Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "CAM combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

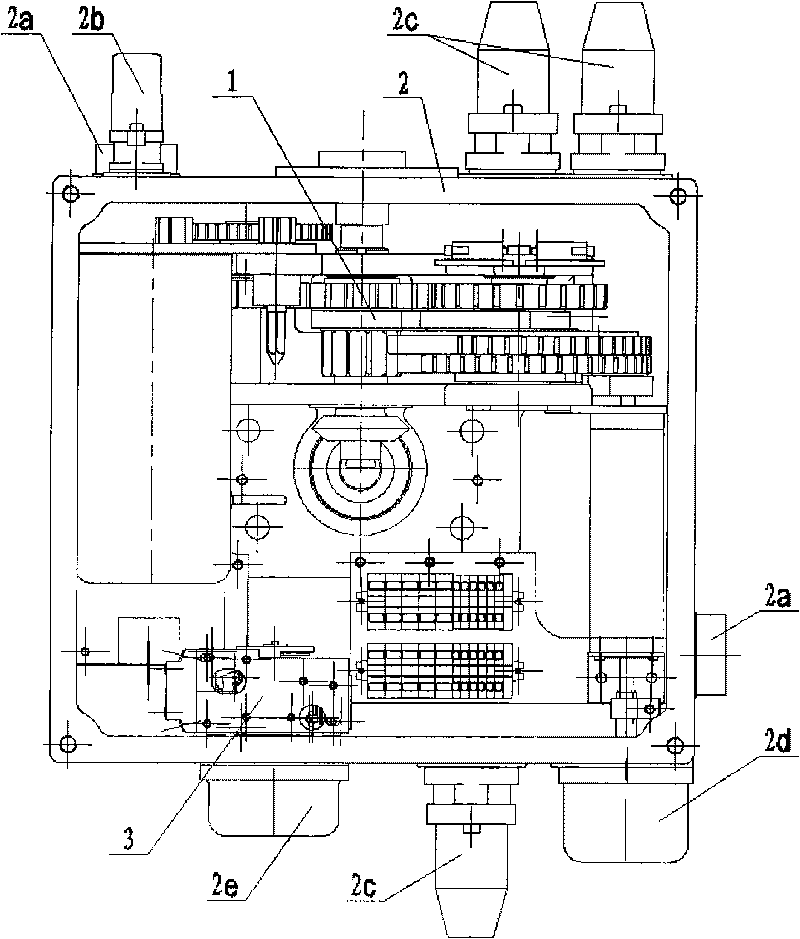

Electrical operating mechanism for switchgear

ActiveCN101714472ASimple structureHigh output corner accuracyContact driving mechanismsSwitch power arrangementsDrive shaftSwitchgear

Owner:西安西电高压开关操动机构有限责任公司 +1

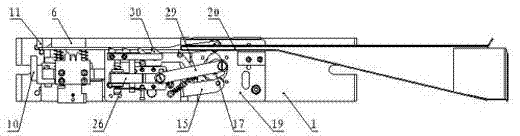

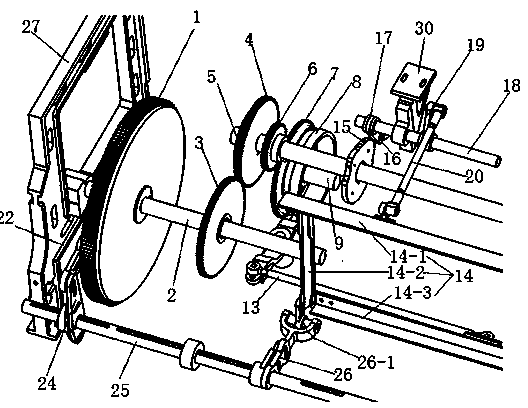

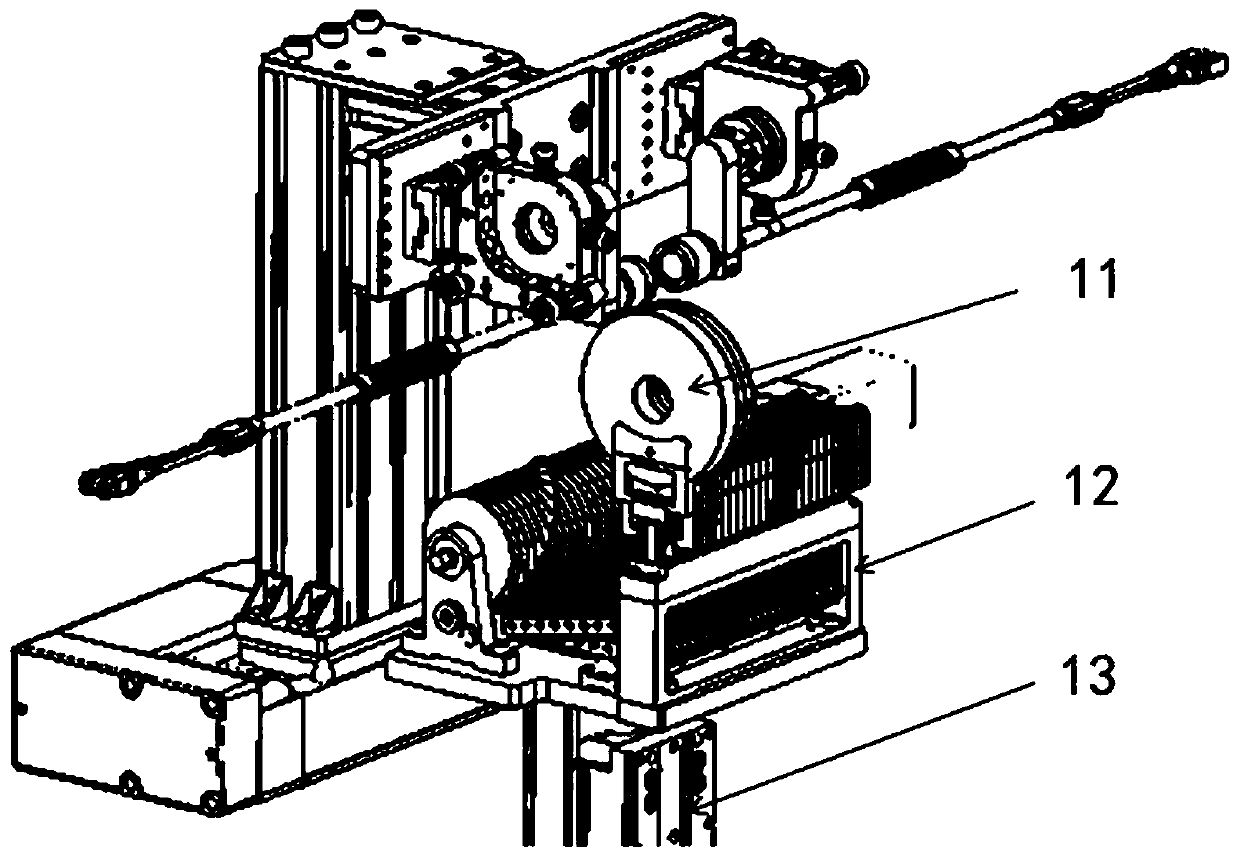

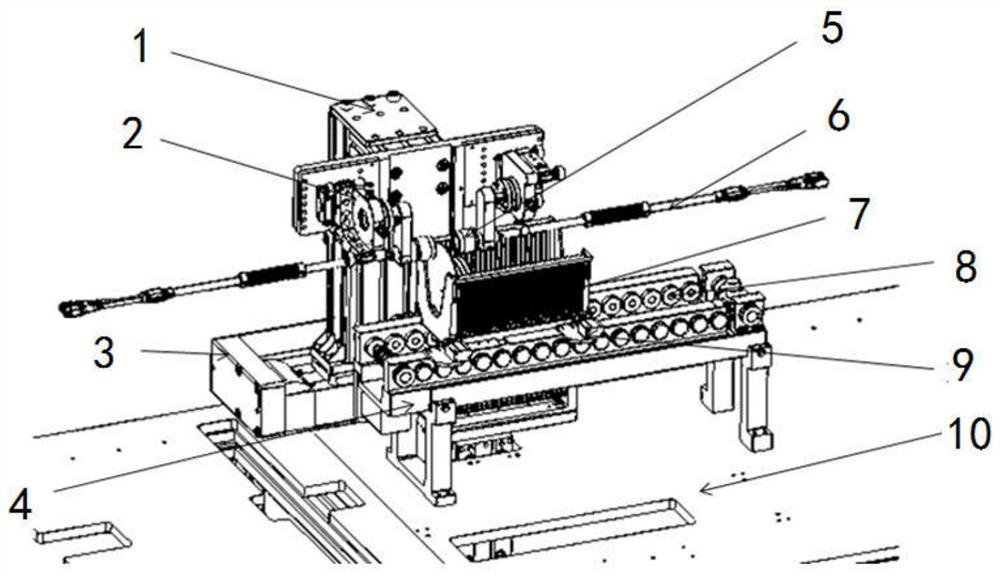

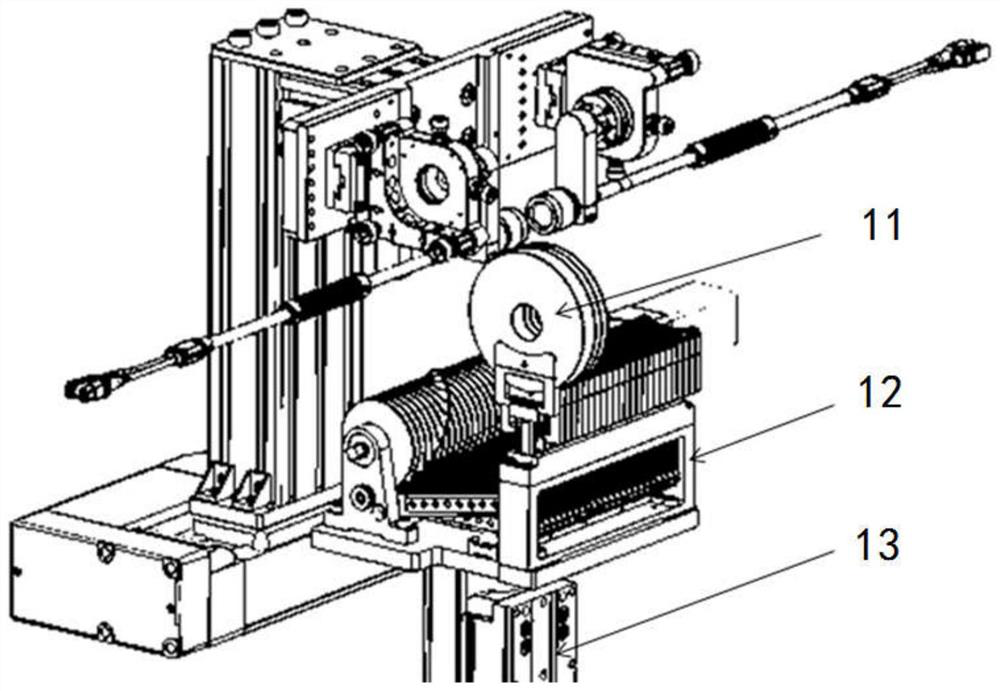

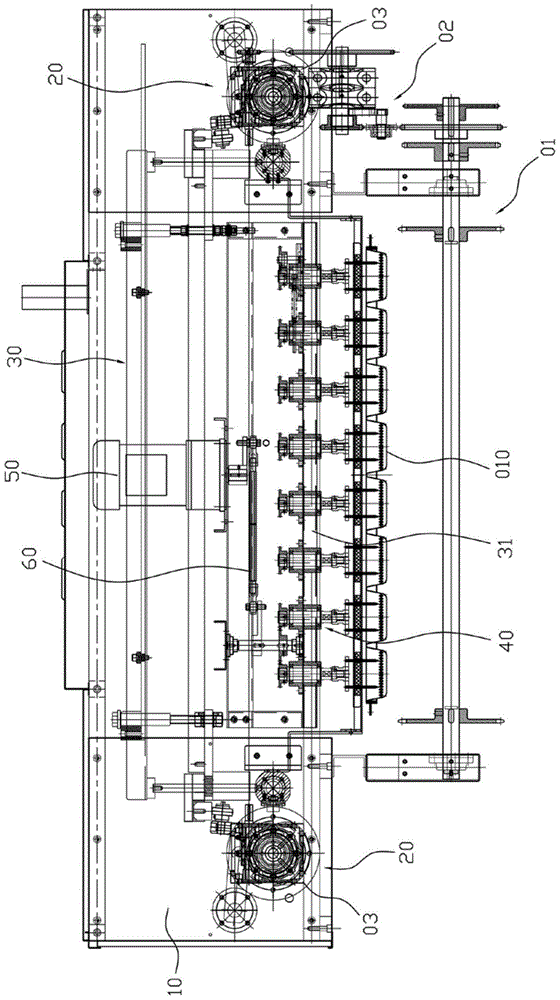

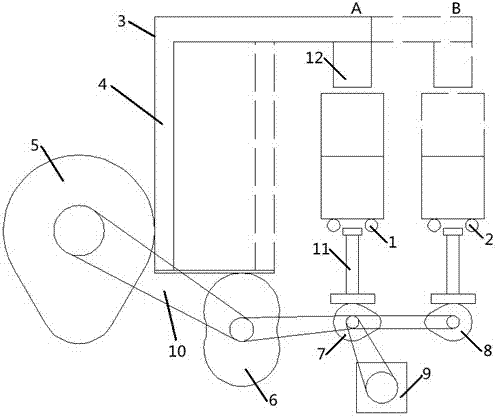

Vertical type component feeder capable of cutting pins and paper tapes and used for automatic component inserting machine

The invention discloses a vertical type component feeder capable of cutting pins and paper tapes and used for an automatic component inserting machine. The vertical type component feeder capable of cutting the pins and the paper tapes and used for the automatic component inserting machine comprises an installation base plate, a speed-down motor, a pin and paper tape cutting mechanism and a feeding mechanism, wherein the pin and paper tape cutting mechanism comprises a pin cutting mechanism installation linear guide rail, a mechanism installation seat, a pin cutting mechanism installation body, a fixed cutter fixing seat, a pin cutting mechanism lever connecting slice, a pin cutting mechanism lever, a pin cutting mechanism pin pressing slice and a component pin locating slice. The feeding mechanism comprises a feeding mechanism active shirting fork, a feeding mechanism retaining shifting fork, a tape rail, an upper installation plate, a feeding mechanism crank and a pin cutting mechanism cam combination body. The vertical type component feeder used for the automatic component inserting machine enables a mechanical arm of the component inserting machine to take materials at the fixed point. Compared with traditional equipment, the component inserting machine with the same amount of feeders is small in size, saves occupied space and can finish automatic pin cutting, paper tape cutting and vertical component feeding simultaneously.

