Process for manufacturing hot rolled steel strips by continuous casting and rolling middle bar strip

A technology of medium-thin slab continuous casting and hot-rolled strip steel, applied in heat treatment furnaces, metal rolling, heat treatment equipment, etc., can solve problems such as increased production costs for electricity, long buffer time, and increased investment, and achieve stable and consistent product performance , The temperature difference between the head and the tail of the steel strip is small, and the effect of reducing construction investment

Active Publication Date: 2010-12-01

BAOSHAN IRON & STEEL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Fifth, the cycle time of maintenance and shutdown required by different processes of steel rolling and continuous casting is different

At the same time, the temperature of the slab entering the furnace in the walking beam heating furnace is low, the latent heat of the slab cannot be fully utilized, and direct rolling cannot be realized

In comparison, the walking beam heating furnace is the most simple and mature, with less investment, low operation and maintenance costs, and easier to master, but it has certain restrictions on the single weight of the billet. If the single weight of the billet is too large, the furnace will be too wide , the investment increased a lot

The straight-through roller bottom tunnel furnace is used the most, and it has been proved to be reliable in production, with smooth process and flexible use, but it occupies a large area, which makes the production line too long and the maintenance cost is too high (mainly the regular replacement of heat-resistant rollers)

Induction heating furnace and hot coil box are relatively new technologies, with long buffer time, flexible heating temperature and heating depth, small footprint, but high maintenance costs, relatively large investment, for countries and regions with high electricity costs increase production costs

In the ISP process, due to the close connection between the roughing mill and the continuous casting machine, there are the following problems: the first cutting machine is arranged after the roughing mill, and the continuous casting machine and the roughing mill are connected by continuous casting slabs, and the production The process is difficult to control; since the continuous casting machine is in continuous low-speed production, it is required that the originally high-speed roughing unit should also be continuously produced at low speed and synchronously with the continuous casting machine. It is easy to deform under the action of the cast slab; without heating, there is a huge temperature difference between the edge and the middle of the slab, resulting in surface defects such as cracks on the edge of the steel plate

Same as the CSP process, there is a long tunnel roller hearth heating furnace, and the length of the entire production line increases

