Carbon nano tube conductive agent sizing for negative electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery, carbon nanotube technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low compaction density of negative electrode materials, achieve good conductivity, reduce polarization resistance, and shorten diffusion paths. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

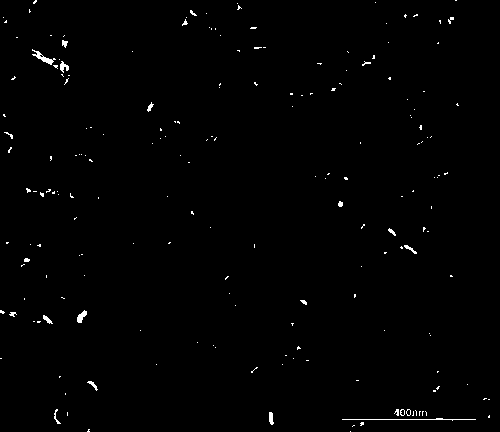

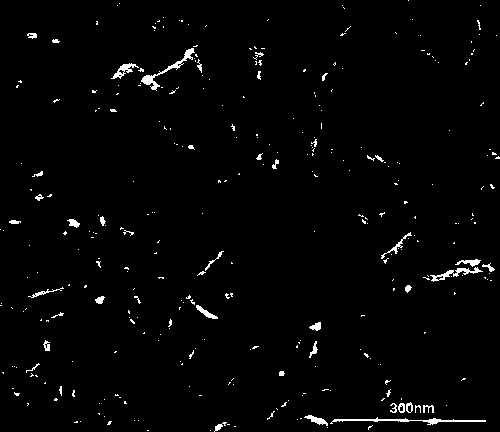

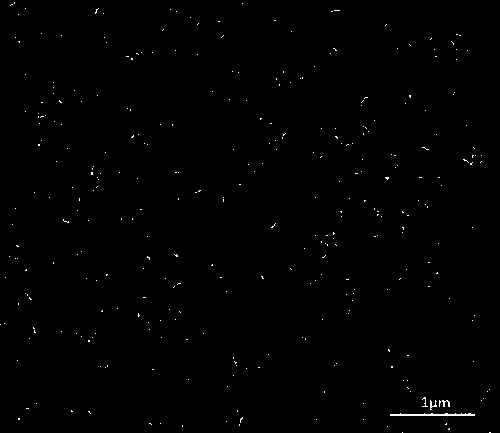

Image

Examples

Embodiment Construction

[0031] Option One:

[0032] Step (1). First turn on the dehumidifier, adjust the indoor humidity to below 15%, fully dry the equipment and instruments used, and clean them with NMP;

[0033] Step (2): Weigh 925g of NMP, put it into the stirring tank, add 3g of PVP during the stirring process, turn on the ultrasonic wave, after fully dissolved, add 2g of VC, fully dissolved;

[0034] Step (3): Add 20g of activated carbon powder while stirring, stir for 30 minutes, then add 50g of CNTs, stir at high speed, and transfer the composite slurry to the sand mill equipment after the carbon material is fully infiltrated;

[0035] Step (4): Adjust the speed of the sand mill to 1000r / min, grind for 10 hours, and use a chiller to keep the temperature of the sand mill bin below 40 degrees.

[0036] The measured moisture content of the conductive paste is 2937ppm, the particle size test is 8μm, and the viscosity test is 10570 mPa•s.

[0037] Option II:

[0038] Step (1). First turn on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com