High-carbon steel wire rod with high strength and high toughness

A high-strength, high-toughness technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of reverse V-type segregation, insufficient, and insufficient segregation grain refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The following examples are given to describe the present invention in more detail.

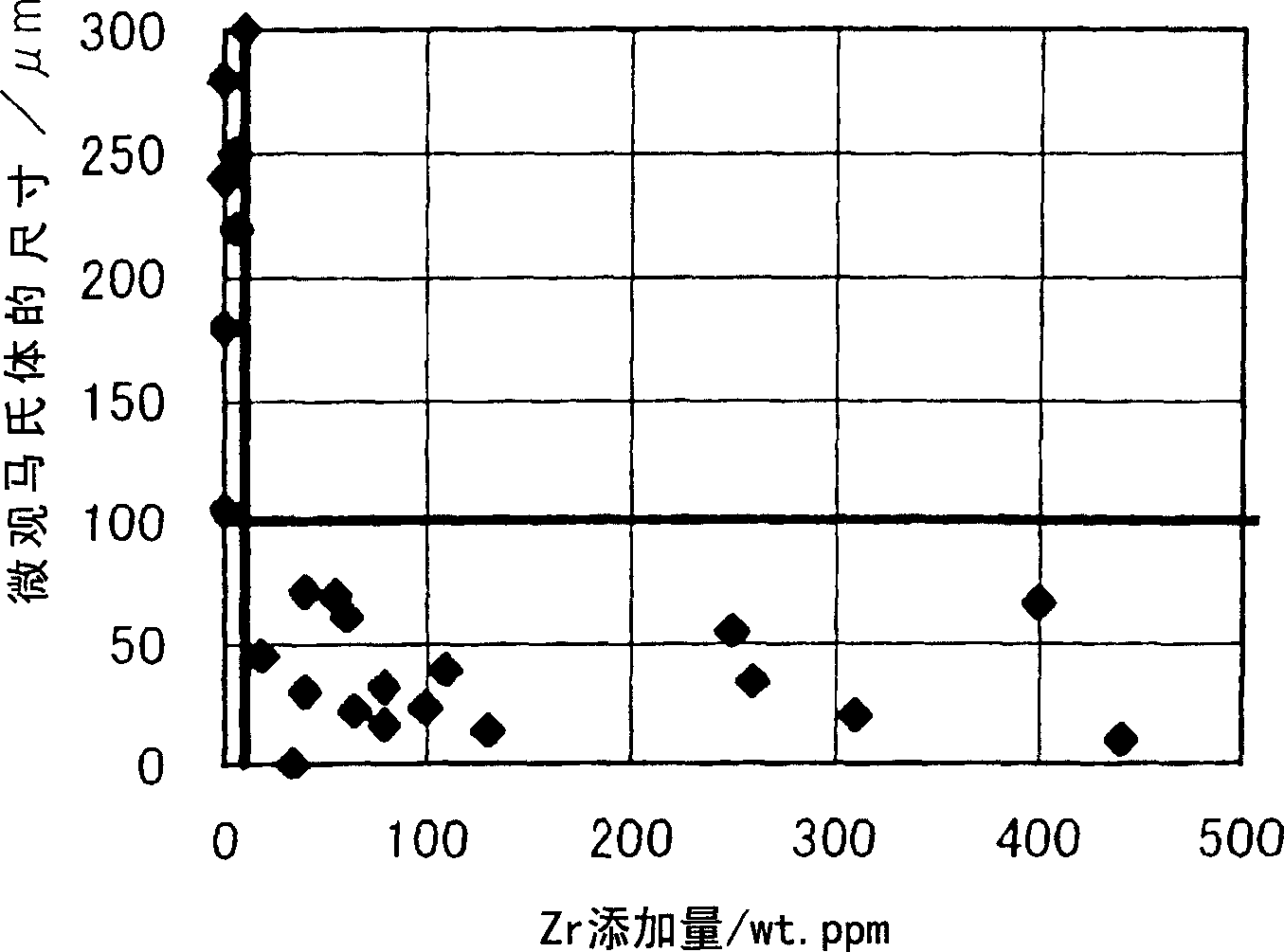

[0067] The hard steel wires with the chemical composition shown in Table 1 were used. After continuous casting, they were hot-rolled to become steel wires with a diameter of 11 mm, and then directly lead-bath quenched or reheated-lead-bath quenched under various conditions. (Lead bath quenching conditions: reheating at 950°C for 5 minutes → isothermal phase transition at 540°C for 4 minutes).