Owner:深圳市硕安迪科技开发有限公司

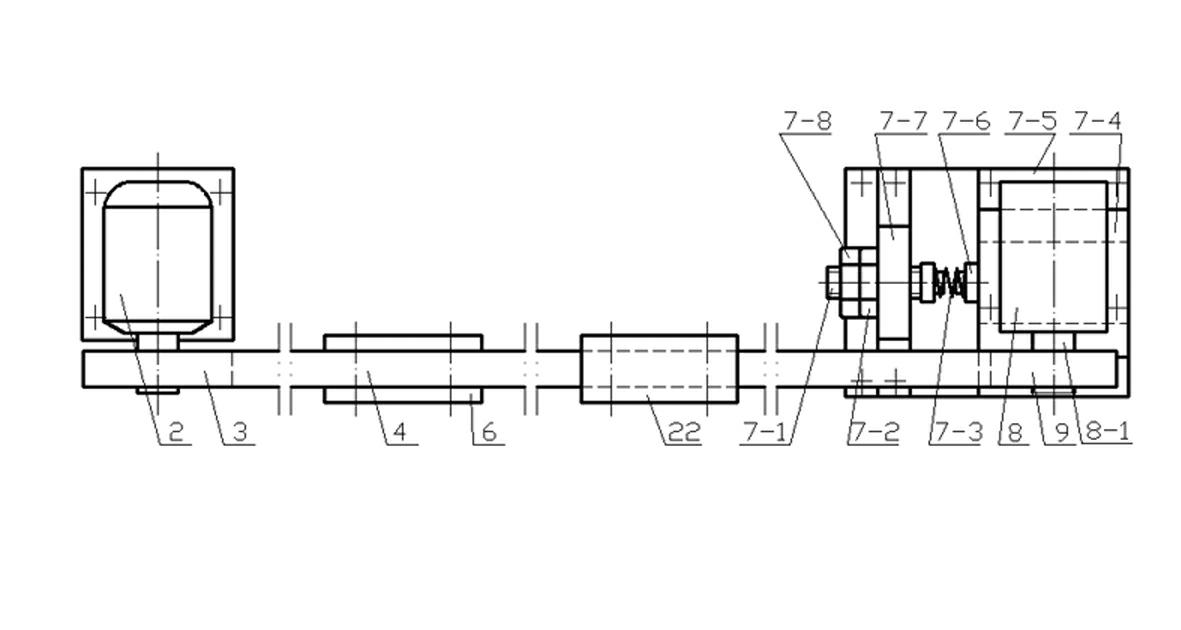

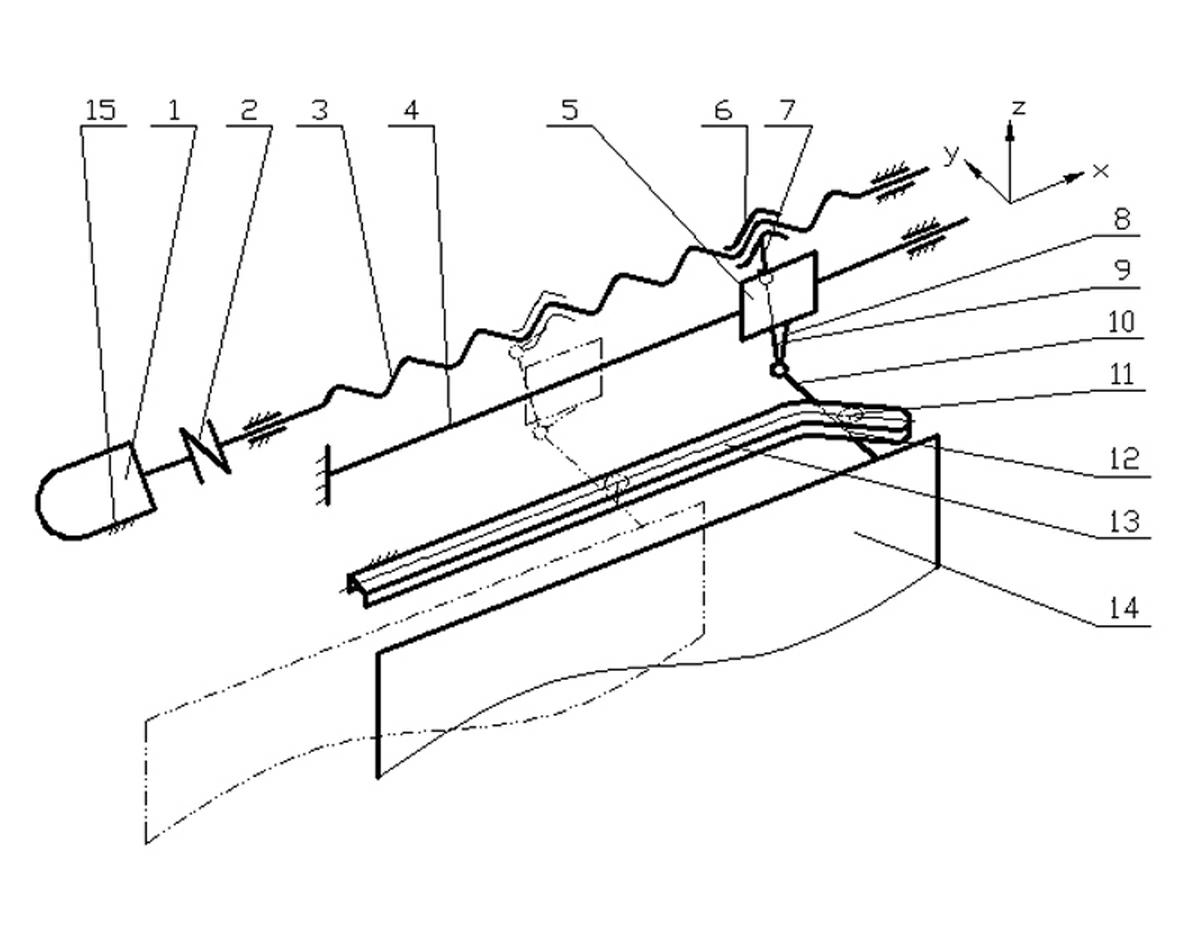

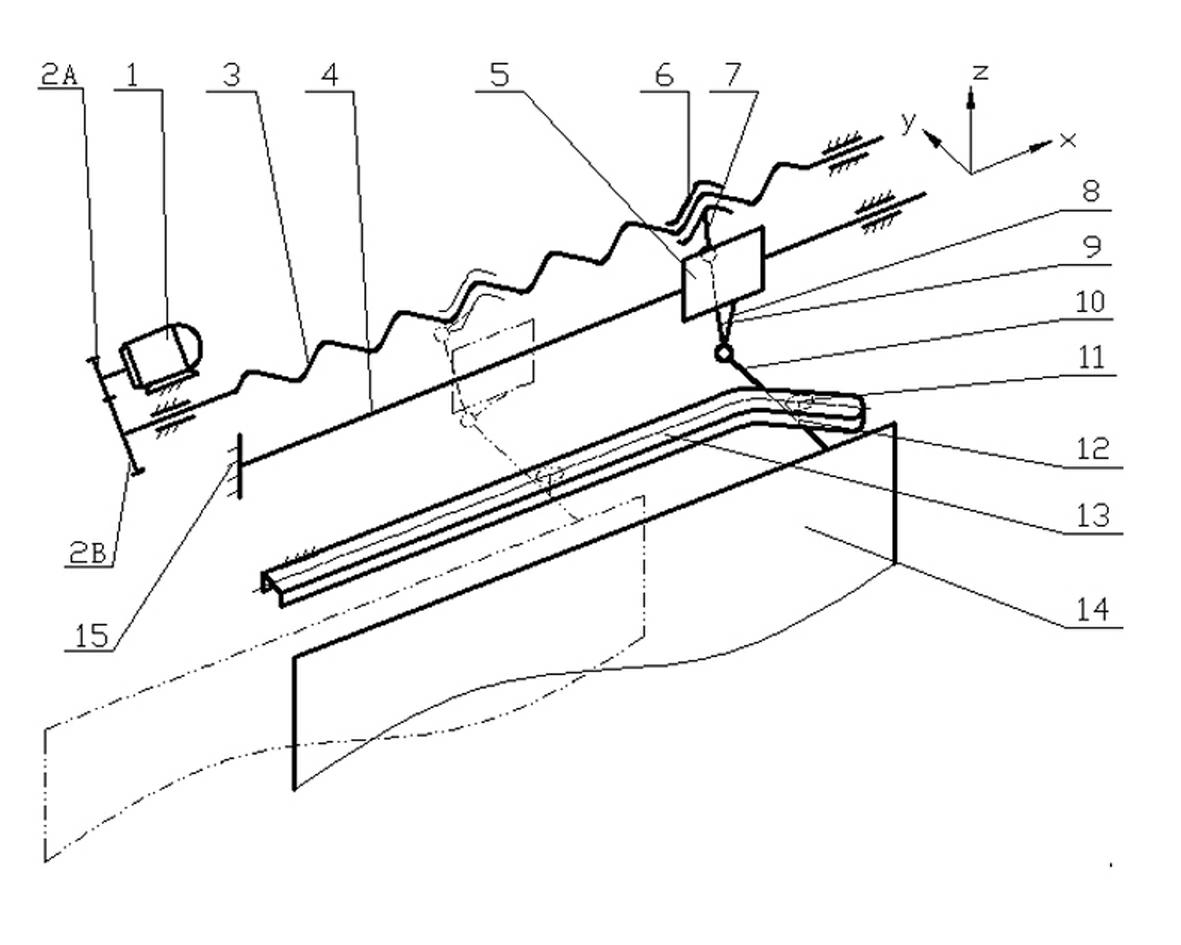

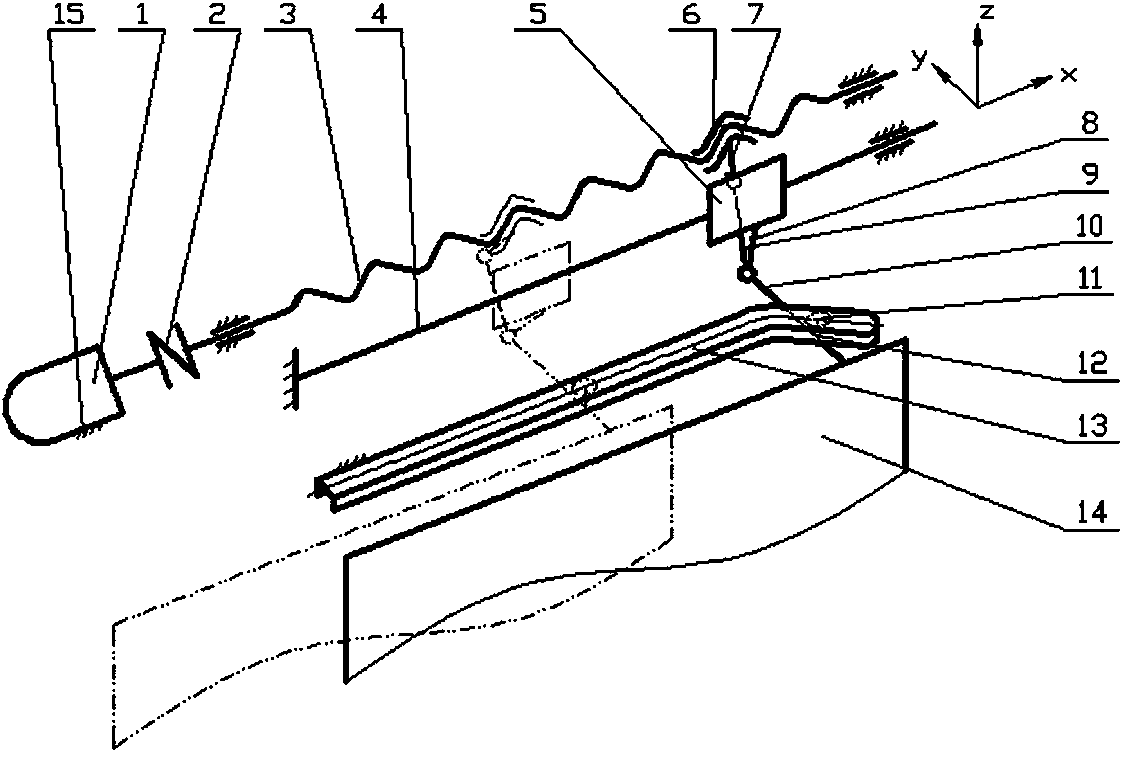

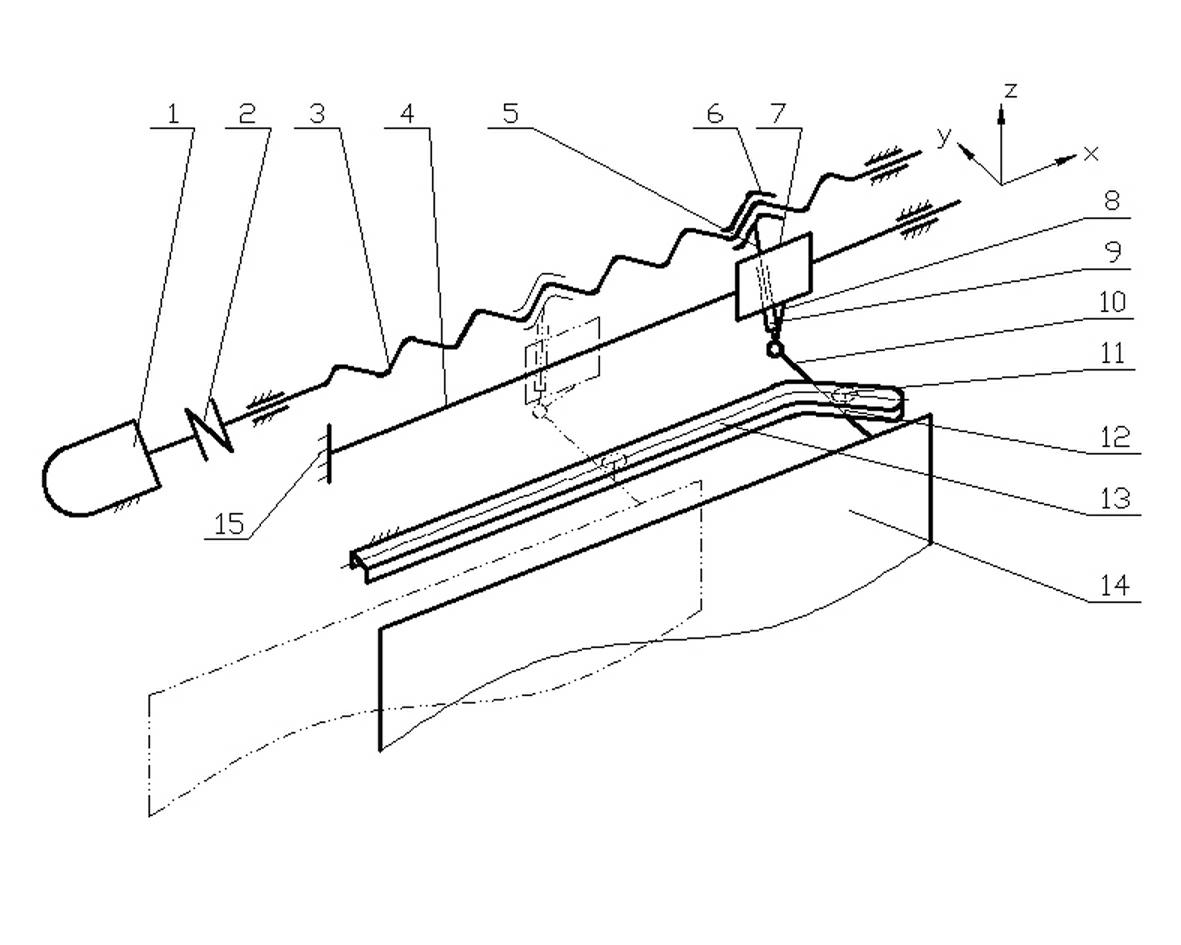

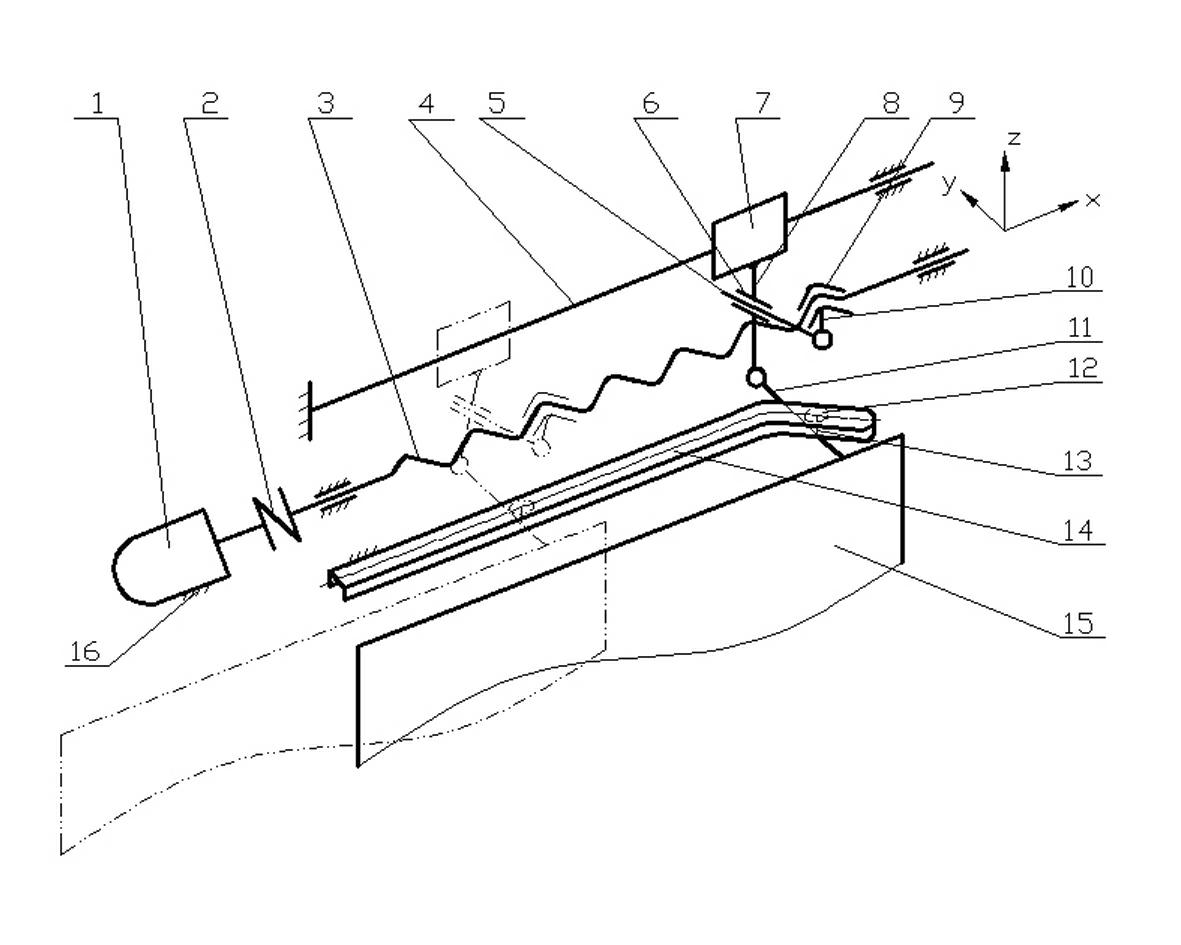

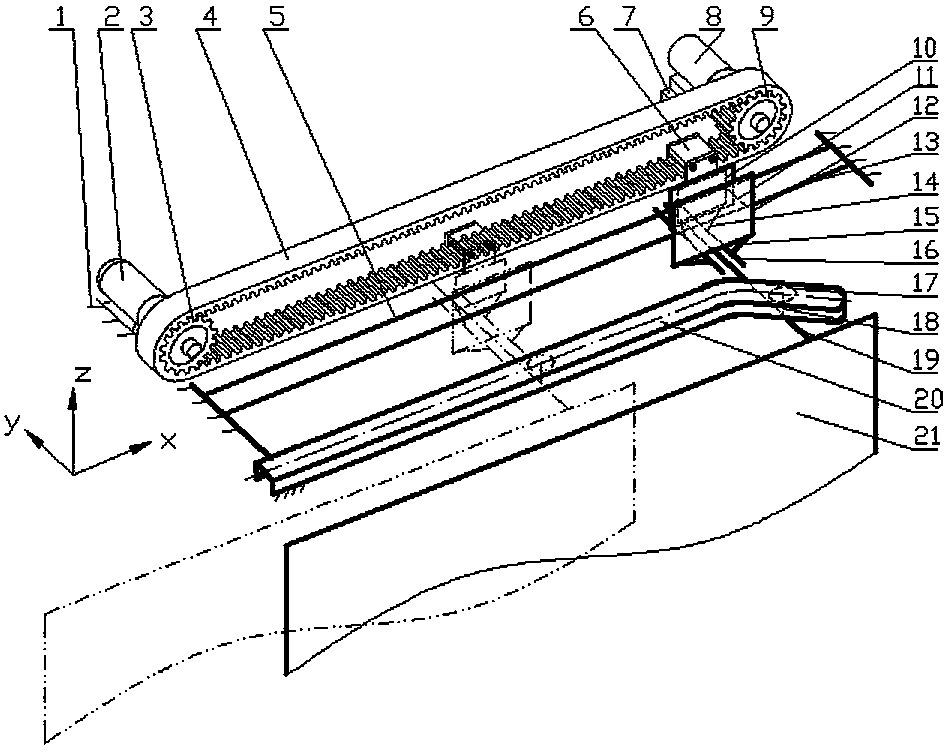

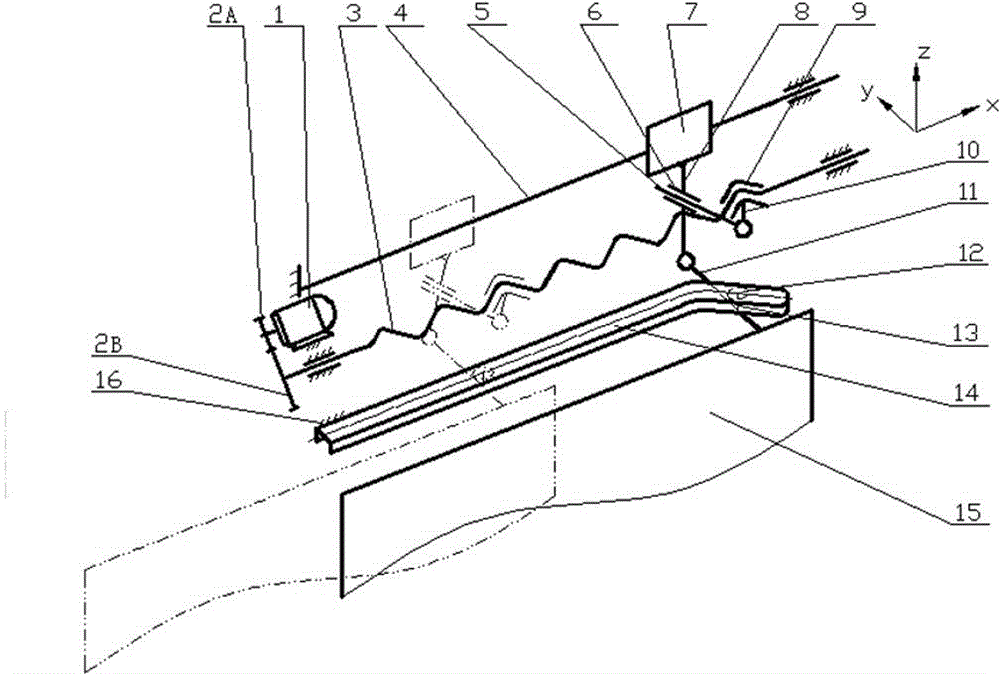

Tooth belt double-shaft guide rod groove cam combination space mechanism for sliding-plug door

InactiveCN102305009AQuick sealQuick opening and closingPower-operated mechanismDoor arrangementDrive wheelCoupling

The invention discloses a tooth belt double-shaft guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the tooth belt double-shaft guide rod groove cam combination space mechanism for high-speed rail or other railway vehicles. The mechanism comprises a door frame, a motor, a driving wheel, a tooth belt, an auxiliary bearing shaft, a belt clamp, a tension device, a bearing pedestal, a driven wheel, an auxiliary shaft sleeve, a coupling rod A, a main shaft sleeve, a main bearing shaft, a coupling shaft B, a coupling shaft C, a guide rod sleeve, a roller, a roller shaft, a door carrying guide rod, a groove cam and a door leaf; a tooth belt transmission mechanism consists of the driving wheel, the tooth belt, a lower belt clamp, the tension device, the bearing pedestal, and the driven wheel; a double-shaft guide rod mechanism consists of the coupling rod A, the main shaft sleeve, the coupling rod B, the coupling rod C and the guide rod sleeve which are connected fixedly and integrally, the main bearing shaft, the auxiliary shaft, and the door frame; and a groove cam mechanism consists of the main shaft sleeve, the main shaft, the coupling rod C, the roller, the roller shaft, the door carrying guide rod, the groove cam, the door leaf, the main shaft sleeve and the door frame.

