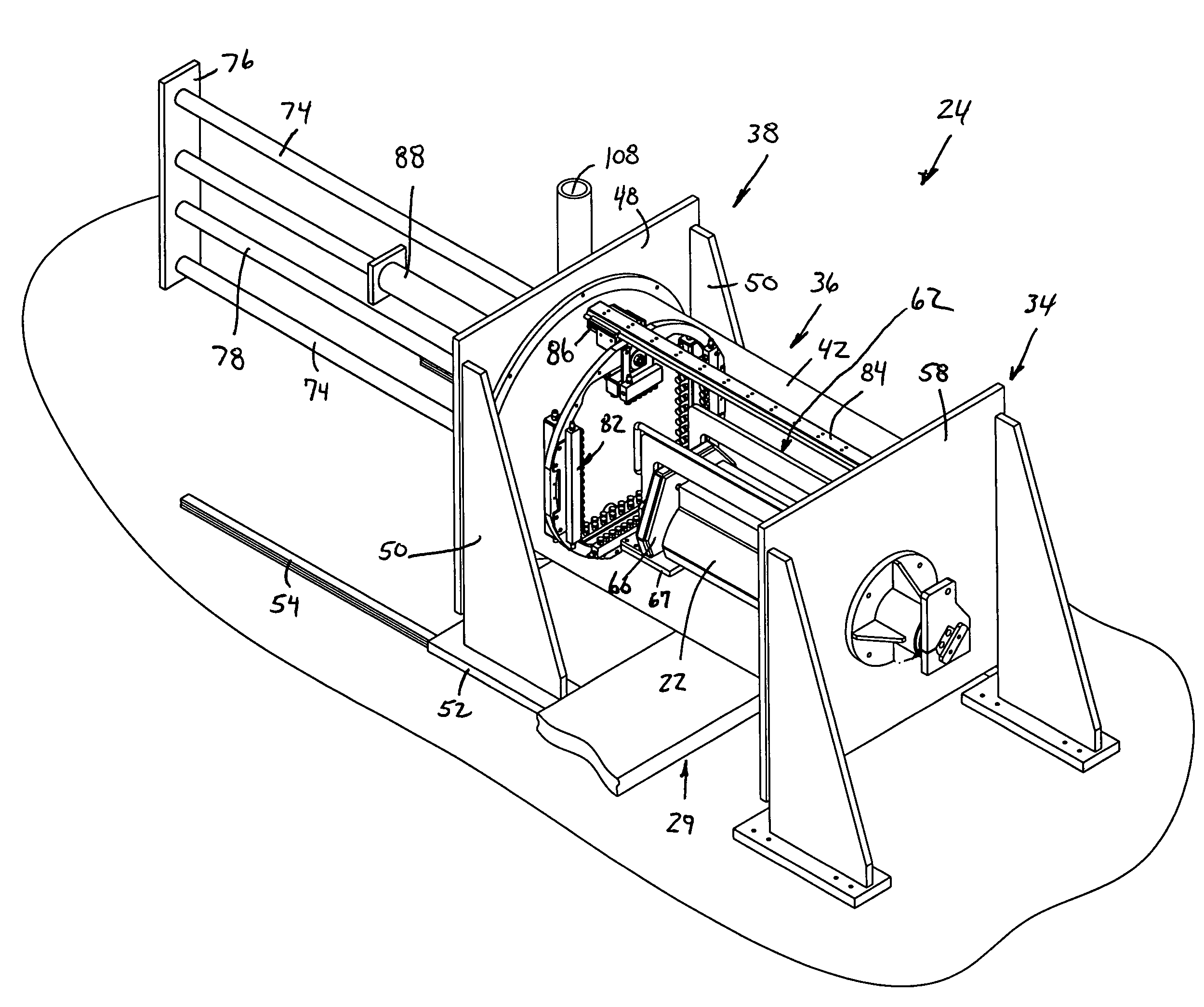

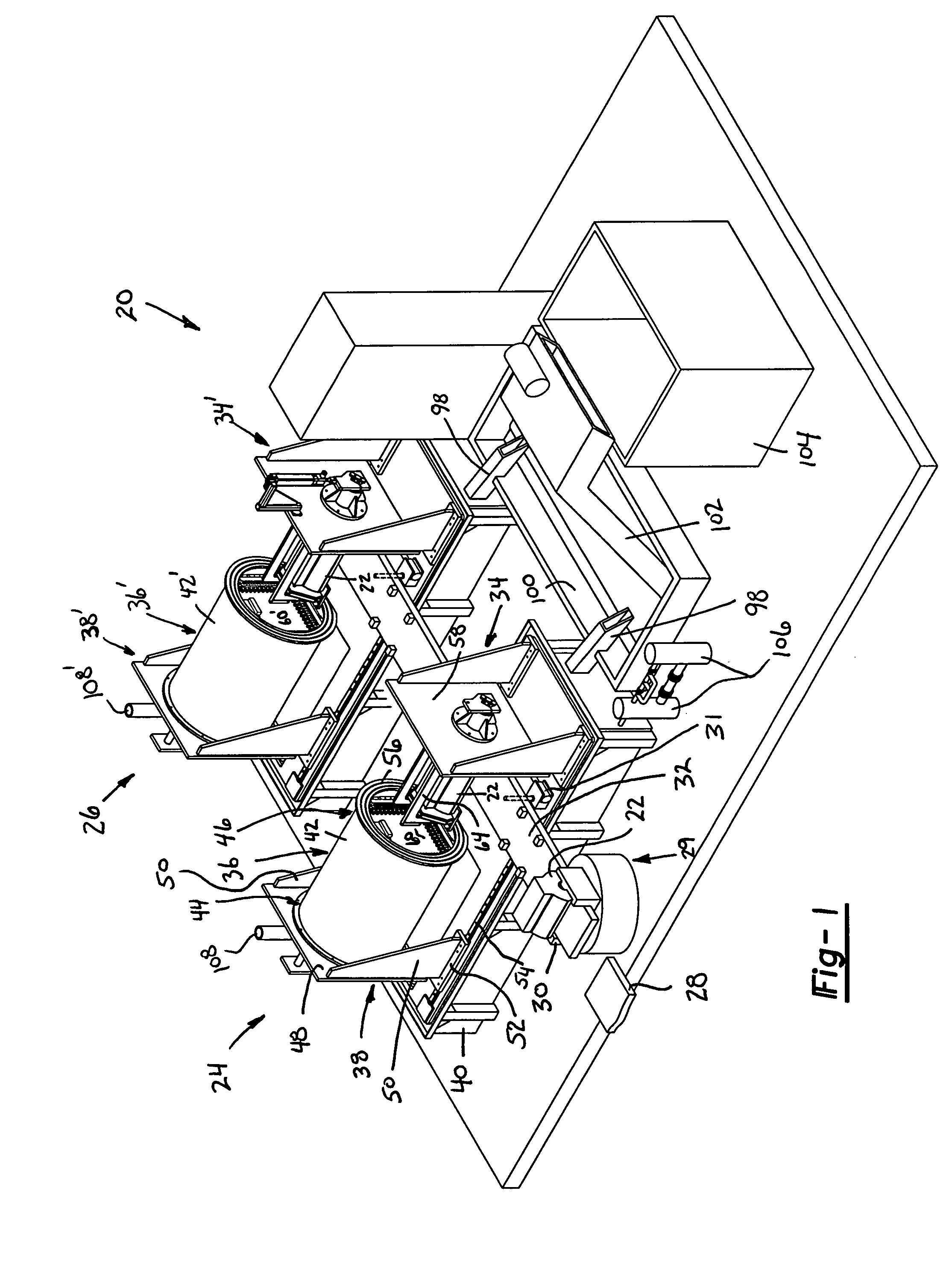

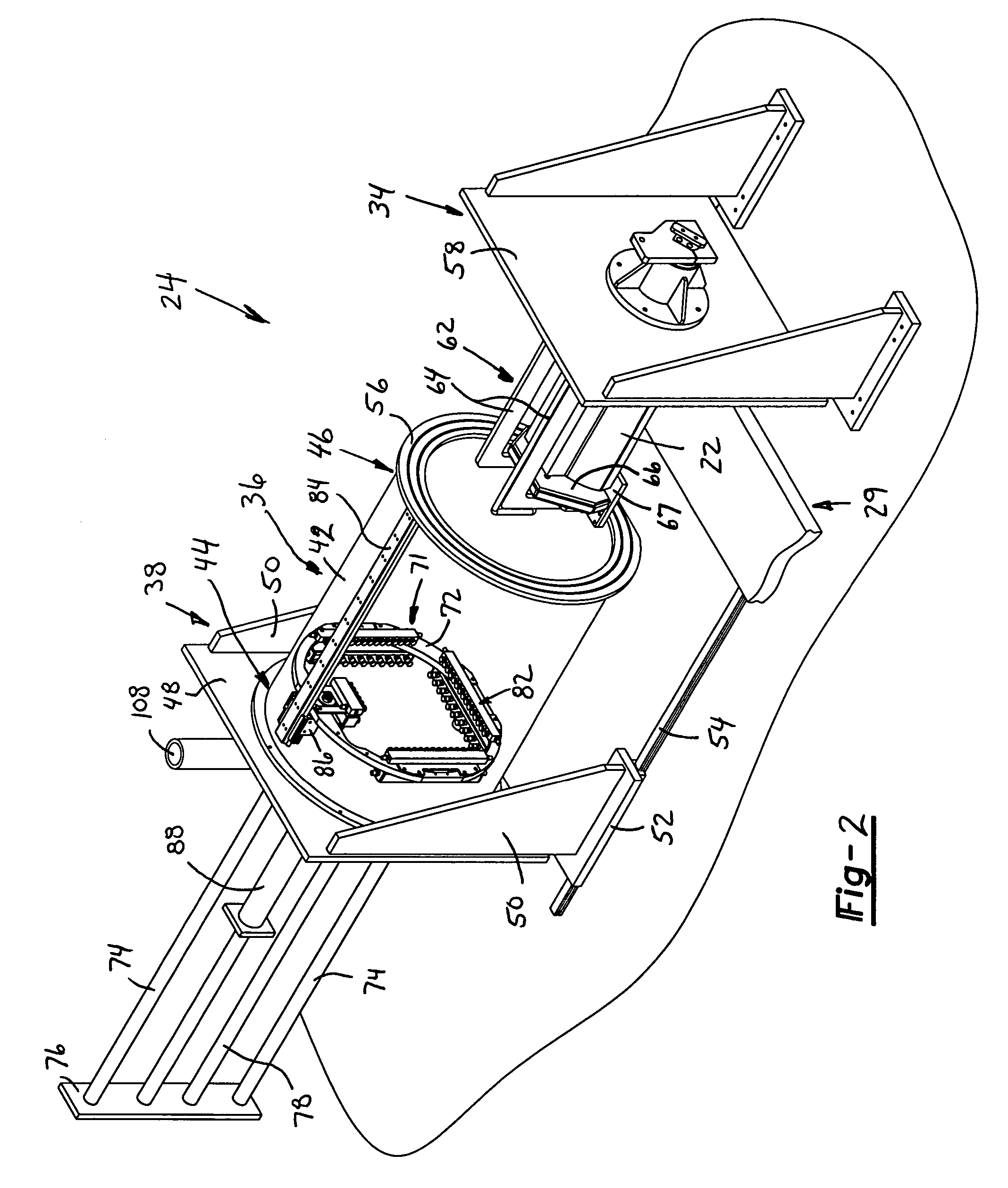

Parts Washer

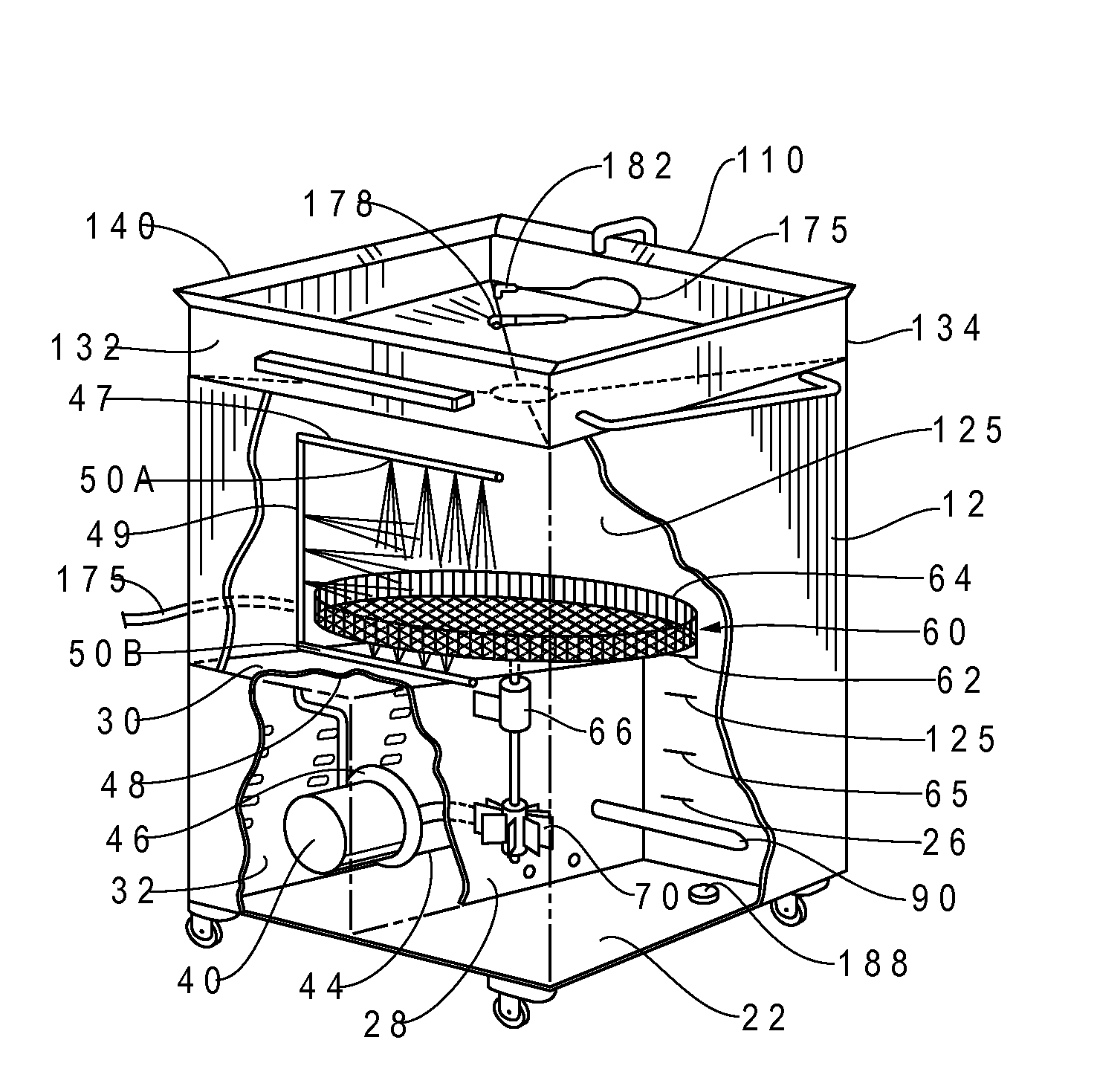

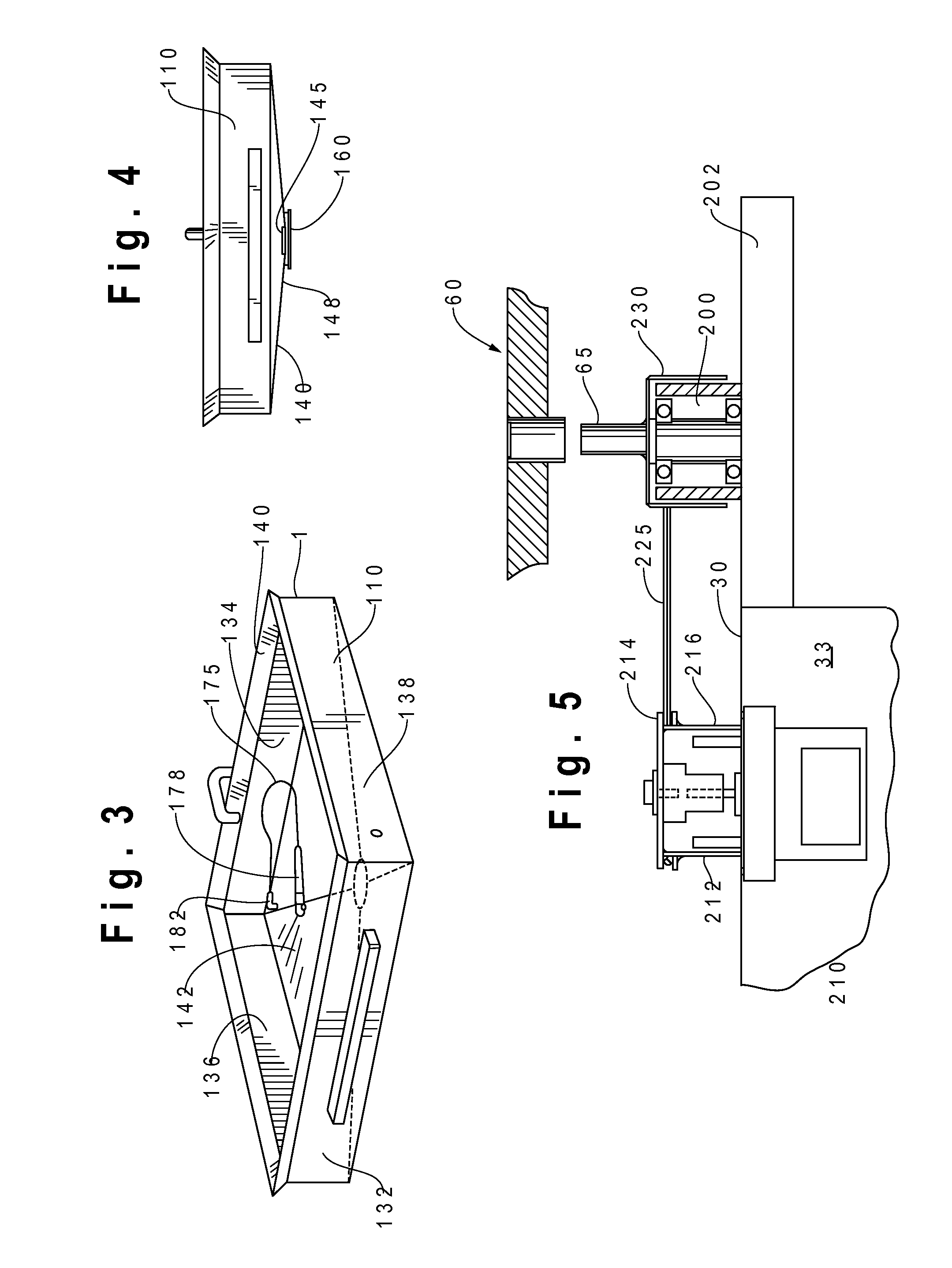

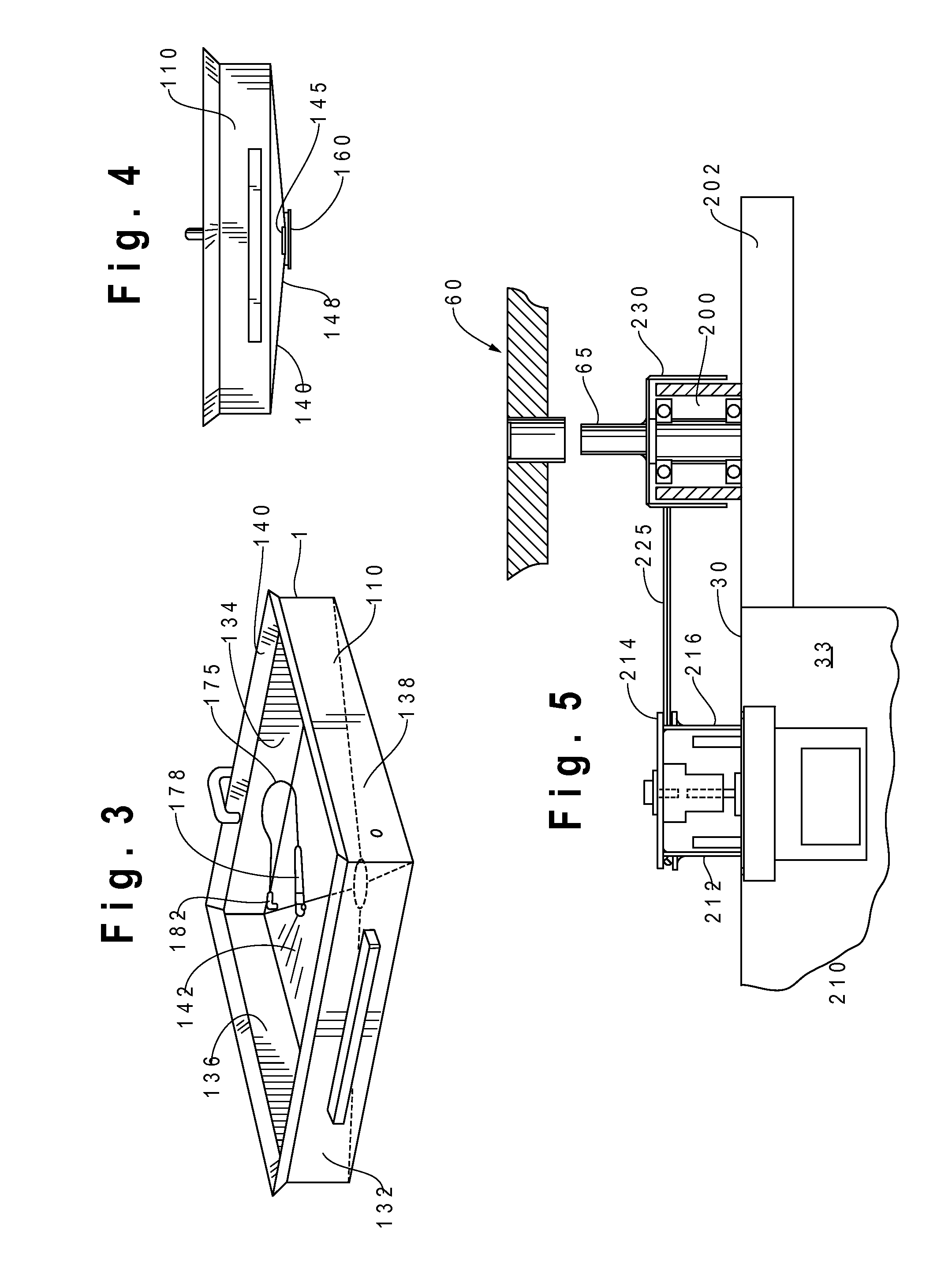

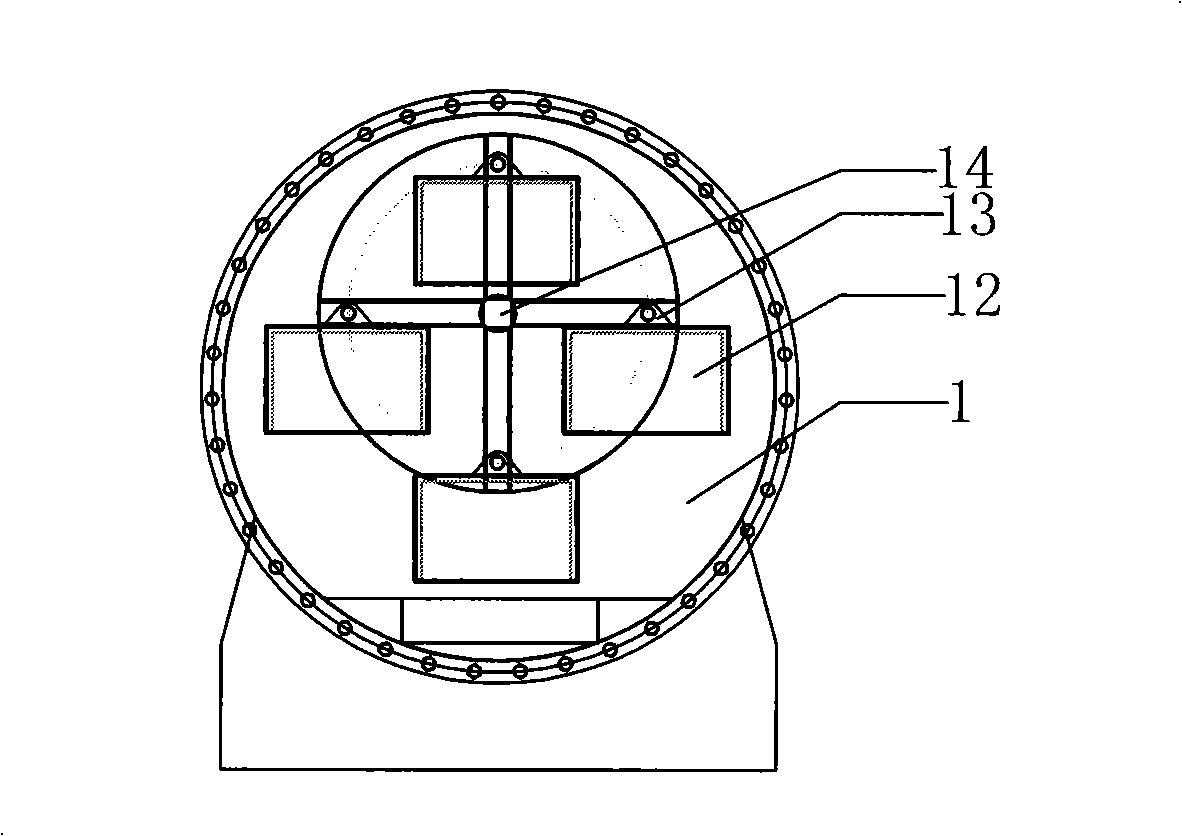

InactiveUS20060266388A1Movable spraying apparatusElectrostatic cleaningReciprocating motionSpray nozzle

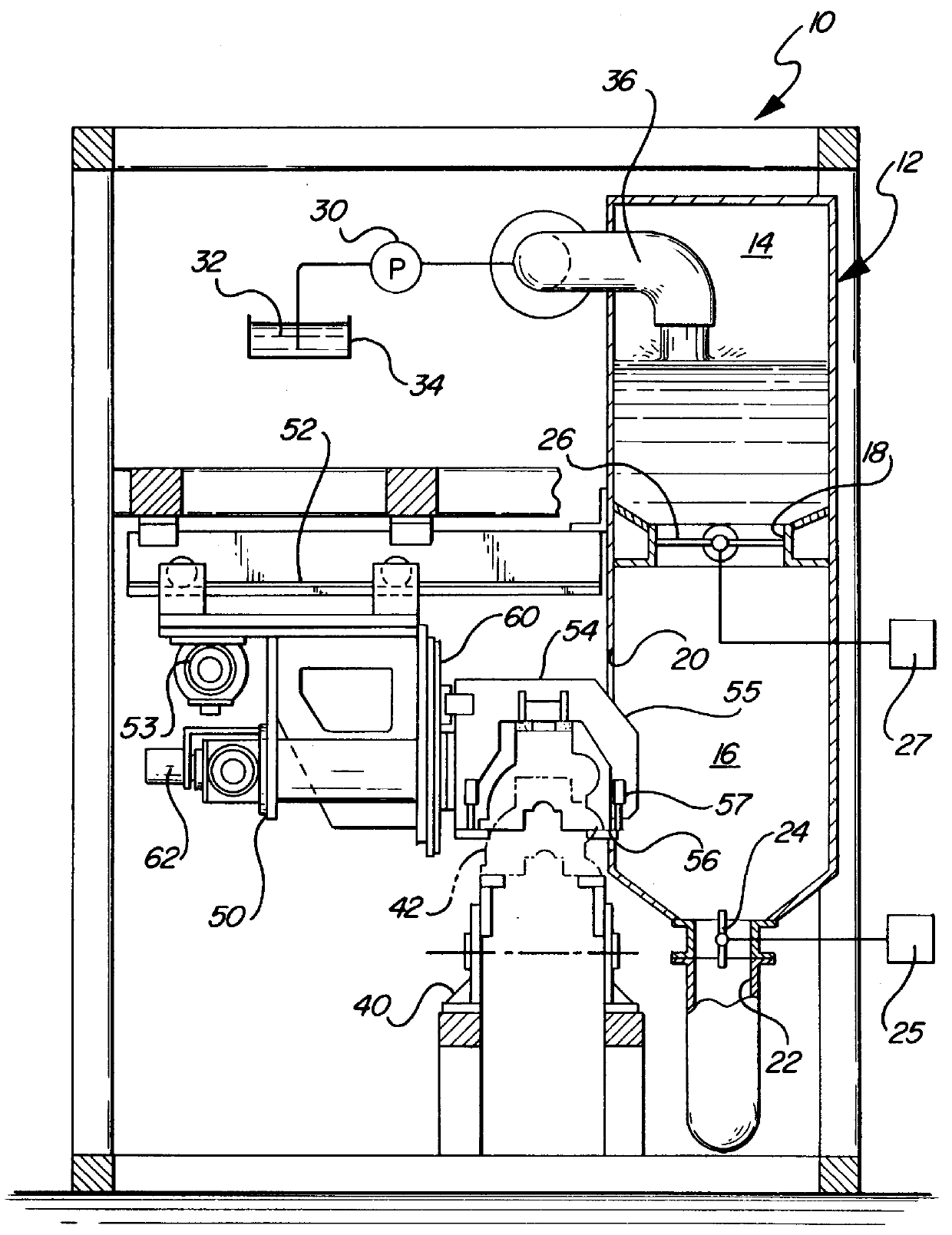

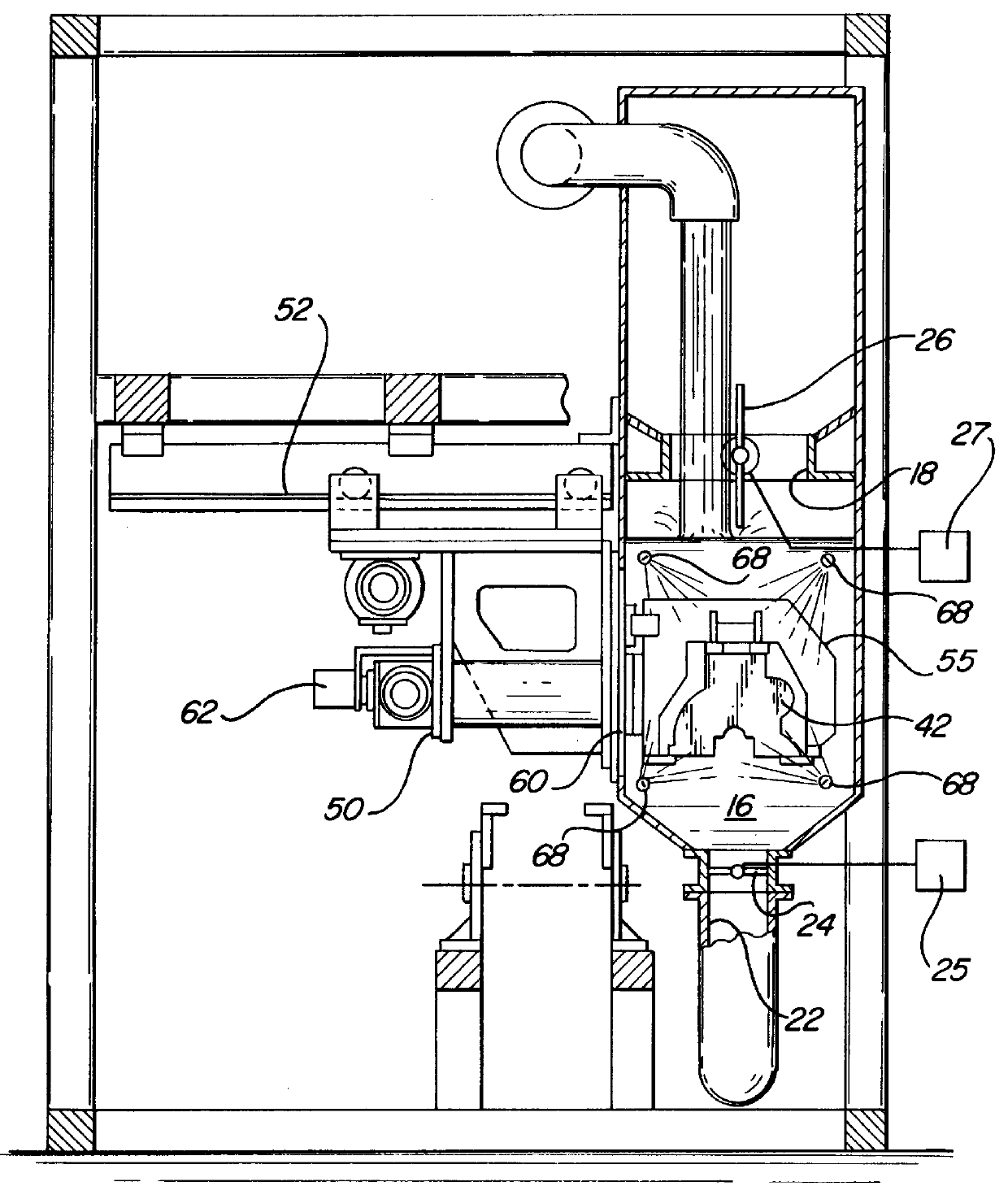

A parts washer having a cleaning chamber and a receptacle into which parts to be cleaned are placed. The receptacle is rotatably mounted within the cleaning chamber and is rotated by a drive device. One or more spray manifolds are provided, each having a plurality of spray jets arranged to spray cleaning fluid onto the parts in the receptacle. The spray manifolds are moveably mounted within the cleaning chamber and are coupled to the drive device such that the drive device causes reciprocating motion of the spray manifolds.

Owner:GODDARD EARL FENTON

Combination agitating parts washer and sink washer

ActiveUS8763619B2Easy to useReduce manufacturing costCleaning using liquidsHydraulic cylinderParts washer

