Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Mass imbalance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass imbalance is a measure of the error in the solution. You would typically set the limit for this in the "Solution Controls" section of the inputs (if using the GUI). For mass imbalance, set the tolerance for residuals on the continuity equation.

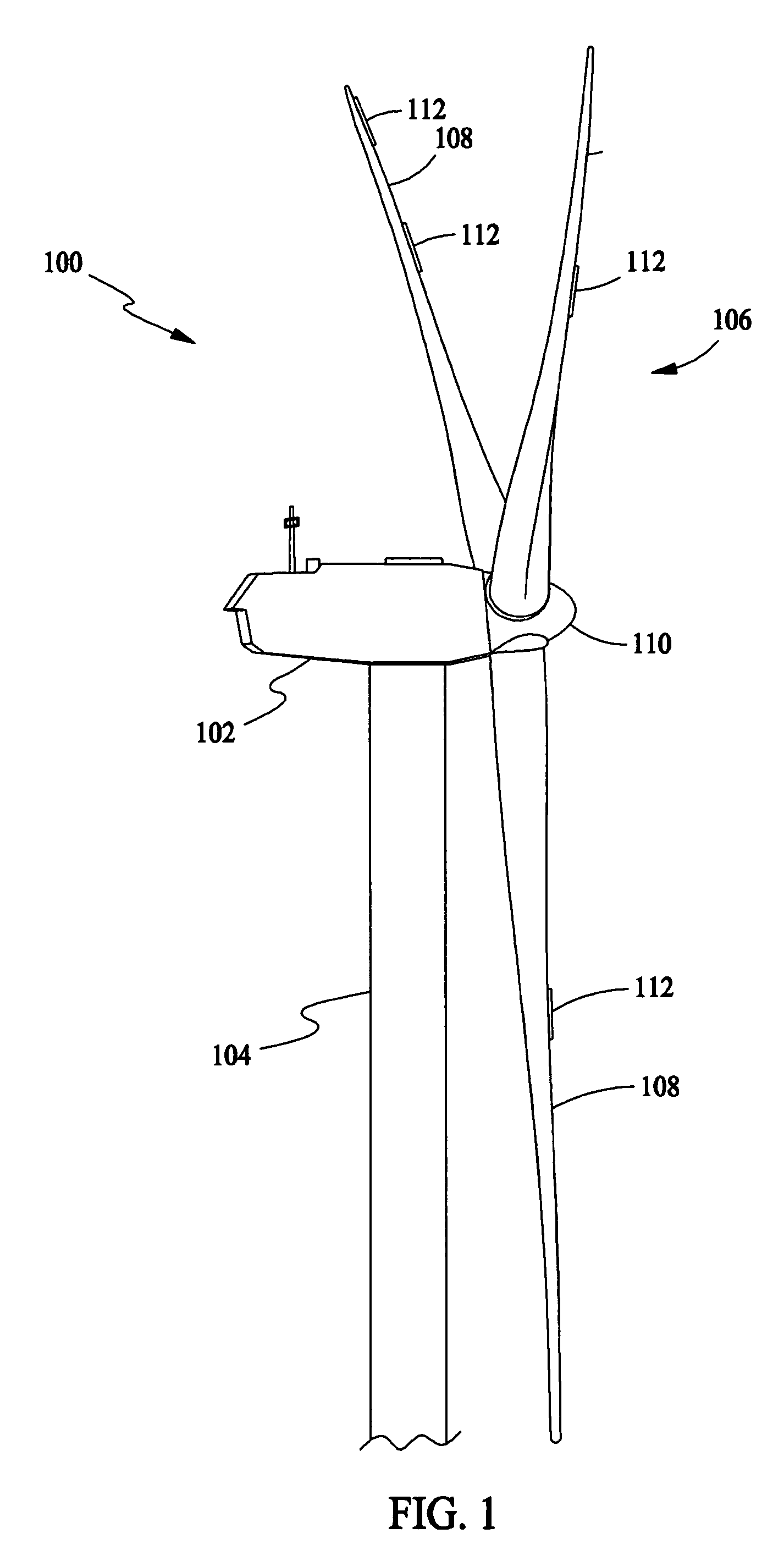

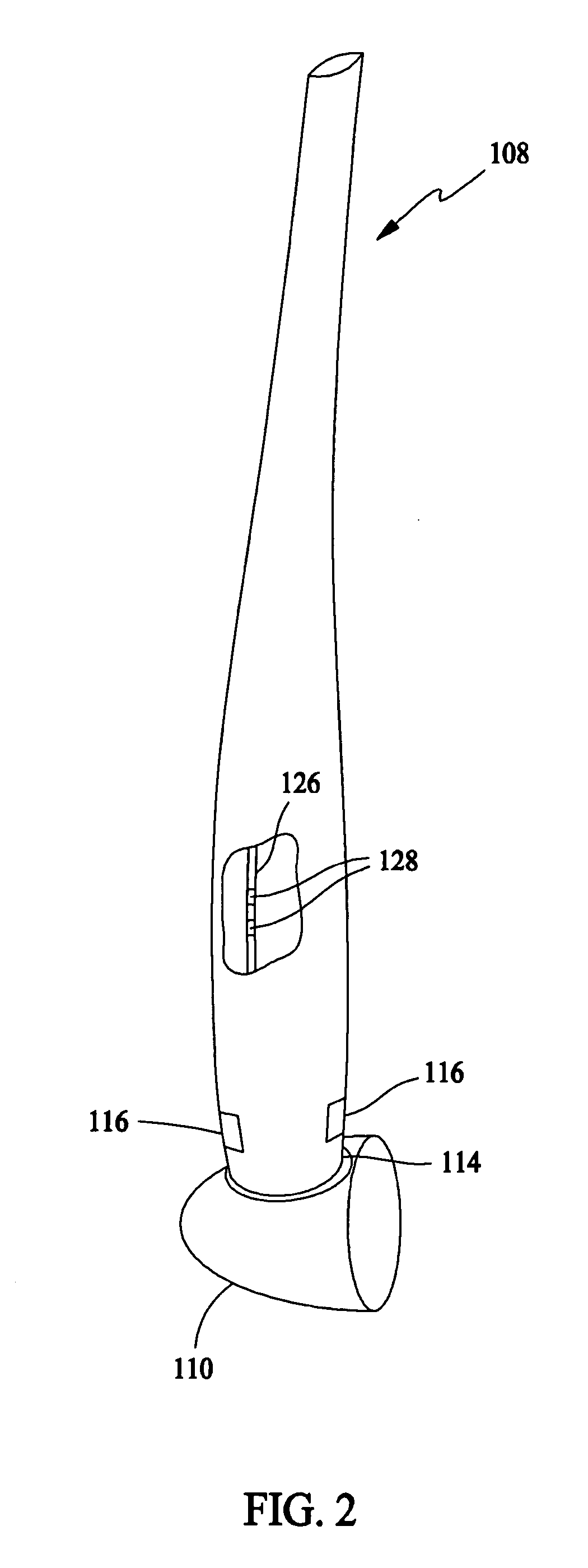

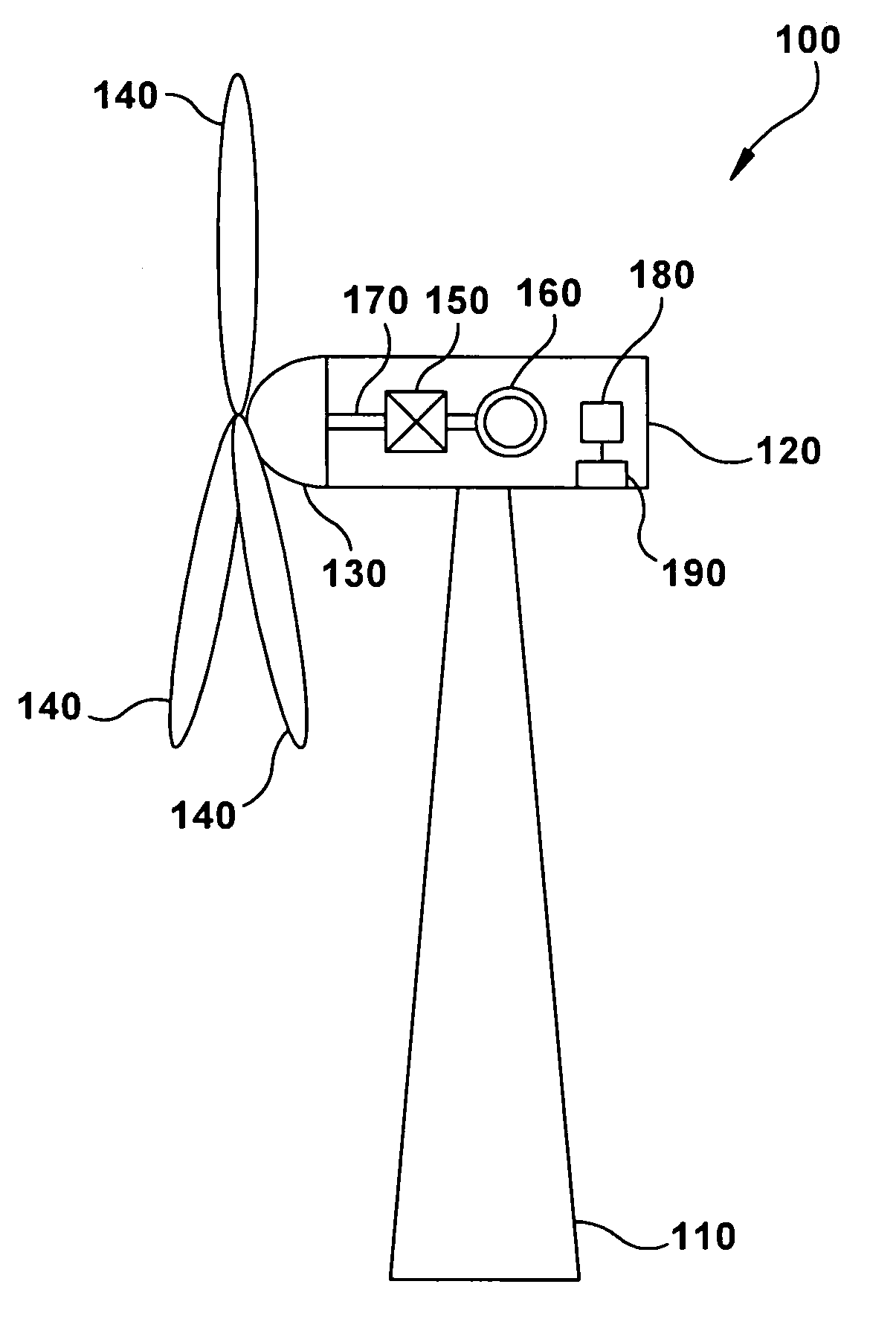

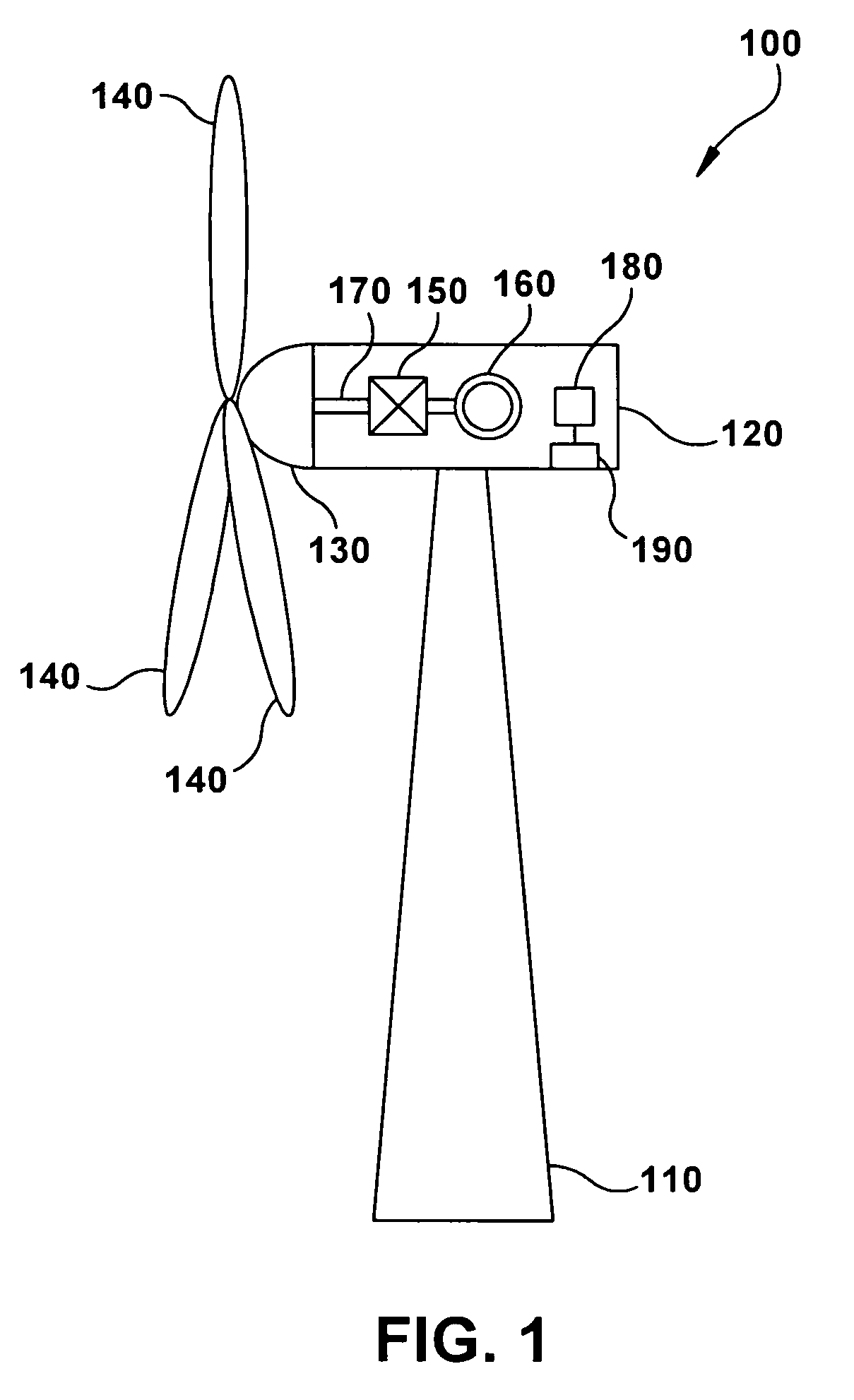

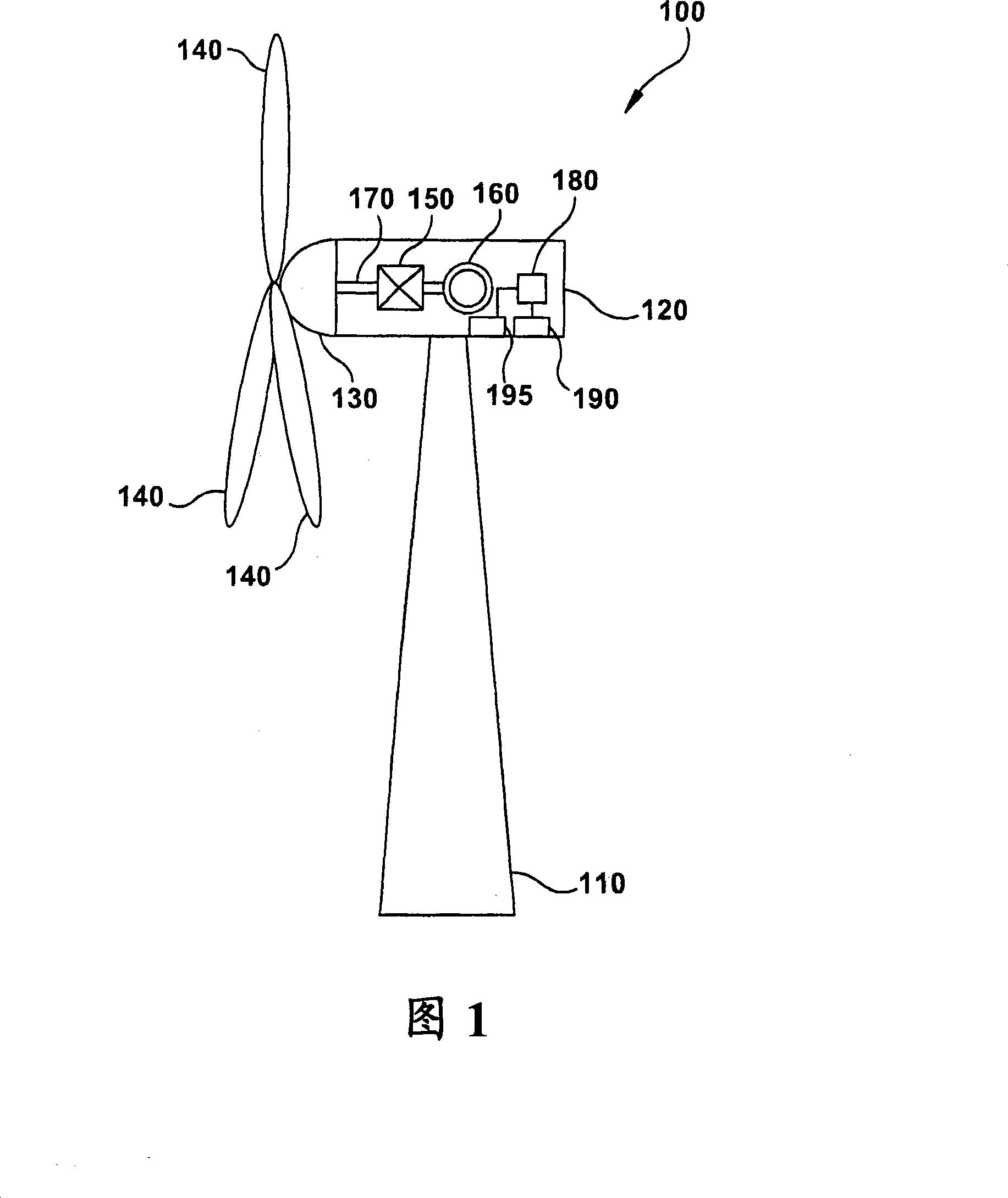

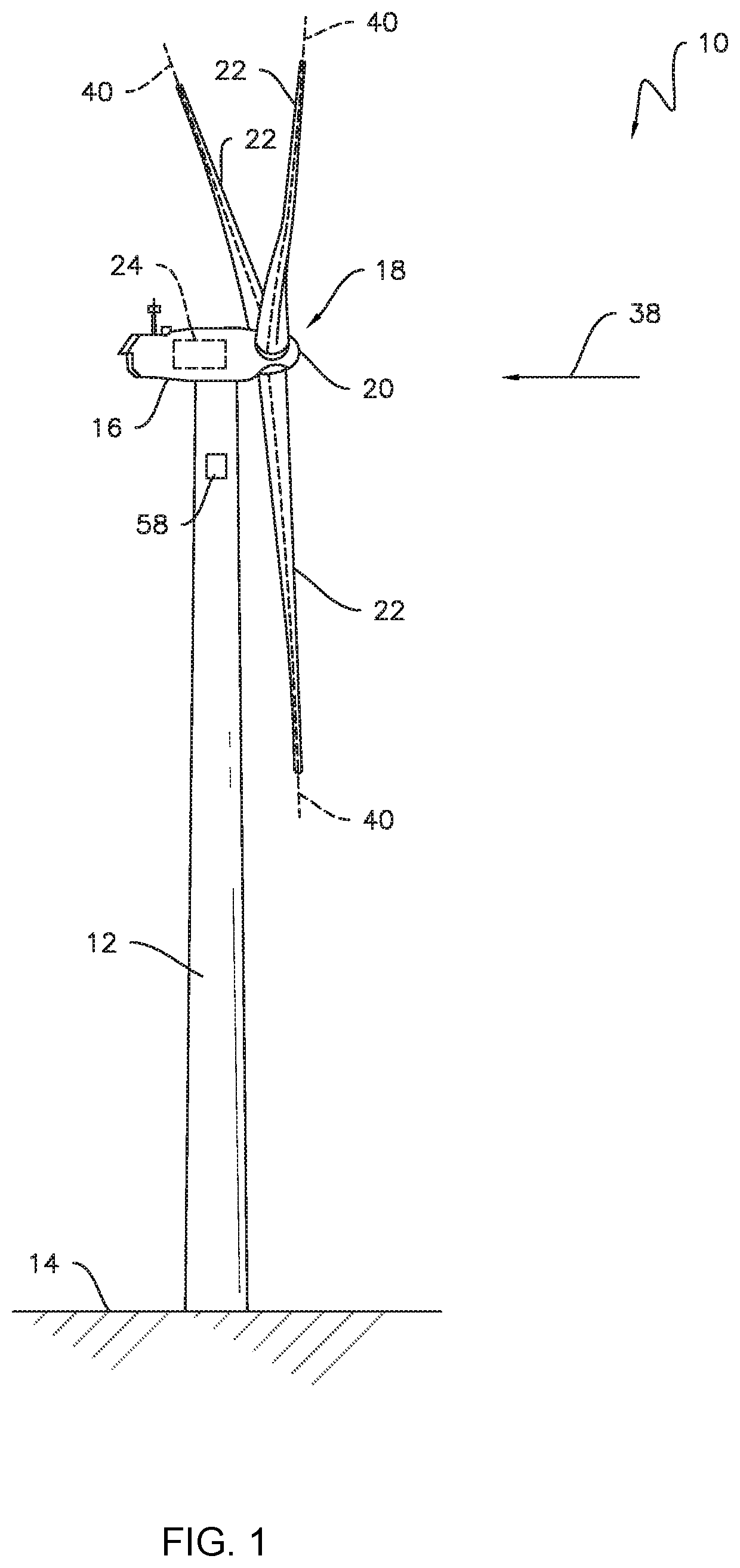

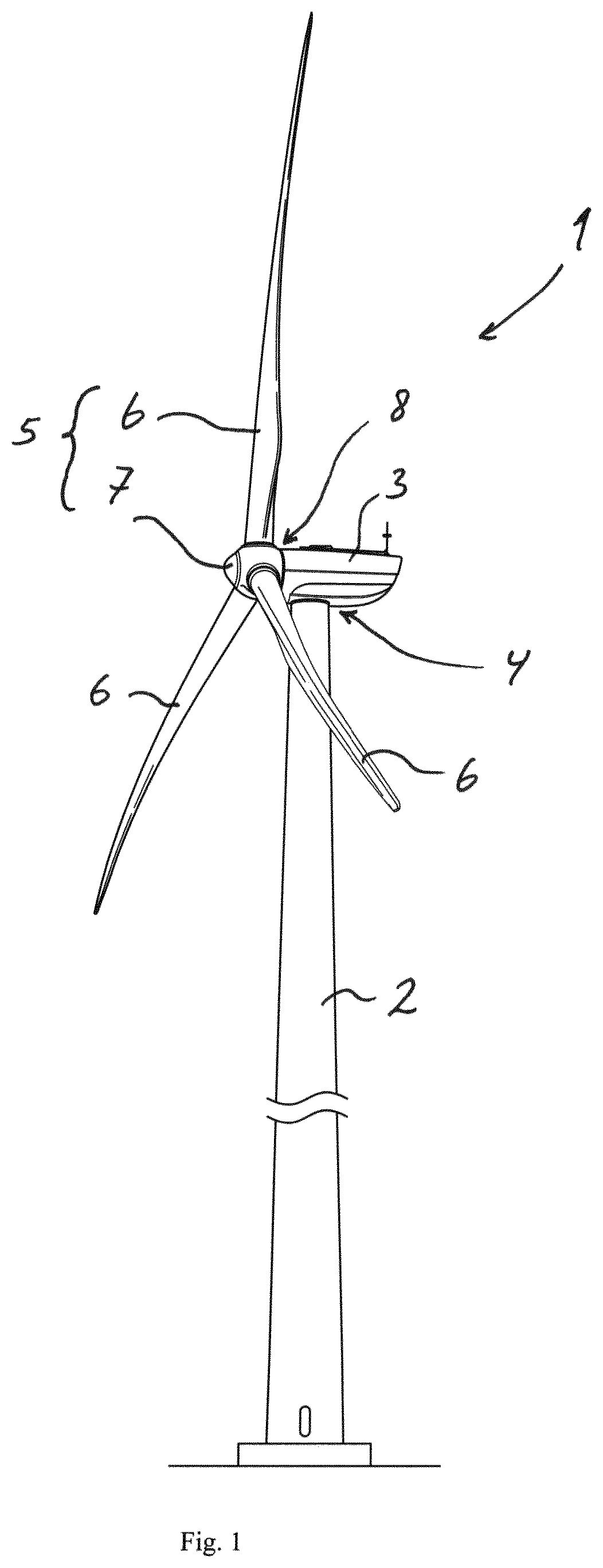

Methods and apparatus for rotor blade ice detection

ActiveUS20050276696A1Reduced lifting capabilityDiminished aerodynamic rotor blade performancePropellersWind motor controlIcing conditionsEngineering

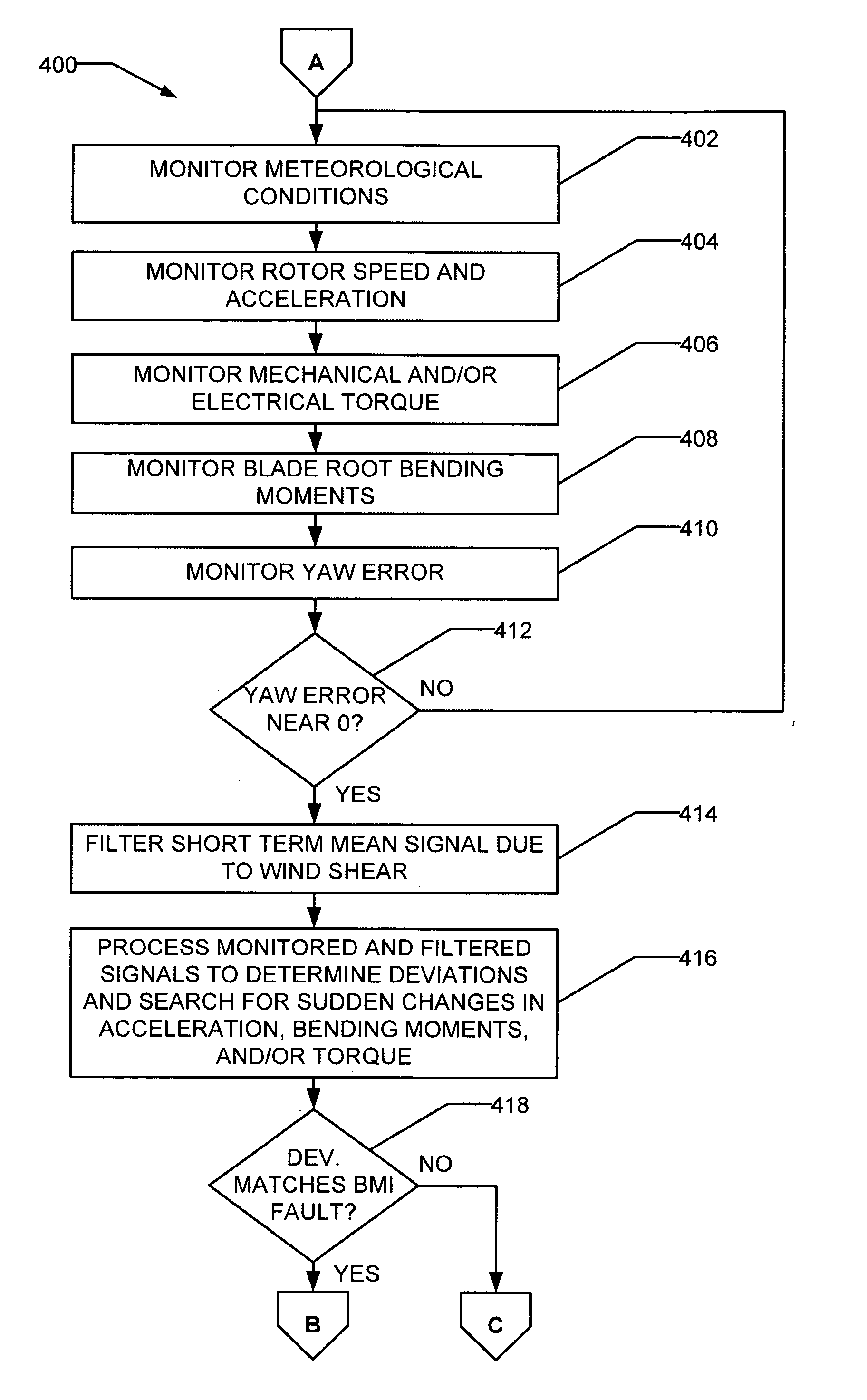

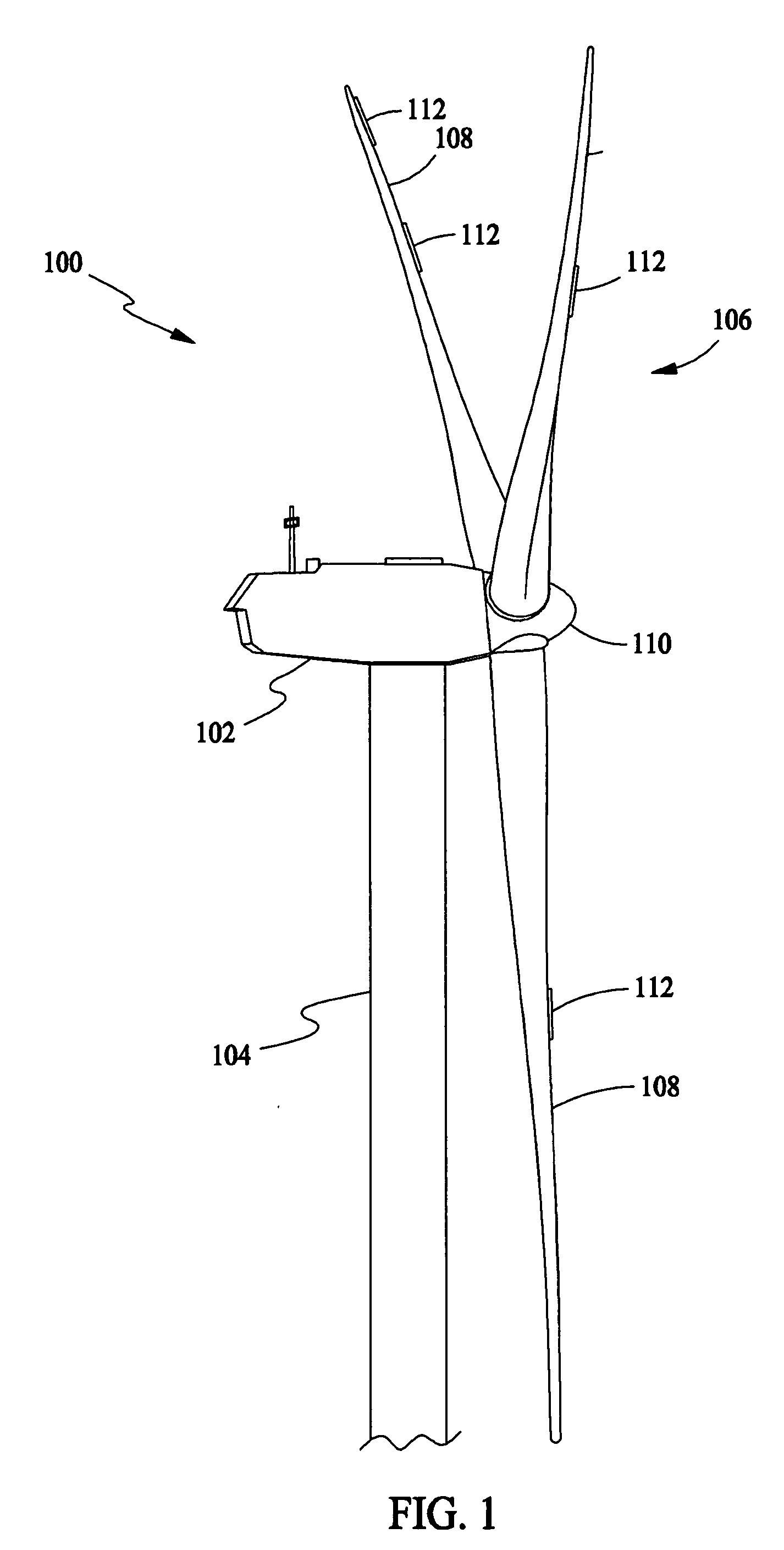

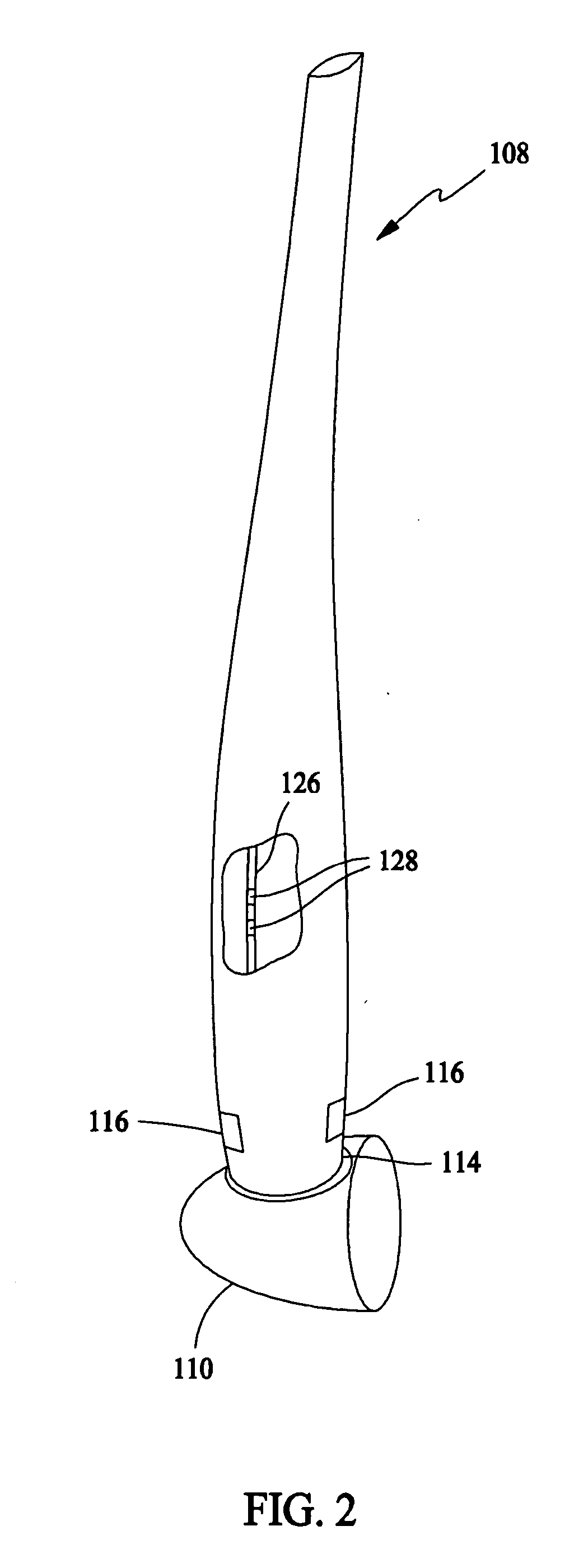

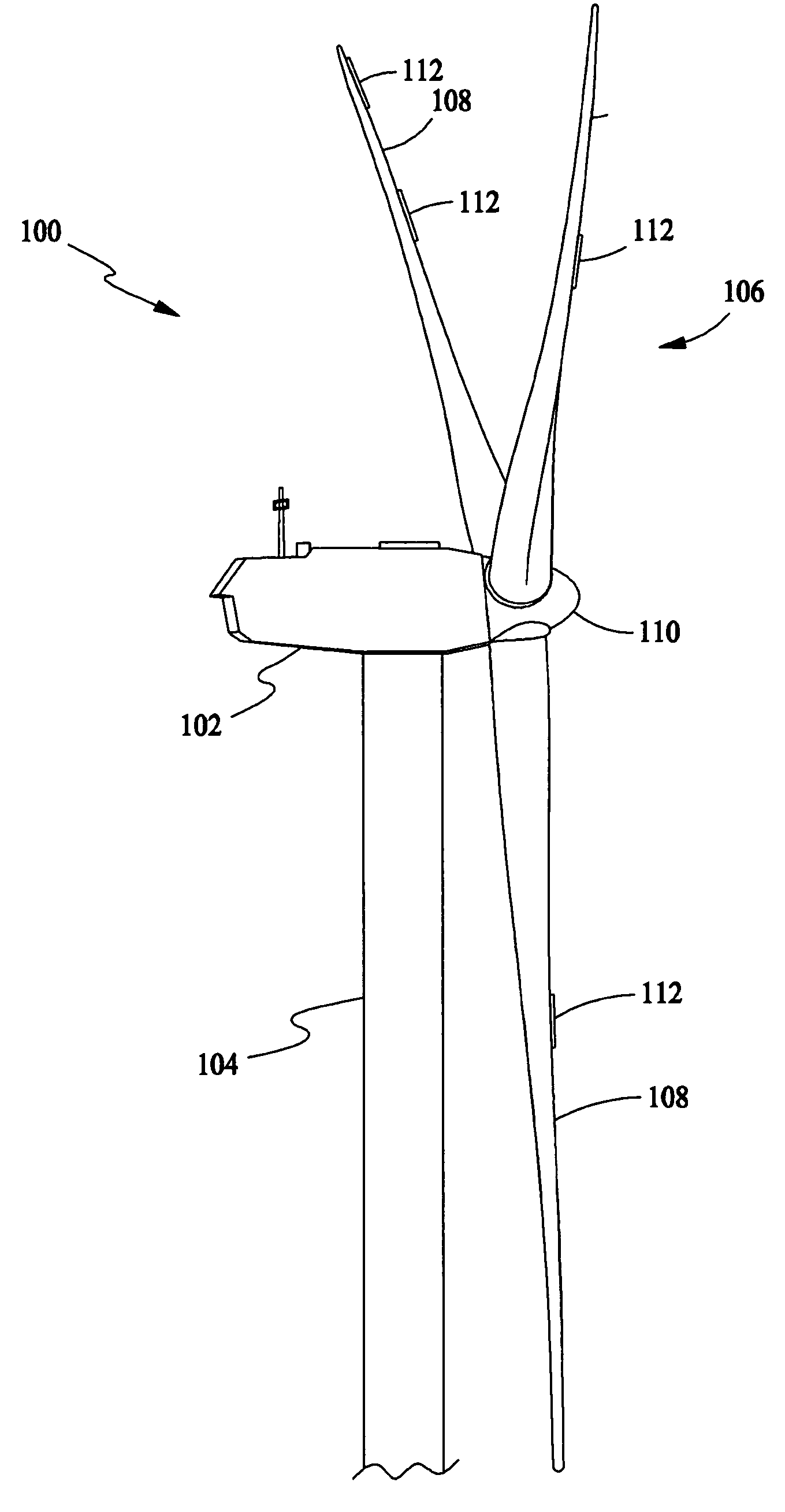

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for rotor blade ice detection

