Parts washer

A cleaning machine and parts technology, applied in the direction of smoke removal, cleaning methods and utensils, cleaning methods using liquid, etc., can solve the problems of long cleaning cycle and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

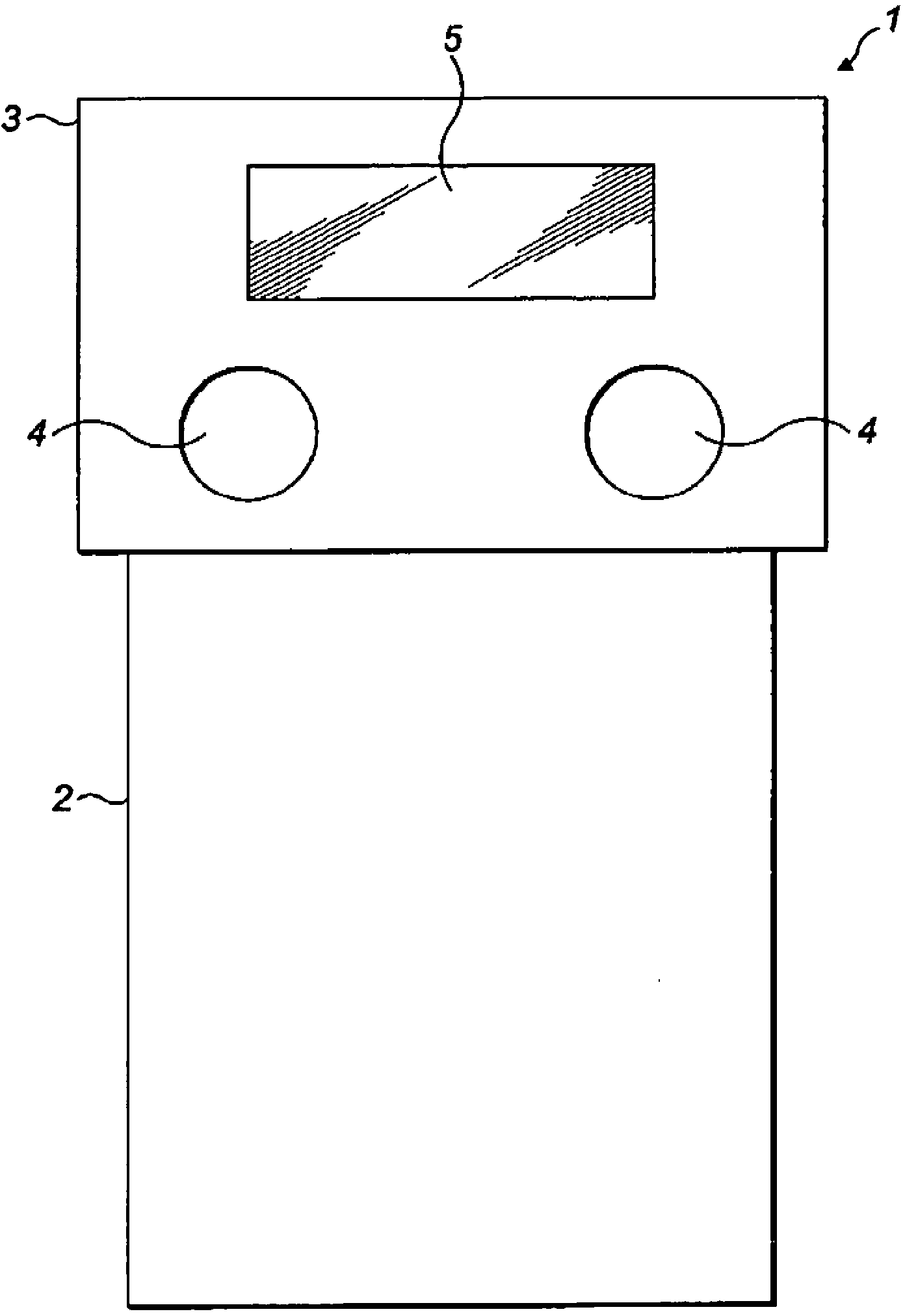

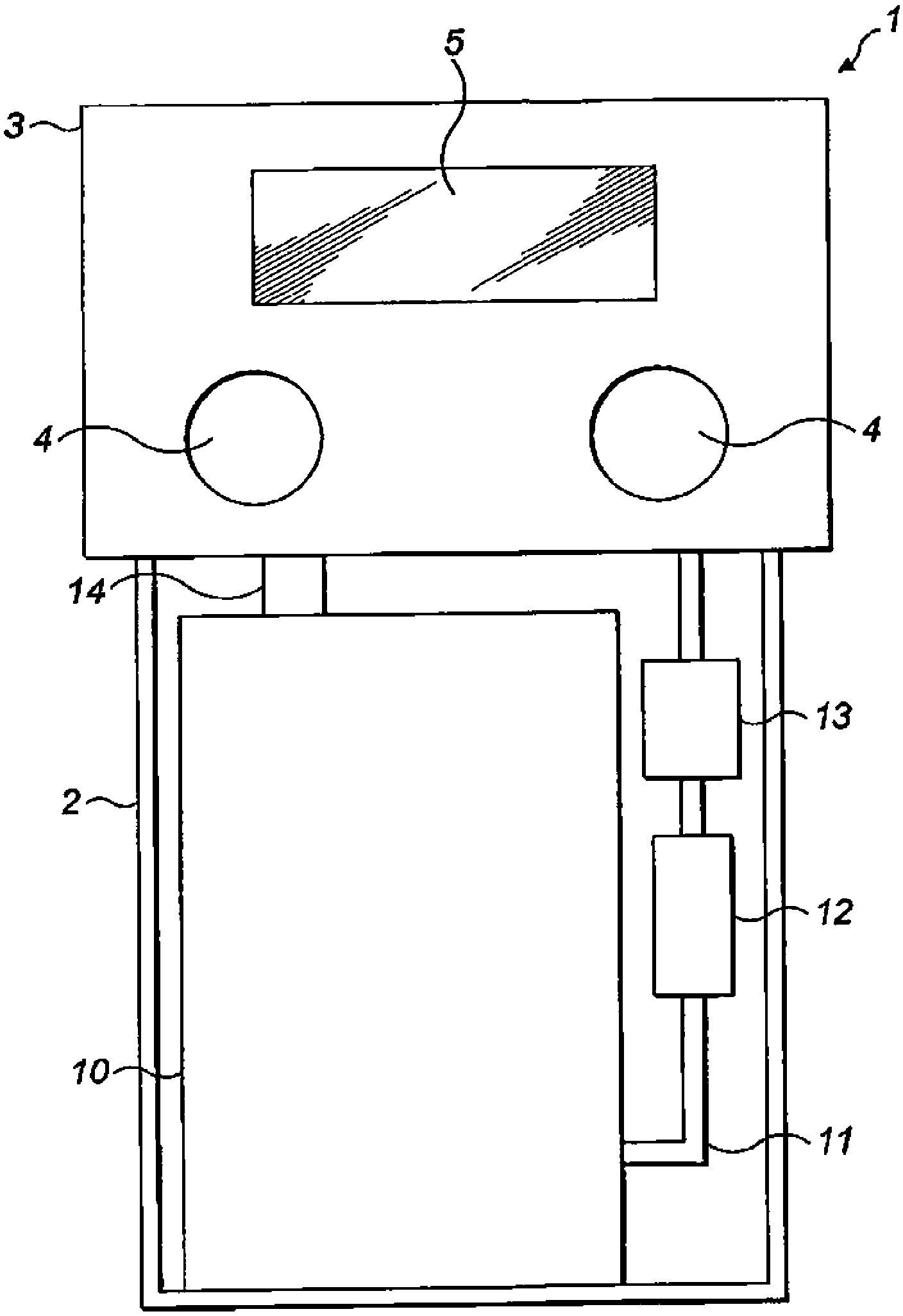

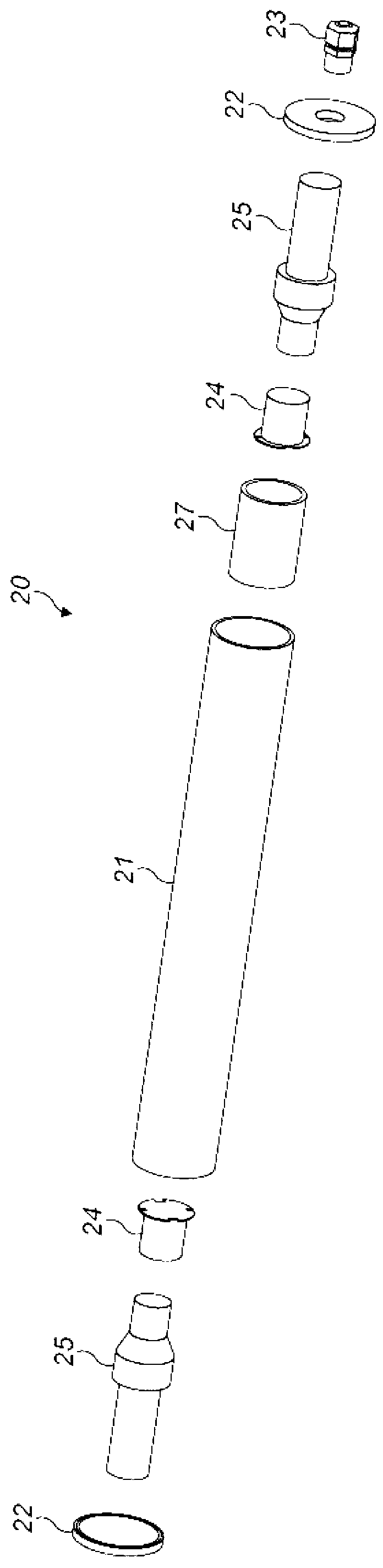

[0029] Please refer to figure 1 , the present invention proposes an aqueous parts washing machine 1 for washing dirty parts that can be disassembled eg from a motor vehicle. The parts washer 1 may comprise a lower part 2 and an upper part 3 . The cleaning fluid, operation control device and high-pressure pump are packaged in the lower part 2. For details, please refer to figure 2 . The upper part includes a cleaning tank, which may or may not include a lid and an internal screen frame or basket for accommodating parts to be cleaned. The cover includes two integrated durable gloves on said cover where the durable gloves are fastened at the air inlet opening 4 . The cover also includes an observation window 5 through which the user can view the parts to be cleaned so as to guide the nozzles to clean the parts thoroughly. In the parts washer 1 one or more through-flow nozzles (not shown) can be provided, which are supplied with high pressure by a high-pressure pump in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com