Owner:NANJING INST OF TECH

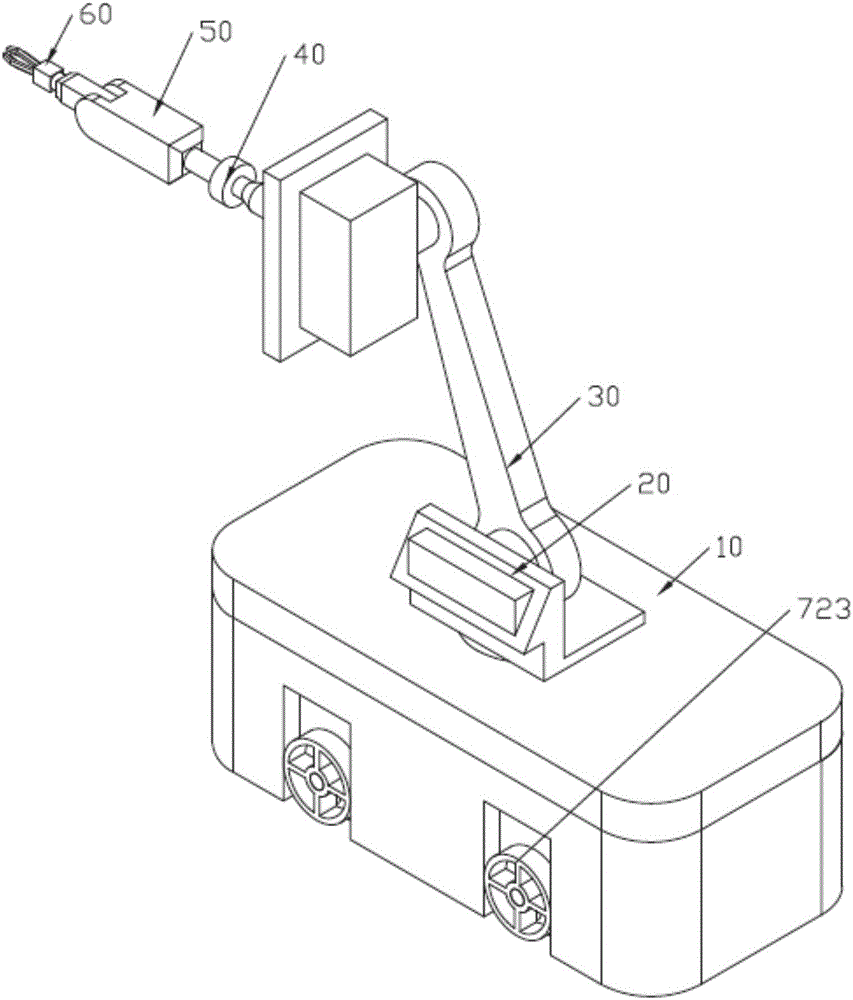

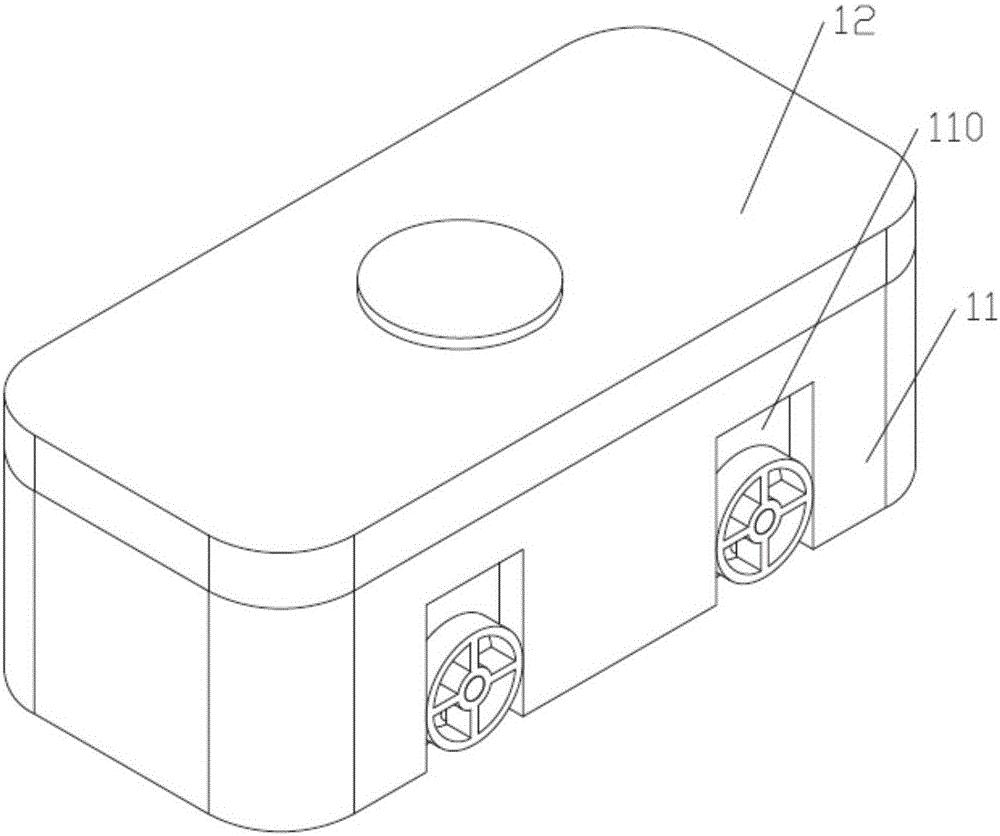

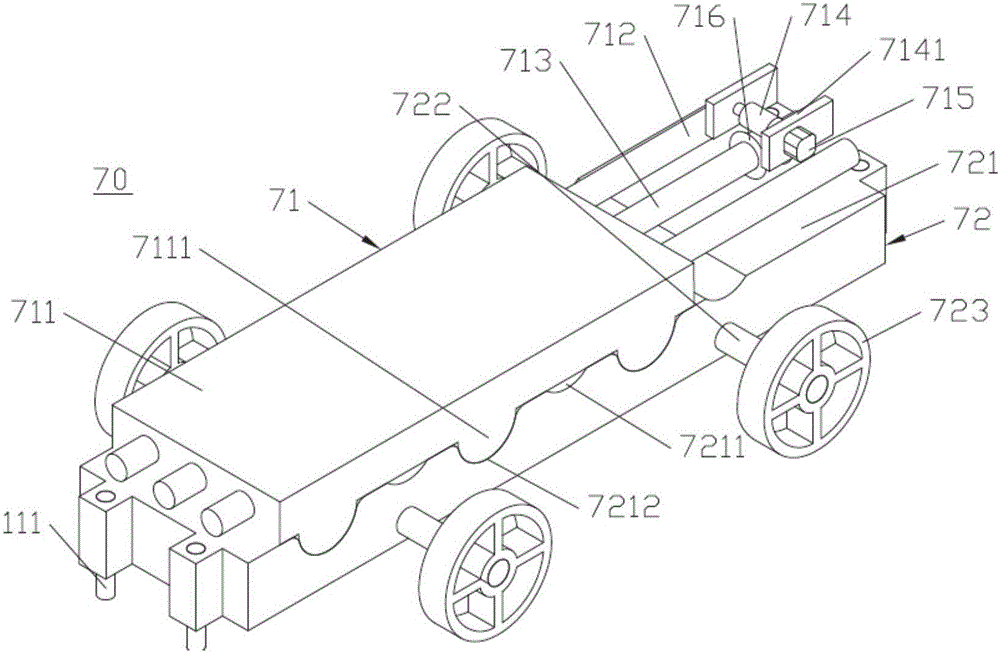

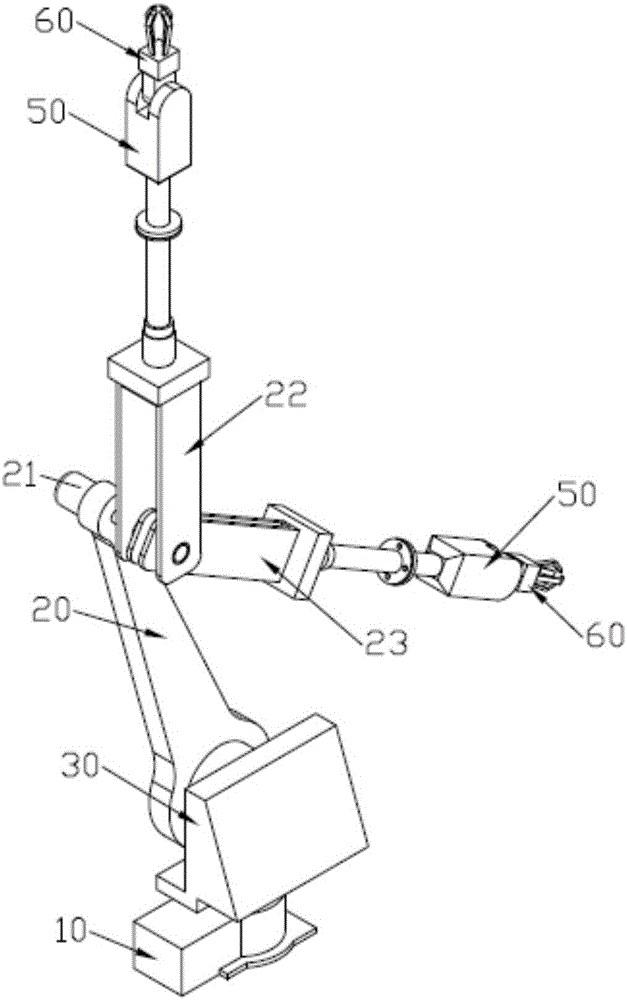

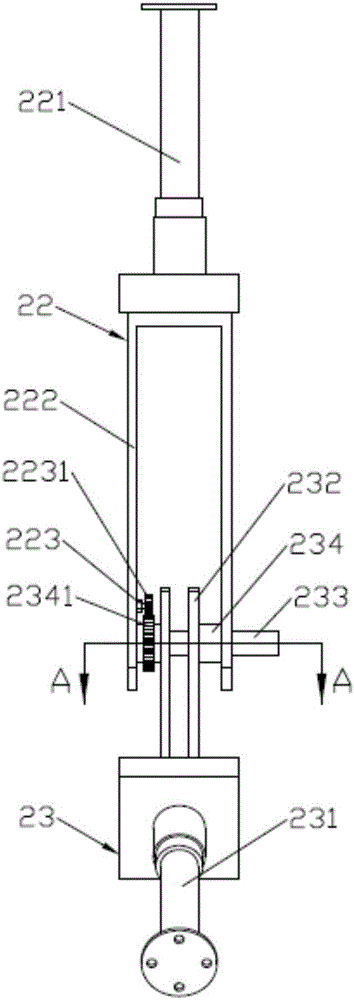

Movable light six-shaft universal robot

ActiveCN105965472AAccurate graspProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a movable light six-shaft universal robot. The robot comprises a base, a waist rotation part connected with the base in a pivoted mode, a large arm connected to the waist rotation part in a pivoted mode and a small arm installed on the large arm, the waist rotation part rotates around the base, and the large arm rotates around the waist rotation part. The base comprises a hollow base body and a base cover covering the base body. The base body is provided with a wheel driving device and a wheel device. The small arm is provided with a manipulator assembly, the manipulator assembly comprises an arm, a swing arm connected at the front end of the arm in a pivoted mode and a manipulator fixed to a rotary plate at the front end of the swing arm. Wheels can be retracted at the two sides of the base body through the wheel driving device, and the whole robot can move by means of the wheels. By means of a gear transmission and cam combination, claws can be driven at the same time, and motion amplitudes of the claws are the same, so that workpieces can be accurately and conveniently grasped by the claws in all directions.

Owner:NANTONG KETI ROBOT SYST CO LTD

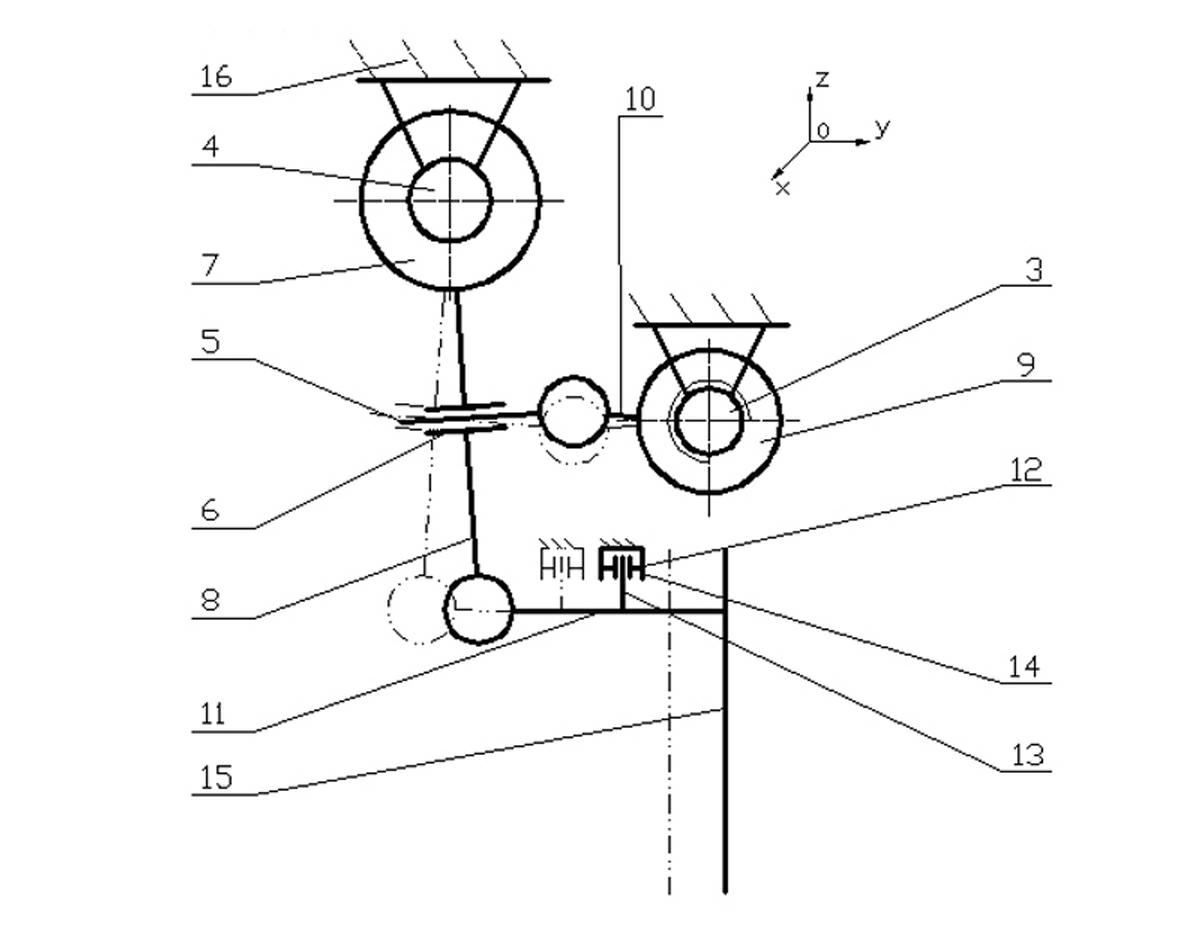

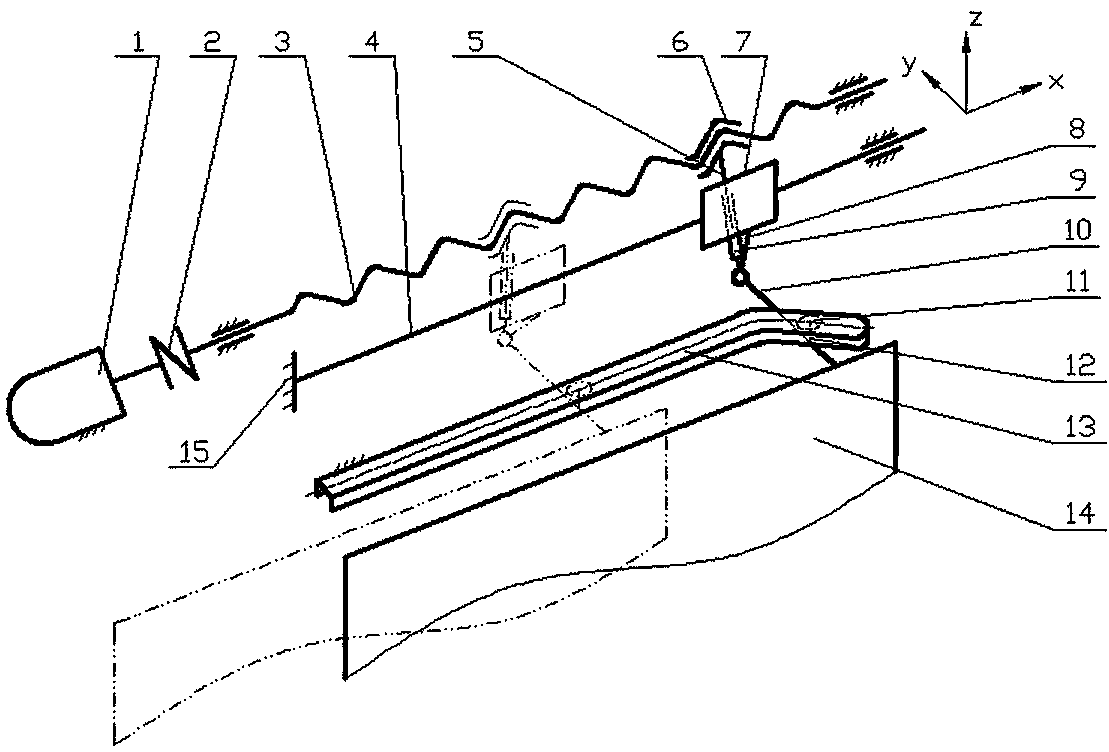

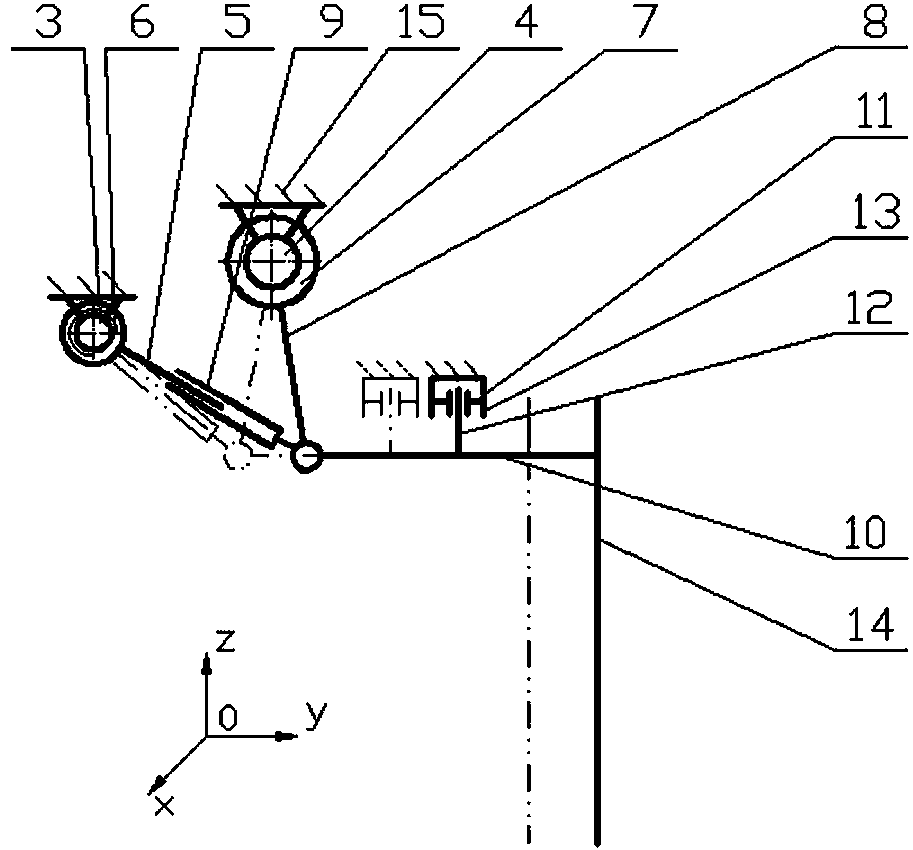

Spiral door carrying guide rod groove cam combination space mechanism for sliding-plug door

ActiveCN102305006ASierra seal is reliableImprove sealingPower-operated mechanismDoor arrangementCouplingEngineering

The invention discloses a spiral door carrying guide rod groove cam combination space mechanism for a sliding-plug door and relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door of a vehicle, in particular to the spiral door carrying guide rod cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a coupling rod A, a nut, a coupling rod B, a shaft sleeve, a coupling rod C, a door carrying rod sleeve, a door carrying guide rod, a roller, a roller shaft, a door handle, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the nut, the screw and the door frame; a door carrying guide rod mechanism consists of the nut, the door carrying rod sleeve, and the shaft sleeve which are connected fixedly and integrally through the coupling rod A, the coupling rod B, and the coupling rod C, the bearing shaft, the door carrying guide rod, and the door frame; a groove cam mechanism consists of the door carrying guide rod, the door handle, and the door leaf which are connected fixedly and integrally, and the bearing shaft, the groove cam, the roller shaft, and the roller; and the three mechanisms are connected with one another to form the spiral door carrying guide rod groove cam combination space mechanism for the sliding-plug door.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

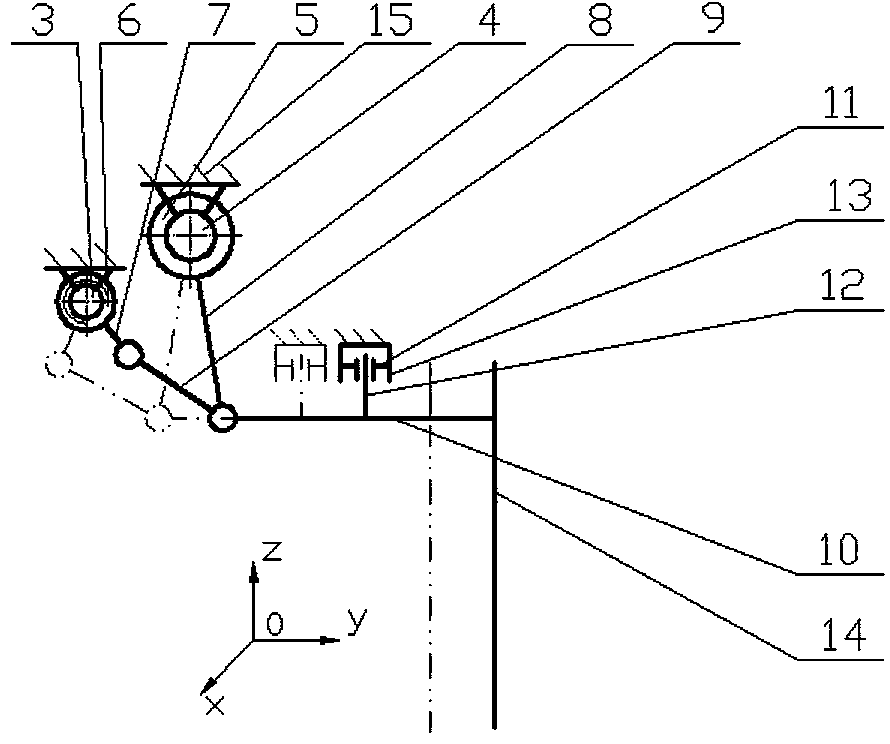

Spiral double-rocker composite hinge groove cam combination space mechanism for sliding-plug door

ActiveCN102305005AThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementEngineeringCam

The invention discloses a spiral double-rocker composite hinge groove cam combination space mechanism for a sliding-plug door, and relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door of a vehicle, in particular to a spiral double-rocker composite hinge groove cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a shaft sleeve, a nut, a short rocker, a door carrying rocker (a rocker for short), a connection rod, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the screw, the nut and the door frame; a double-rocker mechanism consists of the bearing shaft, the shaft sleeve, the short rocker, the rocker, and the connection rod; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf, and the door frame; a rotation pair consists of the upper end of the connection rod and the short rocker; a composite hinge consists of the lower end of the connection rod, the rocker and the door handle; and the spiral mechanism, the double-rocker mechanism and the groove cam mechanism are connected to form the spiral double-rocker composite hinge groove cam combination space mechanism.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

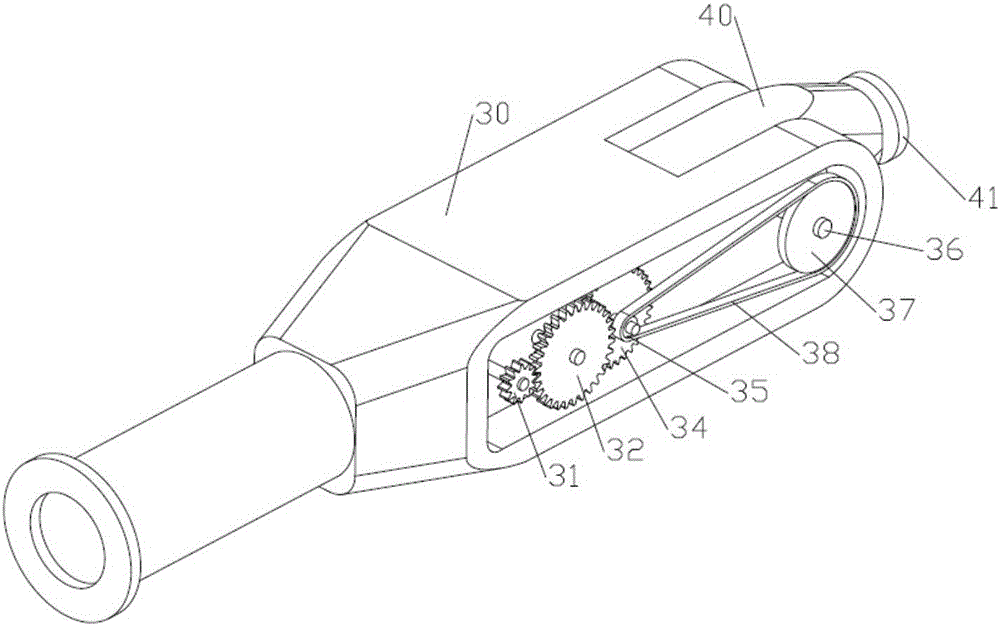

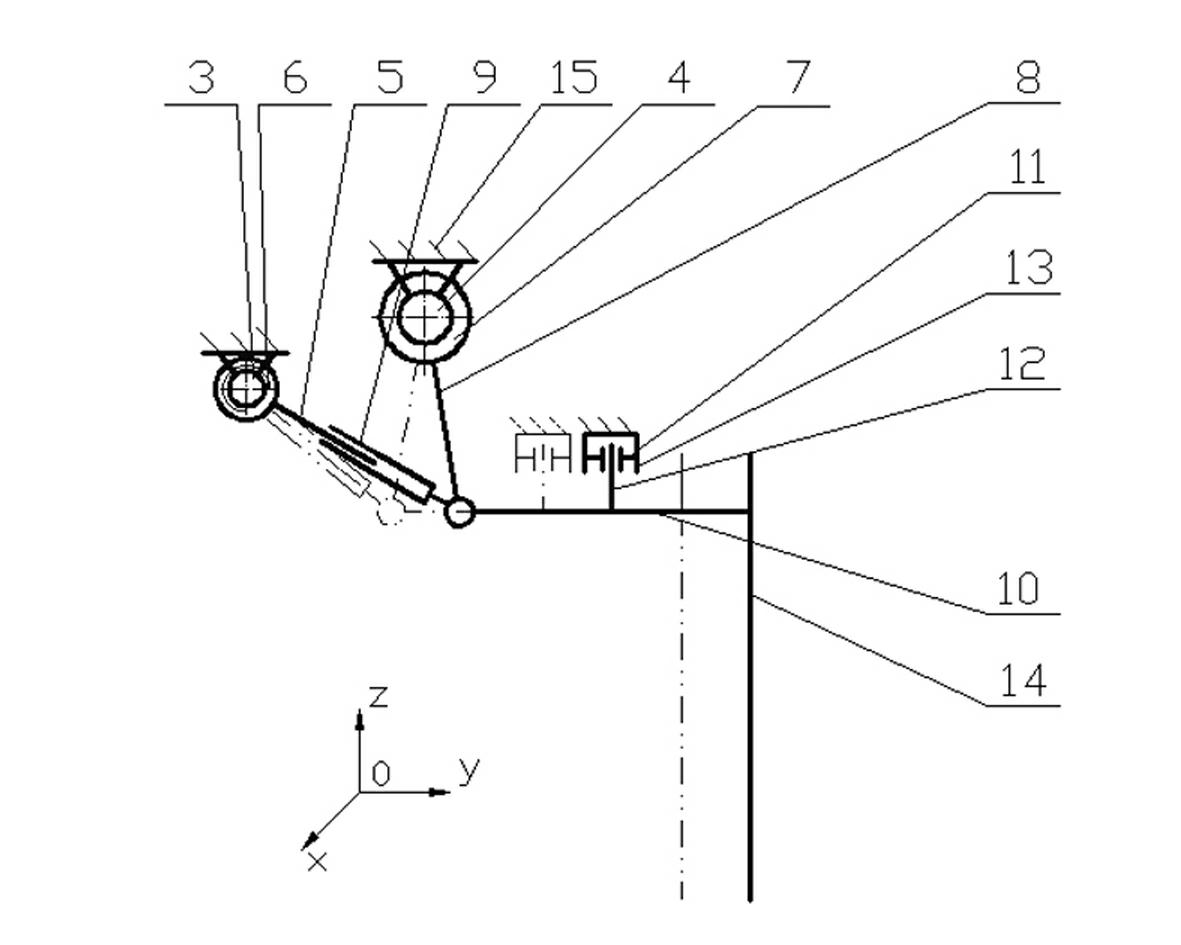

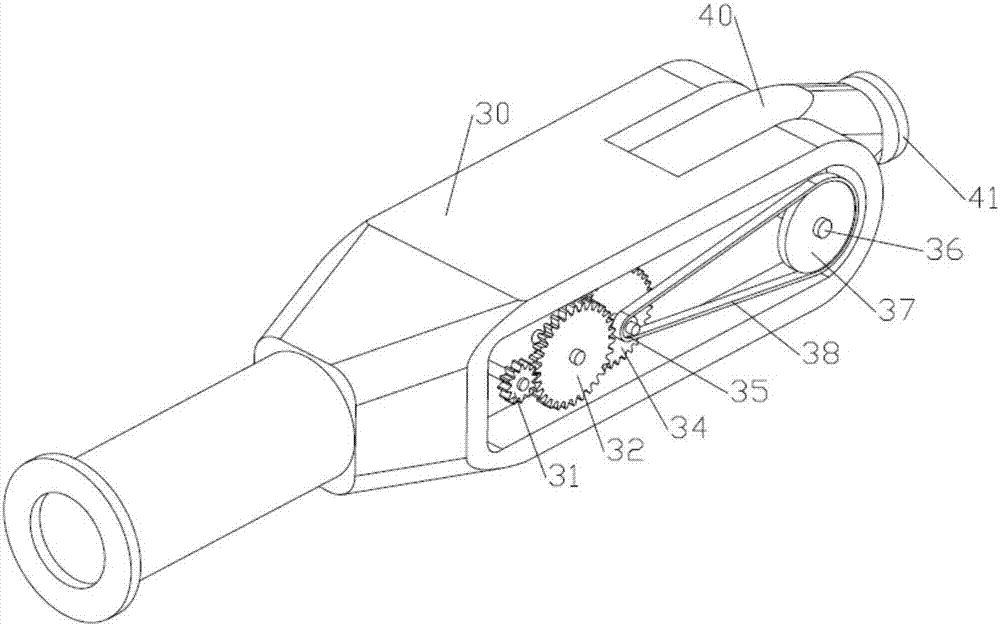

Manipulator component for universal robot

The invention discloses a manipulator component for a universal robot. The manipulator component comprises an arm, a swinging arm pivoted at the front end of the arm and a manipulator fixed on a rotating disc at the front end of the swinging arm. The manipulator comprises a shell and a claw hand drive mechanism; the claw hand drive mechanism comprises a drive motor, a worm, a worm gear, a center gear, a plurality of indexing gears, a plurality of cams and a plurality of claw hands. According to the manipulator component disclosed by the invention, the claw hands can be driven to simultaneously act through gear transmission and cam combination, and have the same motion amplitude so as to accurately grasp workpieces in all directions.