ActiveUS7086834B2Lower performance requirementsPropellersWind motor controlIcing conditionsEngineering

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

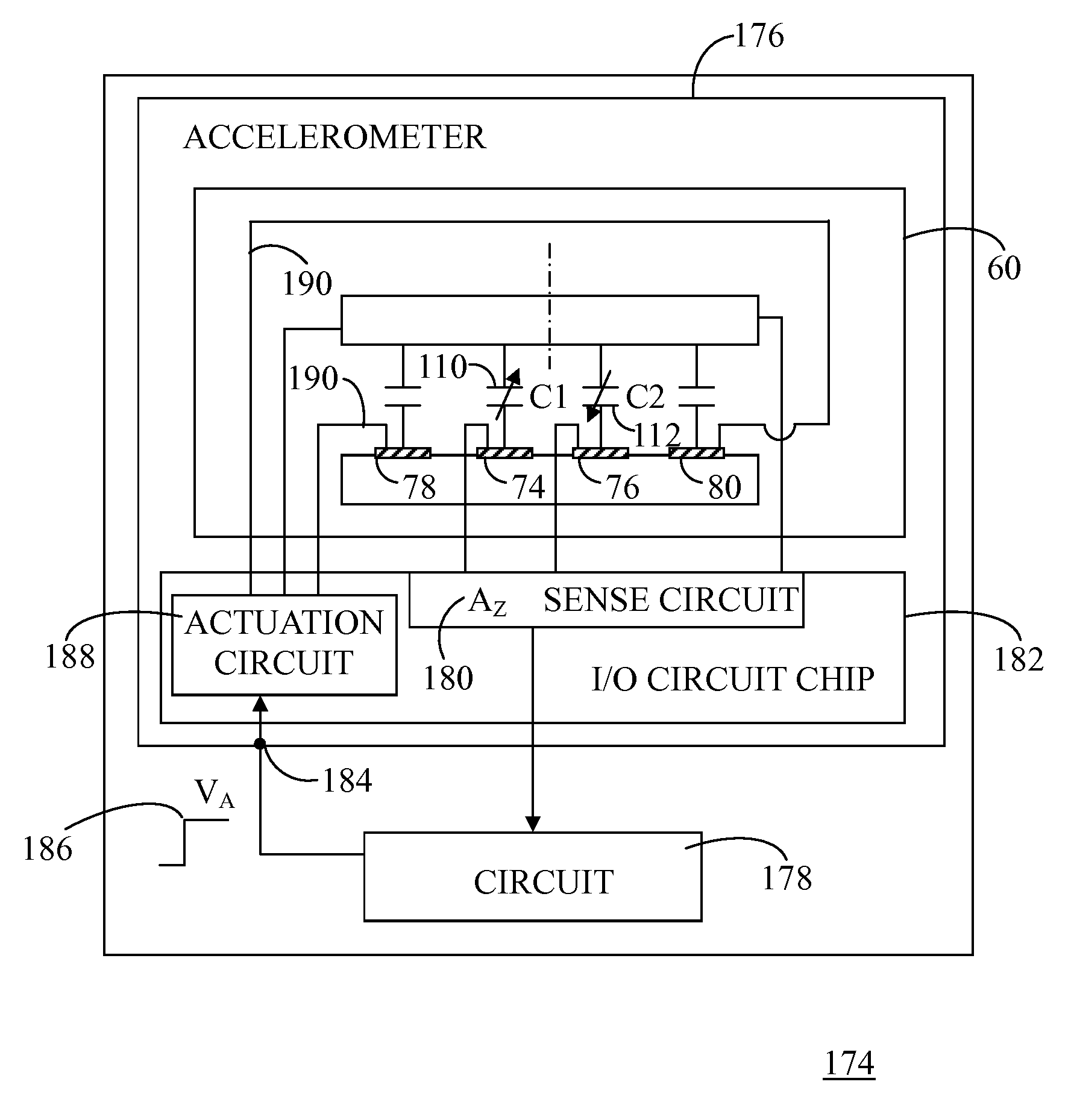

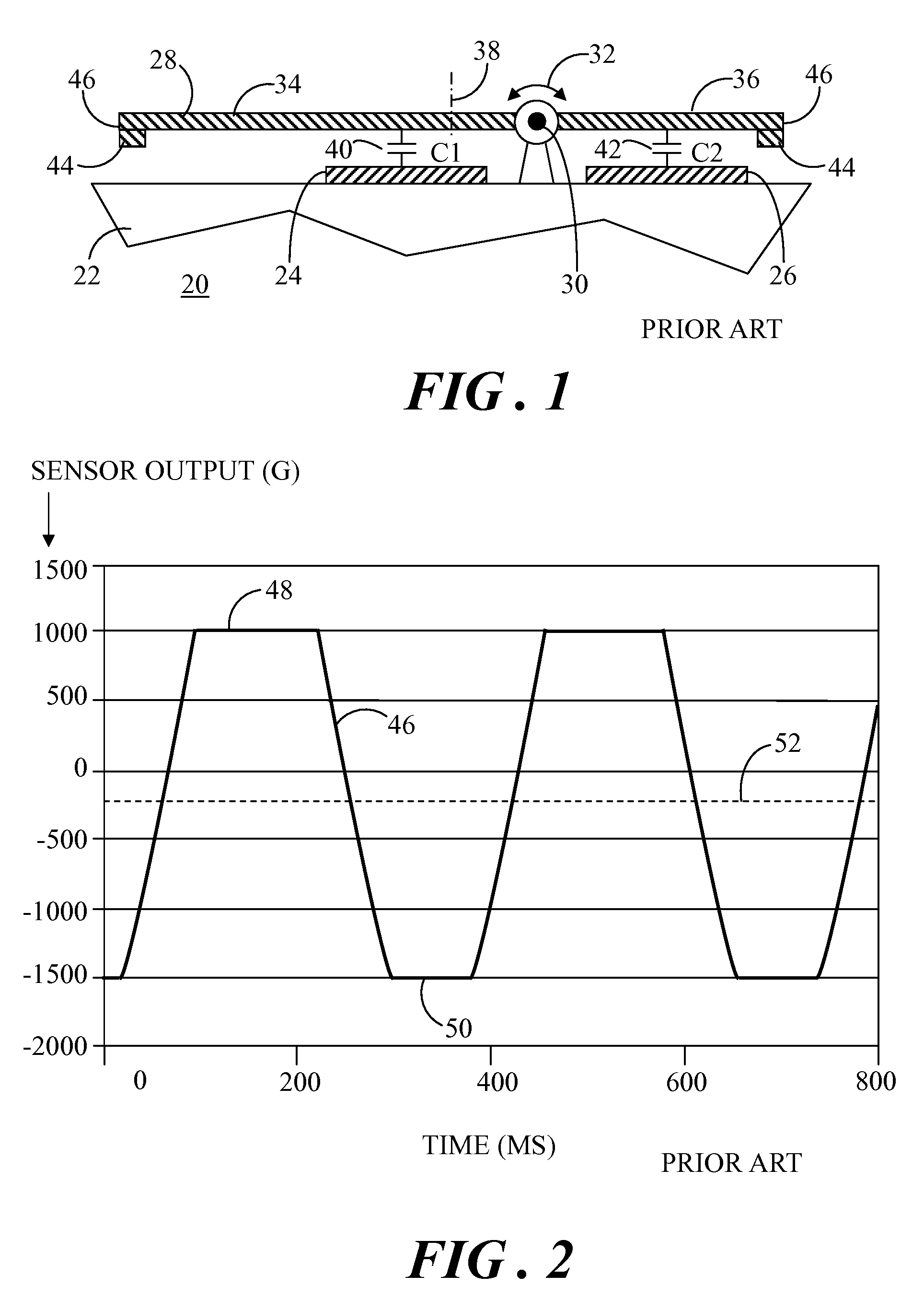

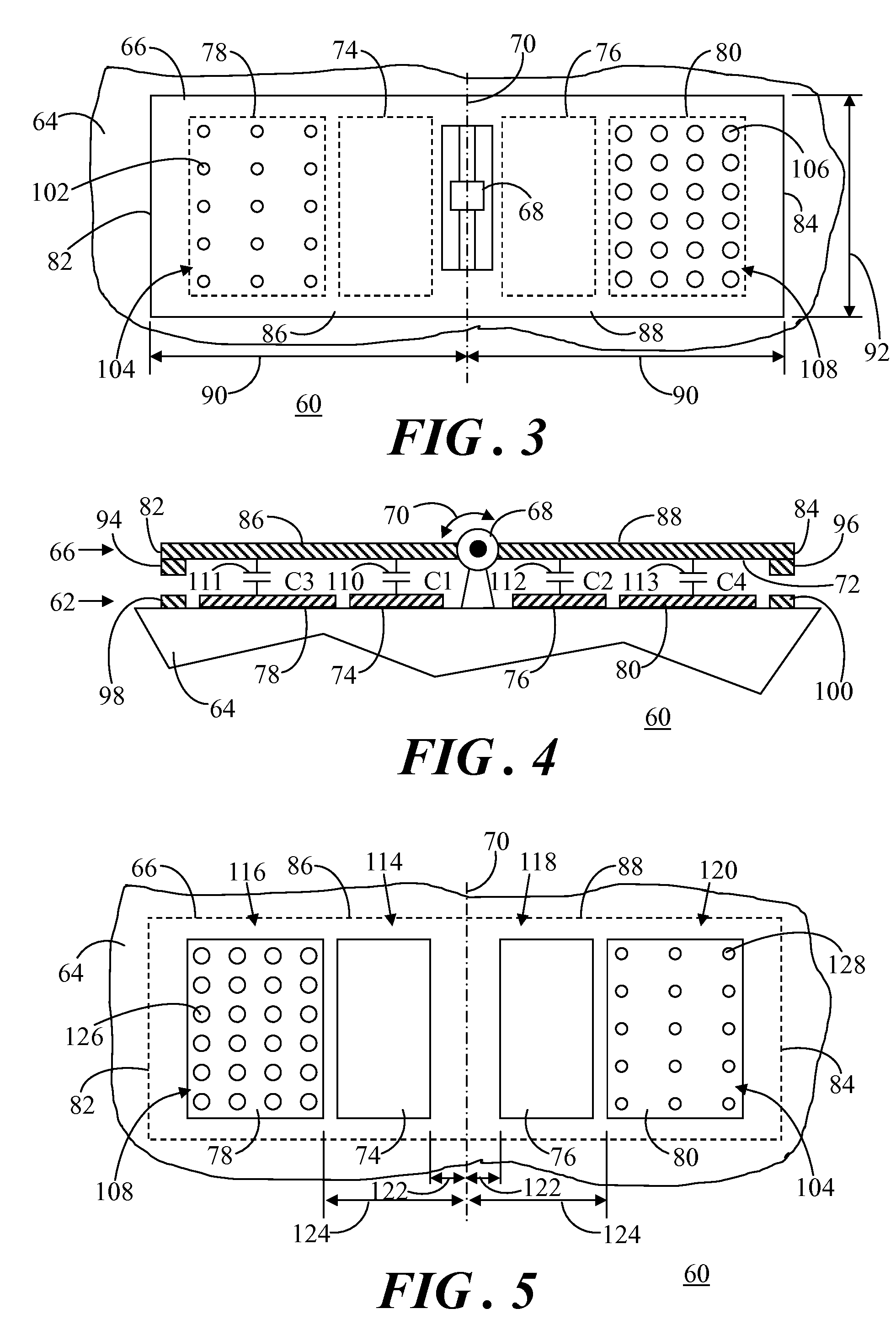

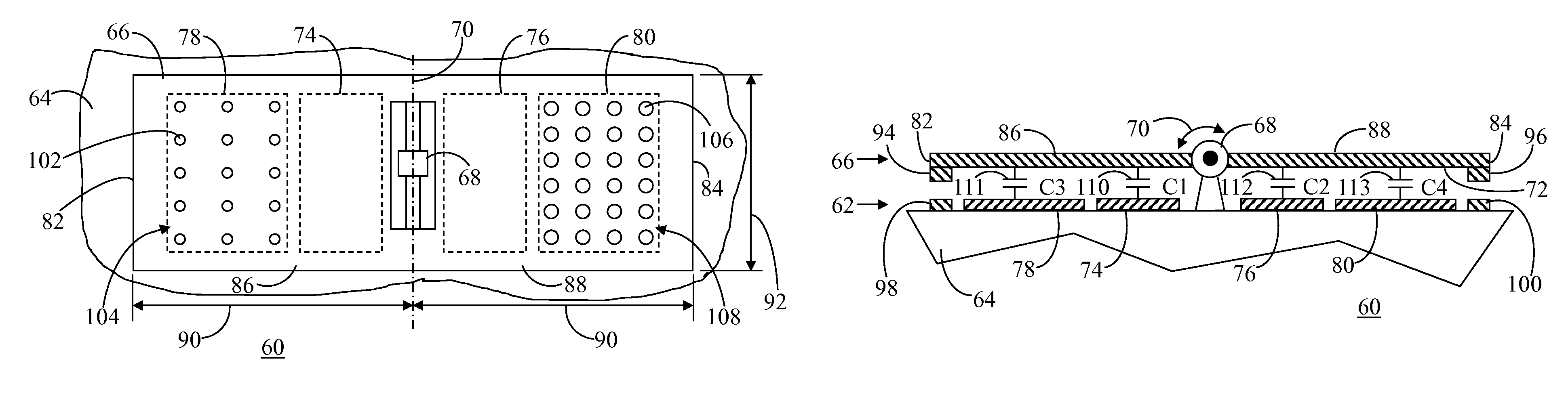

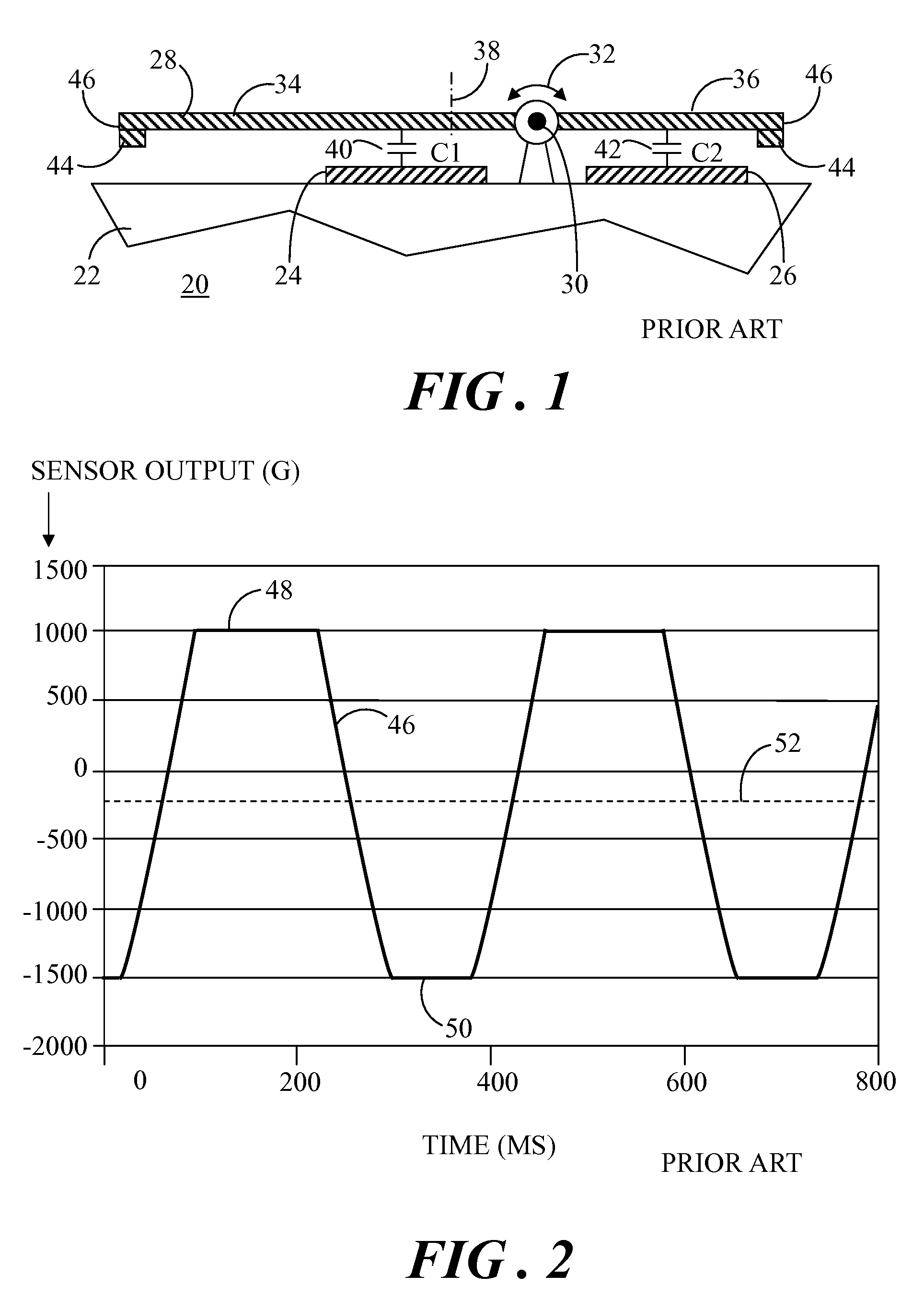

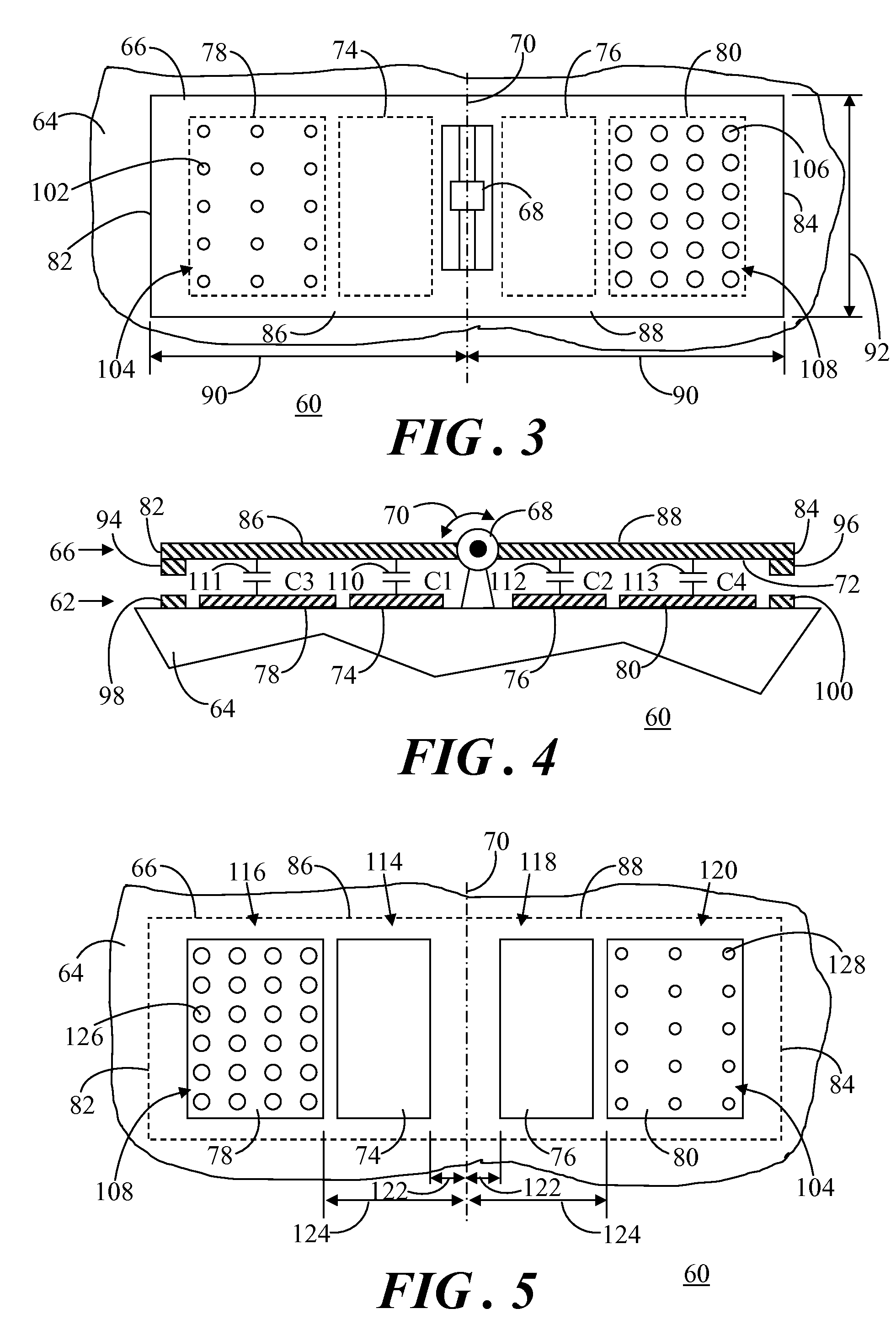

Symmetrical differential capacitive sensor and method of making same

A symmetrical differential capacitive sensor (60) includes a movable element (66) pivotable about a geometrically centered rotational axis (70). The element (66) includes sections (86, 88). Each of the sections (86, 88) has a stop (94, 96) spaced equally away from the rotational axis (70). Each of the sections (86, 88) also has a different configuration (104, 108) of apertures (102, 106). The configurations (104, 108) of apertures (102, 106) create a mass imbalance between the sections (86, 88) so that the element (66) pivots about the rotational axis (70) in response to acceleration. The apertures (102, 106) also facilitate etch release during manufacturing and reduce air damping when the element (66) rotates. Apertures (126, 128) are formed in electrodes (78, 80) underlying the apertures (102, 106) to match the capacitance between the two sections (86, 88) of movable element (86) to provide the same bi-directional actuation capability.

Owner:NORTH STAR INNOVATIONS

Symmetrical differential capacitive sensor and method of making same

A symmetrical differential capacitive sensor (60) includes a movable element (66) pivotable about a geometrically centered rotational axis (70). The element (66) includes sections (86, 88). Each of the sections (86, 88) has a stop (94, 96) spaced equally away from the rotational axis (70). Each of the sections (86, 88) also has a different configuration (104, 108) of apertures (102, 106). The configurations (104, 108) of apertures (102, 106) create a mass imbalance between the sections (86, 88) so that the element (66) pivots about the rotational axis (70) in response to acceleration. The apertures (102, 106) also facilitate etch release during manufacturing and reduce air damping when the element (66) rotates. Apertures (126, 128) are formed in electrodes (78, 80) underlying the apertures (102, 106) to match the capacitance between the two sections (86, 88) of movable element (86) to provide the same bi-directional actuation capability.

Owner:NORTH STAR INNOVATIONS

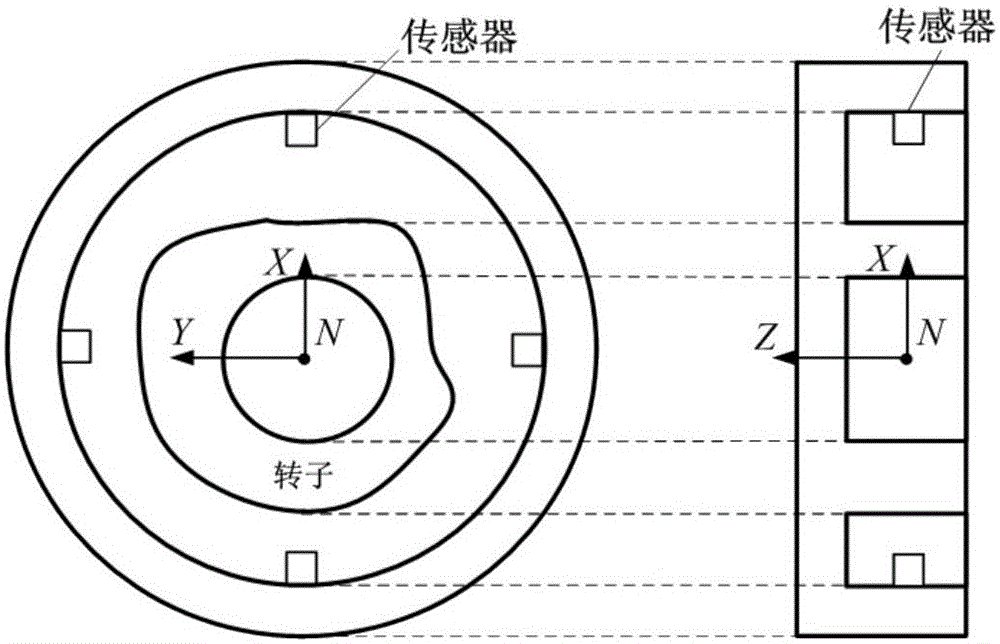

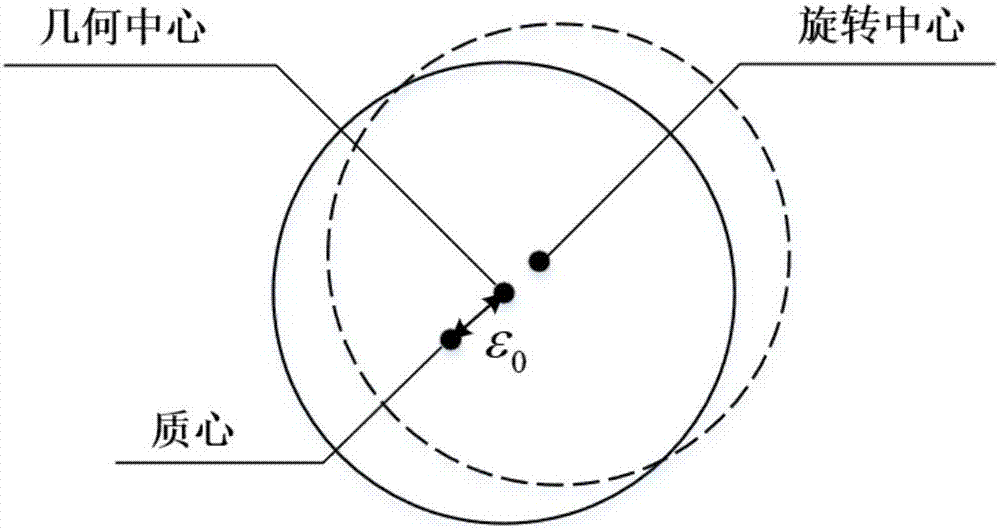

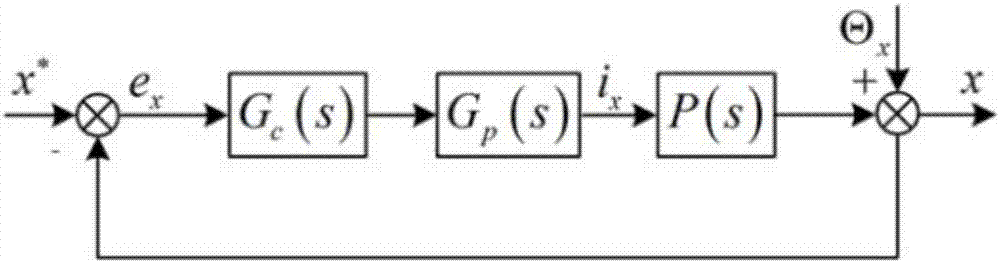

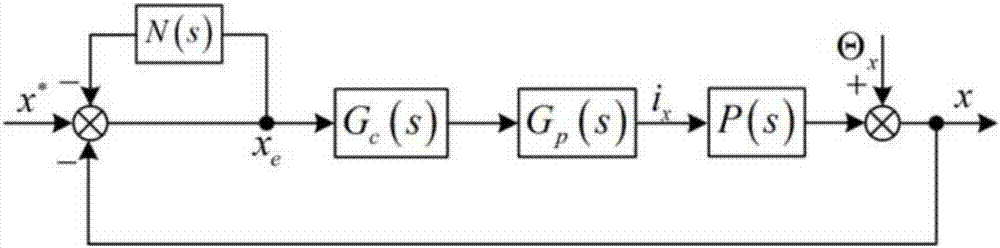

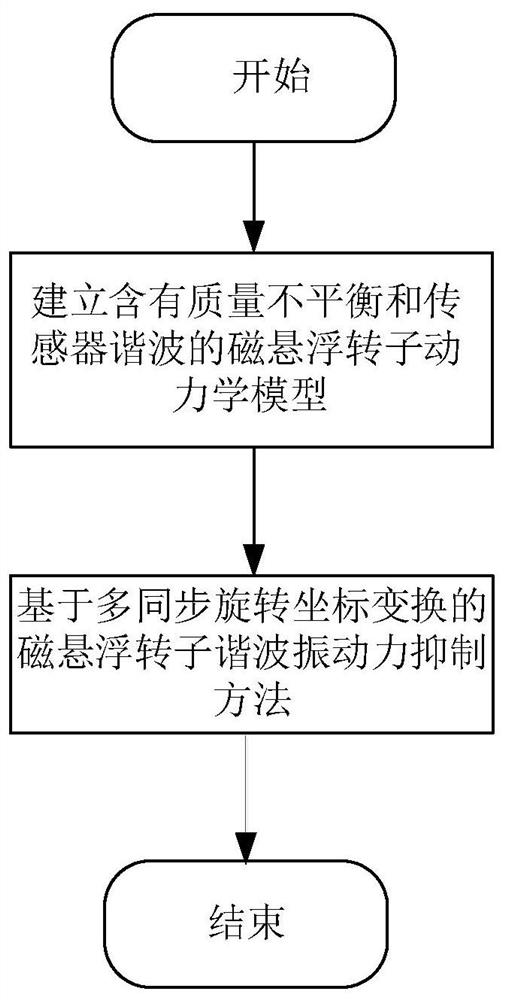

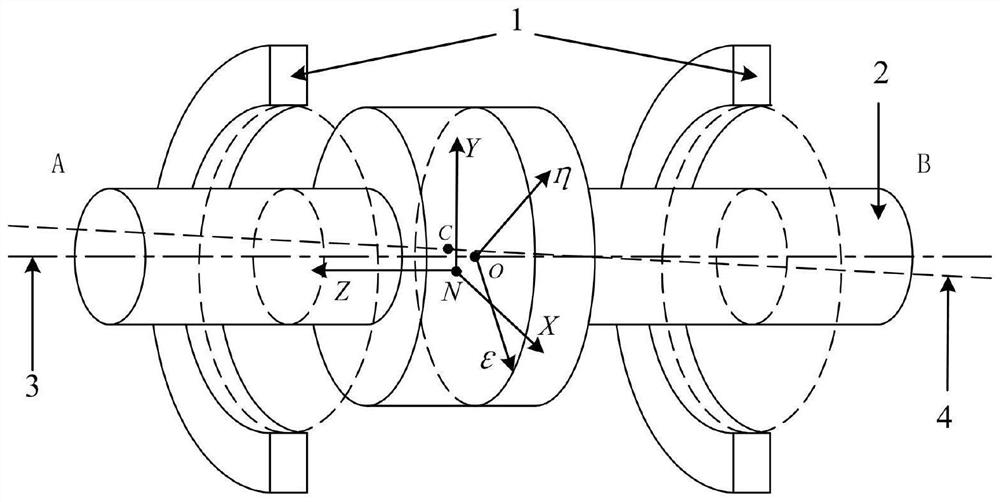

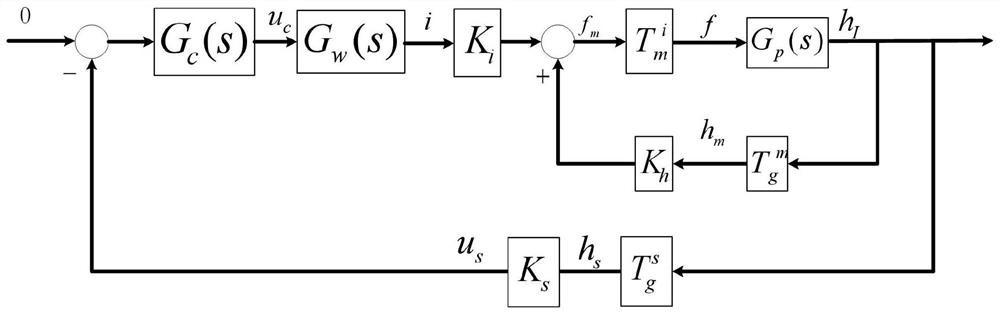

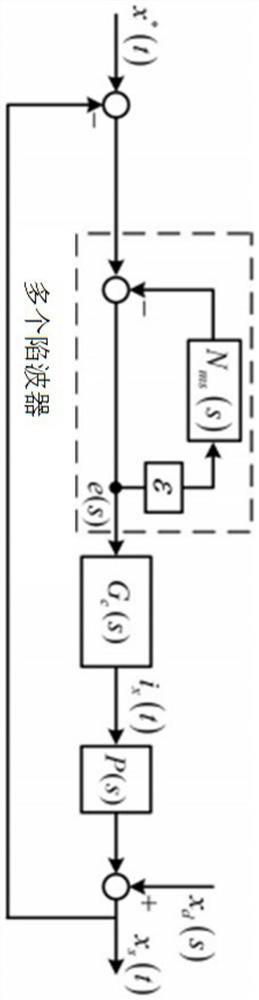

Magnetic suspension rotor harmonic current suppression method based on frequency self-adaptive fractional compensation repetition controller

InactiveCN106773673AAchieve precise suppressionEliminate the effects ofMagnetic holding devicesAdaptive controlGyroscopeLow-pass filter

The invention discloses a magnetic suspension rotor harmonic current suppression method based on a frequency self-adaptive fractional compensation repetition controller. The method comprises the steps that a magnetic suspension rotor dynamic model with unbalanced mass and sensor harmonics is established; after high-band signal amplitude attenuation and phase lag, which are caused by a low-pass filter Q (s), are considered, the disturbance suppression ability of a system is reduced; the low-pass filter Q (s) is moved to the branch of the repetition controller from the inside feedback loop; a fractional order compensation link is replaced by a fractional delay filter; and through online updating of the coefficients of the fractional delay filter, precise harmonic current suspension at any frequency can be realized. According to the invention, precise harmonic current suspension of a magnetic suspension flywheel or a magnetic suspension gyroscope at any rated speed can be realized, and the method is suitable for current suppression of magnetic suspension rotor harmonics with mass imbalance and sensor harmonics.

