Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Air-cooled engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-cooled engines rely on the circulation of air directly over heat dissipation fins or hot areas of the engine to cool them in order to keep the engine within operating temperatures. In all combustion engines, a great percentage of the heat generated (around 44%) escapes through the exhaust, not through the metal fins of an air-cooled engine (12%). About 8% of the heat energy finds its way into the oil, which although primarily meant for lubrication, also plays a role in heat dissipation via a cooler. Air-cooled engines are used generally in applications which would not suit liquid cooling, as such modern air-cooled engines are used in motorcycles, general aviation aircraft, lawn mowers, generators, outboard motors, pump sets, saw benches and auxiliary power units.

Air-cooled engine surface cooler

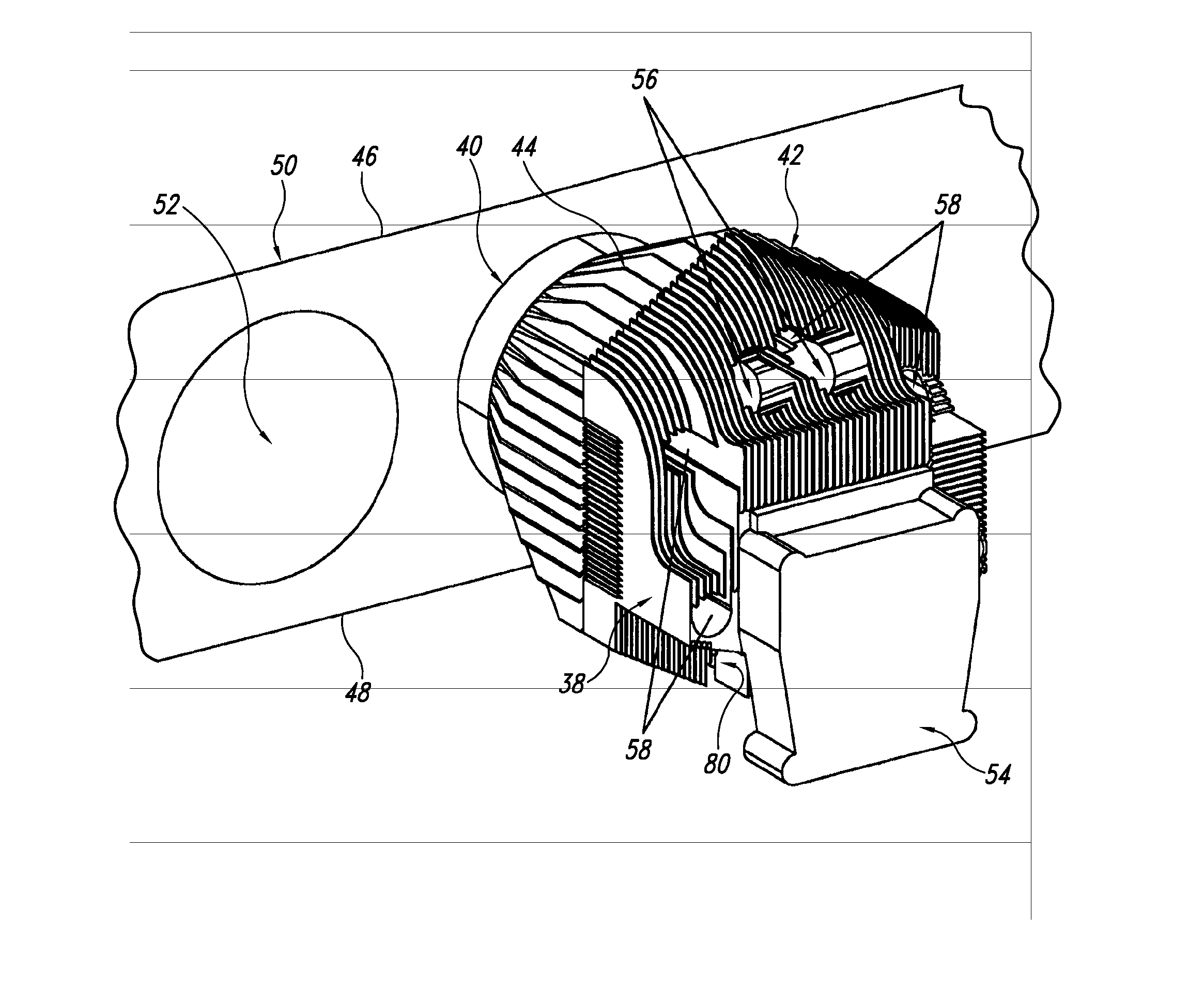

ActiveUS20140027102A1Improve heat transfer performanceIncreasing turbulence levelEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

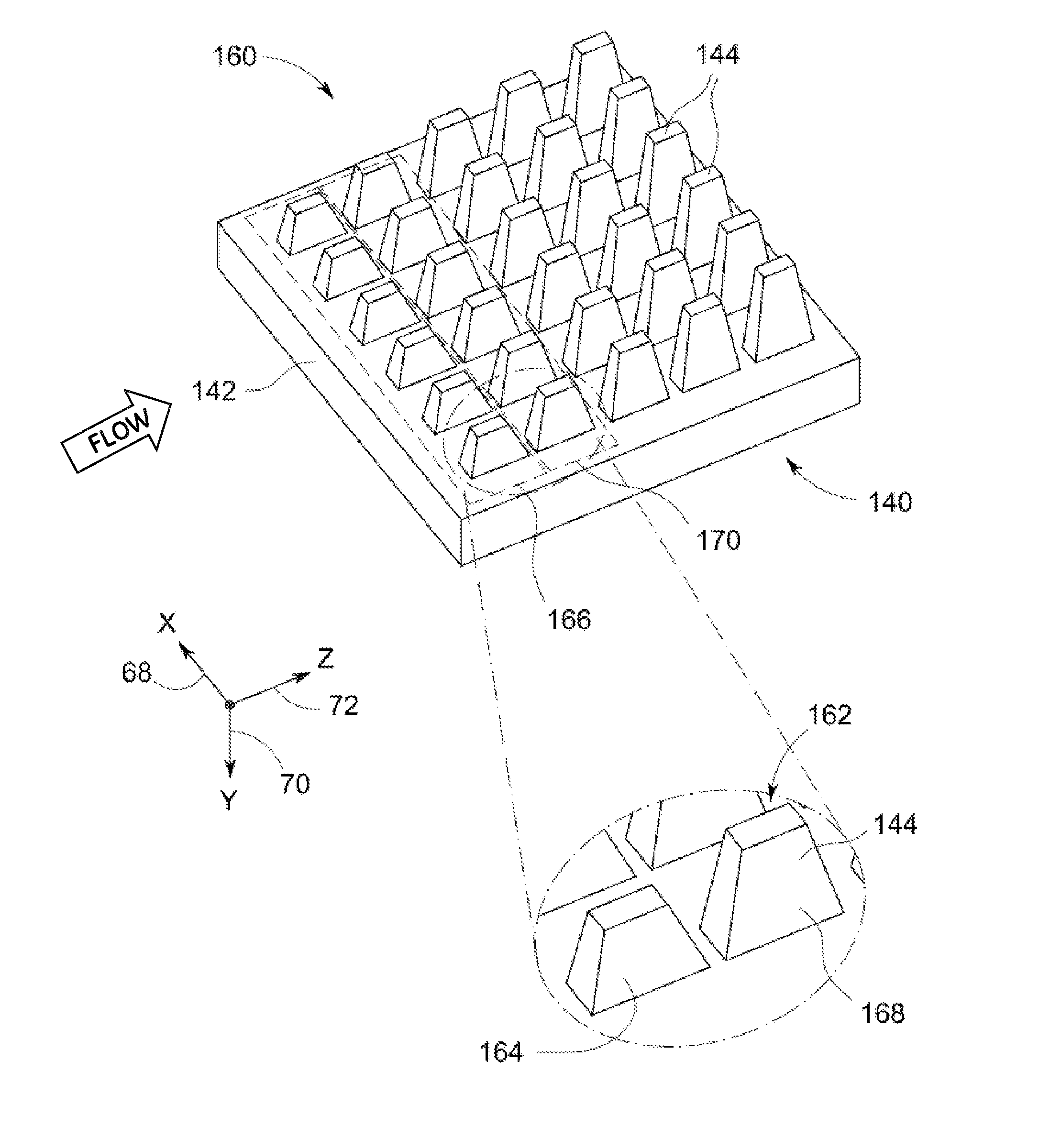

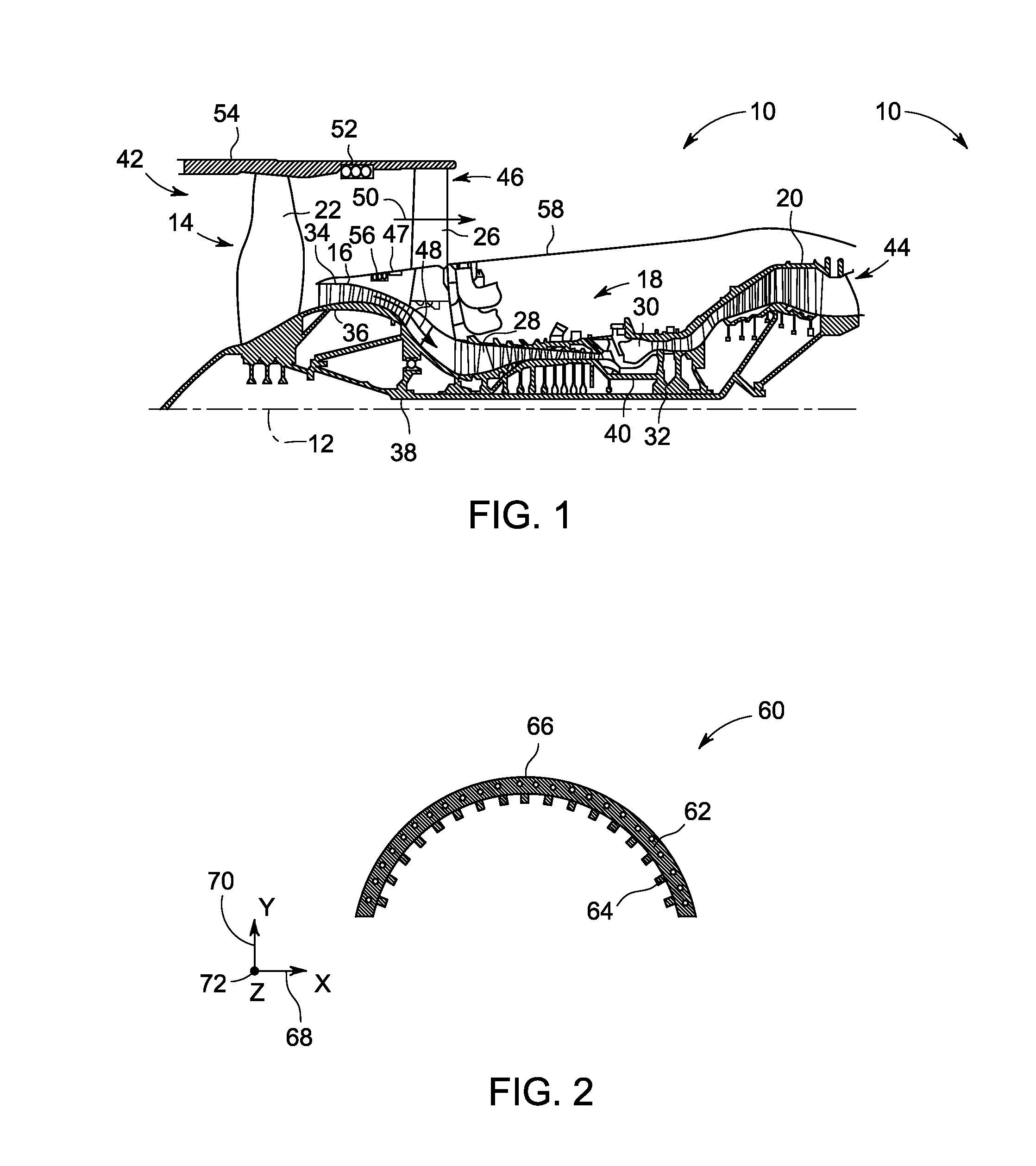

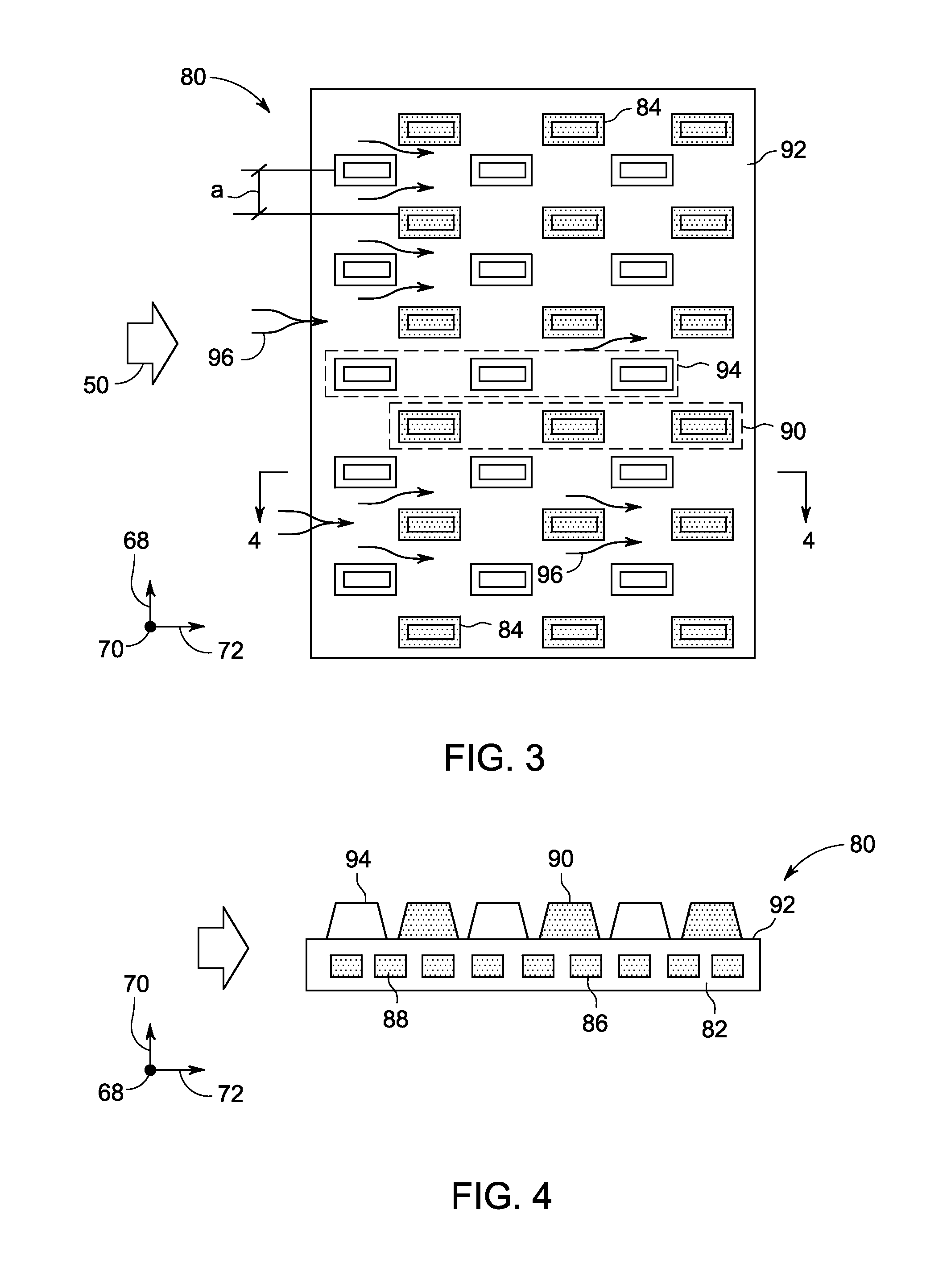

A surface cooler comprises a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

