Method for preparing stabilizing rare-earth oxide grate dielectric film

A rare earth oxide, gate dielectric technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as electrical properties and device performance deterioration, improve reliability and applicability, and improve electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

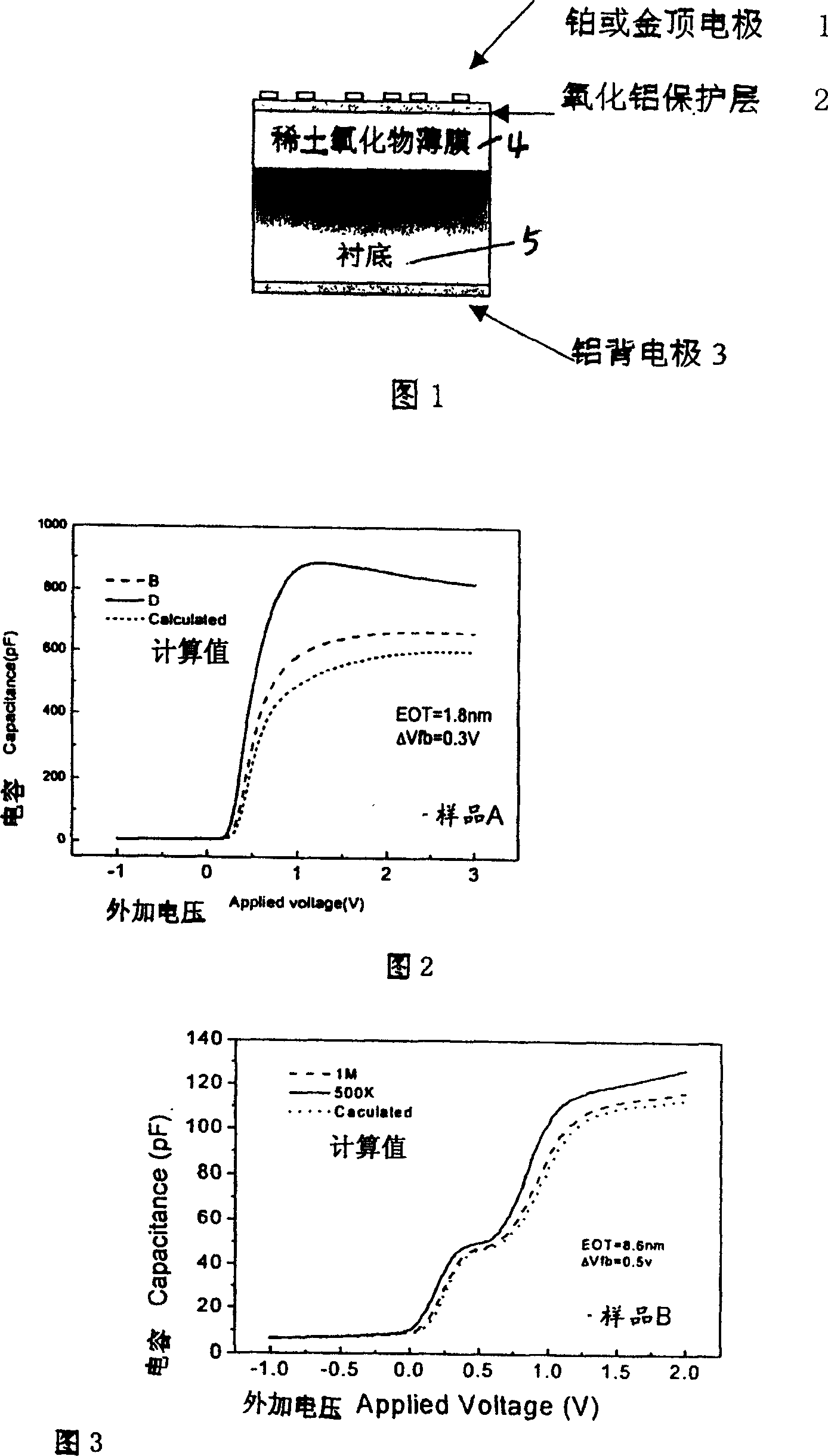

[0018] Using metal-organic chemical vapor deposition (MOCVD), on N-type 2-10Ωcm (100) single crystal silicon substrates, lanthanum β-diketone salts (La (dpm) 3 ) and aluminum acetylacetonate (Al(acac) 3 ) as MO source to prepare lanthanum oxide (La 2 o 3 ) gate dielectric film and aluminum oxide (Al 2 o 3 ) protective layer, the specific growth process parameters are: La (dpm) 3 The use temperature is 185~190℃, Al(acac) 3 The operating temperature is 90-95°C, and the carrier gas is high-purity N 2 , the deposition pressure in the reaction chamber is 2-4 Torr, the deposition temperature is 650°C, and the deposition atmosphere is oxygen. The growth time of the lanthanum oxide film is 5-30 minutes. The growth time of the aluminum oxide film is 0-3 minutes. Taking lanthanum oxide gate dielectric film as an example, chemical vapor deposition (CVD) or physical vapor deposition (PVD) is used to prepare other rare earth oxides with similar growth methods, and the properties of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com