Method used

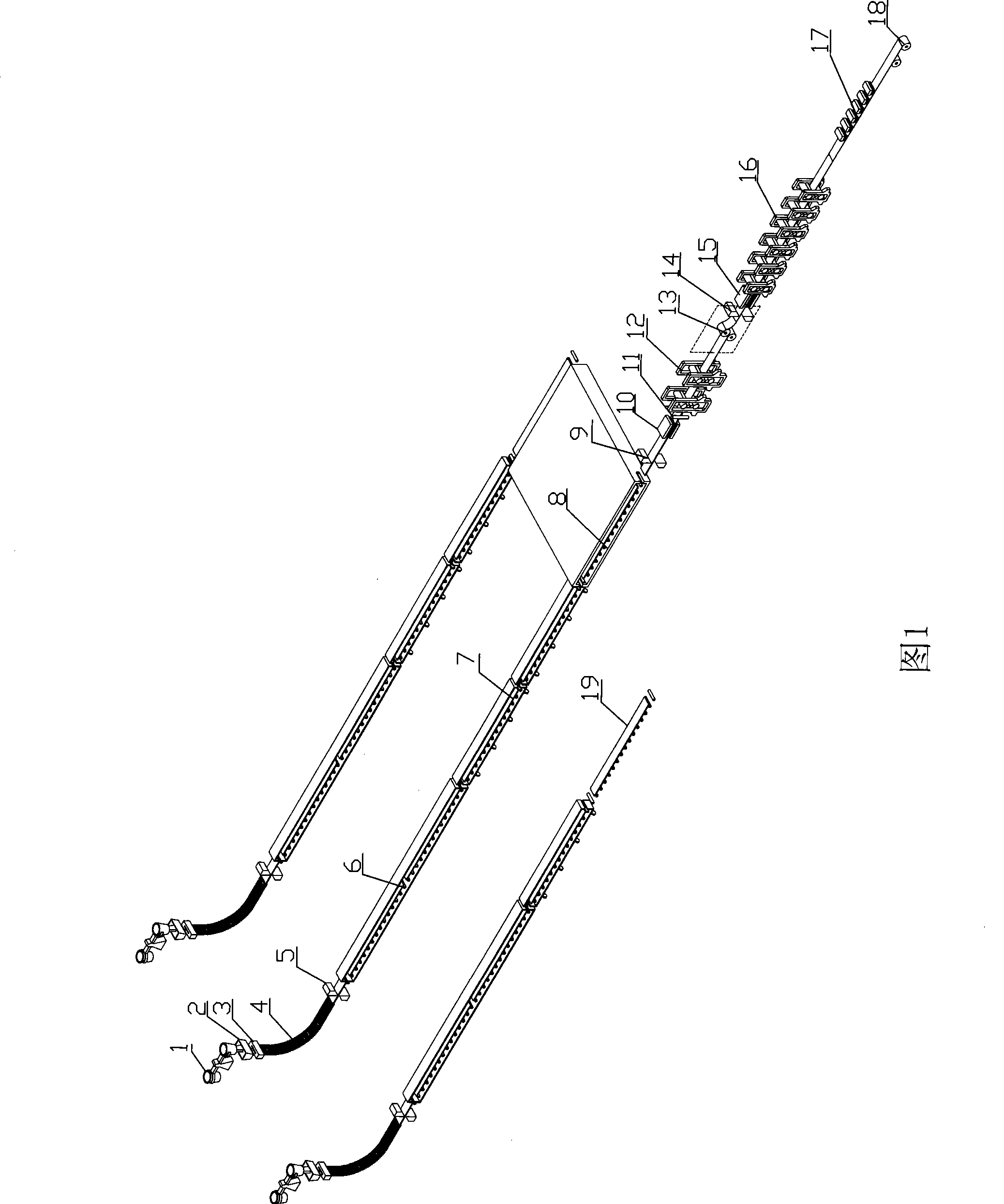

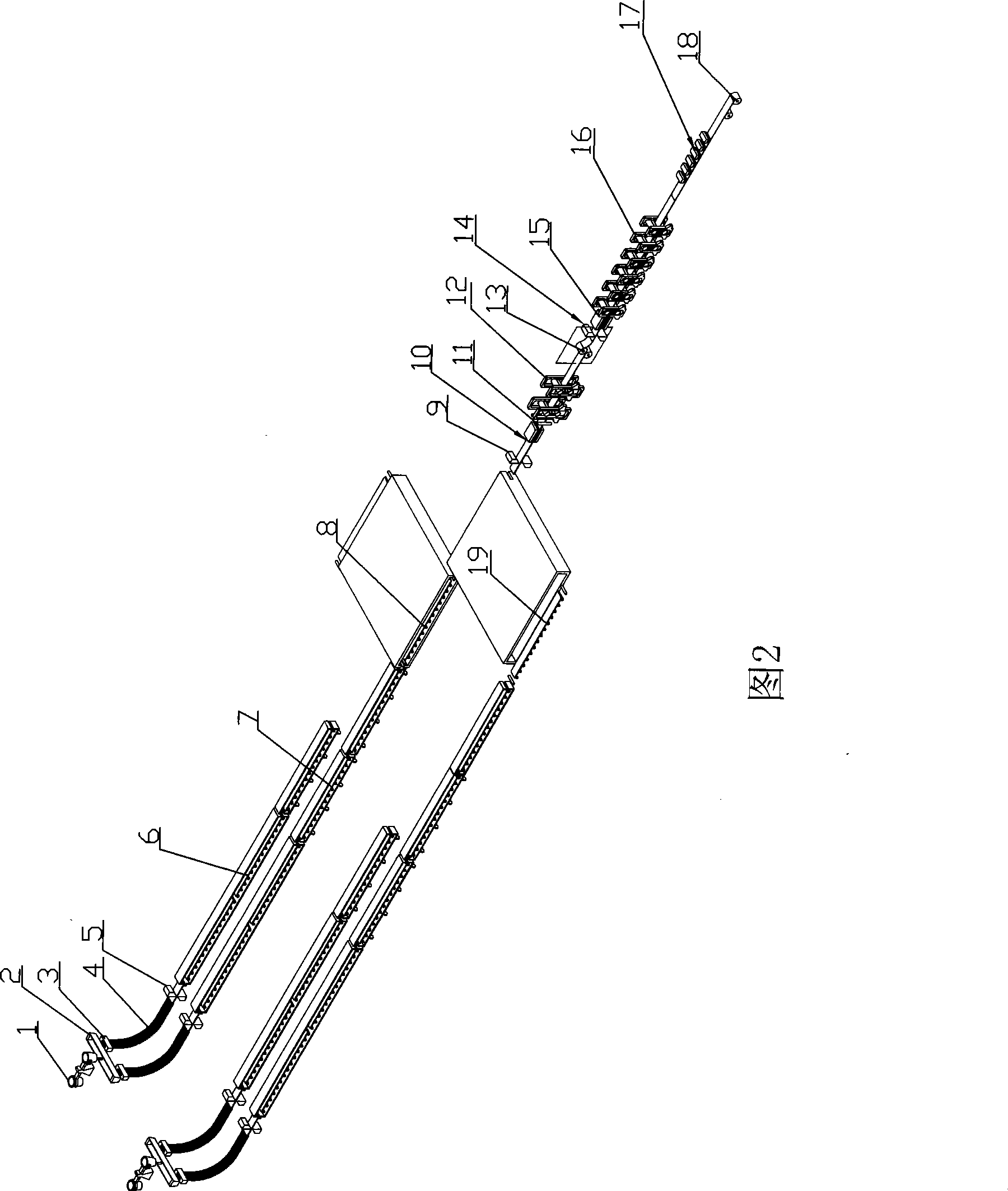

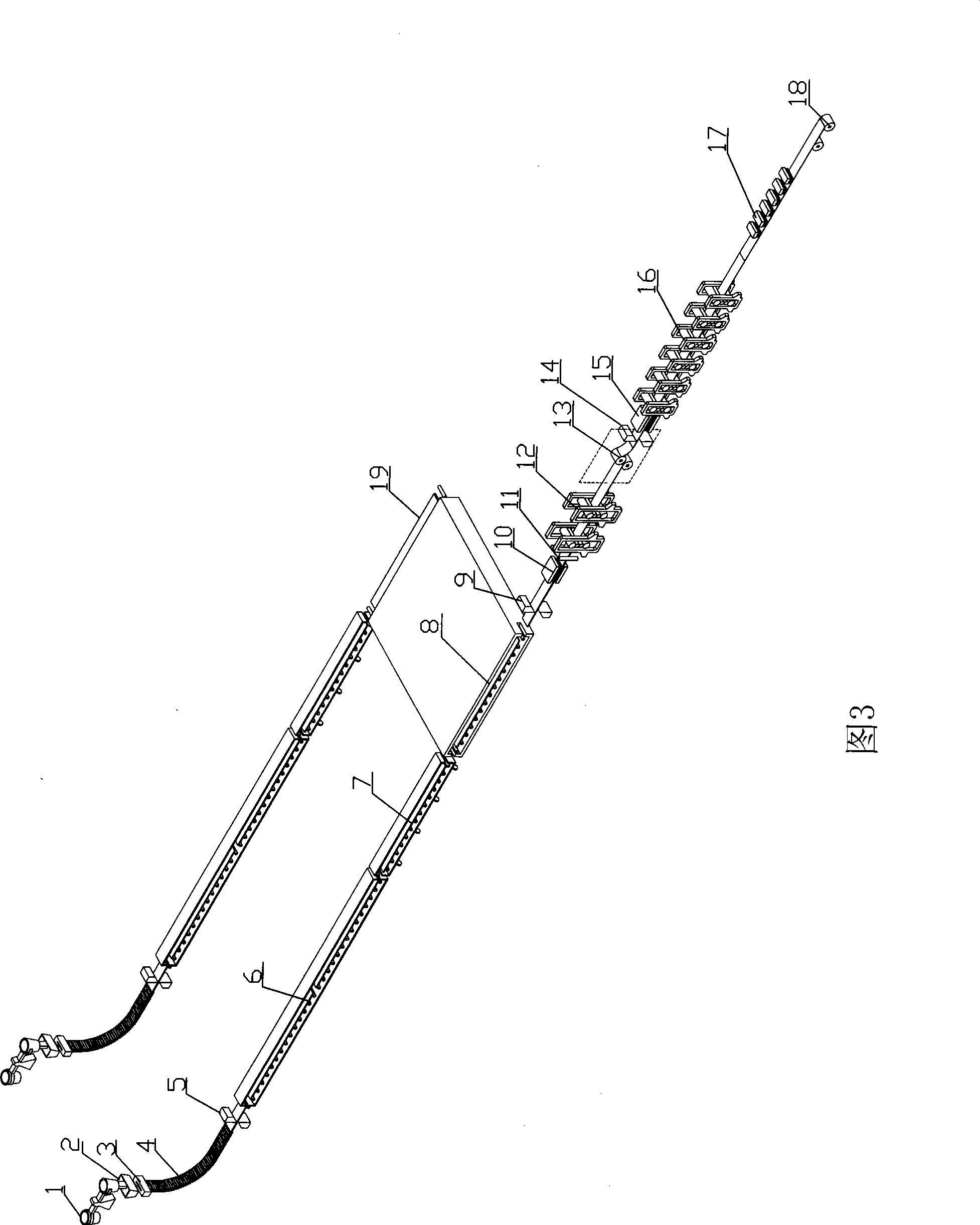

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a continuous casting and tandem rolling method for producing hot rolling strip steel by using medium sheet billet, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled inthe continuous caster to form a casting blank; 2) the casting blank enters a short tunnel roller hearth type heating furnace for heating; 3) a technology of converging a plurality of casting flows isadopted, one of the casting flows is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow, then passes through a walking beam and a holding zone of the roller hearth complex type heating furnace which is provided with a roller way and finally enters high pressure water for descaling; 4) the casting blank is prepared into an intermediate blank by rough rolling; 6) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 7) the steel strip is cooled and coiled into the finished steel coil. The method can reduce investment, save energy resource, improve the quality of products, expand the varieties of the products and lower production cost.

Description

Method for producing hot-rolled strip steel by continuous casting and rolling of medium and thin slabs technical field The invention relates to the technical field of metallurgy, in particular to a method and equipment for producing hot-rolled strip steel by continuous casting and rolling of medium and thin slabs. Background technique The continuous casting and rolling technology is to connect two mature technologies, each of which is a system - continuous casting and continuous rolling through the connecting zone. However, there are many inconsistencies and mismatching factors between these two technologies, so an important feature of continuous casting and rolling technology is the emergence of the connection buffer concept and corresponding technical equipment. First of all, there is a big mismatch between the operating rates of continuous rolling and continuous casting. The operating rate of continuous rolling is very high, up to 80-90%, while the operating rate of co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21B1/46B22D11/00B22D11/12C21D9/70C21D11/00

Inventor 徐荣军方园张立王喆陈应耀沈国强石振仓

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com