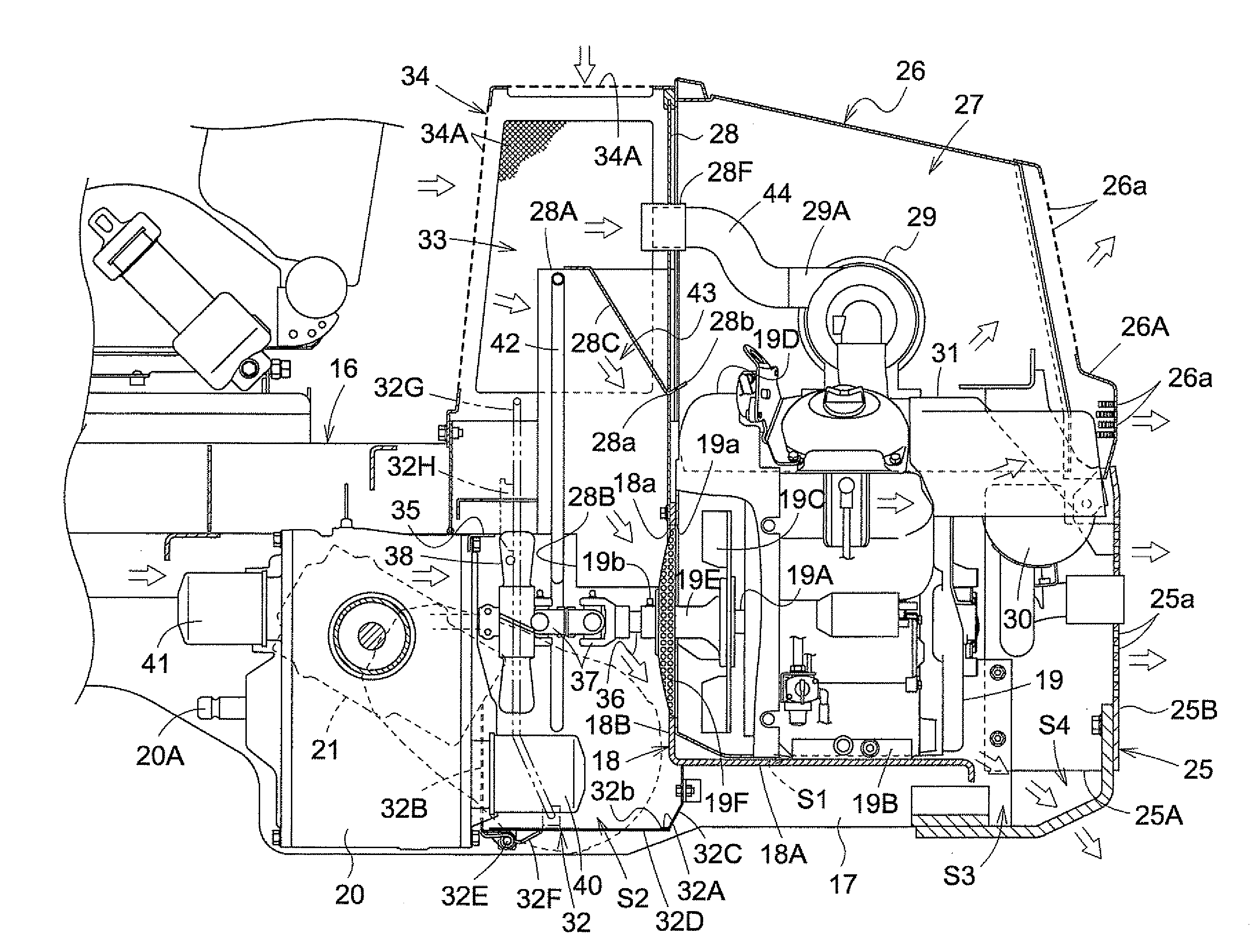

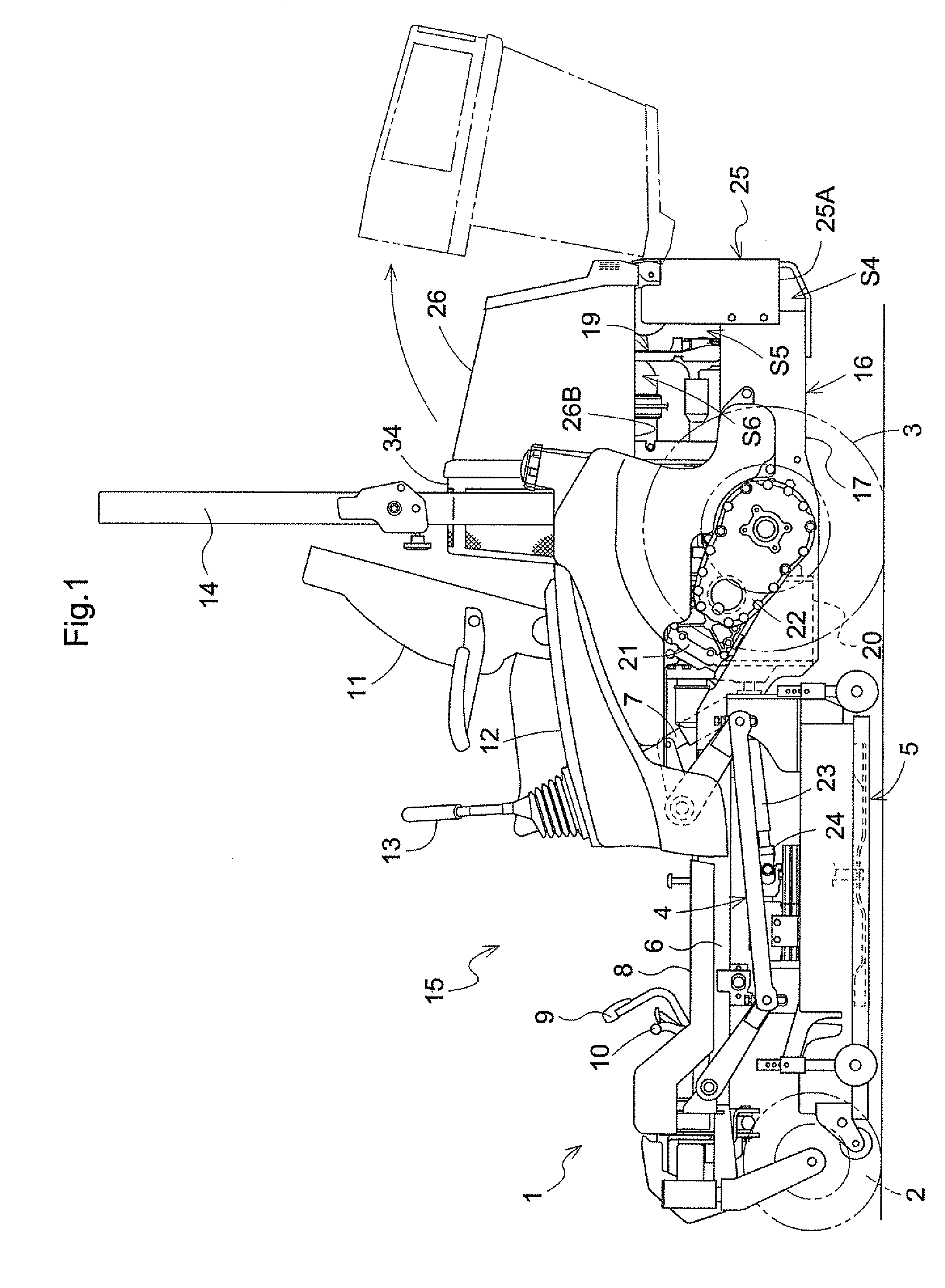

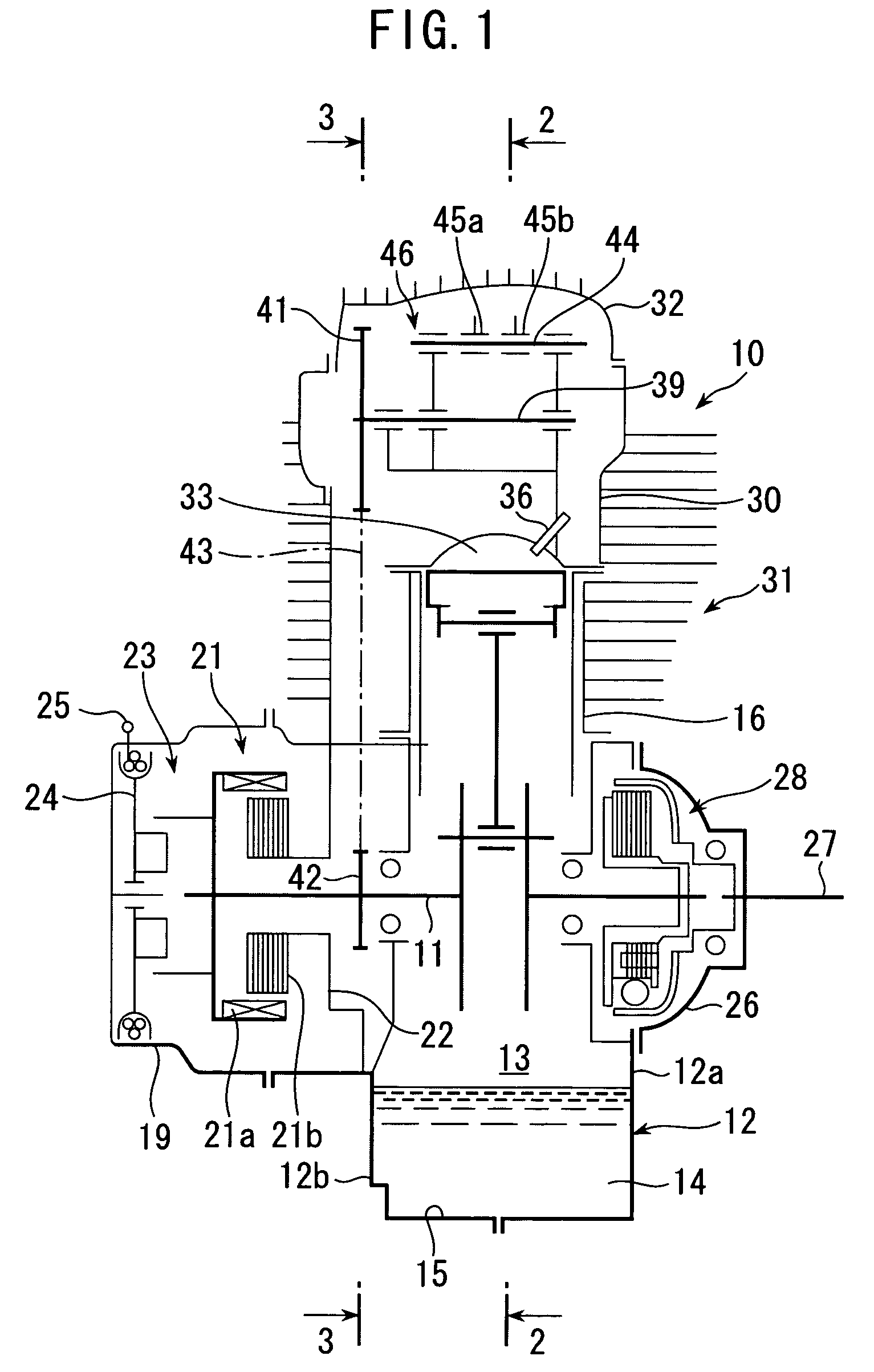

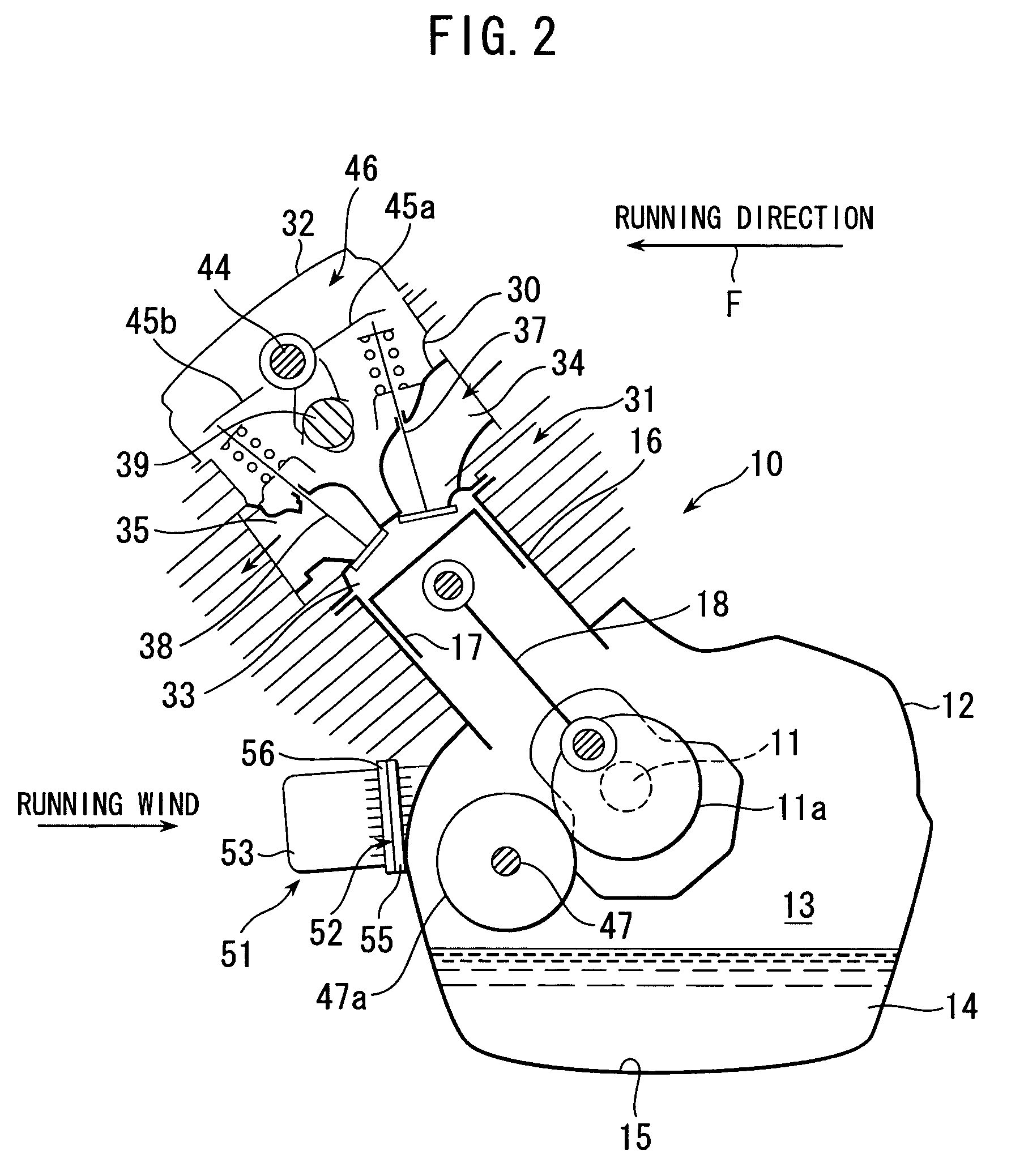

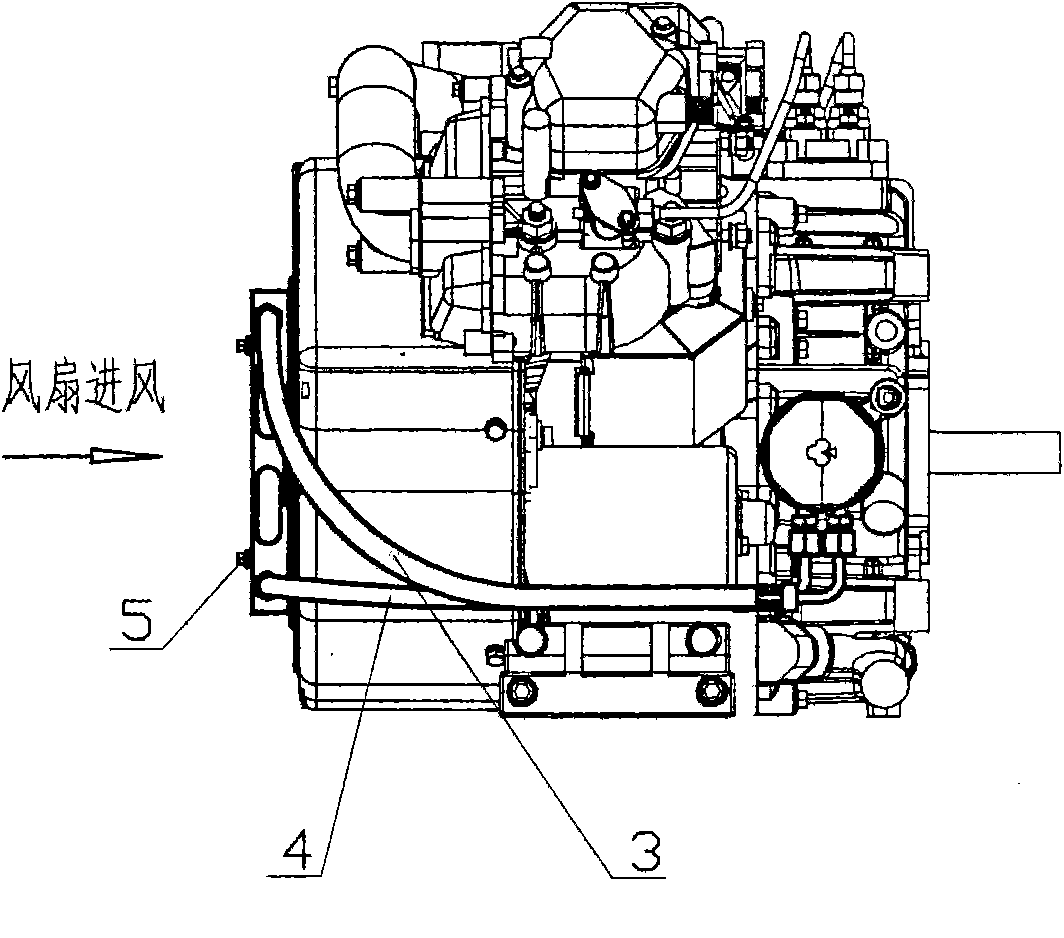

Cooling structure for a work vehicle

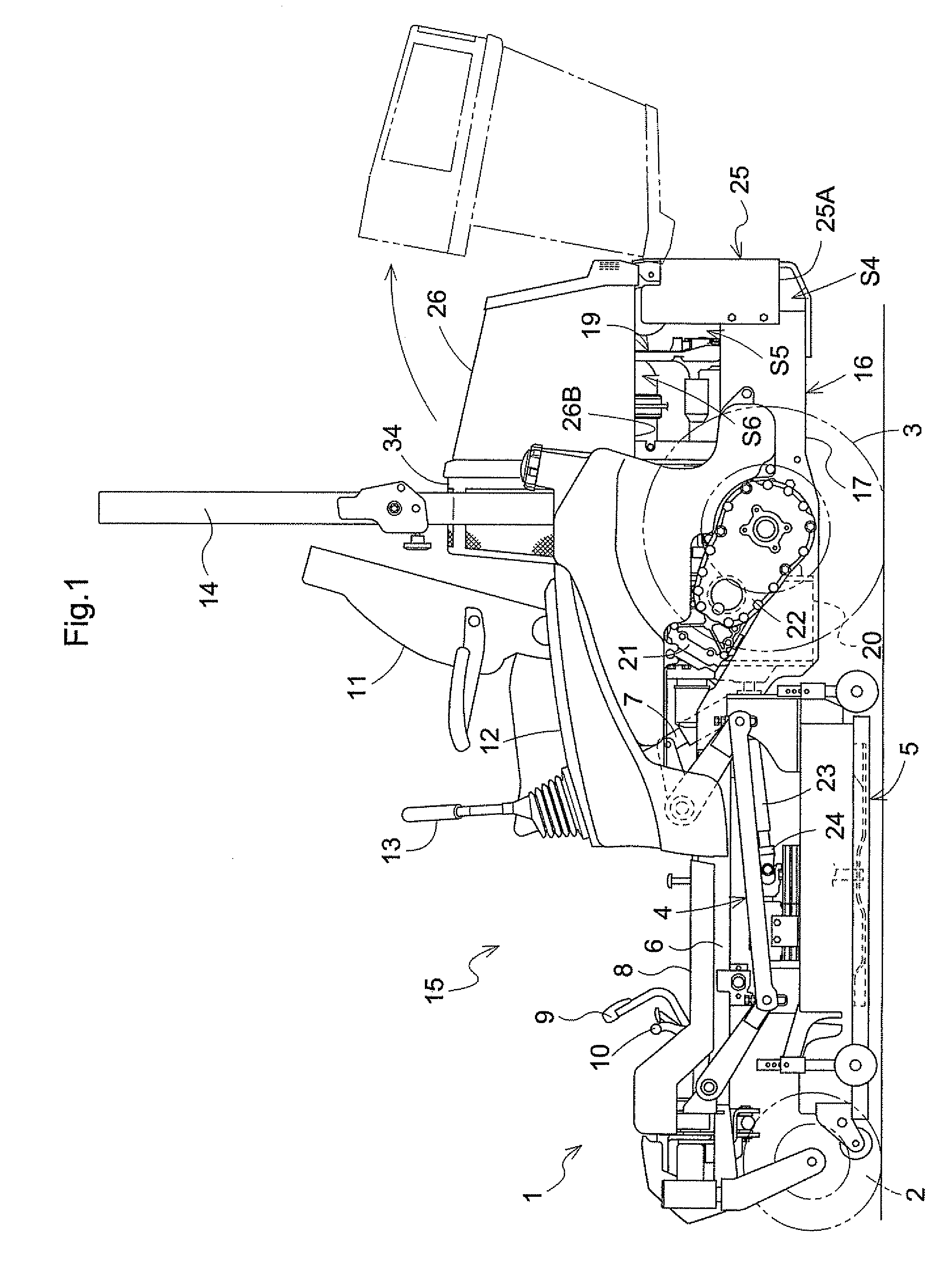

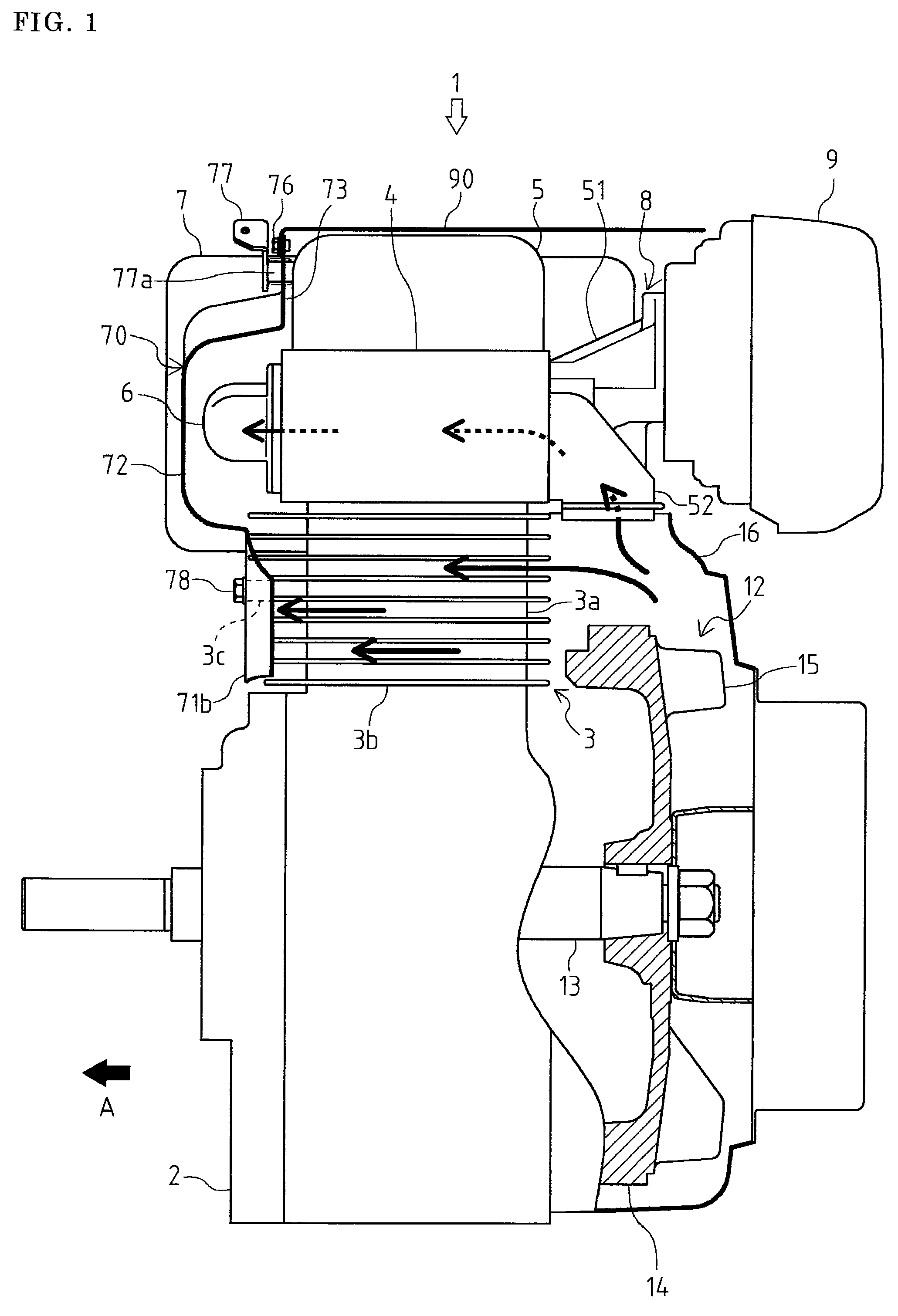

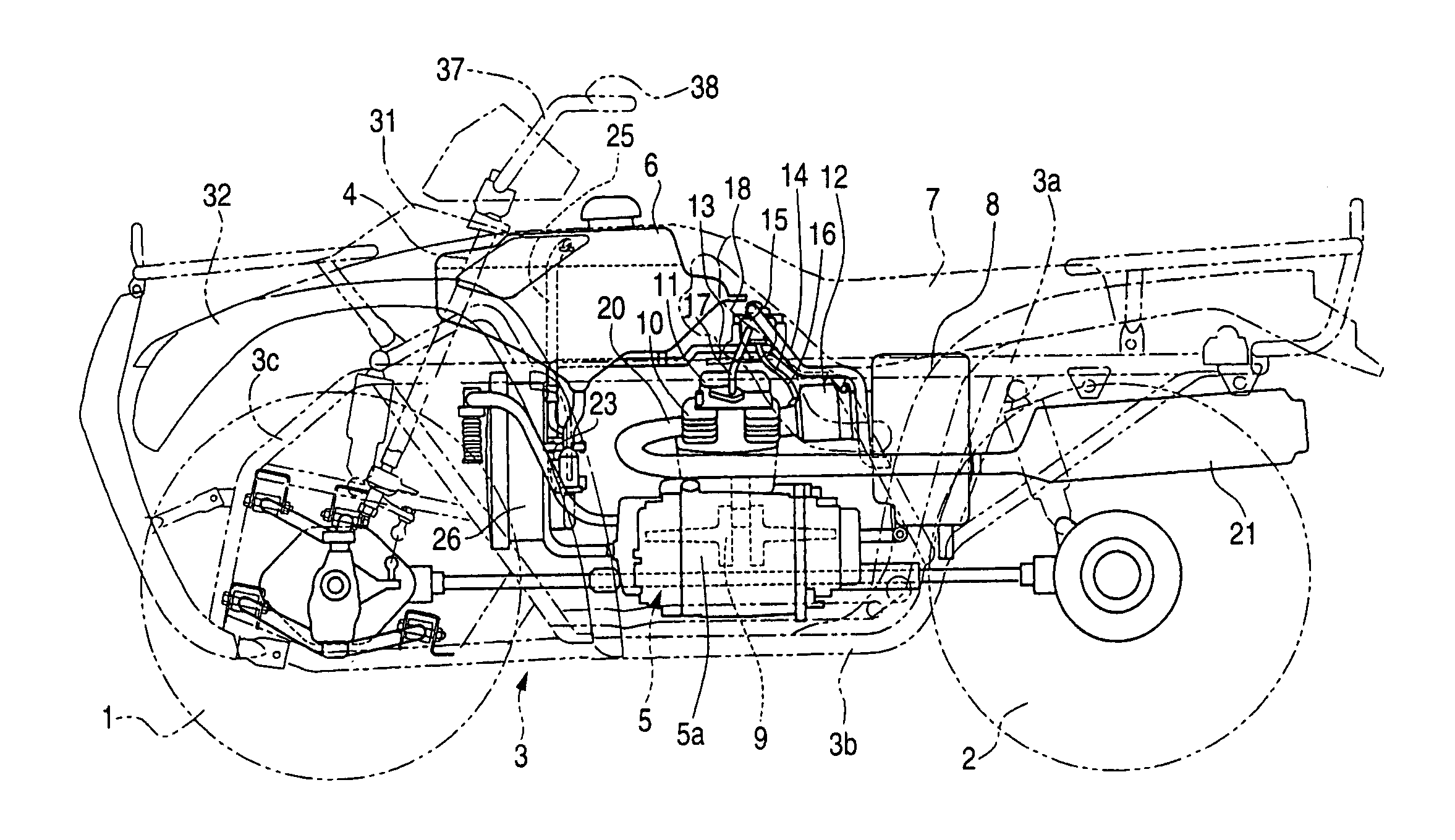

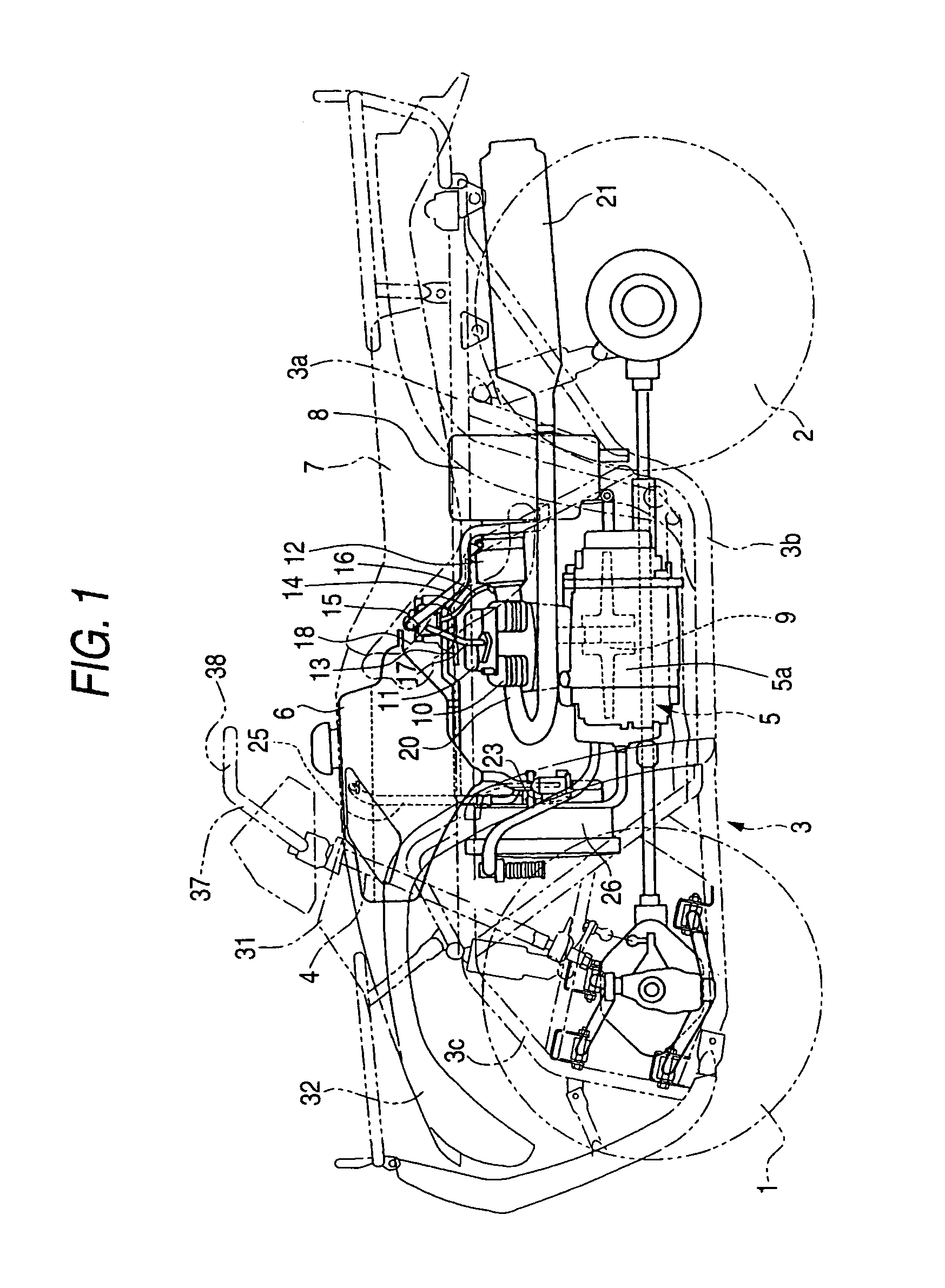

ActiveUS7559295B2Increasing sizeIncreasing costCoolant flow controlAir coolingAir-cooled engineCooling fluid

A cooling structure for a working vehicle with a transmission disposed rearwardly and downwardly of a driver's seat and having a hydrostatic transmission, and an air-cooled engine disposed rearwardly of the transmission. The cooling structure comprising a fan for cooling the engine and a fan for cooling the transmission mounted on a rotary shaft operatively connecting the transmission with an output shaft of the air-cooled engine, the fans being configured such that air flows generated by the fans move from adjacent the transmission toward the engine; an oil cooler for cooling fluid supplied to the hydrostatic transmission, the oil cooler being disposed between the fan for cooling the engine and the fan for cooling the transmission, and disposed to face each of the fans; and an air guiding plate disposed at a position higher than the oil cooler for guiding air to regions of the fans.

Owner:KUBOTA CORP

Plate-like air-cooled engine surface cooler with fluid channel and varying fin geometry

ActiveUS9599410B2Improve heat transfer performanceIncreased turbulenceEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

A surface cooler includes a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

Oil cooling system of an air-cooled engine

InactiveUS20060219208A1Small sizeImprove performanceMachines/enginesLubricant mounting/connectionEngineeringCrankcase

