Part cleaning machine

A technology for cleaning machines and parts, applied in the field of parts cleaning, can solve the problems of low cleaning efficiency, insufficient cleaning power of parts cleaning machines, and low cleanliness of parts, and achieve the effects of improving cleaning degree, low toxicity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

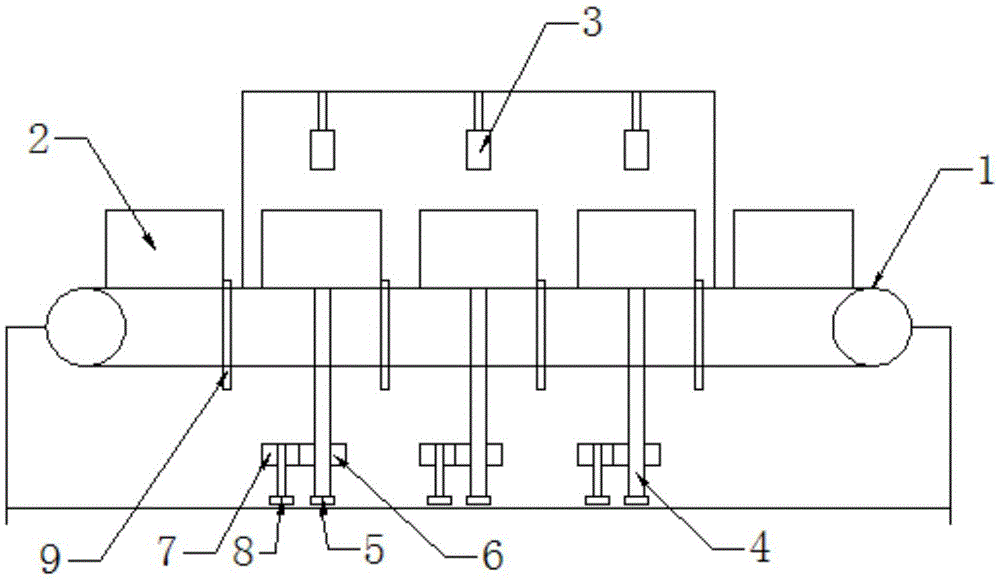

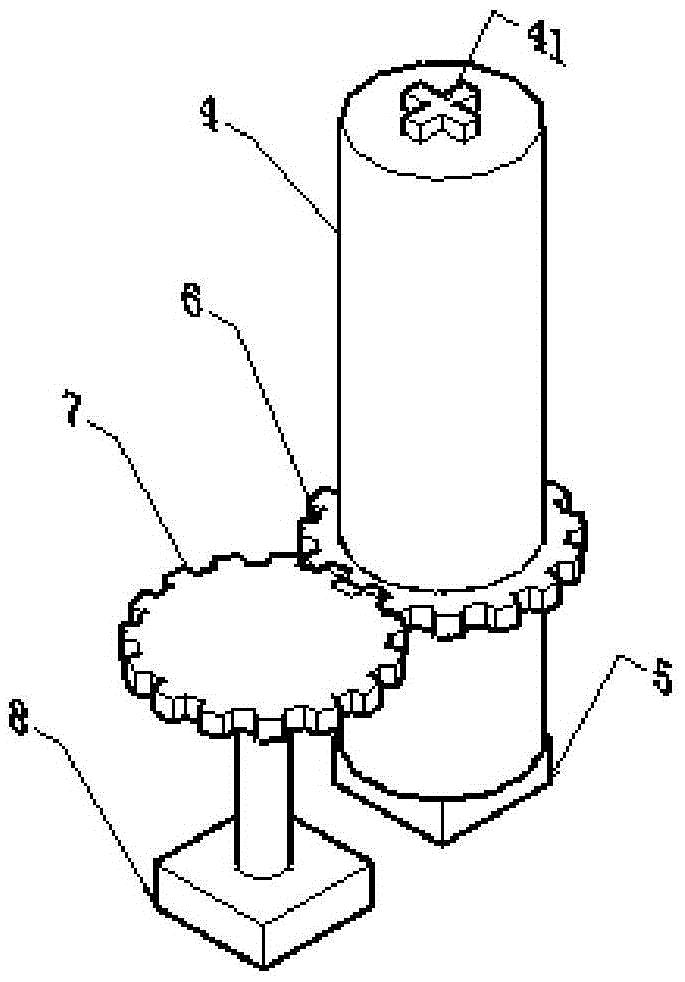

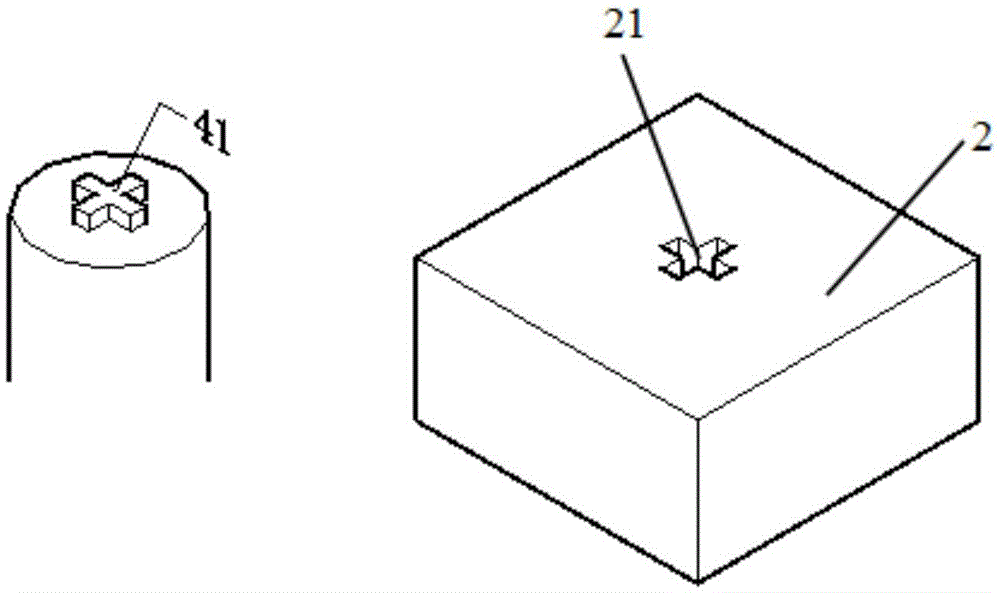

[0024] Such as figure 1 As shown, the parts washing machine of the present invention includes a conveyor belt 1, a material tray 2, and a rotary spraying device 3 located above the conveyor belt 1, and the spraying device 3 is filled with cleaning liquid. The below of the conveyer belt 1 directly below the spraying device 3 is provided with a support rod 4 . Such as figure 2 As shown, the top of the support rod 4 and the center of the bottom of the tray 2 have a locking mechanism that engages with each other, and a pressure cylinder 5 is arranged at the bottom of the support rod 4, and the pressure cylinder 5 can send the cylinder along the conveyor belt 1 to the sprayer in the vertical direction. The material tray 2 directly below the washing device 3 is jacked up, and a gear 6 is also fixedly arranged on the support rod 4, and the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com