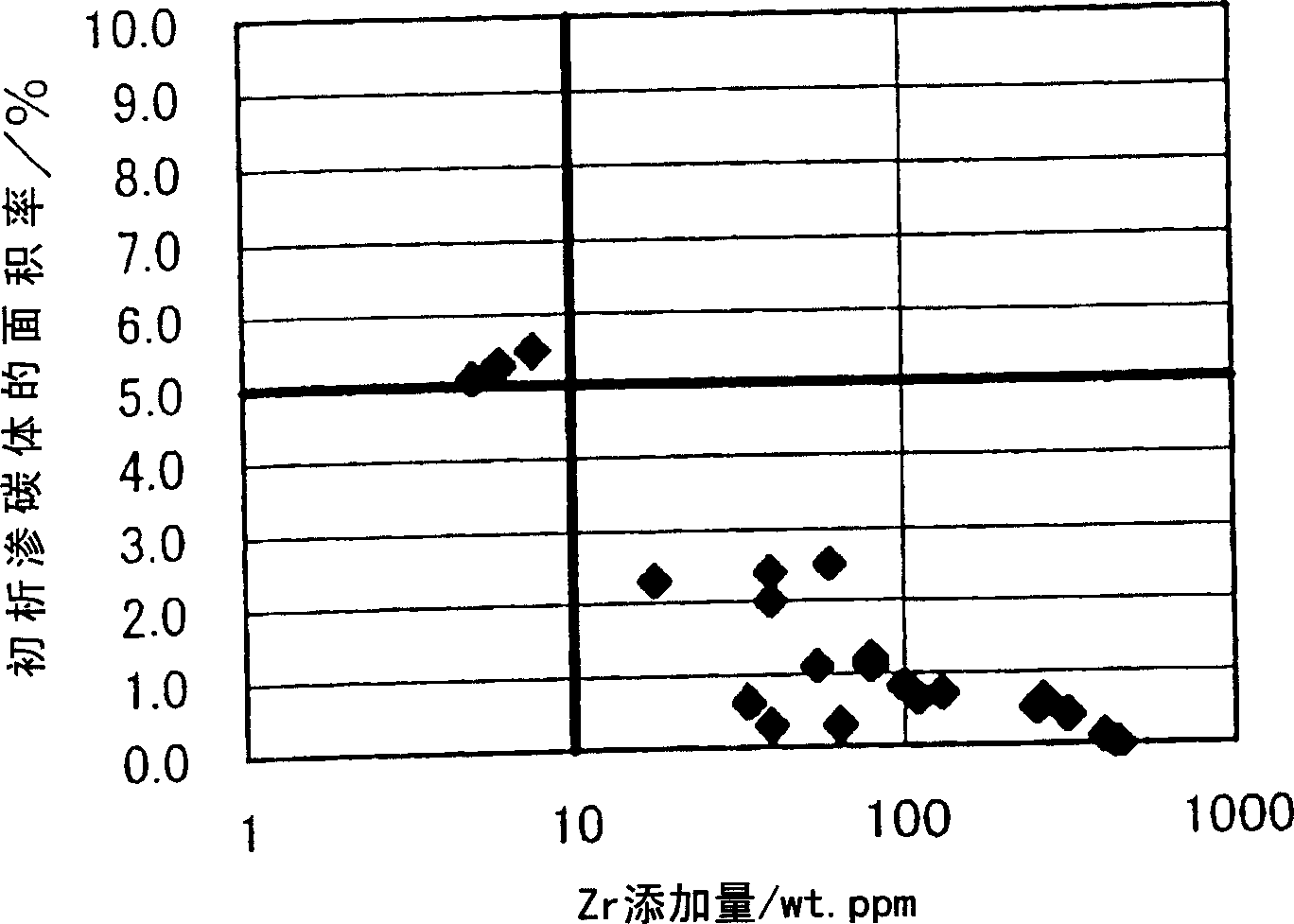

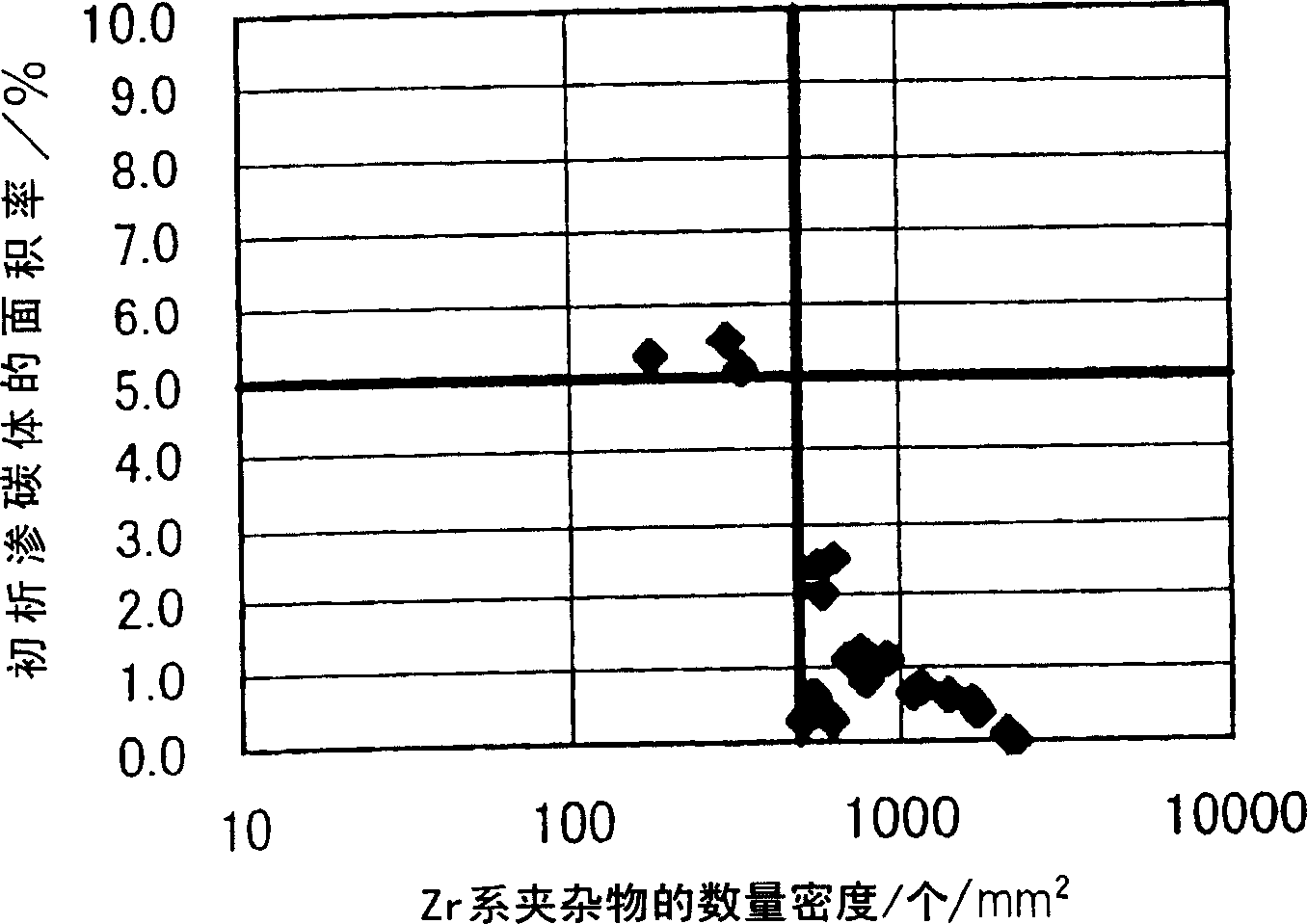

[0068] The lead-bath quenching material was subjected to mounting grinding and chemical corrosion with dodecanesulfonic acid, and the central area (r<0.2 d) Area ratio of proeutectoid cementite. In addition, mount grinding was carried out and chemical etching was carried out with nital etching solution, and the size of the microscopic martensite grains in the C section was determined by SEM observation. Moreover, the number density, size distribution and chemical composition of the inclusions w...

Embodiment 2

[0074] The molten steel containing C: 0.80%, Si: 0.20%, Mn: 0.70%, P: 0.010%, and S: 0.01% is smelted in a converter, and Zr is added to the ladle after adding Ti or Al.

[0075] The molten steel was cast with a bloom continuous casting machine. In the continuous casting machine, electromagnetic stirring is carried out in the crystallizer or in the casting stream, or the casting is carried out in a state of stopping stirring without electromagnetic stirring. In addition, depending on the situation, the light reduction method is used to apply the reduction at the end of the solidification. The size of the billet is 300mm×500mm. The slab was cut, and the solidification structure, center segregation, and inclusions were evaluated by the above method (the slab was rolled into a wire rod after casting, and the area ratio of proeutectoid cementite was measured).

[0076] In Table 3, Comparative Steel 8 is a slab obtained without adding Zr, and almost no equiaxed crystals are forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com