An oil cooling system of an air-cooled engine for cooling the oil reserved in a crankcase of the engine comprises a base plate assembled to the crankcase, an overlapping plate assembled to the base plate; an oil filter supported in the overlapping plate; and radiation fins formed on the base plate and the overlapping plate, wherein the base plate includes an inlet port for receiving the engine oil discharged from an oil pump of the engine, an outlet groove for outputting the engine oil and a first passage groove connecting the inlet port and the outlet groove, the overlapping plate includes an inlet groove opposed to the inlet port, an outlet port opposed to the outlet groove and a second passage groove opposed to the first passage groove to form an oil passage together with the first passage groove, and the base plate and the overlapping plate having through-holes where the filter outlet of the oil filter passes through for the connection with the crankcase.

Owner:SUBARU CORP

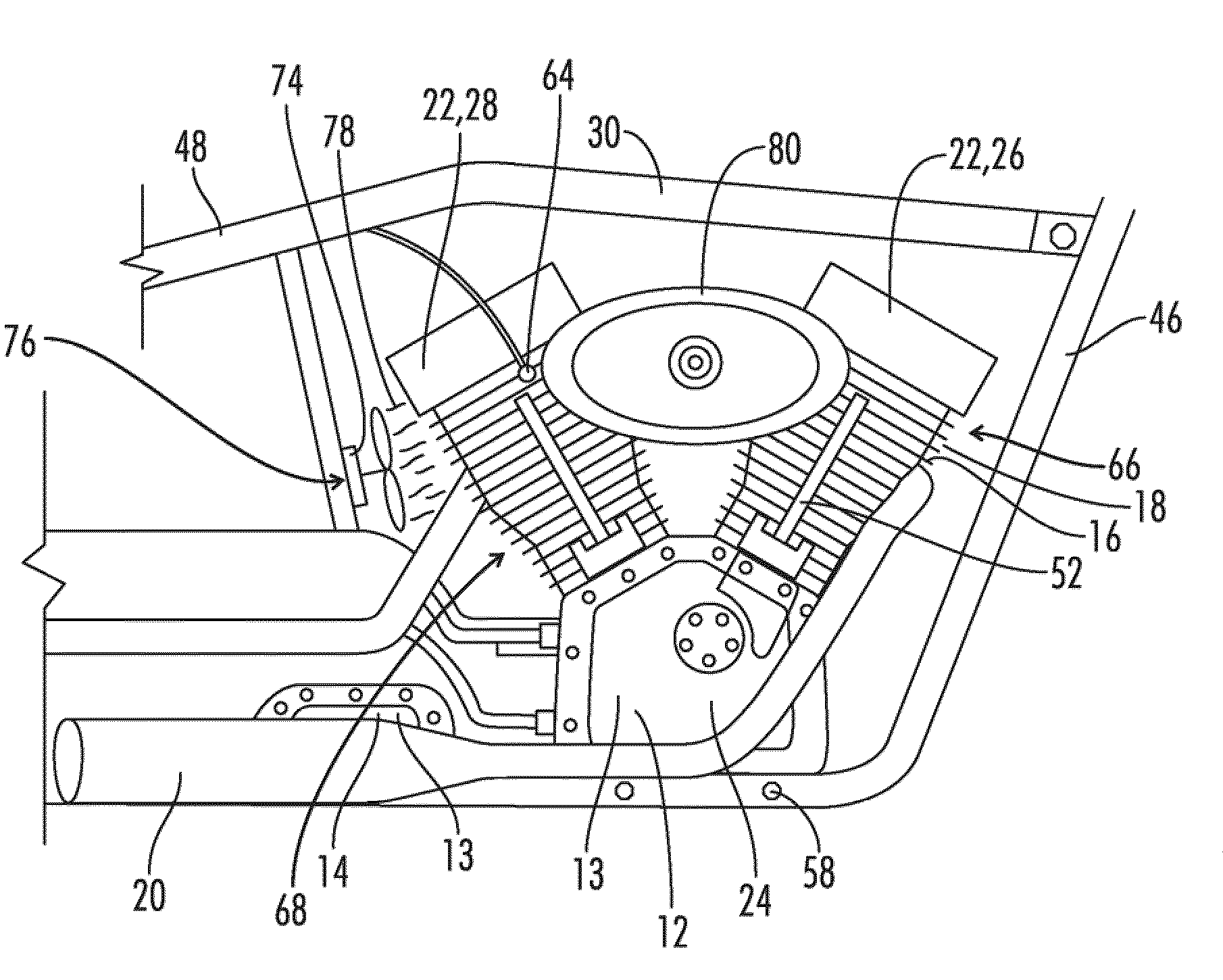

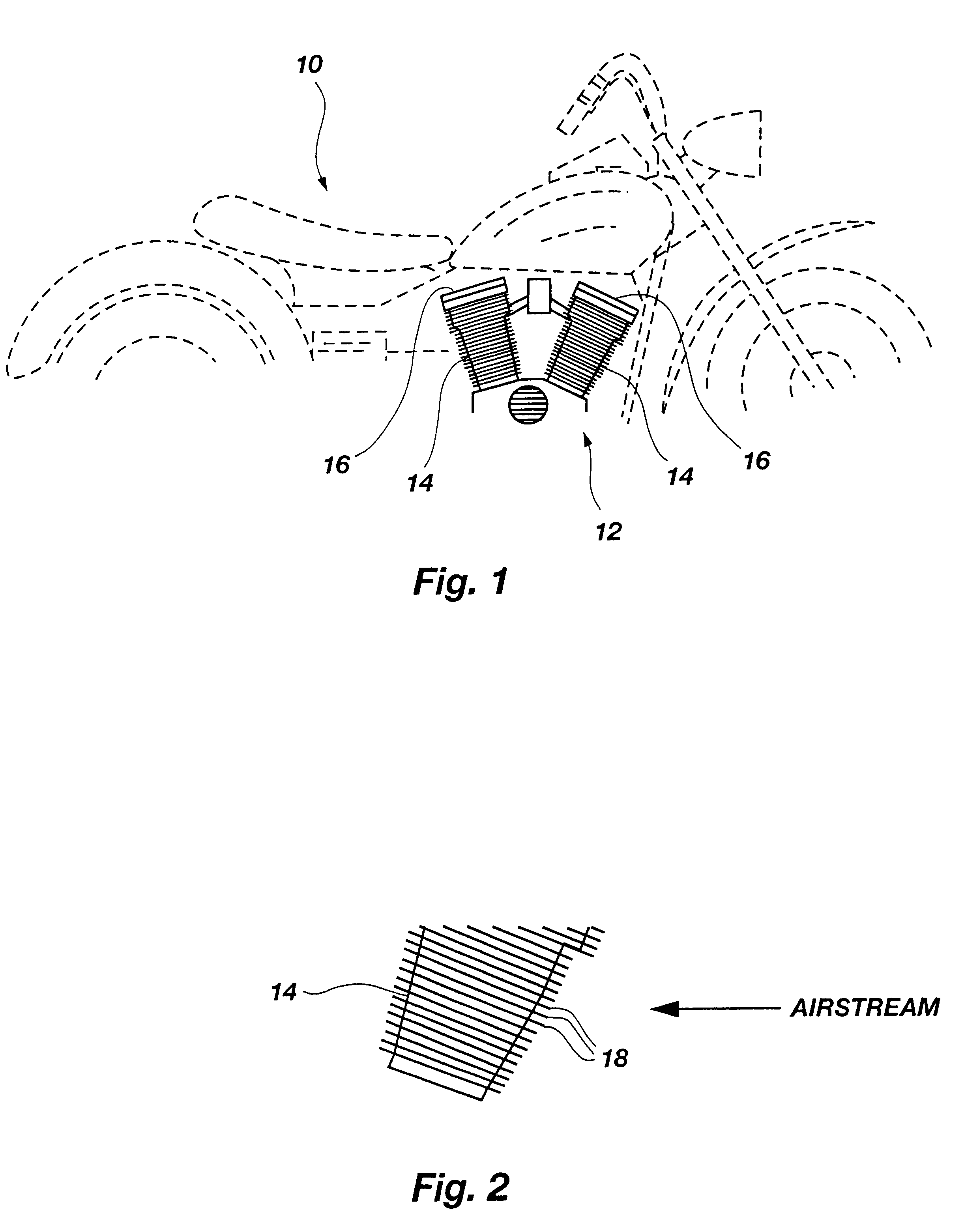

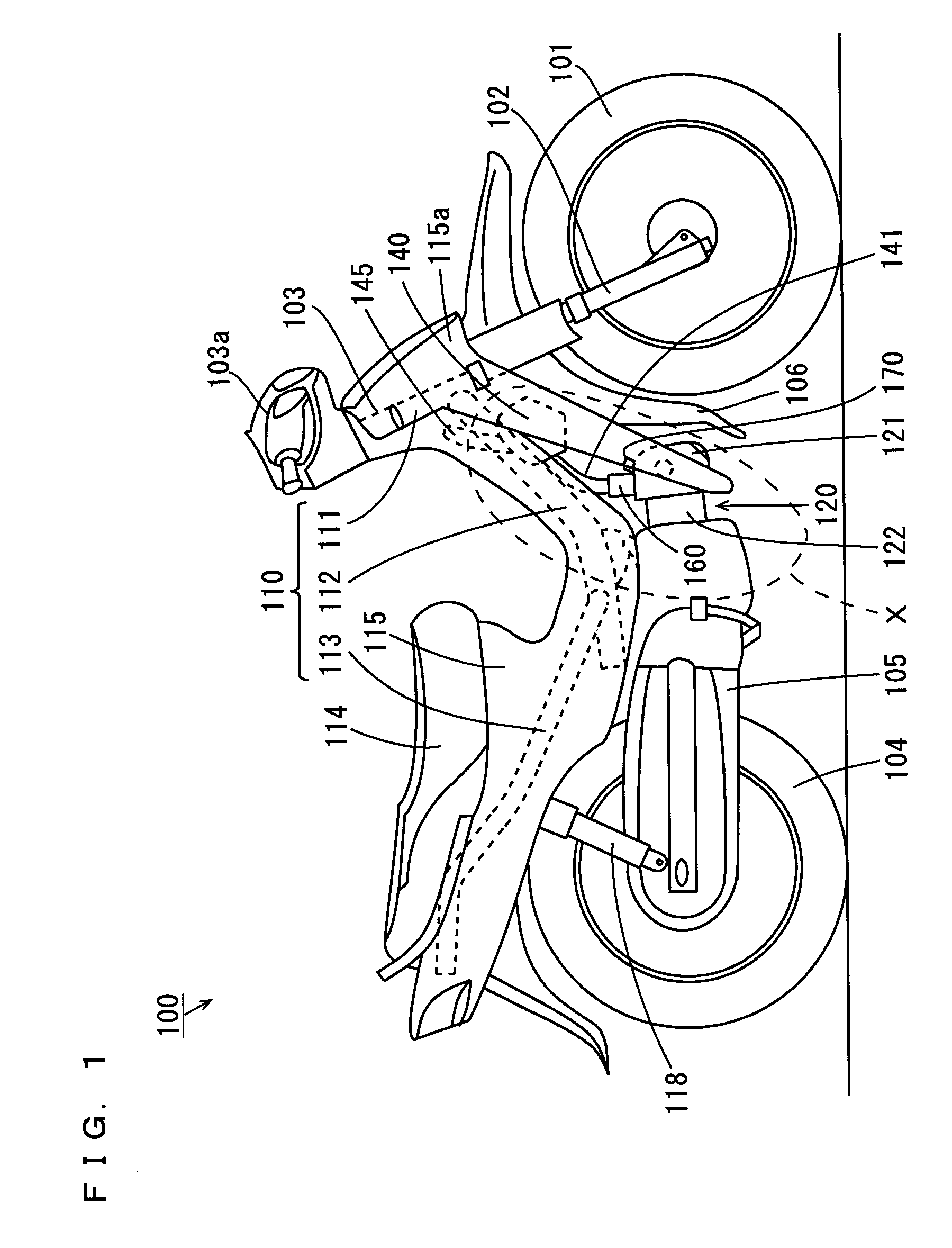

Motorcycle with a blower for engine cooling

A motorcycle has a frame with a front and rear portion. A steering assembly is connected to the front portion, and a rear wheel is connected to the rear portion. The motorcycle includes a drive train with an air cooled engine and a transmission. The engine has a front end and a rear end, as well as a left side and a right side. The engine sides are substantially exposed, such that the engine is substantially visible when the motorcycle is viewed from the side. The motorcycle also includes a blower with an air discharge directed towards one of the front or rear ends of the engine, where the blower aid in cooling the engine.

