A kind of clean conversion method of stone coal

A stone coal and clean technology, applied in the direction of alkaline earth metal silicate, silicate, process efficiency improvement, etc., can solve the problems of low yield and high cost, and achieve the effects of reduced production cost, huge environmental benefits, and elimination of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

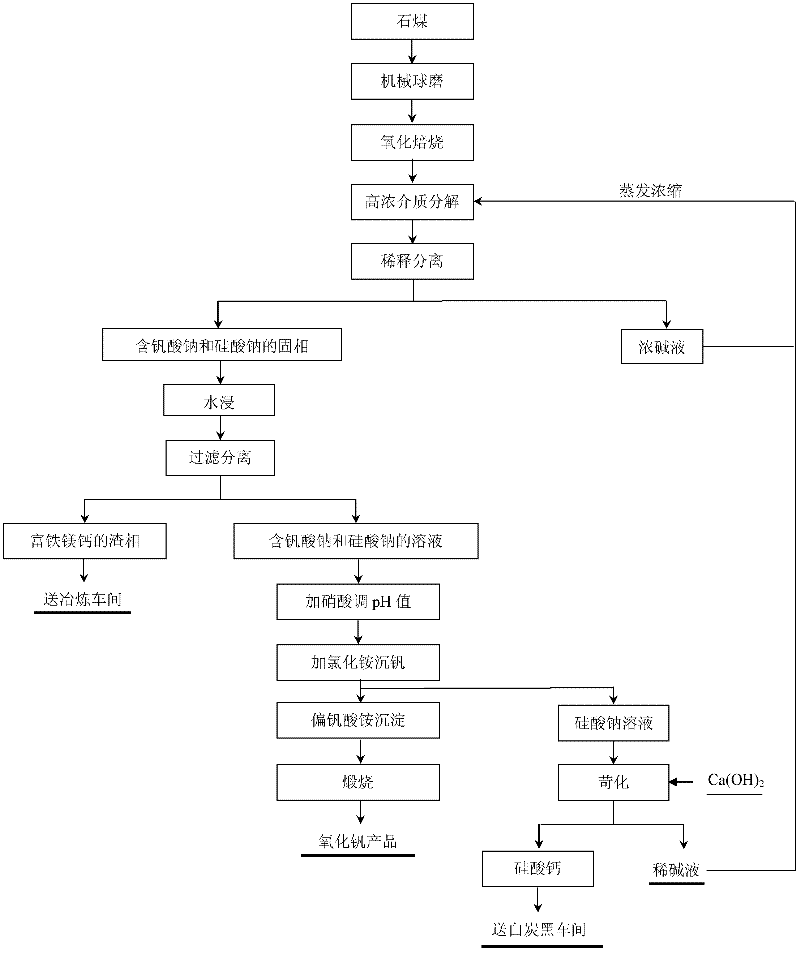

Method used

Image

Examples

Embodiment 1

[0023] NaNO containing NaNO recycled back to the reactor 3 The NaOH lye is heated to 150°C to form a high-concentration medium, in which NaOH+NaNO 3 50% by mass, 50% by moisture, NaNO 3 Accounting for NaOH+NaNO 3 2% of the total mass of solute. The stone coal is ball-milled for 36 hours, passed through a 350-mesh sieve, and then oxidized and roasted at 750°C for 5 hours, according to the solute NaOH and NaNO 3 The mass ratio of the total mass of the mixture to the stone coal is 6:1. Add the treated stone coal powder into the reactor under stirring, and mix and react completely at 150°C for 3 hours to obtain the decomposition product. Dilute the decomposition product with water, and after dilution The concentration of NaOH is 556g / L, the temperature is 30°C, the separation contains NaNO 3 Concentrated NaOH lye and solid phase containing sodium vanadate and sodium silicate, containing NaNO 3 The concentrated NaOH lye is evaporated and concentrated, and then returned to the ...

Embodiment 2

[0025] NaNO containing NaNO recycled back to the reactor 3 The NaOH lye is heated to 200°C to form a high-concentration medium, in which NaOH+NaNO 3 The mass concentration is 68%, moisture accounts for 32%, NaNO 3 Accounting for NaOH+NaNO 3 The total mass of solute is 4%. The stone coal is ball-milled for 24 hours, passed through a 350-mesh sieve, and then oxidized and roasted at 800°C for 3 hours, according to the solute NaOH and NaNO 3 The mass ratio of the total mass of the mixture to the stone coal is 5:1. Add the treated stone coal powder into the reactor under stirring, and mix and react completely at 200°C for 2 hours to obtain a decomposition product. Dilute the decomposition product with water, and after dilution The concentration of NaOH is 632g / L, the temperature is 80°C, the separation contains NaNO 3 Concentrated NaOH lye and solid phase containing sodium vanadate and sodium silicate, containing NaNO 3 The concentrated NaOH lye is evaporated and concentrated ...

Embodiment 3

[0027] Circulation back to the reactor containing NaNO 3 The NaOH lye is heated to 250°C to form a high-concentration medium, in which NaOH+NaNO 3 The mass concentration is 75%, moisture accounts for 25%, NaNO 3 Accounting for NaOH+NaNO 3The total mass of solute is 6%. The stone coal was ball-milled for 16 hours, passed through a 350-mesh sieve, and then oxidized and roasted at 850 °C for 1 hour. 3 The mass ratio of the total mass and the stone coal is 3:1. Under stirring, the treated stone coal powder is added to the reaction kettle, and the reaction is completely mixed at 250 ° C for 1.5 hours to obtain a decomposition product, and the decomposition product is diluted with water. After dilution The concentration of NaOH is 746g / L and the temperature is 110℃. 3 The concentrated NaOH lye and the solid phase containing sodium vanadate and sodium silicate, containing NaNO 3 The concentrated NaOH alkaline solution is evaporated and concentrated and returned to the reactor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com