Resin water stop valve cylinder, installation structure of resin water stop valve cylinder and water stop structure of faucet

A faucet and water stop technology, applied in the valve shell structure, valve operation/release device, valve device, etc., can solve the problems of mechanical strength reduction, corrosion, etc., and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Modes for implementing the invention (hereinafter referred to as embodiments) will be described below. In addition, in each embodiment, the same components, elements, and parts are given the same reference numerals, and descriptions thereof are omitted.

[0080] (valve receiving part)

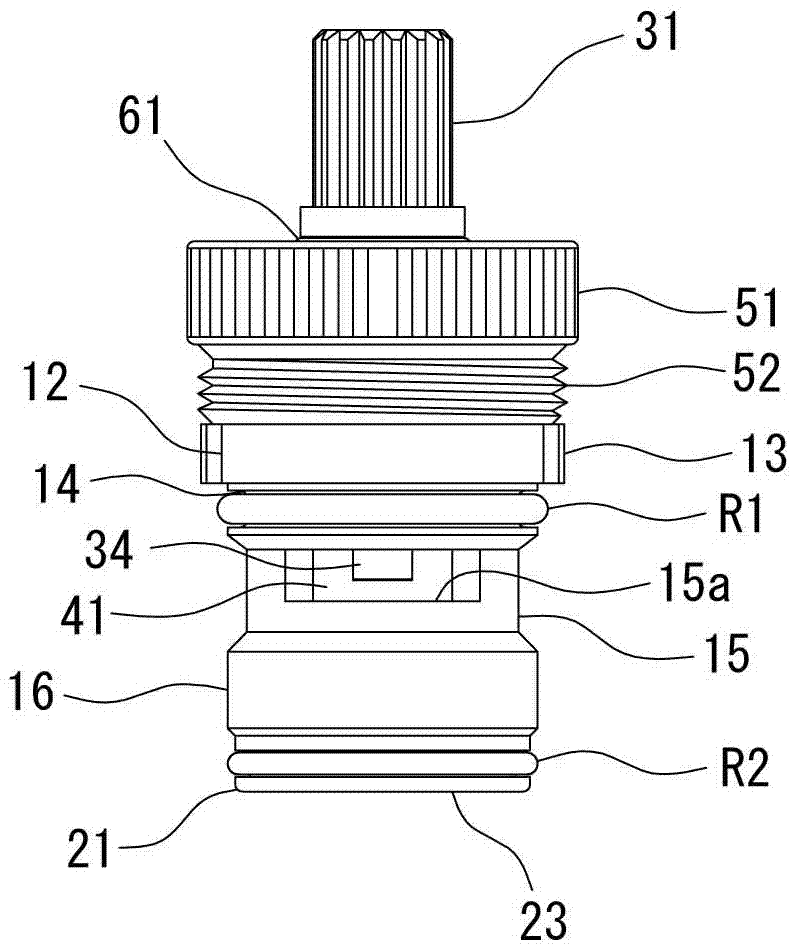

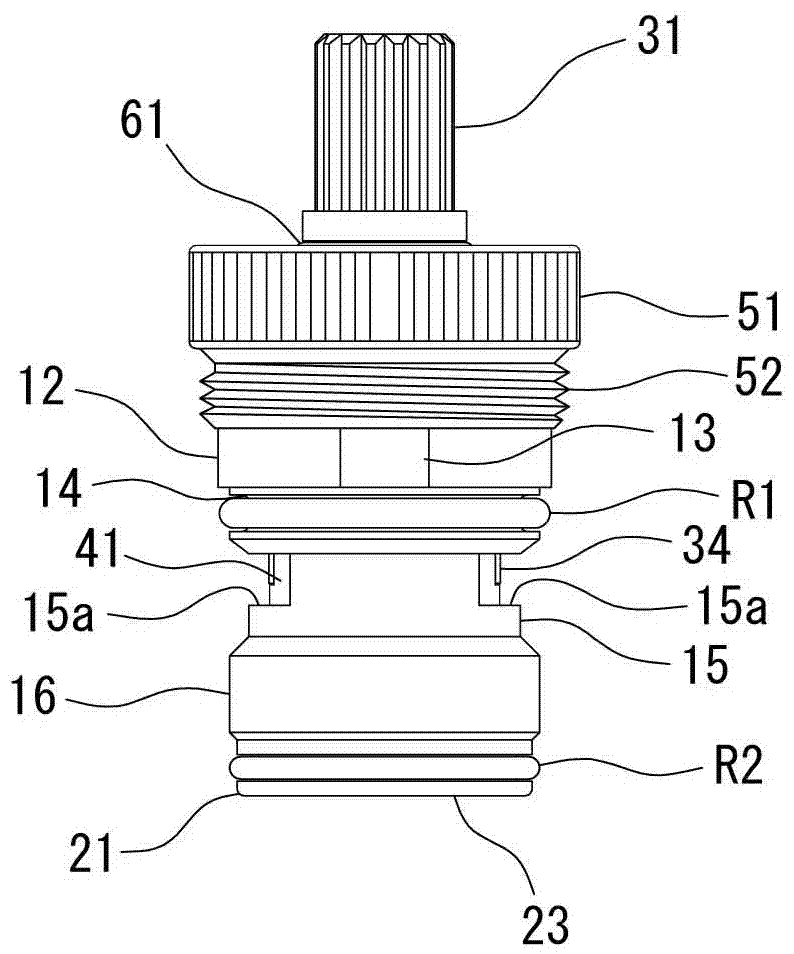

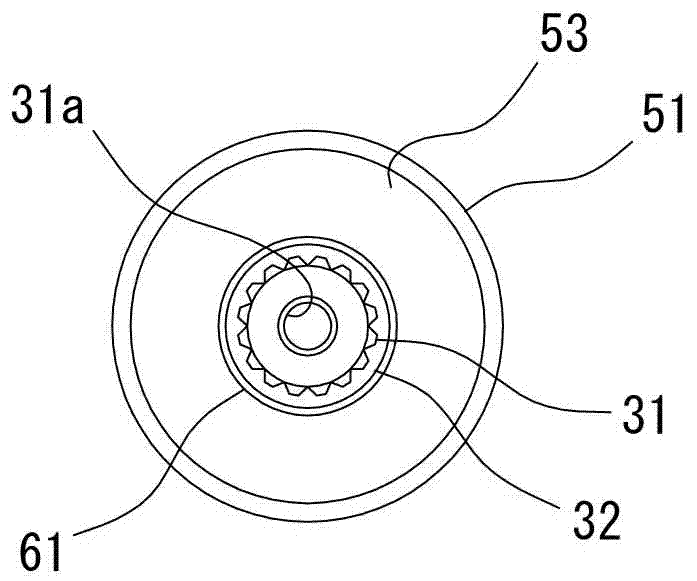

[0081] First refer to Figure 9 , the valve receiving portion 120 which is an attachment object (partner-side member) of the resin water stop valve cylinder of this embodiment will be described. In the valve receiving part 120, a water stop valve cylinder is attached to a water faucet such as a water supply faucet, and it is integrally formed on the water faucet as a member for internal water conduction and water stop by the operation of the water stop valve through the water stop valve cylinder. A predetermined portion of the substantially cylindrical peripheral wall 110 of the main body 100 . The valve receiving portion 120 includes a substantially cylindrical mounting portion 121 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com