Owner:NU TEC INVENTIONS

Engine cooling system and method for making same

InactiveUS6626134B1Transfer heat to the environment more efficientlyImprove cooling effectLiquid coolingAir coolingMobile vehicleEdge surface

Engine cooling system and method for making same wherein an engine, engine casing, or component thereof or a component related thereto has at least one cooling fin (18) having at least a portion of an edge surface (32) including an engraved, or intagliated portion (40). Preferably the surface edge includes a plurality of intagliated portions (40) with each portion including at least two elongated concavities being in preselected orientation and relationship to each other to improve the cooling efficiency of the fin and thus allow the engine to operate in wider, more extreme range of temperature and environments. The present invention is particularly well suited, but not limited to air-cooled engines and related components such as component covers, inspection / access covers, and oil coolers and is therefore readily adaptable to engines used to propel motor vehicles such as, but not limited to, motorcycles.

Owner:DIAMOND HEADS

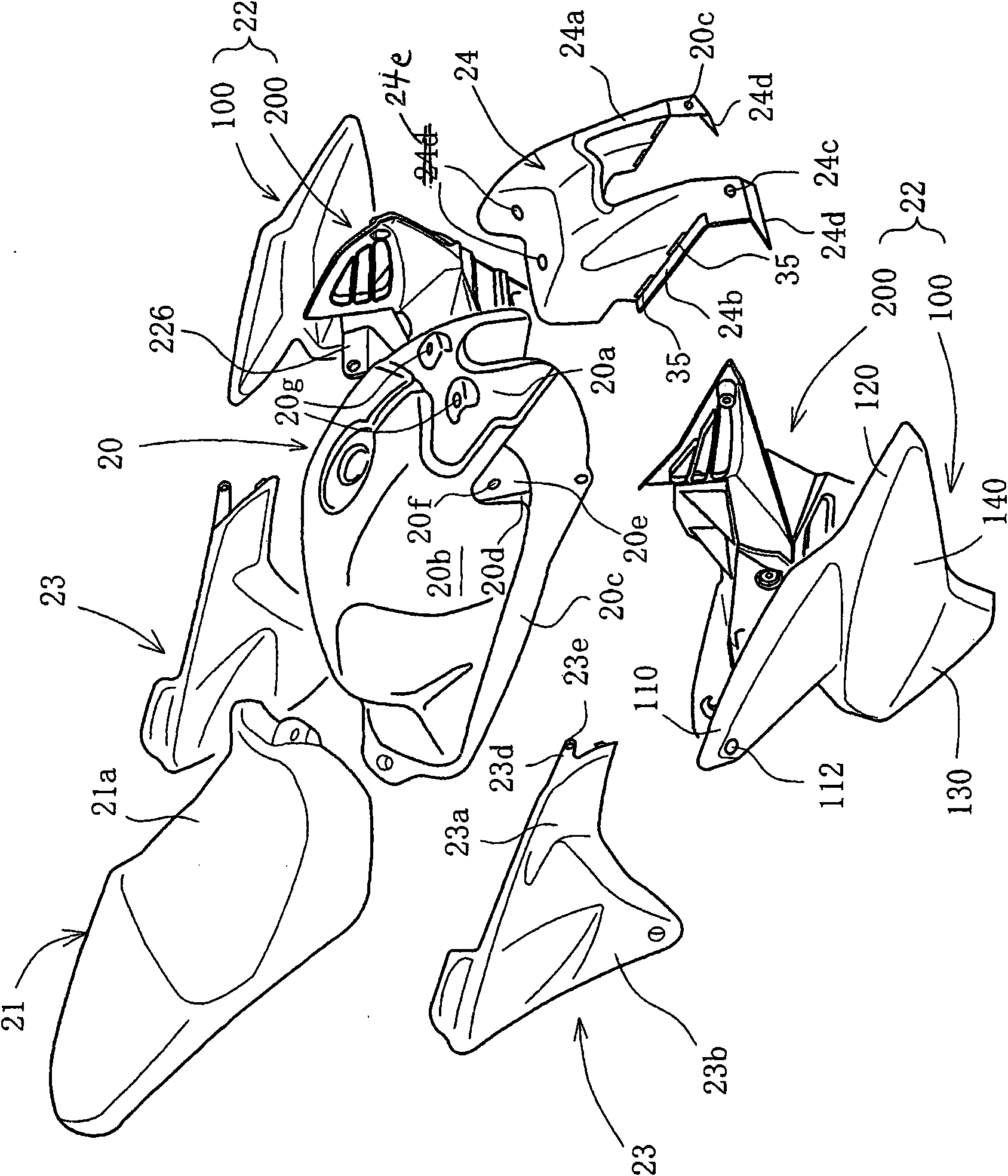

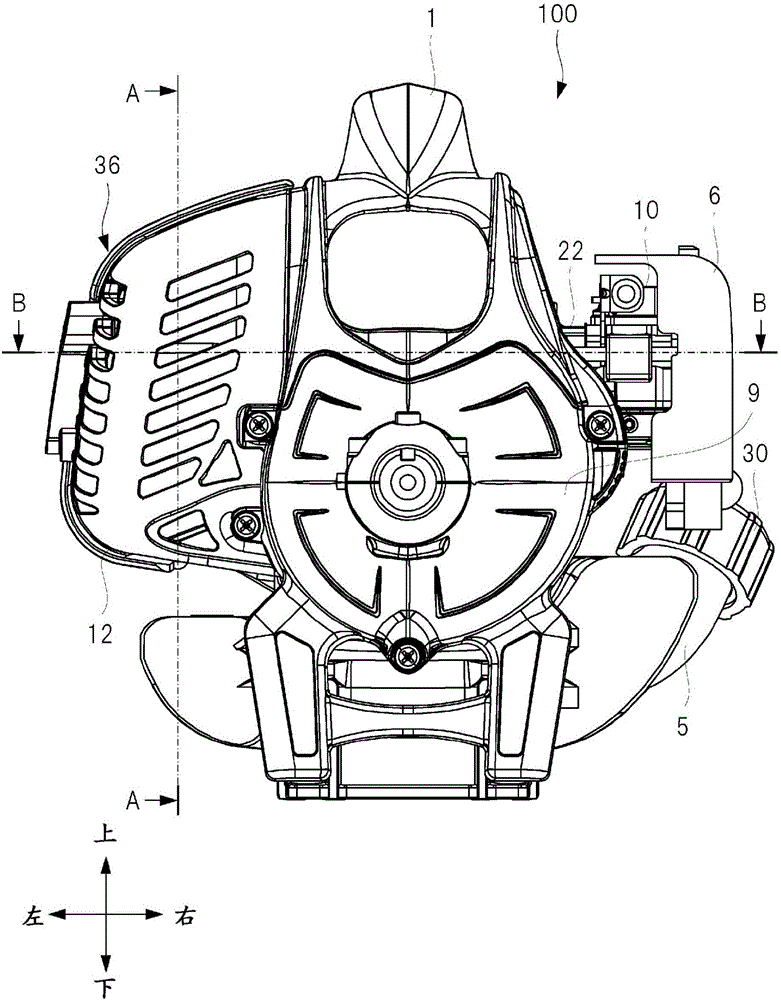

Air guide structure of motorcycle

The invention provides an air guide structure of a motorcycle. Running air is divided into air towards a driver and air for cooling an engine in a simple structure by a shield. An outer shield (100) and an inner shield (200) form a shield (22) for covering each front lateral surface of a fuel tank (20) and a cylinder (5). The inner shield (200) is provided with a first air guide part (210) on theupper part and a second air guide part (240) on the lower part, and each air guide part receives the running air. The running air is received in a first ventilation passage between the outer shield (100) and the inner shield (200) from a first air guide port (210) by the first air guide part (210), is bent towards the oblique upper part to flow to the rear part, flows out of the rear part from anexhaust outlet, and faces a driver seat (21a) through the lateral surface of the fuel tank (20). The lower part of the shield (22) is provided with a second ventilation passage which bends the running air received to the second air guide passage from an air guide port (242) of a second ventilation part (24) to the oblique rear part and the lower part, and the running air flows to the lateral surface of the cylinder (5) of an air-cooled engine to perform cooling.

Owner:HONDA MOTOR CO LTD

Multi-blade fan for air-cooled engine

Owner:HONDA MOTOR CO LTD

Vertical silent generator set

InactiveCN103032159AImprove cooling effectImprove noise reductionMachines/enginesEngine cooling apparatusEngineeringHeat sink

The invention belongs to the technical field of generator sets and particularly discloses a vertical silent generator set. The vertical silent generator set comprises a silent cabinet, an air cooled engine and a generator, wherein the air cooled engine and the generator are arranged in the silent cabinet; the air cooled engine is dynamically connected with the generator through a main shaft on the air cooled engine. The vertical silent generator set is characterized in that the air cooled engine and the generator are respectively located in an upper cavity and a lower cavity in the silent cabinet, and moreover, the air cooled engine and the generator are respectively and vertically arranged; positions on the silent cabinet, which respectively correspond to cooling fins of the air cooled engine, are respectively provided with a first cooling air inlet; a position on the silent cabinet, which corresponds to a fan of the air cooled engine, is provided with a first heat dissipation air inlet; a position on the silent cabinet, which corresponds to the bottom part of the generator, is provided with a second cooling air inlet; and positions on the silent cabinet, which respectively correspond to turbo fans of the generator, are respectively provided with a second heat dissipation air inlet. The vertical silent generator set disclosed by the invention is simple in structure, and on the premise that the cost is reduced, the heat dissipation effect of the whole generator set is improved, and meanwhile, the installation space is saved.