A multi-function parts washer for removing contaminants from parts either by hand or automatically using an aqueous cleaning fluid includes a base cabinet having sides, a floor and an open top defining a compartment. A parts receptacle is mounted in the compartment for receiving parts to be washed. The receptacle is mounted for reciprocating, vertical movement in the compartment. An agitator assembly includes one or more compressed gas bladders mounted to the parts receptacle. The bladder has an inlet for introducing compressed gas into the bladder and an outlet for discharge of the compressed gas from the bladder. As compressed gas is introduced into the bladder, the bladder inflates and the parts receptacle is raised, and as compressed gas is discharged from the bladder, the parts receptacle is lowered to provide an agitating motion of the parts receptacle and the parts thereon in the cleaning fluid. The agitator can include a hydraulic cylinder to effect movement of the parts receptacle.

Owner:HERITAGE CRYSTAL CLEAN

Silverware/flatware or parts washer apparatus and method thereof

ActiveUS20100224220A1Effectively and thoroughly removeHollow article cleaningElectrostatic cleaningPre washingBiomedical engineering

An apparatus and a method of washing (or pre-washing) silverware / flatware, or one or more other objects / parts is provided. The apparatus and method utilizes a fluid-push / pull system and method in which generally an entire volume of fluid is pushed or pulled through a cavity in which the silverware / flatware or other objects / parts are located.