Owner:佛山市夏云智能装备有限公司

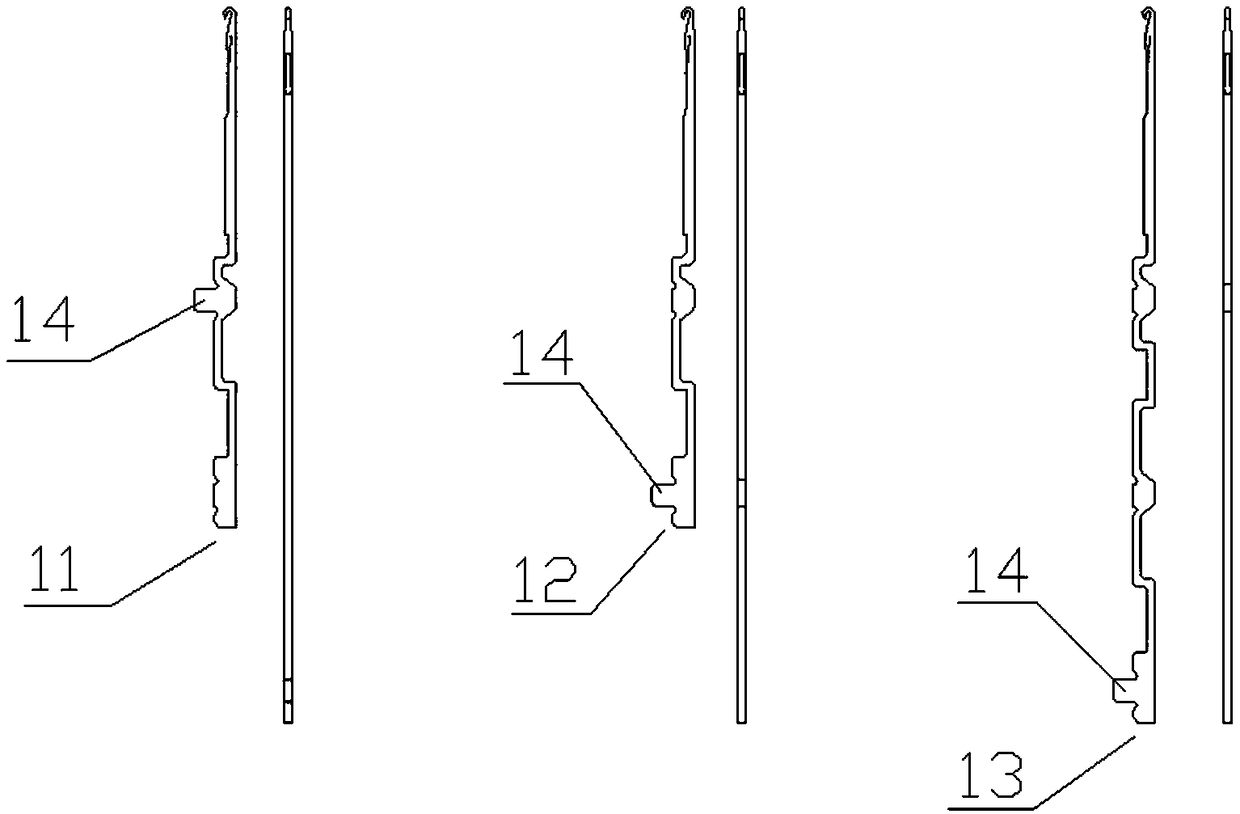

Anti-package loop pile cutting circular machine for double-face knitting

The invention relates to an anti-package loop pile cutting circular machine for double-face knitting. The anti-package loop pile cutting circular machine comprises an upper needle disc and a lower needle cylinder, needle grooves are formed in the upper needle disc, and knitting needles are mounted in the needle grooves; bush hook grooves are formed in the lower needle cylinder, and bush hook assemblies are mounted in the bush hook grooves; needle cams which control the movement rails of the knitting needles are arranged on the upper portion of the upper needle disc and form an annular cam combination in the circumferential direction of the upper needle disc, and cutter cams and hook cams which control the movement rails of the bush hook assemblies are arranged outside the lower needle cylinder and form a cylindrical cam combination around the outer cylinder wall of the lower needle cylinder; sinker grooves are further formed in the upper needle disc, sinkers for pushing away cut fluffare mounted in the sinker grooves, and sinker cams which control the movement rails of the sinkers are arranged on the upper portion of the upper needle disc. The anti-package loop pile cutting circular machine has a double-face knitting technology through special array modes of the cams, and can knit special knitted fabric with increased wool surface density, thick and solid double-surface backing fabric and high heat preservation.

Owner:LIANYUNGANG YUANFENG MACHINERY

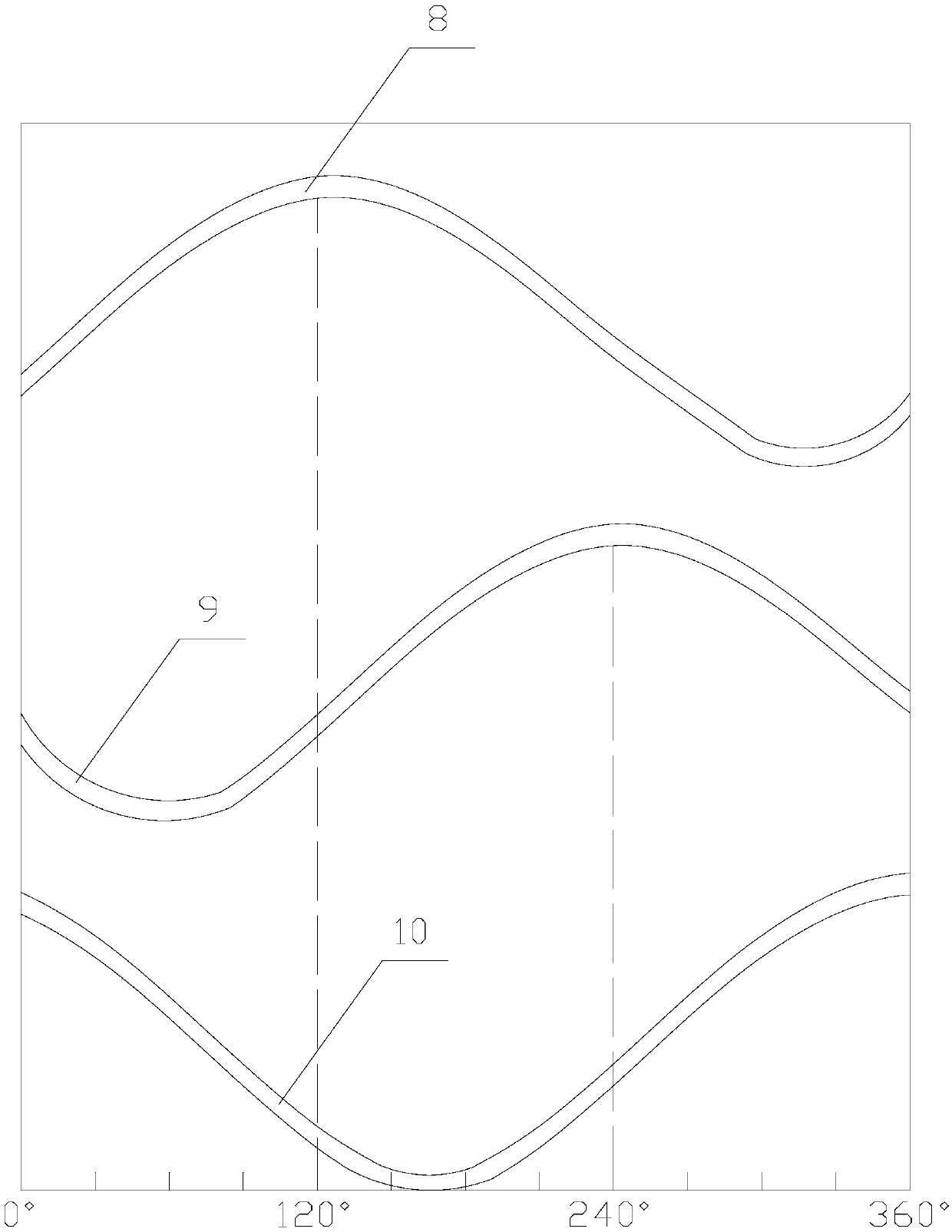

Coaxial multi-cam combination syringe spindle

The invention relates to the field of textiles, in particular to a coaxial multi-cam combination syringe spindle which is characterized in that a syringe is sleeved with a cam seat; two or more groupsof cam combinations are mounted on the cam seat; each group of cam combinations comprises an upper cam and a lower cam, and a cam slot is formed between the upper cam and the lower cam; needle slotswith the group number being the same as that of the cam slots are formed in an outer ring of the syringe in an annular distribution manner; each group of the needle slots is provided with a crochet group driven by the corresponding cam slot; the crochet group in each cam slot corresponds to a yarn of one color and / or material; a woven yarn with a plurality of colors and / or different materials is formed and woven by two or more groups of the crochet groups; yarn tapes of various colors and different materials can be woven by adopting two or more groups of cam combinations; fancy, color, material are more, and independent weaving is implemented, so that needs of the public are met; the decorative effect is good and very bright; the coaxial multi-cam combination syringe spindle is easy to operate, low in cost, relatively good in stability and less in fiber loss in manufacturing the yarn tapes, and the quality of the yarn tapes is improved.

