Far infrared radiating hollow 3-D crimped polyester fiber and its making process

A technology of far-infrared radiation and three-dimensional crimping, applied in the field of far-infrared radiation hollow three-dimensional crimping polyester fiber and its production, can solve the problems of not having health care functions, and achieve the effect of good bulkiness and good health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

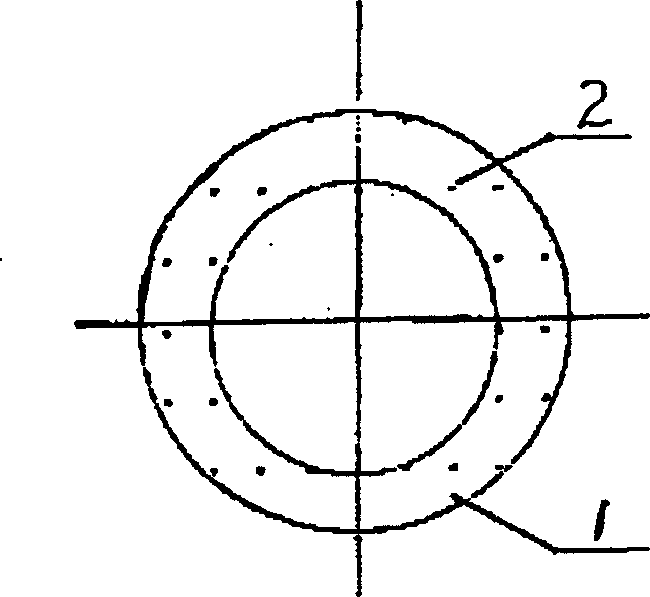

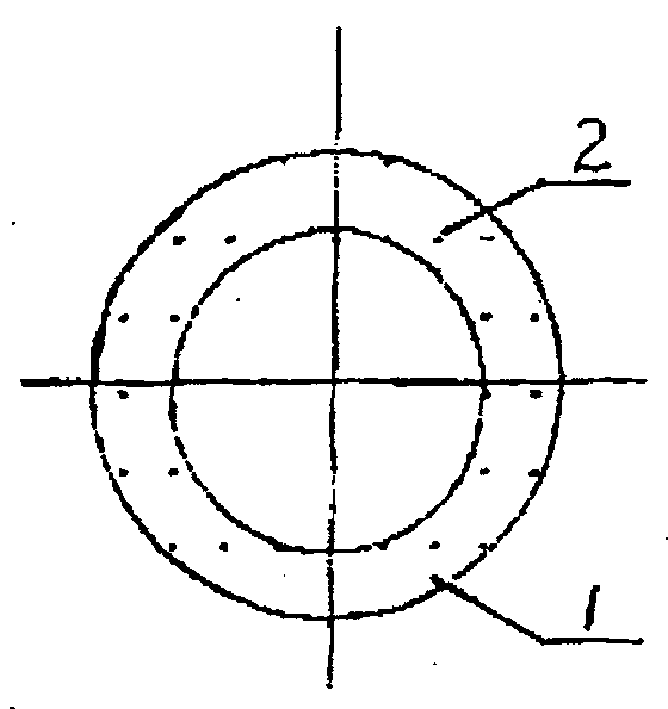

Image

Examples

Embodiment 1

[0034]Take a variety of far-infrared inorganic materials whose basic components are silicon dioxide (28.5%), aluminum oxide (4%), titanium dioxide (61%), and zirconium dioxide (6.5%). Crushed to a particle size of 0.45 μm, then placed in a high-temperature furnace for sintering at a temperature of 900 ° C, sintered and cooled, and then pulverized, the particle size was still controlled at 0.45 μm, and a composite inorganic far-infrared ultrafine powder was obtained. Get 40 parts of the ultrafine powder, 3 parts of tris (dioctyl pyrophosphate) titanate, 1 part of ethylene bis stearamide, and then get 56 parts of polyethylene terephthalate carrier, and They are mixed together in a high-speed mixer, and the obtained mixed powder is sent to a twin-screw extruder for blending and extrusion, and pelletized. The specific masterbatch blending process is as follows:

[0035] Temperature in each zone of the screw ℃ Pressure Main screw speed Feeding screw speed

[0036] Work I ...

Embodiment 2

[0042] Fabricate the fiber of the present invention with polyethylene terephthalate melt that contains about 4% far-infrared radiation additive, have adopted 16 purpose aluminum oxide filter sands and 250 purpose wire mesh to filter melt, at 1180 m / Spinning at a winding speed of 10 minutes, the post-drawing is 3.033 times. Spinning was normal until 72 hours, and the obtained fiber was a qualified product.

Embodiment 3

[0044] The same melt is filtered by 40-mesh sea sand and 250-mesh wire mesh, and is spun and wound under the same conditions as above. Spinning was normal until 36 hours, and the resulting fiber was a qualified product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com