Zinc oxide/metal antibacterial powder and preparation method thereof

A zinc oxide, antibacterial powder technology, applied in the fields of botanical equipment and methods, antifouling/underwater coatings, and biocide-containing paints, etc. , low cost, good product dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

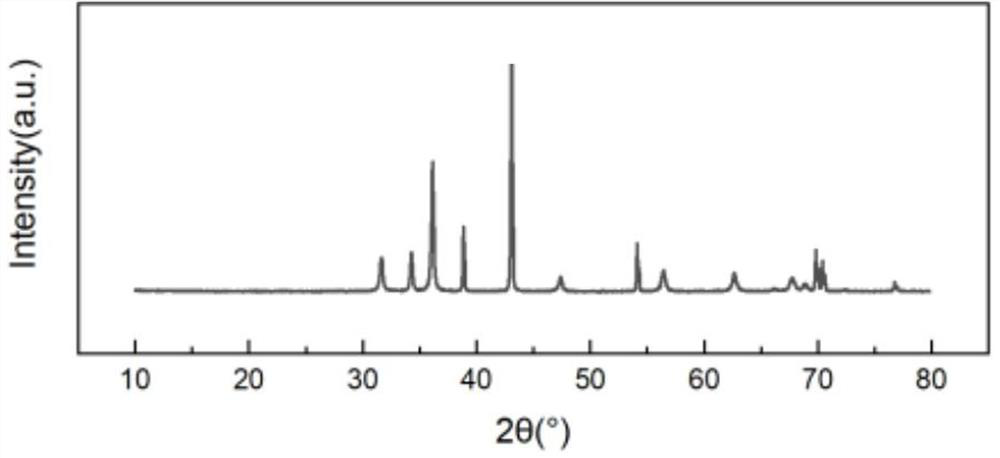

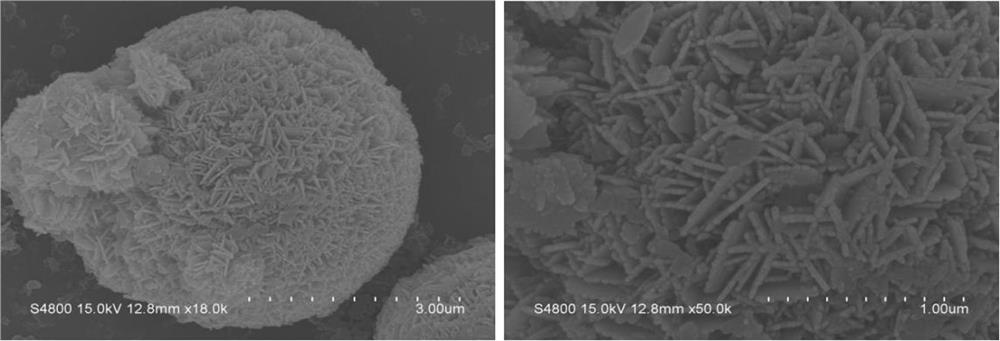

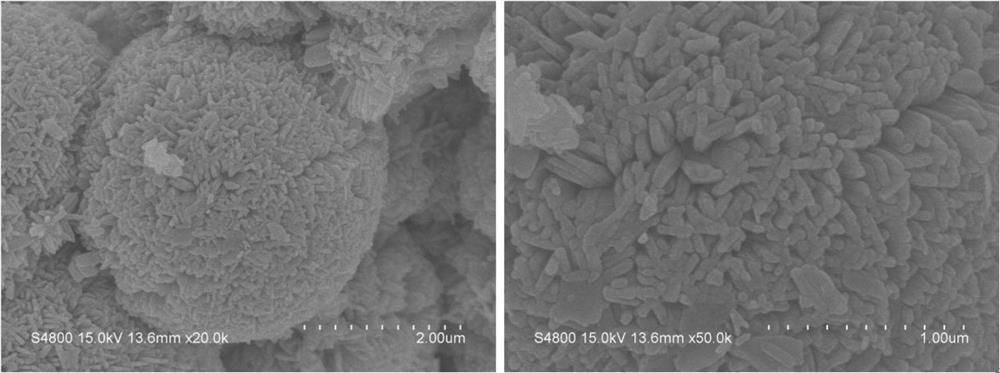

Image

Examples

Embodiment 1

[0035] Prepare 100ml of 0.1mol / L zinc chloride aqueous solution, 100ml of 0.4mol / L sodium hydroxide aqueous solution, add 7.32g of ultrafine Zn powder to the zinc chloride solution, heat to 90°C, add the prepared sodium hydroxide solution, stir After 20 minutes, the precipitate was centrifugally filtered and dried at 100°C to obtain zinc oxide / zinc antibacterial powder.

[0036] The powder was configured as a water-based paint, and the antibacterial rates of Escherichia coli and Staphylococcus aureus were tested by HG / T 3950-2007 standard, and the results were all greater than 99.92%. The antiviral activity rate against H1N1 influenza A virus was tested by ISO 21702:2019, and the result was greater than 99.92%.

Embodiment 2

[0038] Prepare 100ml of 2mol / L zinc nitrate aqueous solution and 100ml of 4mol / L potassium hydroxide aqueous solution, add 0.16g of ultrafine Cu powder to the zinc chloride solution, heat to 70°C, add the prepared potassium hydroxide solution, stir for 180 minutes, The precipitate was centrifugally filtered and dried at 100°C to obtain zinc oxide / copper antibacterial powder.

[0039] The powder was configured into a water-based paint, and the antibacterial rates of Escherichia coli and Staphylococcus aureus were tested by HG / T 3950-2007 standard, and the results were all greater than 99.95%. The antiviral activity rate against H1N1 influenza A virus was tested by ISO 21702:2019, and the result was greater than 99.95%.

Embodiment 3

[0041] Prepare 100ml of 1mol / L zinc sulfate aqueous solution, 100ml of 2mol / L sodium hydroxide aqueous solution, add 8.14g of ultrafine Al powder to the zinc chloride solution, heat to 60°C, add the prepared sodium hydroxide solution, stir for 60 minutes, The precipitate was centrifugally filtered and dried at 100°C to obtain zinc oxide / aluminum antibacterial powder.

[0042] The powder was configured as a water-based paint, and the antibacterial rates of Escherichia coli and Staphylococcus aureus were tested by HG / T 3950-2007 standard, and the results were all greater than 99.90%. The antiviral activity rate against H1N1 influenza A virus was tested by ISO 21702:2019, and the result was greater than 99.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com