Owner:常州市郑陆特种纺机专件有限公司

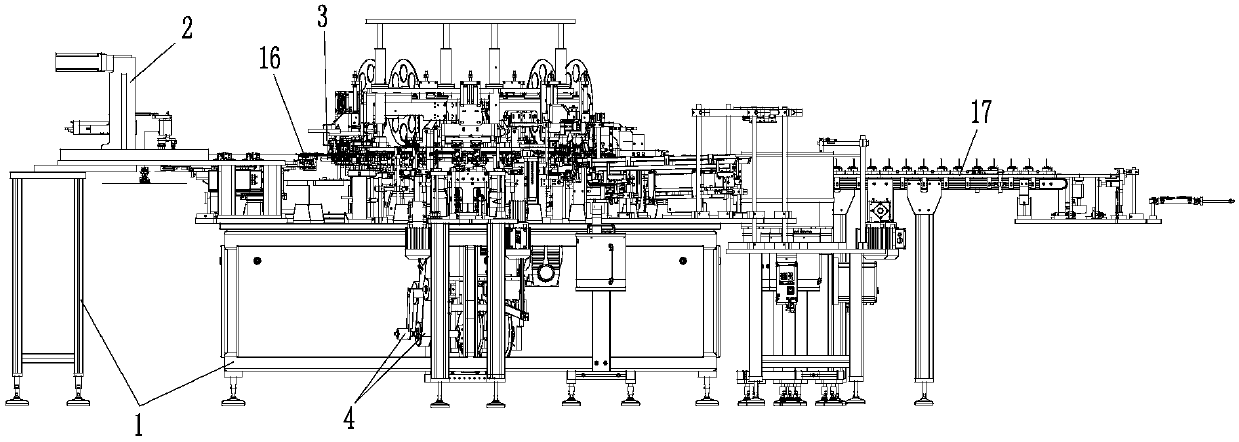

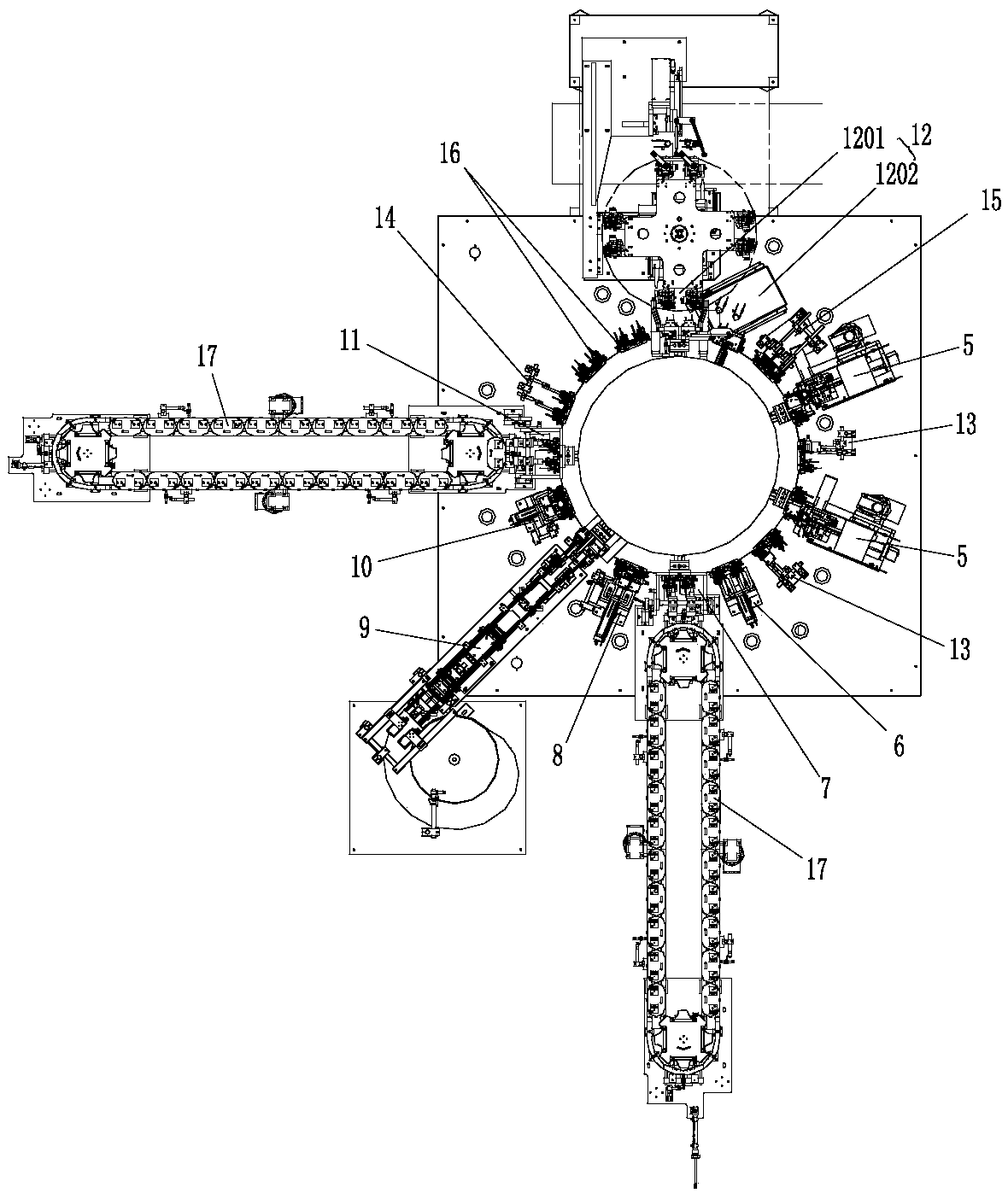

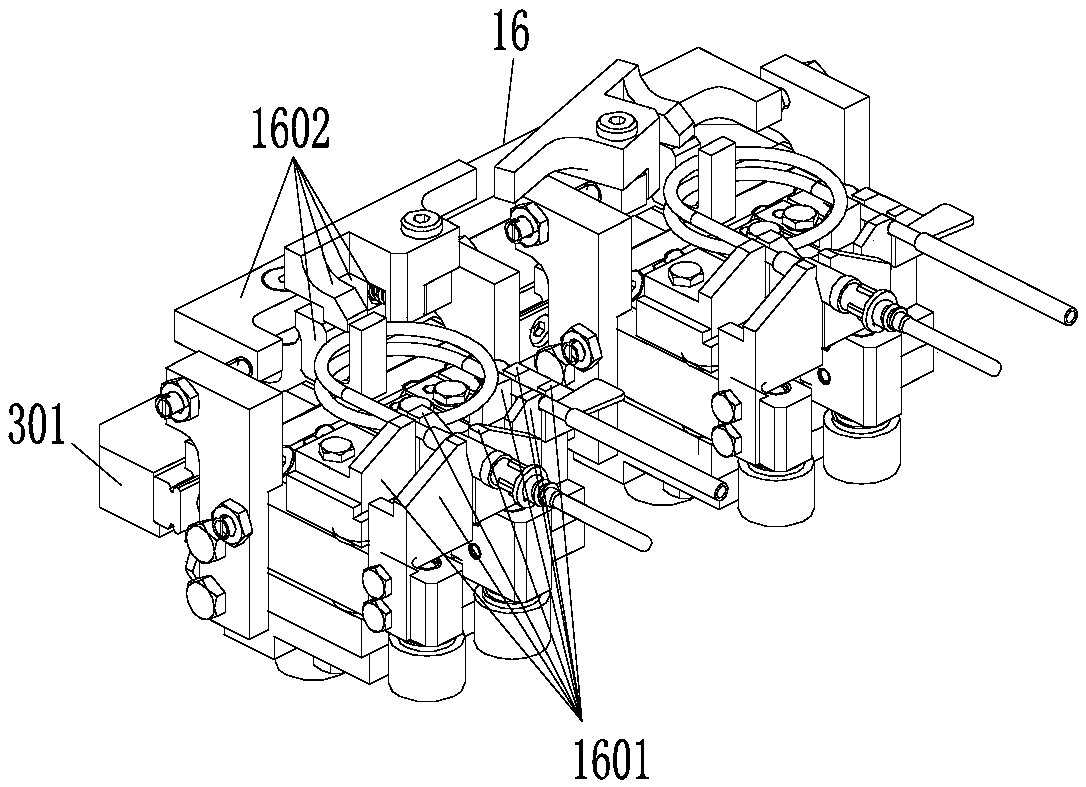

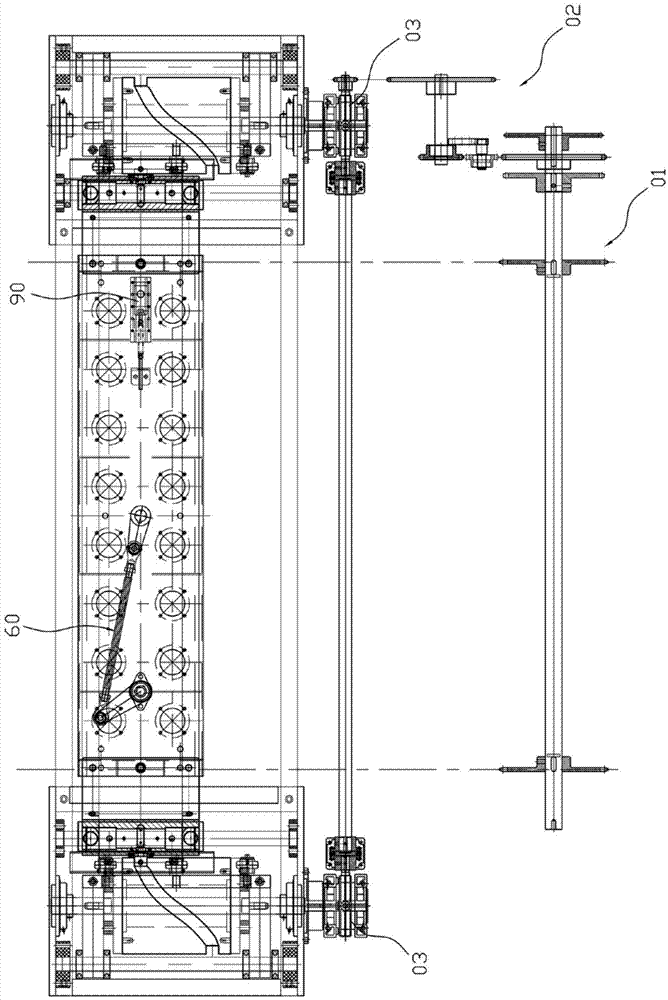

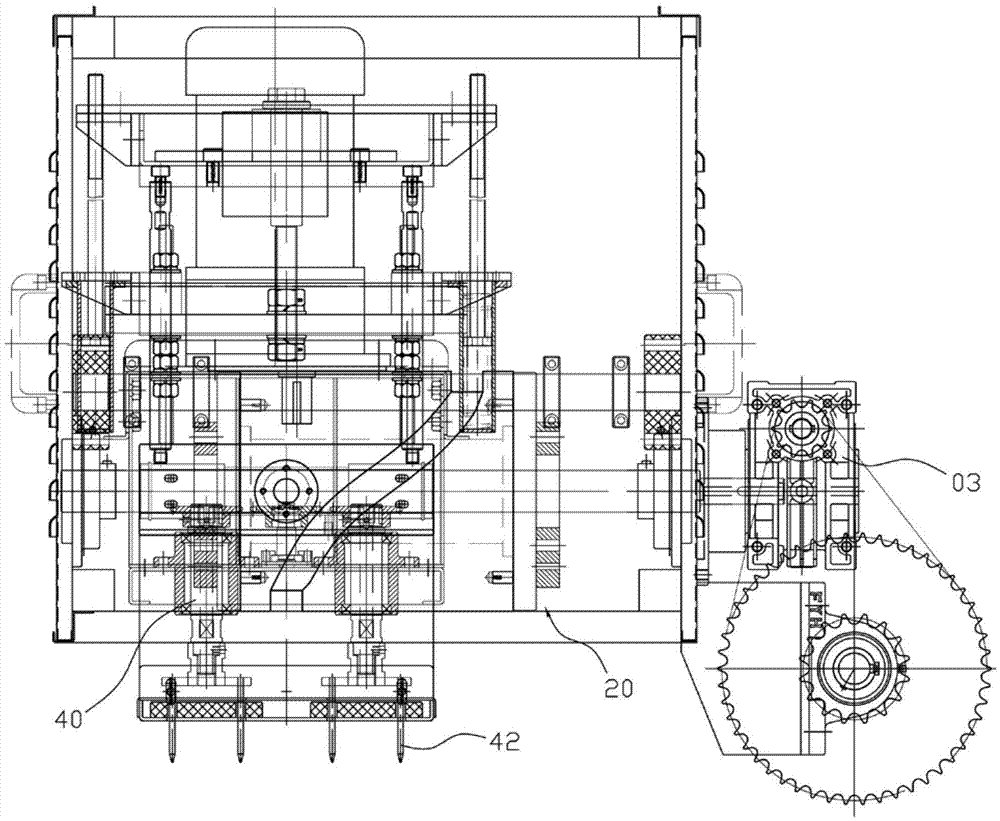

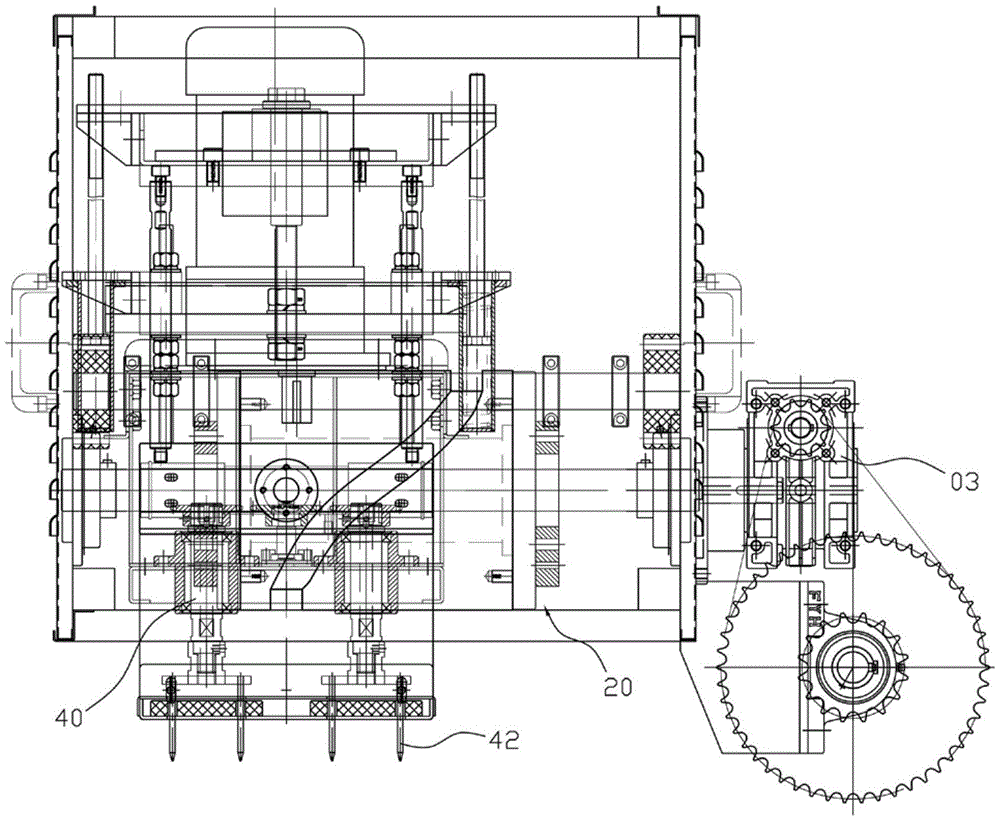

Assembly device of butterfly wing type blood collection needle

ActiveCN105943060ARealize the assemblyLiquid surface applicatorsBlood sampling devicesBlood collectionButterfly wing

The invention discloses an assembly device of a butterfly wing type blood collection needle. The assembly device comprises an installation support and butterfly wing type blood collection needle assembly work stations installed on stations of the installation support respectively. The installation support is provided with a driving rotary plate and cam driving mechanisms used for driving the rotary plates to move along the butterfly wing type blood collection needle assembly work stations in a stepping mode and driving the butterfly wing type blood collection needle assembly work stations to work synchronously. The stepping rotary output ends of the cam driving mechanisms are connected with and drive the driving rotary plates. The butterfly wing type blood collection needle assembly work stations are sequentially distributed in the circumferential directions of the driving rotary plates. Each butterfly wing type blood collection needle assembly work station corresponds to one carrier, used for conveying butterfly wing type blood collection needle assembly materials, on the corresponding driving rotary plate, and the cam driving mechanisms drive different butterfly wing type blood collection needle assembly work stations to work due to the fact that different cam combinations output driving force at different frequencies. Assembly of the butterfly wing type blood collection needle is achieved in a pure mechanical and automatic mode.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

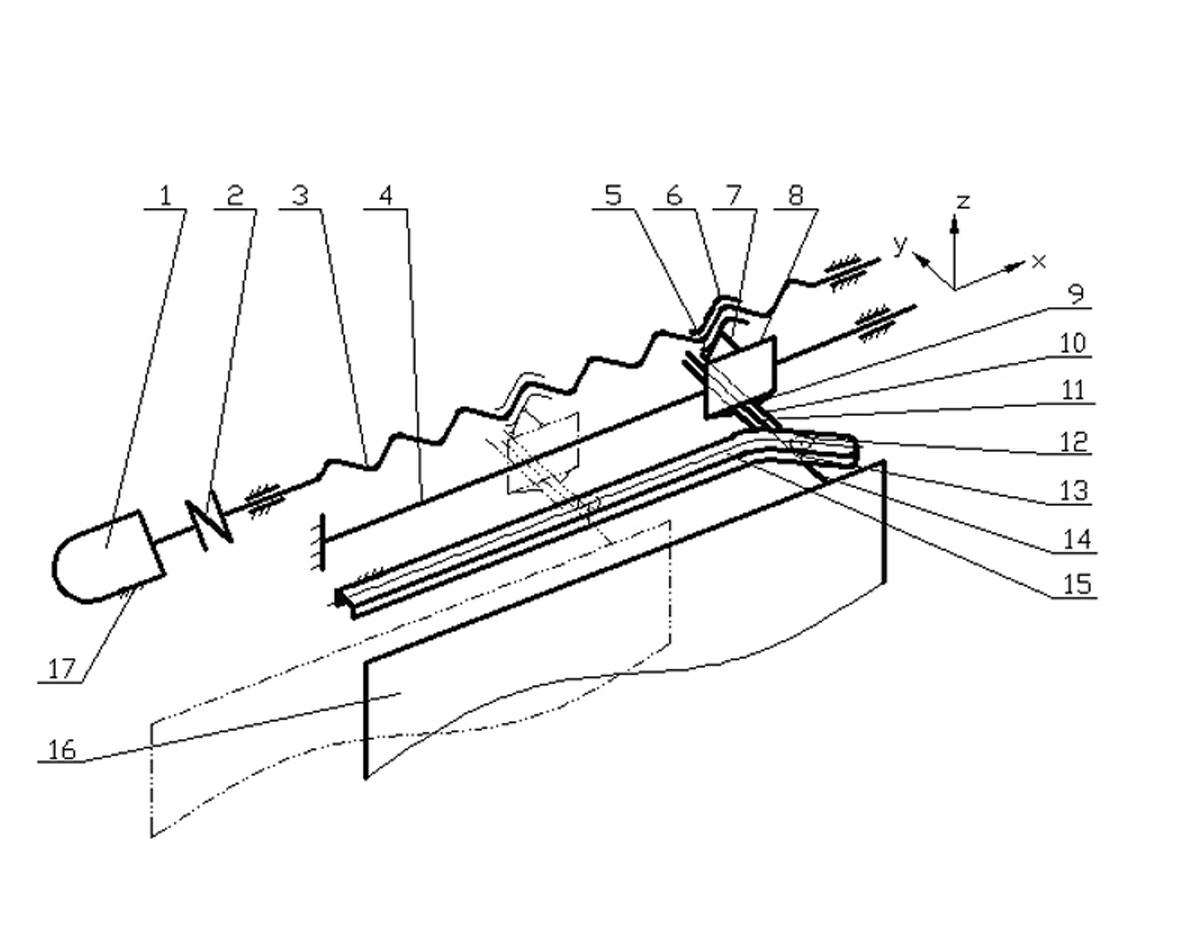

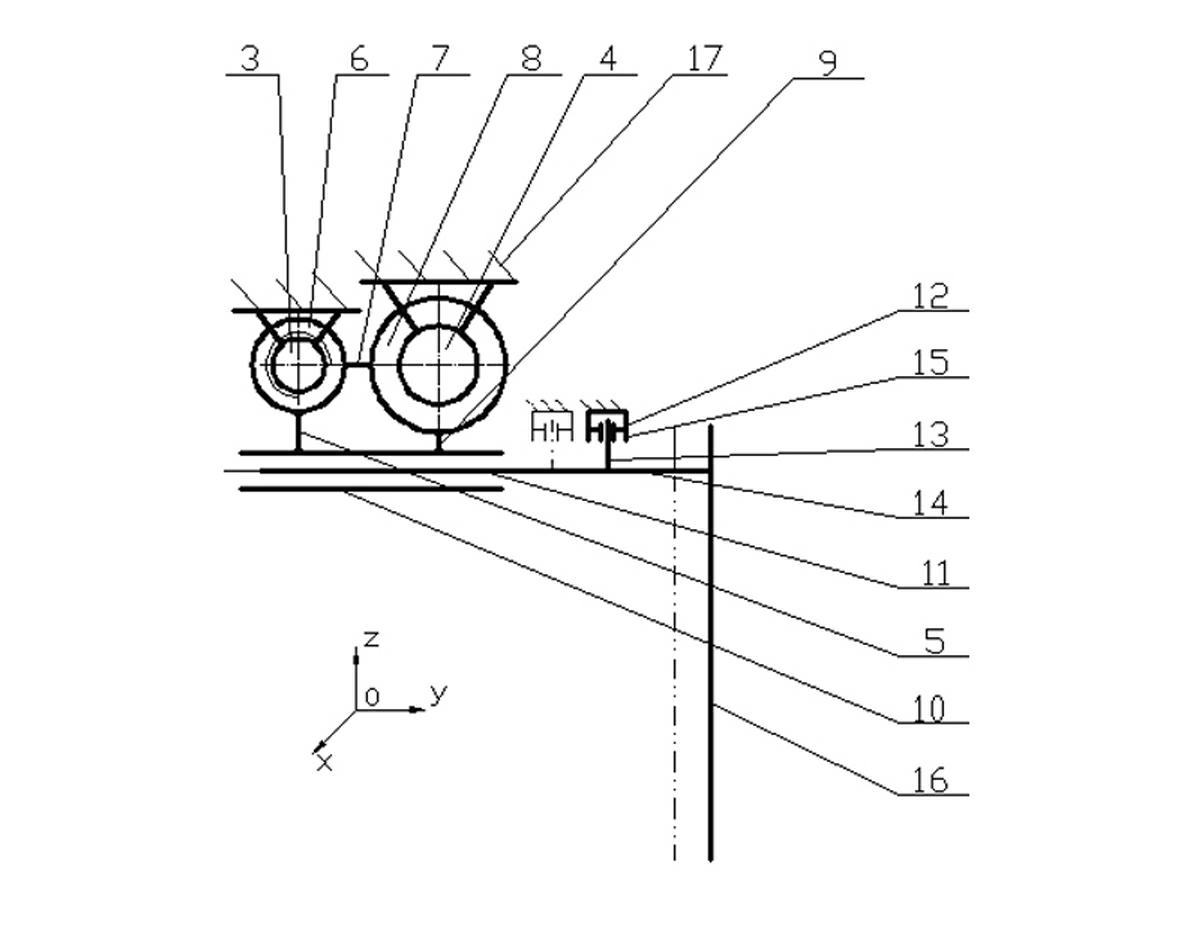

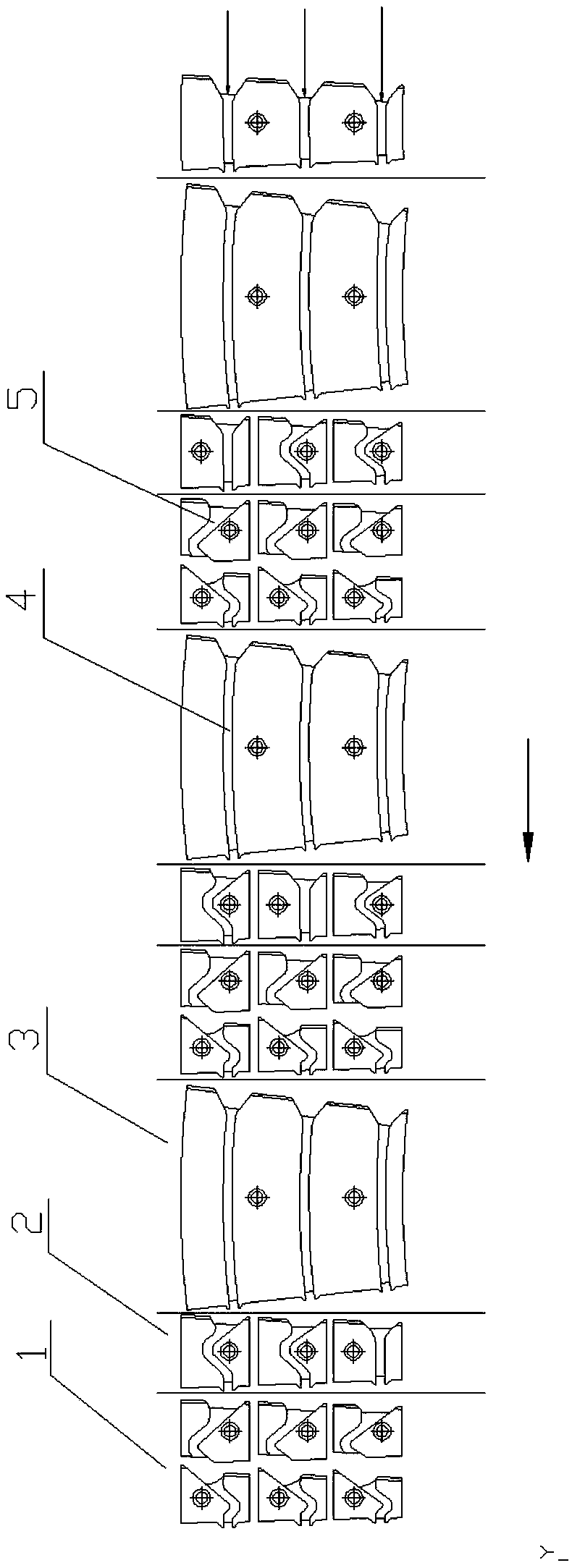

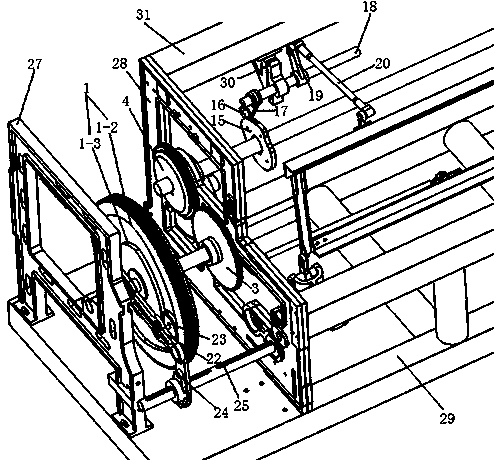

Knotted fishing net machine pore plate moving device

The invention provides a knotted fishing net machine pore plate moving device. The knotted fishing net machine pore plate moving device comprises a gear and cam combination (1), a first gear (3), a second gear (4) and a third gear (6), a main shaft (2), a rotating shaft (5) and a gear and cylindrical cam combination, wherein the main shaft (2) is used for supporting the rotating of the first gear (3) and cam combination (1). The knotted fishing net machine pore plate moving device has the advantages that the requirements for movement of a pore plate in three directions are met by three independent mechanisms respectively, each implementation mechanism is formed by simple mechanisms, complex mechanisms are avoided, and therefore design and analysis are convenient; kinematic pairs in the implementation mechanisms comprise the revolute pair, the cylindrical pair and the spherical pair, all the kinematic pairs are surface contact kinematic pairs, and the surface contact kinematic pairs are large in contact area, low in contact stress, and beneficial to long service life and reliability of the device compared with higher pairs; the kinematic mechanisms in three directions need three types of kinematic input, the three types of kinematic input are driven by the main shaft in a unified mode, as a result, there is no need for multiple driving links, and cost is lowered.

Owner:湖州度信科技有限公司

Spiral double-rocker composite hinge groove cam combination space mechanism for sliding-plug door

ActiveCN102305005BThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementEngineeringCam

The invention discloses a spiral double-rocker composite hinge groove cam combination space mechanism for a sliding-plug door, and relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door of a vehicle, in particular to a spiral double-rocker composite hinge groove cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a shaft sleeve, a nut, a short rocker, a door carrying rocker (a rocker for short), a connection rod, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the screw, the nut and the door frame; a double-rocker mechanism consists of the bearing shaft, the shaft sleeve, the short rocker, the rocker, and the connection rod; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf, and the door frame; a rotation pair consists of the upper end of the connection rod and the short rocker; a composite hinge consists of the lower end of the connection rod, the rocker and the door handle; and the spiral mechanism, the double-rocker mechanism and the groove cam mechanism are connected to form the spiral double-rocker composite hinge groove cam combination space mechanism.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

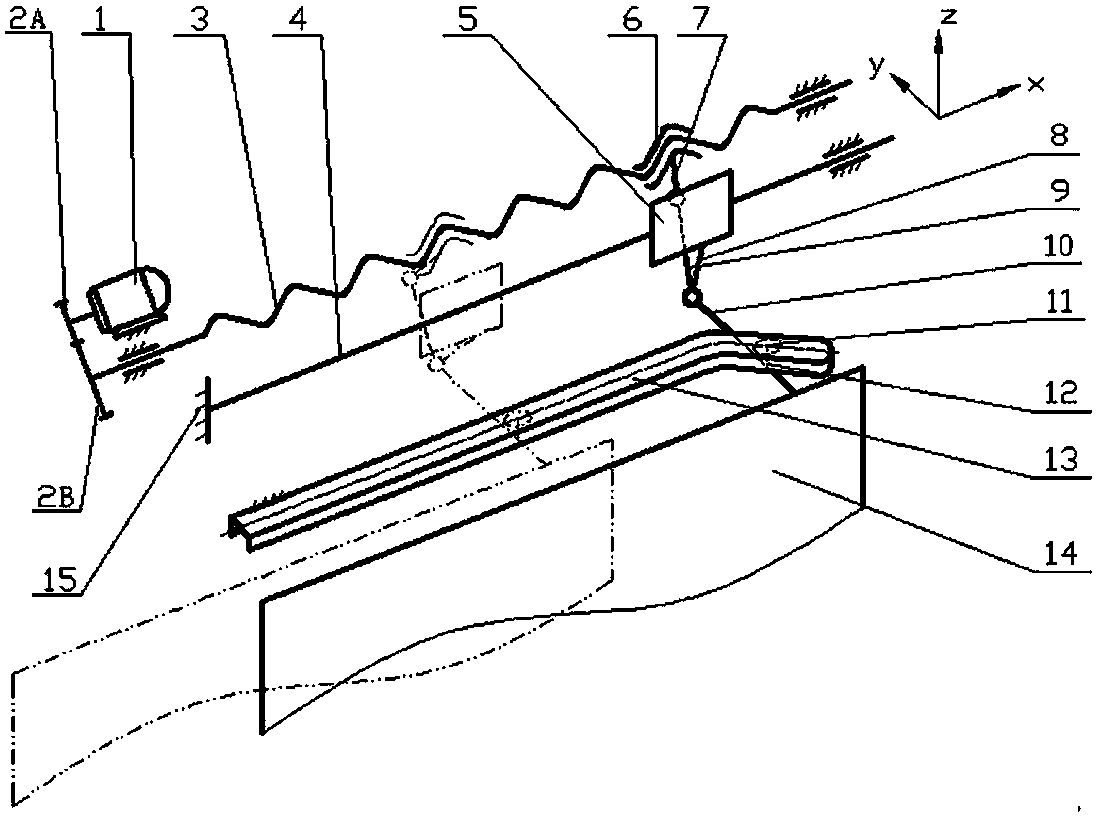

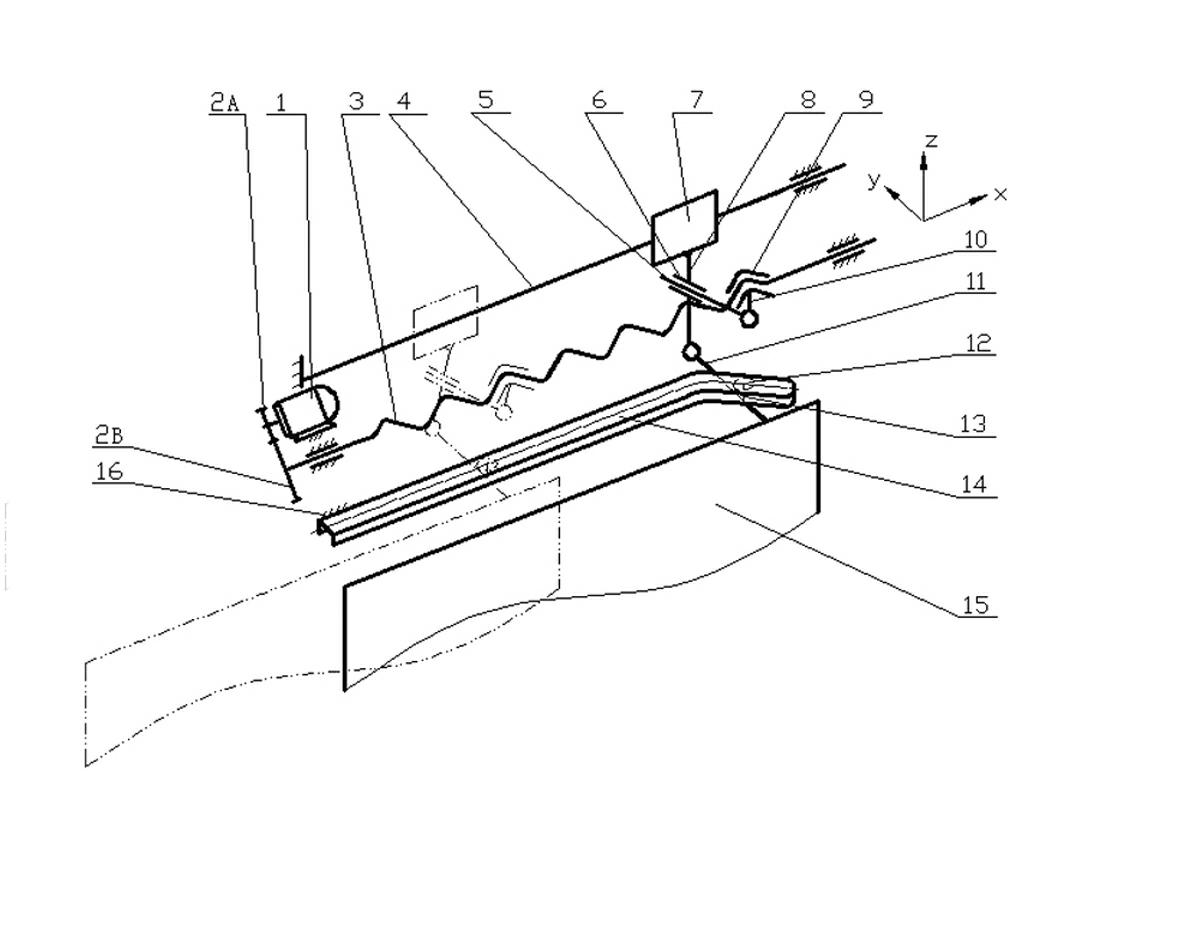

Spiral rocker guide rod composite hinge groove cam combination space mechanism for sliding-plug door

ActiveCN102305008AThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementCamCAM combination

The invention discloses a spiral rocker guide rod composite hinge groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, and opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the spiral rocker guide rod composite hinge groove cam combination space mechanism for the sliding-plug door for high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a guide rod, a nut, a shaft sleeve, a door carrying rocker, a guide rod sleeve, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame; a spiral mechanism consists of the screw, the nut and the door frame; the guide rod and the nut which are fixedly integrated, a rocker guide rod mechanism consists of the guide rod, the rocker, the guide rod sleeve, the shaft sleeve and the bearing shaft; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf, and the door frame; and a composite hinge consists of the guide rod sleeve, the rocker and the door handle; and the spiral mechanism, the rocker guide rod mechanism, and the groove cam mechanism are connected to form the spiral rocker guide rod composite hinge groove cam combination space mechanism.

