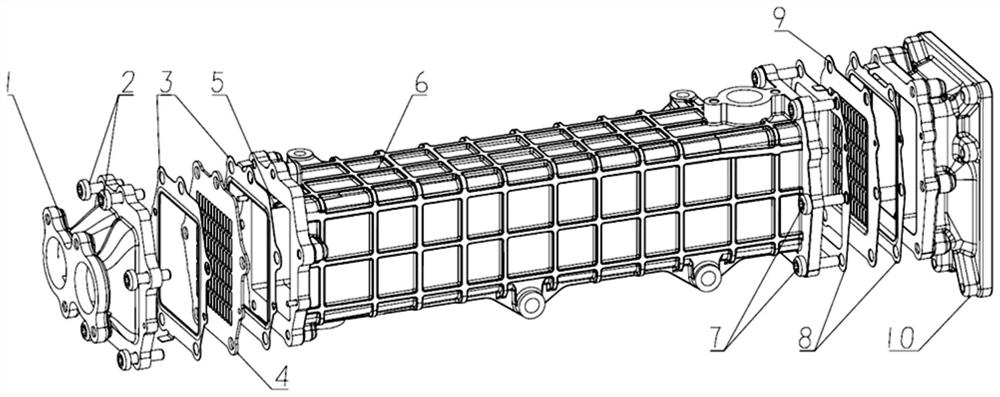

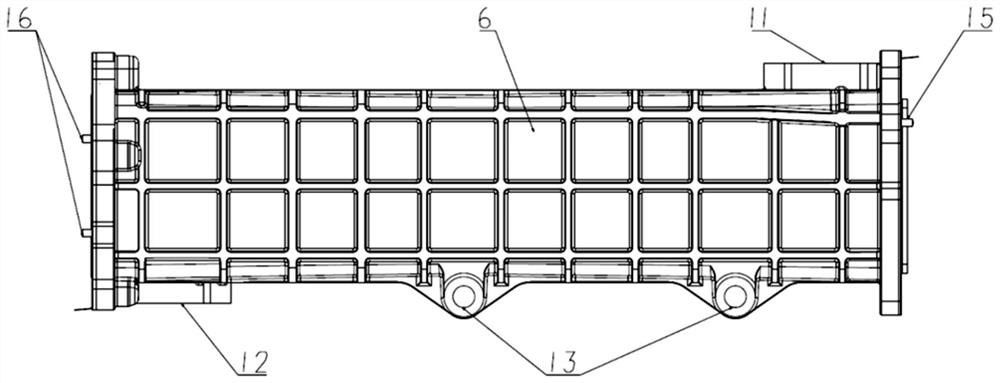

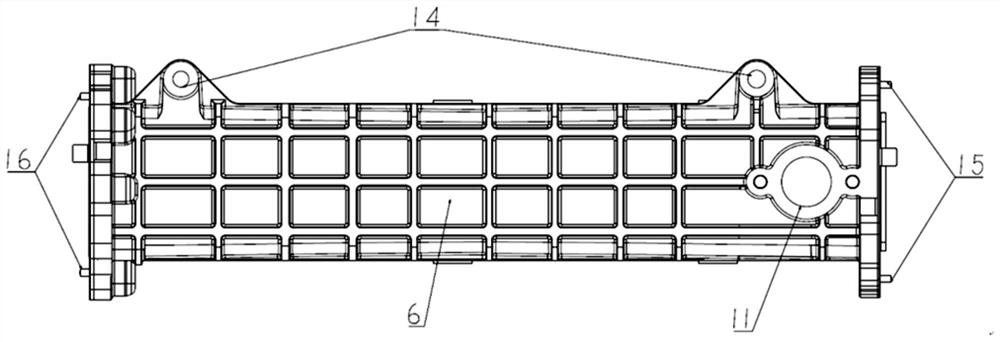

Exhaust gas recirculation cooler

An exhaust gas recirculation and cooler technology, applied in exhaust gas recirculation, machine/engine, charging system, etc., can solve problems such as affecting the assembly size of the engine end, difficulty in designing exhaust gas passages, and reducing assembly accuracy, so as to limit soot Effects of precipitation, reduced risk of boiling, and improved boiling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0043] In the present embodiment, the material of the pitted heat dissipation pipe 5 is stainless steel, and the cross-section is a rectangle.

[0055] The basic principles and main structural features of the present invention have been shown and described above. The present invention is not limited to the above examples

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com