Owner:BEIHANG UNIV

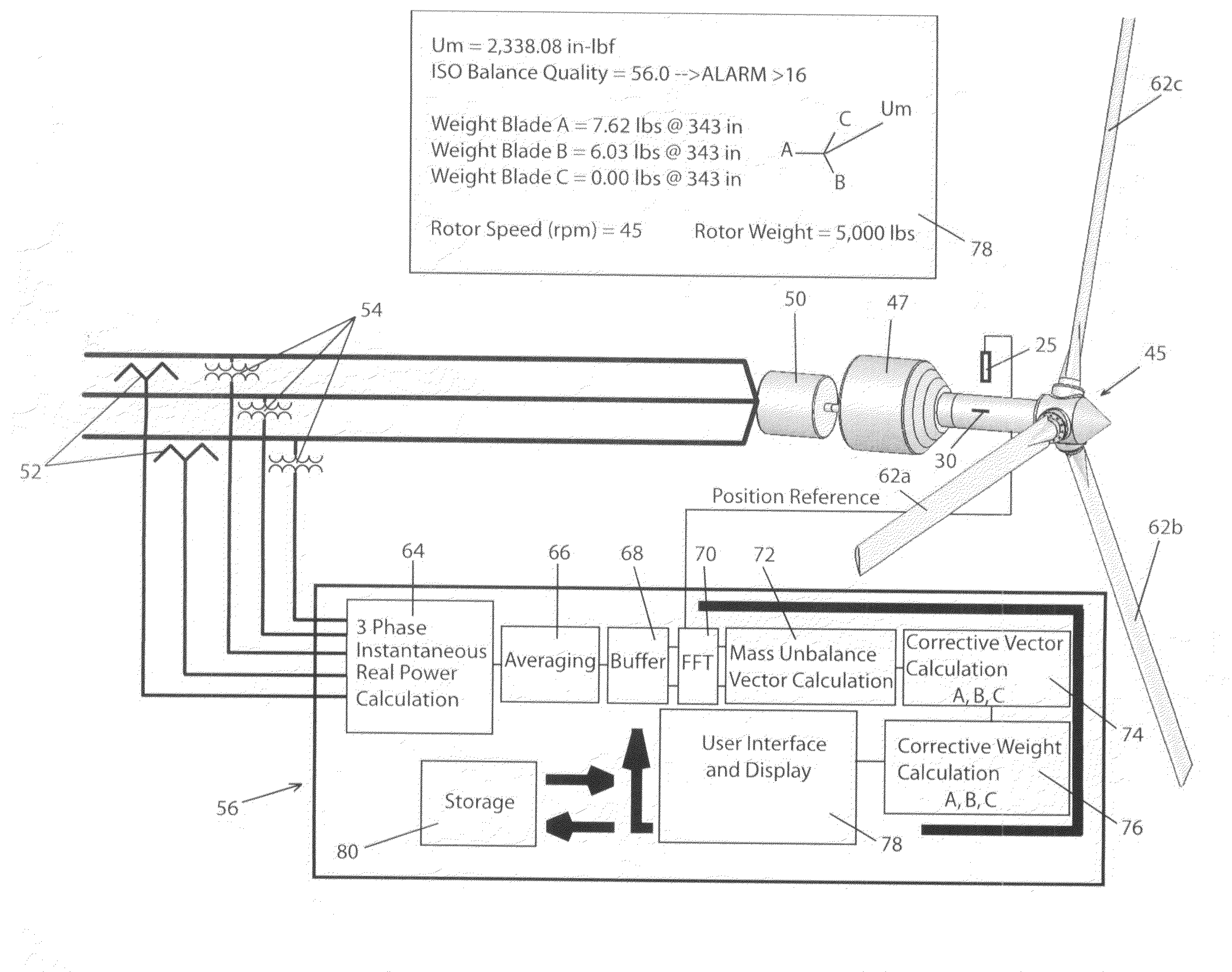

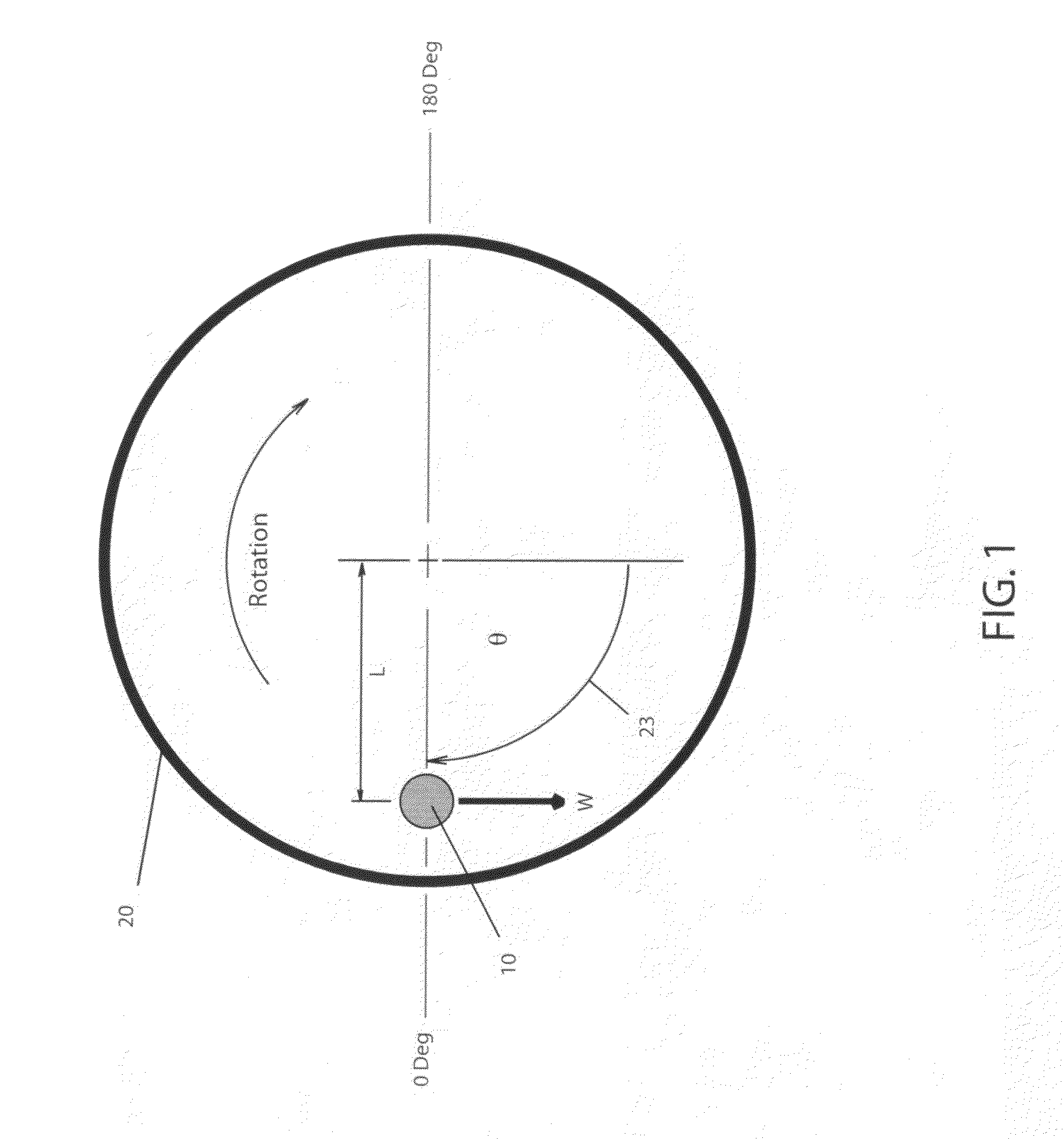

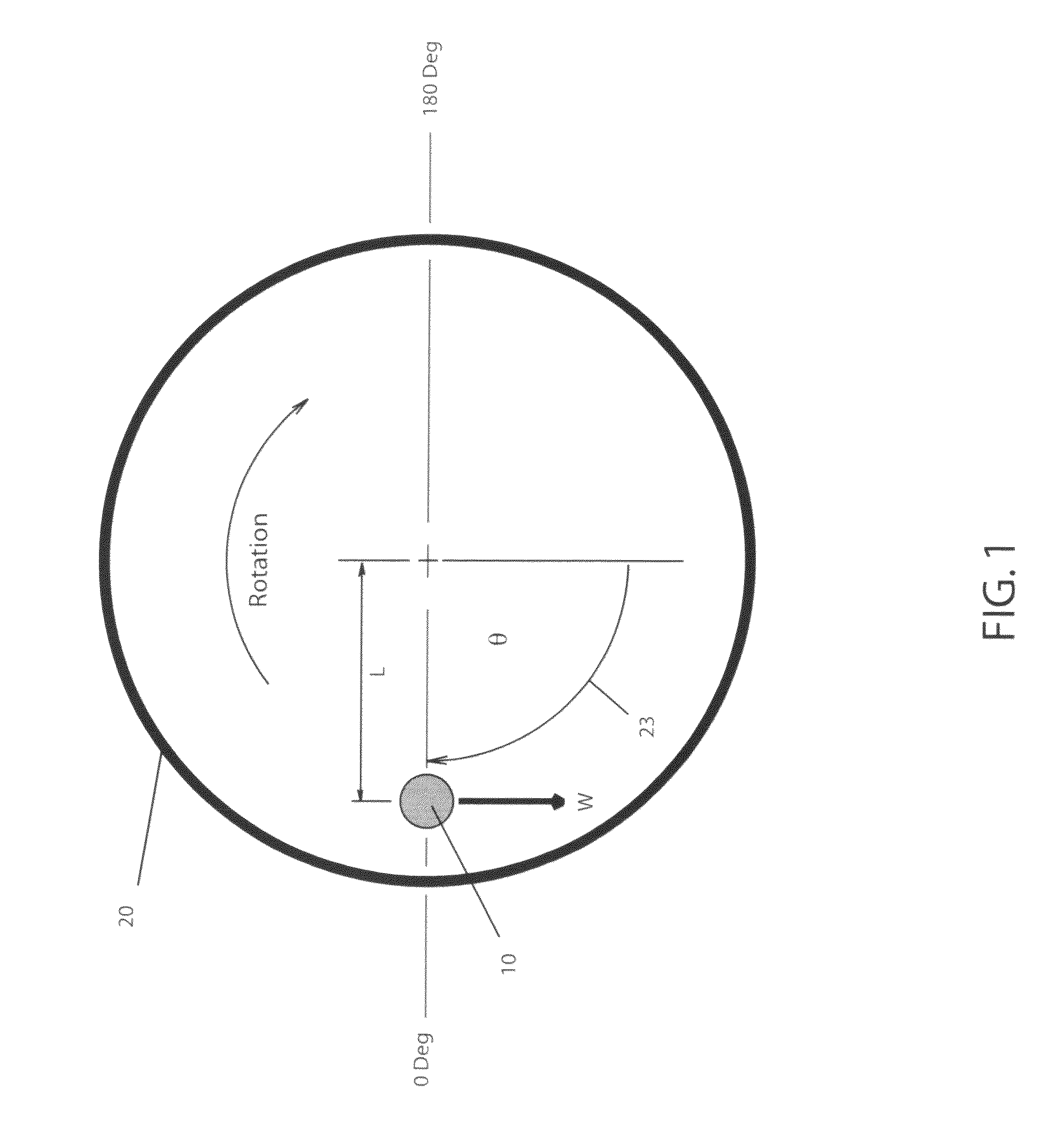

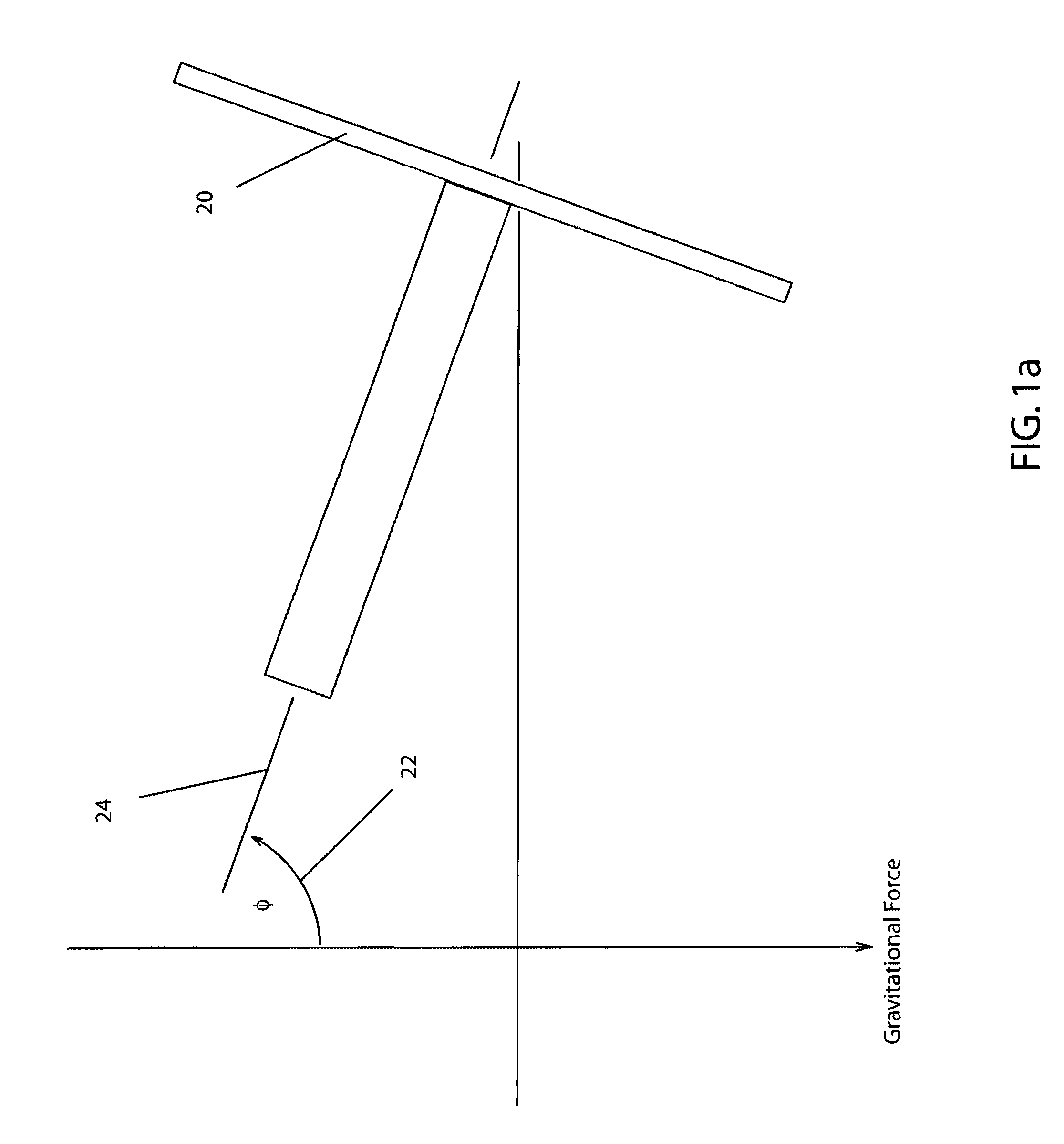

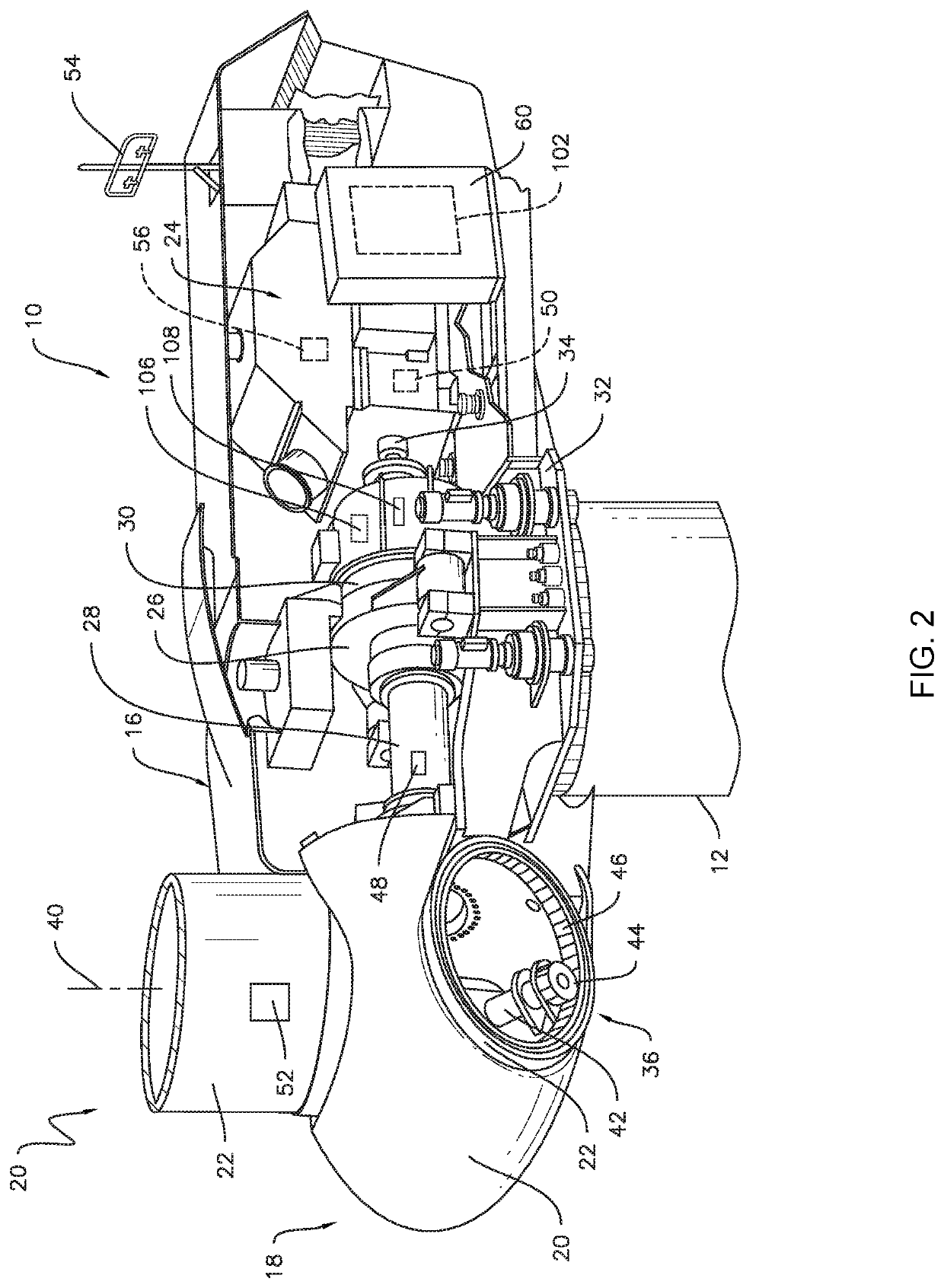

Method and apparatus for in situ unbalance and corrective balance determination for a non-vertical axis rotating assembly

InactiveUS20110036166A1Method is inaccurateSampled-variable control systemsComputer controlPhase differenceFourier transform on finite groups

The invention discloses a novel method and apparatus to determine the degree of residual mass unbalance and a corrective balance solution for a rotating assembly having a non-vertical axis of rotation. When the center of mass of the rotating assembly is not concentric with the axis of rotation, the condition of unbalance exists. When the rotating assembly is driven by a motor or drives a generator, fluctuations in power are produced proportional to the degree of unbalance. The method and apparatus to determine the degree of mass imbalance consists of measuring the average instantaneous real power over an interval of time, calculating the Fourier Transform of the demodulated signal, establishing the peak amplitude and phase associated with the angular velocity of the rotating assembly and calculating the amount of unbalance. The method and apparatus to provide for a corrective solution consists of simultaneously acquiring a position reference signal of the rotating assembly with the average instantaneous real power signal, calculating the phase difference between the two acquired signals at the angular velocity of the rotating assembly, calculating the magnitude of the unbalance, and calculating the quantity and location of corrective weight necessary to minimize the unbalance to an acceptable level.

