Super-weather-resistant coating composition for decorative aluminum veneer and preparation method of super-weather-resistant coating composition

A super-weather-resistant, composite technology, applied in the direction of polyester coatings, anti-corrosion coatings, coatings, etc., can solve the problems of damage, high energy consumption, high price, etc., and achieve the effects of increasing reaction rate, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

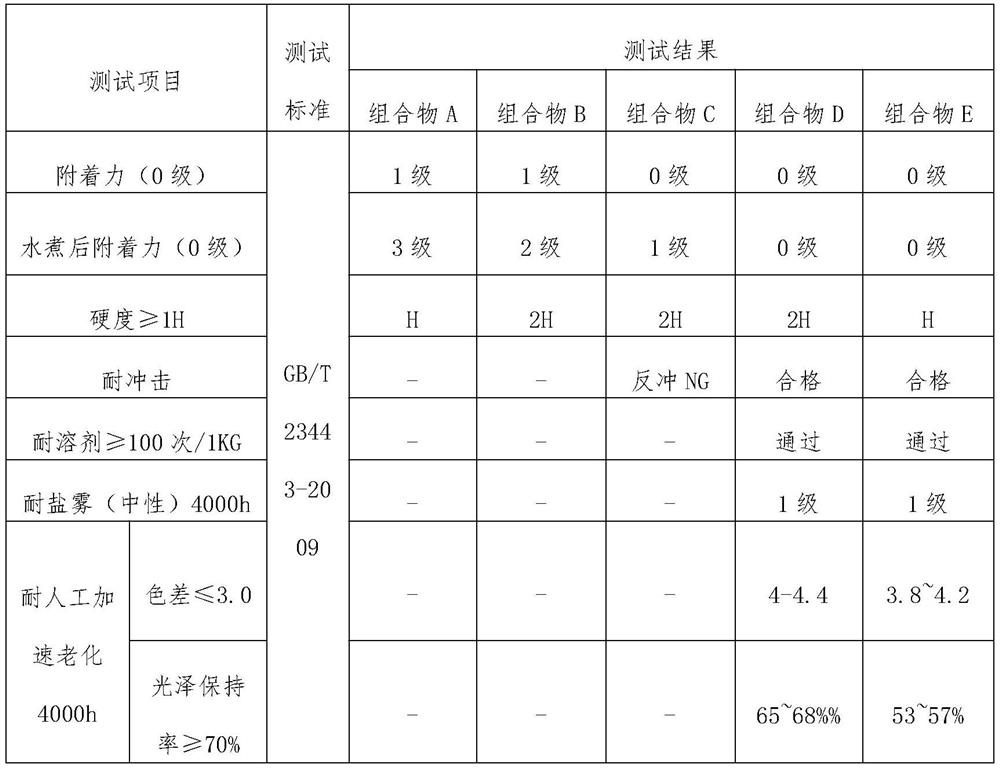

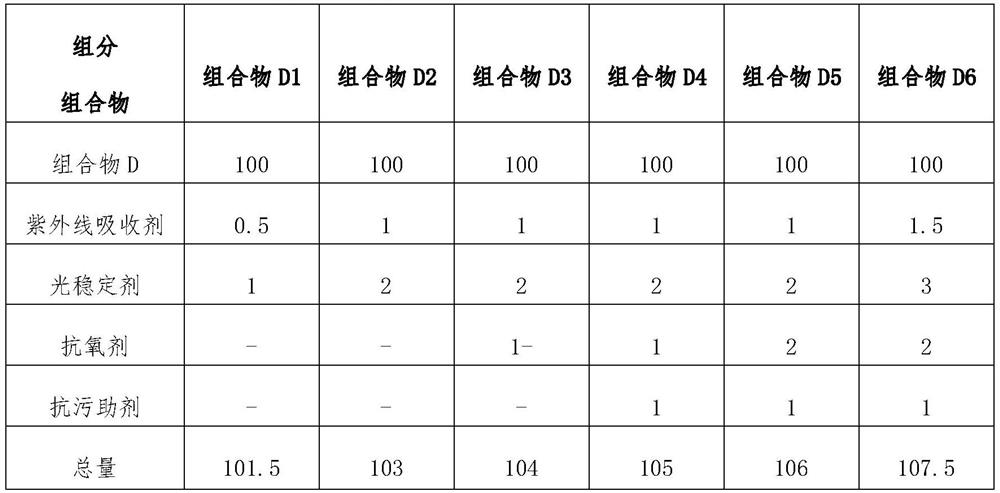

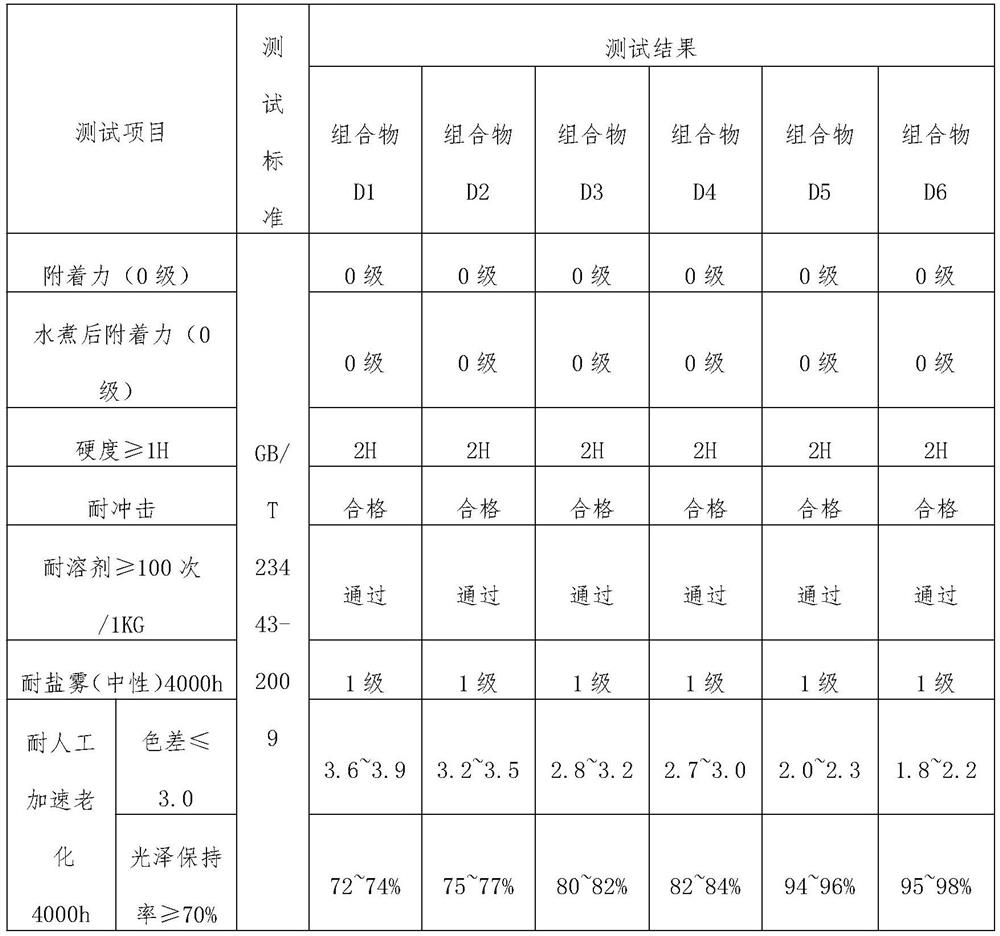

Examples

Embodiment 1

[0027] The preparation of embodiment 1 super weather-resistant coating composition A

[0028] (1) At room temperature, put 35 parts of high molecular weight polymer resin ES-750 into the bucket (add in two times), add 0.3 part of dispersant BYK-163 while stirring at 300-400 rotation speed on the upper disc disperser, then Disperse for 10 to 15 minutes, then add 28 parts of rutile titanium dioxide CR826 while stirring, disperse at 800 to 1200 revolutions for 20 to 30 minutes, take out the material and wait for the temperature to cool to room temperature, then grind it on a sand mill, and control the temperature of the outlet during the grinding process It cannot exceed 45°, the sand mill must have a cooling system, and the fineness of the material to be ground is less than or equal to 10um to be qualified;

[0029] (2) At room temperature, put 35 parts of high molecular weight polymer resin ES-750 into the barrel, put 12 parts of amino resin 303LF into the upper disc disperser ...

Embodiment 2

[0031] The preparation of embodiment 2 super weather-resistant coating composition B

