Solid oxide electrolytic cell working electrode modified by binary alloy nano-particles as well as preparation method and application of solid oxide electrolytic cell working electrode

A solid oxide, working electrode technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of agglomeration, complex preparation process, large size of nanoparticles, etc., and achieve the effect of uniform distribution, simple process, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

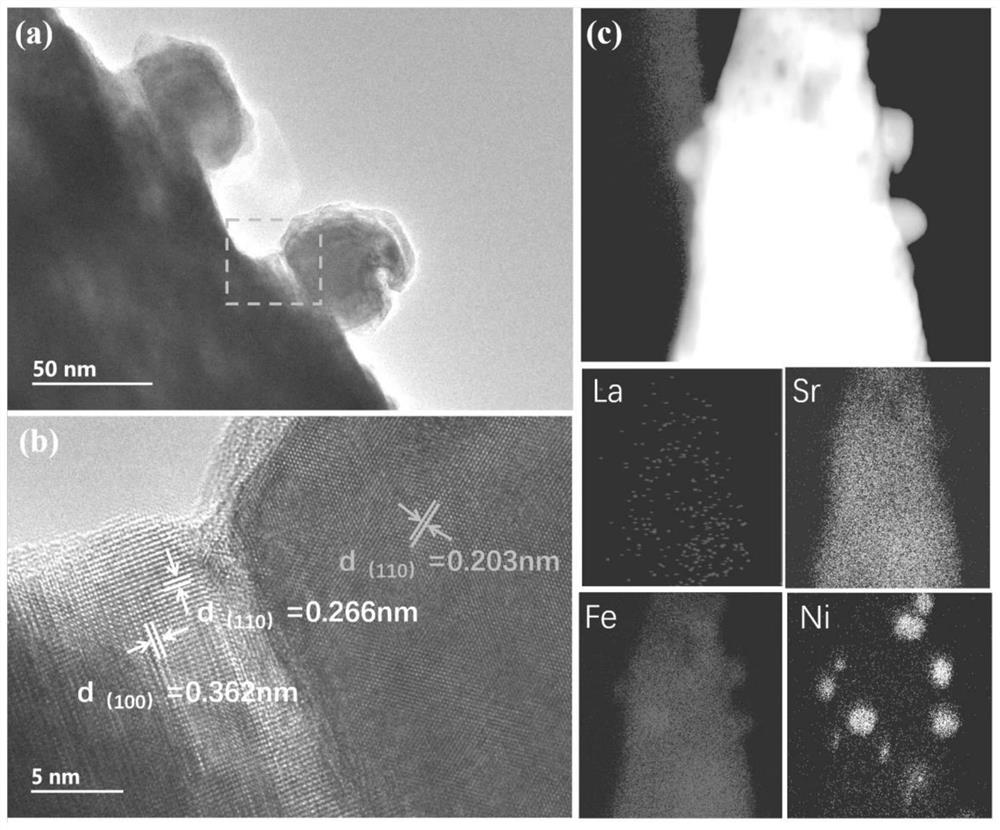

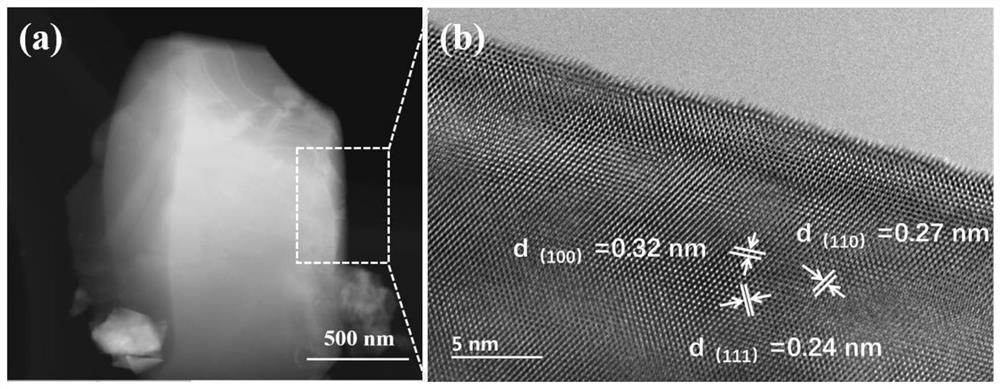

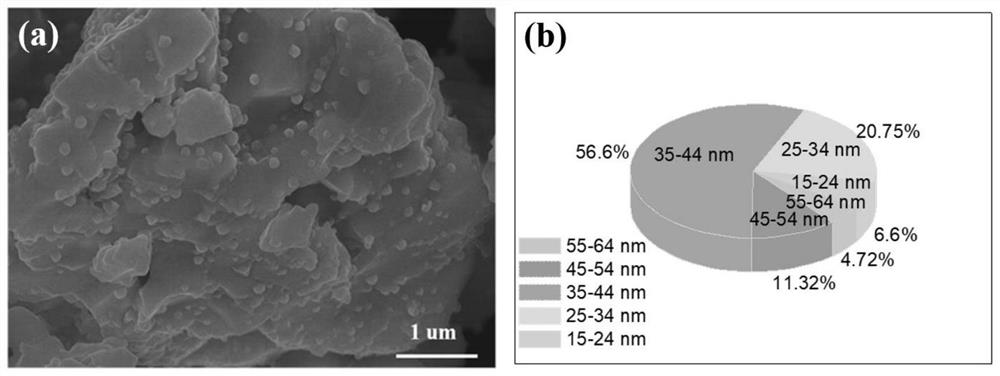

[0038] (1) Weigh lanthanum oxide, strontium carbonate, iron oxide, and nickel oxide, whose masses are 2.5867g, 4.7589g, 3.2657g and 0.5391g, respectively, and mix them by ball milling at a speed of 400r / min, then place them in a high-temperature furnace and sinter at a high temperature of 1200°C. Preparation of perovskite-based matrix La in 7h 0.33 Sr 0.67 Fe 0.85 Ni 0.15 O 3-δ (LSFN);

[0039] (2) Place the synthesized LSFN powder in a flowing 10% H 2 The FeNi@LSF electrode powder modified by binary alloy nanoparticles was obtained by reduction at 850 °C in a mixed atmosphere of / Ar.

Embodiment 2

[0046] (1) Weigh lanthanum oxide, strontium carbonate, iron oxide, and nickel oxide, whose masses are 2.5867g, 4.7589g, 3.2657g and 0.5391g, respectively, and mix them by ball milling at a speed of 400r / min, then place them in a high-temperature furnace and sinter at a high temperature of 1200°C. Preparation of perovskite-based matrix La in 7h 0.33 Sr 0.67 Fe 0.85 Ni 0.15 O 3-δ (LSFN);