Owner:LENZ MICHAEL A W

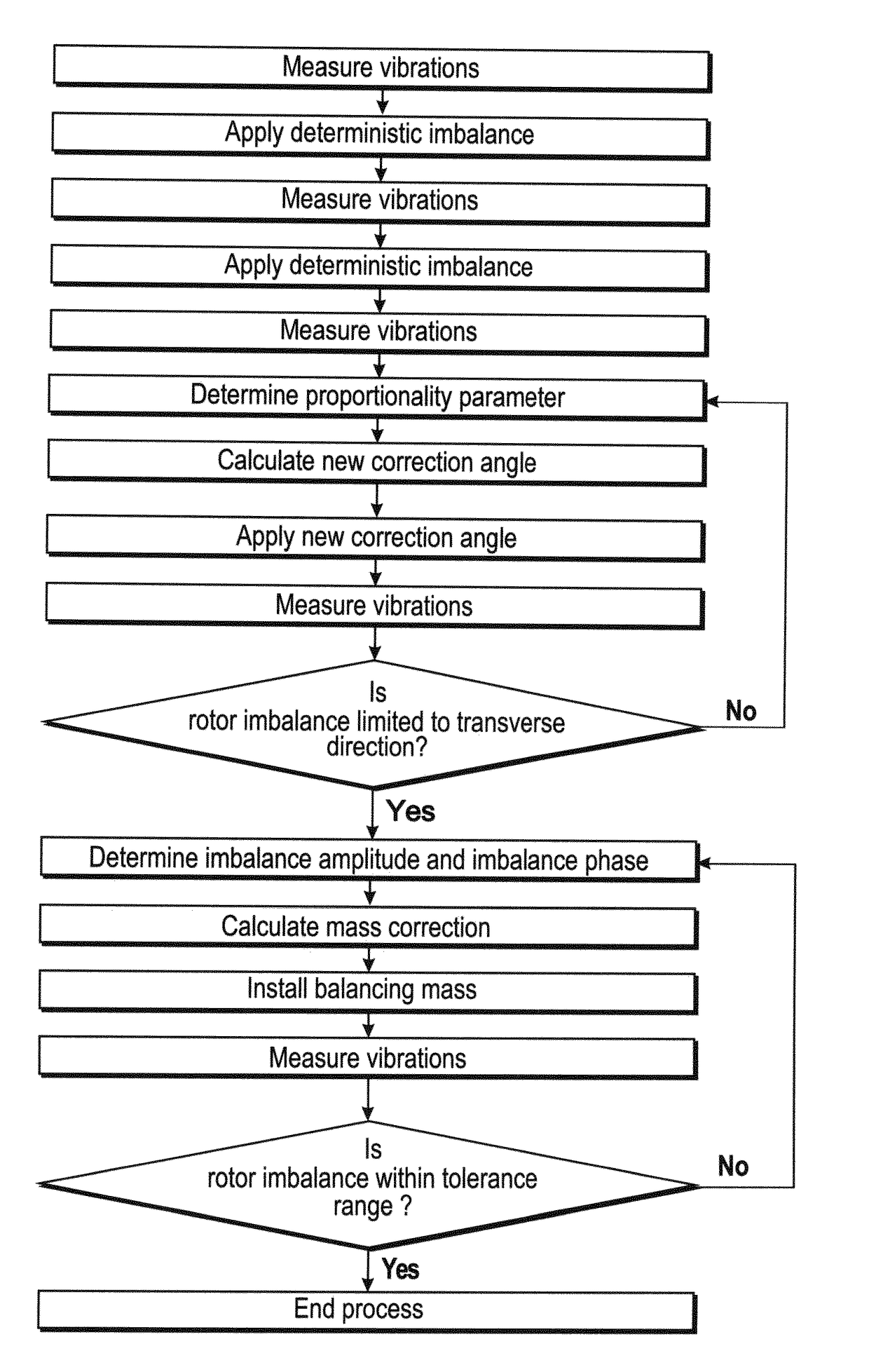

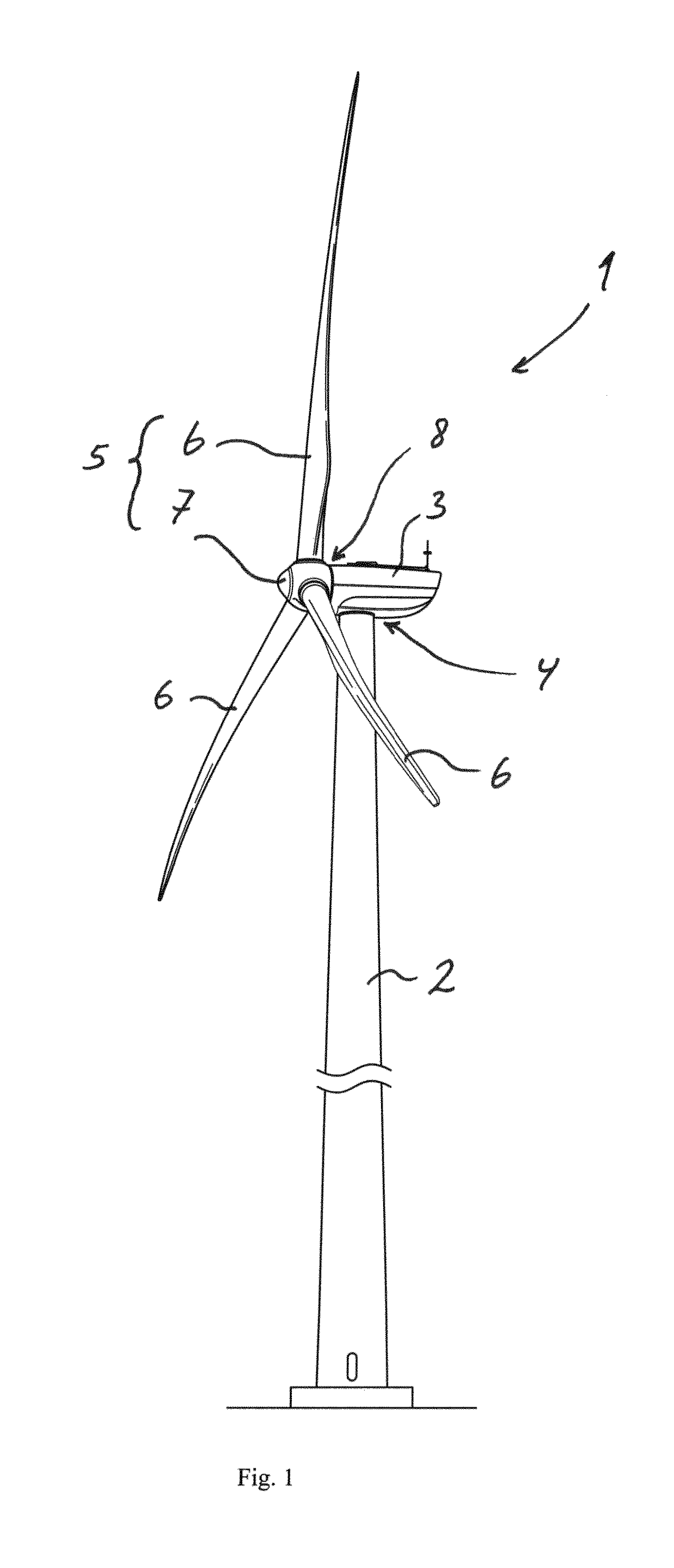

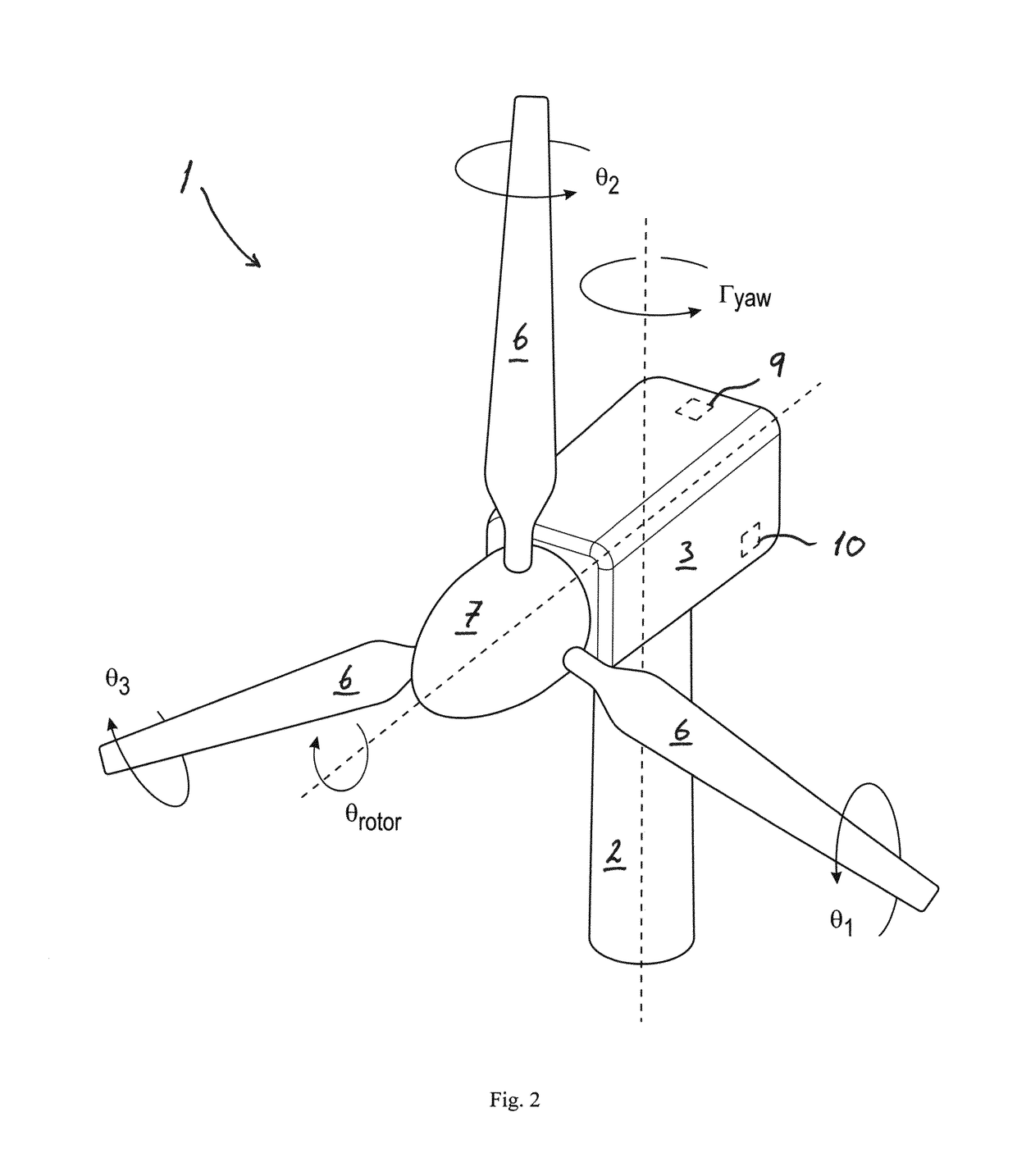

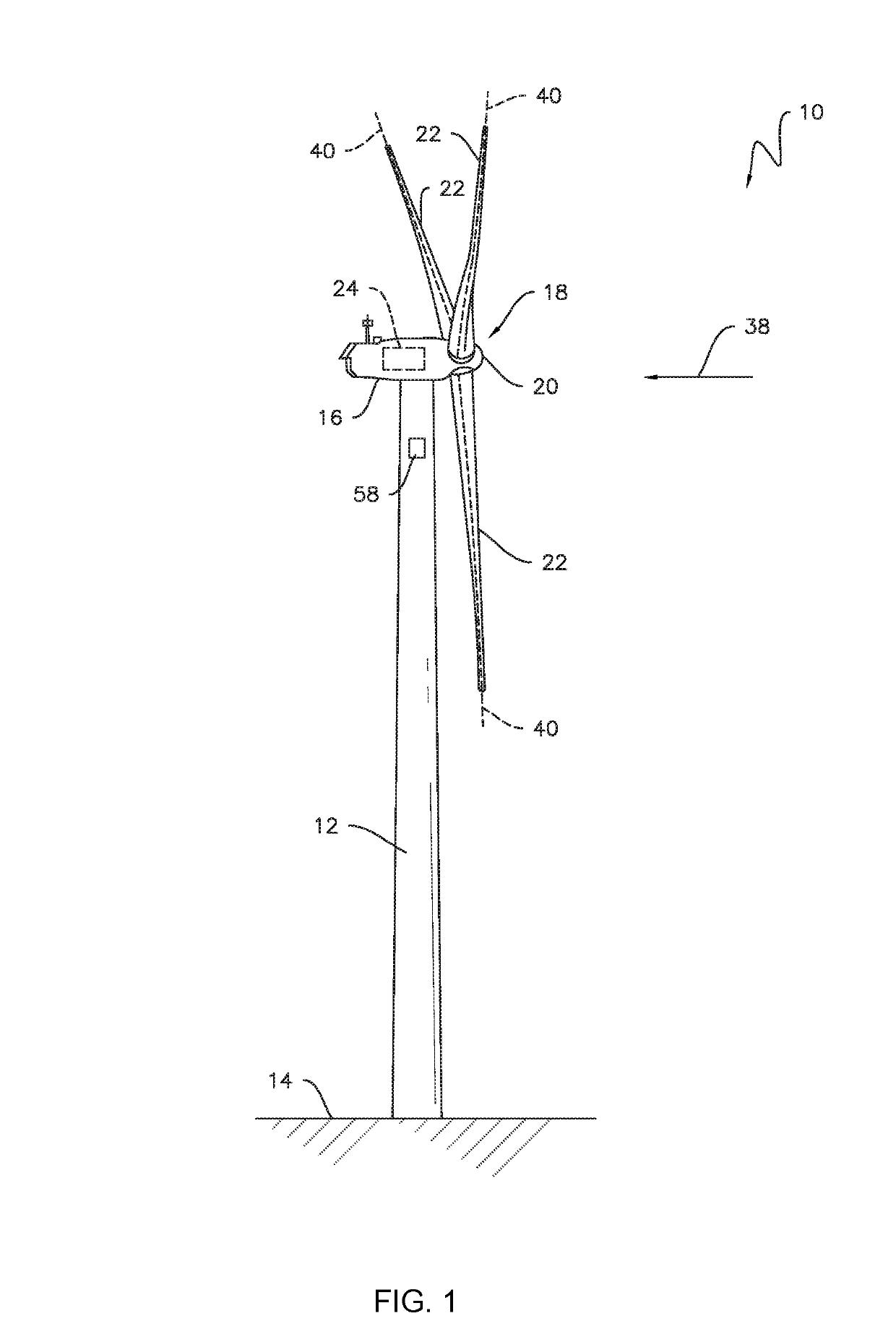

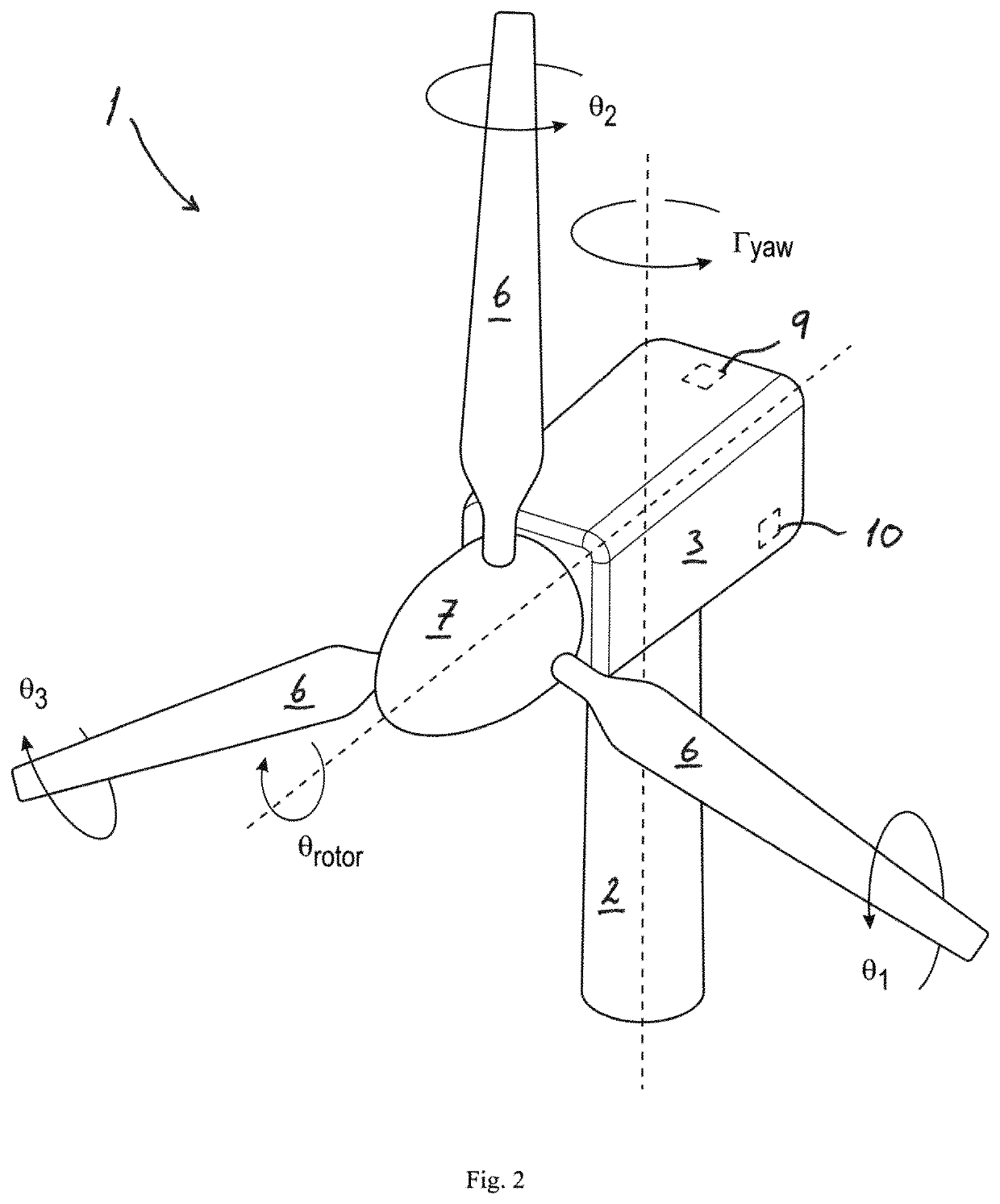

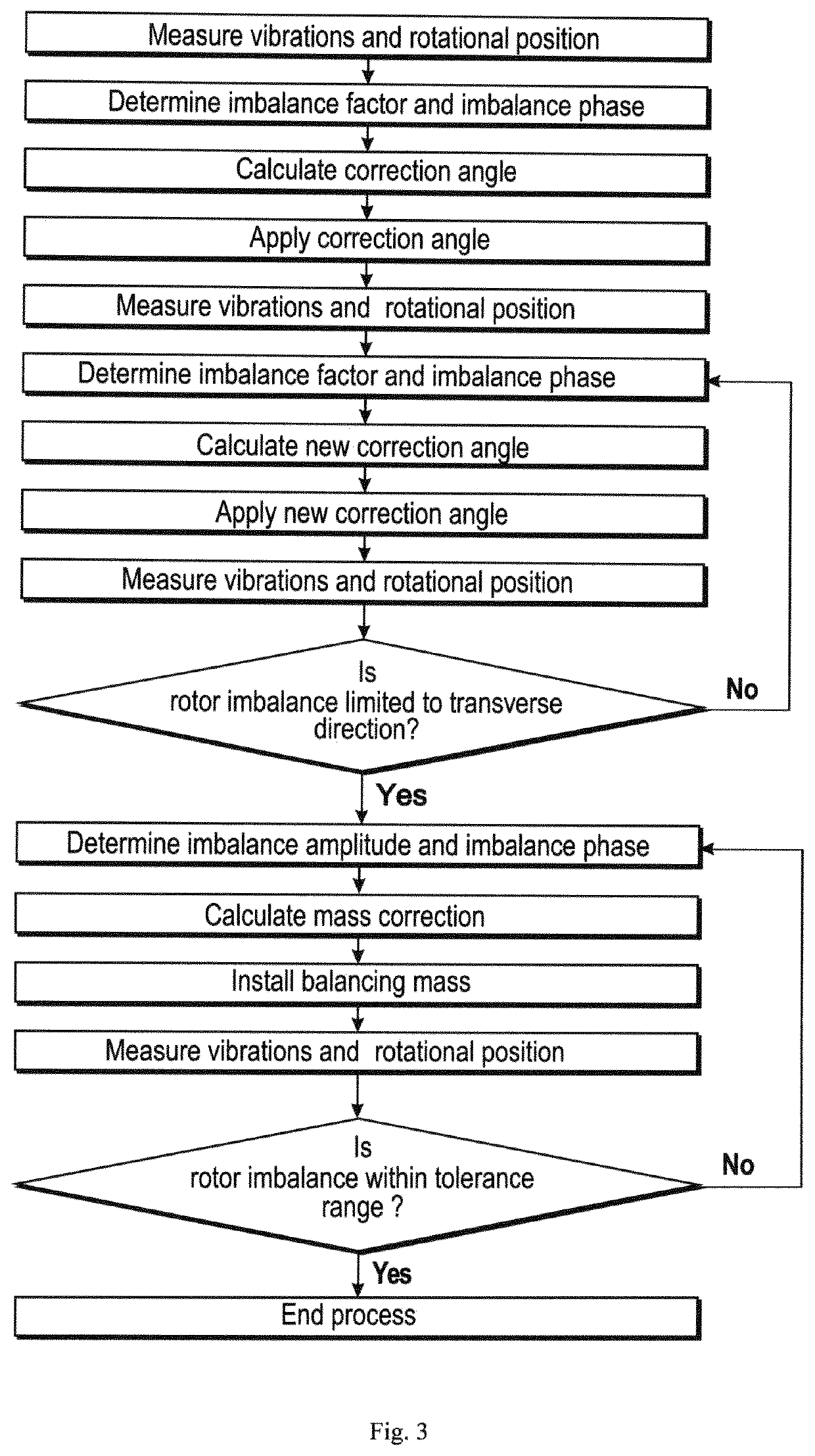

Method of Correcting Rotor Imbalance and Wind Turbine Thereof

ActiveUS20180142676A1Shorten the timeLow costWind motor controlMachines/enginesTurbine bladeEngineering

The present invention relates to a method of correcting rotor imbalance and a wind turbine thereof. The correction method comprises measuring the vibrations within at least one time window and determining an imbalance factor and an imbalance phase. The values of the parameters in the equation for calculating the correction action are then updated based on the imbalance factor and an imbalance phase. A correction angle for each of the wind turbine blades is calculated using these adjusted parameters. The correction angle is used to aerodynamically balance the rotor, and a model may be used to determine the initial values of the parameters. Another imbalance factor and imbalance phase is determined based on another set of measurements. This imbalance factor is then used to calculate a mass moment for correcting the mass imbalance in the wind turbine blades. The weight and location of a balancing mass is finally calculated based on this mass moment and installed in the respective wind turbine blades.

Owner:ENVISION ENERGY DENMARK

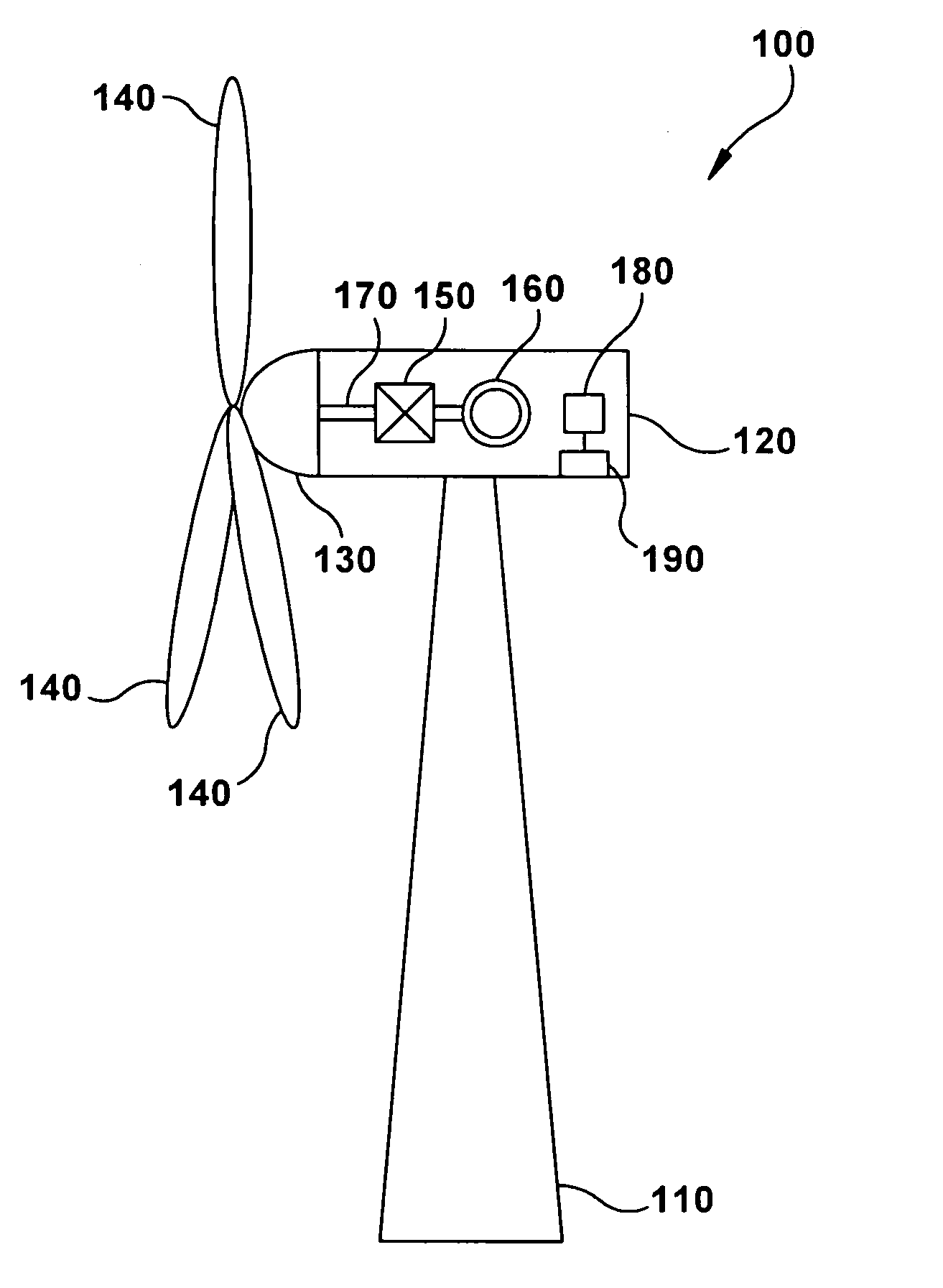

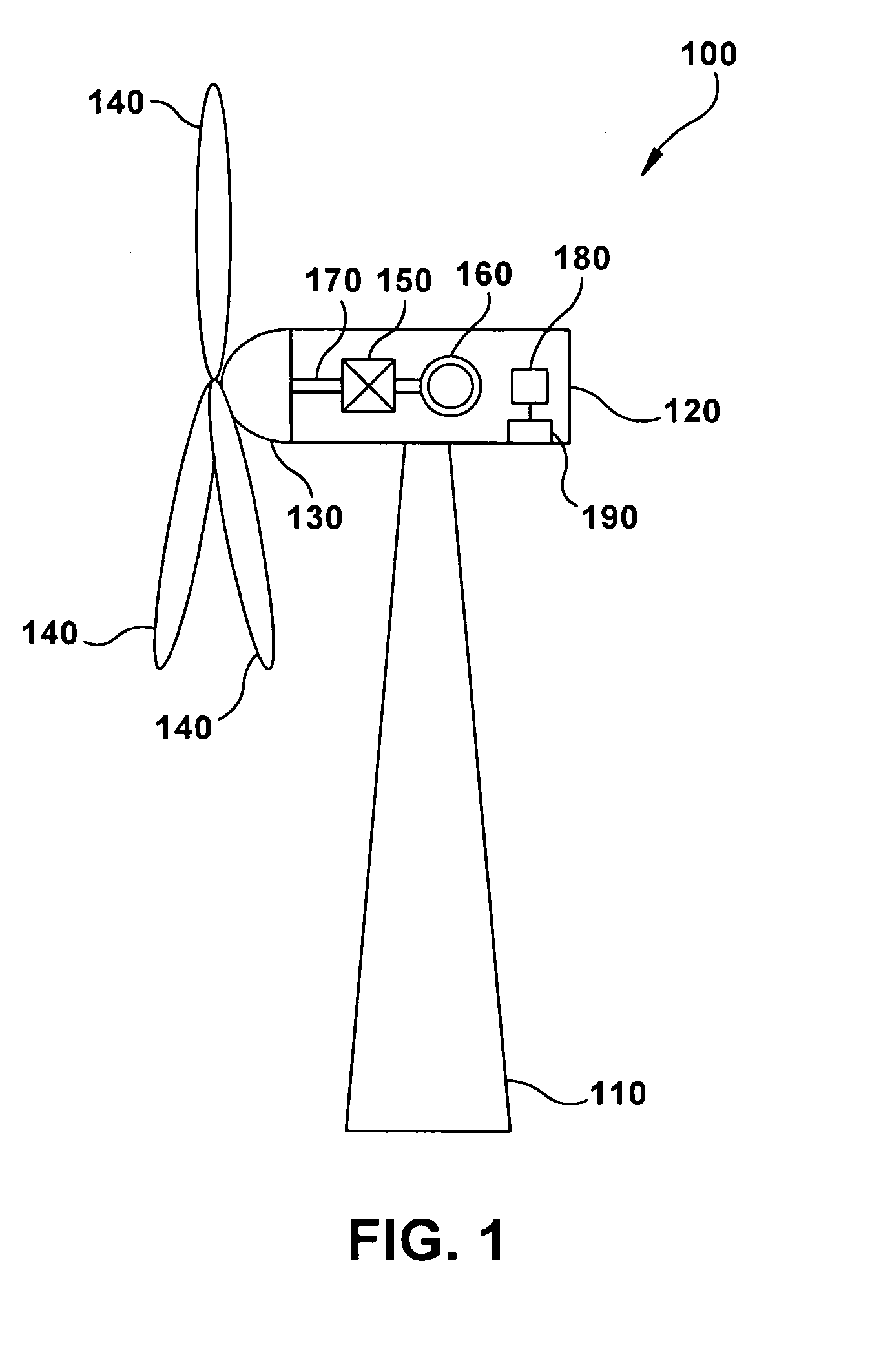

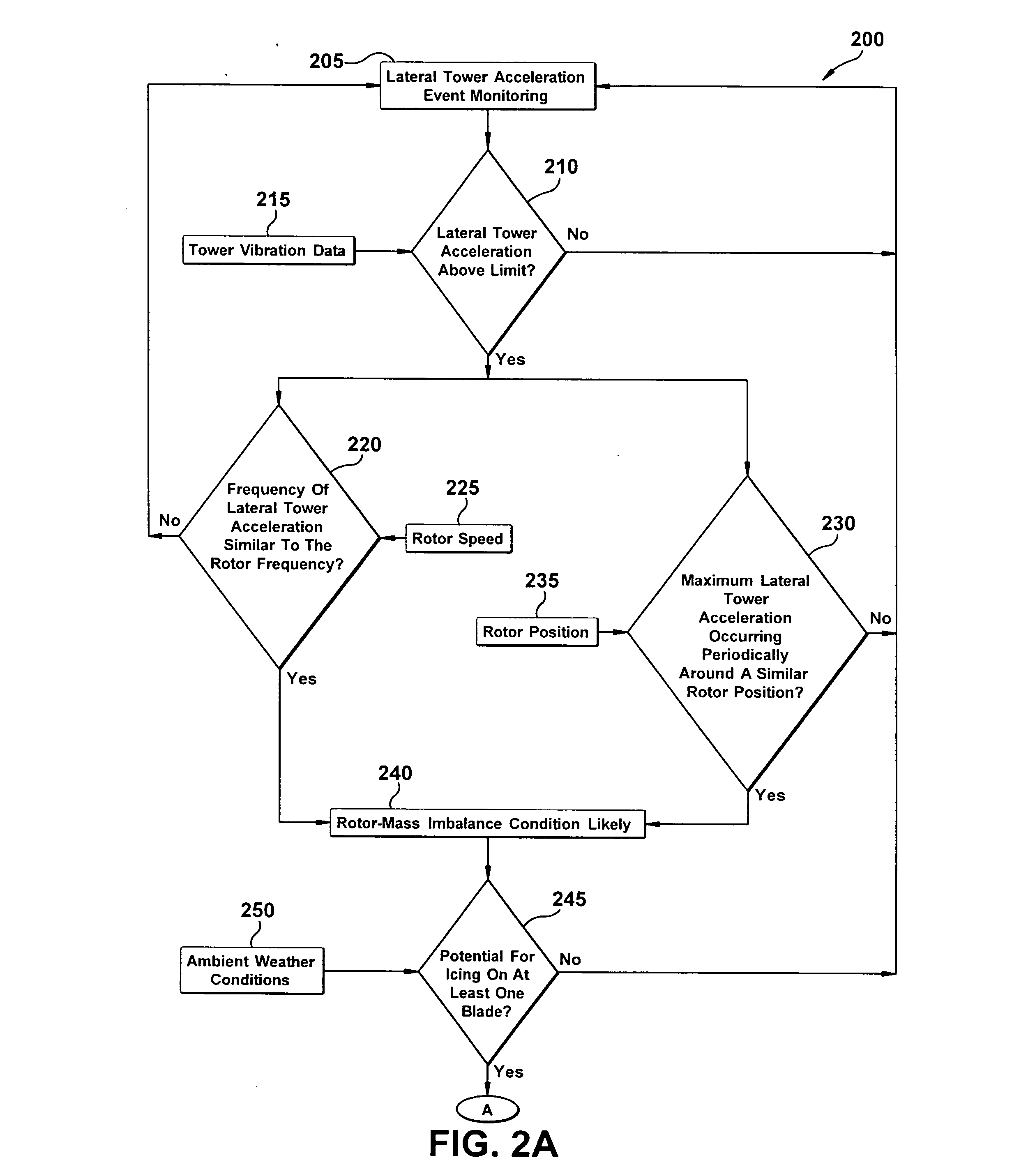

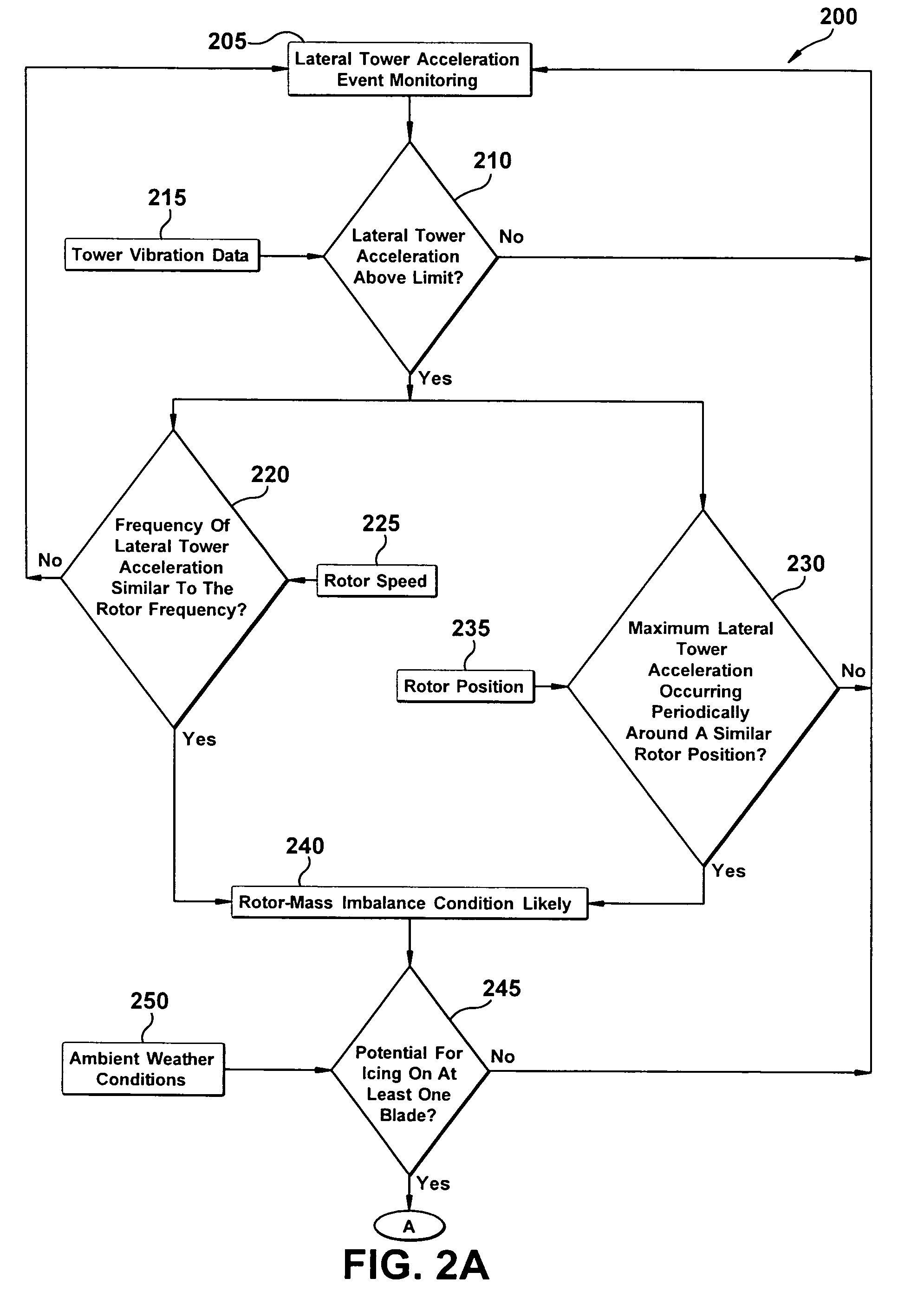

Method and system for utilizing lateral tower acceleration to detect asymmetric icing

A method and system for detecting asymmetric utilizing lateral tower acceleration data may include: providing a lateral tower acceleration monitoring system; determining from the lateral tower acceleration monitoring system whether a lateral tower acceleration is above an acceleration limit; determining whether a rotor-mass imbalance condition exists; and determining whether the lateral tower acceleration coincides with icing on a rotor.

Owner:GENERAL ELECTRIC CO

Method and system for utilizing lateral tower acceleration to detect asymmetric icing

A method and system for detecting asymmetric utilizing lateral tower acceleration data may include: providing a lateral tower acceleration monitoring system; determining from the lateral tower acceleration monitoring system whether a lateral tower acceleration is above an acceleration limit; determining whether a rotor-mass imbalance condition exists; and determining whether the lateral tower acceleration coincides with icing on a rotor.

