Method for nickel and cobalt recovery from laterite ores by reaction with concentrated acid and water leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

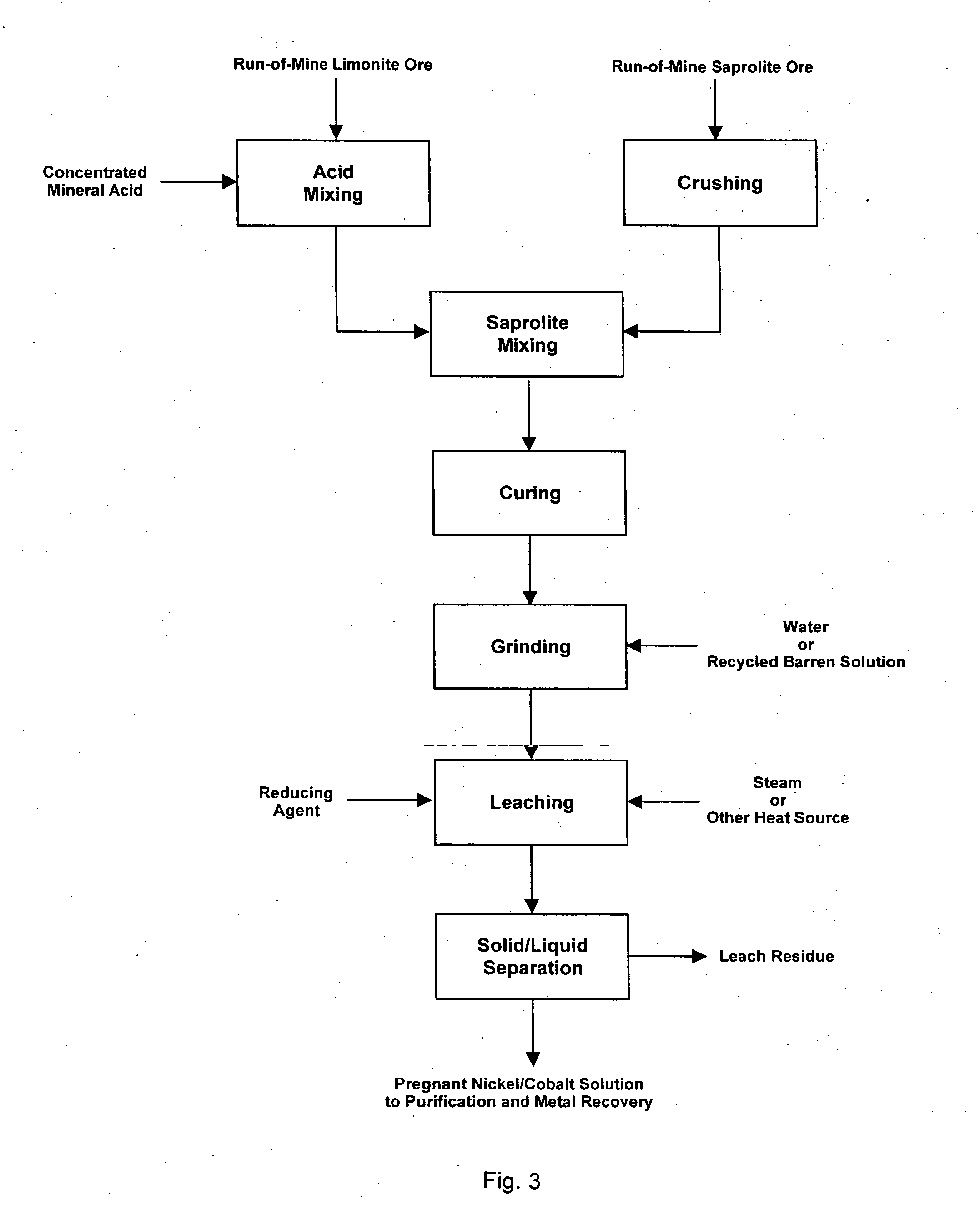

[0069] Approximately 1 kg of saprolite ore was wet ground in a ball mill to approx. 100% passing 100 mesh. The ground slurry was filtered to produce ground saprolite at 41% moisture content. 425.2 g of the moist ground saprolite was blended with 381.7 g of moist limonite ore to produce 500 g of leach feed material with a limonite / saprolite ratio of 1:1 on a dry basis.

[0070] The ore mixture was placed in a 4.5 liter narrow-necked glass bottle. The bottle was rolled at an angle inclined slightly to the horizontal at approximately 47 to 48 rpm on a bottle rolling device. 312.5 g of 96% sulfuric acid was added to the ore mixture in the bottle over a period of about 30 minutes. The ore and acid were blended for approximately 30 min after all of the acid had been added. At the completion of blending the ore and acid had formed a semi-fluid mass and the temperature had risen to between about 70 and 100° C.

[0071] The bottle was removed from the rolling device and the blend of acid and ore...

example 2

[0077] A sample of 381.7 g of limonite ore was blended with 317.7 g of crushed saprolite ore and 95 g of water in a 2-liter flat-bottomed glass beaker. The water was added to simulate the expected moisture content of run-of-mine ore, recognizing that the samples had dried somewhat compared to their in-situ condition. 312.5 g of 96% sulfuric acid was added to the beaker over approximately 30 minutes. The acid was blended with the ore using a stirrer rotating at about 60 rpm. The acid addition was sufficient to give an acid to ore ratio of about 600 kg H2SO4 per tonne of ore (dry basis).

[0078] The ore and acid formed a semi-fluid mass which was poured into a shallow pan for curing at ambient temperature for approximately 72 hours. Some of the mixture was not recovered during this operation. It was estimated that about 13% of the mixture was not recovered, based on weight recovery.

[0079] After this period of curing, the acid / ore mixture, which had hardened considerably, was broken in...

example 3

[0084] This test was carried out in a fashion similar to that of Example 2, with the following exceptions. The amounts of limonite ore, crushed saprolite ore, water, acid, and hematite seed used during the acid blending and subsequent leaching process were 336.9 g, 280.3 g, 84 g, 275.8 g, and 113 g, respectively. The proportions of ore, water and acid were the same as in Example 2.

[0085] After blending the ore with acid, the mixture was transferred to a shallow pan and allowed to cure for only one hour before transfer to a grinding mill for wet grinding and subsequent water leaching. After one hour of curing the mixture was still fluid and could be poured into the mill. 1,776 g of leach slurry were prepared and leached exactly as in Example 2. Recovery of the acid / ore mixture was approximately 96%.

[0086] The results of this test are given in Tables 6 and 7 below.

TABLE 6Time (h)[Ni] g / L[Fe] g / L[H2SO4] g / L15.5322.726.3724.257.5916.74247.49.1413447.1210.816

[0087]

TABLE 7Ni (% or g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com