Method for preparing ridge-shape light-wave-guide of optical crystal by ion injection method

An optical crystal and ion implantation technology, applied in the direction of optical waveguide light guide, optics, light guide, etc., can solve the problems that are difficult to realize, the influence of nonlinear optical properties of optical waveguide, etc., and achieve the effect of easy adjustment and control, and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

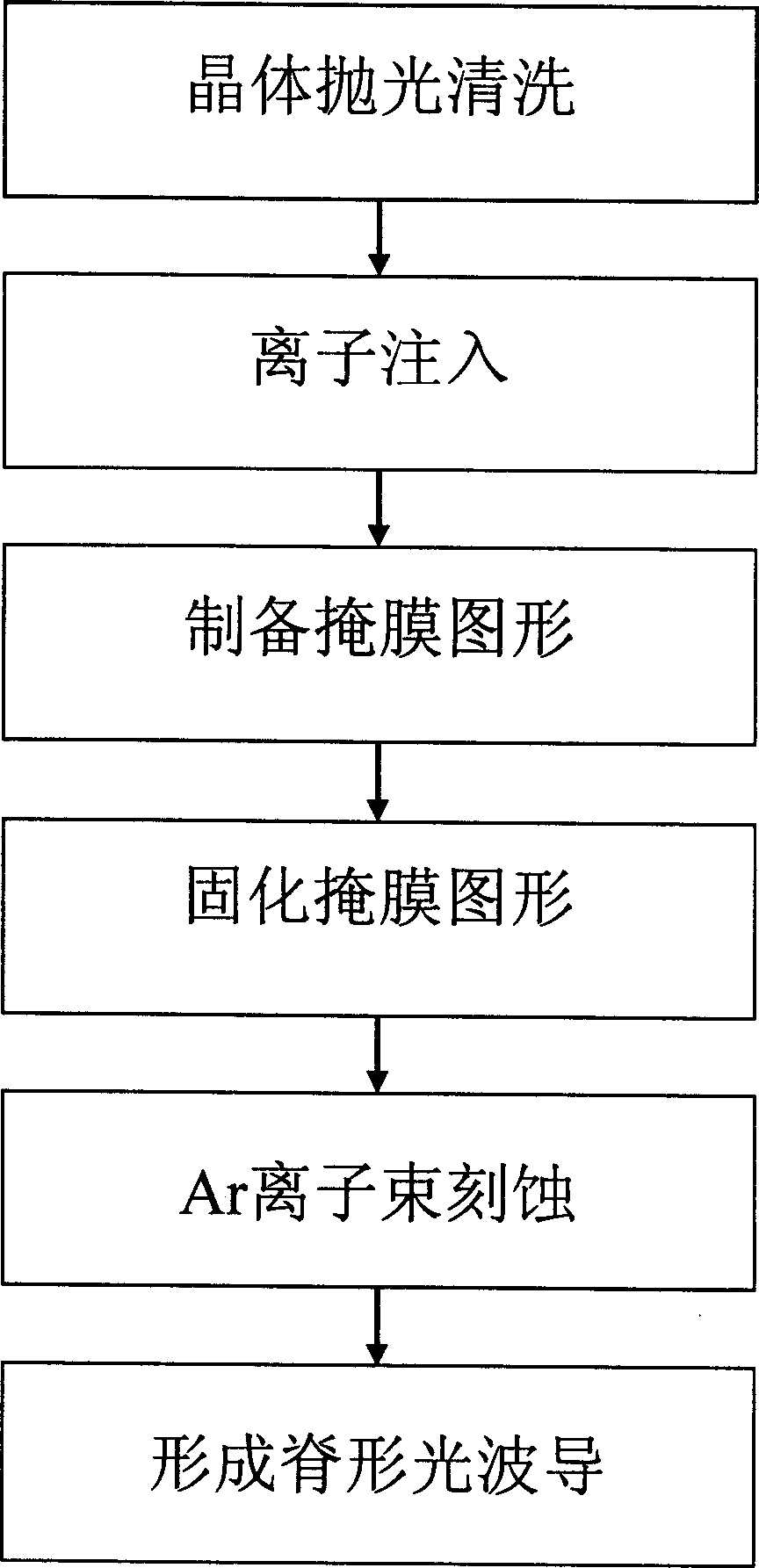

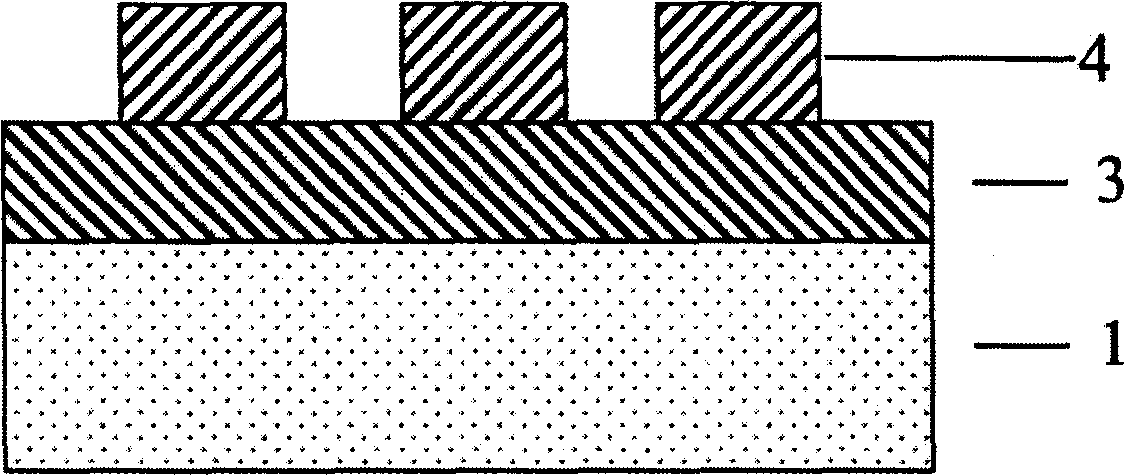

[0017] (5) Specific implementation methods Example 1: Preparation of ridge-shaped optical waveguide with increased refractive index of barium metaborate (β-BBO) crystal

