Intermetallic articles of manufacture having high room temperature ductility

a technology of intermetallic compounds and ductility, which is applied in the manufacture of final products, climate sustainability, prosthesis, etc., can solve the problems fracture toughness of room temperature, high compressive ductility of room temperature, and high compressive ductility of articles of manufacture. , to achieve the effect of high compressive ductility, high ductility and high compressive ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Polycrystalline specimens of equiatomic YAg were produced by arc-melting the pure elements on a water-cooled copper hearth in an inert gas (Ar) atmosphere to form an ingot in the shape of a finger or disk depending on the shape of the mold in the copper hearth. The specimens comprised 50 atomic % Y and 50 atomic % Ag. X-ray diffraction and metallography studies of the cast specimens confirmed that they were single-phase with fully ordered CsCl-type crystal structure. The cast specimens were annealed for 86 kiloseconds at 800 degrees C. and machined into cylindrical tensile test specimens, which were tensile tested to failure in room temperature air at a strain rate of 2×10−4 / second.

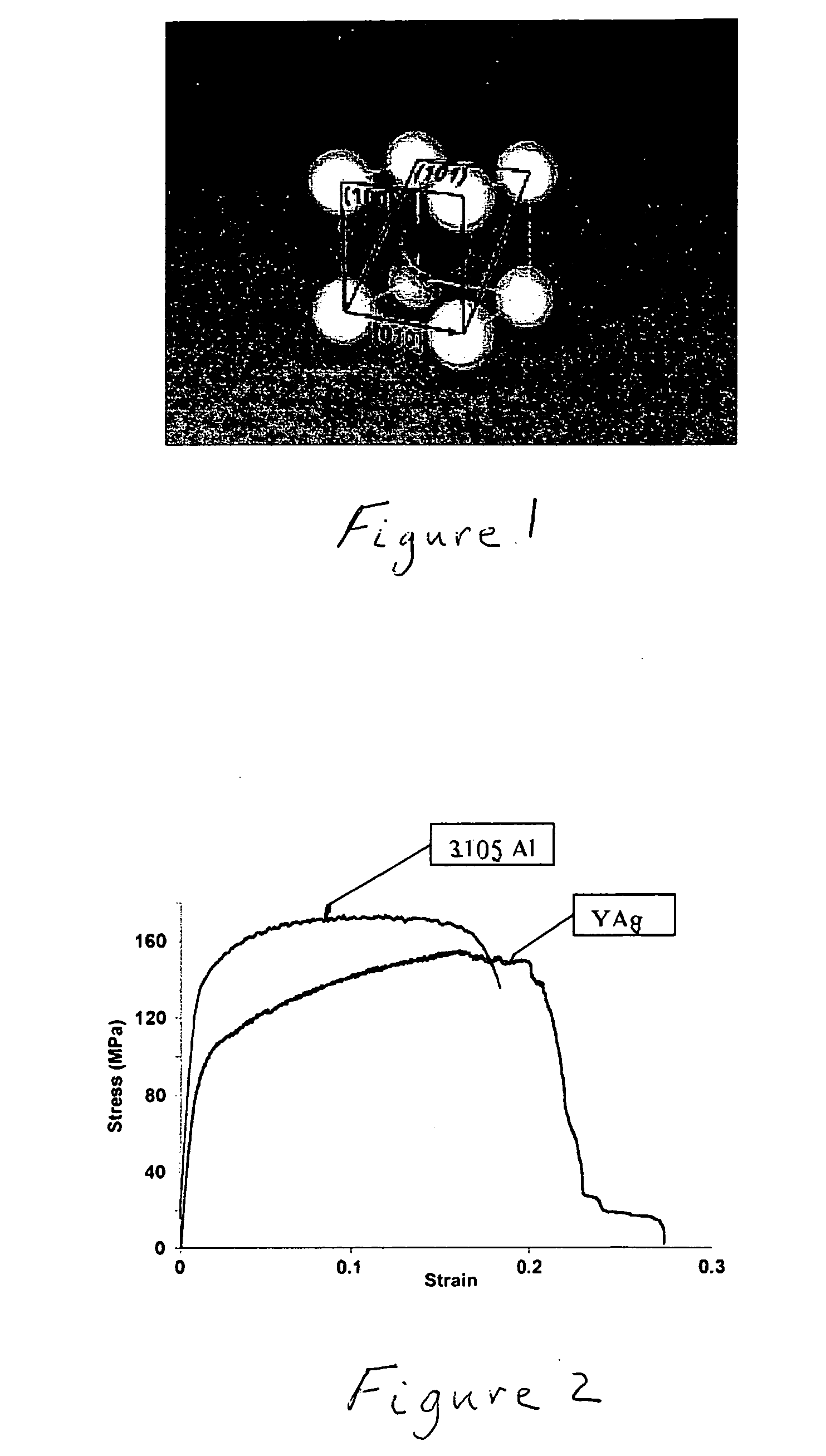

[0044]FIG. 2 is a representative stress-strain curve for the machined YAg specimens. Also shown in FIG. 2 is a stress-strain curve for a commercially available aluminum alloy (3105) widely used for gutters, downspouts, window frames and siding. The machined YAg specimen unexpectedly and surprising...