Owner:UNIFIED BRANDS

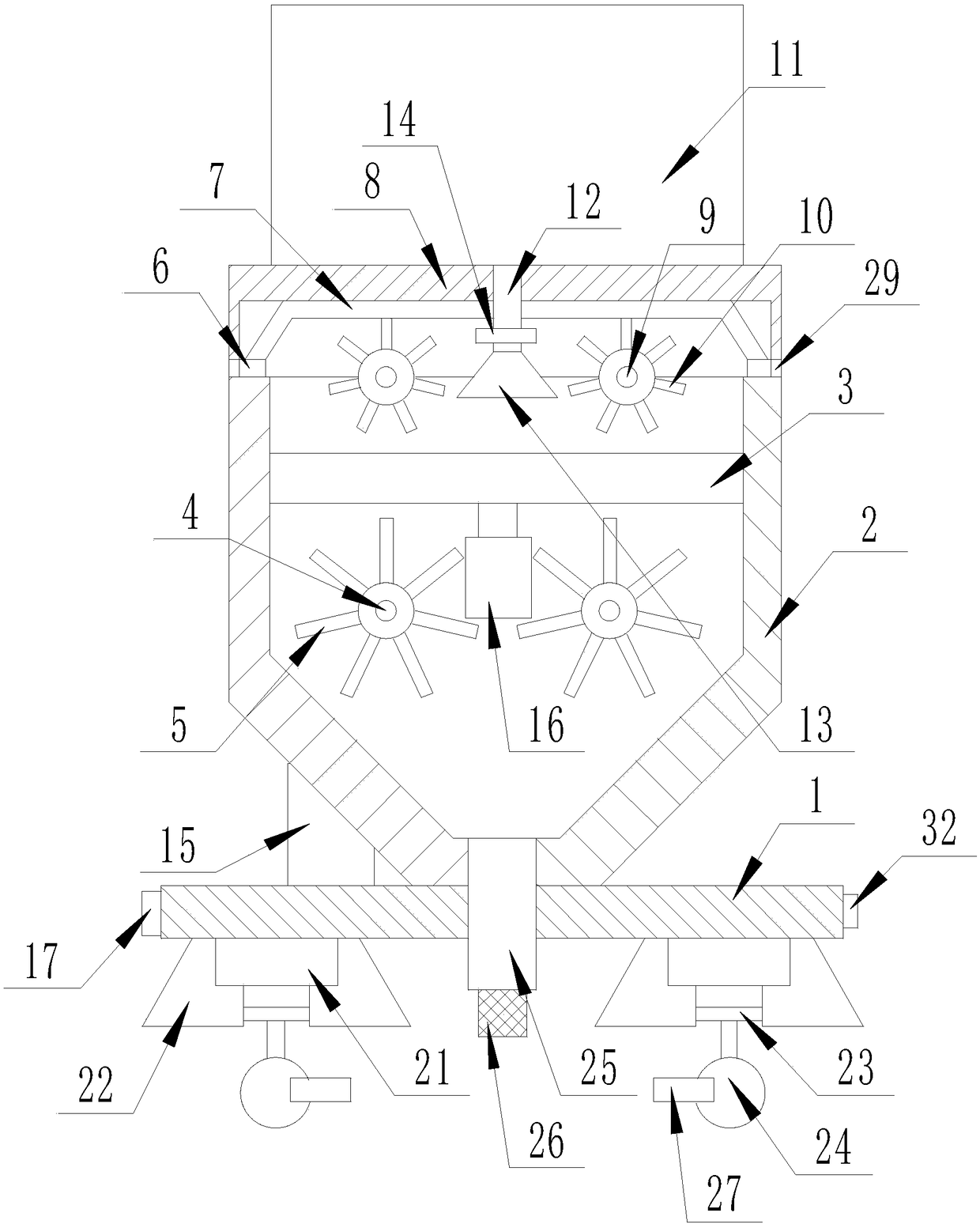

Machine part high-efficiency cleaning device

ActiveCN108906738AEasy to separate, collect and moveEasy to cleanCleaning using toolsCleaning using liquidsEngineeringParts washer