Owner:海宁市袁花镇工业投资有限公司

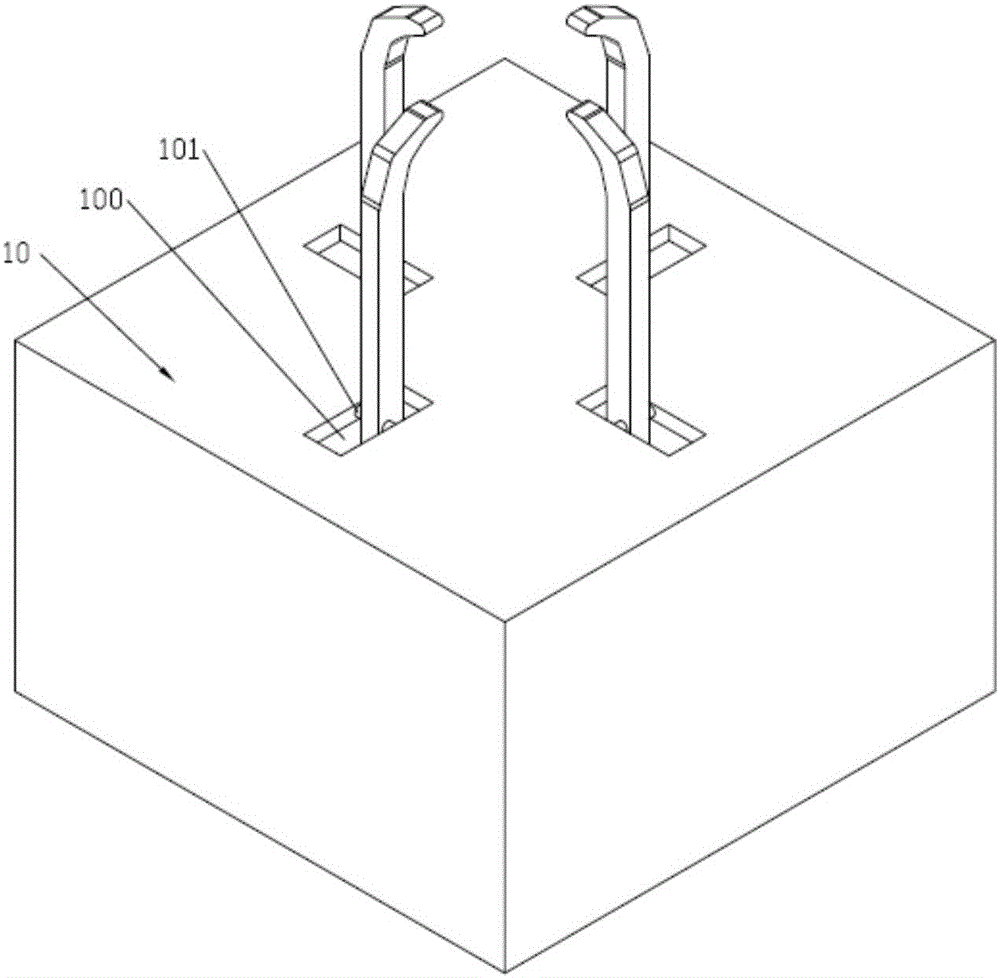

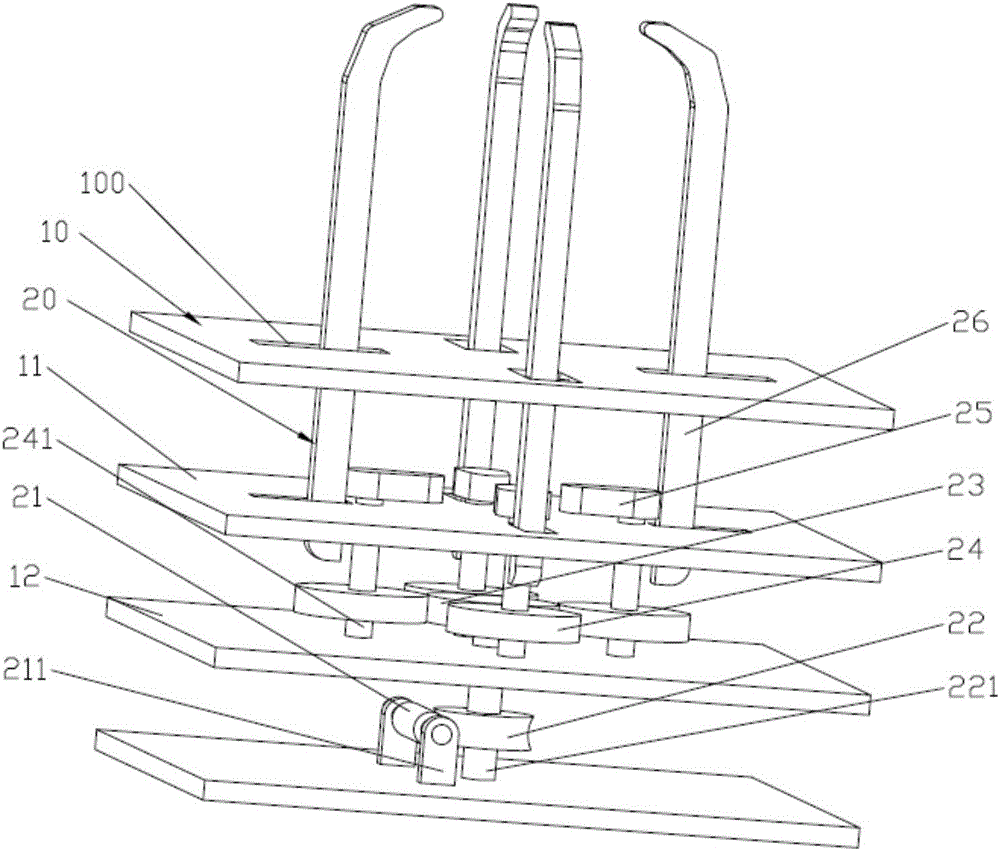

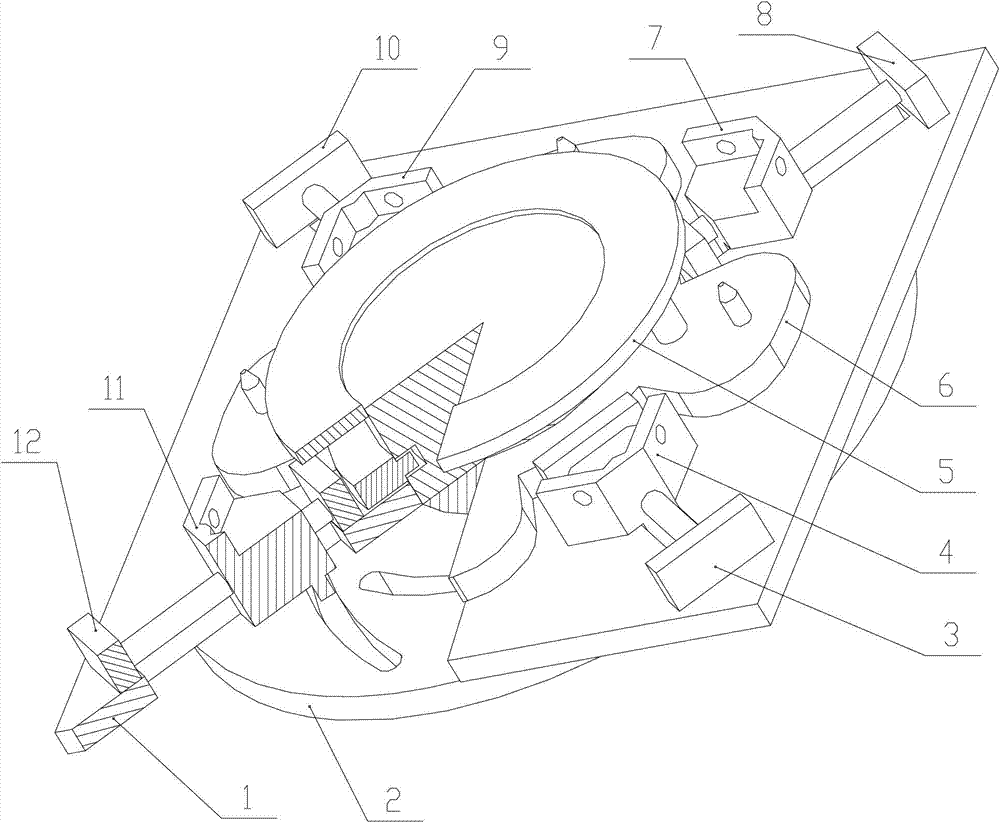

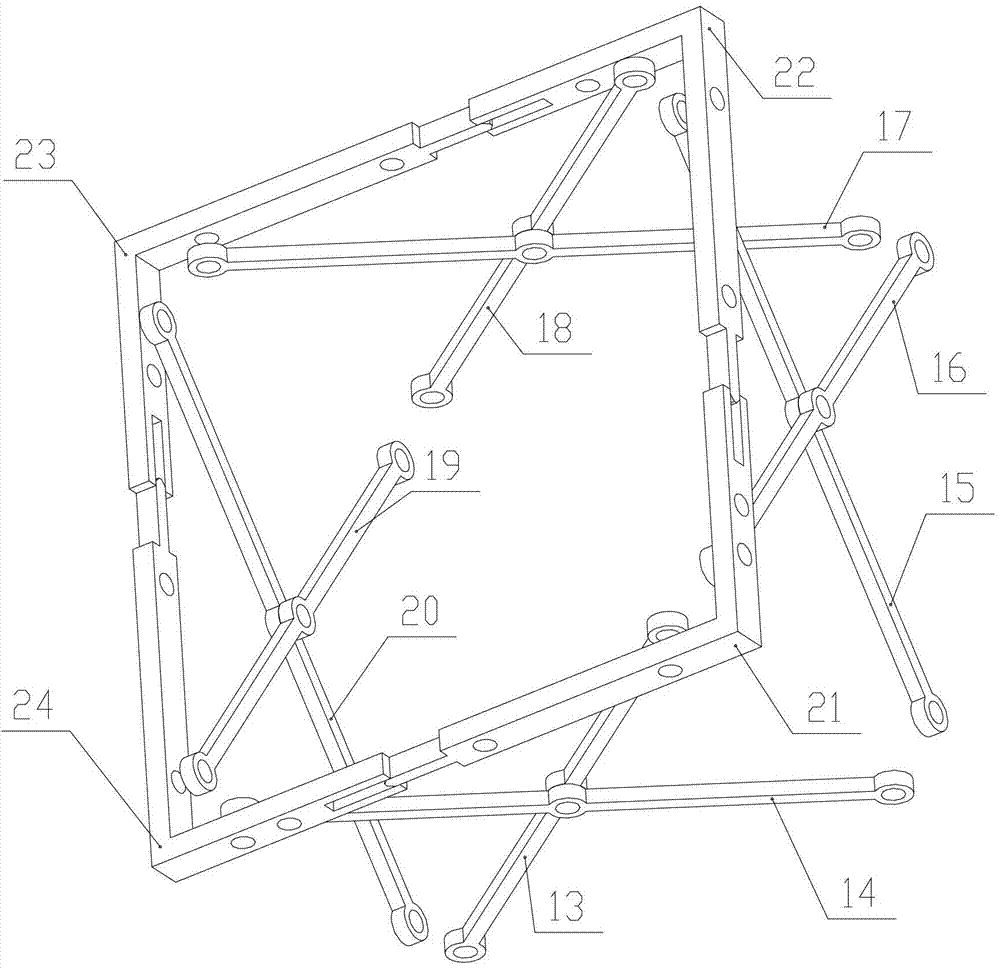

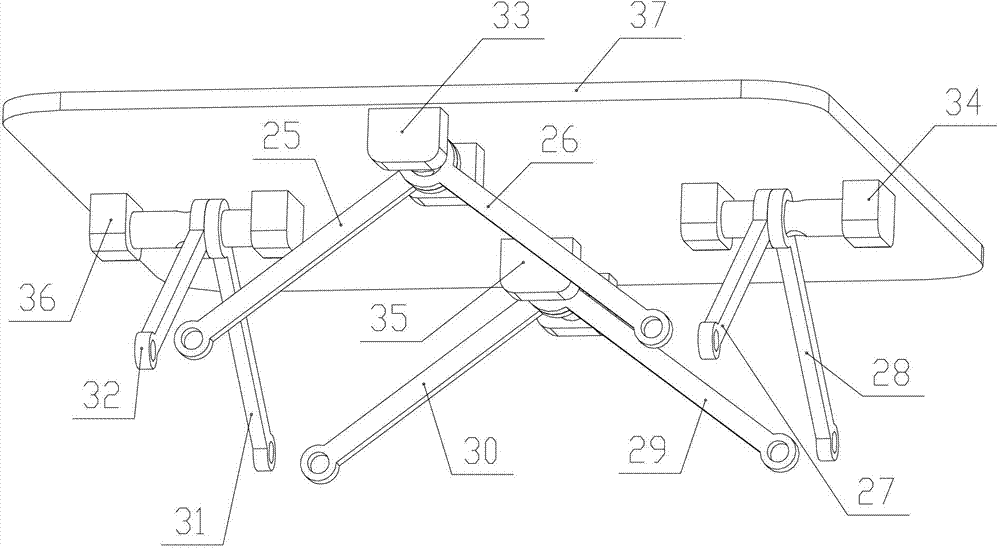

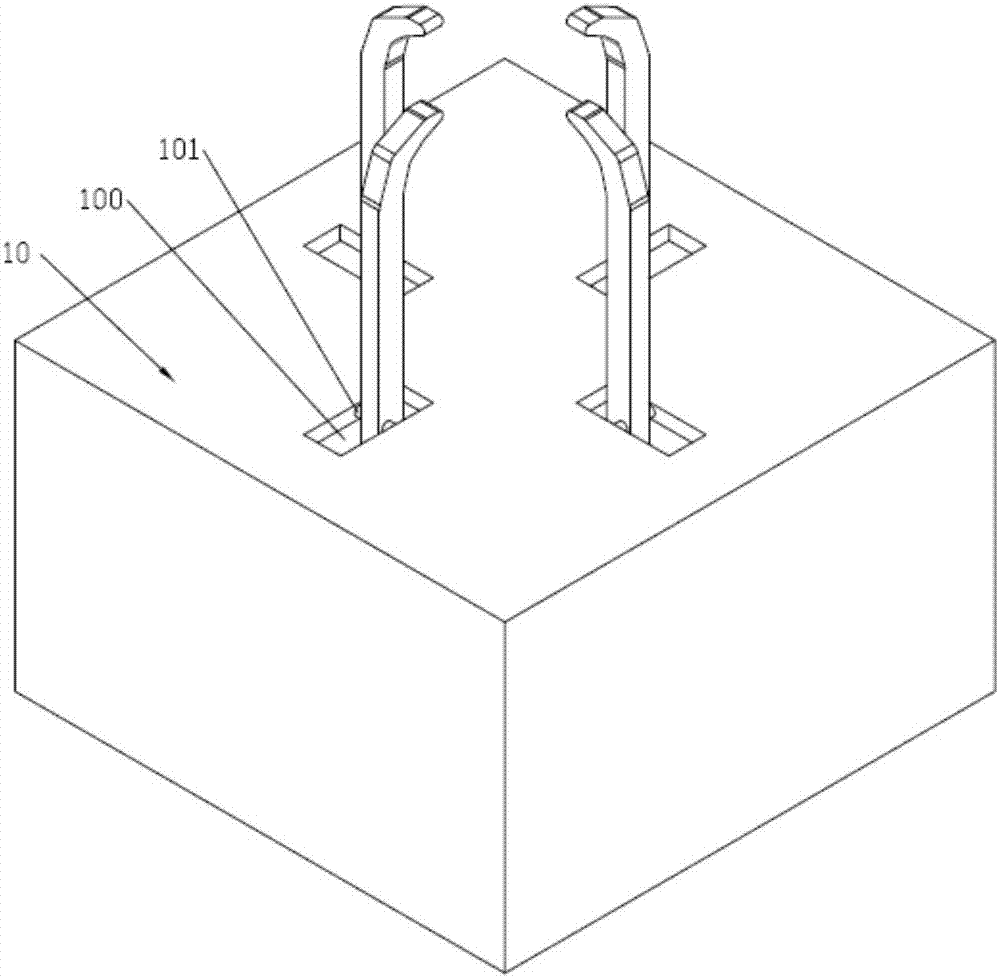

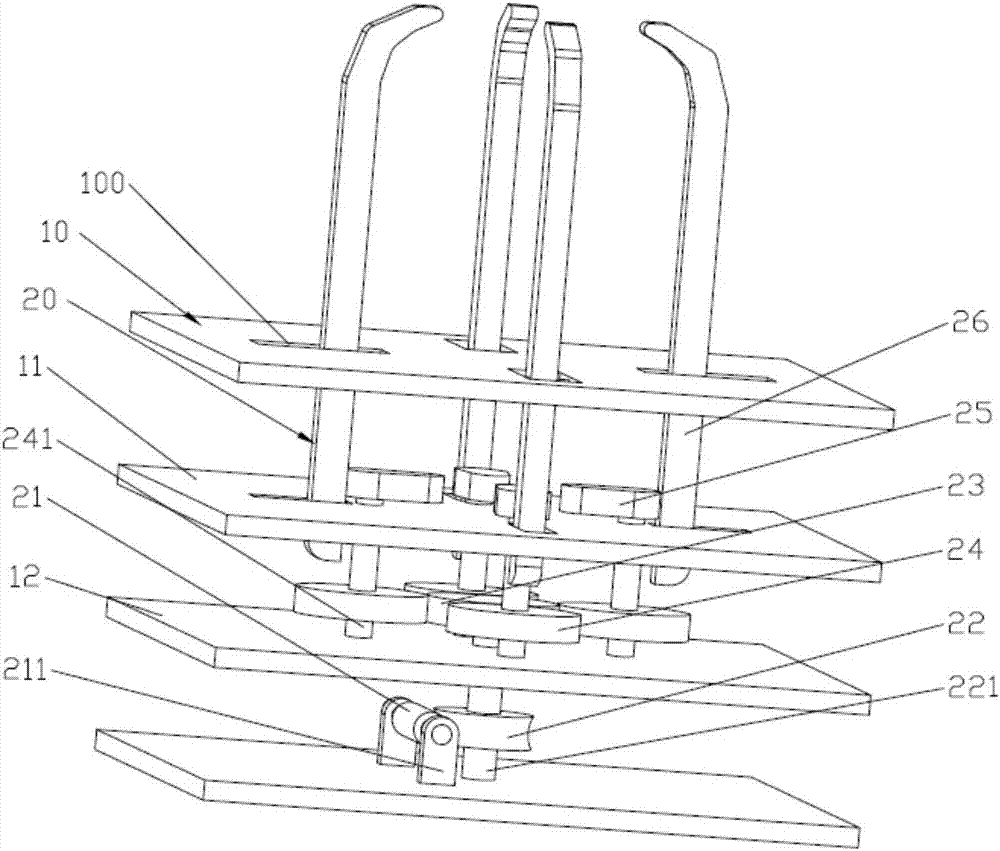

Scissor-type space stretching arm mechanism

InactiveCN102765492BSatisfy the envelope size minimization principlePrecise positioningCosmonautic vehiclesCosmonautic power supply systemsStable stateEngineering

The invention discloses a scissor-type space stretching arm mechanism which comprises a first scissor unit part, a second scissor type unit part, a driving part, a top support part, four first longitudinal support parts and four second longitudinal support parts, wherein the structure of the first scissor type unit part is identical with that of the second scissor type unit part; the structures of the four first longitudinal support parts are identical; the structures of the four second longitudinal support parts are identical; the top support part is mounted on the driving part through the second scissor type unit part and the first scissor type unit part sequentially; and the first longitudinal support parts and the second longitudinal support parts are respectively arranged on four sides of the first scissor unit part and the second scissor type unit part. According to the scissor-type space stretching arm mechanism disclosed by the invention, by adopting the dual-cam combined design, the longitudinal and transverse rigid locking of a space stretching arm is realized through a dual-cam outline on a stepped cylindrical cam, and thus the stable state of the stretched stretching arm is guaranteed to be a rigid truss structure. The scissor-type space stretching arm mechanism disclosed by the invention has the advantages of great folding-unfolding ratio, compact structure and favorable symmetry. The folding-unfolding and locking functions are simultaneously achieved by inputting a single power source, and thus the folding-unfolding precision is ensured. The scissor-type space stretching arm mechanism is applied to the field of foldable-unfoldable mechanisms.

