Organic silicide modified hydrophobic positive electrode material and preparation method thereof

An organosilicon compound and cathode material technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve problems such as alkali adsorption of moisture, achieve low cost, improve material interface stability and stability, and reduce electrolyte erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the organic silicide-modified hydrophobic positive electrode material involved in the present invention comprises the following steps:

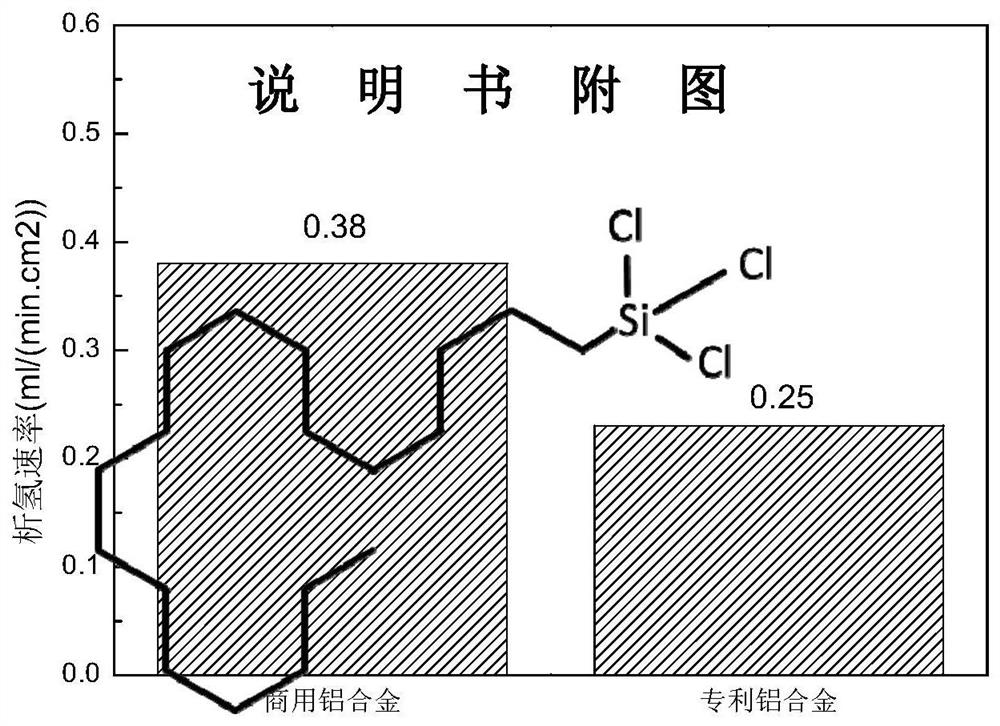

[0023] S1. Co-doping the base positive electrode material with Mo / Al elements, washing with deionized water, and coating with Ce oxide;

[0024] S2, adding the organic silicon compound into the solvent to form a uniform solution; the organic silicon compound is octadecyltrichlorosilane (OTS), and the molecular structure is shown in figure 1 The solvent is one or more of alkanes, ketones, pyridine, ethers, preferably one or more of normal hexane, cyclohexane, acetone, pyridine, propylene glycol ether, ether, more preferably One or more of n-hexane, cyclohexane, and propylene glycol ether. Preferably, the volume ratio of the organic silicon compound to the solvent is 1:(100-300).

[0025] S3, adding the positive electrode material of the matrix into the mixed uniform solution, and stirring at a constant speed ...

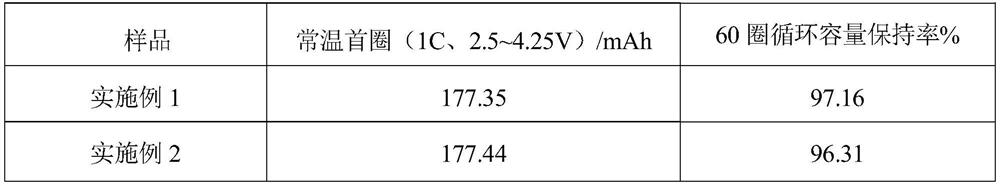

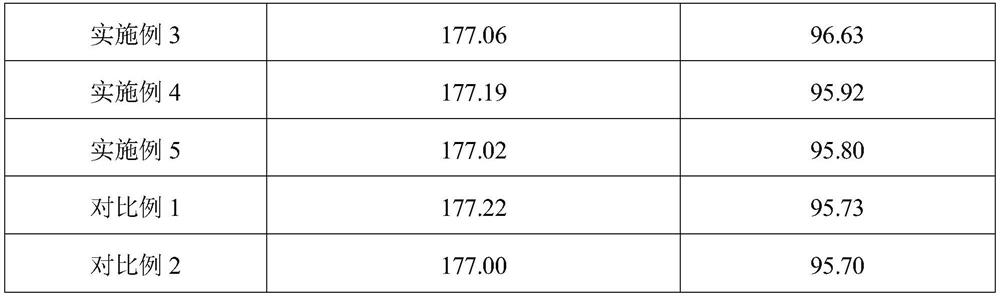

Embodiment 1

[0028] A method for preparing an organosilicon compound-modified hydrophobic positive electrode material, comprising the steps of:

[0029] S1. Co-doping the base positive electrode material with Mo / Al elements, washing with deionized water, and coating with Ce oxide;

[0030] S2. Take octadecyltrichlorosilane and n-hexane separately, configure 200mL n-hexane solution of octadecyltrichlorosilane with a volume ratio of 1:200, and stir evenly;

[0031] S3. Weighing 100 g of the matrix positive electrode material, slowly adding the positive electrode material into the n-hexane solution of octadecyltrichlorosilane, stirring at a constant speed for 3 hours, to obtain a solid-liquid mixture;

[0032] S4. Use filtering equipment to filter the obtained solid-liquid mixture, transfer the filtered solid filter cake to a vacuum oven at 80°C for 12 hours, and the vacuum degree is (-0.1~-0.08) MPa to obtain a hydrophobic positive electrode Material.

Embodiment 2

[0034] S1. Co-doping the base positive electrode material with Mo / Al elements, washing with deionized water, and coating with Ce oxide;

[0035] S2. Weigh octadecyltrichlorosilane and n-hexane respectively, configure 200mL n-hexane solution of octadecyltrichlorosilane with a volume ratio of 1:300, and stir evenly;

[0036] S3. Weighing 100 g of the matrix positive electrode material, slowly adding the positive electrode material into the n-hexane solution of octadecyltrichlorosilane, stirring at a constant speed for 3 hours, to obtain a solid-liquid mixture;

[0037] S4. Use filtering equipment to filter the obtained solid-liquid mixture, transfer the filtered solid filter cake to a vacuum oven at 80°C for 12 hours, and the vacuum degree is (-0.1~-0.08) MPa to obtain a hydrophobic positive electrode Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com