Owner:HANGZHOU YONGDE ELECTRIC APPLIANCES

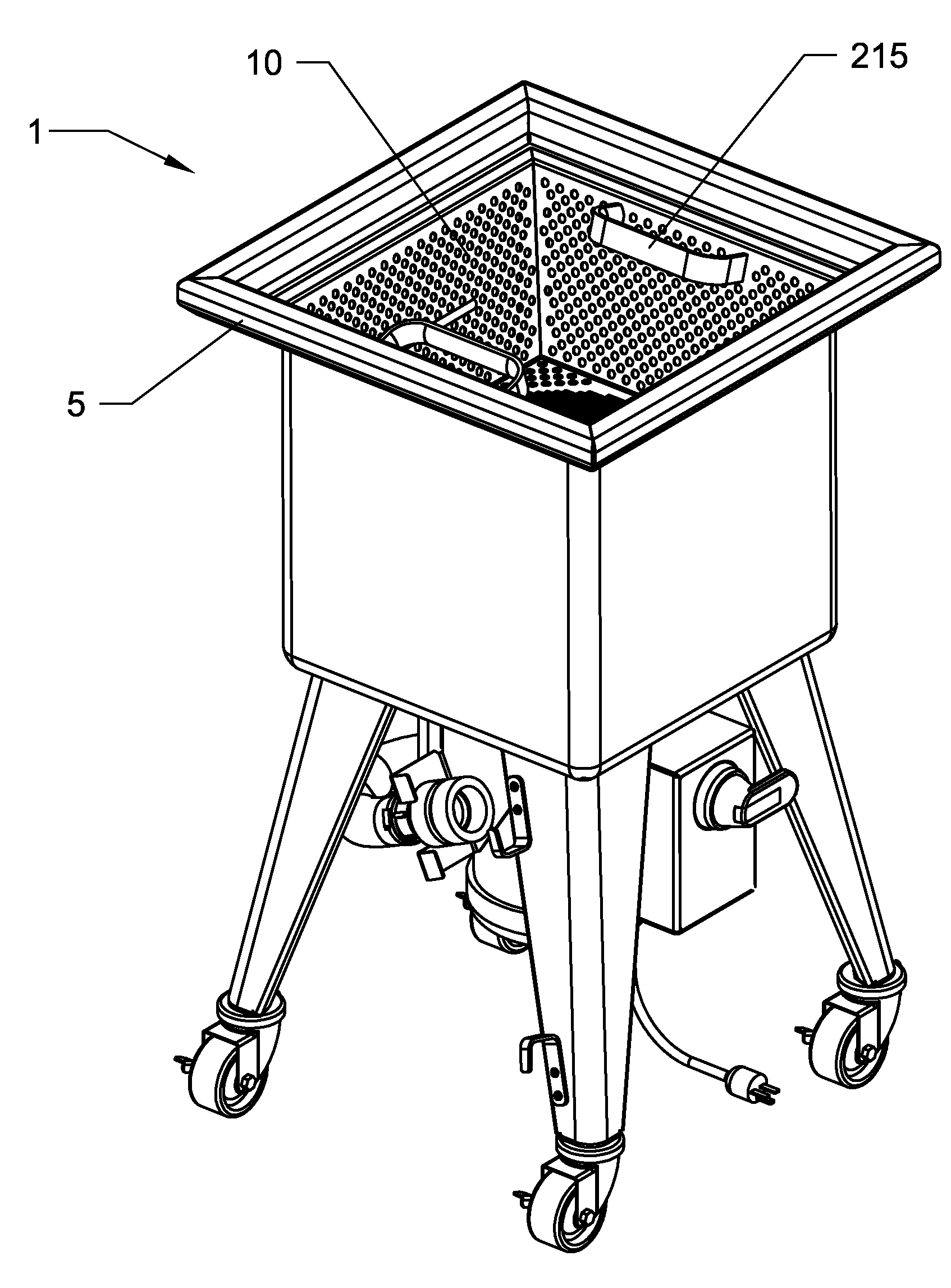

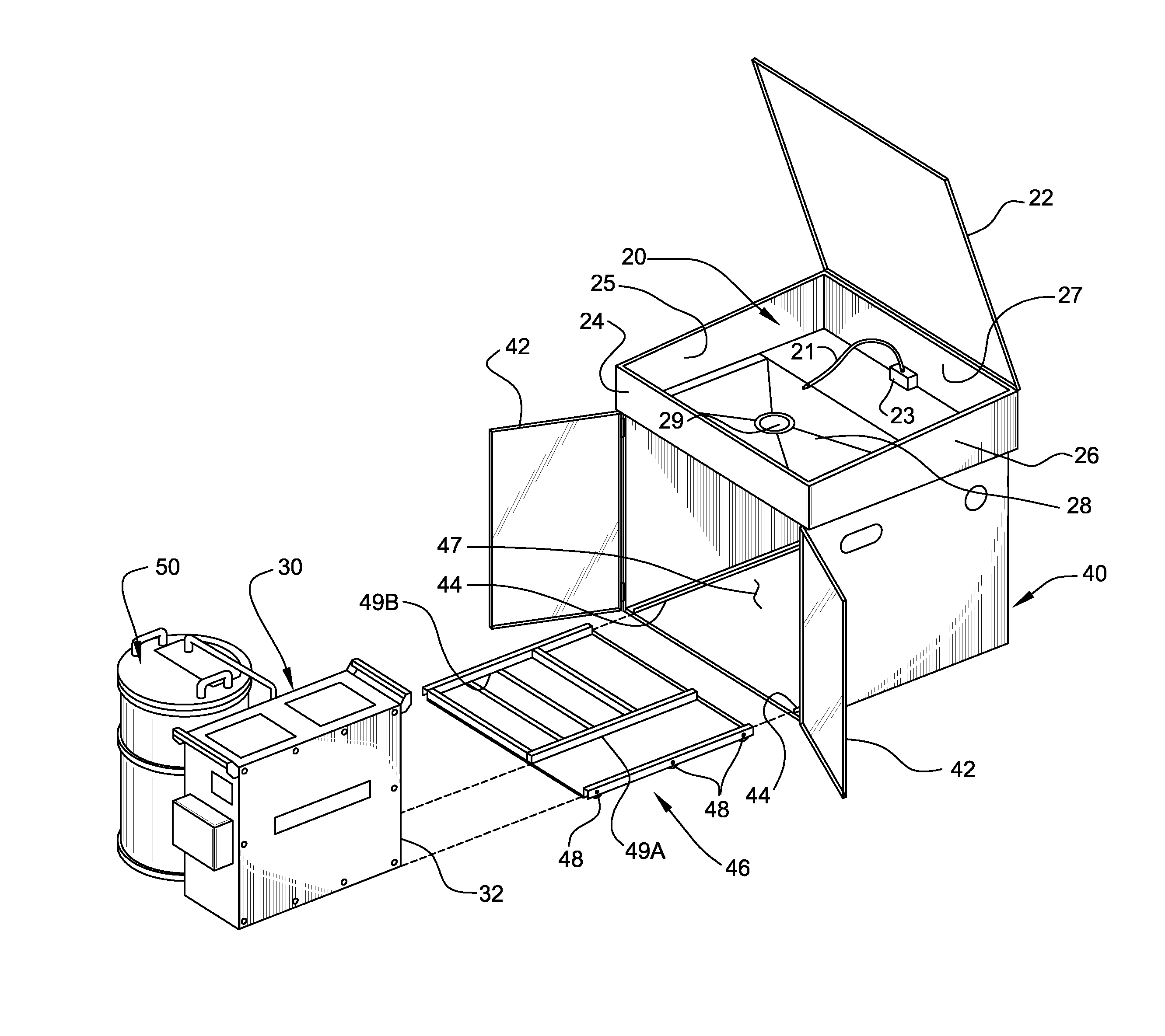

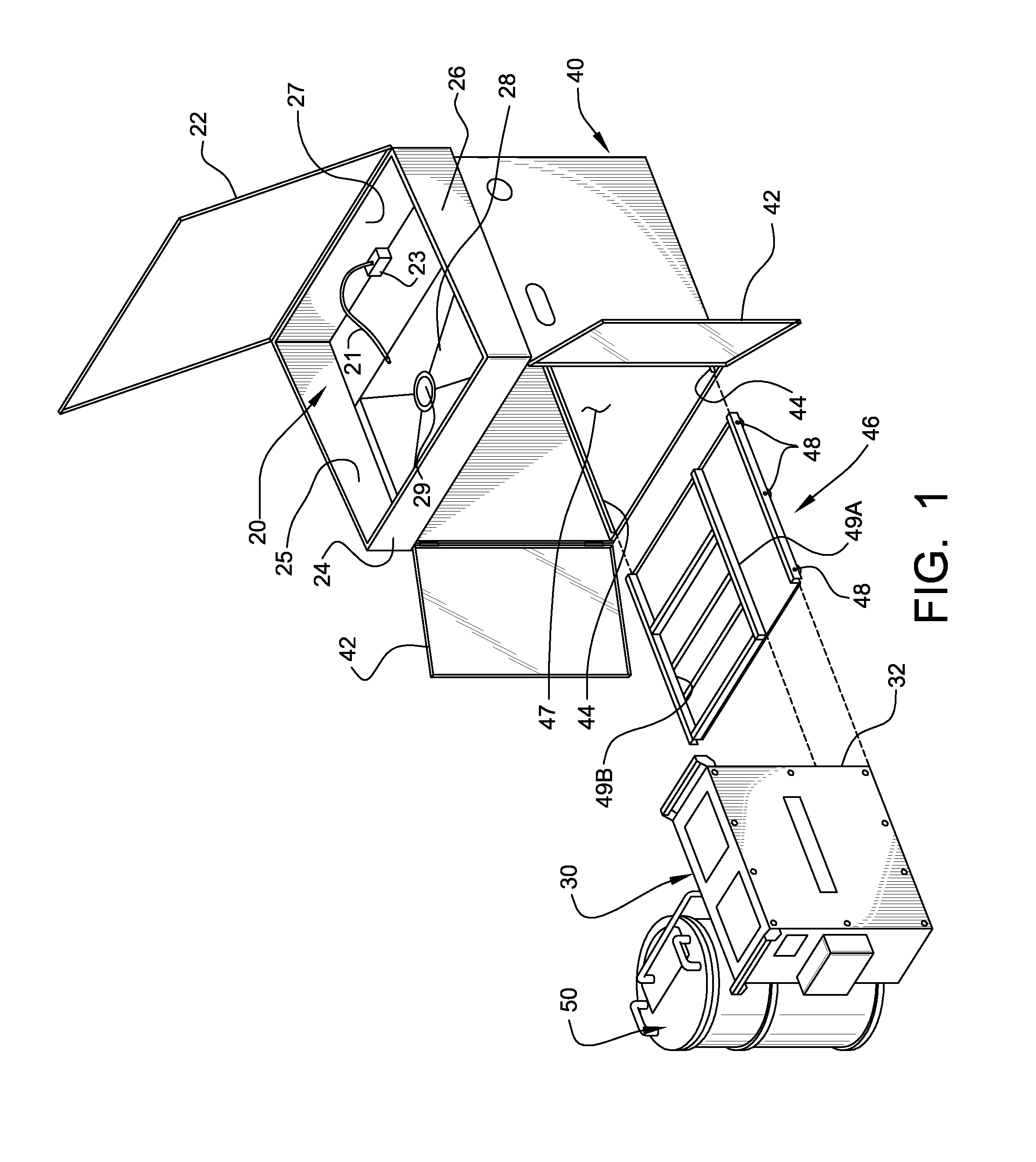

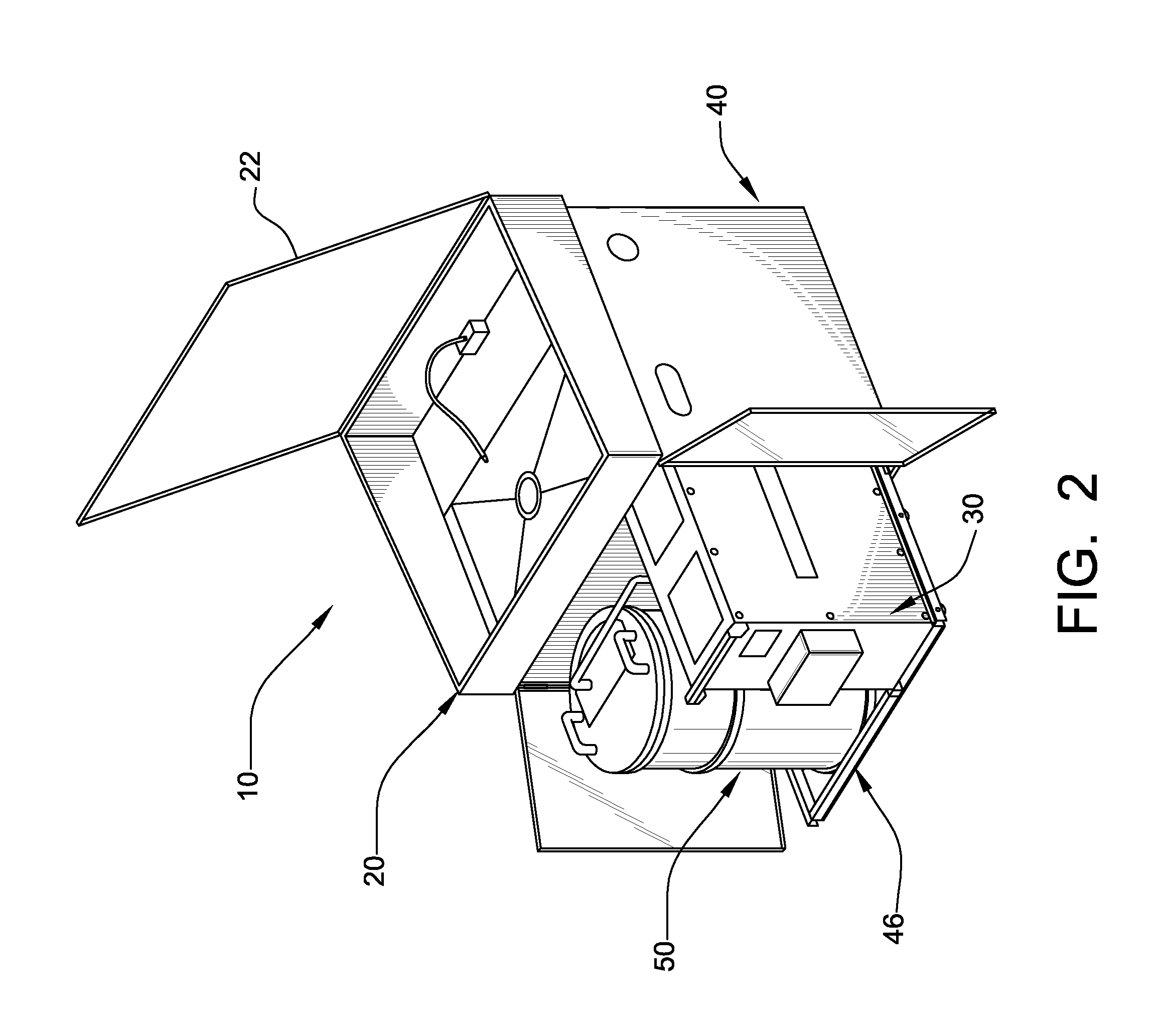

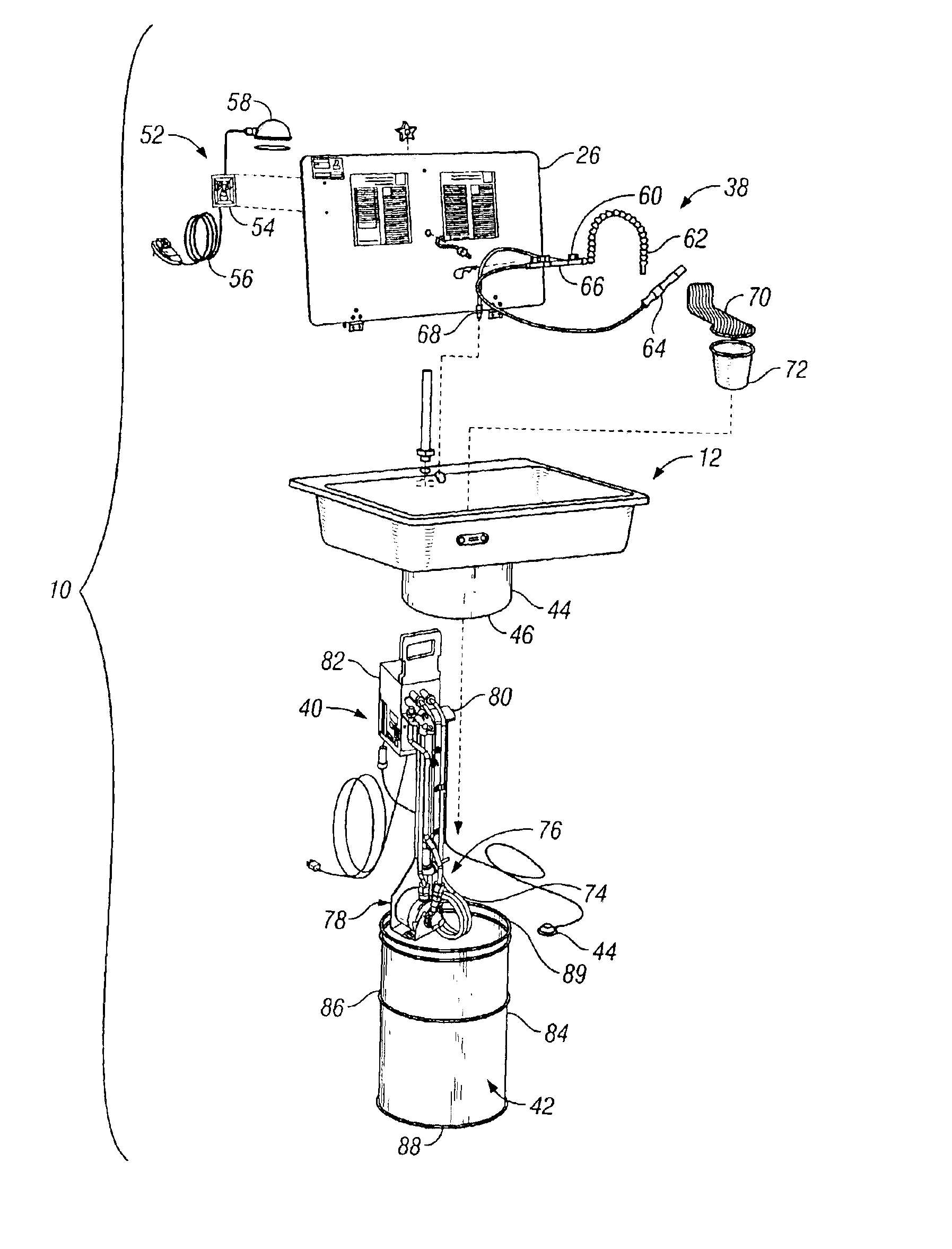

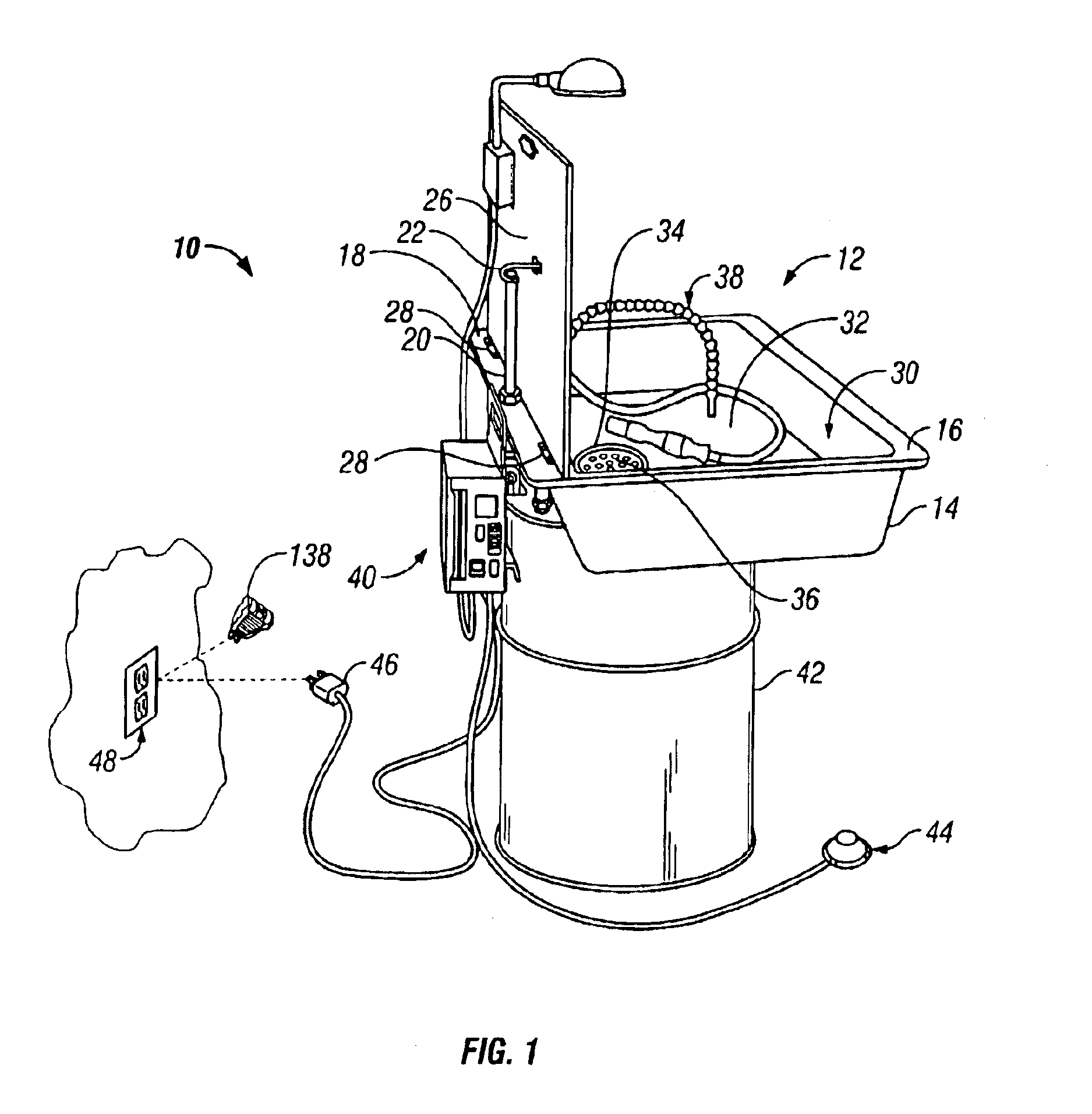

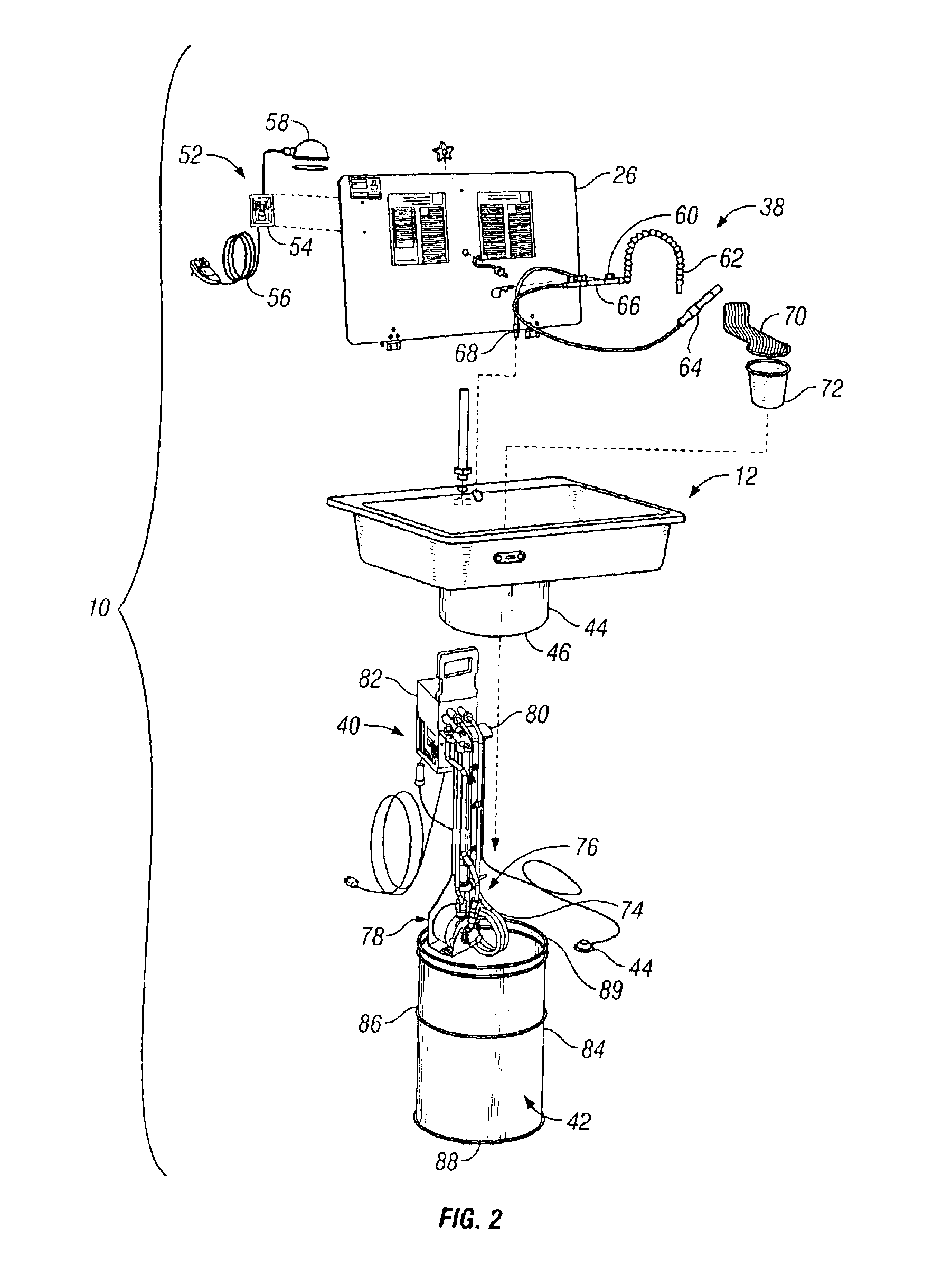

Modular recycler and heavy duty parts washer apparatus

A modular recycler and heavy duty parts washer apparatus for use with a reservoir containing a cleaning solution includes a recycler unit for recycling the cleaning solution that is contained in the reservoir, a wash basin and cabinet surrounding an internal cavity and including an inner facing surface and a track on the inner facing surface sized and configured to support a platform, and the platform being structured to move inwards and outwards from the internal cavity along the tracks of the cabinet, and the platform having a top side that is adapted for removable mounting of the reservoir and recycler unit thereon, wherein the combined assembly of the platform, reservoir and recycler unit can moved inwards and outwards of the internal cavity along the tracks of the cabinet. Each of the recycler unit, cabinet, wash basin and reservoir are individually replaceable.