example 2

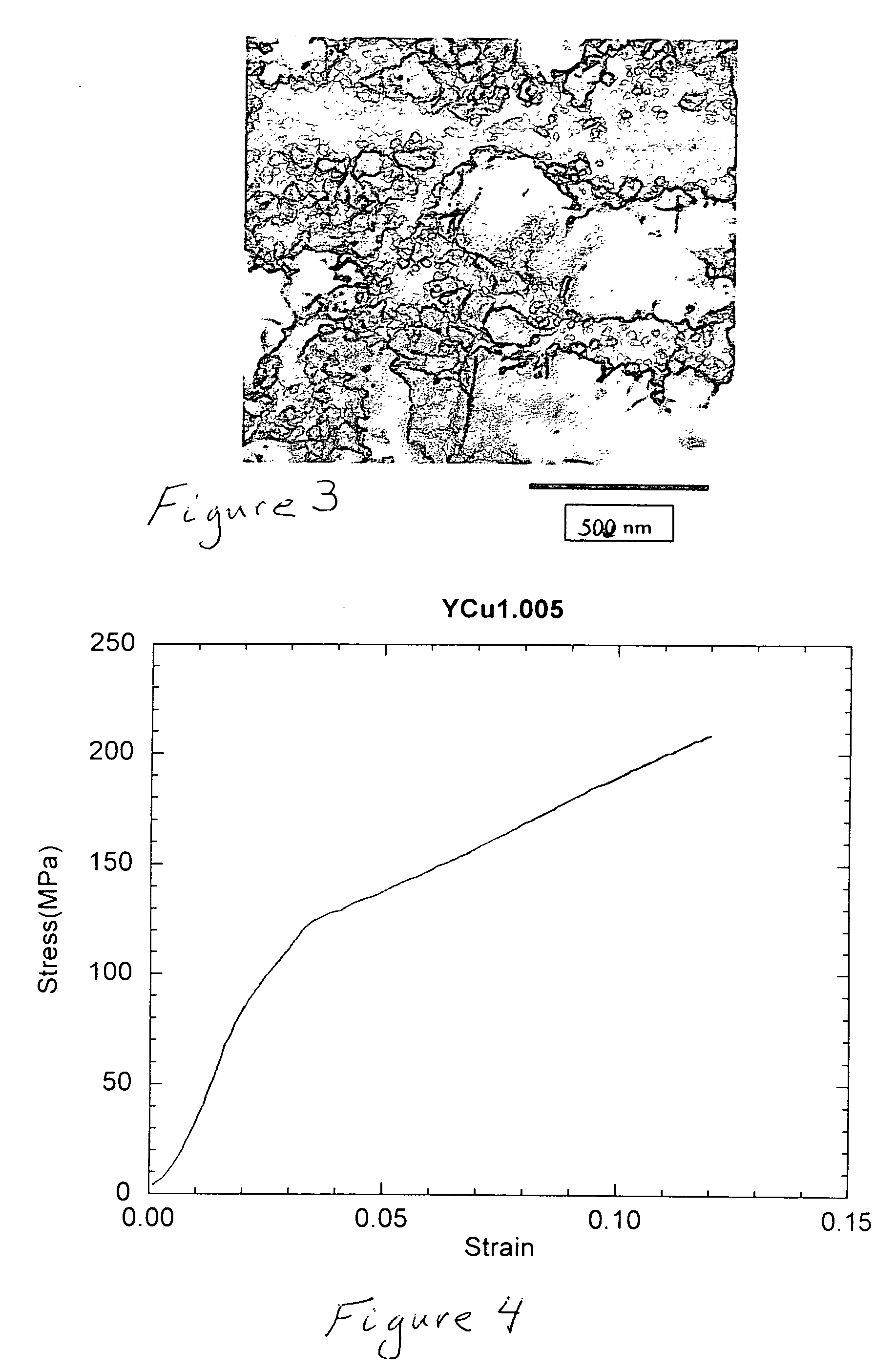

[0045] Polycrystalline specimens of nearly equiatomic YCu1.005 were produced by arc-melting the pure elements on a water-cooled copper hearth in an inert gas (Ar) atmosphere to form an ingot in the shape of a finger or disk depending on the shape of the mold in the copper hearth. This specimen was made with a starting composition of Y1.000Cu1.005 because small losses of Cu occur during arc-melting through vaporization, and this starting composition yields a final cast specimen that is close to the perfect 1:1 stoichiometry. X-ray diffraction and metallography studies of the cast specimens confirmed that they were single-phase with fully ordered CsCl-type crystal structure. The cast specimens were annealed for 36 kiloseconds at 700 degrees C. and machined into cylindrical tensile test specimens, which were tensile tested to failure in room temperature air at a strain rate of 2×10−4 / second.

[0046]FIG. 4 is a representative stress-strain curve for the machined YCu specimens. The machin...

example 3

[0047] Eight single crystal YCu tensile specimens were produced by the well known Bridgman (power-down) technique where a YCu melt in a mold or crucible is directionally solidified therein by gradually reducing induction heating power along the length of the melt to form a single crystal body. The tensile specimens were machined from the single crystal cast bodies and polished by 0.25 micron diamond abrasive in an oil suspension. All eight tensile specimens had a tensile axis of direction [142] with polished surfaces corresponding to the (−812) and (−2 6 −11) planes. The specimens were pulled in tension at room temperature (22 degrees C.) in air at a strain rate of 1×10−4 / second. The specimens exhibited a yield stress of 45 MPa and fractured at 6% to 8% elongation at a stress of 75 to 90 MPa.

[0048]FIG. 5 is an optical photomicrograph of slip bands on the surface of an YCu single crystal test specimen deformed 6% in tension at 22 degrees C. The intersecting lines are slip bands resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile elongation | aaaaa | aaaaa |

| tensile elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com