Owner:GE INFRASTRUCTURE TECH INT LLC

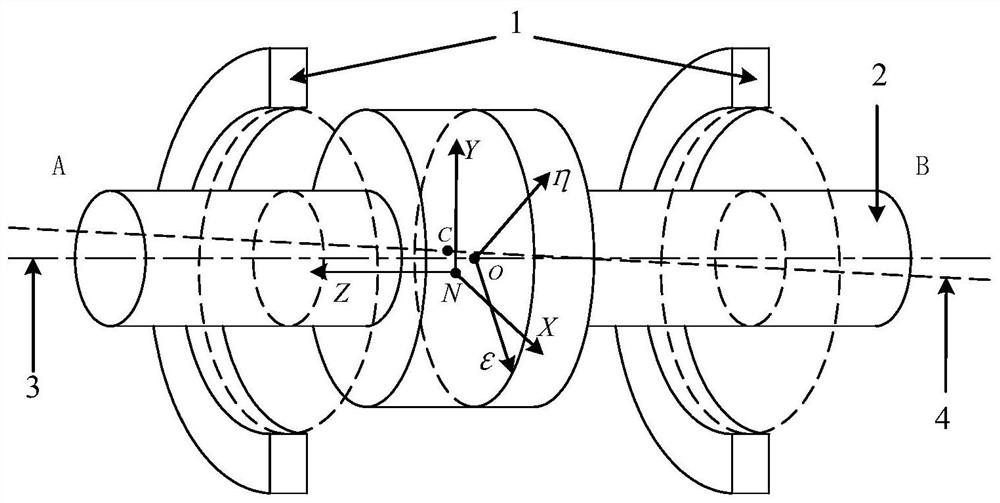

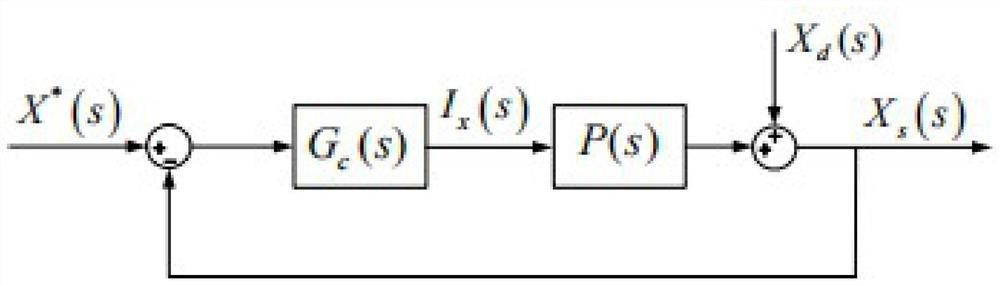

Magnetic suspension flywheel vibration moment suppression method based on synchronous rotation coordinate transformation algorithm

ActiveCN109189114ASuppress the same frequency vibration torqueGuaranteed stabilityMechanical oscillations controlSynchronous motorTransformation algorithm

The invention relates to a magnetic suspension flywheel vibration moment suppression method based on a synchronous rotation coordinate transformation algorithm, and belongs to the field of magnetic suspension flywheel vibration suppression. The method comprises the steps of: establishing a magnetic suspension flywheel kinetic model; establishing an unbalanced force and an unbalanced moment model based on the model; reconstructing a control system with complex coefficients to simplify the structure of the system and to reduce the orders; introducing the synchronous rotation coordinate transformation by establishing a stationary coordinate system and a rotation coordinate system; and identifying the same-frequency component in the vibration moment using the synchronous rotation coordinate transformation, and taking the obtained same-frequency component as the input of a controller to suppress the same-frequency vibration moment. According to the magnetic suspension flywheel vibration moment suppression method based on the synchronous rotation coordinate transformation algorithm, the vibration moment generated by the mass imbalance of magnetic suspension rotors is suppressed based onthe synchronous rotation coordinate transformation algorithm, thereby achieving the control effect of effectively suppressing the vibration moment under the condition of full speed range and ensuringthe system stability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

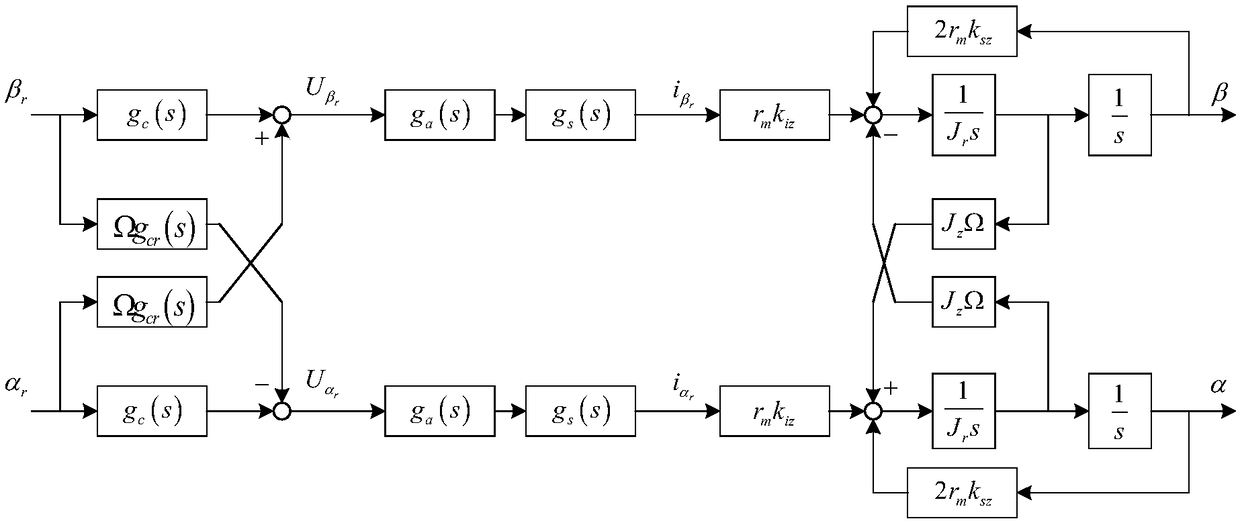

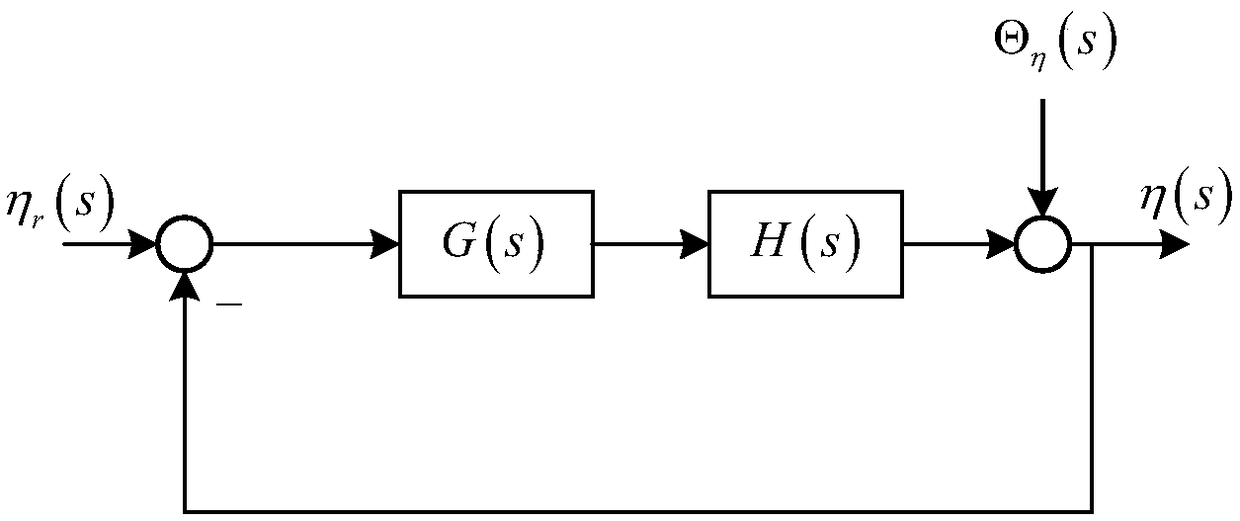

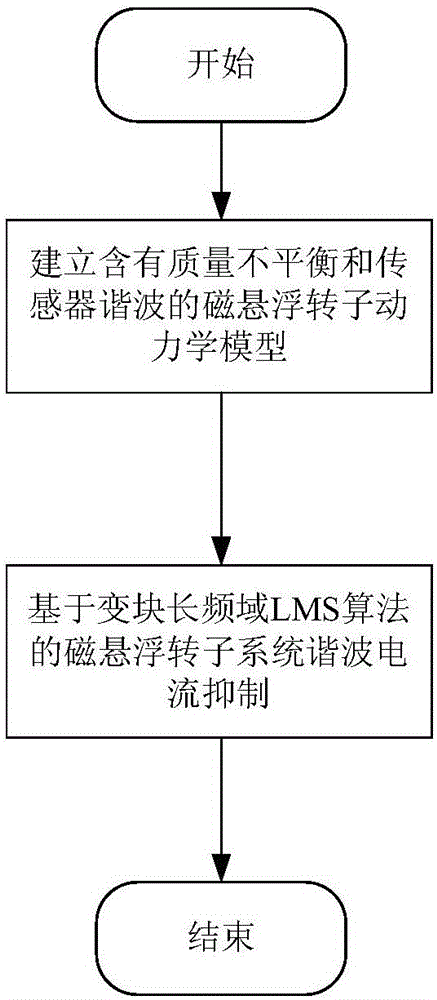

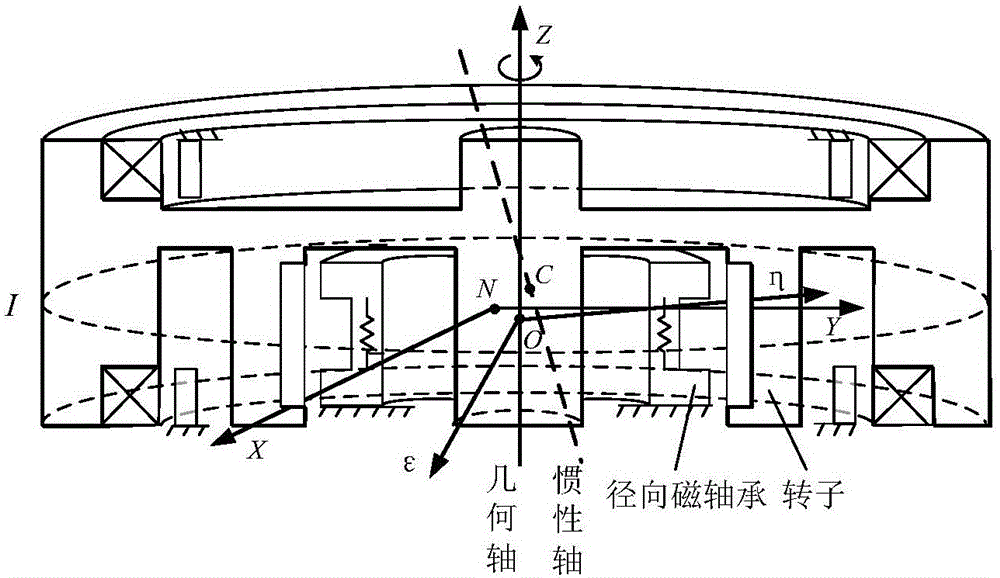

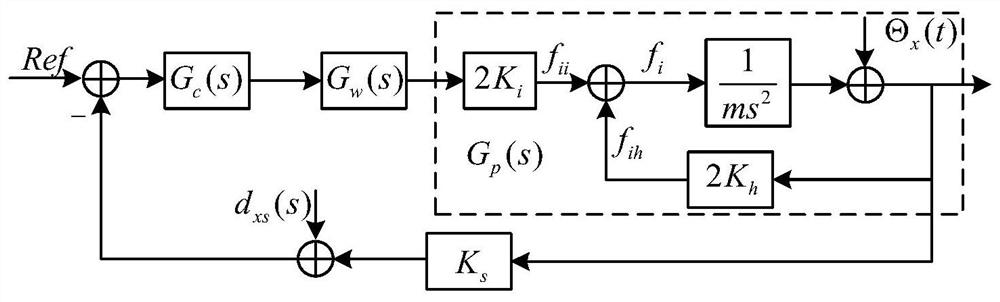

Harmonic current inhibition method for magnetic suspension rotor based on frequency-domain LMS (Least Mean Square) algorithm of variable block length

ActiveCN105159341AFast convergenceReduced stability errorMechanical oscillations controlMagnetic bearingMean square

The invention discloses a harmonic current inhibition method for a magnetic suspension rotor based on a frequency-domain LMS algorithm of variable block length. Aimed at a magnetically suspended control moment gyro, a dynamics model of the magnetic suspension rotor with mass imbalance and sensor harmonic waves is established, the harmonic current inhibition method based on the frequency-domain LMS algorithm of variable block length is designed, the block length can be adjusted adaptively according to errors, and the convergence performance is improved. The method can be used to inhibit the harmonic component in current of a magnetic bearing coil in the magnetic suspension rotor, and is suitable for inhibiting the harmonic current of a magnetic suspension sub system with mass imbalance and the sensor harmonic waves.

Owner:BEIHANG UNIV

Phase-lag-compensation-based same-frequency vibration force suppression method and control system of magnetically suspended flywheel

ActiveCN108008745AGuaranteed stabilitySuppress disturbanceMechanical oscillations controlAdaptive controlPhase shiftedControl system

The invention discloses a phase-lag-compensation-based same-frequency vibration force suppression method and control system of a magnetically suspended flywheel. For a magnetically suspended flywheel,a magnetically suspended rotor kinetic model including a same-frequency vibration force is established by considering rotor mass imbalance; with a phase-shift trap filter, a same-frequency disturbance component in a control current at a time-varying rotation speed frequency is eliminated effectively; and then a residual same-frequency vibration force in displacement stiffness is eliminated completely by using a proportional compensation term and an additional compensation term. Therefore, the high-precision and high-robustness time-varying same-frequency vibration force suppression performance is obtained; and the suppression method and control system have the reference significance in active vibration control of a magnetic suspension-rotor system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

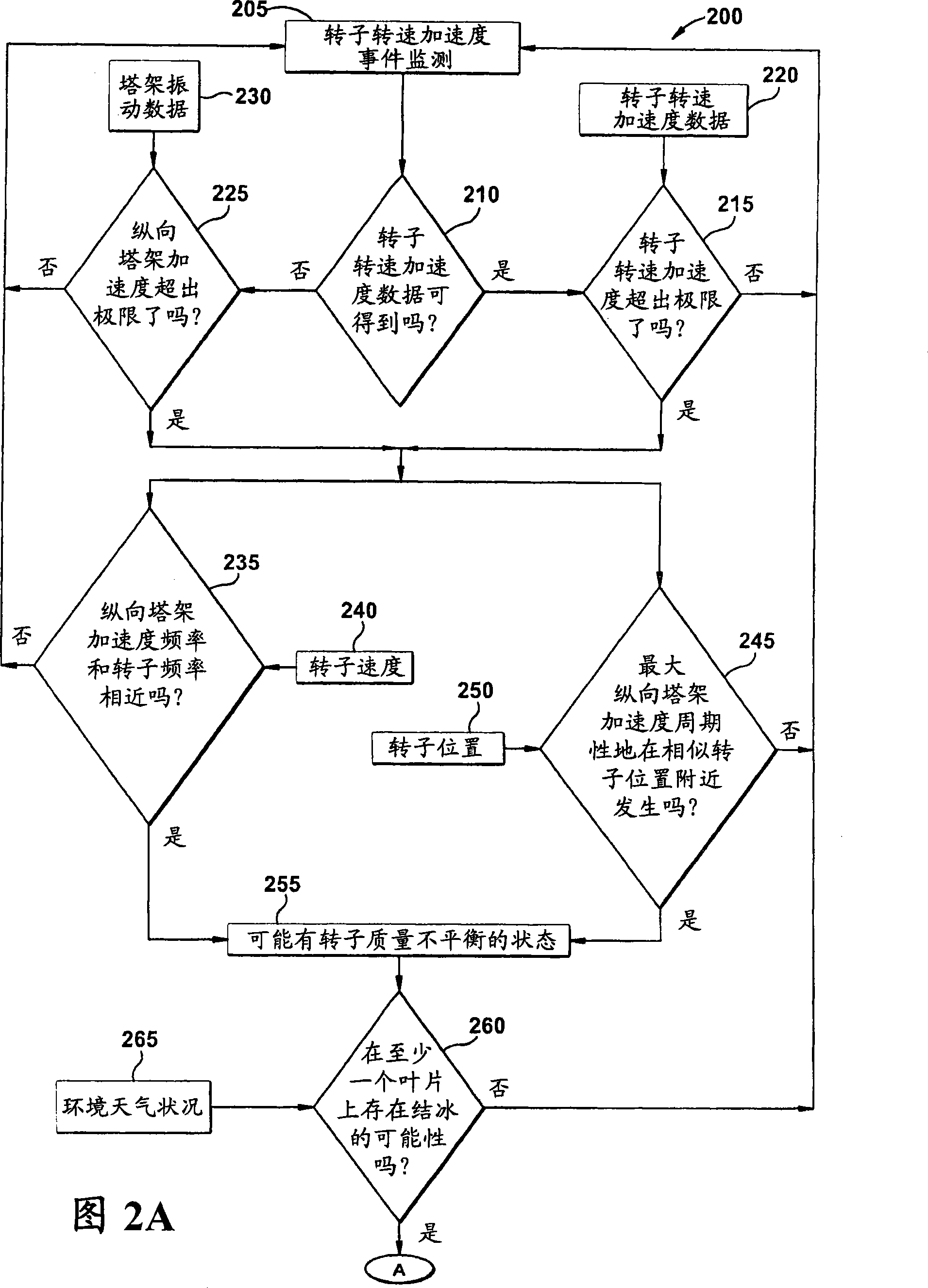

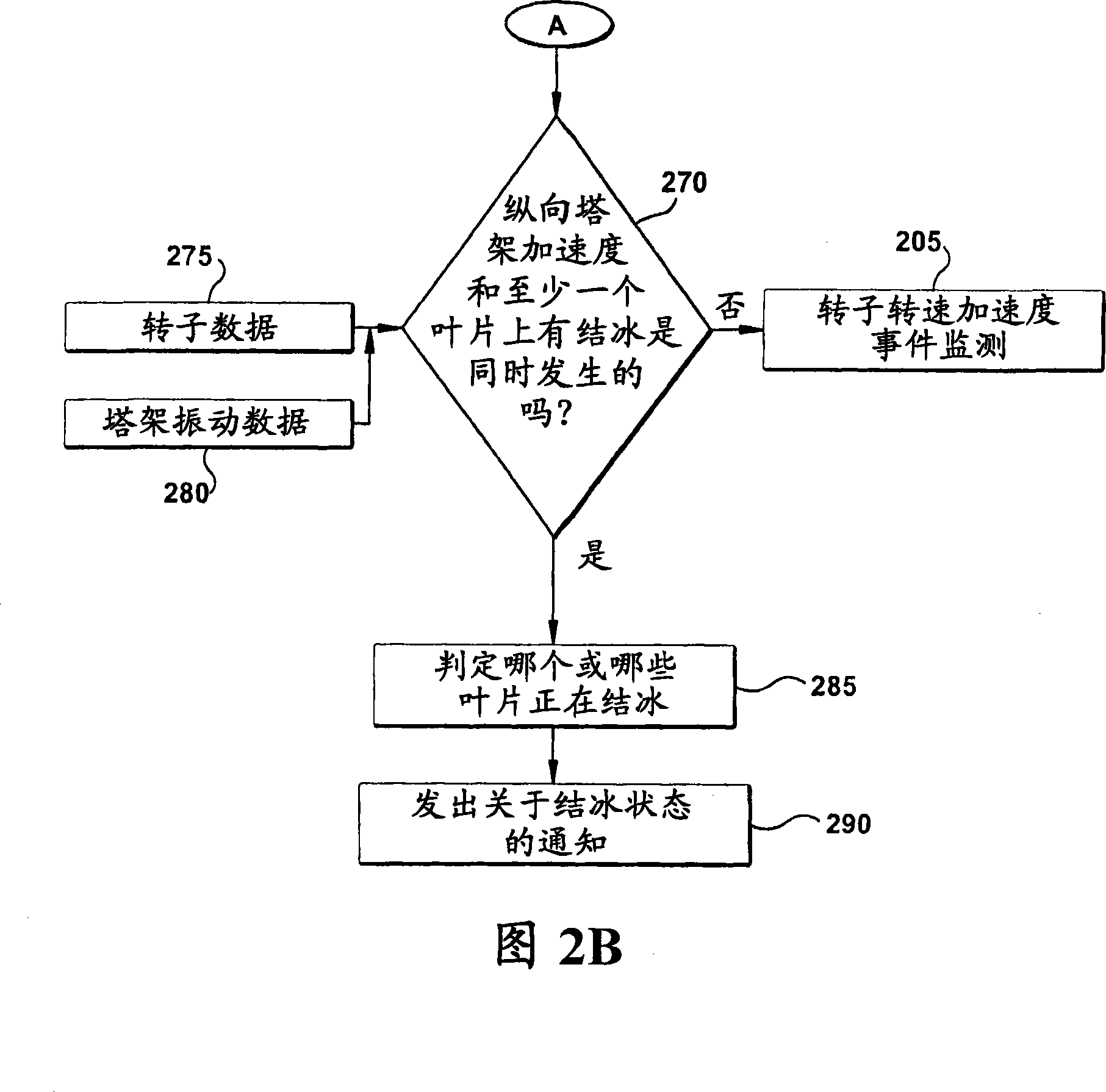

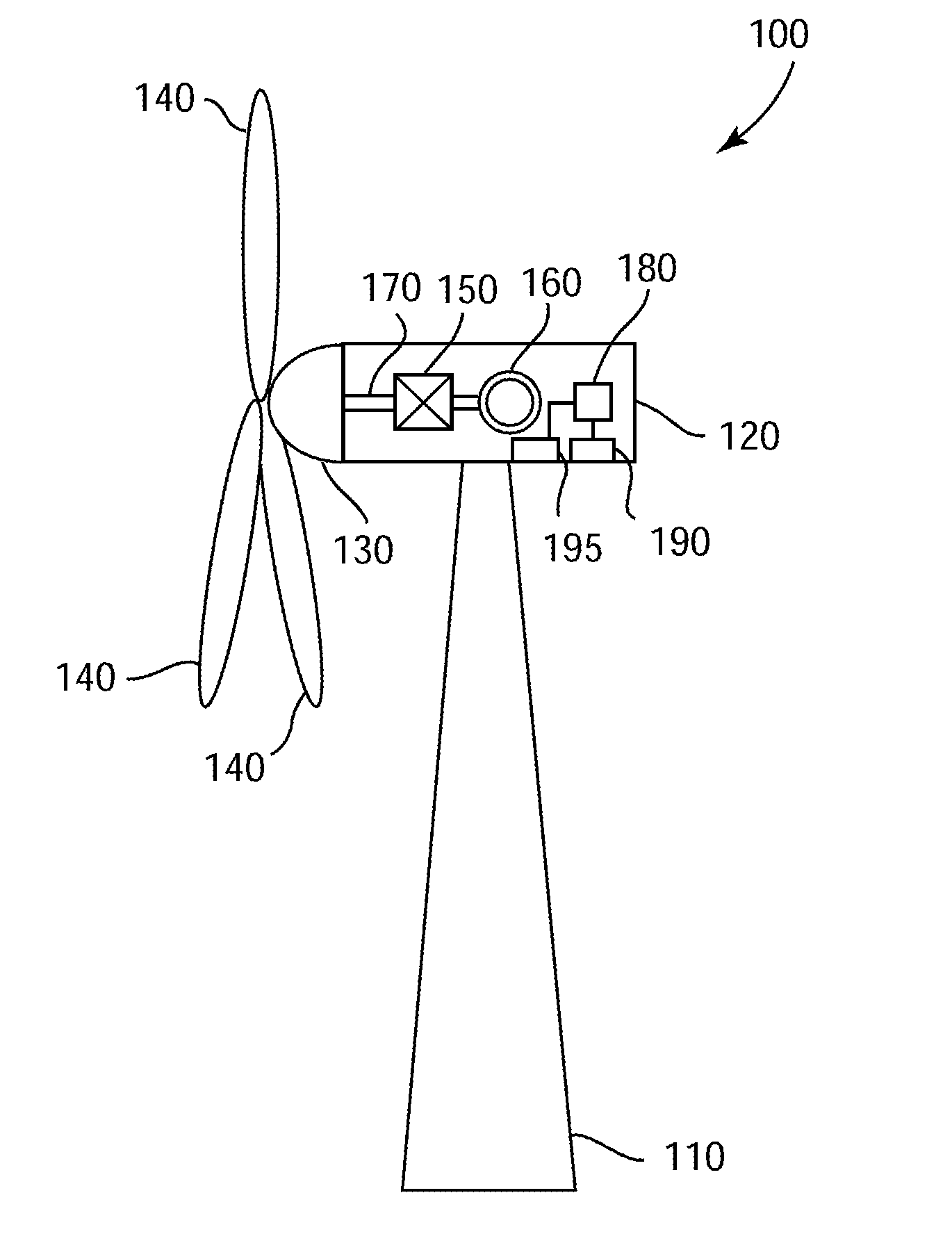

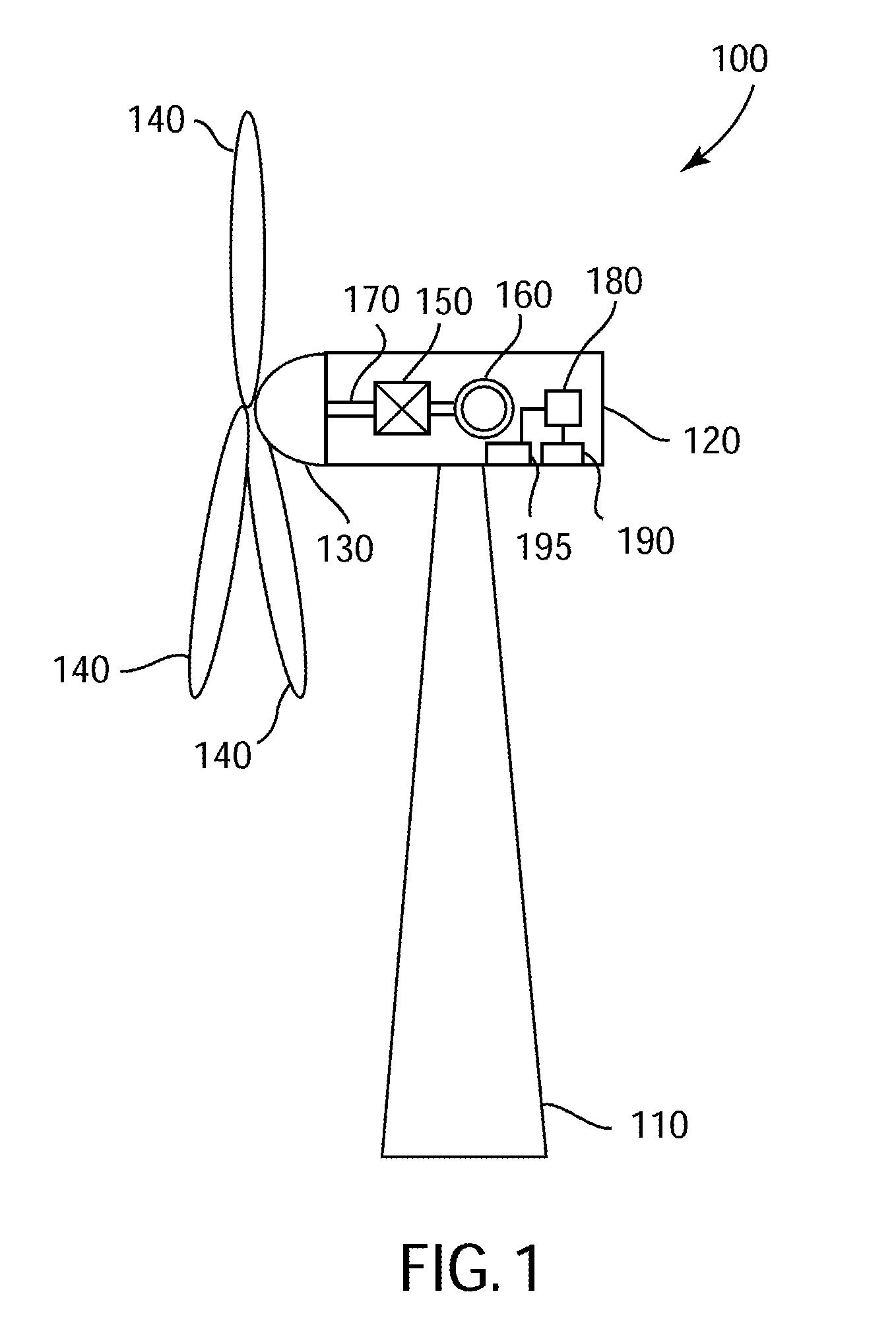

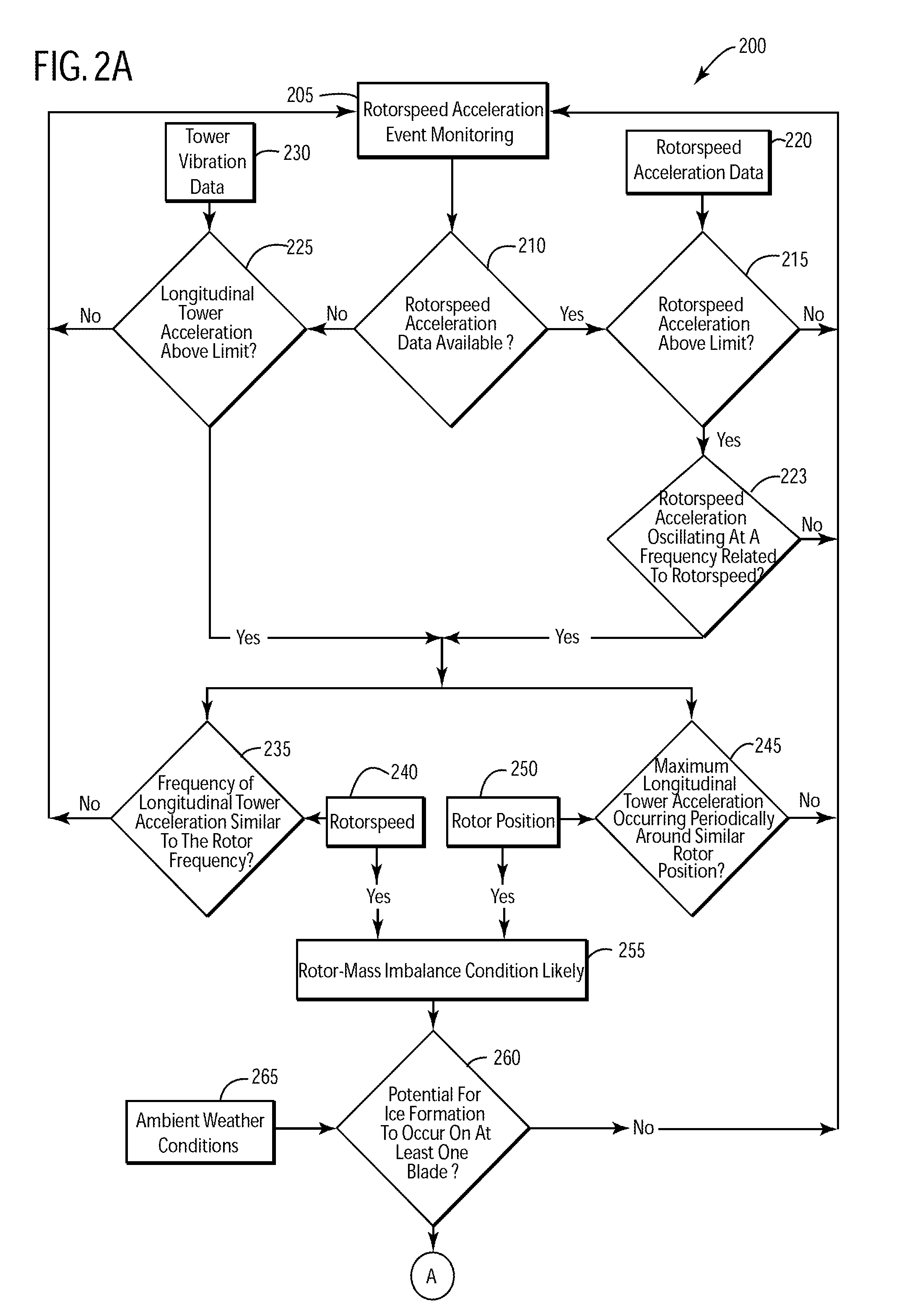

Wind turbine and method of detecting asymmetric icing on a wind turbine

A method (200) for detecting asymmetric utilizing longitudinal tower acceleration data may include: providing a rotorspeed acceleration monitoring system; determining from the rotorspeed acceleration monitoring system whether a rotorspeed acceleration is above a rotorspeed acceleration limit (215); determining whether a rotor-mass imbalance condition exists (235,245); and determining whether a longitudinal tower acceleration coincides with icing on a rotor.

Owner:GENERAL ELECTRIC CO

Method and apparatus for in situ unbalance and corrective balance determination for a non-vertical axis rotating assembly

InactiveUS8291764B2Method is inaccurateSampled-variable control systemsComputer controlPhase differenceFourier transform on finite groups

The invention discloses a novel method and apparatus to determine the degree of residual mass unbalance and a corrective balance solution for a rotating assembly having a non-vertical axis of rotation. When the center of mass of the rotating assembly is not concentric with the axis of rotation, the condition of unbalance exists. When the rotating assembly is driven by a motor or drives a generator, fluctuations in power are produced proportional to the degree of unbalance. The method and apparatus to determine the degree of mass imbalance consists of measuring the average instantaneous real power over an interval of time, calculating the Fourier Transform of the demodulated signal, establishing the peak amplitude and phase associated with the angular velocity of the rotating assembly and calculating the amount of unbalance. The method and apparatus to provide for a corrective solution consists of simultaneously acquiring a position reference signal of the rotating assembly with the average instantaneous real power signal, calculating the phase difference between the two acquired signals at the angular velocity of the rotating assembly, calculating the magnitude of the unbalance, and calculating the quantity and location of corrective weight necessary to minimize the unbalance to an acceptable level.

