Multilayer ceramic capacitor and manufacturing method thereof

A technology of ceramic capacitors and manufacturing methods, applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve problems such as unsatisfactory, and achieve the effect of inhibiting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

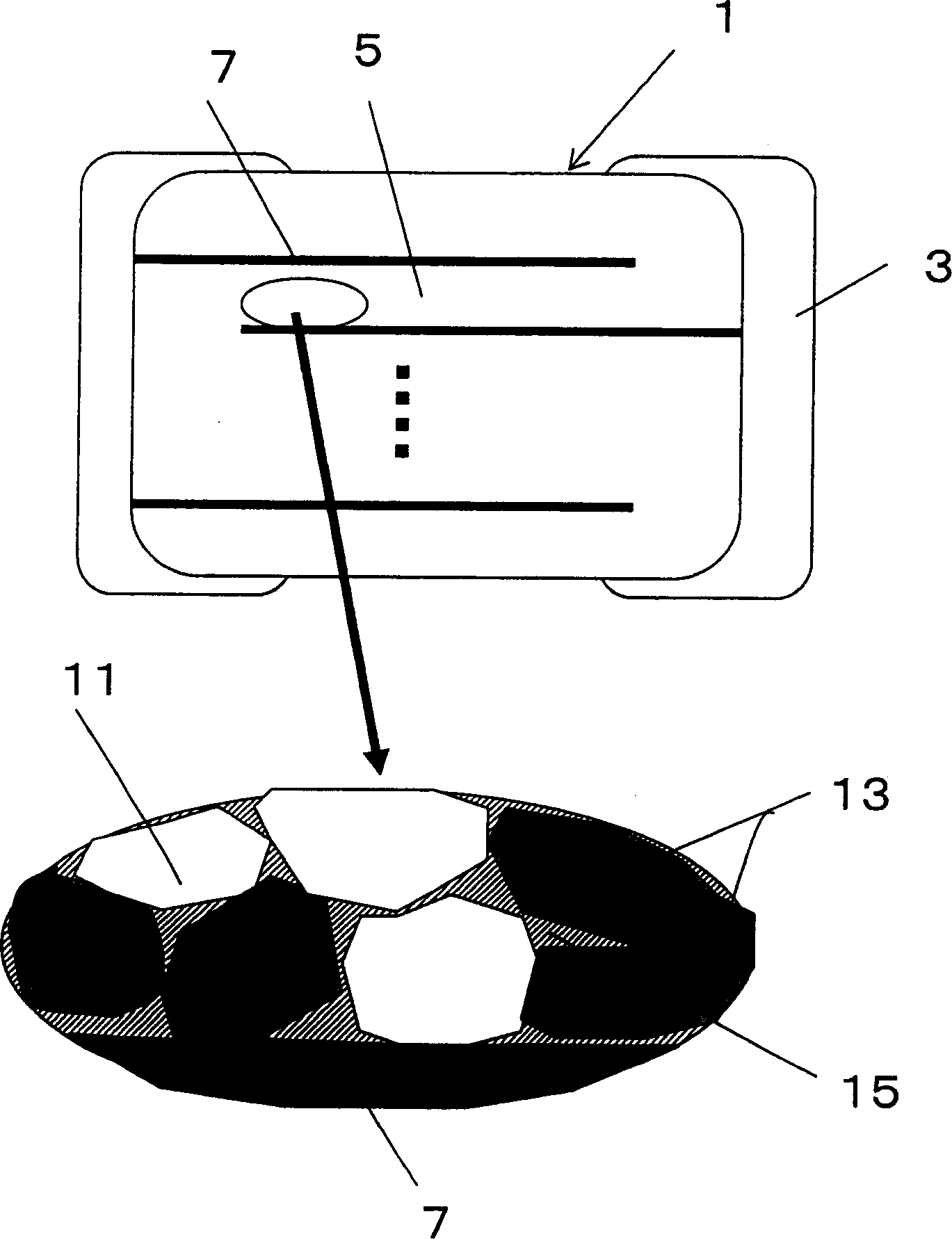

[0040] refer to figure 1 A schematic cross-sectional view of FIG. 2 will describe in detail the multilayer ceramic capacitor of this embodiment. The multilayer ceramic capacitor of the present invention is constituted by forming external electrodes 3 at both ends of a capacitor body 1 . The external electrodes 3 are formed, for example, by sintering Cu or an alloy paste of Cu and Ni.

[0041] Capacitor body 1 is formed by alternately laminating dielectric layers 5 and internal electrode layers 7 . The dielectric layer 5 is composed of dielectric particles 11 mainly composed of Ba and Ti having a low concentration of alkaline earth metals other than Ba, dielectric particles 13 mainly composed of Ba and Ti having a high concentration of alkaline earth metals other than Ba, and Grain boundary phase 15 constitutes. The thickness of the dielectric layer 5 is preferably 4 μm or less, and more preferably 3 μm or less from the viewpoint of increasing the capacitance. In addition, ...

no. 2 Embodiment approach

[0067] A second embodiment of the present invention will be described. The multilayer ceramic capacitor of the second embodiment has the same figure 1 composition shown.

[0068] In the present embodiment, BaTiO having an alkaline earth metal component concentration other than Ba of 0.2 atomic % or less coexists. 3 Particles (BMTL), and BaTiO having a concentration of alkaline earth metal components other than Ba of 0.4 atomic % or more, preferably 0.5 to 2.5 atomic % 3 Particles (BMTH). Importantly, when the average particle diameter of BMTL is defined as DL and the average particle diameter of BMTH is defined as DH, DL>DH, especially DL / DH=1.1-2.

[0069] If the alkaline earth metal component concentration of BMTL particles exceeds 0.2 atomic %, and the alkaline earth metal component concentration of BMTH is less than 0.4 atomic %, the alkaline earth metal component concentrations of BMTL and BMTL are large, and it is difficult to find the dielectric strength of diele...

Embodiment 1

[0093] A multilayer ceramic capacitor is fabricated as follows. First, pre-prepared BaTiO 3 (BT) and (Ba 0.95 Ca 0.05 )TiO 3 (BCT). In BaTiO 3 Add and mix 0.25 mole parts of MgO to the powder, and heat at the temperature shown in Table 1 for 2 hours. Next, relative to the calcined BaTiO 3 Powder and (Ba 0.95 Ca 0.05 )TiO 3 100 moles of powder, mixed with 0.5 moles of Y 2 o 3 , 0.3 moles of MnCO 3 , 0.25 moles of MgO, relative to BaTiO 3 Powder+(Ba 0.95 Ca 0.05 )TiO 3 100 parts by mass, mixed by Li 2 O, SiO 2 0.5 parts by mass of an additional component composed of CaO. Use ZrO with a diameter of 5mm 2 The ball mill wet-mills the mixed powder, adds an organic binder, and prepares a slurry.

[0094] Next, using the obtained slurry, a dielectric green sheet having a thickness of 2.5 μm was fabricated using an auxiliary plate. A conductive paste containing Ni metal was screen-printed on this dielectric green sheet to form internal electrode patterns. 388 diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com