Owner:CHONGQING PANDA MACHINERY

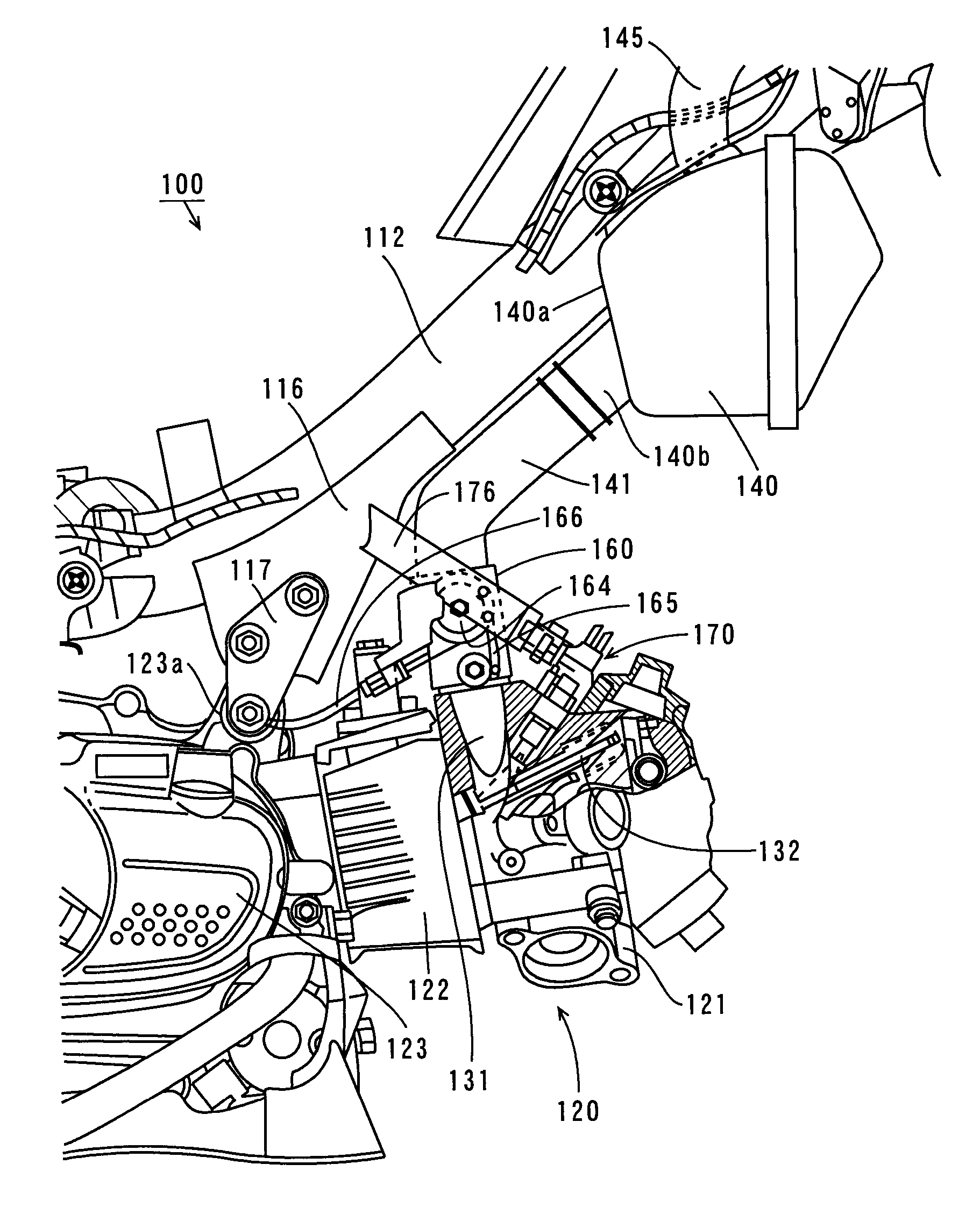

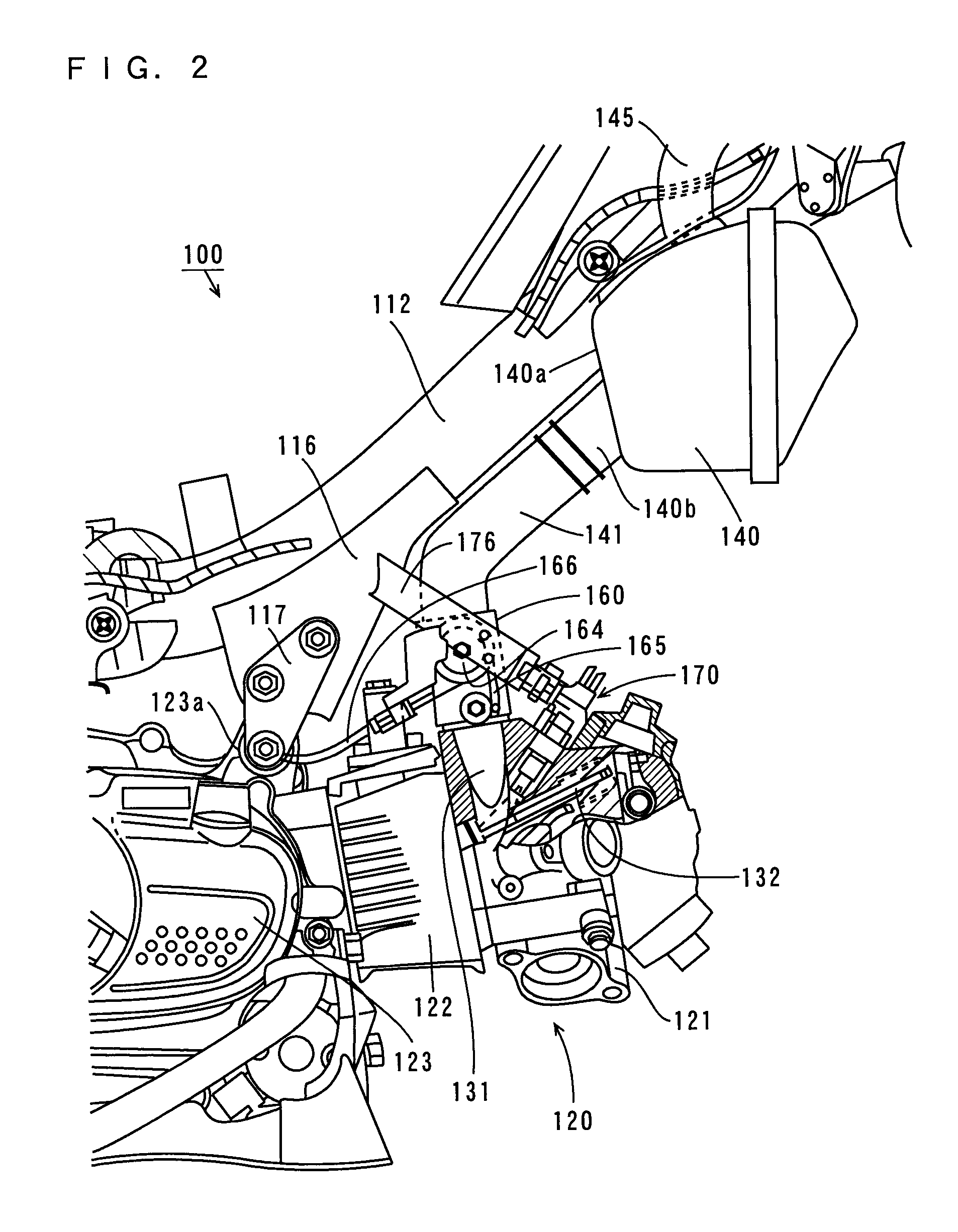

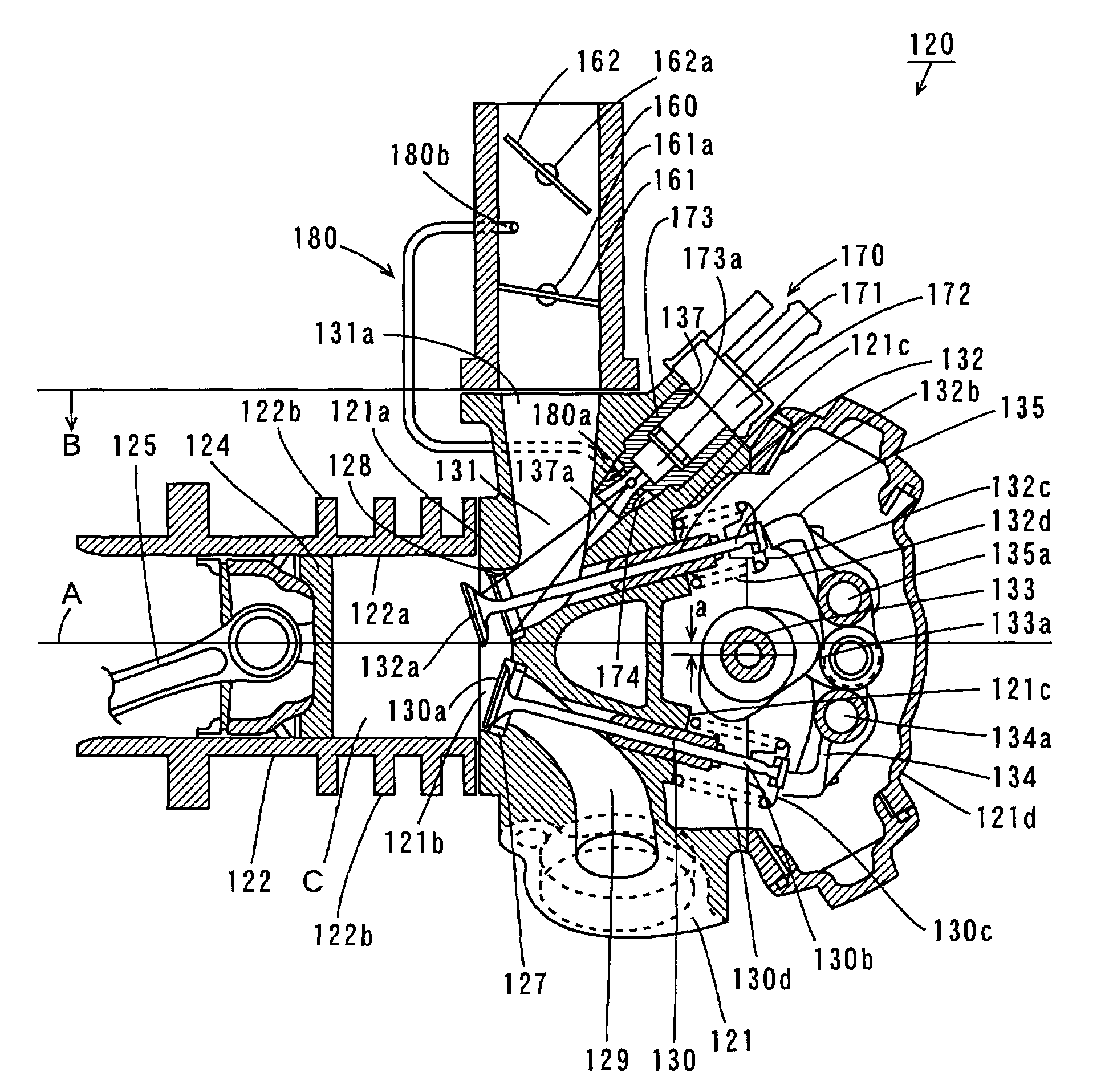

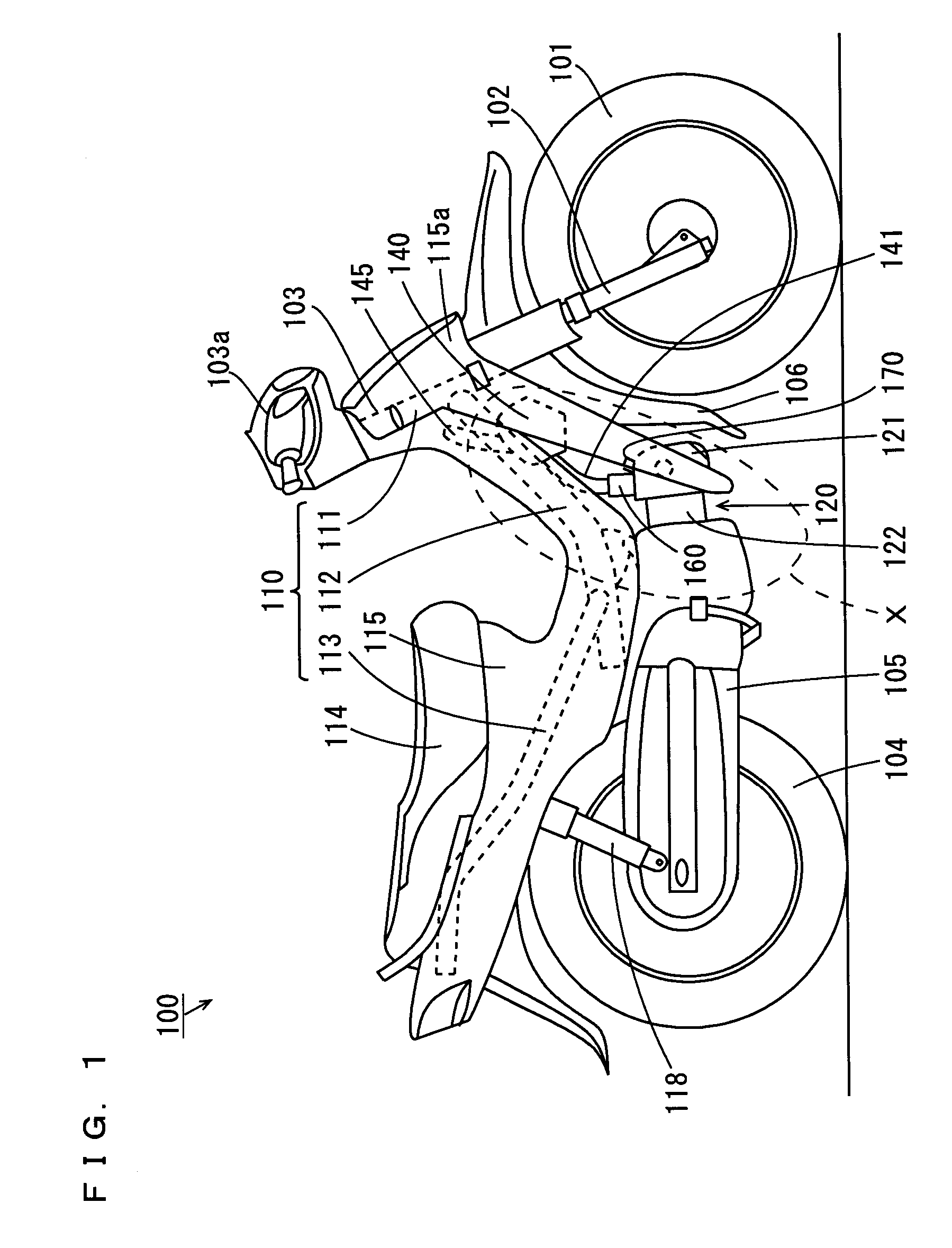

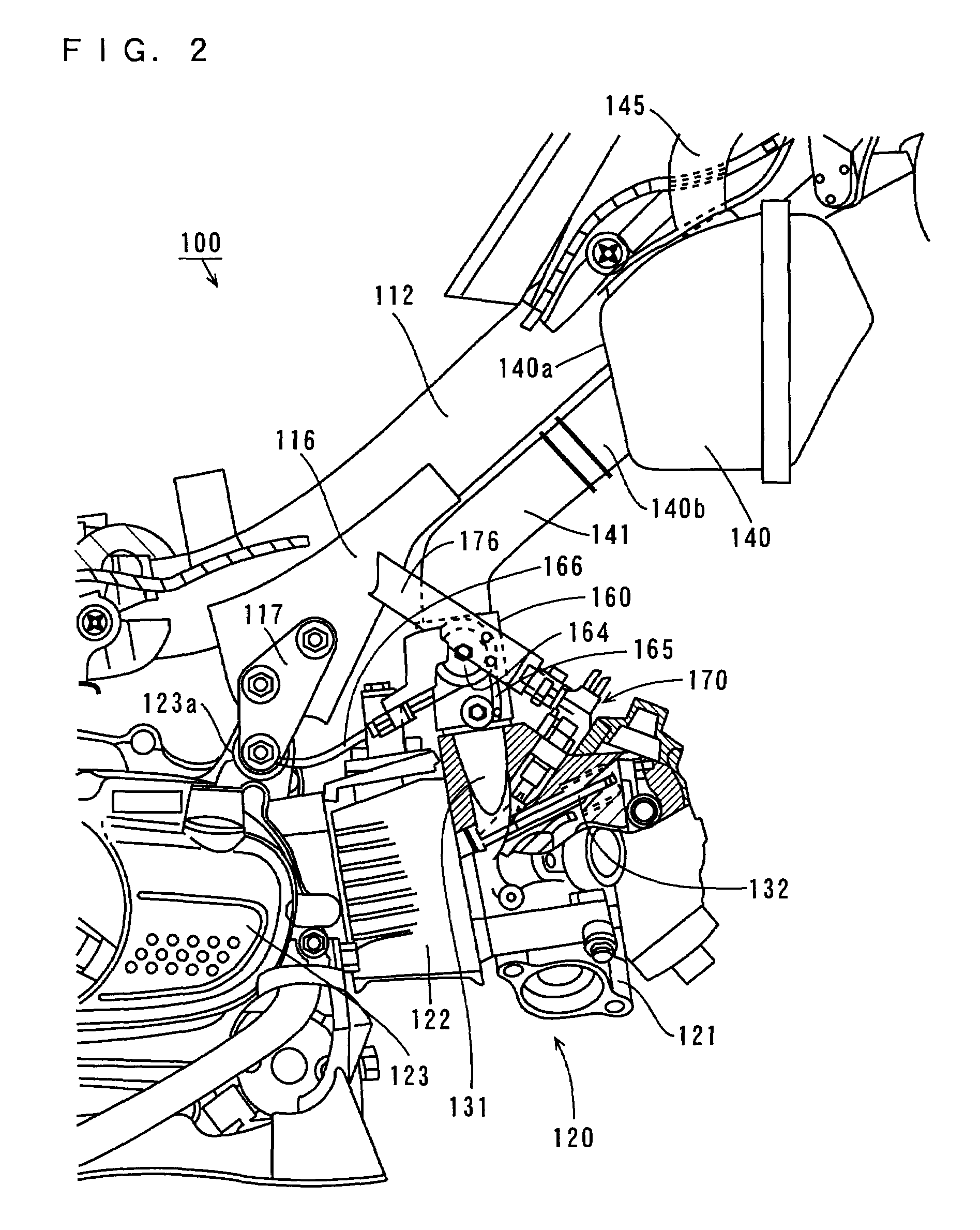

Saddle-straddling type motor vehicle

InactiveUS20070175688A1Simple structureLow costInternal combustion piston enginesMotorised scootersLow speedShortest distance

An air-cooled engine is hung and fixed under a rear part of a backbone of a body frame. The engine is disposed so that the center axis of a cylinder in its cylinder block extends approximately horizontally and so that its cylinder head is directed toward the front. A fuel injection device is located between an intake valve and an intake port in the cylinder head. An injection nozzle of the fuel injection device and an intake valve opening are placed at a short distance. While the vehicle is idling or running at low speed, the vicinity of the tip of an injector of the fuel injection device is cooled by assist air supplied from a throttle body through a secondary passage, and when the vehicle runs normally or at high speed, the fuel injection device is cooled by the wind that hits the cylinder head.

Owner:YAMAHA MOTOR CO LTD

Saddle-straddling type motor vehicle

InactiveUS7302934B2Simple structureLow costInternal combustion piston enginesMotorised scootersVehicle frameLow speed

An air-cooled engine is hung and fixed under a rear part of a backbone of a body frame. The engine is disposed so that the center axis of a cylinder in its cylinder block extends approximately horizontally and so that its cylinder head is directed toward the front. A fuel injection device is located between an intake valve and an intake port in the cylinder head. An injection nozzle of the fuel injection device and an intake valve opening are placed at a short distance. While the vehicle is idling or running at low speed, the vicinity of the tip of an injector of the fuel injection device is cooled by assist air supplied from a throttle body through a secondary passage, and when the vehicle runs normally or at high speed, the fuel injection device is cooled by the wind that hits the cylinder head.

Owner:YAMAHA MOTOR CO LTD

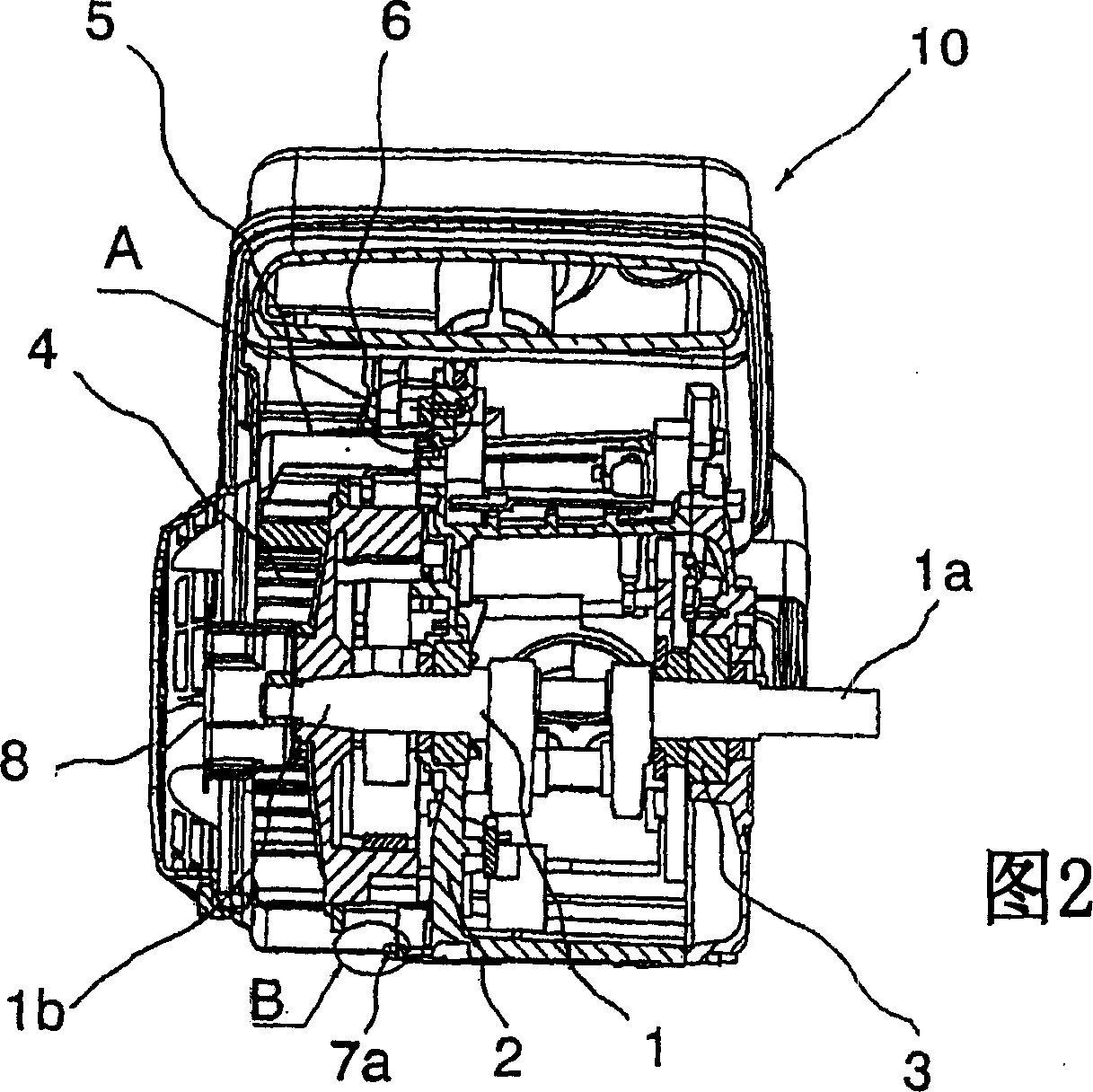

Engine

InactiveUS20080105220A1Improve cooling efficiencyMinimized increaseCoolant flow controlInternal combustion piston enginesExhaust valveInlet valve

The purpose of the present invention is to improve cooling efficiency of a cylinder head of an air-cooled engine.With regard to the construction that a cooling fan is provided at one of ends of a crankshaft, and cooling air from the cooling fan is guided to a cylinder head 4 so as to cool the cylinder head 4, an intake manifold 8 is arranged above the cooling fan, a duct 51 is provided at the lateral center of the intake manifold 8 so as to suck air from an air cleaner, cooling air is sent from both sides of the duct 51 to an intake valve, an exhaust valve and an injection nozzle arranged in the cylinder head 4, and a shielding plate 55 is provided at one of lateral sides of the duct 51.

Owner:YANMAR POWER TECHNOLOGY CO LTD

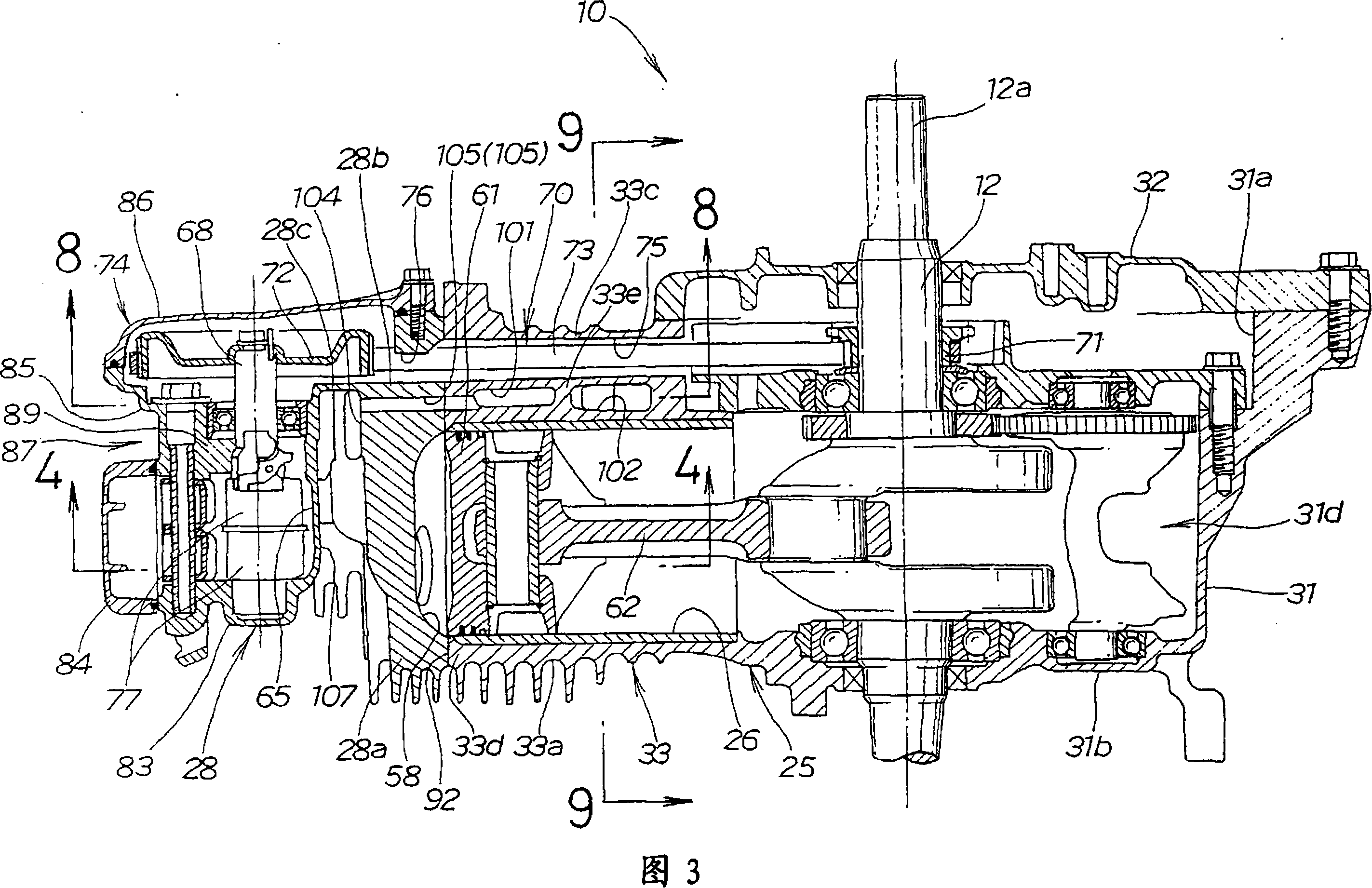

Air-cooled engine

There is provided an air-cooled engine (10) that is cooled by cooling air. The air-cooled engine (10) comprises a cylinder block (33), and a cylinder head (28) that closes off one end of a cylinder (26). The cylinder head (28) includes a base part (81) that is superposed on and secured to the cylinder block (33) by a plurality of bolts (91), and a valve compartment (83) formed integrally on the base part (81). All of the bolts (91) are disposed near the outer periphery of the base part (81) at positions outside of the valve compartment (83).