Owner:SYSTONE TECH

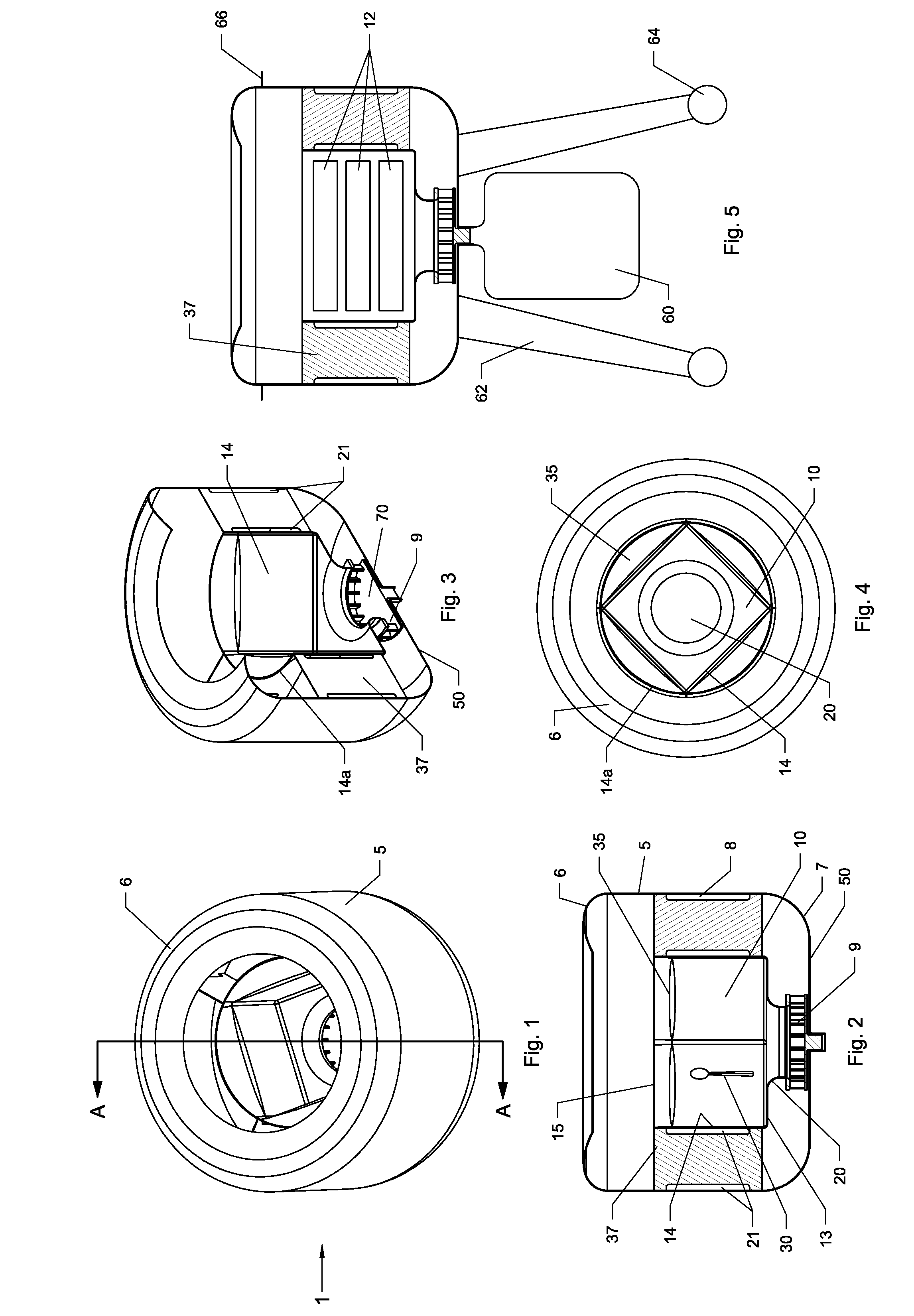

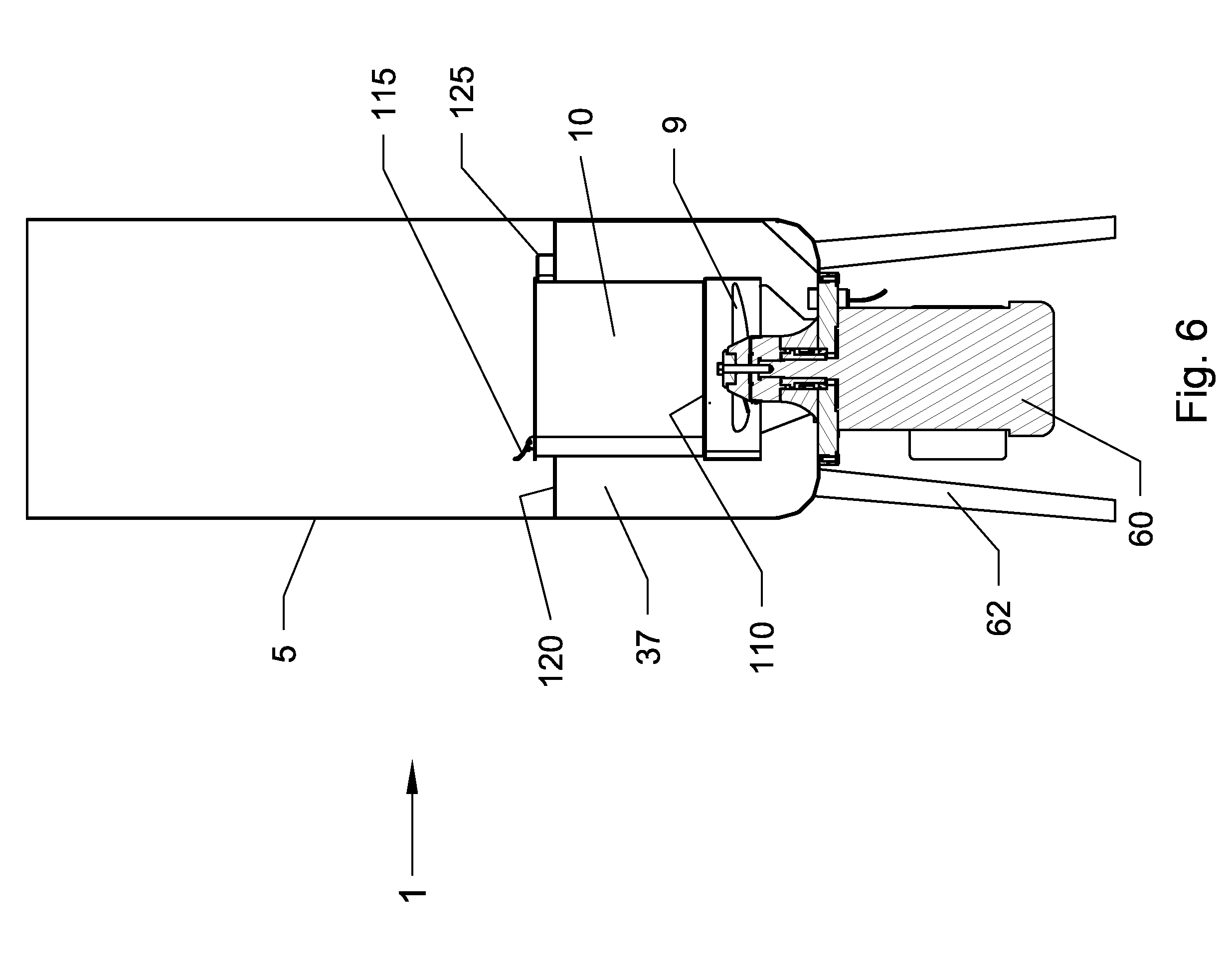

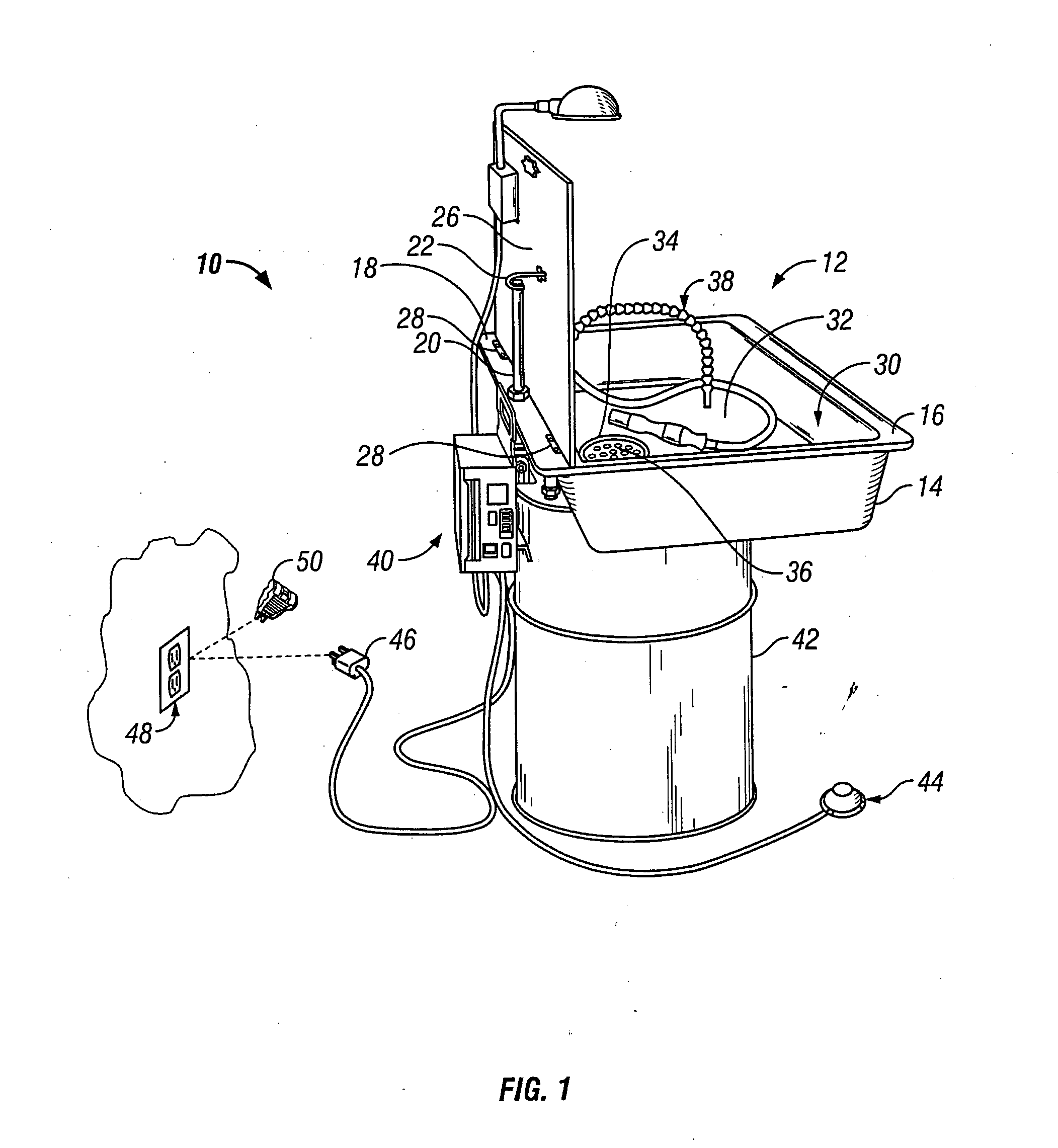

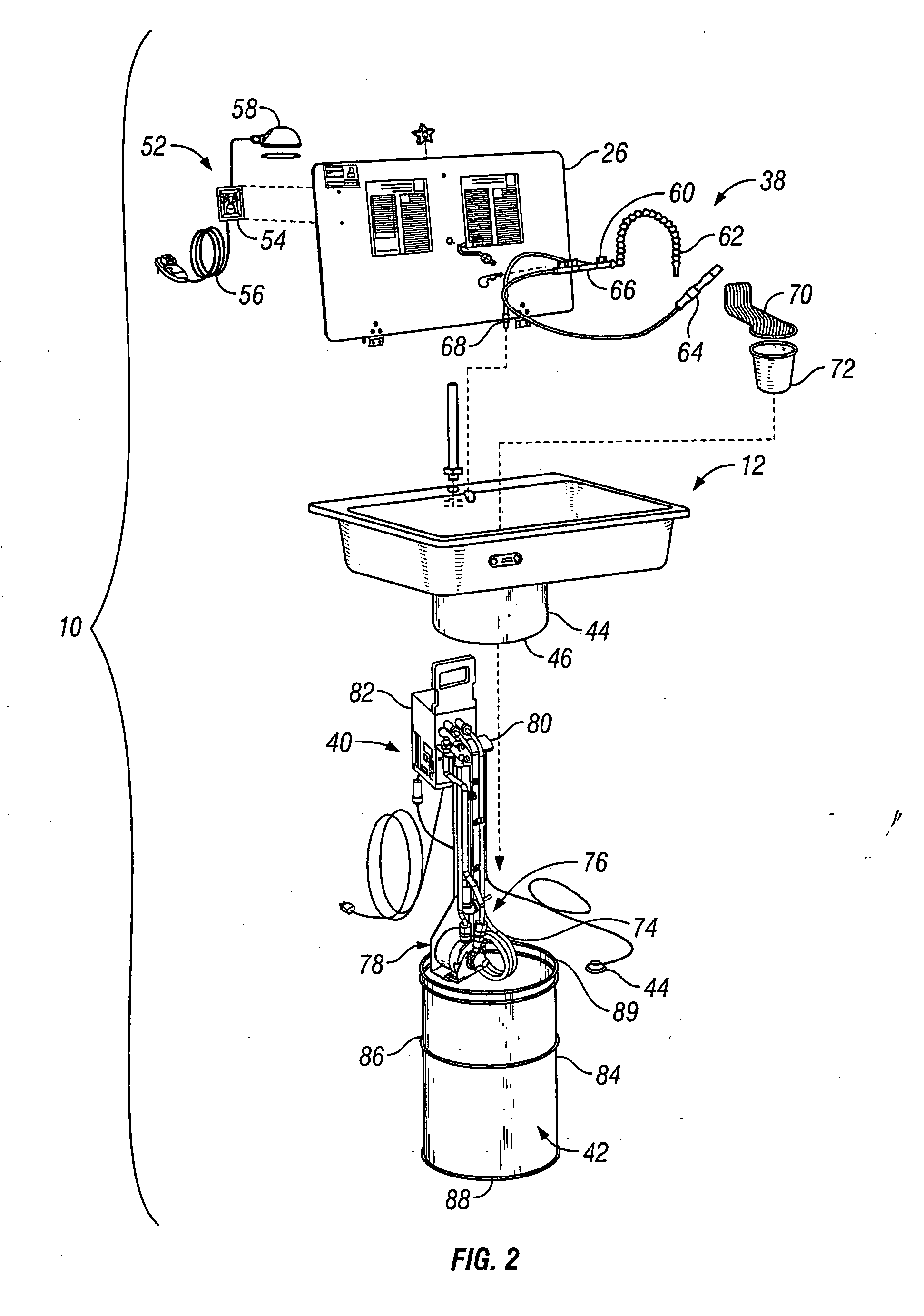

Parts washer with improved temperature and pump control

A parts washer including a receptacle positioned on a reservoir for cleaning liquid having a drain opening and a module which engages a portion of the reservoir in the cleaning liquid for adjusting the temperature of the cleaning liquid and circulating the cleaning liquid into the receptacle. The module includes a heating element, a sensor and pump. An enclosure houses a temperature controller which displays the temperature of the cleaning liquid and a low liquid level condition. A bridge thermally links the heating element to the sensor so that the sensor normally generates a signal representative of the temperature of the cleaning fluid unless the level of the cleaning fluid is disposed below the sensor.

Owner:SAFETY KLEEN SYST INC

Intelligent controllable car washer

ActiveCN109760646AIncrease the cleaning areaImprove car wash efficiencyCleaning apparatus for vehicle exteriorsCircular discImpeller

The invention belongs to the field of car washer equipment, and particularly relates to an intelligent controllable car washer. The intelligent controllable car washer comprises an annular moving guide rail; a moving arm is arranged in the annular moving guide rail, and a cantilever arm is arranged on the moving arm; the cantilever arm comprises a first cantilever and a second cantilever, and thefirst cantilever and the second cantilever are connected through a left-right swinging module; an up-down swinging unit is arranged at an end of the second cantilever; an intelligent controller is arranged on the annular moving guide rail; the up-down swinging unit can drive a disc spray head to carry out up-down cleaning operation on a car, meanwhile, when a hollow worm rotates, an impeller can be driven to rotate in the disc spray head, so that water in the hollow worm is thrown into the disc spray head through the centrifugal force of the impeller, the water in the disc spray head generatespressure and then is sprayed out from the inside of water spraying holes, mist water is produced by the sprayed water due to the fact that the inside of the disc spray head continuously applies pressure, the cleaning area of the car washer is increased, and the car washing efficiency of the car washer is improved.

Owner:苏州南师大科技园投资管理有限公司 +1

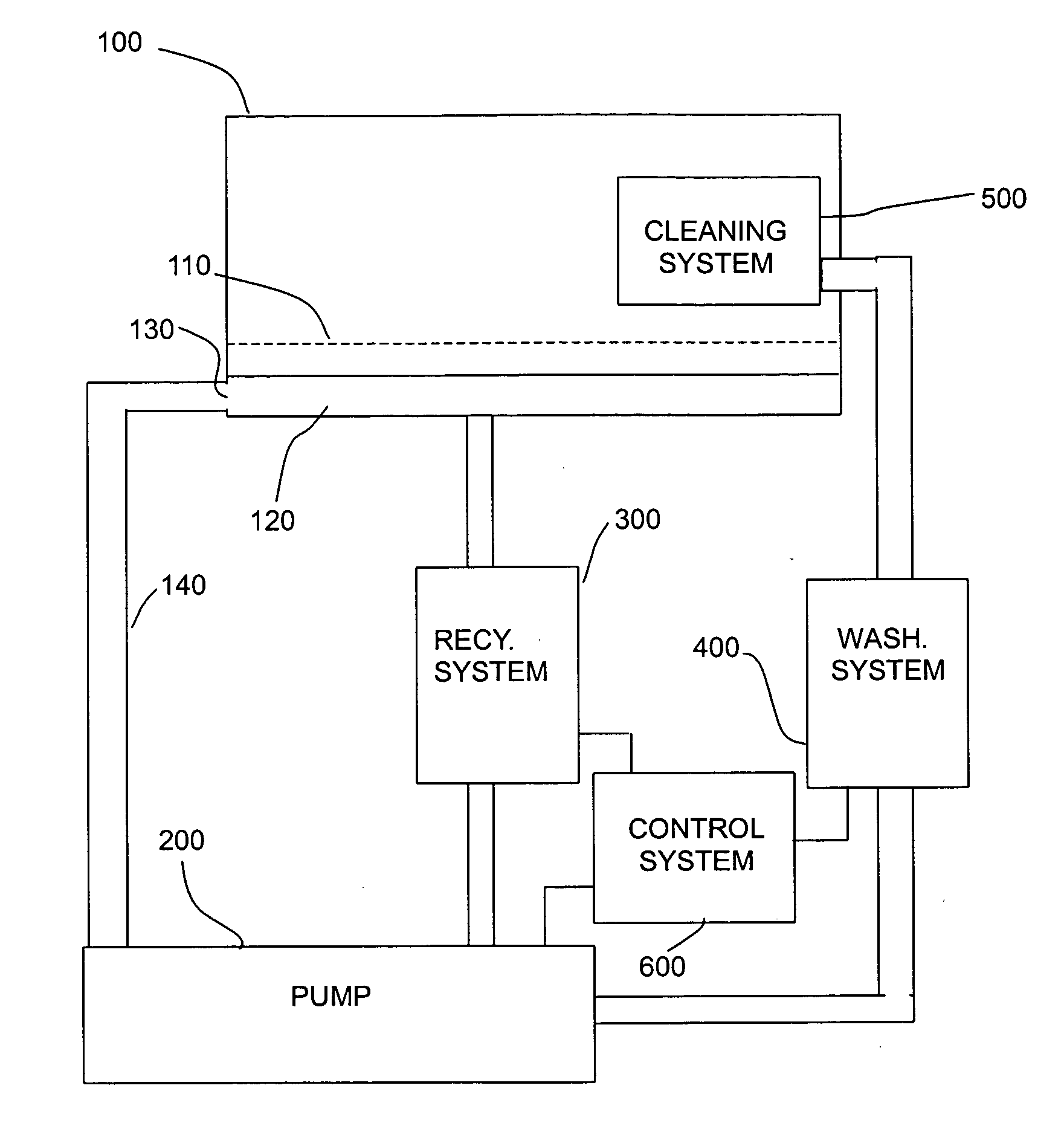

Parts washer with solvent recycler

InactiveUS20080087308A1Easy to usePrecision releaseChemical paints/ink removersOther artistic work equipmentsControl systemEngineering

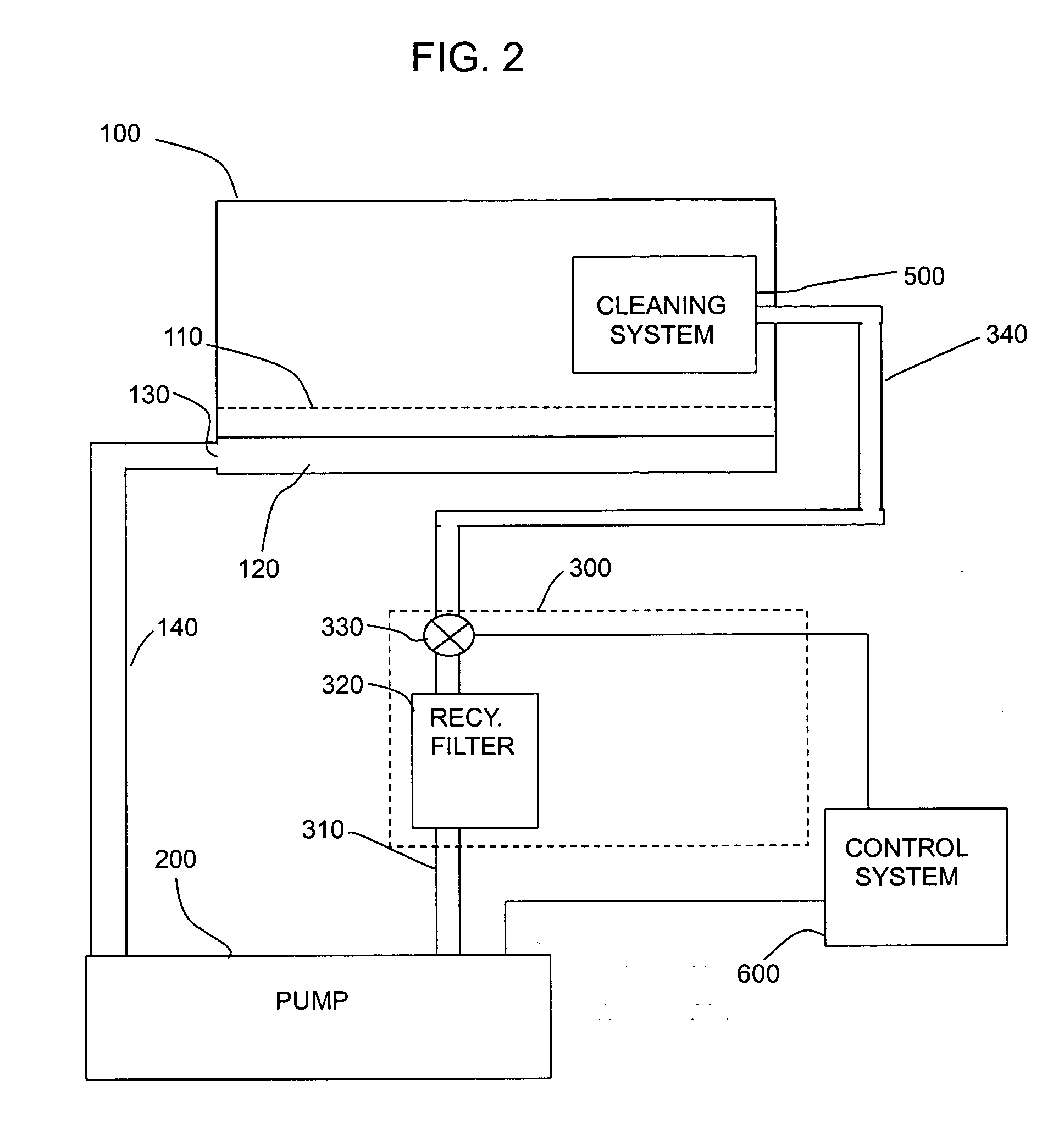

A washing and recycling system for use with removing paint from a coated article. The system includes a basin, a reservoir connected to the basin and which holds a solvent which removes the paint from the coated article, a washing system connected to the reservoir and to the basin such that the solvent from the reservoir is moved past a first filter, and the filtered solvent is moved into the basin so as to remove the paint from the coated article. The system includes a recycling system connected to the reservoir and to the basin such that the solvent from the reservoir is moved past a second filter to remove portions of the paint in the solvent. A control system controls the washing system and the recycling system to supply filtered solvent from the reservoir to the basin during a washing operation and a recycling operation.

