Method for Eliminating Crystalline Oxides on the Surface of Welded Joints

A welding joint and crystalline technology, which is applied in the field of eliminating crystalline oxides on the surface of welding joints, can solve the problems of increased process cost and unclean oxide removal, and achieves the elimination of hidden safety hazards, excellent product surface quality and difficult removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

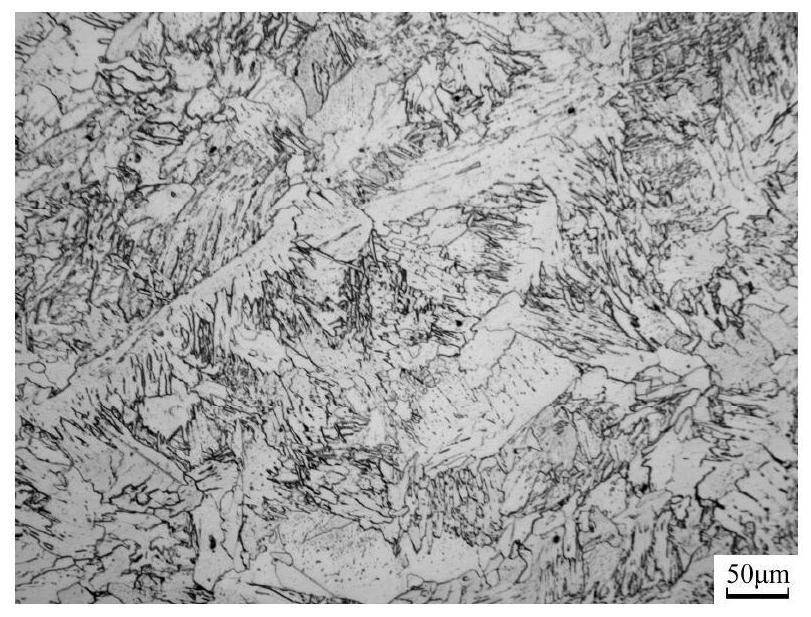

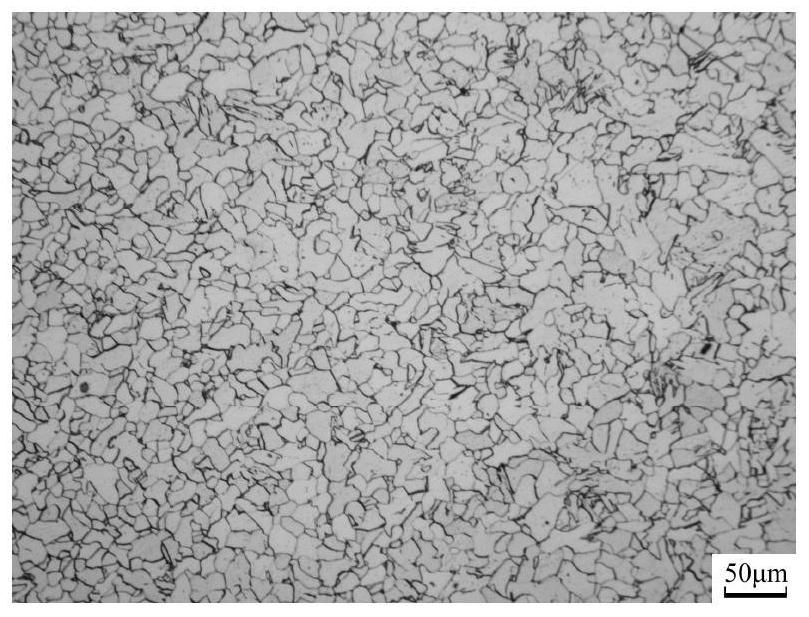

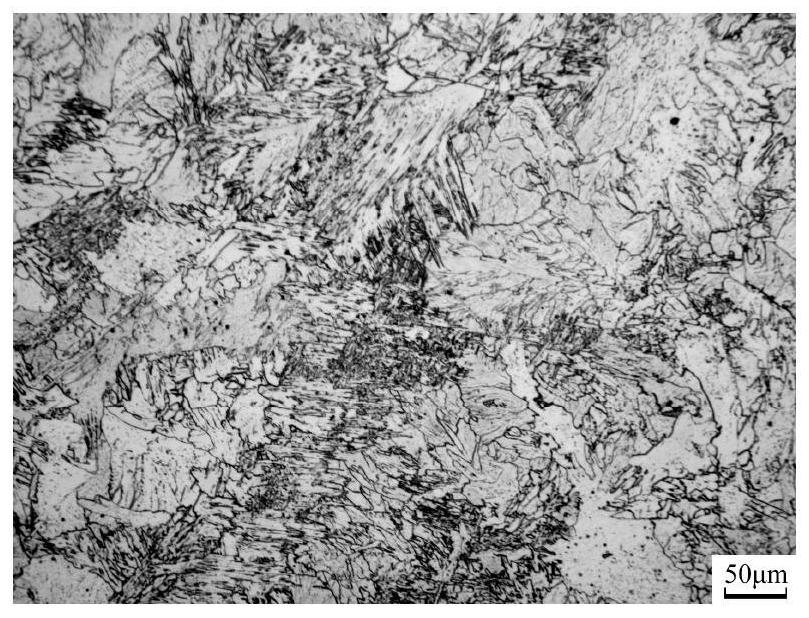

[0022] Embodiment 1: It is carried out by using the conventional plasma welding process of pickling plate, and the welding process parameters are shown in Table 1. The Si element mass percentage value of the pickling board is 0.01%, and the specific chemical composition is shown in Table 2. After implementation, no crystalline oxide was found on the surface of the weld. For the organization of each area of the welded joint, see image 3 , Figure 4 .

Embodiment 2

[0023] Embodiment 2: implement according to the welding process of embodiment 1. The mass percentage value of Si element in the chemical composition of the pickling board is 0.03%, and the specific chemical composition is shown in Table 2. After implementation, no crystalline oxide was found on the surface of the weld. The regional organization of welded joints and image 3 , Figure 4 approximate.

Embodiment 3

[0024] Embodiment 3: implement according to the welding process of embodiment 1. The mass percentage value of Si element in the chemical composition of the pickling board is 0.05%, and the specific chemical composition is shown in Table 2. After implementation, no crystalline oxide was found on the surface of the weld. The regional organization of welded joints and image 3 , Figure 4 approximate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com