[0047] (2) The mass ratio of synthesized LSFN powder to electrolyte powder (GDC), pore-forming agent (PMMA), and binder (ethyl cellulose, turpentine permeate) is 5:5:0.75:1:14.25, and The composite electrode slurry LSFN-GDC was prepared by ball milling at 400 r / min.

[0048] (3) The prepared composite electrode paste LSFN-GDC was coated on an area of 1.766 cm by screen printing. 2 The two sides of the electrolyte GDC were coated with nine layers in total; after drying at 60°C, after sintering at 1000°C for 2 hours, platinum paste was applied to the electrode surfaces on both sides of t...

Embodiment 3

[0060] (1) Weigh lanthanum oxide, strontium carbonate, iron oxide, and nickel oxide, whose masses are 2.5867g, 4.7589g, 3.2657g and 0.5391g, respectively, and mix them by ball milling at a speed of 400r / min, then place them in a high-temperature furnace and sinter at a high temperature of 1200°C. Preparation of perovskite-based matrix La in 7h 0.33 Sr 0.67 Fe 0.85 Ni 0.15 O 3-δ (LSFN);

[0061](2) The mass ratio of synthesized LSFN powder to electrolyte powder (GDC), pore-forming agent (PMMA), and binder (ethyl cellulose, turpentine permeate) is 5:5:0.75:1:14.25, and The composite electrode slurry LSFN-GDC was prepared by ball milling at 400 r / min.

[0062] (3) The prepared composite electrode paste LSFN-GDC was coated on one side of the electrolyte GDC with an area of 1.766 cm2 by screen printing method, and a total of nine layers were coated; the other side of the electrolyte was coated with BCFN-GDC Composite electrode; after drying at 60 °C and sintering at 1000 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com