Owner:HONDA MOTOR CO LTD

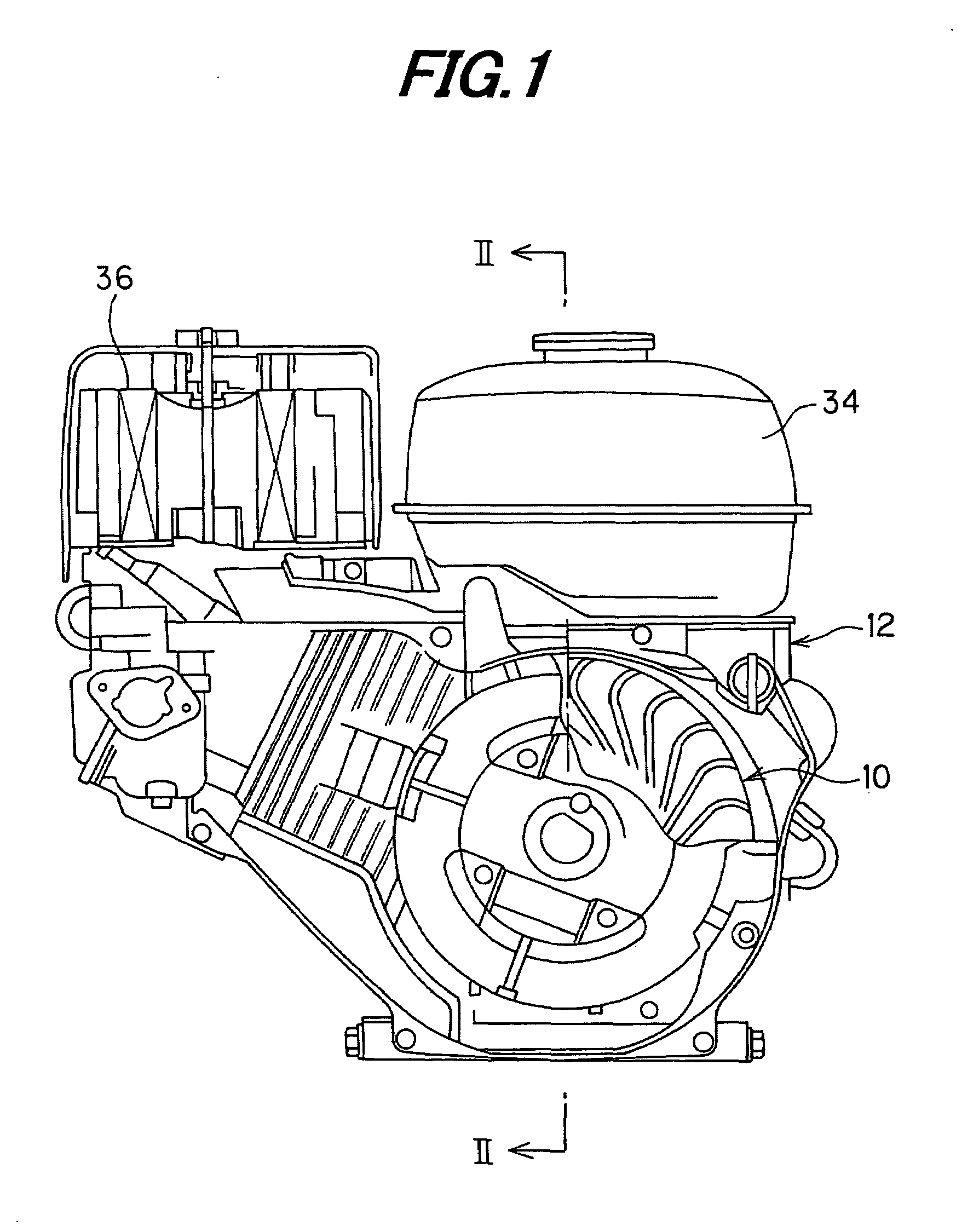

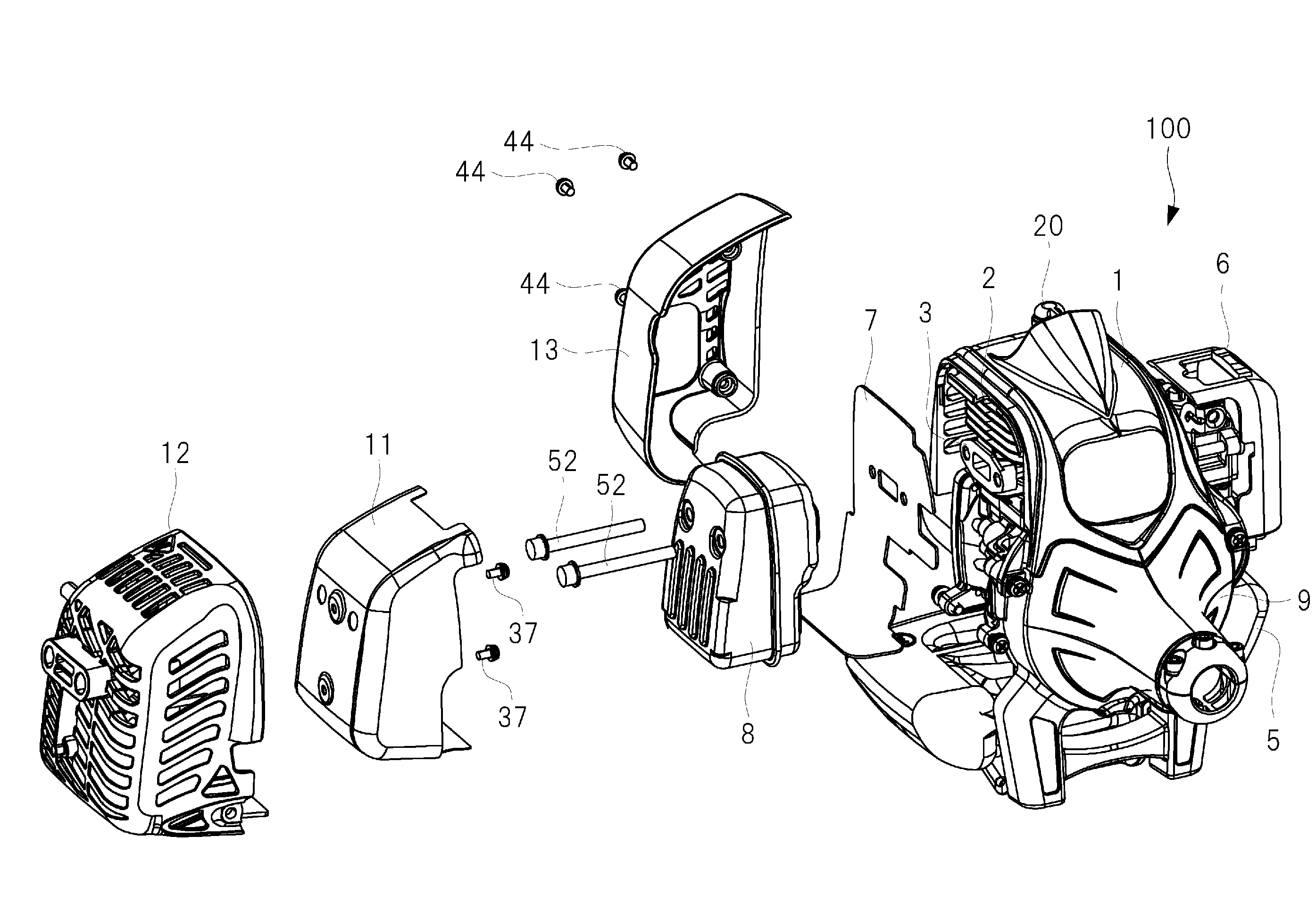

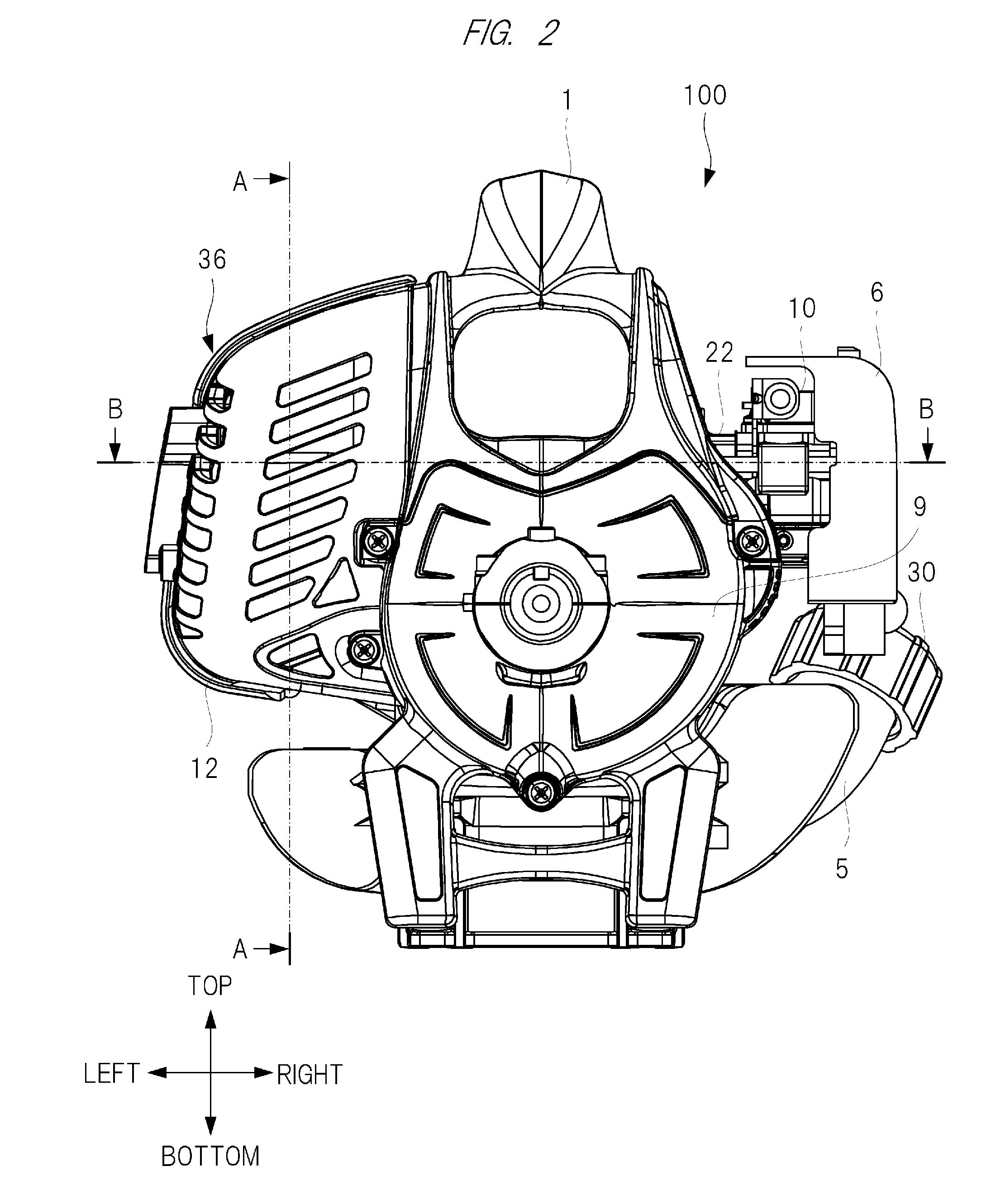

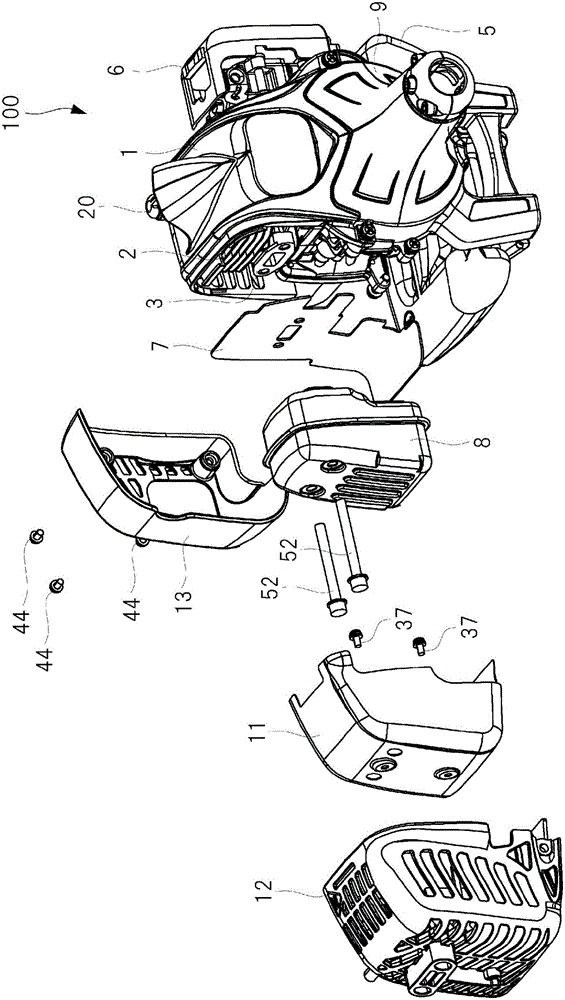

Air-cooled engine and engine working machine

An air-cooled engine includes a muffler that is attached to an exhaust port of a cylinder and a fan case that houses a cooling fan, and a cylinder cooling room is formed by a cylinder cover that houses the cylinder. A muffler cooling room is formed by a first muffler cover that covers at least some of the muffler through a clearance and a second muffler cover that covers at least some of the first muffler cover through a clearance. Some of cooling air generated by the cooling fan is supplied to the muffler cooling room. The cooling air is supplied to at least one of a first space between the muffler and the first muffler cover and a second space between the first muffler cover and the second muffler cover.