Owner:ZHEJIANG SCI-TECH UNIV

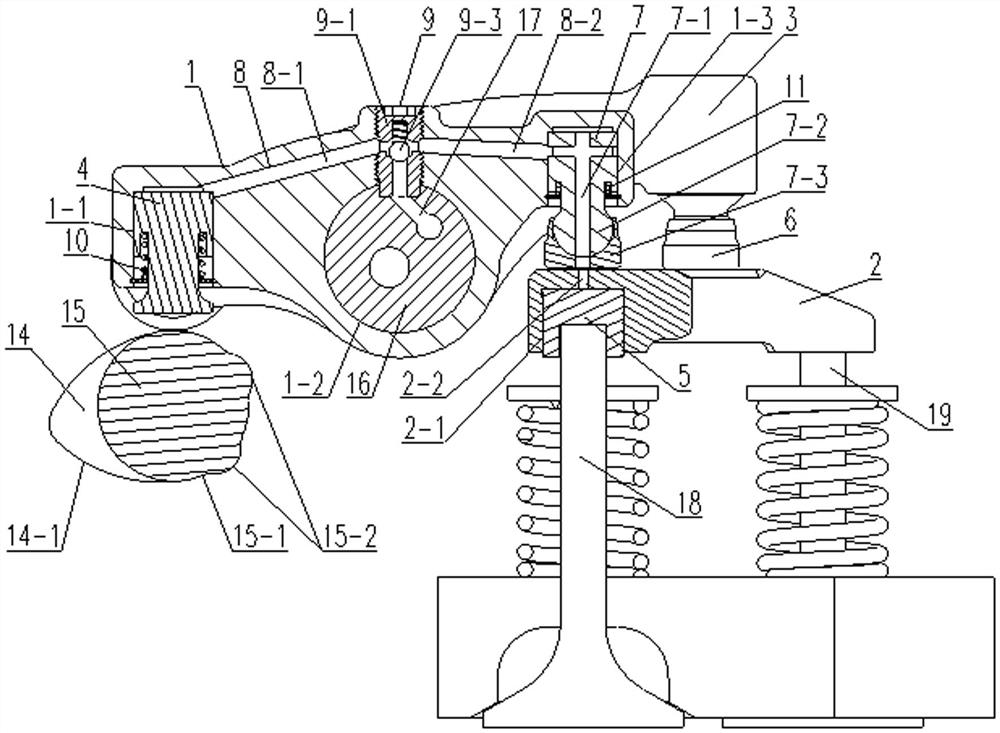

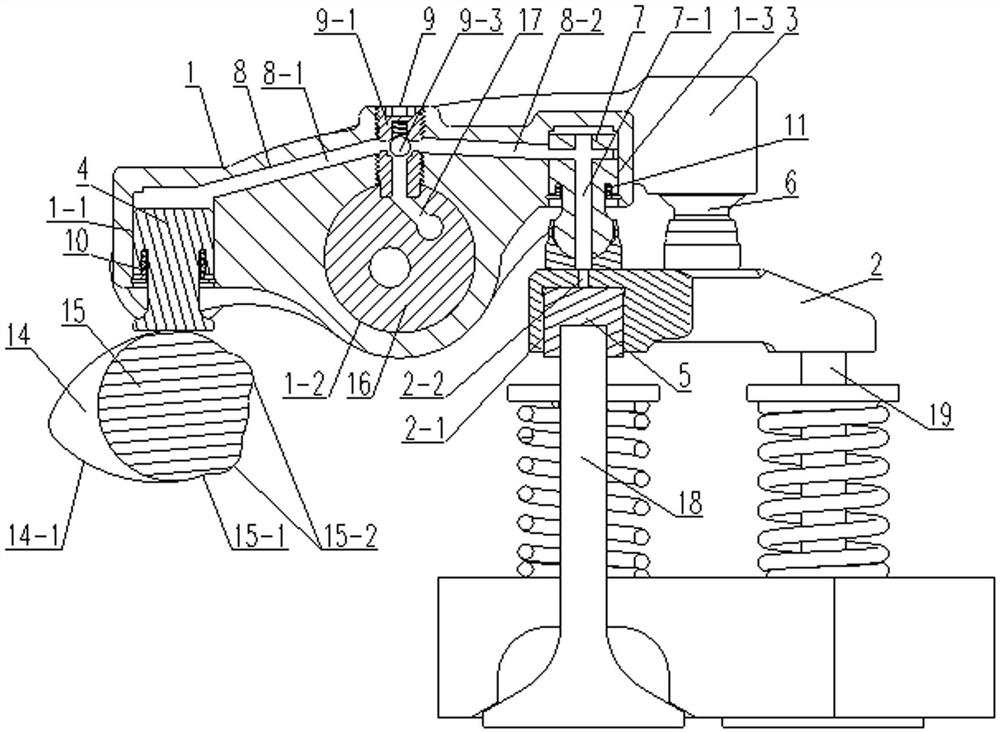

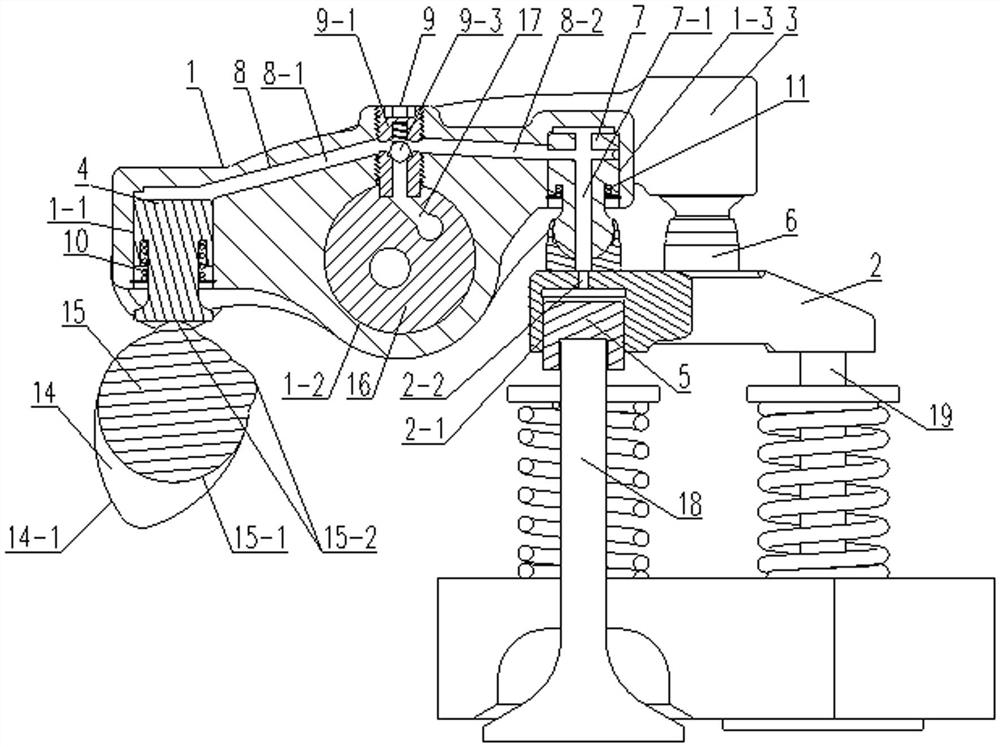

Hydraulic clearance self-adjusting special driving cam combined type valve driving device

ActiveCN114109551ANo power consumptionReduce power consumptionValve drivesMachines/enginesCamEngine valve

The invention relates to the technical field of engine valve driving devices, in particular to a hydraulic clearance self-adjusting special driving cam combined type valve driving device which comprises a driver fixedly mounted on a rocker arm shaft and a rocker arm provided with a hydraulic clearance adjuster. A driving oil path is arranged between the main piston hole and the execution piston hole, and the driving oil path is communicated with the oil supply path through a positioning pressure control unit; when the driving oil way supplies oil, the main piston and the auxiliary piston are hydraulically linked to open the driving air valve; according to the invention, engine power consumption and motion wear caused by motion friction between the driver and the rocker arm shaft are avoided, and the working stability and reliability are improved; during use, the valve clearance does not need to be adjusted, the influence of system clearance change on driving and positive work performance is avoided, engine noise is reduced, engine timing accuracy is improved, and the problem of compatibility of a valve driving function and a hydraulic clearance adjusting function is solved.

Owner:JIANSU JOINTEK PRECISION MASCH CO LTD

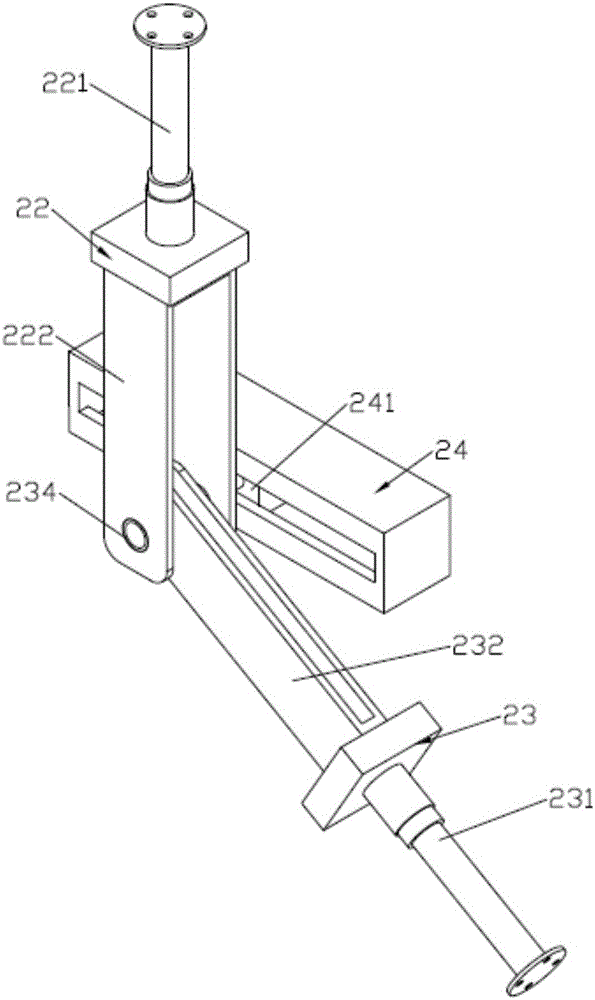

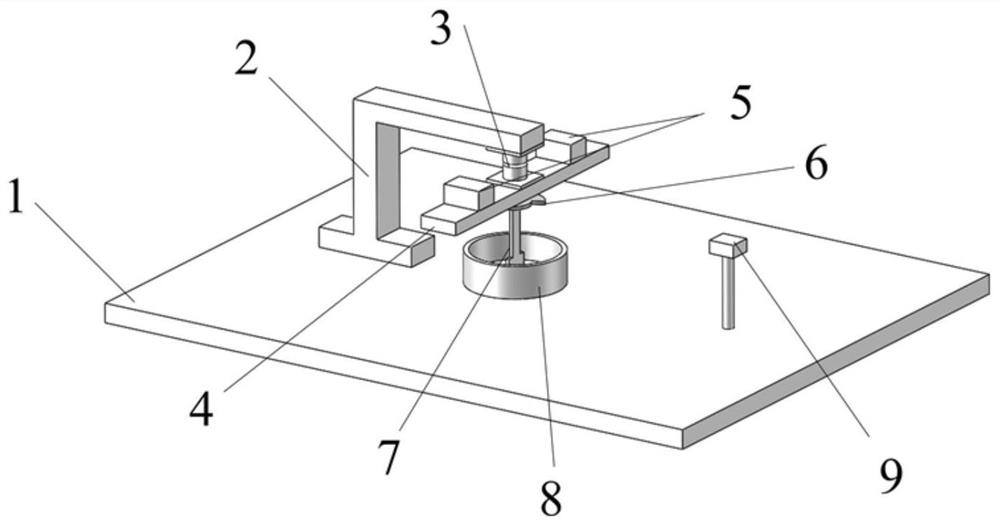

High-precision online rapid measurement device and method for thickness of aluminum substrates

ActiveCN111156910ARealize online real-time thickness measurementRealize blendingUsing optical meansFast measurementAluminum substrate

The invention discloses a high-precision online rapid measurement device and method for the thickness of aluminum substrates. The device comprises a horizontal driving device, a vertical driving device and a conveying rail which are installed on a basic platform, wherein the horizontal driving device is provided with a pair of posture adjusting devices, each posture adjusting device is provided with a laser emitting head, and the pair of laser emitting heads are respectively connected with optical fibers; the vertical driving device is provided with a cam combination, a lever combination and aguide base; a guide rod penetrates through the guide base; the cam combination is driven by a power mechanism to drive the lever combination to jack up the guide rod, so that the plurality of aluminum substrates are driven one by one to sequentially rise to the pair of laser emitting heads to be oppositely emitted to measure the thickness of the aluminum substrates. The measurement device is compact in structure, achieves the online real-time thickness measurement of the whole box of aluminum substrates, is high in measurement precision and speed, and improves the measurement precision of thethickness of the aluminum substrates.

Owner:XIDIAN UNIV

Spiral double-rocker guide rod groove cam combination space mechanism for sliding-plug door

ActiveCN102305007AThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementCouplingEngineering

The invention discloses a spiral double-rocker guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the spiral double-rocker guide rod groove cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a guide rod, a guide rod sleeve, a shaft sleeve, a door carrying rocker, a nut, a short rocker, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the screw, the nut and the door frame; a double-rocker guide rod mechanism consists of the rocker, the short rocker, the guide rod, the guide rod sleeve, the nut, the bearing shaft, and the shaft sleeve; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf and the door frame; the spiral mechanism, the double-rocker guide rod mechanism, and the groove cam mechanism are connected to form the spiral double-rocker guide rod groove cam combination space mechanism; the door frame is fixedly connected with a vehicle body; and the motor which is fixed on the door frame is connected with the screw through the coupler.

Owner:江苏振邮科技产业投资管理有限公司

Tooth belt double-shaft guide rod groove cam combination space mechanism for sliding-plug door

InactiveCN102305009BQuick sealQuick opening and closingPower-operated mechanismDoor arrangementDrive wheelCoupling

The invention discloses a tooth belt double-shaft guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the tooth belt double-shaft guide rod groove cam combination space mechanism for high-speed rail or other railway vehicles. The mechanism comprises a door frame, a motor, a driving wheel, a tooth belt, an auxiliary bearing shaft, a belt clamp, a tension device, a bearing pedestal, a driven wheel, an auxiliary shaft sleeve, a coupling rod A, a main shaft sleeve, a main bearing shaft, a coupling shaft B, a coupling shaft C, a guide rod sleeve, a roller, a roller shaft, a door carrying guide rod, a groove cam and a door leaf; a tooth belt transmission mechanism consists of the driving wheel, the tooth belt, a lower belt clamp, the tension device, the bearing pedestal, and the driven wheel; a double-shaft guide rod mechanism consists of the coupling rod A, the main shaft sleeve, the coupling rod B, the coupling rod C and the guide rod sleeve which are connected fixedly and integrally, the main bearing shaft, the auxiliary shaft, and the door frame; and a groove cam mechanism consists of the main shaft sleeve, the main shaft, the coupling rod C, the roller, the roller shaft, the door carrying guide rod, the groove cam, the door leaf, the main shaft sleeve and the door frame.

Owner:NANJING INST OF TECH

Coarse-cereals noodle carding machine

A disclosed coarse-cereals noodle carding machine comprises a frame, a pair of cam combination mechanisms, a noodle carding support and a noodle carding head; the cam combination mechanisms drive the noodle carding support to make horizontal and vertical motions; the bottom end of the noodle carding support is pivoted to the noodle carding head; and a noodle carding paw at the bottom end of the noodle carding head swings under the driving effect of a gear motor and a crank and rocker mechanism. According to the above technical scheme, a bowl-shaped conveying box holding instant noodle segments makes horizontal conveying motion below the noodle carding support, the cam combination mechanisms make synchronous operation with the bowl-shaped conveying box, and thus, the noodle carding paw continuously stretches into and pulls out from the bowl-shaped conveying box under the driving effect of the cam combination mechanisms, and at the same time, the noodle carding paw swings in the bowl-shaped conveying box for arrangement of messy instant noodle segments.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

Six-axis universal robot with mechanical paws arranged on small arms

ActiveCN106041909AImprove work efficiencyAccurate graspProgramme-controlled manipulatorArmsEngineeringCam

The invention discloses a six-axis universal robot with mechanical paws arranged on small arms. The six-axis universal robot with the mechanical paws arranged on the small arms comprises a base body, a waist rotating component connected to the base body in a pivoted mode, a big arm connected to the waist rotating component in a pivoted mode, and the small arms installed on the big arm. The waist rotating component rotates around the base body, and the big arm rotates around the waist rotating component. The number of the small arms is two, and the two small arms include the first small arm and the second small arm correspondingly and are fixed to a sliding device through split mechanisms. The sliding device is installed on the big arm. Manipulator assemblies are arranged on the two small arms. Each manipulator assembly comprises an arm, a swing arm connected to the front end of the arm in a pivoted mode, and a manipulator fixed to a rotary disc at the front end of the swing arm. According to the six-axis universal robot with the mechanical paws arranged on the small arms, the big arm can drive the pair of small arms to rotate through the sliding device, and the two small arms can be driven by a pair of split supports to rotate relatively and can also be driven by the sliding device to slide linearly; and through gear transmission and cam combination, the paws can be driven to move simultaneously at the same amplitudes.

Owner:徐菊红

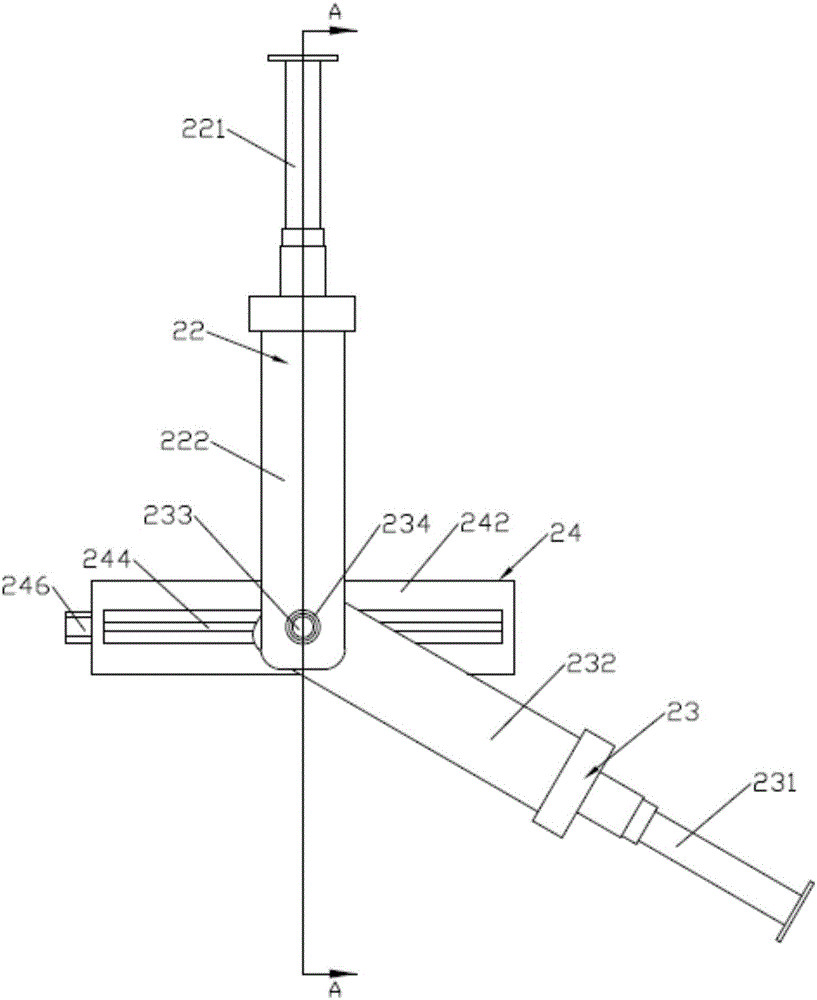

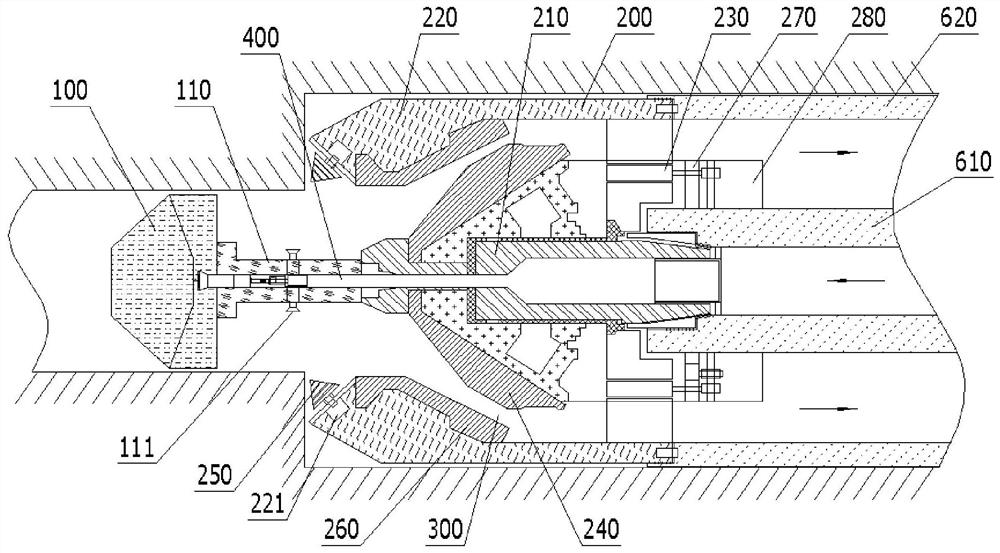

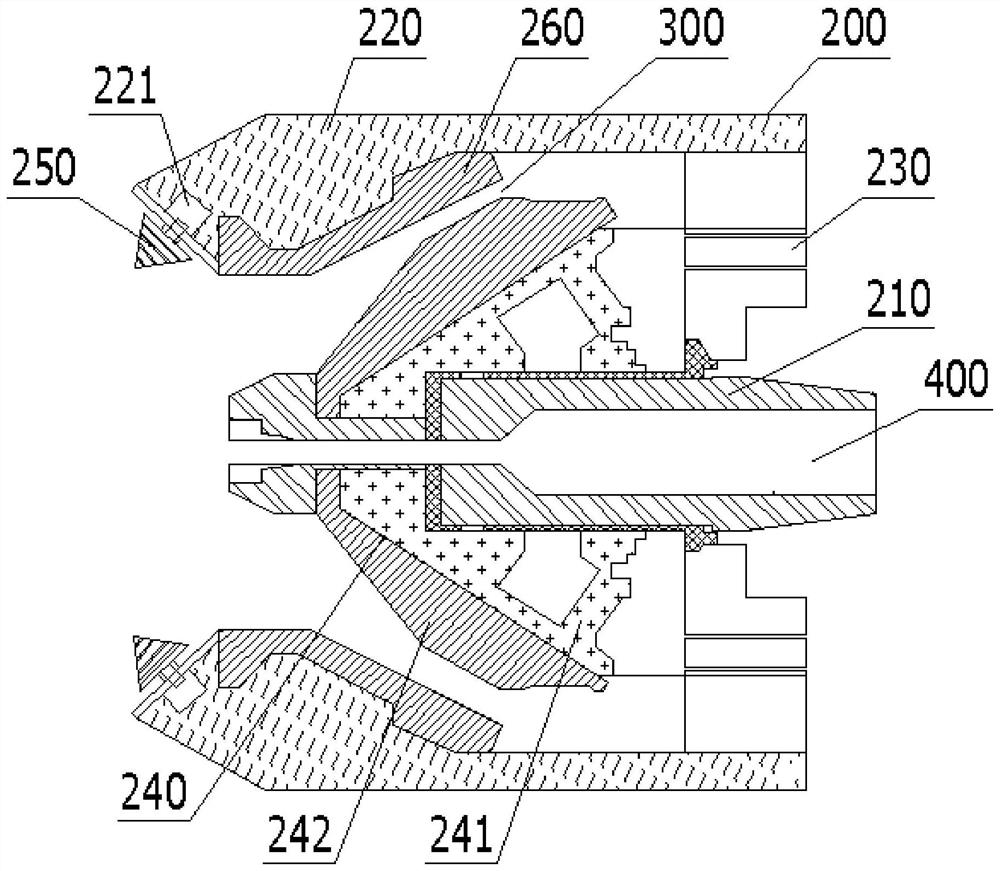

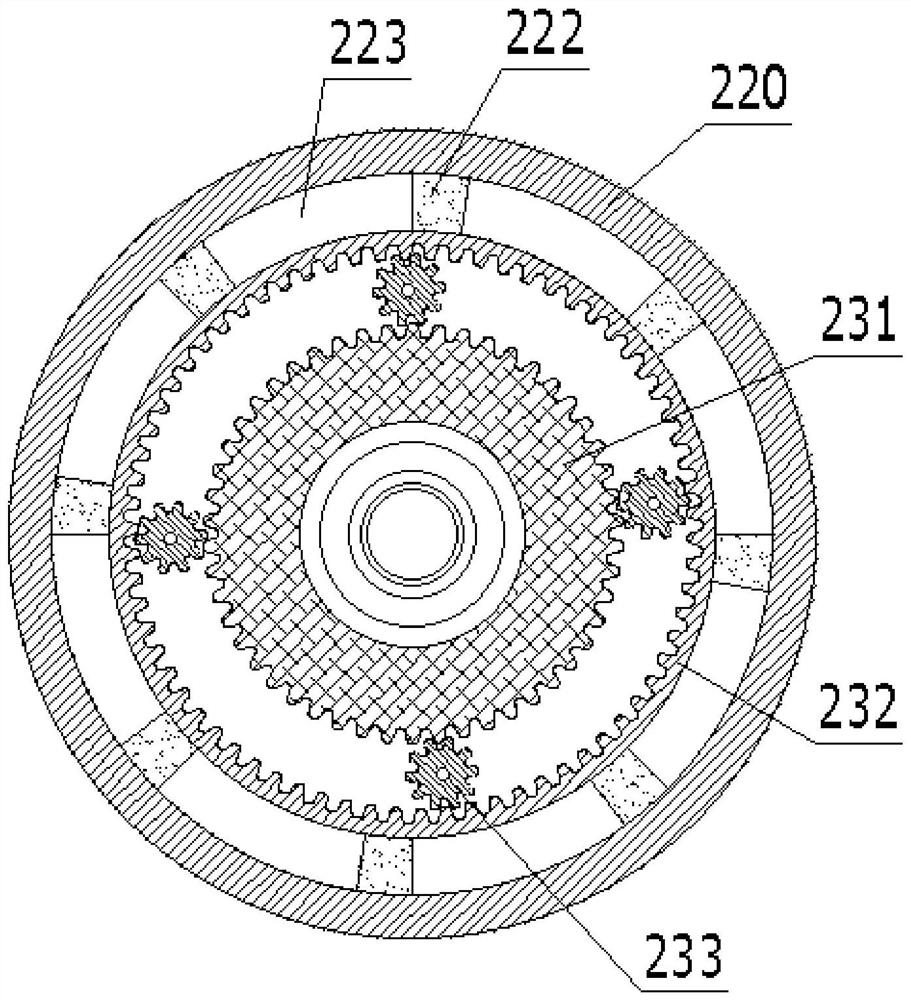

A drilling tool for horizontal directional drilling and reaming

ActiveCN111852336BAvoid enteringHelp with deliveryEarth drilling toolsDrill bitsMining engineeringDrive shaft

