Electrocatalyst for proton exchange film fuel cell

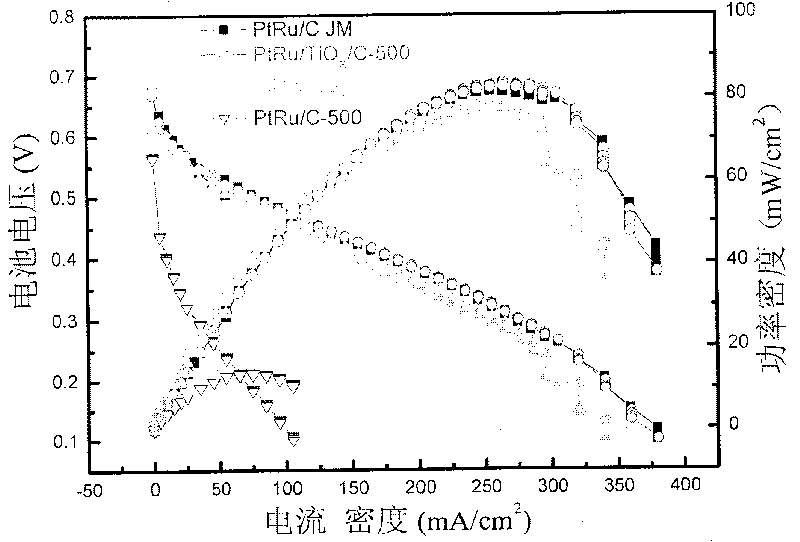

A technology of proton exchange membrane and electrocatalyst, which is applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., to achieve the effects of strong electric field stability, improved sintering resistance and stability, and strong long-term life-span operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

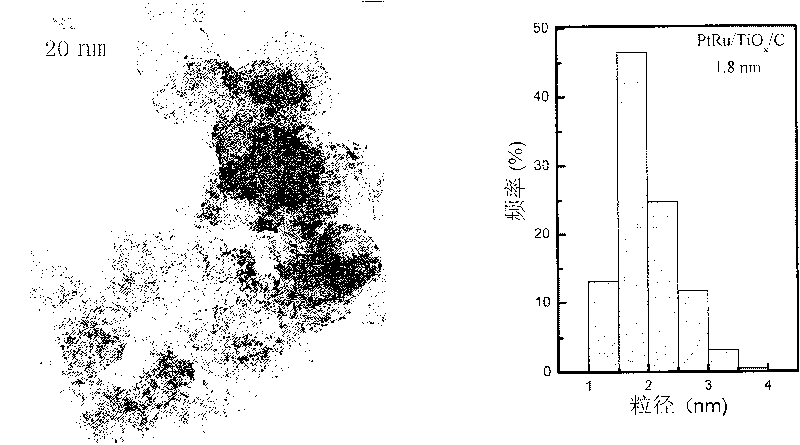

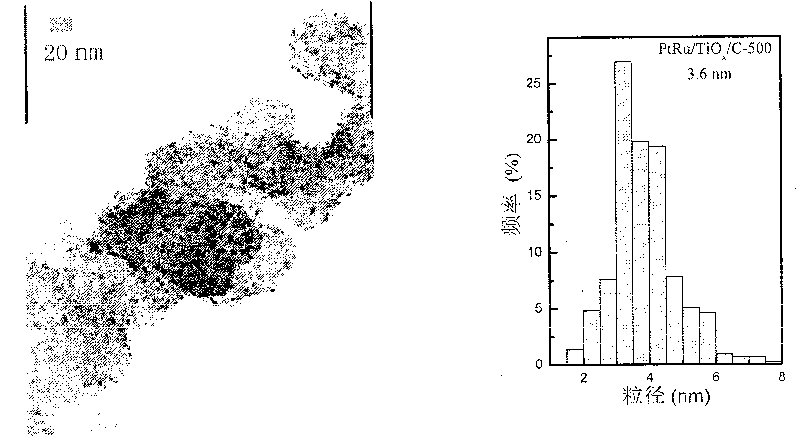

[0048] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage content 40wt.%, atomic ratio Pt:Ti=5:1) Preparation of catalyst.

[0049] Carbon black XC-72R was pre-treated with 2N hydrochloric acid and 5N nitric acid solution, dried at 140℃, weighed 2 grams, dispersed with 100ml isopropanol ultrasonically for 30 minutes to obtain a carbon slurry, added butyl titanate ethylene glycol while stirring Solution (contains 482mg butyl titanate), then add dropwise a mixture of 20ml isopropanol + 15ml water + 1ml nitric acid, stir 4 days after the titanium is fully hydrolyzed, washed with plenty of water, and dried to obtain a composite carrier for use. Prepared composite carrier 1.2 Use 200 ml of ethylene glycol to ultrasonically vibrate for 30 minutes to obtain a carbon slurry. Weigh 2.16 g of chloroplatinic acid (containing 0.799 g of platinum) and dissolve it into 50 ml of ethylene glycol, add it dropwise to the carbon slurry, and stir vigorously for 20 minutes. Adjust the pH to 1...

preparation Embodiment 2

[0051] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage content 40wt.%, atomic ratio Pt:Ti=1:1) Preparation of catalyst.

[0052] Other conditions are the same as in Example 1, changing the atomic ratio of Pt and Ti in the catalyst component to 1:1. The platinum metal loading is maintained at 40wt%. The results of transmission electron microscopy and X-ray diffraction experiments show that the particle size and distribution of the catalyst metal before and after the treatment are similar to those in Example 1.

preparation Embodiment 3

[0054] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage content 40wt.%, atomic ratio Pt:Ti=10:1) Preparation of catalyst.

[0055] Other conditions are the same as in Example 1, changing the atomic ratio of Pt and Ti in the catalyst component to 10:1. The platinum metal loading is maintained at 40wt%. The results of transmission electron microscopy and X-ray diffraction experiments show that the particle size and distribution of the catalyst metal before and after the treatment are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com