NANO complex oxide doped dielectric ceramic material, preparation method thereof and multilayer ceramic capacitors made from the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

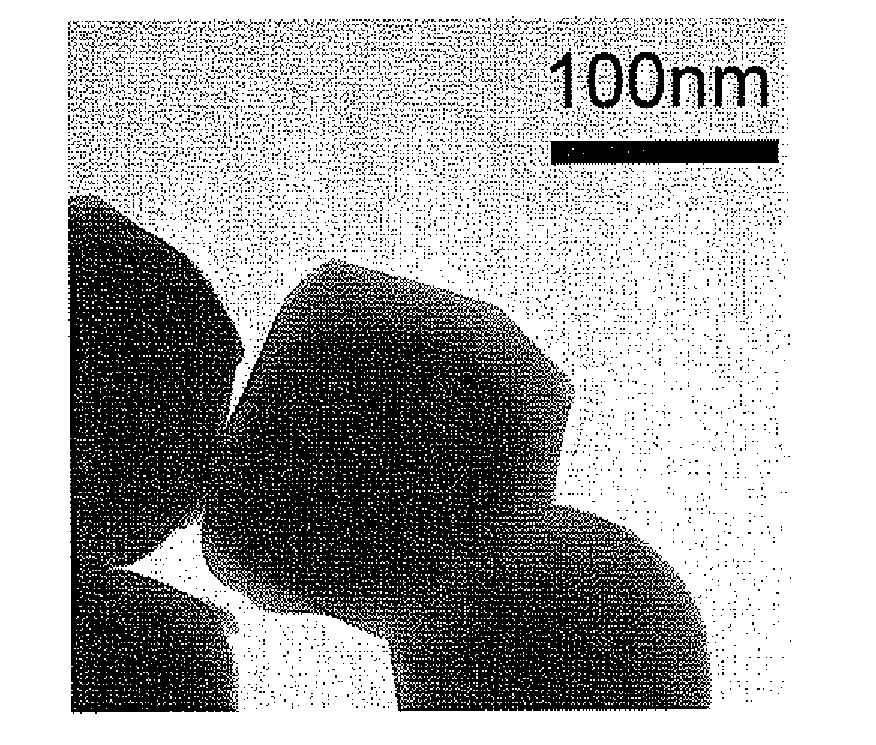

Preparation of a Nano Complex Oxide Doped Dielectric Ceramic Material through a Chemical Coating Process

[0056]BaTiO3 powders (with an average particle size of 120 nm) were ball-milled in ethanol for 12 hours to get a BaTiO3 slurry A; Nitrates corresponding to the oxides in the nano complex oxide were weighed according to molar ratios of Y:Ce:Mn:Mg:Si:Ca=4:1:3:12:5:3 and dissolved in deionized water to obtain a clear solution B; Si(OEt)4, ethanol, acetic acid and deionized water were mixed by volume ratios of Si(OEt)4:ethanol:acetic acid:deionized water=1:10:6:20 to obtain a clear and stable solution C; solution B and solution C were dropwise added to the BaTiO3 slurry A by volume ratios of A:B:C=5:2:1; Ammonia water was added to make the pH to 8 so that the doping elements were coated on to the surface of the BaTiO3 particles through a co-precipitation process; the obtained slurry was dried and then was sintered at 500° C. for 2 hours, followed by sieving to obtain a nano complex ox...

example 2

[0057]Nano complex oxide doped dielectric ceramic materials were prepared by the same way as described in example 1 except that the average particle sizes of the BaTiO3 powders were 120 nm, 135 nm and 150 nm, respectively, the composition of the nano complex oxide dopant in the coating layer (CL) was Y:Ce:Mn:Mg:Si:Ca=3:2:3:12:4:2 (molar ratio), and the molar ratio of the BaTiO3 to the nano complex oxide was 95:5. Thus samples 1˜3 of the nano complex oxide doped dielectric ceramic materials were obtained, as shown in Table 1.