Owner:SCUDERI MARK EHLMAN +1

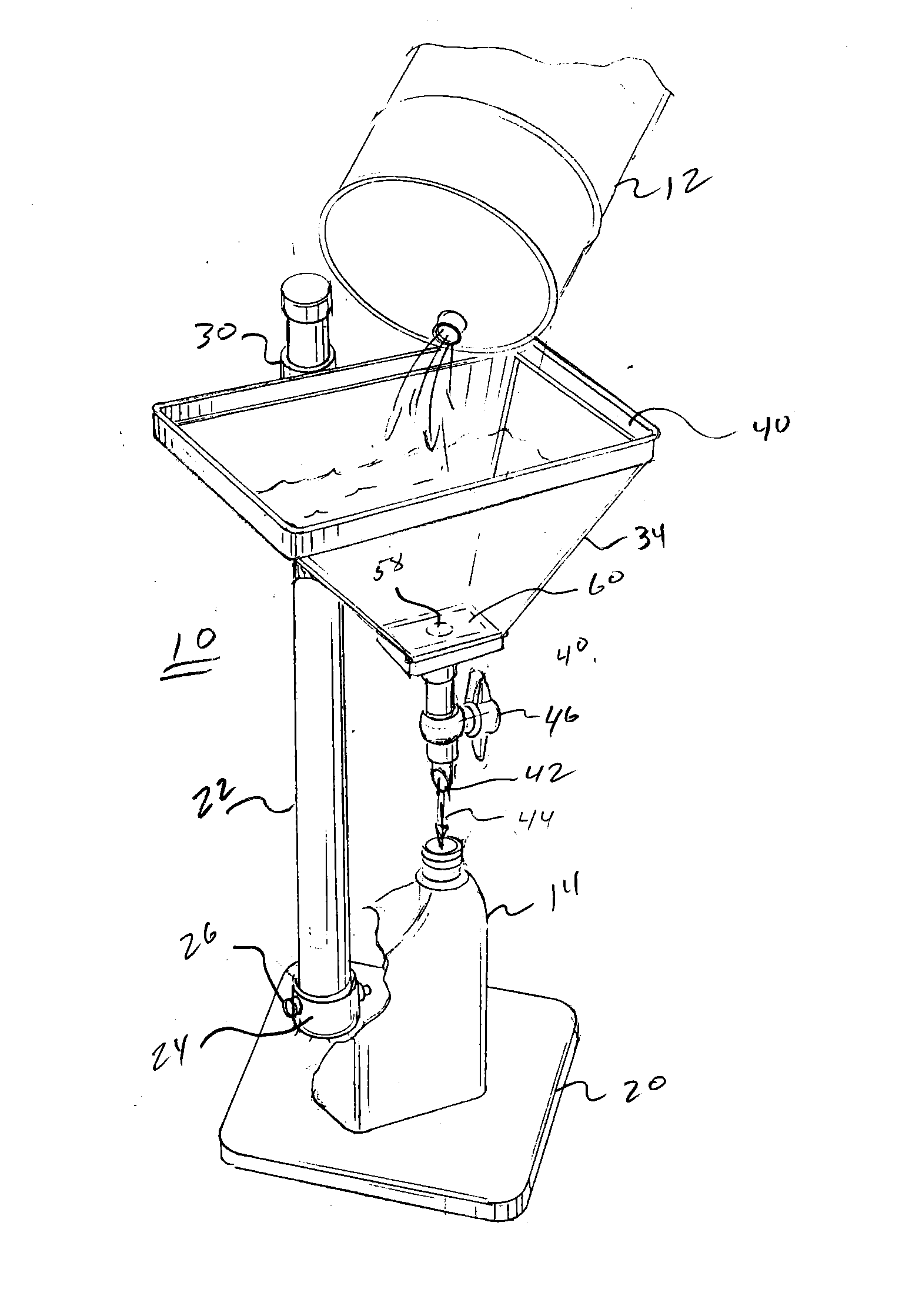

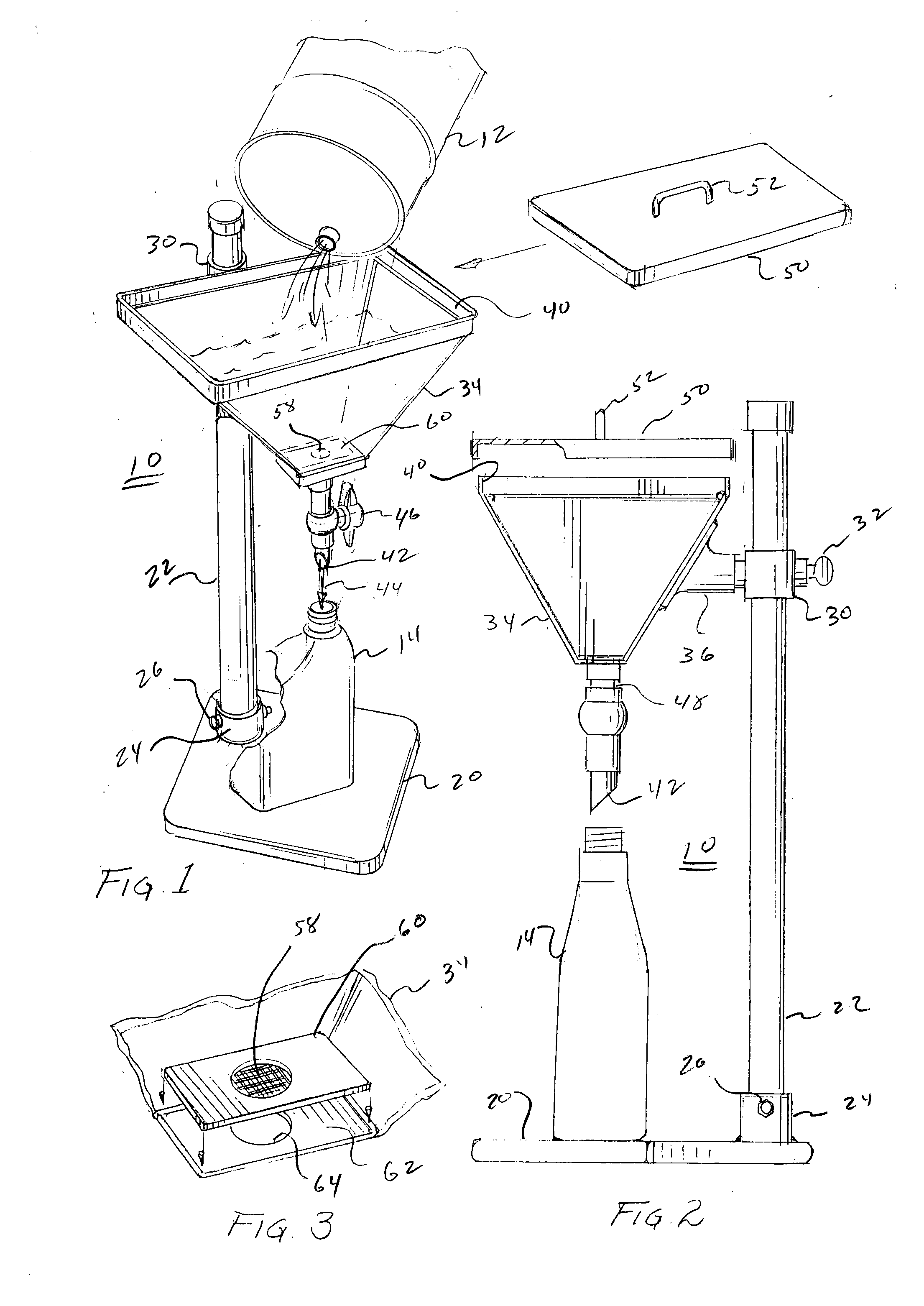

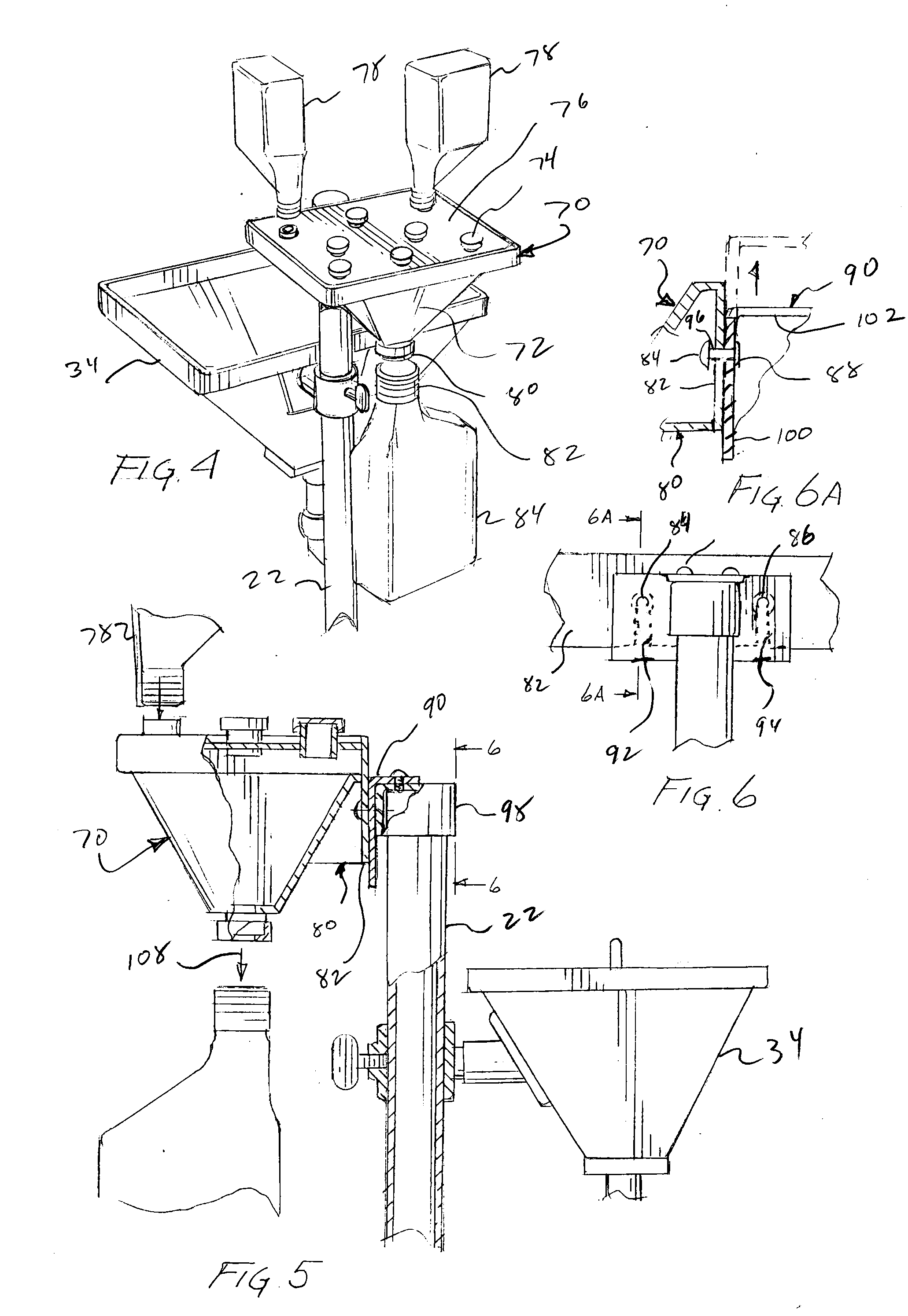

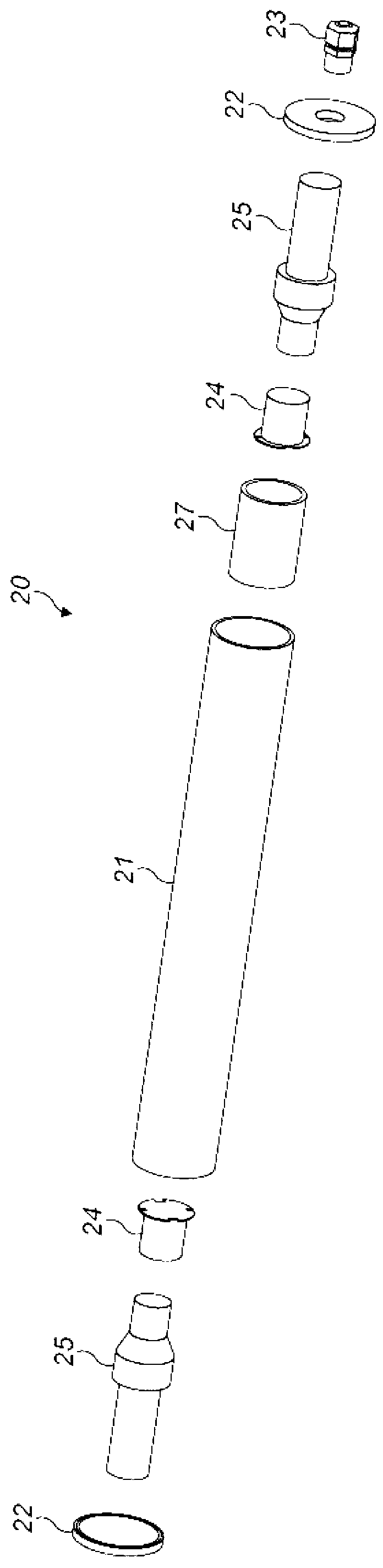

Dismantleable apparatus for transferring fluids between containers

InactiveUS20100084042A1Little probability of spillageEasy dischargeLiquid fillingSolid materialParts washer

Owner:BONNELL DONALD G

Part washer

InactiveUS7905239B2Easy to operateShorten the timeFlow mixersTransportation and packagingEngineeringHigh pressure

Owner:KIM SUNG IL

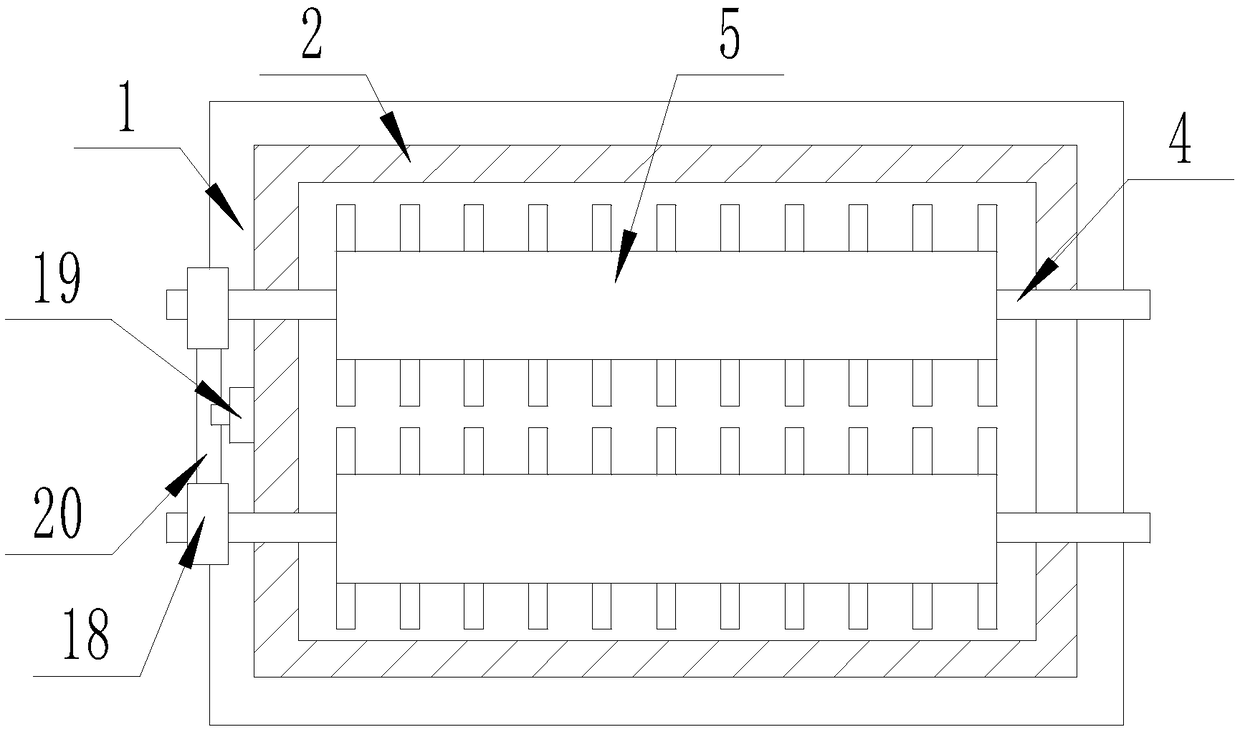

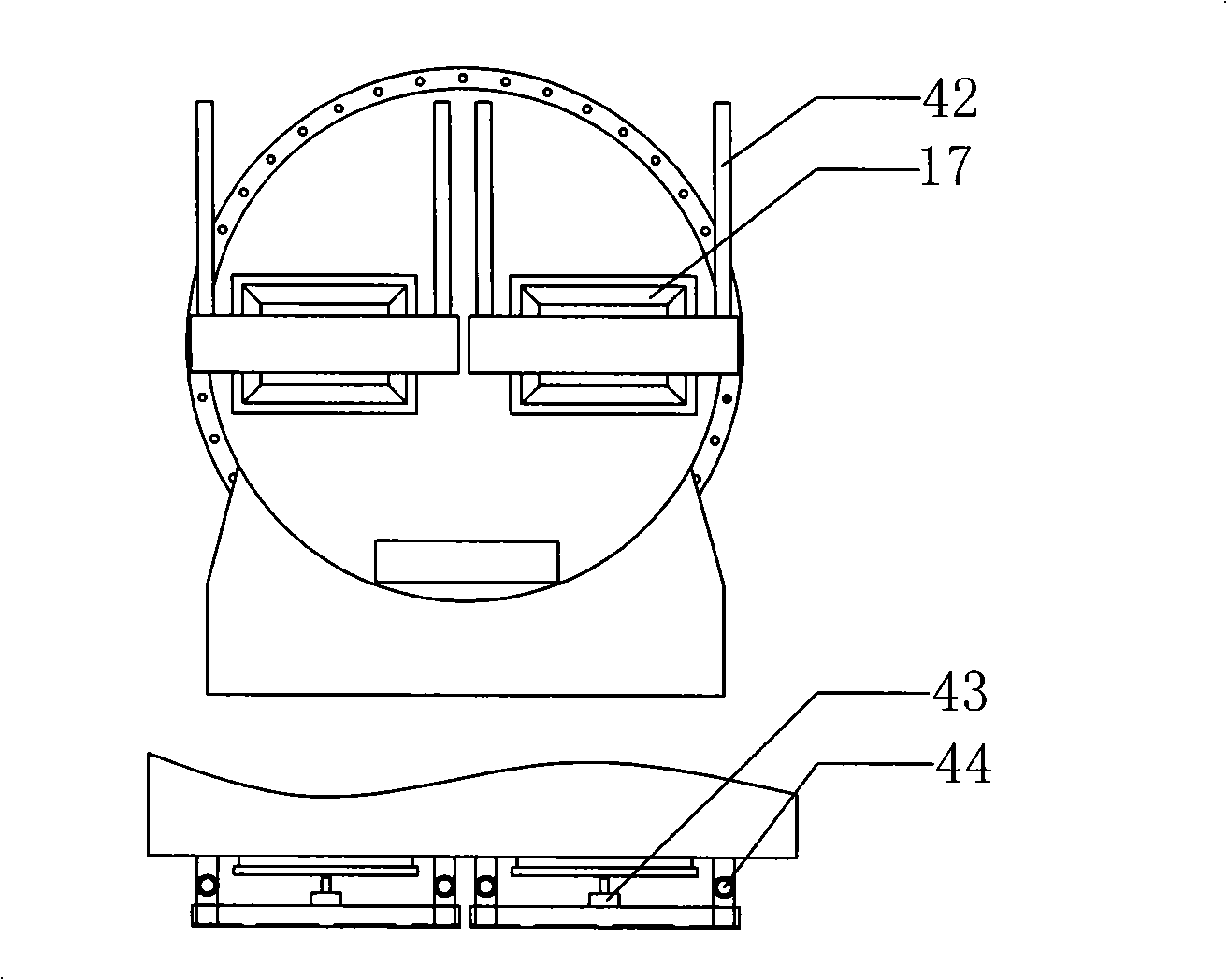

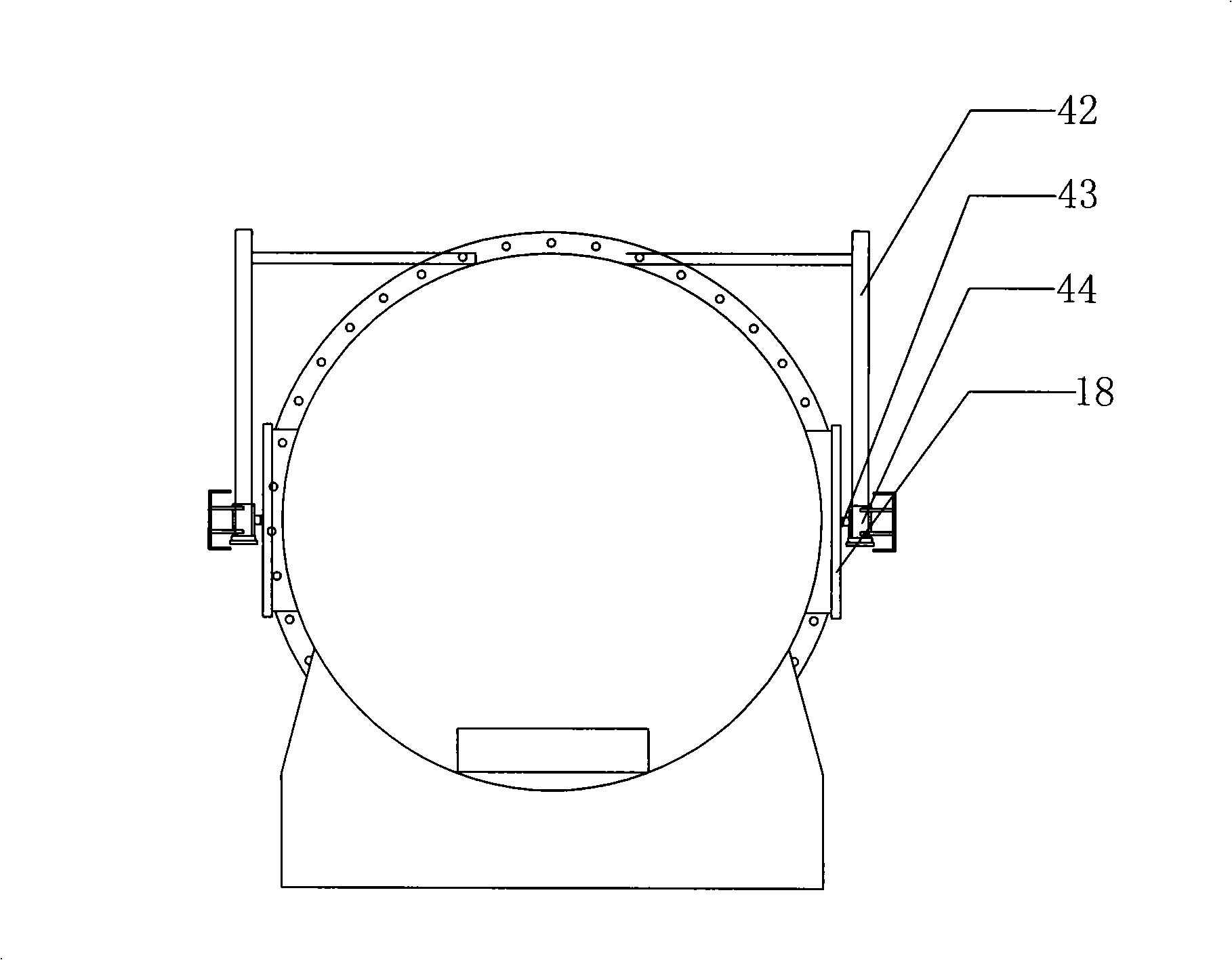

Cleaning structure of industry parts washer

InactiveCN101337226ARealize cycle cleaning operationImprove cleaning efficiencyCleaning using liquidsHanging basketEngineering