Owner:KOKI HLDG CO LTD

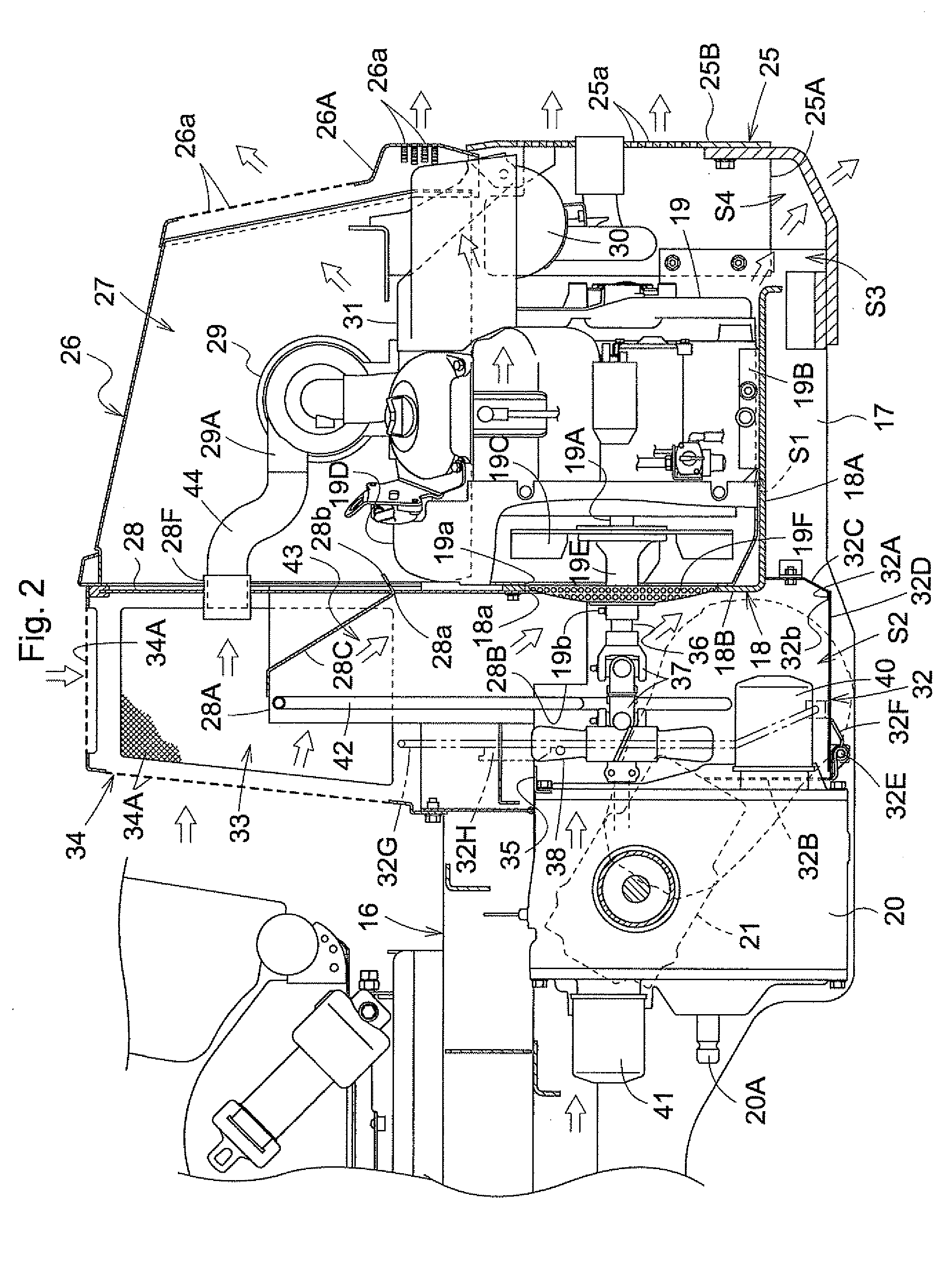

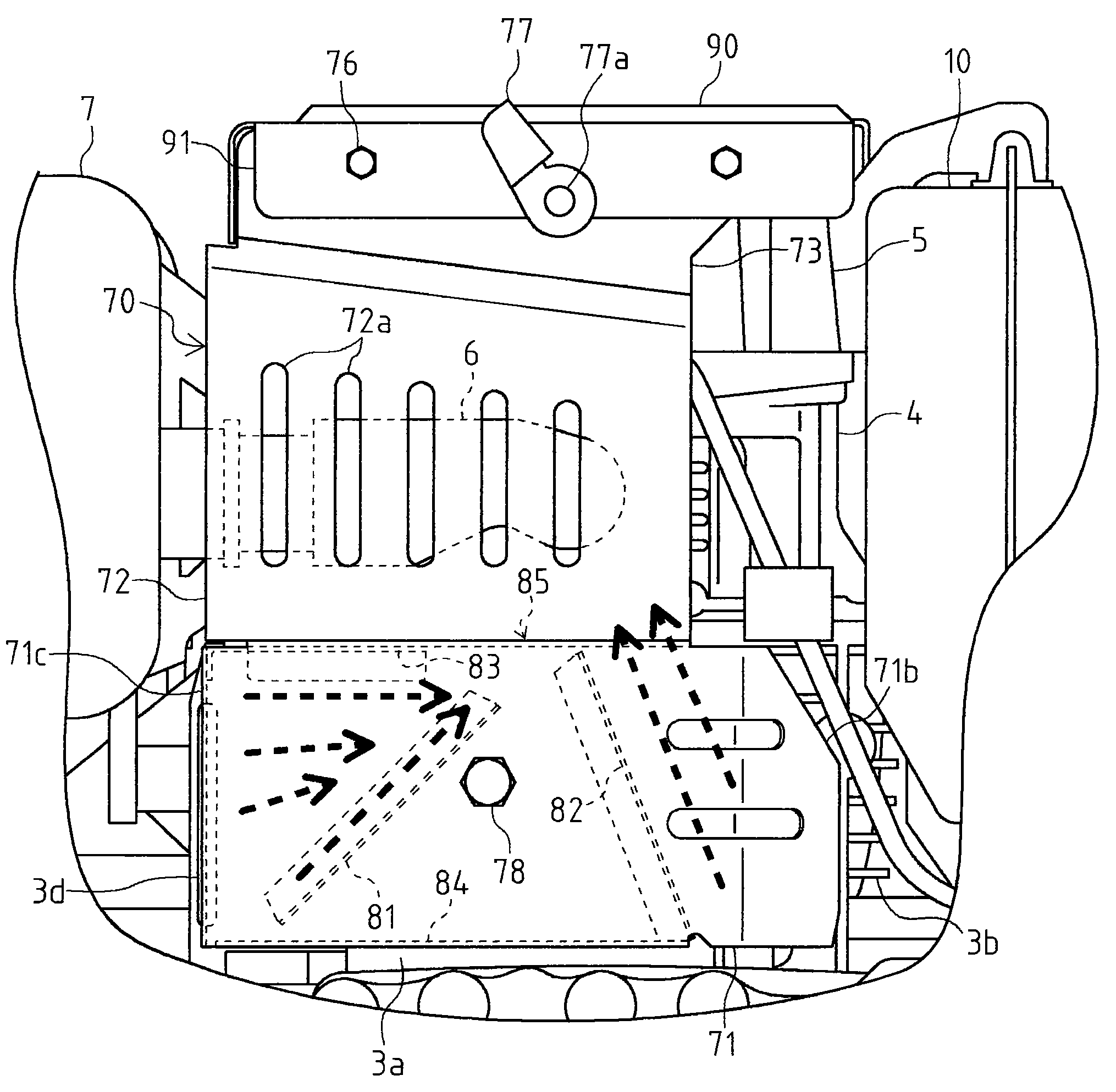

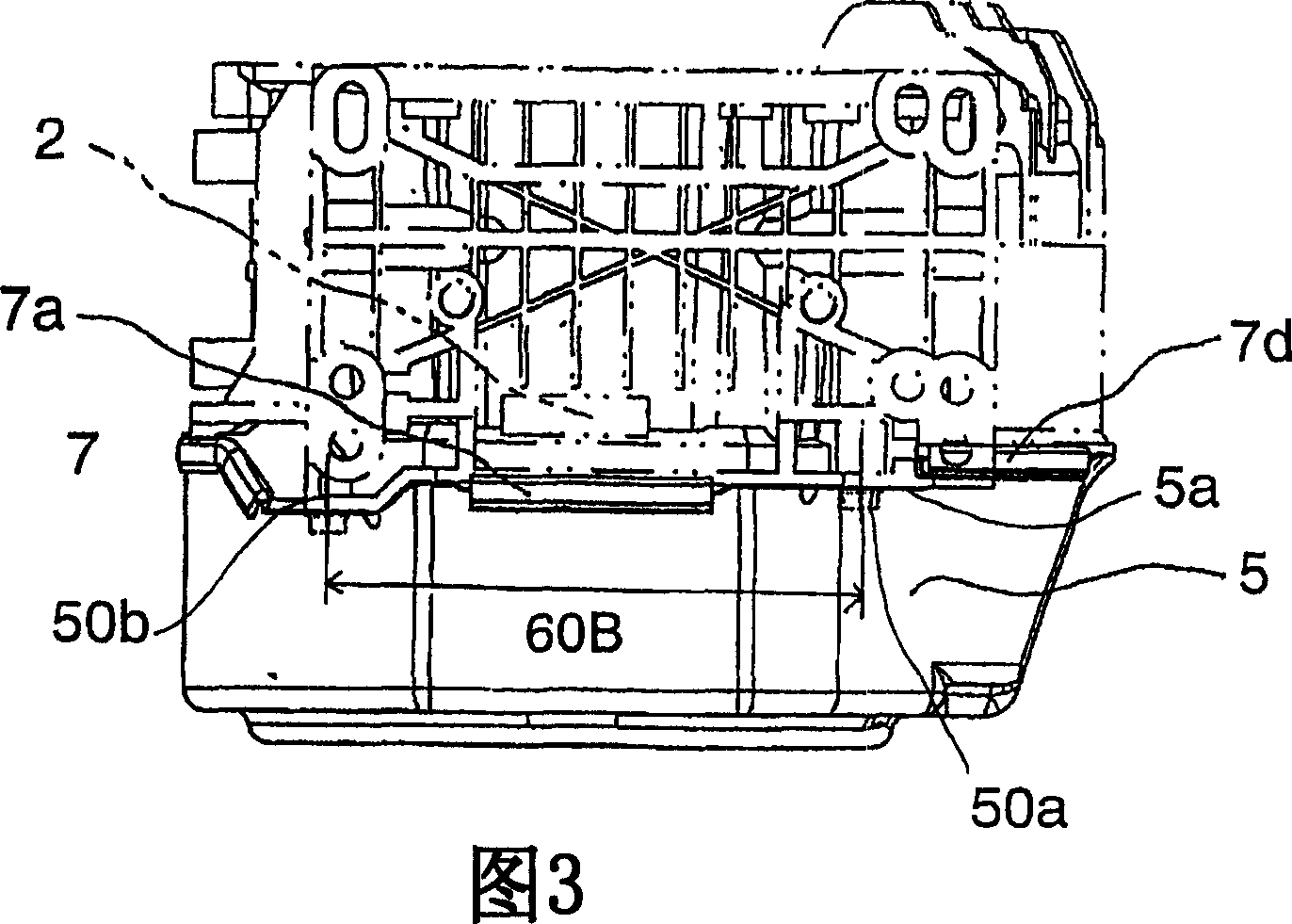

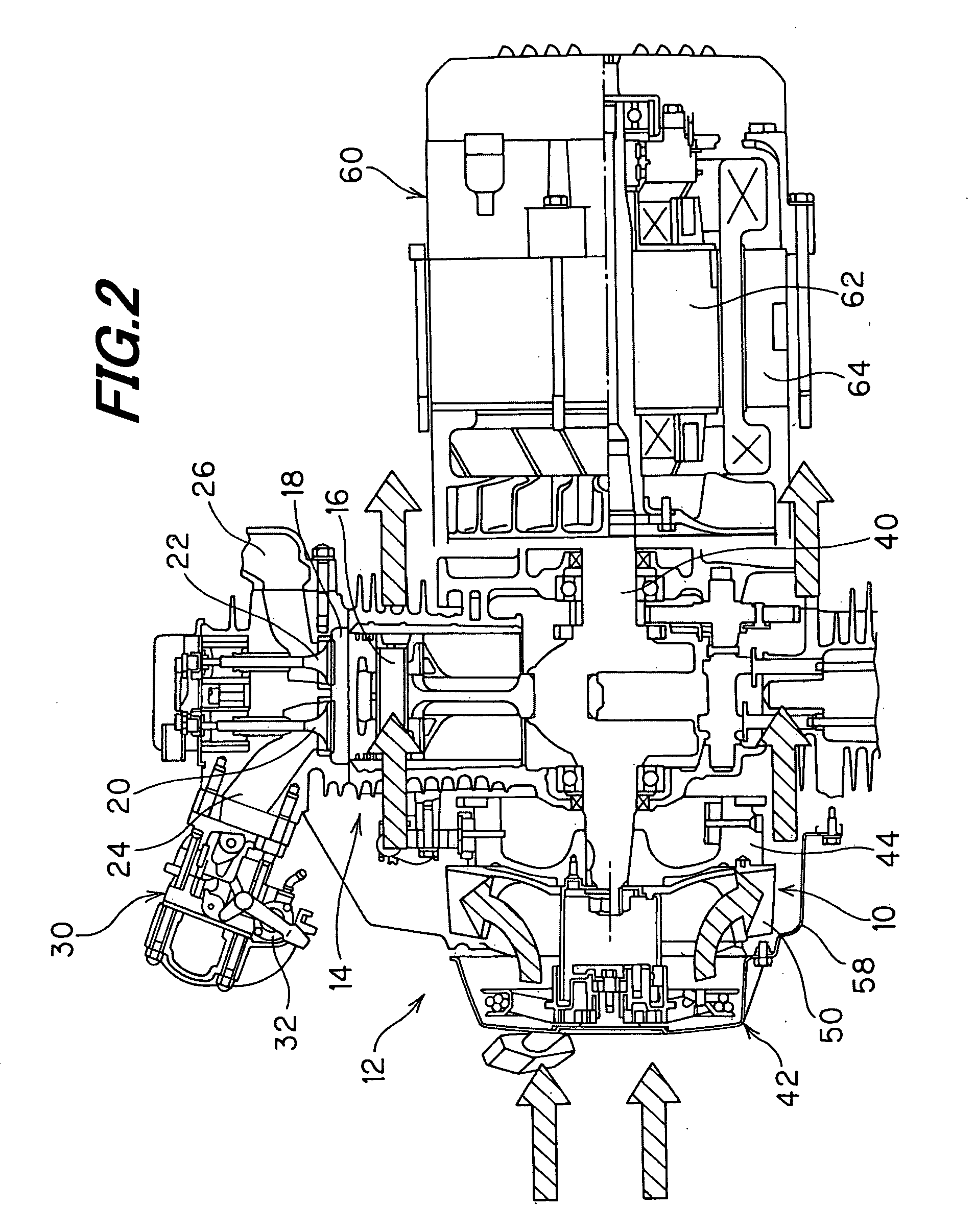

Cooling Structure for a Work Vehicle

ActiveUS20090013942A1Increasing sizeIncreasing costCoolant flow controlAir coolingAir-cooled engineCooling fluid

A cooling structure for a working vehicle with a transmission disposed rearwardly and downwardly of a driver's seat and having a hydrostatic transmission, and an air-cooled engine disposed rearwardly of the transmission. The cooling structure comprising a fan for cooling the engine and a fan for cooling the transmission mounted on a rotary shaft operatively connecting the transmission with an output shaft of the air-cooled engine, the fans being configured such that air flows generated by the fans move from adjacent the transmission toward the engine; an oil cooler for cooling fluid supplied to the hydrostatic transmission, the oil cooler being disposed between the fan for cooling the engine and the fan for cooling the transmission, and disposed to face each of the fans; and an air guiding plate disposed at a position higher than the oil cooler for guiding air to regions of the fans.

Owner:KUBOTA LTD

Oil cooling system of an air-cooled engine

InactiveUS7261080B2Desirable cooling performanceSimple structureMachines/enginesLubricant mounting/connectionBiochemical engineeringCrankcase

An oil cooling system of an air-cooled engine for cooling the oil reserved in a crankcase of the engine comprises a base plate assembled to the crankcase, an overlapping plate assembled to the base plate; an oil filter supported in the overlapping plate; and radiation fins formed on the base plate and the overlapping plate, wherein the base plate includes an inlet port for receiving the engine oil discharged from an oil pump of the engine, an outlet groove for outputting the engine oil and a first passage groove connecting the inlet port and the outlet groove, the overlapping plate includes an inlet groove opposed to the inlet port, an outlet port opposed to the outlet groove and a second passage groove opposed to the first passage groove to form an oil passage together with the first passage groove, and the base plate and the overlapping plate having through-holes where the filter outlet of the oil filter passes through for the connection with the crankcase.

Owner:SUBARU CORP

Vehicle fuel supply construction

InactiveUS20050263141A1Suppress generation of vaporReduce thermal effectsUnderstructuresMachines/enginesFuel tankAir-cooled engine

A throttle body 12 is connected to a rear portion of a cylinder head 10 of an air-cooled engine 5, and a fuel pump 23 is disposed in front of the engine 5. The fuel pump 23 is such as to be disposed below a fuel tank 6 in such a manner as to be separated therefrom and to be integrated with an auxiliary tank. Fuel is sent under pressure from the fuel pump 23 to the throttle body 12 via a fuel feed tube 13, and surplus fuel is returned to the integrated auxiliary tank, consequently, no piping for return fuel being required. Vapor generated in the fuel pump 23 returns to a space above a fuel level resulting when the fuel tank 6 is filled up via an exclusive return tube 25 and is, therefore, prevented from mixing into fuel.

Owner:HONDA MOTOR CO LTD

General purpose engine

ActiveUS20170159600A1Reduce the number of partsIncrease of blow workabilityAir coolingHarvestersGeneral purposeEngineering

A general purpose engine with a cleaning access window defined therein is in the form of an air cooled engine, having a cylinder unit made up of a cylinder and a cylinder head, and includes a housing for covering at least the cylinder unit and a cleaner covering removably fitted to the housing for covering the filter section of the air cleaner, the housing being formed with a blow window so as to confront gaps between a plurality of cooling fins provided in the cylinder unit, and the cleaner covering has a closing section defined therein for covering the blow window.

Owner:KAWASAKI MOTORS LTD

Engine

InactiveUS7694655B2Improve cooling efficiencyIncrease volumeCoolant flow controlInternal combustion piston enginesExhaust valveInlet valve

The purpose of the present invention is to improve cooling efficiency of a cylinder head of an air-cooled engine. With regard to the construction that a cooling fan is provided at one of ends of a crankshaft, and cooling air from the cooling fan is guided to a cylinder head 4 so as to cool the cylinder head 4, an intake manifold 8 is arranged above the cooling fan, a duct 51 is provided at the lateral center of the intake manifold 8 so as to suck air from an air cleaner, cooling air is sent from both sides of the duct 51 to an intake valve, an exhaust valve and an injection nozzle arranged in the cylinder head 4, and a shielding plate 55 is provided at one of lateral sides of the duct 51.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Vehicle fuel supply construction

InactiveUS7287518B2Suppress generationEliminate the effects ofUnderstructuresMachines/enginesFuel tankAir-cooled engine

A throttle body is connected to a rear portion of a cylinder head of an air-cooled engine, and a fuel pump is disposed in front of the engine. The fuel pump is such as to be disposed below a fuel tank 6 such a manner as to be separated therefrom and to be integrated with an auxiliary tank. Fuel is sent under pressure from the fuel pump to the throttle body via a fuel feed tube, and surplus fuel is returned to the integrated auxiliary tank, consequently, no piping for return fuel being required. Vapor generated in the fuel 23 returns to a space above a fuel level resulting when the fuel tank 6 is filled up via an exclusive return tube and is, therefore, prevented from mixing into fuel.

Owner:HONDA MOTOR CO LTD

Forced-air-cooled engine with cooling air guide cover

ActiveCN1975121AEasy to installPrevent leakageCasingsNon-rotating vibration suppressionVibration controlBand shape

The invention provides a method and construction of vibration control supporting a cooling fan cover. In a forcer-air-cooled engine having a cooling fan cover fixed directly by means of fixing bolts to the cylinder block at fixing foot parts provided at a peripheral border of the fan cover, band-like vibration damping members are disposed between the peripheral border of the fan cover and the cylinder block in each region of the peripheral border belonging to each sector part defined between two adjacent fixing points of two adjacent fixing foot parts among said plurality of fixing foot parts respectively so that each of said damping members is pressed against the cylinder block by each region of the peripheral border when the bolts are tightened, said band-like damper members are flexible damping members each of which is disposed in an essential part of loop of vibration of the periphery for preventing generation of noise due to vibration of the fan cover with the fixing points as nodes of vibration resonating to cylinder block vibration, and said band-like flexible vibration damping members are adjusted thereby to adjust elastic force and damping capacity of the damping members so that resonance of the fan cover occurs at a rotation speed of engine higher than normal rotation speed thereof.

Owner:MITSUBISHI HEAVY IND MEIKI ENGINES CO LTD

Engine combined-cooling system on small single-rotor-wing unmanned helicopter

PendingCN105422304AStable jobExtended service lifeCylinder headsSealing arrangements for enginesWater storage tankPropeller

The invention discloses an engine combined-cooling system on a small single-rotor-wing unmanned helicopter. The engine combined-cooling system comprises a cylinder A, a water cooled jacket A, a cylinder B, a water cooled jacket B, a water cooling evaporator, a water storage tank and a water pump. When a double-cylinder-oppositely-arranged type air cooled engine works, cooling water enters an annular water cavity A through a water inlet connector of the water cooled jacket A, absorbs heat of the cylinder A and is then drained out through a water outlet connector of the water cooled jacket A; the drained cooling water enters an annular water cavity B through a pipe and a water inlet connector of the water cooled jacket B, absorbs heat of the cylinder B, is then drained out through a water outlet connector of the water cooled jacket B, enters the water cooling evaporator through a pipe and is forcedly cooled through wind generated by a propeller and wind generated by flight; and the cooled water then enters the annular water cavity A through a hose, the water storage tank, a hose, the water pump, a hose and the water inlet connector of the water cooled jacket A in sequence and circulates according to the above path.