The invention provides a drilling tool for horizontal directional drilling and reaming, comprising: a pilot drill bit, one side of which is connected with a hollow drill rod; a reaming drilling tool, which is sleeved on the drilling rod, and the reaming drilling tool includes: a transmission shaft, The drive shaft is detachably connected to the drill pipe; a tapered cam is set on it; the cuttings guide is rotatably set on one end of the drive shaft, and the end of the cuttings guide is provided with a number of roller cone bits. The inner side of the chip guide is provided with a conical grinding disc; the driving part is arranged at one end of the transmission shaft, which is used to drive the transmission shaft and the cuttings guide to rotate in reverse synchronously; a mud is arranged between the conical cam and the conical grinding disc. Channel, with the rotation of the conical cam, the inner diameter of the mud channel gradually increases or decreases. Through the combination of the conical grinding disc and the conical cam, the grinding part of the mud block is formed. Through the reverse rotation of the conical cam and the conical grinding disc, the reaming soil and cleaning liquid can be ground and mixed into mud, which is helpful for the reaming process. Transportation of mud.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

A high-precision on-line rapid measurement device and measurement method for the thickness of an aluminum substrate

ActiveCN111156910BRealize online real-time thickness measurementImprove test accuracyUsing optical meansFast measurementEngineering

Owner:XIDIAN UNIV

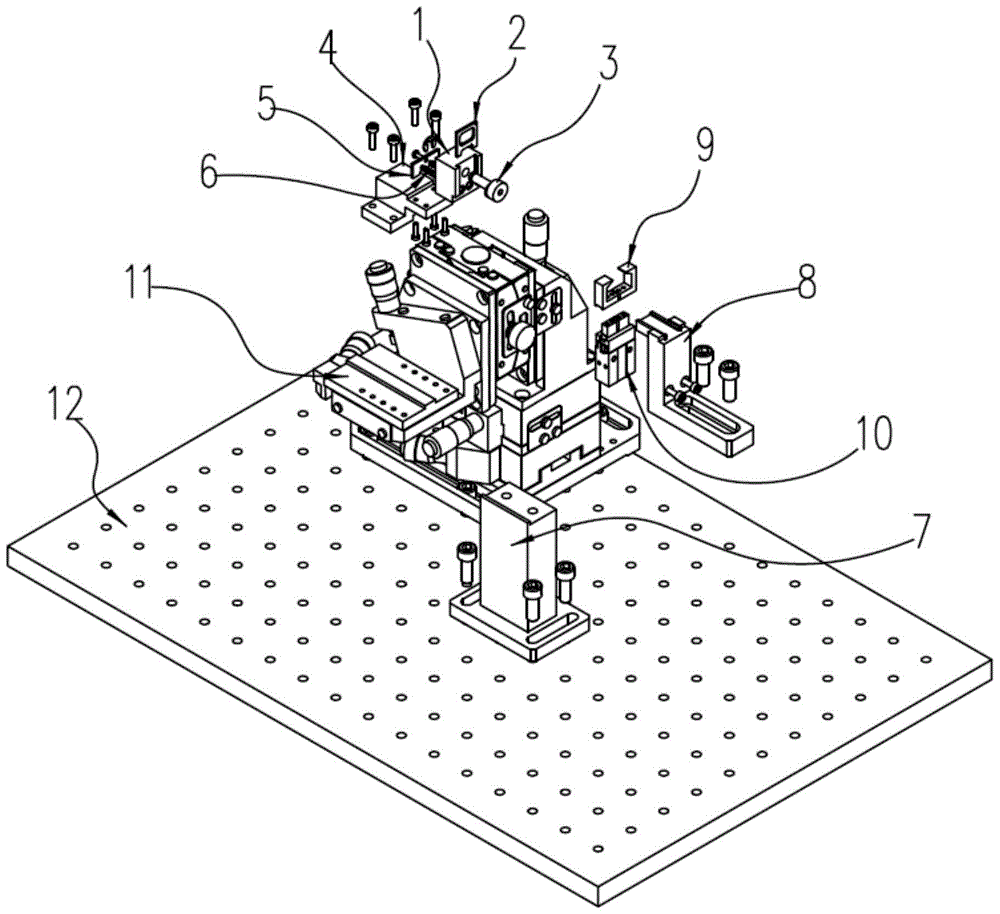

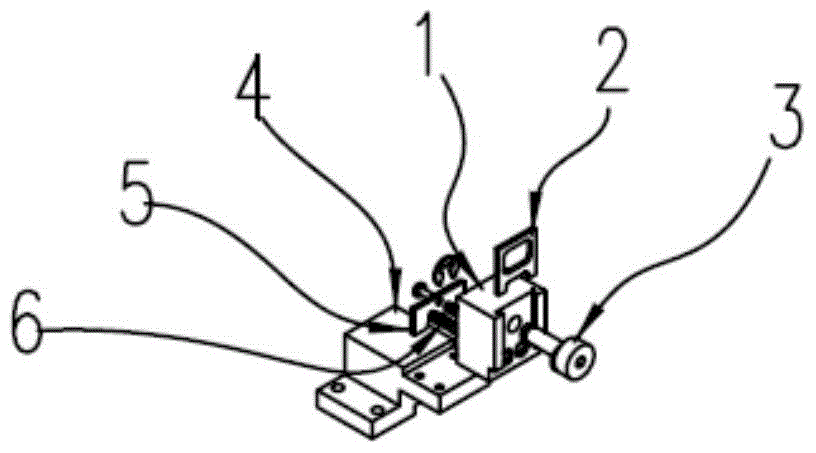

A coupling platform for SFP+COB module components for optoelectronic communication

ActiveCN105259624BSimple processLow costCoupling light guidesMountingsInternet communicationCoupling

The present invention provides a coupling platform for SFP+COB module assembly for photoelectric communication, which includes a lens clamping part, a PCB board clamping part, a coupling adjustment part and a support part, and the lens clamping part includes a clamping seat, a movable part, a cam, Connecting seat, jumper press plate and jumper; PCB board clamping part includes PCB seat, gripper and air claw; the main body of coupling adjustment part is multi-axis fine-tuning frame; The combination of seat, movable part and cam makes the cam drive the movable part to slide up and down in the slot of the clamping seat when the cam rotates. When the movable part runs on the upper end, the LC optical port of the plastic lens can be inserted into the clamping seat without hindrance ;When the movable part runs at the lower end, the LC optical port of the plastic lens is limited by the limit gap of the movable part; The technical problem of positioning the lens and bonding it to the PCB board has achieved good results in improving quality, efficiency and reducing production costs.

Owner:WUHAN TELECOMM DEVICES

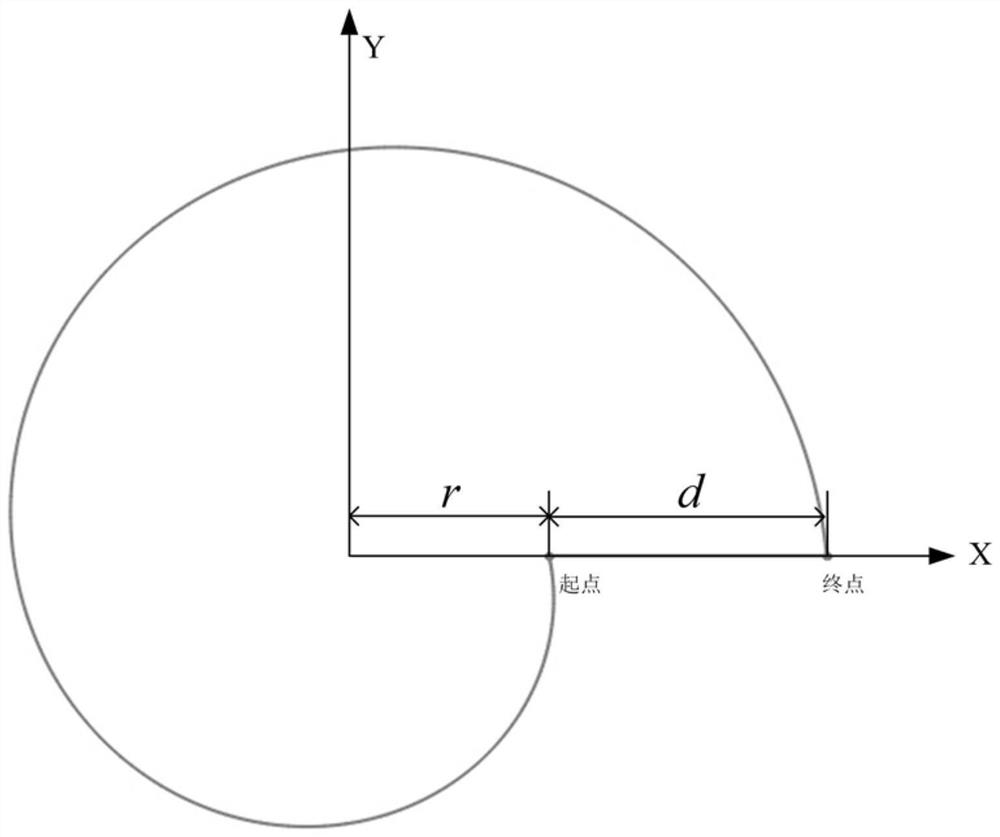

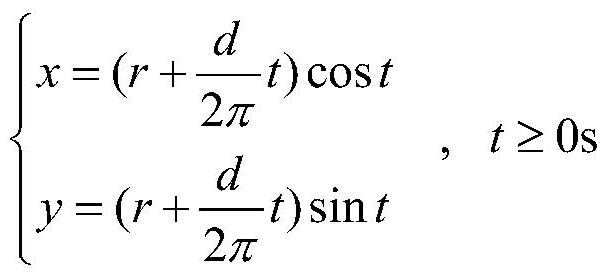

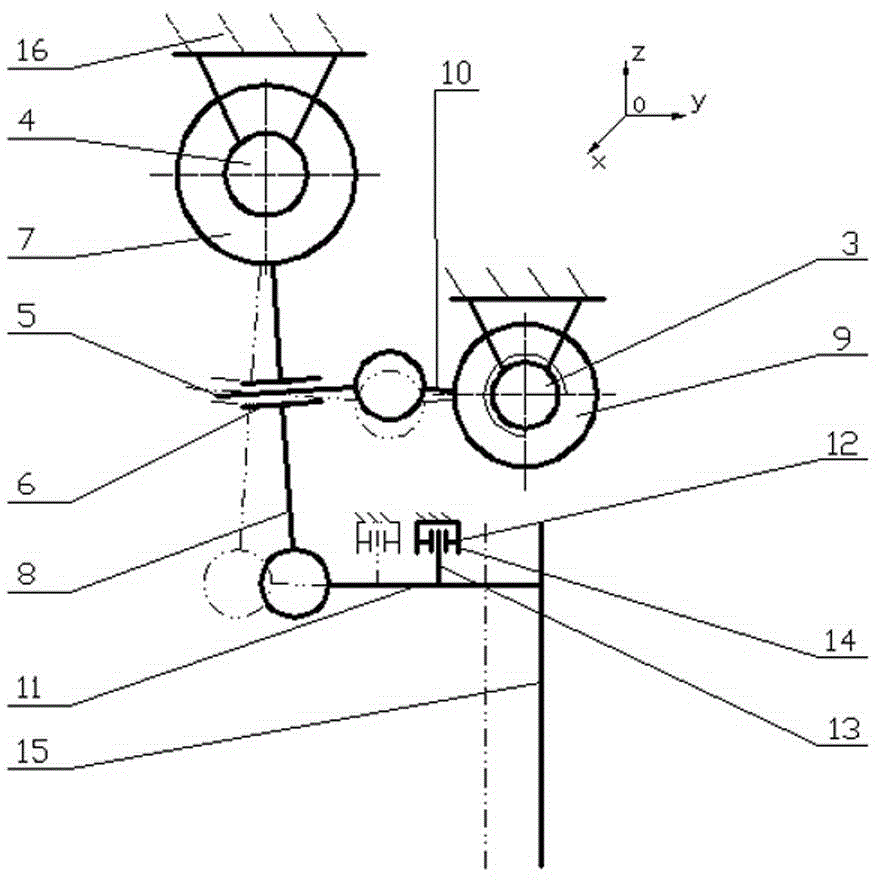

A Micro Thrust Measuring Device Based on Cam Rotation Angle Measurement

ActiveCN113340499BLarge measuring rangeGuaranteed angular measurement resolutionUsing optical meansApparatus for force/torque/work measurementEngineeringCam

The present invention is a tiny thrust measuring device based on cam rotation angle measurement. In the device, a rotating beam, an elastic shaft and a mounting seat are combined and connected together. The cam is installed on the rotating beam, and the center of the cam circle is located on the combined central axis of the elastic shaft and the mounting seat. , the damping plate is connected with the cam; the damping oil pool is installed on the bottom plate, and the damping plate is immersed in the damping oil pool; the displacement measuring device adopts a non-contact optical displacement measuring device, which is installed on the bottom plate, and the measuring point is on the side of the cam. The mass block is used for system parameter calibration of the measuring device. The rotation angle of the rotating shaft can be measured by using the combination of the displacement sensor and the cam. This rotation angle measurement method can measure a wide range of rotation angles, which is different from the measurement method that uses linear displacement to approximate the rotation angle.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Spiral double-rocker guide rod groove cam combination space mechanism for sliding-plug door

ActiveCN102305007BThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementCouplingEngineering

The invention discloses a spiral double-rocker guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the spiral double-rocker guide rod groove cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a guide rod, a guide rod sleeve, a shaft sleeve, a door carrying rocker, a nut, a short rocker, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the screw, the nut and the door frame; a double-rocker guide rod mechanism consists of the rocker, the short rocker, the guide rod, the guide rod sleeve, the nut, the bearing shaft, and the shaft sleeve; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf and the door frame; the spiral mechanism, the double-rocker guide rod mechanism, and the groove cam mechanism are connected to form the spiral double-rocker guide rod groove cam combination space mechanism; the door frame is fixedly connected with a vehicle body; and the motor which is fixed on the door frame is connected with the screw through the coupler.

Owner:江苏振邮科技产业投资管理有限公司

Spiral rocker guide rod composite hinge groove cam combination space mechanism for sliding-plug door

ActiveCN102305008BThe plug seal of the plug door is reliableSierra seal is reliablePower-operated mechanismDoor arrangementEngineeringCam

The invention discloses a spiral rocker guide rod composite hinge groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, and opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the spiral rocker guide rod composite hinge groove cam combination space mechanism for the sliding-plug door for high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a guide rod, a nut, a shaft sleeve, a door carrying rocker, a guide rod sleeve, a door handle, a roller, a roller shaft, a groove cam, a door leaf and a door frame; a spiral mechanism consists of the screw, the nut and the door frame; the guide rod and the nut which are fixedly integrated, a rocker guide rod mechanism consists of the guide rod, the rocker, the guide rod sleeve, the shaft sleeve and the bearing shaft; a groove cam mechanism consists of the bearing shaft, the rocker, the roller, the roller shaft, the groove cam, the door handle, the door leaf, and the door frame; and a composite hinge consists of the guide rod sleeve, the rocker and the door handle; and the spiral mechanism, the rocker guide rod mechanism, and the groove cam mechanism are connected to form the spiral rocker guide rod composite hinge groove cam combination space mechanism.

Owner:海宁市袁花镇工业投资有限公司

A kind of miscellaneous grain noodle machine

A disclosed coarse-cereals noodle carding machine comprises a frame, a pair of cam combination mechanisms, a noodle carding support and a noodle carding head; the cam combination mechanisms drive the noodle carding support to make horizontal and vertical motions; the bottom end of the noodle carding support is pivoted to the noodle carding head; and a noodle carding paw at the bottom end of the noodle carding head swings under the driving effect of a gear motor and a crank and rocker mechanism. According to the above technical scheme, a bowl-shaped conveying box holding instant noodle segments makes horizontal conveying motion below the noodle carding support, the cam combination mechanisms make synchronous operation with the bowl-shaped conveying box, and thus, the noodle carding paw continuously stretches into and pulls out from the bowl-shaped conveying box under the driving effect of the cam combination mechanisms, and at the same time, the noodle carding paw swings in the bowl-shaped conveying box for arrangement of messy instant noodle segments.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

Six-axis universal robot for material grabbing

ActiveCN106078725AImprove work efficiencyAccurate graspProgramme-controlled manipulatorEngineeringCam

The invention discloses a six-axis universal robot for material grabbing. The six-axis universal robot comprises a base body, a waist rotating component in pin joint to the base body, a large arm in pin joint to the waist rotating component and small arms mounted on the large arm. The waist rotating component rotates around the base body, and the large arm rotates around the waist rotating component. The two small arms comprise the first small arm and the second small arm. The two small arms are mounted on the large arm through a split mechanism. A mechanical hand assembly is arranged on the two small arms and comprises an arm, a swing arm in pin joint to the front end of the arm and a mechanical hand fixed to a rotating disc at the front end of the swing arm. The two small arms of the six-axis universal robot can rotate relative to the large arm through the split mechanism, the two small arms can oppositely rotate under drive of the split mechanism so as to adapt to various processing conditions, and the operation efficiency of the robot is improved. Grippers can be driven to move at the same time through gear transmission and cam combination and are the same in motion amplitude so that the mechanical grippers can grab workpieces accurately in an omnibearing manner.

Owner:GUANGZHOU XINNAN NUMERICAL CONTROL TECH

Manipulator component of a general robot

The invention discloses a manipulator component for a universal robot. The manipulator component comprises an arm, a swinging arm pivoted at the front end of the arm and a manipulator fixed on a rotating disc at the front end of the swinging arm. The manipulator comprises a shell and a claw hand drive mechanism; the claw hand drive mechanism comprises a drive motor, a worm, a worm gear, a center gear, a plurality of indexing gears, a plurality of cams and a plurality of claw hands. According to the manipulator component disclosed by the invention, the claw hands can be driven to simultaneously act through gear transmission and cam combination, and have the same motion amplitude so as to accurately grasp workpieces in all directions.

Owner:佛山市夏云智能装备有限公司

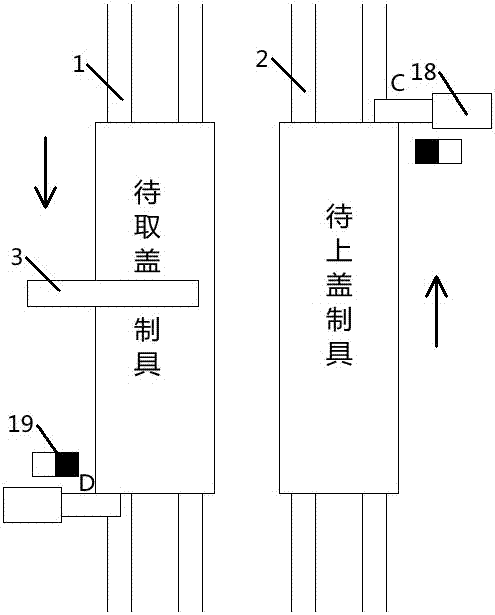

A device for automatically removing the upper cover of a tuning fork crystal

The invention discloses a device for automatically taking an upper cover of a tuning fork crystal. The device comprises a cover-taking system rail and a cover-adding system rail, which are rotated in an inverted manner. An upper cover-taking mechanism is arranged at the outside of the cover-taking system rail. The upper cover-taking mechanism comprises a rack, a rack X-axis cam, a rack Z-axis cam, an upper cover cam, a cover-taking cam and a drive motor. The rack X-axis cam, the rack Z-axis cam, the cover-taking cam, the upper cover cam and the drive motor are connected with each other via a synchronous belt. Top rods are arranged at the tops of the cover-taking cam and the upper cover cam , and a cover-clamping device is arranged on the rack. Through the coordination of cam combination in a transmission mechanism and the cover-clamping device, the device of the invention could be used for precisely placing a crystal plate on a substrate in a perfect manner so as to free workers from high-intensitive work. The device of the invention is high in automatic level and greatly improves work efficiency.

Owner:HUBEI TKD ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com