[0032] (1) At room temperature, put 35 parts of high molecular weight polymer resin ES-750 into the bucket (add in two times), add 0.3 parts of dispersant BYK-1630 while stirring at 300-400 rotation speed on the upper disc disperser, and then disperse For 10 to 15 minutes, add 28 parts of rutile titanium dioxide CR826 while stirring, disperse at 800 to 1200 revolutions for 20 to 30 minutes, take out the material and wait for the temperature to cool to room temperature and then grind it on a sand mill. If it exceeds 45°, the sand mill must have a cooling system, and the fineness of the material to be ground is less than or equal to 10um.

[0033] (2) At room temperature, put 35 parts of high molecular weight polymer resin ES-750 into the barrel, put 12 parts of amino resin 303LF into the upper disc disperser at 300-400 rotation speed while stirring and disperse for 10-20 minutes, and then gri...

Embodiment 3

[0035] The preparation of embodiment 3 super weather-resistant coating composition C

[0036](1) At room temperature, put 37 parts of high molecular weight polymer resin ES-750 into the bucket (add in two times), add 0.3 part of dispersant BYK-163 while stirring at 300-400 rotation speed on the upper disc disperser, then Disperse for 10 to 15 minutes, then add 28 parts of rutile titanium dioxide CR826 while stirring, disperse at 800 to 1200 revolutions for 20 to 30 minutes, take out the material and wait for the temperature to cool to room temperature, then grind it on a sand mill, and control the temperature of the outlet during the grinding process It cannot exceed 45°, the sand mill must have a cooling system, and the fineness of the material to be ground is less than or equal to 10um to be qualified;

[0037] (2) At room temperature, put 30 parts of high molecular weight polymer resin ES-750 into the barrel, put in 3 parts of Bayer BL3175, a sealing curing agent, and 10 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com