Owner:LENZ MICHAEL A W

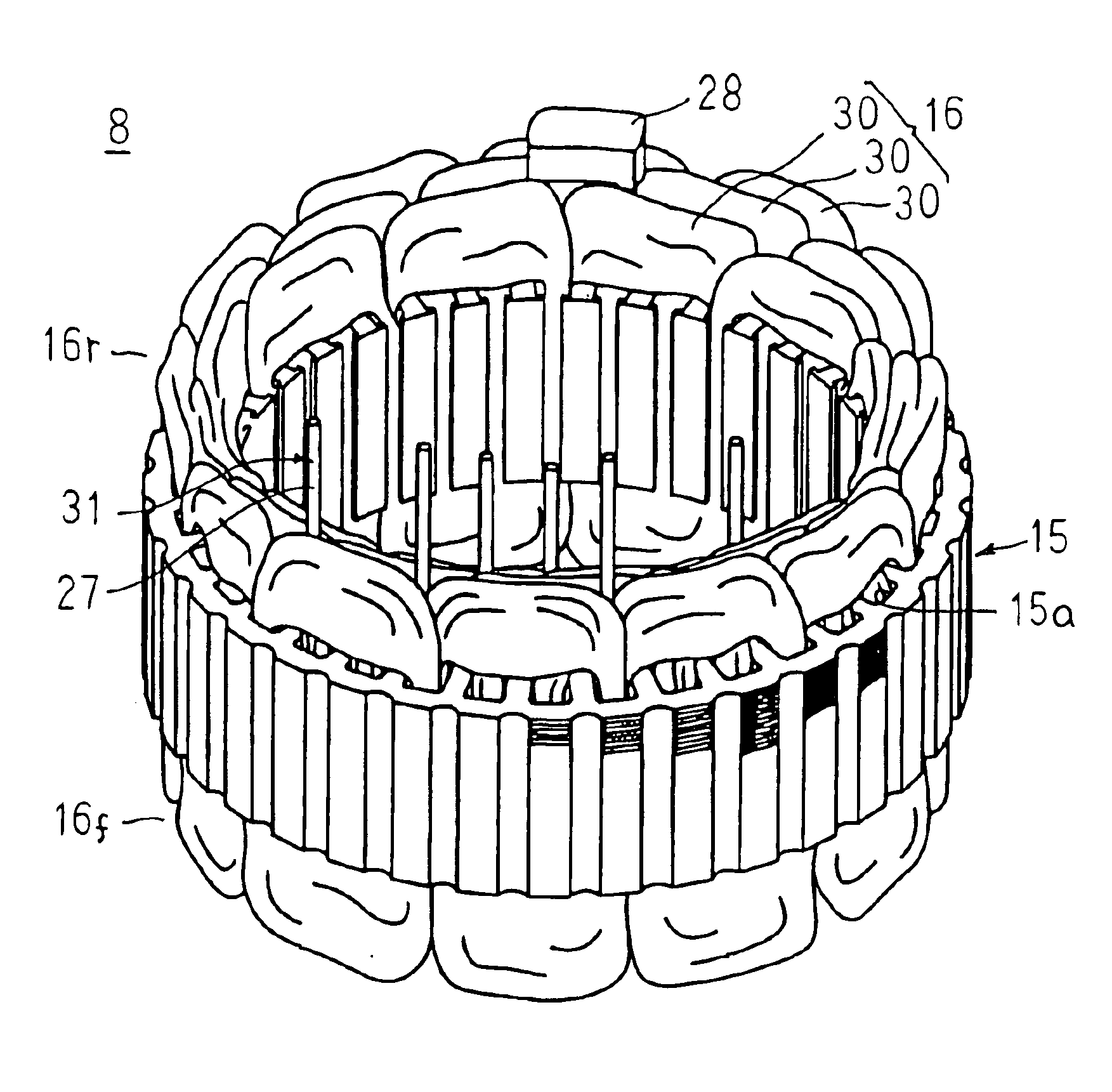

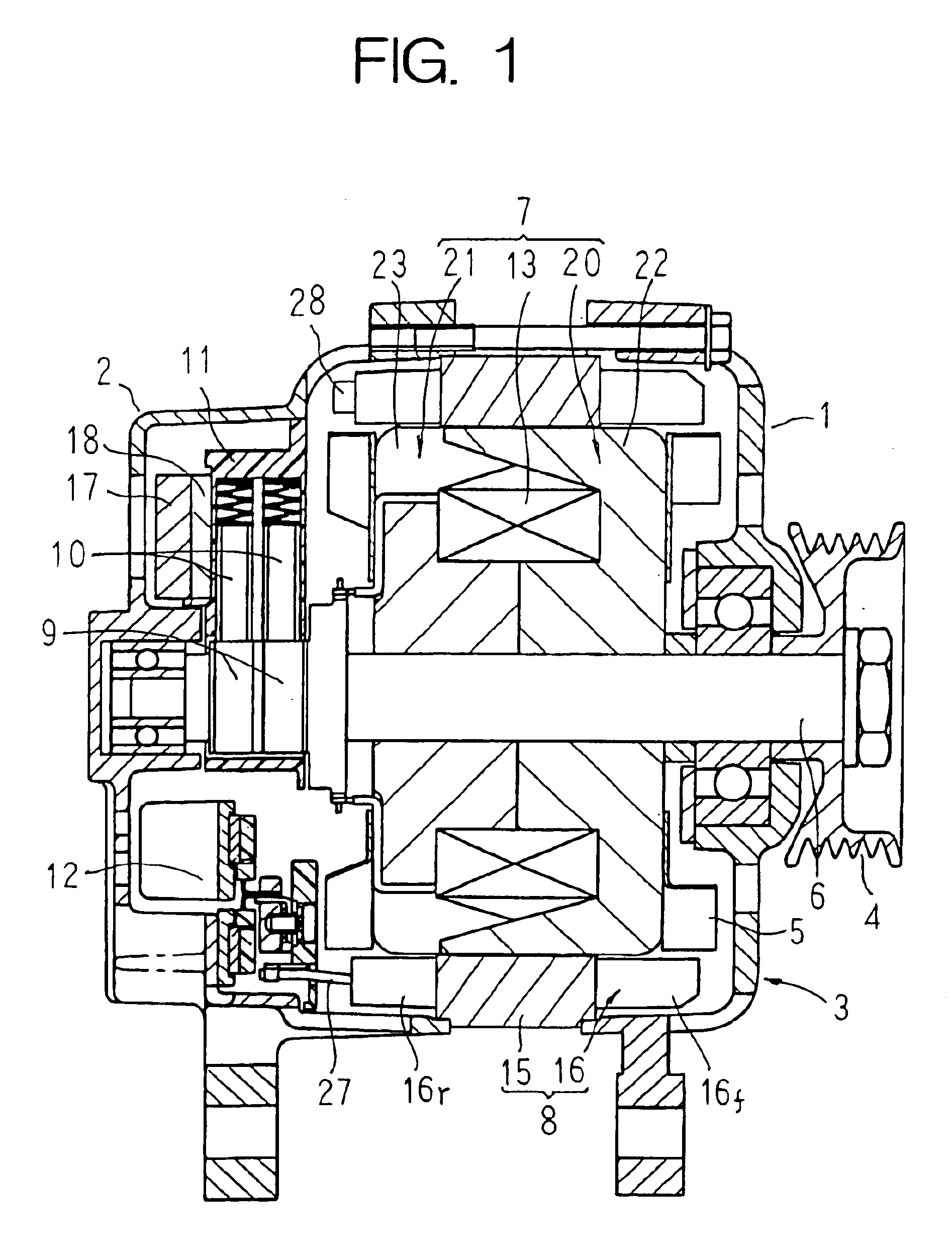

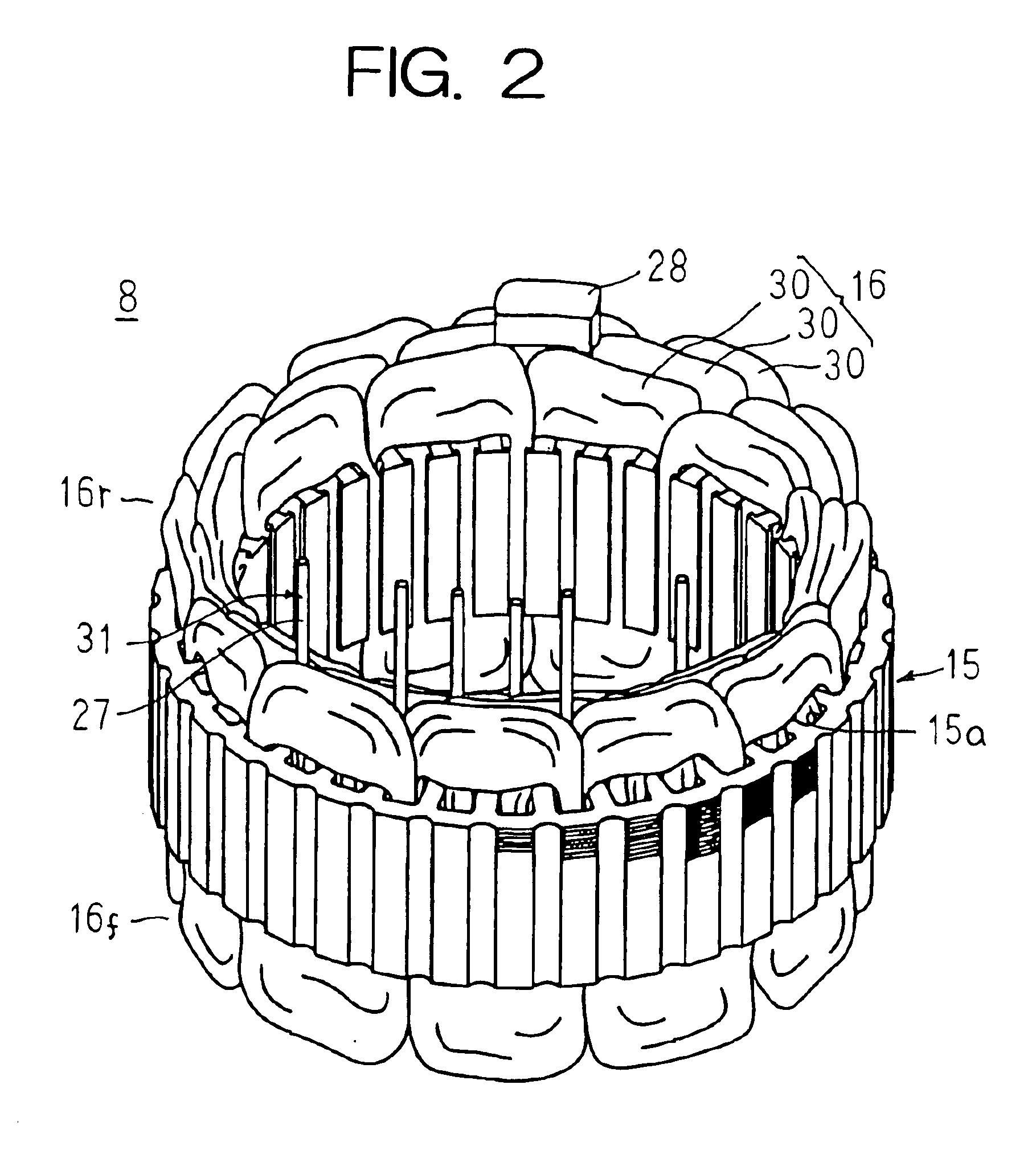

Stator for a dynamoelectric machine

A stator for a dynamoelectric machine includes an annular stator core in which a large number of slots extending in an axial direction are disposed in a circumferential direction so as to open radially inward; a stator winding having a plurality of winding phase portions installed in the stator core, lead wires of the plurality of winding phase portions being led axially outward within a predetermined circumferential range from an axial end of a first coil end group formed at a first axial end of the stator core; and a first mass adjusting portion disposed at a first end of the stator core, the first mass adjusting portion adjusting a circumferential mass imbalance relative to a central axis of the stator core resulting from a circumferential bias in positions from which the lead wires are led out.

Owner:MITSUBISHI ELECTRIC CORP

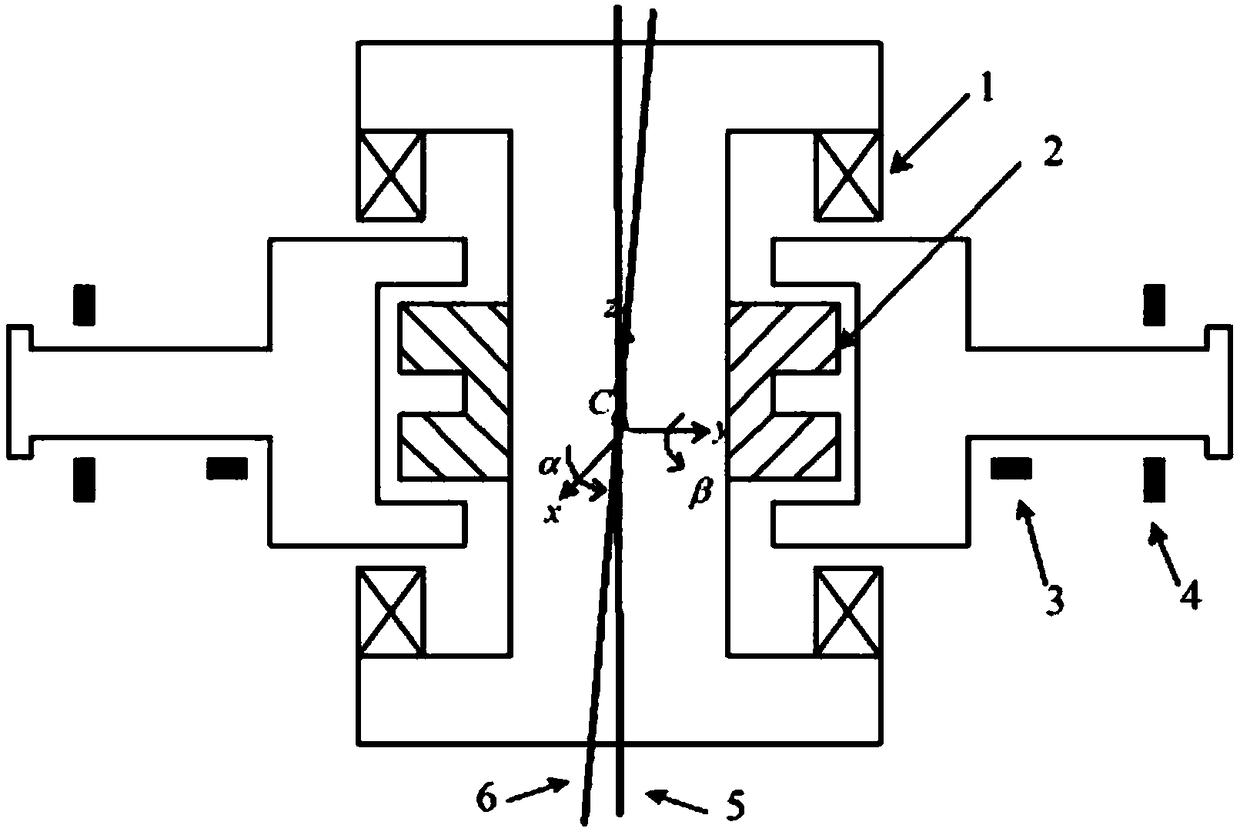

Harmonic vibration force suppression method based on multi-synchronous rotating coordinate transformation

The invention discloses a magnetic suspension rotor harmonic vibration force inhibition method based on a multi-synchronous coordinate transformation method. The method comprises the steps of firstlybuilding a magnetic suspension rotor dynamic model comprising mass imbalance and sensor harmonic waves, and then employing the MSRFT-based magnetic suspension rotor harmonic vibration force inhibitionmethod. The MSRFT can accurately suppress harmonic vibration force, and one controller is used for suppressing vibration in the X direction and the Y direction at the same time, so that hardware computing resources are reduced, and the dynamic process of suppression is accelerated. Meanwhile, the introduction of the phase compensation angle can guarantee the absolute stability of the system in alarger frequency range. The MSRFT controller is simple in structure, convenient to use in practical application, capable of restraining harmonic vibration force in the magnetic suspension rotor, and suitable for restraining harmonic vibration force of a magnetic suspension rotor system with mass imbalance and sensor harmonic waves.

Owner:BEIHANG UNIV

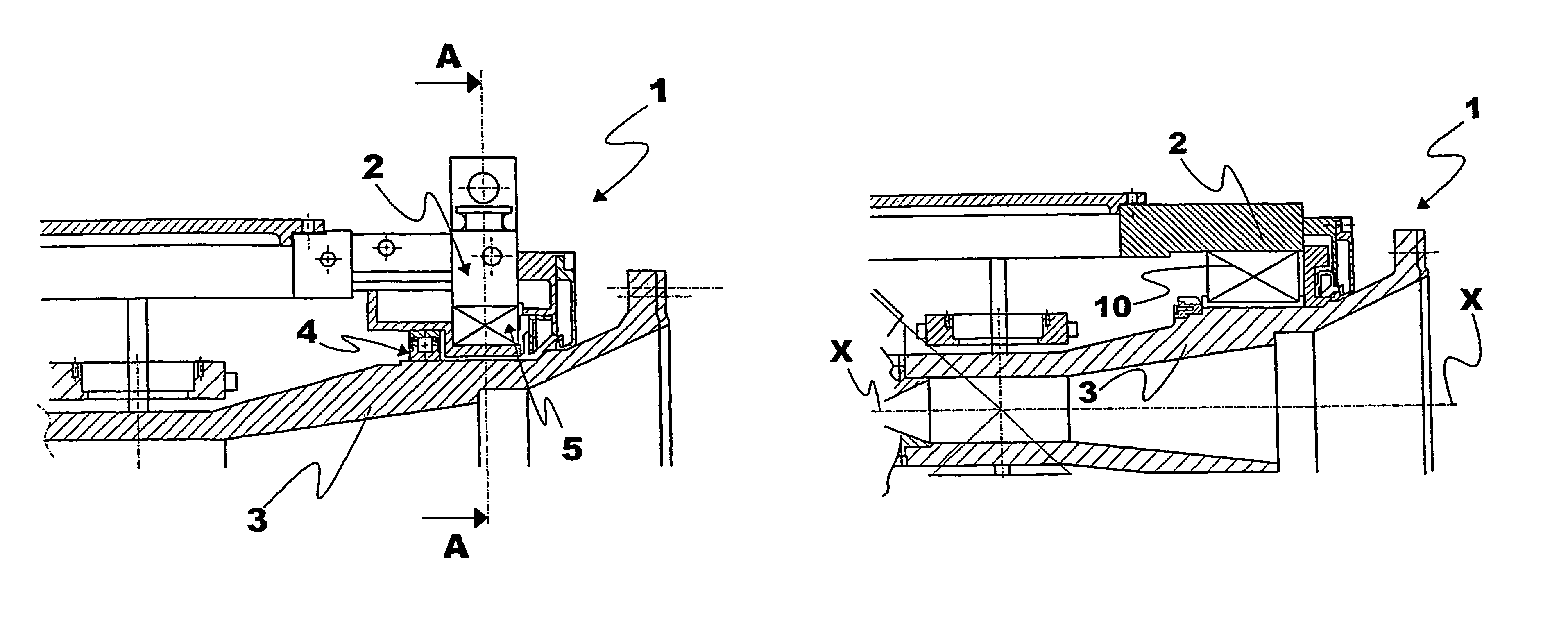

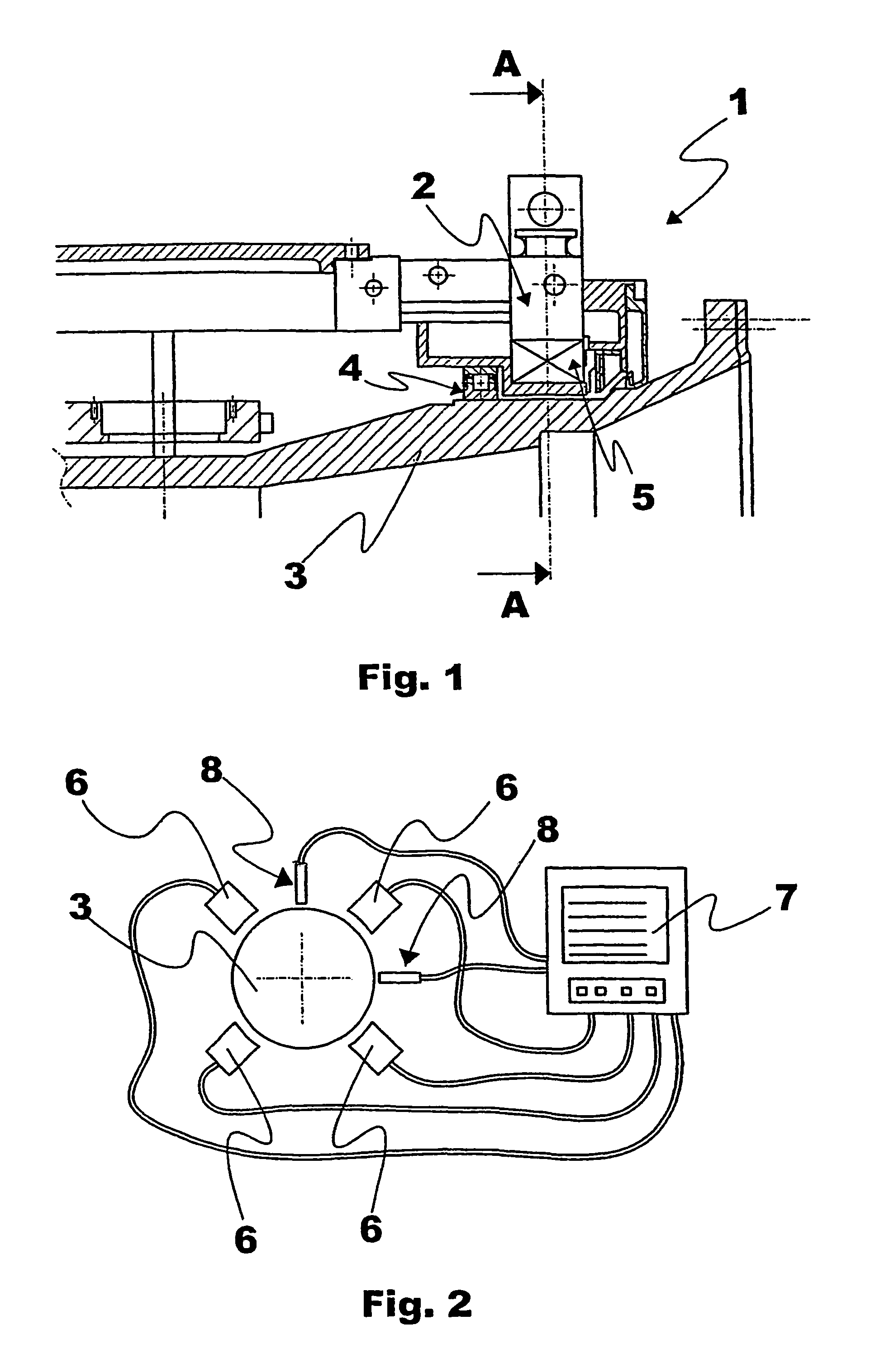

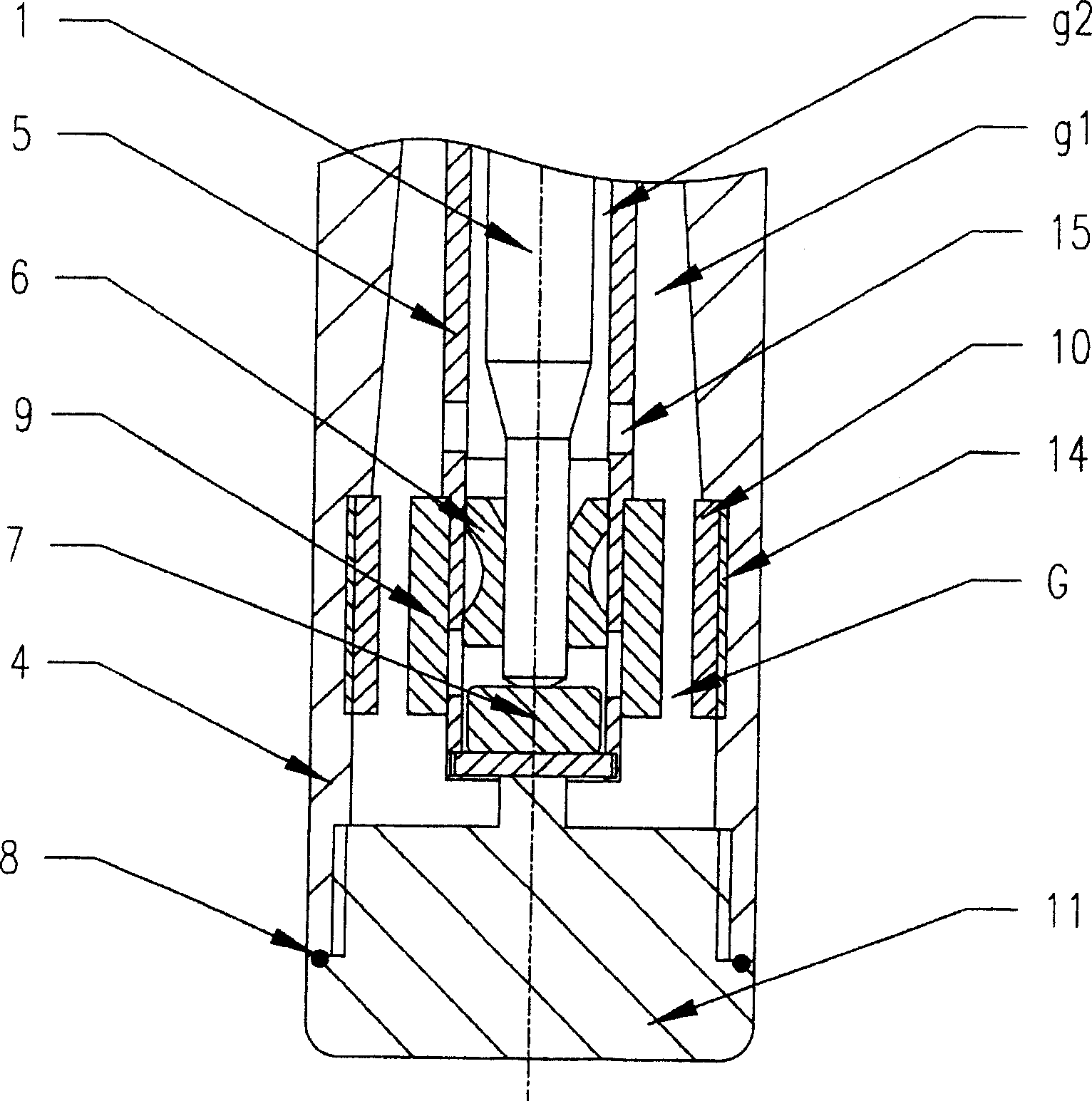

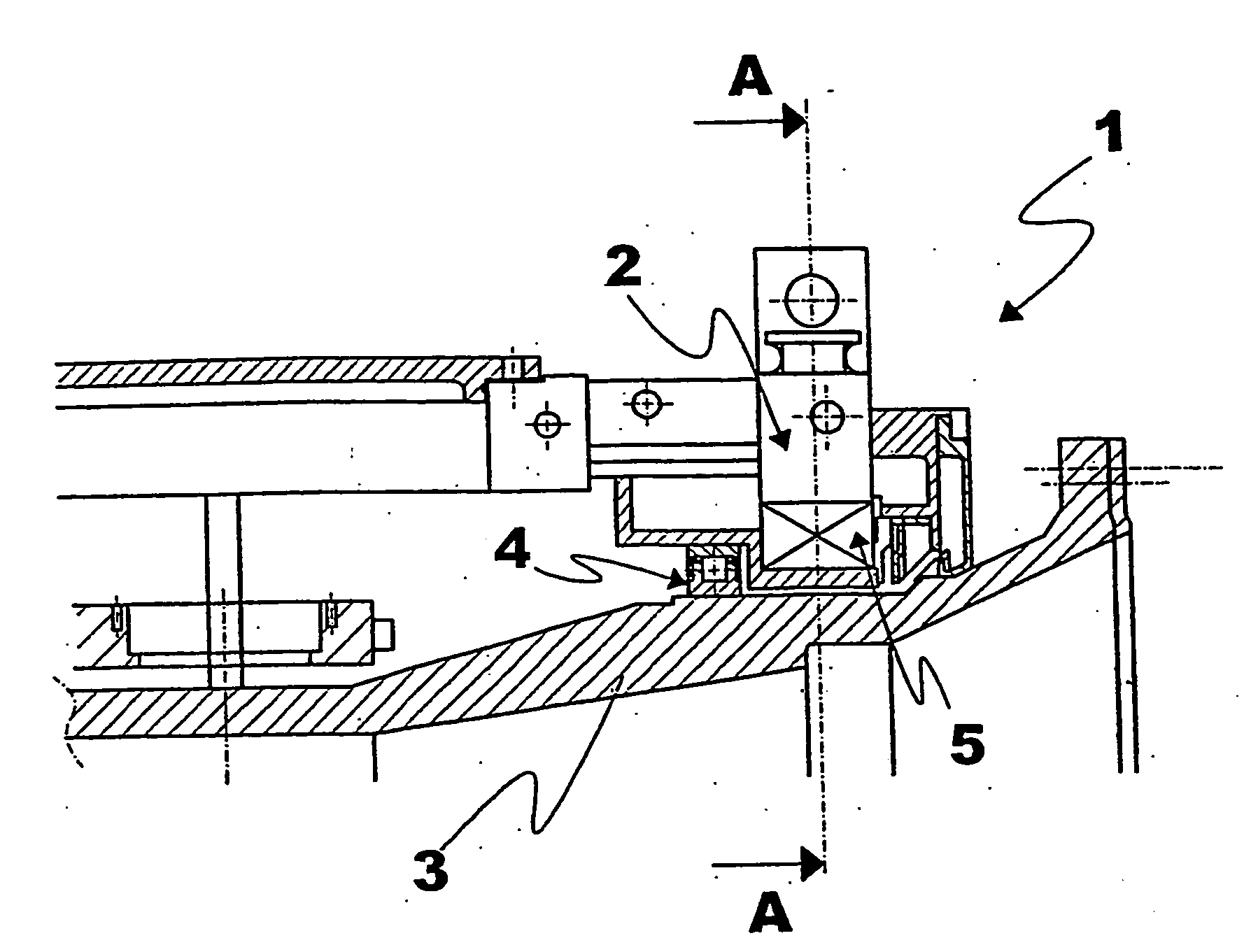

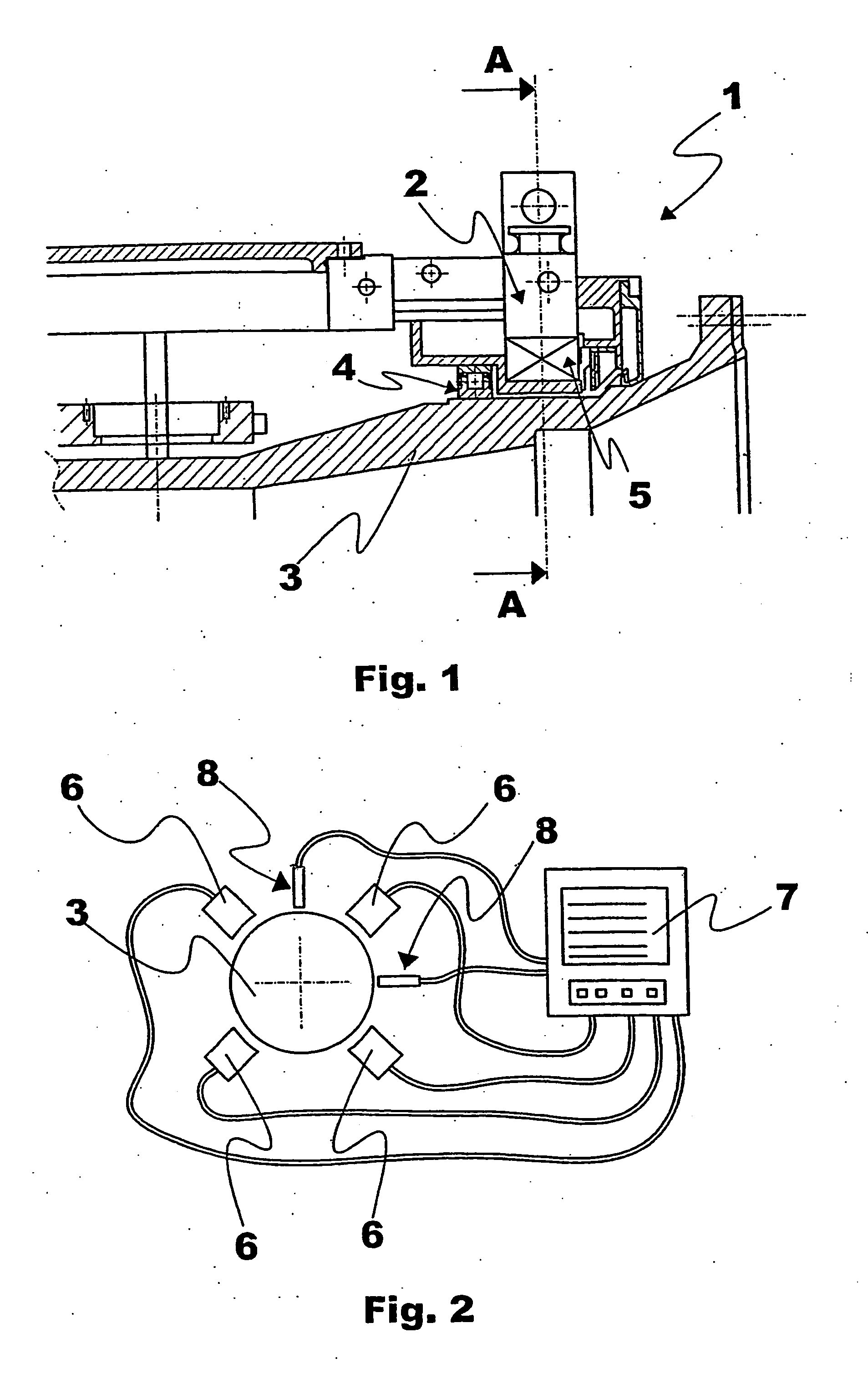

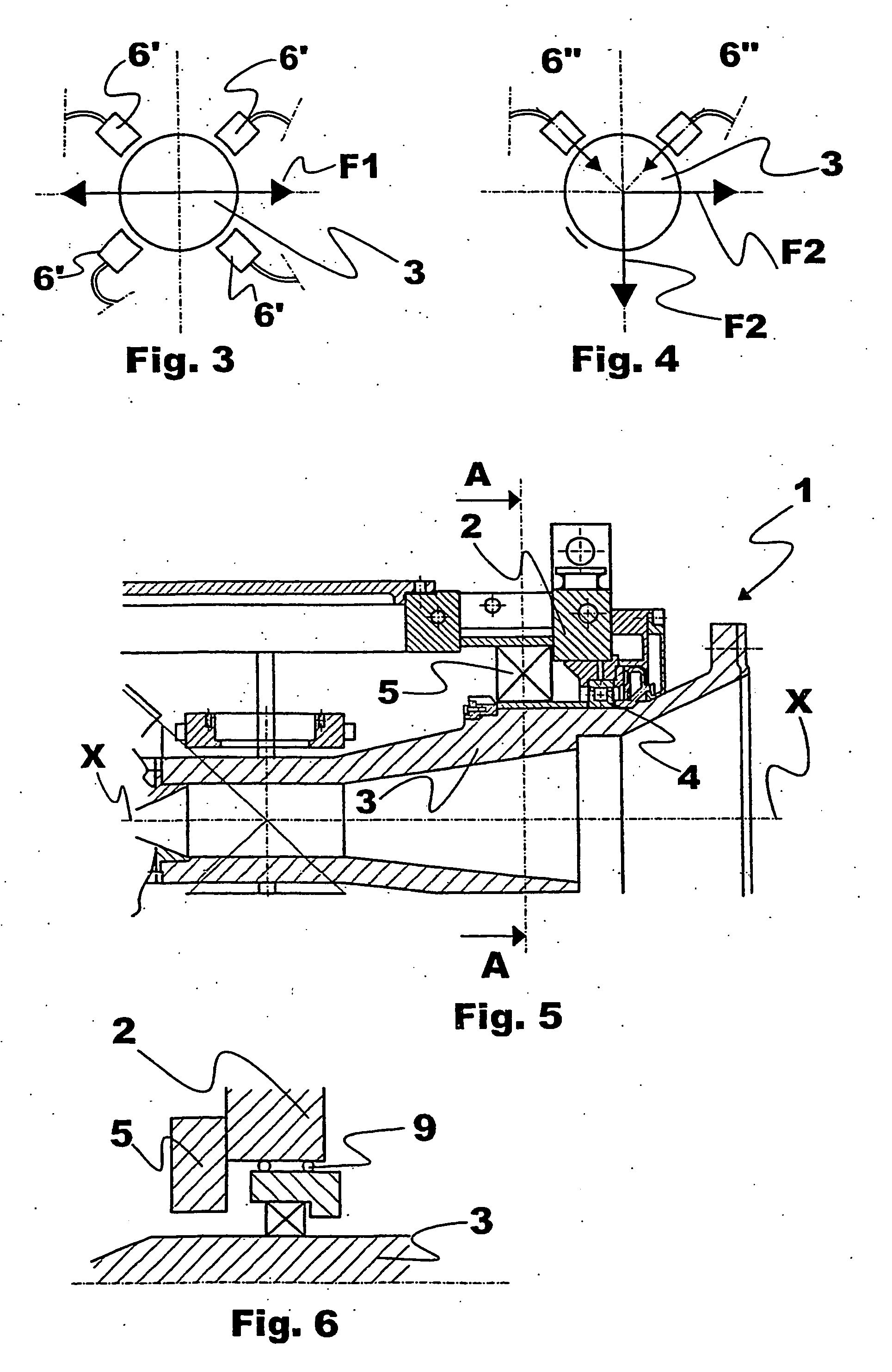

Laying head with a vibration damping device

A laying head for forming coils using continuous and substantially rectilinear rolled products such as rods or wire, having vibration damping means integrated in one of two rotor supports (3), preferably the one on the rolled product outlet side. Said means comprise a plurality of coils (6, 6′, 6″) arranged around the rotor (3), rotating about its axis (X), which generate a magnetic field actively controlled by a computer, the resultant force of which is perpendicular to the axis (X) and of a predetermined intensity so as to eliminate the inertial forces generated by the mass imbalances. Alternatively, the damping means incorporated in one of the supports are comprised of oil film bearings.