The invention relates to a cleaning bin structure for an industrial component cleaning machine. The cleaning bin is cylindrical; a hanging basket charged with a plurality of components is mounted in the cleaning bin, and suspended on a hanging basket support; the hanging basket support is provided with an eccentric main shaft relative to the cylindrical cleaning bin; the main shaft is driven by a main transmission system provided with a speed reducer to rotate; the hanging basket support can rotate clockwise or anticlockwise; two bin gates are formed in the following two ways: firstly, the two bin gates are horizontally formed on the cylindrical end surface of the cleaning bin; secondly; the two bin gates are horizontally formed on the cylindrical side surface of the cleaning bin. The cleaning bin structure has the advantages that the two bin gates of the cleaning bin can be used for assembling and disassembling the components simultaneously, thereby realizing cycle-cleaning operation, and enhancing the cleaning efficiency.

Owner:田飞

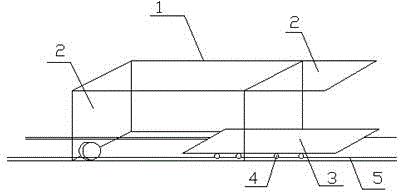

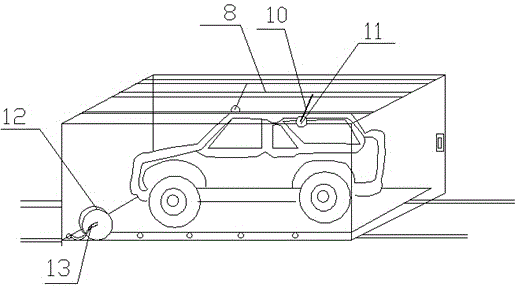

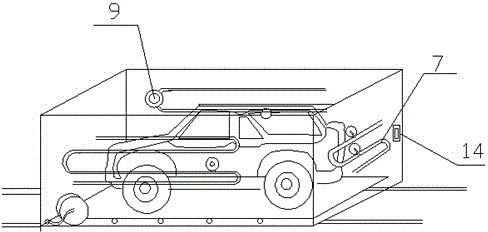

Automatic car washer

ActiveCN105459971AEasy to carryMove quicklyCleaning apparatus for vehicle exteriorsReciprocating motionSlide plate

The invention discloses an automatic car washer which comprises a car washer composed of a three-dimensional steel frame; automatic doors are arranged at the front and rear sides; an iron slide plate is arranged at the bottom of the three-dimensional steel frame; high-pressure spray pipes for spraying water and detergent are installed on the inner top face, left and right side faces and front and rear side faces of the car washer; high-pressure nozzles are installed on the high-pressure spray pipes; each of the front and rear side faces of the car washer is provided with a set of S-shaped chute; the automatic door at the inlet side of the car washer is provided with a set of S-shaped chute for washing and wiping the tail of a car; the top face of the car washer is provided with 4 straight chutes; and each of the S-shaped chutes and the straight chutes is internally provided with 1-2 washing and wiping devices capable of reciprocating in the chutes. By adopting the automatic car washer disclosed by the invention to replace the traditional manual car washing way, the working efficiency can be greatly improved; the sewage can be treated so as to realize secondary utilization, so that the energy is saved and the environment is protected; the space is saved; the cost is lowered; and the automatic car washer is convenient to carry.

Owner:东莞市良晟服饰有限公司

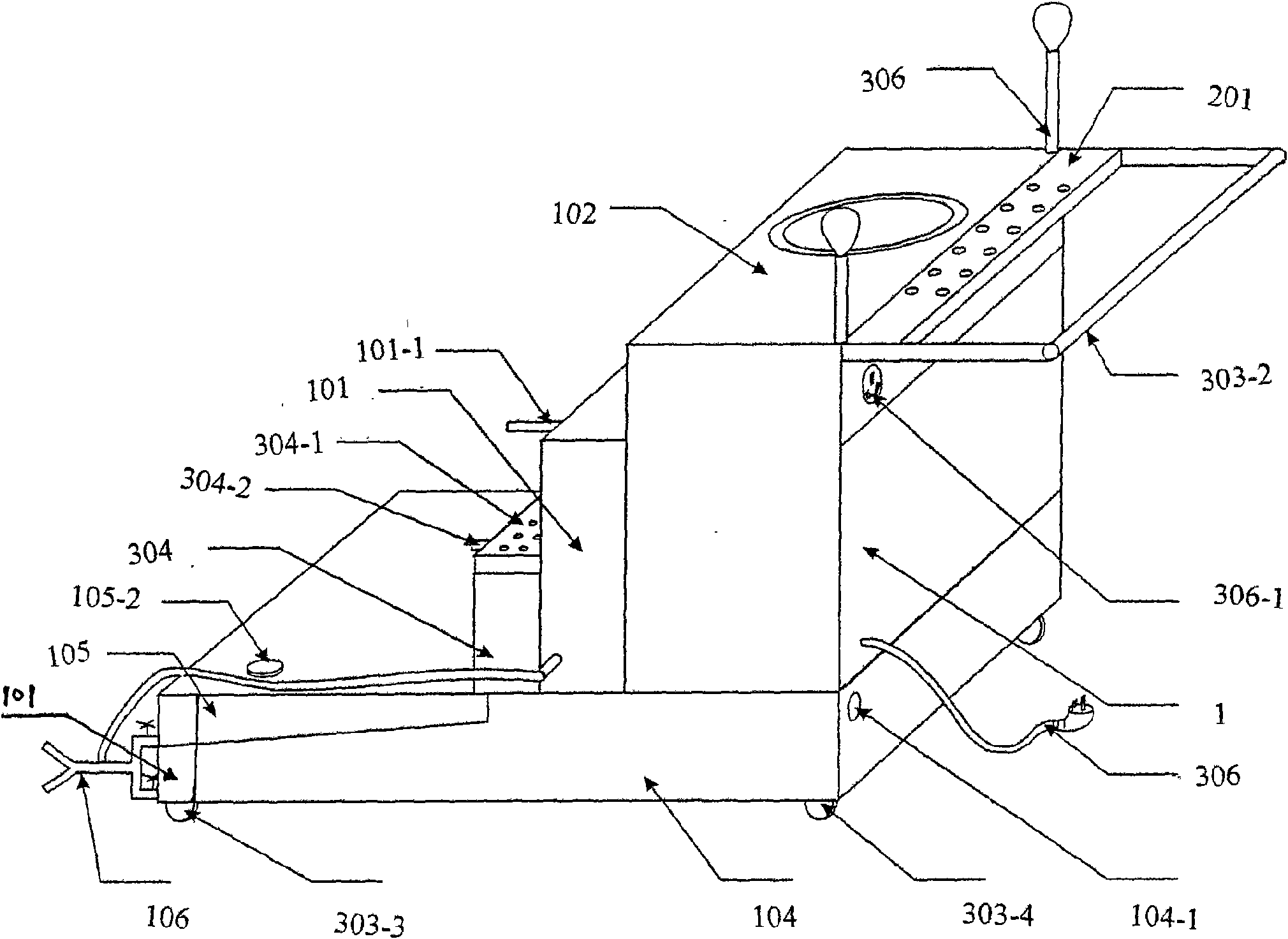

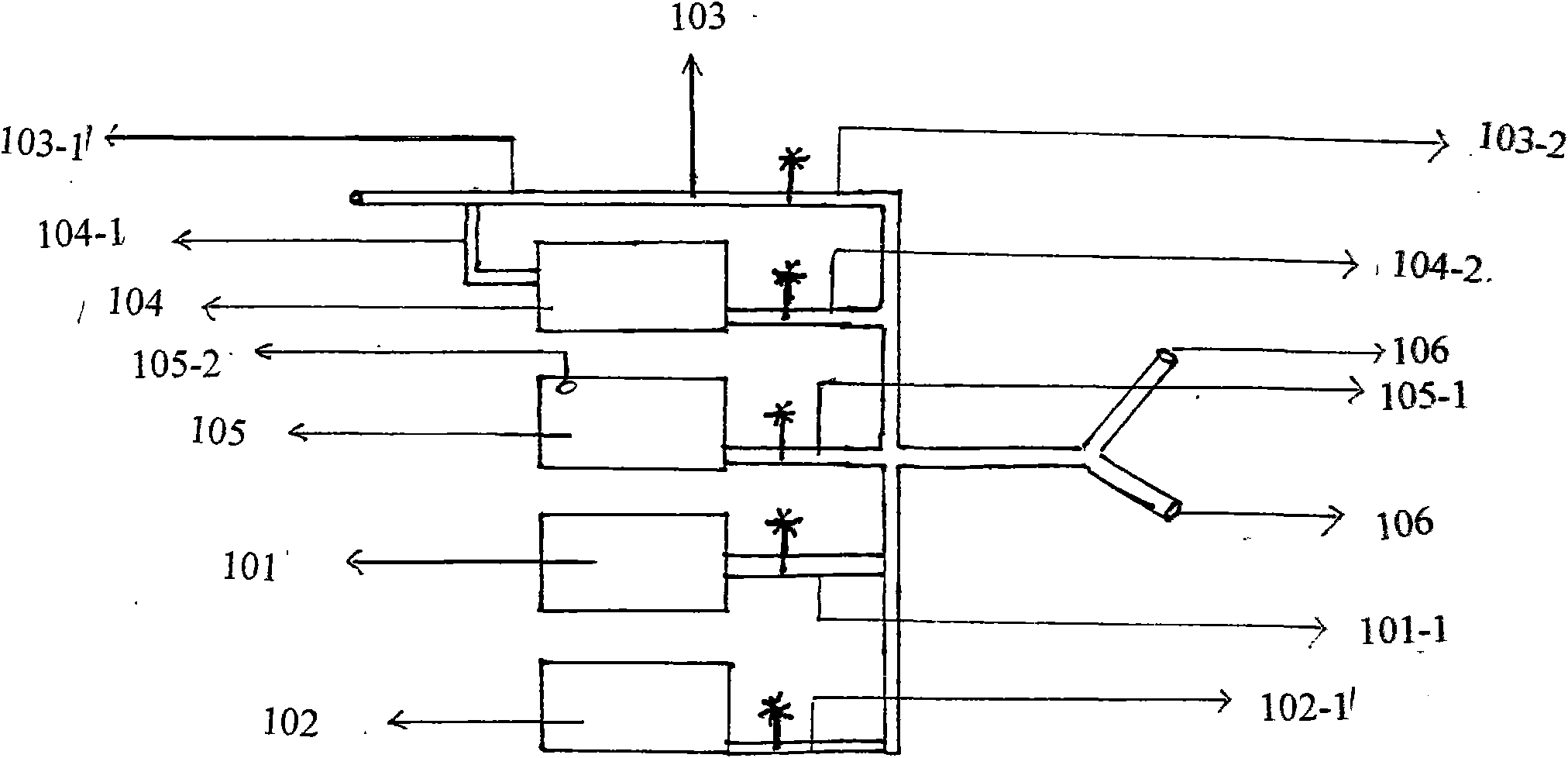

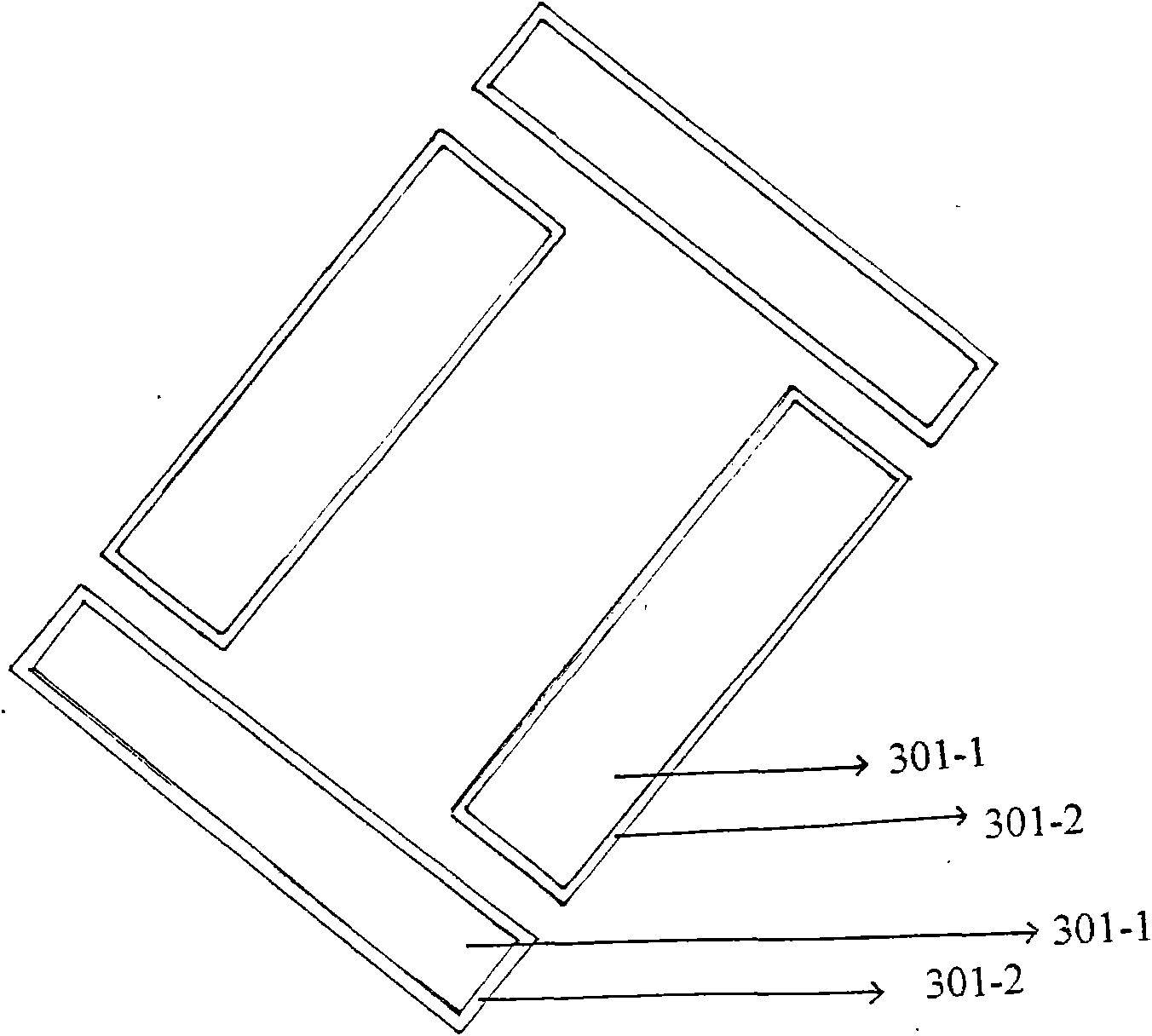

Mobile spraying-collecting car washer

InactiveCN101574959AReasonable and practical structureLow costCleaning apparatus for vehicle exteriorsVehicle frameSprayer

The invention discloses a mobile spraying-collecting car washer, comprising three parts of a spraying-collecting part, a control part and an accessory part; the spraying-collecting part comprises a water sprayer, a water-spraying washing scrubber, a water collector, a water-collecting wiper, an external adapter tube of running water, a clean water tank and a foam tank; the control part comprises an electronic control panel; and the accessory part comprises a waste water collector, an anti-contamination work fence, a chassis, a recycling bin and an illumination lamp bracket. When the car washeris used, a power supply is connected with a running water tap firstly, then a water outlet tube switch of the external adapter tube of running water is turned on by adopting the electronic control panel, the water flows into the water-spraying washing scrubber via a general exit and is sprayed out from a water-spraying hole arranged on the water-spraying washing scrubber, and the original water pressure is hardly lowered down; the water-spraying washing scrubber is provided with fluff and a water form regulating switch, therefore that washing the surface of an object is very flexible and safe, instead of adopting traditional high-pressure car washing every time; after the car is washed, the water drops on the car and the waste water on the ground are removed by the water collector and thewater-collecting wiper, thus improving the speed and safety for washing cars, and achieving stopping with washing at any time and zero-pollution discharge.

Owner:成都易禧科技管理发展有限公司

Automatic cleaning machine for hardware parts

InactiveCN105945001AReduce the number of replacementsImprove efficiencyCleaning using liquidsMotor driveElectric machinery

The invention discloses an automatic cleaning machine for hardware parts. The automatic cleaning machine comprises a cleaning box, wherein a placing plate is arranged at the bottom of the front side of the cleaning box; a side frame rod is arranged in the middle of the side surface of the cleaning box; a shaft sleeve is arranged at the upper end part of the side frame rod; a rotating shaft is arranged in the shaft sleeve; and a speed reducing motor is arranged on the right side of the cleaning box. According to the automatic cleaning machine for the hardware parts, the speed reducing motor drives a groove plate to rotate, when the groove plate rotates to a locating seat, a filter cylinder slides to the end part of the groove plate as the vertical position of the locating seat is lower than that of the rotating shaft, an air heater operates to dry parts in the filter cylinder, vanes are arranged on the side surface of the filter cylinder, and wind blows the filter cylinder to rotate, so that the efficiency is higher, the hardware parts do not need to be manually taken out of the cleaning box, and the working efficiency is improved; the cleaning box is provided with a circulation pipeline including a filter and a circulating pump, and a washing liquor is filtered and purified, so that the change time of the washing liquor inside the cleaning box is reduced; and the device is easy to use and high in working efficiency, and the automation is basically achieved.

