Novel bonding structure for a hard disk drive suspension using anisotropic conductive film

a technology of anisotropic conductive film and hard disk drive, which is applied in the direction of supporting heads, maintaining head carrier alignment, printed circuit aspects, etc., can solve the problems of inability to separate bonded parts in the future to be reworked without damaging the fpc or the suspension, and the difficulty of one-time bonding, so as to avoid high-temperature bonding. , the effect of reducing the size of the bonding pad and floating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Referring to FIG. 1, this is a standard wireless suspensions. Trace 112 is patterned on top of a flexture piece which runs from slider 120 to bonding pads 102, 104, 106, and 108, transporting electro-magnetic signals from slider 120. Base plate 100 supports bonding pads 102, 104, 106, 108, to which a FPC is bonded for transmitting signals to elsewhere in a hard disk drive, such as a circuit on the actuator arm. The number of contact pads shown here is for illustrative purposes only, and there could be more or fewer contact pads without deviating from the spirit of the invention.

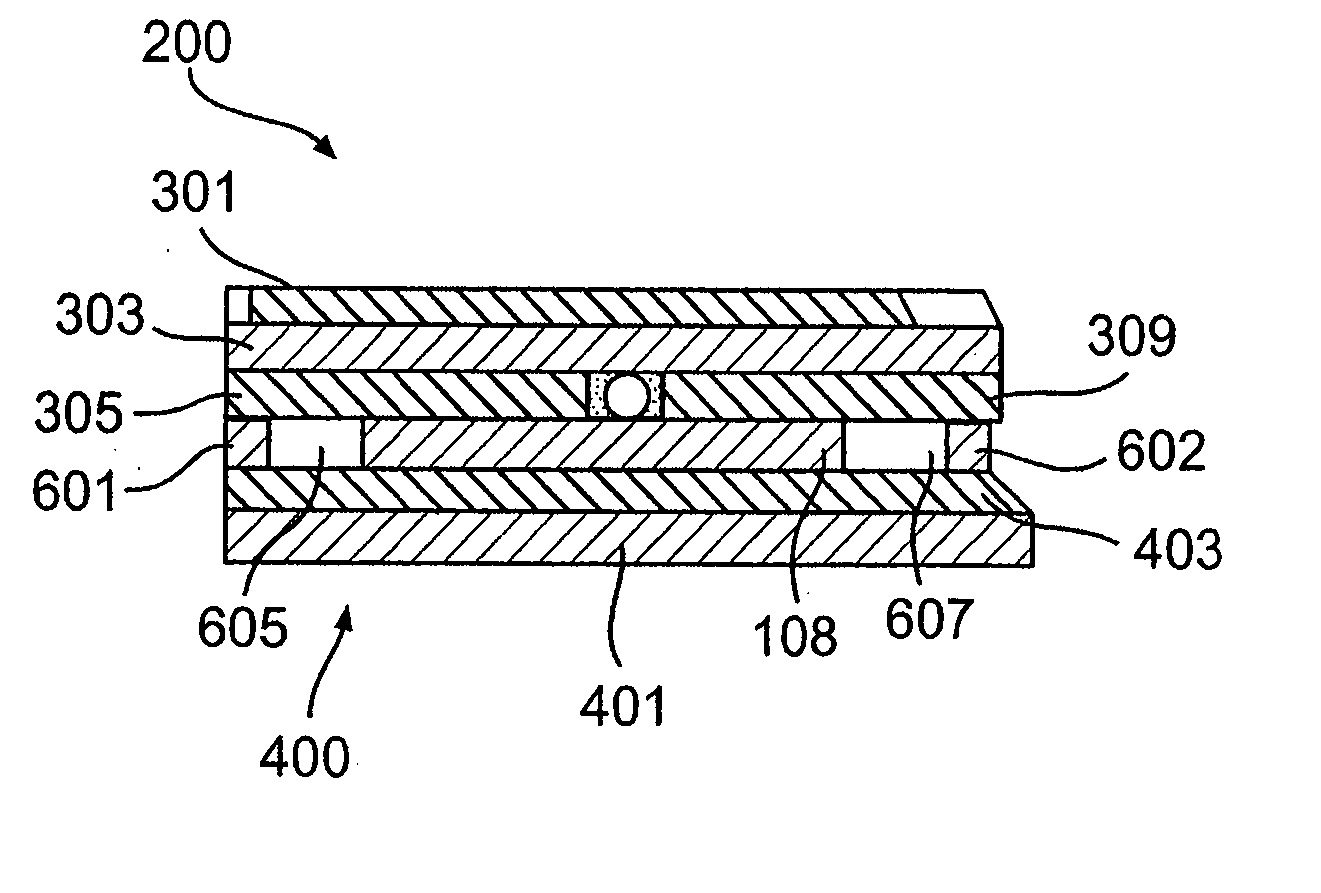

[0028] Referring to FIG. 2, a FPC 200 is attached to contact pads 102, 104, 106, 108 (not shown) in the circled area 210. Traditionally, FPC can be bound to contact pads using ultrasonic bonding or soldering. With soldering, additional solder bumps need to be incorporated As mentioned, both prior art bonding methods tend to be cost- and labor-intensive, and bonding using anisotropic conductive adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| bonding time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com