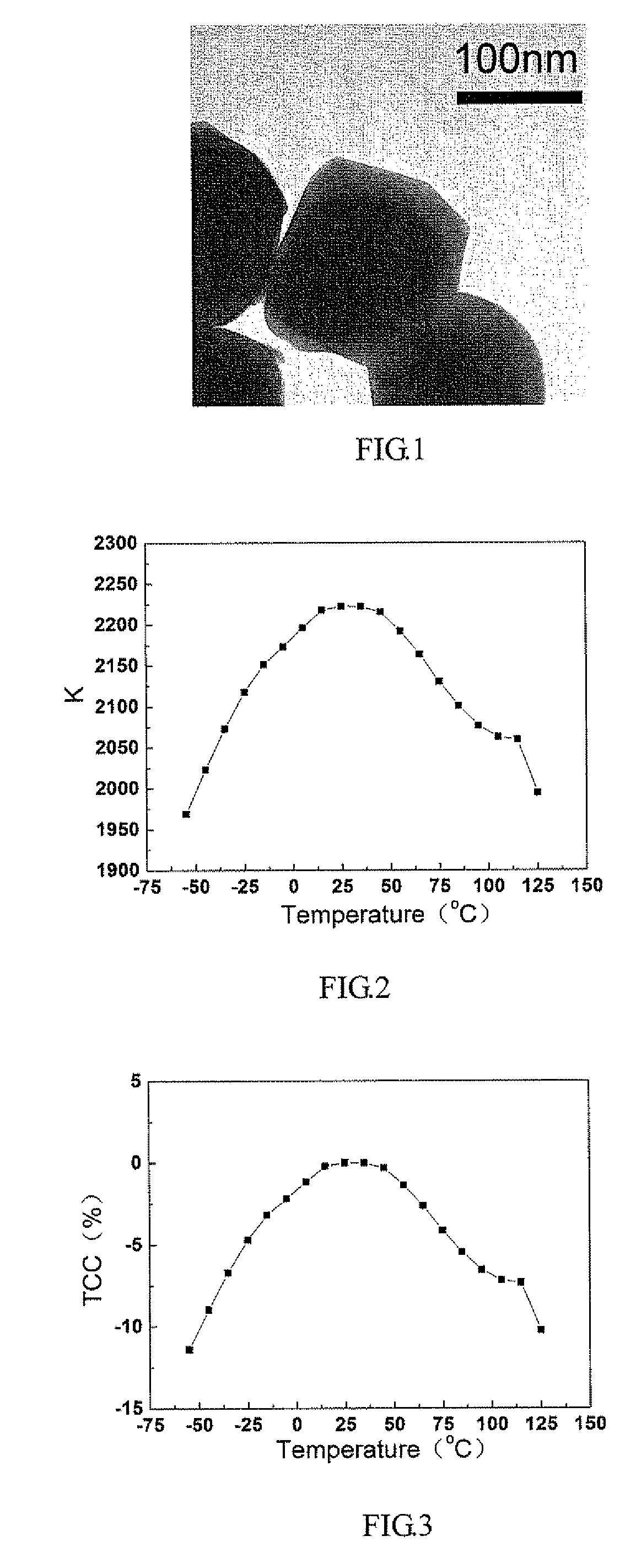

[0058]Tests of the dielectric properties of samples 1˜3.

[0059]Each of samples 1˜3 was pressed into a pellet with a diameter of 10 mm and sintered in a reducing atmosphere at 1200° C. for 2 h (N2:H2=30:1), followed by reoxidizing in a weak oxidation atmosphere at 1050° C. for 2 h. Silver electrodes were deposited onto both the main sides of the pellet to conduct dielectric measurement. The dielectric properties and grain size of these samples are listed in Table 1...