Owner:DANIELI & C OFF MEC SPA

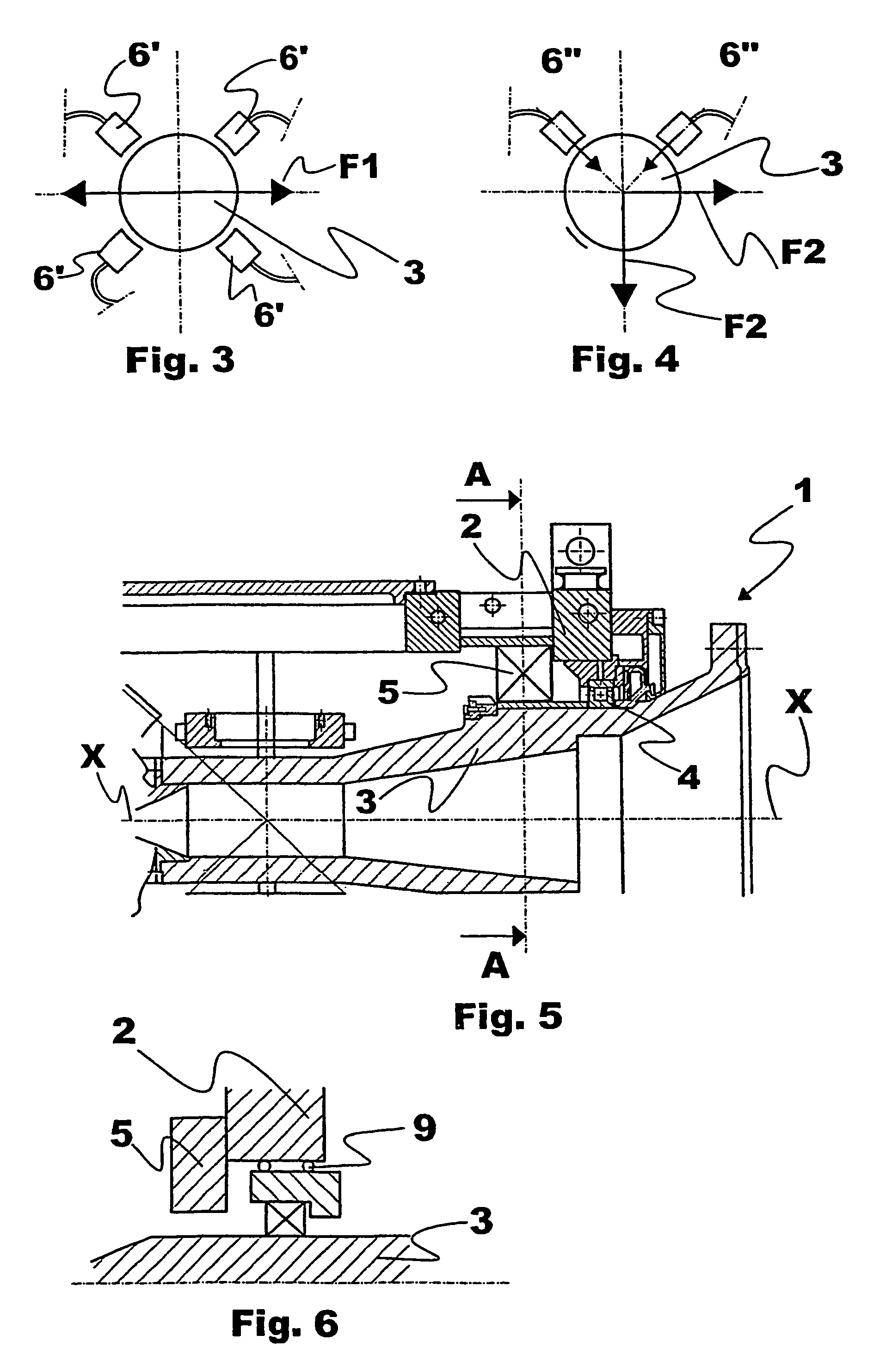

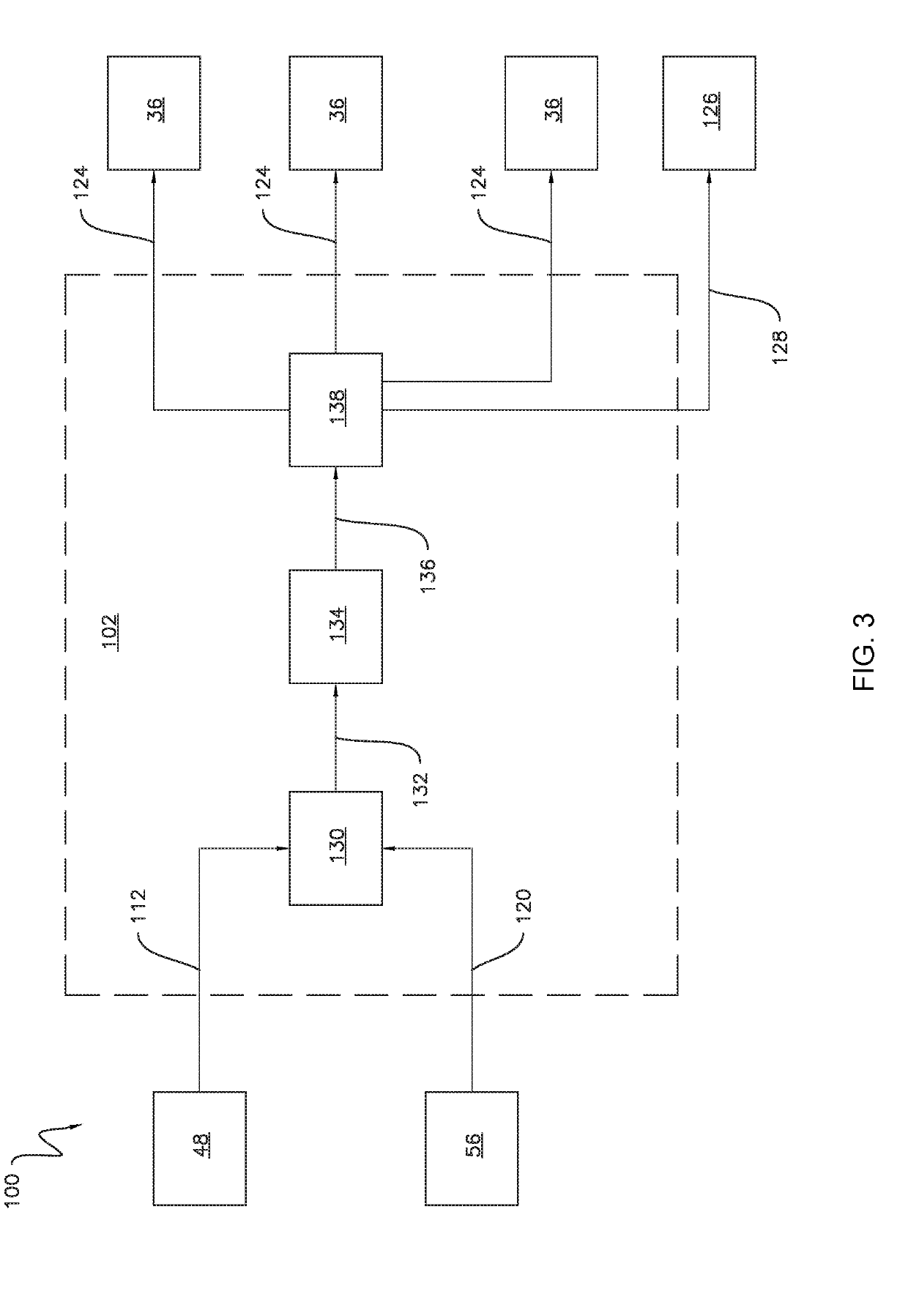

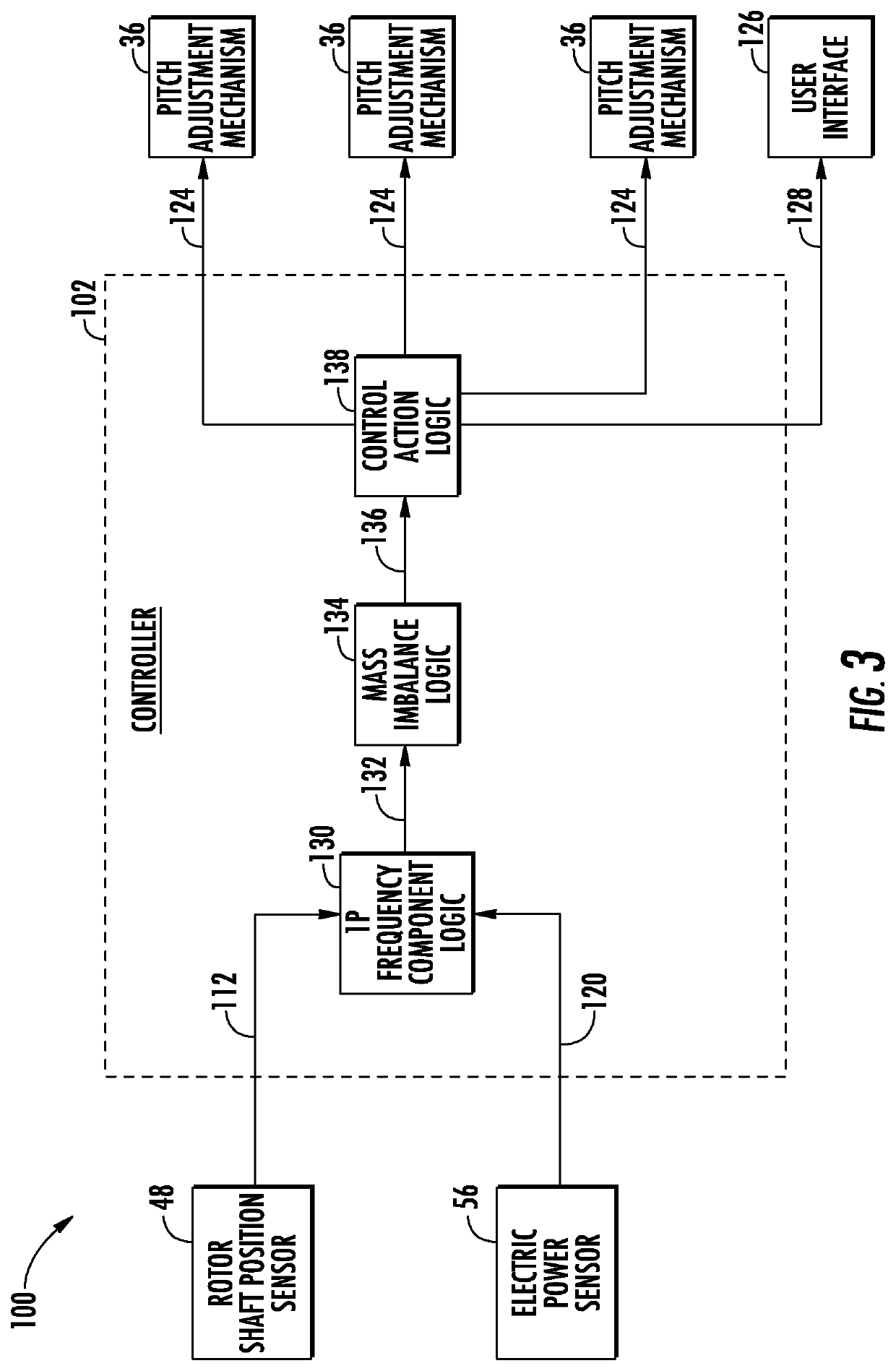

Method and system for detecting a mass imbalance in a wind turbine rotor

ActiveUS20190145381A1Reduce mass effectVibration measurement in solidsWind motor controlEngineeringMass imbalance

The present disclosure is directed to a method for detecting a mass imbalance in a rotor of a wind turbine. The method includes receiving, with a computing device, sensor data indicative of an operating characteristic of the wind turbine. The method also includes determining, with the computing device, a mean amplitude of a designated frequency component of the operating characteristic. Furthermore, the method includes determining, with the computing device, when a mass imbalance is present within the rotor based on the mean amplitude of the designated frequency component.

Owner:GENERAL ELECTRIC CO

Method and system for utilizing rotorspeed acceleration to detect asymmetric icing

A method and system for detecting asymmetric utilizing longitudinal tower acceleration data may include: providing a rotorspeed acceleration monitoring system; determining from the rotorspeed acceleration monitoring system whether a rotorspeed acceleration is above a rotorspeed acceleration limit; determining whether a rotor-mass imbalance condition exists; and determining whether a longitudinal tower acceleration coincides with icing on a rotor.

Owner:GENERAL ELECTRIC CO

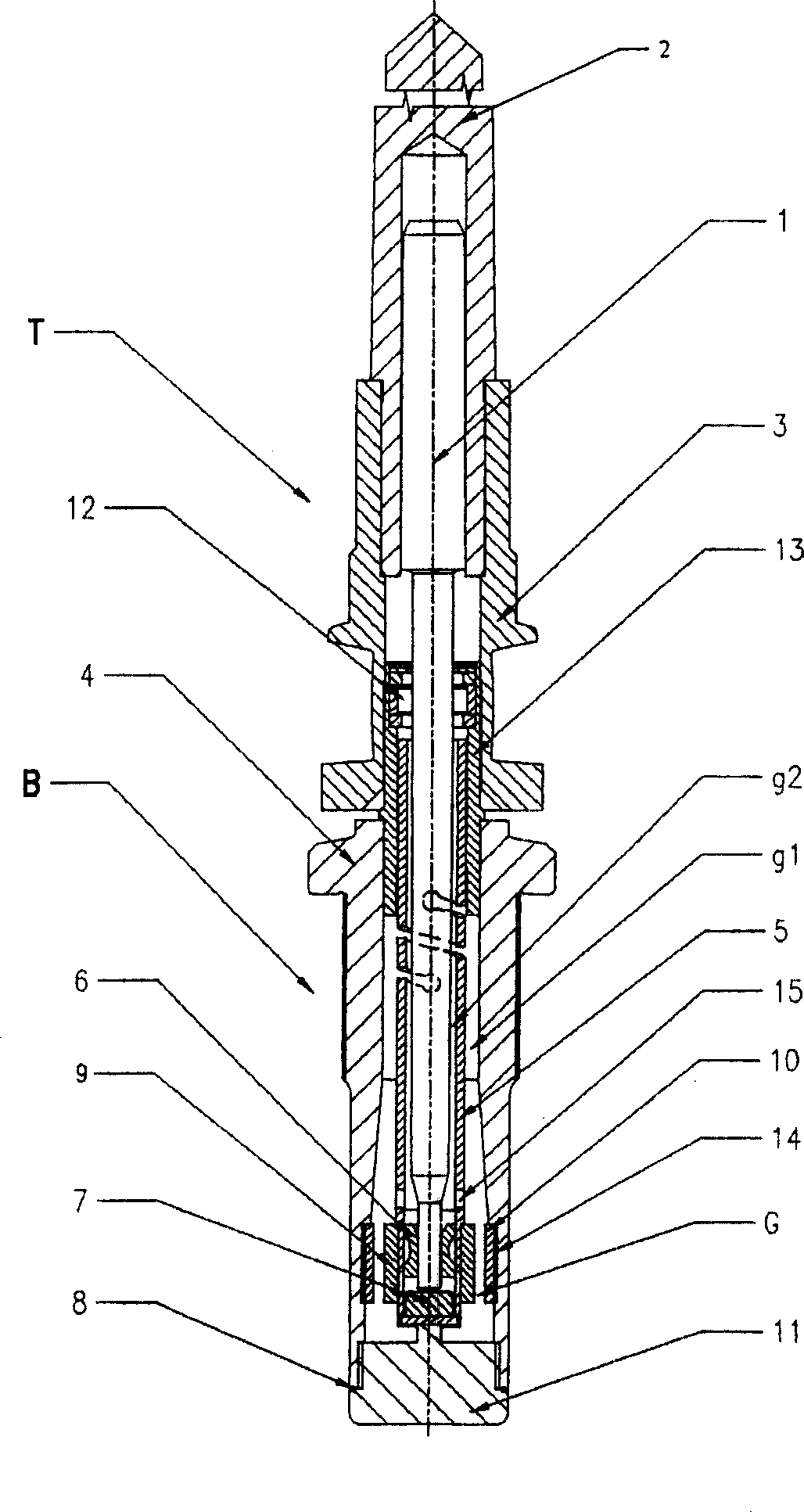

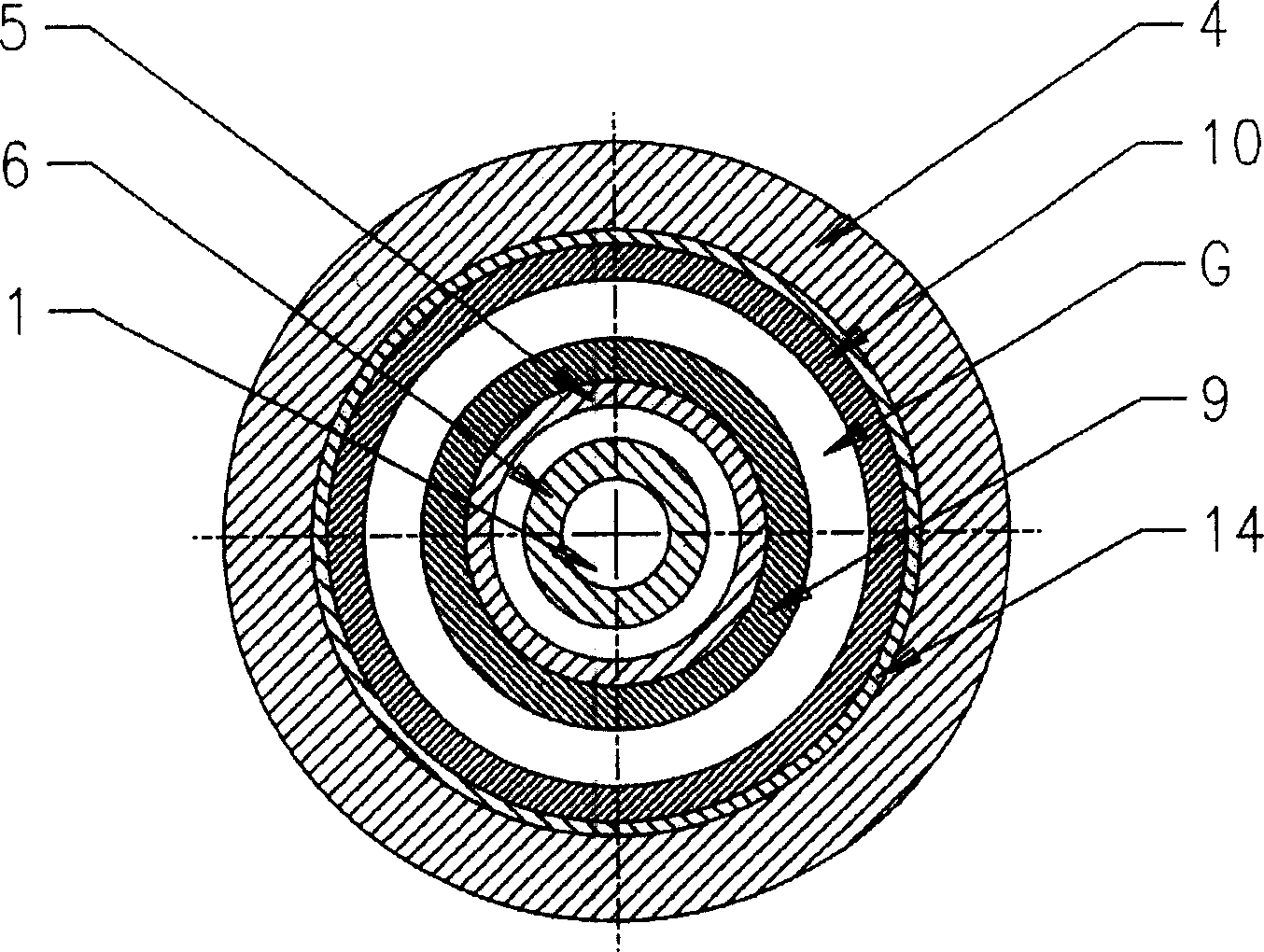

Spinning spindle assembly with damping device

A spindle assembly for spinning and twisting machine which includes: a top components; a rotary spindle blade with the top parts disposing on the top components; a spindle pedestal; a centering sleeve designed for containing the bottom of the spindle blade disposed on the spindle pedestal; at least one permanence magnet connected to the centering sleeve and at least one permanence magnet connected to the inner surface of the spindle pedestal, an air gap is provided between the two permanence magnets. the polarity of the permanence magnets are arranged to generate a repulsion force. The centering sleeve deviates from the original position in accordance with the mass imbalance generated during the cop forming process when the spindle rotates, as a result, the deviation generates a repulsive magnetic force pushing the centering sleeve to the revolving spindle, the axes of the centering sleeve and the spindle are aligned to provide a damping effect to the spindle assembly.