[0018] Sample polishing: Cut the β-BBO crystal as a Z-cut with a size of 10 mm × 7 mm and a thickness of 2 mm, and the surface is optically polished. After the optical crystal (1) is cleaned with neutral detergent, deionized water and absolute ethanol, it is ready for ion implantation.

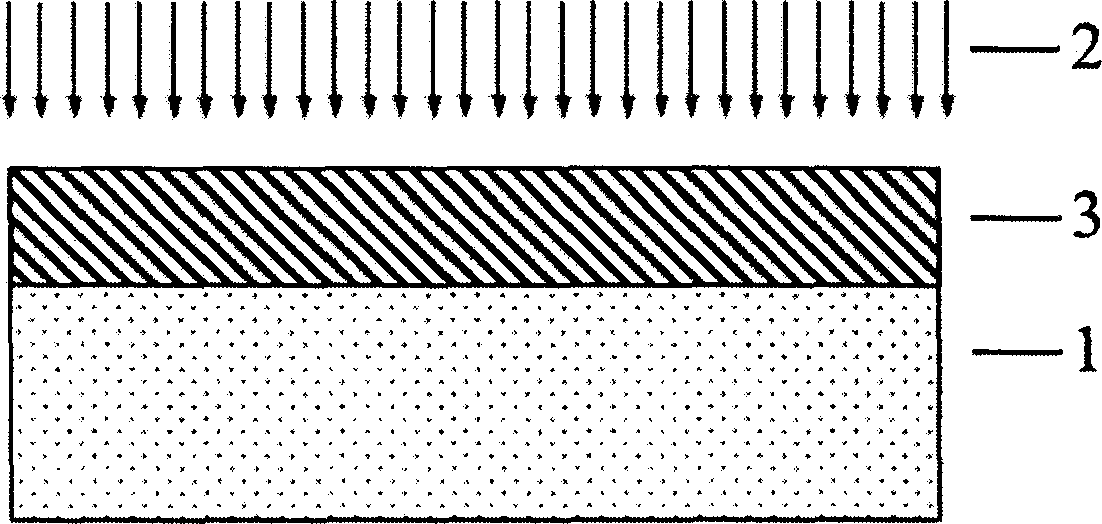

[0019] Ion implantation: put the prepared bottom sample in the target chamber of the accelerator, and evacuate to 10 -4 Pascal (Pa) magnitude. MeV energy ion implantation (2), the implantation conditions are: implanted ions: oxygen ions (O + ), ion energy: 2.2 megaelectric volts (MeV), implant dose: 5.0×10 14 ions / cm2. The ion beam current was 60 nanoamperes and the scanning area was 15 cm x 20 cm. Under this condition, a planar optical waveguide (3) with increased anomalous light refractive index in the waveguide region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com