example 3

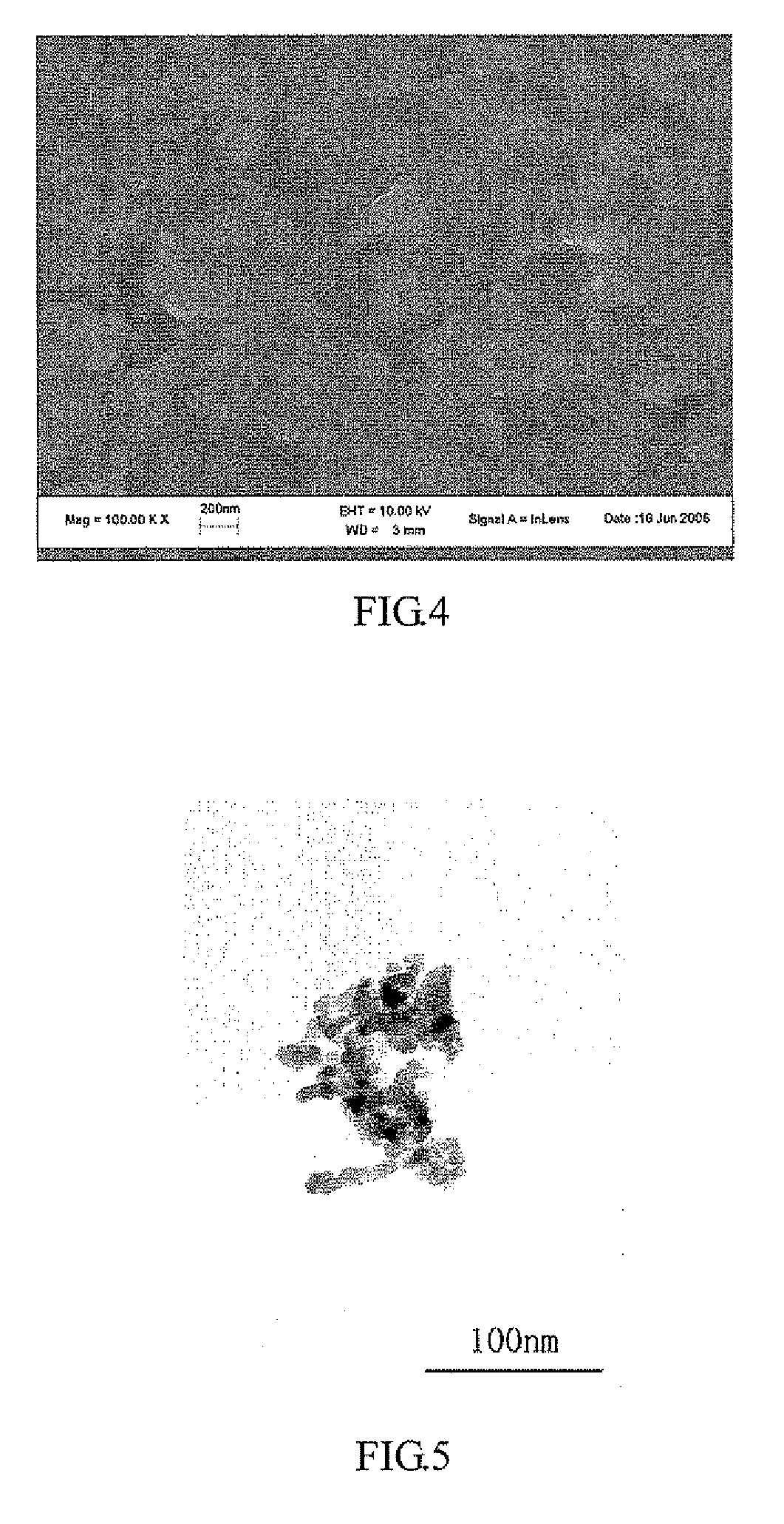

[0060]Nano complex oxide doped dielectric ceramic materials were prepared by the same way as described in example 1 except that the average particle sizes of the barium titanate, the mole ratios of barium titanante to the nano complex oxide and the compositions of the nano complex oxides in the coating layer (CL) were different, as listed in Table 2 and Table 3 Thus samples 4˜9 of nano complex oxide doped dielectric ceramic materials were obtained.

[0061]Tests of the dielectric properties of samples 4˜9.

[0062]Each of samples 4˜9 was pressed into a pellet with a diameter of 10 mm and sintered in a reducing atmosphere at 1150° C.˜1250° C. for 2 h (N2:H2=35:1), followed by reoxidizing in a weak oxidation atmosphere at 1050° C. for 3 h. Silver electrodes were deposited onto both the main sides of the pellet to conduct dielectric measurement. The dielectric properties and the average grain sizes of these samples are listed in Table 3.

TABLE 2Nano complex oxidein the coating layerCompositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com