Owner:衡阳云雁航空科技有限公司

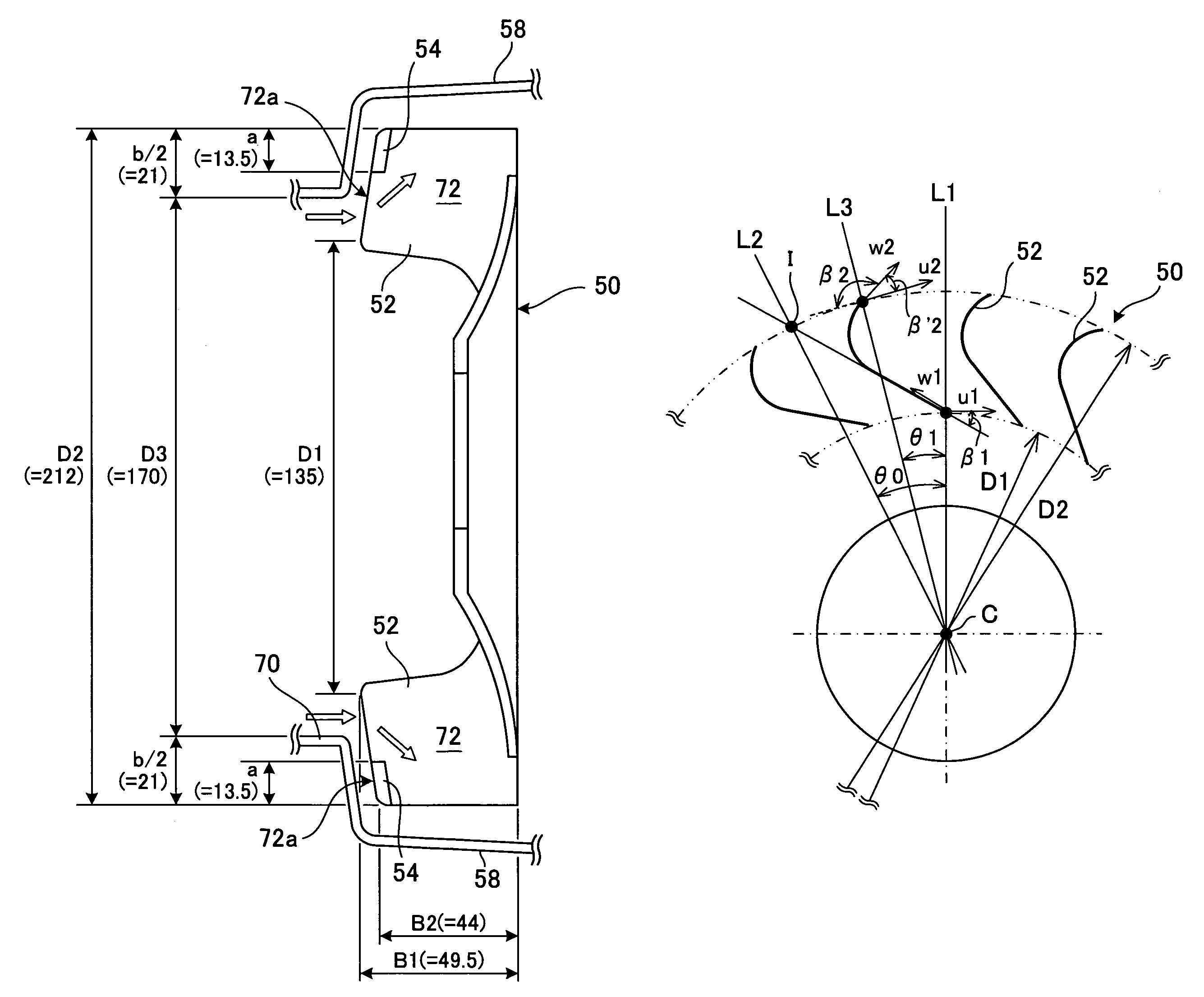

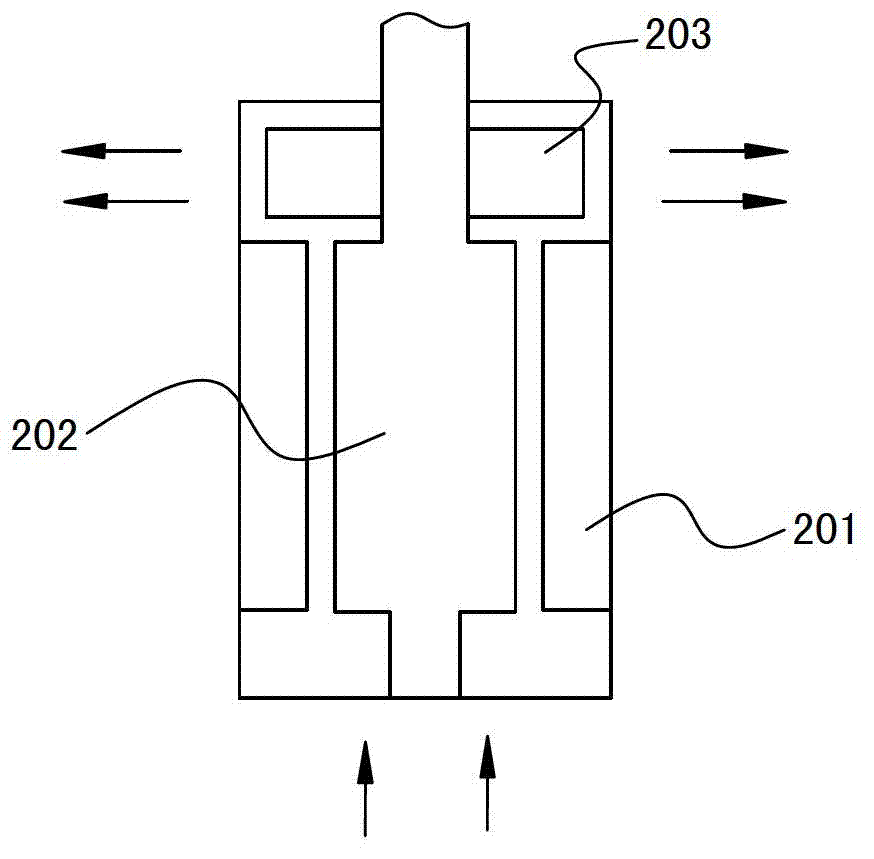

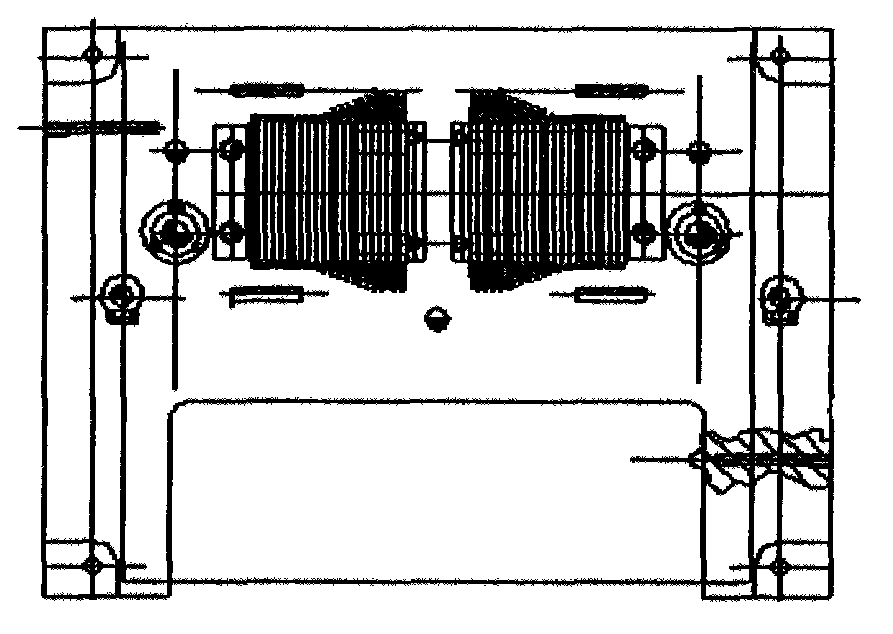

Multi-blade fan for air-cooled engine

In a multi-blade fan for an air-cooled engine, by defining the inlet angle β1 and the angle β′2 to make the sum thereof less than 80° (preferably defining β1 as 32° and β′2 as 36°), the multi-blade fan achieves greater air volume than in the case where the sum is made 80° or greater, where β1 is the angle between the relative velocity direction and the peripheral direction on the inlet side of the blades,β2 is the angle between the relative velocity direction and the peripheral direction on the outlet side of the blades, and β′2 is the difference obtained by subtracting β2 from 180°. The number of blades can therefore be reduced to realize lower noise level while still maintaining the same air volume as the prior art multi-blade fan.

Owner:HONDA MOTOR CO LTD

Casting method of air-cooled engine cylinder

ActiveCN102921900ASimple process planImprove production environmentFoundry mouldsFoundry coresSetting timeAir-cooled engine

The invention discloses a casting method of an air-cooled engine cylinder. The casting method comprises the following steps: processing an inner die casting mould of an air-cooled engine cylinder sleeve; processing an outer die casting mould of the air-cooled engine cylinder sleeve; placing the inner die casting mould into the outer die casting mould, assembling and forming a double-layered mould; pouring metal liquid at 1300-1400 DEG C to the double-layered mould, rotating the double-layered mould along the horizontal axial direction to generate a centrifugal force, so that the metal liquid is fully filled in the double-layered mould; controlling time of adding water and cooling time; when set time of adding the water and the set cooling time are reached, adding the water to cool the double-layered mould; taking out a cooled inner die casting mould; obtaining the air-cooled engine cylinder sleeve. The casting method disclosed by the invention is simple in technique, high in utilization rate of molten iron, good in product quality, and high in yield.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

Engine cooling system and method for making same

InactiveUS20030213441A1Transfer heat to the environment more efficientlyImprove cooling effectAir coolingMachines/enginesEdge surfaceEngineering

Engine cooling system and method for making same wherein an engine, engine casing, or component thereof or a component related thereto has at least one cooling fin (18) having at least a portion of an edge surface (32) including an engraved, or intagliated portion (40). Preferably the surface edge includes a plurality of itagliated portions (40) with each portion including at least two elongated concavities being in preselected orientation and relationship to each other to improve the cooling efficiency of the fin and thus allow the engine to operate in wider, more extreme range of temperatures and environments. The present invention is particularly well suited, but not limited to air-cooled engines and related components such as component covers, inspection / access covers, and oil coolers and is therefore readily adaptable to engines used to propel motor vehicles such as, but not limited to, motorcycles.

Owner:BRINTON KEITH A

Air-cooled engine and engine working machine

ActiveCN106030070AReduce heat damageFree from damageAir coolingExhaust apparatusEngineeringAir-cooled engine

An air-cooled engine includes a muffler (8) that is attached to an exhaust port of a cylinder (2) and a fan case (9) that houses a cooling fan (18), and a cylinder cooling room (34) is formed by a cylinder cover that houses the cylinder (2). A muffler cooling room (35) is formed by a first muffler cover (11) that covers at least some of the muffler (8) through a clearance and a second muffler cover (12) that covers at least some of the first muffler cover (11) through a clearance. Some of cooling air generated by the cooling fan (18) is supplied to the muffler cooling room (35). The cooling air is supplied to at least one of a first space (32A) between the muffler (8) and the first muffler cover (11) and a second space (32B) between the first muffler cover (11) and the second muffler cover (12).

Owner:KOKI HLDG CO LTD

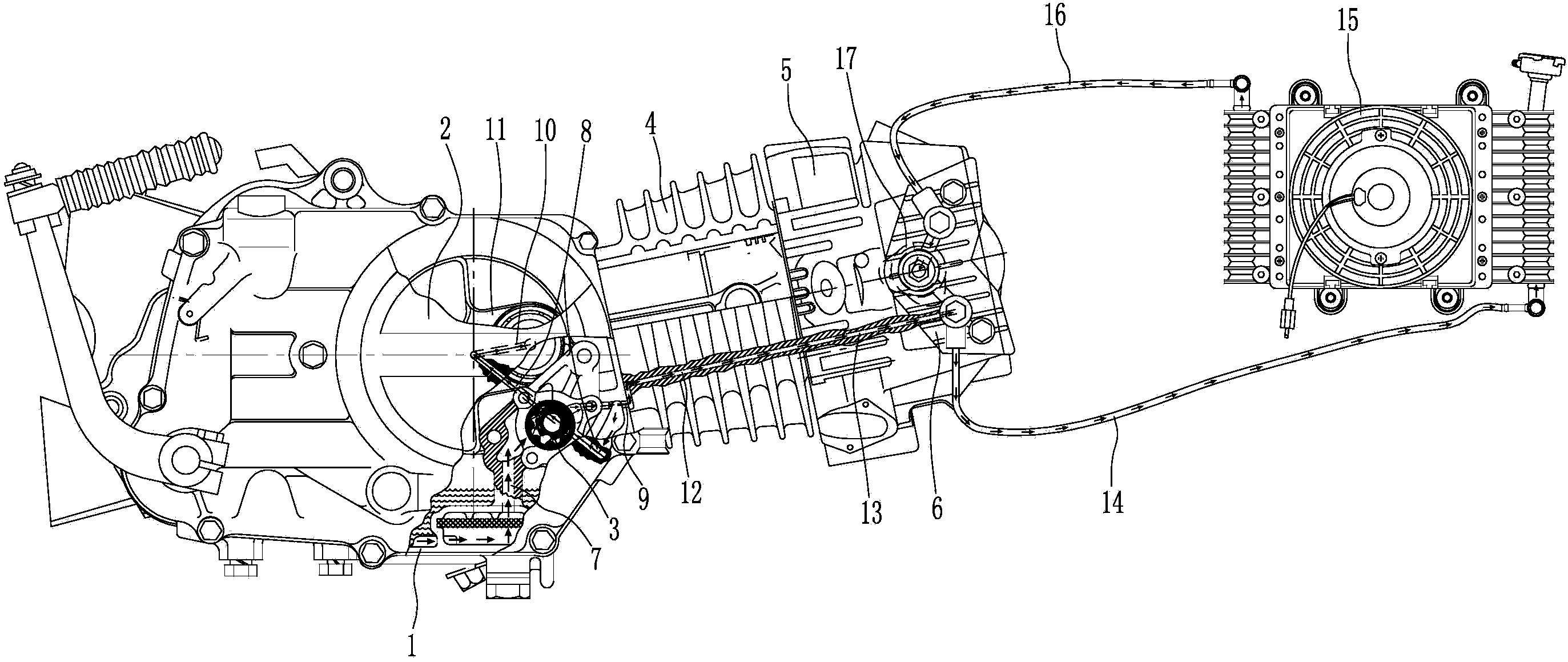

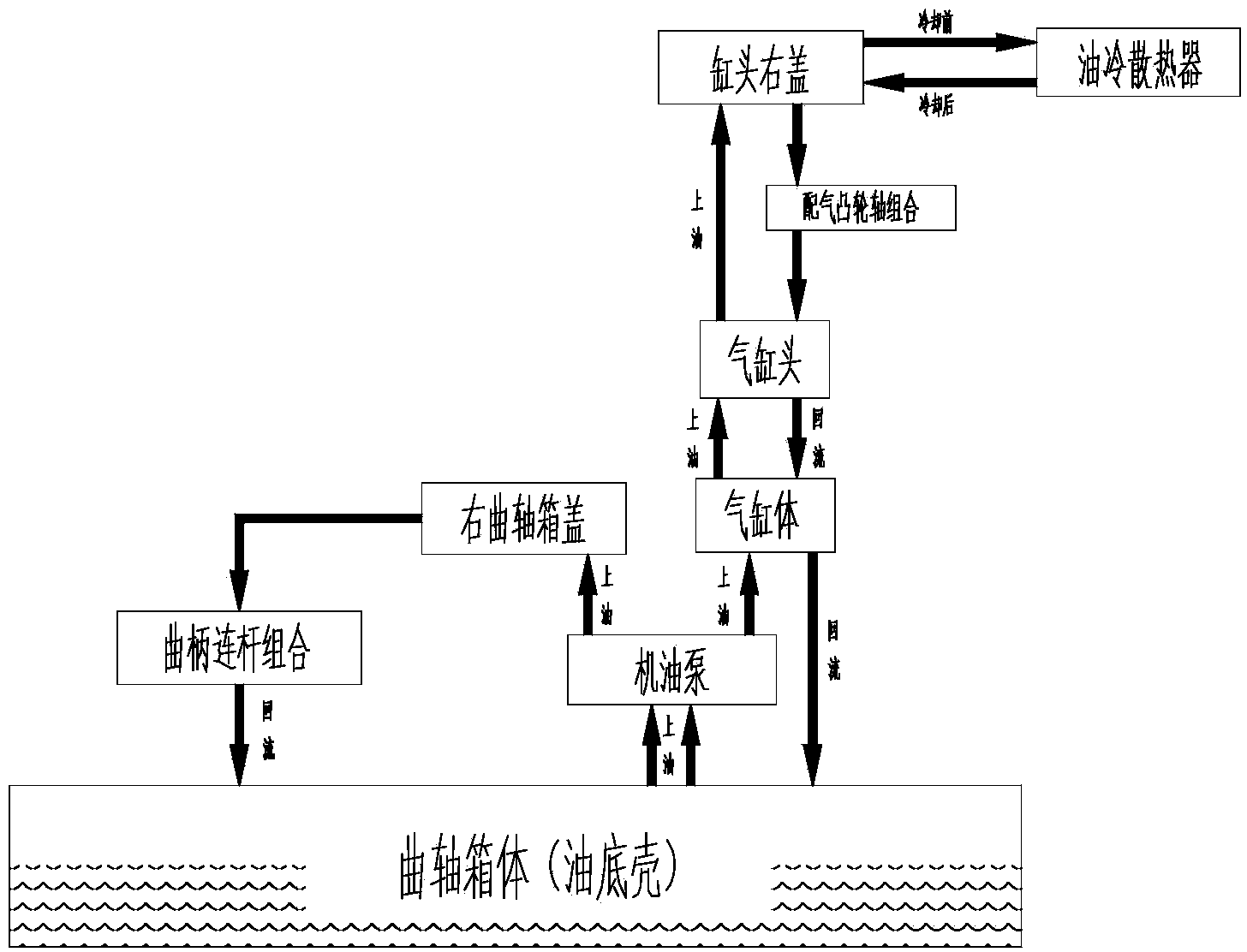

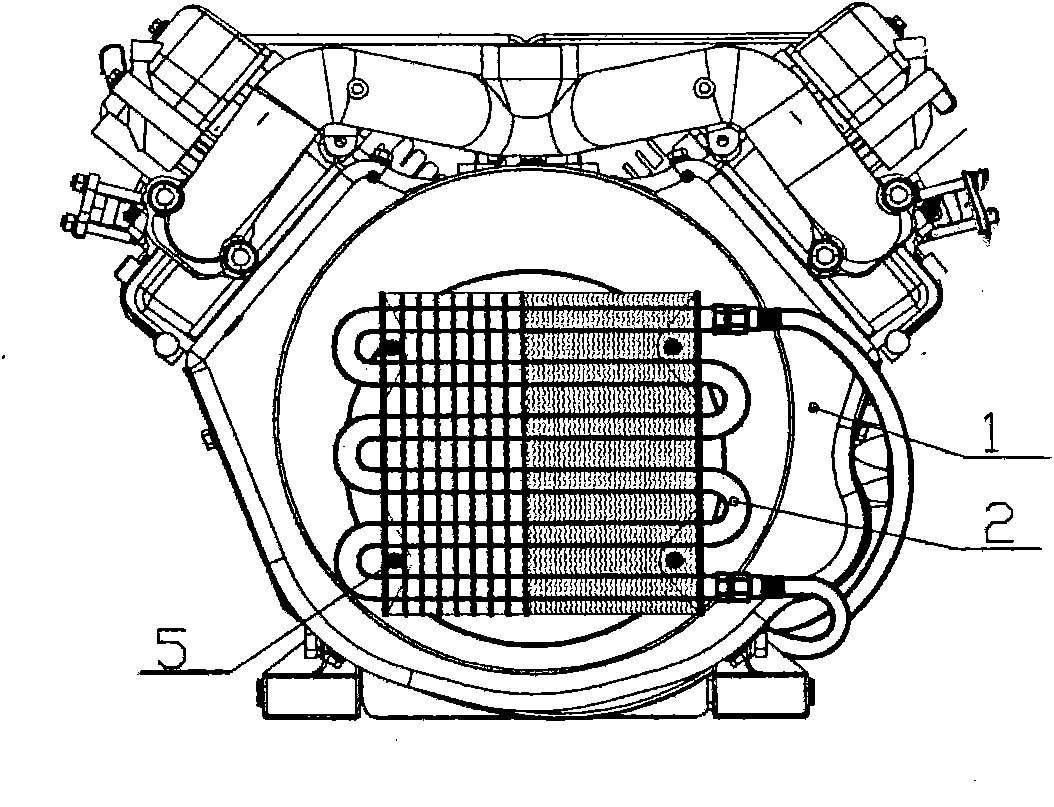

Motorcycle engine oil cooling and lubricating system

InactiveCN104074568AEffective lubricationGood lubricating and cooling effectCylinder headsCylindersOil coolingAir-cooled engine

The invention discloses a motorcycle engine oil cooling and lubricating system. A cylinder end right cover (6) is provided with a right cover oil inlet hole (6a) and a right cover oil outlet hole (6b), the inlet of the right cover oil inlet hole (6a) is communicated with the outlet of a cylinder oil inlet hole (13), the outlet of the right cover oil inlet hole (6a) is connected with an oil cooling radiator oil inlet pipe (14) which is connected with the inlet of an oil cooling radiator (15), the outlet of the oil cooling radiator (15) is connected with an oil cooling radiator oil outlet pipe (16), and the oil cooling radiator oil outlet pipe (16) is connected with the inlet of the right cover oil outlet hole (6b). The motorcycle engine oil cooling and lubricating system can directly convert the cooling manner of an engine from an air cooling mode to an oil cooling mode without large-area structural modification and part replacement of an existing air cooled engine, solves the problem that the cooling mode of a traditional motorcycle air cooled engine cannot be directly expanded in the later period, and greatly reduces the usage cost of the oil cooled engine.

Owner:力帆科技(集团)股份有限公司

Axial flow cooling for air-cooled engines

A head for an air-cooled engine having at least two cylinders, each cylinder having a longitudinal axis, the head having a rocker arm mounted to rotate about a rocker arm axis in the head, the head further including an intake port and an exhaust port, and the head mounted on a first cylinder of the two cylinders to define a combustion chamber, the head having at least two fins, each fin having a height-to-thickness ratio of greater than or equal to 5, each fin having a length that is at least 5 times the distance between the at least two fins at a location on the head that is between the first cylinder and the rocker arm axis on the head, and each fin positioned on the head with the fin length oriented along an axis that is substantially parallel to the longitudinal axis of the first cylinder.

Owner:CORDY JR CLIFFORD B

Air-cooled engine

ActiveCN101233306AImprove cooling effectFully introduceAir coolingCylinder headsCylinder blockAir-cooled engine

An air-cooled engine (10) cooled by cooling air (Wi). The air-cooled engine (10) includes a cylinder block (33) and a cylinder head (28). The cylinder block (33) has cylinder cooling passages (101, 102) capable of transmitting cooling air (Wi) on the outer periphery of the cylinders (26). The cylinder head (28) has cylinder head cooling ducts (104) capable of conveying cooling air (Wi). The cylinder cooling passage (101, 102) and the cylinder head cooling passage (104) extend in a direction perpendicular to the axis (109) of the cylinder (26), and communicate with each other through connecting passages (105, 105).

Owner:HONDA MOTOR CO LTD

Novel engine oil cooling system externally equipped with condenser at air inlet of air-cooled engine

InactiveCN101915152AIncrease cooling areaReasonable structureMachines/enginesEngine cooling apparatusAir volumeCooling effect

The invention discloses a novel engine oil cooling system externally equipped with a condenser at an air inlet of an air-cooled engine. The novel engine oil cooling system comprises an engine oil inlet pipe and an engine oil outlet pipe, wherein one end of the engine oil inlet pipe is connected with an oil outlet of an engine body chamber cover, the other end of the engine oil inlet pipe is connected with the condenser; one end of the engine oil outlet pipe is connected with an oil inlet of the engine body chamber cover, and the other end of the engine oil outlet pipe is connected with the condenser; and the condenser is installed on an air inlet of an engine air guide cover. The novel engine oil cooling system has reasonable structure, and enjoys extremely excellent cooling effect by sucking engine oil from the inside of an engine and enabling an engine oil cooler to have the maximum cooling area through large supply air rate of the air inlet of the air guide cover.

Owner:NANTONG WINSUN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com