Owner:LAKSHMI MACHINE WORKS

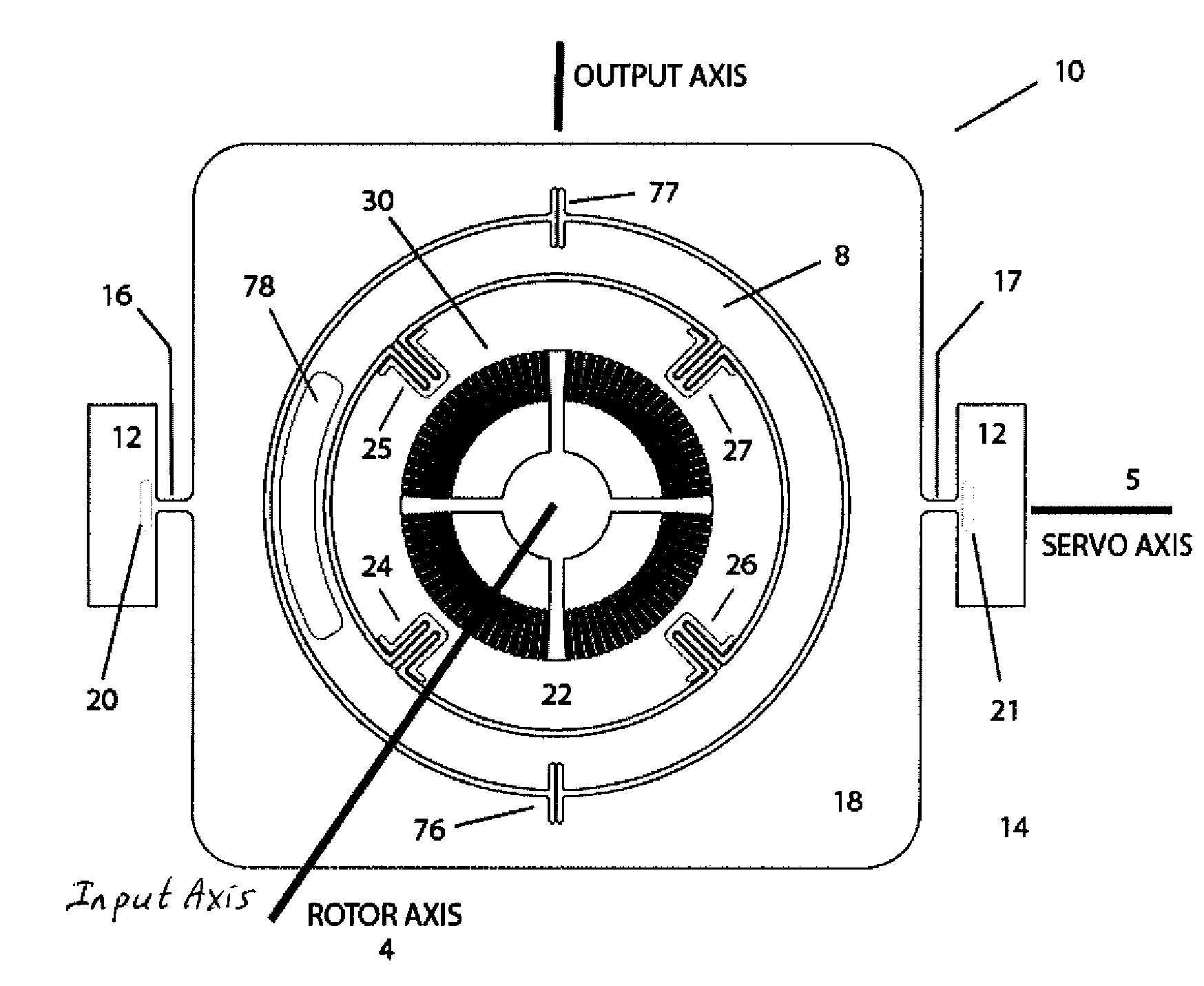

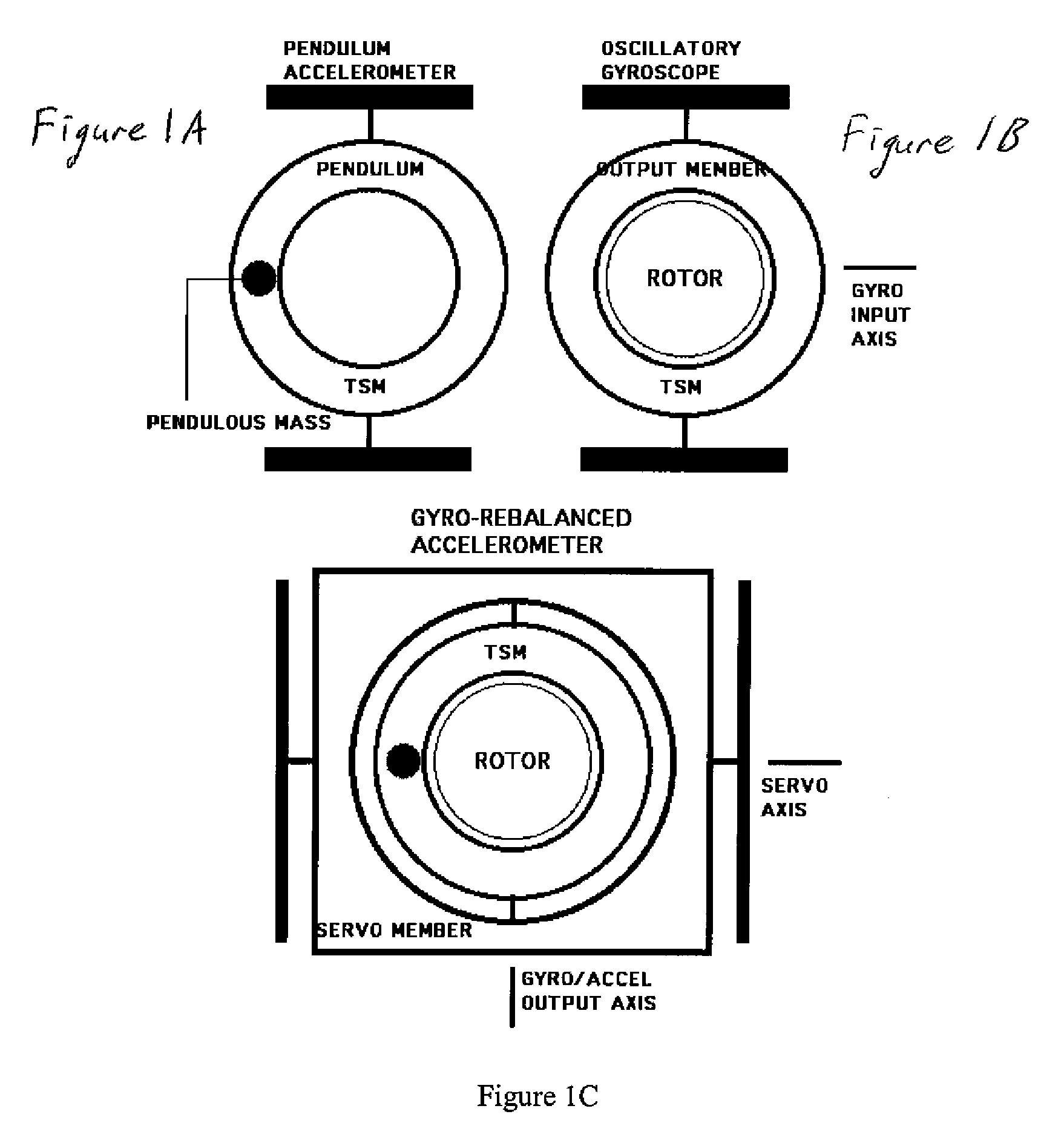

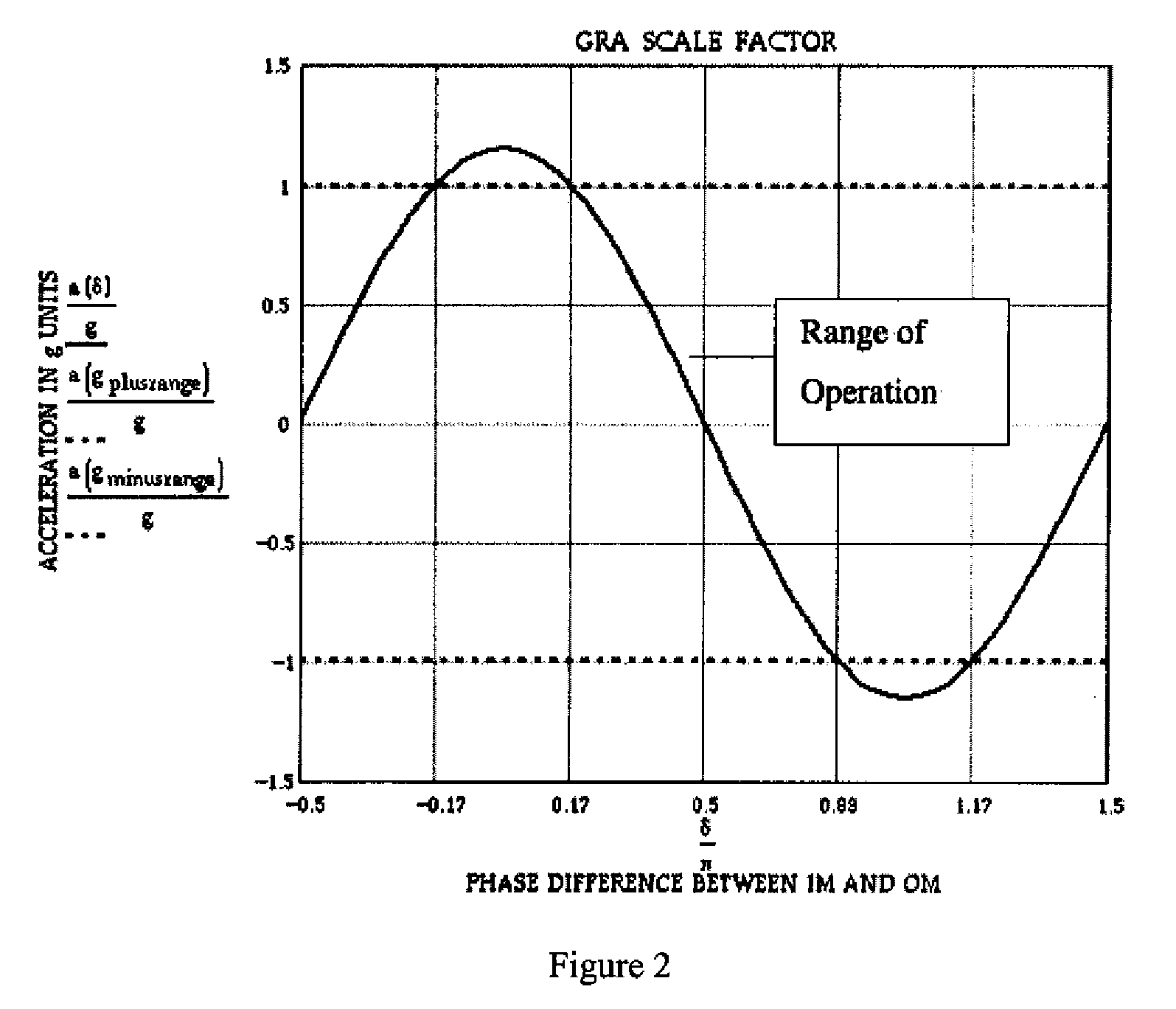

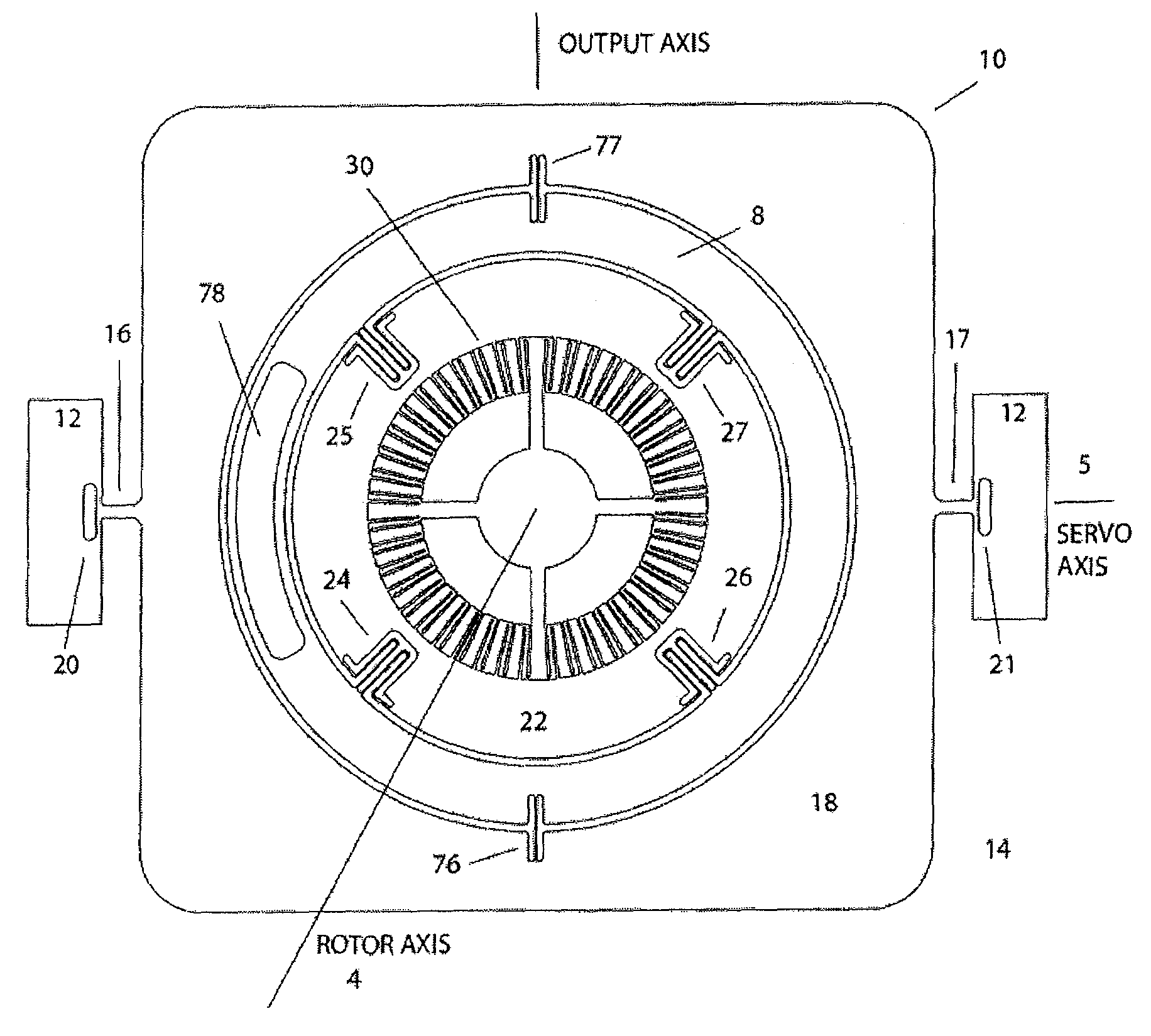

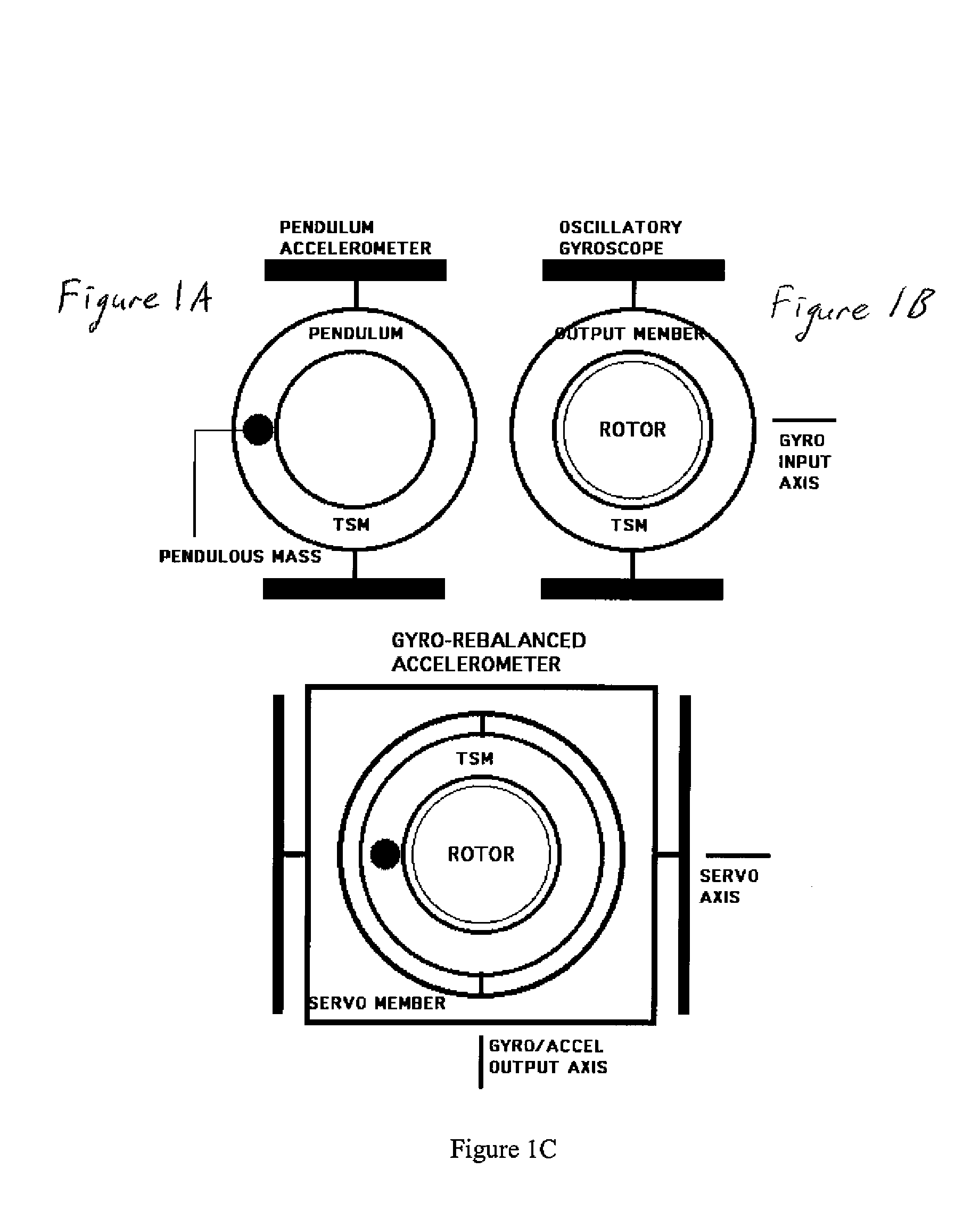

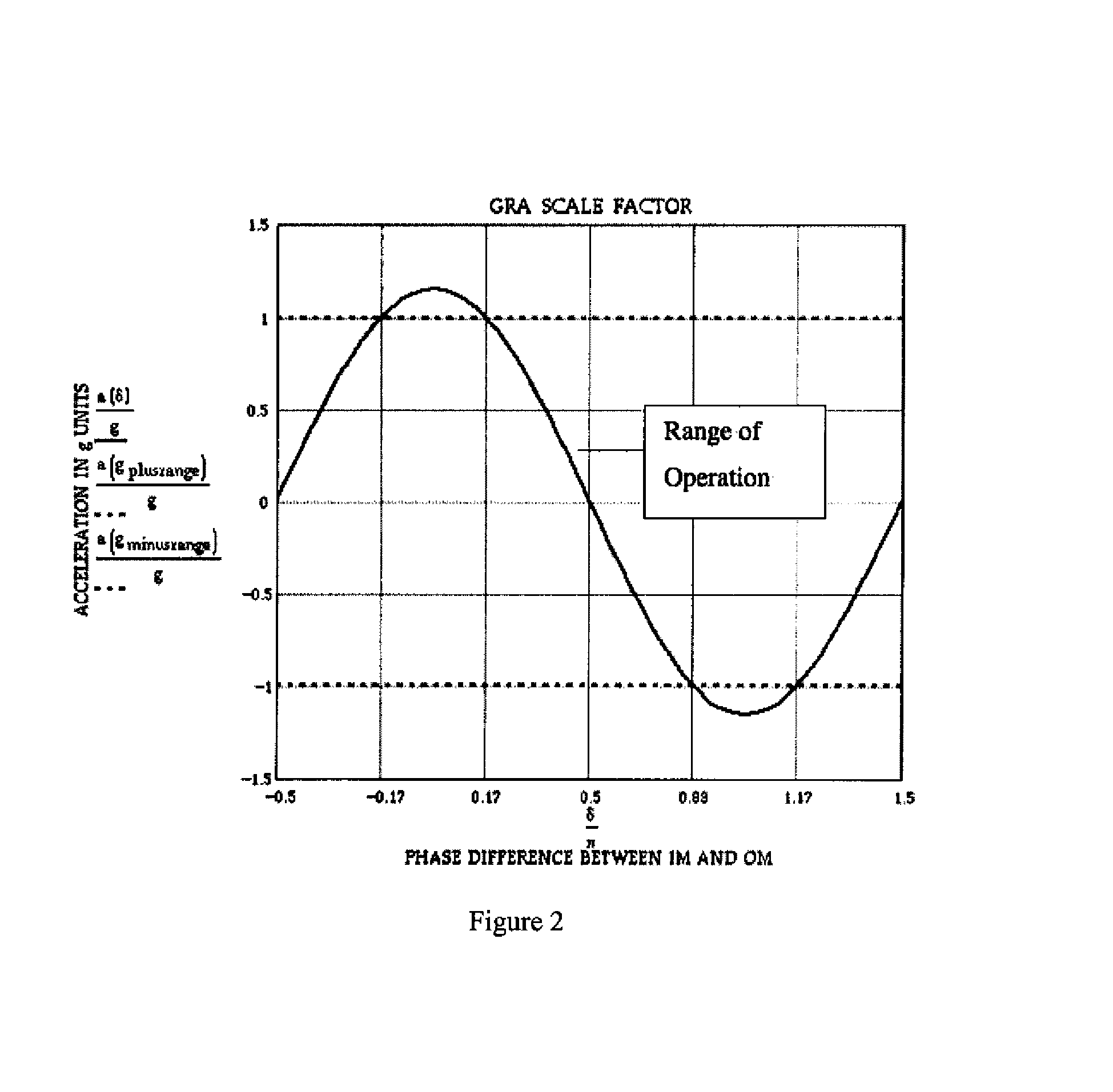

Gra MEMS accelerometer

InactiveUS20090007667A1Minimize structural instabilityAcceleration measurement using interia forcesAcceleration measurement using gyroscopesAccelerometerMass imbalance

An accelerometer that lies generally in a plane, for detecting acceleration along an input axis. There is a substrate, a generally planar Servo Member (SM) flexibly coupled to the substrate such that it is capable of oscillatory motion about a servo axis that lies in the plane, a generally planar Torque Summing Member (TSM) coplanar with and flexibly coupled to the SM such that the TSM is capable of rotary motion relative to the SM about an output axis that is in the plane and orthogonal to the servo axis, wherein the TSM is mass-imbalanced relative to the output axis, and a generally planar rotor coplanar with and flexibly coupled to the TSM such that it is capable of rotary oscillatory motion relative to the TSM about a rotor axis that is orthogonal to the plane of the members. There are drives for oscillating the rotor about the rotor axis and for oscillating the SM about the servo axis. Output sensors detect oscillation of the rotor about the rotor axis and of the SM about the servo axis. Output sensors detect rotation of the TSM about the output axis.

Owner:CARDARELLI DONATO

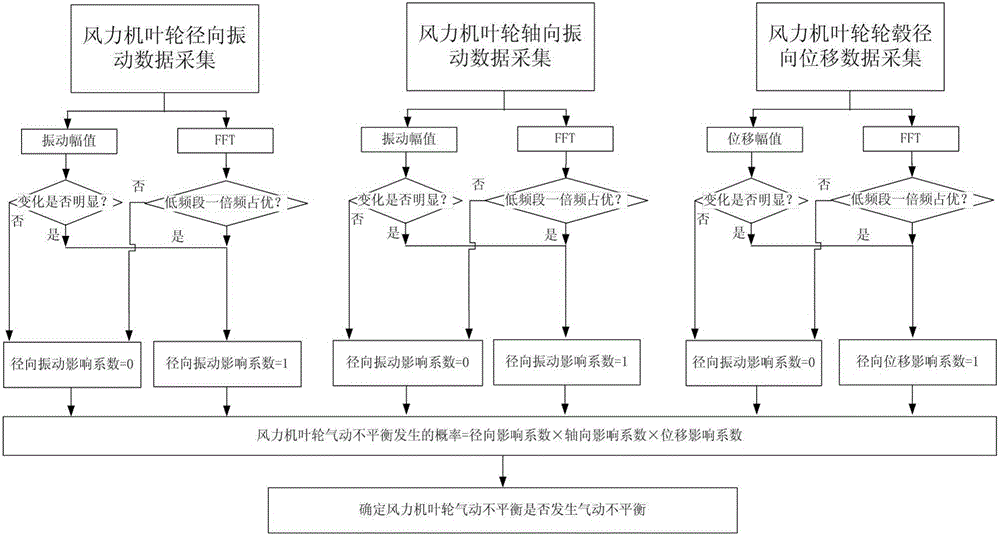

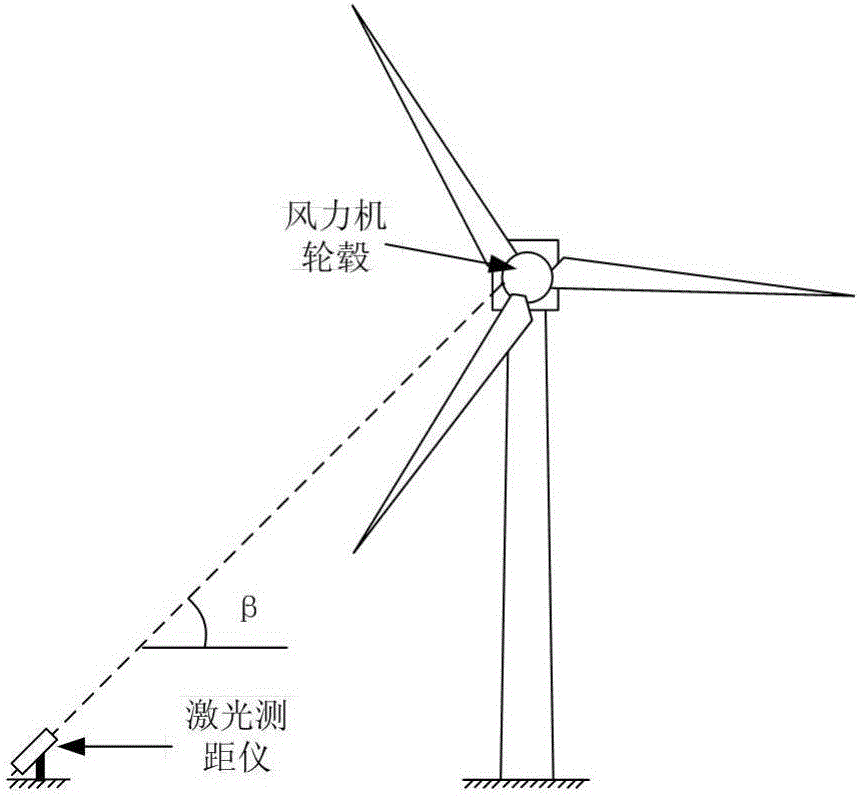

Method for detecting and diagnosing aerodynamic imbalance of impellers of wind turbine

InactiveCN106197849ADiagnosing Pneumatic Imbalance FaultsDistinguish balanceStatic/dynamic balance measurementImpellerVibration amplitude

A method for detecting and diagnosing aerodynamic imbalance of the impellers of a wind turbine is provided which comprises steps of: obtaining a comparison between an impeller radial vibration amplitude and historical data under the same working condition, and assigning 0 to an impeller radial vibration influence coefficient in the case of an unobvious vibration amplitude change; performing FFT on a radial vibration signal and assigning 1 to the radial vibration influence coefficient if a first-harmonic signal relative to the impeller rotating speed in the frequency spectrum is dominant in the low-frequency band and an vibration amplitude change is obvious, or assigning 0 to the radial vibration influence coefficient; performing the same diagnosis method on impeller radial vibration data and impeller hub radial displacement data; multiplying the obtained influence coefficients to obtain the probability of occurrence of the aerodynamic imbalance of the impellers of the wind turbine, and determining that the impellers of the wind turbine generates aerodynamic imbalance when the probability is equal to 1, and assigning 0 to the probability of occurrence of the aerodynamic imbalance of the impellers of the wind turbine as long as one of the three influence coefficients is 0. The method can effectively distinguish between impeller aerodynamic imbalance and mass imbalance of the impellers of the wind turbine, more accurately determines the aerodynamic imbalance of the impellers of the wind turbine, and increases the work efficiency and accuracy in the detection and diagnosis of the aerodynamic imbalance of the impellers of the wind turbine.

Owner:XIAN THERMAL POWER RES INST CO LTD

GRA MEMS accelerometer

InactiveUS7472596B1Minimize structural instabilityAcceleration measurement using interia forcesAcceleration measurement using gyroscopesAccelerometerMass imbalance

An accelerometer that lies generally in a plane, for detecting acceleration along an input axis. There is a substrate, a generally planar Servo Member (SM) flexibly coupled to the substrate such that it is capable of oscillatory motion about a servo axis that lies in the plane, a generally planar Torque Summing Member (TSM) coplanar with and flexibly coupled to the SM such that the TSM is capable of rotary motion relative to the SM about an output axis that is in the plane and orthogonal to the servo axis, wherein the TSM is mass-imbalanced relative to the output axis, and a generally planar rotor coplanar with and flexibly coupled to the TSM such that it is capable of rotary oscillatory motion relative to the TSM about a rotor axis that is orthogonal to the plane of the members. There are drives for oscillating the rotor about the rotor axis and for oscillating the SM about the servo axis. Output sensors detect oscillation of the rotor about the rotor axis and of the SM about the servo axis. Output sensors detect rotation of the TSM about the output axis.

Owner:CARDARELLI DONATO

Method and system for detecting a mass imbalance in a wind turbine rotor

ActiveUS10781795B2Vibration measurement in solidsWind motor controlClassical mechanicsMass imbalance

Owner:GENERAL ELECTRIC CO

Method of correcting rotor imbalance and wind turbine thereof

ActiveUS10907615B2Low costShorten the timeWind motor controlMachines/enginesTurbine bladeClassical mechanics

The present invention relates to a method of correcting rotor imbalance and a wind turbine thereof. The correction method comprises measuring the vibrations within at least one time window and determining an imbalance factor and an imbalance phase. The values of the parameters in the equation for calculating the correction action are then updated based on the imbalance factor and an imbalance phase. A correction angle for each of the wind turbine blades is calculated using these adjusted parameters. The correction angle is used to aerodynamically balance the rotor, and a model may be used to determine the initial values of the parameters. Another imbalance factor and imbalance phase is determined based on another set of measurements. This imbalance factor is then used to calculate a mass moment for correcting the mass imbalance in the wind turbine blades. The weight and location of a balancing mass is finally calculated based on this mass moment and installed in the respective wind turbine blades.

Owner:ENVISION ENERGY DENMARK

Laying Head with a Vibration Damping Device

A laying head for forming coils using continuous and substantially rectilinear rolled products such as rods or wire, having vibration damping means integrated in one of two rotor supports (3), preferably the one on the rolled product outlet side. Said means comprise a plurality of coils (6, 6′, 6″) arranged around the rotor (3), rotating about its axis (X), which generate a magnetic field actively controlled by a computer, the resultant force of which is perpendicular to the axis (X) and of a predetermined intensity so as to eliminate the inertial forces generated by the mass imbalances. Alternatively, the damping means incorporated in one of the supports are comprised of oil film bearings.

Owner:DANIELI & C OFF MEC SPA

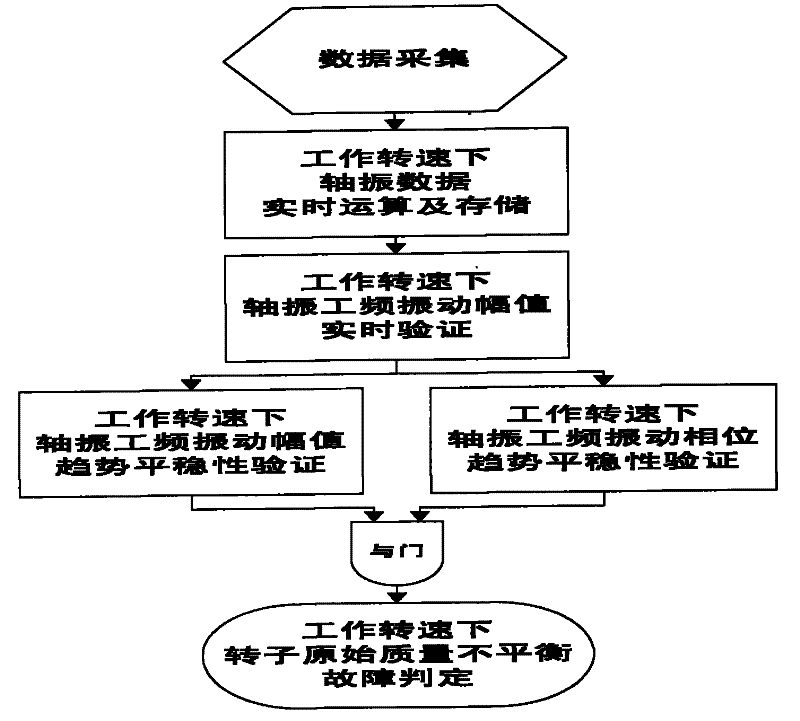

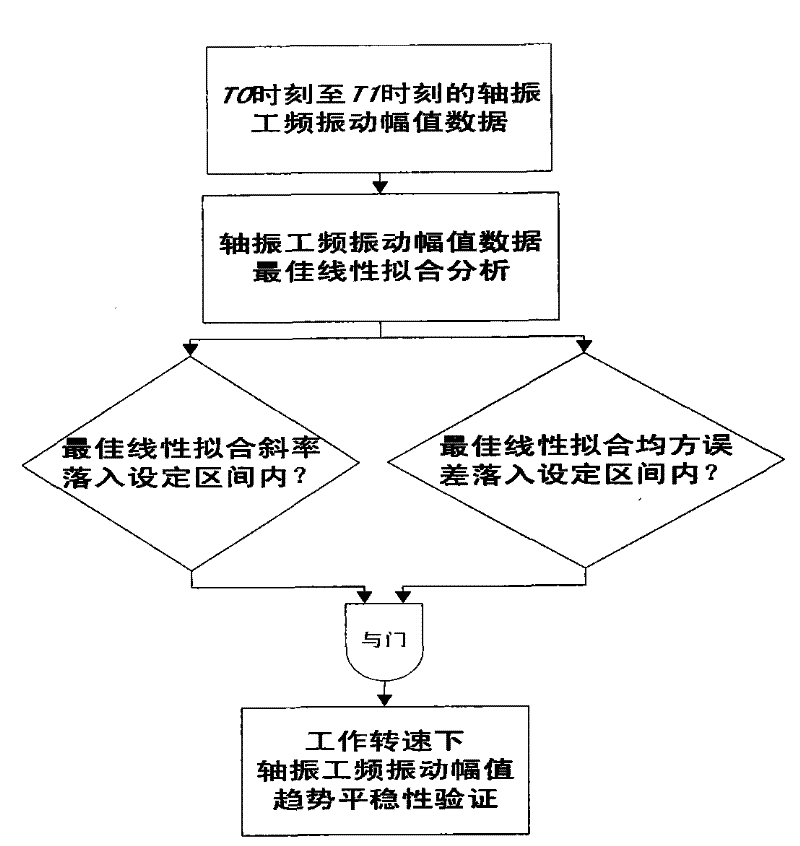

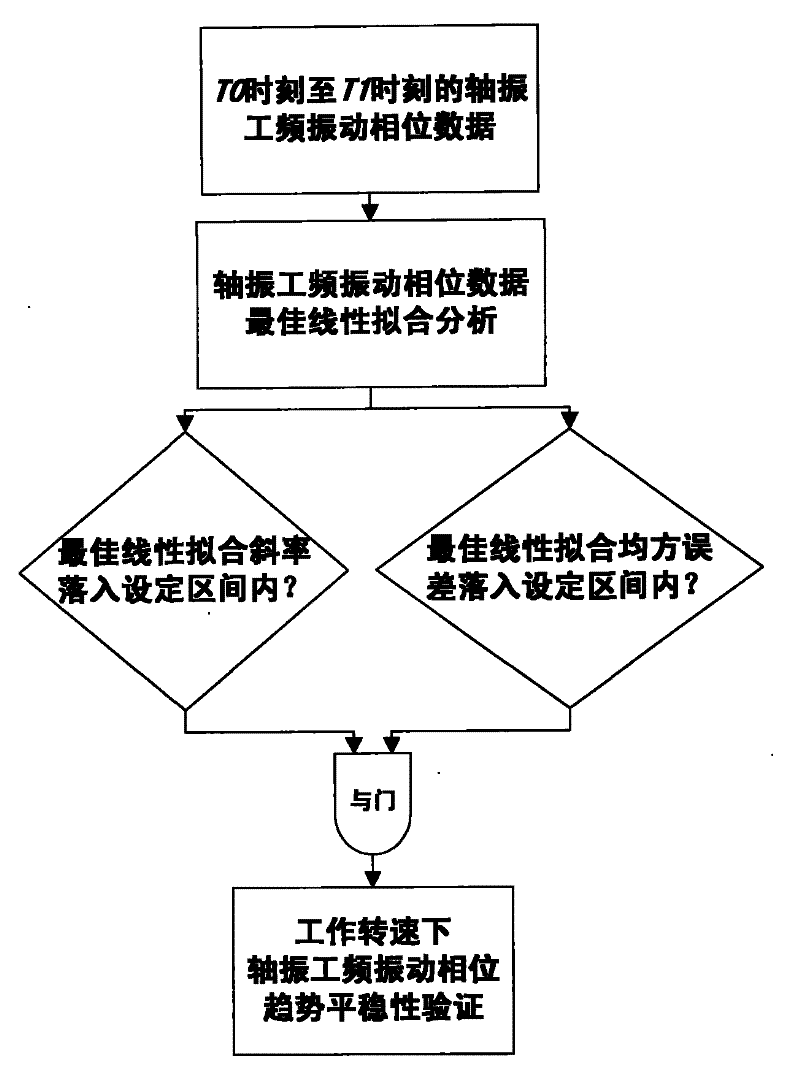

Real-time Diagnosis Method of Original Mass Unbalance Fault of Turbine Generator Set Rotor

InactiveCN101738293BMethod scienceConclusion scienceStatic/dynamic balance measurementVibration amplitudePresent method

The invention discloses a real-time diagnosis method for the unbalanced fault of the original mass of the rotor at the operating speed of the steam turbine generator set, which belongs to the field of fault diagnosis. By collecting the vibration signal of the rotor shaft of the steam turbine unit, the necessary calculation, analysis and judgment are carried out on the vibration data, the real-time calculation and storage of the power frequency vibration amplitude and phase value of the shaft relative vibration on both sides of the rotor, and the real-time verification of the shaft vibration power frequency vibration amplitude, Judging whether the amplitude of the shaft vibration and power frequency vibration on any side of the rotor is greater than the vibration amplitude threshold; combined with the least square method, the shaft vibration and power frequency vibration data are verified for the stability of the shaft vibration power frequency vibration amplitude trend at the working speed and the operating speed Real-time quantitative calculation and analysis such as the verification of the phase stability of the power frequency vibration phase trend of the lower shaft vibration. Combined with various verification results, automatic real-time online diagnosis of whether the rotor original mass imbalance fault occurs at the working speed of the unit. The invention has the advantages of scientific method, reliable conclusion, automatic real-time on-line monitoring, fault diagnosis and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

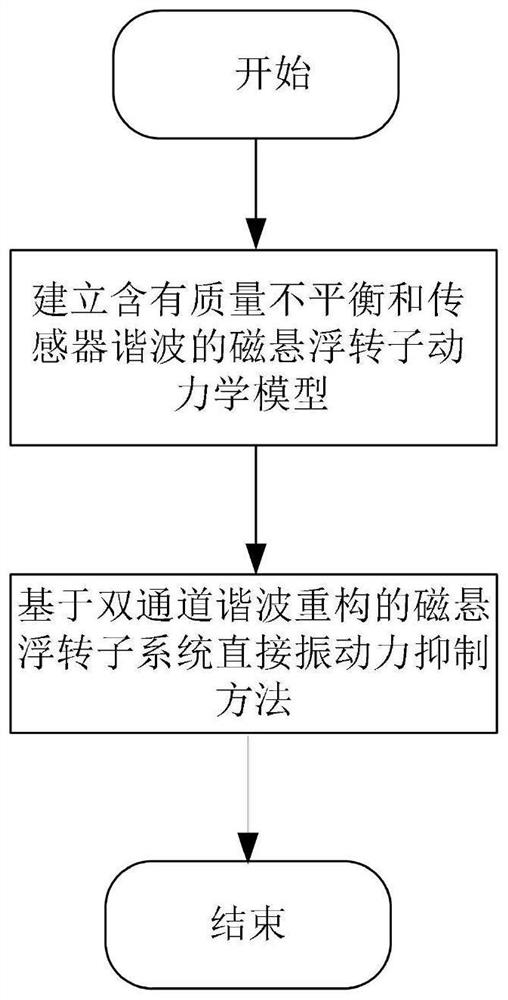

Magnetic suspension rotor direct vibration force suppression method based on dual-channel harmonic reconstruction

PendingCN114326409AIncreased computational burdenReduce computational complexityAdaptive controlHarmonicDynamic models

The invention discloses a magnetic suspension rotor direct vibration force suppression method based on dual-channel harmonic reconstruction, which comprises the following steps: firstly, establishing a magnetic suspension rotor dynamic model containing mass imbalance and sensor harmonic, and then, adopting a magnetic suspension rotor direct vibration force suppression method based on a DCHR controller. Wherein the DCHR can quickly and accurately estimate and suppress the vibration force of the system. Meanwhile, the DCHR uses the vibration force as the same-frequency input compensation displacement stiffness force, the harmonic detection performance is improved through double-frequency amplitude compensation, and the stability of the system within the full rotating speed range is guaranteed through a compensation phase angle. The DCHR controller is simple in structure, small in hardware calculation burden, capable of effectively restraining the harmonic vibration force in the magnetic suspension rotor and suitable for restraining the vibration force of a magnetic suspension rotor system containing mass imbalance and sensor harmonic waves.

Owner:BEIHANG UNIV

Harmonic Suppression Method and System for Maglev Rotor Vibration with Multiple Notch Filters in Parallel

ActiveCN109976403BSuppress harmonic currentGuaranteed stabilityMechanical oscillations controlMagnetic bearingHarmonic mitigation

The invention discloses a method and system for suppressing vibration harmonics of a magnetic levitation rotor with multiple traps connected in parallel. The signal extraction point of the device is placed at the input end of the magnetic levitation controller, and the signal insertion point of the parallel phase shift notch filter is placed at the displacement error signal. The invention is aimed at the magnetic levitation rotor, considering the influence of rotor mass imbalance and sensor vibration, and establishing a harmonic The magnetic levitation rotor dynamics model of wave disturbance effectively suppresses the different frequency disturbance components of the harmonic current at the variable speed frequency by connecting multiple traps with different phase shifts in parallel, thereby effectively suppressing the harmonic vibration and ensuring the closed-loop stability of the system at the same time. And it has reference significance to the harmonic suppression problem under the condition of variable speed of the magnetic levitation-rotor system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

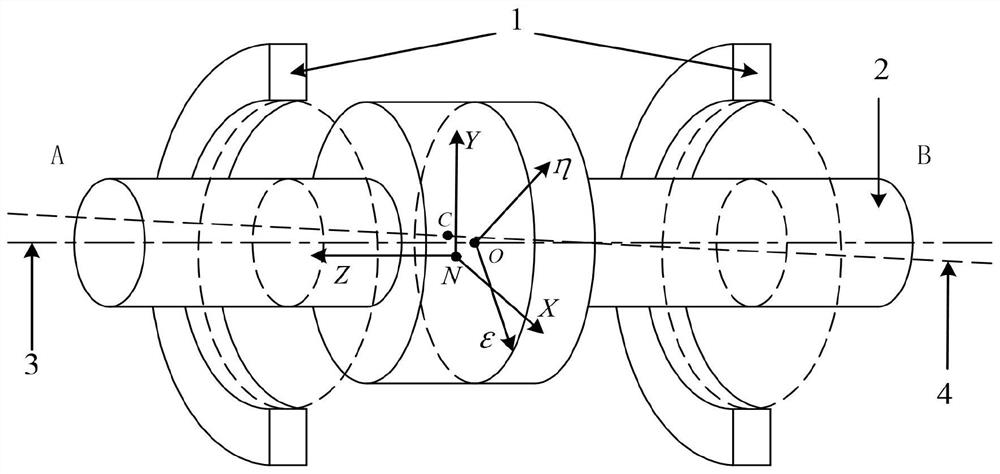

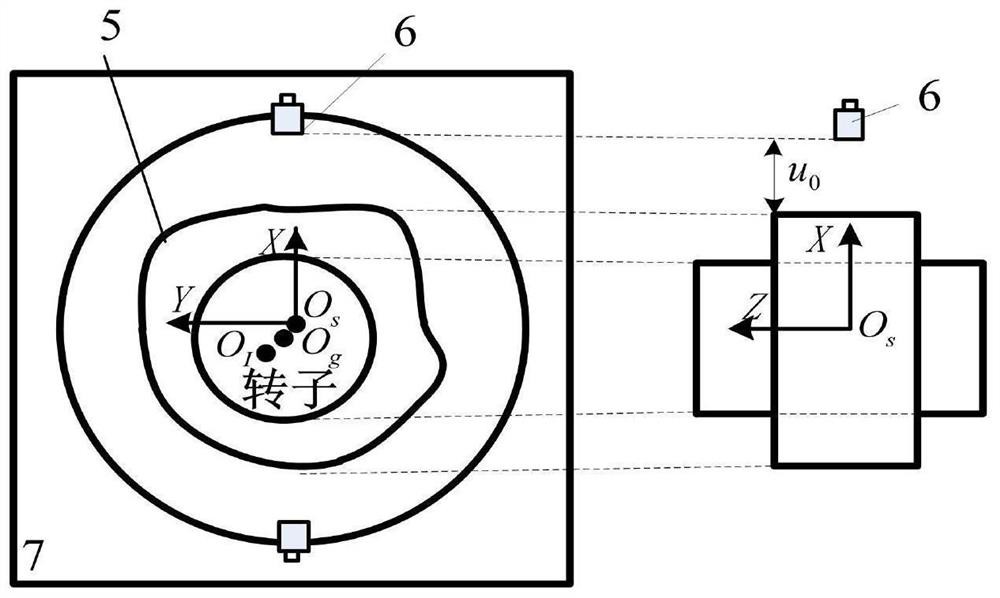

Harmonic current suppression method based on virtual sampling second-order repetitive control

ActiveCN112525179AImprove robustnessAvoid computationRotary gyroscopesHarmonic reduction arrangementHarmonicControl engineering

The invention discloses a harmonic current suppression method based on virtual sampling second-order repetitive control. The method comprises the following steps: firstly, establishing a magnetic suspension rotor kinetic model containing mass imbalance and sensor harmonic waves; secondly, using virtual sampling to ensure that the ratio of a disturbance basic period to a sampling period is an integer under the condition that the physical sampling frequency is not changed, enhancing the robustness of the system through second-order repetitive control, and keeping a good suppression effect when the frequency fluctuates to a certain extent; and a novel stability analysis method is provided for solving the problem that the high-order repetitive control stability is difficult to prove. Accordingto the virtual sampling second-order repetitive controller, the robustness of the system is improved by changing the implementation mode of unit delay, the virtual sampling second-order repetitive controller is suitable for harmonic current suppression of the magnetic suspension rotor with mass imbalance and sensor harmonic waves, a novel stability analysis method is provided, and the calculatedamount is reduced to a great extent.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com