Electrocatalyst for proton exchange film fuel cell

A proton exchange membrane and electrocatalyst technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., to achieve good thermal stability, strong long-term operating stability, and improved sintering resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

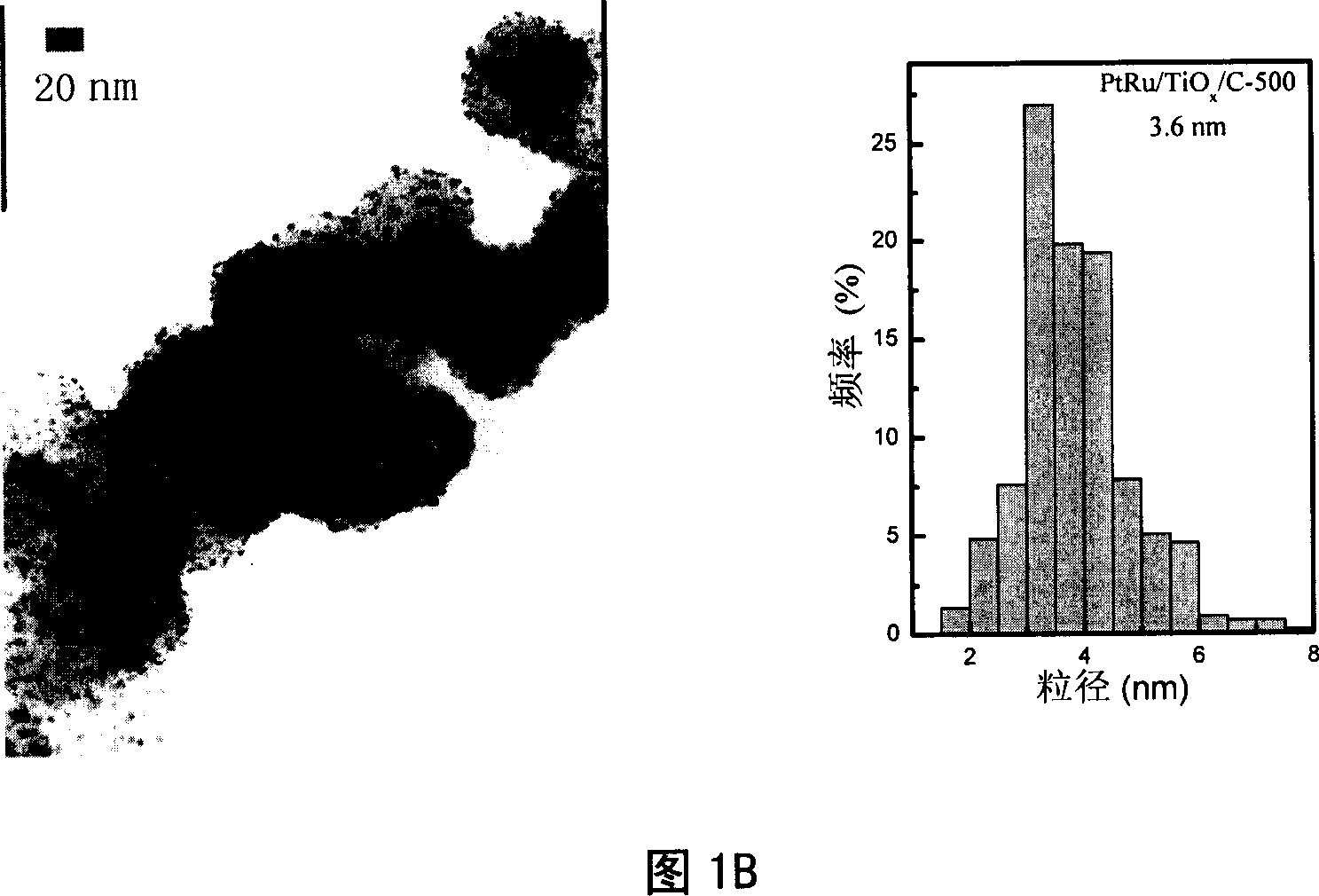

[0048] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage 40wt.%, atomic ratio Pt:Ti=5:1) catalyst preparation.

[0049] Carbon black XC-72R is treated with 2N hydrochloric acid and 5N nitric acid solution in advance, after drying at 140°C, weigh 2 grams and disperse with 100ml isopropanol for 30 minutes by ultrasonic oscillation to obtain a carbon slurry, and add ethylene glycol of butyl titanate under stirring solution (containing 482 mg butyl titanate), then dropwise added a mixture of 20 ml isopropanol + 15 ml water + 1 ml nitric acid, stirred for 4 days, titanium was fully hydrolyzed, washed with a large amount of water, and dried to obtain a composite carrier for use. 1.2 g of the prepared composite carrier was ultrasonically vibrated with 200 ml of ethylene glycol for 30 minutes to obtain a carbon slurry. Weigh 2.16g of chloroplatinic acid (containing 0.799g of platinum) and dissolve it in 50ml of ethylene glycol, add it dropwise to the carbon slurry, and after...

preparation Embodiment 2

[0051] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage 40wt.%, atomic ratio Pt:Ti=1:1) catalyst preparation.

[0052] Other conditions are the same as in Example 1, except that the atomic ratio of Pt and Ti in the catalyst component is changed to 1:1. The platinum metal loading was maintained at 40 wt%. Transmission electron microscopy and X-ray diffraction experimental results show that the catalyst metal particle size and distribution before and after treatment are similar to those in Example 1.

preparation Embodiment 3

[0054] Platinum Titanium Carbon (Pt / TiO x / C) (Pt mass percentage 40wt.%, atomic ratio Pt:Ti=10:1) preparation of catalyst.

[0055] Other conditions are the same as in Example 1, except that the atomic ratio of Pt and Ti in the catalyst component is changed to 10:1. The platinum metal loading was maintained at 40 wt%. Transmission electron microscopy and X-ray diffraction experimental results show that the catalyst metal particle size and distribution before and after treatment are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com