Process for preparing submicron grade barium strontium phthalate powder by packing method

A barium strontium titanate, submicron technology, applied in the field of ceramic powder preparation, can solve problems such as difficulty in obtaining stoichiometric ratio, difficulty in removing impurity ions, and limiting practical application, and achieves fine particle size, low dielectric loss, The effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of ultrafine BST powder under the condition of pH=7

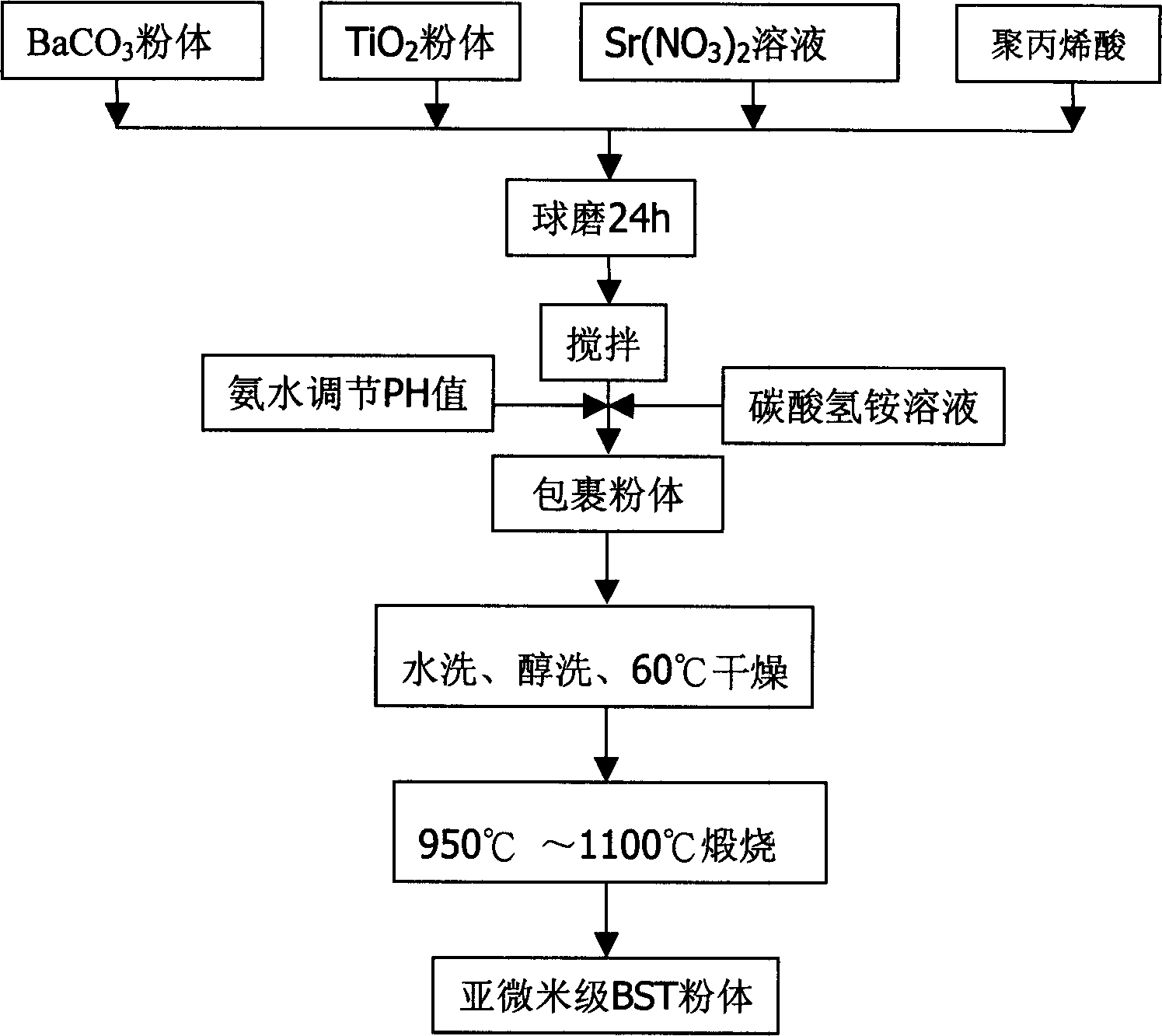

[0021] according to figure 1 As shown in the process, first configure a certain concentration (1mol / l) of strontium nitrate solution, then mix barium carbonate, titanium dioxide and strontium nitrate solution according to the stoichiometric ratio (Ba:Sr:Ti=0.70:0.30:1.00), and add 0.5%-1% polyacrylic acid with a concentration of 50% relative to the total weight of the barium carbonate and titanium dioxide solids is used as a dispersant and a surfactant, and wet ball milled for 24 hours. Take out the mixed slurry, add the pre-prepared, excess ammonium bicarbonate solution (concentration: 1mol / l) under stirring, adjust the pH value to about 7 with ammonia water, so that the strontium ions are evenly wrapped in the form of strontium carbonate precipitation A stable slurry is formed on the surface of barium carbonate and titanium dioxide particles. The precipitate is filtered, washed, dried and c...

Embodiment 2

[0022] Example 2: Preparation of ultrafine BST powder under the condition of pH=10

[0023] according to figure 1As shown in the flow chart, a strontium nitrate solution with a certain concentration (2mol / l) is first configured, then barium carbonate, titanium dioxide and strontium nitrate solution are mixed according to the stoichiometric ratio (Ba:Sr:Ti=0.90:0.10:1.00), and Add 0.5%-1% polyacrylic acid with a concentration of 50% relative to the total weight of barium carbonate and titanium dioxide solids as a dispersant and surfactant, and wet ball mill for 24 hours. Take out the mixed slurry, add the pre-prepared and excess ammonium bicarbonate solution (concentration is 1mol / l) under stirring, and adjust the pH value to about 10 with ammonia water, so that the strontium ions are evenly distributed in the form of strontium carbonate precipitation Wrapped on the surface of barium carbonate and titanium dioxide particles to form a stable slurry. The precipitate is filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com