Multi-element positive electrode material as well as preparation method and application thereof

A positive electrode material and multi-component technology, applied in the field of multi-component positive electrode materials and its preparation, can solve problems such as poor structural stability, serious side reactions, and inability to meet application requirements, and achieve improved stability, improved gram capacity, and improved oxygen evolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the above-mentioned product includes roasting and calcining process, wherein the heating process of the roasting process below 600 ° C adopts an oxygen-depleted or oxygen-free atmosphere with an oxygen content of <20vol%, and at 600 ° C and above, an oxygen content of ≥ 20vol% is used. Air and / or oxygen atmosphere.

[0054] A second aspect of the present invention provides a method for preparing a multi-element positive electrode material, characterized in that the method comprises the following steps:

[0055] (1) Prepare mixed salt solution with nickel salt, cobalt salt and manganese salt according to the molar ratio of n(Ni):n(Co):n(Mn)=x:y:(1-x-y-a-b); Mixing agent, dispersing agent and optionally first additive, respectively formulated as precipitant solution, complexing agent solution, dispersing agent solution and optionally first additive mixture;

[0056] (2) the mixed salt solution, the precipitant solution, the complexing agent solu...

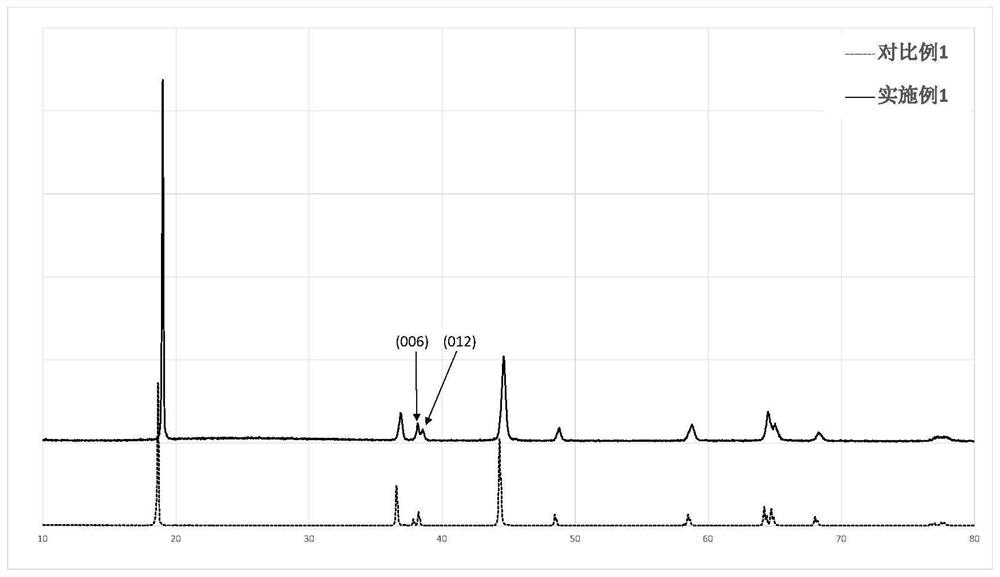

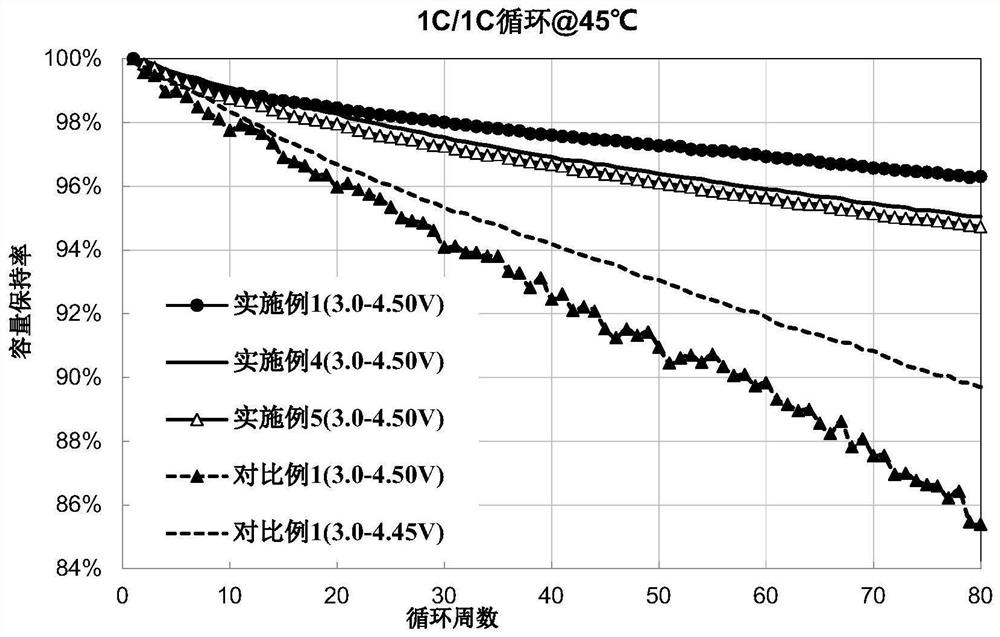

Embodiment 1

[0206] S1, prepare 2mol / L nickel cobalt manganese sulfate mixed solution (molar ratio Ni:Co:Mn=50:19:28.6), 2.5mol / L NaOH solution, 3mol / L ammonia water, 20g / L PEG1000 dispersion Aqueous solution, 1mol / L Al 2 (SO 4 ) 3 solution, the above-mentioned several solutions are passed into the reactor in a co-current manner, wherein Al 2 (SO 4 ) 3 The feeding amount was [n(Ni)+n(Co)+n(Mn)]:n(Al)=0.976:0.003, the reaction temperature was kept at 60°C, and the reaction pH was 12.0. After the reaction was completed, it was aged for 6 hours, then filtered, washed, dried at 110°C, sieved, and then heat-treated at 500°C for 8 hours in an air atmosphere to obtain a multi-element cathode material precursor.

[0207] S2, the multi-component cathode material precursor, lithium carbonate, yttrium diboride (YB 2 ), according to the ratio of [n(Ni)+n(Co)+n(Mn)]:n(Li):n(Y)=0.976:1.05:0.002, fully mixed in a high mixer, at a temperature of 1000℃ Roasting for 12h, in which, the heating process...

Embodiment 2

[0212] S1, prepare 1.5mol / L nickel cobalt manganese sulfate mixed solution (molar ratio Ni:Co:Mn=50:18:24), 3mol / L NaOH solution, 2mol / L ammonia water, 15g / L PEG1000 dispersion Aqueous solution, 0.5mol / L Al 2 (SO 4 ) 3 solution, the above-mentioned several solutions are passed into the reactor in a co-current manner, wherein Al 2 (SO 4 ) 3 The feeding amount was [n(Ni)+n(Co)+n(Mn)]:n(Al)=0.92:0.01, the reaction temperature was kept at 50°C, and the reaction pH was 11. After the reaction was completed, it was aged for 12 hours, then filtered, washed, dried at 110 °C, sieved, and then heat-treated at 400 °C for 10 hours in an air atmosphere to obtain a multi-component cathode material precursor.

[0213] S2, the multi-component cathode material precursor, lithium carbonate, yttrium diboride (YB 2 ), according to the ratio of [n(Ni)+n(Co)+n(Mn)]:n(Li):n(Y)=0.92:1.20:0.01, fully mixed in a high-mixer at a temperature of 900℃ Roasting for 18h, in which, the heating process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com