Epoxy resin composition, fiber-reinforced composite material, and method for producing the same

a technology of epoxy resin and composite material, which is applied in the direction of weaving, transportation and packaging, textiles and paper, etc., can solve the problems of reducing the tg and elastic modulus the improvement of the toughness of the epoxy resin cured product, and the inability to achieve the desired toughness-enhancing effect, etc., to achieve good impregnation of reinforcing fibers, low viscosity, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0093]Hereinbelow, the present invention will be more specifically described with reference to the following examples. Resin raw materials, a method for preparing an epoxy resin composition, a method for producing a cured product, and measurement methods of various properties used in the examples are as follows.

[0094]

[0095]An epoxy resin composition was prepared using the following commercially-available products.

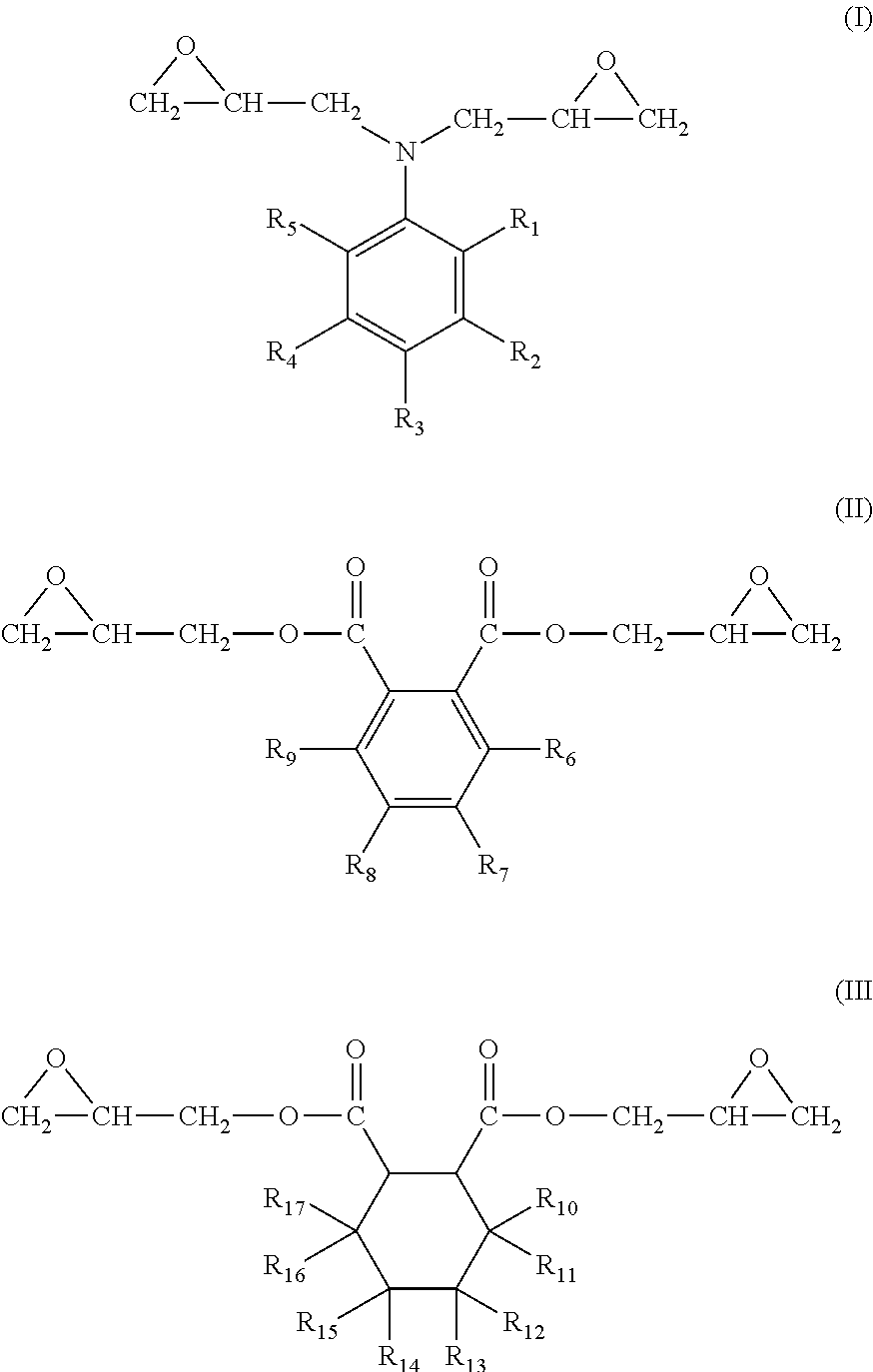

[0096](1) Epoxy Resins

[0097](a) Bifunctional Epoxy Resins (Component A)

[0098]GAN (N,N-diglycidyl aniline manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent: 125 g / mol)

[0099]GOT (N,N-diglycidyl-o-toluidine manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent: 135 g / mol)

[0100]“DENACOL™” EX721 (phthalic acid diglycidyl ester manufactured by Nagase Chemtex Corporation, epoxy equivalent: 154 g / mol)

[0101]AK601 (hexahydrophthalic acid diglycidyl ester manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent: 154 g / mol)

[0102](b) Tri- or Higher-Functional Aromatic Epoxy...

examples 1 to 9

[0173]Epoxy resin compositions were prepared using the resin raw materials shown in Table 1, and the initial viscosity of each of the epoxy resin compositions at 70° C. was measured. As a result, all the epoxy resin compositions had sufficiently low viscosity. Then, the epoxy resin compositions were cured to obtain cured products, and the Tg, flexural modulus, and mode I fracture toughness of each of the cured products were measured. As a result, all the cured products had high Tg, high elastic modulus, and high toughness. From the result, it was found that all the cured products of Examples 1 to 9 were excellent. Among them, the cured products of Examples 2, 3, 5, 6, and 8 had very high Tg, very high elastic modulus, and very high toughness. From the result, it was found that the cured products of Examples 2, 3, 5, 6, and 8 were particularly excellent.

TABLE 1Unit of resin raw material content: part(s) by massExam-Exam-Exam-Exam-Exam-Exam-Exam-Exam-Exam-ple 1ple 2ple 3ple 4ple 5ple ...

examples 10 and 11

[0174]Epoxy resin compositions were prepared using the resin raw materials shown in Table 2, and the initial viscosity of each of the epoxy resin compositions at 70° C. was measured. As a result, both the epoxy resin compositions had sufficiently low viscosity. Then, the epoxy resin compositions were cured to obtain cured products, and the Tg, flexural modulus, and mode I fracture toughness of each of the cured products were measured. As a result, both the cured products had high Tg, high elastic modulus, and high toughness. From the result, it was found that the cured products of Examples 10 and 11 were excellent. However, the epoxy resin compositions of Examples 1 and 2 had lower viscosity as compared to the epoxy resin compositions of Examples 10 and 11, and the cured products of Examples 1 and 2 had higher Tg as compared to the cured products of Examples 10 and 11. From the result, it was found that the cured products of Examples 1 and 2 were more excellent as compared to the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume-average particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com