Coaxial multi-cam combination syringe spindle

A technology of multiple cams and combined needles is applied in the field of spinning, which can solve the problems of single structure of hollow tape yarn, poor decorative effect and not enough beauty, and achieve the effects of improving production quality, good decorative effect and less fiber loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

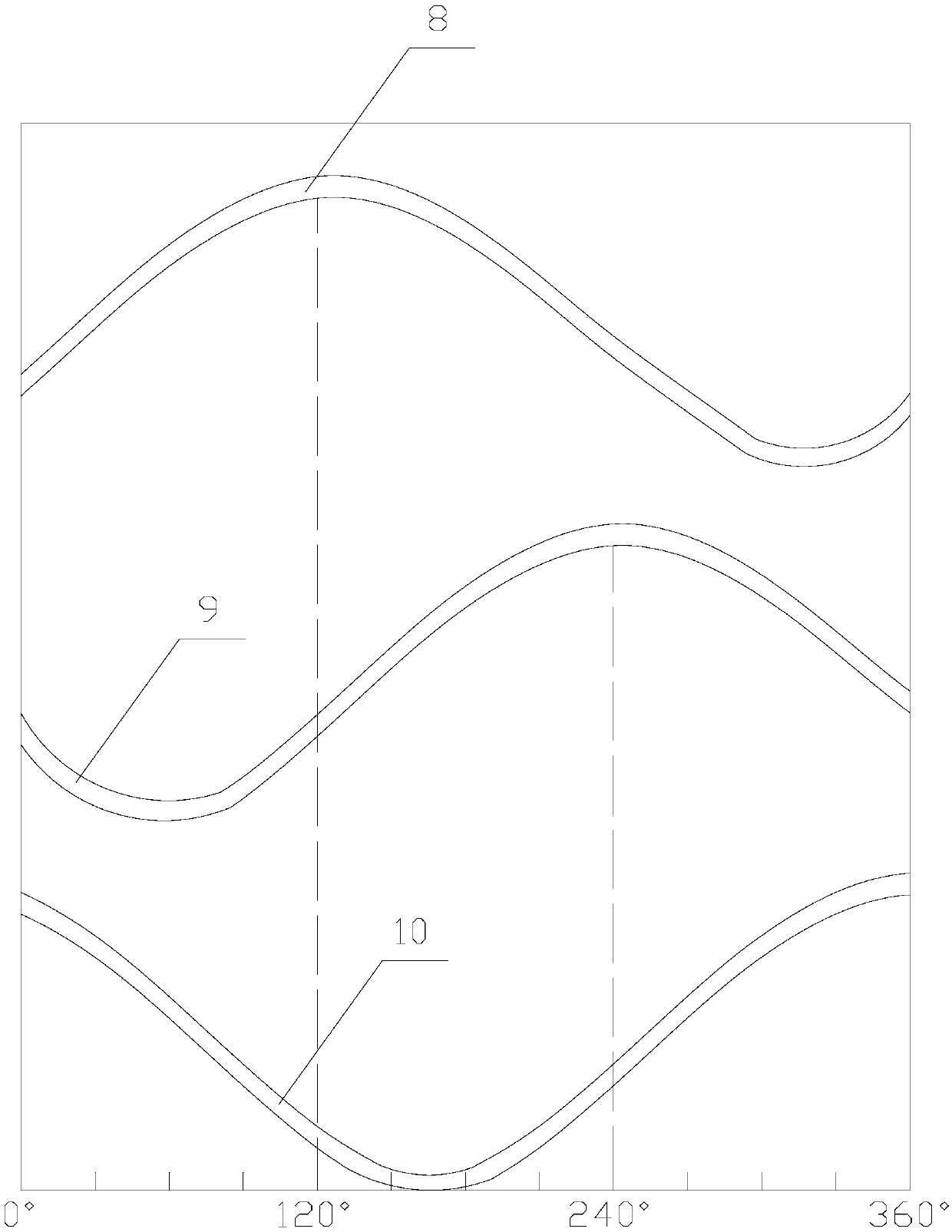

[0023] specific as Figure 1~2 As shown, three sets of cam combinations are sleeved on the cam base 1, and the three sets of cam combinations form the first cam groove 8, the second cam groove 9, and the third cam groove 10, which can enter different materials and / or multi-color yarns. For knitting, needle slots with the same number of groups as the number of cam slots are circularly distributed on the outer ring of the needle cylinder 4. Each group of needle slots has a group of crochet needles driven by the corresponding cam slots for knitting. At this time, the combination of three sets of cams can only The cam base 1 is fixed, and the needle cylinder rotates to feed the yarn. Otherwise, it will cause inconvenient yarn guiding, knotting and winding phenomenon. Meanwhile, the upper and lower cams in the middle can be cam parts that are connected as one.

Embodiment 2

[0025] Specifically, when the cams installed on the cam base 1 are combined into two groups, the cam base 1 can be used to feed the yarn, and the needle cylinder 4 can also be used to rotate to feed the yarn, so that the yarn will not be knotted or entangled.

[0026] It can be seen from the above that using two or more cam sets can weave yarn ribbons of various colors and materials, with many styles, colors and materials, and can be woven independently to meet the needs of the public. The decorative effect is good and very bright. Its manufacturing yarn The tape operation is simple, the cost is low, the stability is good, the fiber loss is small, and the production quality of the yarn tape is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com