Owner:无锡梦舟实业有限公司

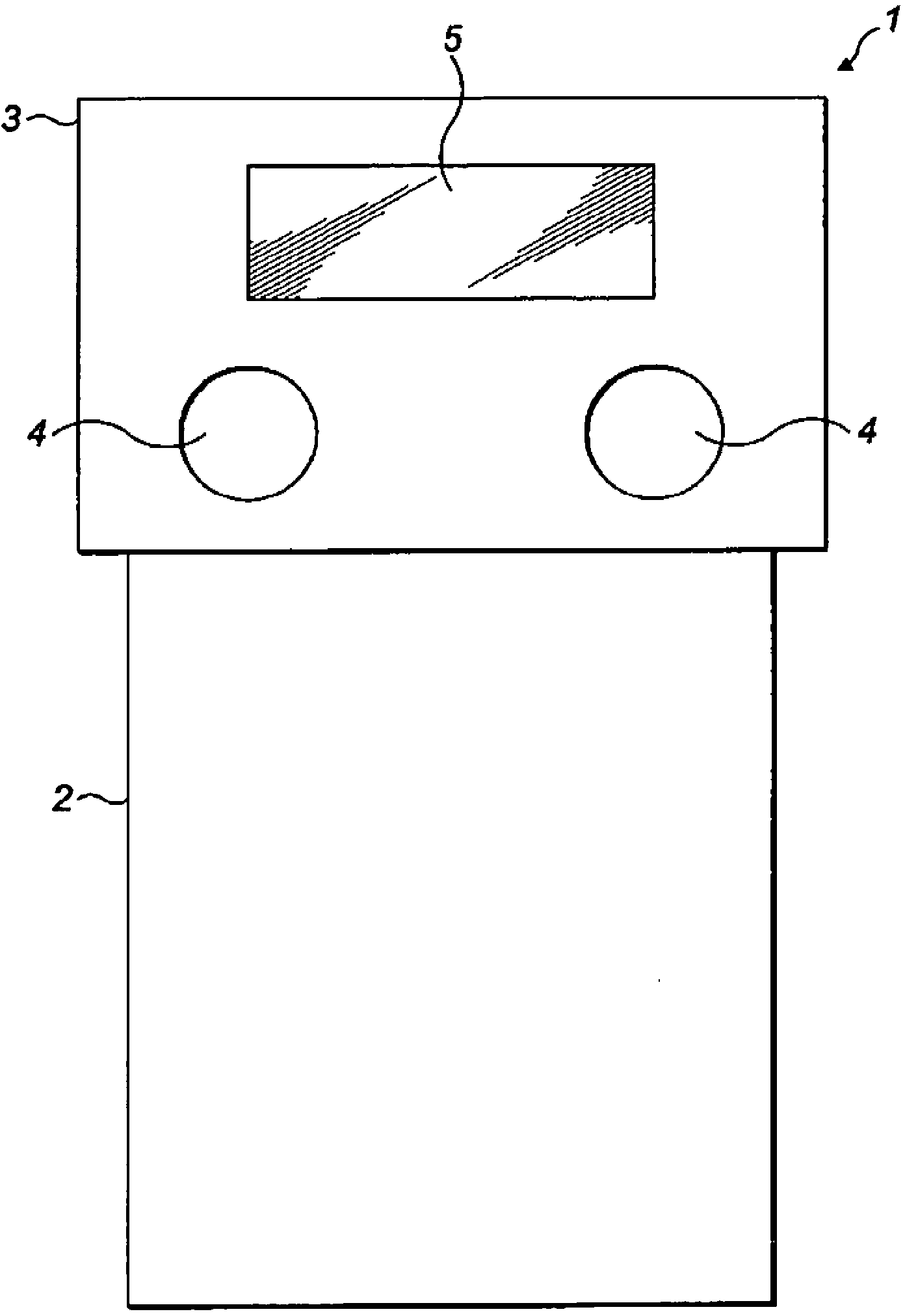

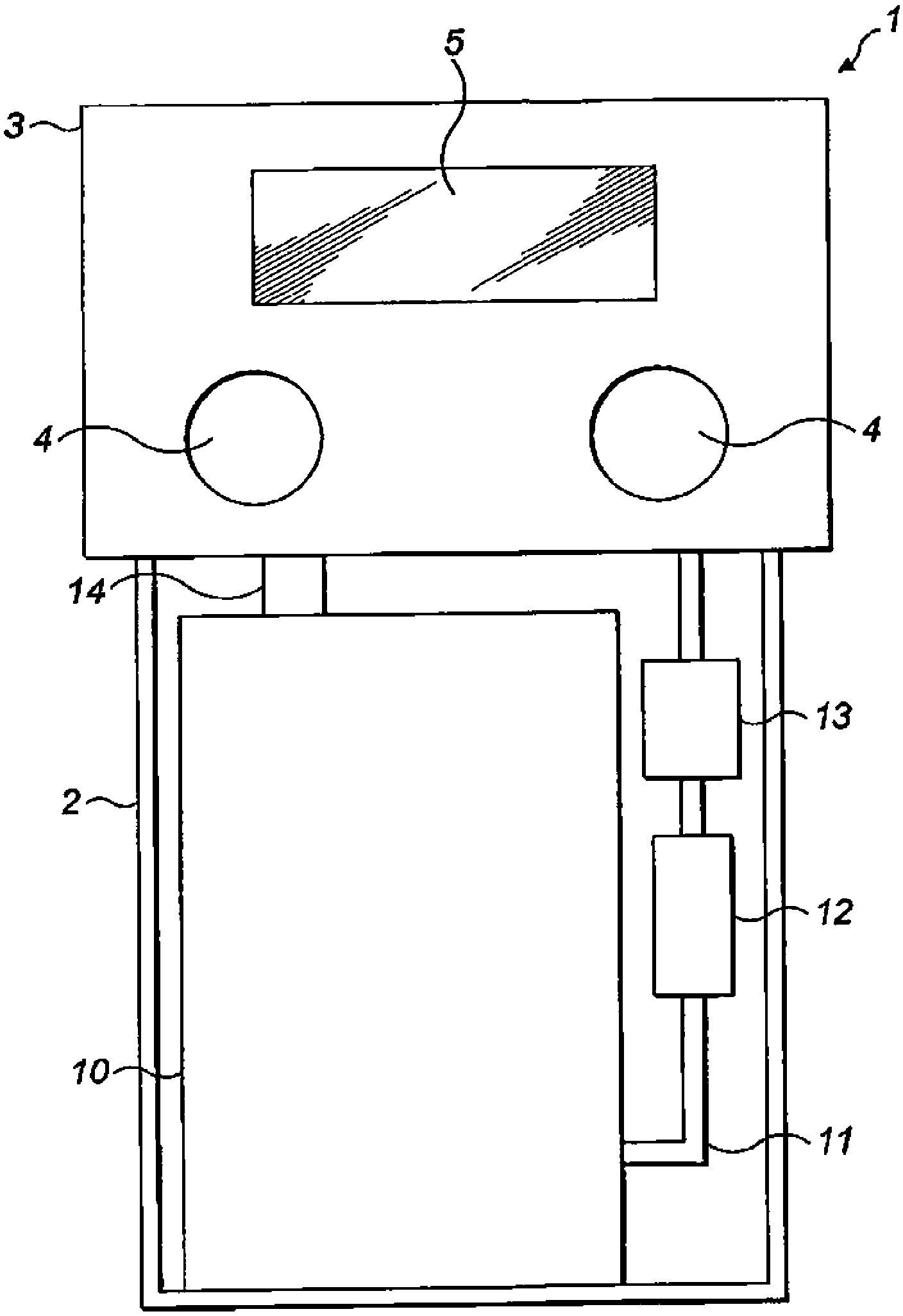

Parts washer

ActiveCN103201051AReduce chemical propertiesExtended service lifeDirt cleaningCleaning using gasesProcess engineeringParts washer

A parts (1) washer comprising an upper portion (3) and a lower portion (2), in which the part may be washed in the upper portion (3) and the lower portion (2) includes a drum (10) for containing the aqueous cleaning solution. A method of washing an article in a parts washer (1) and a method of regenerating the cleaning solution within the parts washer are also disclosed.

Owner:华阳恩赛有限公司

Catenary suspension pass-type reciprocating rotation water curtain part cleaning machine

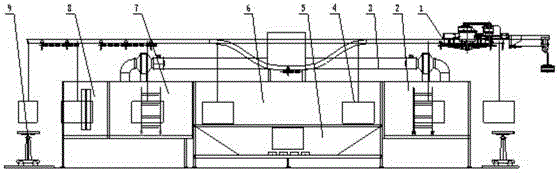

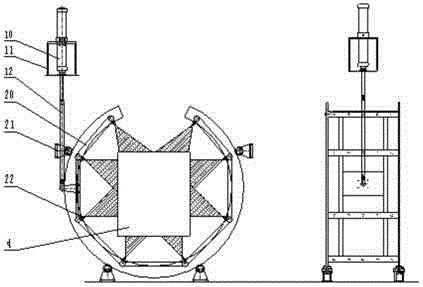

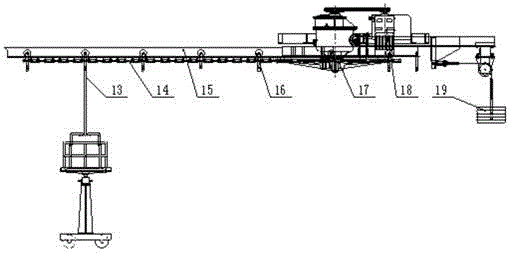

The invention relates to a catenary suspension pass-type reciprocating rotation water curtain part cleaning machine. The cleaning machine comprises a catenary suspension conveying mechanism, and two ends of the catenary suspension conveying mechanism are provided with feeding and blanking trolleys. A cleaning room body is disposed below the catenary suspension conveying mechanism, a coarse cleaning work room, an ultrasonic work room, a rinsing work room, a hot wind drying room and the like are successively disposed in the cleaning room body, and a steam condensing system is further disposed over the cleaning room body. Cleaning material frames are hung onto the catenary suspension conveying mechanism, and to-be-cleaned parts are placed in the cleaning material frames. The to-be-cleaned parts successively pass through the coarse cleaning work room, the ultrasonic work room, the rinsing work room, the hot wind drying room and the like under the drive of the catenary suspension conveying mechanism, so the continuous operation process of coarse cleaning, ultrasonic cleaning, rinsing, hot wind drying and the like is achieved; and reciprocating rotation water curtain assemblies disposed in the coarse cleaning work room and the rinsing work room perform reciprocating rotation jet flow cleaning for the to-be-cleaned parts. The cleaning machine has the advantages of simple structure, convenient operation, comprehensive and thorough cleaning, the high degree of automation and the like.

Owner:BEIJING ROWSUN TIMES SCI & TECH DEV CO LTD

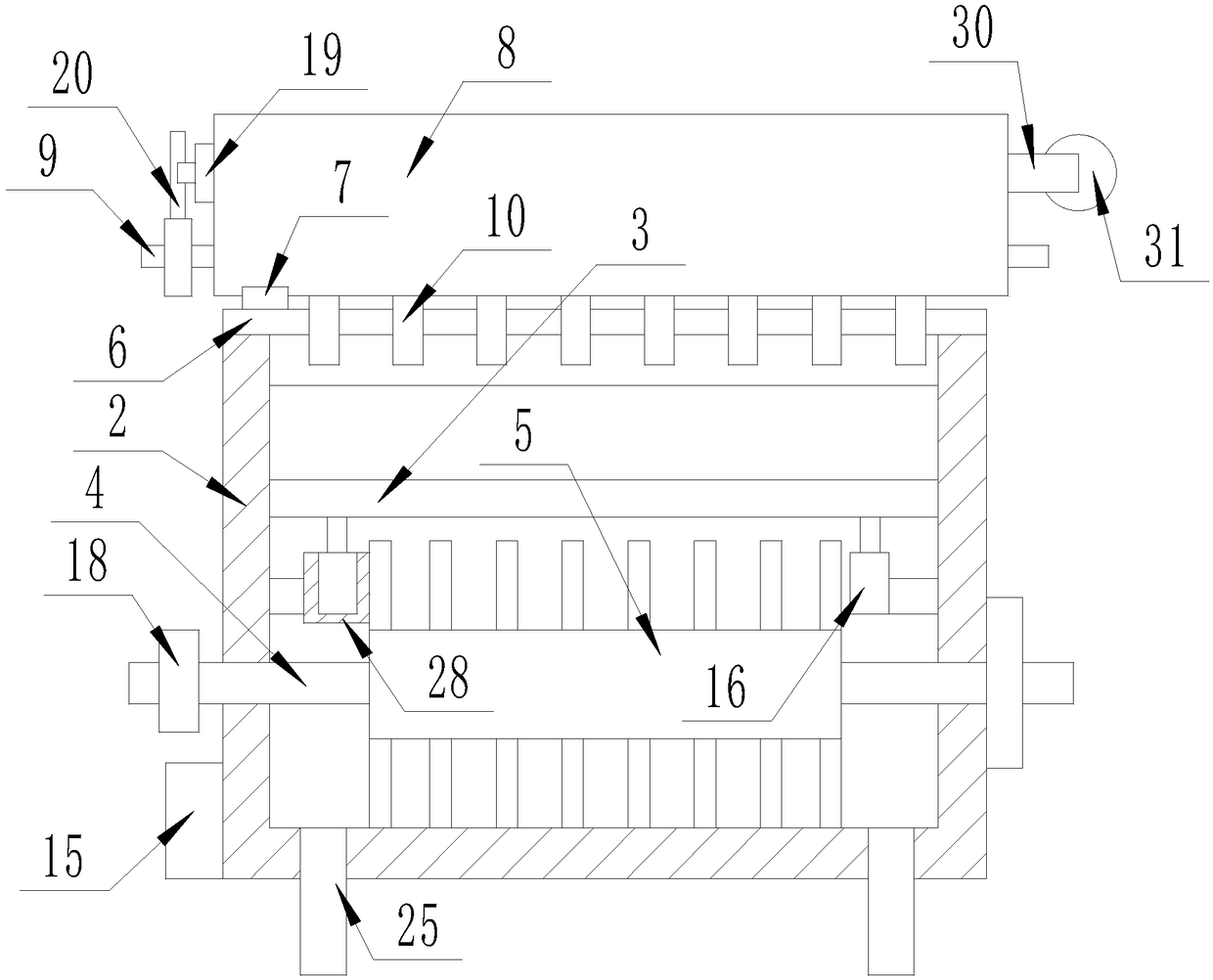

Part cleaning machine

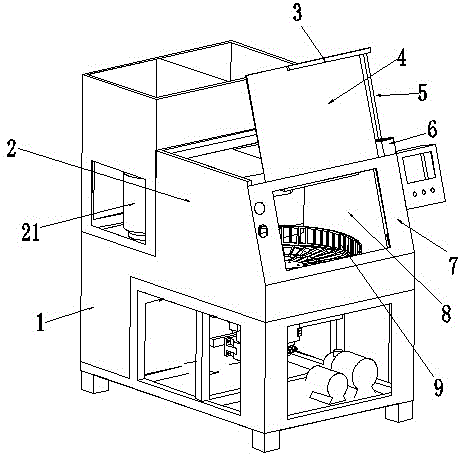

PendingCN105414102AReasonable layout of body structureImprove work efficiencyCleaning using liquidsMachine partsEngineering

The invention discloses a part cleaning machine and solves the problem that the conventional cleaning machine has poor structural compactness and easily occupies overlarge indoor space. The technical scheme adopted in the invention is as follows: a machined part cleaning machine comprises a cleaning box, a liquid storage box and a filter unit, wherein a cleaning rack is arranged in the cleaning box; a power mechanism is in transmission connection with the cleaning rack; the liquid storage box communicates with the filter unit through a water pump and a pipeline; a water pump motor is in transmission connection with the water pump; the cleaning box is located above the liquid storage box; the power mechanism is located below the cleaning box; the inner bottom surface of the cleaning box is at least flush with the outer top surface of the liquid storage box; a filter port is formed in a top plate of the liquid storage box; a basket type filter screen is arranged in the filter port; an open type liquid flow passage is arranged between the inner bottom surface of the cleaning box and the outer top surface of the liquid storage box; the liquid flow passage leads to the filter port; the filter unit is located above the liquid flow passage; and a liquid outlet of the filter unit faces the liquid flow passage and is used for flushing the bottom surface of the liquid flow passage.

Owner:TAIZHOU QUAN QIU YING IND & TRADE

Parts washer method

InactiveUS20070034237A1Sure easyImprove cleaning qualityHollow article cleaningCleaning using liquidsIndustrial engineeringParticle detector

Owner:STOCKERT DAVID L

Housingless washer

An industrial parts washer includes a stand adapted to support a part, a chamber selectively movable from a first position clear of the part to a second position engaging the stand where the chamber forms a closed volume encapsulating the part. A nozzle is positioned within the chamber to supply pressurized fluid for cleaning the part. The industrial parts washer may include a washing station positioned adjacent a drying station where each of the washing and drying stations include chambers selectively movable to enclose the part.

Owner:CINETIC AUTOMATION

Wheel brush water outlet equipment of car washer

PendingCN110481515AImprove cleanlinessCompact structureCleaning apparatus with conveyorsCleaning apparatus for vehicle exteriorsPortal frameWater spray

The invention discloses wheel brush water outlet equipment of a car washer. The equipment comprises a base and a portal frame, the portal frame is arranged on the upper wall face of the base, and a water spraying structure, a first moving structure, a second moving structure and an adjusting structure are installed in the portal frame. The beneficial effects are that the equipment is reasonable instructure, convenient to use, and low in cost; a vehicle is driven into the position right below the portal frame; water can be uniformly and comprehensively sprayed on the surface of the vehicle through the water spraying structure; the two sides of the vehicle can be uniformly and comprehensively brushed and washed through the first moving structure; the upper side, the front side and the rearside of the vehicle can be brushed and washed through the second moving structure; and the adjusting structure drives the water spraying structure, the first moving structure and the second moving structure to move front and back to repeatedly brush and wash the vehicle, so the cleanliness of the vehicle brushed and washed by the car washer is improved.

Owner:江苏奇禧智能科技有限公司

Parts washer with improved temperature & pump control

A parts washer including a receptacle positioned on a reservoir for cleaning liquid having a drain opening and a module which engages a portion of the reservoir in the cleaning liquid for adjusting the temperature of the cleaning liquid and circulating the cleaning liquid into the receptacle. The module includes a heating element, a sensor and pump. An enclosure houses a temperature controller which displays the temperature of the cleaning liquid and a low liquid level condition. A bridge thermally links the heating element to the sensor so that the sensor normally generates a signal representative of the temperature of the cleaning fluid unless the level of the cleaning fluid is disposed below the sensor.

Owner:SAFETY KLEEN SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com